Freezing box cold air leakage detection and early warning device for cold chain equipment and implementation method of device

A leak detection and early warning device technology, applied in general control systems, instruments, computer control, etc., can solve the problems of lack of air-conditioning leak detection equipment, inability to ensure the tightness of the connection, affecting the quality of materials, etc., to achieve the isolation of airborne temperature , Improve the service life and improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

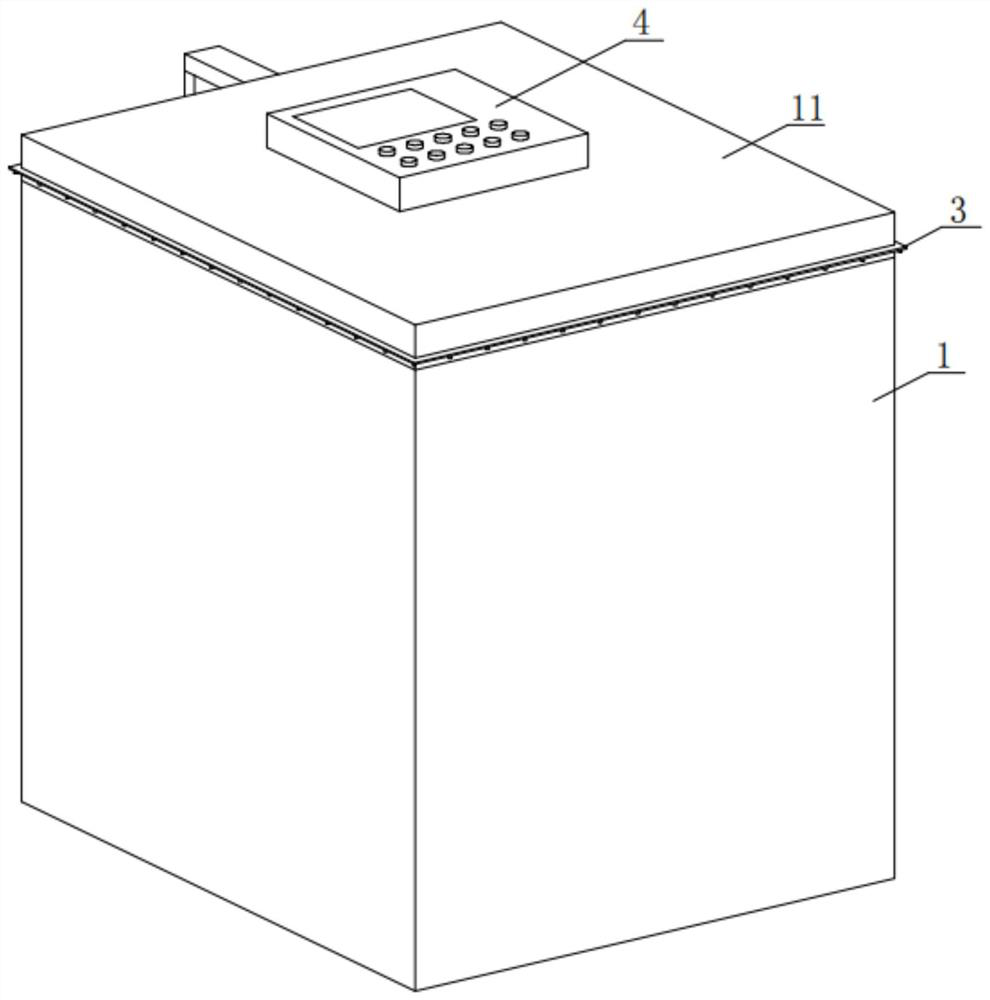

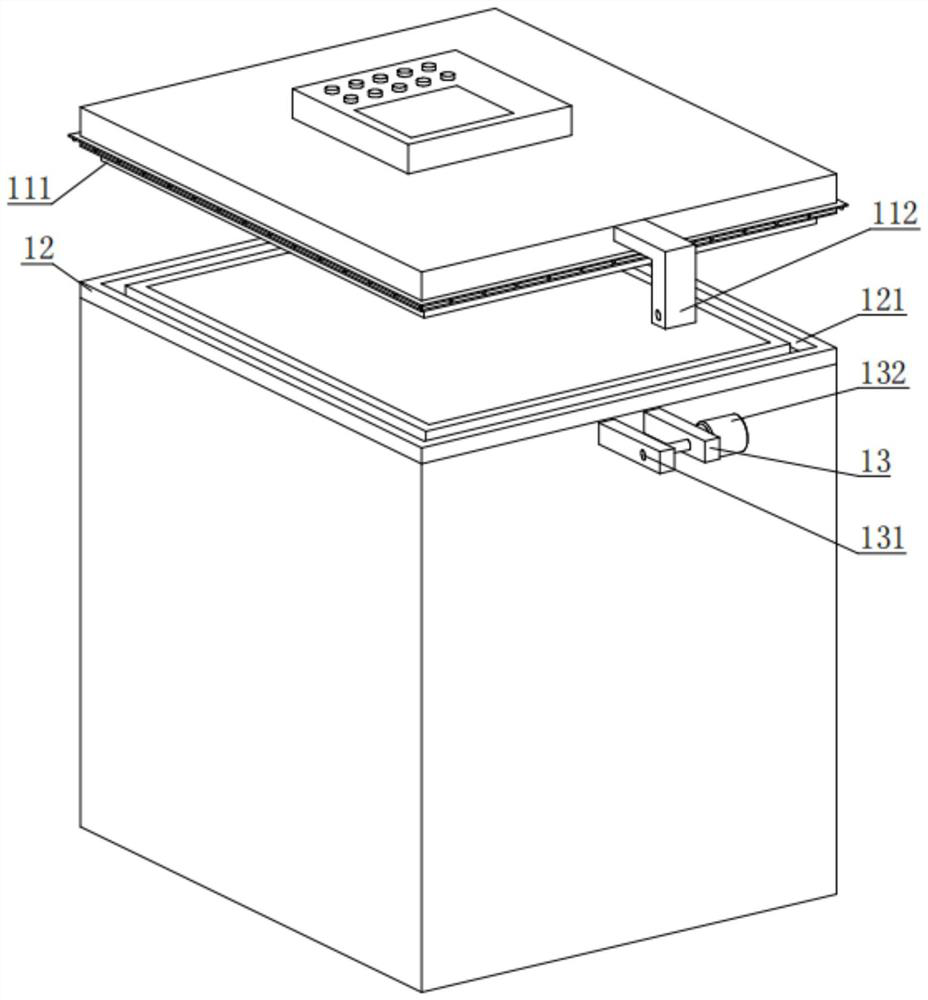

[0039] see figure 1 A cold air leakage detection and early warning device for a refrigerated box for cold chain equipment and an implementation method thereof, comprising a refrigerated box 1 and an inner box 2 arranged inside the refrigerated box 1, a box cover 11 is arranged above the refrigerated box 1, A cold air detection device 3 is arranged between the case cover 11 and the refrigerated case body 1, and the cold air detection device 3 is electrically connected to the early warning control system 4, and the outer shell of the early warning control system 4 is fixed on the top of the case cover 11.

