Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Big graph" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Generation and search method for reachability chain list of directed graph in parallel environment

ActiveCN103399902AReduce sizeReduce computing loadSpecial data processing applicationsData compressionSkip list

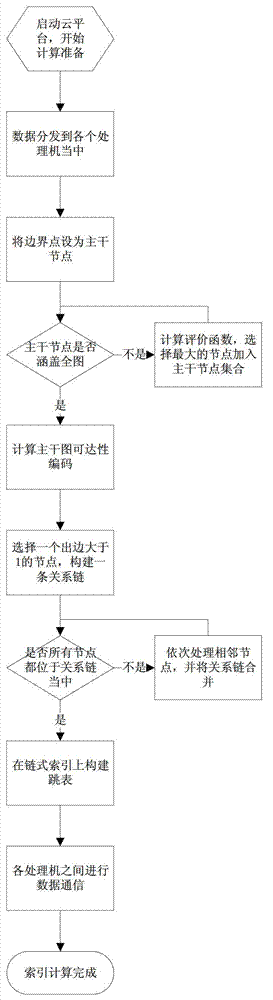

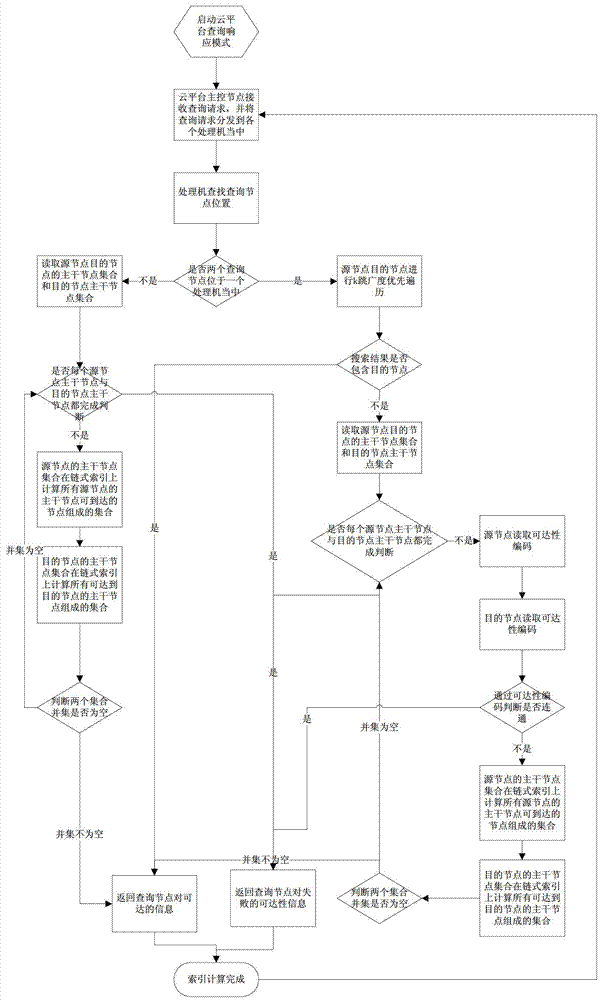

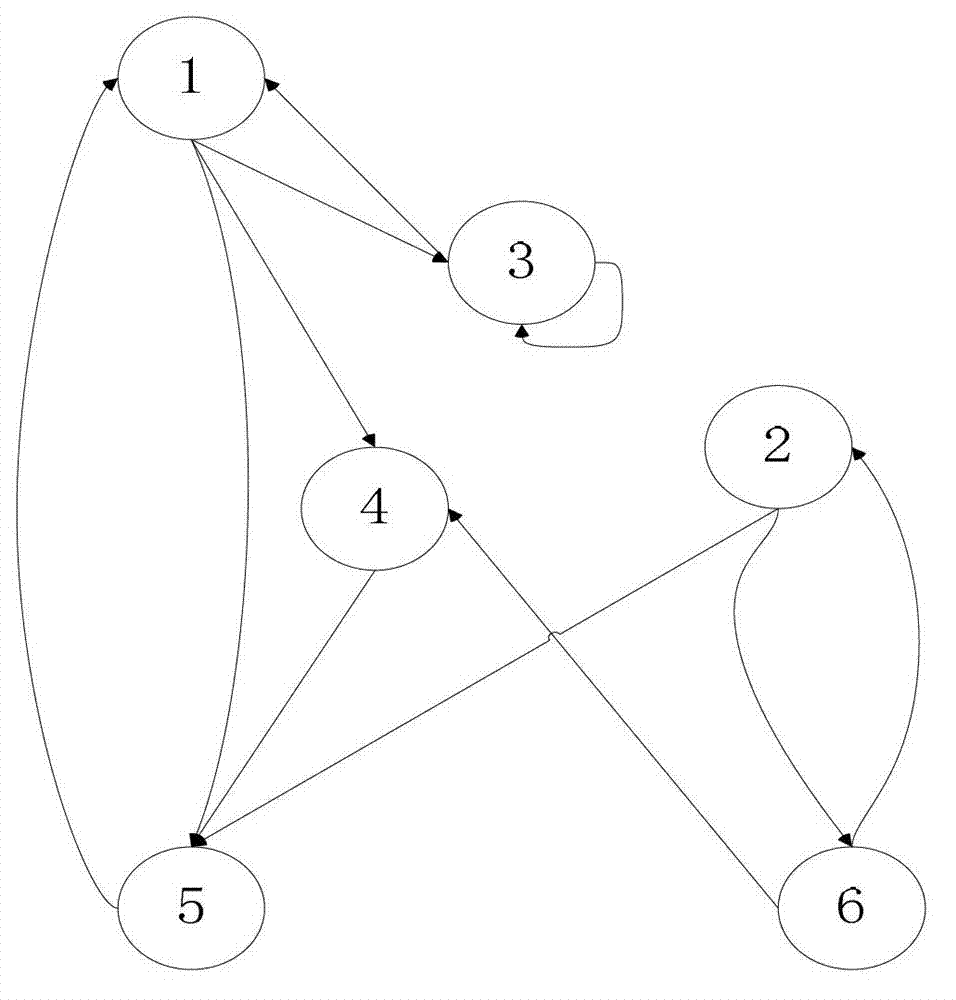

The invention belongs to the field of data processing for large graphs and relates to a generation and search method for reachability chain list of a directed graph in the parallel environment. The method includes distributing the directed graph to every processor which stores nodes in the graph and sub-nodes corresponding to the nodes; compressing graph data split to the processors; calculating a backbone node reachability code of a backbone graph; building a chain index; building a skip list on the chain index; allowing data communication among the processors; allowing each processor to send skip list information to other processors; allowing each processor to upgrade own skip list information; and building a reachability index of a total graph. Through use of graph reachability compression technology in the parallel environment, the size of graph data is greatly reduced, system computing load is reduced, and a system can process the graph data on a larger scale. The method has the advantages that the speed of reading data from a disk is higher, search speed is indirectly increased, accuracy of search results is guaranteed, and network communication cost and search time are reduced greatly for a parallel computing system during searching.

Owner:NORTHEASTERN UNIV

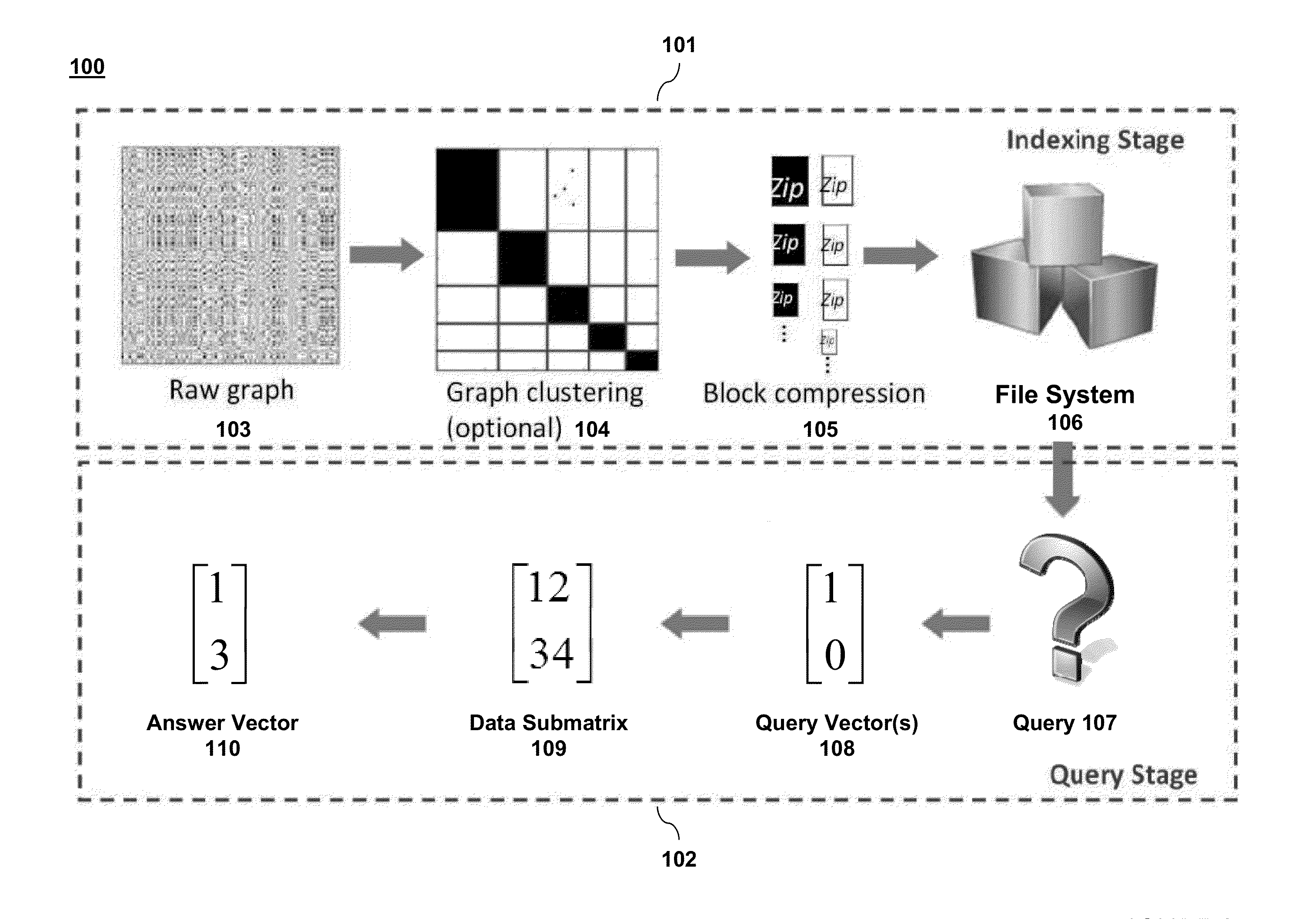

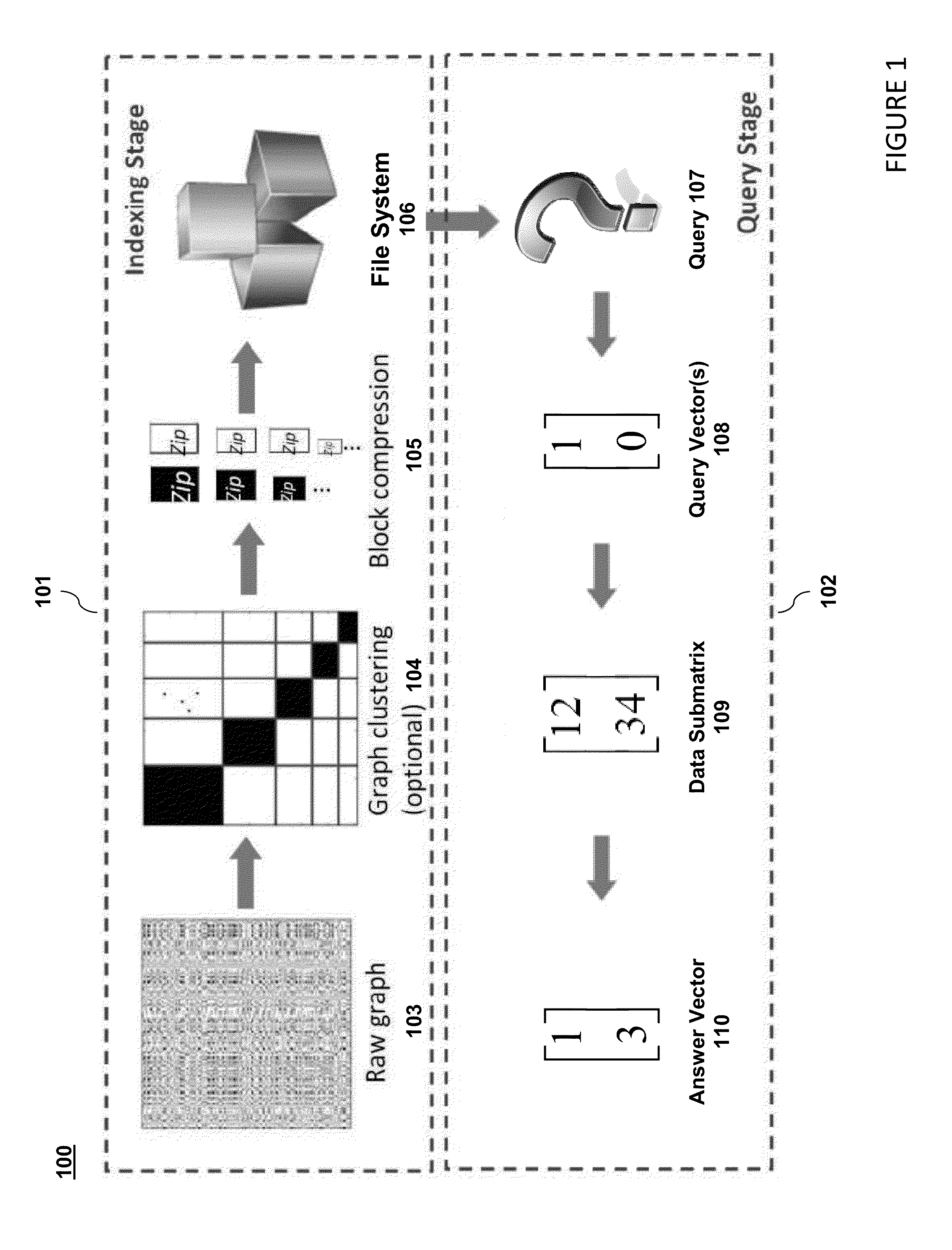

Method and system for managing and querying large graphs

InactiveUS20130124488A1Digital data information retrievalDigital data processing detailsKnowledge managementComputer program

A method, system and computer program product for managing and querying a graph. The method includes the steps of: receiving a graph; partitioning the graph into homogeneous blocks; compressing the homogeneous blocks; and storing the compressed homogeneous blocks in files where at least one of the steps is carried out using a computer device.

