Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "Boiler explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A boiler explosion is a catastrophic failure of a boiler. As seen today, boiler explosions are of two kinds. One kind is a failure of the pressure parts of the steam and water sides. There can be many different causes, such as failure of the safety valve, corrosion of critical parts of the boiler, or low water level. Corrosion along the edges of lap joints was a common cause of early boiler explosions.

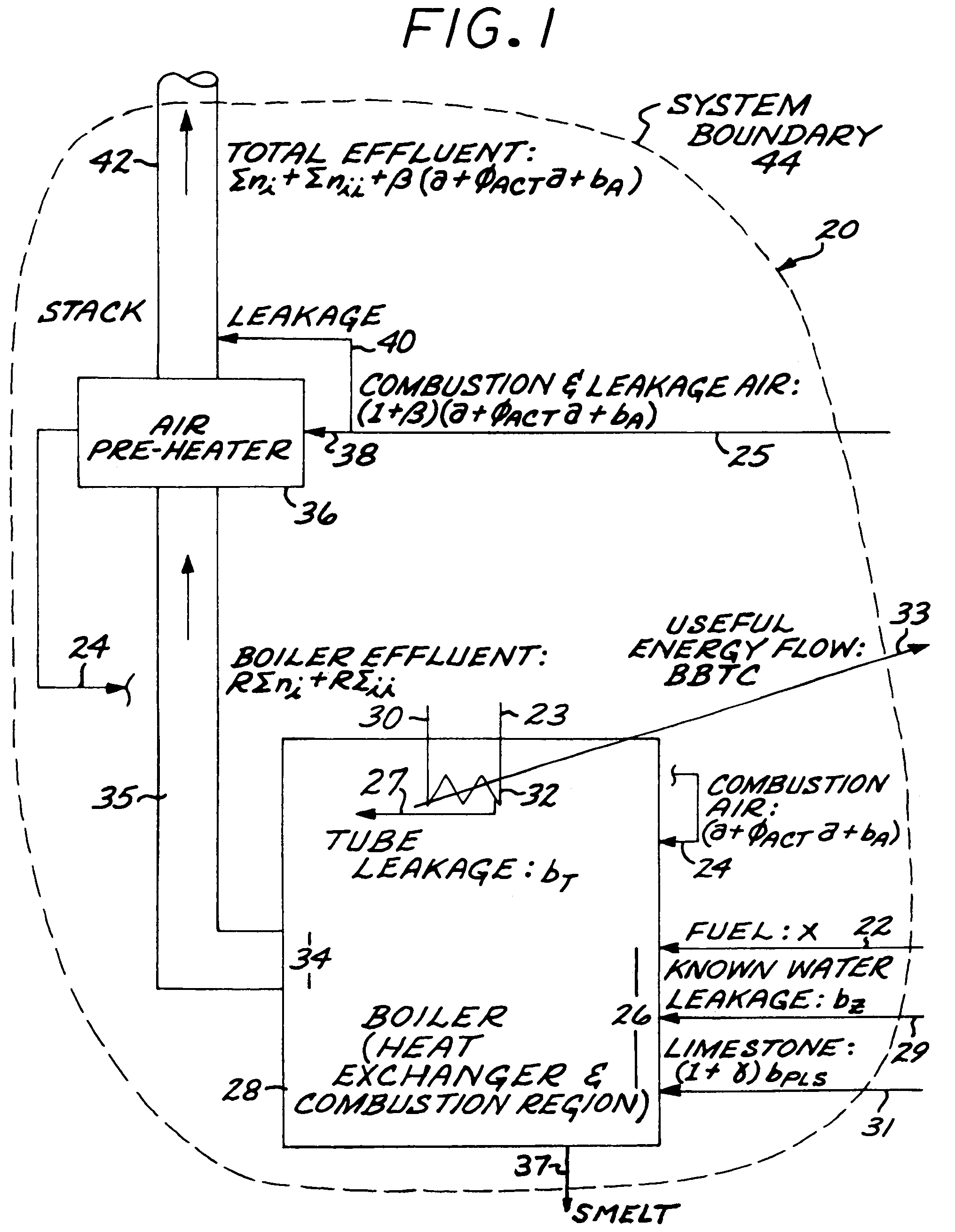

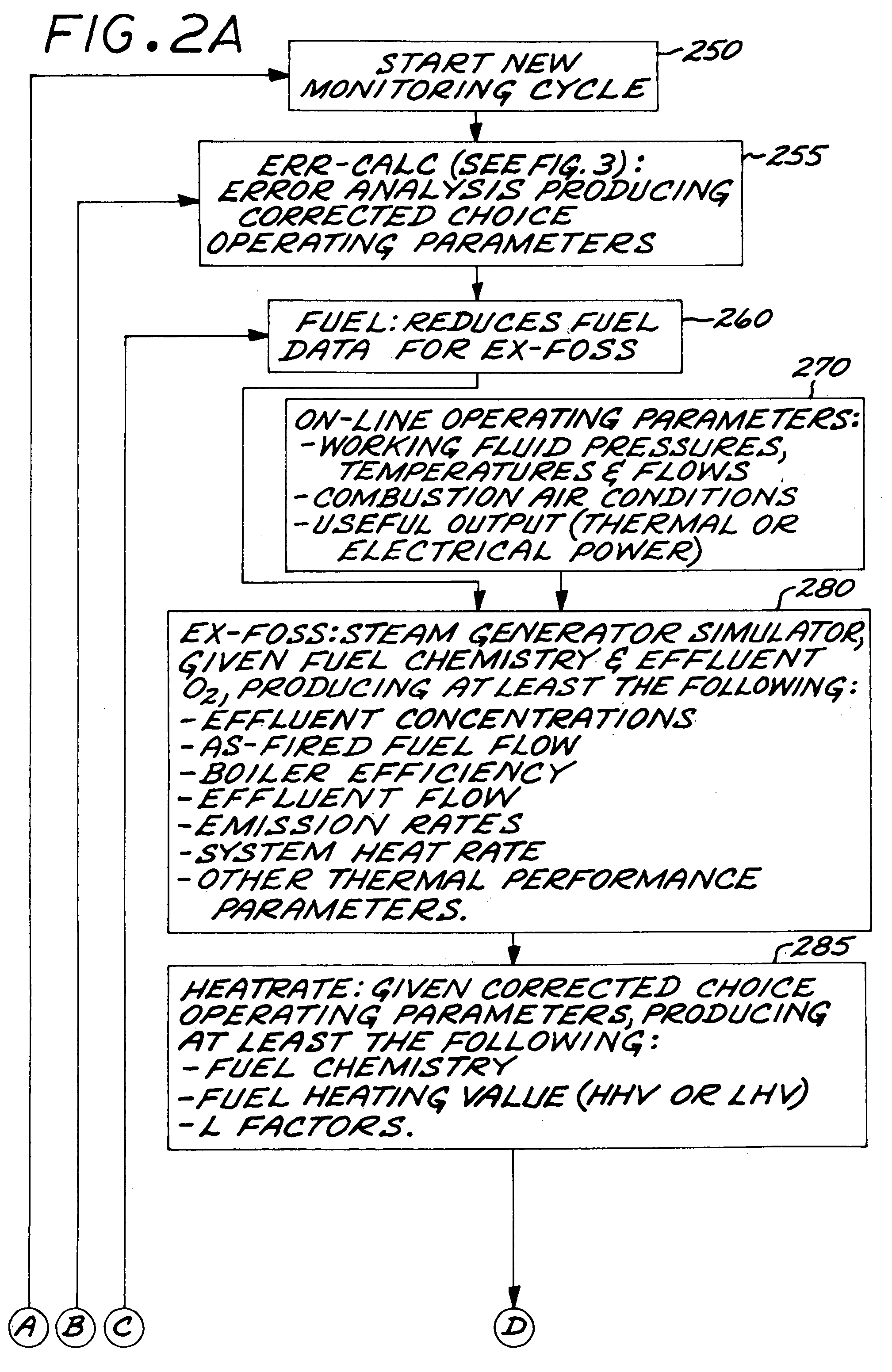

Method for detecting heat exchanger tube failures and their location when using input/loss performance monitoring of a recovery boiler

InactiveUS7039555B2Improve abilitiesReduce outage timeCombustion pretreatment/prehandlingCombustion measurementsRepair timeBlack liquor

This invention relates to a recovery boiler as used by the pulp and paper industry burning black liquor, and, more particularly, to a method for rapid detection of tube failures and the location of the affect heat exchanger within the recovery boiler, without need for direct instrumentation, thereby preventing more serious equipment damage, preventing boiler explosion, preventing injury to operators and minimizing repair time on the affected heat exchanger. This method is applicable to Input / Loss methods of monitoring recovery boilers.

Owner:EXERGETIC SYST

Method of viscosity reduction and cold production of shallow oil reservoir

The invention relates to the technical field of thickened oil development, and discloses a method of viscosity reduction and cold production of a shallow oil reservoir. The method is carried out by the first step, firstly confirming that the oil reservoir has the following characteristics: the ground crude oil viscosity is 50 mPa.s-20000 Mpa.s when the temperature is 20 DEG C, the acid value of the thickened oil is 0.6 mgKOH / g-2.3 mgKOH / g, the reservoir thickness is more than 5 m; the bury depth of the heavy oil reservoir is less than 800 m, the reservoir porosity is more than 15%; the permeability is more than 50x10<-3> mu m2; the reservoir is a reverse rhythmic stratum. Compared with the steam driving method, the development cost of the shallow oil reservoir by the method is reduced by 28-36%; for the shallow oil reservoir is developed without using the steam driving and other methods, the problems of steam channeling at post period of development, serious 'over-coating' phenomenon, and low gas injection utilization efficiency at post period are also not existed; meanwhile, high-temperature steam is also not produced without fuel gas; therefore, boiler explosion, high-temperature scalding and other safety accidents cannot be happened; greenhouse gases are not generated; compared with the steam driving development, the output is further improved.

Owner:XINJIANG KELI NEW TECH DEV

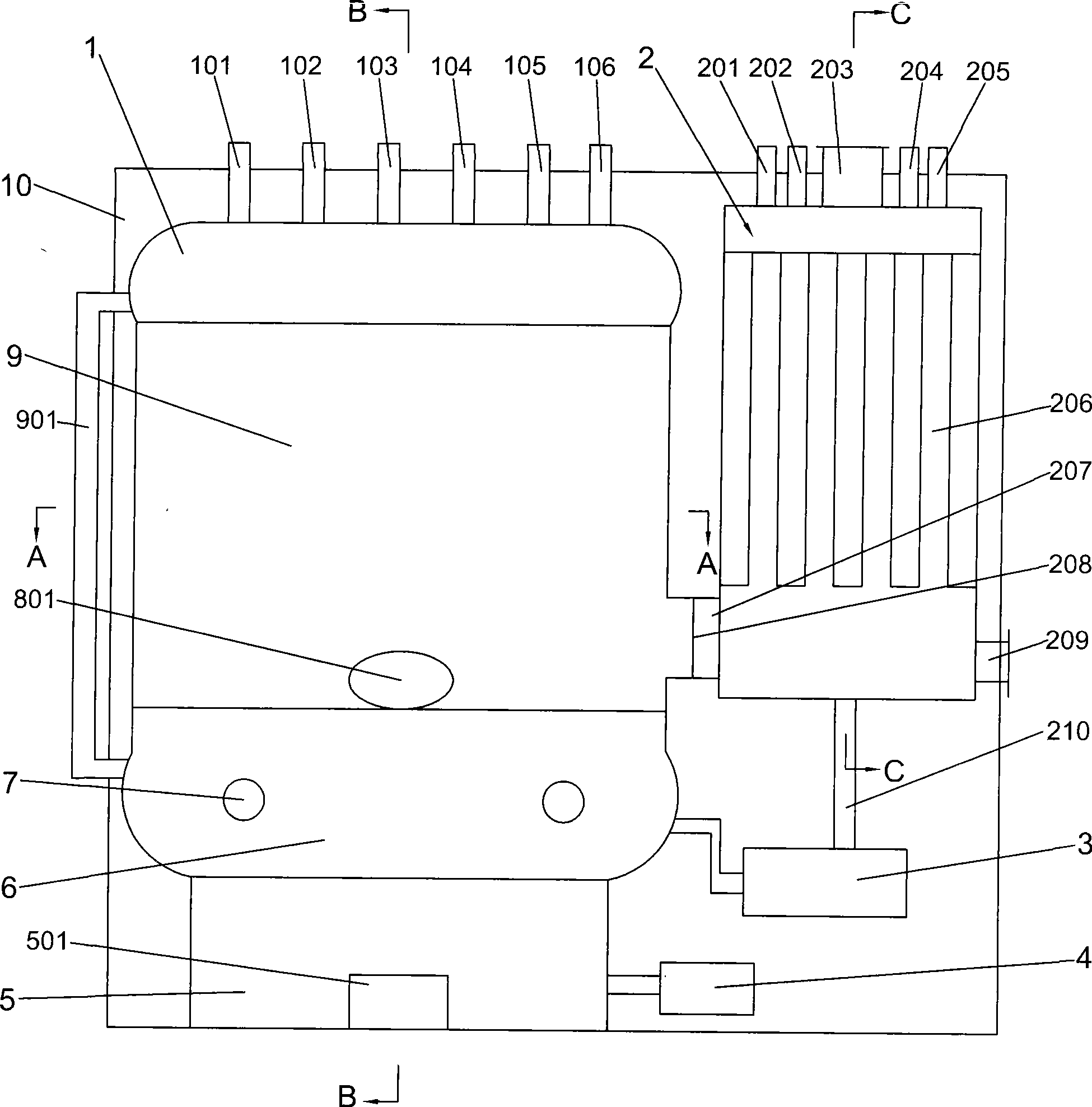

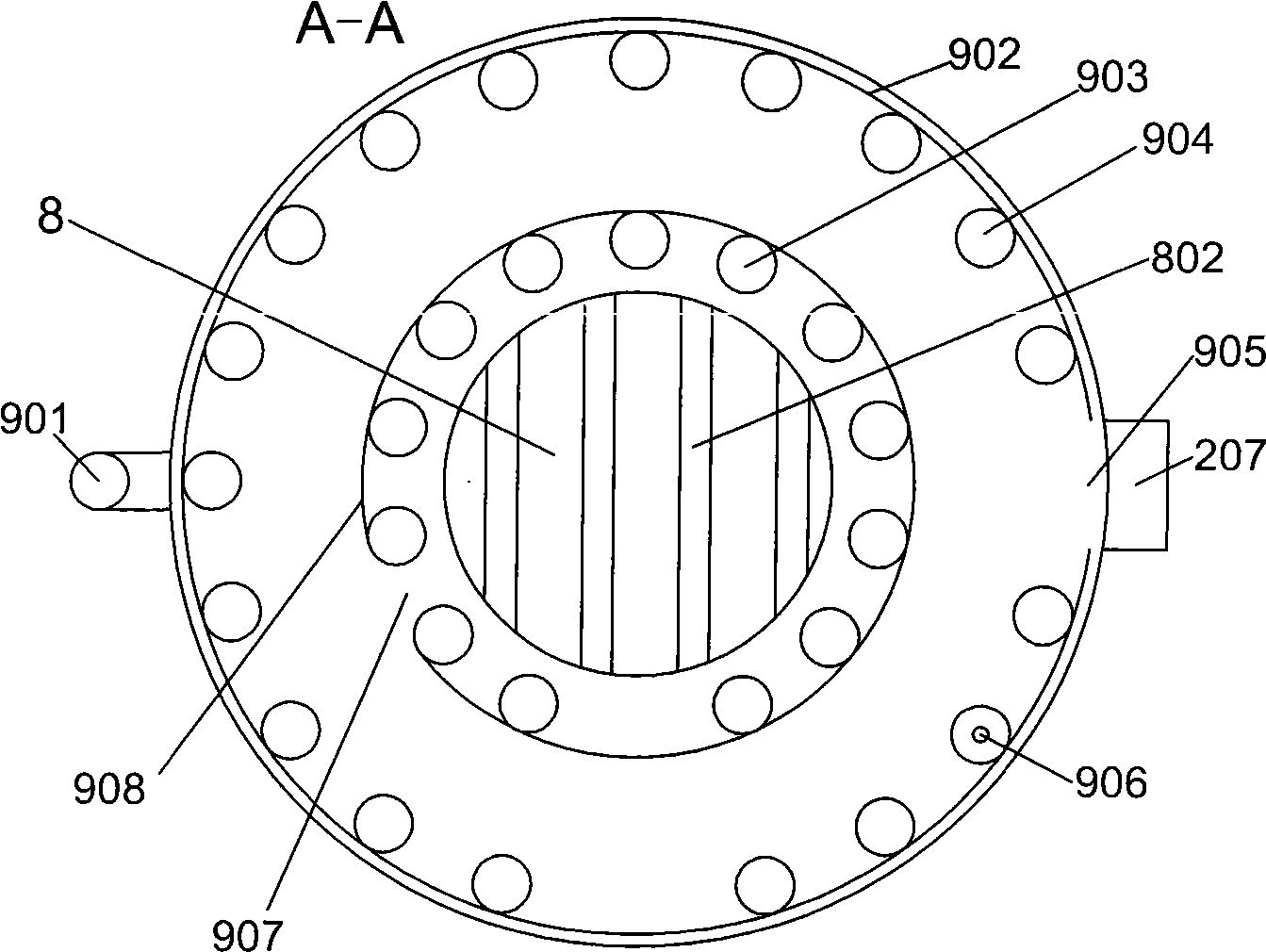

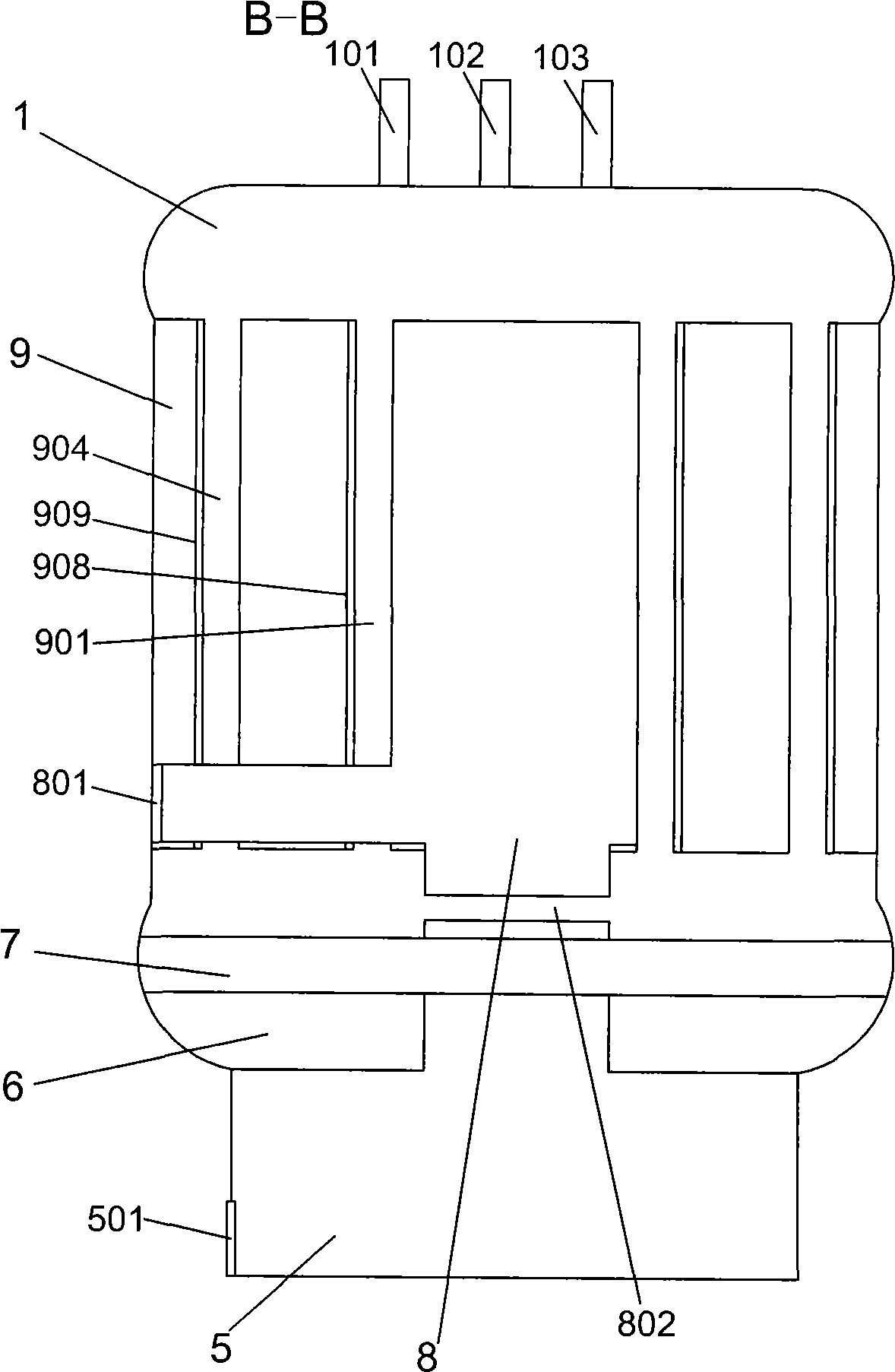

Dual purpose energy-saving boiler for hot water and steam

InactiveCN101532722ASignificant comprehensive benefitsEasy to take outSteam generation heating methodsWater heatersThermal energyCombustion chamber

The invention provides a dual purpose energy-saving boiler for hot water and steam. The boiler comprises an upper water liner, a lower water liner, a main liner body, a subsidiary water tank, a combustion chamber and an electric heating tube, wherein the main liner body comprises an inner circle of a water pipe and an outer circle of a water pipe, and is a pipeline structure, thereby not only increasing the heating area in the main liner body, improving the heat utilization rate of heat energy, but also having strong pressure resistance, preventing occurrence of boiler explosion, and ensuring the safety of the boiler; after the subsidiary water tank heats cold water by residual heat, the water enters the lower water liner, the main liner body and the upper water liner, thereby improving the efficiency of heat energy, and saving energy. The boiler can select different heat modes conveniently according the requirement of different production situations, selects different single fuels or mixture fuels or electric heating, such as coal, firewood, electricity, fuel, gas and the like. The boiler can be used both as a steam boiler and a hot water boiler, is the energy-saving environment-friendly boiler with steam and hot water dual purposes.

