Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Back-illuminated sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

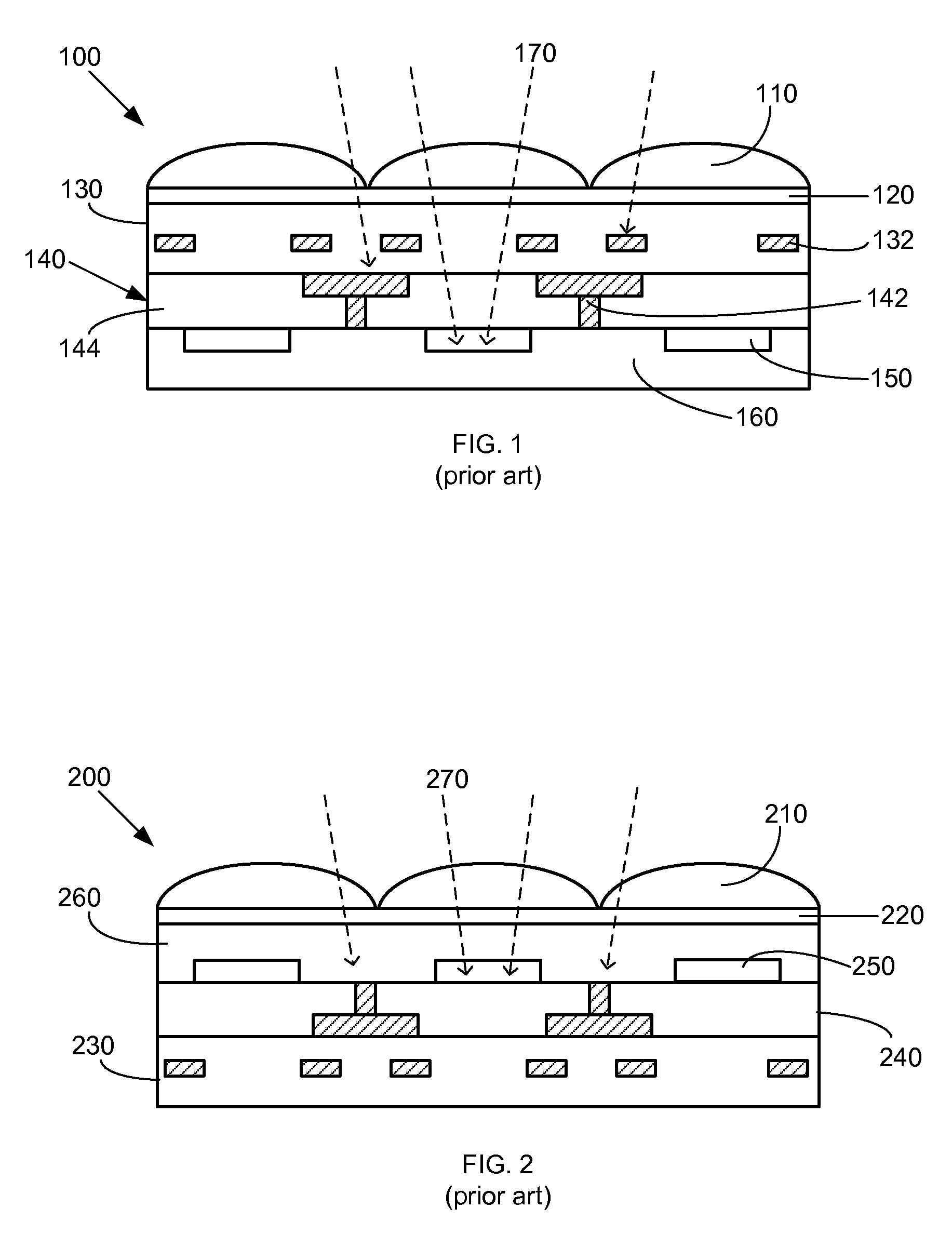

A back-illuminated sensor, also known as backside illumination (BSI or BI) sensor, is a type of digital image sensor that uses a novel arrangement of the imaging elements to increase the amount of light captured and thereby improve low-light performance.

Back illuminated sensor with low crosstalk

ActiveUS20100148289A1Improved crosstalk performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

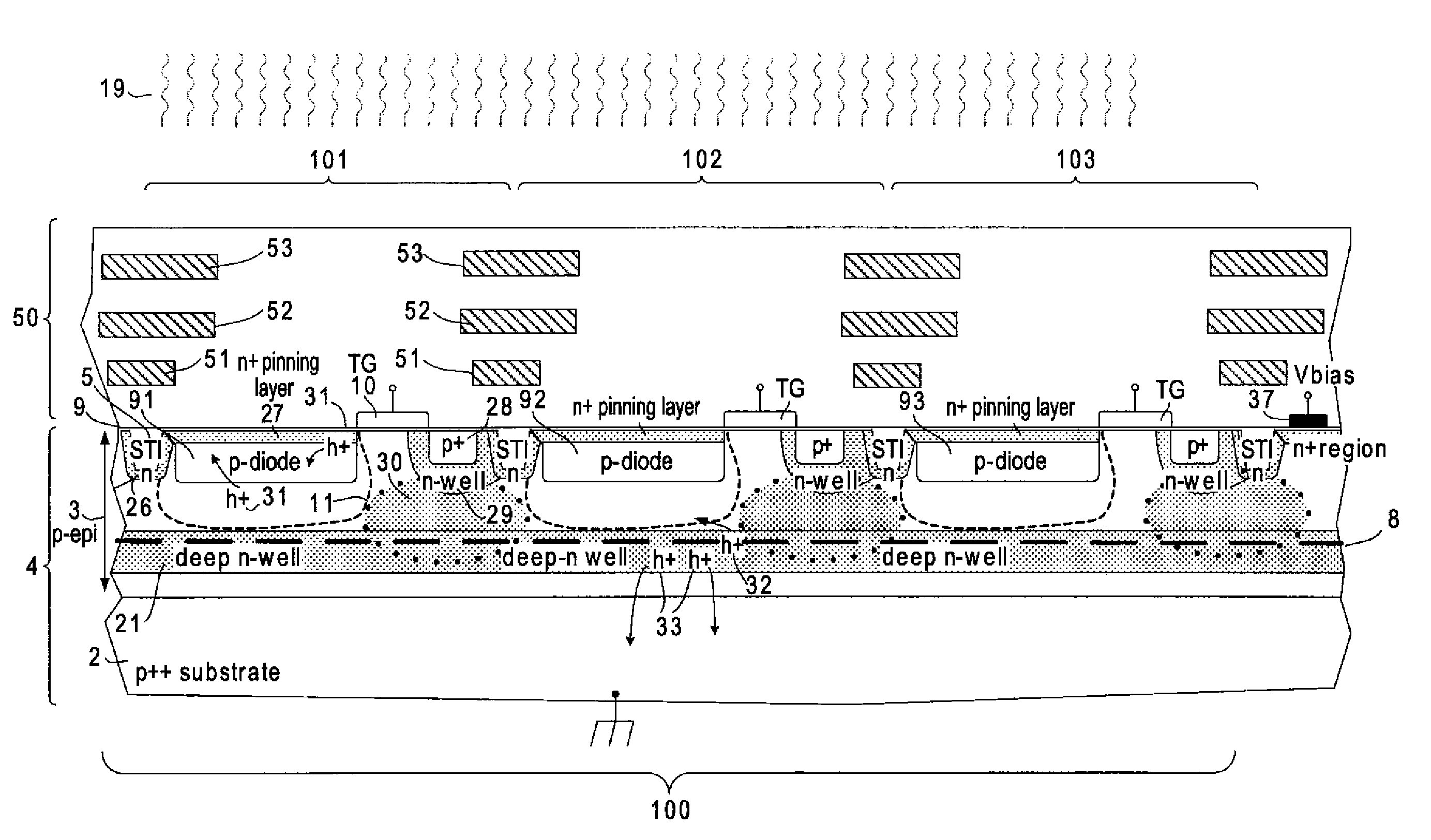

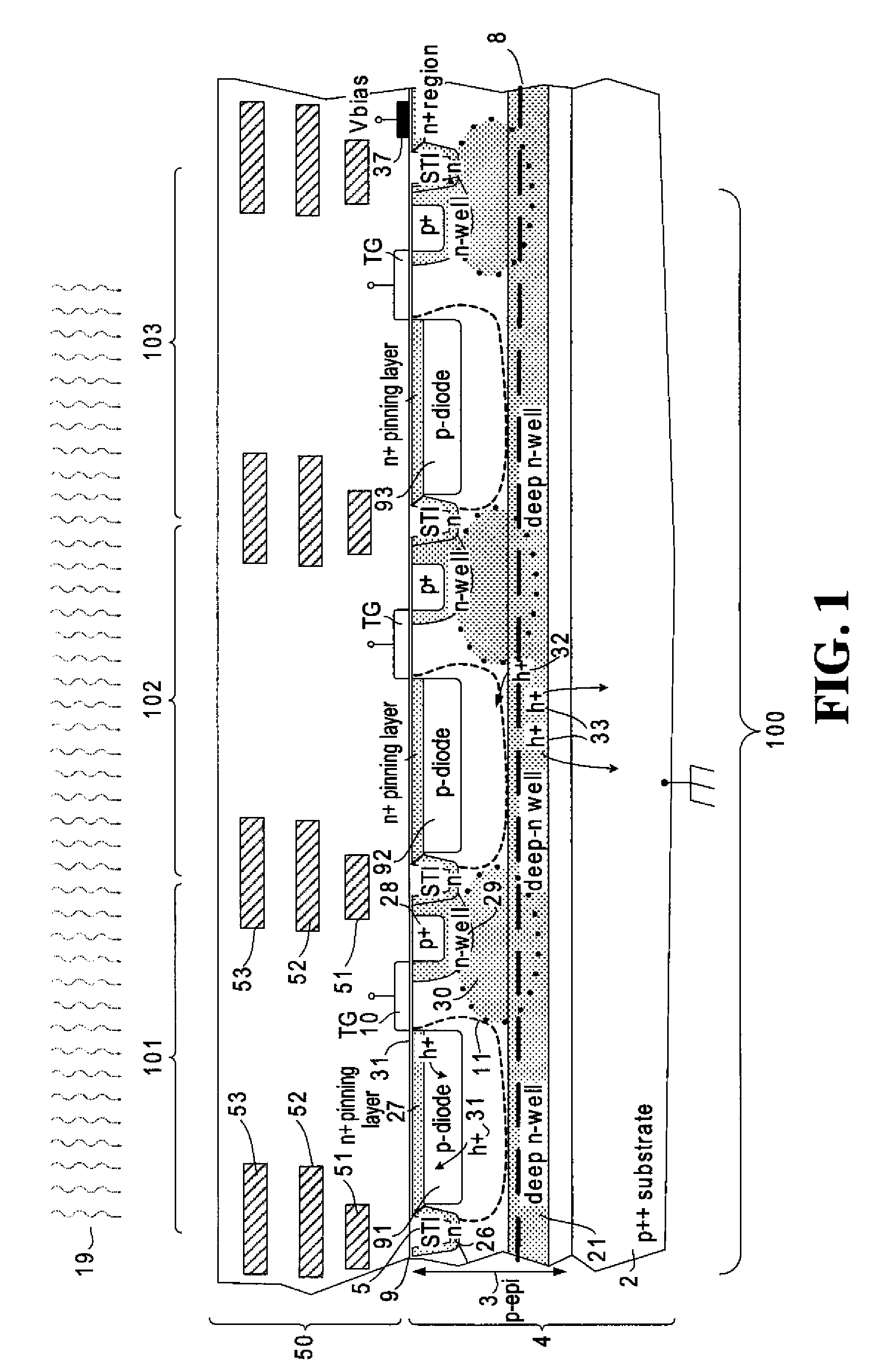

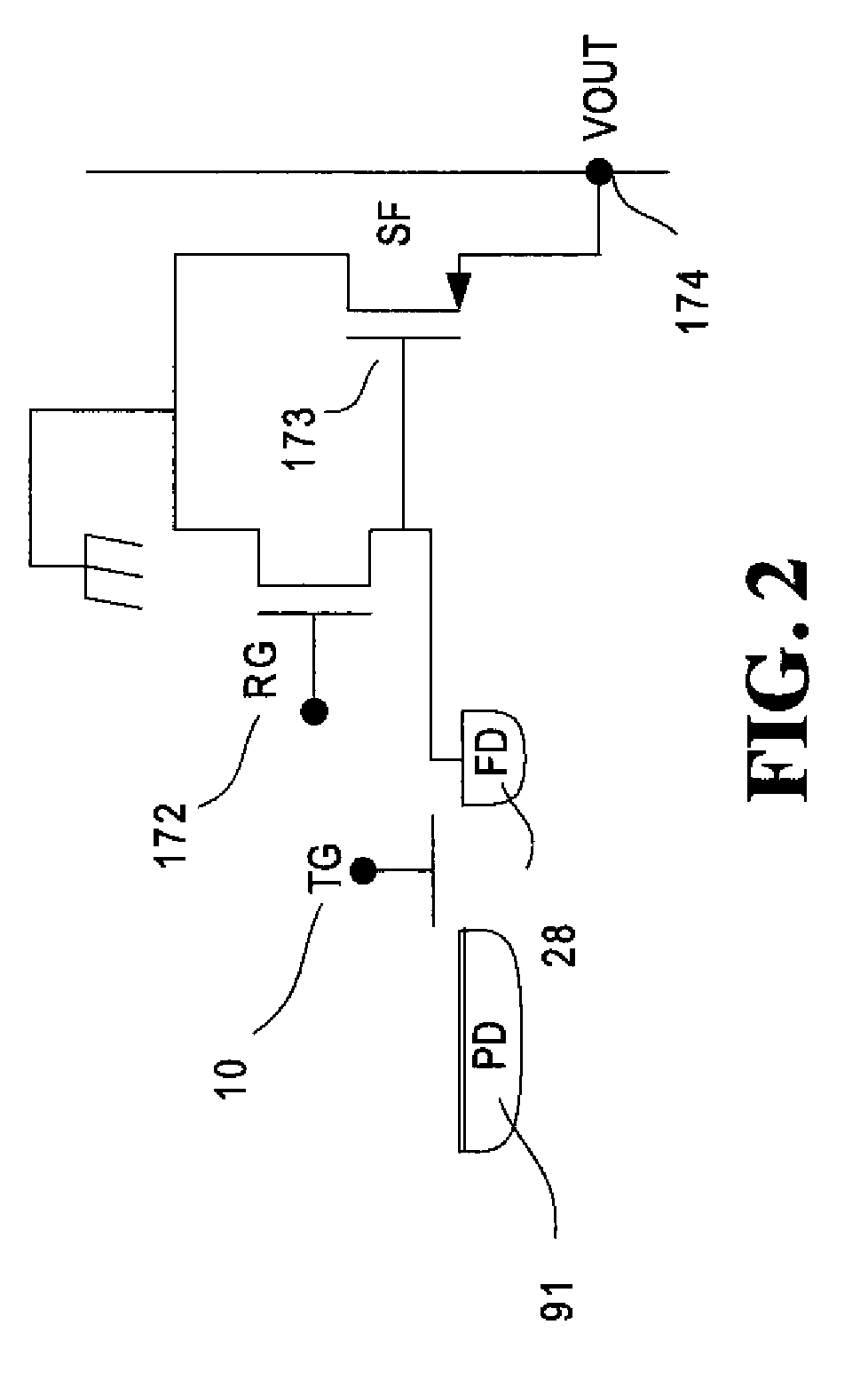

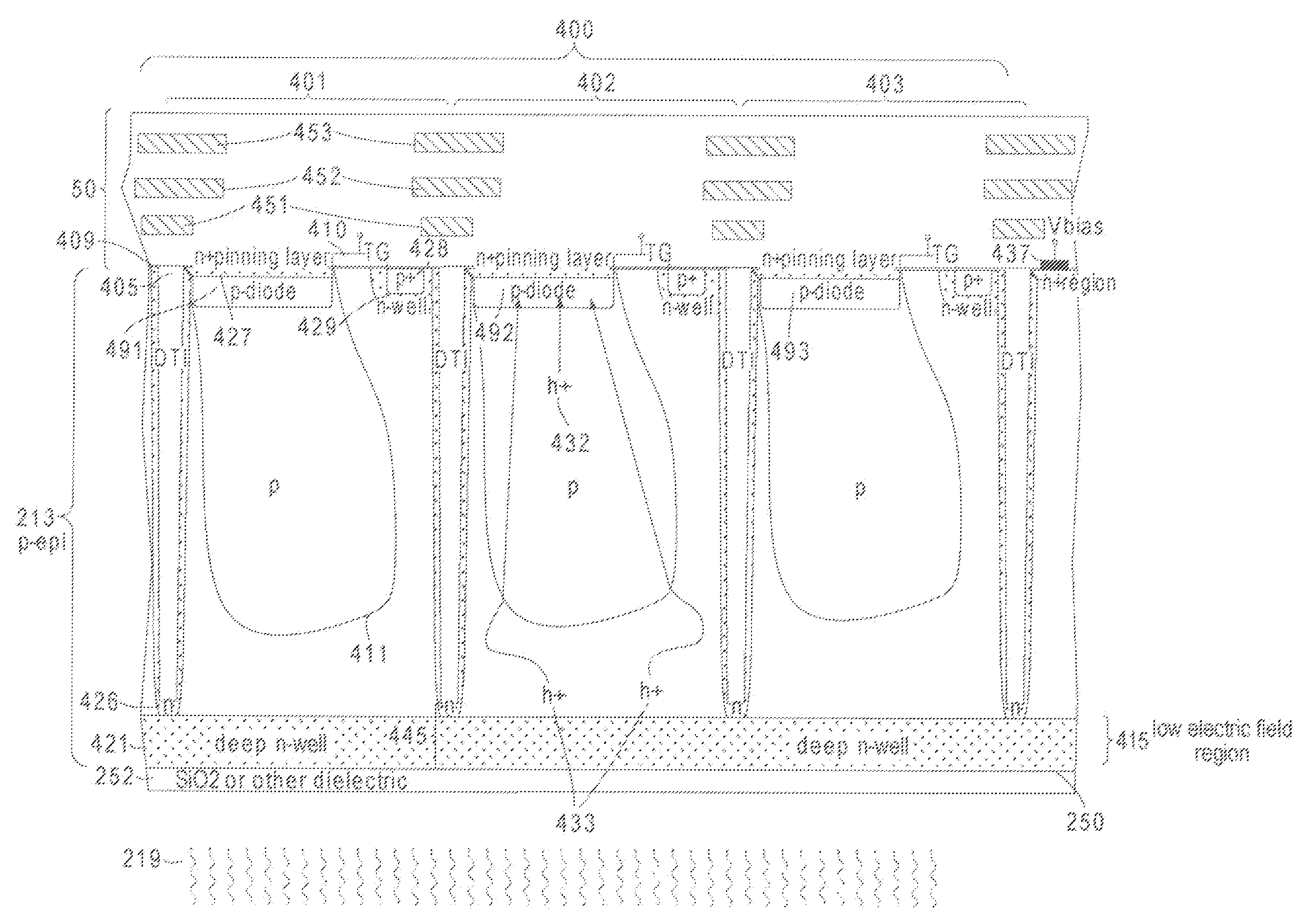

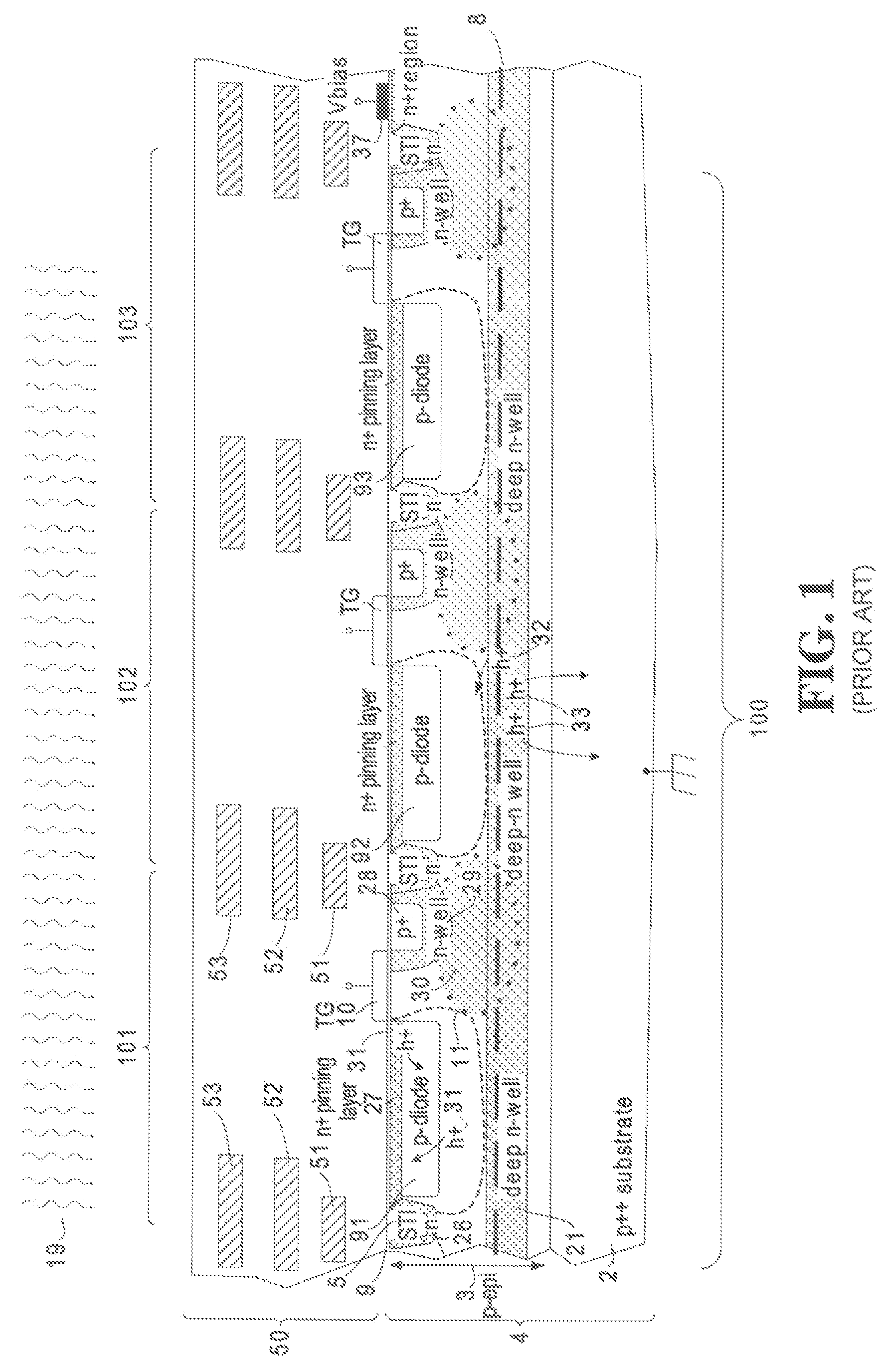

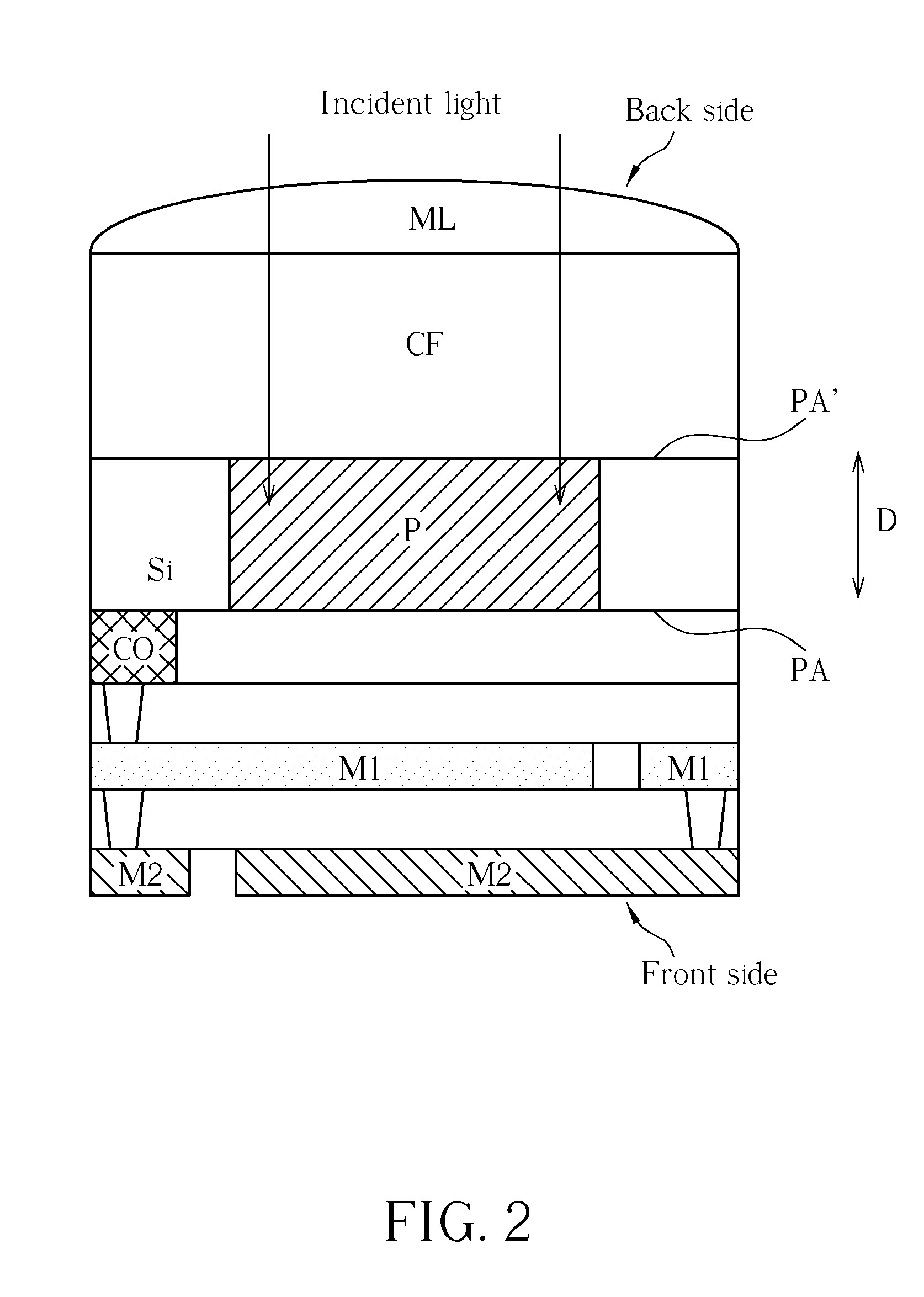

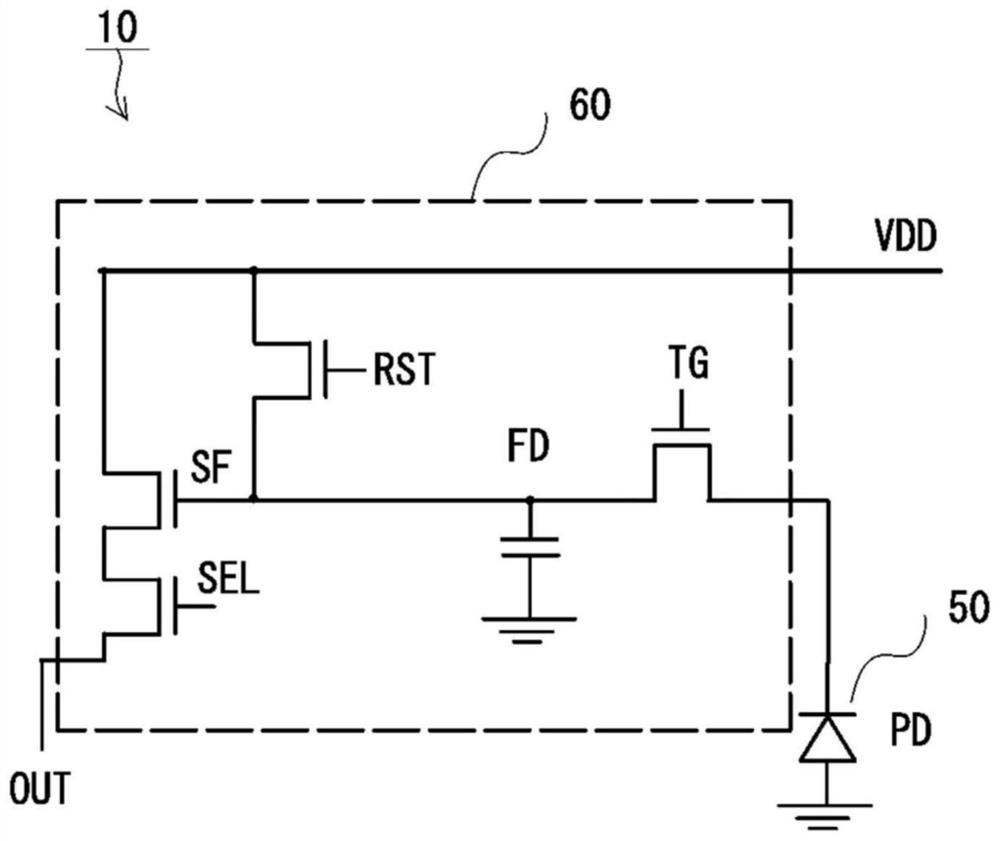

A back-illuminated image sensor includes a sensor layer having a frontside and a backside opposite the frontside. An insulating layer is situated adjacent the backside and a circuit layer is adjacent the frontside. A plurality of photodetectors of a first type conductivity convert light incident on the backside into photo-generated charges. The photodetectors are disposed in the sensor layer adjacent the frontside. A region of a second type conductivity is formed in at least a portion of the sensor layer adjacent the frontside and is connected to a voltage terminal for biasing the second type conductivity region at a predetermined voltage. A well of the second type conductivity is formed in the sensor layer adjacent the backside. Trench isolations in the sensor layer start at the frontside and extend beyond the depletion region of the photodiodes.