Owner:IBM CORP

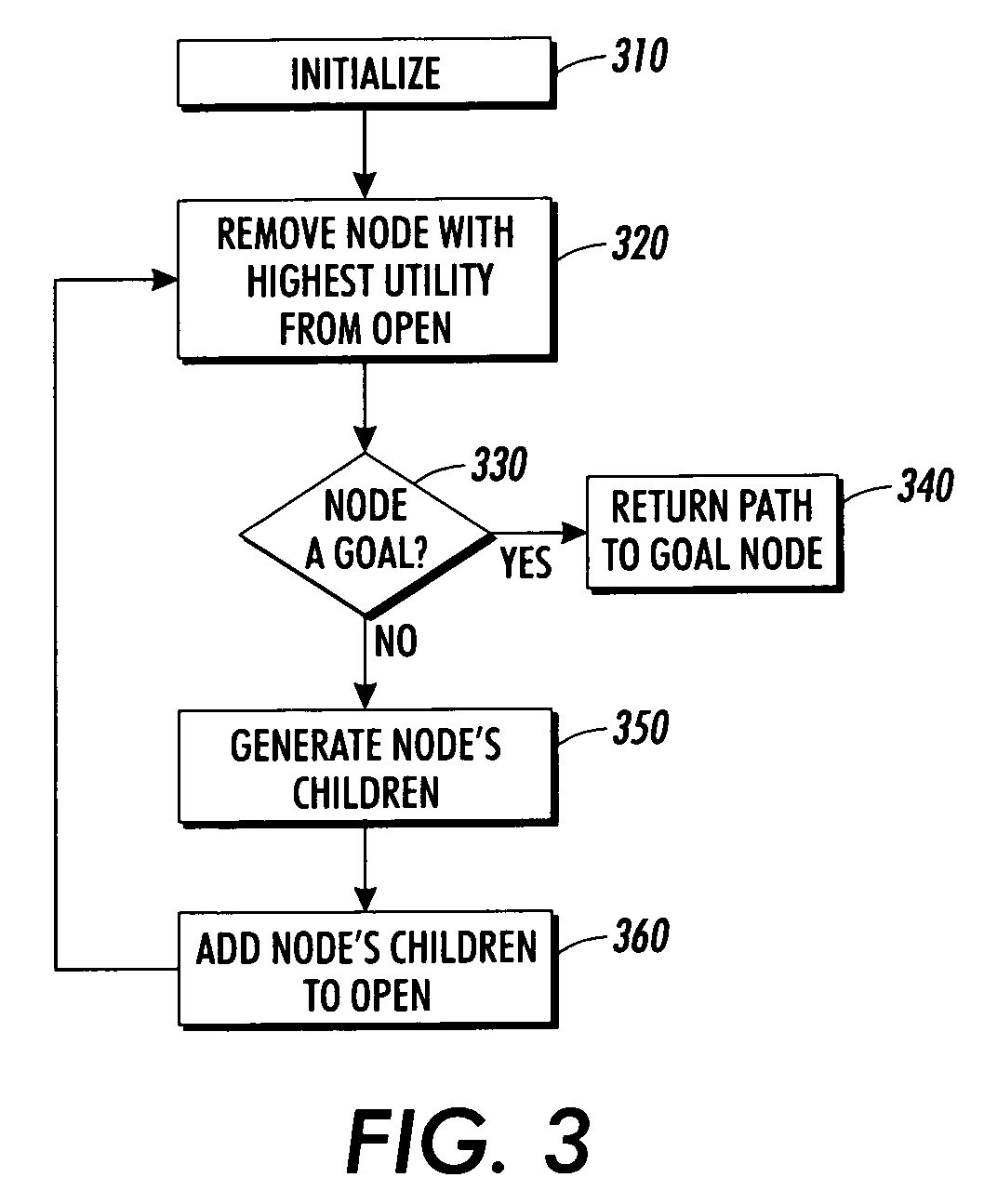

System and method for time-aware path finding

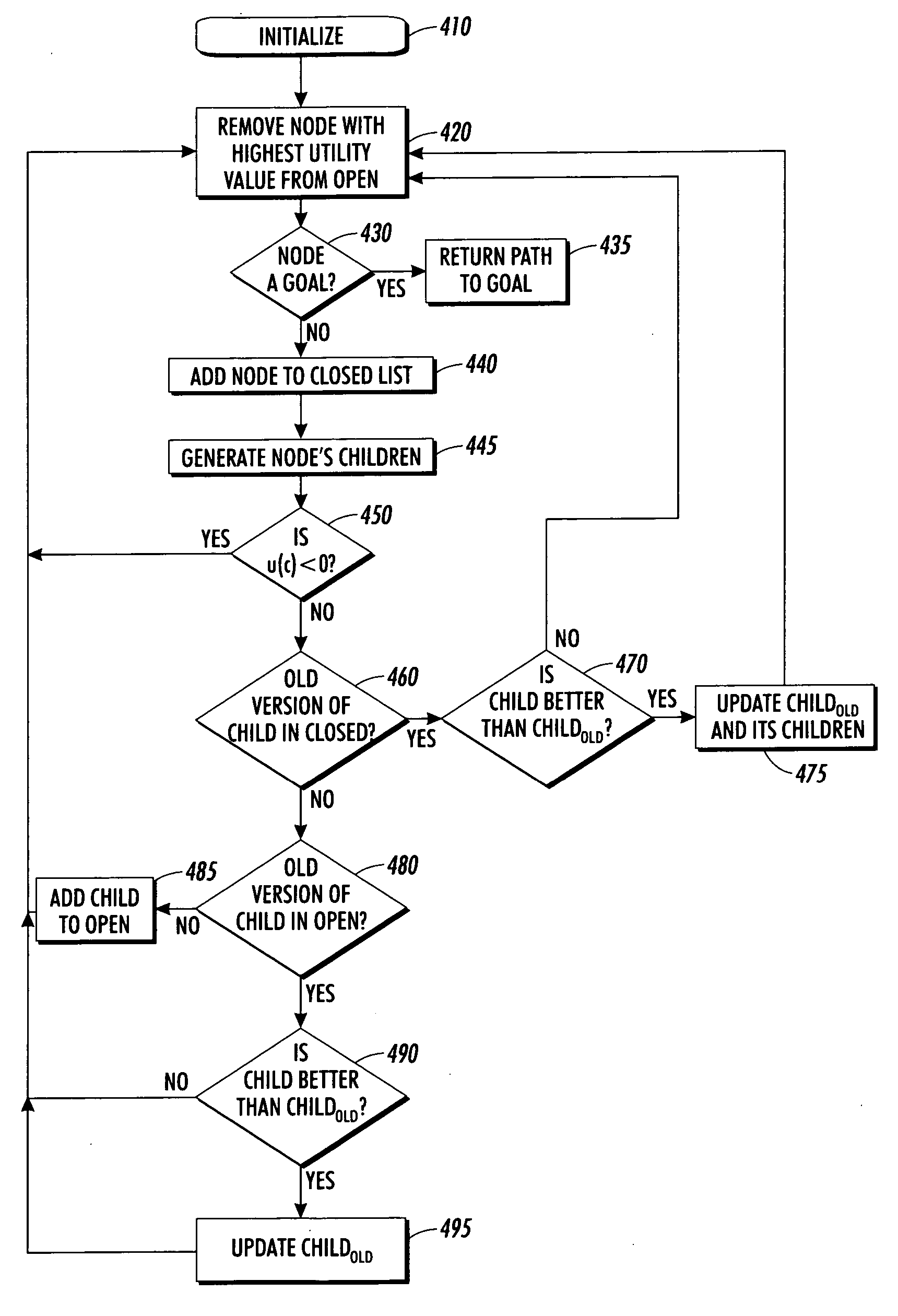

A method for obtaining solutions to combinatorial problems by way of a discrete state-based search approach utilizes a node evaluation function based both on solution quality and distance in search steps to a goal. The method considers the problem as finding the shortest path between an initial state and a goal state in a large graph and performs solution evaluation utilizing computation time balanced against solution quality. Rather than solely using a lower bound on the solution cost achievable below a search node, an estimate of the distance (in search steps) to the nearest solution below a search node is also utilized. These are combined using the user's stated utility function (represented as a function of time and cost) to evaluate candidate search nodes.

Owner:XEROX CORP

Method and system for managing and querying large graphs

InactiveUS8645339B2Digital data information retrievalDigital data processing detailsLibrary scienceComputer program

A method, system and computer program product for managing and querying a graph. The method includes the steps of: receiving a graph; partitioning the graph into homogeneous blocks; compressing the homogeneous blocks; and storing the compressed homogeneous blocks in files where at least one of the steps is carried out using a computer device.

Owner:INT BUSINESS MASCH CORP

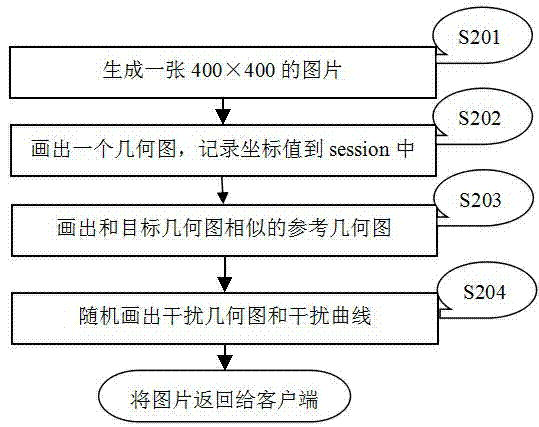

Verification code generating and verifying method based on graphs

InactiveCN103927465AFriendly interfaceIt is difficult to automatically identifyUser identity/authority verificationDigital data authenticationGraphicsValidation methods

The invention provides a verification code generating and verifying method based on graphs. The method includes: a system server draws a large geometric graph combined by lines to serve as a target graph on a picture, a plurality of interference geometric graphs identical in size and different in shapes are randomly generated near the large geometric graph, and a small geometric graph similar to the target graph is drawn to serve as a reference graph. When verification is needed, a system client displays the picture with multiple geometric graphs and construct a viewing frame, a user uses a mouse to drag the viewing frame to frame the large graph identical with the reference small geometric graph in shape according to page prompts, the client acquires the coordinates of the viewing frame and transmits the same to the server, the server judges whether the coordinates are equal to the coordinates of the target graph after receiving the coordinates or not, if so, verification passes, and or else verification fails. By the method, difficulty for automatic verification code identification by programs can be increased effectively, and attack resistance of a verification system is increased.

Owner:艾文卫

MapReduce-based big picture distance connection query method

InactiveCN102737114AReduce the number of iterationsNarrow down the search spaceSpecial data processing applicationsNODALBidirectional search

The invention discloses a MapReduce-based big picture distance connection query method. The method comprises the steps of: (1) extracting initialized query parameters including original picture, accessed nodes, extension range and query result; (2) conducting two-way extension on the original picture on hadoop, starting extension from a source node set and a target node set, conducting each extension on the basis of a cost model, conducting pruning operation by adopting dynamic threshold, and adding newly-extended node to the accessed node set; (3) continuously traversing the incompletely extended remaining nodes until all the nodes meeting the extension range are extended; and (4) after completing iteration, recording route query results between the target nodes and the source nodes in the accessed node set, and returning a query result. The invention provides a cost model-based self-adaption method under the MapReduce environment, reduces the extension space and iteration times by utilizing dynamic threshold-based pruning two-way searching algorithm and Segment index, and improves the task execution efficiency.

Owner:PEKING UNIV

Video live broadcast processing method, system and device based on free viewpoint and medium

InactiveCN111355967ASwitch freelyGuaranteed strict synchronizationSelective content distributionComputer networkEngineering

The invention discloses a live video broadcast processing method, equipment and system based on a free viewpoint, a chip and a medium. The method comprises the following steps: collecting a pluralityof synchronous videos at multiple angles; splicing the plurality of synchronous videos into a large graph, and transmitting the large graph to a server; and decoding on a server to obtain a large graph, and selecting an angle for playing. According to the invention, a user can freely switch viewpoints, and the effect of customizing the bullet time is realized through sliding control.

