Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

649 results about "Cell Computing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

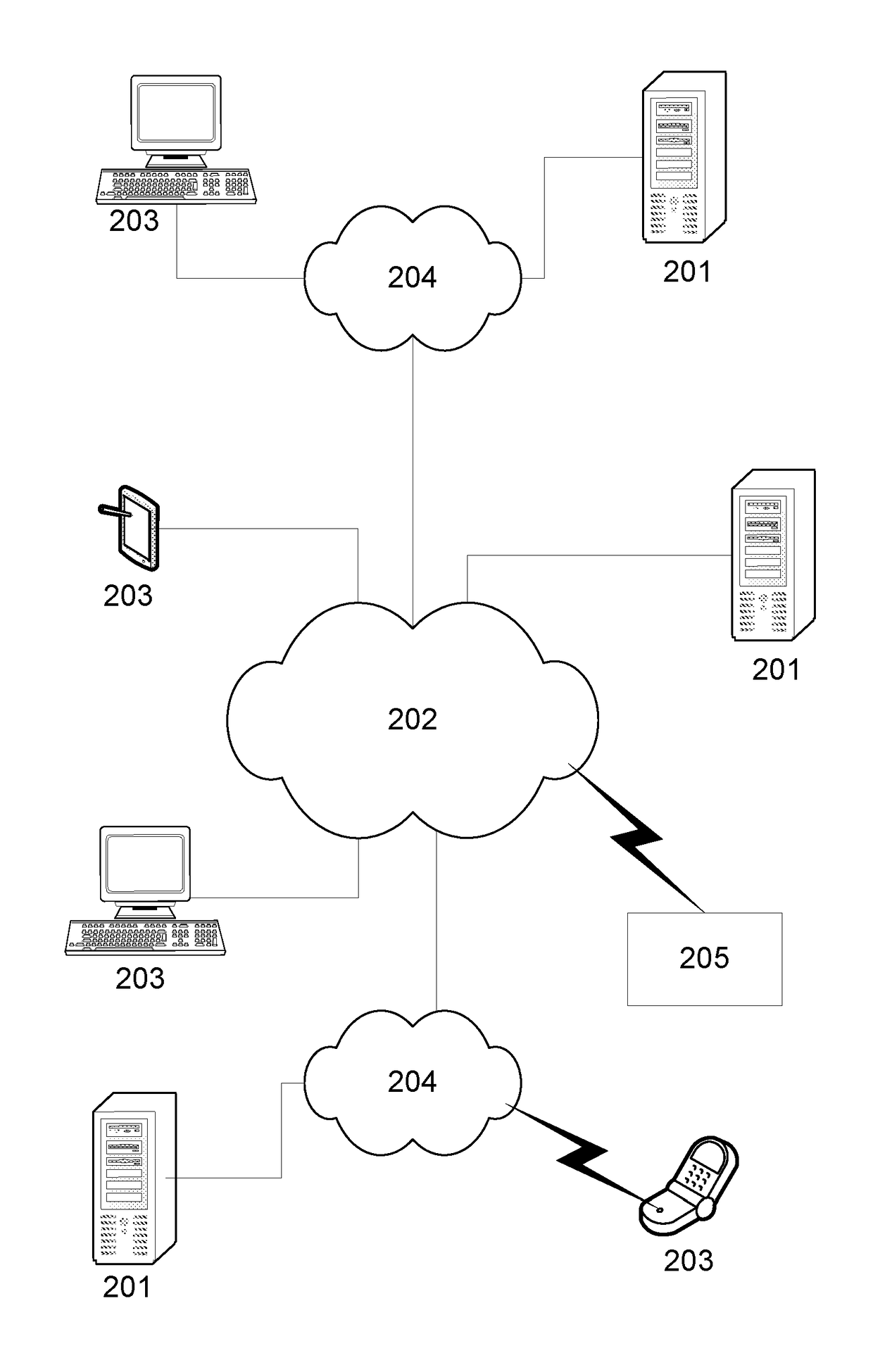

Cell Computing is a now-defunct distributed computing project that was operated by NTT Data to perform biomedical research. It used the Berkeley Open Infrastructure for Network Computing (BOINC) platform; however, it was initially launched using the United Devices Grid MP platform in 2002.

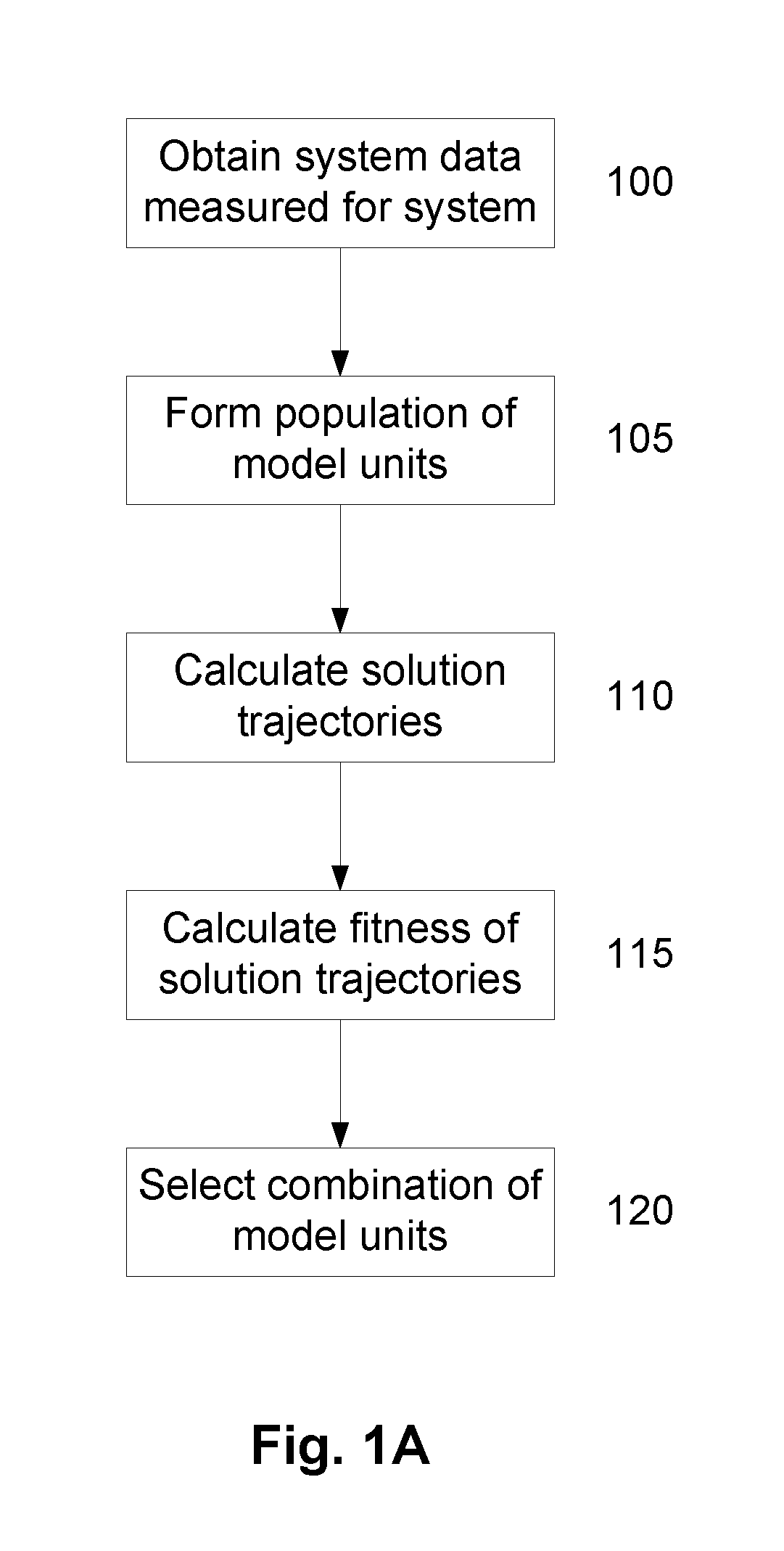

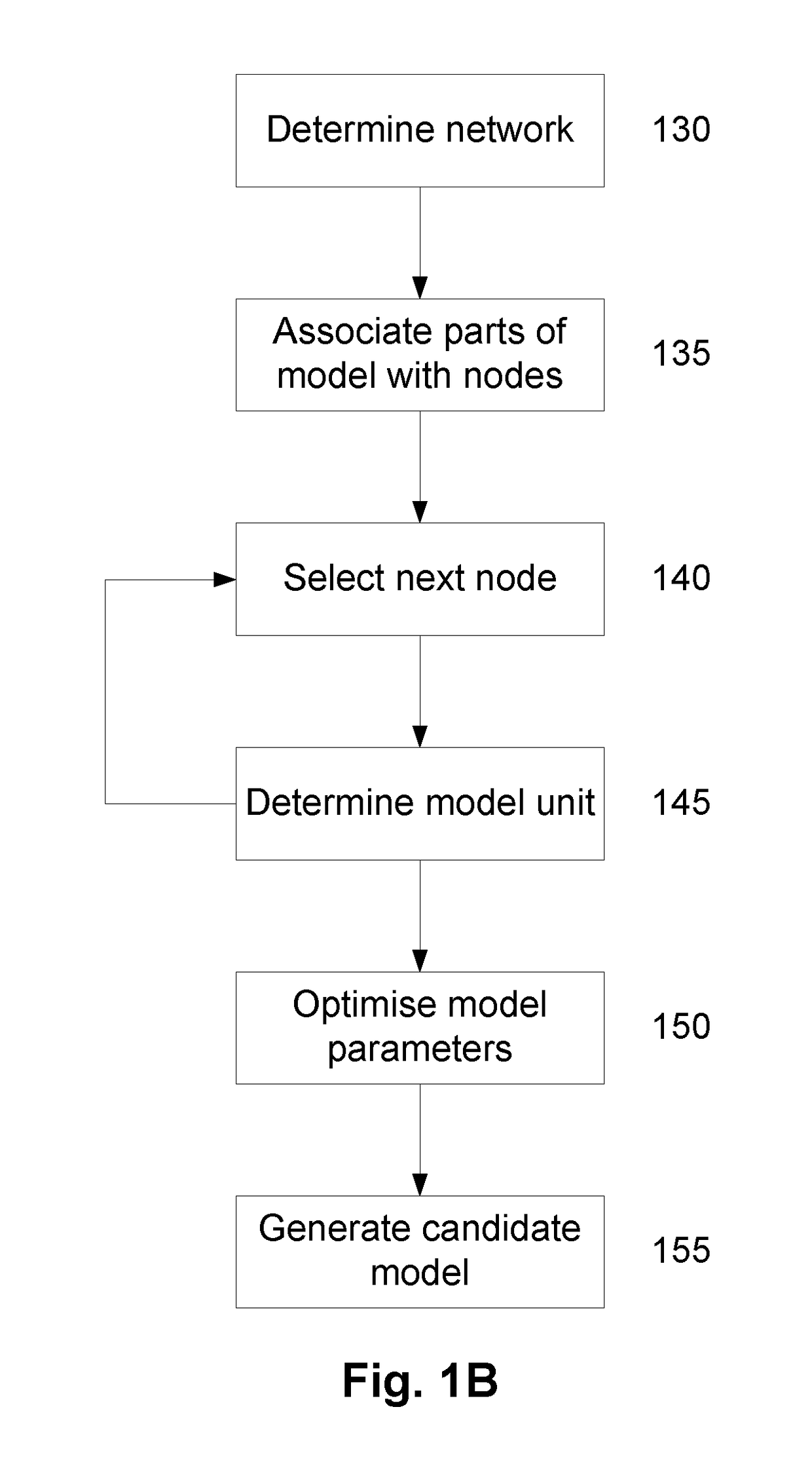

A System and Method for Modelling System Behaviour

ActiveUS20170147722A1Reduce the impactReduce impactMedical simulationDesign optimisation/simulationCollective modelModel system

A method of modelling system behaviour of a physical system, the method including, in one or more electronic processing devices obtaining quantified system data measured for the physical system, the quantified system data being at least partially indicative of the system behaviour for at least a time period, forming at least one population of model units, each model unit including model parameters and at least part of a model, the model parameters being at least partially based on the quantified system data, each model including one or more mathematical equations for modelling system behaviour, for each model unit calculating at least one solution trajectory for at least part of the at least one time period; determining a fitness value based at least in part on the at least one solution trajectory; and, selecting a combination of model units using the fitness values of each model unit, the combination of model units representing a collective model that models the system behaviour.

Owner:EVOLVING MACHINE INTELLIGENCE

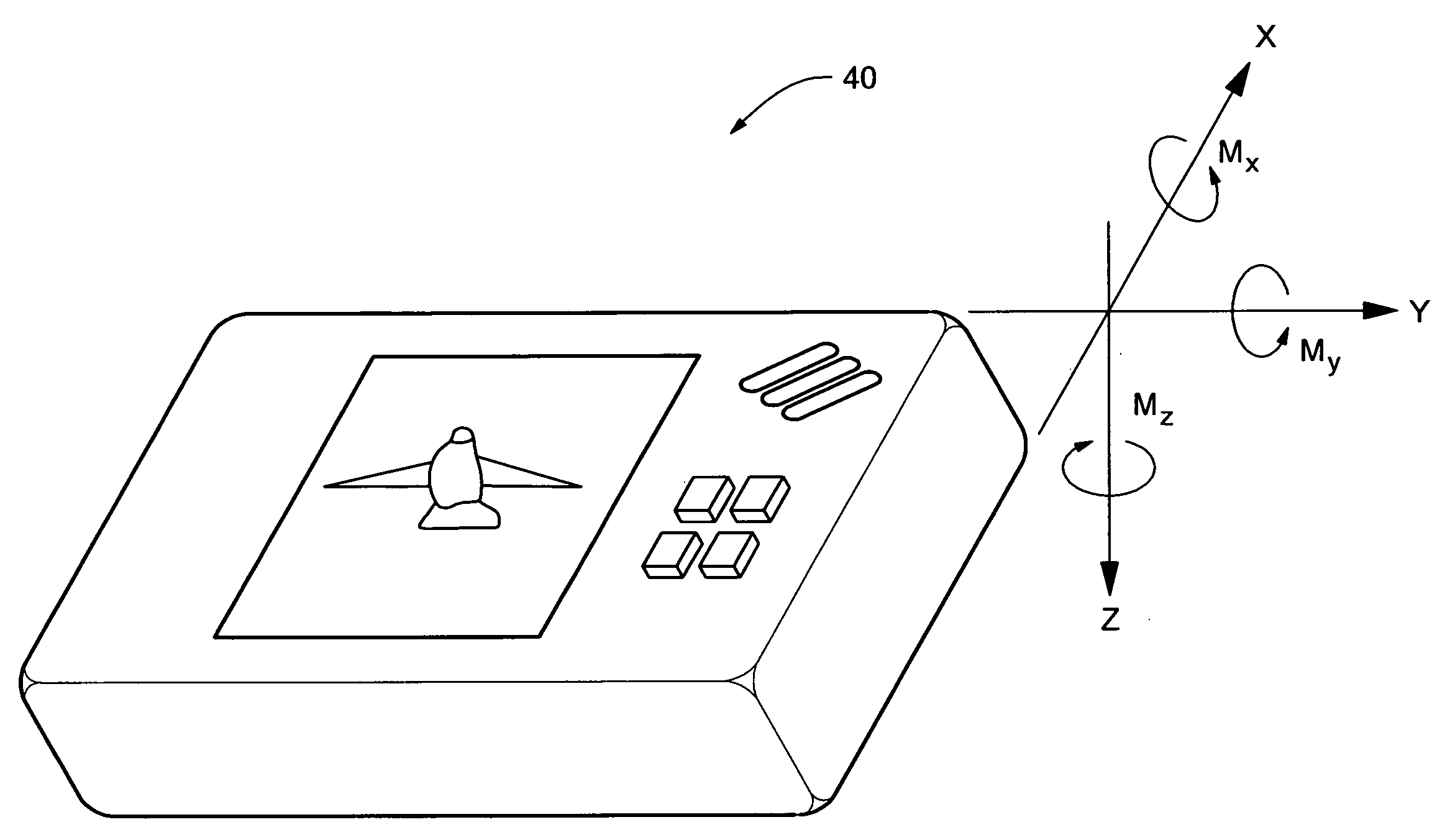

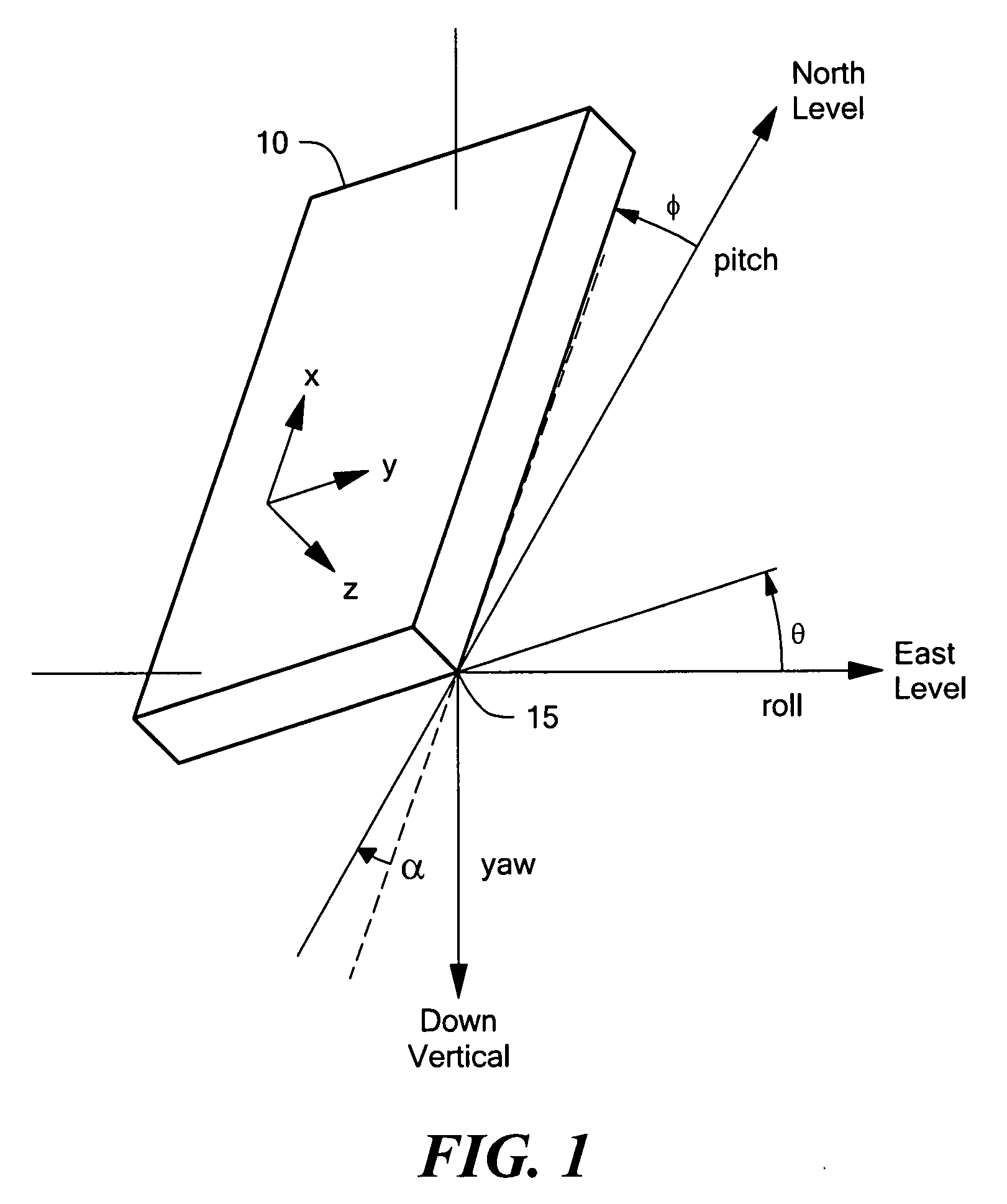

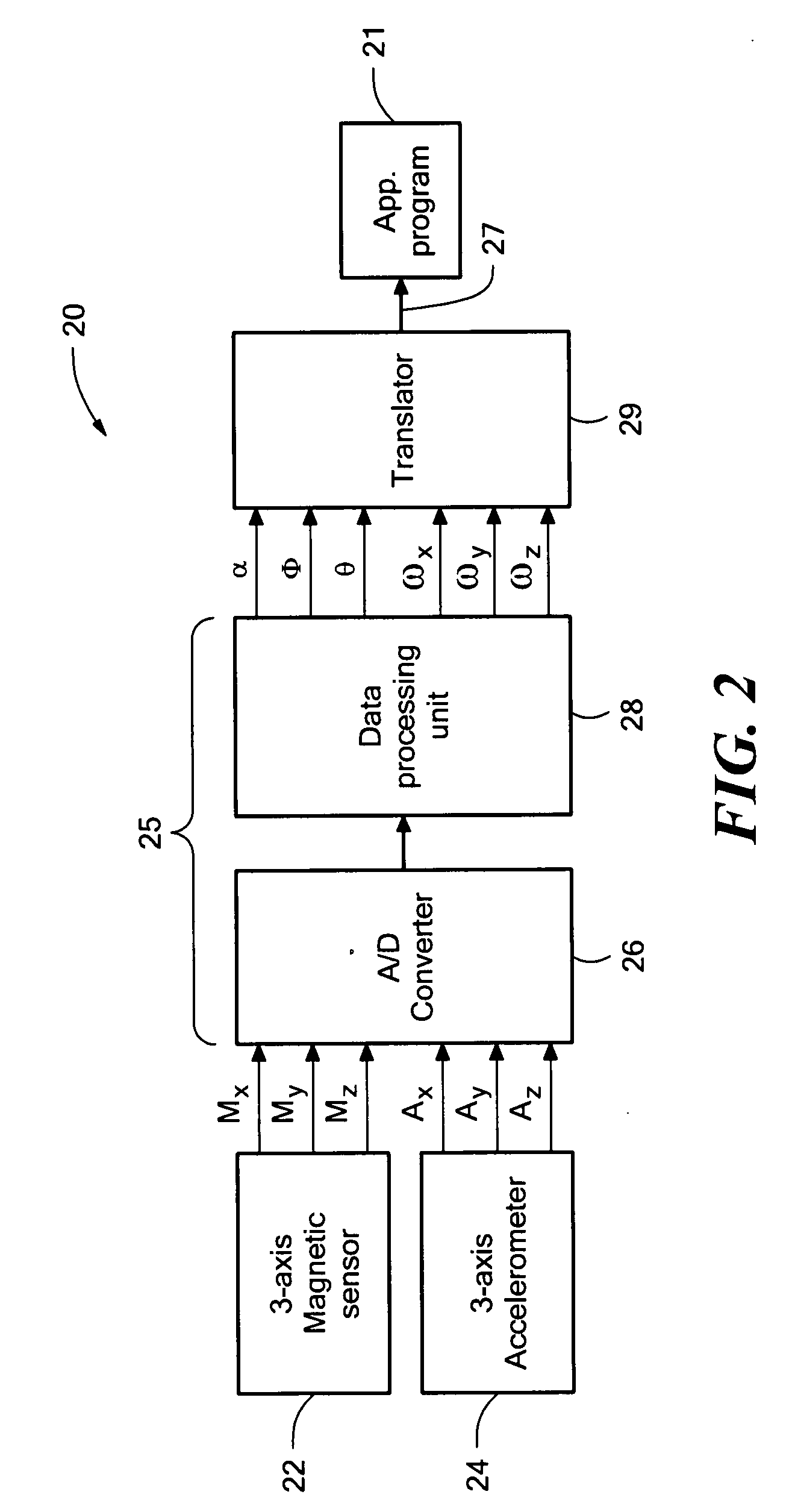

System for sensing yaw rate using a magnetic field sensor and portable electronic devices using the same

InactiveUS20080042973A1Digital data processing detailsAcceleration measurementTriaxial accelerometerMEMS magnetic field sensor

An attitude- and motion-sensing system for an electronic device, such as a cellular telephone, a game device, and the like, is disclosed. The system, which can be integrated into the portable electronic device, includes a two- or three-axis accelerometer and a three-axis magnetic compass. Data about the attitude of the electronic device from the accelerometer and magnetic compass are first processed by a signal processing unit that calculates attitude angles (pitch, roll, and yaw) and rotational angular velocities. These data are then translated into input signals for a specific application program associated with the electronic device.

Owner:MEMSIC

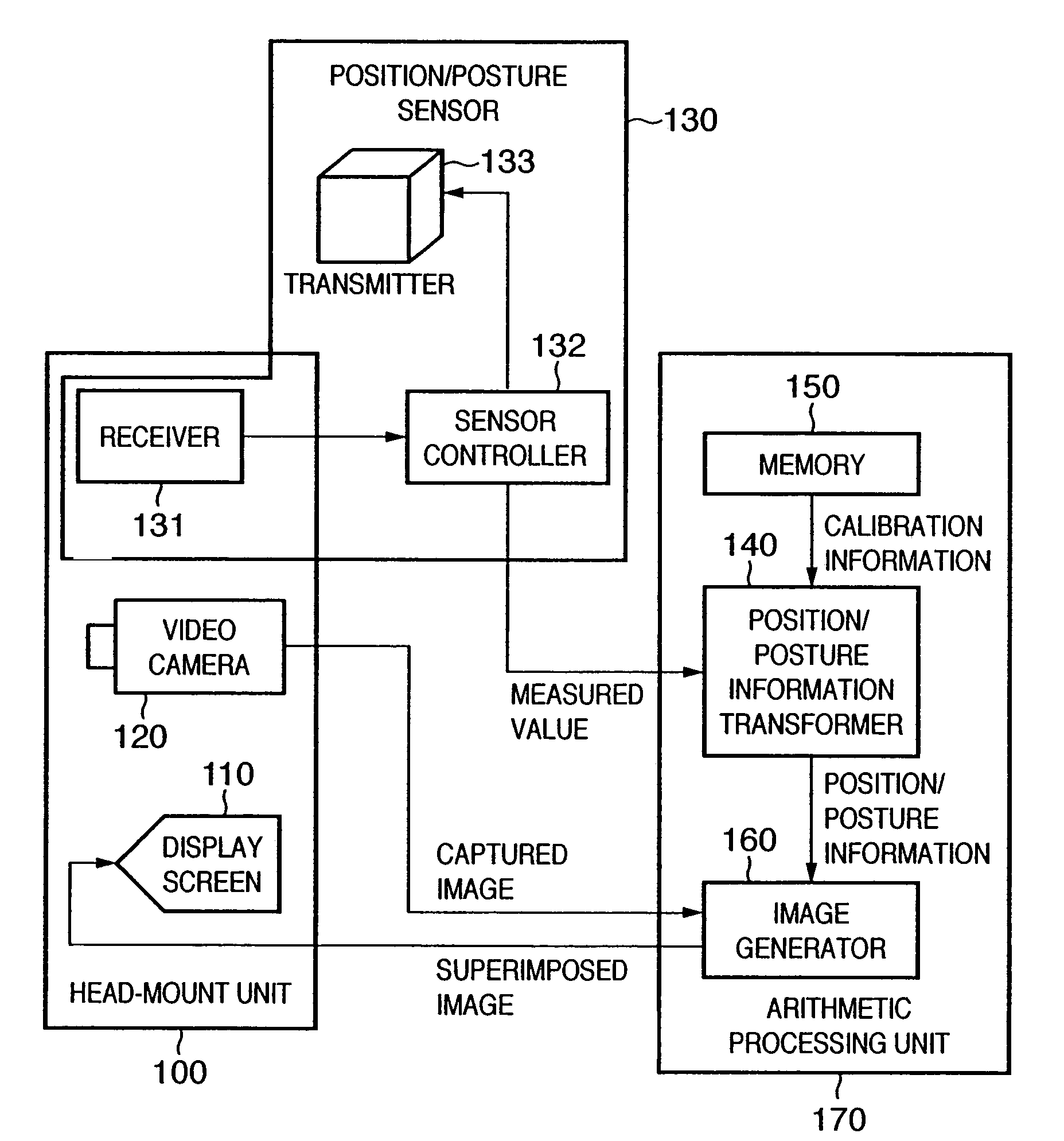

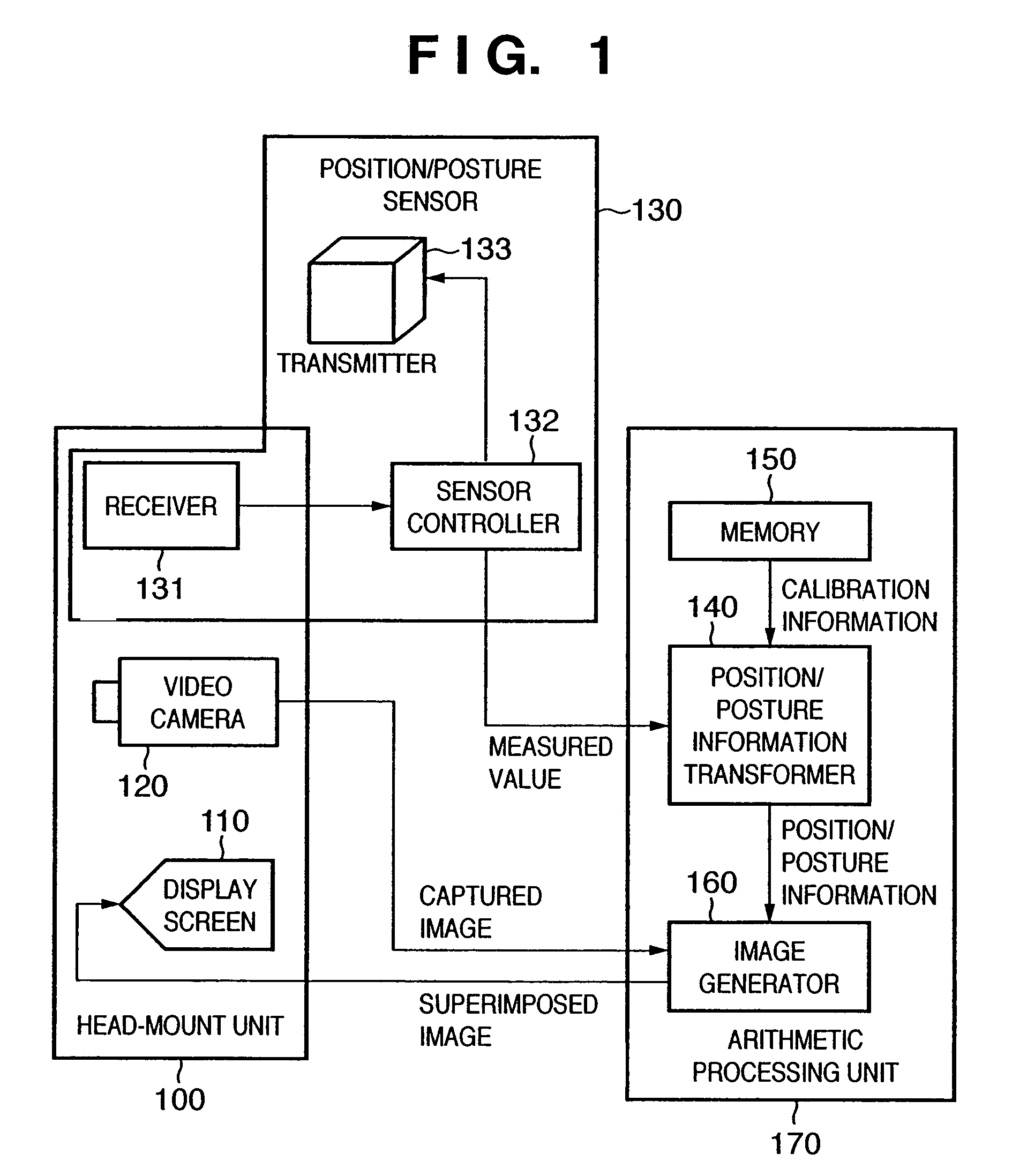

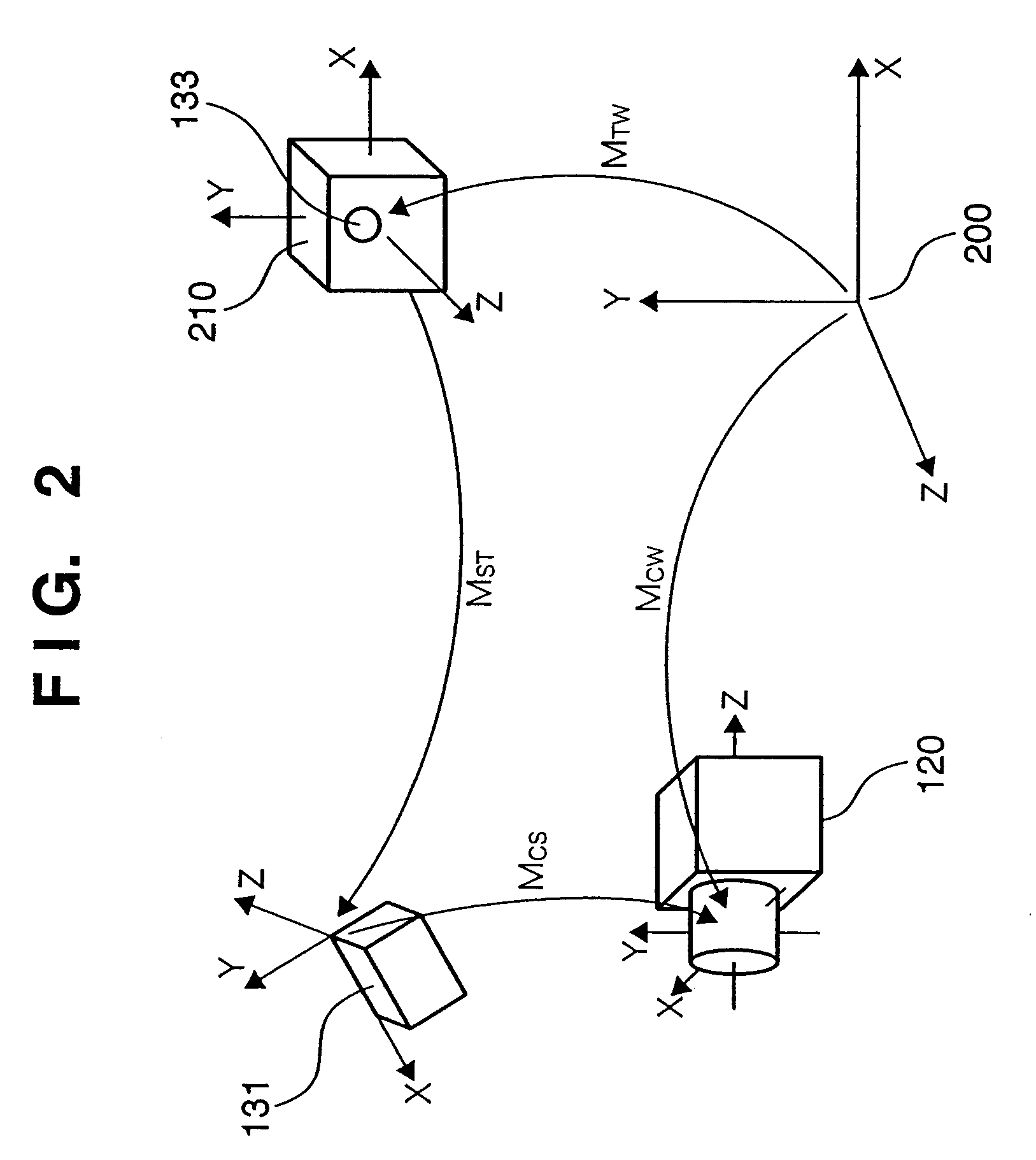

Sensor calibration apparatus, sensor calibration method, program, storage medium, information processing method, and information processing apparatus

A calibration information calculation unit 340 calculates the first coordinate positions of feature points included in images obtained by an image sensing apparatus at timings from an instruction unit 350 using position data, on world coordinate system, of a plurality of feature points held by a world coordinate holding unit 310 and the measured values of a position / posture sensor 130 input to a data management unit 330 at the timings. The unit 340 receives the second coordinate positions, which are acquired by an image coordinate acquisition unit 320, of the feature points included in the images obtained by the image sensing device at the timings. The unit 340 calculates calibration information using the first and second coordinate positions.

