System and method for intelligently detecting duct piece splicing quality based on image identification

A technology for segment assembly and intelligent detection, applied in measuring devices, optical devices, instruments, etc., can solve the problems of inability to realize real-time monitoring of the safety status of subway shield segments, uneven longitudinal settlement, and poor real-time detection, etc. Simplify the wrong stage detection process, achieve the effect of detection accuracy and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with specific embodiments.

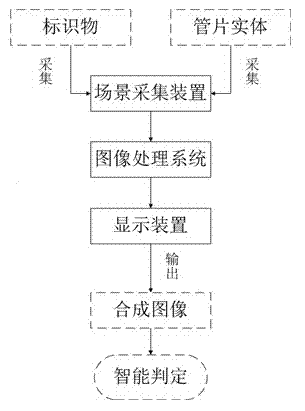

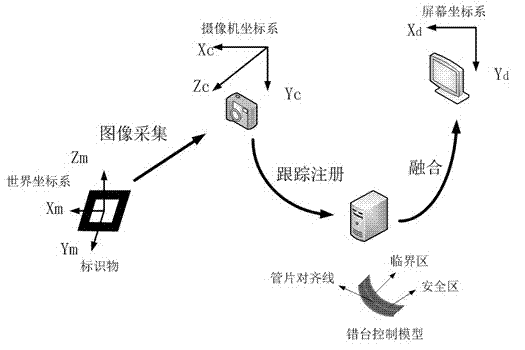

[0034] Such as figure 1 As shown, the basic units required for the implementation of the present invention include markers, image acquisition devices, image processing systems, and display devices, and each unit operates around the segment entity and the segment error control model.

[0035] The marker is a paper pattern printed in black and white, and the periphery of the paper pattern is surrounded by a black box. The role of the marker is to assist in image recognition. When in use, the marker is placed on the shield segment, and the best position is the adjacent segment contact.

[0036] The image acquisition device is composed of an ordinary USB camera, which is used to collect image information including image markers and segment entities, and transmit the collected information to the image processing system. During use, the shooting angle and distance of the USB ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com