Owner:OMNIVISION TECH INC

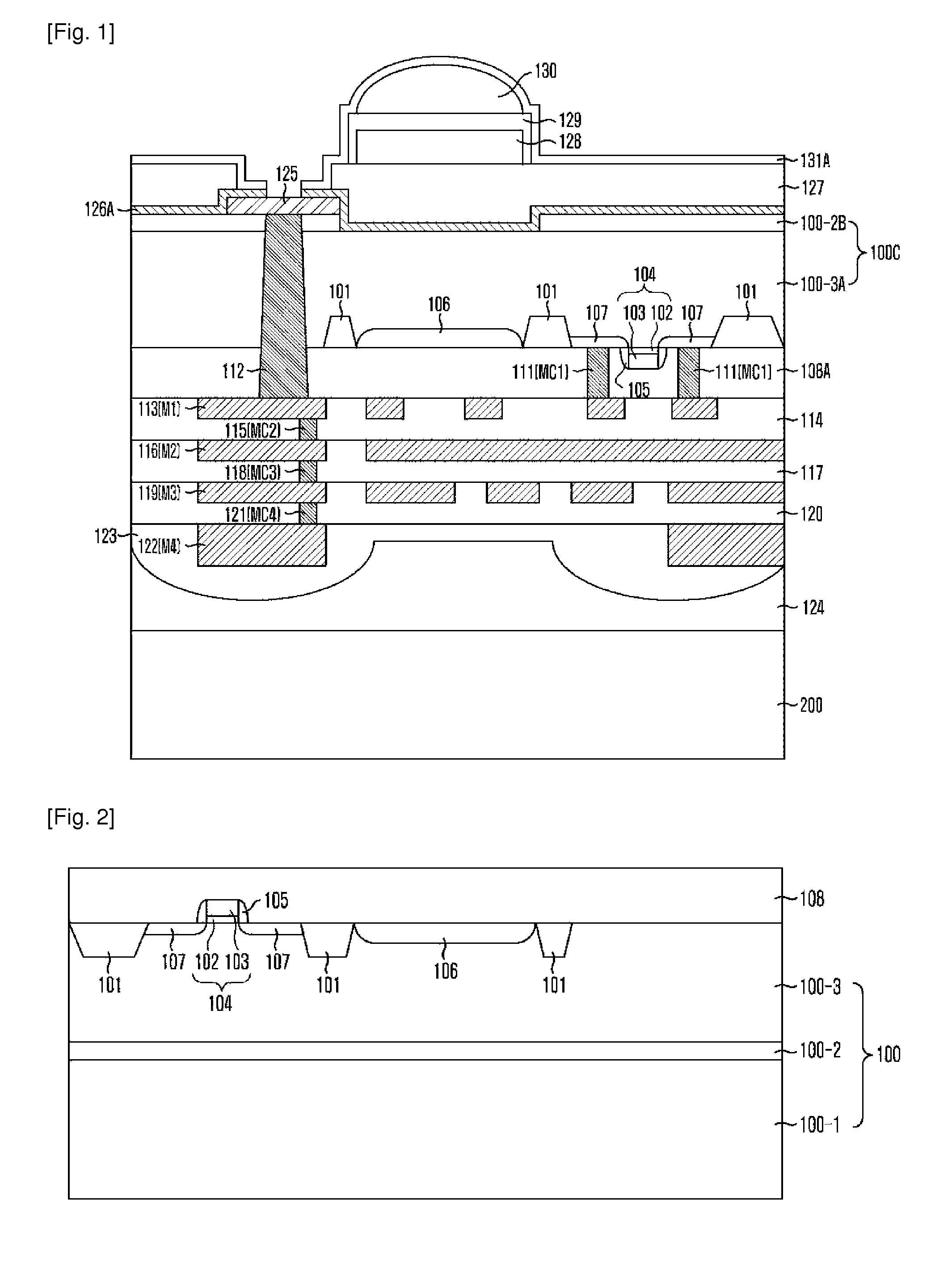

Backside illuminated sensor and manufacturing method thereof

ActiveUS20110186951A1Improve light receiving efficiencyReduce light lossSemiconductor/solid-state device detailsSolid-state devicesInsulation layerInterconnection

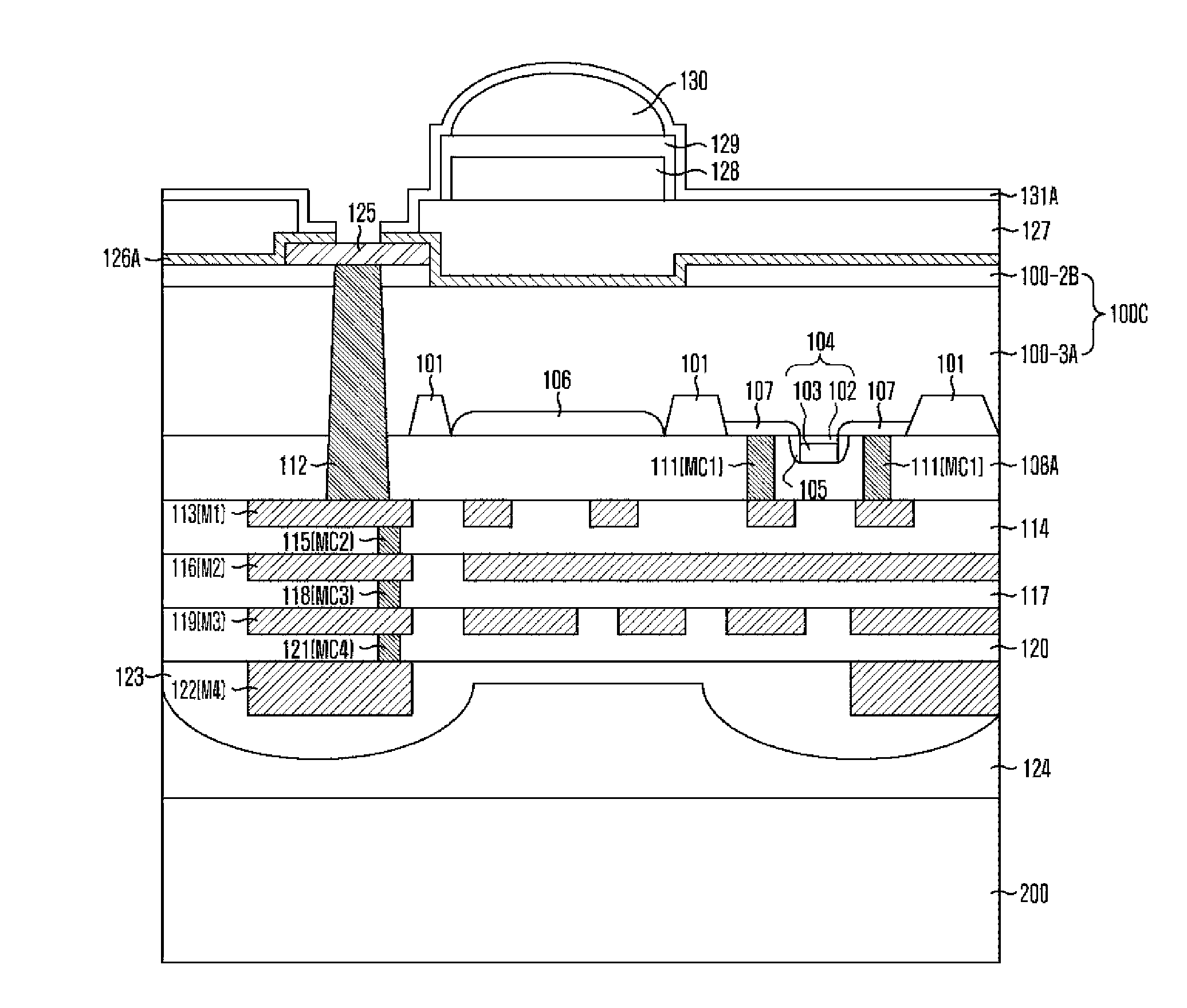

Disclosed is a backside illuminated image sensor including a light receiving element formed in a first substrate, an interlayer insulation layer formed on the first substrate including the light receiving element, a via hole formed through the interlayer insulation layer and the first substrate while being spaced apart from the light receiving element, a spacer formed on an inner sidewall of the via hole, an alignment key to fill the via hole, interconnection layers formed on the interlayer insulation layer in a multilayer structure in which a backside of a lowermost layer of the interconnection layers is connected to the alignment key, a passivation layer covering the interconnection layers, a pad locally formed on a backside of the first substrate and connected to a backside of the alignment key, and a color filter and a microlens formed on the backside of the first substrate corresponding to the light receiving element.

Owner:SK HYNIX INC

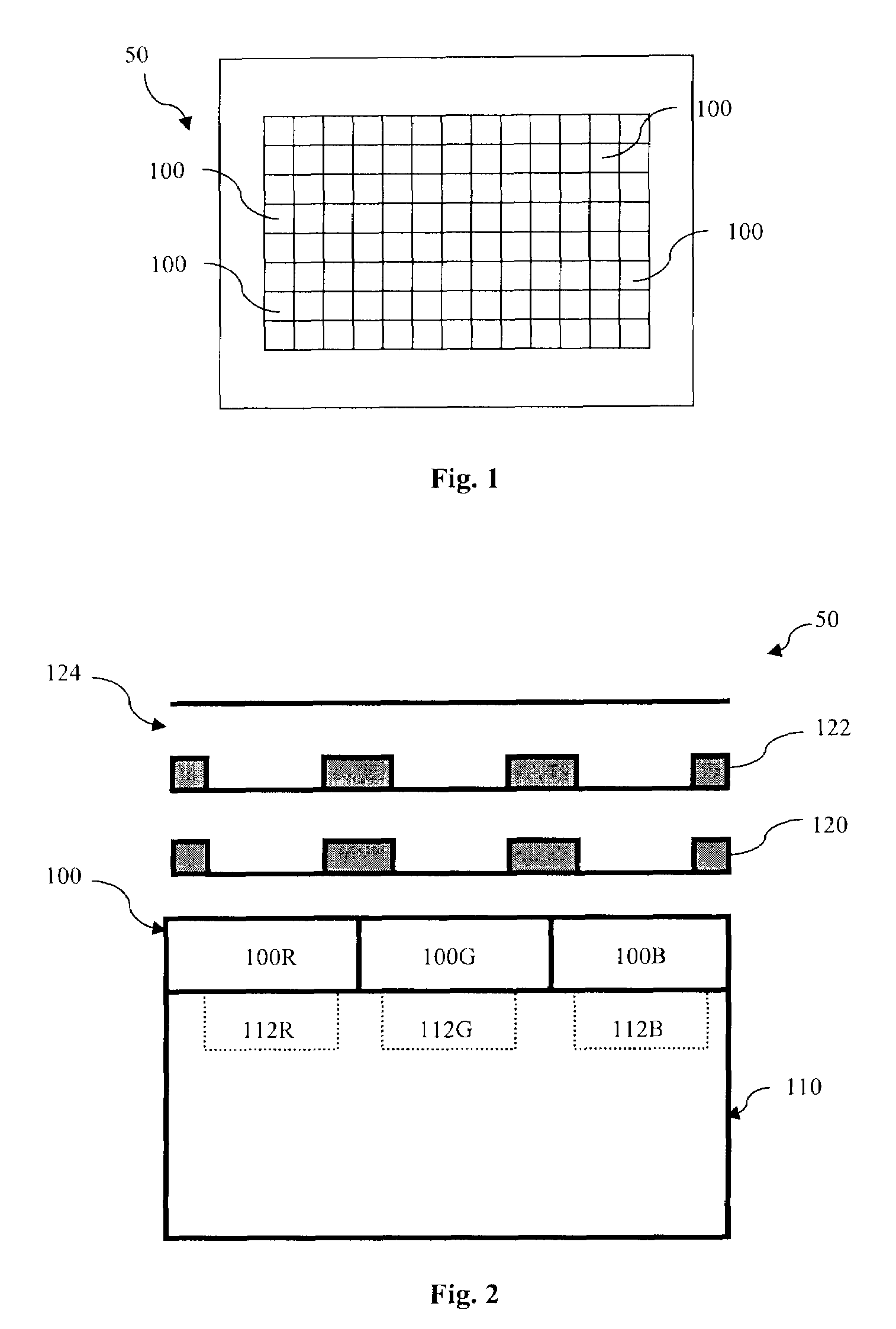

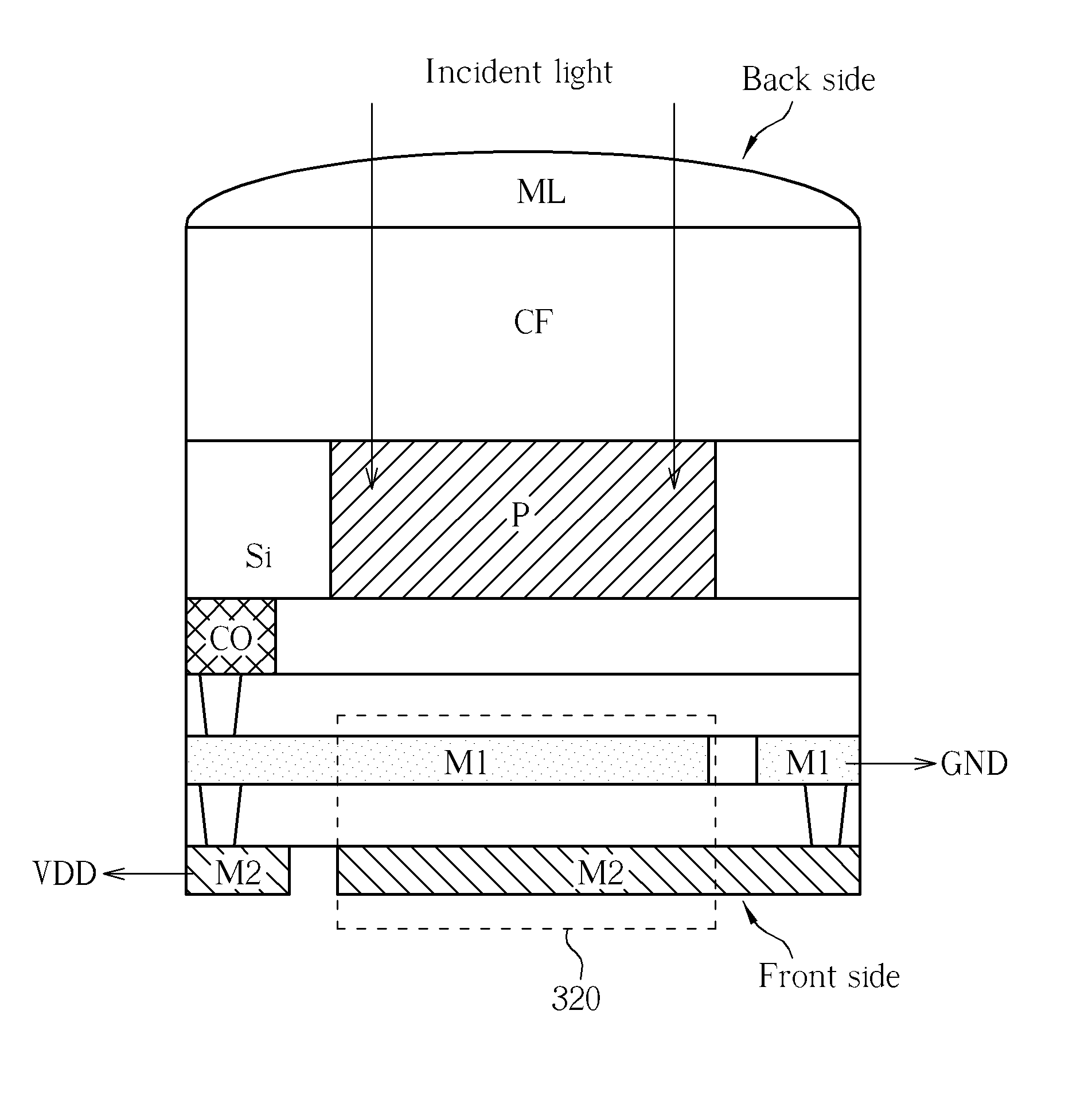

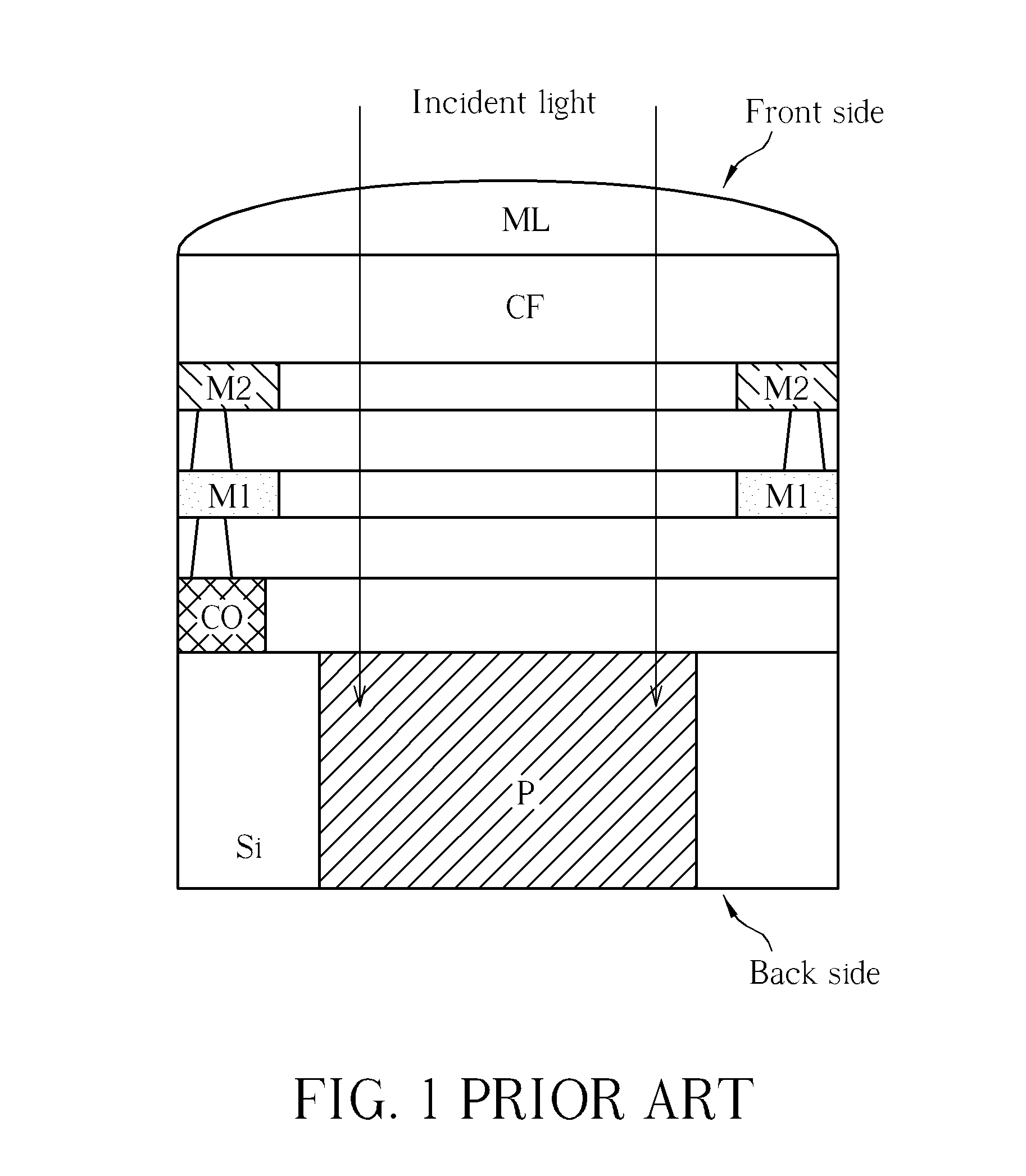

Image sensor element for backside-illuminated sensor

ActiveUS7999342B2Enhance the imageSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

Provided is a backside-illuminated sensor including a semiconductor substrate having a front surface and a back surface. A plurality of image sensor elements are formed on the front surface of the semiconductor substrate. At least one of the image sensor elements includes a transfer transistor and a photodetector. The gate of the transfer transistor includes an optically reflective layer. The gate of the transfer transistor, including the optically reflective layer, overlies the photodetector. In one embodiment, the gate overlies the photodetector by at least 5%.

Owner:TAIWAN SEMICON MFG CO LTD

Back illuminated sensor with low crosstalk

ActiveUS7838956B2Improved crosstalk performanceSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

A back-illuminated image sensor includes a sensor layer having a frontside and a backside opposite the frontside. An insulating layer is situated adjacent the backside and a circuit layer is adjacent the frontside. A plurality of photodetectors of a first type conductivity convert light incident on the backside into photo-generated charges. The photodetectors are disposed in the sensor layer adjacent the frontside. A region of a second type conductivity is formed in at least a portion of the sensor layer adjacent the frontside and is connected to a voltage terminal for biasing the second type conductivity region at a predetermined voltage. A well of the second type conductivity is formed in the sensor layer adjacent the backside. Trench isolations in the sensor layer start at the frontside and extend beyond the depletion region of the photodiodes.

Owner:OMNIVISION TECH INC

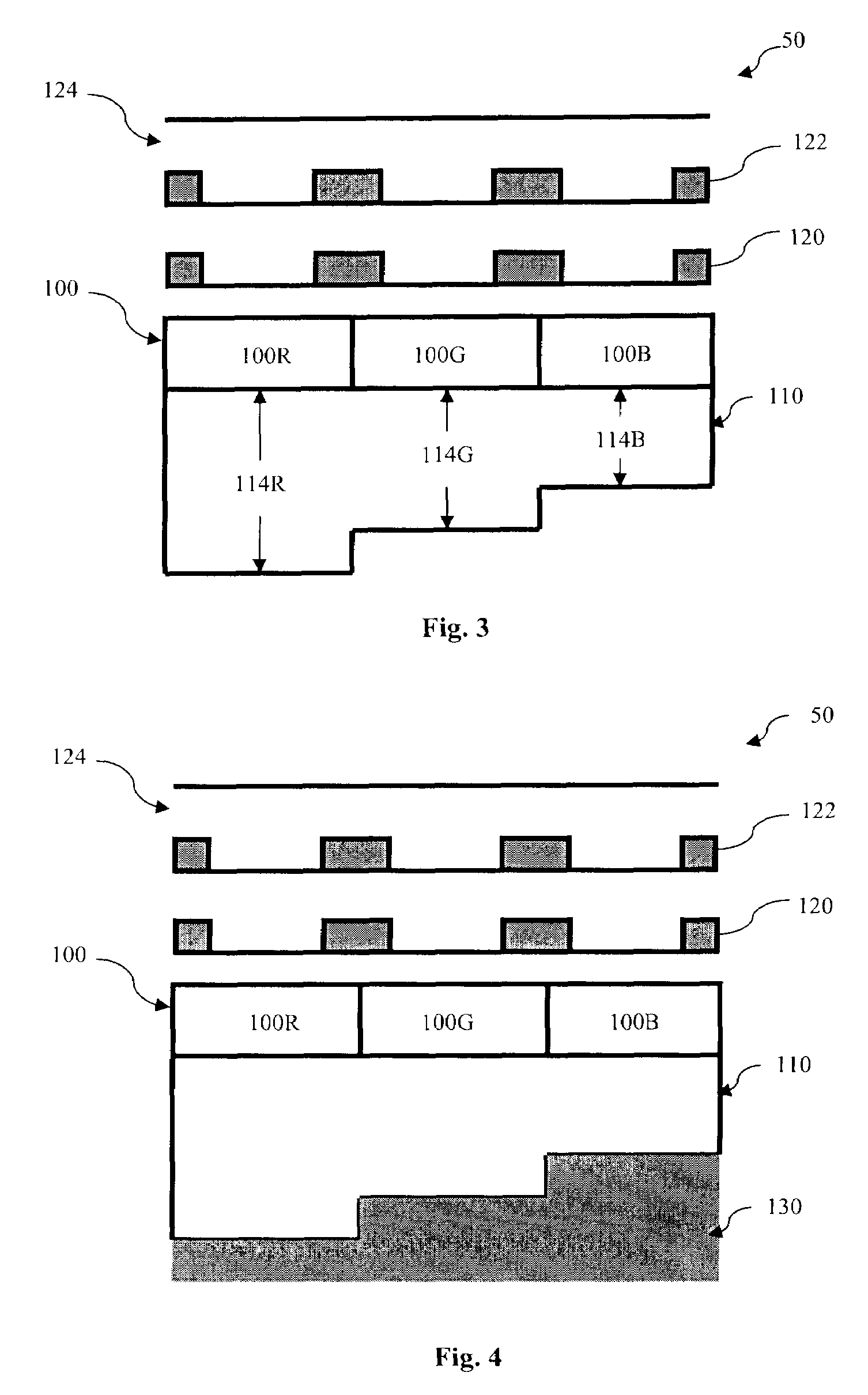

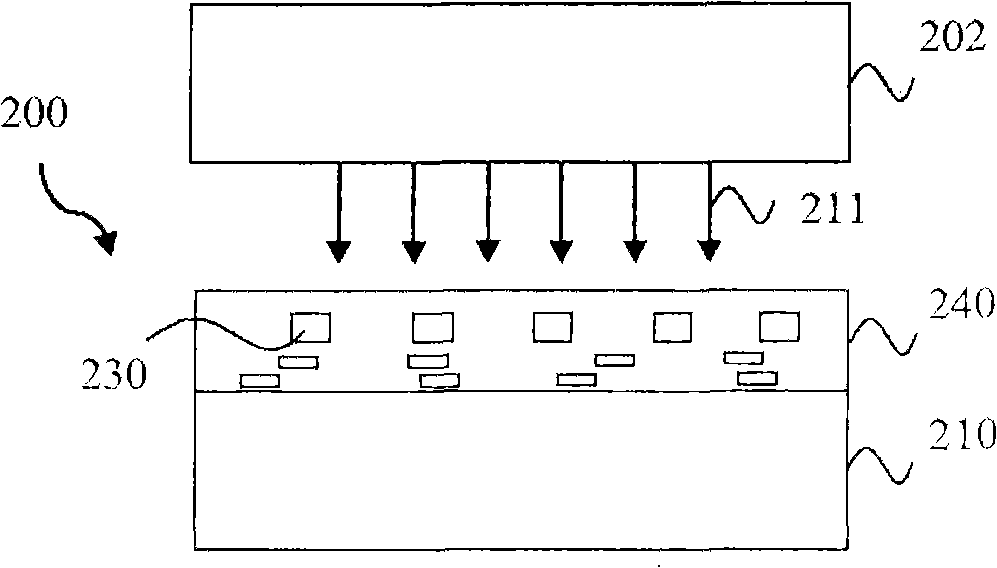

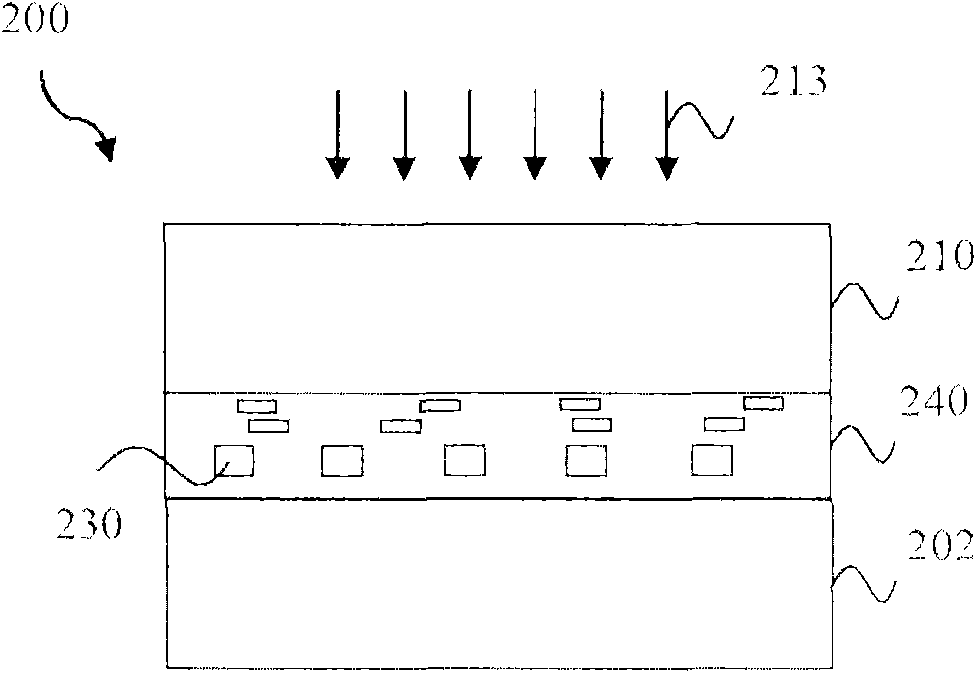

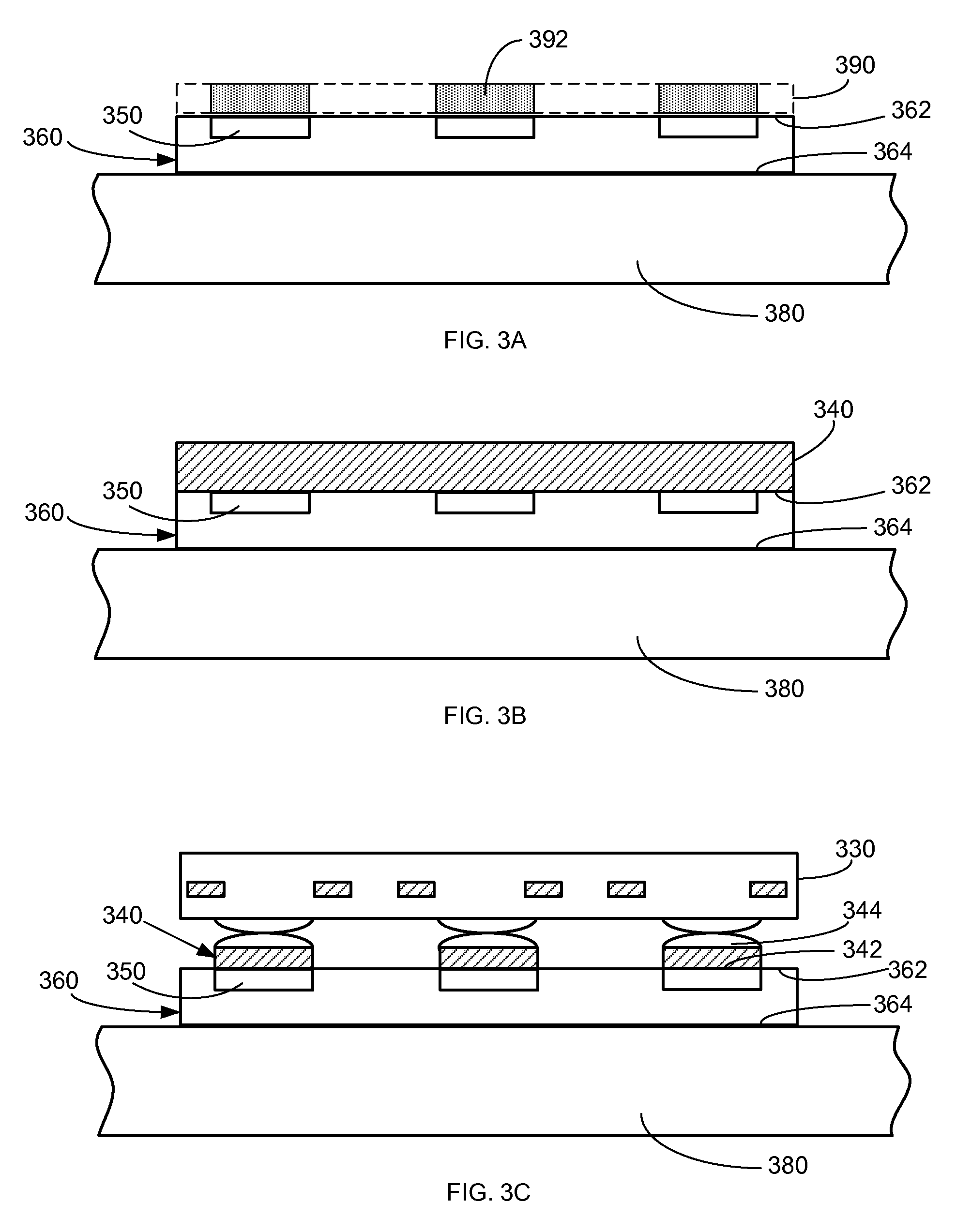

Method of making wafer structure for backside illuminated color image sensor

InactiveUS20070262364A1Solid-state devicesSemiconductor/solid-state device manufacturingColor imageEngineering