Owner:王爱清

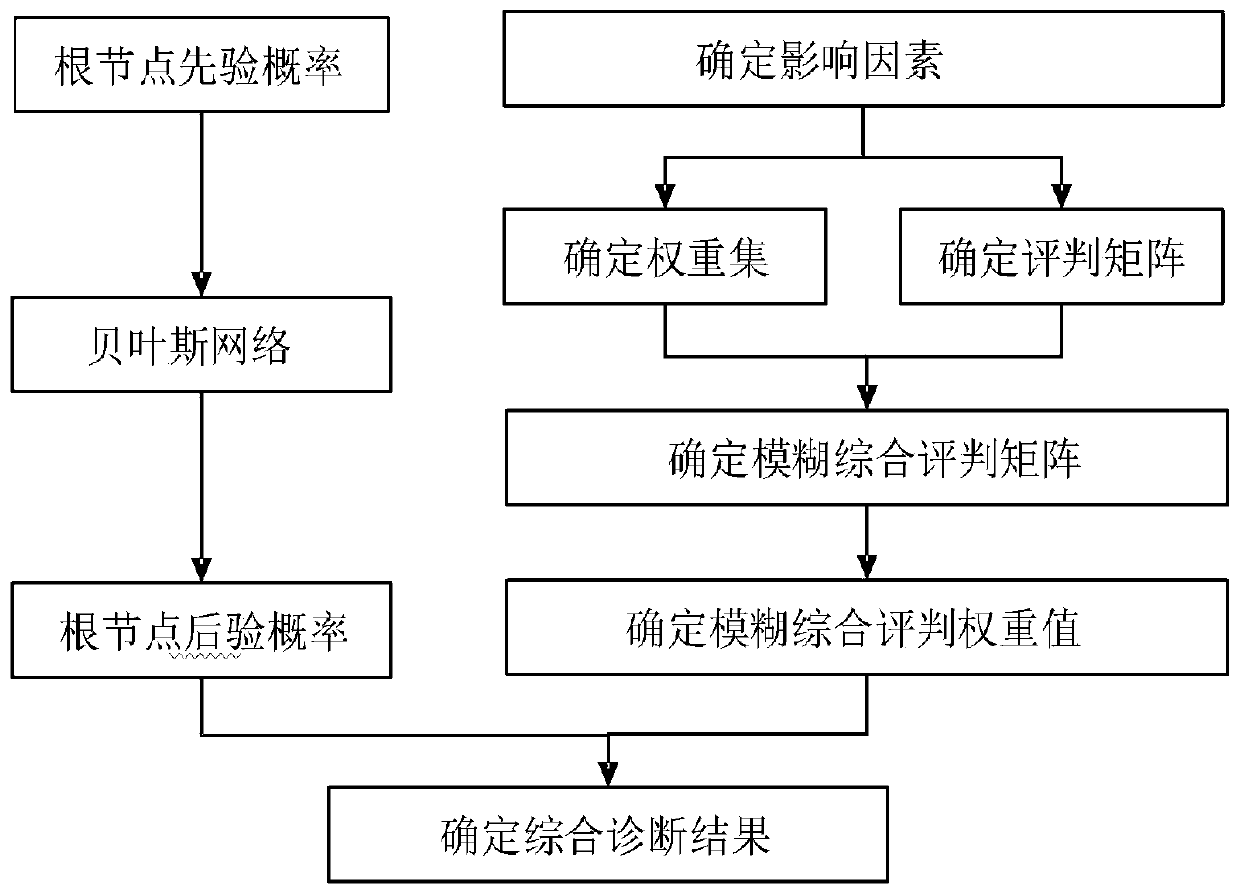

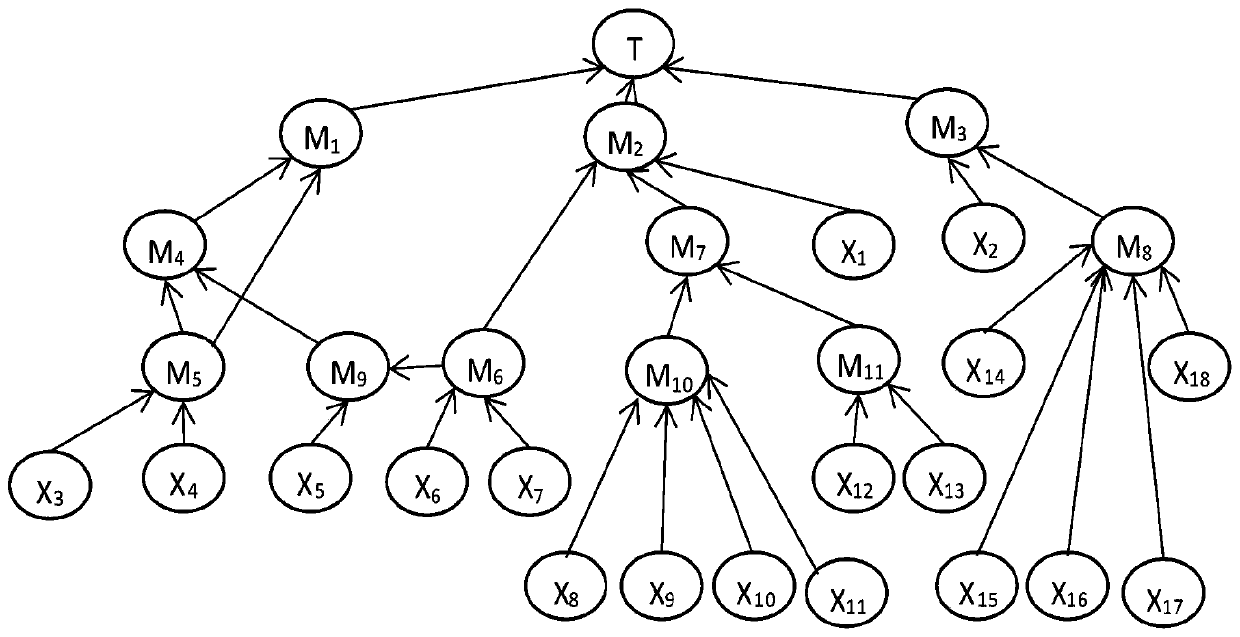

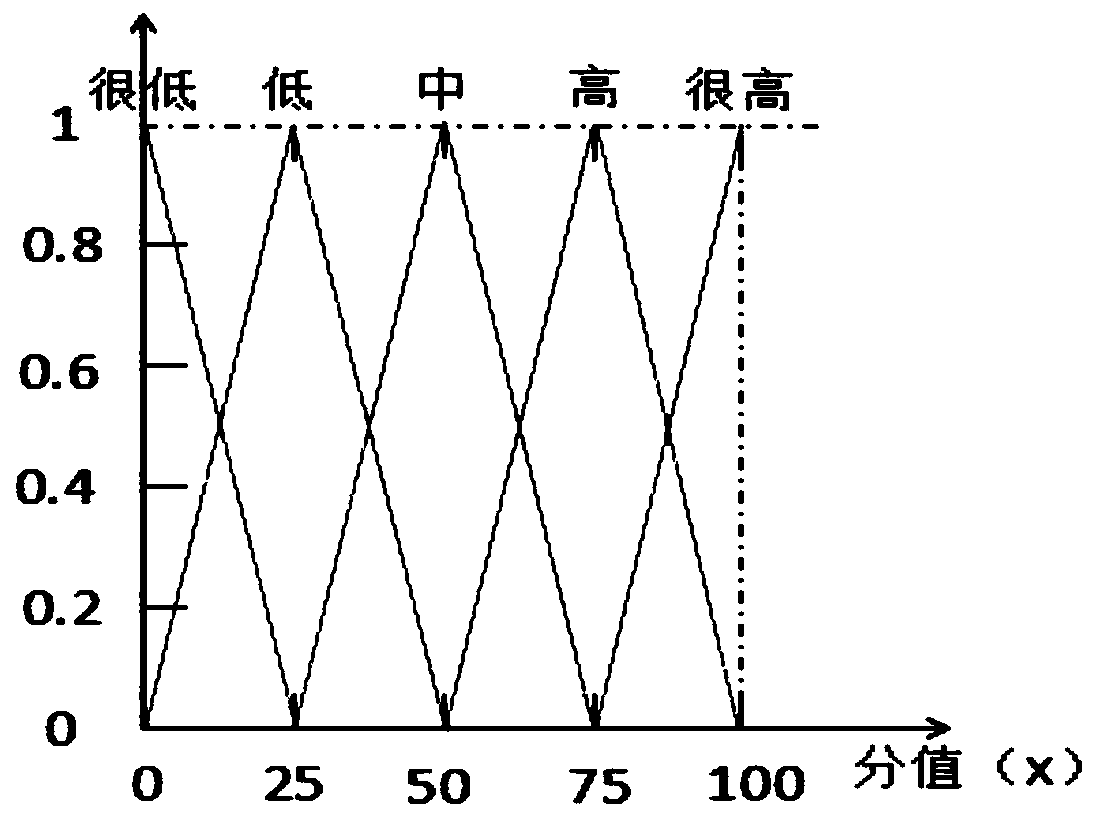

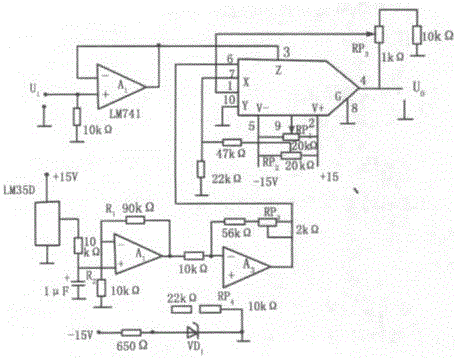

Boiler waste heat explosion fault diagnosis and analysis method

InactiveCN110427015AGuaranteed safe operationPrevent unexcused leave from workProgramme controlElectric testing/monitoringFault modelAnalysis method

The invention, which belongs to the field of waste heat boiler accident diagnosis analysis, relates to a boiler waste heat explosion fault diagnosis and analysis method. With the provided method having advantages of high diagnosis efficiency and low maintenance cost, accident occurrence can be prevented and the safety running of the waste heat boiler can be guaranteed. According to the invention,a Bayesian network model is constructed; a root node prior probability of a waste heat boiler fault model is obtained; a posterior probability of the root node is obtained; an influence factor set isestablished and an evaluation set is established; a single influencing factor type fuzzy evaluation matrix is determined; a factor weight set is determined; a fuzzy comprehensive evaluation matrix ofan explosion accident factor weight set of the waste heat boiler is calculated; and the posterior probability is diagnosed by using a Bayesian network diagnosis method and comprehensive diagnosis is performed by combining the fuzzy evaluation method, and influence factors are ranked in a descending order to obtain ranks of waste heat explosion failure factors of the boiler. The method is mainly applied to the diagnosis of boiler waste heat explosion faults.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

Ignition boosting methoe for gas boiler

InactiveCN1563804APrevent deflagration accidentsNormal burningAir supply regulationEngineeringProduct gas

The present invention relates to the ignition and pressure lifting method for medium temperature and medium pressure gas burning boiler with coke oven gas as fuel. During ignition, lifting pressure and normal operation, hot blast baffle opening, blower baffle opening, induced draft fan baffle opening, gas regulating door opening and negative hearth pressure in the boiler are set and regulated, so as to control the inflammable gas density inside the boiler during ignition and lifting pressure below the explosion limit and to avoid boiler explosion accident. The ignition and pressure lifting method of the present invention is suitable for all types of gas burning boilers with PLC program controlled ignition system.

Owner:山西焦化股份有限公司

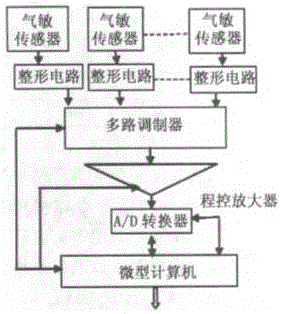

Monitoring system for steam explosion in furnace

The invention, which relates to the technical field of the monitoring system of the boiler explosion, discloses a monitoring system for a steam explosion in a furnace. The system comprises a real-time data acquisition module in a furnace. According to a boiler explosion early-warning system included by the real-time data acquisition module, a pressure sensor and a gas sensor are arranged in a boiler and collect relevant data in the furnace; and the relevant data are operated by using a relevant model in the software design. The system has the following beneficial effects: at a hardware design stage, the pressure sensor and the gas sensor are used for collecting and controlling data; and at a software design stage, a temperature element is added. With a particle swarm intelligent mining searching algorithm, a possible dangerous situation in a furnace is detected in artificial intelligence; and the explosion early-warning accuracy rate of the system is high on the condition of different boiler laying situations.

