Defect detection method applied to motor coil based on cascade expansion FCN network

A defect detection and network application technology, applied in neural learning methods, biological neural network models, instruments, etc., can solve problems such as easy overkill, reduce labor costs, improve detection efficiency, and have broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

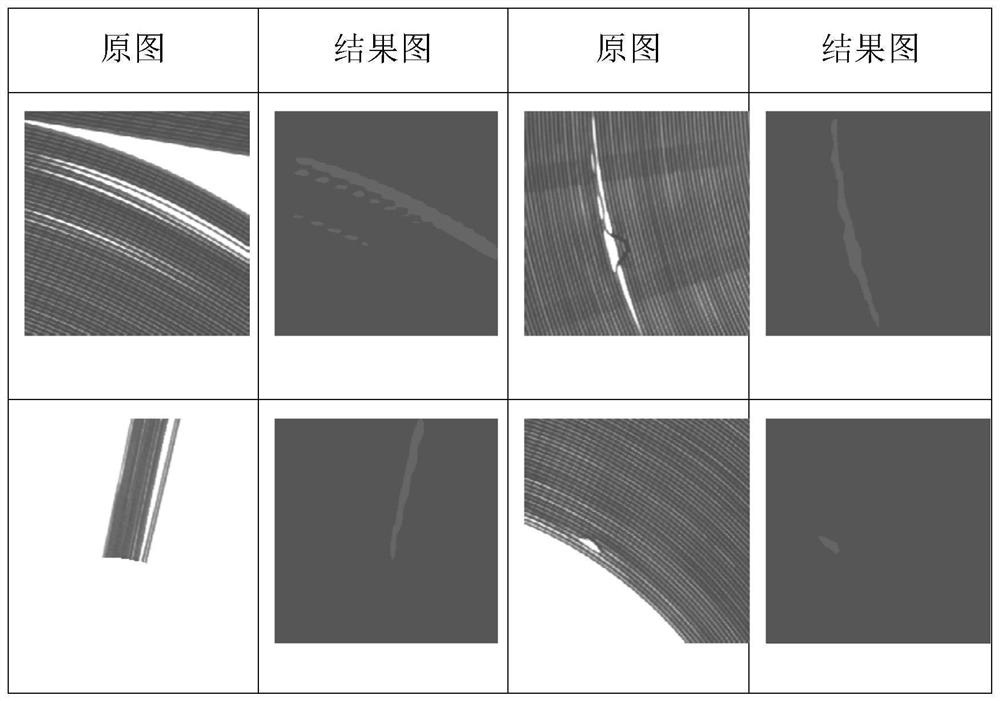

[0029] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

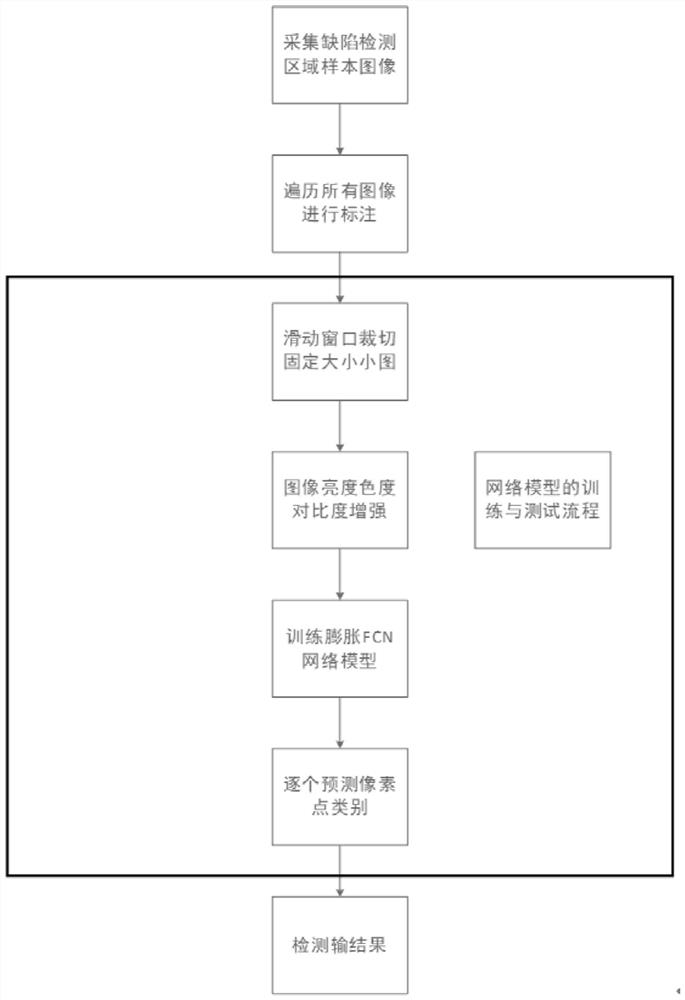

[0030] Such as figure 1 A defect detection method based on the cascaded expanded FCN network applied to the motor coil is shown, including the following detection steps:

[0031] First, collect sample images of the target area that need to be detected for defects; collect at least 15 large images, and generally the image pixels are relatively large, taking 2000*2000 as an example; the sizes in this article are all pixel sizes;

[0032] Secondly, traverse all the sample images and mark the defect position of each image; when the defect is marked, it needs to overflow 2 pixels at the defect position, the pixel at the defect p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com