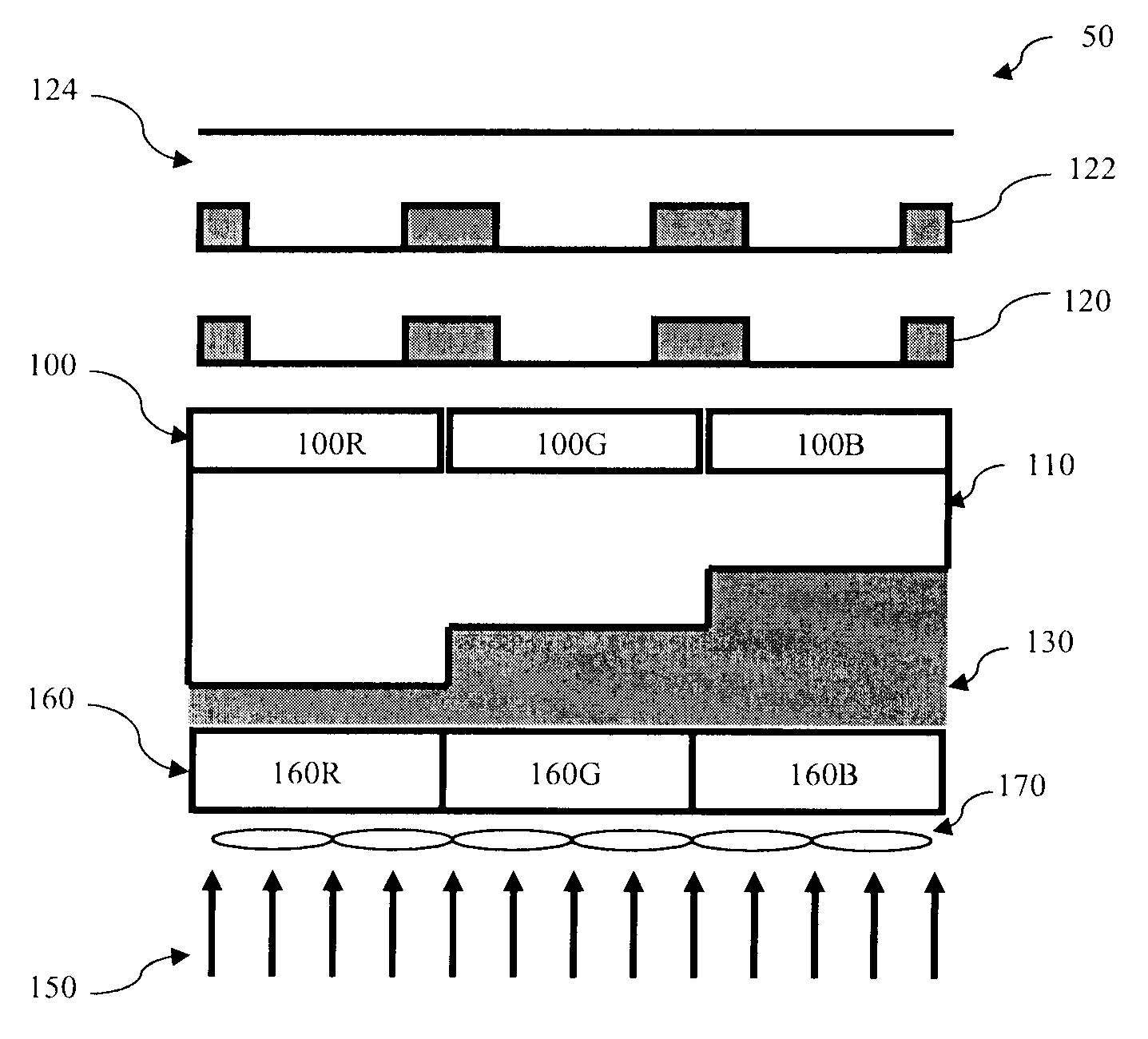

A backside illuminated sensor includes a semiconductor substrate having a front surface and a back surface, and a plurality of pixels formed on the front surface of the semiconductor substrate. The sensor further includes a plurality of absorption depths formed within the back surface of the semiconductor substrate. Each of the plurality of absorption depths is arranged according to each of the plurality of pixels. A method for forming a backside illuminated includes providing a semiconductor substrate having a front surface and a back surface and forming a first, second, and third pixel on the front surface of the semiconductor substrate. The method further includes forming a first, second, and third thickness within the back surface of the semiconductor substrate, wherein the first, second, and third thickness lies beneath the first, second, and third pixel, respectively.

Owner:TAIWAN SEMICON MFG CO LTD

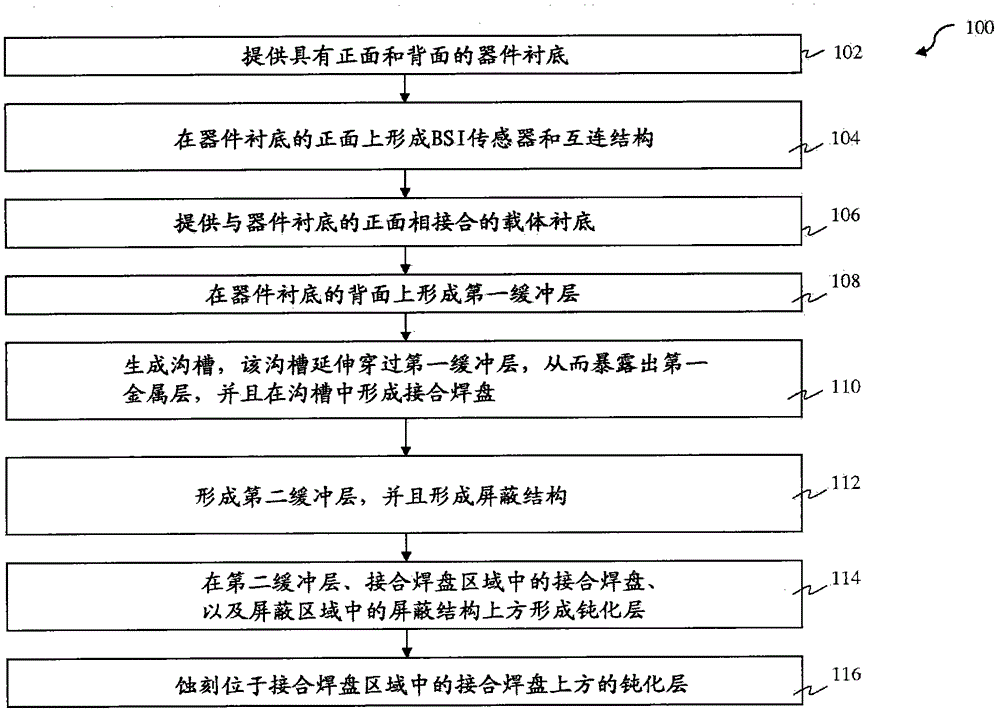

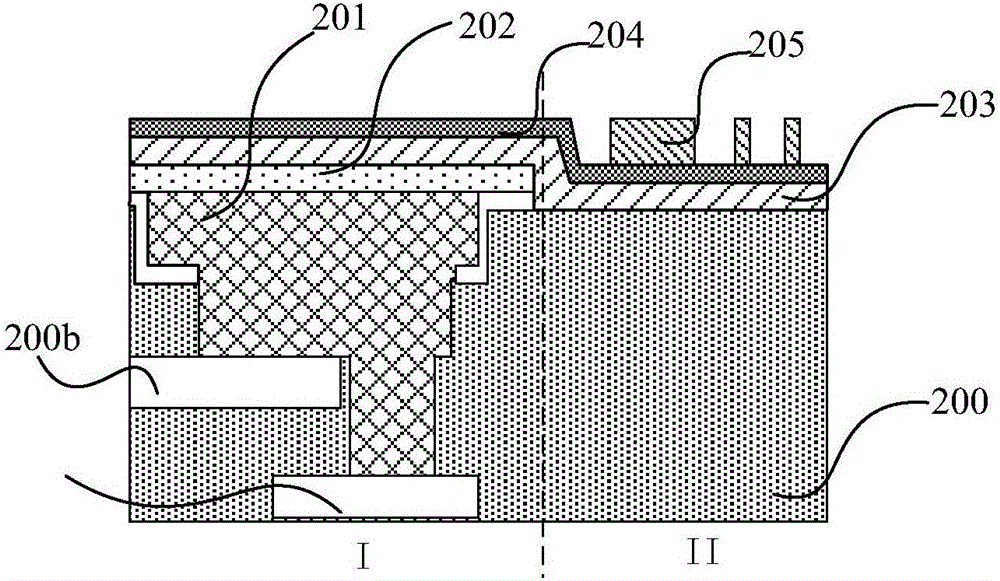

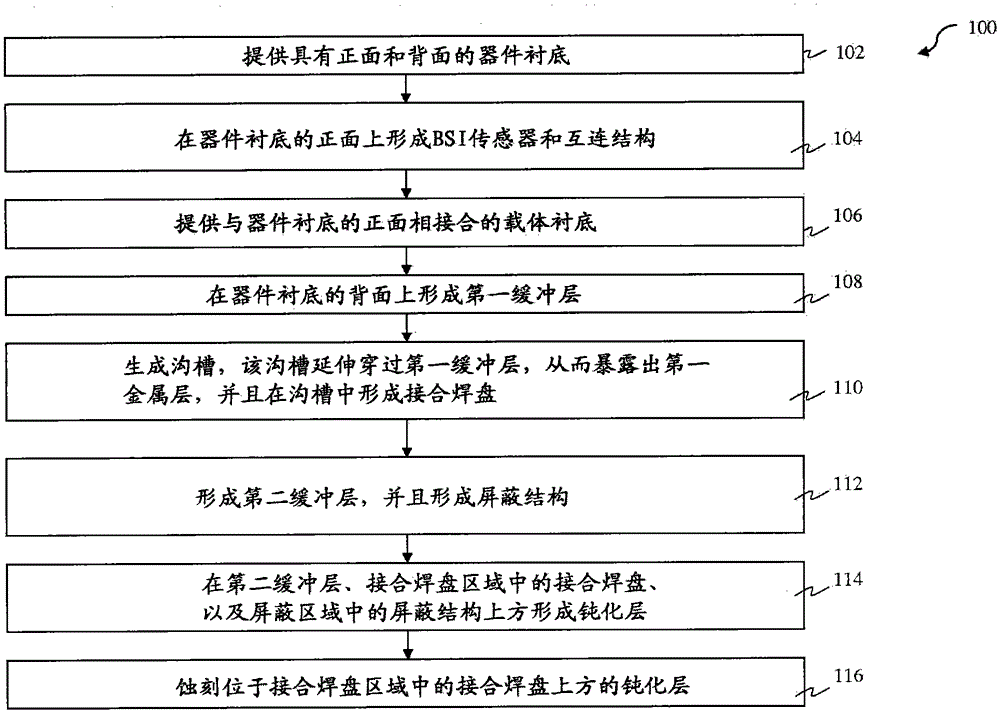

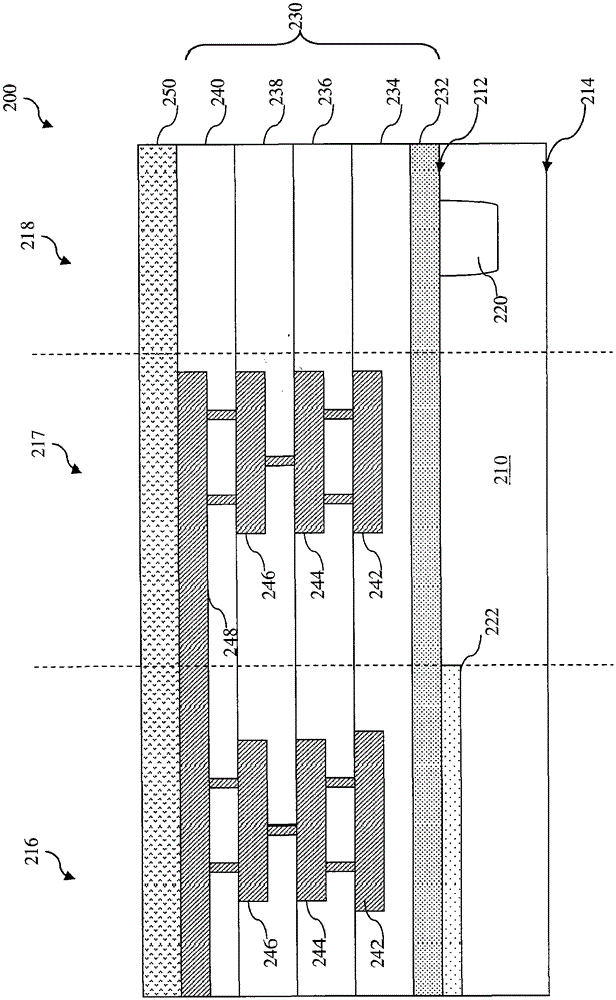

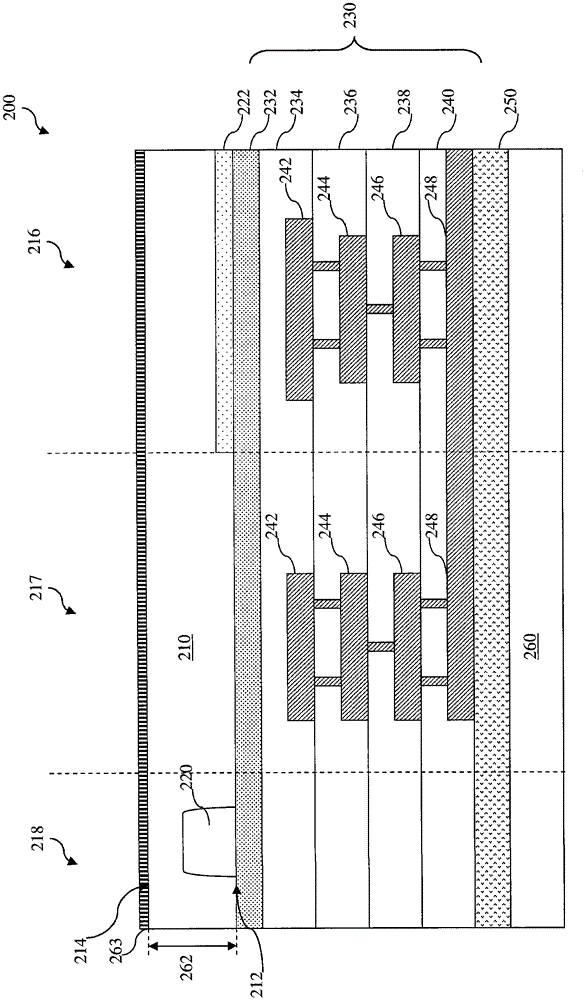

Backside illumination sensor having a bonding pad structure and method of making the same

ActiveCN102867832ASemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor structure

The present disclosure provides one embodiment of a semiconductor structure. The semiconductor structure comprises a device substrate having a front side and a back side; an interconnect structure disposed on the front side of the device substrate; and a bonding pad connected to the interconnect structure. The bonding pad comprises a recessed region in a dielectric material layer; a dielectric mesa of the dielectric material layer interposed between the recessed region; and a metal layer disposed in the recessed region and on the dielectric mesa.

Owner:TAIWAN SEMICON MFG CO LTD

Backside illuminated sensor and manufacturing method thereof

ActiveUS8564135B2Light receiving efficiencyReduce lossesSemiconductor/solid-state device detailsSolid-state devicesInsulation layerInterconnection

Disclosed is a backside illuminated image sensor including a light receiving element formed in a first substrate, an interlayer insulation layer formed on the first substrate including the light receiving element, a via hole formed through the interlayer insulation layer and the first substrate while being spaced apart from the light receiving element, a spacer formed on an inner sidewall of the via hole, an alignment key to fill the via hole, interconnection layers formed on the interlayer insulation layer in a multilayer structure in which a backside of a lowermost layer of the interconnection layers is connected to the alignment key, a passivation layer covering the interconnection layers, a pad locally formed on a backside of the first substrate and connected to a backside of the alignment key, and a color filter and a microlens formed on the backside of the first substrate corresponding to the light receiving element.