Owner:JIANGSU COLLEGE OF INFORMATION TECH

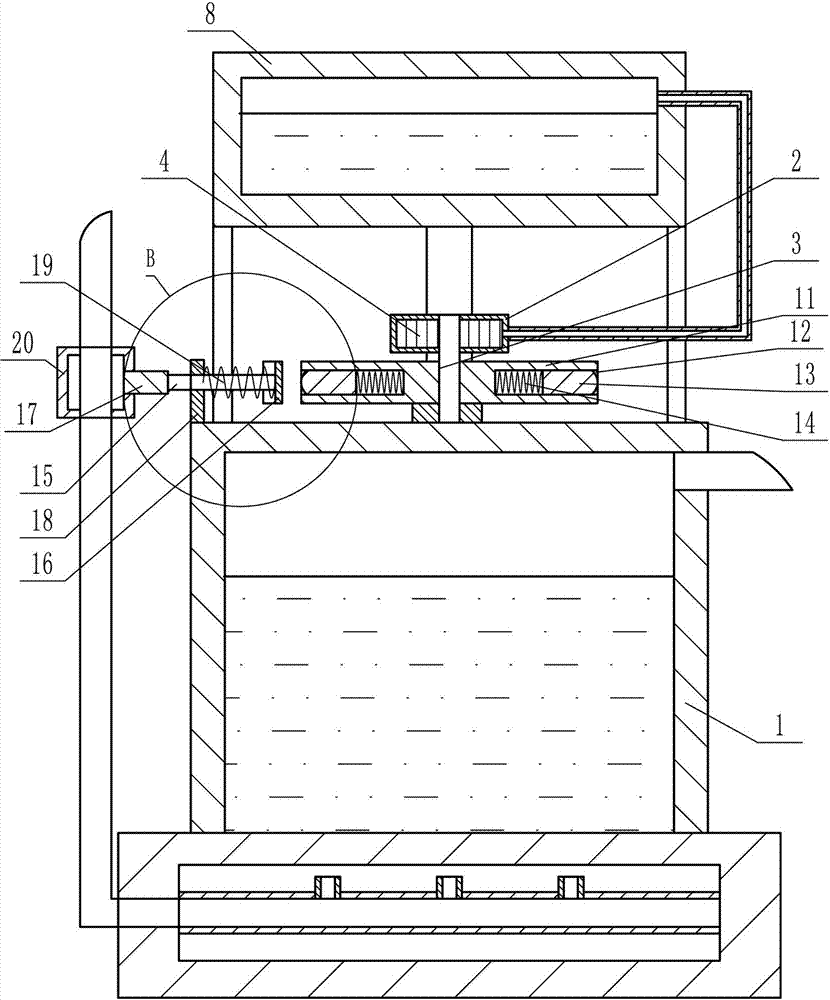

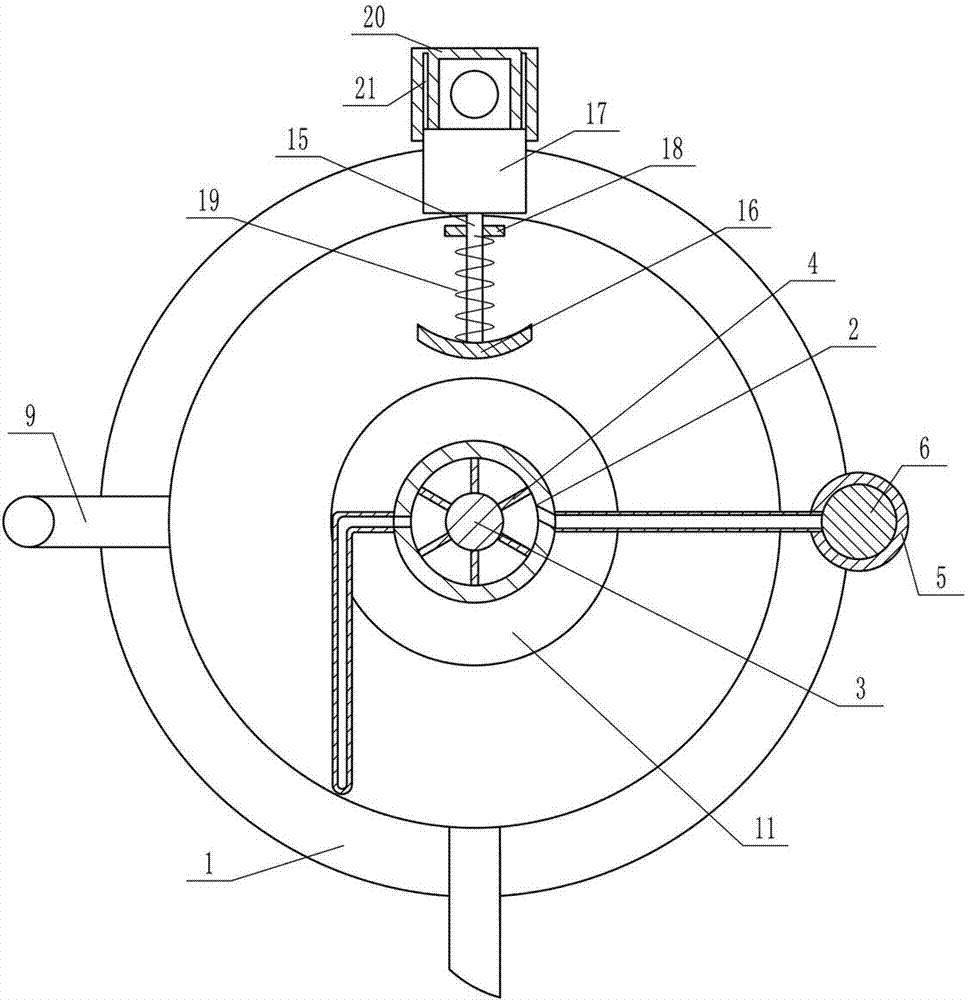

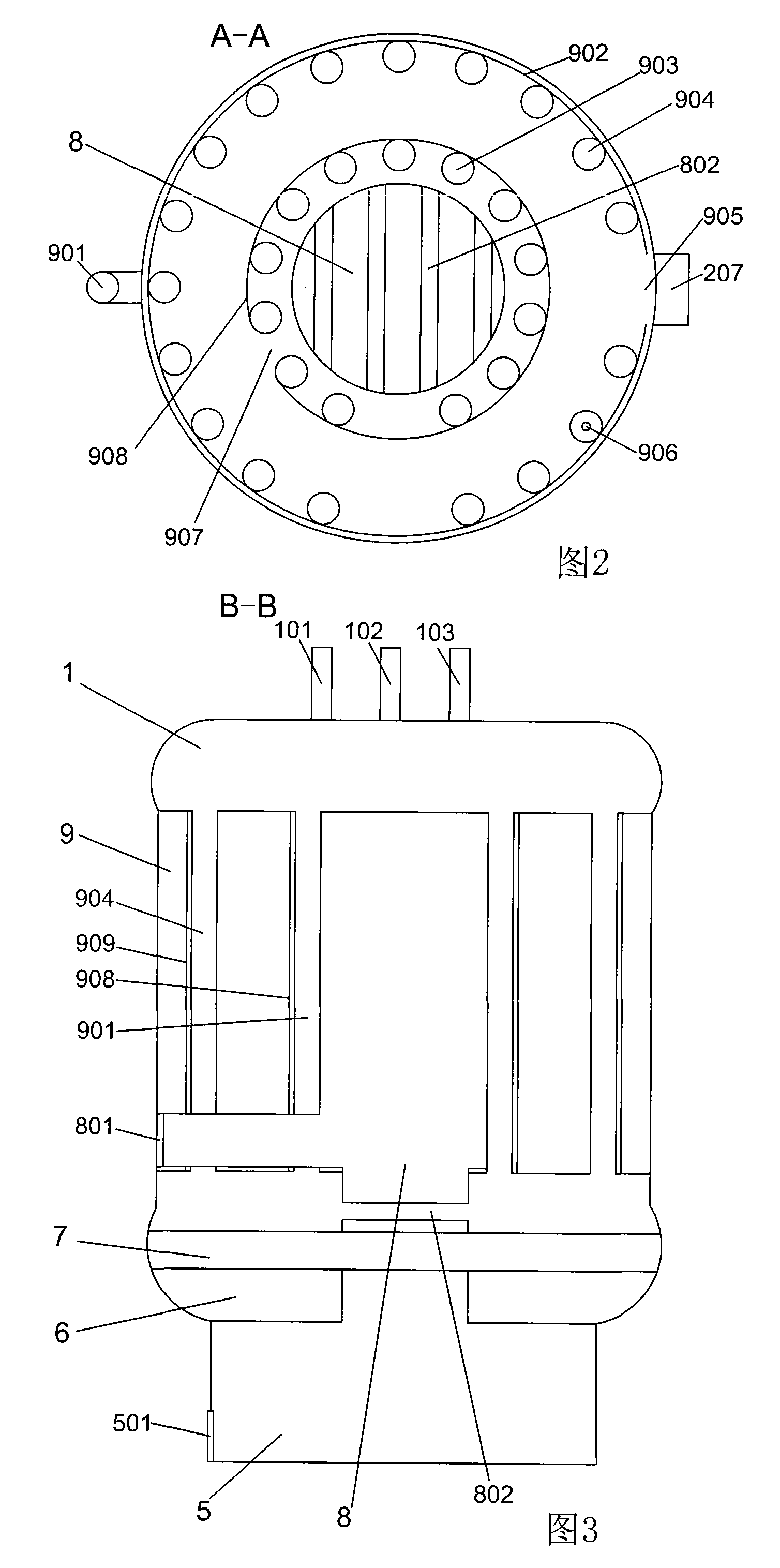

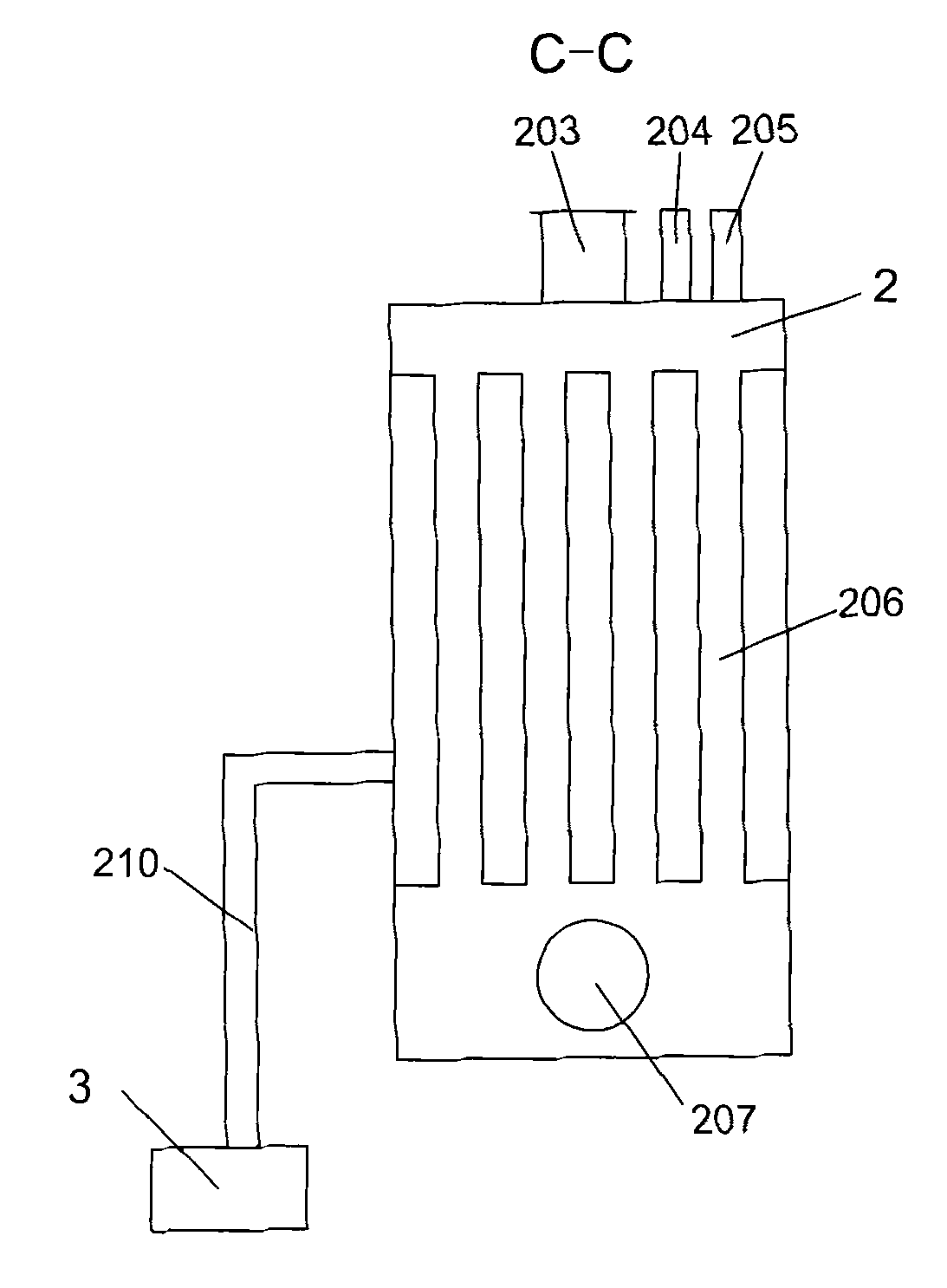

Boiler safety explosion-proof device

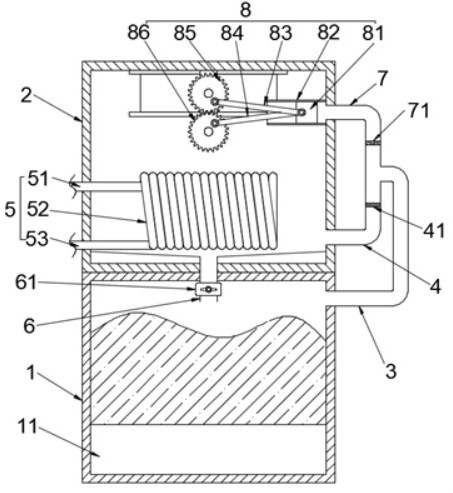

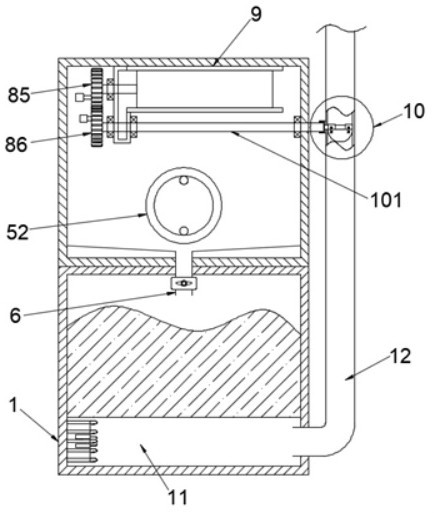

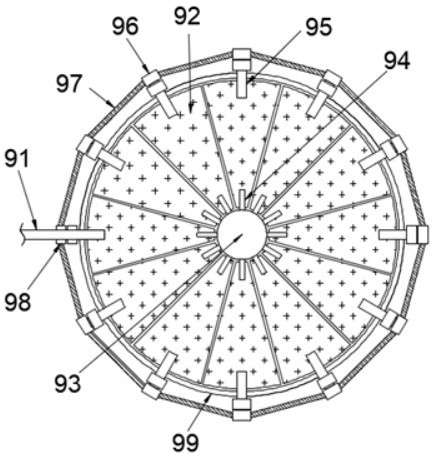

ActiveCN107504475AAchieve explosion-proof functionImprove cooling effectSteam boilersSteam boilers componentsCircular discEngineering

The invention relates to a boiler safety explosion-proof device and effectively solves the problem that after an existing boiler explosion-proof device exists, the existing boiler explosion-proof device is not complete in explosion-proof function. According to the technical scheme, the boiler safety explosion-proof device comprises a furnace body; a hollow disk is arranged above the furnace body; a rotating shaft is installed in the center of the hollow disk, and is evenly provided with a plurality of fan blades; a first pipeline is arranged on the right side of the hollow disk, and is internally provided with a first slider; the first slider is connected with the upper end of the first pipeline through a first pressure spring; the hollow disk is communicated with a cavity of the first pipeline through a steam pipeline; a water tank is arranged above the hollow disk which is communicated with the water tank; the lower end of the water tank is communicated with a furnace body 1 through a water draining pipe which is provided with a check valve; the rotating shaft is provided with a rotating disk in which a plurality of blind holes are formed; second sliders are formed in the blind holes, and are connected with the blind holes through tension springs; an oil conveying pipeline is arranged on the rear side of the rotating disk; and an oil control device is arranged between the rotating disk and the oil conveying pipeline. The boiler safety explosion-proof device is more convenient, fast and humanized.