Owner:PLEX VR DIGITAL TECH CO LTD

Large image cache method based on power grid topological analysis, and display method and system thereof

ActiveCN107612970AImprove loading efficiencyImprove display efficiencyData switching networksNODALParallel computing

The invention relates to a large image cache method based on power grid topological analysis, and a display method and a display system thereof. The large image cache method comprises the step of computing cache weights of each node, and caching the nodes with the cache weights more than a set threshold, wherein computation of the cache weights specifically comprises the sub-step of comprehensively considering influence, vulnerability and topological structure characteristics of the nodes, and overlapping to form the final cache weights, wherein the influence is measured by tight centrality orbetweenness centrality of the node, the vulnerability is measured by an element online rate, and the topological structure characteristics correct the cache weight of the node according to the position of the node in a topological structure. Compared with the prior art, the method provided by the invention caches the nodes with better user preference according to priorities, and thus next front-end loading efficiency is improved.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

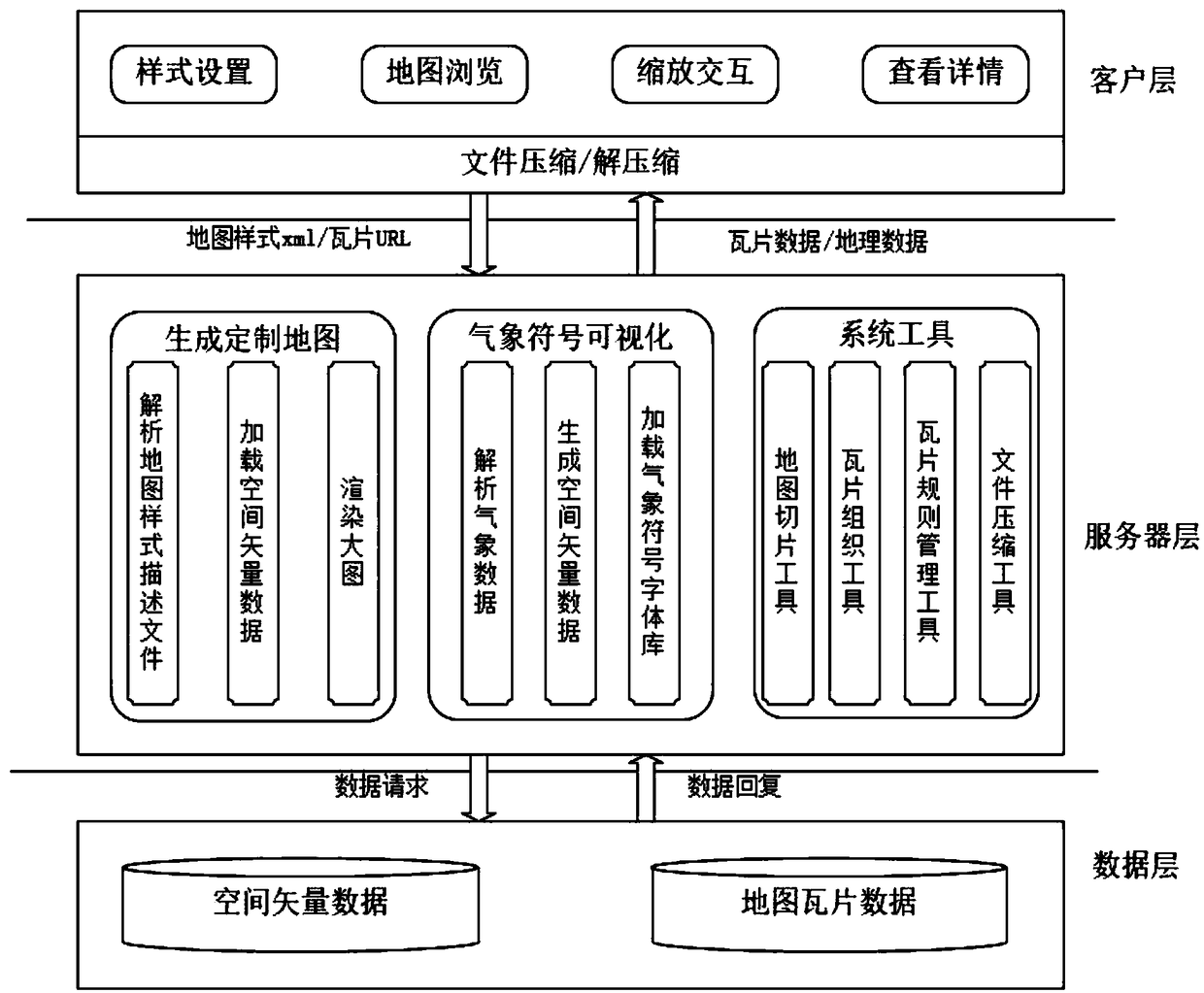

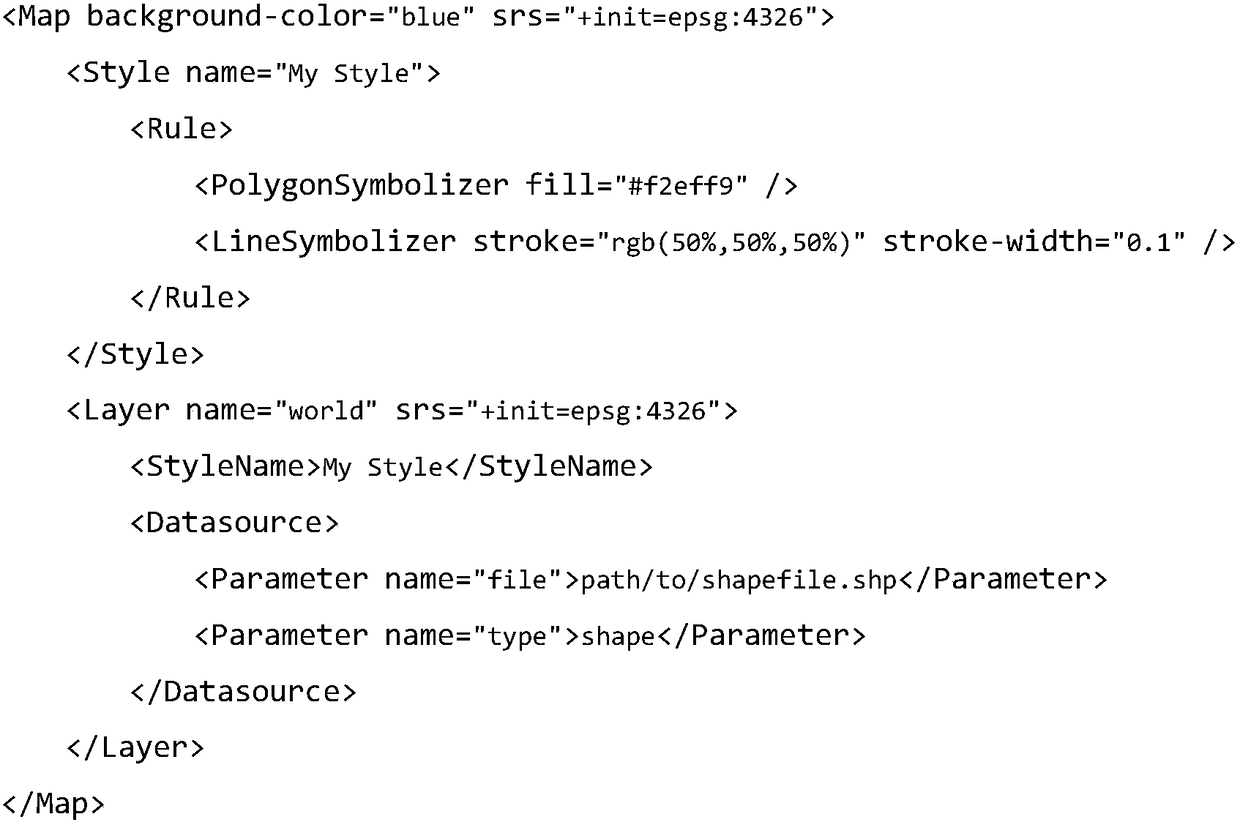

Weather map system with customizable pattern

InactiveCN108256127AEasy to use browsingLive View TrackingGeographical information databasesSpecial data processing applicationsMessage queueBig graph

The invention discloses a weather map system with a customizable pattern. A server provides real-time reading and analysis of weather data and generates spatial vector data; a large picture is generated according to a map pattern xml description file provided by a client; the large picture is cut into standard tiles; the tiles are uniformly organized according to TMS (tile map system) rules; the organized tiles and tile files are compressed; all logs are recorded in detail; the client provides map pattern setting that is described as an xml file sent to the server; tile data are acquired fromthe server to provide map browsing and interaction; the client is communicated with the server through currently-popular efficient ZeroMq message queue; the tile data are transceived for MD5 check, sothat data transceiving is intact and correct.

Owner:BEIJING UNIV OF TECH

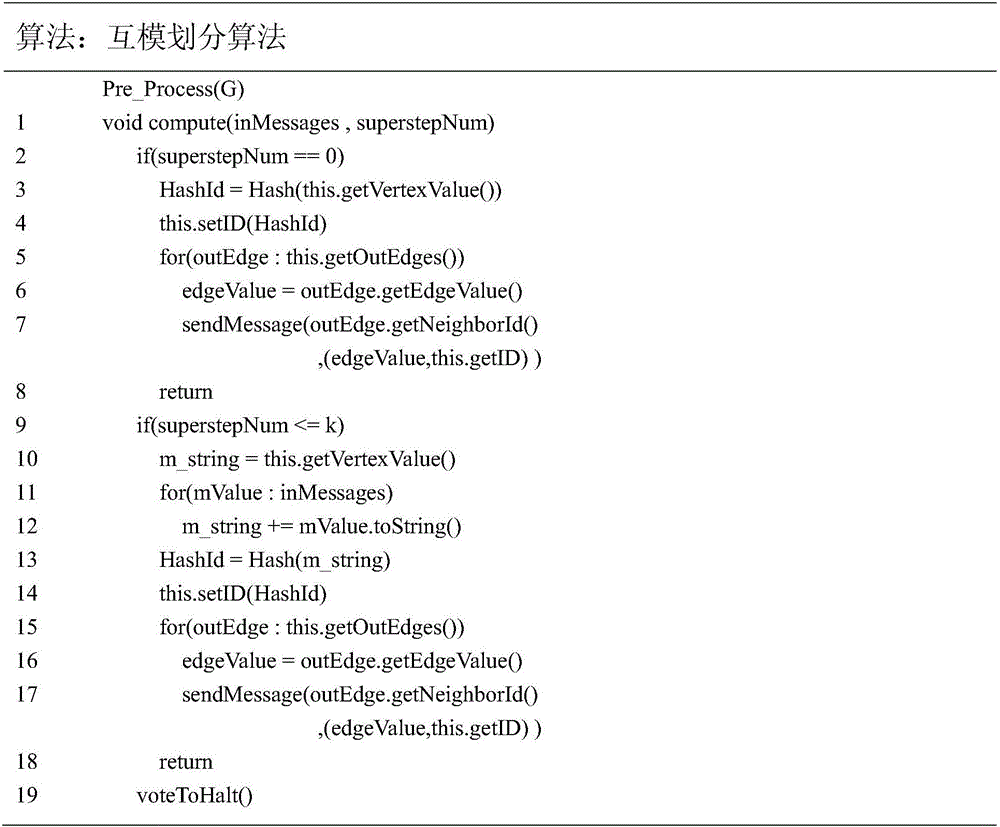

k-bisimulation calculation method based on GPS (global positioning system) platform

InactiveCN106250563AImprove operational efficiencyImprove efficiencyResource allocationSemi-structured data indexingAlgorithmNetwork data

The invention discloses a k-bisimulation calculation method based on a GPS (Global Positioning System) platform. The method comprises the following steps of graph pre-division processing and the distributed calculation of k-bisimulation features, wherein the graph pre-division processing is used for reducing an number of edges which are distributed to graphs on different working nodes, and guaranteeing the scale of a point processed by each working node to be equivalent; the distributed calculation of k-bisimulation features comprises the following steps: updating point feature numbers, calculating the numbers of node features and calculating the k-bisimulation division feature of each point in the graph; and the graph pre-division processing and the distributed calculation of the k-bisimulation features are both based on a GPS distributed graph data processing platform of node programming and are used for stipulating space locality. Algorithm operation efficiency is drastically improved by the frame and the programming thought of a distributed graph processing platform, a network data transmission amount can be only 1 / 2-1 / 12 of the network data transmission amount of a MapReduce calculation model algorithm. In addition, for the calculation of the local bisimulation division of a big graph which contains several hundred millions of edges and points, the algorithm disclosed by the invention is characterized in that required calculation time is only 1 / 7-1 / 16 of the required calculation time of the MapReduce calculation model algorithm.

Owner:JIANGSU MINGTONG TECH

Large graph sampling visualization method based on graph representation learning

ActiveCN110889001APreserve the context structureScale reductionStill image data browsing/visualisationSpecial data processing applicationsAlgorithmTheoretical computer science

The invention discloses a large graph sampling visualization method based on graph representation learning, and belongs to the field of graph visualization and graph sampling. According to the method,nodes in an original network are converted into high-dimensional vectors through a node2vec algorithm, then the high-dimensional vectors of the nodes are projected to a low-dimensional space througha dimension reduction algorithm, and the semantic structure similarity of the corresponding nodes in the network space can be effectively expressed through the distance between projection points. Secondly, a multi-target sampling model of adaptive blue noise sampling is designed to effectively maintain a topological structure of an original network; and measurement indexes based on network attribute characteristics are proposed, quantitative evaluation is carried out on different sampling algorithms to obtain graph sampling result evaluation, and the graph sampling result evaluation is presented by utilizing a visualization method. According to the method, the nodes are sampled in the representation space, the context structure of the original network is well simplified and reserved, and the topological structure of the network is effectively kept while the node scale is reduced.

Owner:ZHEJIANG UNIV OF FINANCE & ECONOMICS

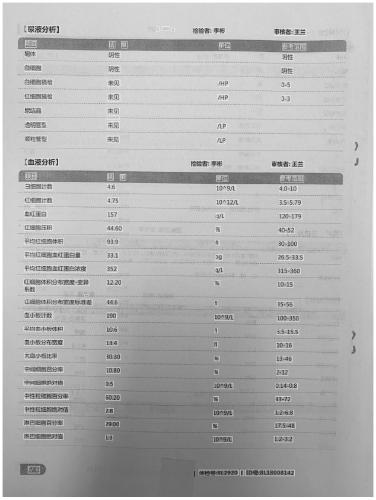

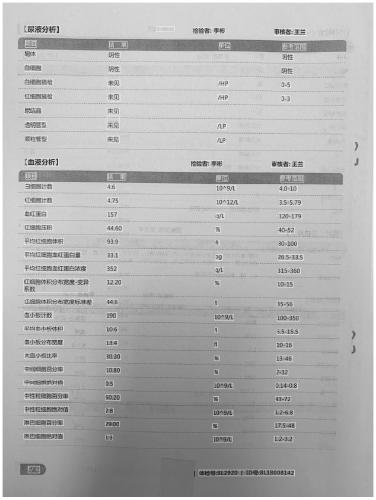

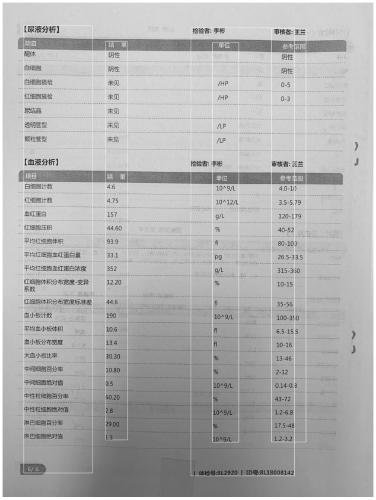

Medical examination report character recognition and correction method

PendingCN111090990AEffective segmentationGuaranteed recognition accuracyNatural language data processingCharacter recognitionDatasheetText detection

The invention discloses a medical examination report character recognition and correction method, and relates to the technical field of character recognition, and the method comprises the steps: carrying out text detection of a medical examination report image, and obtaining a plurality of first textboxes; deleting the first textboxes which do not meet the preset aspect ratio condition, and combining the remaining first textboxes to obtain a plurality of second textboxes; combining the two second textboxes meeting the preset transverse distance according to columns to obtain a plurality of column textboxes; judging the row number and the column number of the second textboxes; performing screenshot on the characters contained in the second textboxes, and recording the position of each smallgraph in the large graph; performing character recognition on a large graph by using a trained CRNN to obtain a character recognition result and a character detection positioning result, adding the character recognition result to a corresponding position of a data table, and inputting the character recognition result into Excel; correcting the text in Excel through the NLP technology to acquire afinal recognition report. The method has the advantages of being high in recognition accuracy and high in table format reduction degree.