Owner:SK HYNIX INC

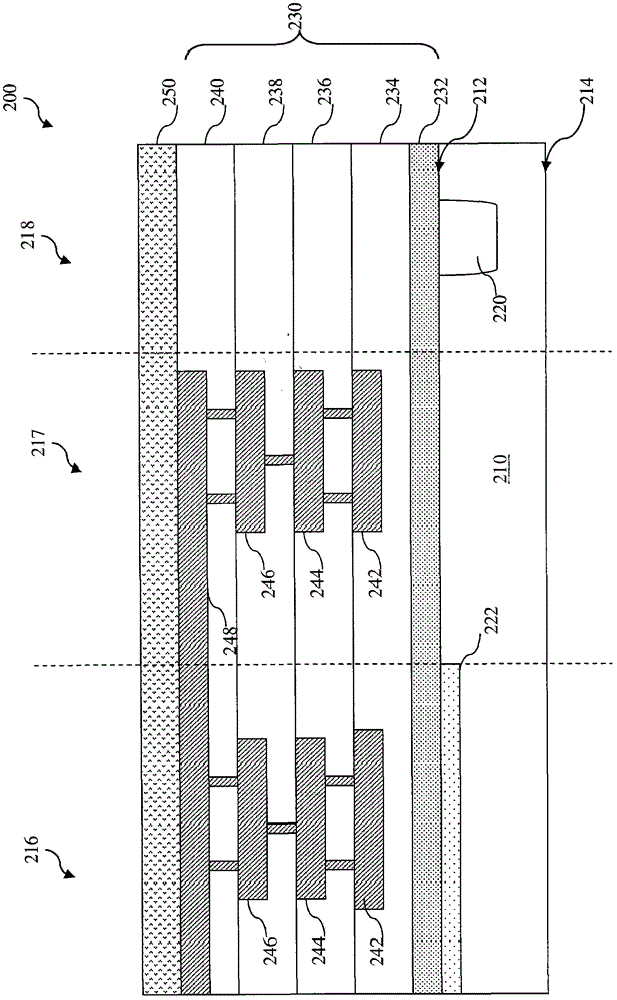

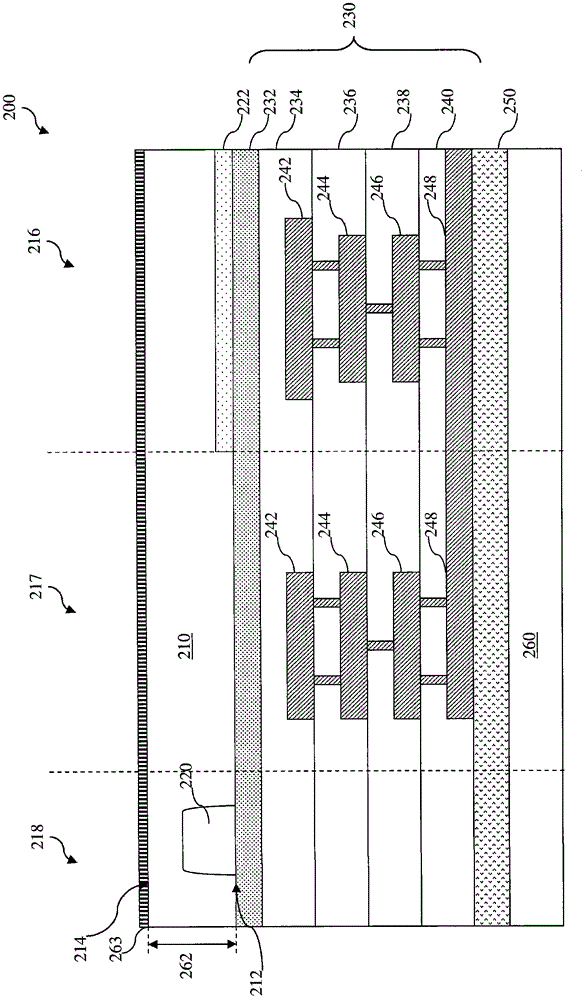

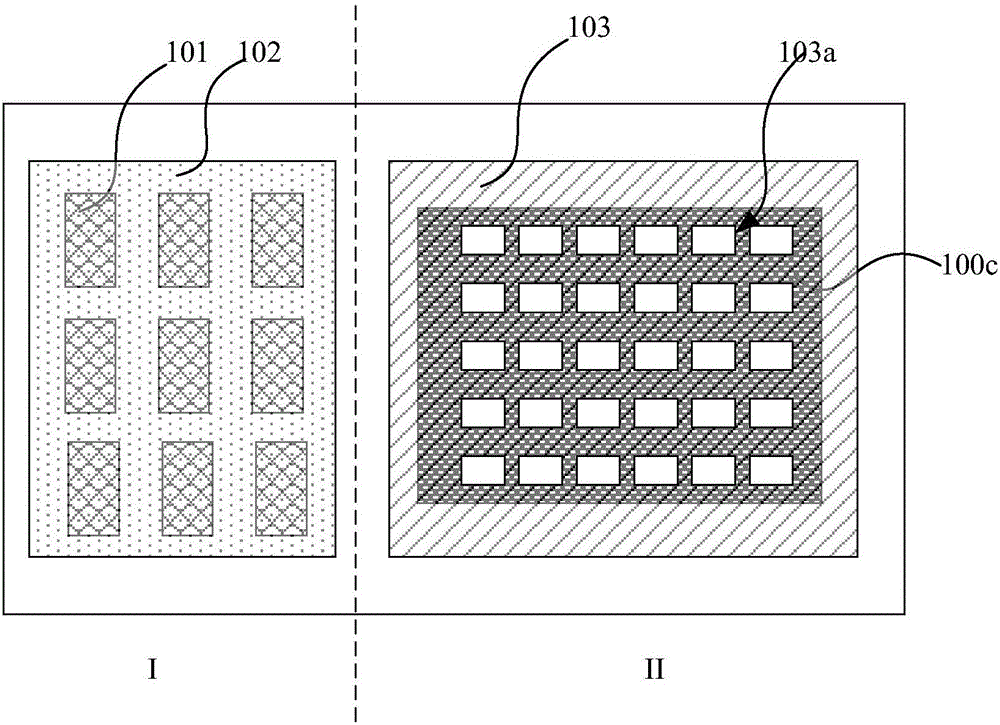

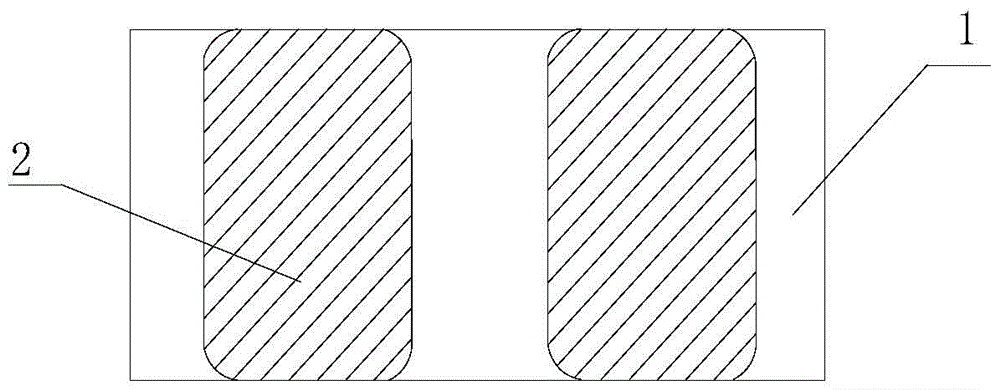

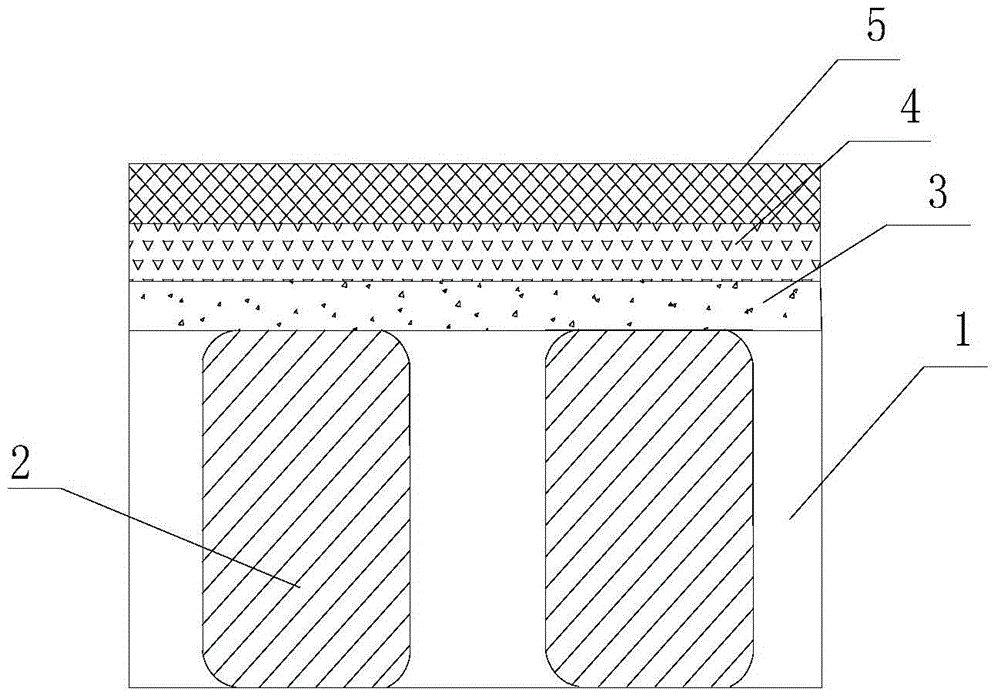

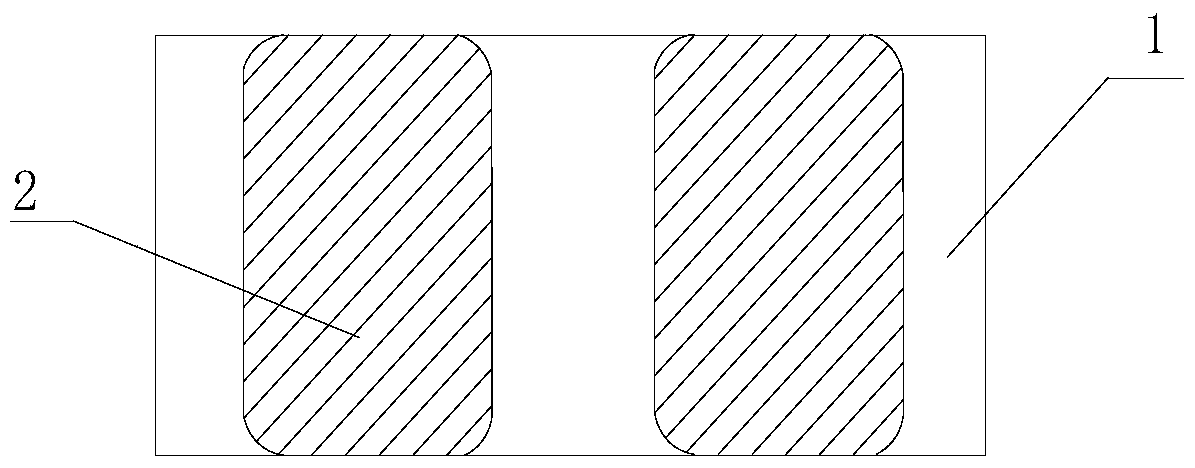

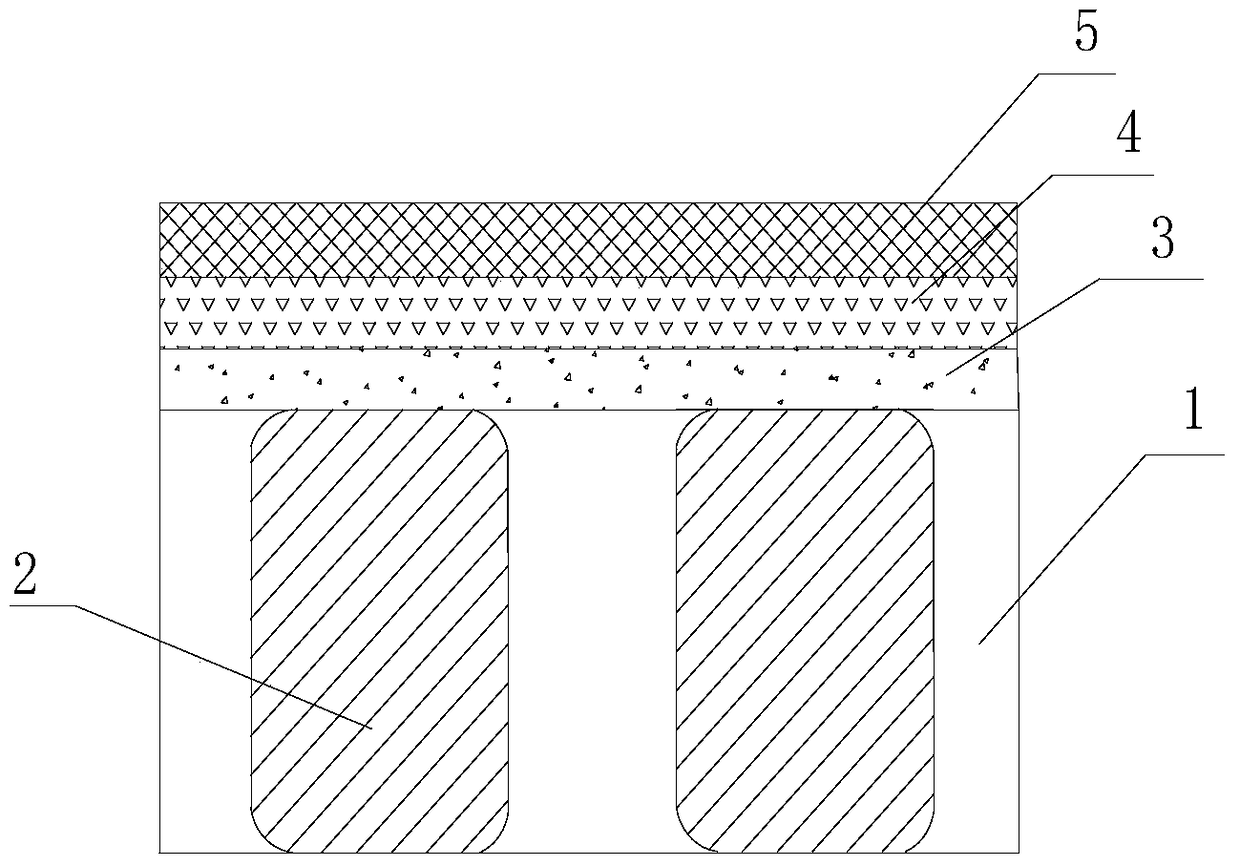

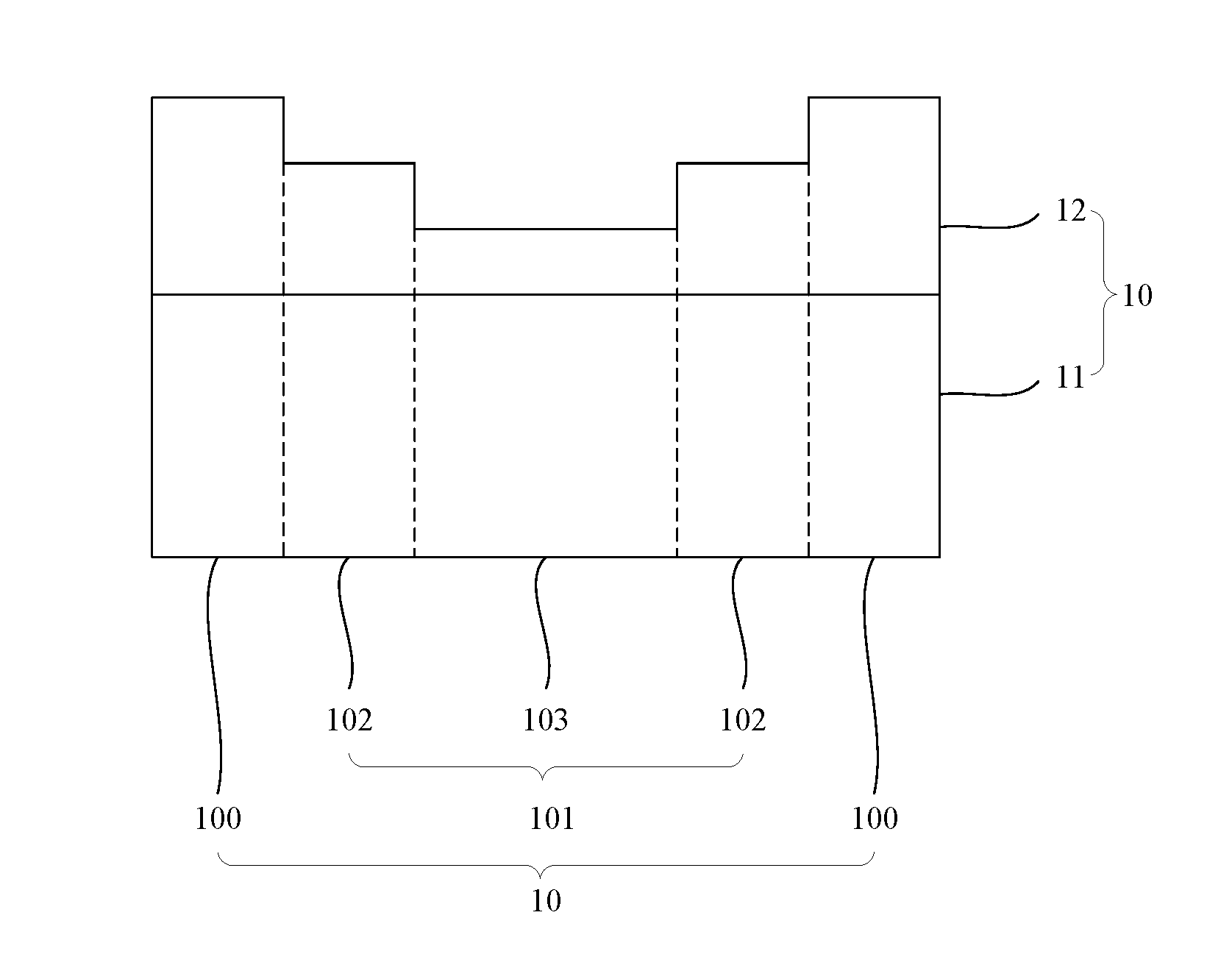

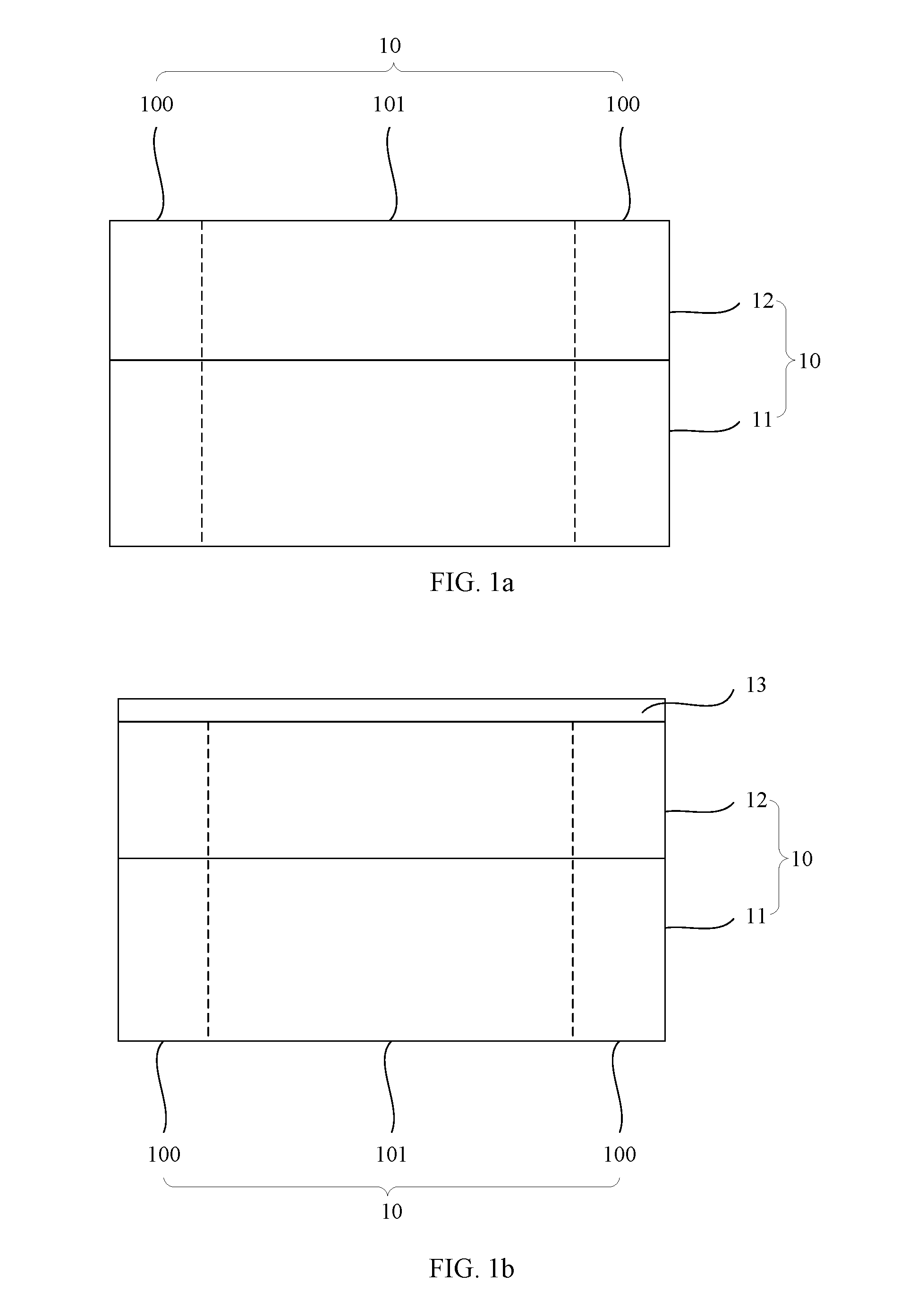

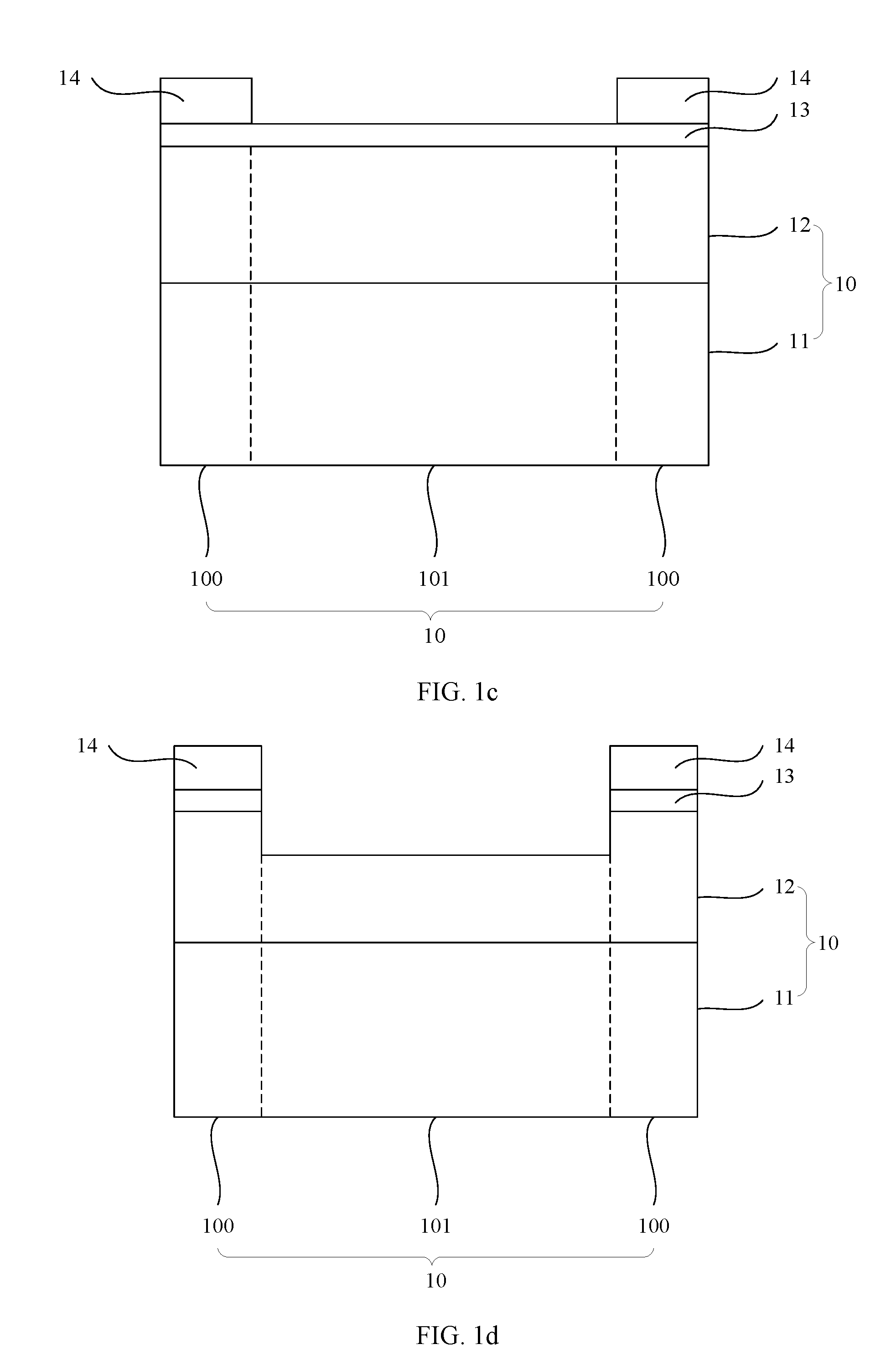

Manufacturing method and layout structure of back-illuminated sensor

ActiveCN106783901AAvoid Residual DefectsAvoid affecting light transmittanceSolid-state devicesRadiation controlled devicesTransmittanceProtection layer

The invention provides a manufacturing method and layout structure of a back-illuminated sensor. In the layout structure, the range of a metal grid layer at least covers the boundary of a pixel layer of a protection layer near the pixel region, and thus in the manufacturing method, when the metal grid of the back-illuminated sensor is manufactured according to a new layout structure, the metal at the step of the protection layer and the pixel layer does not need to be etched, and thus the defects of metal residues can be avoided, the impact of the light transmittance in the pixel region can be avoided, and the performance of the back-illuminated image sensor chip which is finally prepared can be increased.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

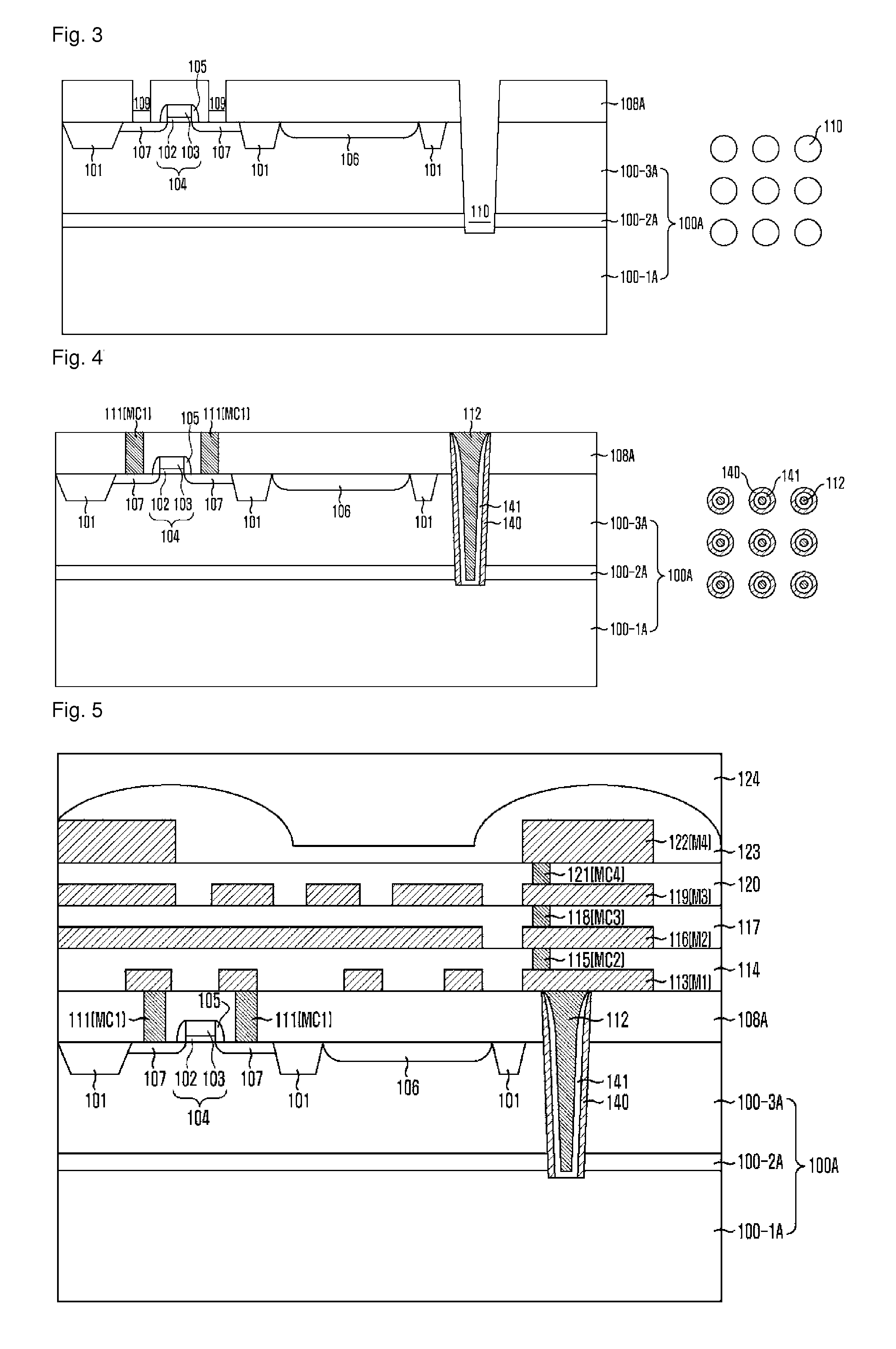

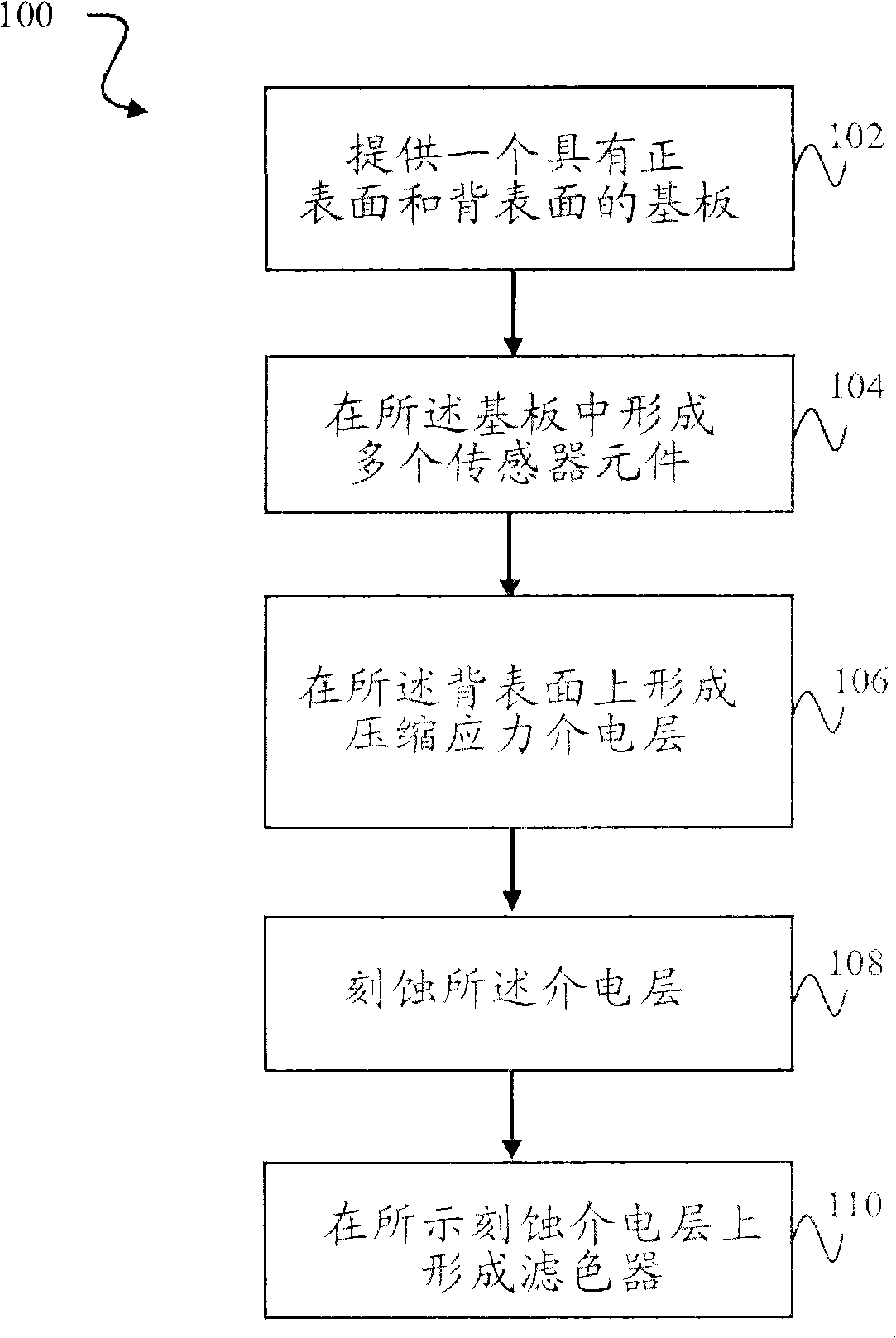

Back-illuminated sensor process

InactiveCN102280459ADoes not cause or reduce negative effectsDoes not cause or reduce changesSolid-state devicesDiodeDielectric layerSemiconductor

The present disclosure provides methods and apparatus for reducing dark current in a backside illuminated semiconductor device. In one embodiment, a method of fabricating a semiconductor device includes providing a substrate having a frontside surface and a backside surface, and forming a plurality of sensor elements in the substrate, each of the plurality of sensor elements configured to receive light directed towards the backside surface. The method further includes forming a dielectric layer on the backside surface of the substrate, wherein the dielectric layer has a compressive stress to induce a tensile stress in the substrate. A backside illuminated semiconductor device fabricated by such a method is also disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Backside-illuminated sensor

InactiveCN101399276AHigh sensitivitySolve the punch-through problemSolid-state devicesRadiation controlled devicesPhotodetectorOpto electronic

Provides is a backside-illuminated sensor including a semiconductor substrate having a front surface and a back surface. A plurality of image sensor elements is formed on the front surface of the semiconductor substrate. At least one of the image sensor elements includes a transfer transistor and a photodetector. The gate of the transfer transistor includes an optically reflective layer. The gate of the transfer transistor, including the optically reflective layer, overlies the photodetector. In one embodiment, the gate overlies the photodetector by at least 5%. The invention can resolve the penetrating problem and improve the sensitivity for the image sensor element.