Owner:河南鑫安利安全科技股份有限公司

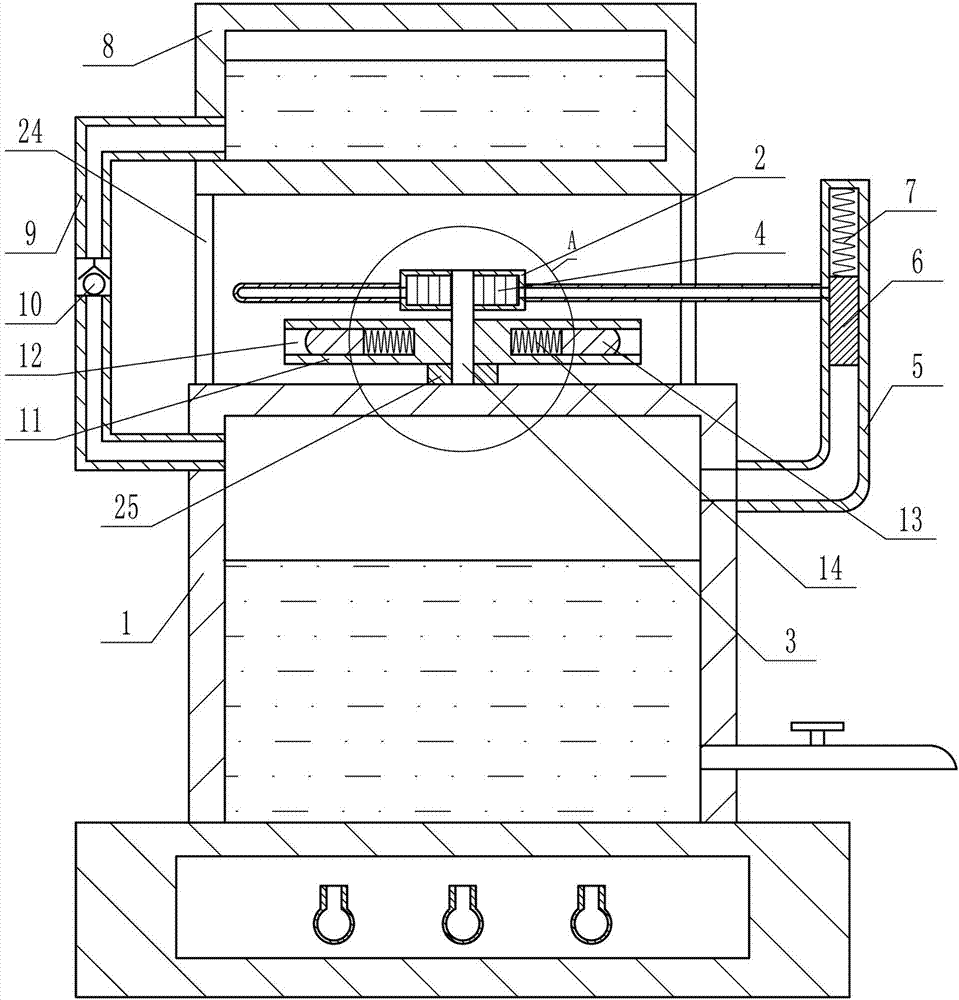

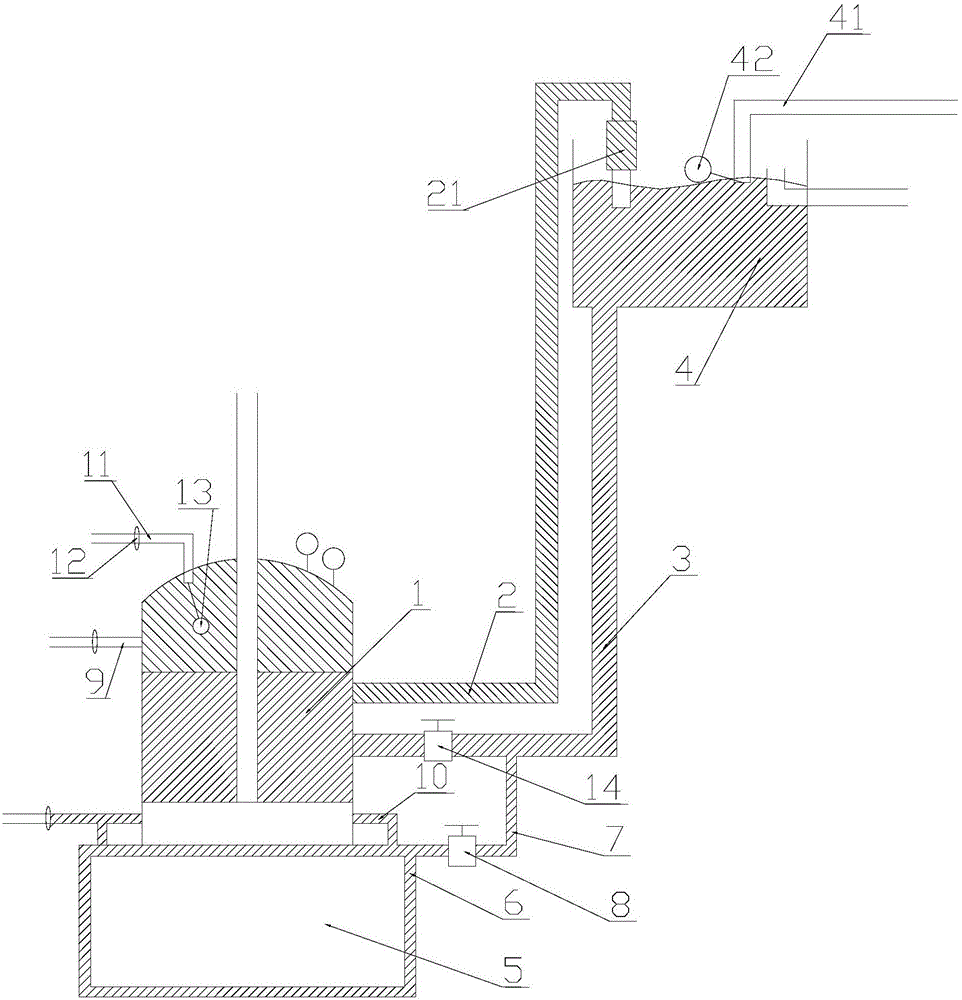

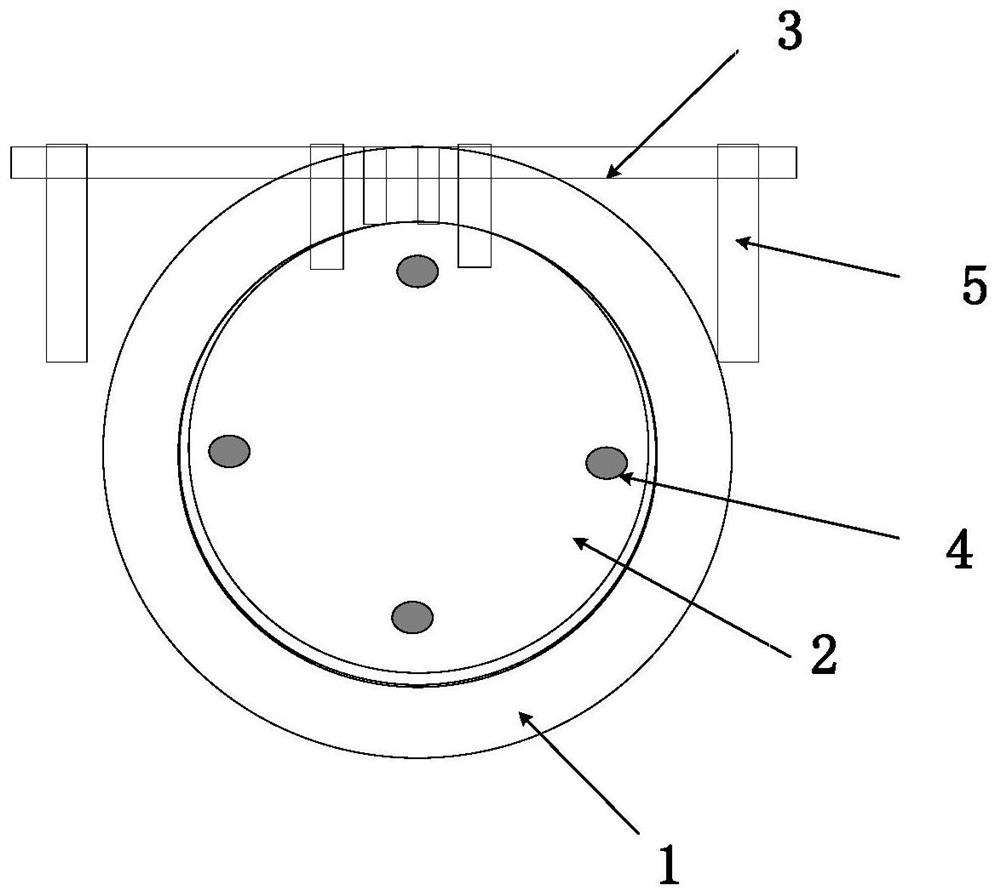

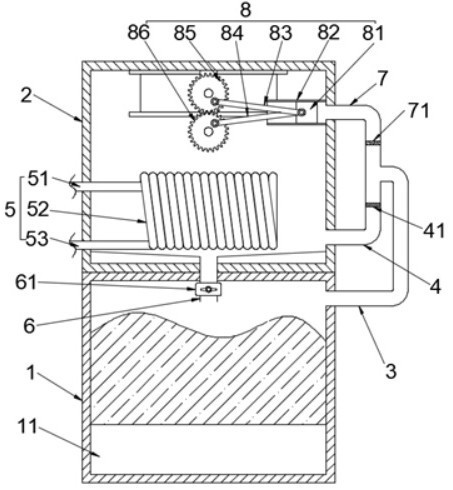

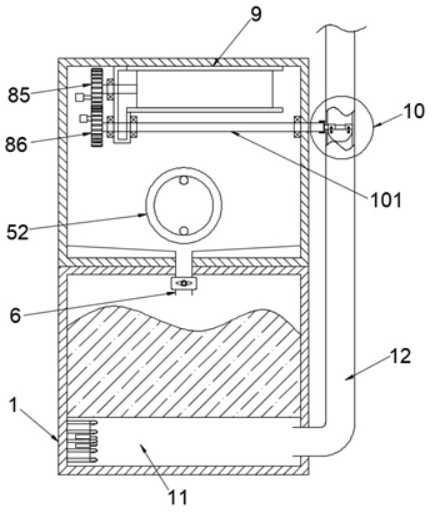

Explosionproof automatic pressure relief boiler

ActiveCN106642724ARealize automatic water replenishmentAchieve explosion-proofFluid heatersWater vaporExplosion protection

The invention provides an explosionproof automatic pressure relief boiler which comprises a boiler body, a pressure relief pipe, a communicating pipe and an automatic feedwater tank. The lower part of the automatic feedwater tank communicates with the boiler body by means of the communicating pipe, so that water is fed in the boiler body through the communicating pipe by automatic feedwater tank. One end of the pressure relief pipe communicates with the boiler body, and the other end of the pressure relief pipe extends into the water surface of the automatic feedwater tank, so that the excessive high-pressure water vapor generated in the boiler body is discharged through the pressure relief pipe, and the condition that the pressure in the boiler body is too high, resulting in boiler explosion is avoided; the automatic feedwater tank is arranged above the boiler body, and is higher than the boiler body, so that water in the automatic feedwater tank can flow in the boiler body automatically, the whole process does not need to be supervised manually, and automatic water feed and explosion protection can be realized; and besides, the integral structure is relatively simple, the manufacturing cost is low, and the explosionproof automatic pressure relief boiler is suitable for popularization and application.

Owner:谭潘

Ignition boosting method for gas boiler

InactiveCN1270124CPrevent deflagration accidentsNormal burningAir supply regulationFlammability limitProduct gas

The present invention relates to the ignition and pressure lifting method for medium temperature and medium pressure gas burning boiler with coke oven gas as fuel. During ignition, lifting pressure and normal operation, hot blast baffle opening, blower baffle opening, induced draft fan baffle opening, gas regulating door opening and negative hearth pressure in the boiler are set and regulated, so as to control the inflammable gas density inside the boiler during ignition and lifting pressure below the explosion limit and to avoid boiler explosion accident. The ignition and pressure lifting method of the present invention is suitable for all types of gas burning boilers with PLC program controlled ignition system.

Owner:山西焦化股份有限公司

Explosion-proof door structure of oil-fired boiler

The invention provides the explosion-proof door structure of the oil-fired boiler, which can effectively reduce the explosion damage in the furnace and play the explosion-proof function of the explosion-proof door. It includes a boiler furnace, which is characterized in that: an explosion-proof door is installed at the tail of the boiler furnace, and an explosion-proof door stop flat steel ring is arranged on the outer end face side of the explosion-proof door, and the explosion-proof door and the explosion-proof door stop flat steel ring Compression springs are installed between them, and the two ends of the compression springs are installed on the outer end surface of the explosion-proof door and the inner end surface of the explosion-proof door stop flat steel ring respectively, and the explosion-proof door has a fire viewing hole.

Owner:JIANGSU TAIHU BOILER

Quick drainage device after silicon leakage of single crystal furnace

PendingCN112626610AVacuum does not affectGuaranteed not to melt throughPolycrystalline material growthBy pulling from meltThermodynamicsWater leakage

The rapid drainage device comprises a vertical channel, an overflow groove and an upper cover, the top end of the vertical channel is communicated with the bottom of the single crystal furnace, the bottom end of the vertical channel is communicated with the overflow groove, the upper cover is installed on the upper end face of the overflow groove, and a vacuum cavity is formed in the overflow groove. According to the rapid drainage device after silicon leakage of the single crystal furnace, the overflow groove is formed in the periphery of the bottom of the single crystal furnace, wherein the exhaust pipeline is connected with the vertical channel, the overflow groove is connected below the vertical channel, the overflow groove is connected with the whole furnace body, and when the silicon leakage phenomenon occurs, the vertical channel drains a silicon solution into the overflow groove, so that molten silicon rapidly flows into the overflow groove and does not make contact with stainless steel filled with cooling water; therefore, it is guaranteed that molten silicon does not melt through the stainless steel furnace bottom, boiler explosion caused by rapid increase of internal pressure of a boiler due to instantaneous vaporization of cooling water leakage is avoided, and the overflow groove can be opened from the upper cover to take out solidified silicon solution in the overflow groove for further installation and use.

Owner:四川晶科能源有限公司

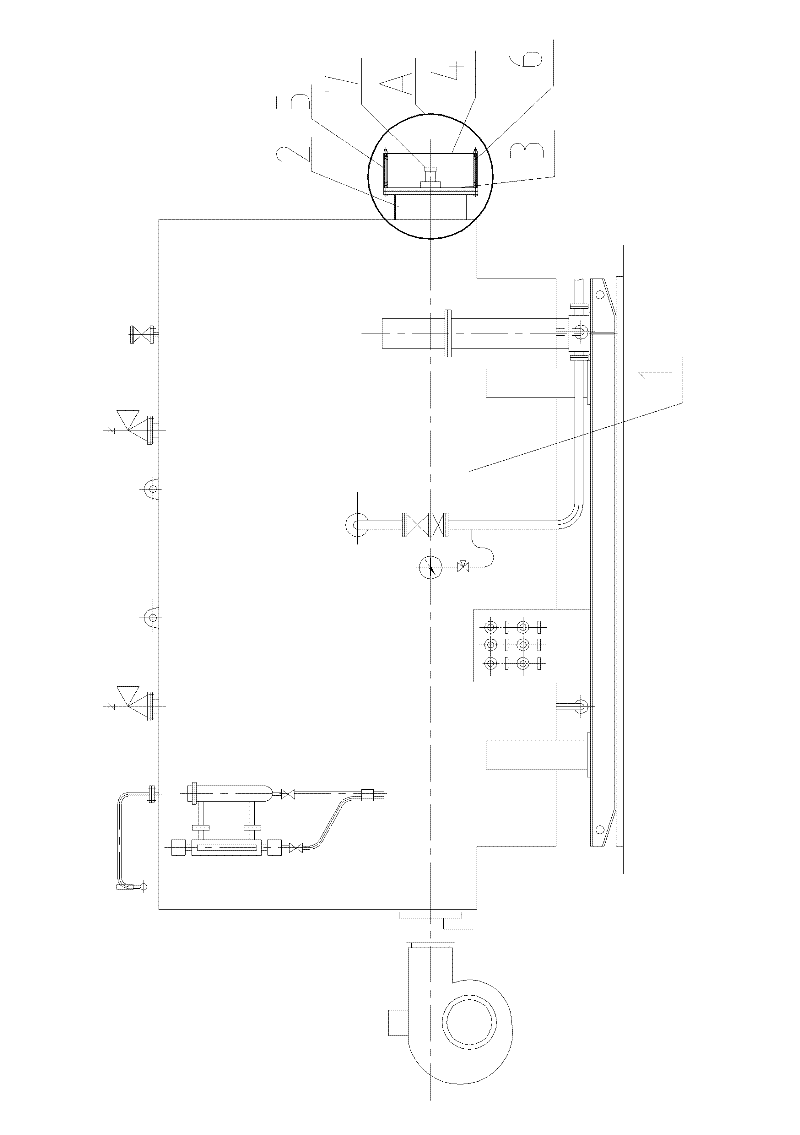

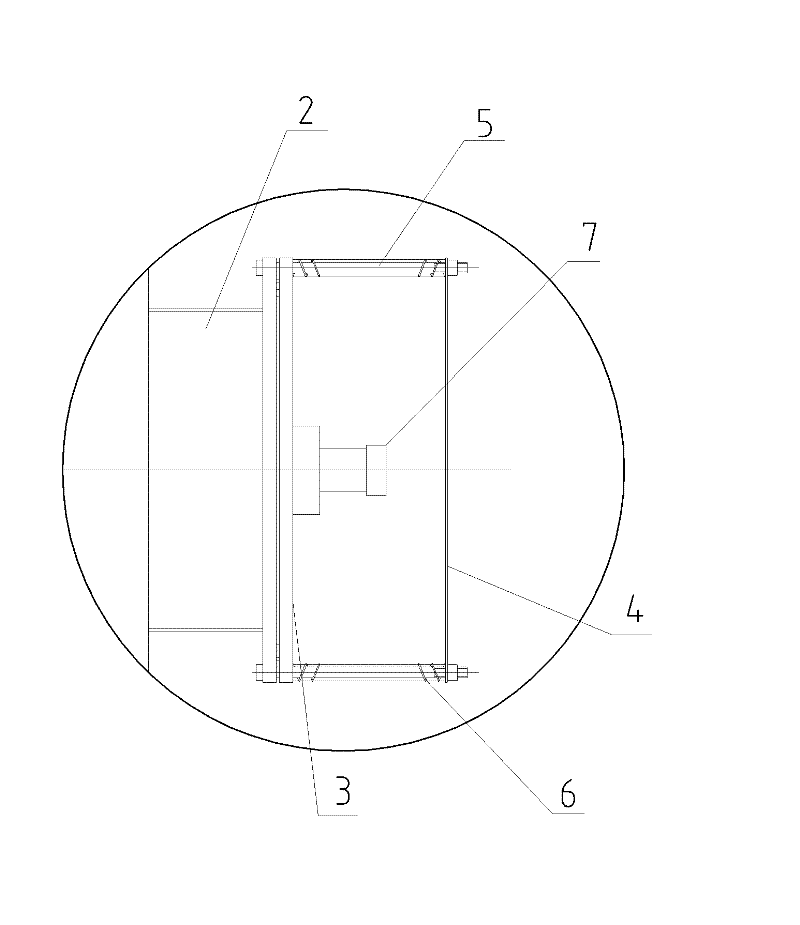

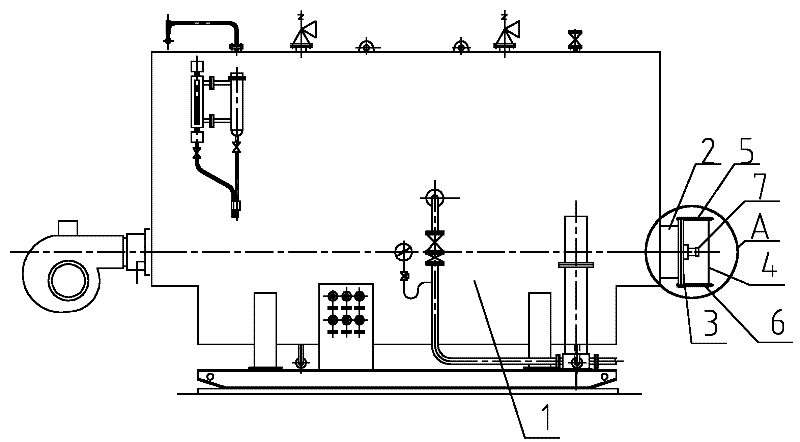

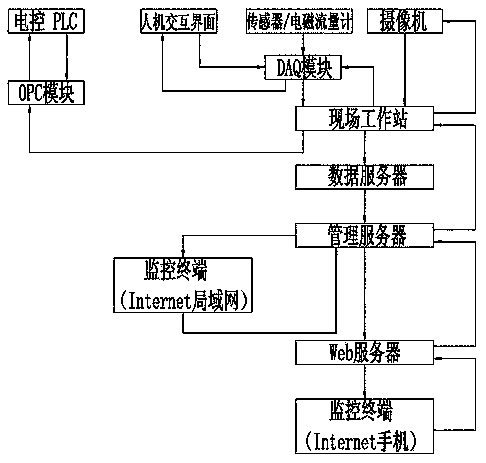

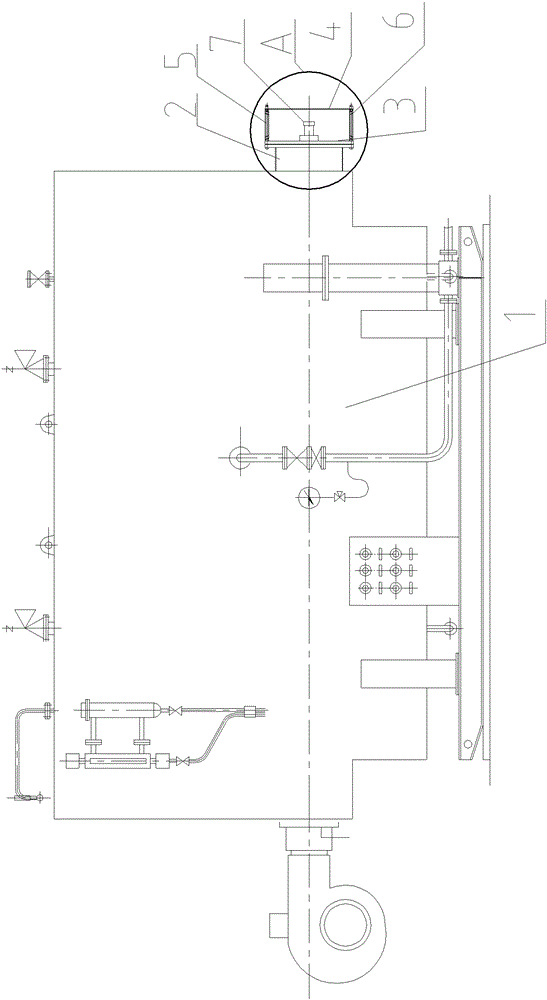

Remote intelligent control full-automatic boiler vehicle and control method thereof

PendingCN108952627AOnline monitoring operationEasy to settle inCleaning apparatusItem transportation vehiclesVideo monitoringHigh pressure

The invention discloses a remote intelligent control full-automatic boiler vehicle and a control method thereof, and belongs to the technical field of oil field special vehicles. The boiler vehicle integrates real-time equipment working data monitoring, vehicle positioning and video monitoring, meanwhile, paraffin removal operation can be performed on an oil well shaft of an oil field, and the boiler vehicle can also be used for high-pressure well washing, pressure testing and pipe and rod paraffin removal and other operations carried out in cooperation with workover operation, so that one vehicle is multipurpose. Feedback information of all sensors, electromagnetic flow meters and the like is collected so that the real-time working states of a boiler, a combustion machine, a water cabinet, an oil cabinet and the like can be monitored in real time, and the technical problems that a traditional boiler vehicle cannot timely and rapidly eliminate the fault hidden dangers such as incapability of ignition, boiler explosion and the like of the combustion machine, construction operation data cannot be stored locally and cannot be remotely transmitted, reasons are not easy to analyze whenabnormal conditions of the construction occur, and manufacturers cannot carry out real-time tracking on the boiler vehicle are solved; and the boiler vehicle is simple in structure and high in automation degree.