Owner:CANON KK

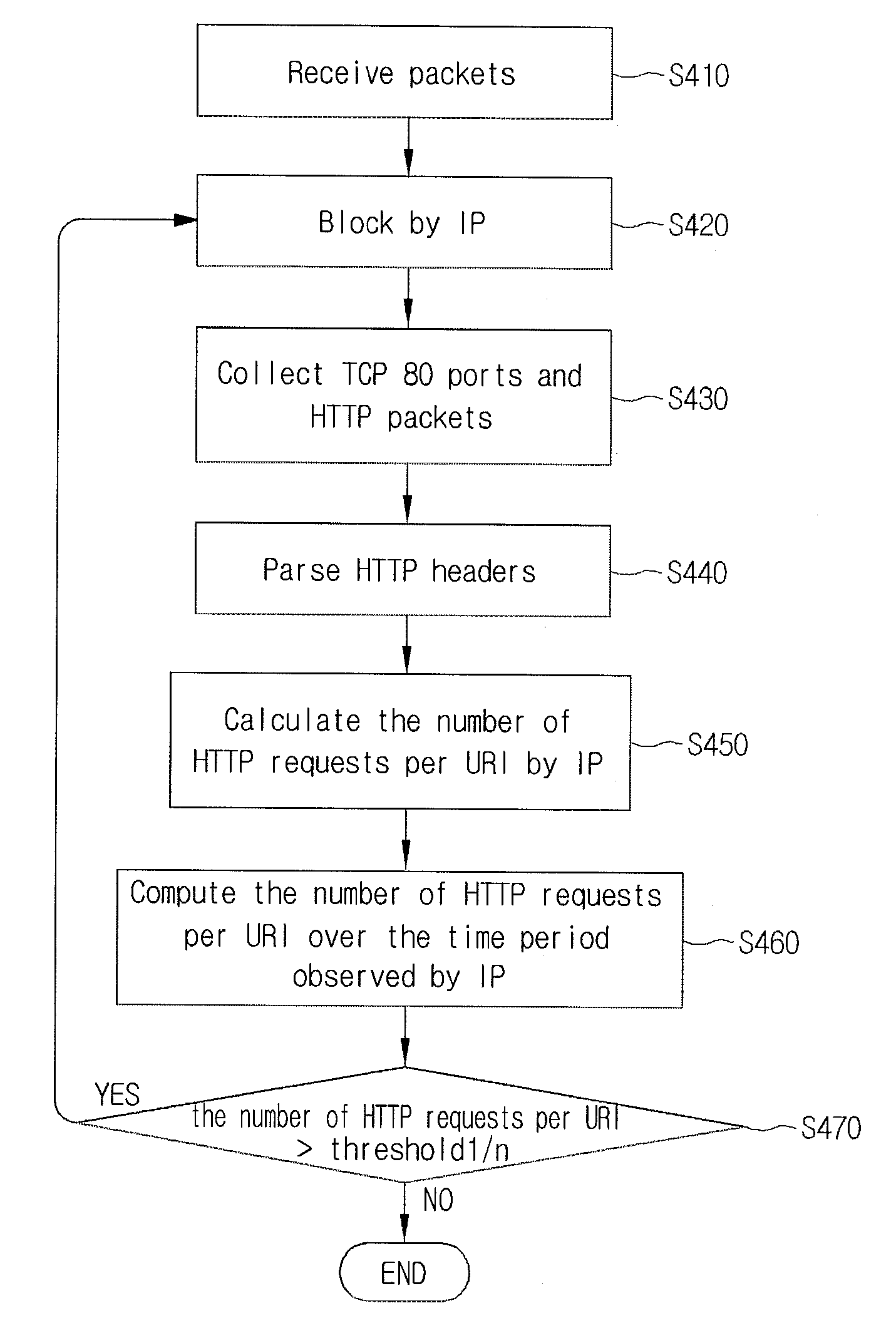

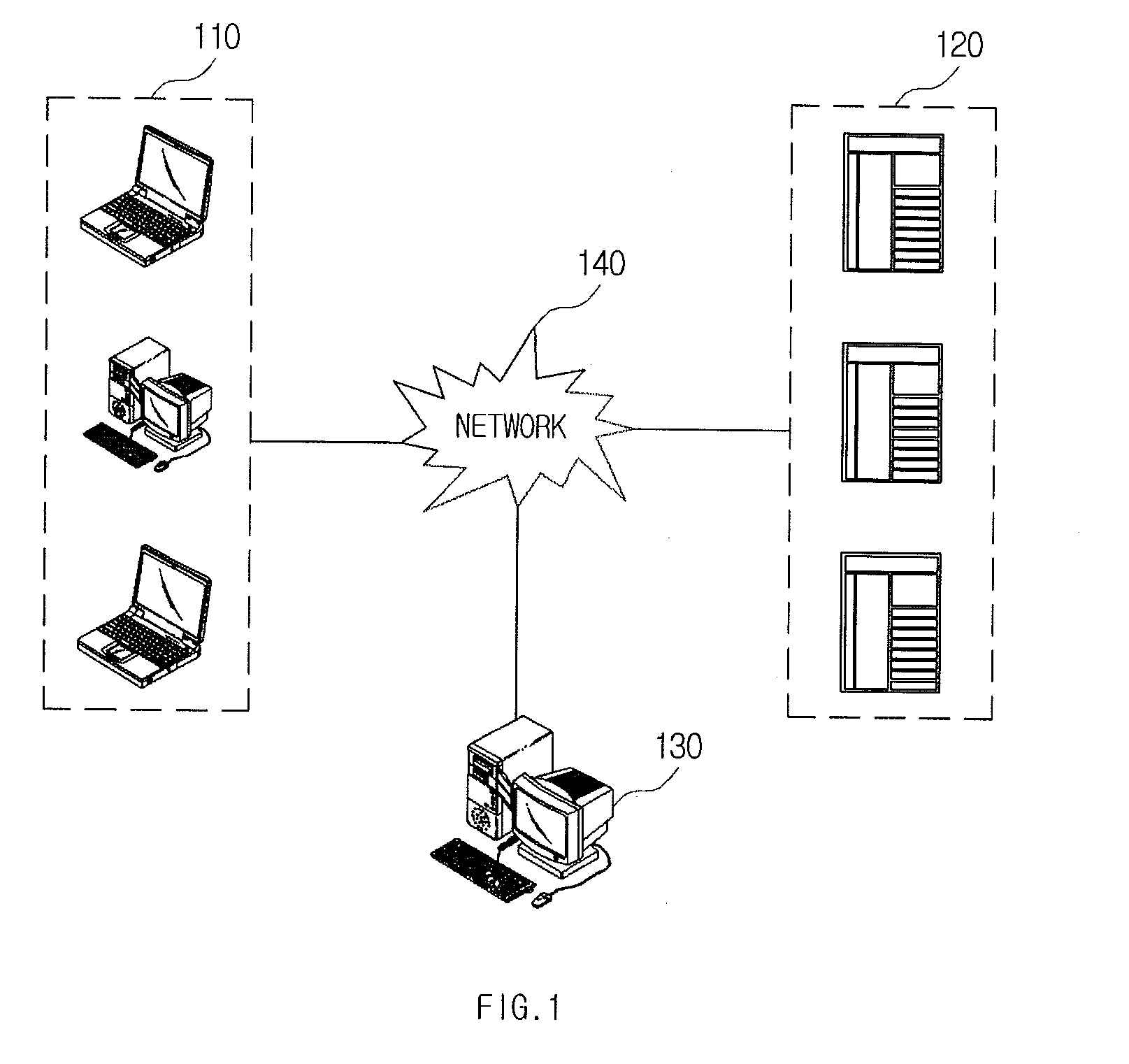

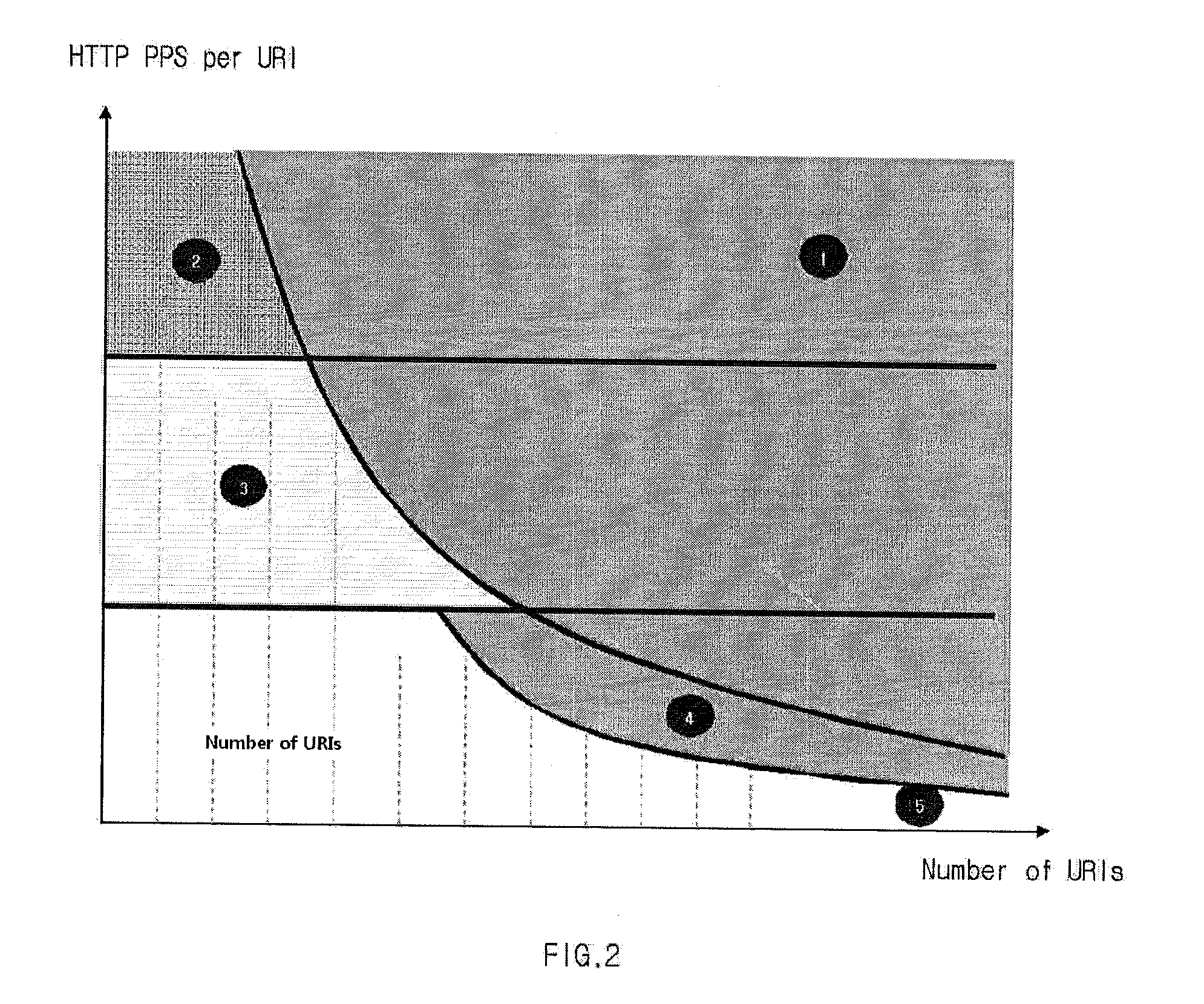

Apparatus for detecting and filtering application layer ddos attack of web service

InactiveUS20110099622A1Minimum arithmetic complexityMemory loss protectionError detection/correctionData packIp address

Owner:KOREA INTERNET & SECURITY AGENCY

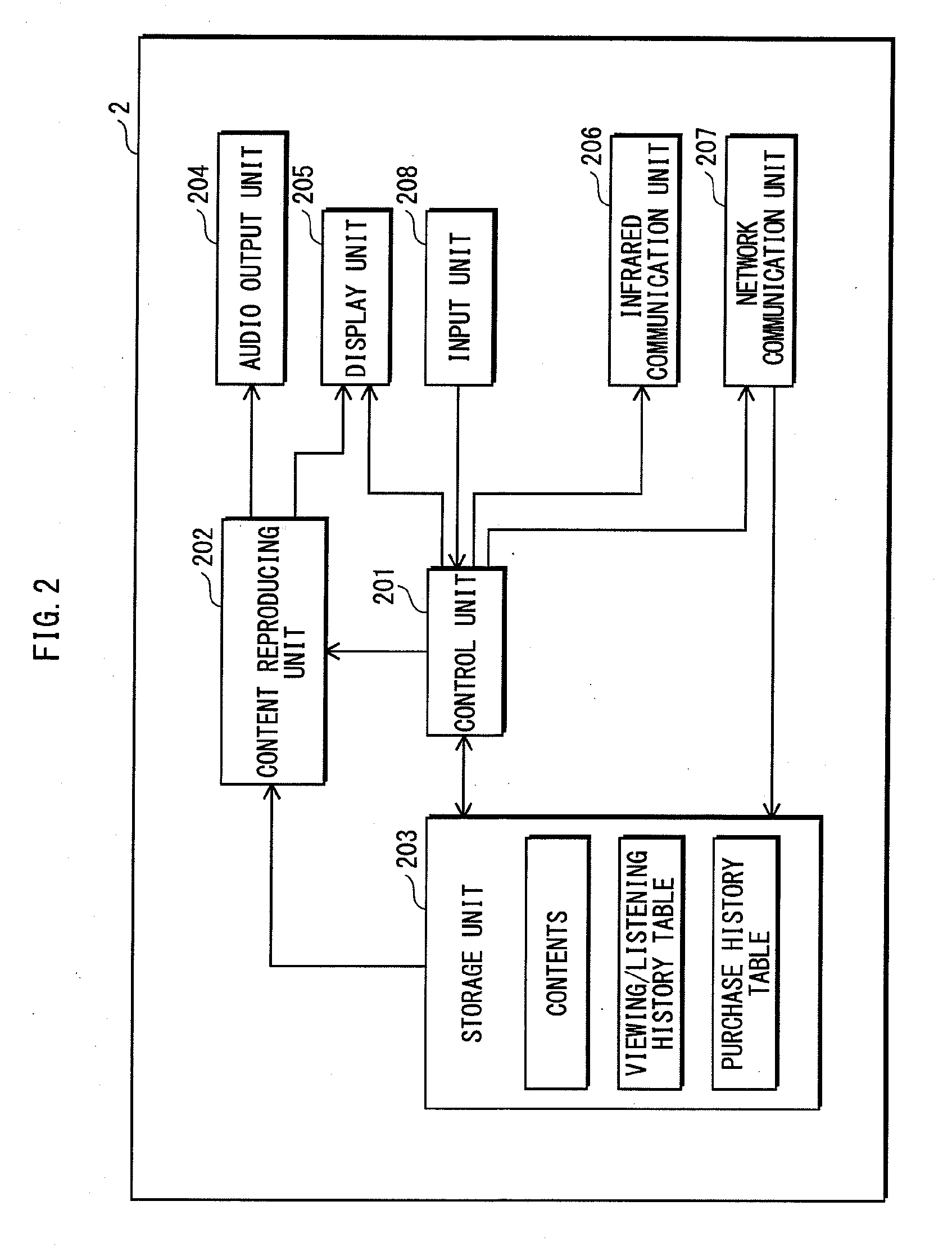

Information processing apparatus, information processing method, program for implementing information processing method, information processing system, and method for information processing system

InactiveUS20050165782A1Data processing applicationsDigital data processing detailsFeature vectorInformation processing

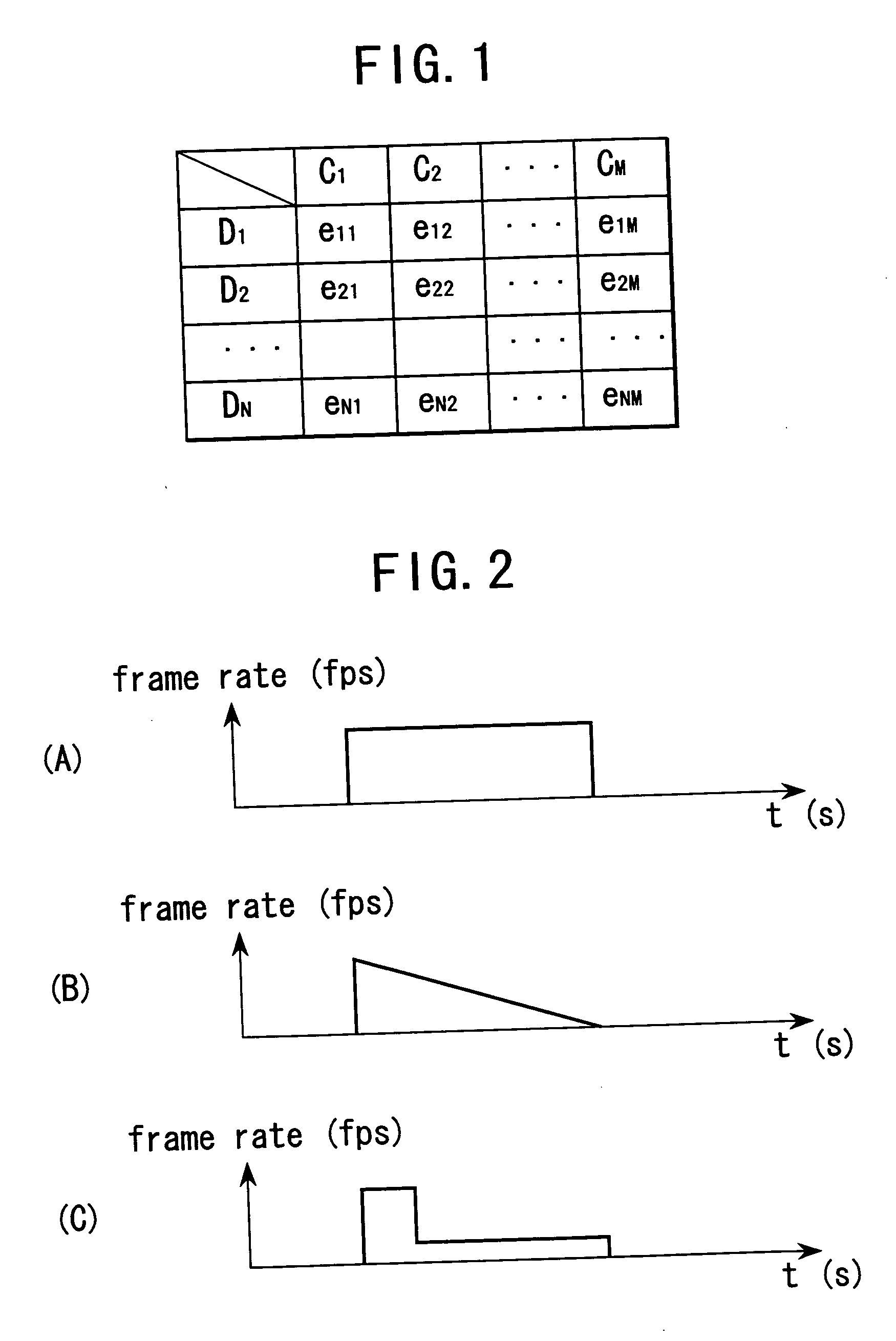

An information processing apparatus selects a proper content that well matches preference of a user and recommends it. A matrix calculator acquires M (one or more) feature vectors CCV whose elements are given by weight values assigned to a total of N (two or more) pieces of content meta information and context information. The matrix calculator produces a matrix CCM whose columns are given by the M feature vectors CCV and converts it into an approximate matrix CCM* by modifying the weight values of the respective elements of the M feature vectors CCV such that correlations of elements among the M feature vectors CCV are emphasized. Based on the approximate matrix CCM*, a user preference vector (UPV) generator produces a user preference vector UPV*. A matching unit calculates similarity between the user preference vector UPV* and a feature vector CCV produced from new content meta information or context information.

Owner:SONY CORP

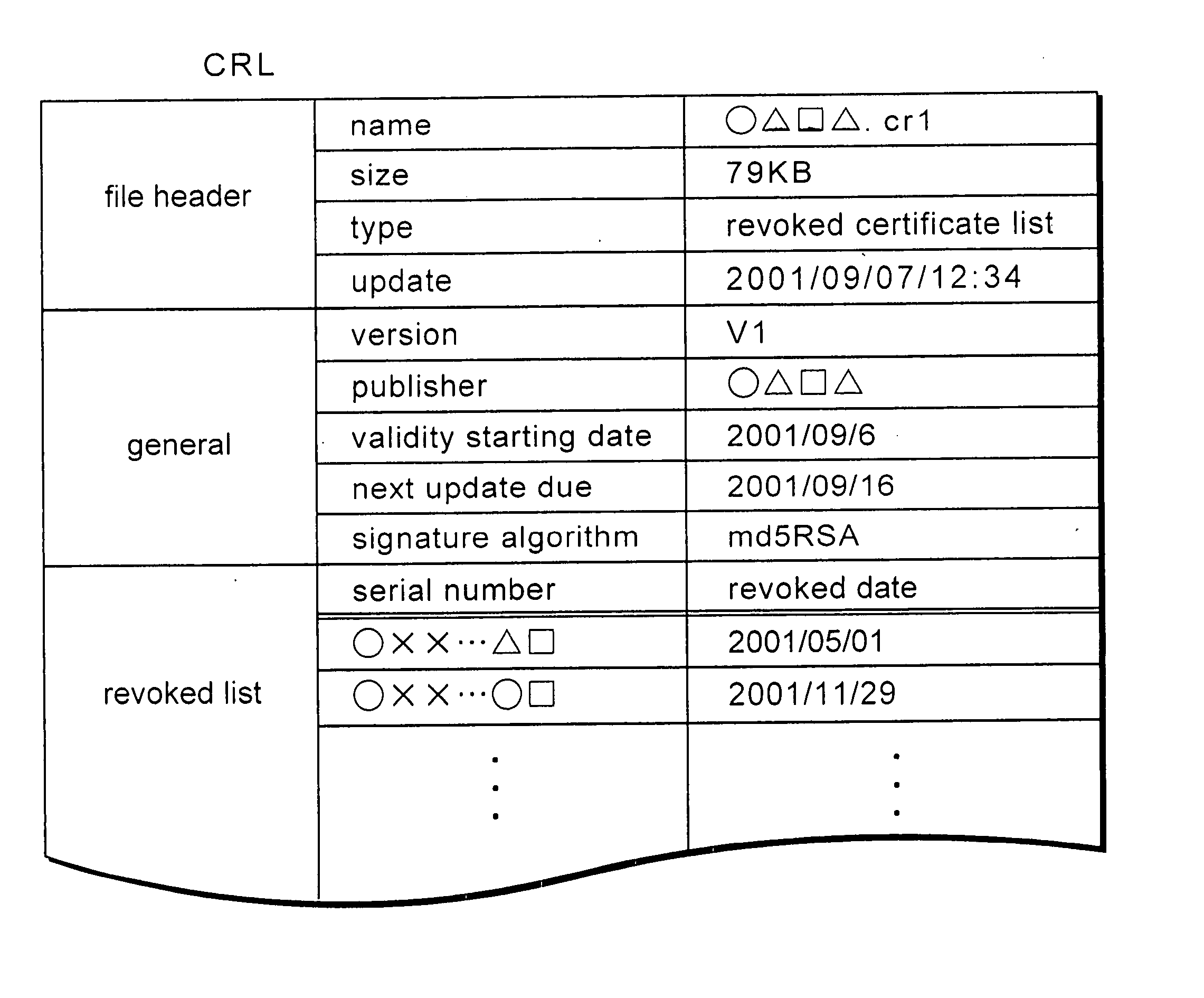

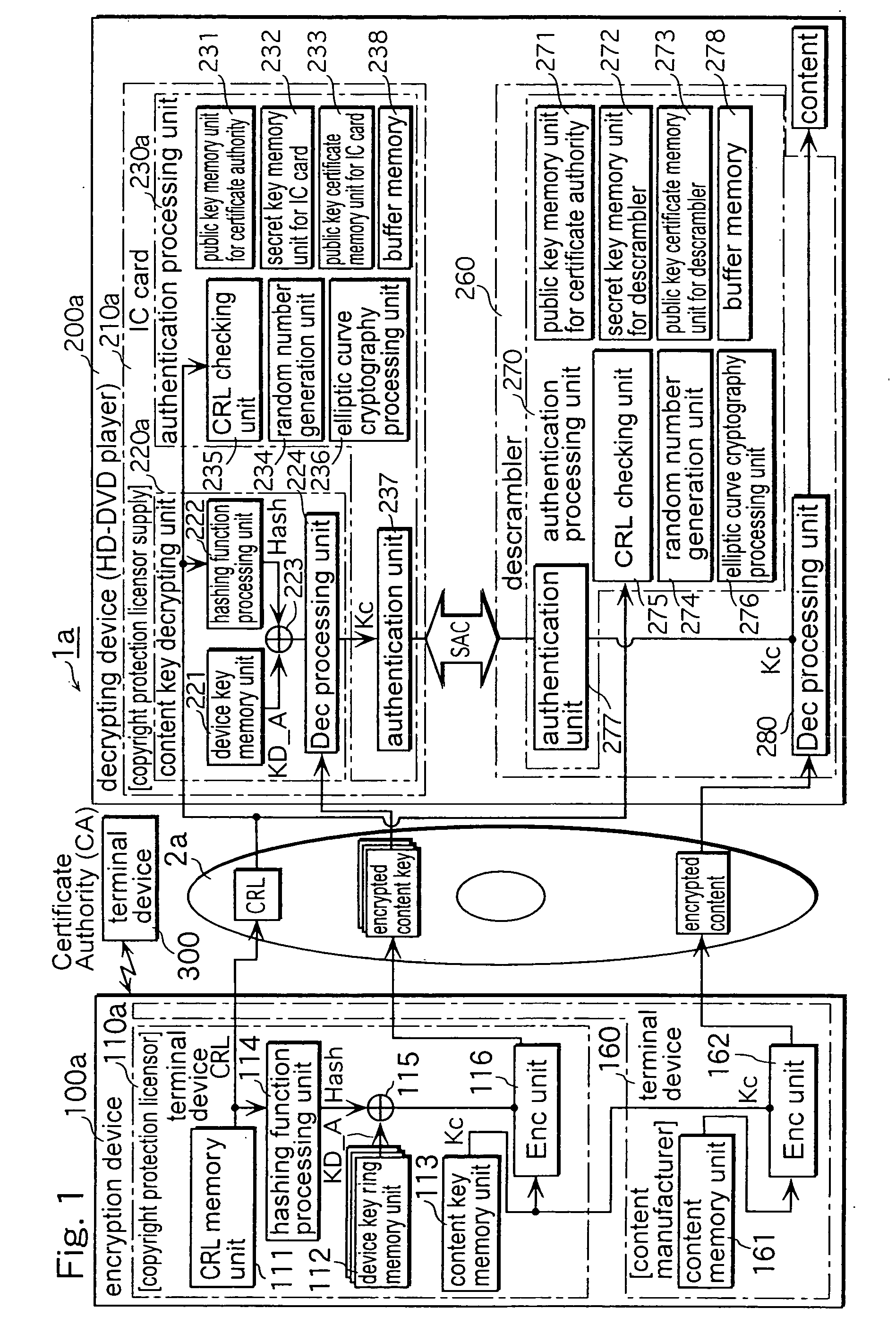

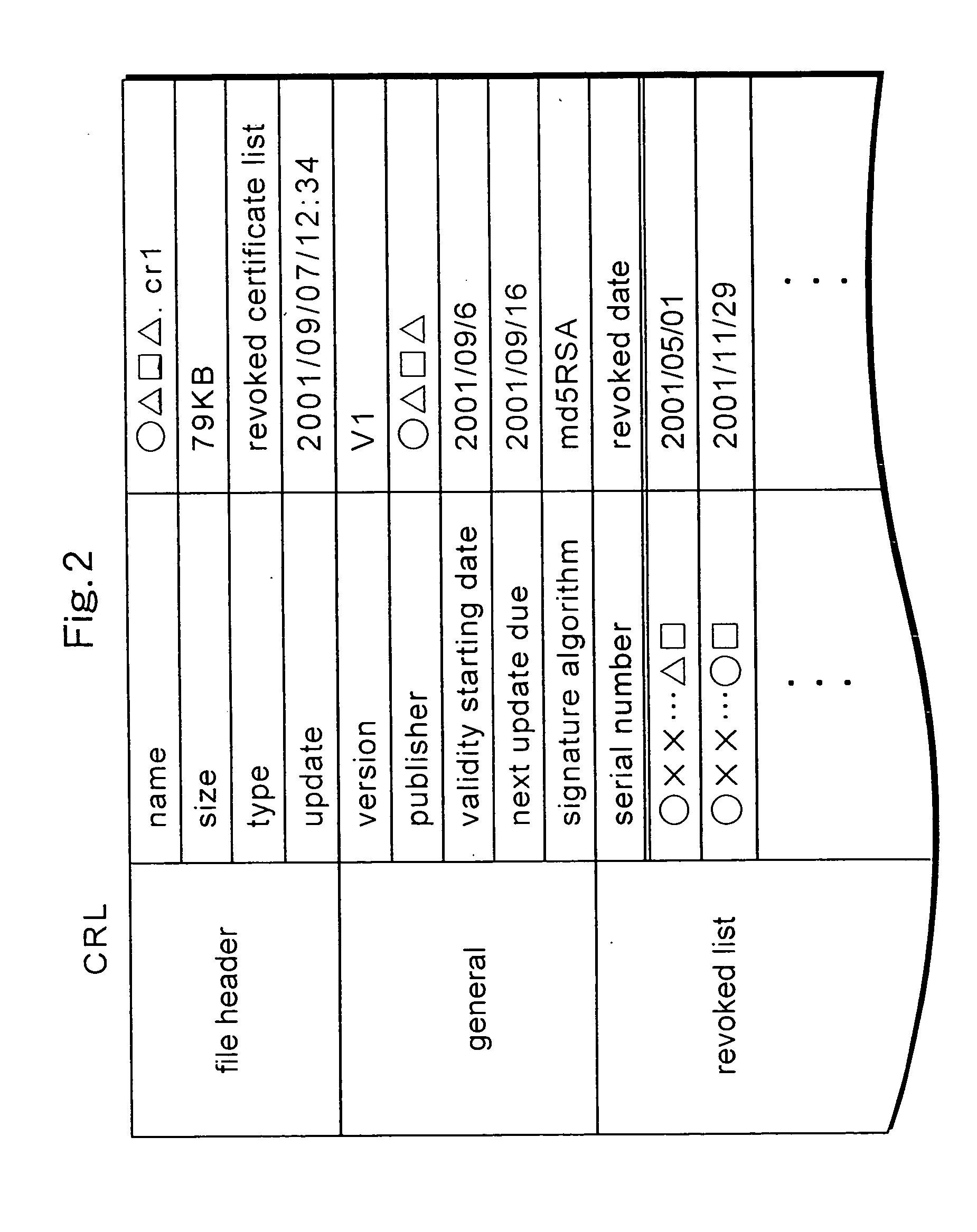

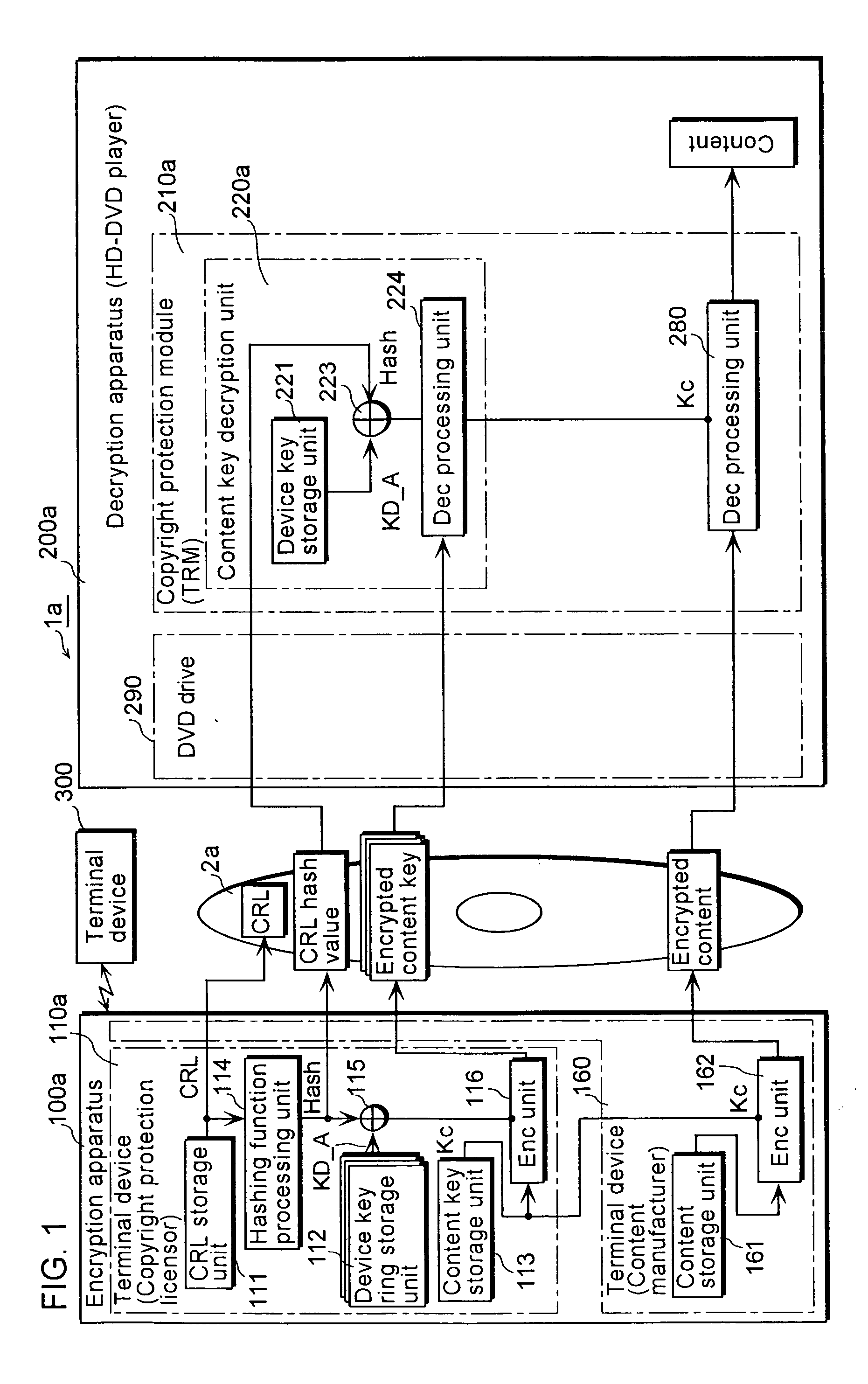

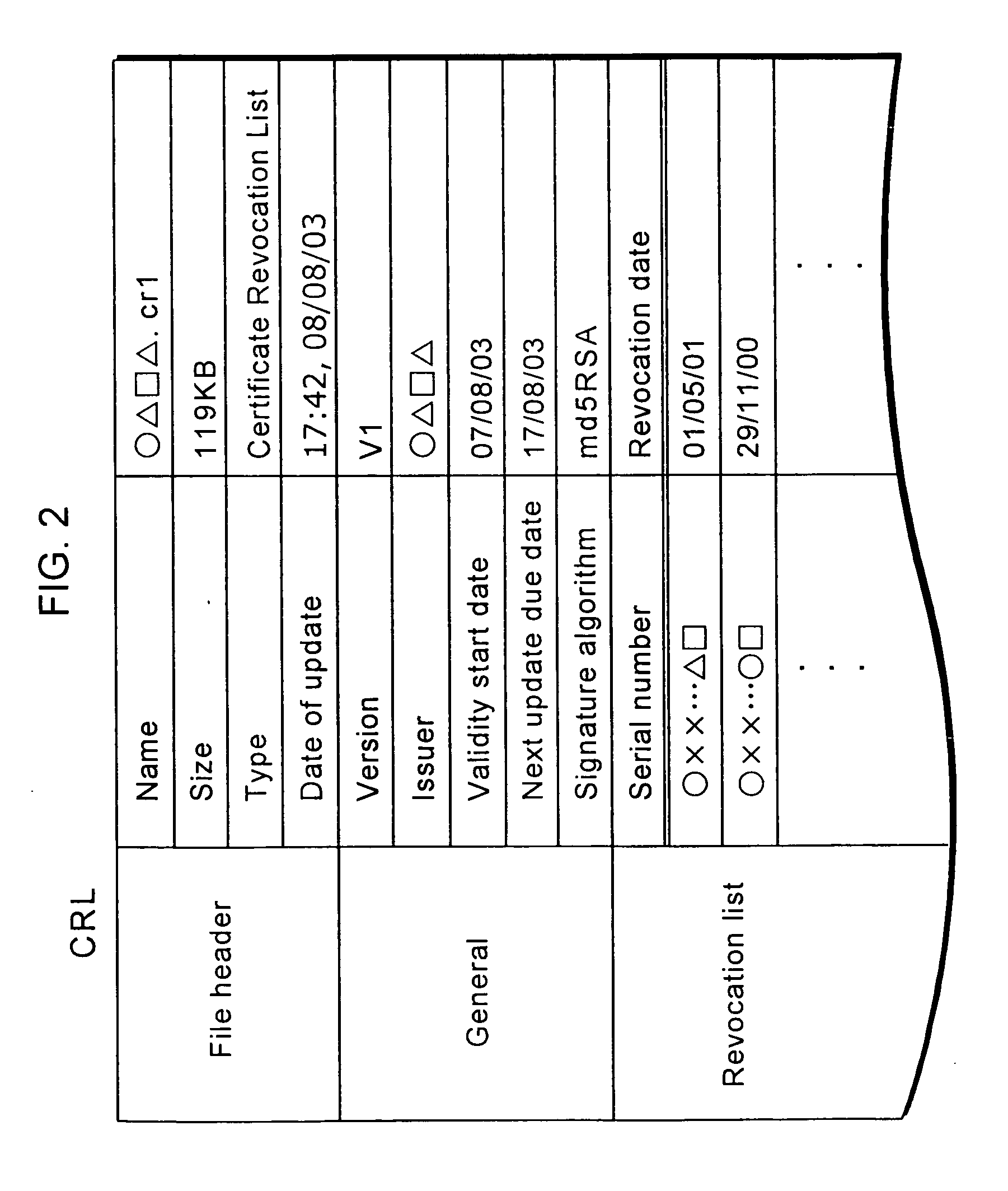

Encryption device a decrypting device a secret key generation device a copyright protection system and a cipher communication device

InactiveUS20050021941A1Reduce processingSecure transmissionKey distribution for secure communicationMultiple keys/algorithms usageComputer hardwareHash function

An encryption device, a decrypting device, a secret key generation device, a copyright protection system and a cipher communication device comprise: a CRL memory unit 111 that memorizes a CRL, a device key ring memory unit 112 that memorizes a peculiar device key KD A in every IC card 210a used in a decrypting device 200a, a content key memory unit 113 that memorizes a content key Kc which is a secret key for decrypting content, a hashing function processing unit 114 that calculates a hashing value of the CRL memorized in the CRL memory unit 111, an Ex-OR unit 115 that carries out an exclusive OR between the hashing value and the device key KD A memorized in the device key ring memory unit 112, and an Enc unit 116 that encrypts the content key Kc memorized in the content key memory unit 113 with an output value of an Ex-OR unit 115.