Owner:TAIWAN SEMICON MFG CO LTD

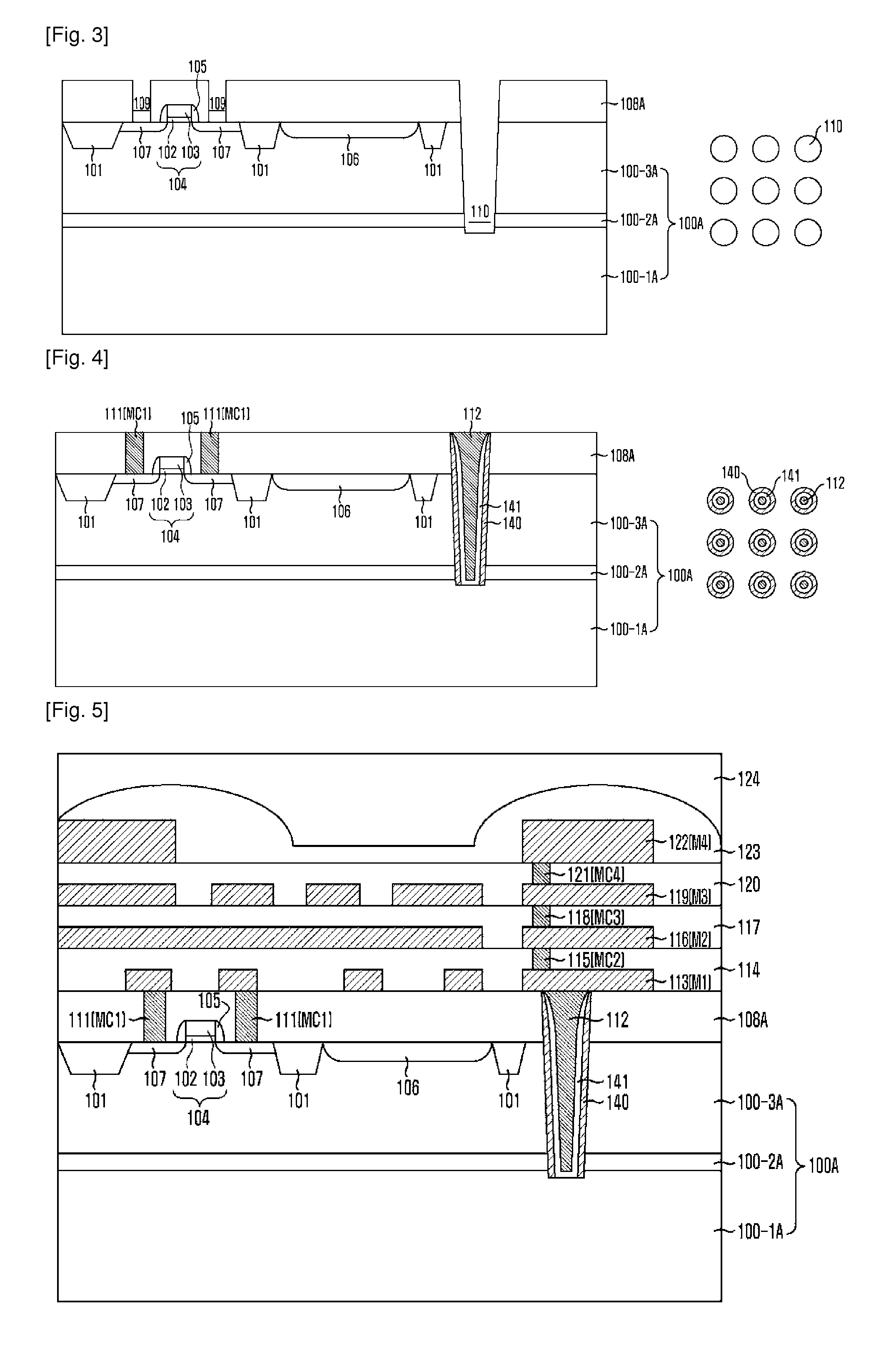

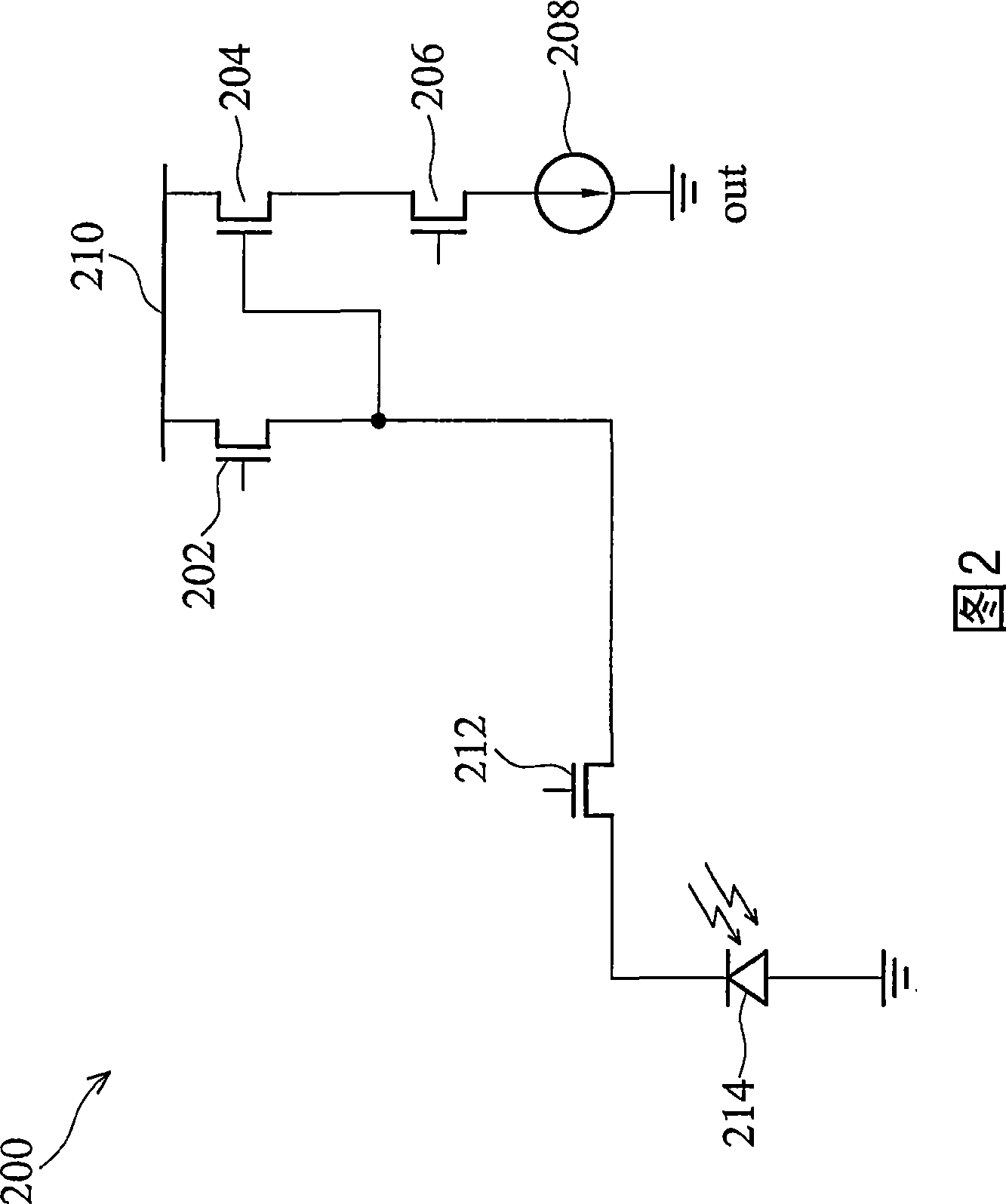

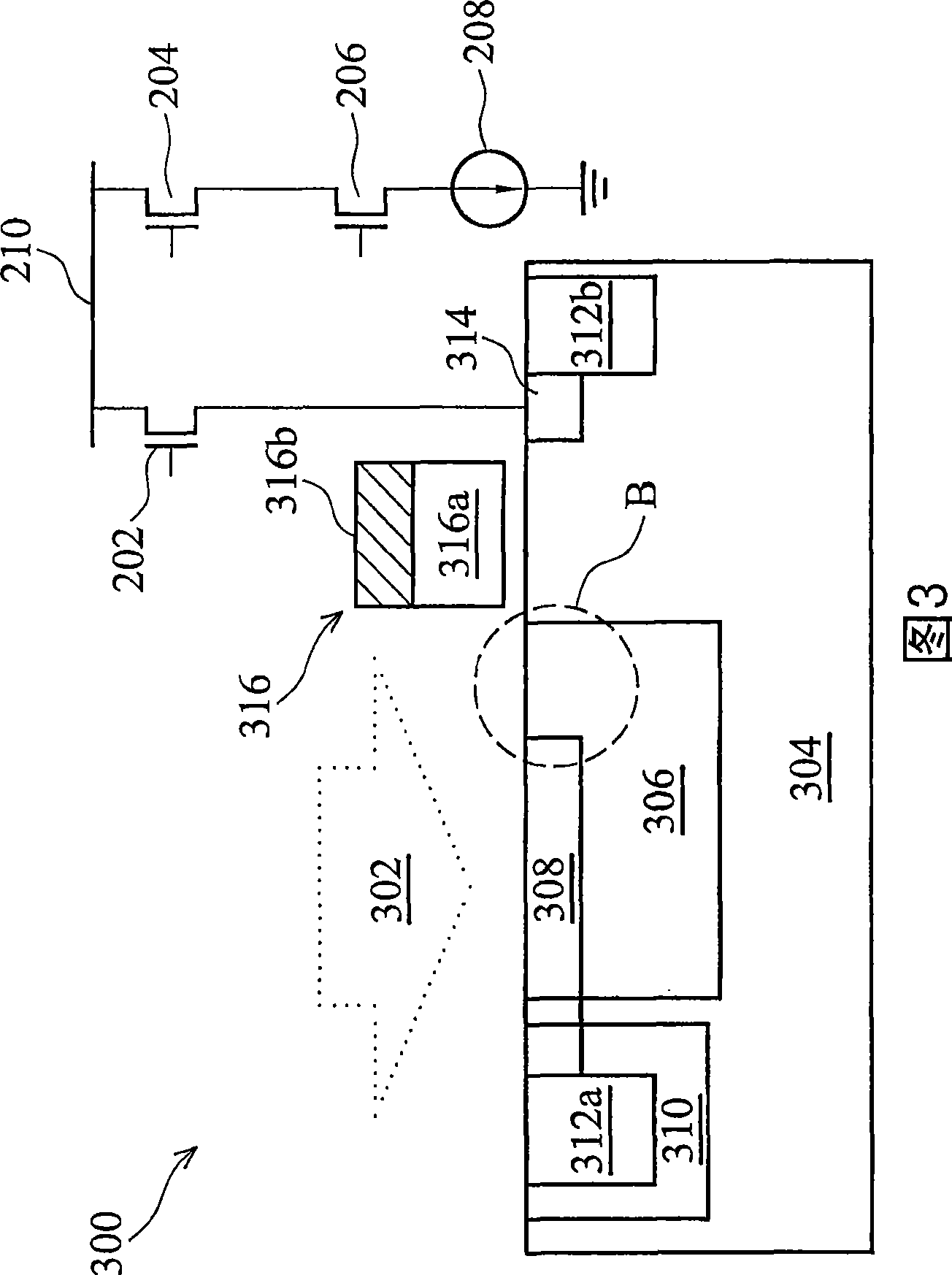

Backside-illuminated sensor with noise reduction

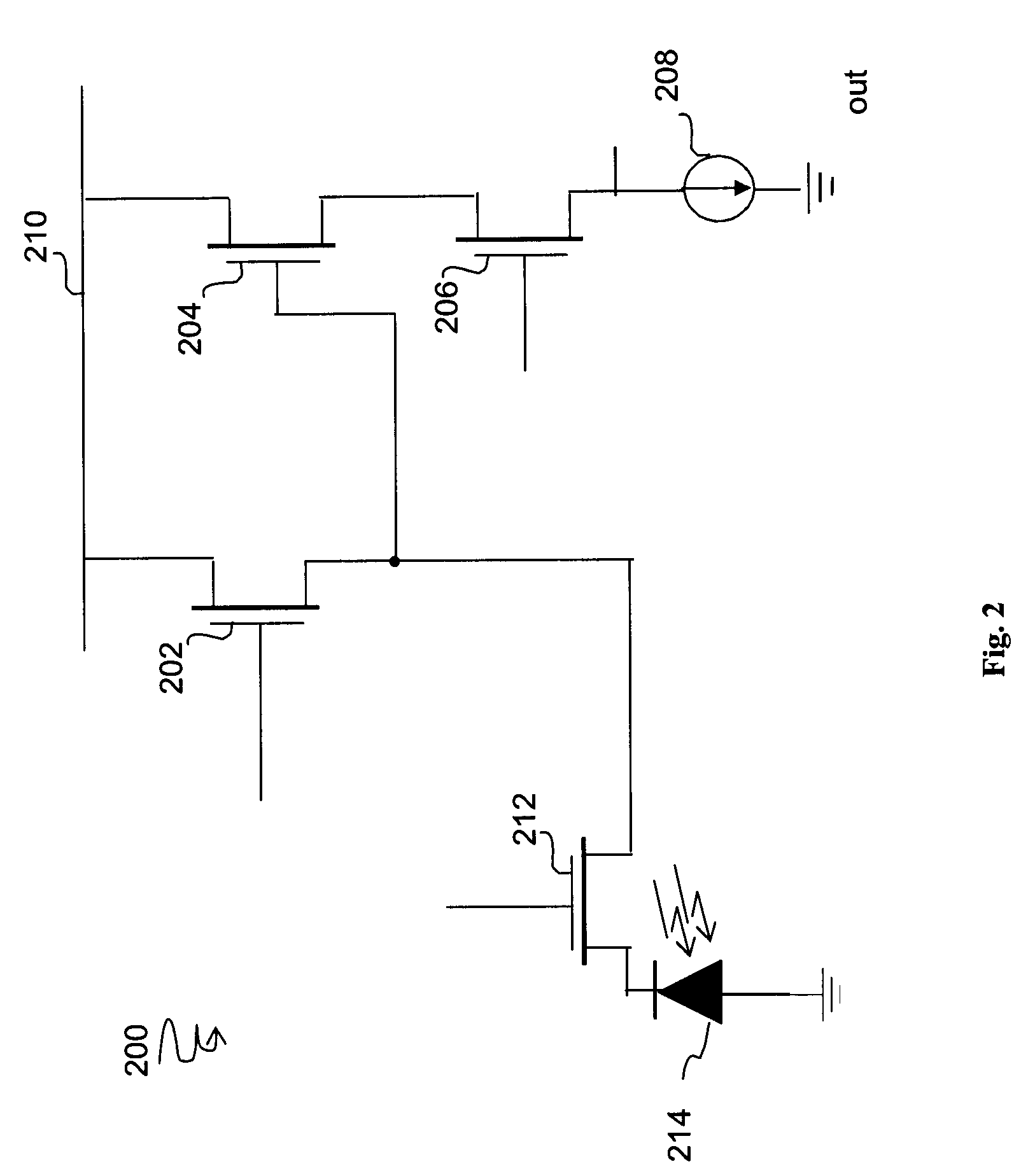

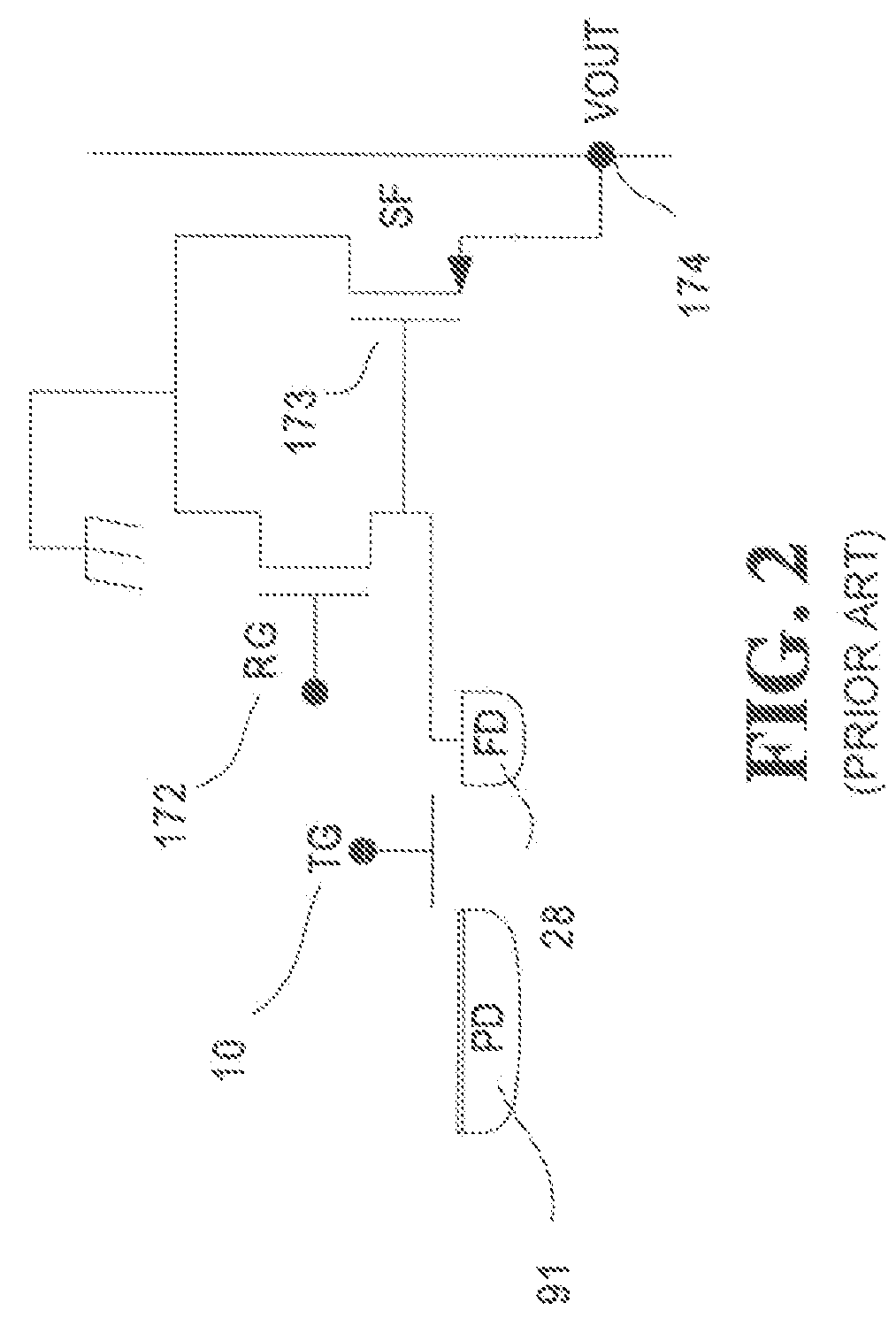

InactiveUS20110278687A1Efficient reductionReduce noiseSolid-state devicesDiodeProject areaOptoelectronics

A backside-illuminated sensor includes a substrate, at least one lens and at least one pixel structure. The substrate has a front surface and a backside surface, and the lens is formed on the backside surface of the substrate and the pixel structure is formed on a pixel area included in the front surface of the substrate, where a projected area of the pixel area on the backside surface in a thickness direction of the substrate is covered by the lens. The pixel structure includes a first power node for receiving a first supply voltage, a second power node for receiving a second supply voltage different from the first supply voltage, a sensing element and a capacitor for noise reduction. The sensing element generates a sensing signal according to an incident luminance from the lens.

Owner:HIMAX IMAGING LIMITED

Semiconductor device and manufacturing method thereof

ActiveCN102214664ASuppress leak toEliminate electrical crosstalkSolid-state devicesRadiation controlled devicesSilicon oxideOxygen