Owner:中电健康云科技有限公司

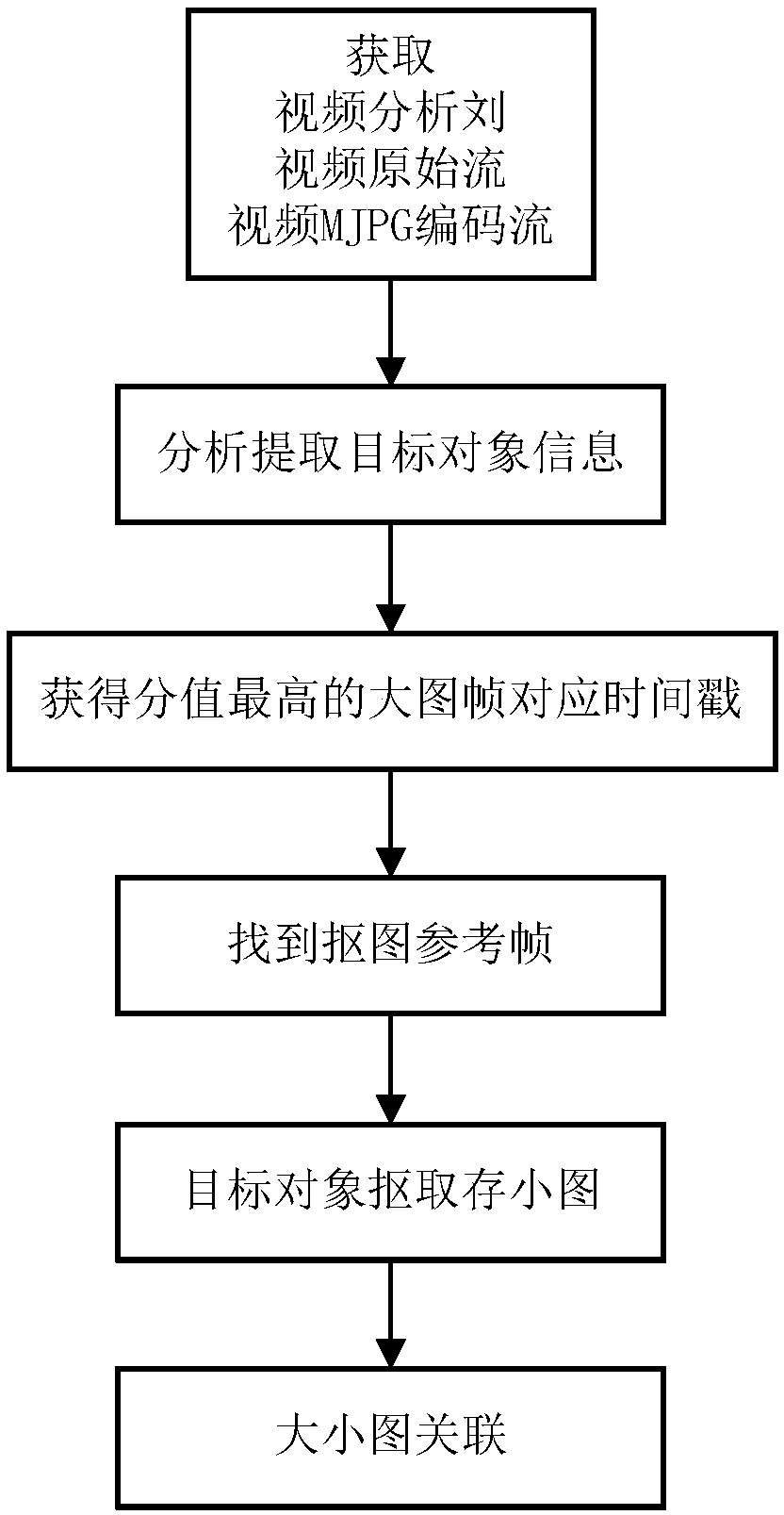

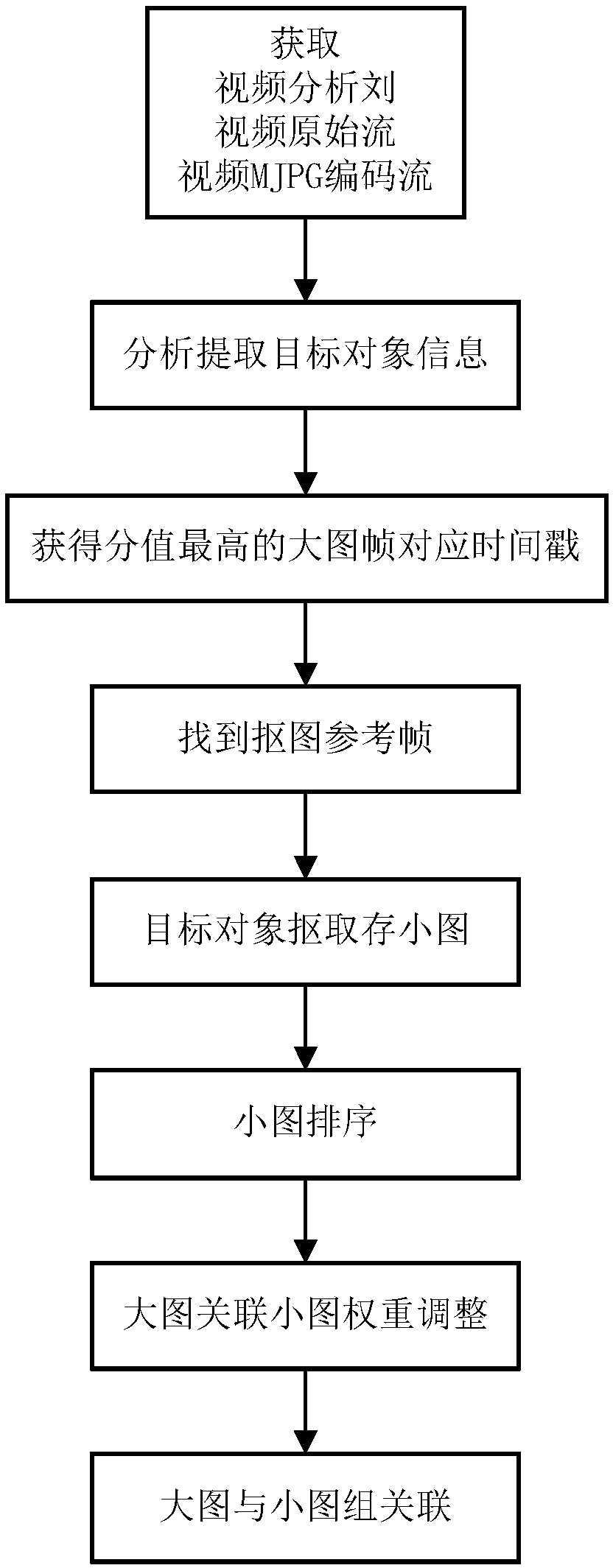

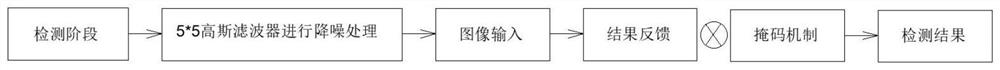

Method and device for associating small and big pictures in intelligent snapshot device

ActiveCN109660762AAvoid space consumptionMeet practical application needsClosed circuit television systemsSelective content distributionComputer graphics (images)Big graph

The invention provides a method and a device for associating small and big pictures in an intelligent snapshot device. By applying resources of equipment, a time stamp serves as a link, and a target object is obtained through fast analysis of a video analysis stream; then the small picture is extracted from a video MJPG code stream, and the big picture is obtained from an original video stream; and the big picture and the small picture are associated. Therefore, the space consumption for storing a large amount of videos is avoided, and the requirements of actual application can be met.

Owner:SHENZHEN INFINOVA TECH LTD

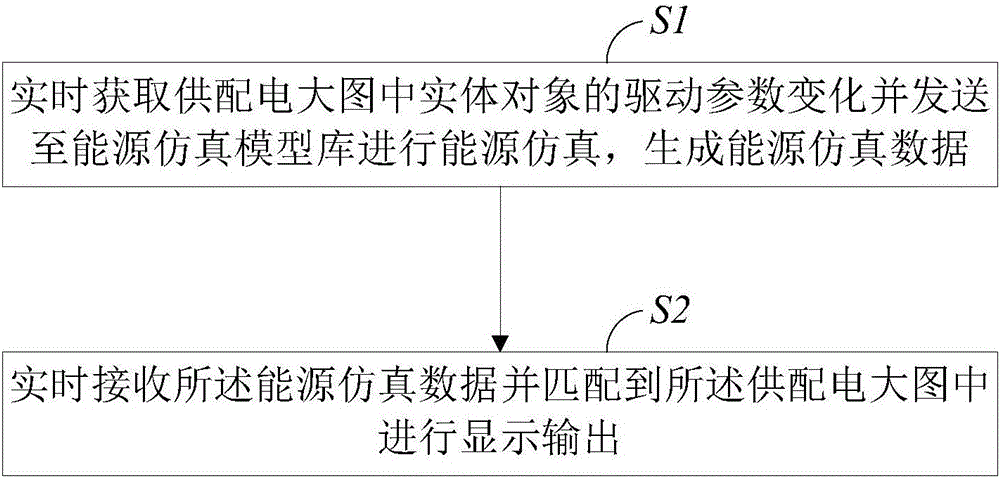

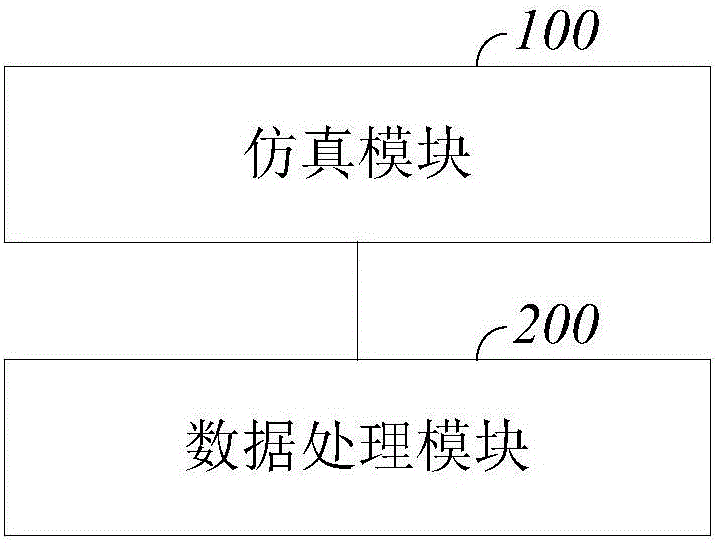

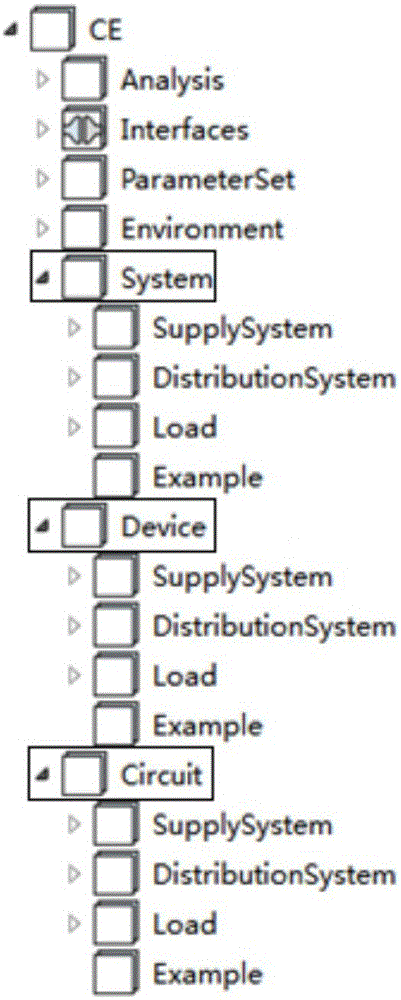

Fusion method and fusion system for spacecraft power supply and distribution big image and energy simulation data

InactiveCN106202677AAchieve integrationRealize simulationData processing applicationsDesign optimisation/simulationAnimationSimulation

The invention provides a fusion method and a fusion system for a spacecraft power supply and distribution big image and energy simulation data. The method comprises the steps of: acquiring variations of driving parameters of entity objects in the power supply and distribution big image in real time, sending the variations of the driving parameters to an energy simulation model library to carry out energy simulation, and generating the energy simulation data, wherein the driving parameters of the entity objects comprise an electrical characteristic variable, a driving parameter of a dynamic component, a driving parameter of a simulation animation flight orbit and a driving parameter of a key curve; and receiving the energy simulation data in real time and matching the energy simulation data into the power supply and distribution big image to carry out display output. According to the fusion method and the fusion system which are provided by the invention, by establishing the energy simulation model library matched and related with the driving parameters of the entity objects in the spacecraft power supply and distribution big image, acquiring the simulation data according to a single-step solution step length, carrying out automatic fusion, distinguishing and regulation and attaching the simulation data to display objects of the power supply and distribution big image, information fusion of the spacecraft power supply and distribution big image and the energy simulation data is implemented, and digital modeling, simulation, analysis and verification are implemented.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