Owner:ZYT GASOLINEEUM EQUIP

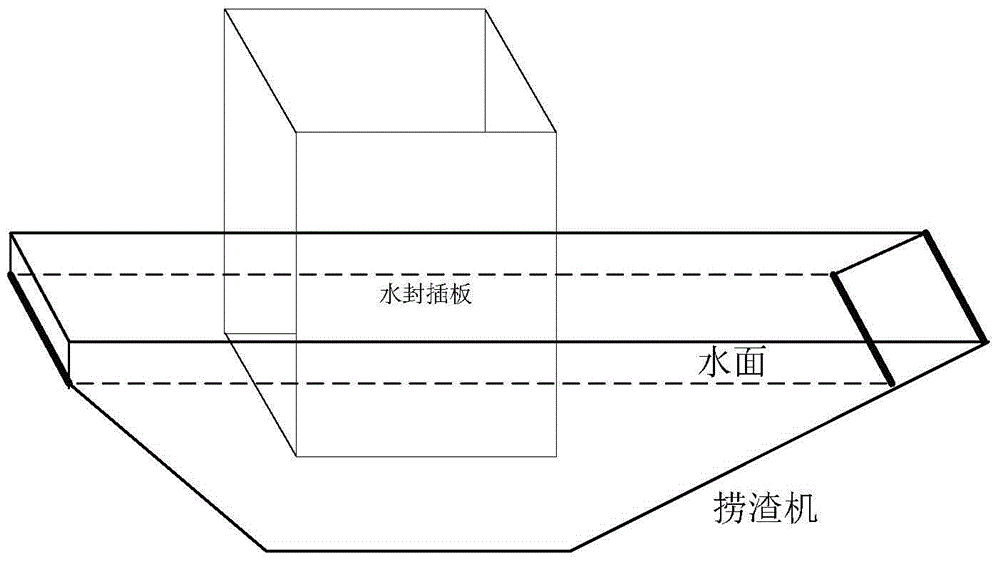

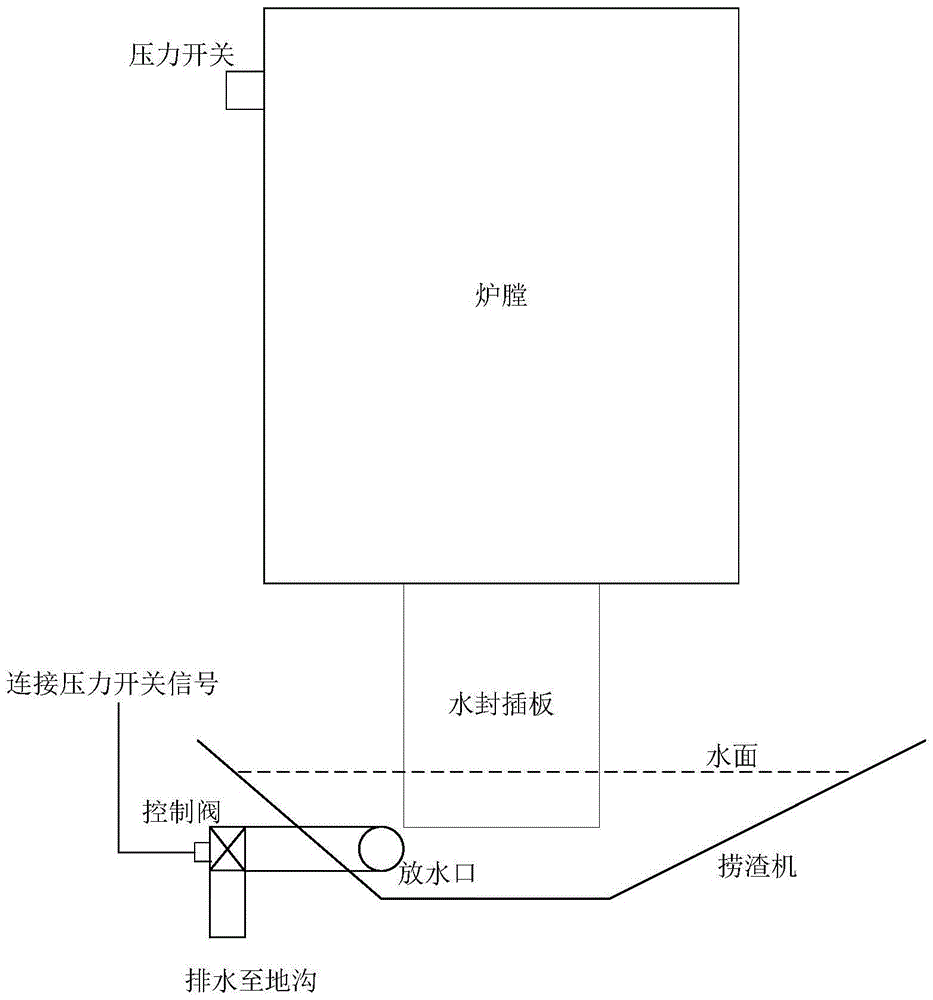

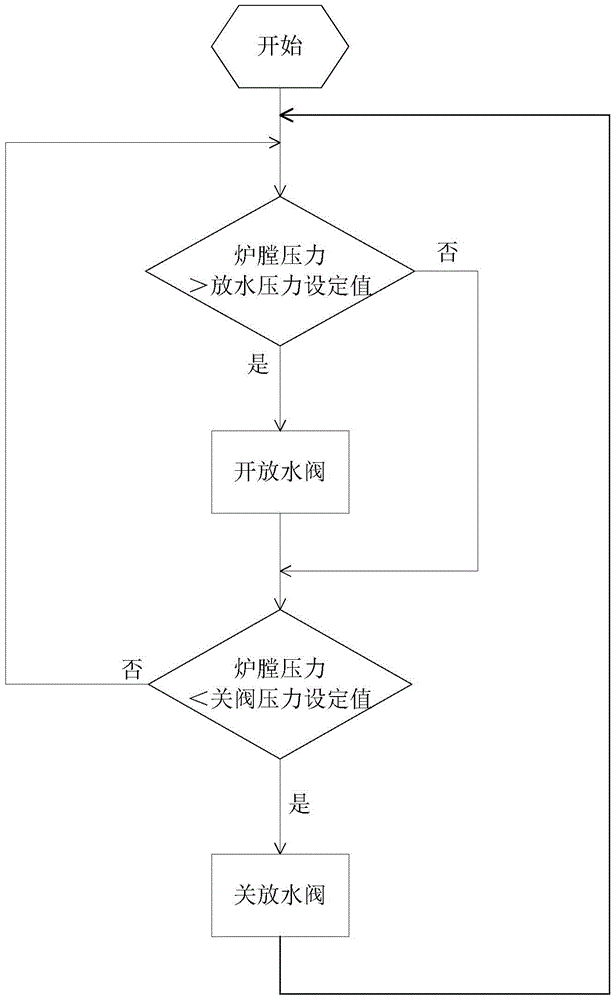

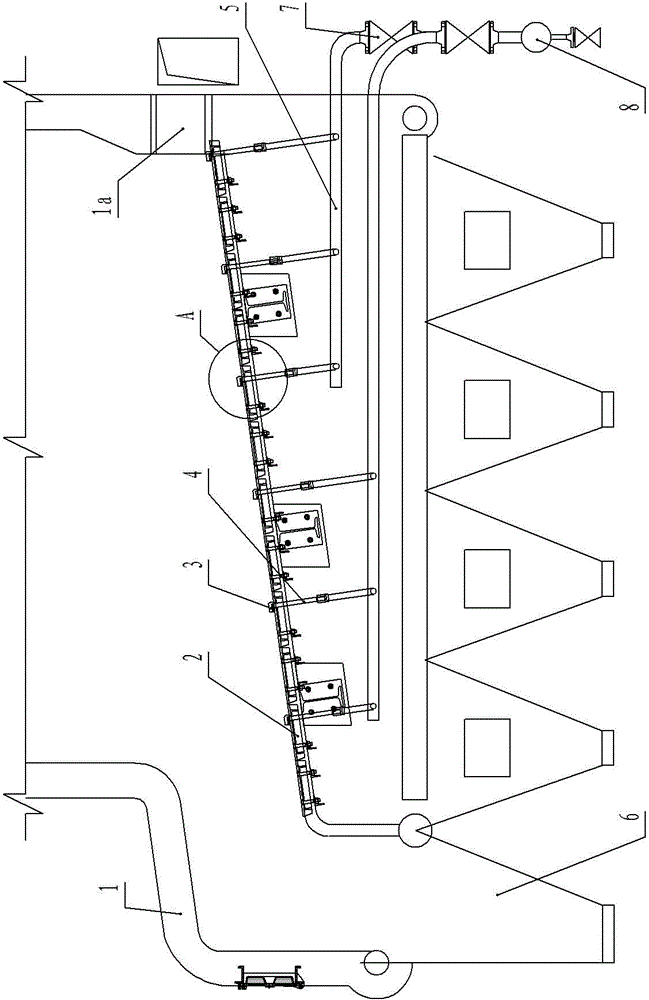

A system and method for preventing boiler explosion

The invention discloses a system and method for preventing a boiler from exploding outside. The system comprises a hearth, a water seal plug board, a slag conveyor and a water drainage system. The lower end of the hearth is fixedly provided with the water seal plug board. The slag conveyor is arranged at the lower end of the water seal plug board. The water drainage system is arranged on the slag conveyor and comprises a water drainage valve, a control valve and a pressure detection device. A pressure monitoring device is arranged on the hearth and used for detecting the pressure inside the hearth of the boiler and transmitting a detection signal to the control valve. The control valve is connected with a water drainage switch. The water drainage switch is arranged in a water tank of the slag conveyor. By means of the system and method, when the difference value of the pressure inside the hearth and the environment pressure reaches the preset value, a pressure switch of the system acts, the water drainage switch is opened automatically, the water surface goes down, the space in the hearth is communicated with the atmospheric environment outside the hearth, the pressure balance is reached, and the hearth is protected effectively.

Owner:STATE GRID CORP OF CHINA +1

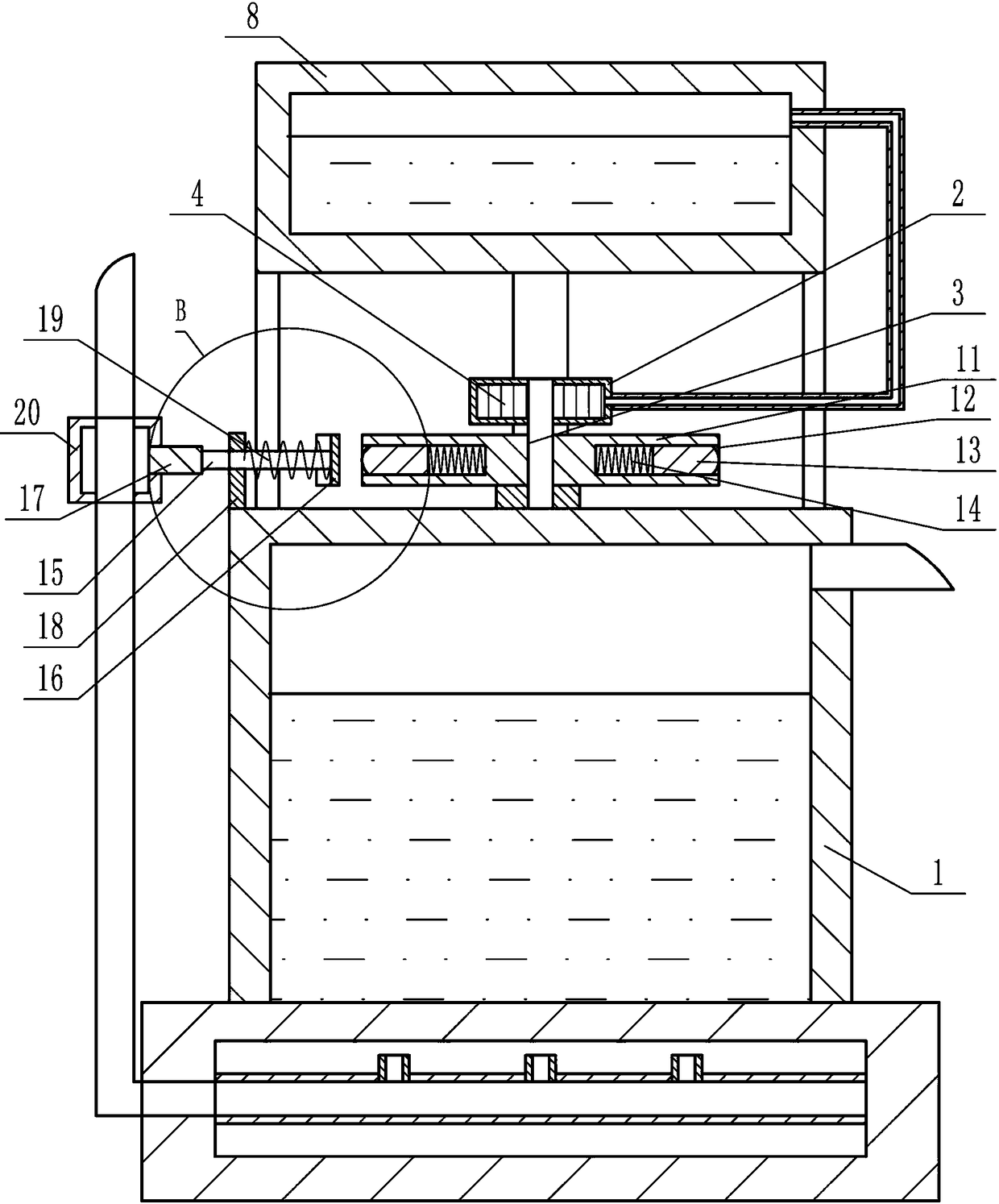

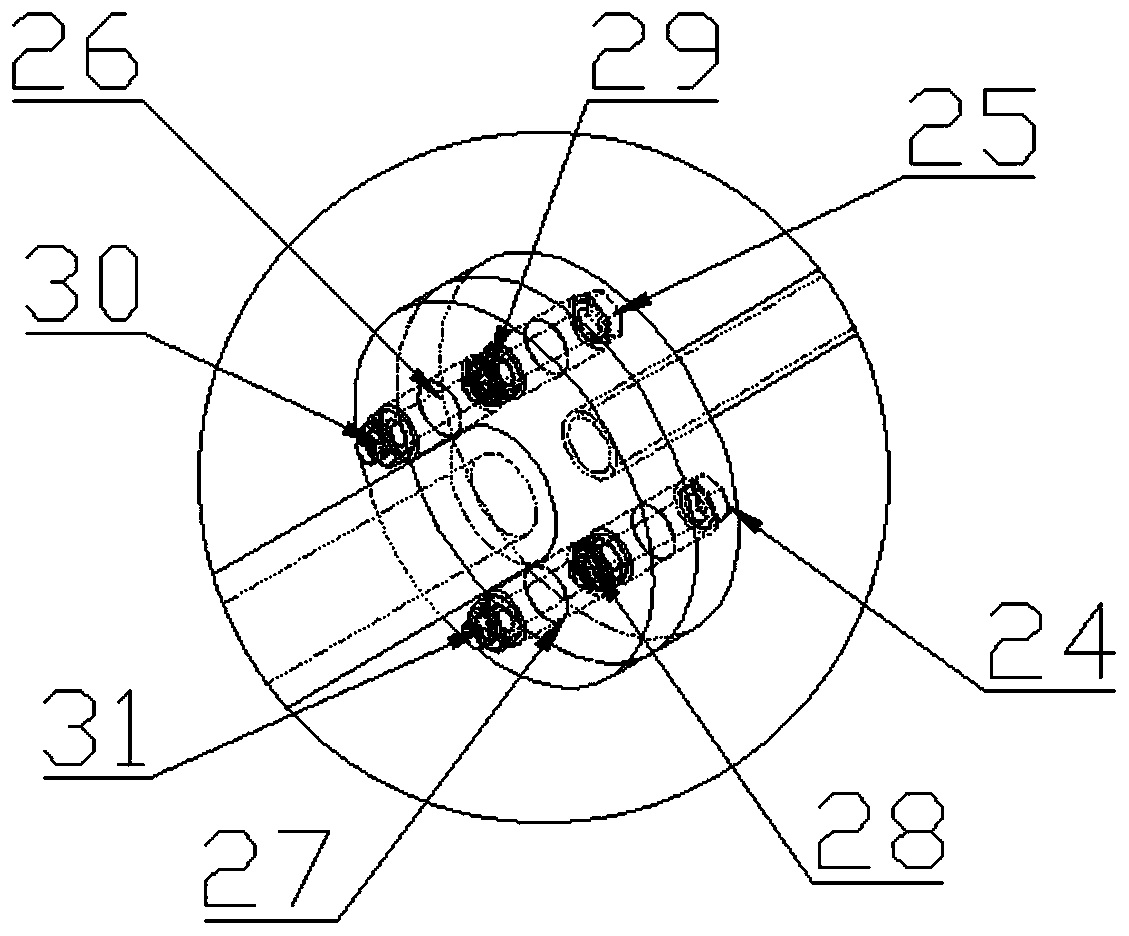

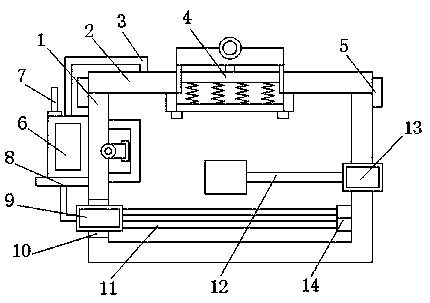

A boiler safety explosion-proof device

ActiveCN107504475BAchieve explosion-proof functionImprove cooling effectSteam boilersSteam boilers componentsCircular discFan blade

The invention relates to a boiler safety explosion-proof device and effectively solves the problem that after an existing boiler explosion-proof device exists, the existing boiler explosion-proof device is not complete in explosion-proof function. According to the technical scheme, the boiler safety explosion-proof device comprises a furnace body; a hollow disk is arranged above the furnace body; a rotating shaft is installed in the center of the hollow disk, and is evenly provided with a plurality of fan blades; a first pipeline is arranged on the right side of the hollow disk, and is internally provided with a first slider; the first slider is connected with the upper end of the first pipeline through a first pressure spring; the hollow disk is communicated with a cavity of the first pipeline through a steam pipeline; a water tank is arranged above the hollow disk which is communicated with the water tank; the lower end of the water tank is communicated with a furnace body 1 through a water draining pipe which is provided with a check valve; the rotating shaft is provided with a rotating disk in which a plurality of blind holes are formed; second sliders are formed in the blind holes, and are connected with the blind holes through tension springs; an oil conveying pipeline is arranged on the rear side of the rotating disk; and an oil control device is arranged between the rotating disk and the oil conveying pipeline. The boiler safety explosion-proof device is more convenient, fast and humanized.