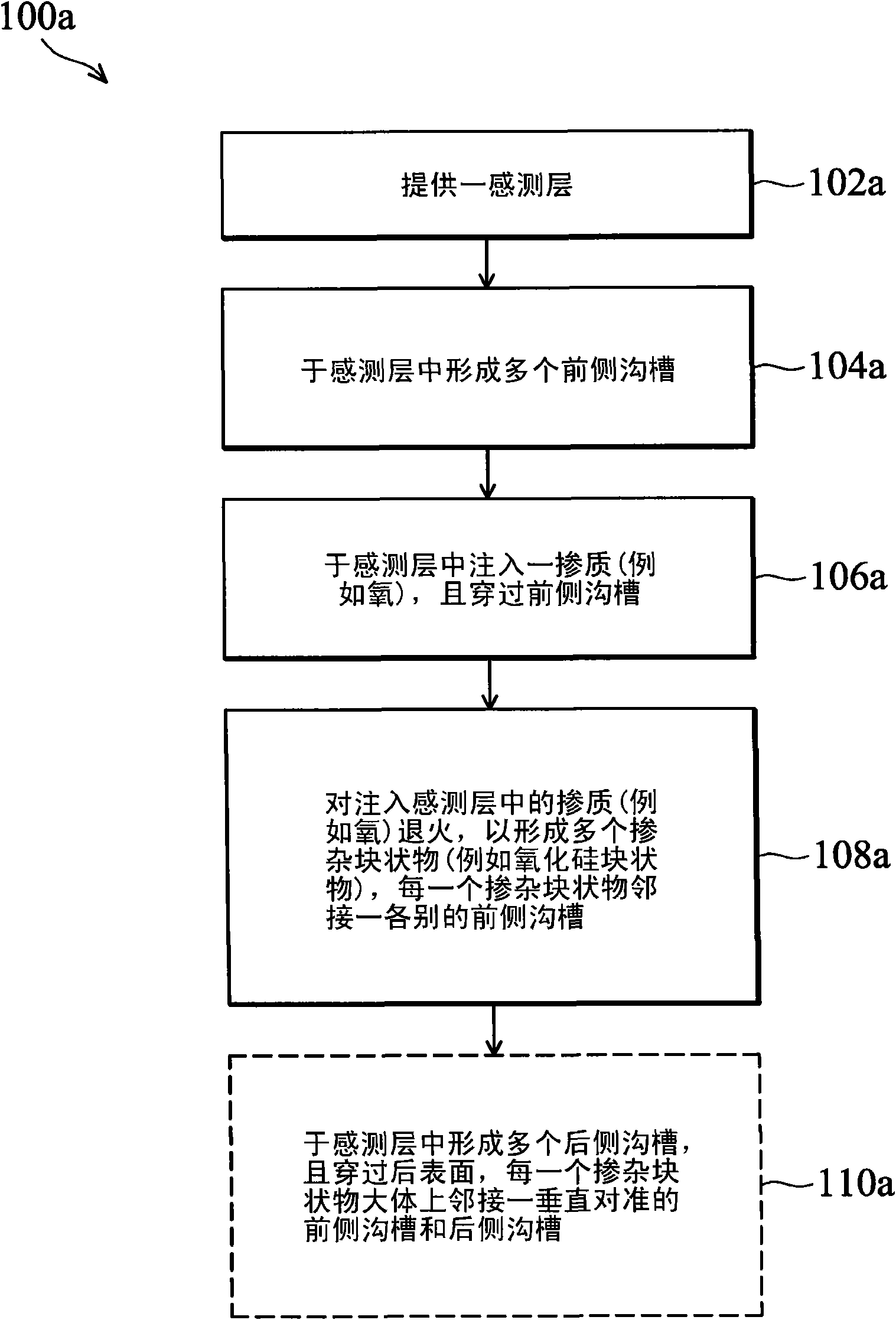

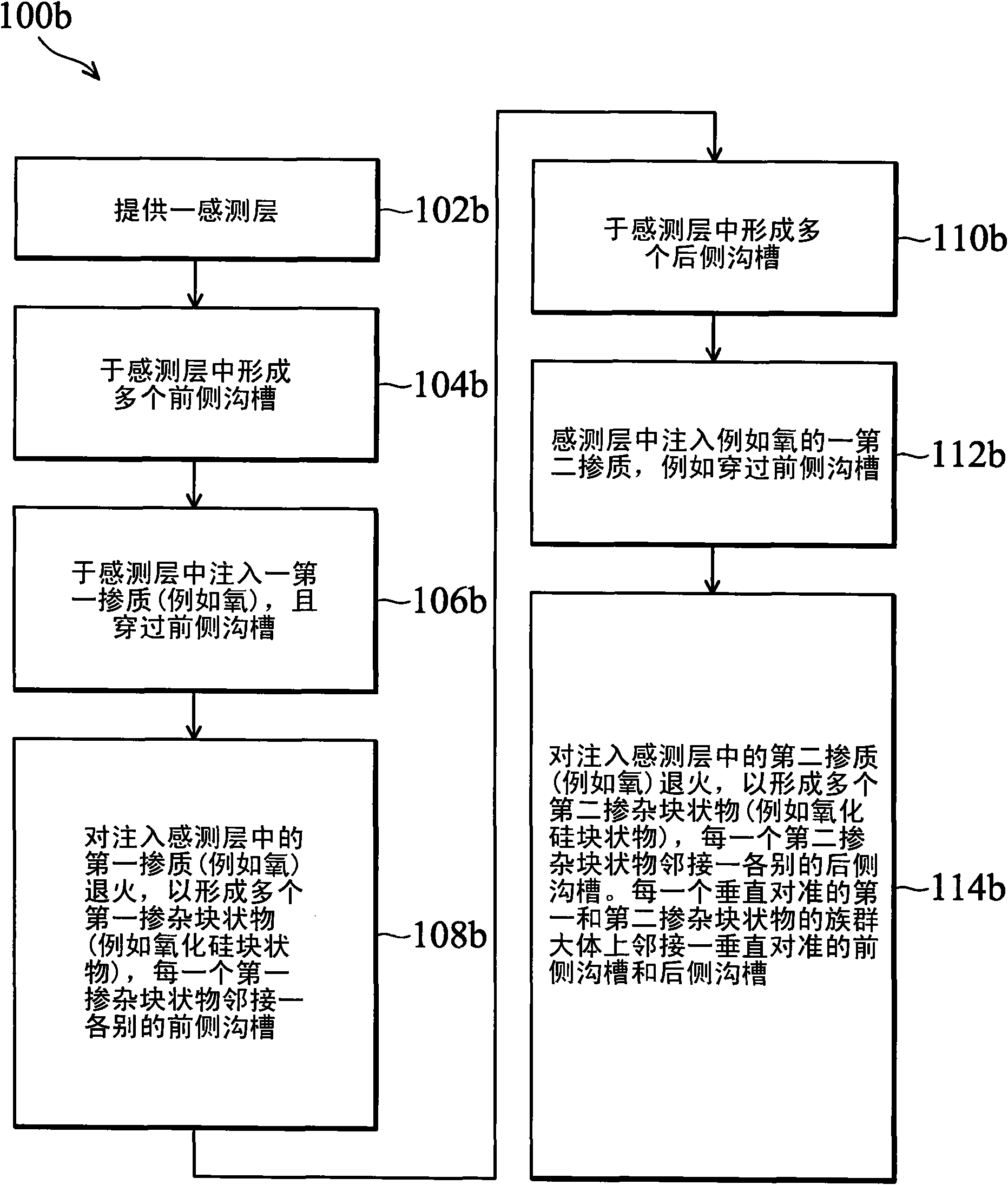

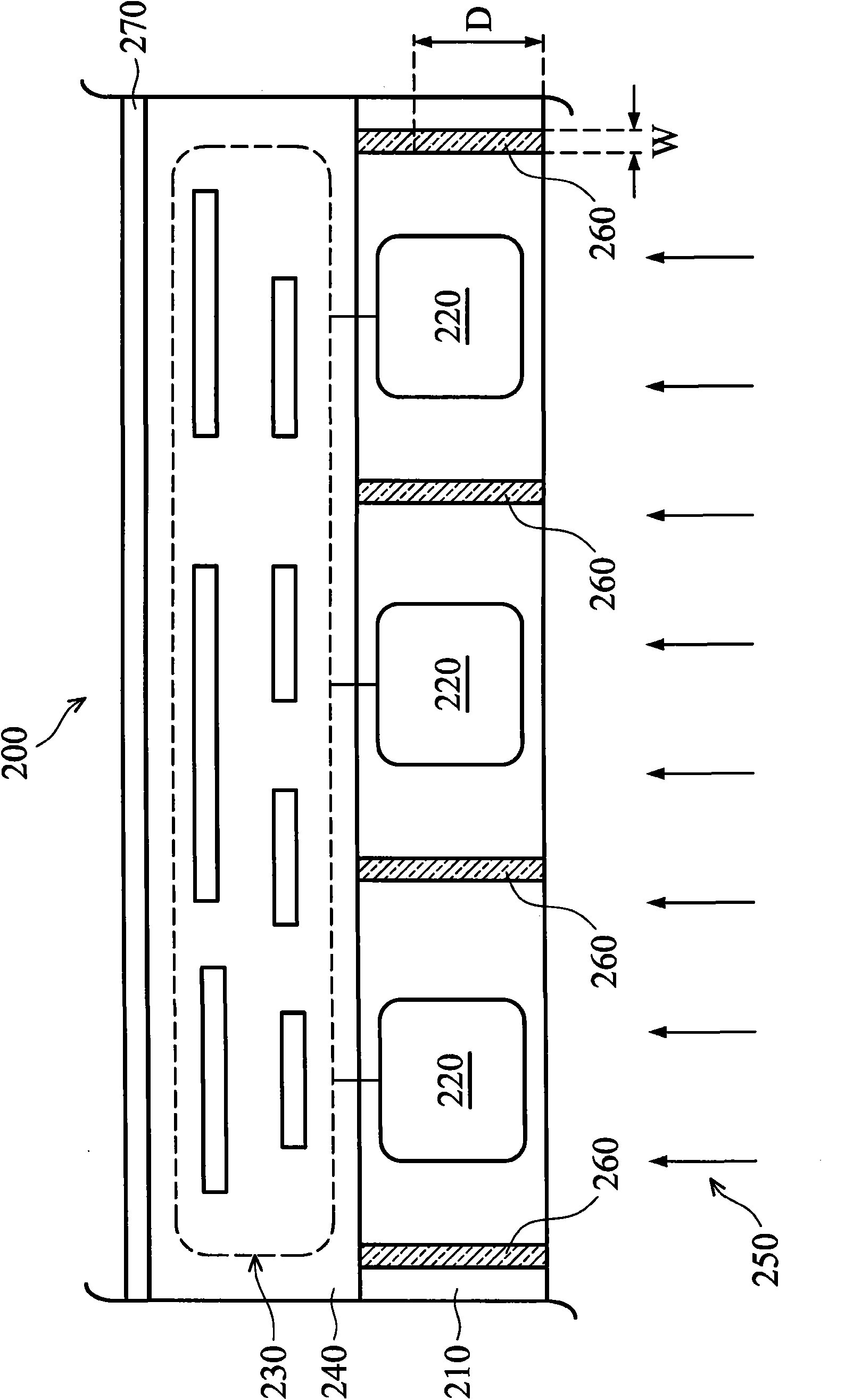

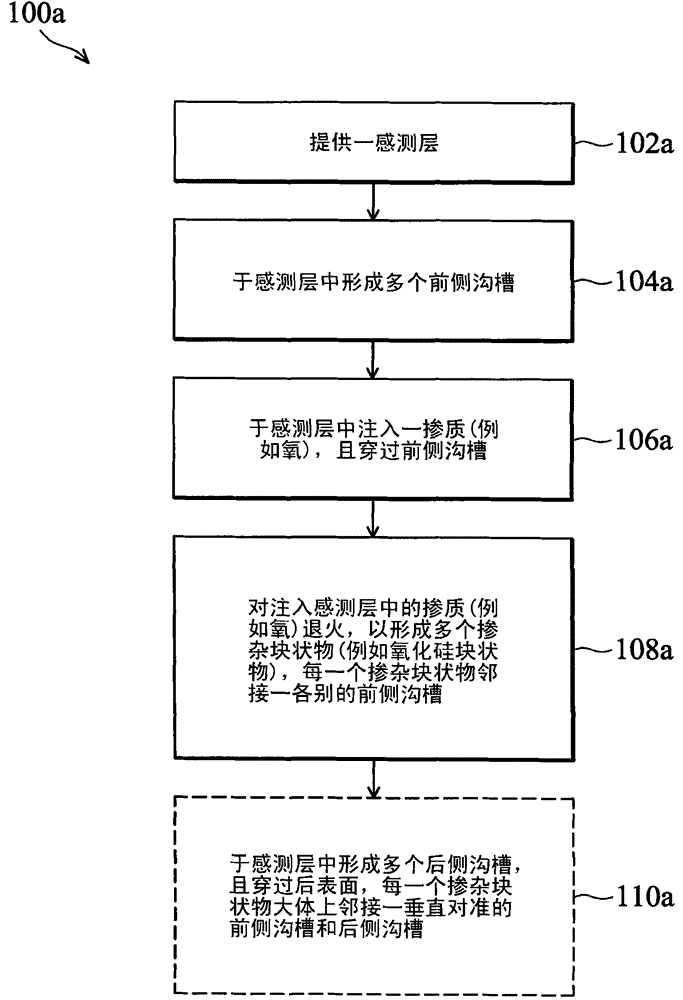

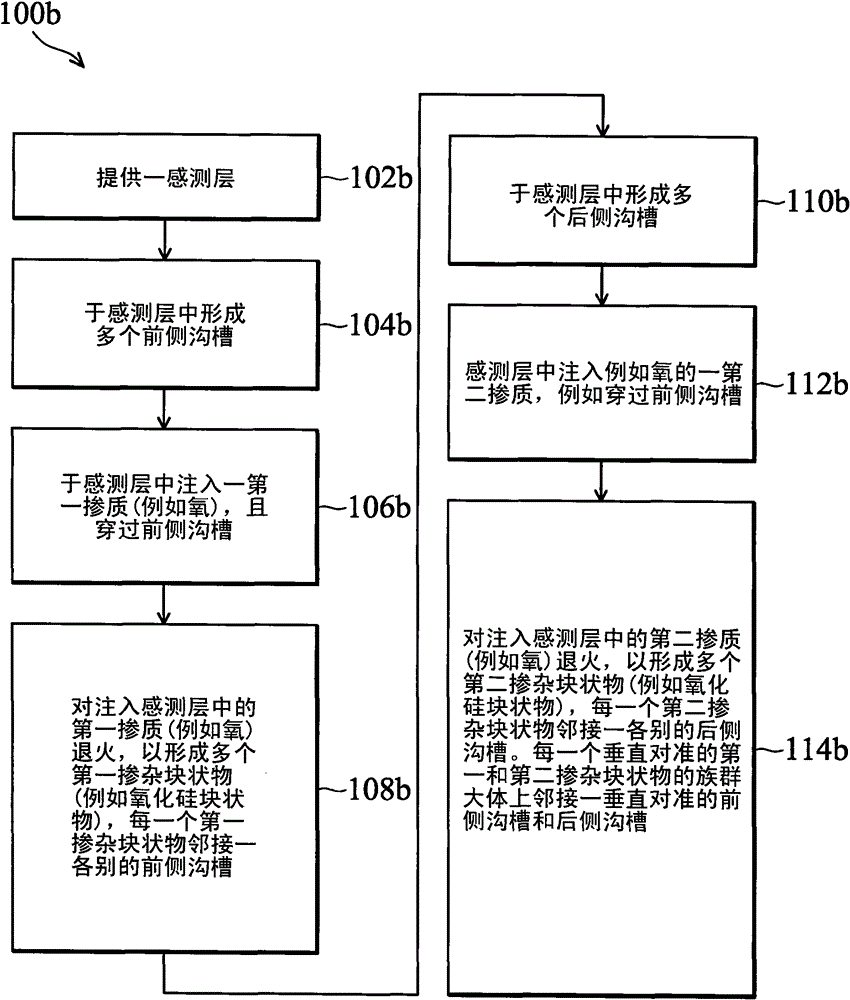

The present disclosure provides methods and apparatus for sensor element isolation in a backside illuminated image sensor. In one embodiment, a method of fabricating a semiconductor device includes providing a sensor layer having a frontside surface and a backside surface, forming a plurality of frontside trenches in the frontside surface of the sensor layer, and implanting oxygen into the sensor layer through the plurality of frontside trenches. The method further includes annealing the implanted oxygen to form a plurality of first silicon oxide blocks in the sensor layer, wherein each first silicon oxide block is disposed substantially adjacent a respective frontside trench to form an isolation feature. The invention could prevent the photoelectron from leaking to the adjacent pixel so as to reduce or substantially eliminate the electric cross talk between the sensor elements.

Owner:TAIWAN SEMICON MFG CO LTD

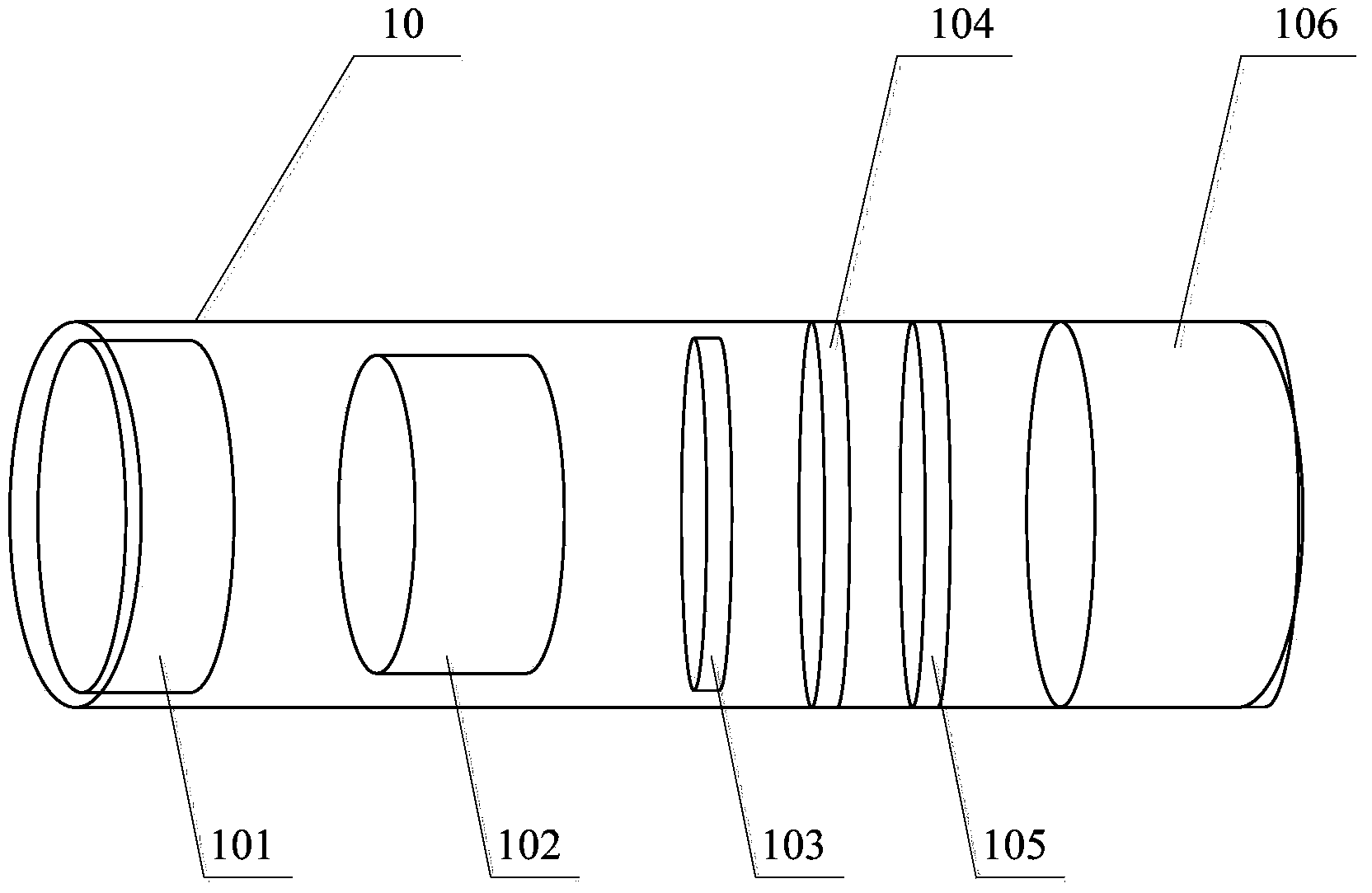

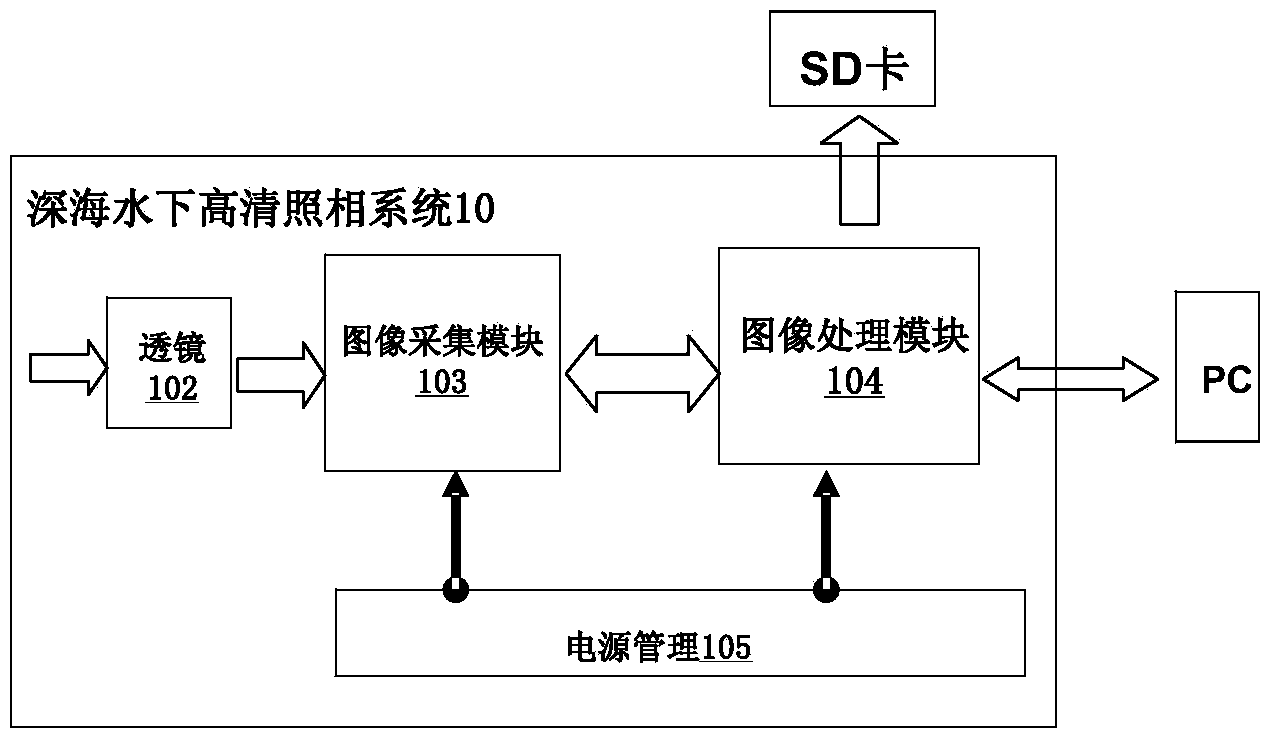

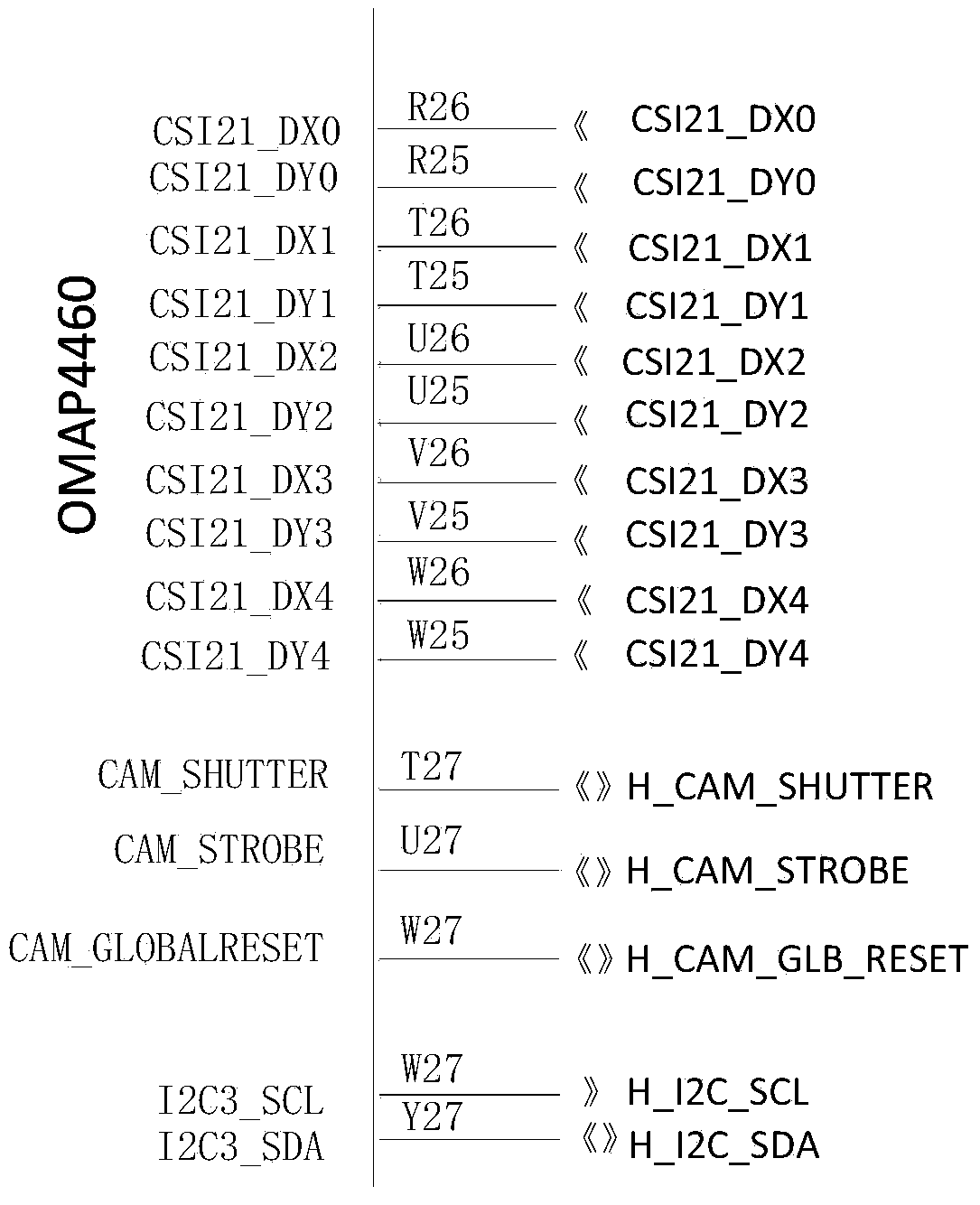

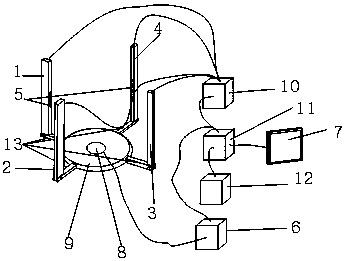

Underwater high-definition photographic system for deep sea

InactiveCN104079809AAccurate collectionHigh speed data transmissionTelevision system detailsColor television detailsCamera lensCMOS sensor

The embodiment of the invention discloses an underwater high-definition photographic system for a deep sea. The underwater high-definition photographic system comprises pressure-resistant glass, a 16-mm fixed camera lens, an image collecting module, an image processing module, a power source management module and an interface, wherein the thickness of the pressure-resistant glass is 15 mm-20 mm, the fixed camera lens is arranged at the rear end of the pressure-resistant glass, the image collecting module is arranged at the rear end of the lens, the image processing module is arranged at the rear end of the image collecting module, the power source management module is arranged at the rear end of the image processing module, and the interface is formed in the rear end of the power source management module. The pressure-resistant glass, the lens, the image collecting module, the image processing module, the power source management module and the interface are packaged through a frame which is wholly sealed and resistant to pressure. Images are collected through a low-pressure-difference serial port of the MIPI interface and a backside-illuminated CMOS sensor, image quality can be better under the condition of insufficient light in the deep sea, and a towed body working in the deep sea can be higher in image collecting speed and anti-interference capacity when shaken violently in ocean currents.

Owner:HANGZHOU MORUI ELECTROMECHANICAL SCI & TECH

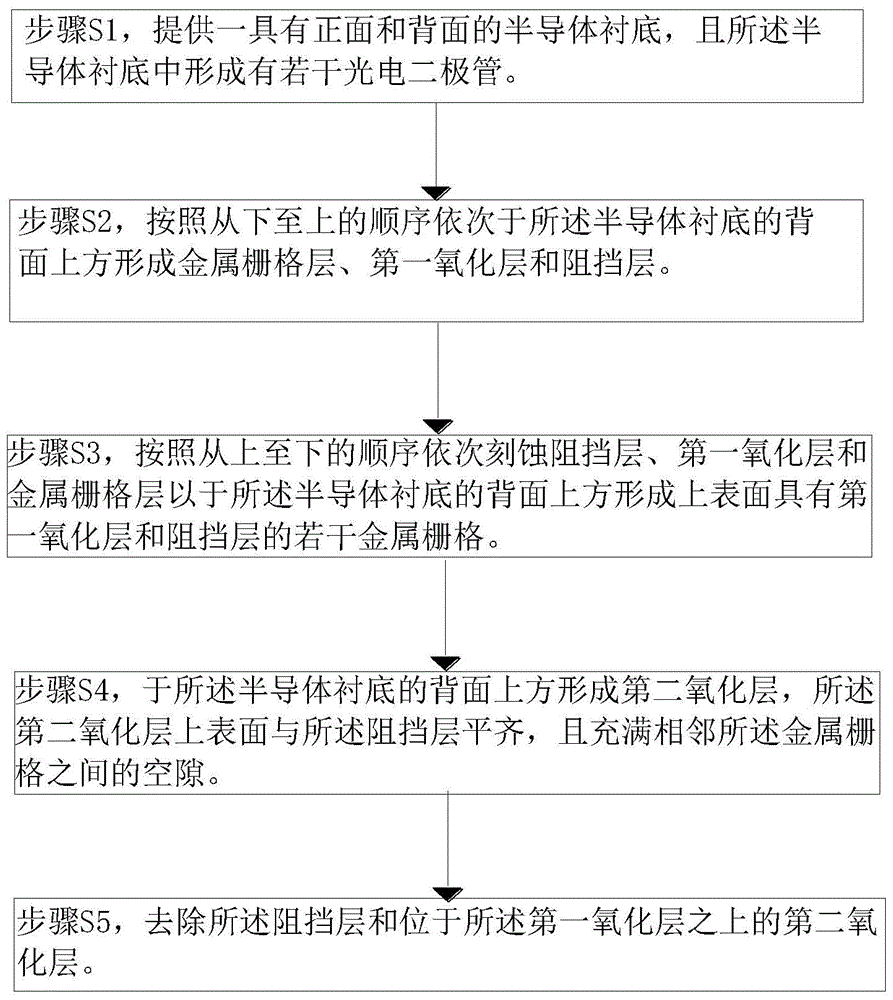

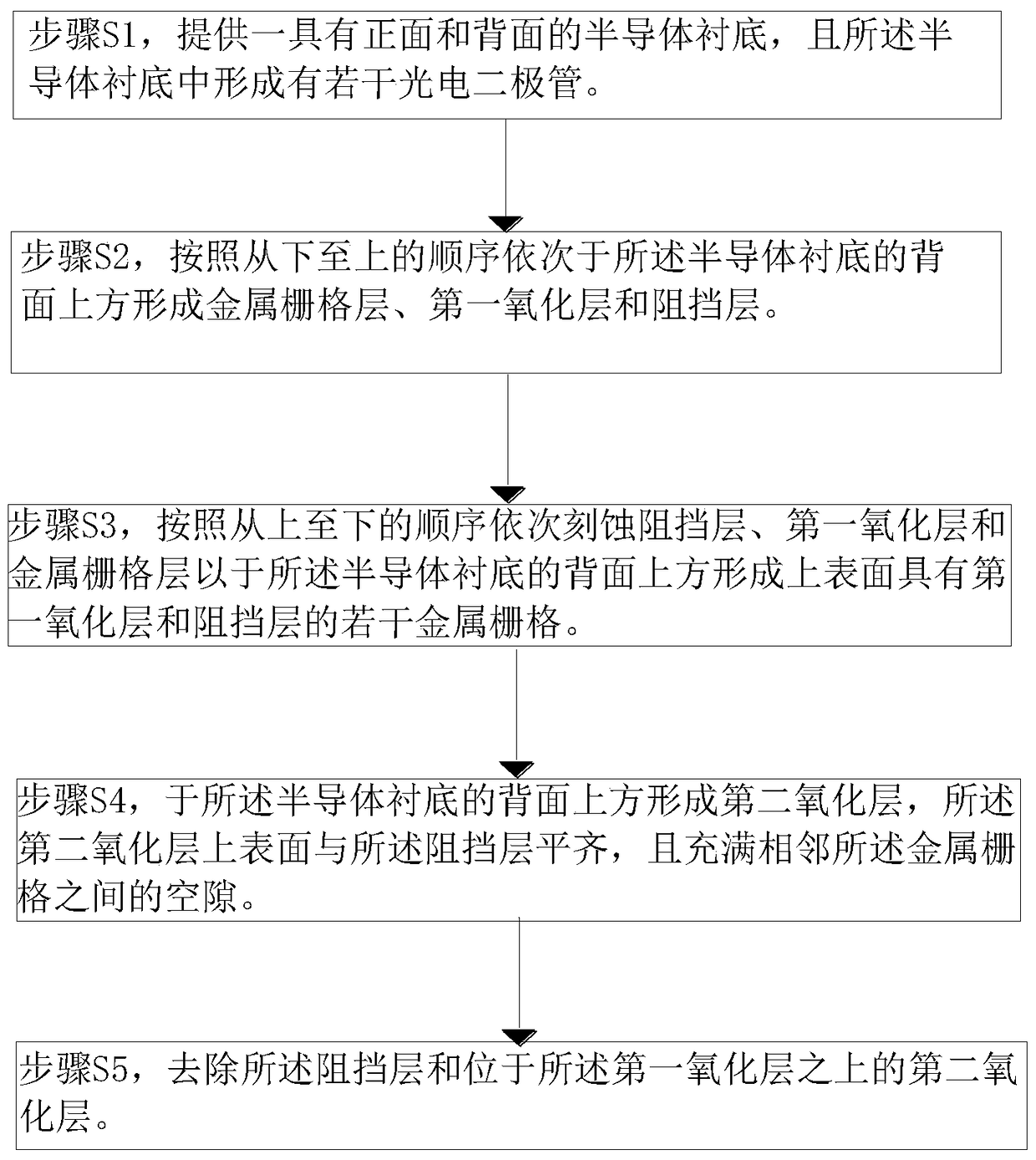

A manufacturing method for a backside-illumination sensor

ActiveCN105702695AEliminate color anomaliesMinimizes variance in incident light lossSolid-state devicesRadiation controlled devicesImaging qualitySemiconductor

The invention relates to the technical field of semiconductor manufacturing, and especially relates to a manufacturing method for a backside-illumination sensor. A metal grid layer, a first oxide layer and a barrier layer sequentially form from bottom to top on the back surface of a semiconductor substrate; after a process of forming several metal grids through etching, a second oxide layer, of which the upper surface is level with the upper surface of the barrier layer, forms; and then, the barrier layer and the second oxide layer positioned on the first oxide layer are removed to form an oxide layer positioned on the upper surface of the metal grid layer and having uniform thickness. Difference of incident light losses is reduced, so that color abnormity of the appearance of a wafer of the backside-illumination sensor can be eliminated and the imaging quality can be raised.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