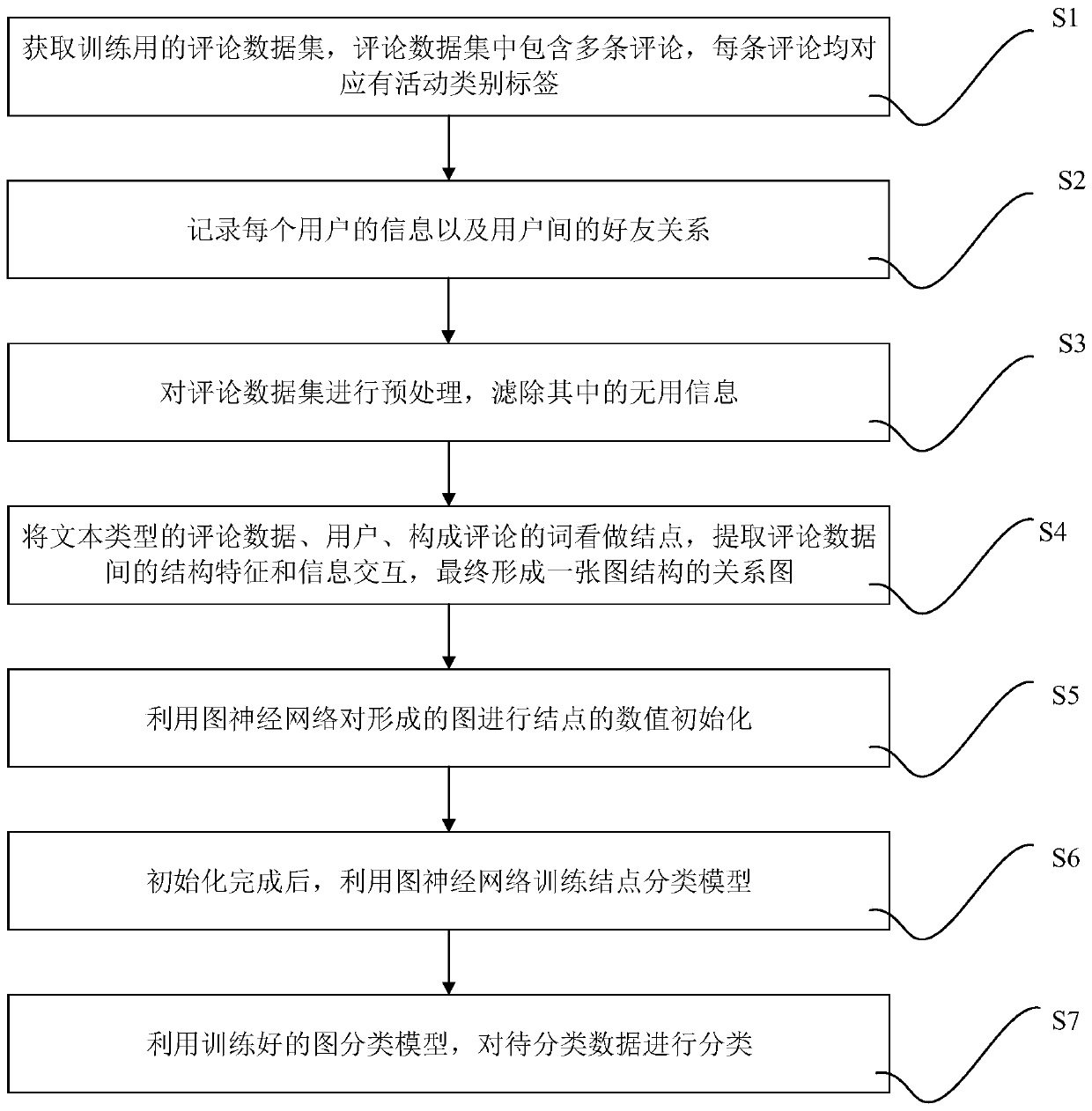

User activity type identification method based on social media

ActiveCN111191099AImprove recognition accuracyWeb data indexingWebsite content managementActivity classificationSocial media

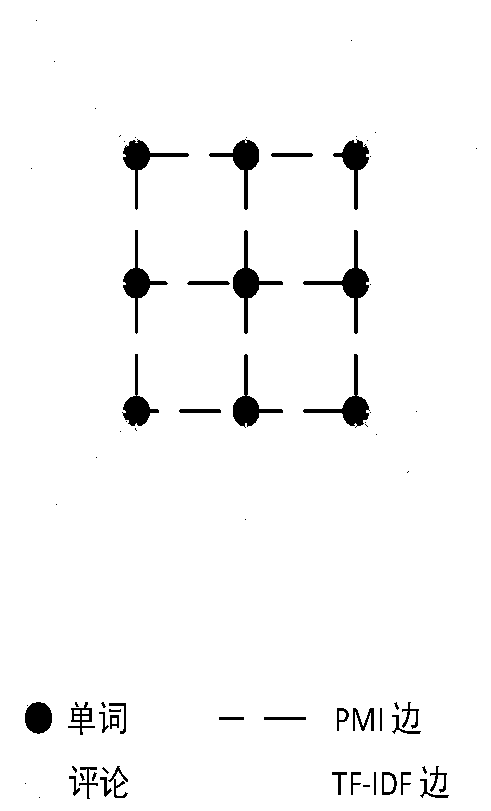

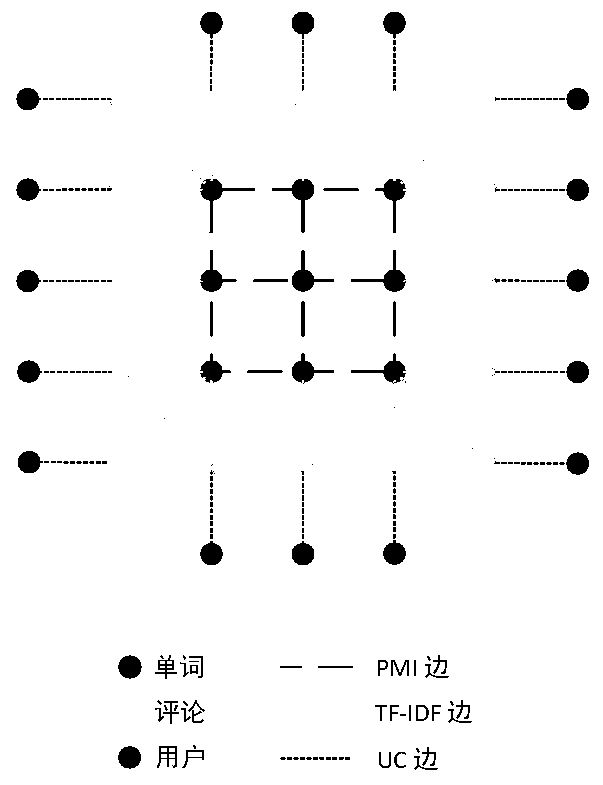

The invention provides a user activity type identification method based on social media. Generally, a graph is composed of nodes and edges. The method comprises the following steps: firstly, taking all user comments and words forming the comments as a plurality of nodes in the graph, and defining weights and relationships of edges between different words and between words and comments to form a most basic graph; secondly, regarding the users who make comments as another type of nodes, defining the weights of the users and the edges between the comments according to the publishing relation between the users and the comments, and adding user nodes into the formed graph; then other friends of the user who makes the comments are regarded as nodes of a new class, relation weights between the user and the friend nodes corresponding to the user are defined, and a large graph containing text information and structure information of the comments is formed; and finally, performing node classification on the formed large graph by utilizing a graph convolution network to obtain the accuracy of user activity classification.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Defect detection method applied to motor coil based on cascade expansion FCN network

ActiveCN111738338ARealize real-time detectionImprove detection efficiencyCharacter and pattern recognitionNeural architecturesSample graphEngineering

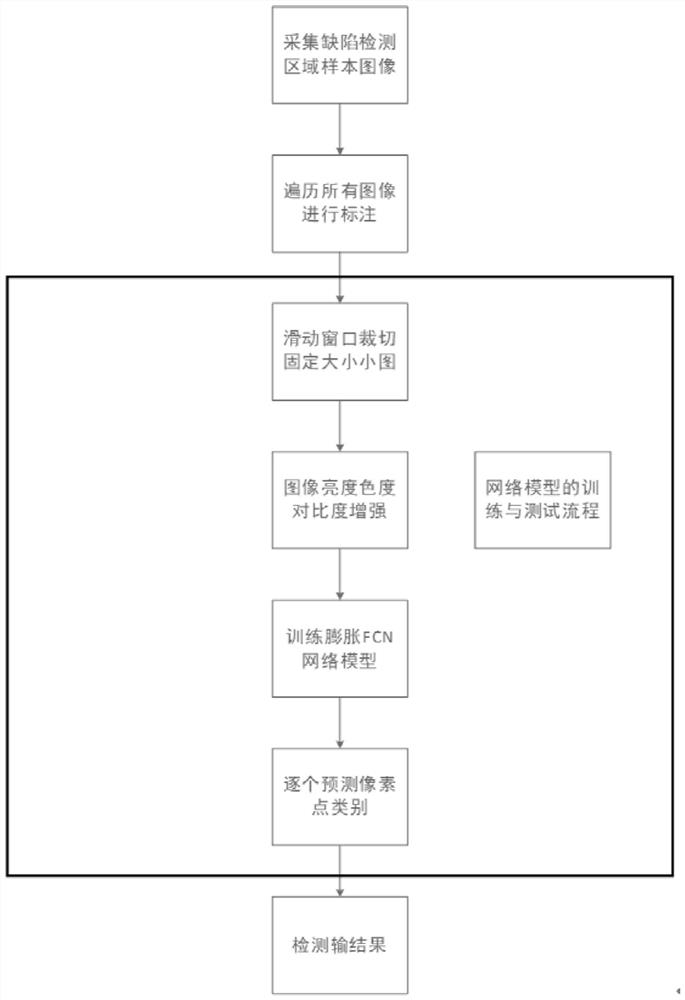

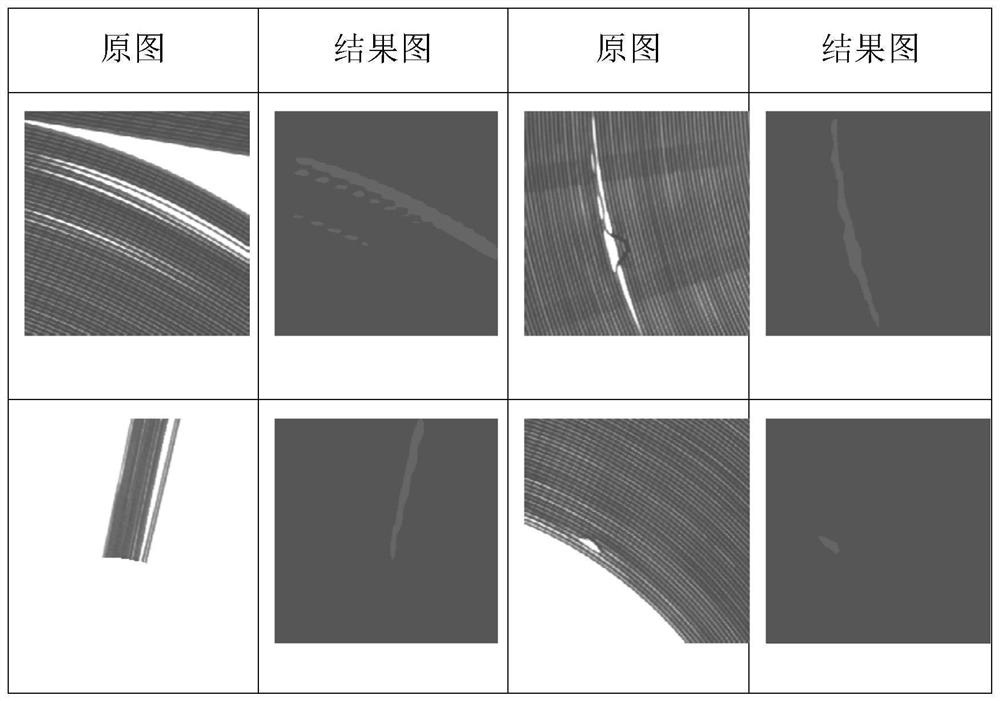

The invention relates to a defect detection method applied to a motor coil based on a cascade expansion FCN network, and the method comprises the following steps: 1), collecting a sample image, i.e.,a big image, of a target region needing defect detection; 2) traversing all the sample images, and marking the defect position of each image; 3) performing sliding image segmentation on the large image by adopting a window sliding method, and segmenting the marked large image into small images with fixed sizes for training; 4) performing data enhancement on the small graph cut from the sliding window, and expanding the cut small graph; 5) applying the expanded small graph to the training of a network model, evaluating the defect detection effect, and adjusting parameters; and 6) obtaining a feature map output by the last layer of the network model, i.e., a segmentation position of the defect, i.e., a final output result. According to the method, the trained model can be added to an industrial production machine, whether the product has the defect or not can be automatically recognized, the defective product can be automatically shunted, the detection efficiency can be improved, and thelabor cost can be reduced.

Owner:BEIJING FOCUSIGHT TECH

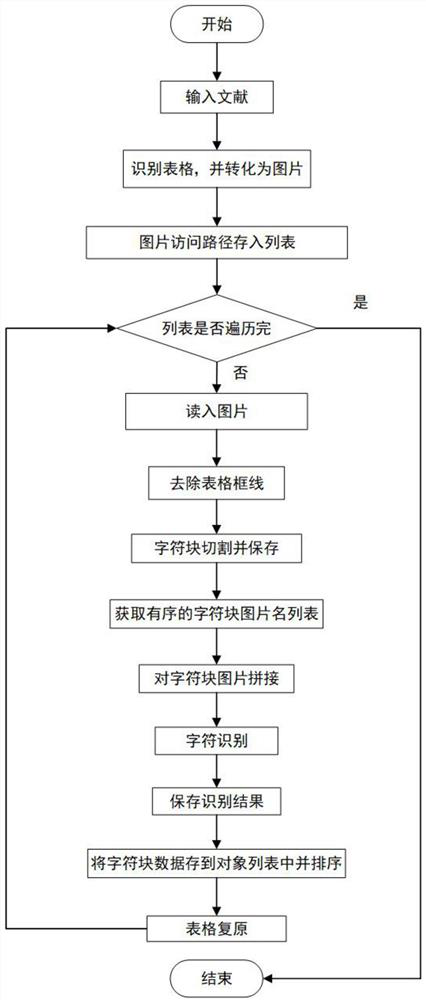

Literature table content recognition and information extraction method based on image processing

ActiveCN112861736AFast recognitionAchieve acquisitionCharacter and pattern recognitionOther databases retrievalText recognitionImage manipulation

The invention discloses a literature table content recognition and information extraction method based on image processing, which is used for realizing content recognition, information extraction and structure restoration of a literature table picture by applying a computer image detection method. The method comprises the following steps: firstly, reading a table picture, and removing table frame lines by using a morphological method; then finding out a character region by using contour detection, and intercepting and storing the region; selecting and splicing a plurality of character block pictures into a large picture, calling a character recognition model to recognize characters on the large picture, analyzing and storing a recognition result; and finally, reading character block information data, restoring the table according to a row discovery and self-adaptive column alignment restoration algorithm based on character block coordinates, and storing the restored table in a database. According to the content recognition and information extraction method for the table picture in the literature, frame line removal, content recognition and structure recovery can be realized, the literature information extraction speed is improved, a method is provided for constructing a database of a corresponding subject, and research and development of the corresponding subject are promoted.