Owner:INTERTRUST TECH CORP

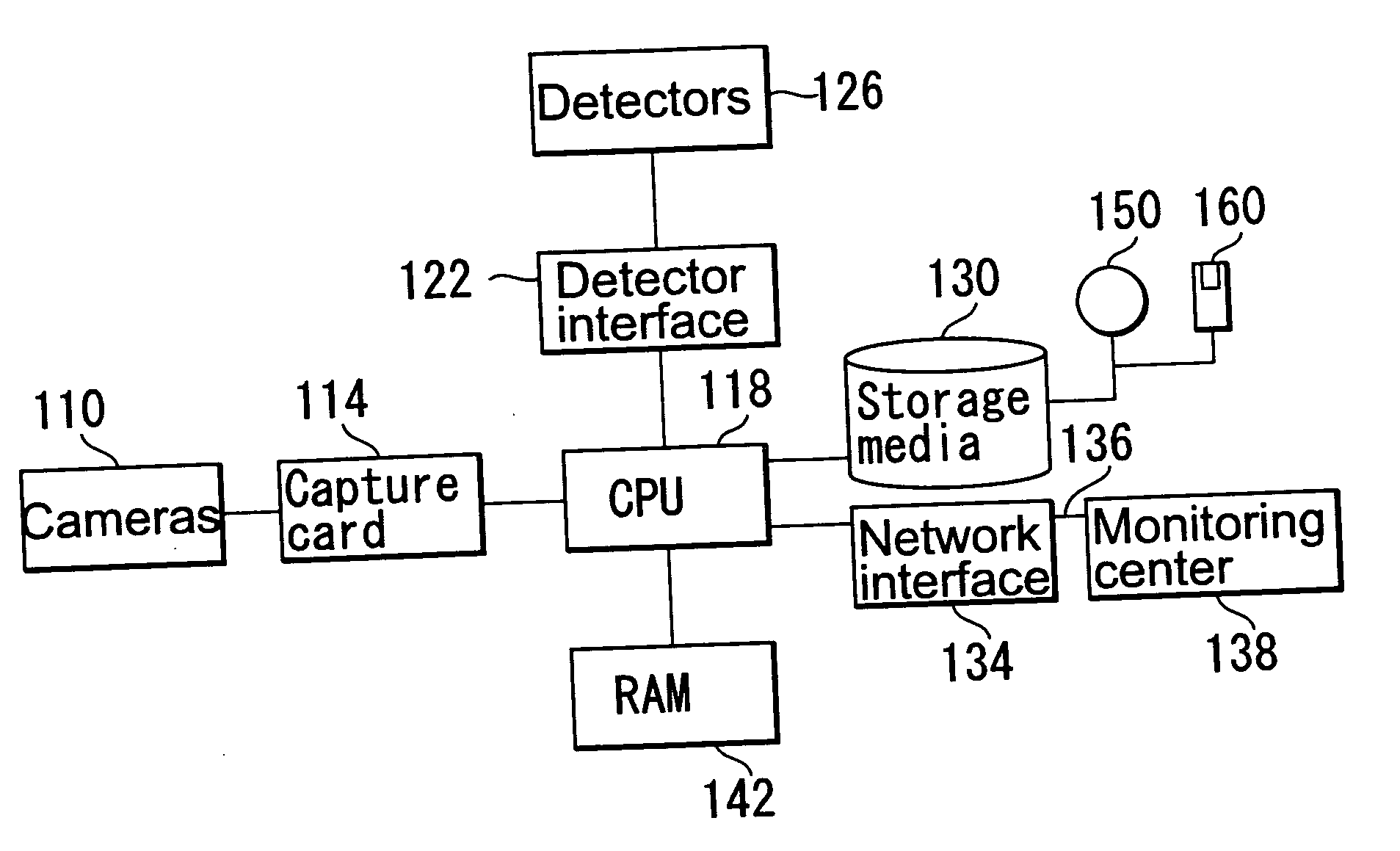

Imaging apparatus, imaging system and method thereof

InactiveUS20050018049A1Reduce required storage spaceAttenuation bandwidthTelevision system detailsColor television with pulse code modulationImaging equipmentImaging data

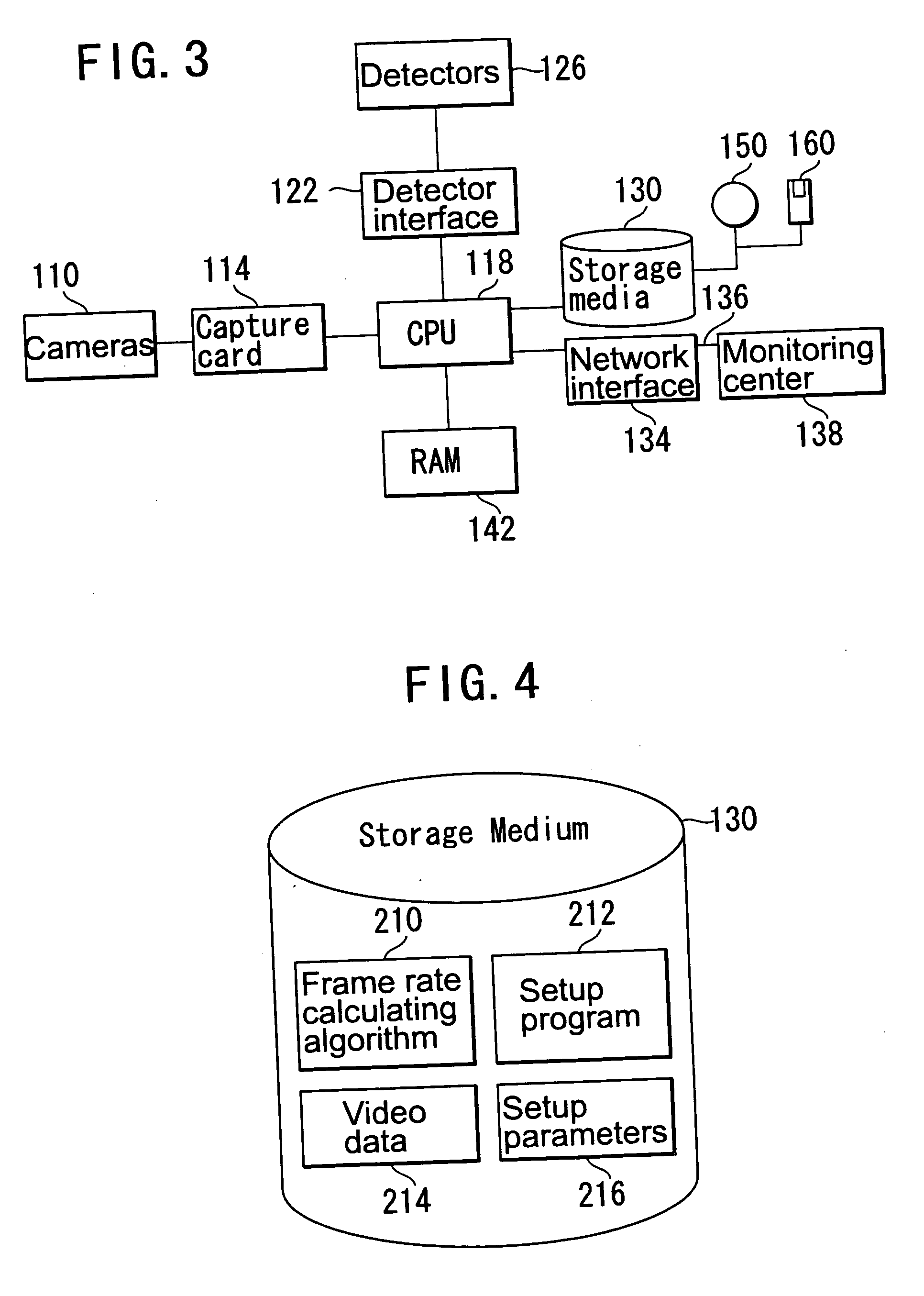

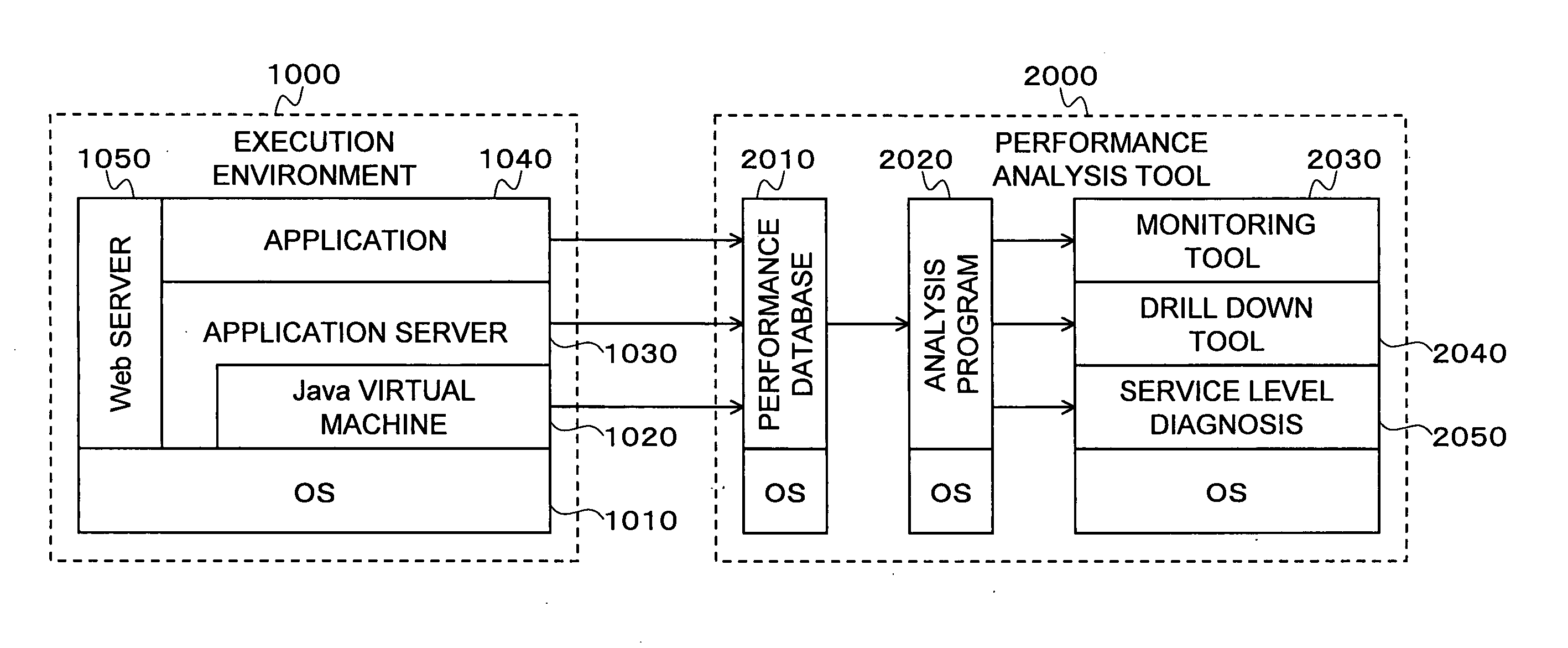

To provide a system, apparatus and method of changing frame rate of cameras according to the detector that has sent an alarm signal, in order to optimize utilization of hardware resources. An apparatus for setting a frame rate under which images are captured by a camera in an image capturing system having a plurality of cameras and a plurality of detectors, the apparatus including: detector interface for receiving a first signal from at least one of the sensors; association unit for associating the first signal with information related to the camera; calculation unit for calculating a frame rate of each of the plurality of cameras based on the association between the first signal and the information related to the cameras; setting unit for setting the frame rate of the camera calculation by the calculation unit; and second reception unit (capture card) for receiving image data from the camera at a frame rate set by the setting unit.

Owner:SONY CORP

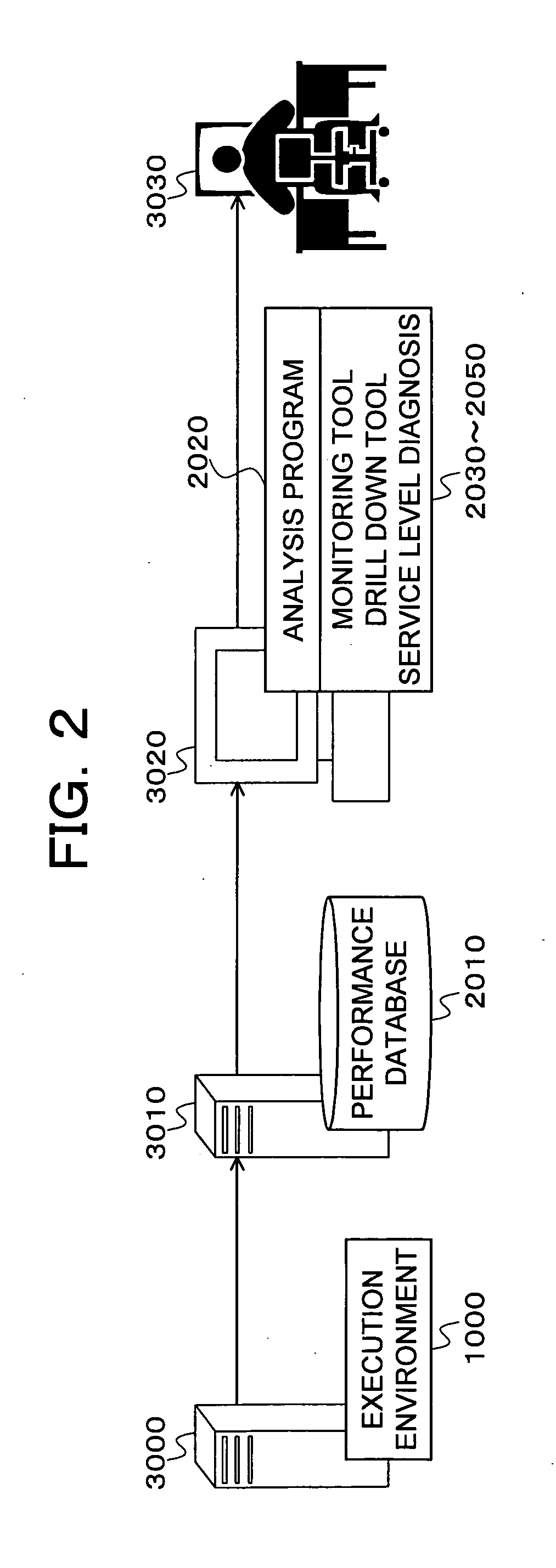

Method for predicting and avoiding danger in execution environment

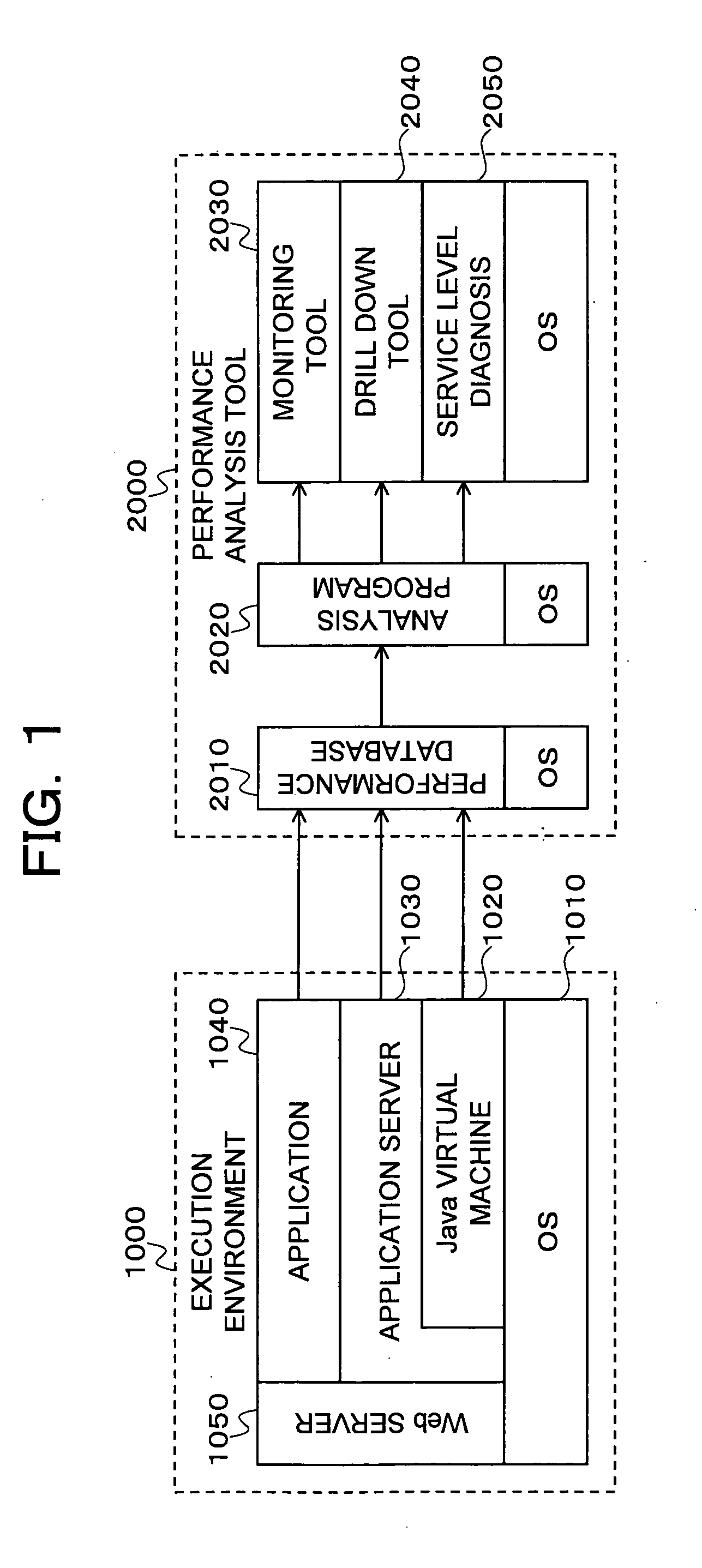

InactiveUS20050240641A1Reduce loadShort timeData processing applicationsMemory adressing/allocation/relocationApplication serverOut of memory

Measurement / analysis unit in a Java virtual machine has the function of measuring data when an event of garbage collection occurs, and the function of periodically measuring data. The measurement / analysis unit analyzes the measured data and predicts a danger of a memory shortage, and predicts a danger using an algorithm depending on the type of garbage collection used by the Java virtual machine. An application server is notified of a warning of the predicted danger of a memory shortage by an analysis result notification means by an inter-process communication, or the like. The measurement / analysis unit calculates a memory capacity required to avoid the predicted danger of a memory shortage, and the calculated memory capacity is transmitted to the application server by the analysis result notification means by an inter-process communication, or the like in the same way as the warning.

Owner:FUJITSU LTD

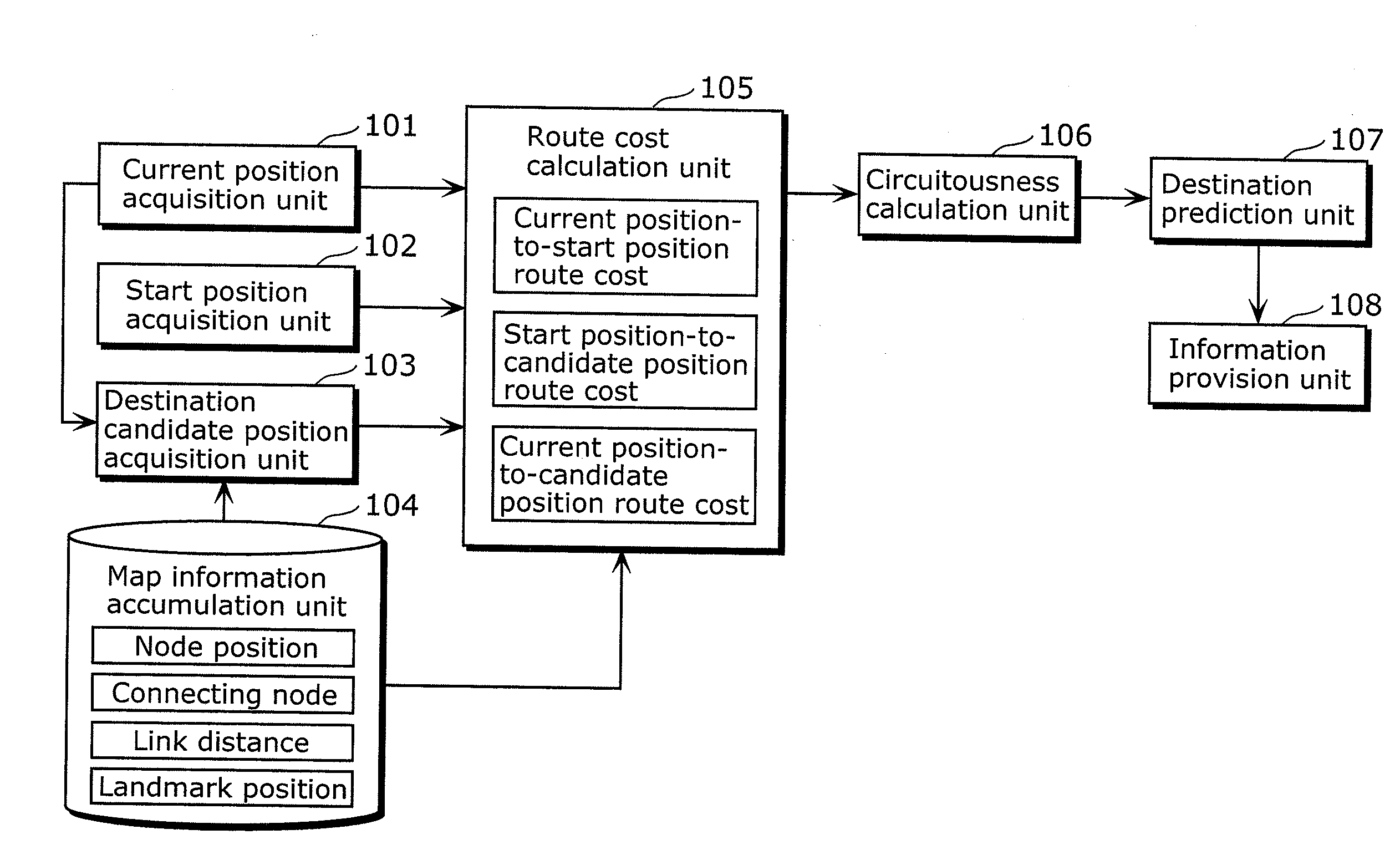

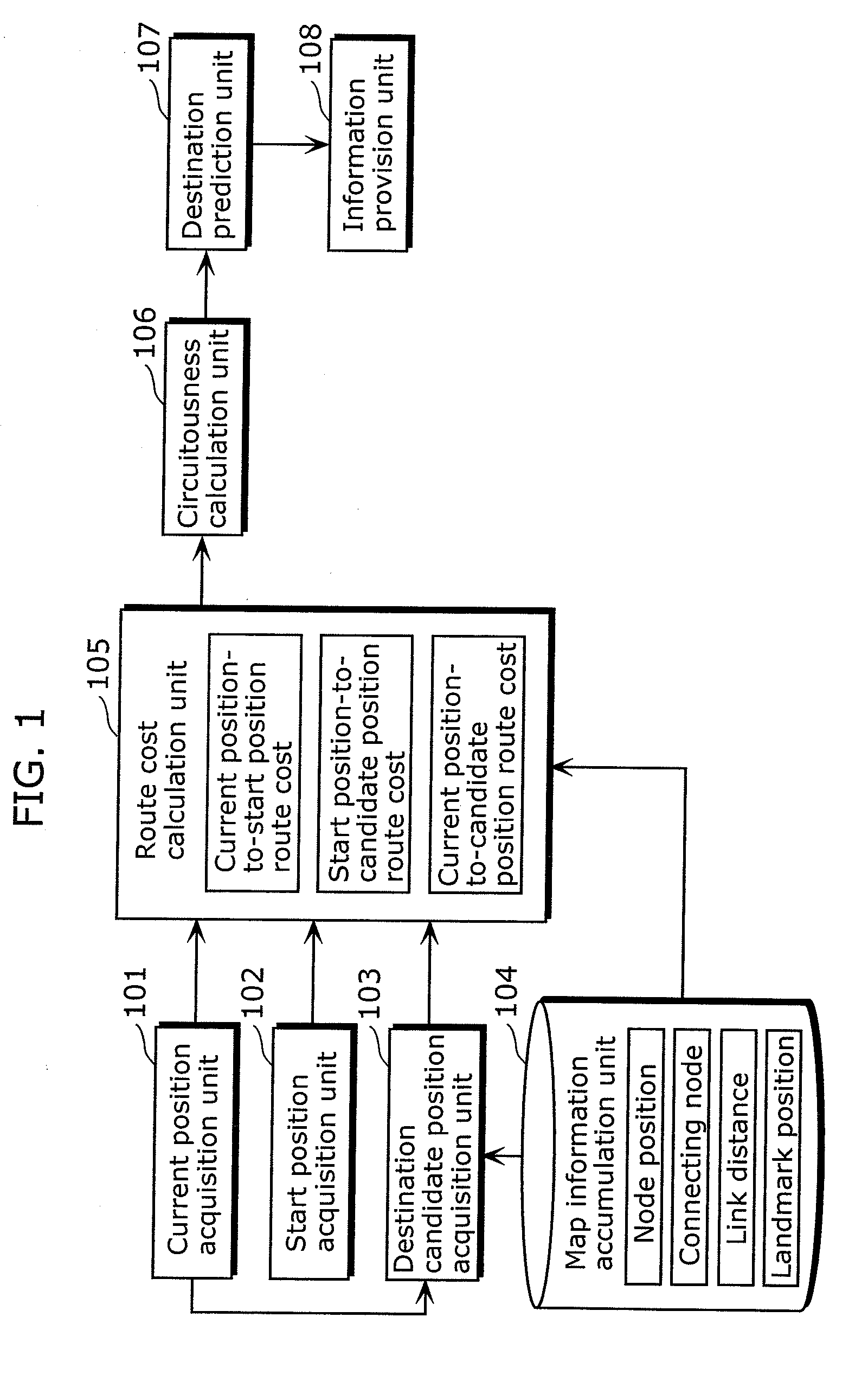

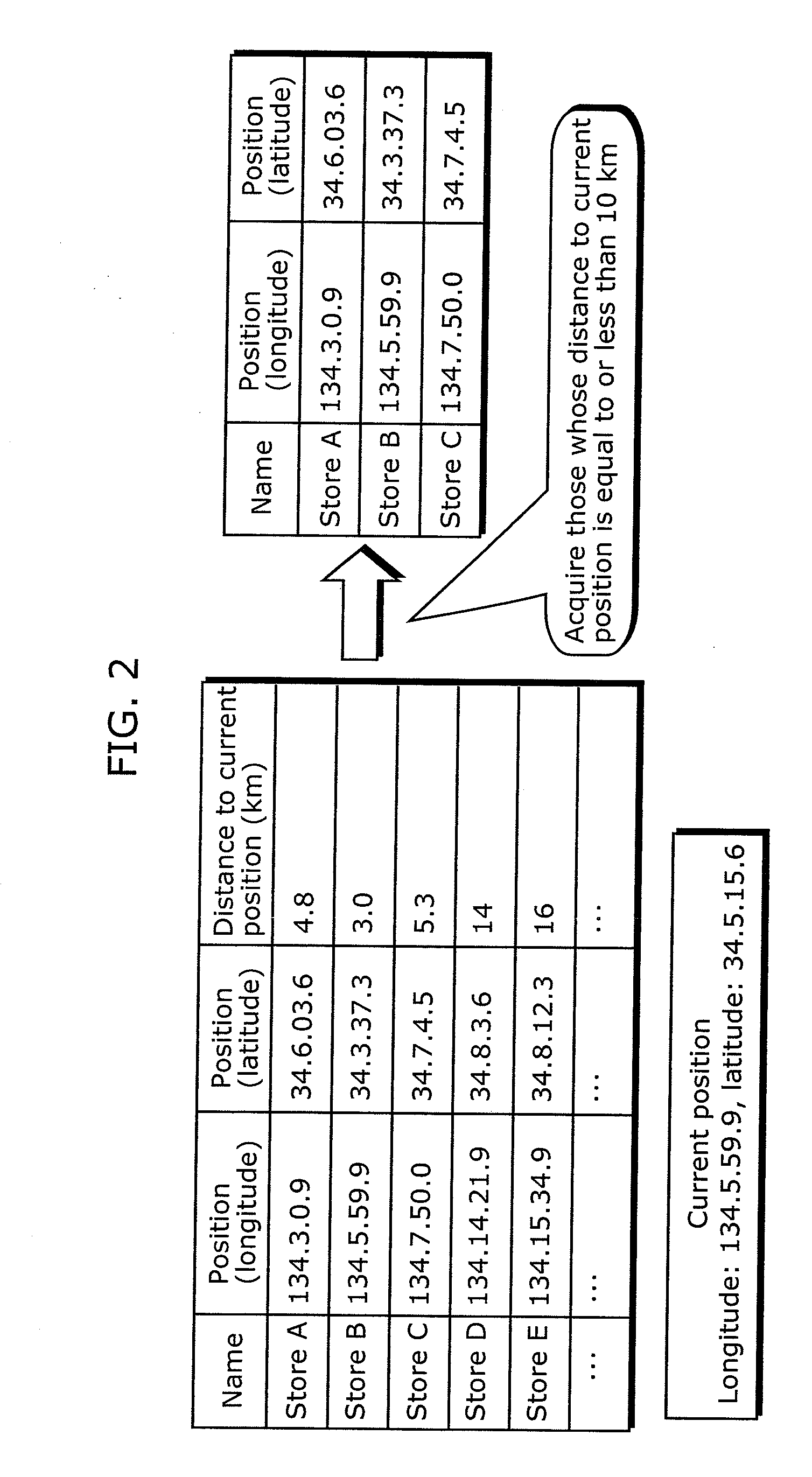

Destination prediction device and destination prediction method

InactiveUS20090105934A1Analogue computers for vehiclesInstruments for road network navigationPredictive methodsSimulation

To provide a destination prediction device that predicts a destination of a mobile body without being dependent on the availability of a history of the destination.A destination prediction device includes: a map information accumulation unit (104) that accumulates map information including at least positions of a plurality of points on a map and routes between the plurality of points; a start position acquisition unit (102) that acquires a start position of the mobile body; a current position acquisition unit (101) that acquires a current position of the mobile body; a destination candidate position acquisition unit (103) that acquires positions of a plurality of destination candidates that may potentially become destinations of the mobile body from the map information accumulation unit (104) based on the acquired current position; a circuitousness calculation unit (106) that calculates a circuitousness which is a deviation of a route from the start position to the position of the destination candidate including the current position with respect to a route having minimum route cost from the start position to the position of the destination candidate; and a destination prediction unit (107) that predicts, as a destination, a destination candidate whose calculated circuitousness is the smallest among the destination candidates.