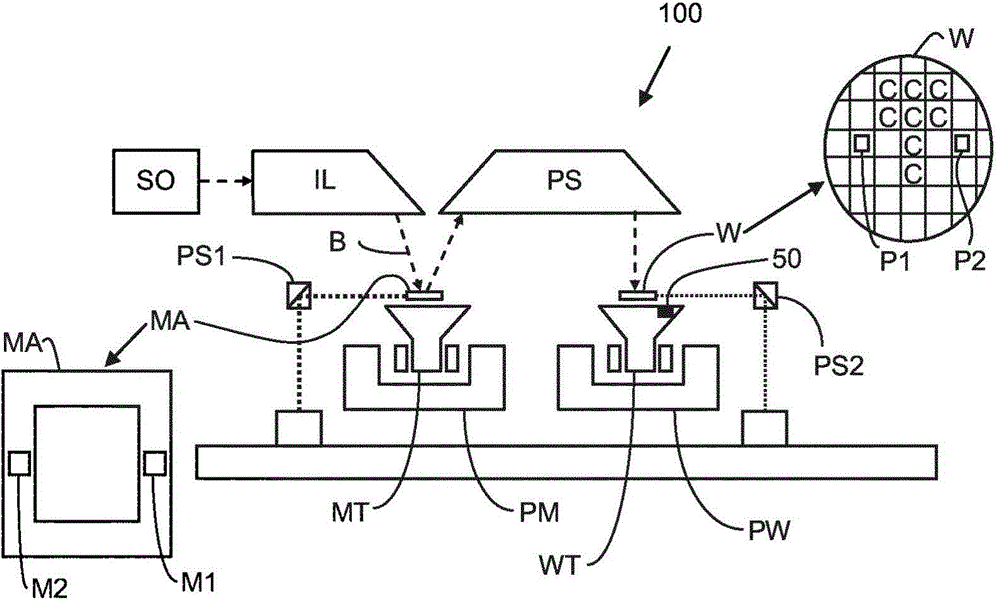

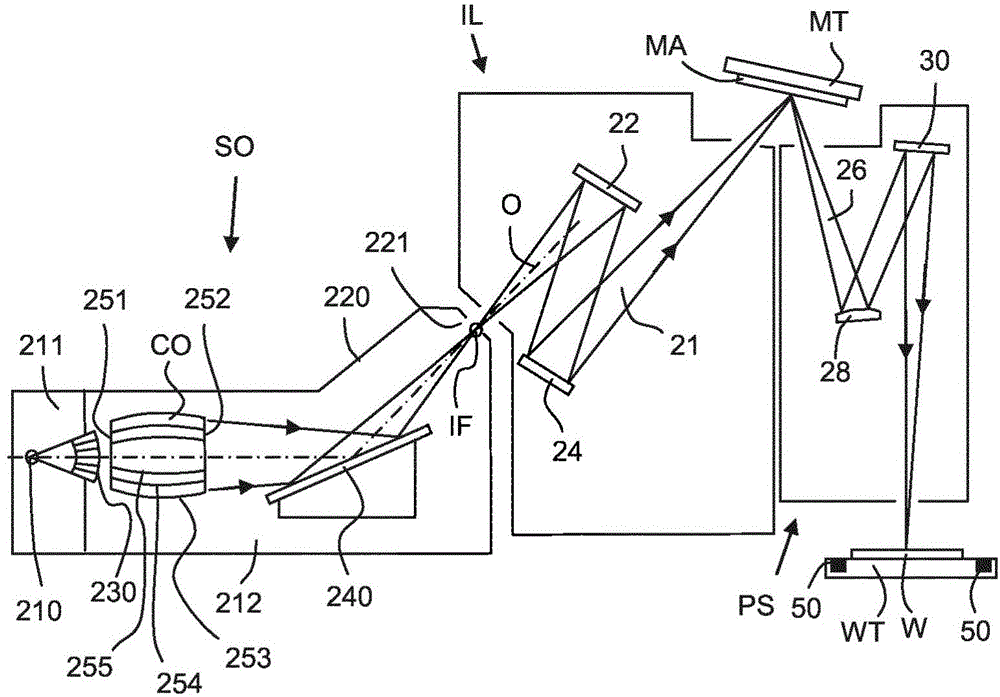

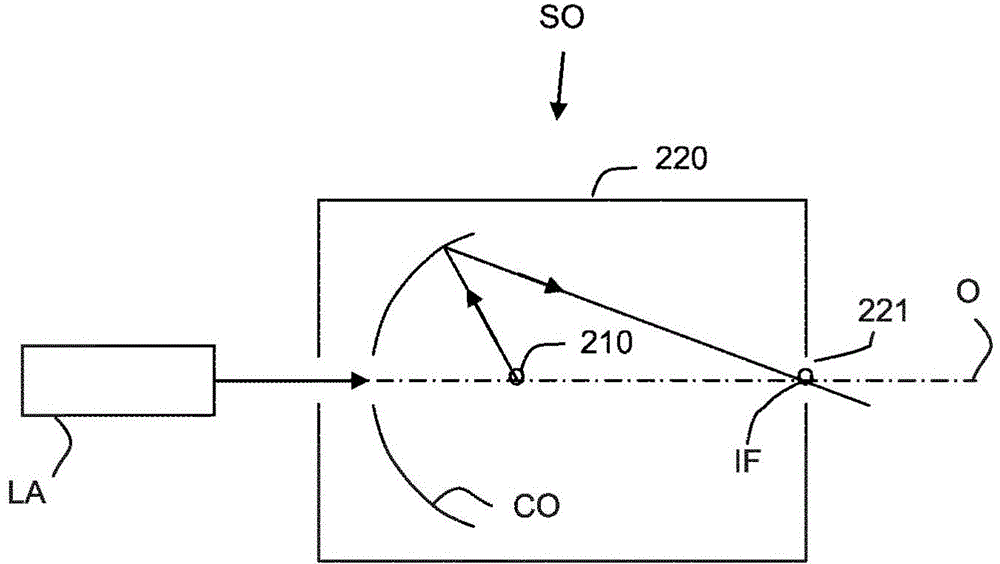

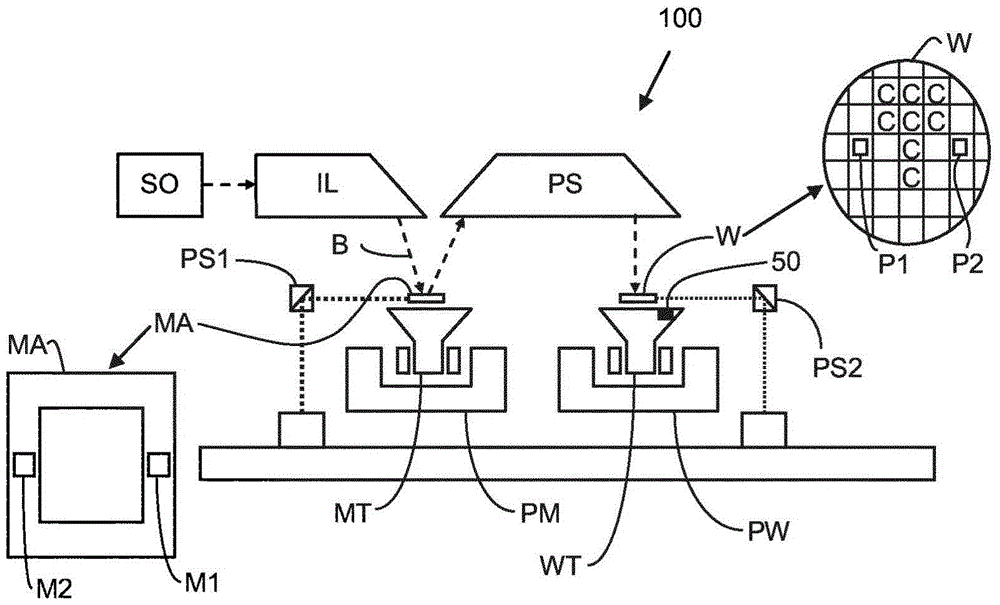

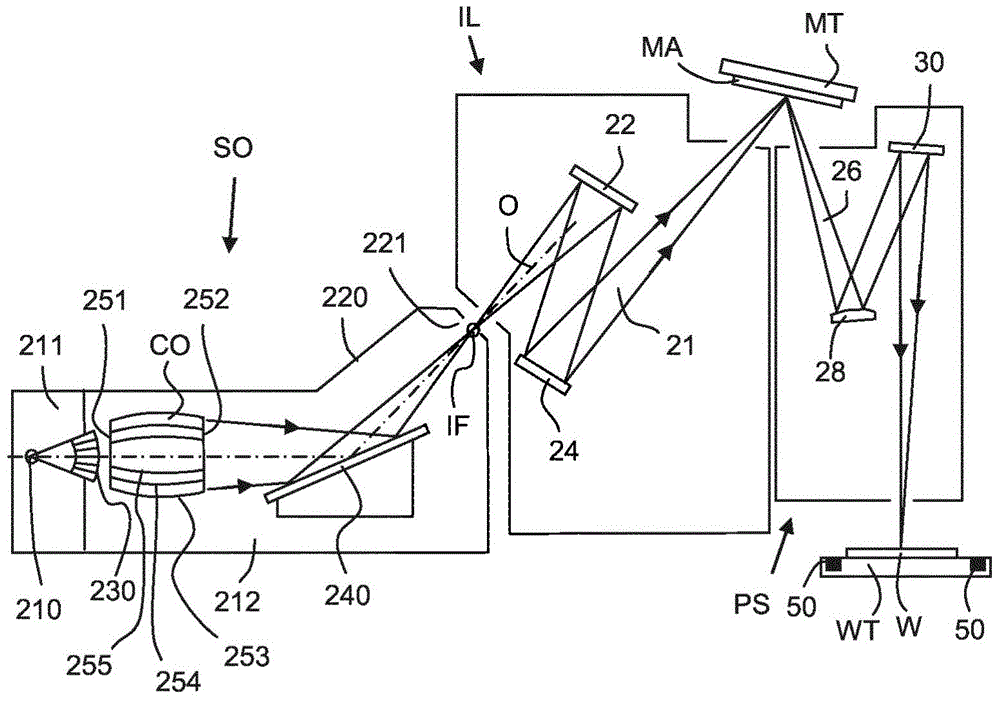

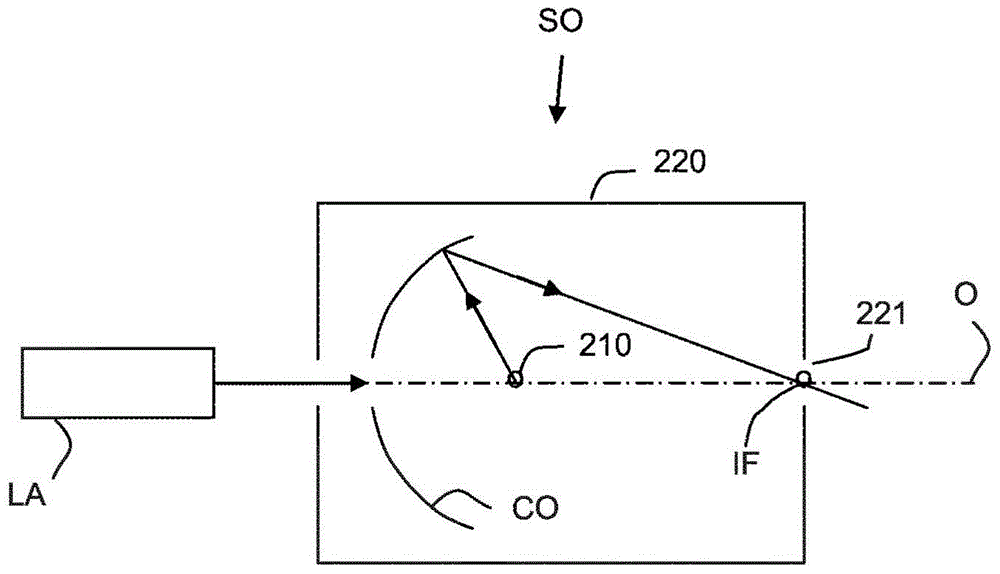

Sensor and lithographic apparatus

A backside illuminated sensor comprising a supporting substrate, a semiconductor layer which comprises a photodiode comprising a region of n-doped semiconductor provided at a first surface of the semiconductor layer, and a region of p-doped semiconductor, wherein a depletion region is formed between the region of n-doped semiconductor and the region of p-doped semiconductor, and a layer of p-doping protective material provided on a second surface of the semiconductor layer, wherein the first surface of the semiconductor layer is fixed to a surface of the supporting substrate.

Owner:ASML NETHERLANDS BV

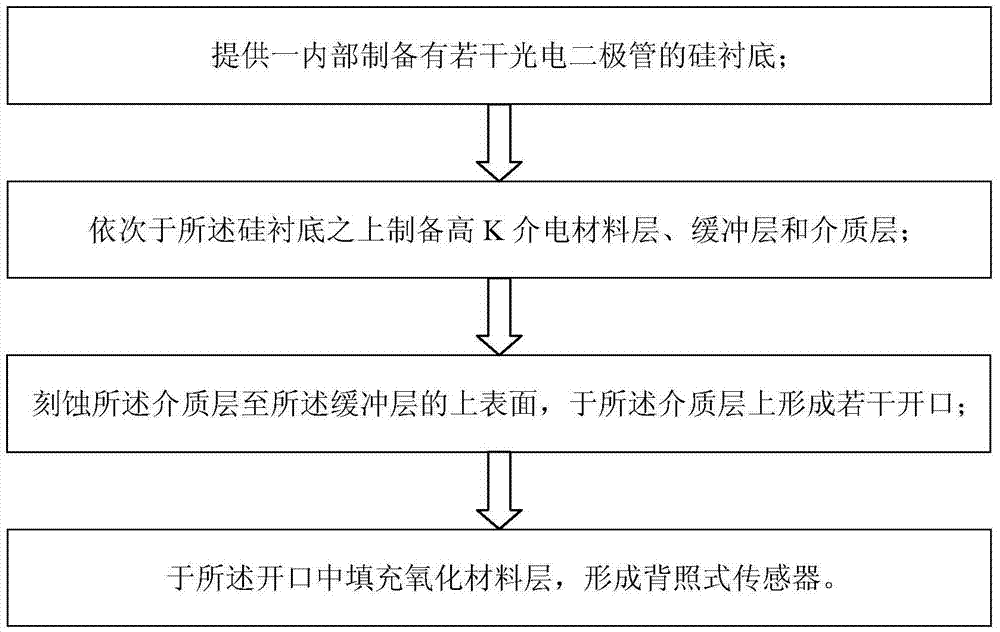

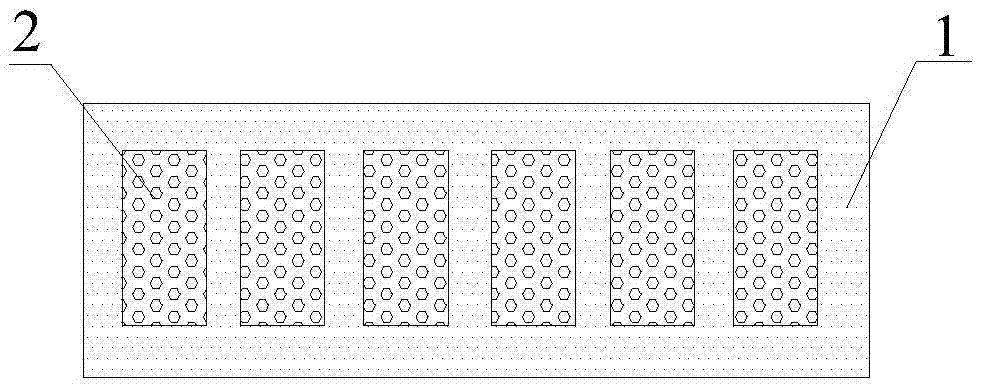

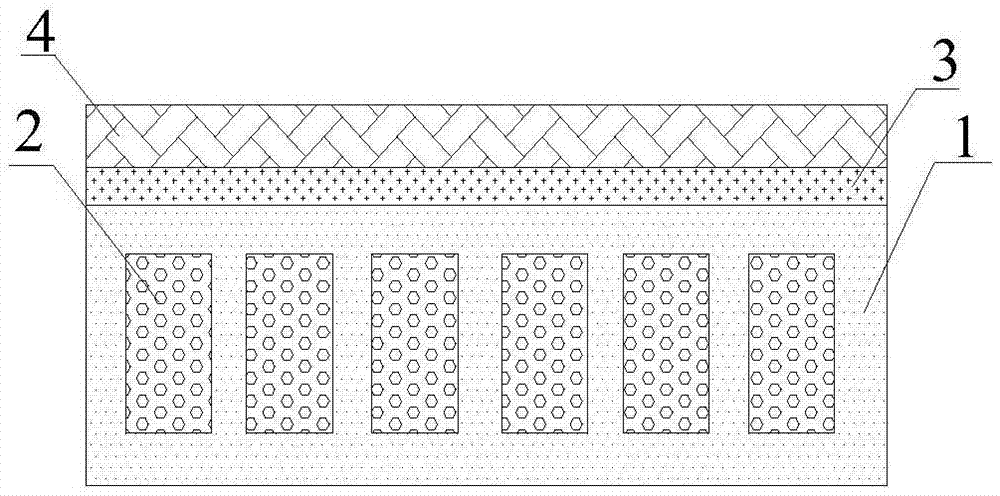

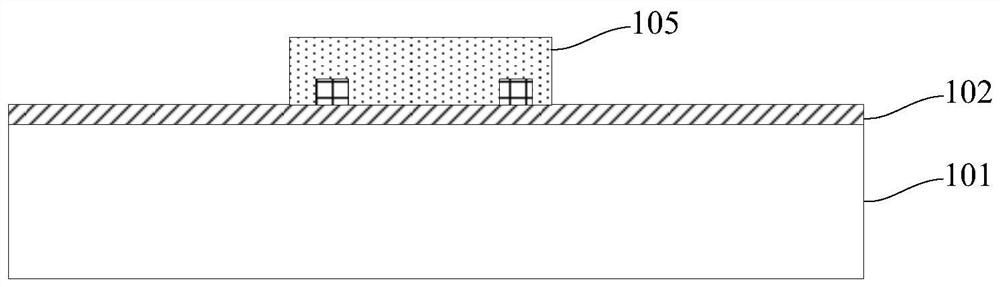

Backside-illuminated sensor and manufacturing process thereof

ActiveCN105448943ASimple processImprove performanceSolid-state devicesRadiation controlled devicesQuantum efficiencyMedia layer

The invention relates to the technical field of semiconductor preparation processes, and especially relates to a backside-illuminated sensor manufacturing process. The manufacturing process comprises the following steps: providing a silicon substrate in which a plurality of photodiodes are prepared; sequentially preparing a high-K dielectric material layer, a buffer layer and a medium layer on the silicon substrate; etching the medium layer to the upper surface of the buffer layer to form a plurality of openings in the medium layer; and filling the openings with an oxide material layer to form a backside-illuminated sensor of which the medium layer is inlaid with the oxide material layer. The backside-illuminated sensor preparation process disclosed by the technical scheme is simple, can meet the requirements of different backside illumination processes, improves the quantum efficiency, and improves the performance of chips.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

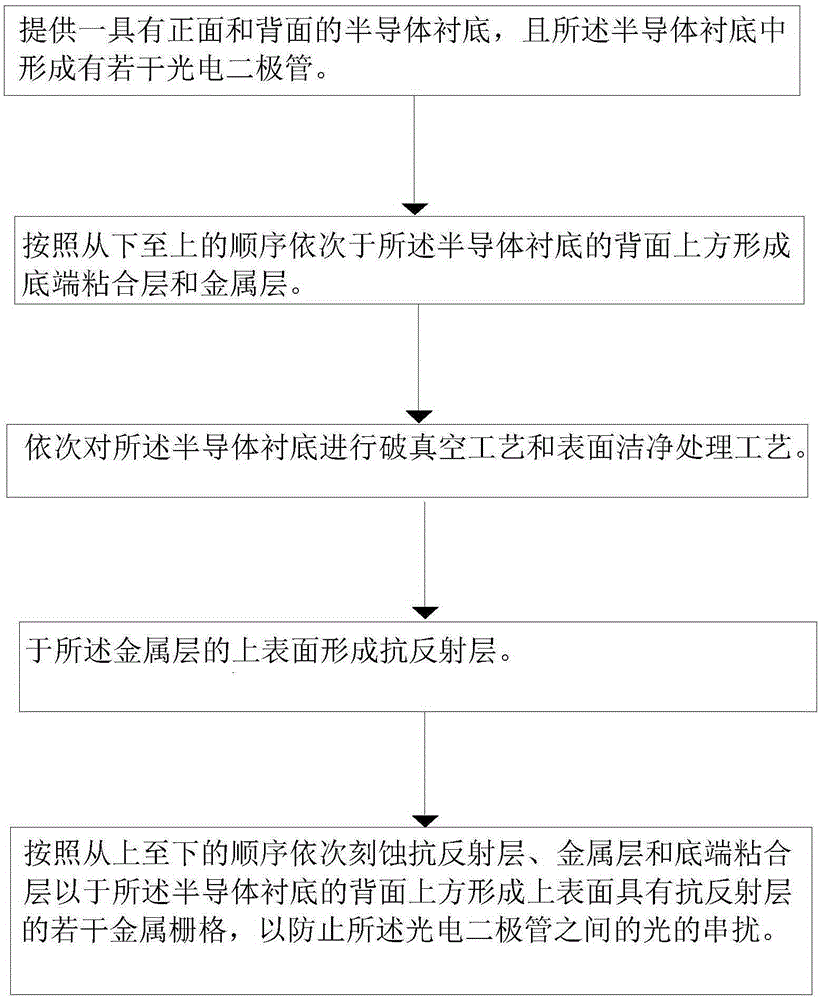

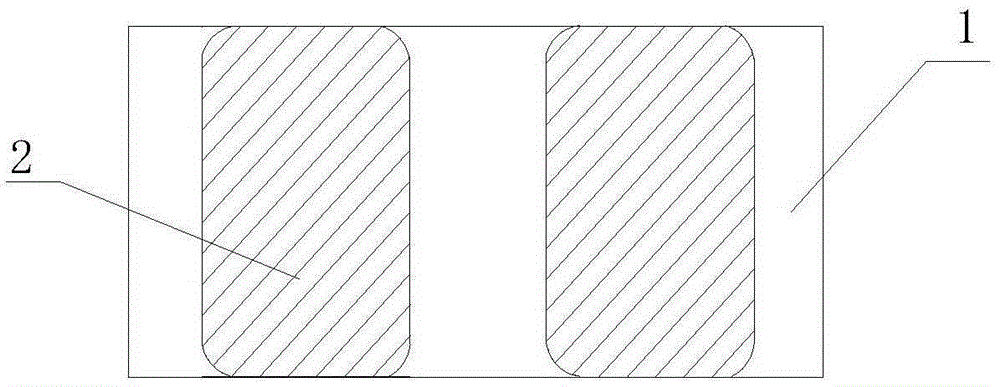

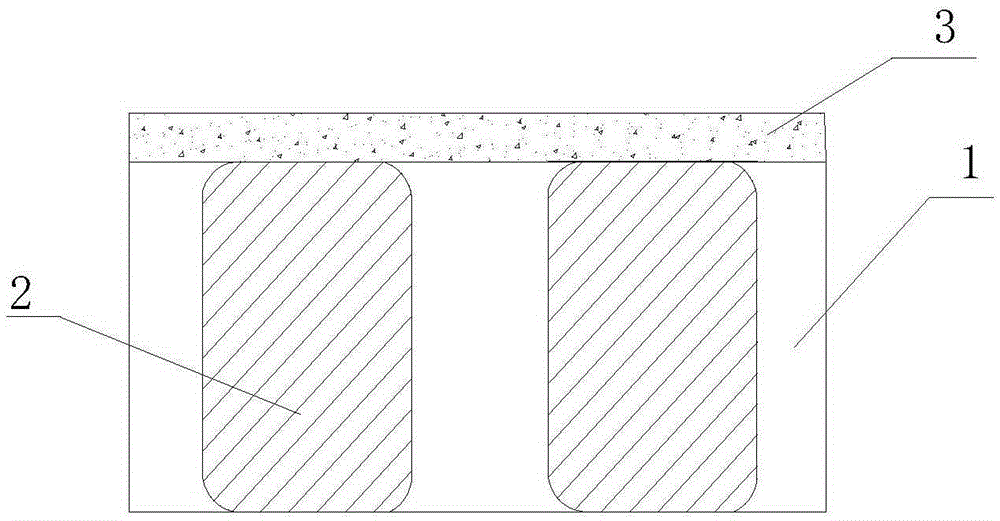

Method for preparing backside-illuminated sensor

InactiveCN105304667AAvoid light crosstalkImprove performanceRadiation controlled devicesAbnormal growthsSurface cleaning

The invention relates to the technical field of semiconductor manufacture, particularly to a method for preparing a backside-illuminated sensor. After a metal grid bottom bonding layer and metal layer film-coating process, a vacuum breaking process and a surface cleaning treatment process are performed on a semiconductor substrate in sequence, then an anti-reflection layer is deposited on the metal layer, and finally a plurality of metal grids whose upper surfaces have anti-reflection layers are formed through patterning and etching, thereby avoiding an abnormal projection phenomenon in a reverse side metal grid layer process, reducing abnormal growth, avoiding extra light crosstalk between different pixels, and improving performance of a backside-illuminated sensor chip.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Device for acquiring three-dimensional data of human body by adopting backside illuminated CMOS sensor.

The invention provides a device for acquiring three-dimensional data of a human body by adopting a backside illuminated CMOS sensor. A high-definition CCD sensor is adopted to carry out three-dimensional model coloring. SOC FPGA is used for collecting and synchronizing all three-dimensional and planar image information at a high speed. Four sets of same acquisition devices are used for acquiring three-dimensional and color data of the human body in four directions. A ground weight scale and a capacitive touch sensor are adopted to carry out human body weighing and foot bottom three-dimensionalscanning. The invention provides a human body high-frame-rate three-dimensional scanning device adopting back-illuminated CMOS. Rapid three-dimensional scanning can be realized multiple times in themoving process of the human body. The external shape can be manually corrected in the scanning process. Modeling is carried out according to a symmetric comparison fuzzy modeling method. so that the accuracy and practicability of final human body actual modeling after scanning are improved. Data splicing and 3D modeling are carried out at a PC terminal. A complete 3D model is finally output. Oarameter information needed by various kinds of needed clothes is generated, and the parameter information is transmitted to a server to be stored.

Owner:李保德

Packaging method of back-illuminated cmos sensor

ActiveCN107611152BImprove reliabilityReduce package sizeRadiation controlled devicesCMOS sensorElectrical connection

The invention provides a method for packaging a backside illuminated CMOS sensor, which comprises a re-wiring layer, a backside illuminated CMOS sensor structure fixedly connected to the second surface of the re-wiring layer, a logic chip arranged on the first surface of the re-wiring layer, a packaging material coated on the logic chip, a through hole formed in the packaging material, and a metallead structure formed in the through hole so as to realize the electrical lead out of the re-wiring layer, the backside illuminated CMOS sensor structure and the logic chip. According to the invention, the backside illuminated CMOS sensor, the logic chip and the metal lead structure are electrically connected through the method of the re-wiring layer, so that the packaging backside illuminated CMOS sensor is small in packaging size, high in sensing performance and high in device reliability. The electrical lead out of the re-wiring layer can be realized only by manufacturing metal columns inthe packaging materials in advance, so that the processes of silicon perforation and the like are not needed. The process cost can be greatly saved.

Owner:SJ SEMICON JIANGYIN CORP

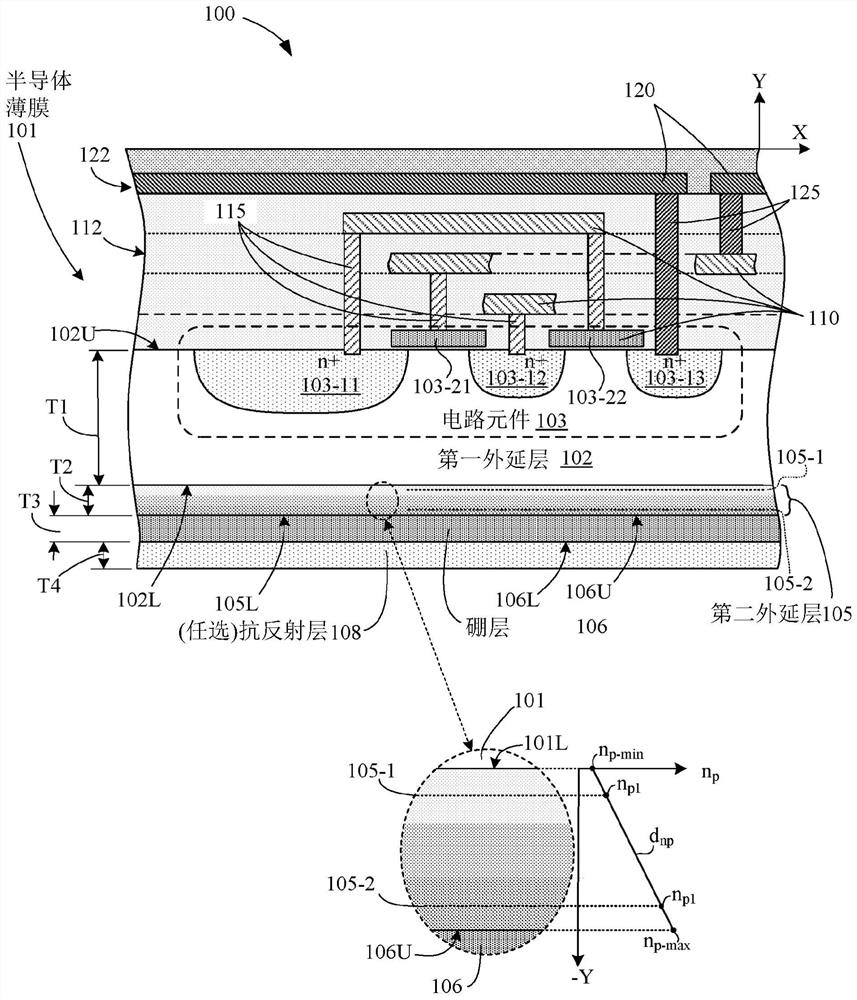

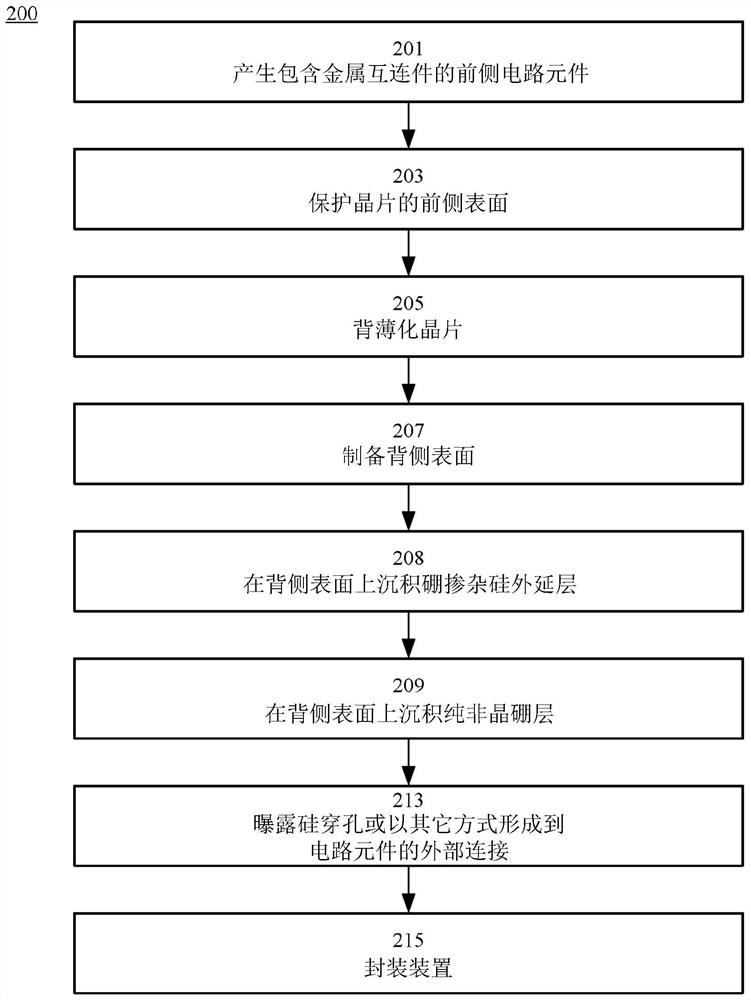

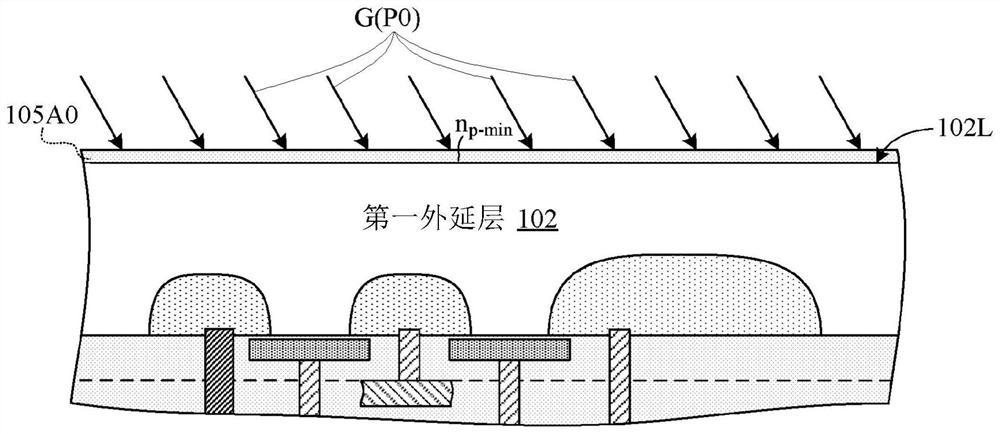

Back-illuminated sensor and a method of manufacturing a sensor

An image sensor utilizes a pure boron layer and a second epitaxial layer having a p-type dopant concentration gradient to enhance sensing DUV, VUV or EUV radiation. Sensing (circuit) elements and associated metal interconnects are fabricated on an upper surface of a first epitaxial layer, then the second epitaxial layer is formed on a lower surface of the first epitaxial layer, and then a pure boron layer is formed on the second epitaxial layer. The p-type dopant concentration gradient is generated by systematically increasing a concentration of p-type dopant in the gas used during deposition / growth of the second epitaxial layer such that a lowest p-type dopant concentration of the second epitaxial layer occurs immediately adjacent to the interface with the first epitaxial layer, and such that a highest p-type dopant concentration of the second epitaxial layer occurs immediately adjacent to the interface with pure boron layer.