Owner:河南鑫安利安全科技股份有限公司

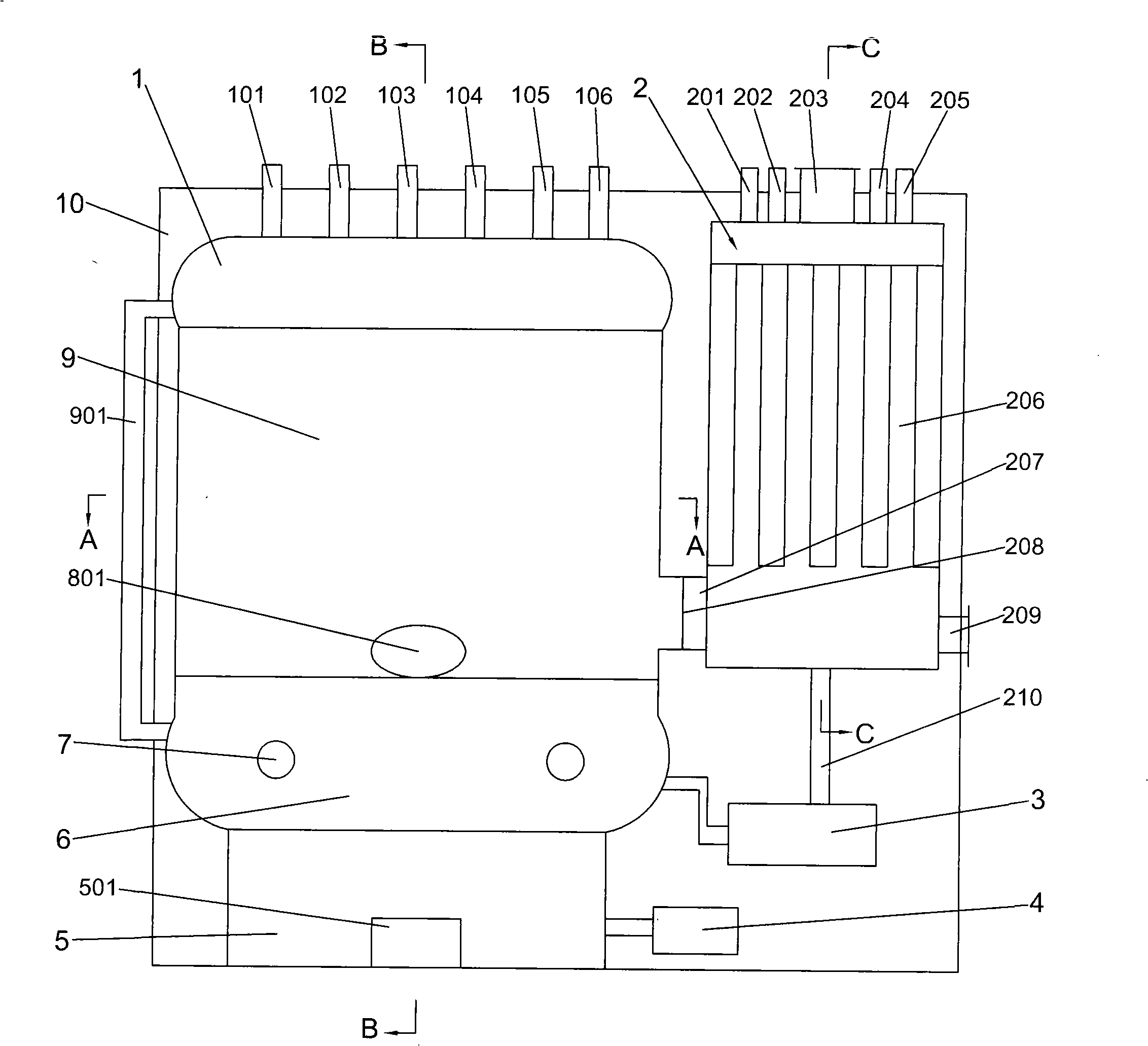

Dual purpose energy-saving boiler for hot water and steam

InactiveCN101532722BLow costEasy to useSteam generation heating methodsWater heatersThermal energyCombustion chamber

The invention provides a dual purpose energy-saving boiler for hot water and steam. The boiler comprises an upper water liner, a lower water liner, a main liner body, a subsidiary water tank, a combustion chamber and an electric heating tube, wherein the main liner body comprises an inner circle of a water pipe and an outer circle of a water pipe, and is a pipeline structure, thereby not only increasing the heating area in the main liner body, improving the heat utilization rate of heat energy, but also having strong pressure resistance, preventing occurrence of boiler explosion, and ensuringthe safety of the boiler; after the subsidiary water tank heats cold water by residual heat, the water enters the lower water liner, the main liner body and the upper water liner, thereby improving the efficiency of heat energy, and saving energy. The boiler can select different heat modes conveniently according the requirement of different production situations, selects different single fuels ormixture fuels or electric heating, such as coal, firewood, electricity, fuel, gas and the like. The boiler can be used both as a steam boiler and a hot water boiler, is the energy-saving environment-friendly boiler with steam and hot water dual purposes.

Owner:王爱清

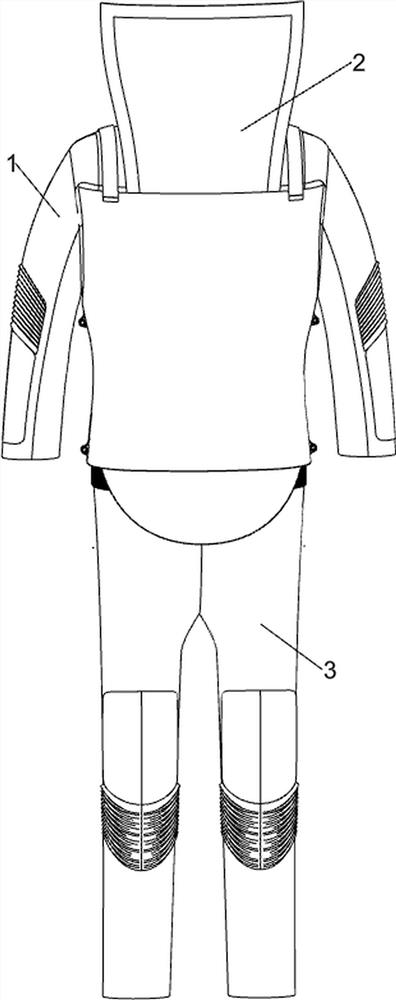

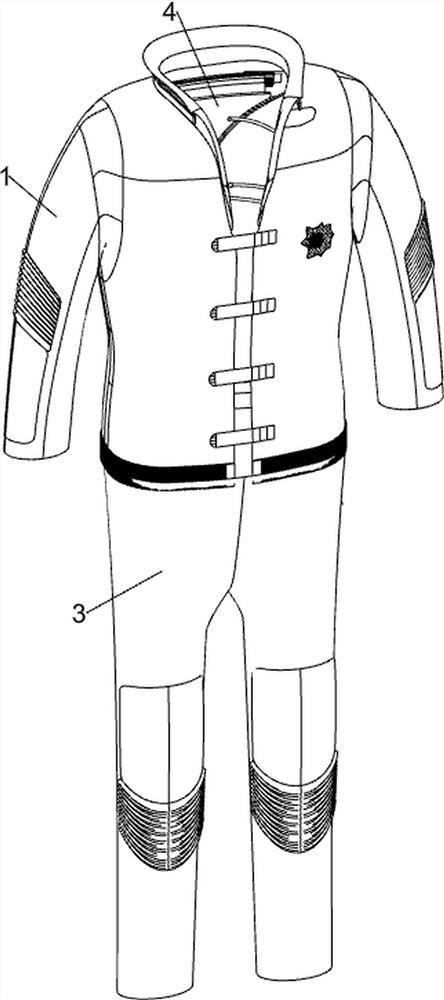

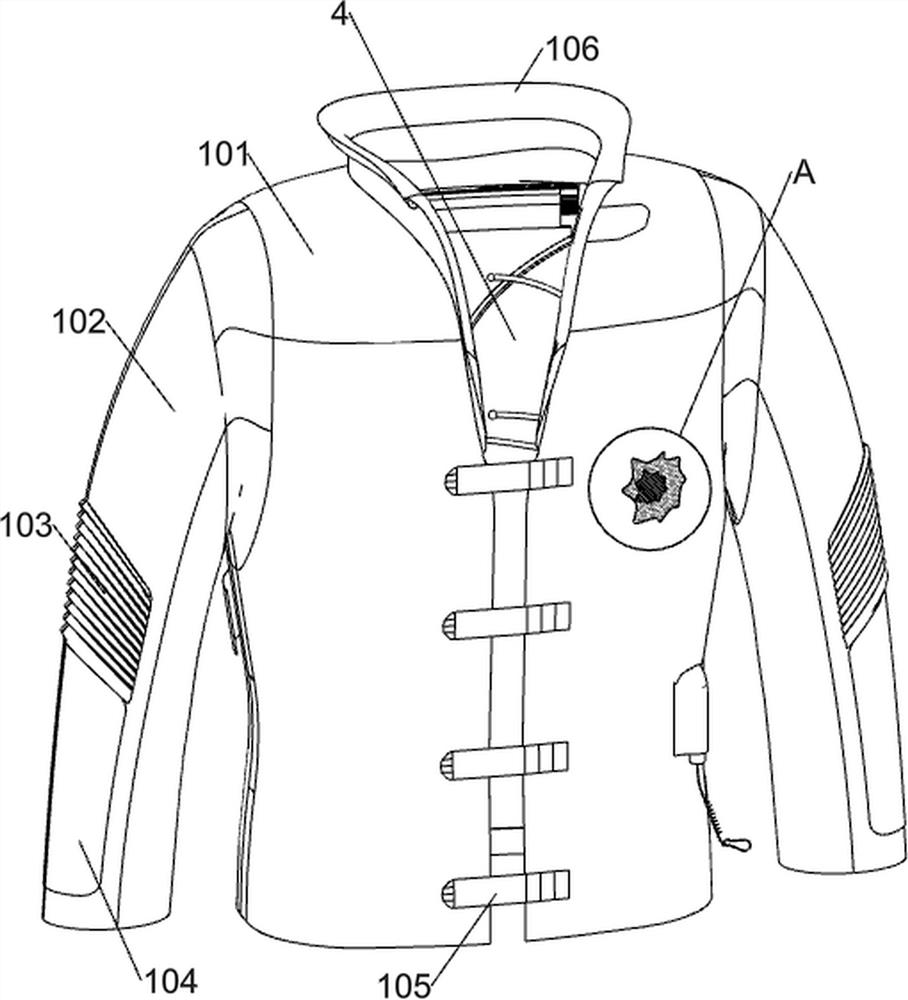

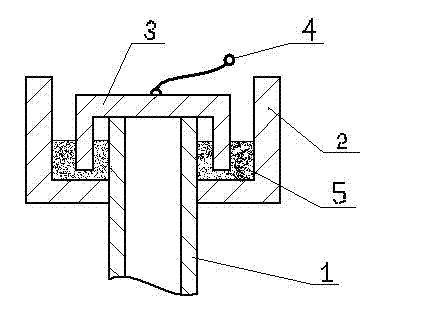

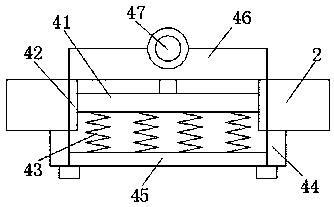

Polyethylene fiber special garment capable of reducing impact

The invention relates to the field of special garments, in particular to a polyethylene fiber special garment capable of reducing impact. In order to solve the technical problem that in the boiler operation process, the pressure vessel operation process and the blasting operation process, workers are prone to being hurt by impact and burnt during boiler operation, the polyethylene fiber special garment capable of reducing the impact comprises a protective upper garment, a working protective assembly, a protective lower garment and a back protective assembly; and the outer side of the protectiveupper garment is connected with the working protective assembly. Effective whole-body protection is achieved for workers in the boiler operation, pressure container operation and blasting operation process, it is guaranteed that the workers can work normally while protection is conducted, and the effects that impact of blasting and broken stones, impact of metal fragments and impact of hot air flow during boiler explosion are stopped are achieved; automatic adjustment type air bag buffering protection effect is achieved for the head and neck and backup of workers aiming at falling and retreating impact of the workers after the workers are impacted.

Owner:新乡市新科防护科技有限公司

Explosion-proof device for boiler

The invention discloses an explosion-proof device for a boiler and relates to the technical field of boiler machinery manufacturing. It includes an intermediate hollow shaft that can go deep into the airflow channel inside the boiler body, a groove that surrounds the upper end of the intermediate hollow shaft, and its connection with the intermediate hollow shaft is a seamless and fixed connection, and covers the upper end surface of the intermediate hollow shaft. Cover with raised edges. Due to the adoption of the above structure, the present invention has the advantages of simple structure, low cost and good explosion-proof effect.

Owner:吴叔广

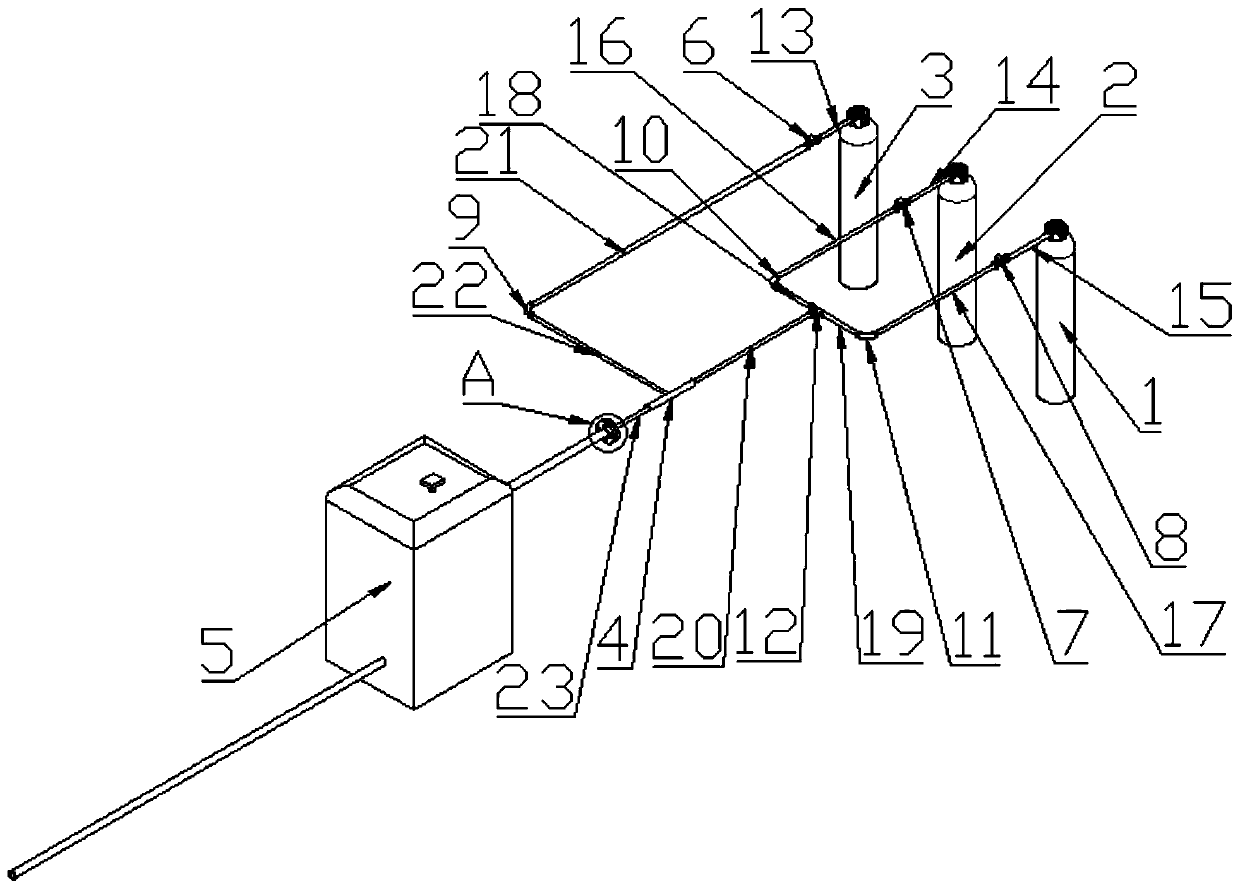

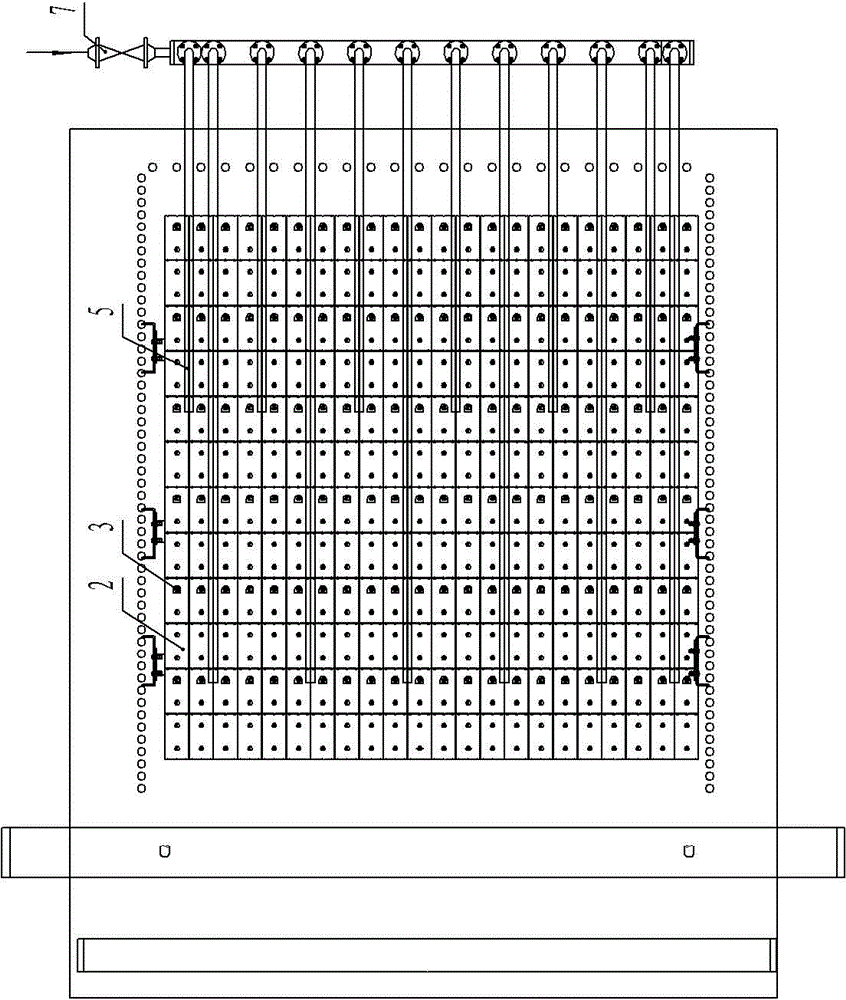

Boiler explosion ash blowing technology injecting inert gas for flame retarding

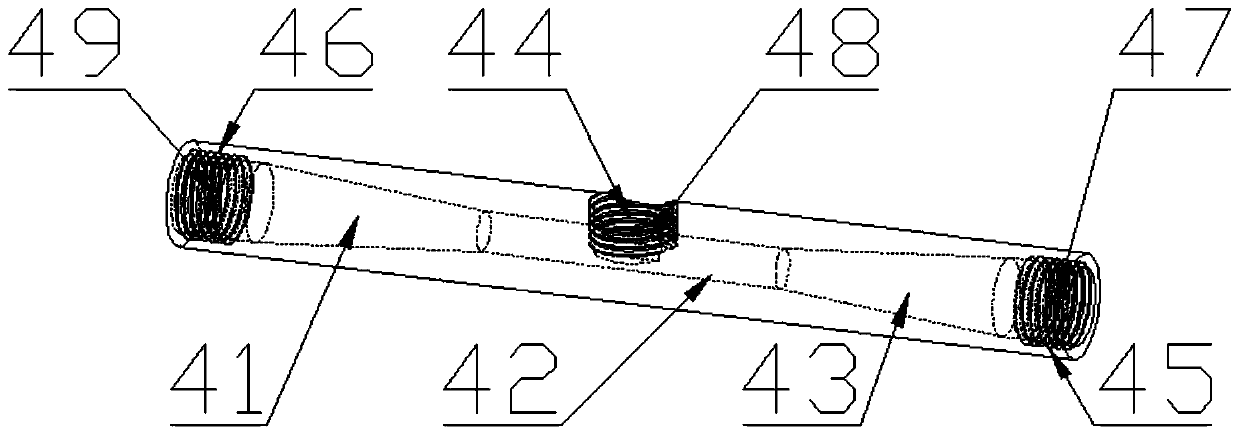

The invention discloses a boiler explosion ash blowing technology injecting inert gas for flame retarding. An oxygen gas cylinder, an acetylene gas cylinder, a nitrogen gas cylinder, a Venturi injector, a combustion explosion device, solenoid valves, elbows, tee joints, circular straight pipes, a circular connecting pipe, bolts and nuts are included. An air flow generated by an explosion of oxygenand acetylene in the combustion explosion device is utilized to inject the inert gas, namely nitrogen when reversely passing through the Venturi injector, thus shock of the explosion to a gas delivering pipeline and the solenoid valves is weakened, the nitrogen can block a backfire face generated by the explosion, thus the combustion backfire face is prevented from extending towards the gas cylinders and the solenoid valves, the service life of equipment is prolonged, and the safety of an explosion ash blowing system is improved.