Owner:GK BRIDGE 1

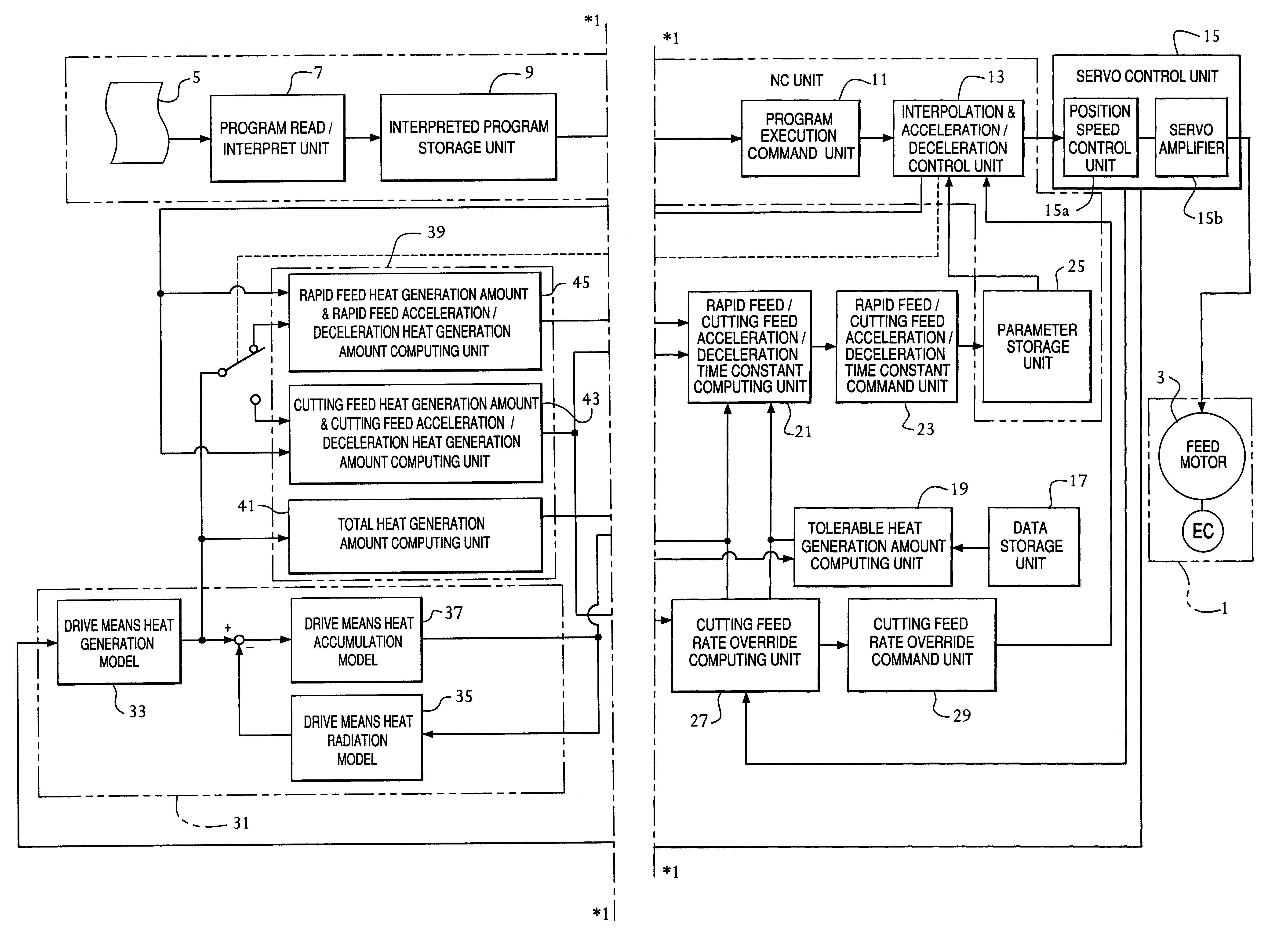

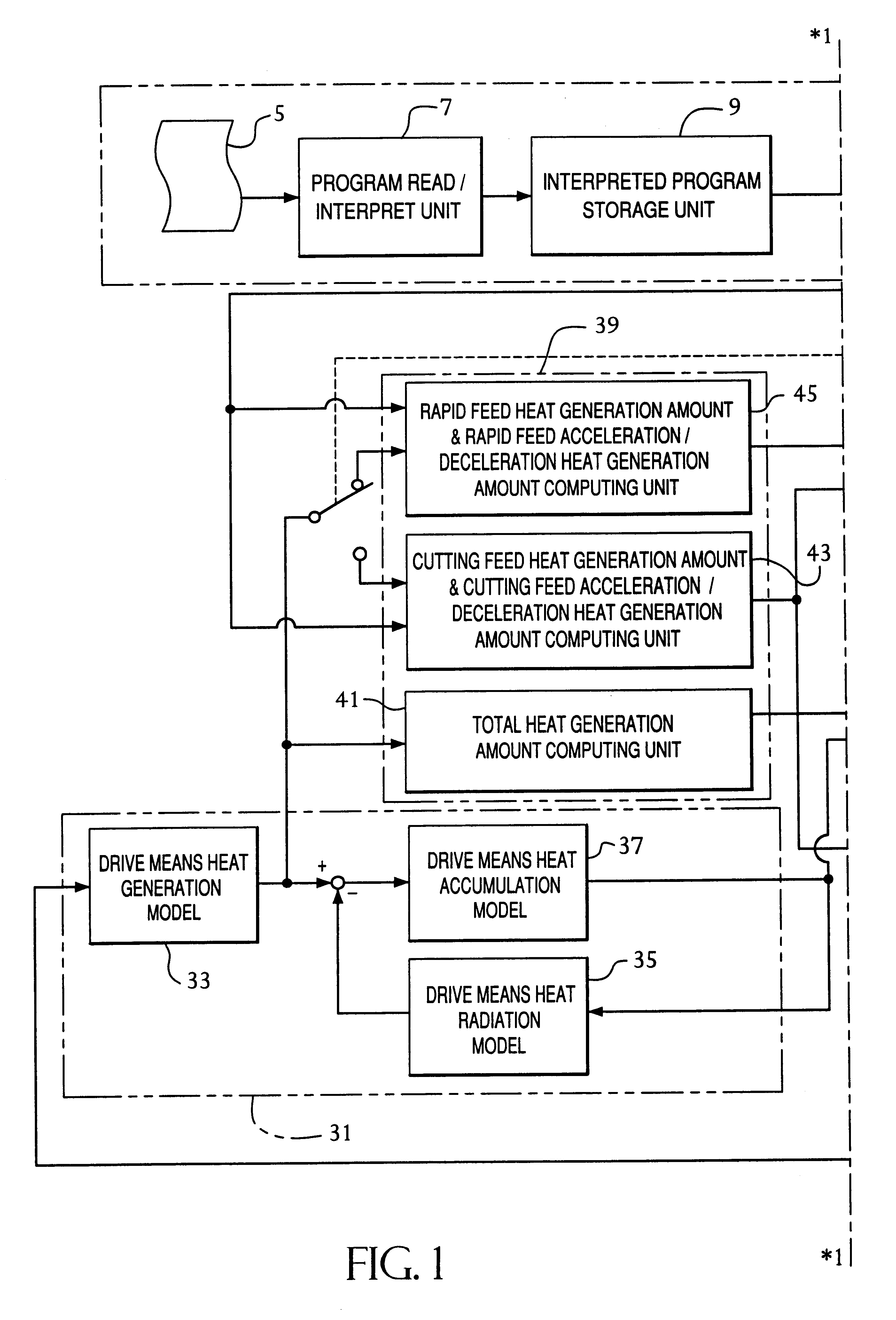

Method and apparatus for controlling numerically controlled machine tool

InactiveUS6291959B1Programme-controlled manipulatorAutomatic control devicesNumerical controlProcess engineering

A method and an apparatus for controlling a numerically controlled machine tool, wherein the heat generation amount and the temperature of a drive unit including a servo amplifier 15b and a feed shaft motor 3 are computed by a drive unit heat generation amount computing unit 31 by simulation, and from the computed heat generation amount and the computed temperature, the total heat generation amount of the drive unit, the cutting feed heat generation amount, the cutting load heat generation amount, etc. are computed by a feed heat generation amount computing unit 39, so that the cutting feed rate override value of the numerically controlled machine tool 1 is computed by a cutting feed rate override computing unit 27 and effectuated by being output to a NC unit. Further, based on the temperature of the drive unit computed by a computing unit 31 or the temperature computed by a temperature data computing unit 47 or the temperature detected by a temperature detection sensor 49, etc., the proper values of the feed acceleration / deceleration time constants τ<SMALLCAPS>r < / SMALLCAPS>and τ<SMALLCAPS>c < / SMALLCAPS>are computed and output as a ratio with respect to the set and stored initial values τ<SMALLCAPS>r0 < / SMALLCAPS>and τ<SMALLCAPS>C0 < / SMALLCAPS>thereby to control the NC commanded rate. The overheating of the feed axis drive unit is prevented while at the same time improving the machining efficiency.

Owner:MAKINO MILLING MASCH CO LTD

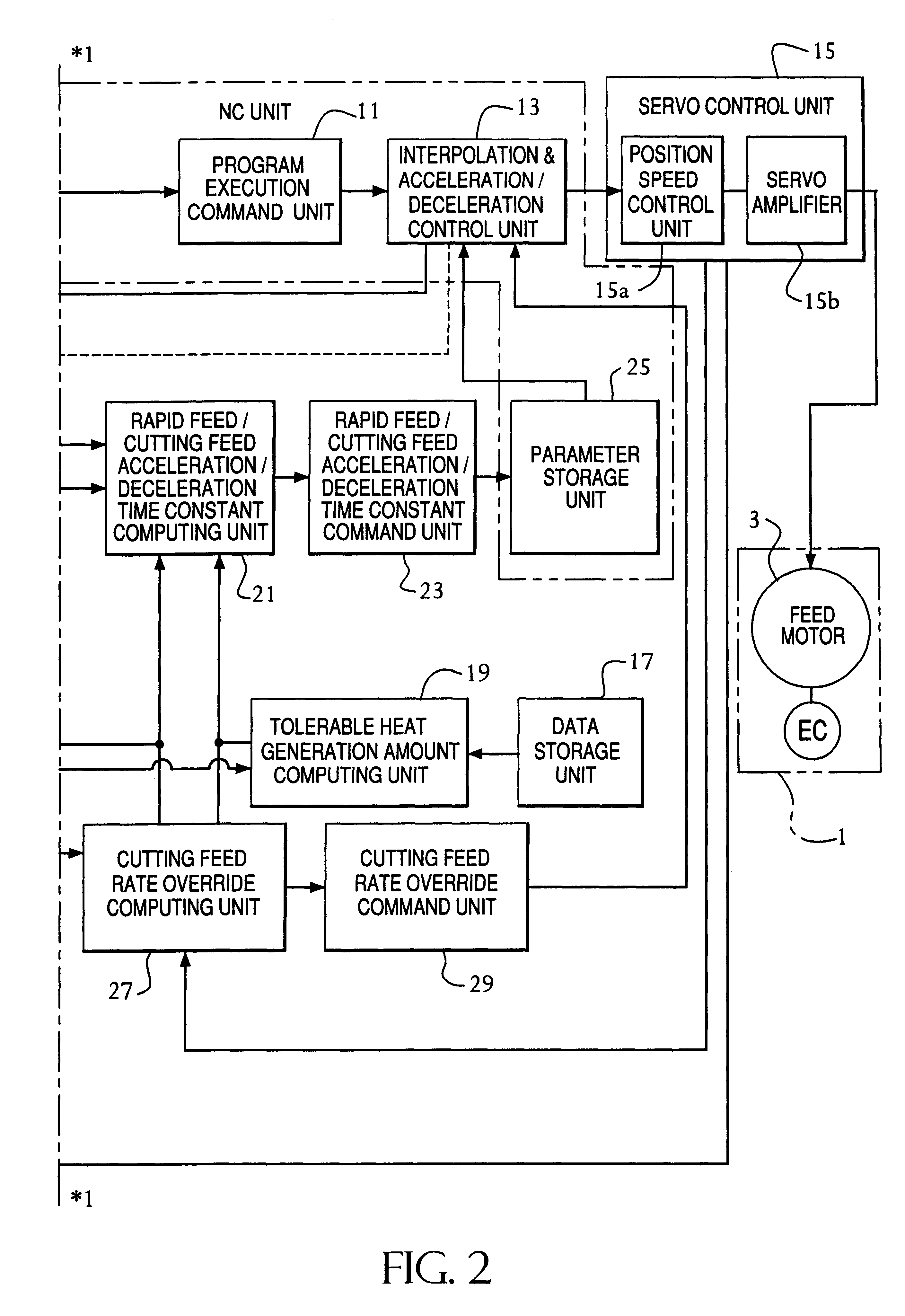

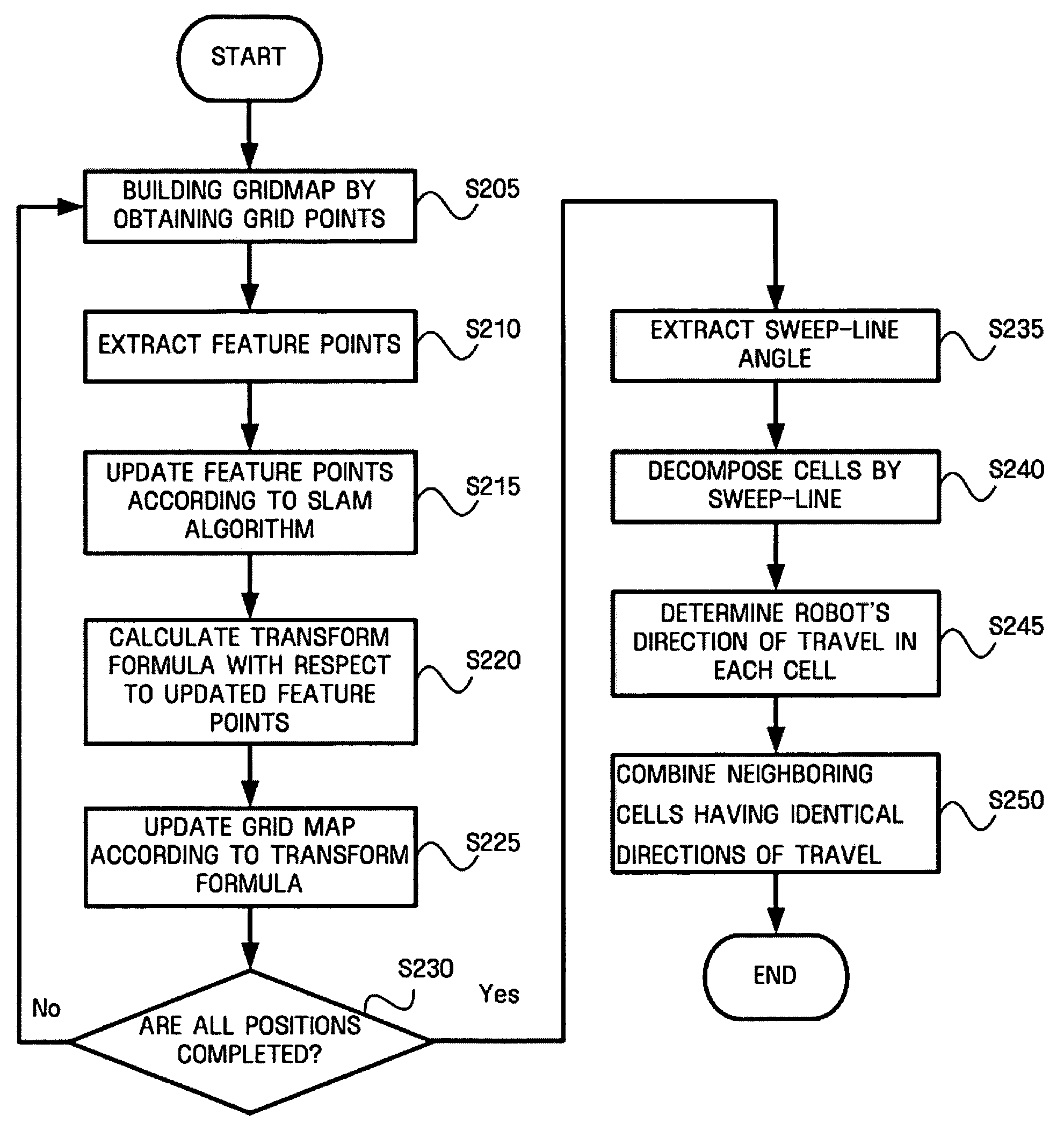

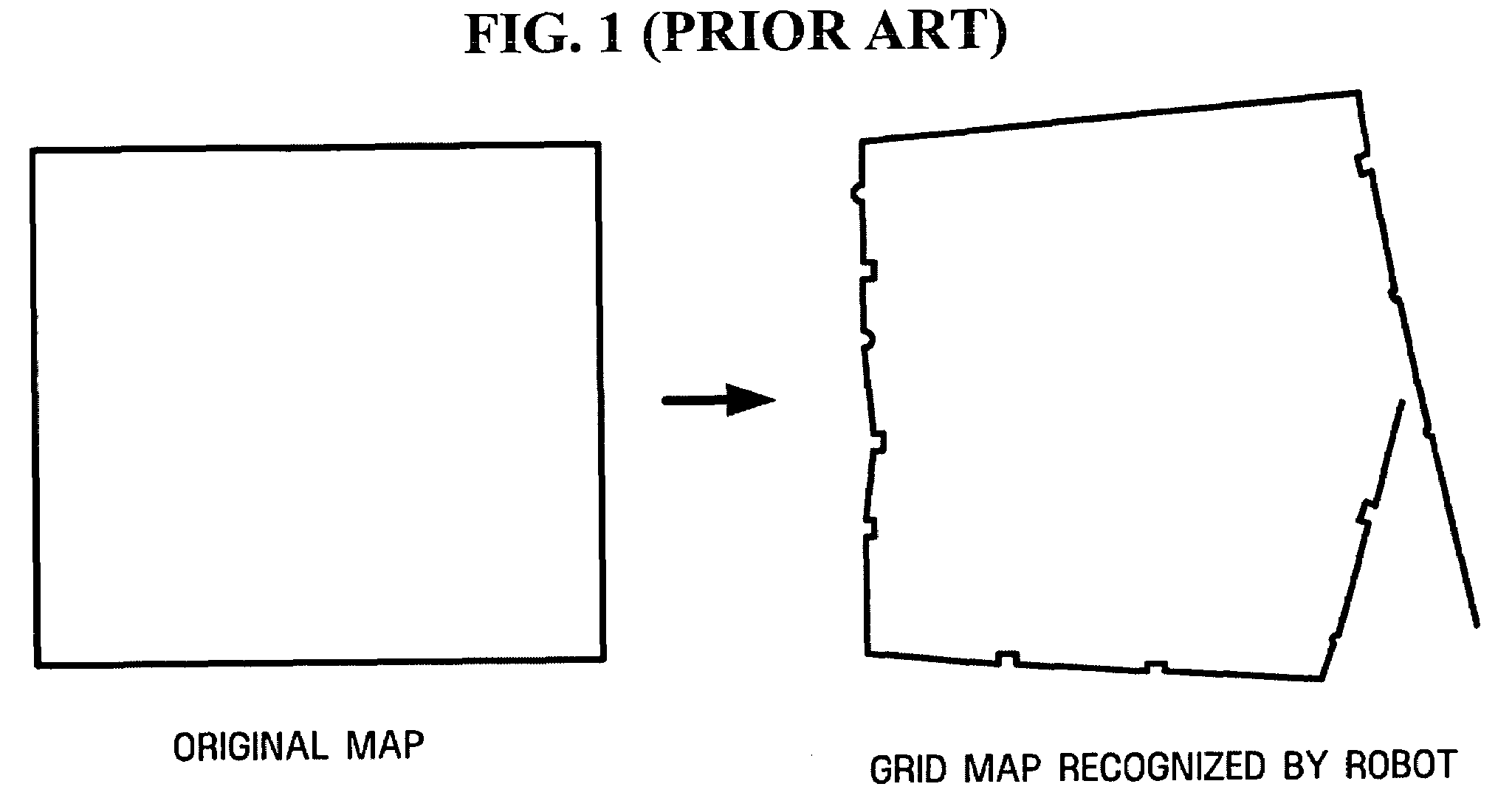

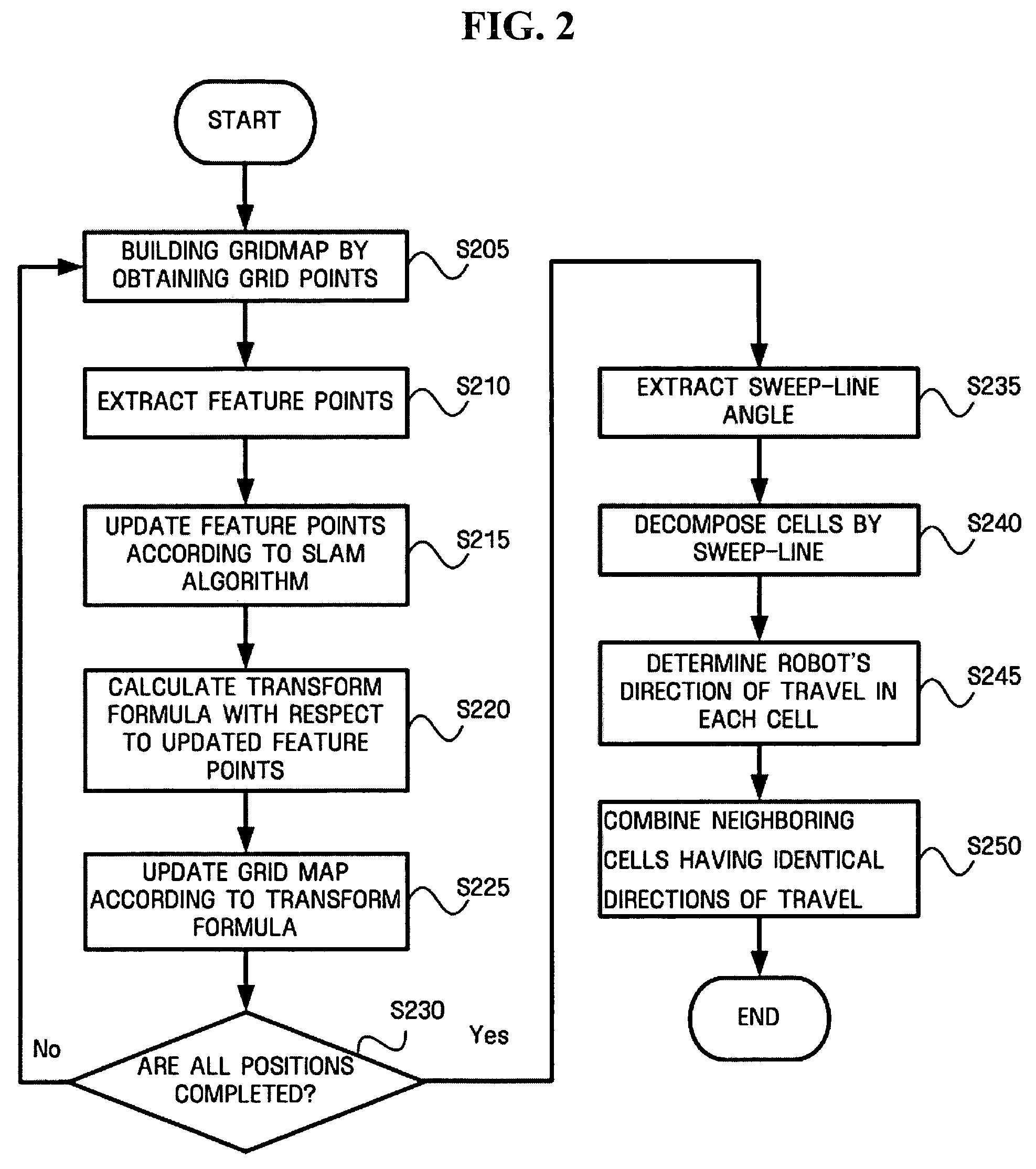

Method, apparatus, and medium for building grid map in mobile robot and method, apparatus, and medium for cell decomposition that uses grid map

Owner:SAMSUNG ELECTRONICS CO LTD

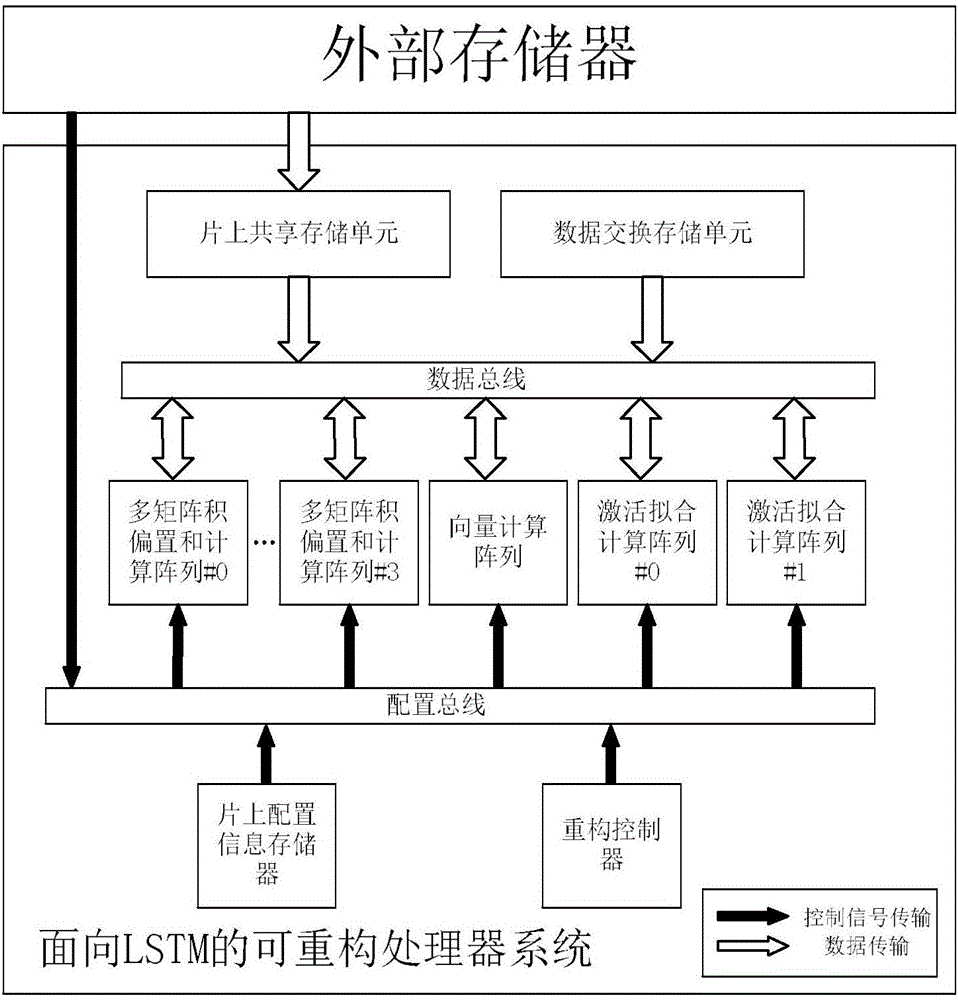

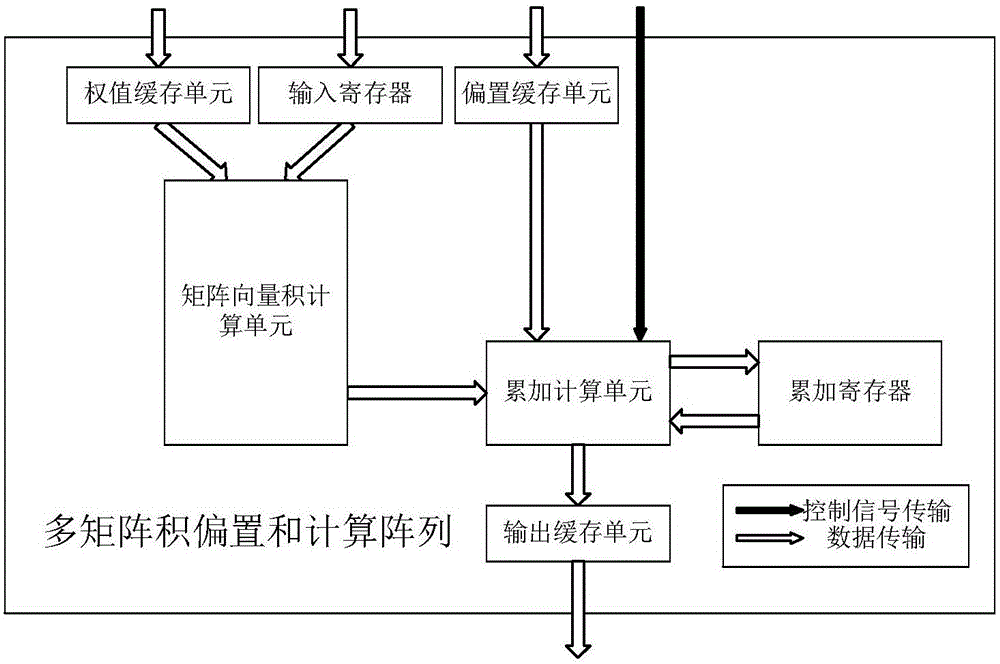

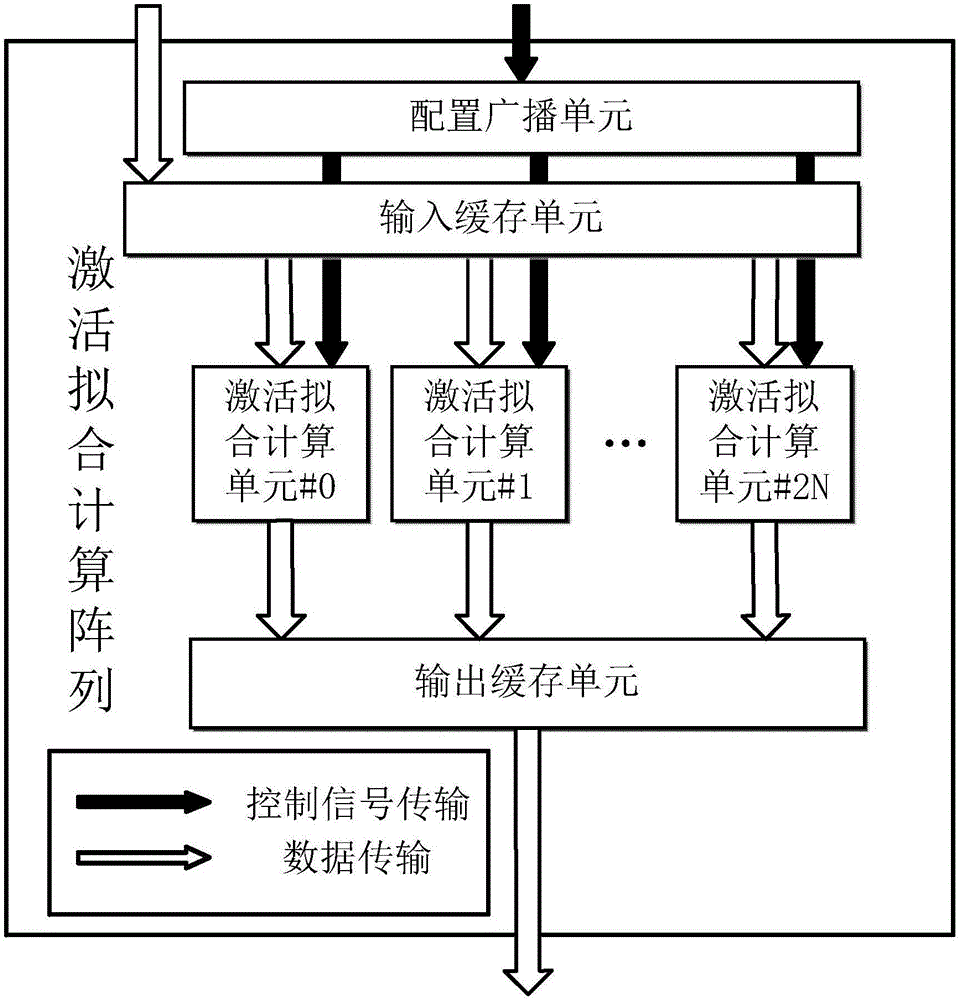

Multi-computing-unit coarse-grained reconfigurable system and method for recurrent neural network

ActiveCN106775599AConcurrent instruction executionPhysical realisationActivation functionControl signal

The invention discloses a multi-computing-unit coarse-grained reconfigurable system and method for a recurrent neural network LSTM (long short-term memory). The system comprises multi-matrix-product bias and calculation arrays, activation fitting calculation arrays and vector quantity calculation arrays. The multi-matrix-product bias and calculation arrays are used for realizing calculation and accumulation operation of multiple matrix vector products in the recurrent neural network and perform addition bias calculation under control of control signals, and output values are outputted through corresponding output cache units. The activation fitting calculation arrays are used for realizing a piecewise linear fitting calculation function of activation functions in the recurrent neural network LSTM, activation fitting calculation units are controlled by the control signals to perform corresponding activation function piecewise linear fitting calculation when input values enter input cache units, and output values are outputted through corresponding output cache units. The vector quantity calculation arrays are used for realizing dimension-based vector multiplication and vector addition calculation, and after multiplication units finish calculation, data are transmitted to vector addition units or directly outputted under control of the control signals. Parallelism degree, calculation speed and array utilization rate of the reconfigurable system are increased.