Owner:SHANGHAI UNIV

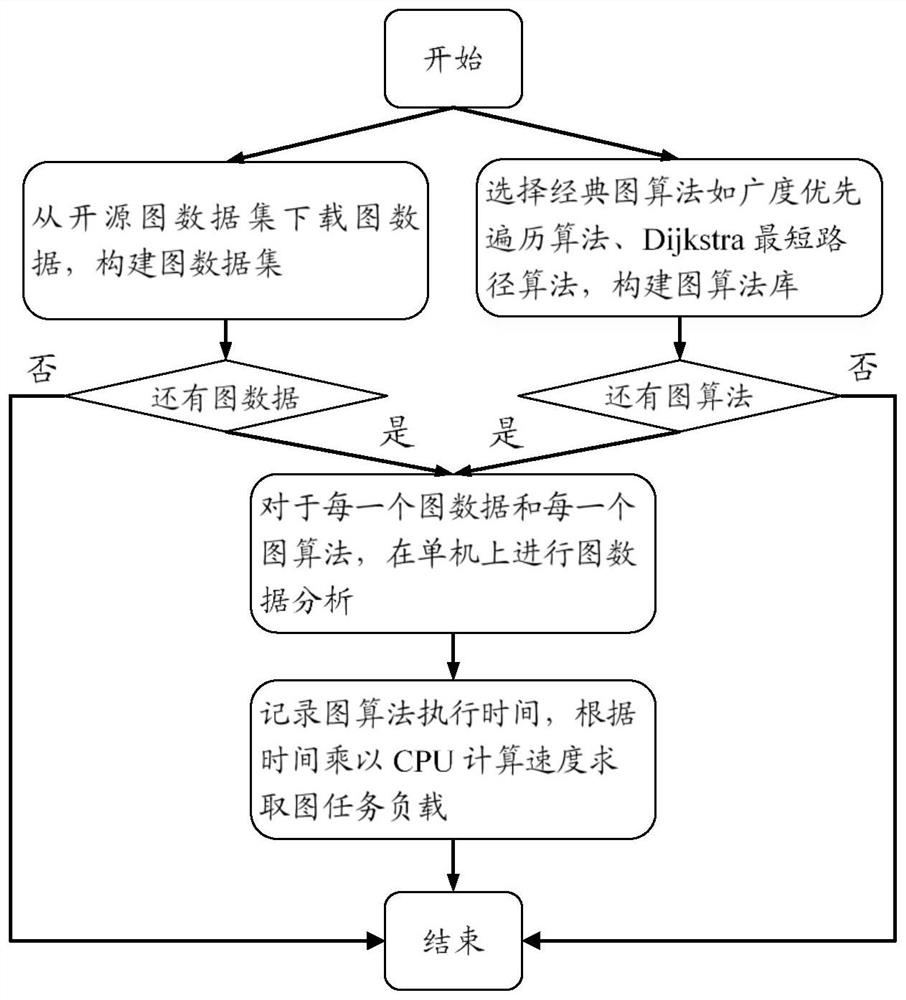

Method and system for expanding stand-alone graph neural network training to distributed training, and medium

ActiveCN112149808AImplement distributed trainingConvergence Speed GuaranteeResource allocationNeural architecturesData synchronizationComputational logic

The invention discloses a method for expanding stand-alone graph neural network training to distributed training. The method, by providing functions of graph division and data synchronization expansion, using a stand-alone graph neural network frame with automatic back propagation, and just adding a small number of data synchronization codes to original stand-alone graph neural network model codes, and then allocating a large graph to multiple servers, can realize distributed large graph training equivalent to stand-alone graph neural network training by the multiple servers under the condition of not modifying the stand-alone graph neural network framework or modifying calculation logic of an original stand-alone graph neural network model. In addition, the invention also discloses a system for expanding stand-alone graph neural network training to distributed training. In addition, the invention discloses a computer readable storage medium storing a computer program.

Owner:SHANGHAI JIAO TONG UNIV

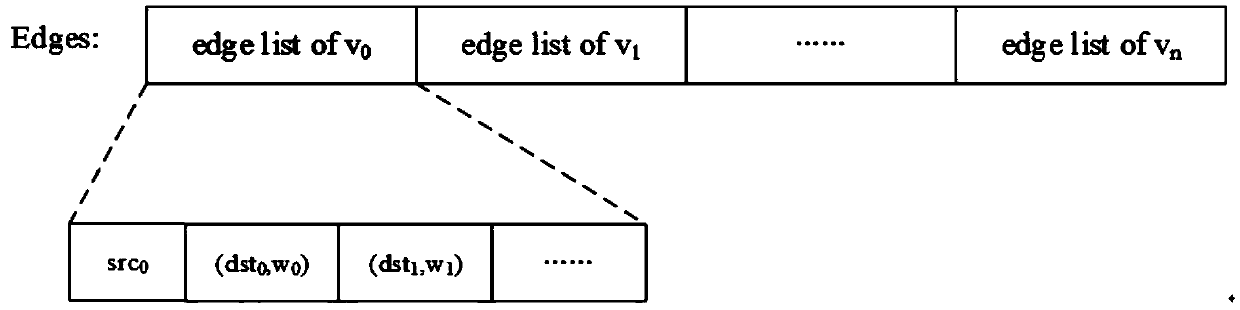

Data access method and system in large graph calculation

ActiveCN110688055AImprove performanceReduce overheadInput/output to record carriersExternal storageAlgorithm

The invention provides a data access method and system in large graph calculation. The method comprises the steps of preprocessing a target graph data file; obtaining a compact graph data file corresponding to the target graph data file, recording active vertexes of the target graph data file in each iteration step through the index bitmap; determining useful edge data and useless edge data in each iteration step according to the active vertexes; determining all useful edge data blocks corresponding to each iteration step according to the useful edge data and the useless edge data; and generating an I / O request according to the initial position and the size of the useful edge data block, so as to directly accessing each piece of edge data in the corresponding useful edge data block from the compact graph data file according to the initial position and the size when the I / O request is processed. According to the method and the system, the addressing overhead of the external storage equipment and the I / O overhead of the external storage equipment are comprehensively considered, the I / O of the external storage equipment of useless side data is reduced to a certain extent, the access sequence of the side data is ensured, and the overall performance of large graph calculation is effectively improved.

Owner:TSINGHUA UNIV

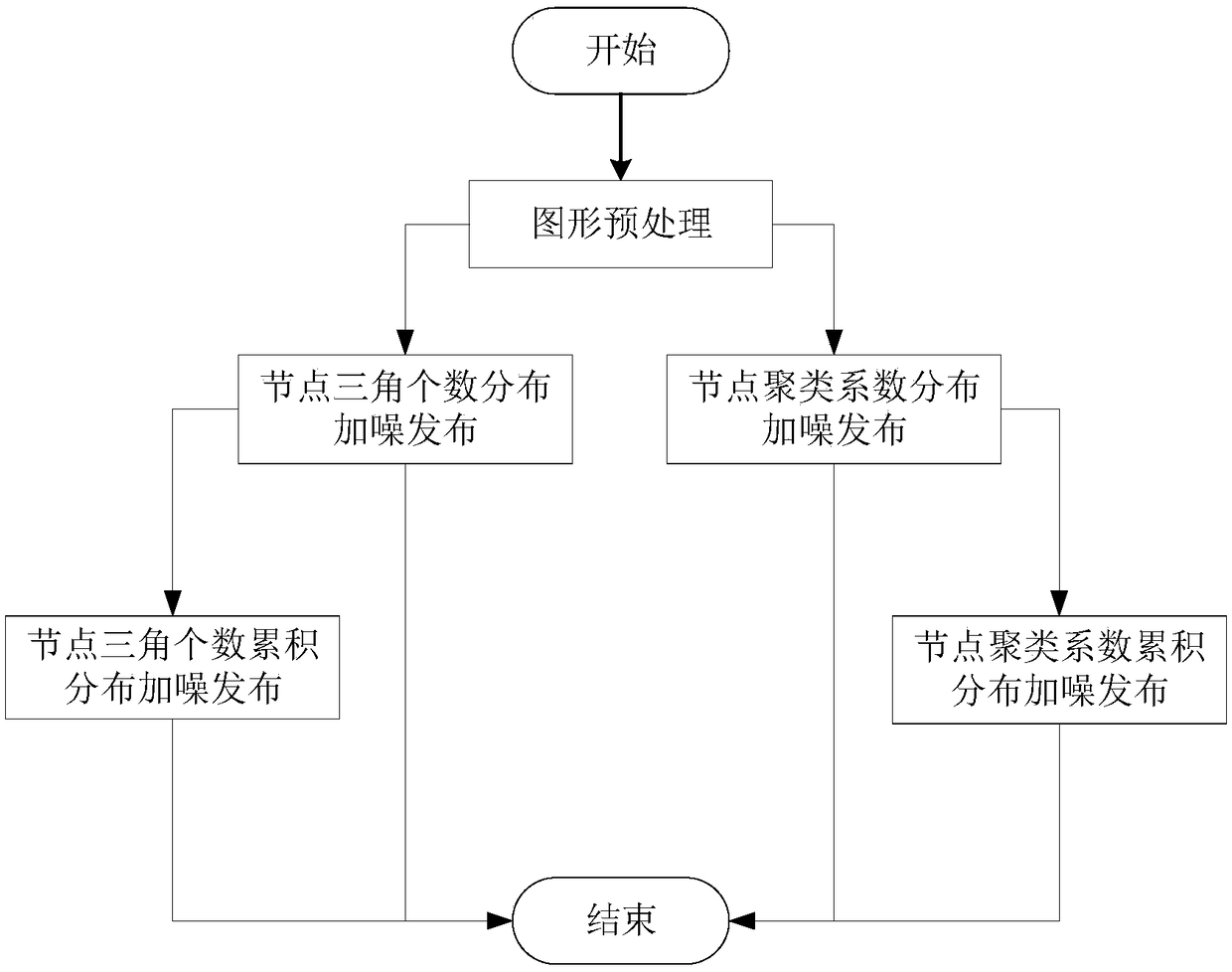

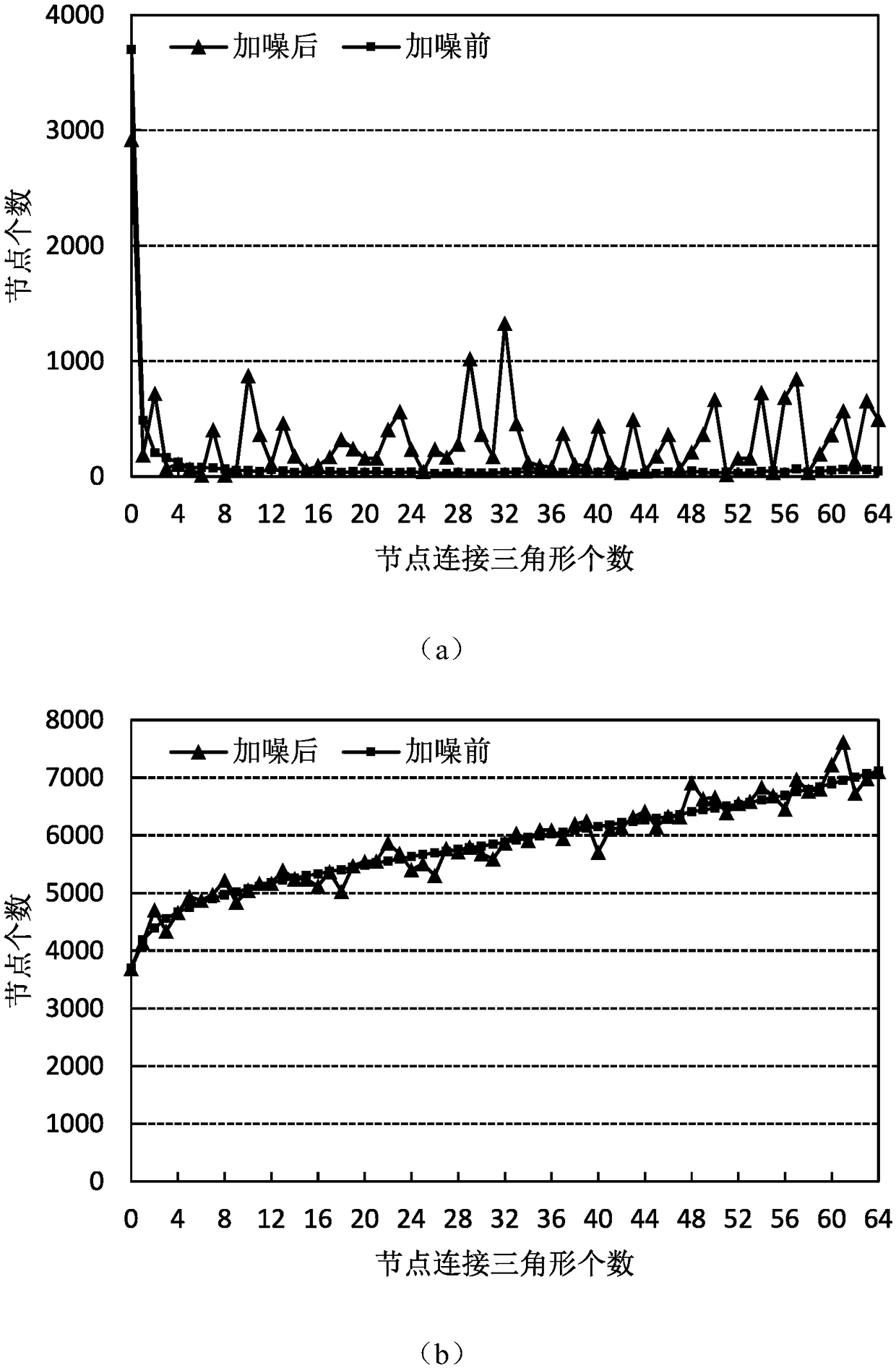

Privacy protection method and a privacy protection system for triangular data publishing in a graph

ActiveCN109344643AProtect privacy and securityImprove publishing performanceDigital data protectionPrivacy protectionUsability

The invention discloses a privacy protection method and a privacy protection system oriented to triangular data release in a graph. The method comprises the following steps: deleting edges of originalgraph data to obtain a new graph with a threshold value lambda of the number of triangles connected by a single node; The sensitivity upper bounds of the histogram of the number of triangles and thenumber of corresponding nodes are calculated to determine the amount of noise added and the histogram of the distribution of the number of triangles after noise addition is issued. The sensitivity upper bounds of the histogram of the number of triangles and the number of corresponding nodes are calculated. The cumulative histogram sensitivity upper bound of the number of triangles and the number of corresponding nodes is calculated, and the cumulative histogram of the noised triangles is published. The local clustering coefficients are divided into k groups, and the sensitivity upper bounds ofthe clustering coefficients and the distribution histograms corresponding to the number of nodes in each group are calculated, and the distribution histograms of the clustering coefficients after noising are published. The sensitivity upper bound of cumulative histogram of clustering coefficients after grouping is calculated, and the cumulative histogram of clustering coefficients after noising is published. The invention publishes the triangular calculation result of the large graph data on the premise of ensuring privacy, and has certain usability and security.