Owner:XI AN JIAOTONG UNIV +1

Boiler water processing device

InactiveCN110921851AReduce hardnessAvoid formingWater softeningWater/sewage treatment by ion-exchangeIon-exchange resinMagnesium ion

The invention discloses a boiler water processing device, and specifically relates to the technical field of water treatment. The boiler water processing device comprises a first water tank. A first water injection pipe is fixedly arranged on the top of the first water tank. One side of the first water injection pipe is provided with a discharge opening. One side of the discharge opening is provided with a U shaped pipe. The U shaped pipe is arranged in the first water tank and stretches out of the top of the first water tank. The bottom of the U shaped pipe is fixedly provided with a verticalpipe. A first switch valve sleeves the vertical pipe. One side of the first water tank is provided with a second water tank. Sodium ion exchange resin is fixedly arranged in the second water tank. One end of the vertical pipe penetrates the sodium ion exchange resin. Lime is used to precipitate sodium and magnesium ions in water; then through the sodium ion exchange resin, residual calcium and magnesium ions are absorbed; the water hardness is reduced therefore, the scale formation is avoided, and the risk of boiler explosion is avoided too.

Owner:XUZHOU TIANYI PLASTIC PROD CO LTD

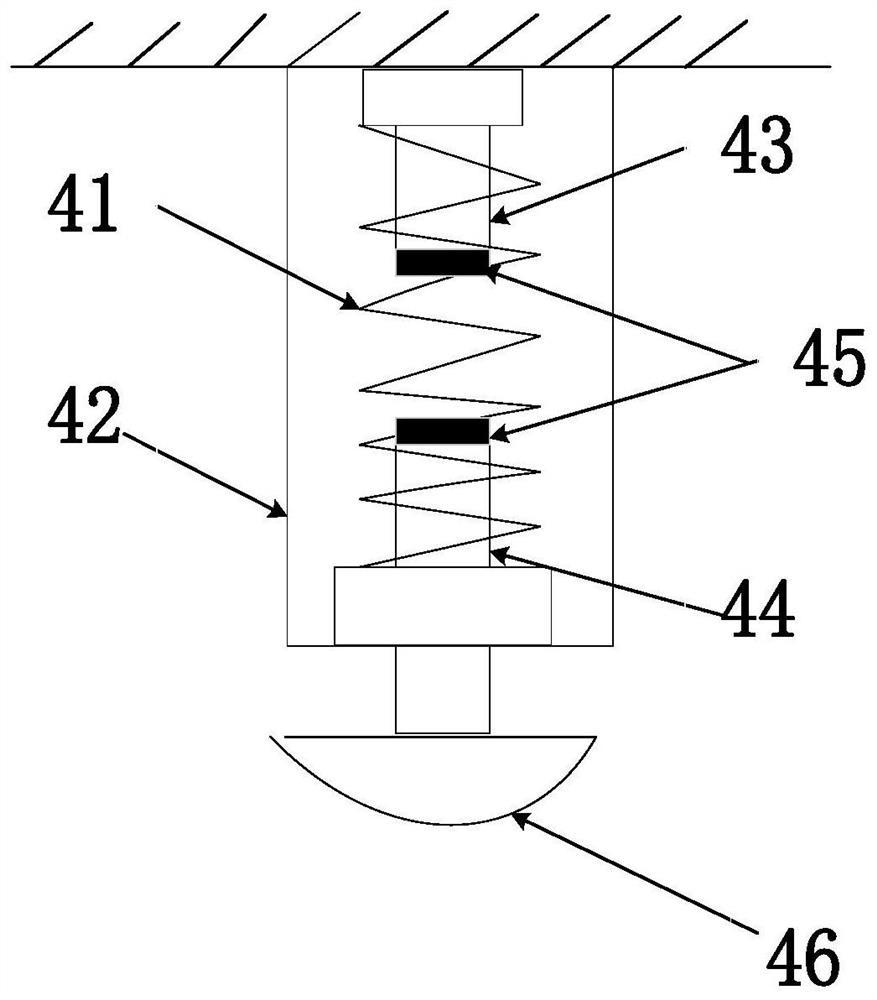

Boiler explosion door and boiler thereof

PendingCN113915636AExtended service lifeReduce impactFluid heatersSteam boilersImpactIndustrial engineering

The embodiment of the invention discloses a boiler explosion door and a boiler thereof. According to the boiler explosion door and the boiler thereof, the impact force on a door frame when a door cover rotates and resets by a large margin is effectively reduced, and the door frame is protected from deformation. The boiler explosion door comprise the door frame, the door cover, a door spindle and at least two damping mechanisms. The door spindle is rotationally fixed on the door frame. The door cover is fixedly connected to the door spindle and rotates synchronously with the door spindle. The at least two damping mechanisms are installed on the periphery of the inner side of the door cover, each damping mechanism comprises a spring, a guide pipe, a first limiting rod and a second limiting rod, the bottom ends of the guide pipes are fixedly attached to the inner wall of the door cover, and the first limiting rods are fixed to the bottom ends of the guide pipes. The second limiting rods are installed at the top ends of the guide pipes and extend out of the guide pipes, the springs are installed between the first limiting rods and the second limiting rods in a penetrating mode, and gaps are formed between the first limiting rods and the second limiting rods.

Owner:湖南华润电力鲤鱼江有限公司

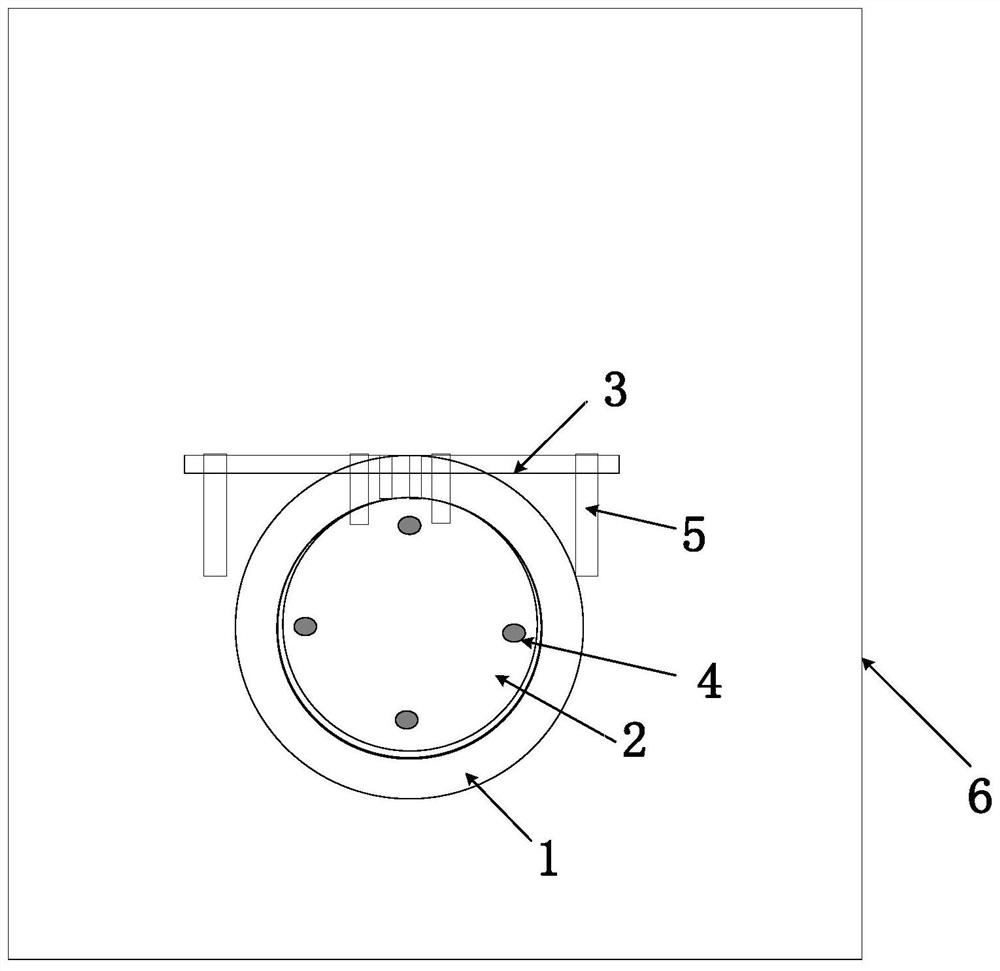

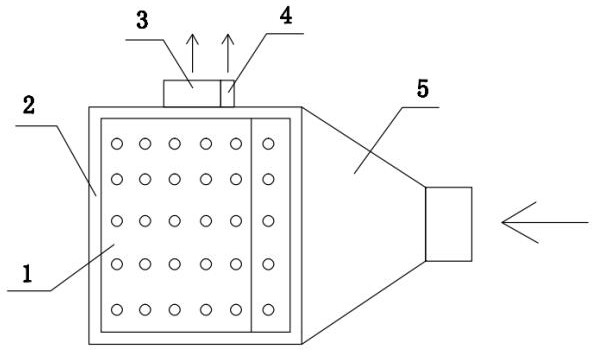

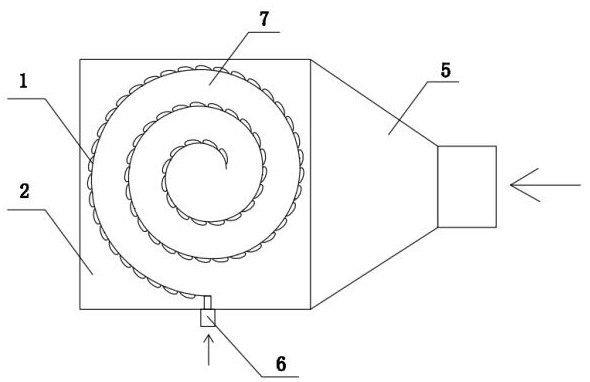

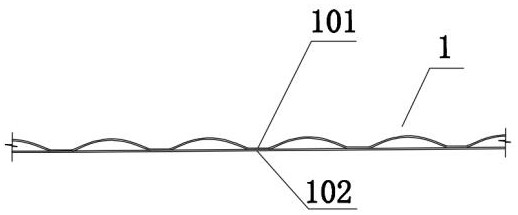

Pillow-shaped corrugated plate type spiral hot water boiler

PendingCN114543355AImprove heat transfer efficiencyIncrease the heat exchange areaWater heatersFlue gasEngineering

The pillow-shaped corrugated plate type spiral hot water boiler comprises a boiler shell and a heat exchange corrugated plate, the heat exchange corrugated plate is arranged in the boiler shell in a spiral mode, and therefore a spiral heating channel is formed in the boiler shell; the periphery of the heat exchange corrugated plate is closed, a hollow cavity is formed in the heat exchange corrugated plate, and a water inlet and a water outlet which are communicated with the hollow cavity are formed in the heat exchange corrugated plate. The boiler has the advantages that the heat exchange corrugated plate is spirally arranged in the boiler shell, cold water is introduced into the spiral heat exchange corrugated plate and enters the spiral heating channel through high-temperature flue gas for heat exchange, the heat exchange area is large, and the heat exchange efficiency is high; the boiler is compact in overall structure, small in size and high in heat exchange efficiency, hot water is available immediately after the boiler is opened, and the risk of boiler explosion cannot be caused by the adoption of the heat exchange corrugated plates.

Owner:壹科帆(浙江)科技有限公司

Boiler combustion explosion-proof equipment

InactiveCN114321873APrevent intrusionAvoid ignitionFire rescueSteam boilersThermodynamicsBoiler furnace

The invention belongs to the field of boiler explosion prevention, and particularly relates to boiler combustion explosion-proof equipment which comprises a boiler body, an upper feeding chamber is installed above the boiler body, a side feeding chamber is installed on the side edge of the boiler body, and a steam pipeline is fixedly arranged on the side, close to the side feeding chamber, of the upper feeding chamber. An anti-explosion module is arranged below the steam pipeline in the boiler body, a first anti-explosion baffle and a second anti-explosion baffle which are used for preventing further deflagration and the like are arranged on the anti-explosion module in a sliding mode, the first anti-explosion baffle is close to one side of the upper feeding chamber valve, and the second anti-explosion baffle is close to one side of the side feeding chamber valve. A switching module for changing the pressure relief flux is arranged in the anti-explosion module, a first-stage air inlet channel is formed in the side edge of the steam channel, and multi-stage targeted treatment can be conducted on the air pressure in the boiler, and pretreatment can be conducted on uncontrollable explosion.