Owner:NANJING UNIV OF TECH

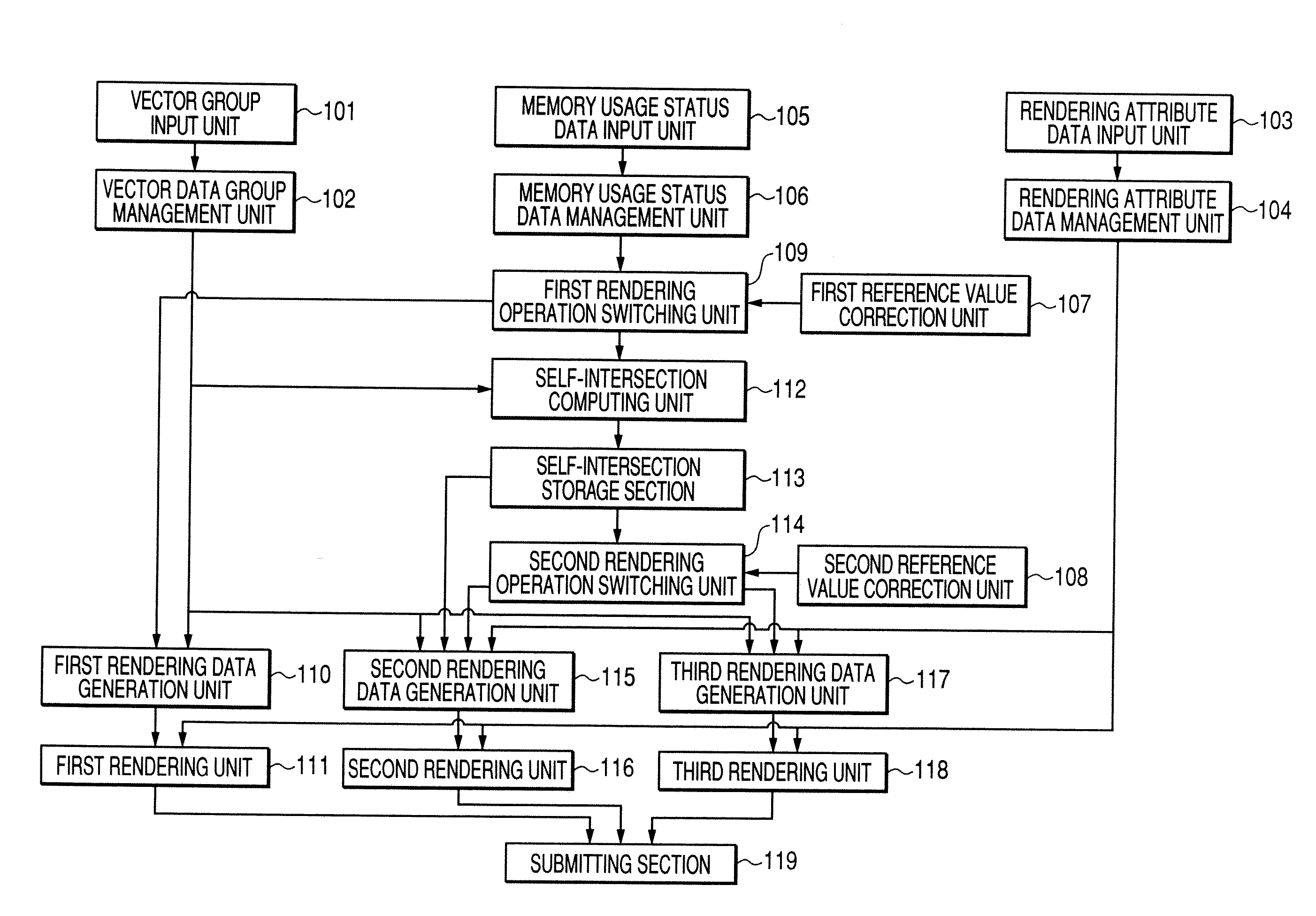

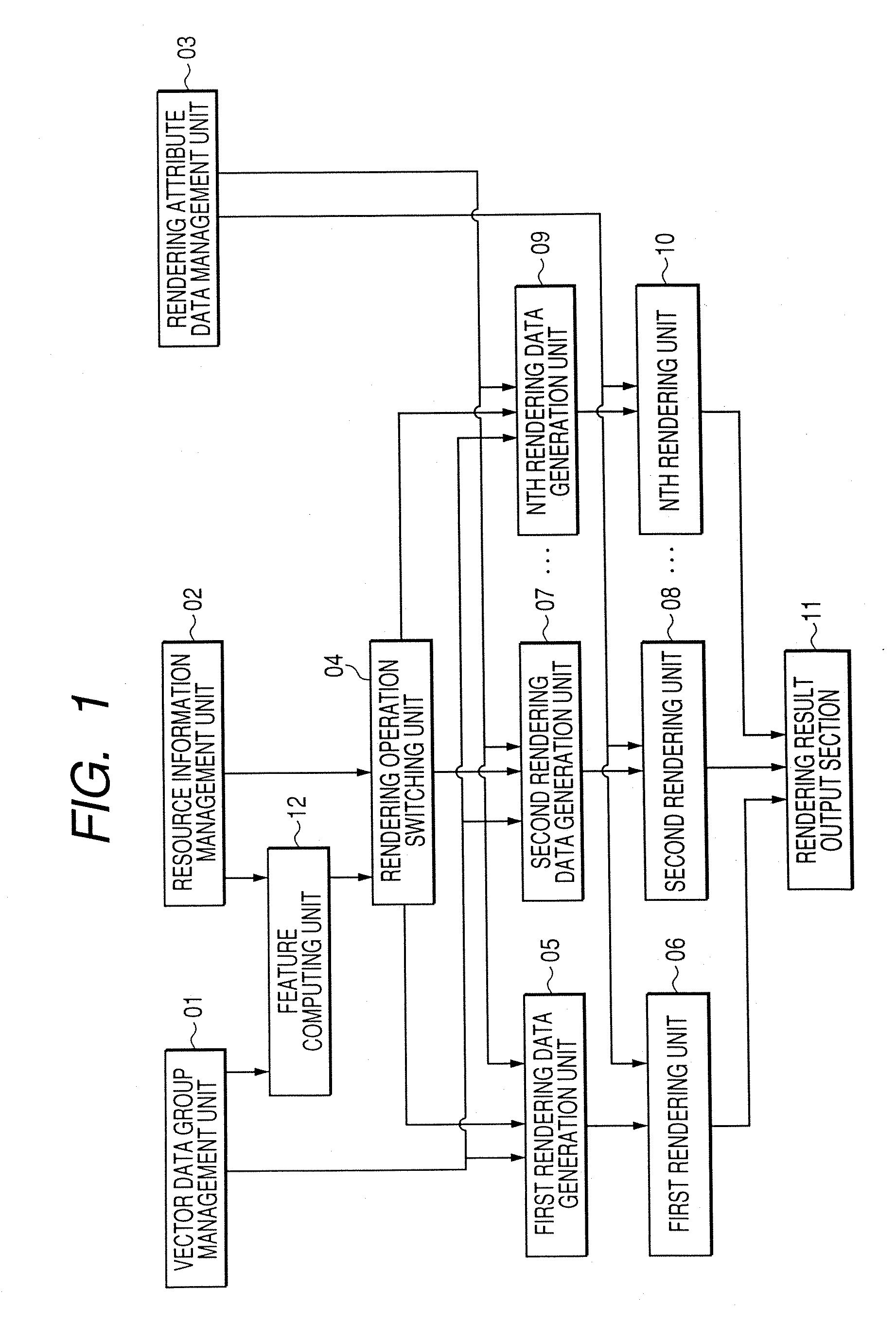

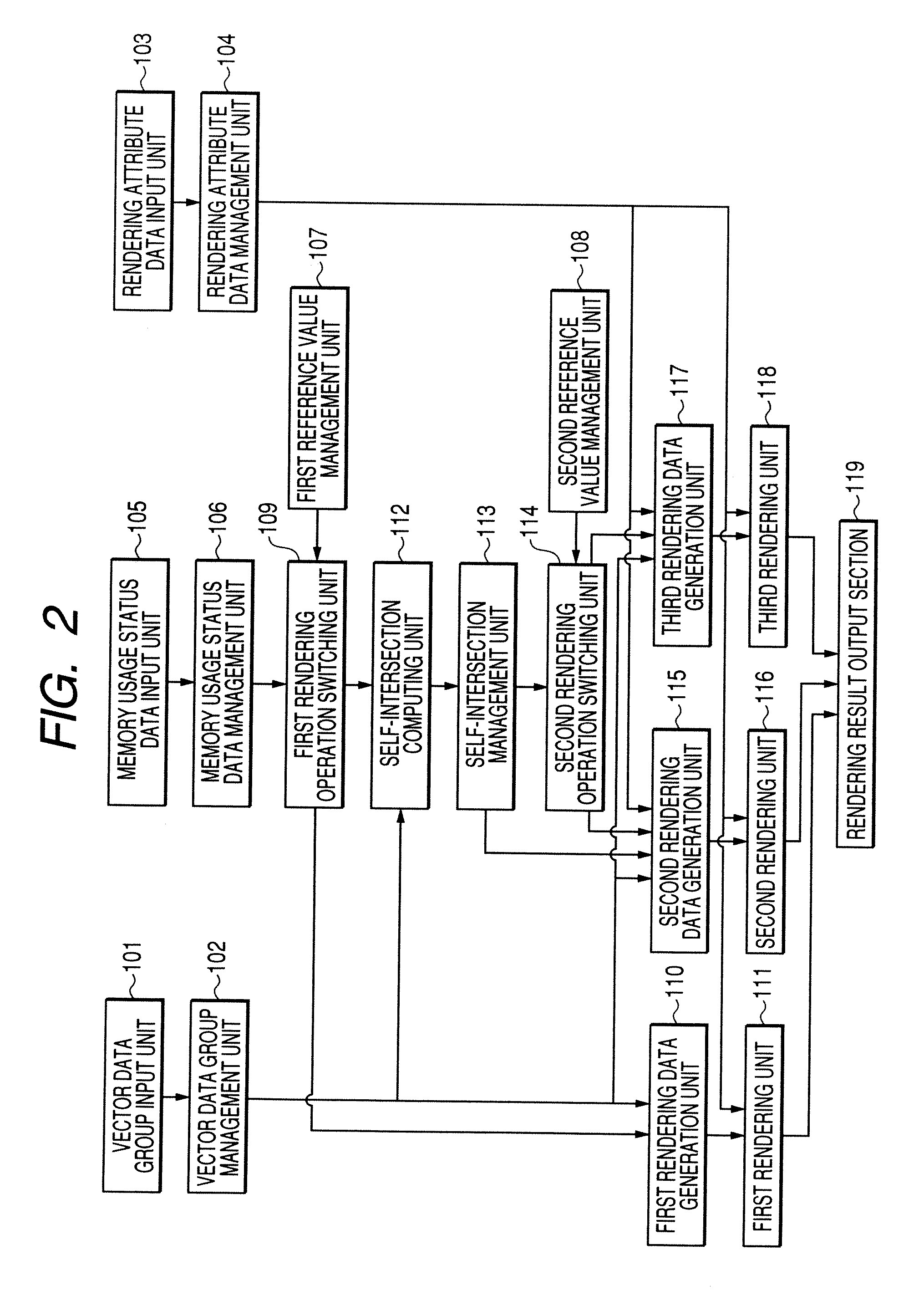

Graphics-rendering apparatus

InactiveUS20070236498A1Guaranteed high-speed and stable operationLower performance requirementsDrawing from basic elementsCathode-ray tube indicatorsGraphicsManagement unit

Graphics-rendering operation is performed by a procedure including: inputting a vector data group representing the shape of a graphic object to a vector data group management unit; inputting, to a rendering attribute data management unit, rendering attribute data representing information pertains to internal attributes of the graphic object; inputting resource information indicating a usage status into a resource information management unit; reading the managed vector data group from the vector data group management unit; computing a feature indicating the geometrical feature of the input graphic object by means of the feature computing unit; reading the computed graphic feature level and the resource information managed by the resource information management unit; effecting switching to generation of optimum rendering data; reading the vector data group managed by the vector data group management unit and the rendering attribute data managed by the rendering attribute data management unit; generating rendering data; reading the generated rendering data and the rendering attribute data managed by the rendering attribute data management unit; and performing rendering operation.

Owner:KK TOSHIBA

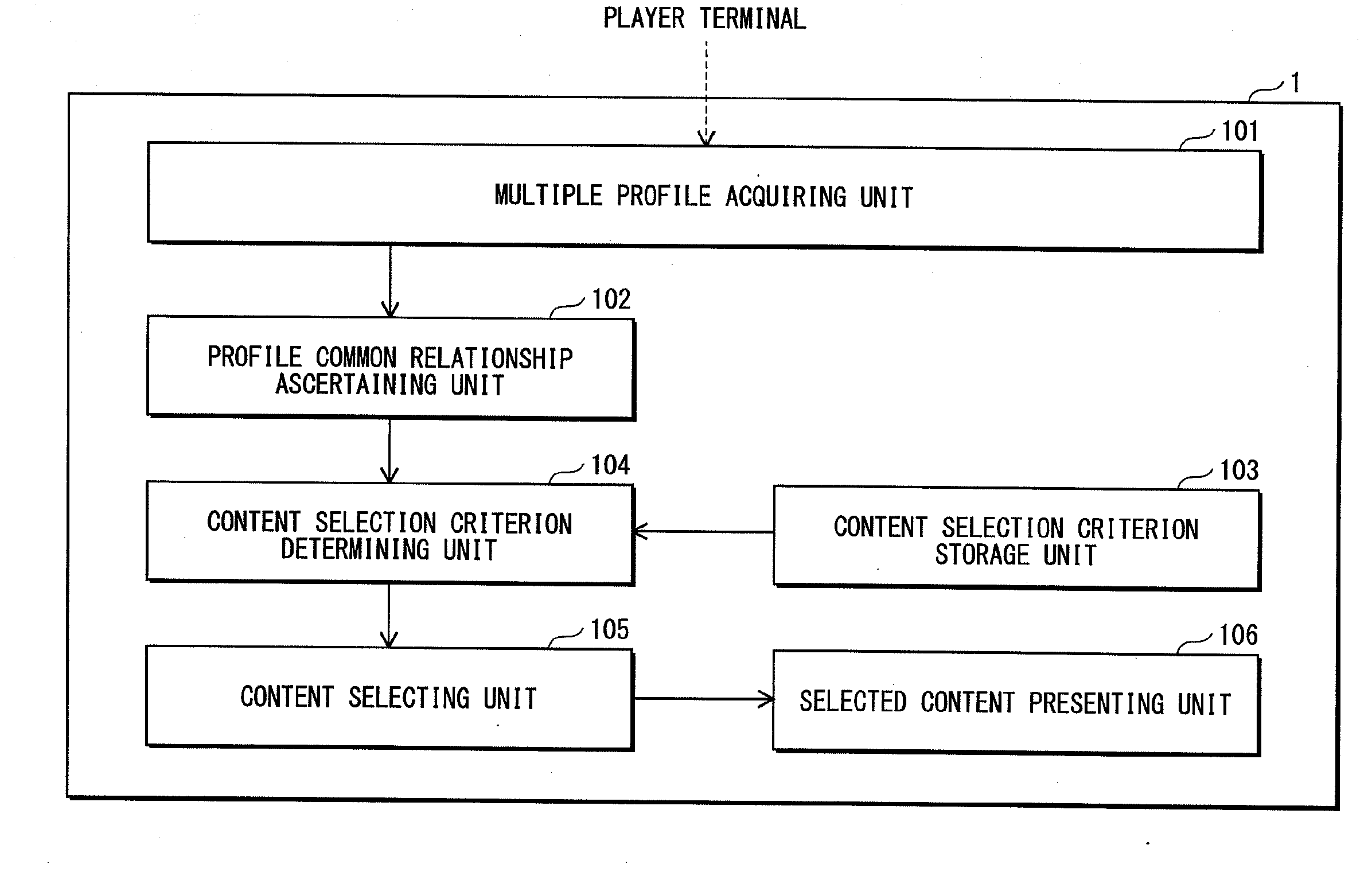

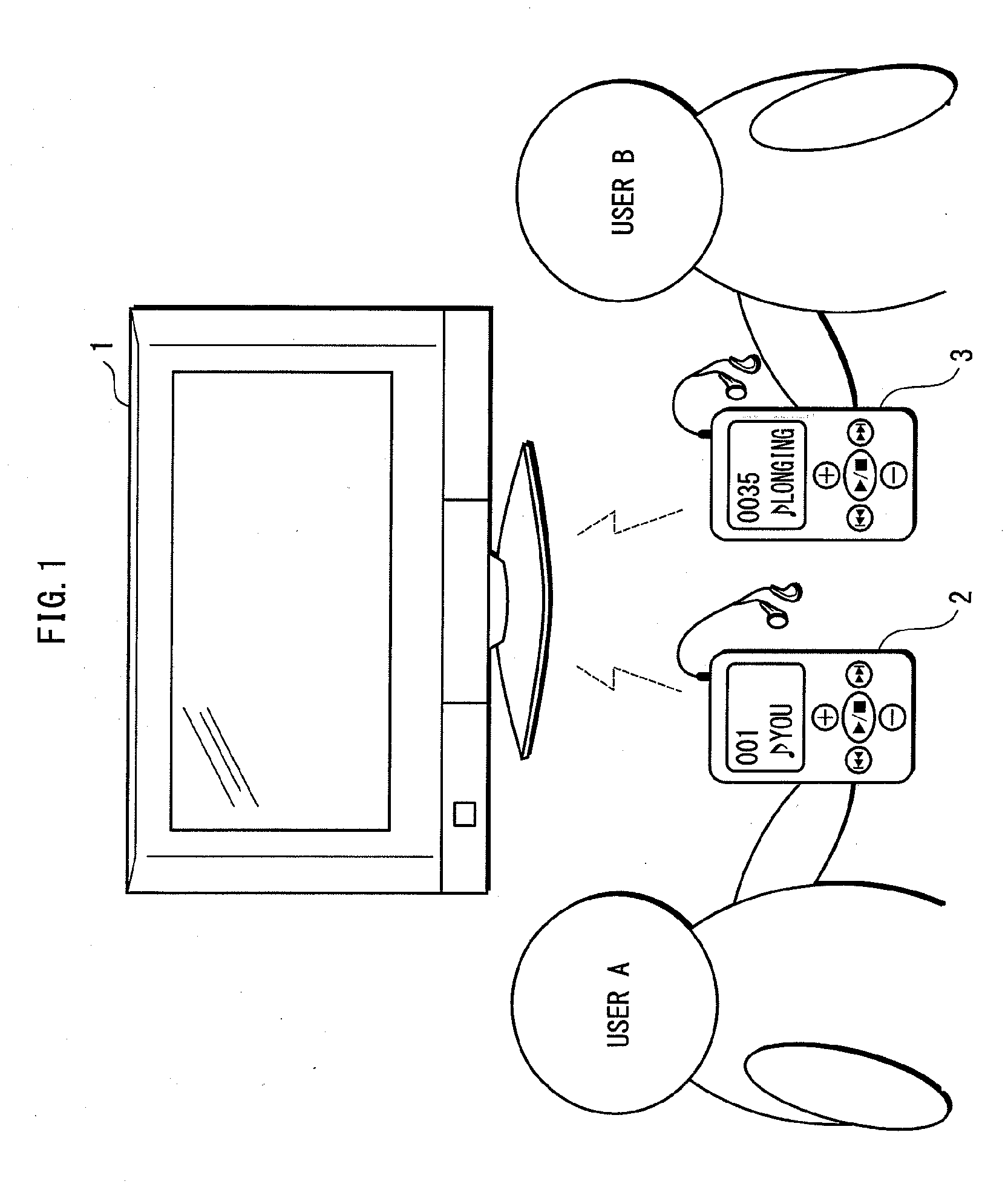

Information presenting device, information presenting method, information presenting program, and integrated circuit

ActiveUS20100010986A1Easy to understandEasy to distinguishMultimedia data browsing/visualisationVideo gamesAs elementViewpoints

An information presenting device for narrowing down information such as contents beneficial for users and stimulating interest in users from various viewpoints, and presenting the information to users in an easily ascertainable manner. A content recommending device 1 displays an image 1100. A commonality map image 1121 includes a title image 1131, a Venn diagram image 1134, and a details button image 1137. The Venn diagram in the commonality map image 1111 relating to all content is narrowed down to a Venn diagram about the set containing, as elements, content IDs of content having an attribute value “Mayumi Hamada” for an attribute “artist”. In the content recommending device 1, a multiple profile acquiring unit 101 acquires viewing / listening history tables including content IDs of content viewed / listened to in player terminals, and a profile common relationship ascertaining unit 102 calculates an extent of a common portion of the acquired viewing / listening history tables. The commonality is expressed as a Venn diagram.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

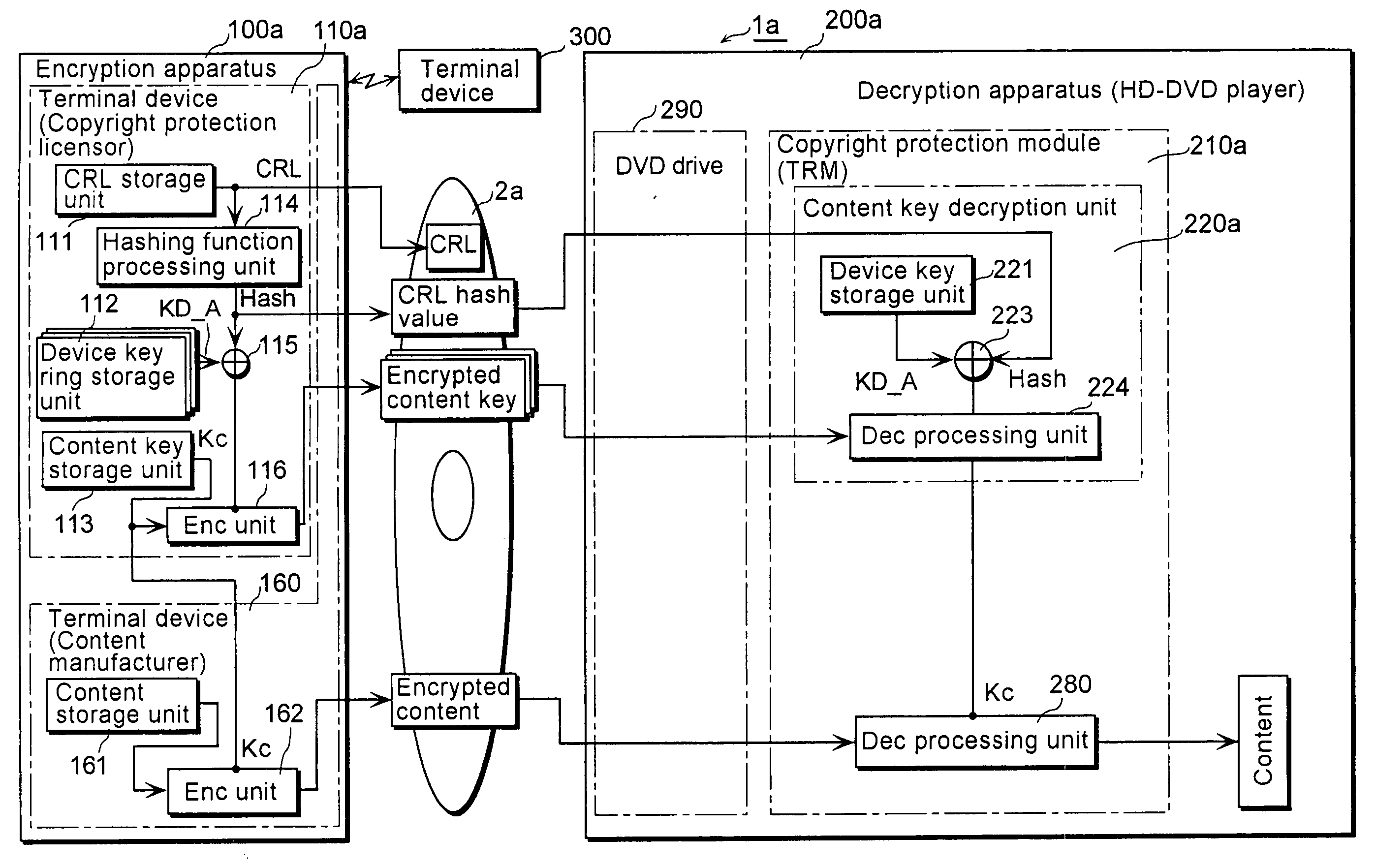

Encryption apparatus, decryption apparatus, secret key generation apparatus, and copyright protection system

InactiveUS20050078825A1High cost performanceSecure transmissionUser identity/authority verificationRecord information storageComputer hardwareHash function

An encryption apparatus 100a is comprised of the following: a CRL storage unit 111 that stores a CRL; a device key ring storage unit 112 that stores a device key KD_A specific to each copyright protection module 210a used by a decryption apparatus 200a; a content key storage unit 113 that stores a content key Kc that is a secret key for encrypting a content; a hashing function processing unit 114 that calculates a hash value of the CRL stored in the CRL storage unit 111 according to a hashing function; an Ex-OR unit 115 that obtains an exclusive OR value between the hash value and the device key KD_A; and an Enc unit 116 that encrypts the content key Kc using an output value from the Ex-OR unit, and stores the hash value, the encrypted content key and the encrypted content in a DVD2a.

