Seabed type conical investigating and drilling integrated machine

An all-in-one machine and conical drilling technology, which is applied in the direction of rotary drilling rigs, percussion drilling, rotary drilling, etc., can solve the problems of unsatisfactory drilling sampling depth, low reliability and efficiency, and oil and gas exploration requirements, etc., to achieve increased Friction coefficient, fast and stable leveling, impact mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

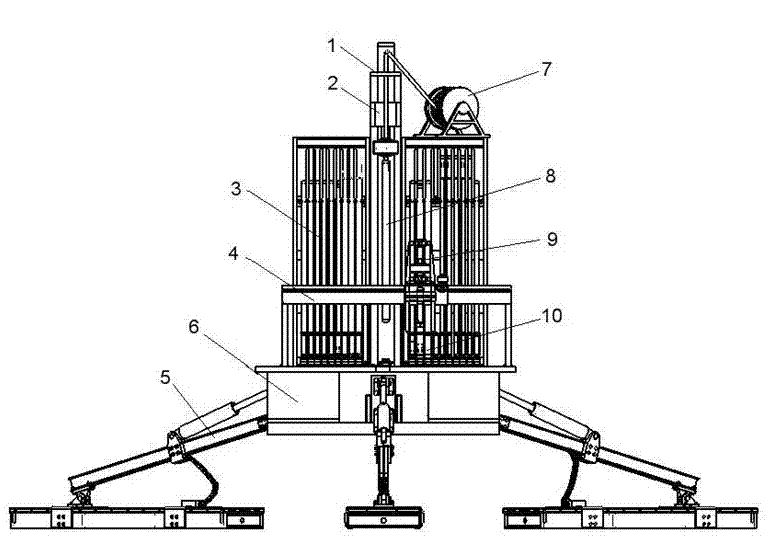

[0041] Embodiment 1: the seabed type conical drilling integrated machine of the present invention, its structure is as follows figure 1 As shown, it includes: a tower 1, a power head 2, a drilling tool magazine 3, a manipulator mechanism 4, a leveling mechanism 5, an instrument box 6, a winch 7, a drilling tool 8, a gripper 9 and a hydraulic pump 10; where:

[0042] Power head 2: fixed on the tower 1, mainly used to provide power for coning and drilling.

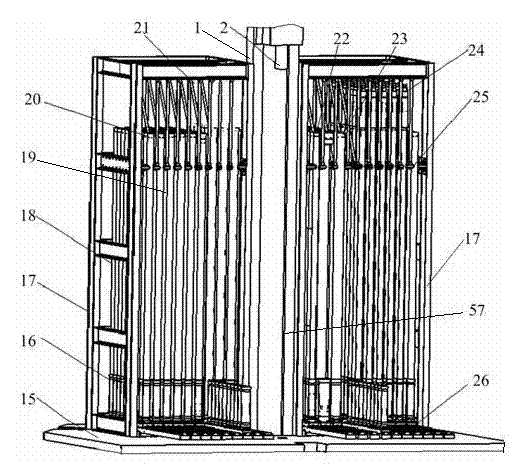

[0043] Drilling tool warehouse 3: mainly used to store various drilling tools. According to the drilling and coning process, there are five types of drilling tools stored, a total of more than 100 pieces, namely: 18 small drill pipes, 21 large core pipes, 22 probe pipes, 23 large drill pipes, and 24 small core pipes. The lower end of the sleeve 16 is fixed on the locking mechanism 26 .

[0044] Manipulator mechanism 4: it is the core component of the all-in-one machine for automatically accessing the drilling tool 8, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com