Leakproof device for water storing container

A water storage container and anti-leakage technology, which is applied in the field of anti-leakage devices and anti-leakage devices for water storage containers, can solve the problems of complex structure, untimely alarm and cut-off control, and occupying too much space, and achieves simple connection. Convenience, avoid continuous leakage, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

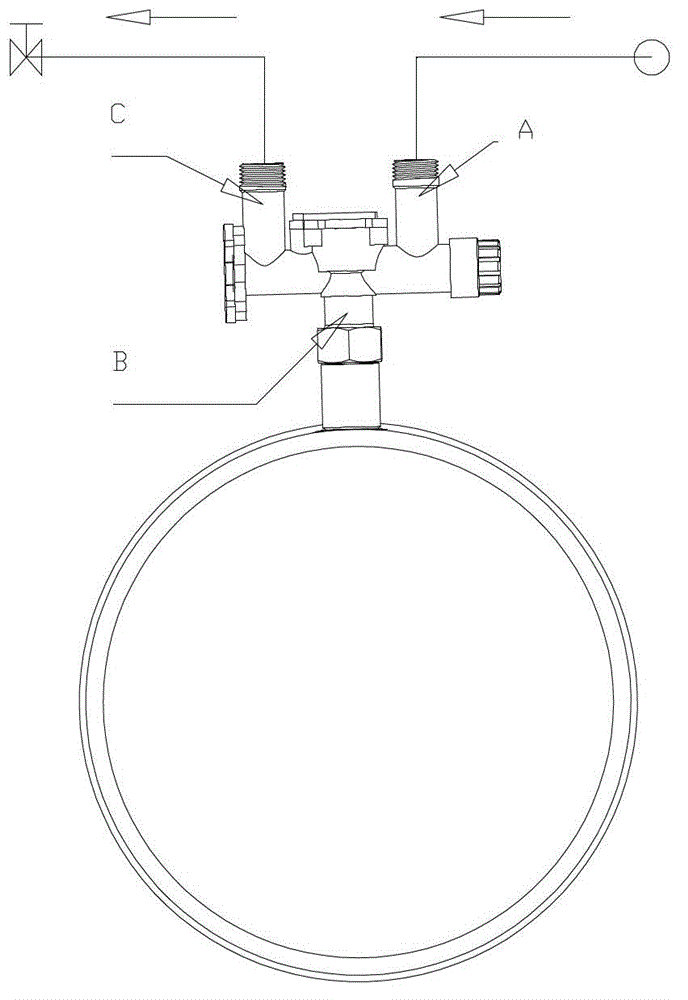

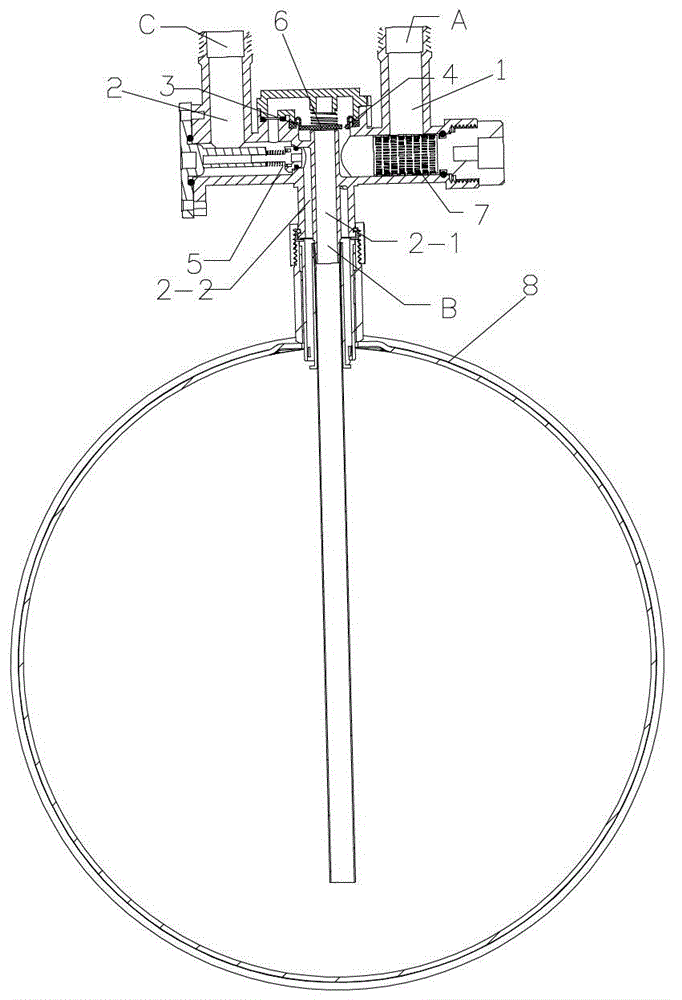

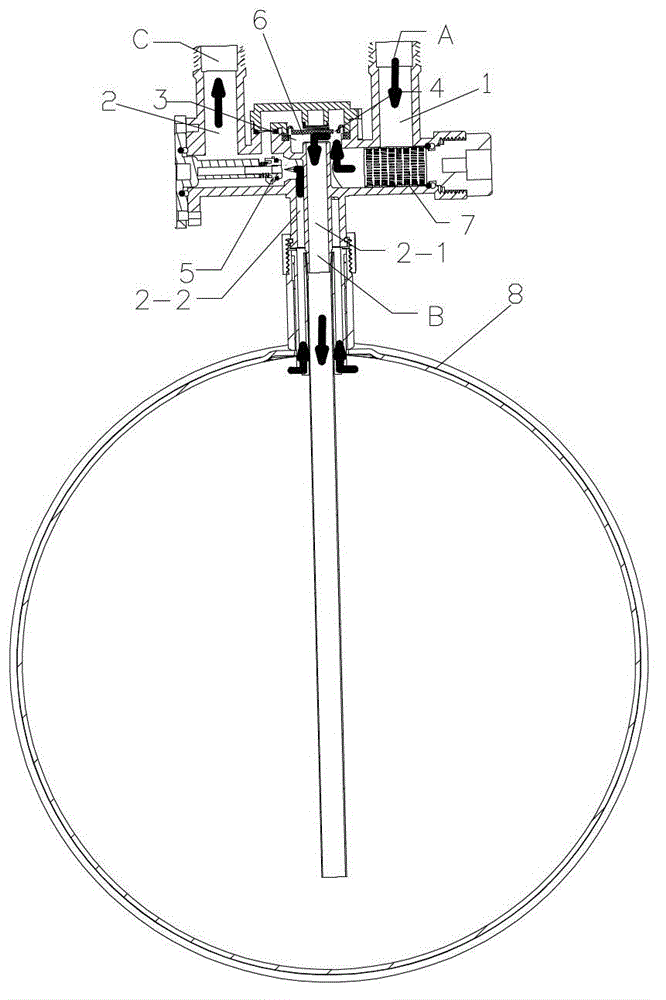

[0021] This embodiment is an anti-leakage device for an external water storage container applied to an electric water heater, such as figure 1 As shown, it includes a first port A for communicating with a tap water supply pipeline, a second port B for communicating with an electric water heater storage container (commonly known as an inner tank) 8 and a third port for communicating with the water end of the faucet C; The second port B is composed of a water inlet chamber and a water outlet chamber, and a water flow loop is formed between the outer wall of the water inlet chamber and the inner wall of the water outlet chamber. Between the first port A and the second port water inlet chamber is a first water flow channel 1, and between the second port water outlet chamber and the third port C is a second water flow channel 2. by figure 2 with image 3 It can be seen that the first water flow channel 1 between the first port A and the second port water inlet chamber is provided wi...

Embodiment 2

[0029] The anti-leakage device of the external water storage container of this embodiment is as Figure 4 As shown, the basic structure is the same as the first embodiment, the difference is that the water inlet chamber and the water outlet chamber are respectively composed of a water inlet pipe 2-1 and a water outlet pipe 2-2, and the water inlet pipe 2-1 and the water outlet pipe 2-2 They are separated by a partition board 9. The effect is the same as that of the first embodiment, and will not be described in detail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com