Owner:INTERTRUST TECH CORP

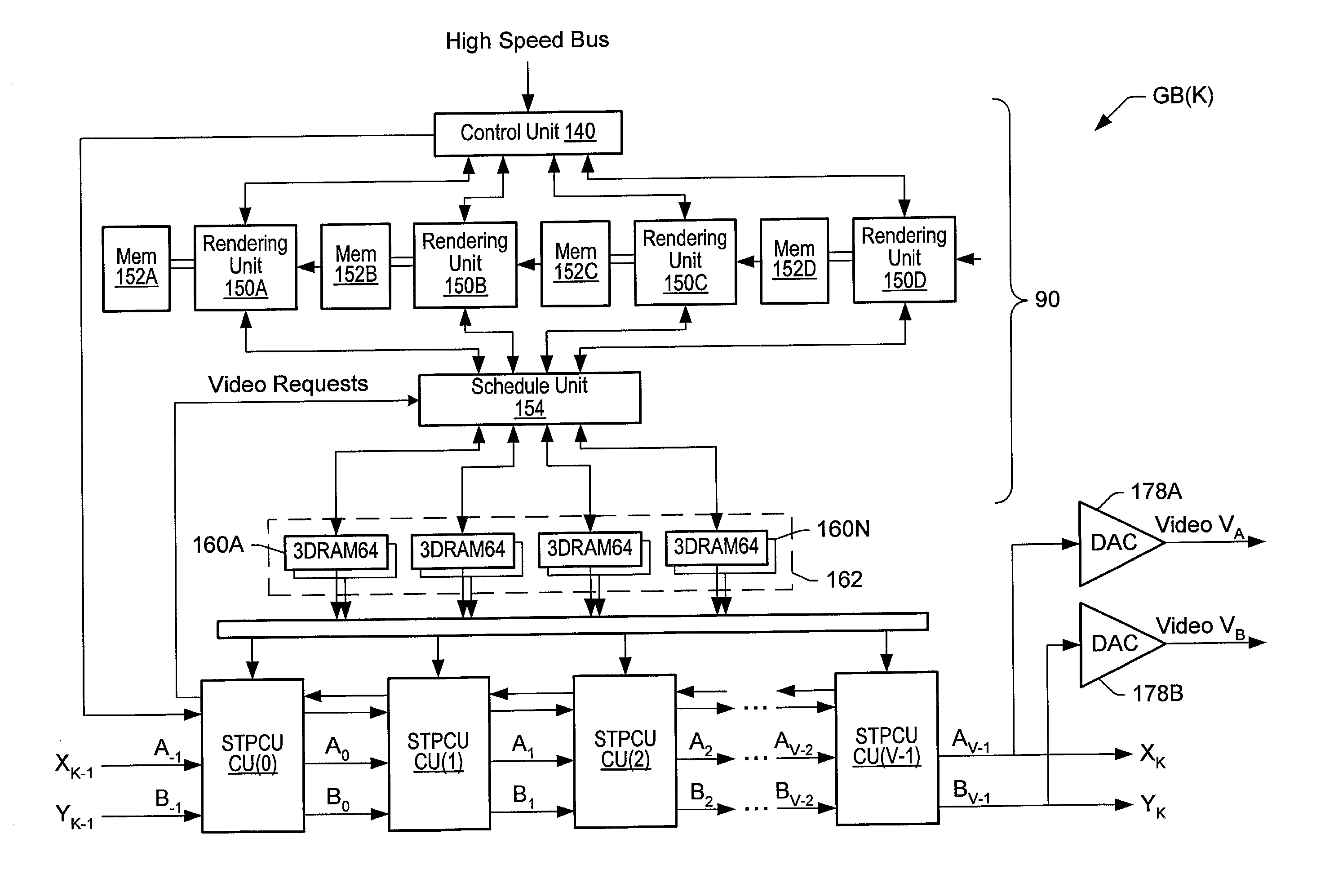

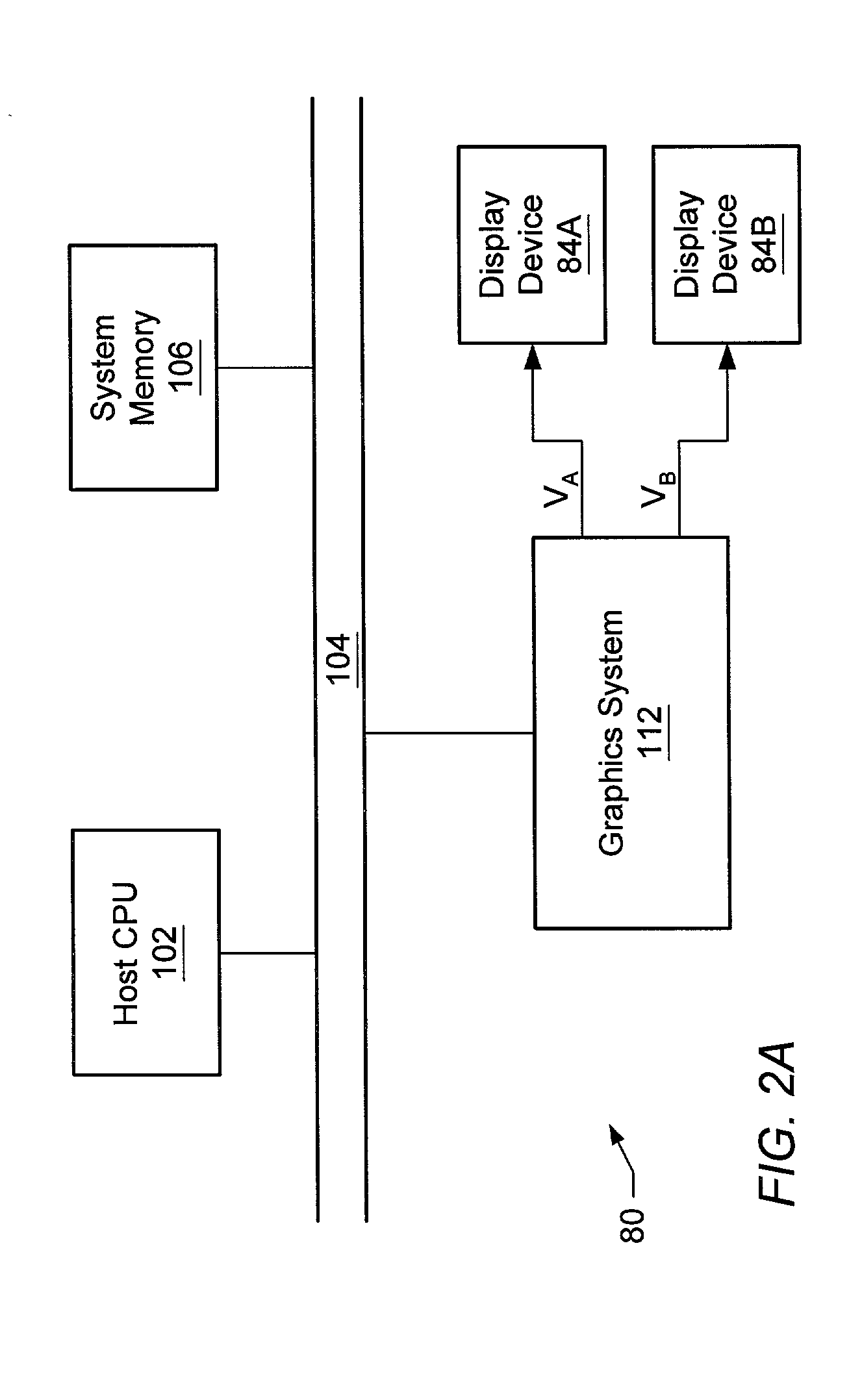

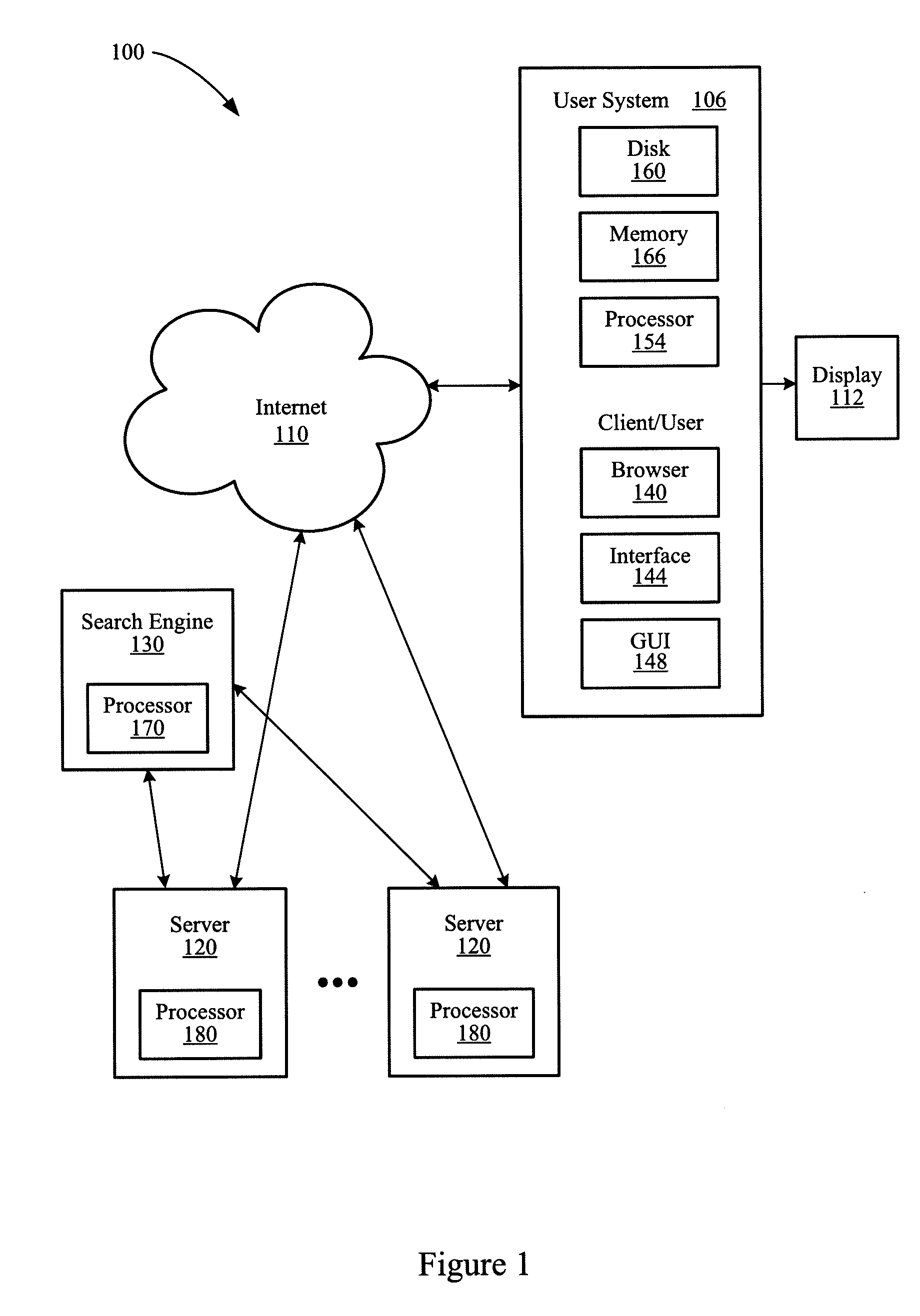

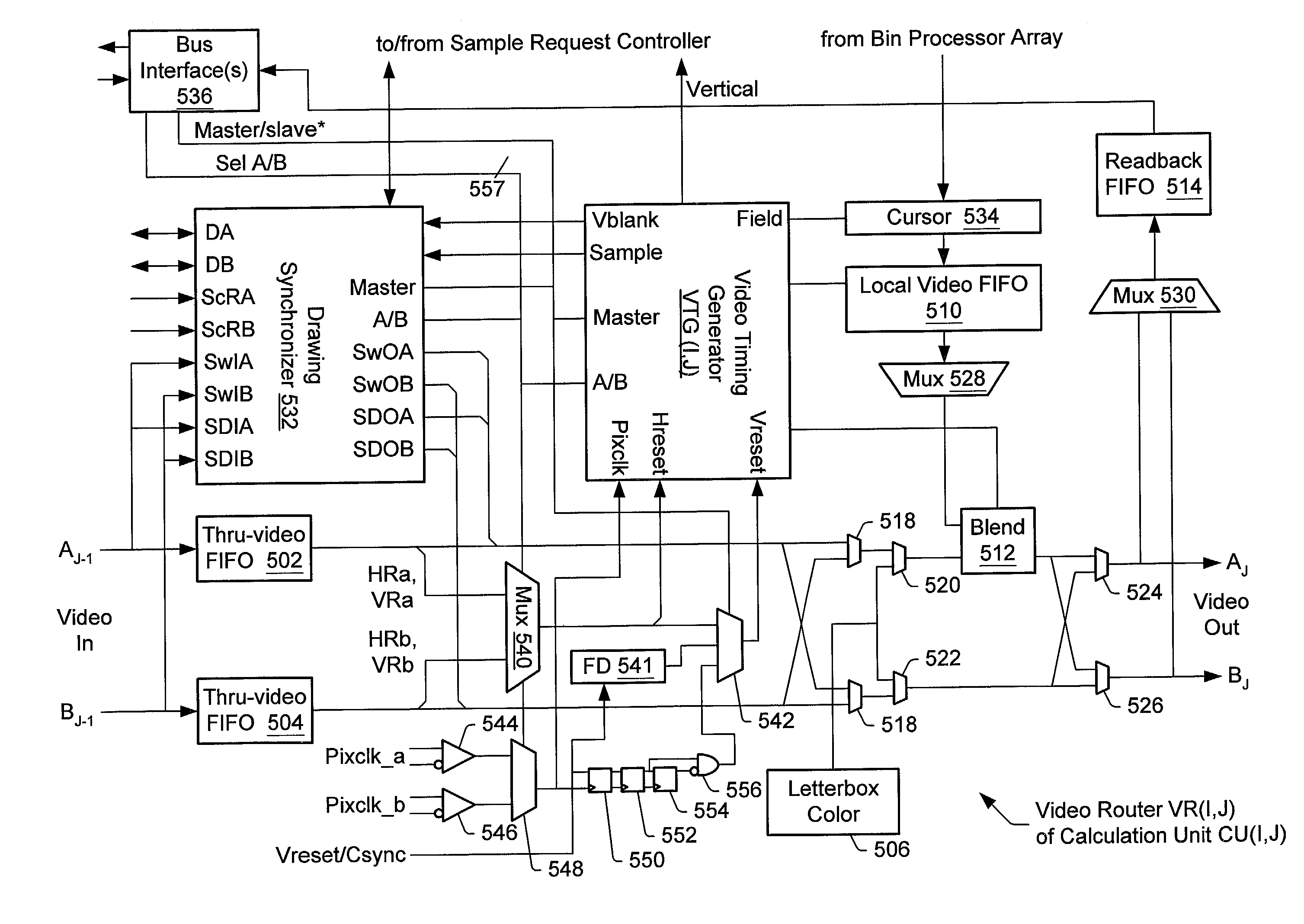

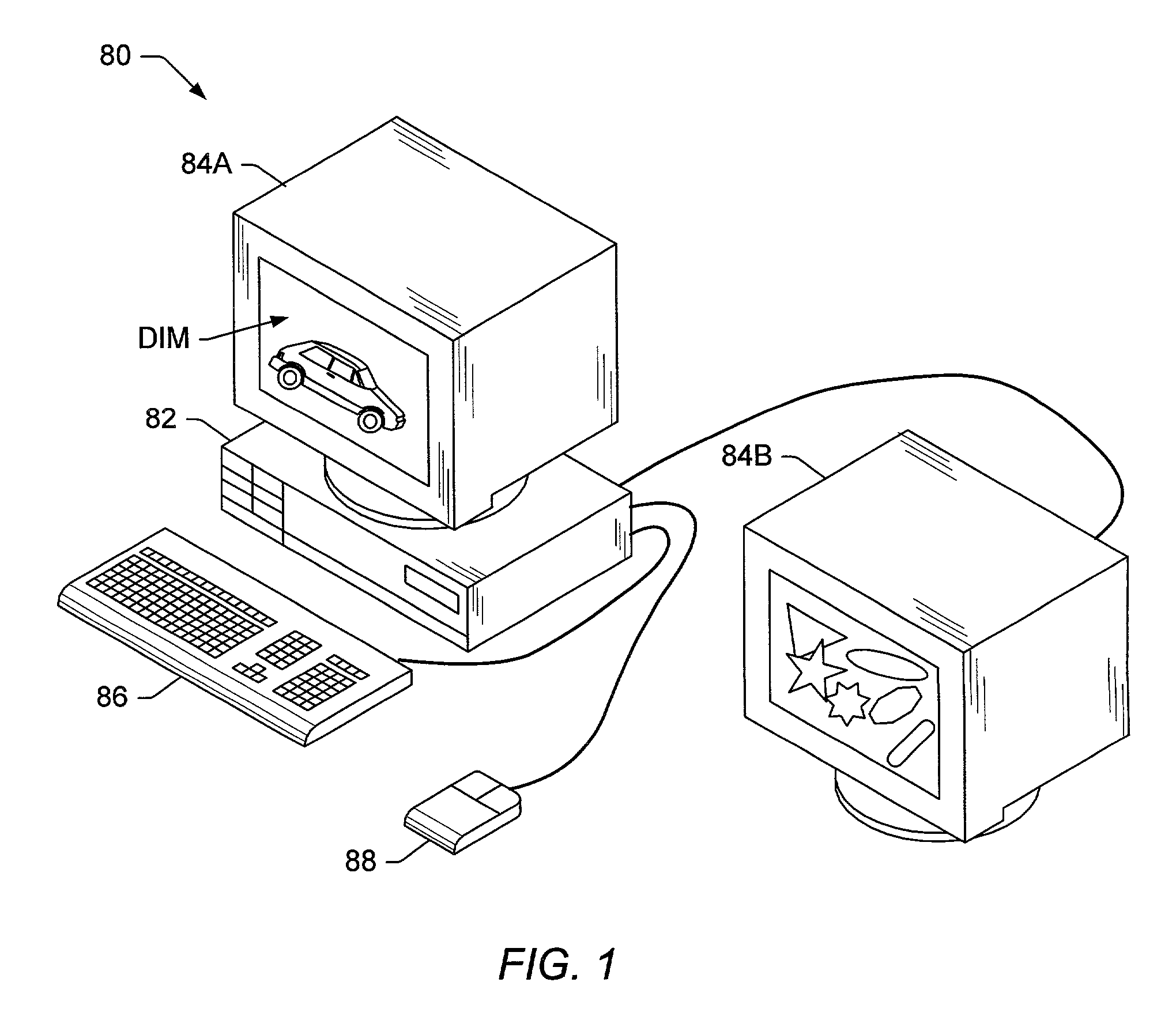

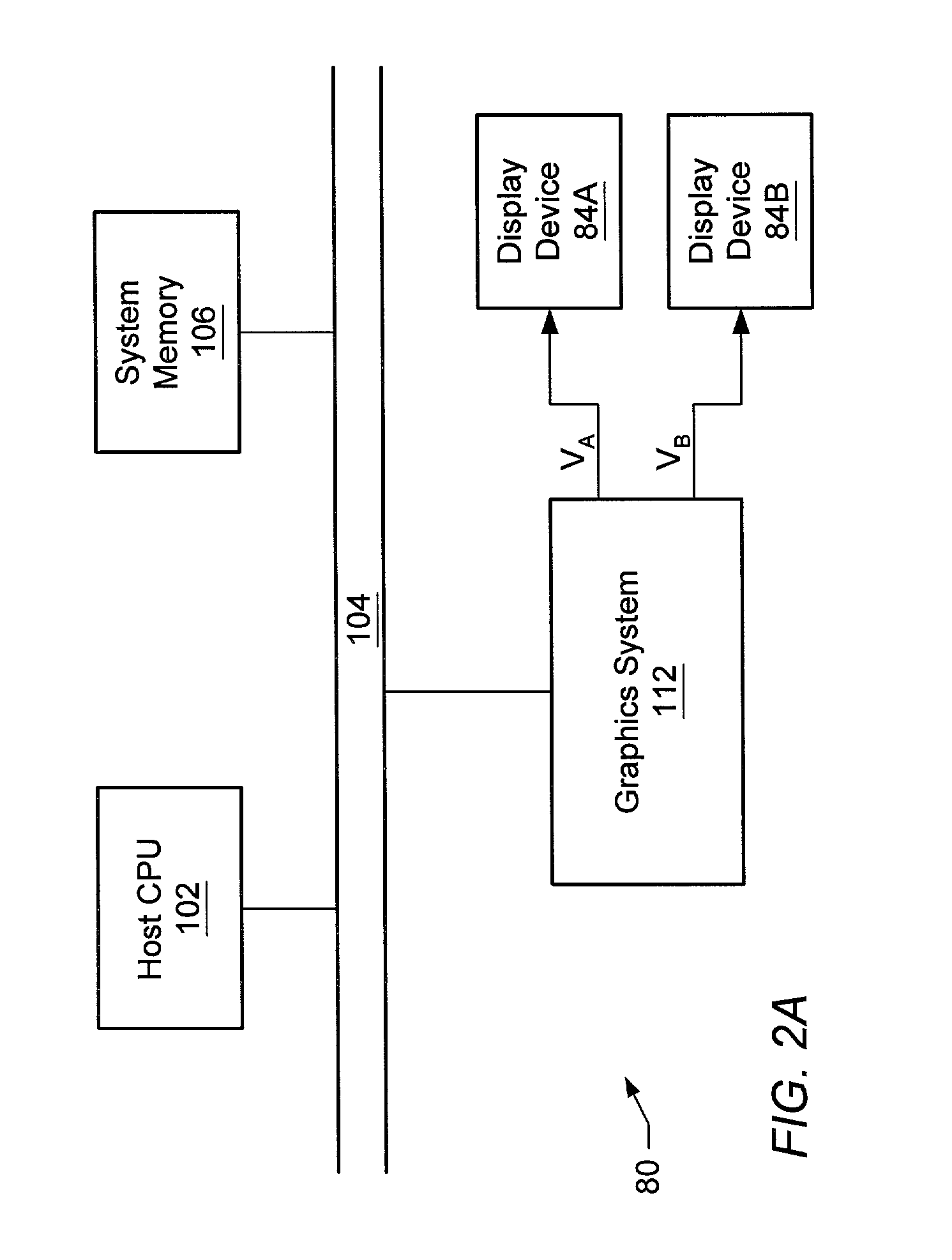

Flexible video architecture for generating video streams

ActiveUS20020033828A1Multiple digital computer combinationsData switching networksDigital videoGraphics

A graphics system comprising a series of calculation units. The calculation units comprise a first subset and a second subset of calculation units. A first calculation unit of the series generates a first digital video stream and a second digital video stream. Each calculation unit of the first subset: (a) passes the second digital video stream to a next calculation unit of the series unmodified; and (b) computes first pixel values, injects or mixes the first pixel values into the first digital video stream, and passes the modified first digital video stream to the next calculation unit. Similarly, each calculation unit of the second subset injects or mixes second pixel values into the second digital video stream, and passes the first digital video stream unmodified. A last calculation unit of the series drives one or more display devices in response to the first and second digital video streams.

Owner:ORACLE INT CORP

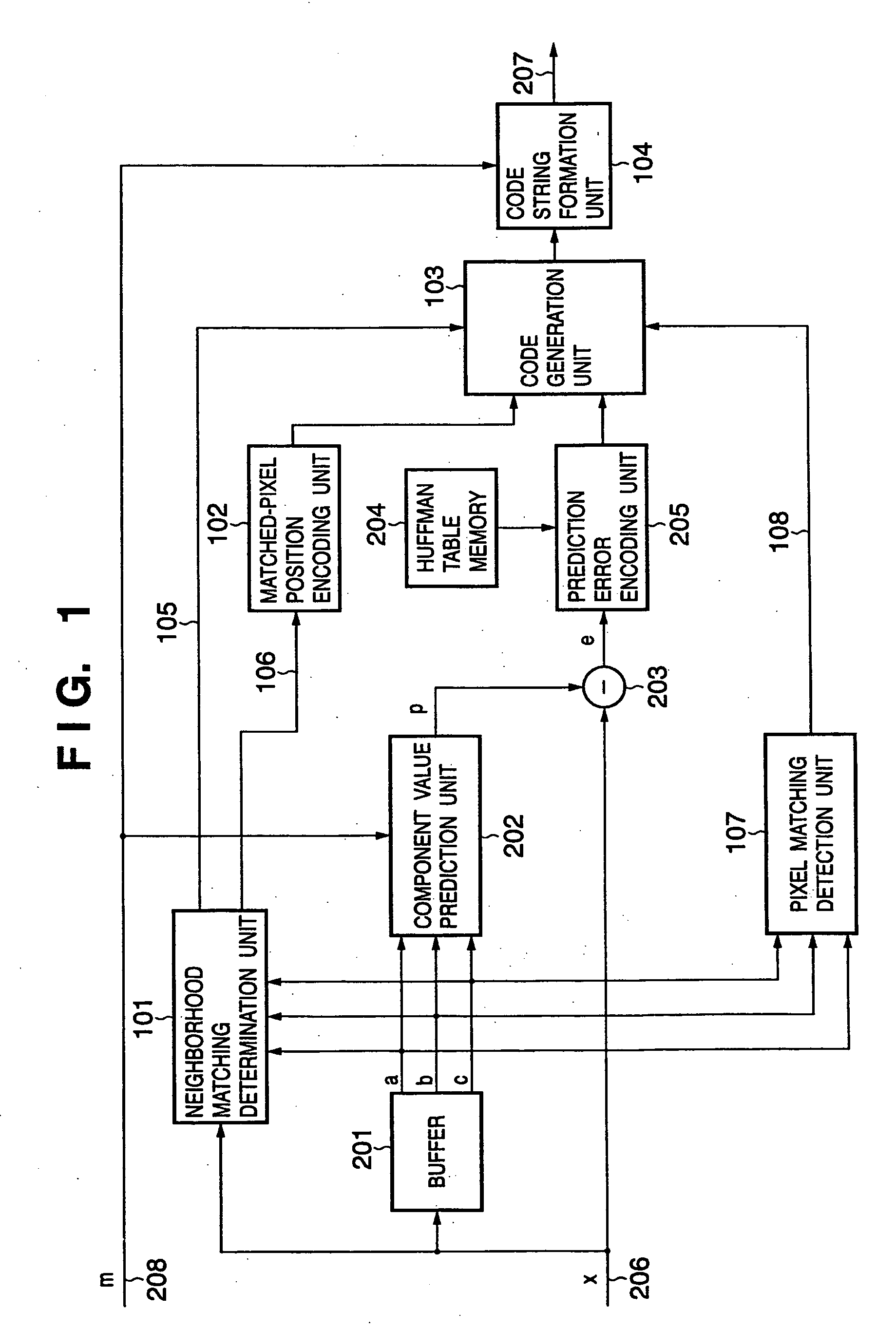

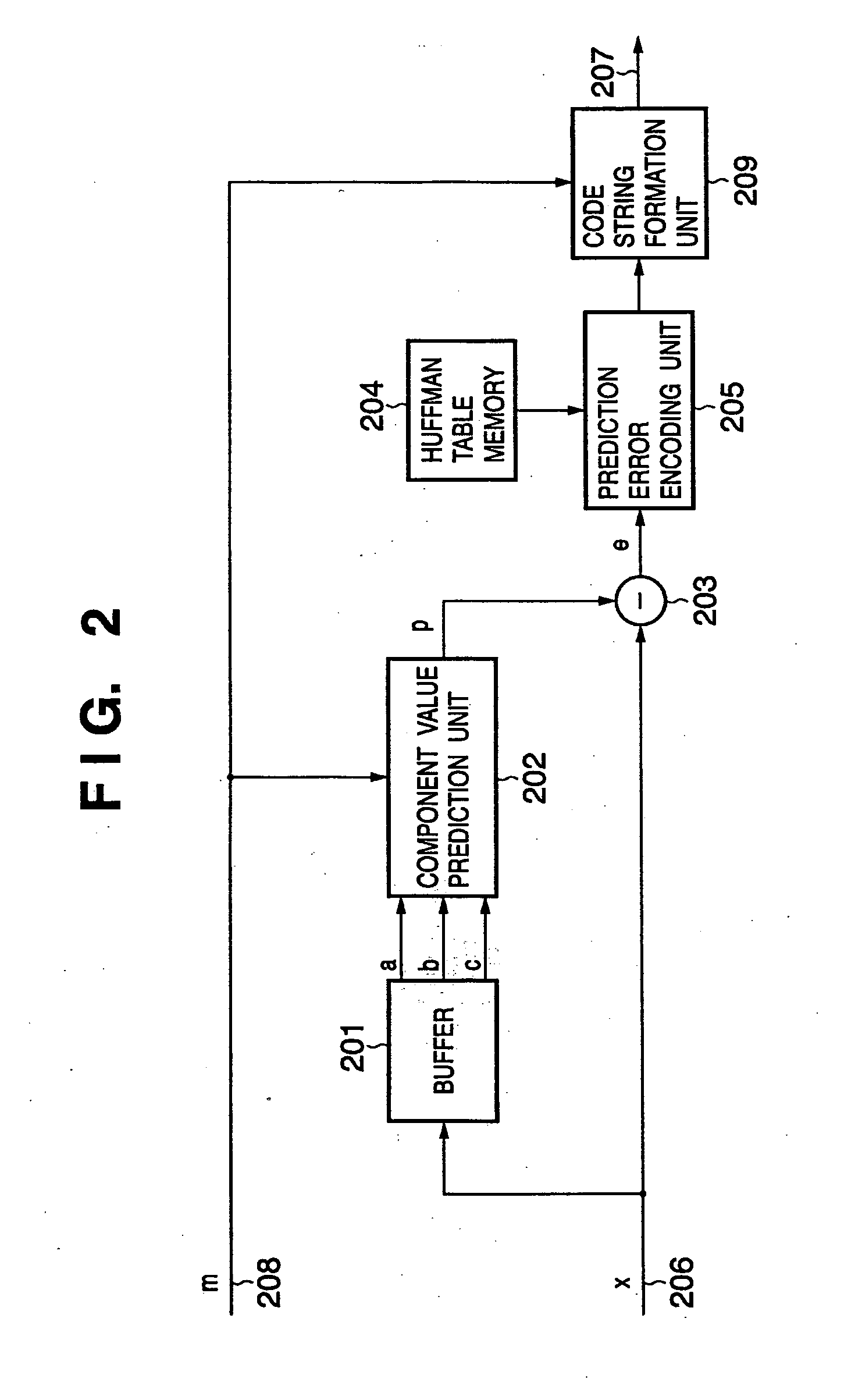

Image encoding apparatus, image decoding apparatus, control method therefor, computer program, and computer-readable storage medium

InactiveUS20060210176A1Efficiently natural imageNumber of appearance is limitedCharacter and pattern recognitionDigital video signal modificationPattern recognitionLossless coding

According to this invention, while the encoding efficiency of image data (e.g., a natural image) substantially maintains the conventional one, an image (e.g., a CG image or text document) having a small number of appearance colors is losslessly encoded at higher compression ratio. For this purpose, pixel data are input in the raster order and temporarily stored in a buffer. Pixel data at positions having undergone encoding are stored. A neighborhood matching determination unit generates first information representing whether a pixel having the same color as that of the pixel of interest exists in neighboring pixels a, b, and c, and second information for specifying whether a pixel having the same color as that of the pixel of interest exists, and if the pixel having the same color exists, specifying the neighboring pixel. A pixel matching detection unit counts the number of colors contained in the neighboring pixels a, b, and c, and generates information representing whether the number of colors is two or less, or three or less. On the basis of the first information and second information, a code generation unit outputs one or both of encoded data from a matched-pixel position encoding unit and prediction error encoding unit.

Owner:CANON KK

Apparatus and method for providing conference call roster information with speaker voice identification

InactiveUS20030081751A1Increase amplitudeTelephone data network interconnectionsSpecial service for subscribersComputer monitorDisplay device

An apparatus and method is disclosed that allows a participant in a conference call to receive conference call roster information at a telephone display unit, at a computer display or at both types of display. The conference call information is updated during the call and includes identification of the speaker during a conference call. The conference callers are connected together and identified either by standard caller identification or by other identification provided by the operator. The conference callers' identifications are then transmitted in two ways. First, a coded signal is sent over the telephone connection to a telephone display unit. Second, an information packet is transmitted over the Internet to a conference call participant's computer. A server computer monitors the conference call and the identification of parties involved is updated a parties are added or disconnected. The speaking party is identified in one two ways. First, during the call, the speaker's telephone line will have a higher transmission amplitude than the other telephone lines and the line with the highest transmission amplitude will be identified by the server computer. Second, voice identification data is gathered before the conference call and stored in the server computer for use in identifying the speaker.

Owner:CISCO TECH INC

Device and method for estimating health status and state of charge of battery pack on line

ActiveCN103744030AAchieve decouplingOvercome the defect that the estimation accuracy of the state of charge gradually decreasesElectrical testingCapacitanceElectrical battery

The invention discloses a device and a method for estimating the health status and the state of charge of a battery pack on line. A monitoring unit measures the running status of the battery pack in real time; a storage unit stores data measured by the monitoring unit; an iterative computation unit computes an iteration parameter of a battery model; a voltage prediction unit calculates and outputs a voltage predicted value; an error computation unit computes an error between the voltage predicted value and a measured value; a parameter prediction unit calculates equivalent internal resistance and equivalent capacitance of the battery pack; an average temperature computation unit computes an environmental temperature average value within one hour; a temperature correction unit converts the parameter value of the battery pack into a corrected value at the normal temperature of 25DEG C; a health status estimation unit predicts the health status of batteries; a decoupling unit decouples the heath status and the state of charge of the batteries; a stage of charge estimation unit predicts the state of charge of the batteries. The device can estimate the health status and the state of charge of the batteries under real-time working condition.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

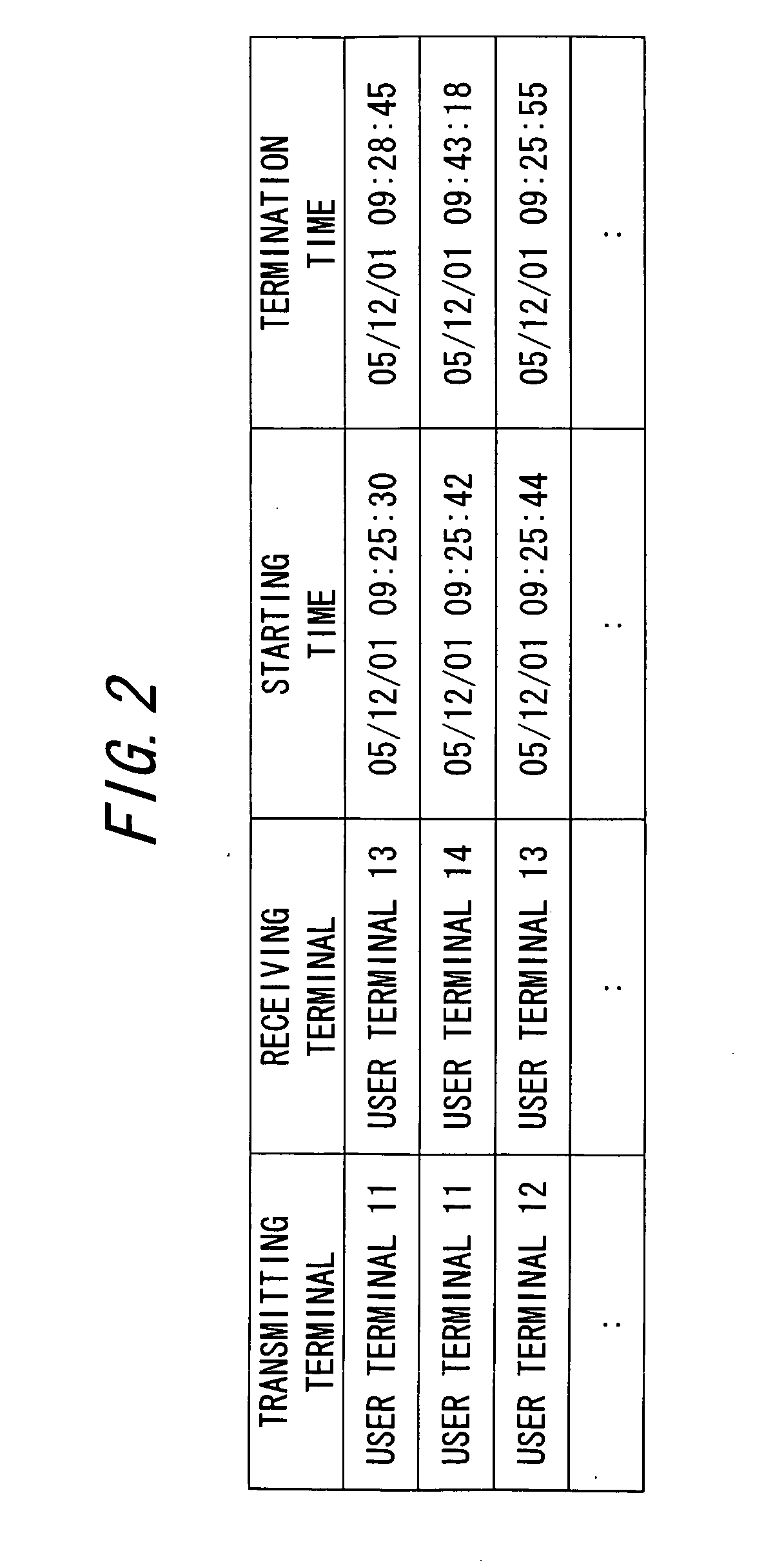

Service quality management device and service quality management method

InactiveUS20070230346A1Improve communication service qualityEfficient use ofError preventionTransmission systemsQuality of serviceInformation gain

A service quality management device, preventing deterioration of a quality of a communication service provided on a network while effectively utilizing network resources by managing the quality of the communication, comprises an information acquiring unit acquiring service information containing information about each of sessions for the communication service and the network configuration information, an information generation unit generating a traffic volume of each of the sessions, a route determination unit determining a packet route for each of the sessions based on the respective information, a calculation unit calculating a traffic volume and a load of each of the links based on the traffic volume of each of the sessions and the packet route for each of the sessions, and a quality judging unit judging a quality of service actualized by each of the sessions based on the calculated load of each of the links.

Owner:FUJITSU LTD

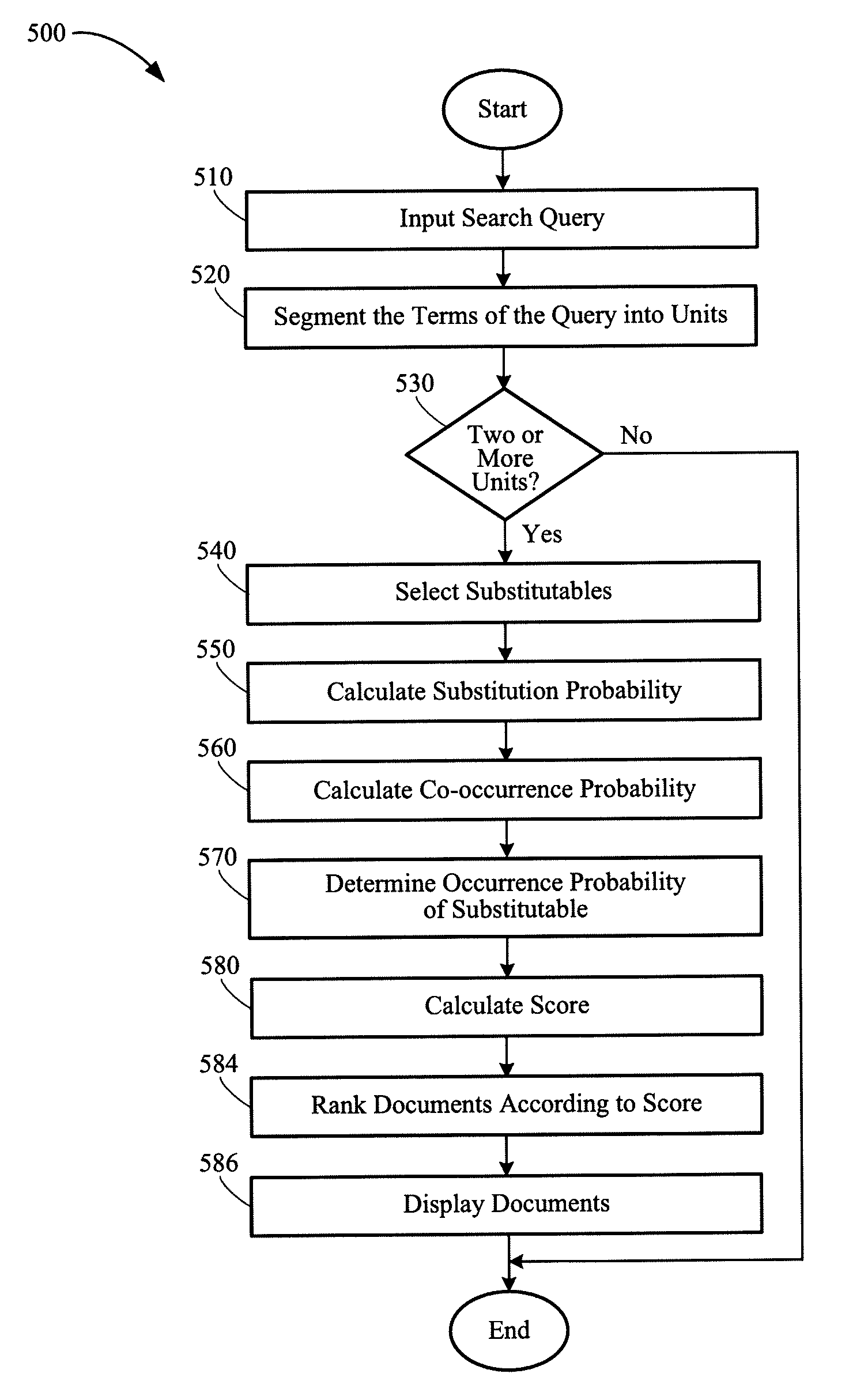

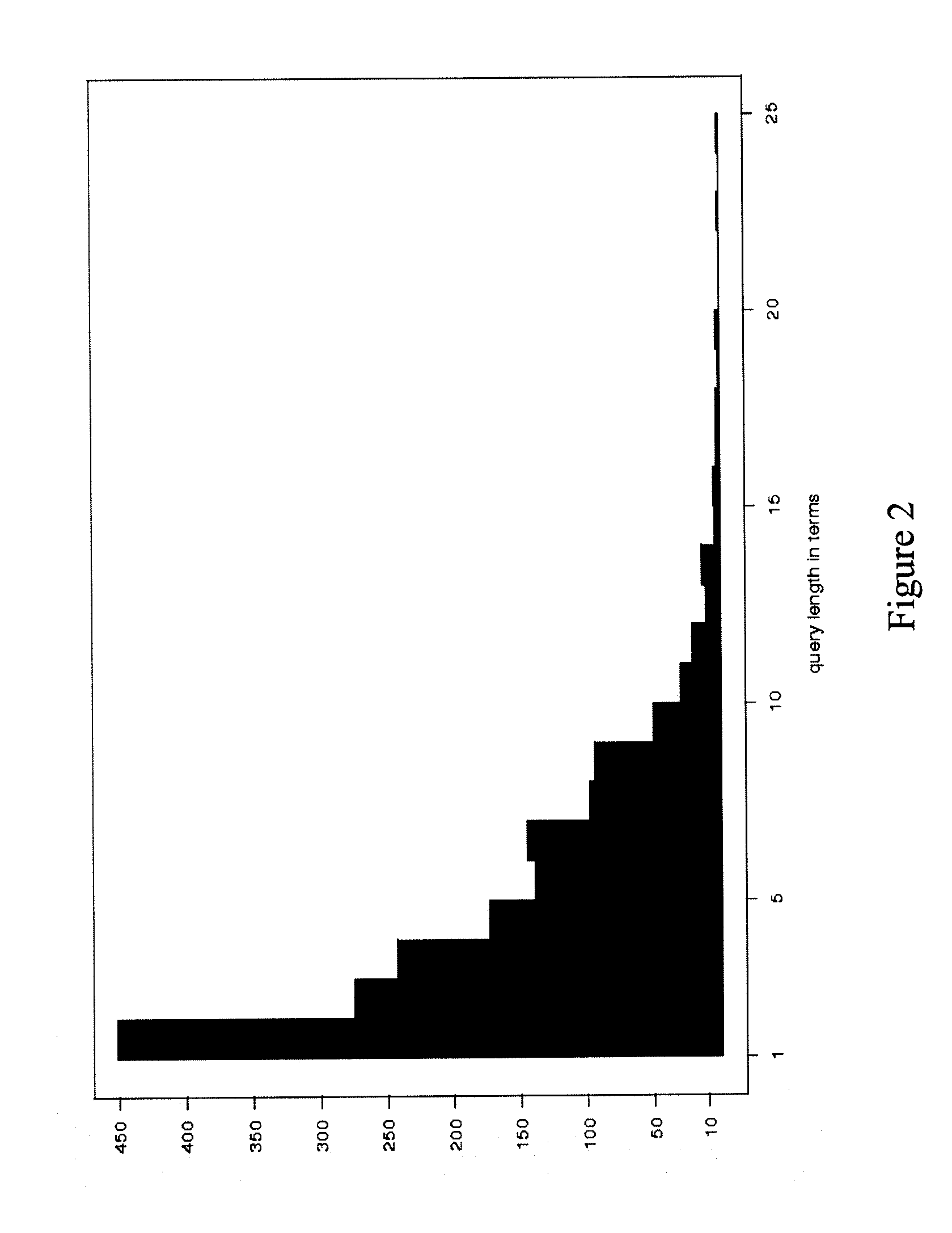

Context-sensitive query expansion

InactiveUS20090198672A1Digital data information retrievalDigital data processing detailsCo-occurrenceData mining

Owner:R2 SOLUTIONS

Flexible video architecture for generating video streams

InactiveUS6989835B2Multiple digital computer combinationsProcessor architectures/configurationDigital videoGraphics

A graphics system comprising a series of calculation units. The calculation units comprise a first subset and a second subset of calculation units. A first calculation unit of the series generates a first digital video stream and a second digital video stream. Each calculation unit of the first subset: (a) passes the second digital video stream to a next calculation unit of the series unmodified; and (b) computes first pixel values, injects or mixes the first pixel values into the first digital video stream, and passes the modified first digital video stream to the next calculation unit. Similarly, each calculation unit of the second subset injects or mixes second pixel values into the second digital video stream, and passes the first digital video stream unmodified. A last calculation unit of the series drives one or more display devices in response to the first and second digital video streams.