Owner:瑞安市明亮机械有限公司

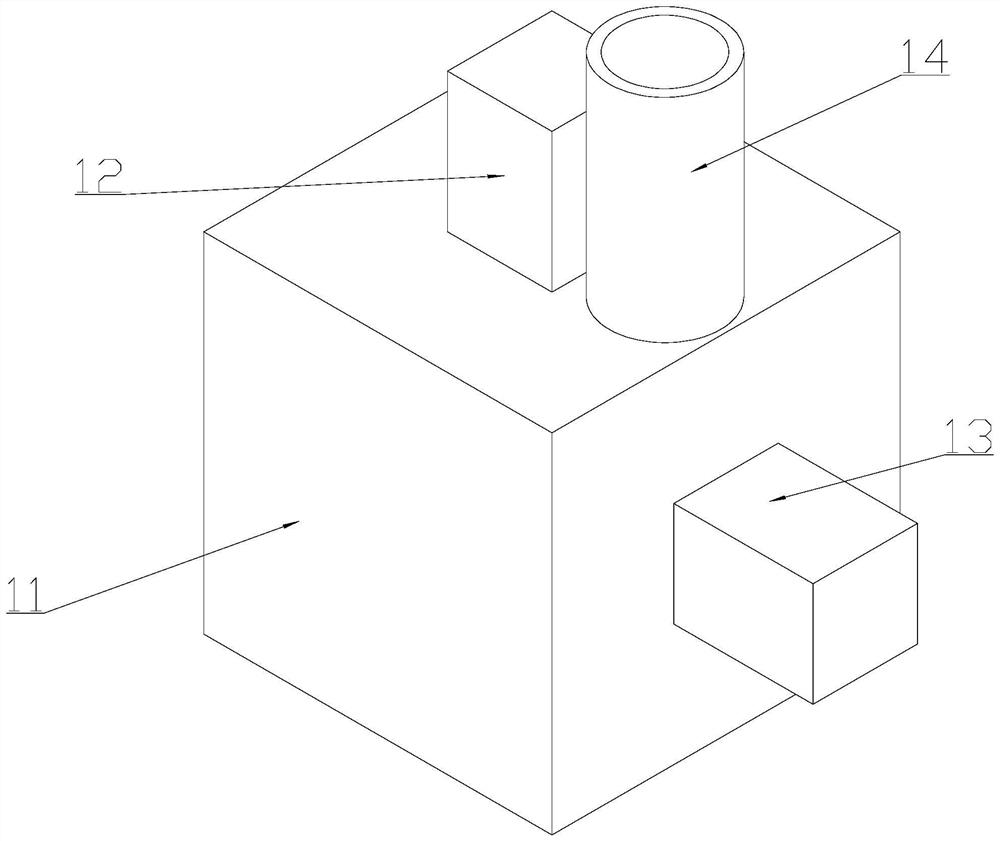

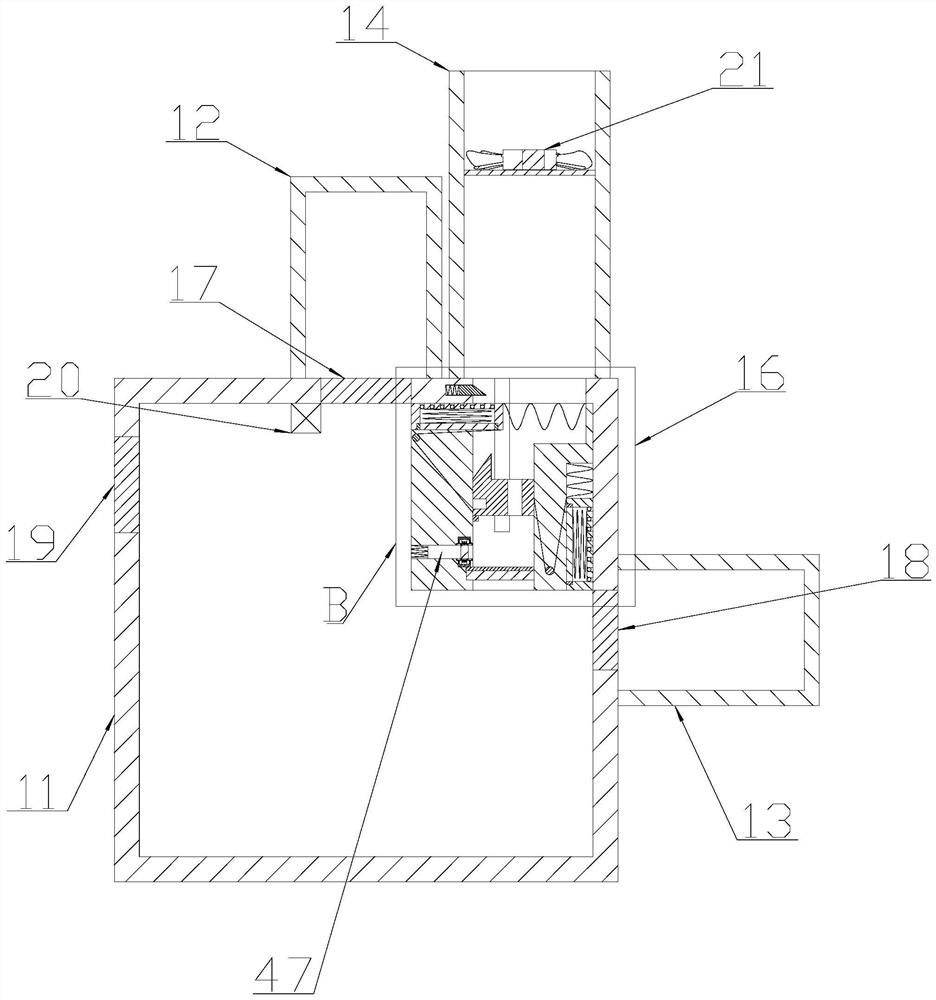

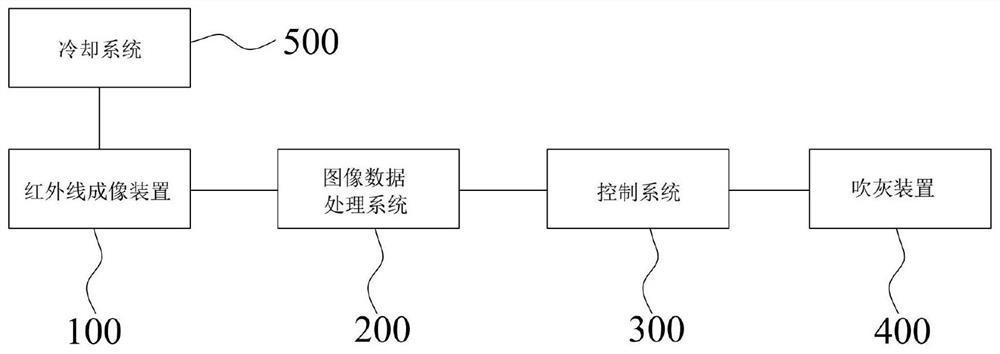

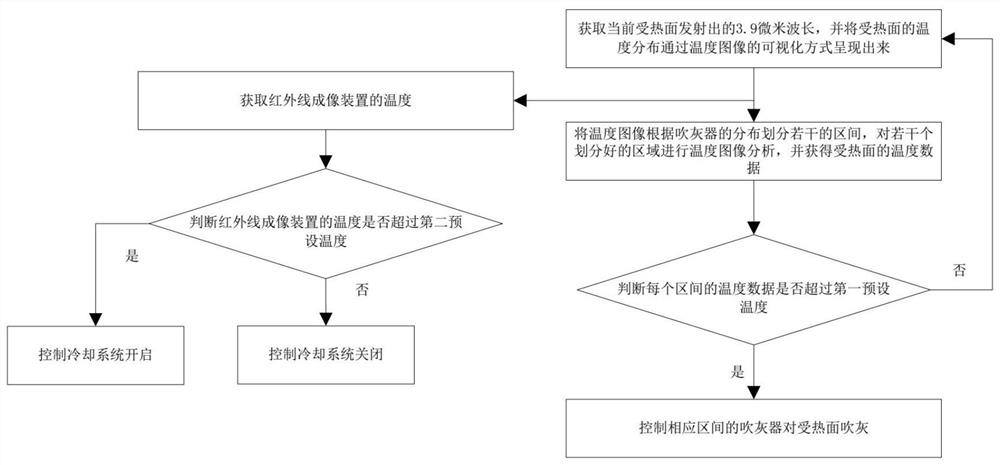

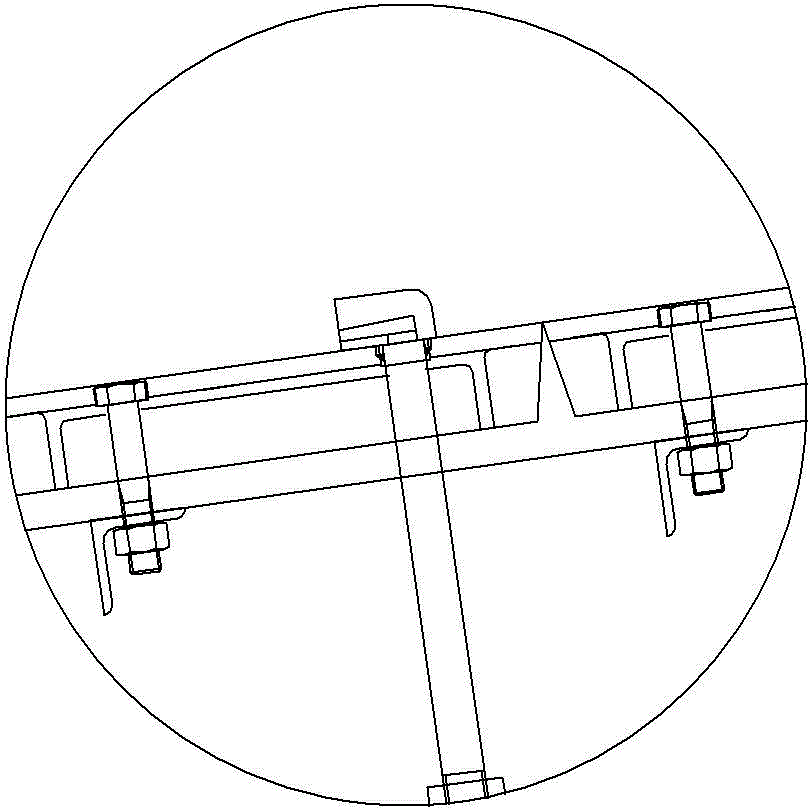

Boiler heating surface soot blowing control system and control method

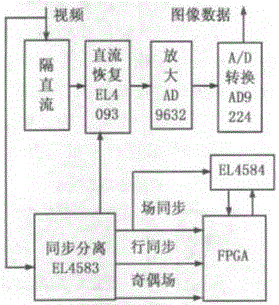

InactiveCN113357657AGuaranteed service lifeReduce corrosion wearTemperatue controlSolid removalInfraredData processing system

The invention belongs to the technical field of boilers, and discloses a boiler heating surface soot blowing control system and control method. The boiler heating surface soot blowing control system comprises an infrared imaging device, an image data processing system, a control system and a soot blowing device, wherein the infrared imaging device is configured to absorb the wavelength emitted by a heating surface and output thermal imaging of the heating surface, the image data processing system is connected with the infrared imaging device, the control system is connected with the image data processing system, the soot blowing device is connected with the control system, and when the heating surface exceeds a first preset temperature, the control system controls the soot blowing device to blow soot. According to the boiler heating surface soot blowing control system, in the operation process of a boiler, intelligent soot blowing can be carried out on the heating surface, accurate visual soot blowing of the boiler is realized, the soot blowing effect is improved, moreover, the waste of high-temperature steam and the abrasion and corrosion of the heating surface are effectively reduced, the thinning rate of the heating surface caused by soot blowing is greatly reduced, and the risk of boiler shutdown caused by boiler explosion is reduced.

Owner:YANTAI LONGYUAN POWER TECH

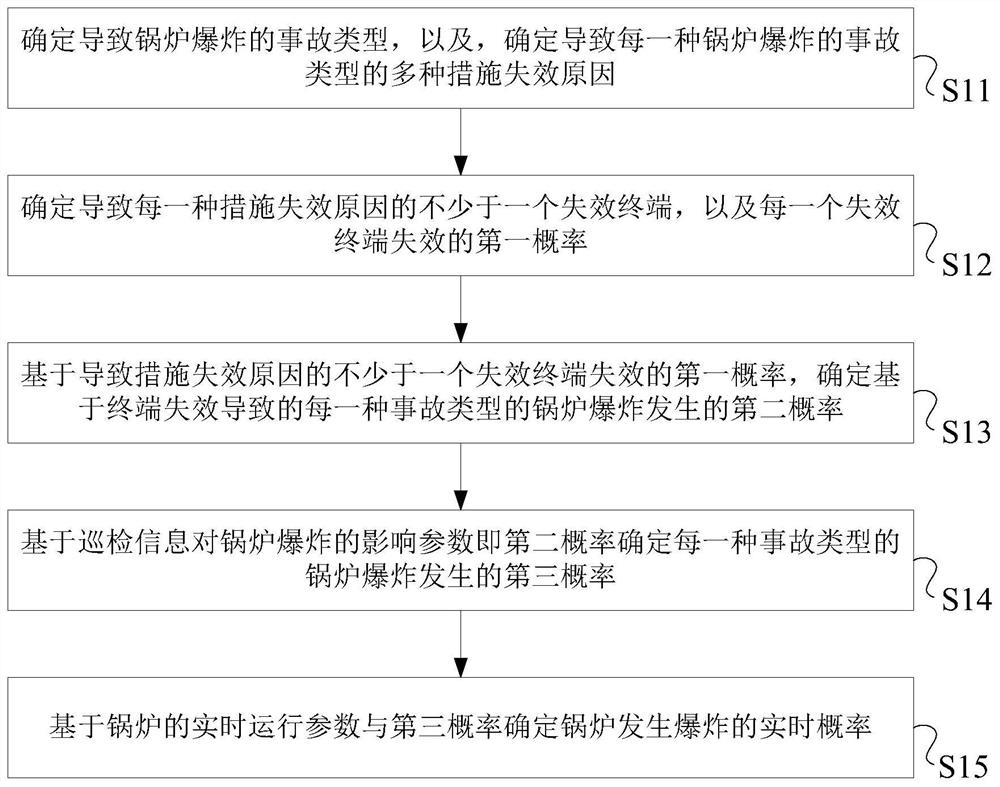

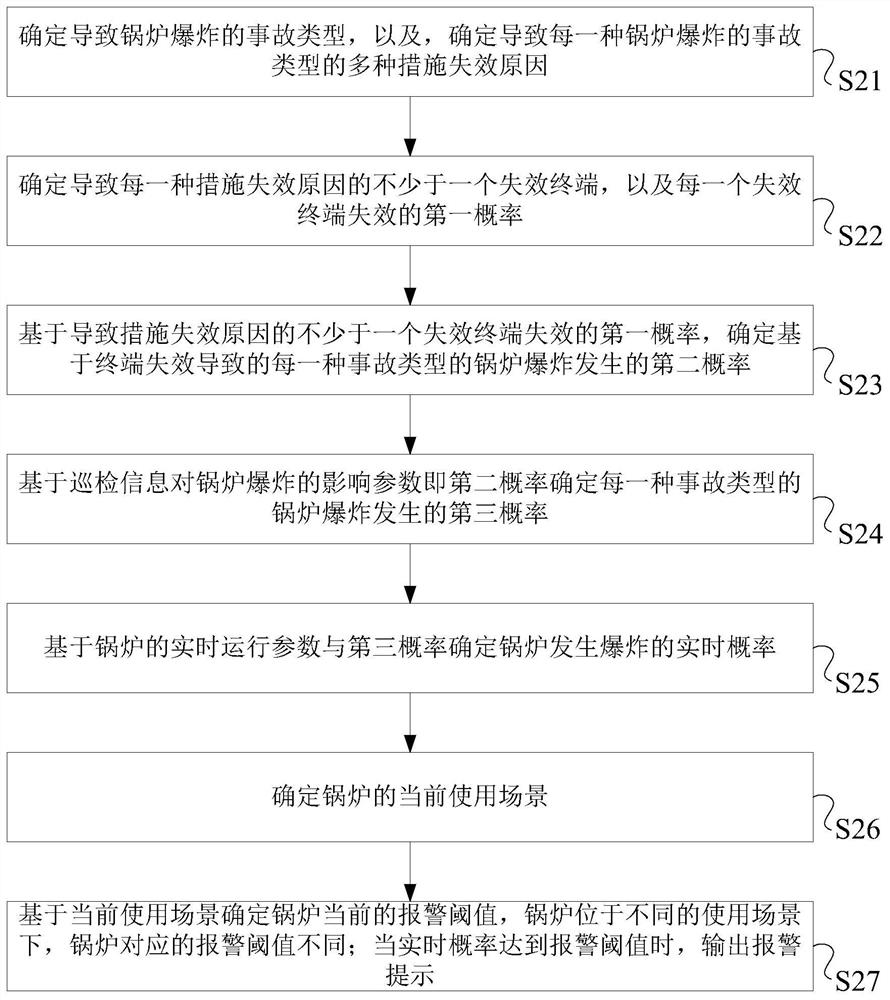

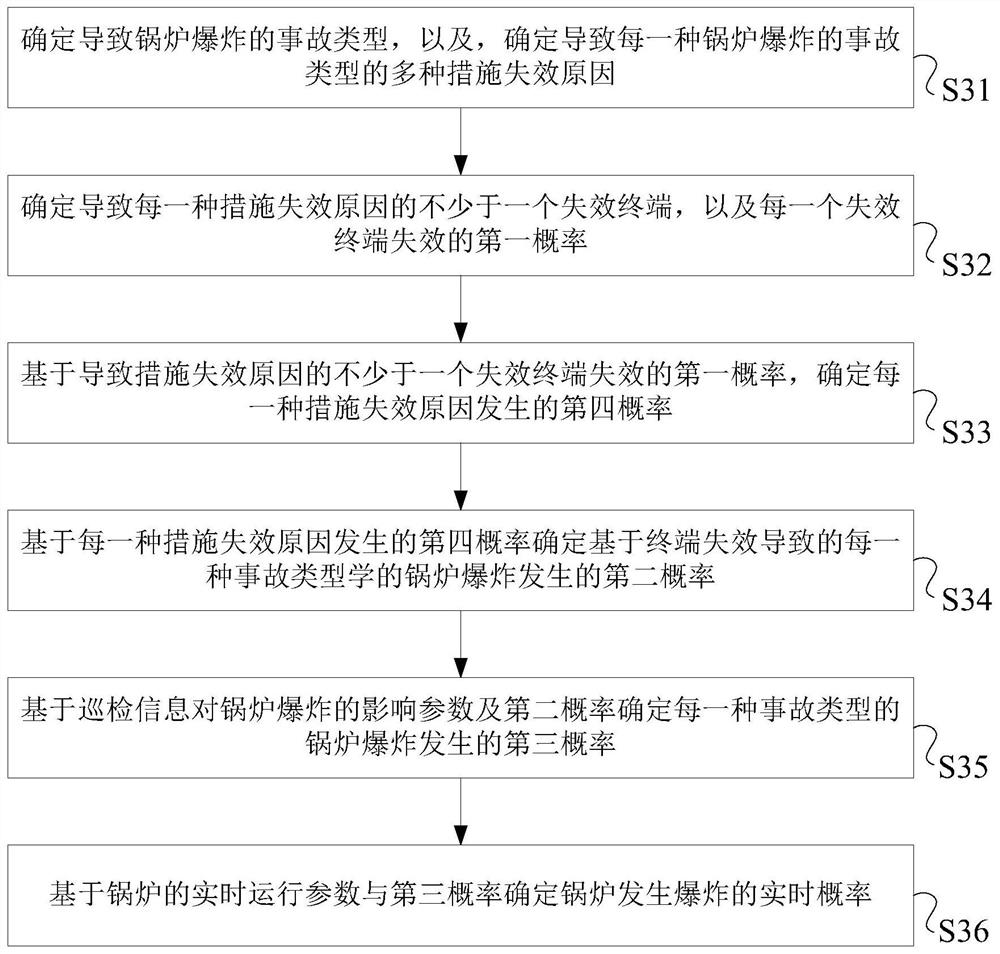

Boiler safety evaluation method, device and system

PendingCN113887822ARealize early warningIncrease success rateForecastingResourcesProcess engineeringIndustrial engineering

The invention discloses a boiler safety evaluation method, device and system, and the method comprises the steps: firstly determining the occurrence probability of each accident type of boiler explosion based on the cause of each accident type of explosion of a boiler and a failure terminal; and determining the real-time probability of the explosion of the boiler based on the real-time operation parameters and the inspection information of the boiler and the determined probability value, so that early warning of the explosion of the boiler based on the terminal state of the equipment, the inspection information and the real-time operation parameters of the boiler is realized, and the success rate of early warning is improved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

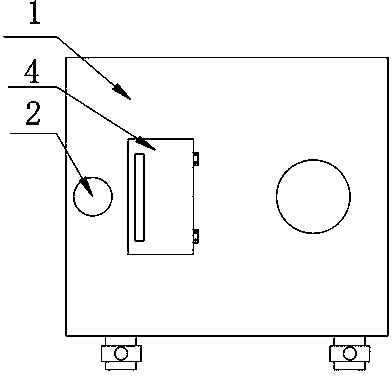

Boiler device based on programmable Logic controller (PLC)

The invention relates to a boiler device based on a programmable Logic controller (PLC). The boiler device based on the PLC comprises a boiler body. A boiler comprises the boiler body, a cover plate,a pressure detection device, the PLC, a wireless signal receiver and a stirring rod; a placement plate horizontally penetrates through the left side of the boiler body; the PLC is arranged on the placement plate; the wireless signal receiver is arranged on the left side of the upper surface of the PLC; when the boiler is in use, an electromotor drives the stirring rod to rotate, so that the temperature in the boiler is uniform, and the problems such as boiler explosion caused by nonuniform heating are avoided; when the boiler is in use, heating is carried out through a heating pipe, so that the heat loss is avoided; and meanwhile, a heat insulation chamber is further arranged, and a camera is arranged in the heat insulation chamber, so that the interior can be monitored conveniently.

Owner:西安安迈工业自动化技术有限公司

Explosion-proof device for a bursting membrane boiler

The invention is applicable to the technical field of explosion-proof equipment, and provides an explosion-proof device for a bursting membrane boiler, which includes a device box, which is fixedly installed on the furnace body, and also includes: a drive assembly, which is installed on the device In the box; a flame retardant assembly, the flame retardant assembly is installed in the fuel pipe; and a dispersal assembly, the dispersal assembly includes a first rotating part, a dispersing part, a support, a first movable part, a second movable part, a first connection piece, the second connecting piece, the third connecting piece and the fixing frame. The bursting membrane boiler explosion-proof device in the present invention can quickly disperse the steam through the flame-retardant component and the dispersing component, and can also block the fuel and block the steam from regenerating, which improves the working efficiency and efficiency of the explosion-proof device. practicality.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

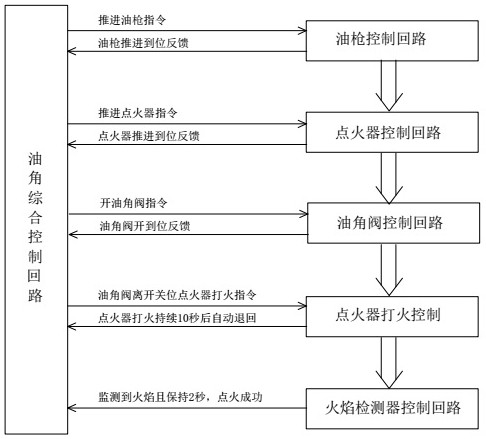

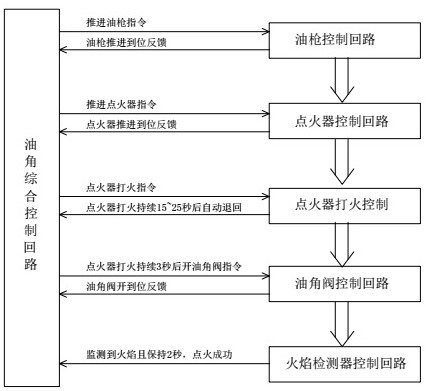

Optimal control method for improving automatic ignition success rate of boiler fuel oil

The invention discloses an optimal control method for improving the automatic ignition success rate of boiler fuel oil, and belongs to the technical field of automatic ignition control of boiler fueloil. The optimal control method comprises an oil angle comprehensive control loop, an oil gun control loop, an igniter control loop, an oil angle valve control loop, a flame detector control loop andother sub-control loops. According to the technical scheme, on the basis that the automatic ignition sequence control principle of an existing oil system is basically not changed, the ignition time ofan igniter is properly advanced, the ignition time is properly prolonged, the problems that an electrode is polluted by water in fuel oil, short circuit is caused, and stable combustion energy is insufficient in the early stage of oil gun ignition are solved, and it is ensured that automatic ignition succeeds at a time; and automatic ignition time prolonging caused by unsuccessful ignition and the safety risk of boiler explosion caused by fuel oil accumulation are prevented. The optimal control method is simple in logic system and convenient to modify, and can effectively improve the automatic ignition success rate of boiler fuel oil.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Rupture disk type boiler explosion-proof device

ActiveCN113418182ASolve recurrenceDisperse fastFluid heatersSteam boilersThermodynamicsProcess engineering

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

Bagasse burning boiler

InactiveCN104654321AImprove economyImprove reliabilityLighting and heating apparatusCombustion chamberEngineering

The invention discloses a bagasse burning boiler and belongs to the technical field of boilers. The bagasse burning boiler comprises a boiler body. A feeding port communicated with a combustion chamber is arranged in the boiler body, a fire grate is arranged in the combustion chamber, the fire grate is formed by splicing fire grate pieces with through holes, and gaps are formed between the fire grate pieces. The bagasse burning boiler is characterized in that the fire grate is arranged in an inclining mode, the front end of the fire grate is close to the feeding port and is higher than the tail end of the fire grate, a material receiving hopper is arranged below the tail end of the fire grate, a nozzle connected with a steam pipeline through a spraying pipe is arranged on the fire grate, and the nozzle faces the tail end of the fire grate. The bagasse burning boiler can solve the problem of boiler explosion caused by the fact that fire grate holes of the boiler are blocked.

Owner:GUANGXI XIJIANG BOILER MFG

Explosion-proof door structure of oil-fired boiler

Owner:JIANGSU TAIHU BOILER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com