High-performance leakage-proof flexible joint

A flexible interface, high-performance technology, applied in the direction of adjustable connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problems of interface leakage, high interface processing cost, complex interface structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

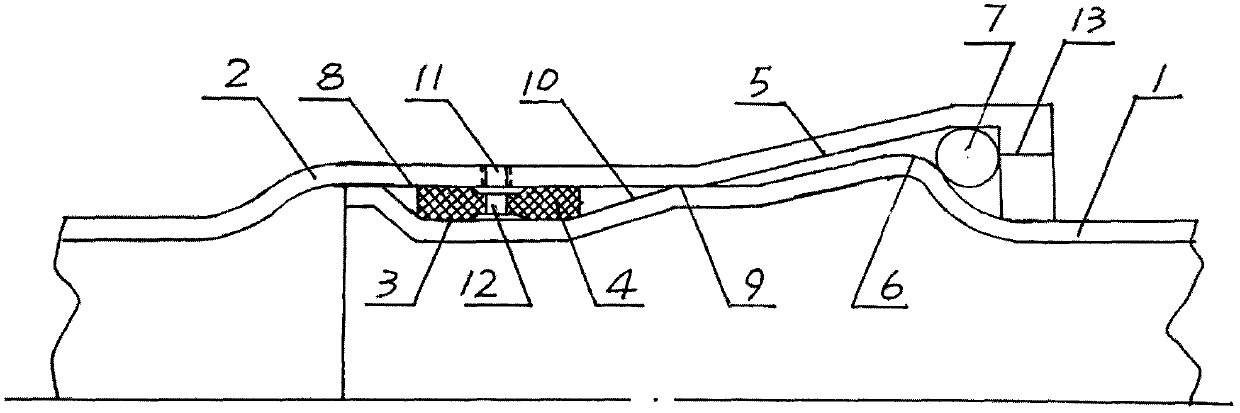

[0008] Set the double-convex ring sealing rubber ring 3 whose inner diameter is smaller than the outer diameter of the groove on the groove 3 of the plug 1, and apply the lubricant on the conical inclined surface 5 of the socket head 2 and the sealing inner hole 8, The plug 1 is pulled into the socket 2 by external force, and the resistance generated by the sliding friction between the outer circle of the double-convex ring sealing rubber ring 3 and the conical slope 5 of the socket and the sealing inner hole 8 is smaller than that of the double-convex The thrust generated by the dry friction between the inner hole of the ring sealing rubber ring 4 and the outer circle of the groove 3 of the plug 1, and the cross section of the double convex ring sealing rubber ring 4 is prolate, so that it cannot roll and move, so that the two The convex ring sealing rubber ring 4 can be inserted into the socket 2 together with the plug 1, and the compressed convex colloid on both sides is wed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com