Owner:ORACLE INT CORP

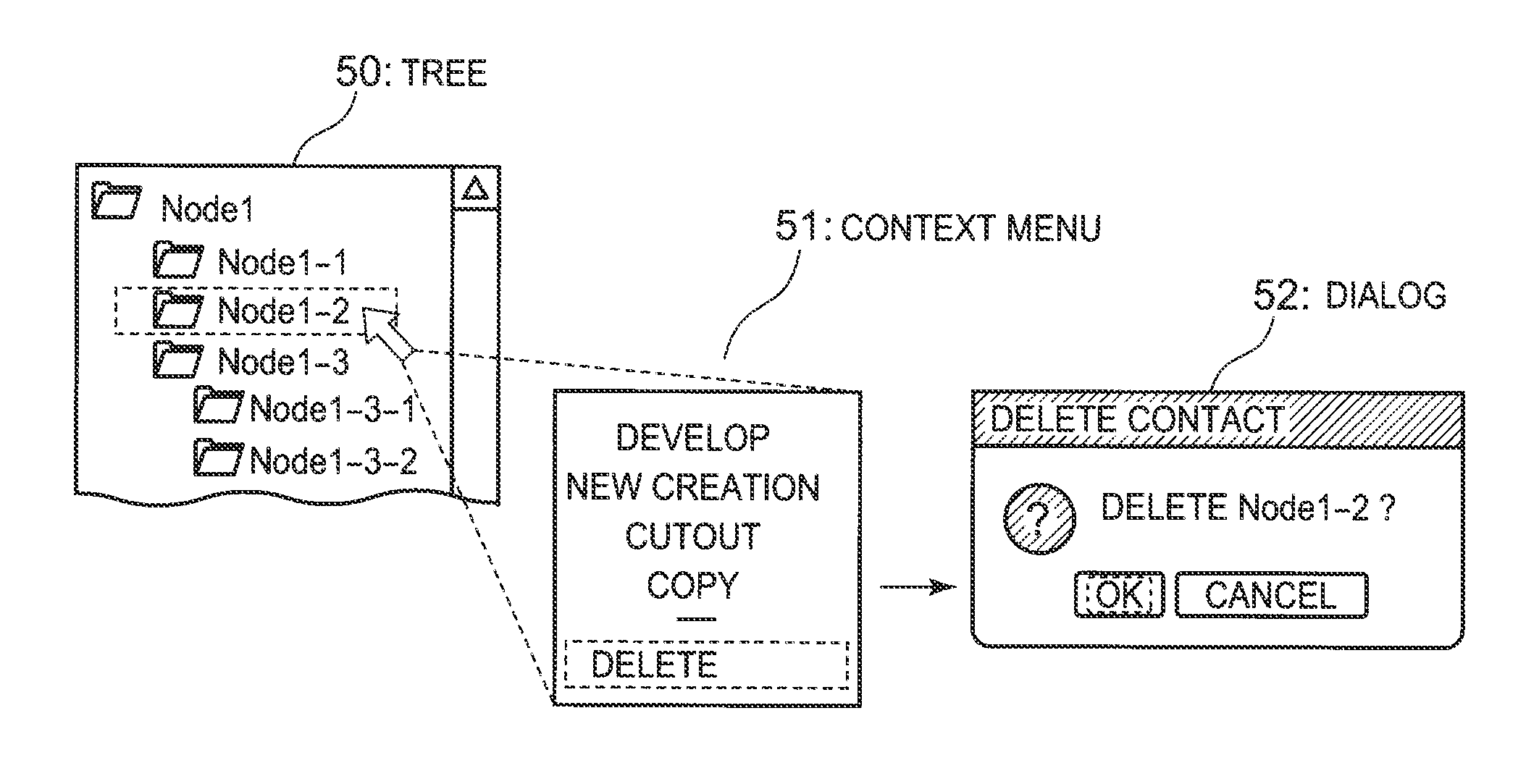

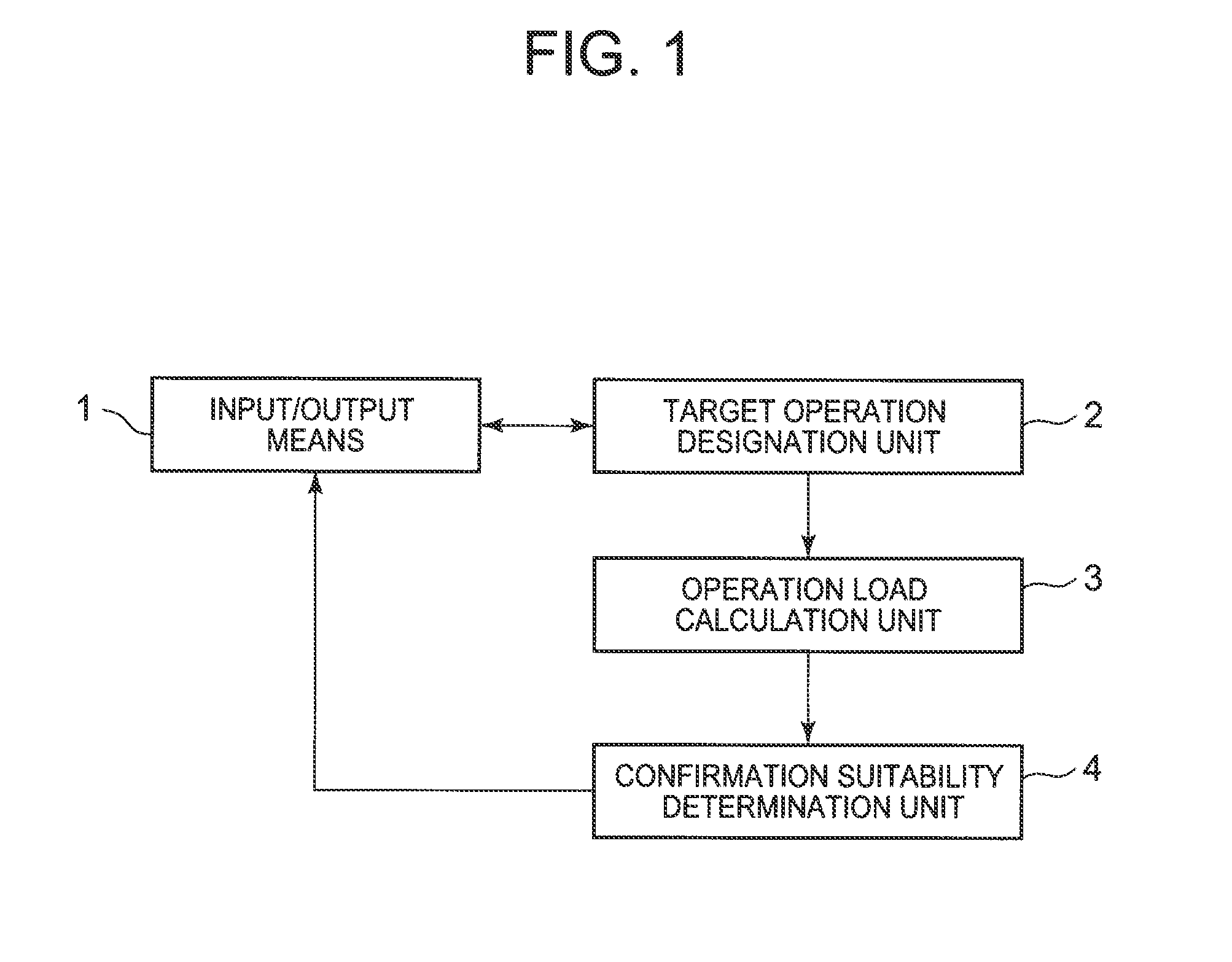

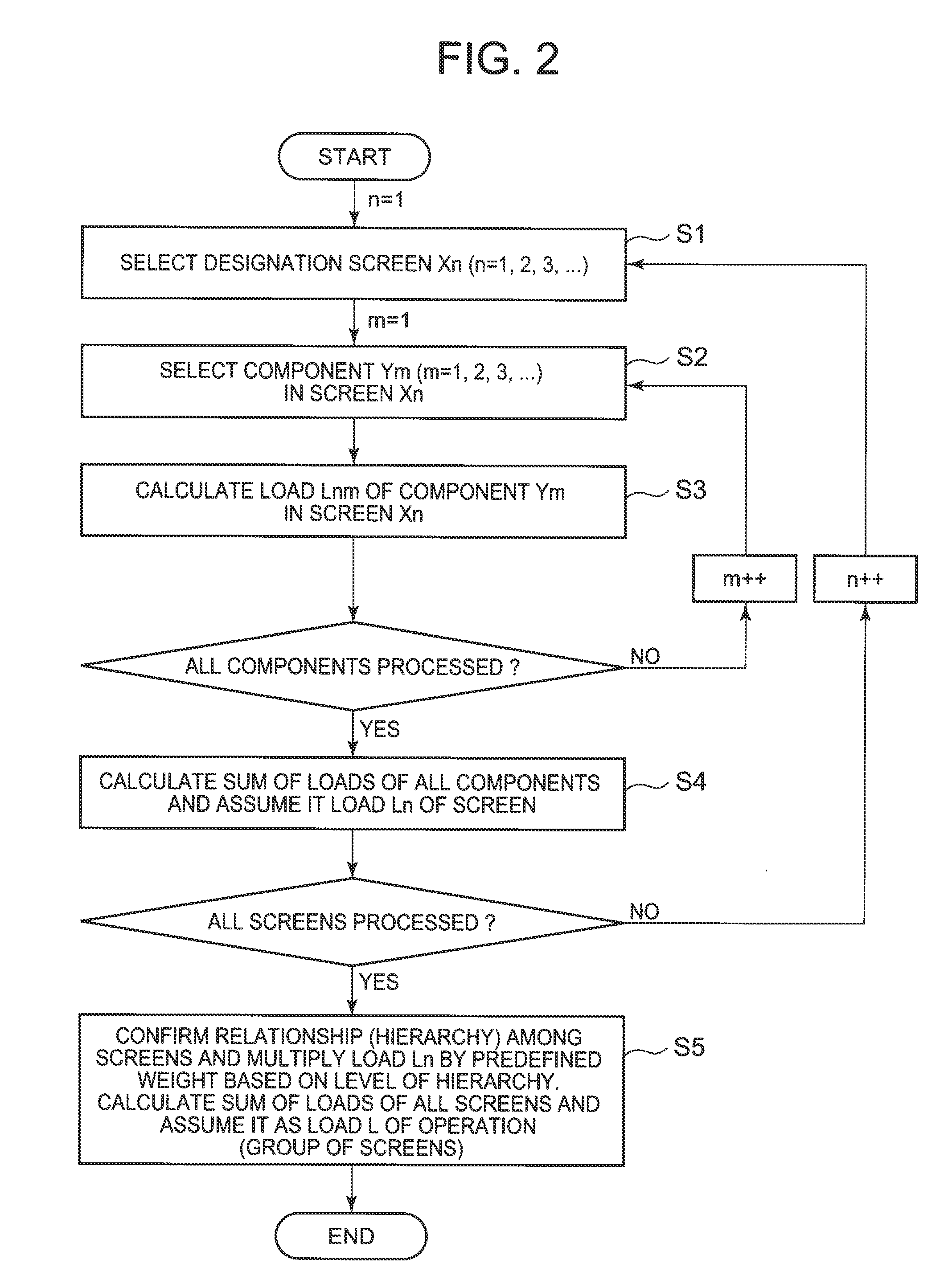

GUI evaluation system, method and program

A GUI evaluation system for evaluating GUI usability includes an operation load calculation unit which calculate a load value indicating a level of load of an operation based on attributes of UI components used for a GUI to be evaluated, and a confirmation suitability determination unit which determines suitability of a confirmation method related to the operation based on a load value calculated by the operation load calculation unit.

Owner:NEC CORP

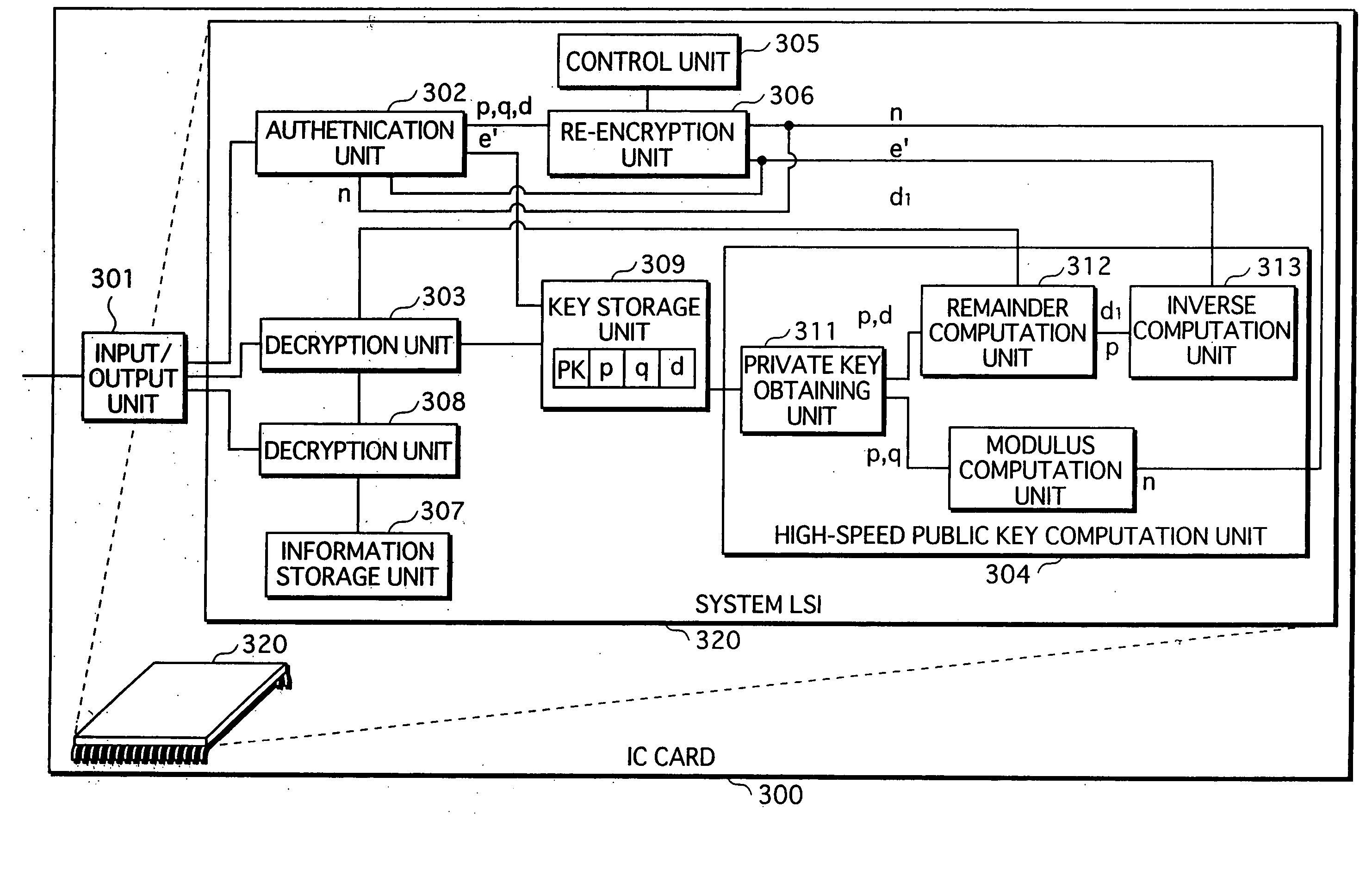

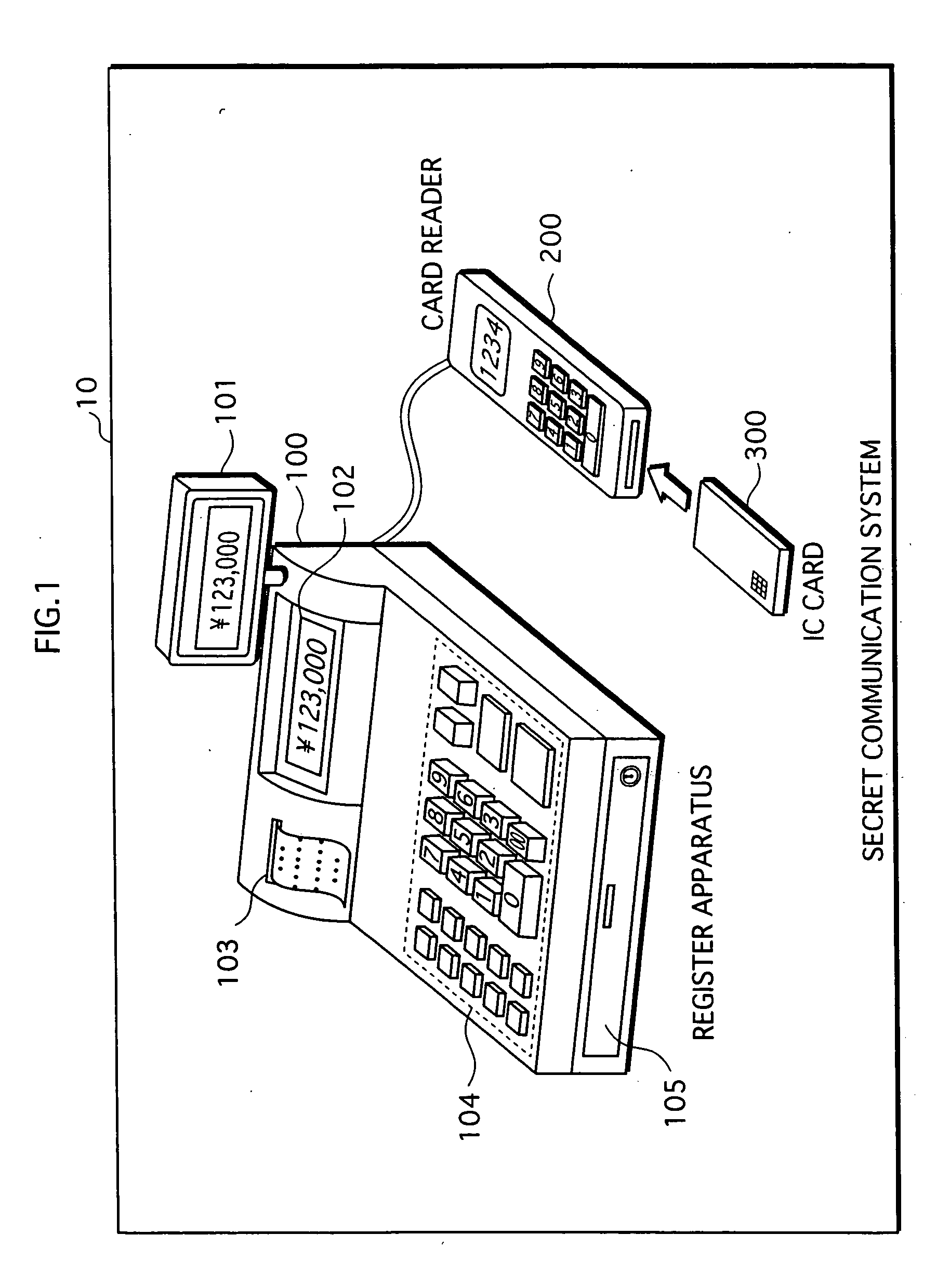

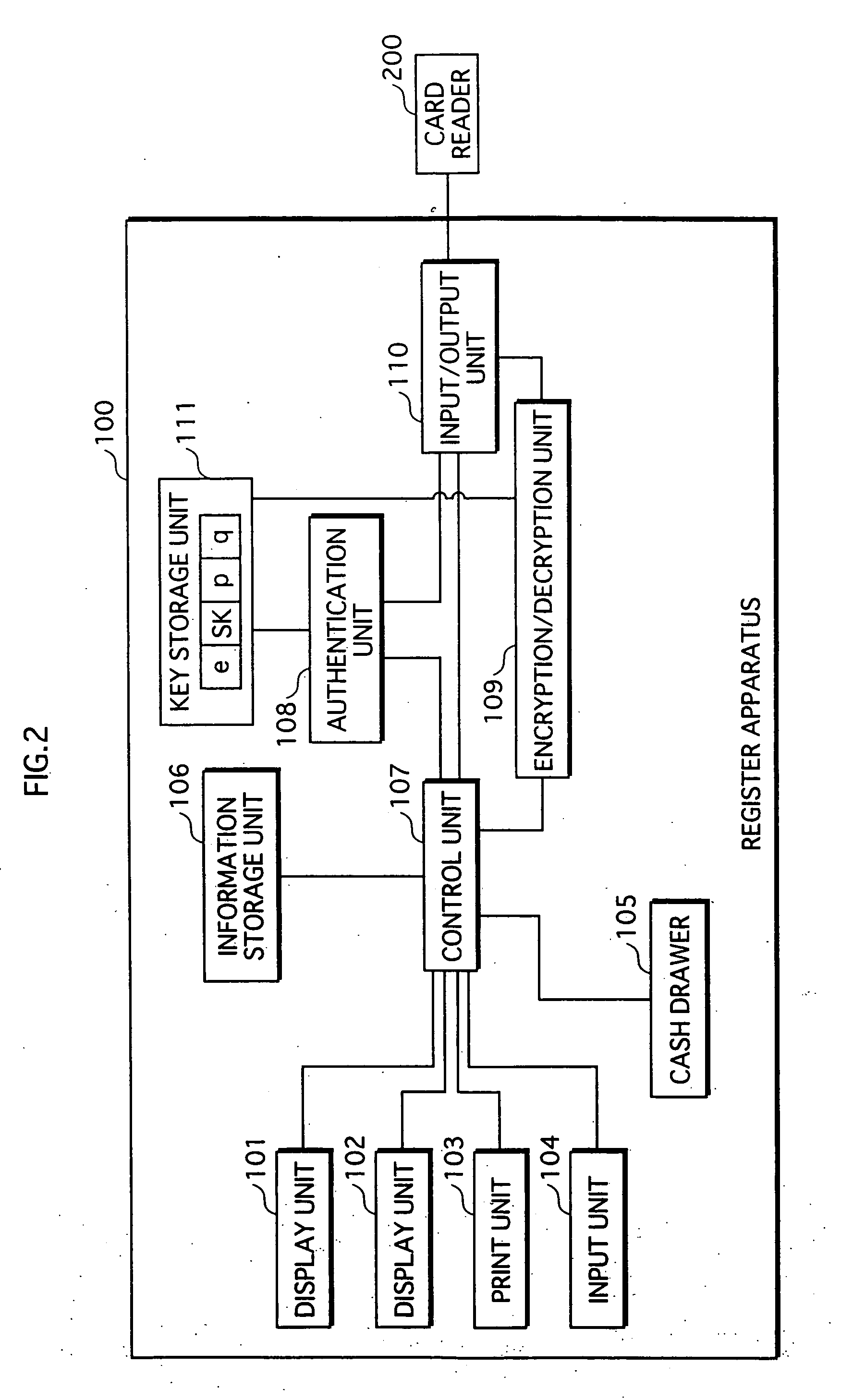

RSA public key generation apparatus, RSA decryption apparatus, and RSA signature apparatus

InactiveUS20050157872A1Increase speedPublic key for secure communicationUser identity/authority verificationComputer hardwareSource Data Verification

An RSA decryption apparatus that is used in an IC card or the like counters a differential fault attack. The RSA decryption apparatus computes at high speed a public key used in data verification, without having to obtain the public key from an external source. The RSA decryption apparatus includes a remainder computation unit 412 that calculates dp=d mod (p−1), and an inverse computation unit 414 that finds an inverse of dp over a residue field with p−1 as a modulus. The RSA decryption apparatus verifies a decipher text with use of the inverse of dp as the public key. The reduced bit count in inverse computation compared to if the inverse of d is found as the public key increases computing speed.

Owner:PANASONIC CORP

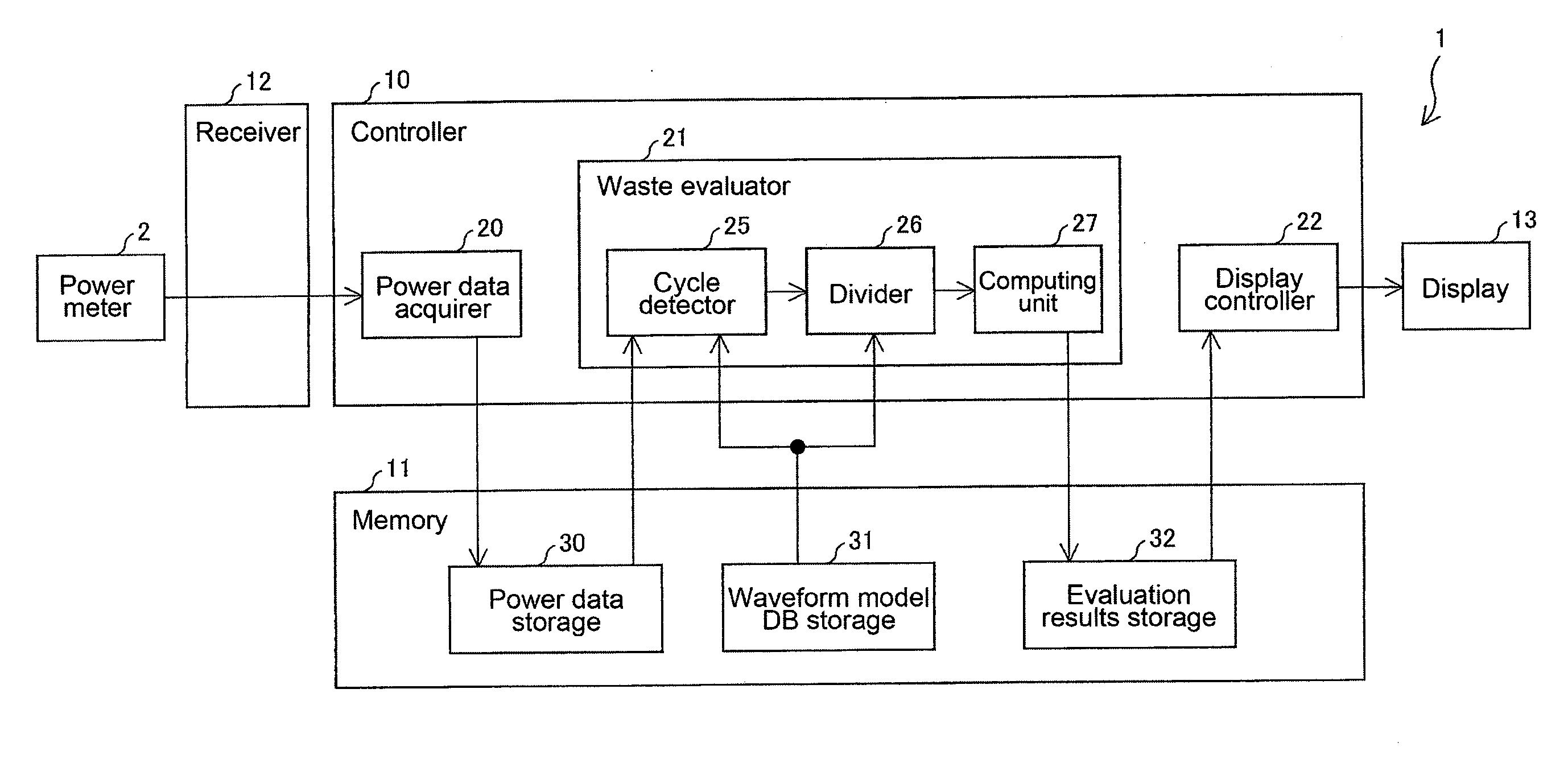

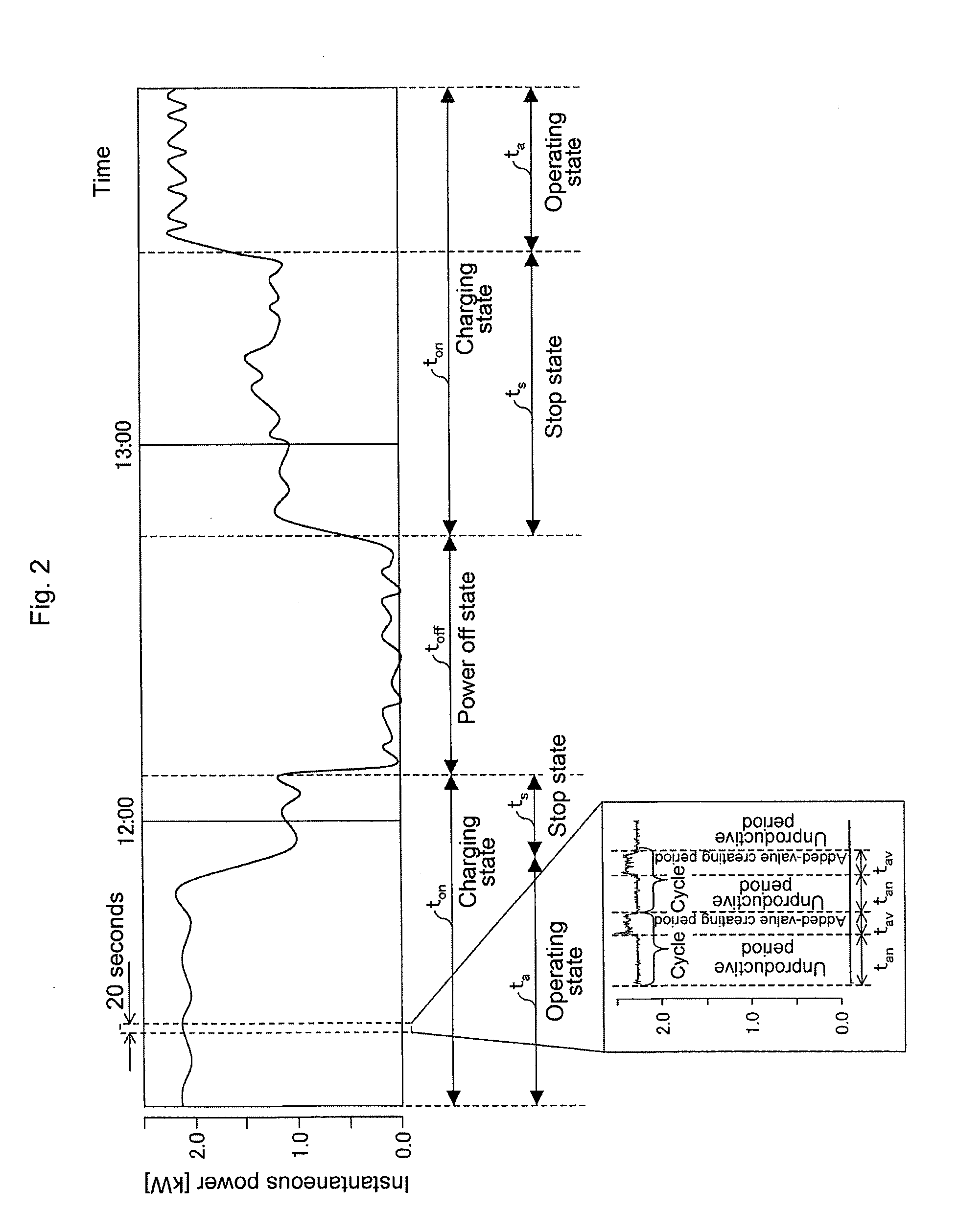

Energy monitoring device and control method therefor, and energy monitoring program

ActiveUS20120084030A1Easy to detectEffectively and simply evaluatedProgramme controlElectric devicesProcess engineeringSingle cycle

A processing machine processes a work and repeats processes on the work, thereby consuming energy. Within the consumed energy, room for improvement is computed by an energy monitoring device and is referred to as an amount of energy that can be improved. An energy monitoring device includes a power data acquirer that acquires a time-series power data measured by a power meter, a cycle detector that detects a single-cycle power data from the power data acquired by the acquirer, a divider that divides the single-cycle power data detected by the detector into an added-value creating portion and an unproductive portion, and a computing unit that computes an amount of energy consumed in the unproductive portion divided by the divider and defines it as the amount of energy to be improved.

Owner:ORMON CORP

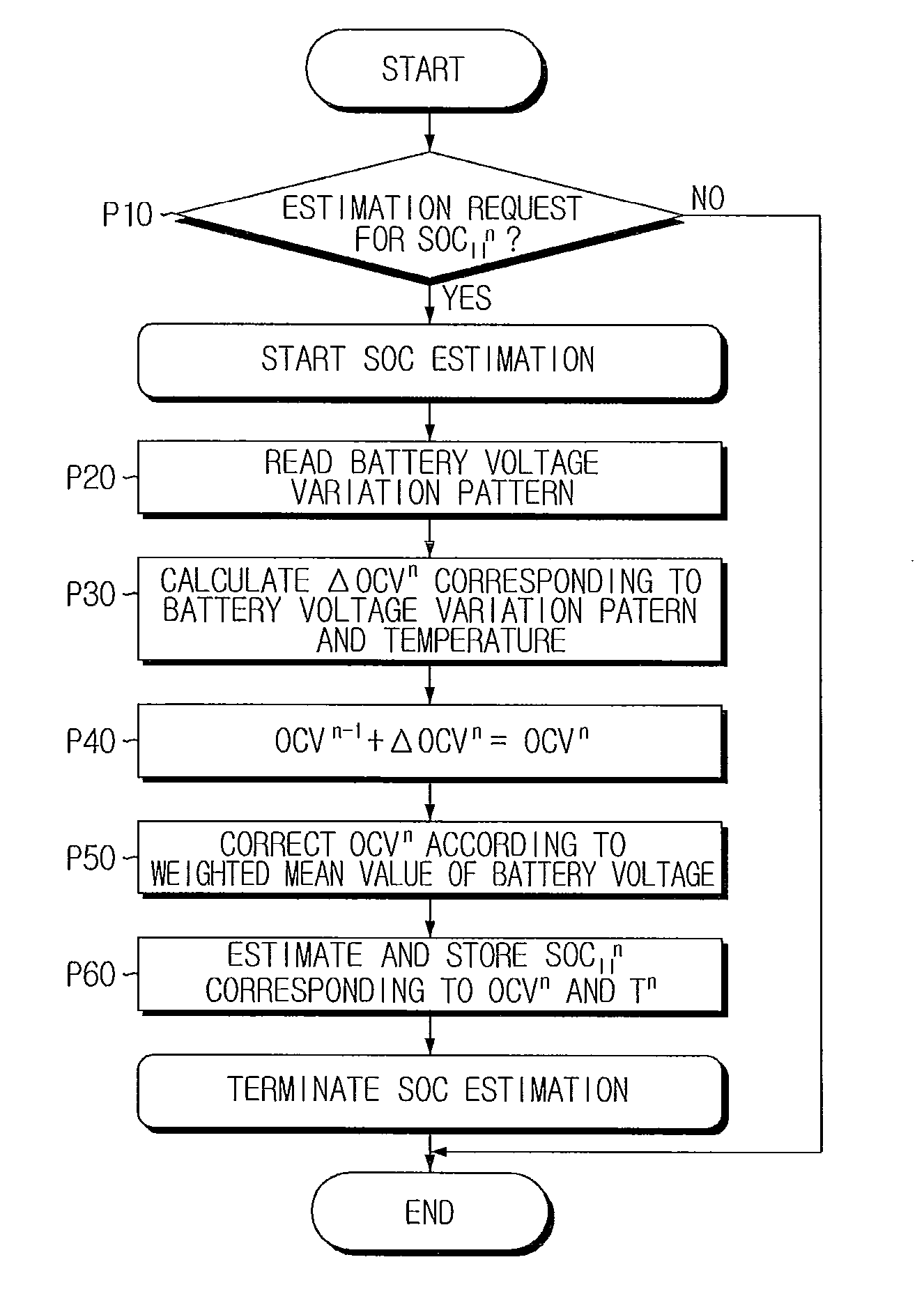

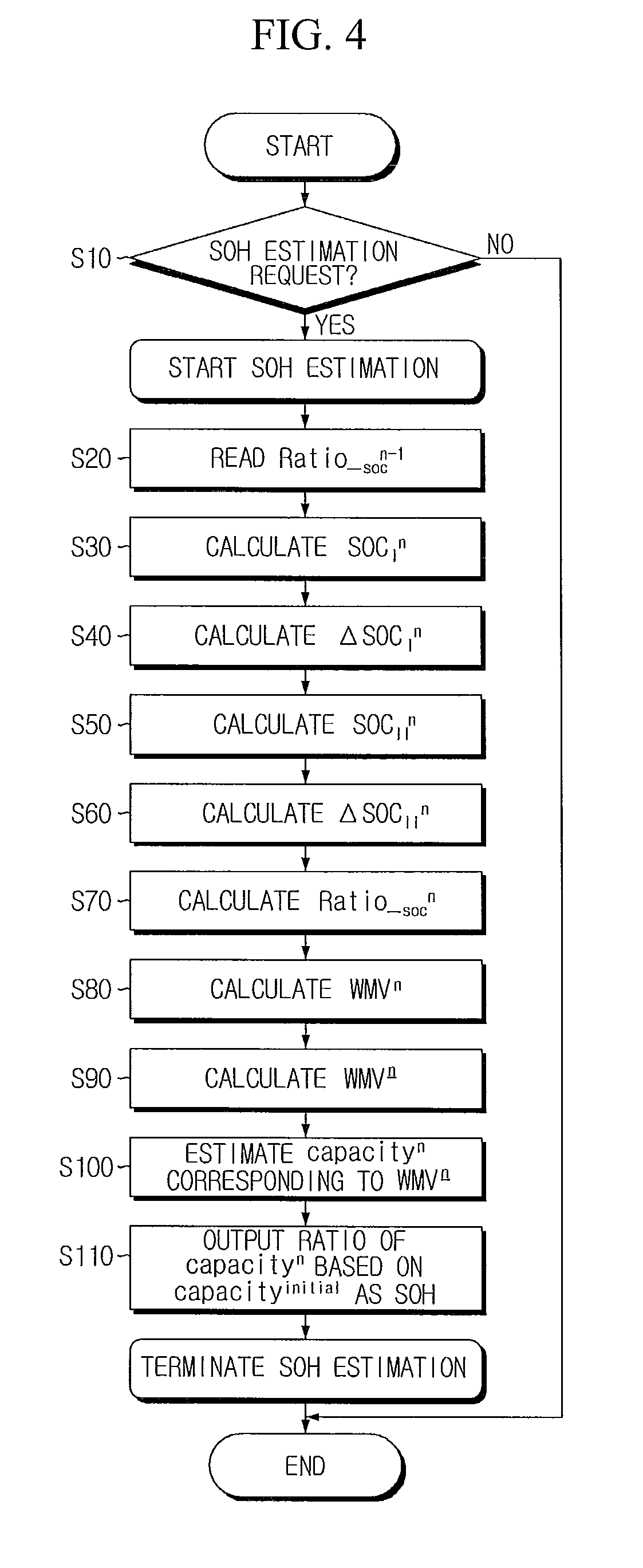

Apparatus and method for estimating state of health of battery based on battery voltage variation pattern

ActiveUS8046181B2Improve accuracyBatteries circuit arrangementsElectric devicesElectrical batteryState of health

An apparatus estimates SOH of a battery based on a battery voltage variation pattern. A data storing unit obtains and stores battery voltage, current and temperature data from sensors, at each SOH estimation. A first SOC estimating unit estimates first SOC by current integration using the battery current data. A second SOC estimating unit estimates open-circuit voltage from the voltage variation pattern, and calculates and stores second SOC corresponding to the open-circuit voltage and temperature using correlations between the open-circuit voltage / temperature and SOC. A weighted mean convergence calculating unit calculates and stores convergence value for weighted mean value of ratio of the second SOC variation to the first SOC variation. A SOH estimating unit estimates capacity corresponding to the weighted mean convergence value using correlation between the weighted mean convergence value and the capacity, estimates relative ratio of the estimated capacity to an initial capacity, and stores it as SOH.

