Monitoring system for steam explosion in furnace

A monitoring system and water vapor technology, applied in data mining, the application field of water vapor explosion monitoring system in the furnace, can solve the problems of personnel safety and property loss, explosion, output value growth that does not conform to the scientific development concept, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described,

[0011] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to To limit the present invention,

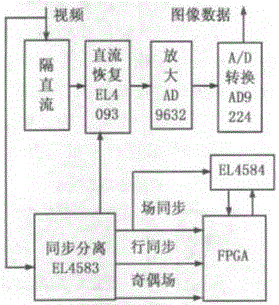

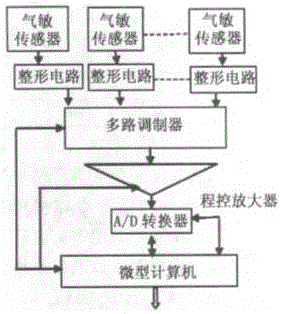

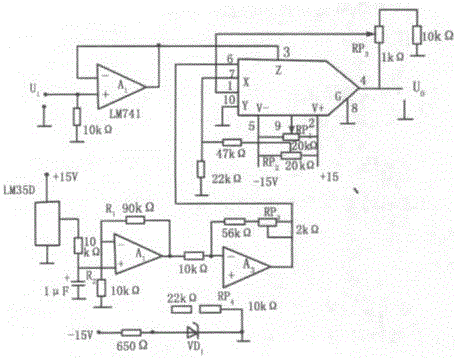

[0012] Such as Figure 1-4 As shown, this embodiment adopts the following technical scheme: it includes a real-time data acquisition module in the furnace; the boiler explosion warning system included in the real-time data acquisition module collects relevant data in the furnace by equipping a pressure sensor and a gas sensor in the boiler, and then Use the relevant model in the software design to operate the relevant data to obtain the explosion model information...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com