Owner:HUAZHONG UNIV OF SCI & TECH

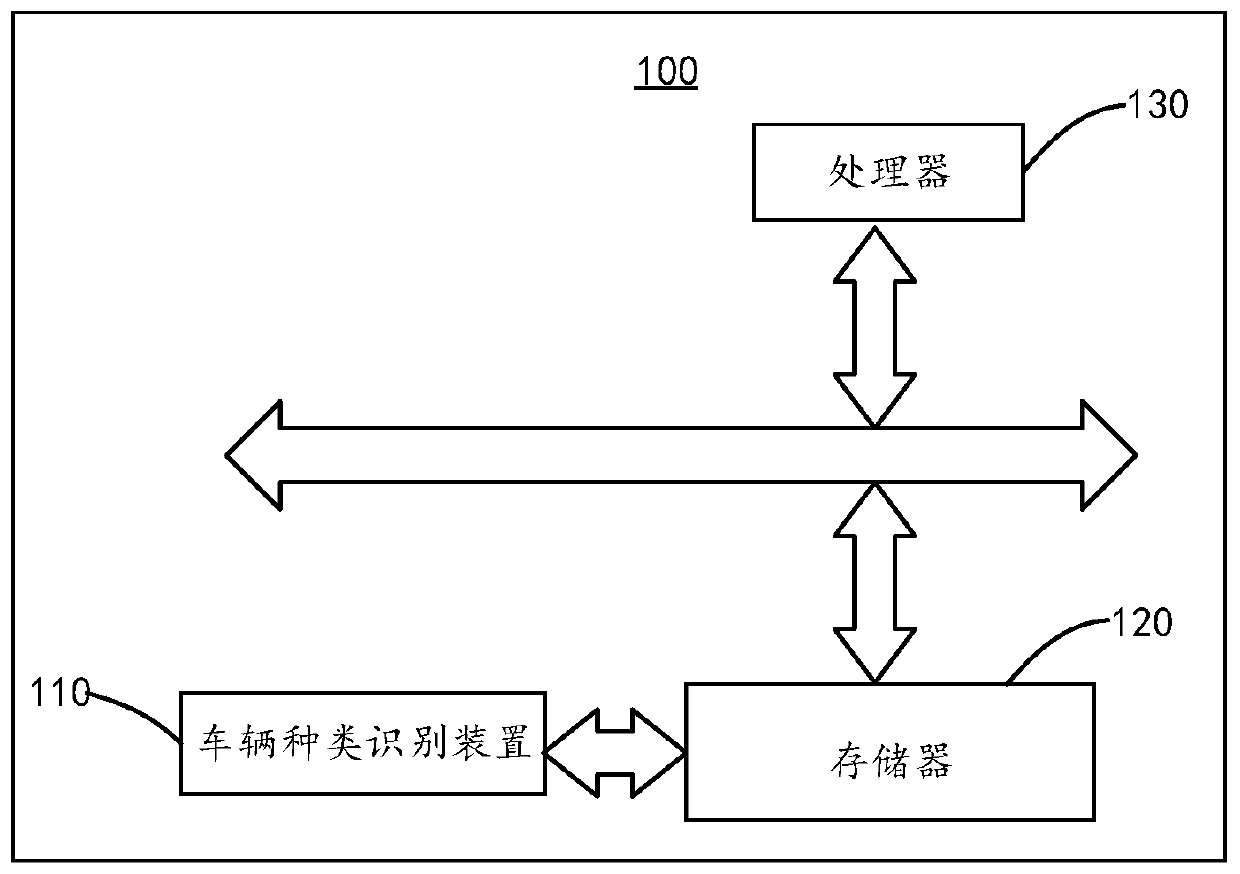

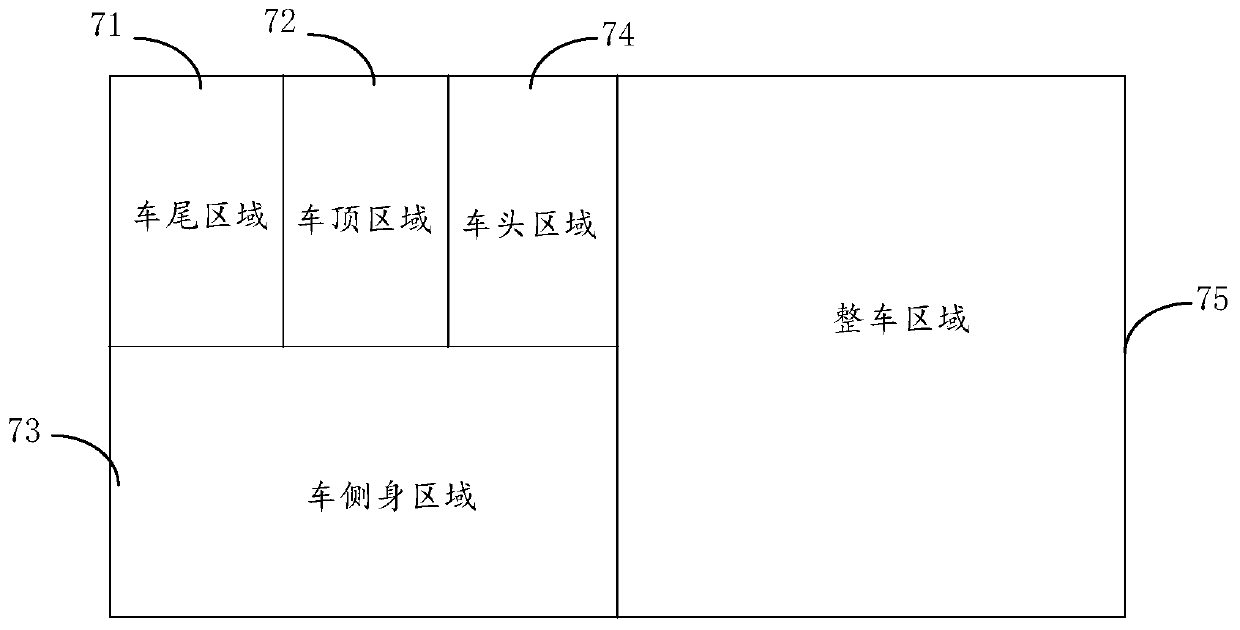

Vehicle type identification method and device

PendingCN110689481AImprove species recognition rateReduce calculation stepsImage analysisGeometric image transformationEngineeringNetwork model

The invention provides a vehicle type identification method and device. The vehicle type identification method includes: obtaining the overall vehicle picture, and segmenting the vehicle to obtain thelocal pictures of the multiple different parts; splicing the local pictures of the different parts of the vehicle into a large picture according to the positions corresponding to the different parts;and sending the spliced large graph into a neural network model to extract features, and classifying vehicles according to the extracted features. According to the vehicle type identification methodand device provided by the invention, the vehicle type identification rate at different shooting angles is improved; compared with the prior art that the global image features and the local image features of the vehicle are respectively extracted through a plurality of convolutional networks and then fused, the calculation steps and the calculation amount are reduced.

Owner:CHENGDU TOPPLUSVISION TECH CO LTD

High-performance image tile graph generation method under big data

PendingCN111915488AAccurate splicingComputationally efficientGeometric image transformationGeographical information databasesMinimum bounding boxAlgorithm

The invention discloses a high-performance image tile graph generation method under big data, and the method comprises the following steps: building a coordinate system according to tile graph levelsfrom the top to the bottom, and obtaining a position mapping table of any image in a spliced big graph; traversing the coordinate range of any image, and solving the rectangular area of any image in the splicing plane and the minimum bounding box of the projected image; splitting the image of the spliced large image into a plurality of subtasks with fixed sizes; solving the number of tile graphs of any level and the optimal partition number; putting the image of the spliced large image into a minimum enclosing rectangular bounding box, and solving tile image indexes of the sub-regions on a coordinate system by adopting a division and metallurgy strategy; according to the overlapping relationship between the subareas and the minimum enclosing rectangular bounding box of any image, solving amatrix of any image under the tile map level; and generating a sub-region graph according to the matrix of any image under the tile graph level, and segmenting the sub-region graph to obtain a tile graph.

Owner:成都圭目机器人有限公司

Method and device for obtaining multi-hop neighbor node

The invention discloses a method and a device for obtaining a multi-hop neighbor node. The method and the device are used for improving the calculation efficiency of inquiring the multi-hop neighbor node in a big graph. The method for obtaining the multi-hop neighbor node comprises the steps of obtaining a zero-hop neighbor of each node in a topological network to obtain a full node zero-hop neighbor set; when a first node serves as an appointed node, calculating a k+1-hop neighbor set of the first node through an iterative calculation process below, wherein the iterative calculation process comprises a step a of obtaining the k-hop neighbor set of the first node and a step b of connecting the k-hop target node in the k-hop neighbor set of the first node and two node pairs with the same initial nodes in the full node zero-hop neighbor set into a node pair, and obtaining the k+1-hop neighbor set of the first node after the connection of the node pair is finished; and when the hop number k+1 of the k+1-hop neighbor set of the first node is equal to kmax, outputting the k+1-hop neighbor set of the first node and a corresponding k+1 hop path.

Owner:HONOR DEVICE CO LTD

Graph division method and device and computer readable storage medium

ActiveCN112445940AImprove efficiencyEasy to handleOther databases indexingSpecial data processing applicationsConcurrent computationAlgorithm

The invention discloses a graph division method and device and a computer readable storage medium. The method comprises the following steps: determining a graph division rule for proportionally distributing graph data to each computing node in advance according to the computing performance of each computing node of the parallel computing system and a preset measurement mechanism; in a graph division process, determining a data reading range of each loading thread according to a graph vertex number and a loading thread number, simultaneously calling a plurality of loading threads to read graphdata to be divided in parallel by taking a vertex as a unit, and transmitting the graph vertex data read by each loading thread to a corresponding division thread. Each division thread determines a sub-graph to which each piece of graph vertex data transmitted into the corresponding thread belongs according to a graph division rule based on the graph data divided at the current moment, and finallydivides each piece of graph vertex data to the corresponding calculation node based on a corresponding relationship between the sub-graph and the calculation node. The large graph can be efficientlyand accurately divided into a series of sub-graphs with the vertex number or the connecting edge number meeting any proportional relation.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

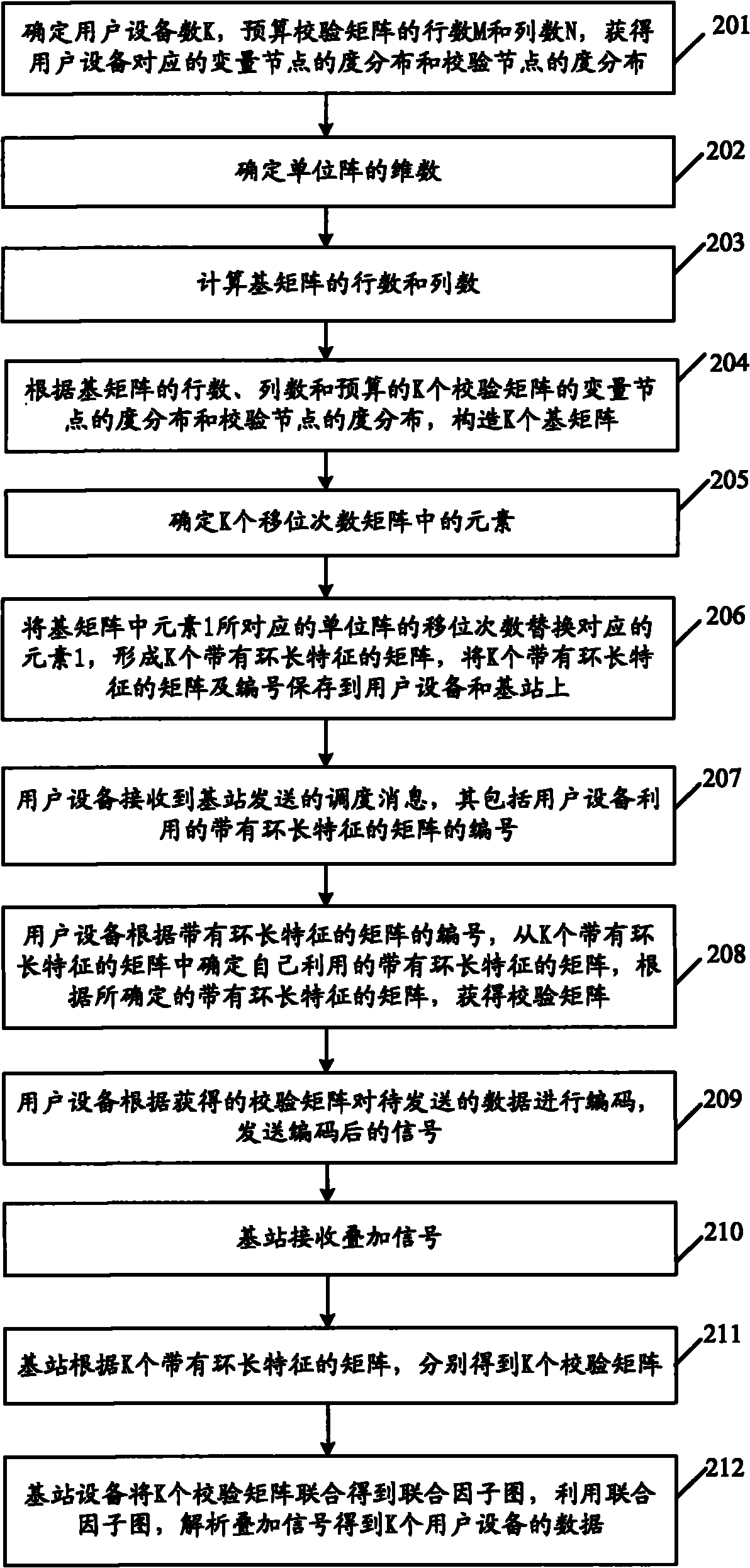

Data transmission method and equipment

ActiveCN101924602AReduce the burden onError preventionError correction/detection using multiple parity bitsBig graphData transmission

The embodiment of the invention provides a data transmission method and equipment. The method comprises the following steps of: constructing K basis matrixes which can be utilized by user equipment sharing the same section of resources; acquiring the shifting frequency of unit matrixes corresponding to 1 in the K basis matrixes; storing matrix information for indicating the shifting frequency of corresponding K basis matrixes and the unit matrixes corresponding to 1 in the K basis matrixes onto multiple user equipment; obtaining check matrixes by the user equipment according to the determinedmatrix information; and coding data to be sent and then sending, wherein the step for constructing K basis matrixes comprises the following procedures of: constructing a first basis matrix on a bipartite graph by utilizing a PEG algorithm; respectively connecting variable nodes corresponding to first k-1 basis matrixes in the bipartite graphs and the variable node in the kth bipartite graph through channel nodes to form a big graph; and constructing a kth basis matrix on the big graph by utilizing the PEG algorithm. The technical scheme of the embodiment of the invention is convenient for acquiring the check matrixes.