Owner:LG ENERGY SOLUTION LTD

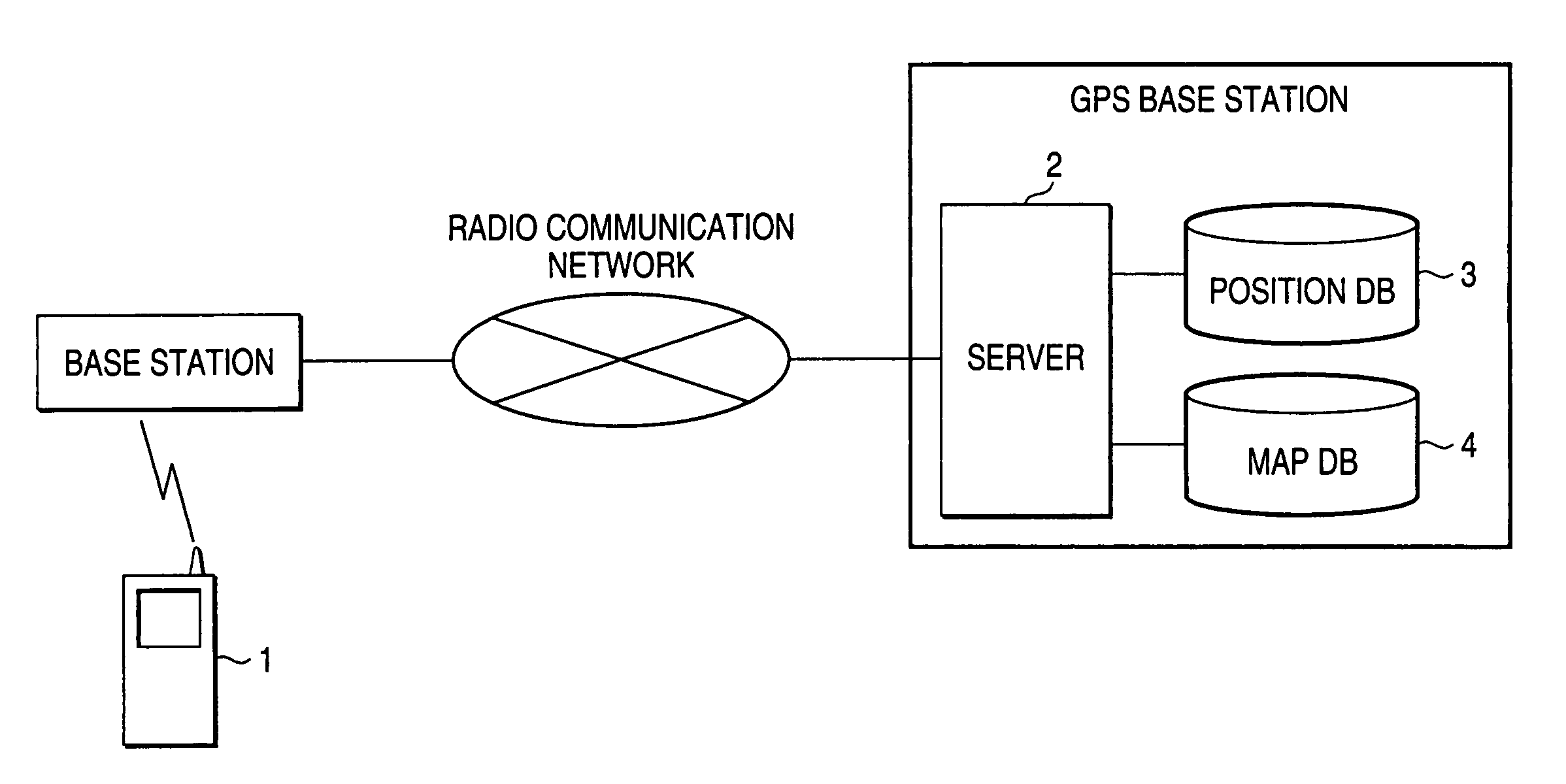

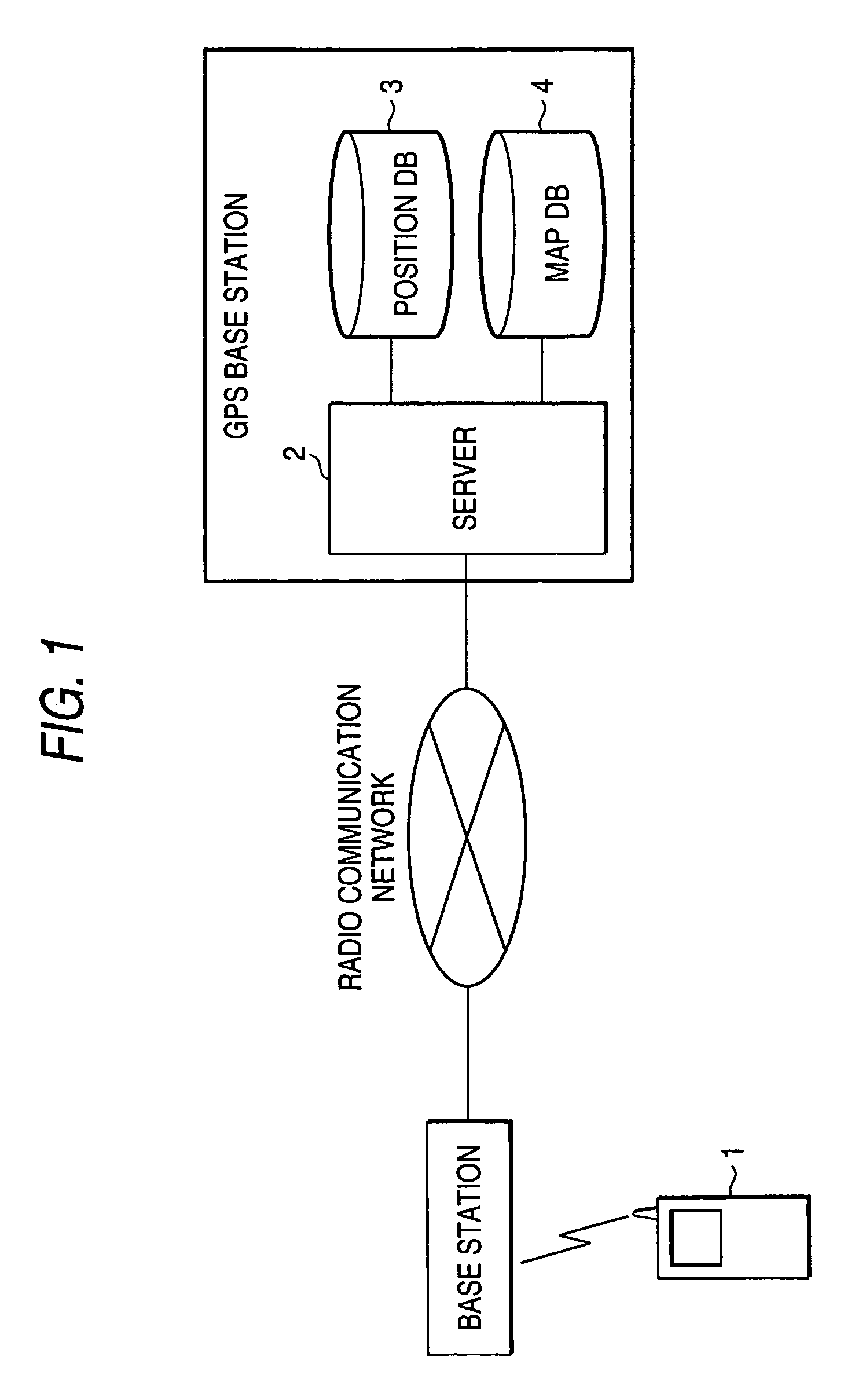

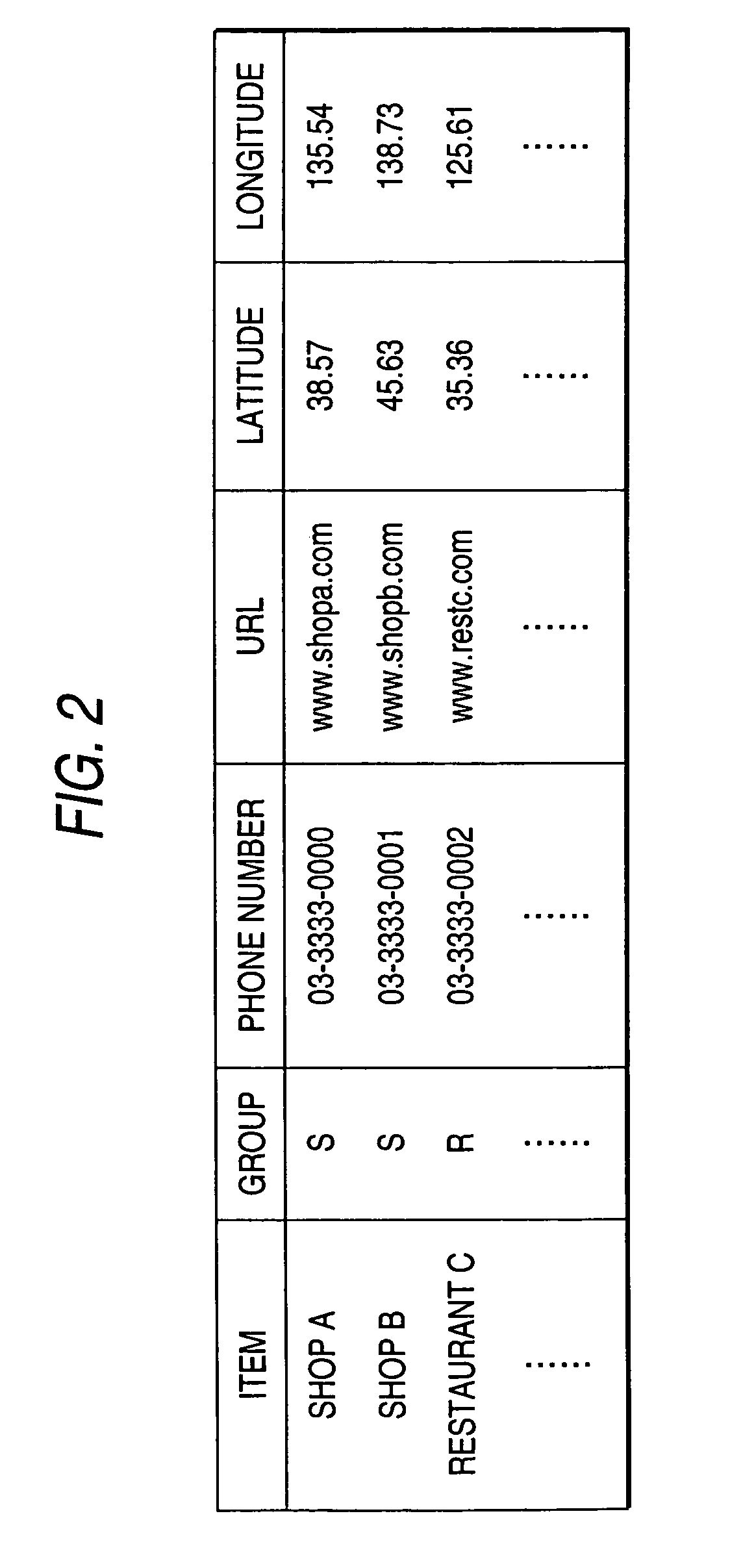

Mobile terminal device having route guiding function and route guiding method utilizing mobile terminal device

InactiveUS7471955B2Instruments for road network navigationNetwork traffic/resource managementLocation detectionTarget capture

A mobile terminal device having a route guiding function of guiding a route by obtaining map information from a server system via a radio communication network includes: a position detecting unit which detects a current position of the mobile terminal device; a bearing detecting unit which detects a first bearing to which the mobile terminal device is directed; a target bearing calculating unit which calculates a second bearing from a current position to the destination; a displaying unit which displays a map based on the acquired map information on a section containing the destination and the current position, displays icon images at a position of the destination and the current position respectively, and displays an icon image indicating the first bearing; and a target capturing unit which produces a sound effect in response to a difference between the first and second bearings.

Owner:YAMAHA CORP

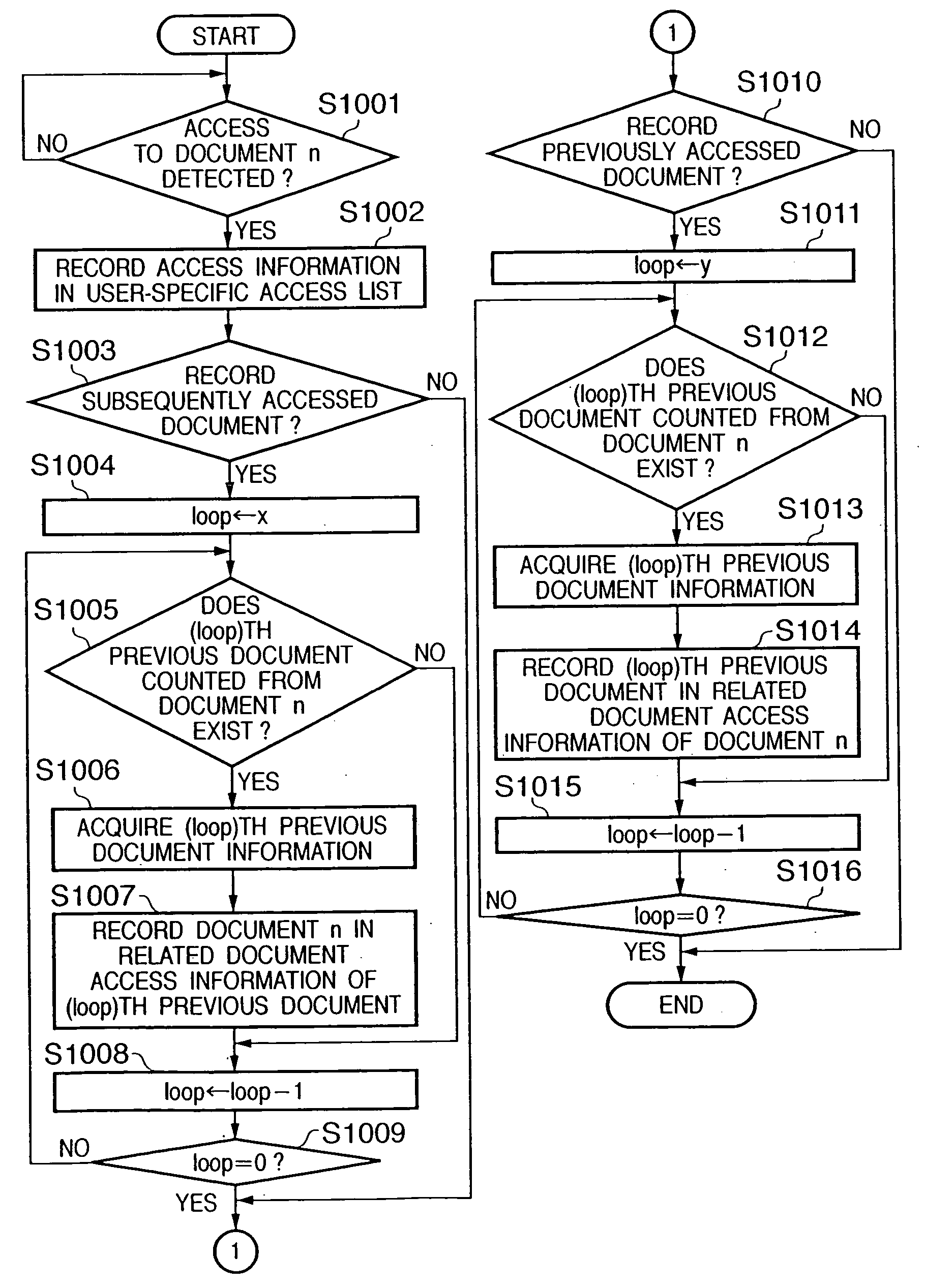

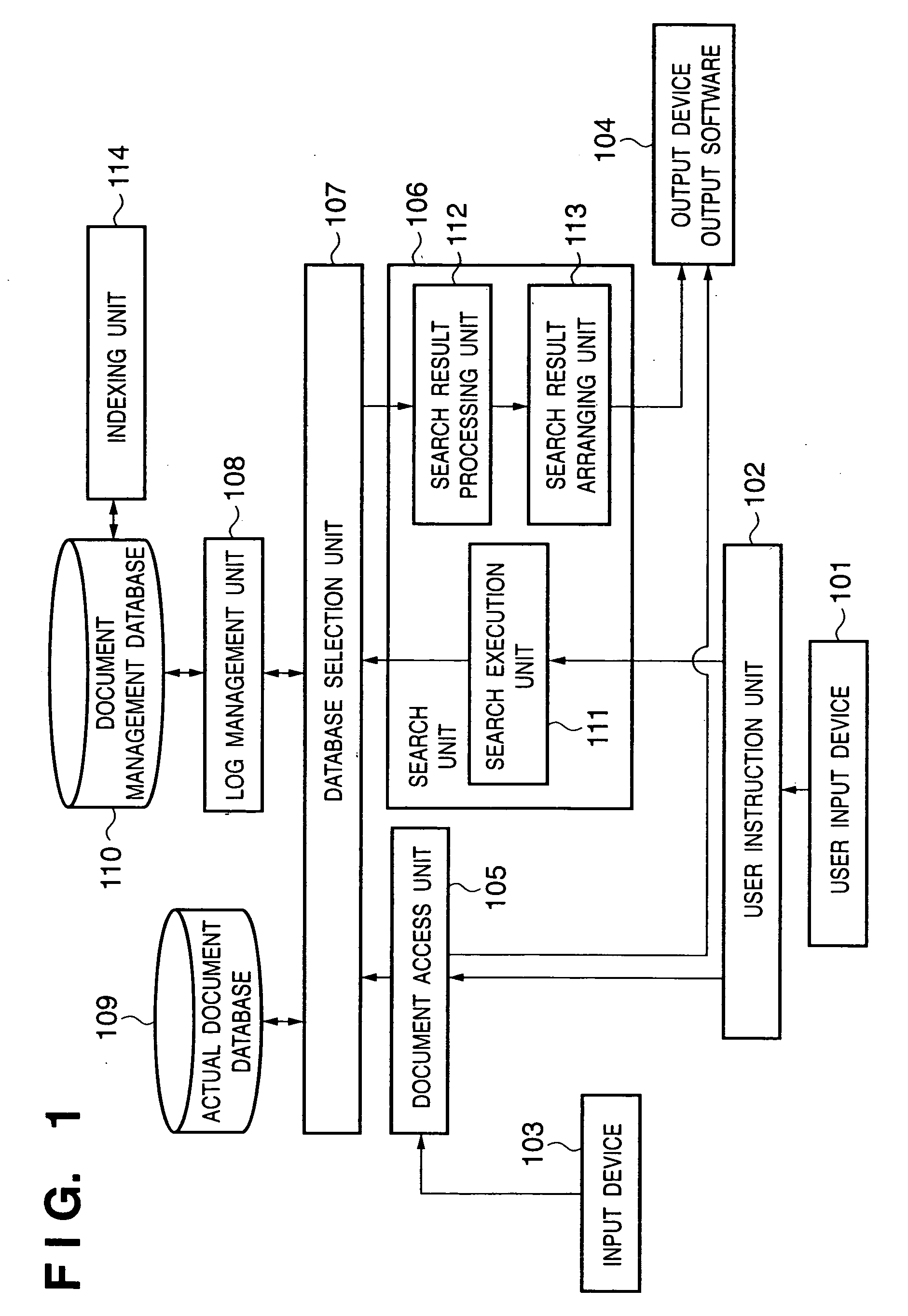

Information processing apparatus, document search method, program, and storage medium

InactiveUS20060031211A1Short timeSpecial data processing applicationsDocument management systemsInformation processingPaper document

There is provided a search technique capable of outputting a proper number of accurate search results within a short time in searching a plurality of databases for a document. To achieve this object, an information processing apparatus according to this invention has the following arrangement. That is, an information processing apparatus which searches a plurality of databases for a document includes a unit which searches for a document stored in an arbitrary database among the plurality of databases, a unit which records access information to documents stored in the plurality of databases, a unit which extracts a document close in access order to the searched document by using the access information and calculates a related level to the searched document on the basis of the access order, and a unit which can outputs as search results the searched document and the document whose related level is calculated.

Owner:CANON KK

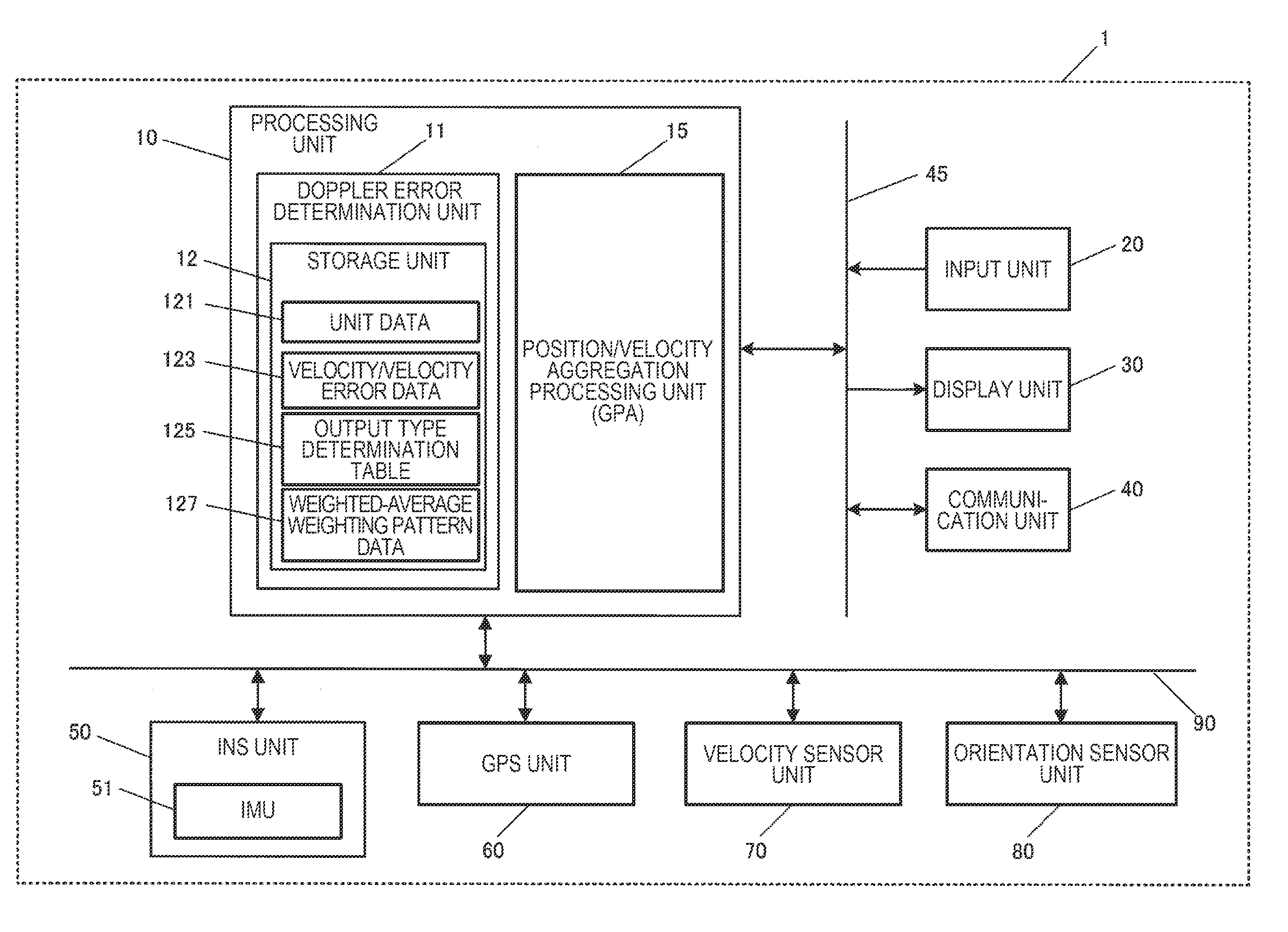

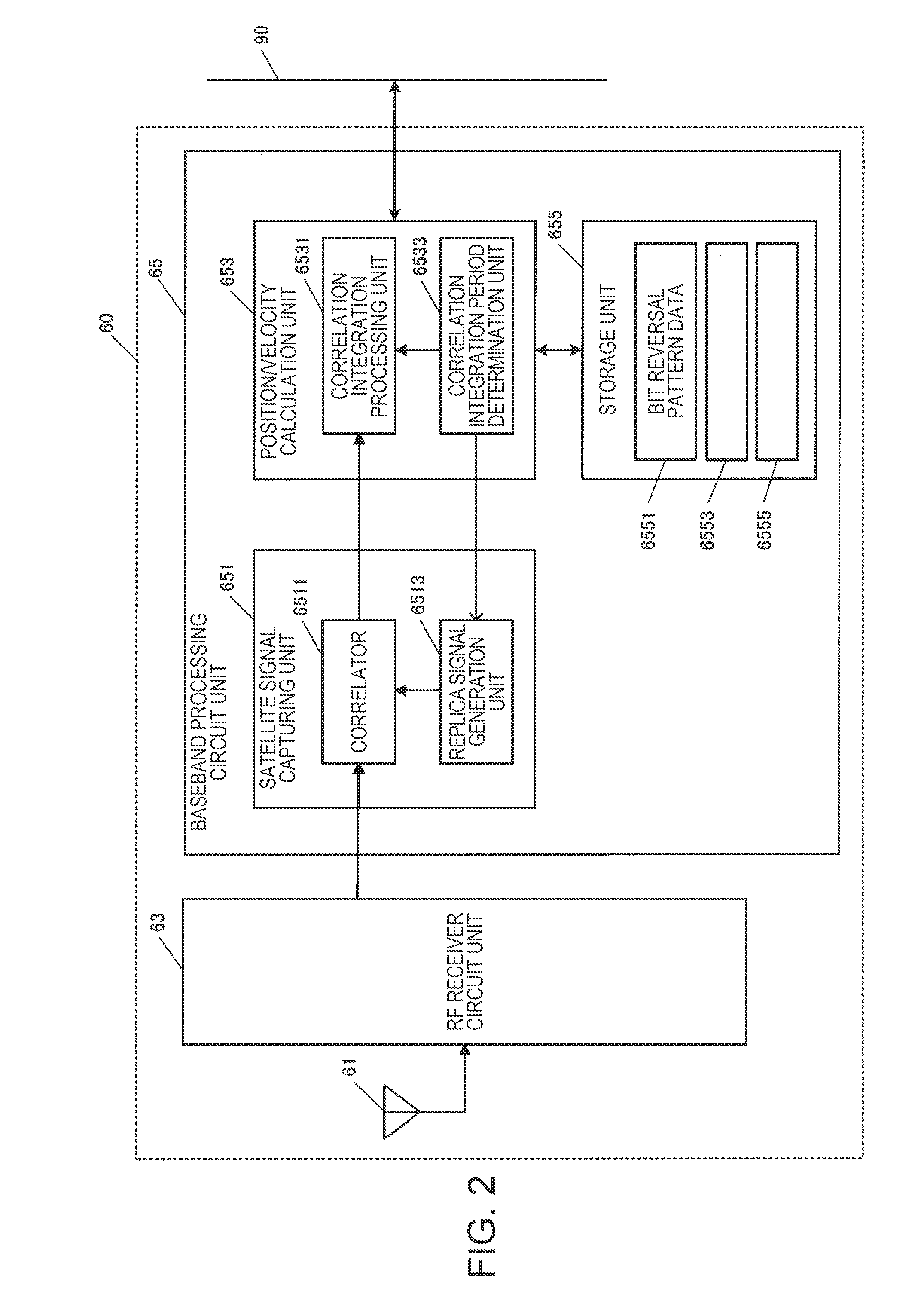

Method and system for calculating position

InactiveUS20110148695A1Accurate velocity errorImprove accuracySatellite radio beaconingMobile vehicleSatellite

A method for calculating a position of a moving vehicle using a first unit that performs a correlation process on a satellite signal received from a satellite to capture the satellite signal and calculate the position and velocity of the moving vehicle and a second unit capable of detecting at least the velocity of the moving vehicle includes: calculating a determination velocity which is the velocity determined using the results of the calculation by the first unit and the results of the detection by the second unit; determining a correlation integration period used when the first unit performs the correlation process using the error in the determination velocity; and calculating the position of the moving vehicle using the results of the calculation by the first unit and the results of the detection by the second unit.

Owner:SEIKO EPSON CORP

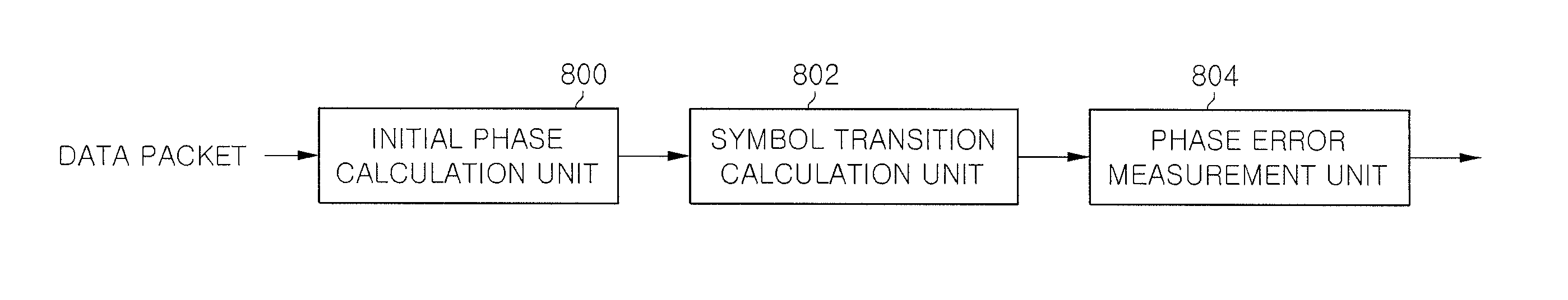

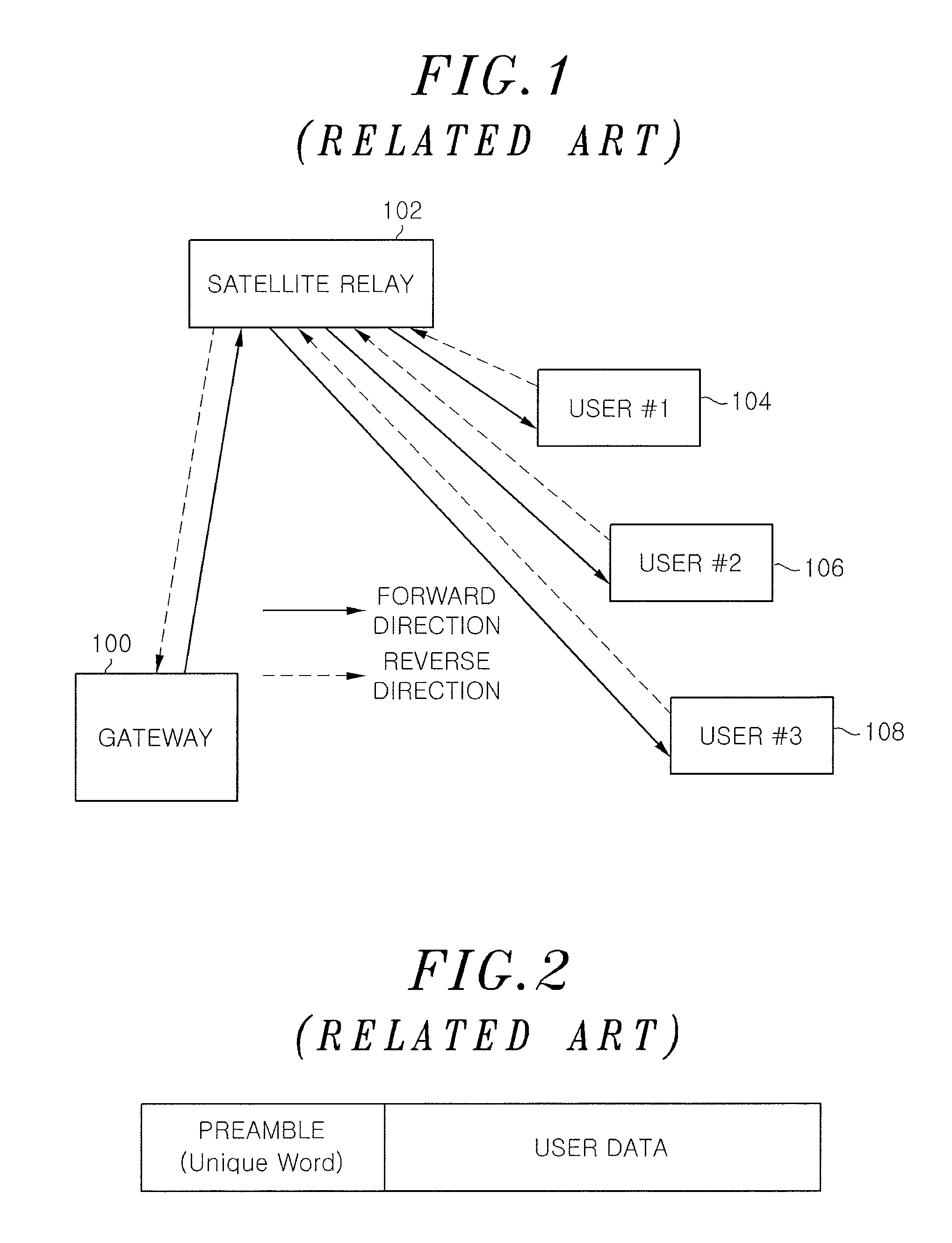

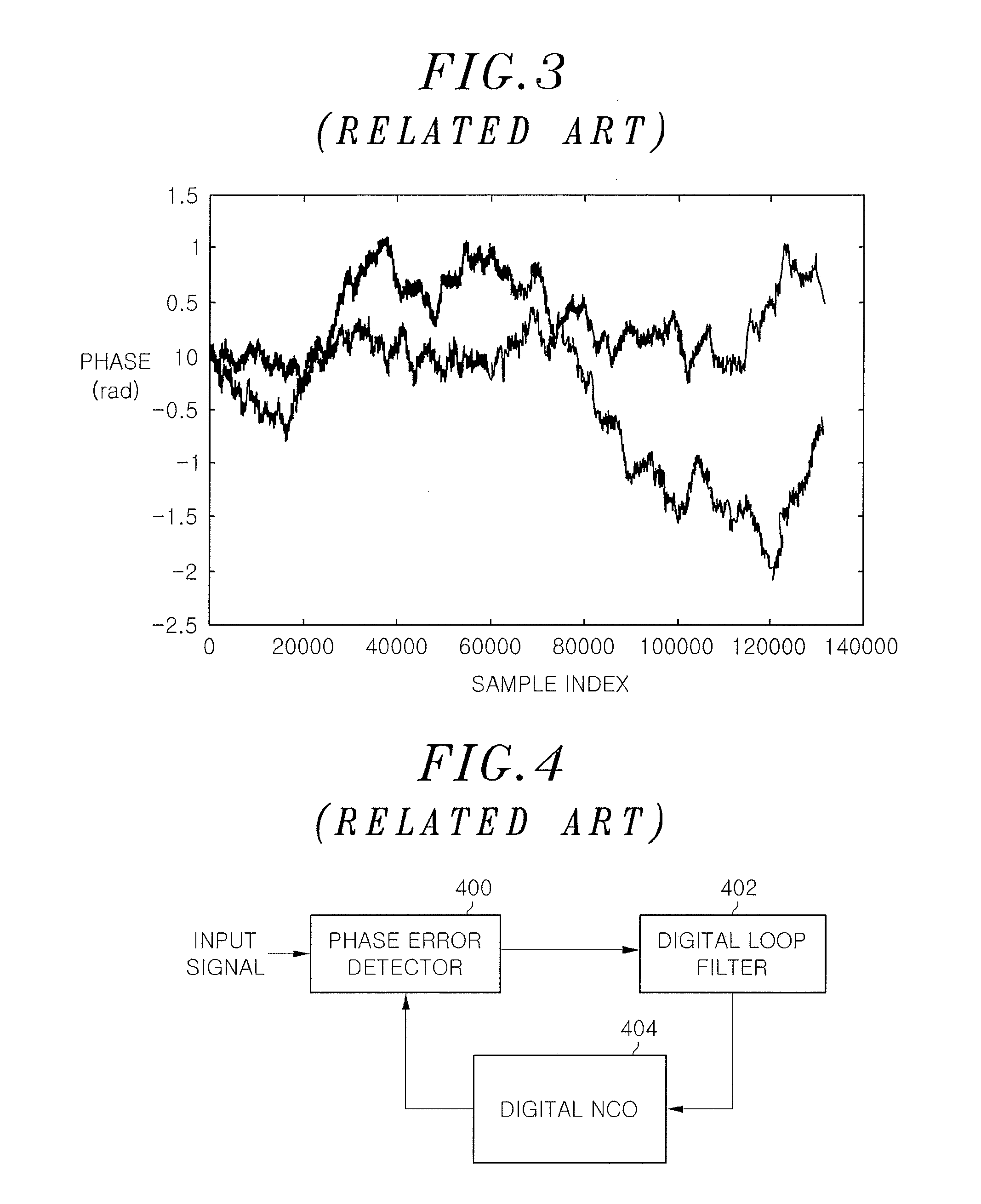

Data transmission and reception method and apparatus robust against phase noise for high efficiency satellite transmission

A data transmission and reception apparatus is used for a high efficiency satellite transmission. The apparatus includes an initial phase calculation unit to calculate initial phase information using a preamble and a postamble of a data packet applied thereto, a symbol transition calculation unit to perform forward and backward metric operations using the initial phase information calculated by the initial phase calculation unit and a pilot symbol in the data packet to calculate a symbol transition of the data packet, and a phase error estimation unit to calculating a phase error using the pilot symbol in a spot where the pilot symbol is positioned, the calculated phase error being provided to the symbol transition calculation unit.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com