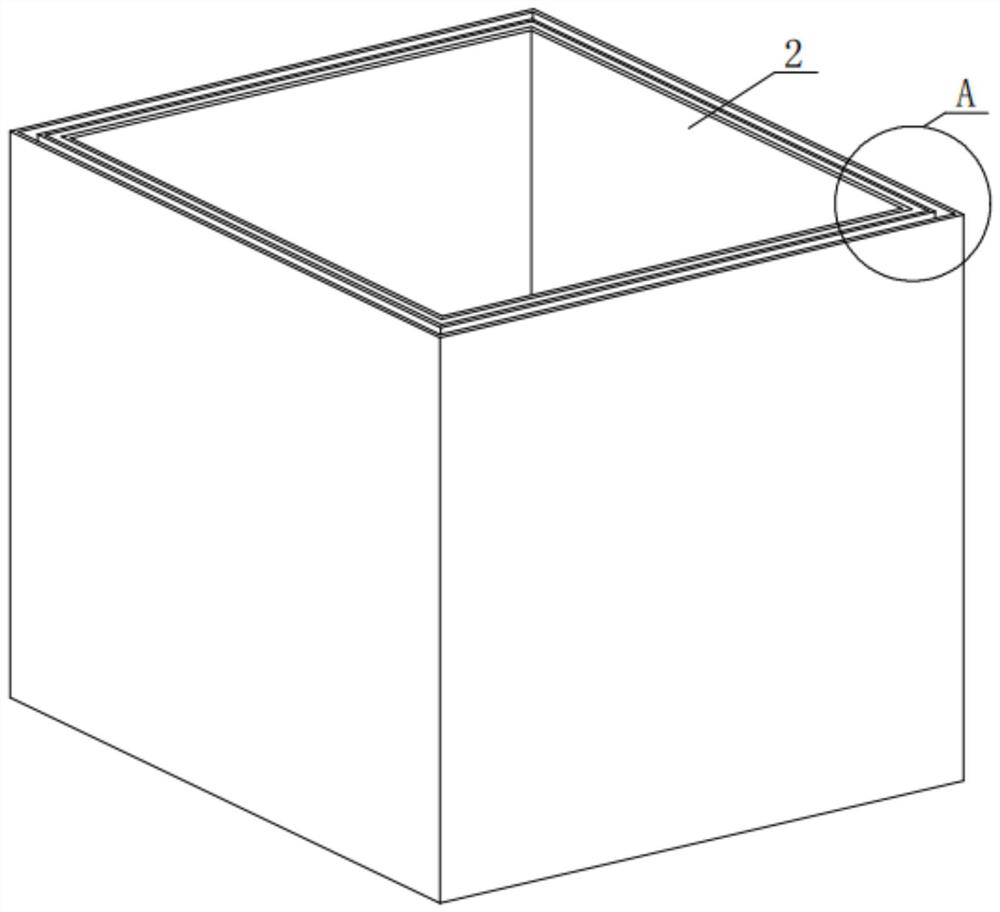

[0040] see Figure 2-Figure 4 , the inner box 2 is composed of two layers of covering body 21, and the temperature insulating fiber layer 22 is filled between the inner and outer covering body 21, and a temperature insulation gap is opened between the inner box body 2 and the freezing box body 1, and the inner box body Vacuum treatment in the gap between the box body 2 and t...

Embodiment approach

[0043] In order to better demonstrate the process of realizing the cold air leakage detection and early warning device for refrigerated boxes for cold chain equipment, this embodiment proposes an implementation method for the cold air leak detection and early warning device for refrigerated boxes for cold chain equipment, including the following steps:

[0044] Step 1: When the box cover 11 is pressed together with the refrigerated box body 1, multiple groups of air sensors 31 at the joint between the box cover 11 and the refrigerated box body 1 work, and the air sensors 31 are used to detect whether there is cold air leakage in the joint gap;

[0045] Step 2: When the air sensor 31 detects that there is gas in the gap, the signal is transmitted to the general control circuit 41 through the wireless signal receiving module 43, and the analysis module 44 analyzes the detected data. When the data shows that the cold air leaks, the general control circuit 41 transmits information ...

Embodiment 2

[0048] see Figure 9 A cold air leakage detection and early warning device for a refrigerated box for cold chain equipment and an implementation method thereof, comprising a refrigerated box 1 and an inner box 2 arranged inside the refrigerated box 1, a box cover 11 is arranged above the refrigerated box 1, A cold air detection device 3 is arranged between the case cover 11 and the refrigerated case 1, the cold air detection device 3 is electrically connected to the early warning control system 4, the outer casing of the early warning control system 4 is fixed on the top of the case cover 11, and the case body of the refrigerated case 1 A pressing component 5 is arranged on the outside.

[0049] see Figure 10 , the pressing assembly 5 includes an L-shaped pressing plate 51, a shaft connecting rod 52, a shaft connecting motor 53 and a downward pressure cylinder 54. One end of the L-shaped pressing plate 51 is movably socketed on the outer end surface of the freezing box 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com