Owner:HUAWEI TECH CO LTD +1

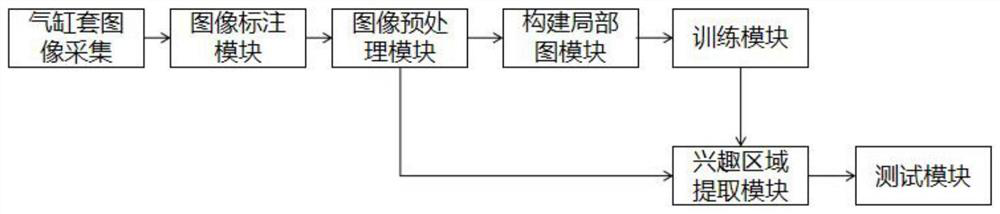

Cylinder sleeve defect mark detection method based on deep learning

PendingCN114549446AReduce search timeHigh precisionImage enhancementImage analysisGraph mappingAlgorithm

The invention provides a cylinder sleeve defect mark detection method based on deep learning, and the method comprises the following steps: collecting a cylinder sleeve image to construct an original data set, carrying out the preprocessing and marking of the images in the original data set, and obtaining a local defect graph of a training set; carrying out modeling by using a Mask R-CNN algorithm based on a Swin converter to obtain a network model; detecting the images of the test set through the obtained network model; extracting a region of interest from a detection result through a mask mechanism to enhance a detection effect; evaluating the detection performance of the network model; and performing defect mark detection on the acquired cylinder sleeve image through the obtained network model. According to the invention, through image preprocessing, cylinder liner noise influence reduction, local graph construction of an original graph, obtaining of a new batch of training data, through a method of mapping a large graph with a small graph, obtaining of a detection result of the original graph, through a mask mechanism, filtering of a noise area, and improvement of small target detection precision.

Owner:NANJING INST OF TECH

Batch processing drawing method for 3D simulation scene image based on edge calculation

InactiveCN110992462ASolve different problemsMeet the requirements for merging into a batchGeometric image transformation3D-image renderingPattern recognitionBatch processing

The invention relates to the technical field of image processing, in particular to a batch processing drawing method for a 3D simulation scene image based on edge computing, which comprises the following steps of: firstly, loading a picture, then judging whether the picture is a single picture or not, and if the picture is the single picture, directly entering the next step, if the pictures are aplurality of pictures, splicing the pictures into a large picture through a puzzle algorithm, updating vertex coordinates and texture coordinates, storing the vertex coordinates and the texture coordinates into a CPU memory, uploading the vertex coordinates and the texture coordinates to a GPU through the CPU, executing Draw Call once, completing drawing of all pit positions, and finally displaying the pit positions on a screen. According to the method for combining spliced images to draw objects made of different materials, texture pictures to be displayed in all pit positions are spliced into a large texture picture, and each pit position uses a sub-region of the large texture picture, so that each pit position has the same texture data, and the requirement of combining the pit positionsinto a patch is met.

Owner:CHONGQING UNIV OF ARTS & SCI

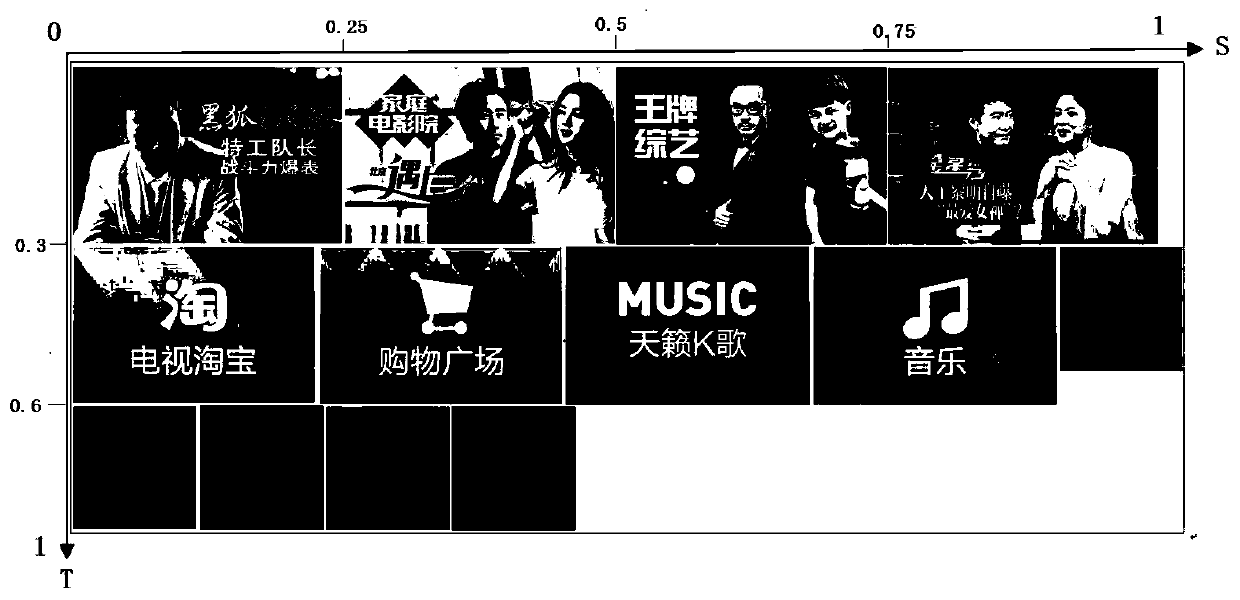

Hierarchical compressed image matching method and system based on orthogonal attention mechanism

ActiveCN111783879AAccurate acquisitionExtract meticulouslyCharacter and pattern recognitionNeural architecturesAlgorithmGraph match

The invention discloses a hierarchical compressed graph matching method and system based on an orthogonal attention mechanism. The method comprises the following steps: acquiring a to-be-matched big picture data pair, and carrying out preprocessing on big picture data; training a big picture matching model based on an orthogonal attention mechanism according to a historical graph library; and inputting the preprocessed big picture data pair into the big picture matching model to obtain a matching result, and outputting the matching result. According to the invention, the picture attention network is used to carry out dimension reduction training on pictures in the process of acquiring picture vectors, point vectors are updated so as to allow the point vectors to better express the topological structures and node information of the pictures; the point vectors having undergone dimension reduction and an adjacent matrix are input into an orthogonal attention network for picture scale compression; through layer-by-layer compression, the extraction of picture information is finer, a more accurate picture vector is finally obtained; and then picture matching is performed through the compressed accurate picture vector, so the accuracy of a picture matching result is improved, a calculation amount is small, and calculation is quicker and more accurate.

Owner:NAT UNIV OF DEFENSE TECH

A Directed Graph Reachability Linked List Generation and Query Method in Parallel Environment

ActiveCN103399902BReduce sizeReduce computing loadSpecial data processing applicationsData compressionSkip list

A directed graph reachability linked list generation and query method in a parallel environment, belonging to the field of large graph data processing. Distribute a directed graph to each processor, and each processor stores the nodes in the graph and the child nodes corresponding to the nodes; compresses the graph data divided into each processor; calculates the reachability of the backbone nodes on the backbone graph Encoding; constructing a chained index; establishing a skip table on the chained index; performing data communication between processors: each processor sends skip table information to other processors; each processor updates its own skip table information; establishes a full graph accessibility index. The present invention uses graph reachability compression technology in a parallel environment to greatly reduce graph data size and system computing load, allowing the system to process larger-scale graph data. The invention improves the speed of reading data from the disk, indirectly speeds up the query speed, ensures the accuracy of the query results, and greatly reduces the network communication cost and query time of the parallel computing system during query.

Owner:NORTHEASTERN UNIV LIAONING

Data processing method and device, equipment and storage medium

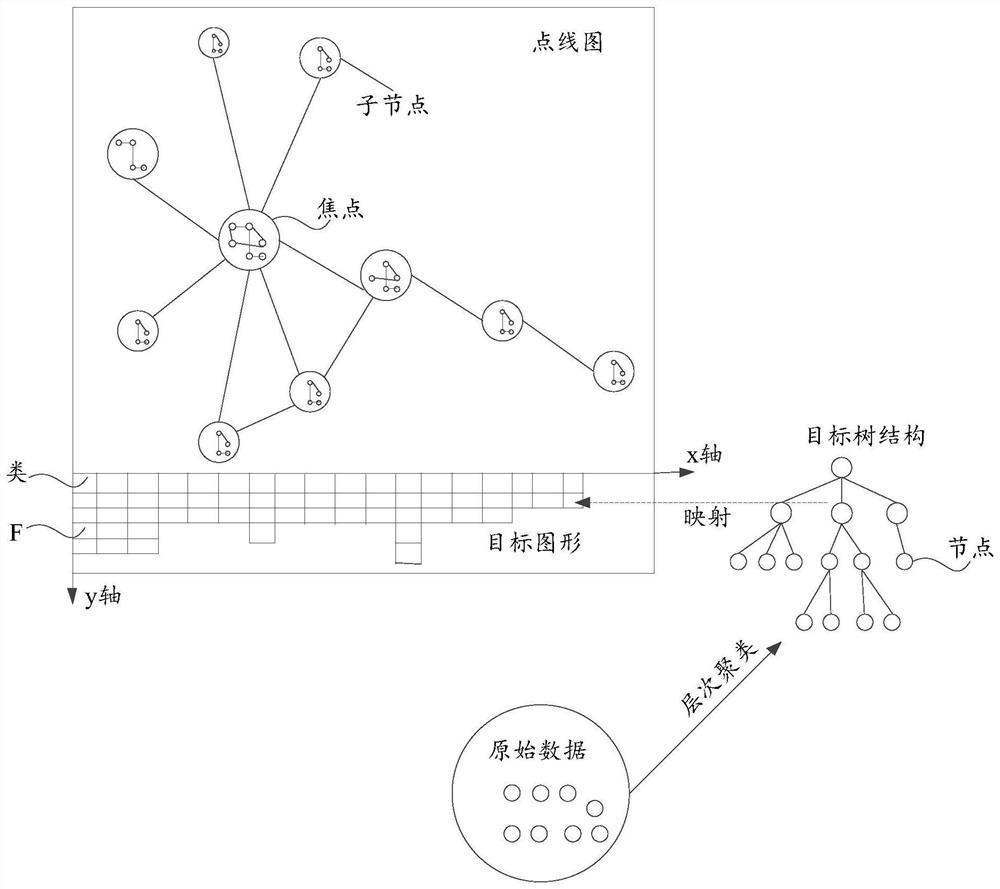

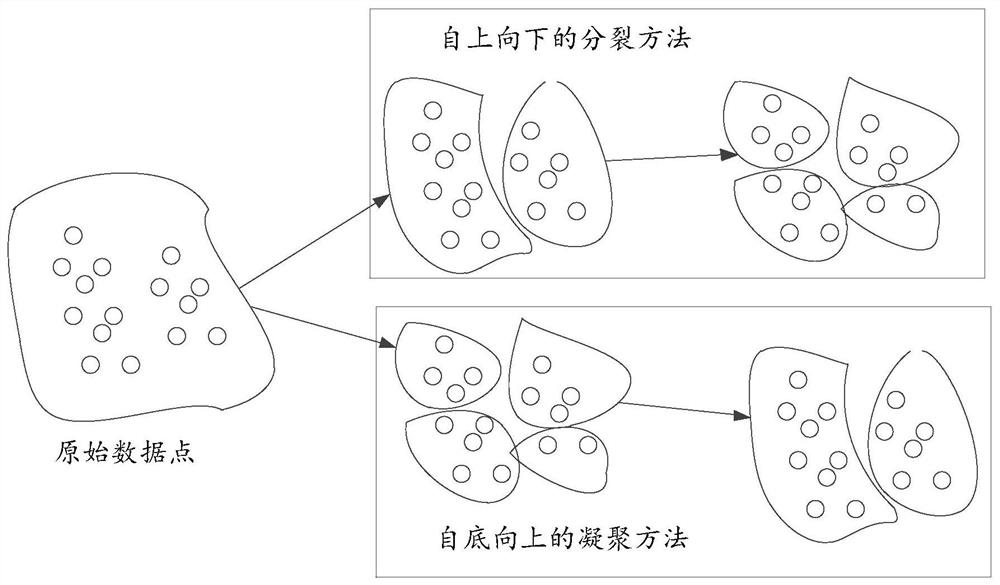

PendingCN113867850AImprove readabilityReduce complexityVisual data miningStructured data browsingGraphicsData graph

The embodiment of the invention provides a data processing method and device, equipment and a storage medium, and aims to solve the problem of relatively high complexity of a graph layout algorithm in the prior art. The method comprises the following steps: displaying a target graph on a display interface, wherein the target graph is obtained by mapping a target tree structure; determining a focus of the target graph, and displaying data information of the focus; and displaying a detail graph in large-scale data through a point-line graph, and simplifying a large graph. A visual display form convenient for exploring and mining hidden information in a large graph is provided; and the analysis efficiency of the visual data graph is improved, and the auxiliary ability of the visual data graph to decision-making problems is improved.

Owner:ALIBABA GRP HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com