Owner:KLA CORP

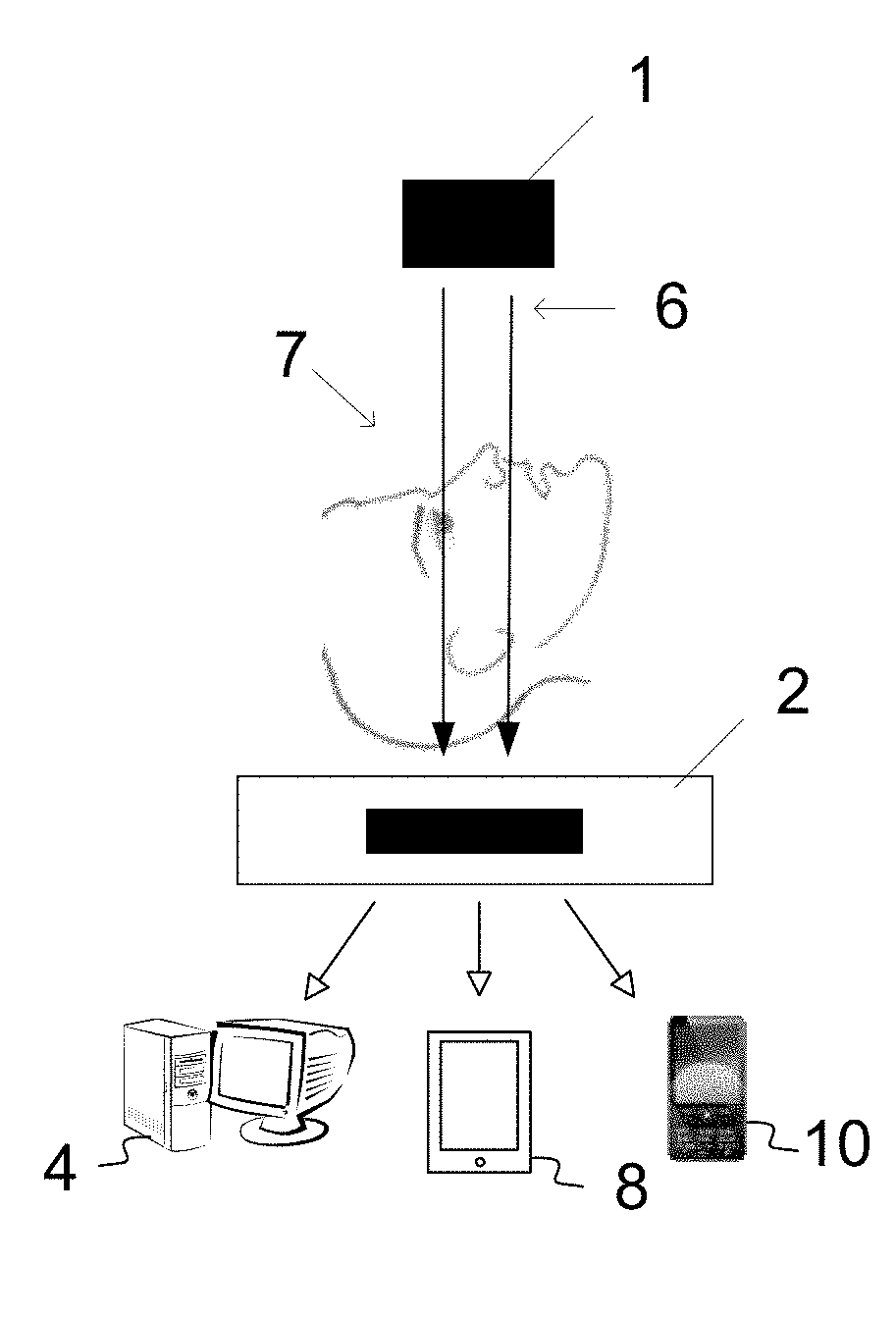

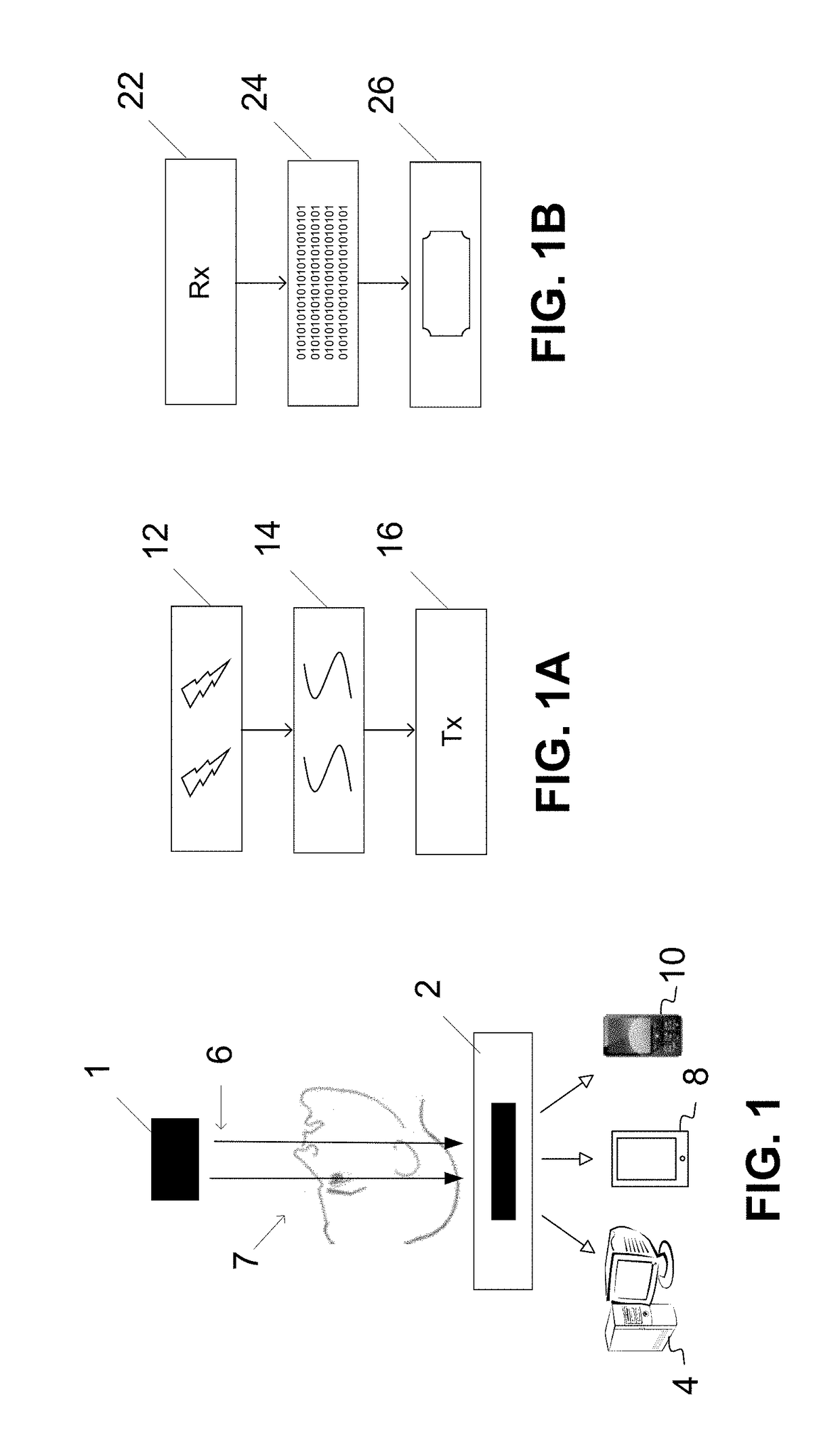

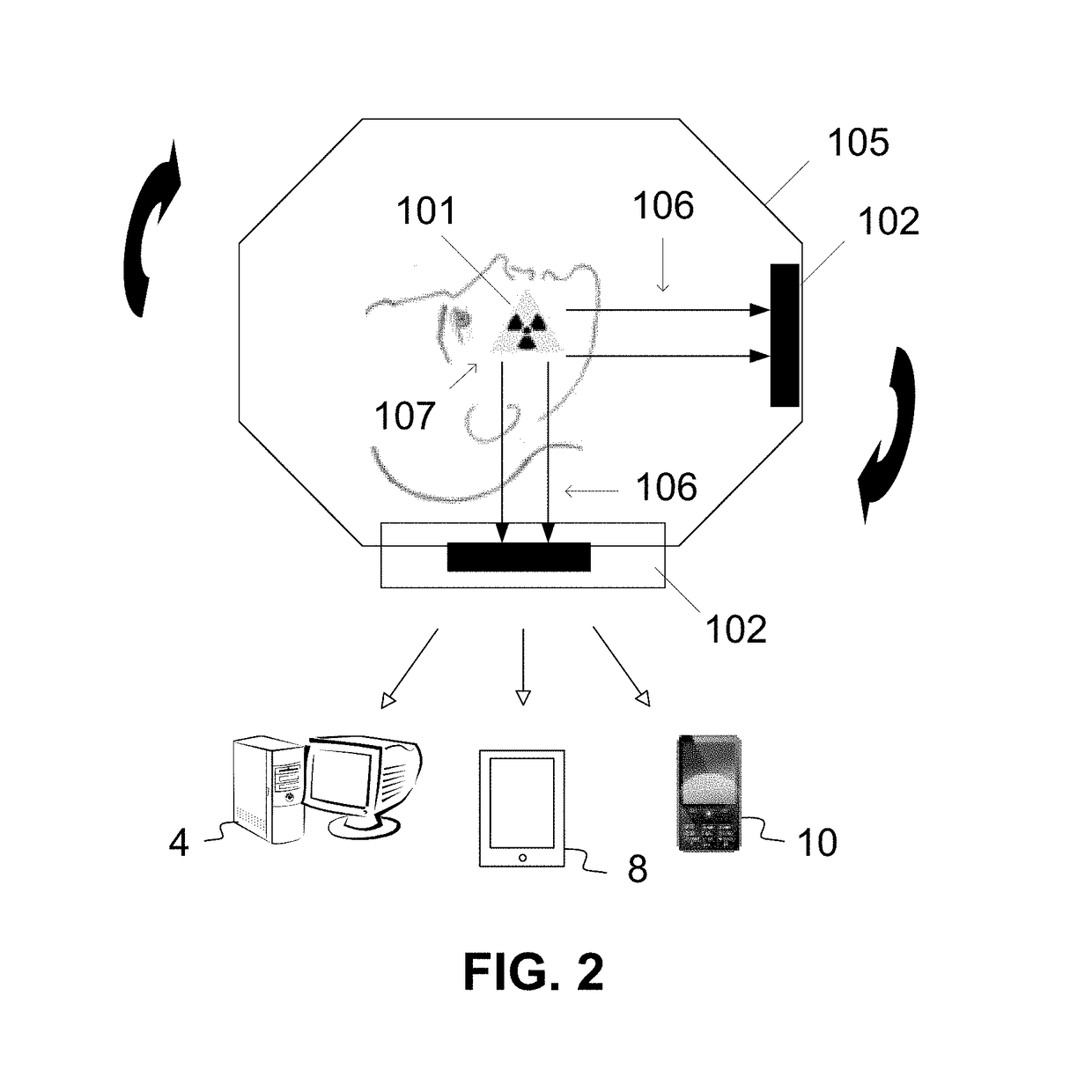

Low-dose x-ray imaging system

ActiveUS20170325768A1Reduce in quantityMinimize radiationRadiation diagnosis data transmissionComputerised tomographsPhotocathodeX-ray

A back illuminated sensor preferably is included as a collector component of a detector for use in intraoral and extraoral 2D and 3D dental radiography, positron emission tomography (PET) and single-photon emission computed tomography (SPECT). The disclosed imaging method includes one or more intraoral or extraoral emitters for emitting a low-dose gamma ray or x-ray beam through a dental examination area; and one or more intraoral or extraoral detectors for receiving the beam, each detector including a back illuminated sensor. Within the detector, the beam preferably is converted into light and then focused and collected at a photocathode layer without passing through the wiring layer of the back illuminated sensor.

Owner:REAL TIME IMAGING TECH

A kind of preparation method of back-illuminated sensor

ActiveCN105702695BEliminate color anomaliesMinimizes variance in incident light lossSolid-state devicesRadiation controlled devicesImaging qualityBack-illuminated sensor

The present invention relates to the technical field of semiconductor manufacturing, in particular to a method for preparing a back-illuminated sensor, by forming a metal grid layer, a first oxide layer and a barrier layer on the back surface of the semiconductor substrate in sequence from bottom to top , and after etching to form a number of metal grids, a second oxide layer whose upper surface is flush with the upper surface of the barrier layer is formed, and then the barrier layer and the second oxide layer located on the first oxide layer are removed, so as to Forming an oxide layer with a uniform thickness on the upper surface of the metal grid layer reduces the difference in incident light loss, thereby eliminating color abnormalities in the appearance of the back-illuminated sensor wafer and improving imaging quality.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

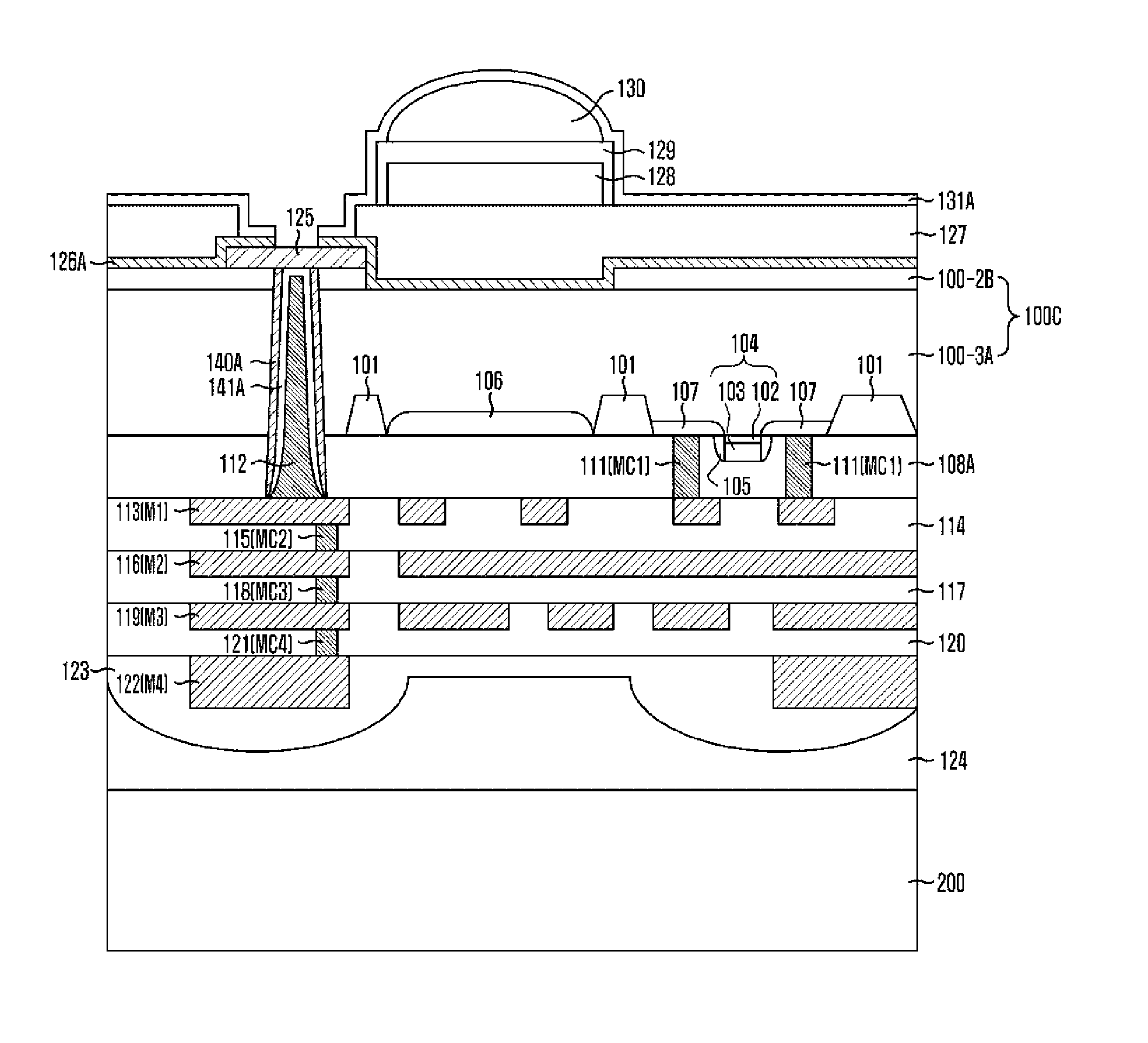

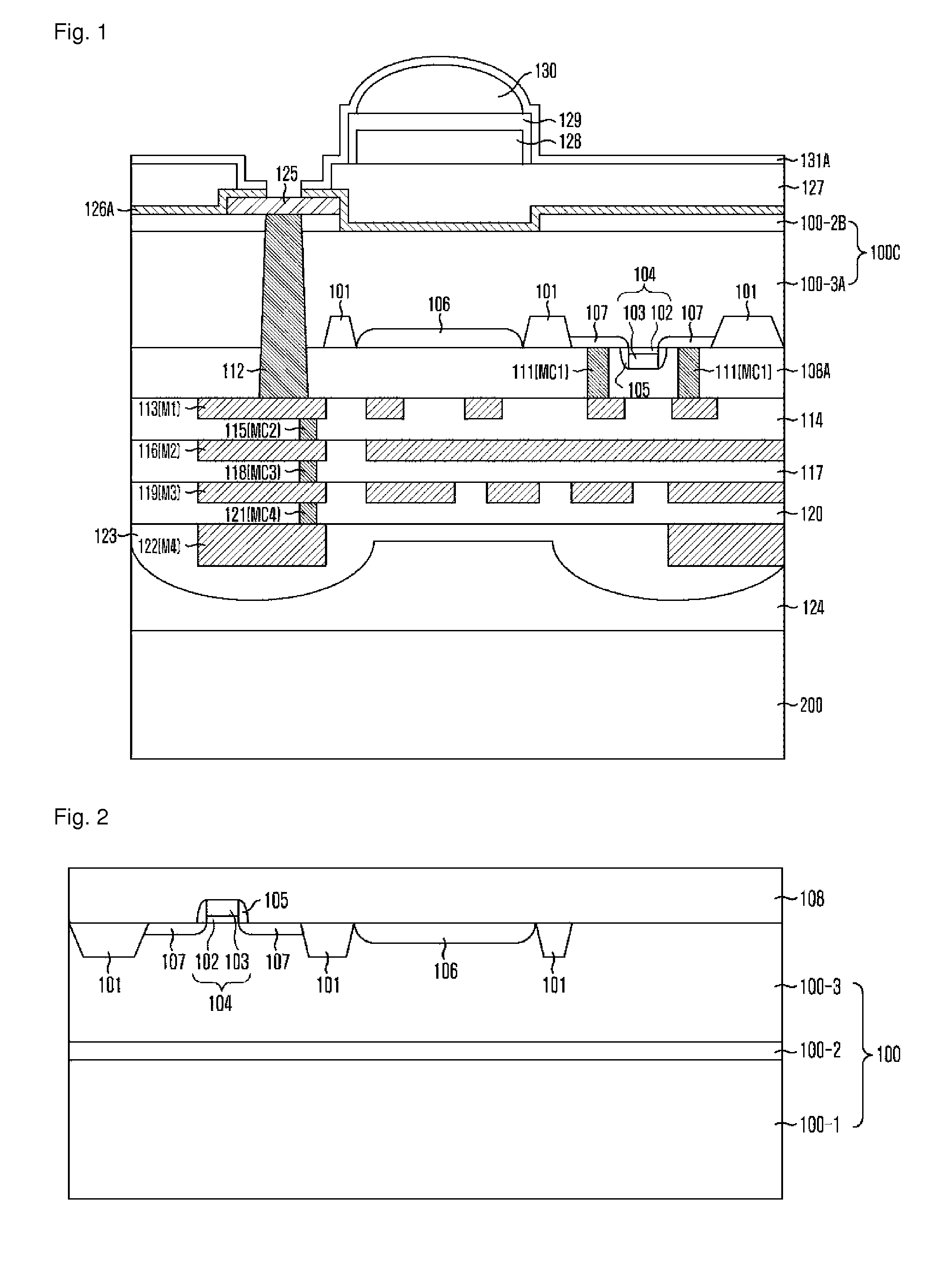

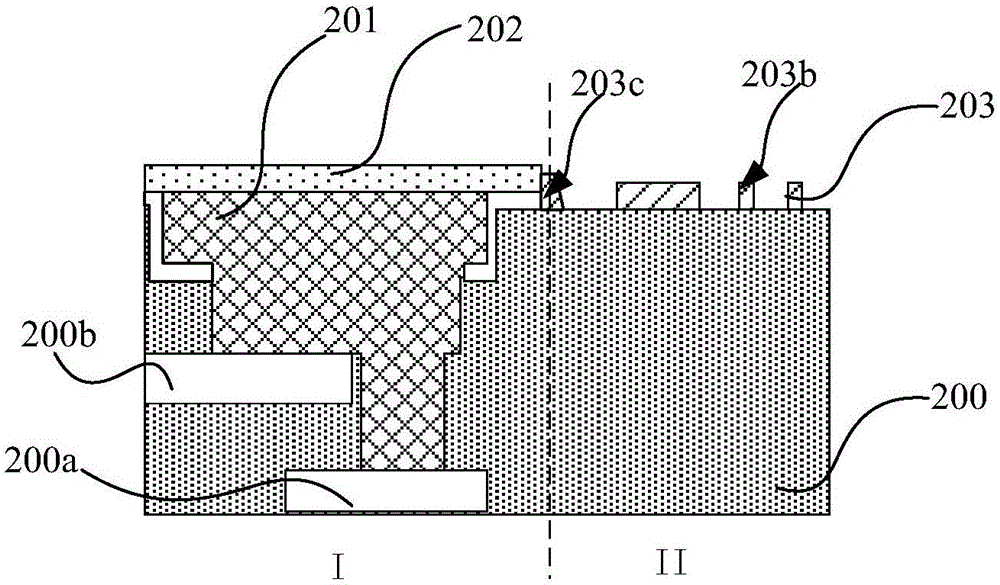

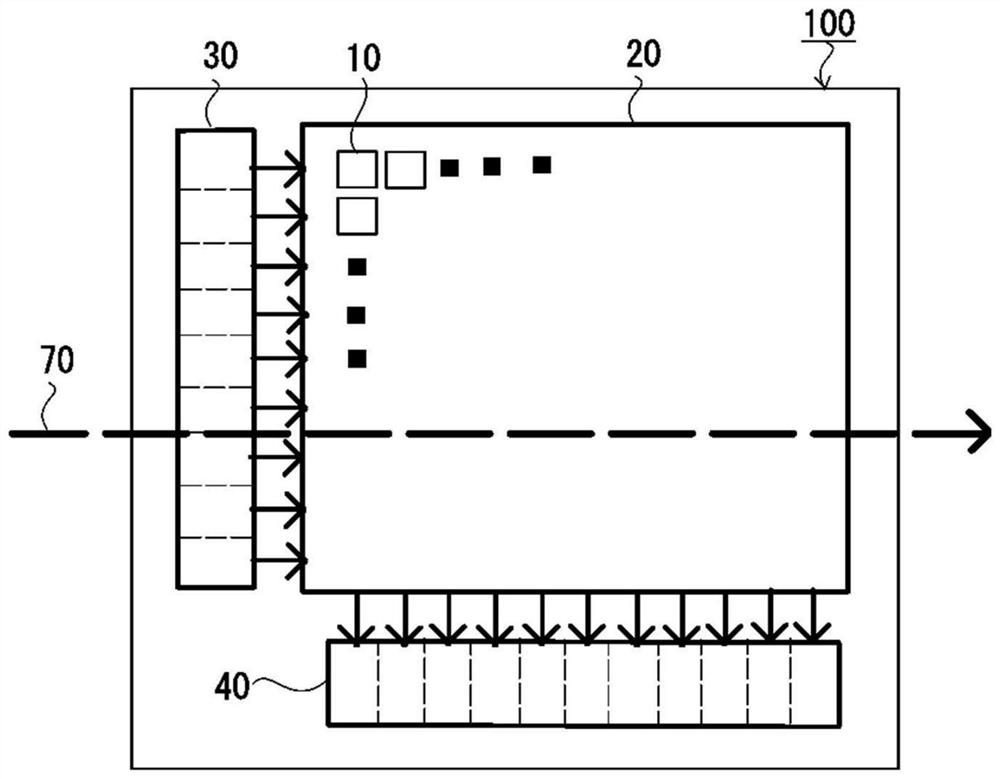

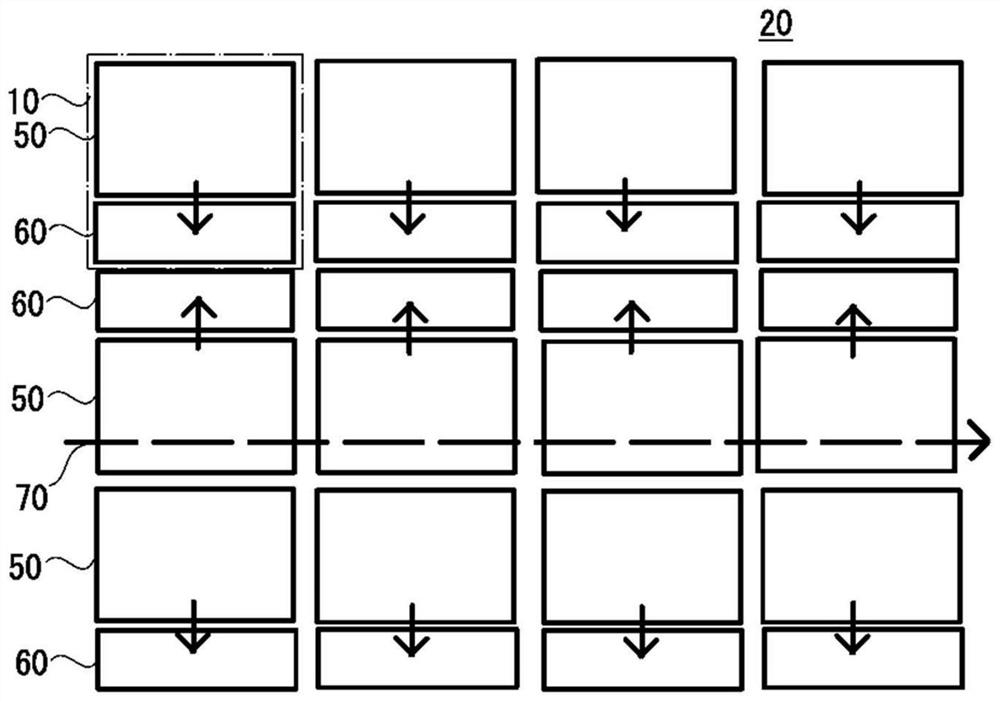

Manufacturing method of backside illuminated and electronic impact type CMOS sensors, pixel and sensor

PendingCN112992952APrevent Sensitivity DeteriorationWon't pass throughSolid-state devicesRadiation controlled devicesCMOS sensorHemt circuits

The invention provides a manufacturing method of a backside illuminated CMOS sensor and a method for manufacturing an electron impact CMOS sensor, wherein the backside illuminated CMOS sensor and the electron impact CMOS sensor are capable of suppressing variation and increase of variation of characteristics of an analog circuit formed on a surface. This method for manufacturing a backside illuminated CMOS sensor (100) comprises: a formation step in which an N-type photosensitive region (50) is formed inside a silicon substrate (305); an implantation step in which ions for forming a P + diffusion layer (270) are implanted into the back surface of the silicon substrate (305); and an irradiation step in which laser light is irradiated from the back surface in order to activate the implanted ions, wherein the laser light is irradiated to the back-illuminated CMOS sensor (100) excluding the region where the analog circuit (40) is formed on the surface.

Owner:长春长光辰芯光电技术有限公司(日本)

Semiconductor device and manufacturing method thereof

ActiveCN102214664BSuppress leak toEliminate electrical crosstalkSolid-state devicesRadiation controlled devicesSilicon oxideOxygen

The present disclosure provides methods and apparatus for sensor element isolation in a backside illuminated image sensor. In one embodiment, a method of fabricating a semiconductor device includes providing a sensor layer having a frontside surface and a backside surface, forming a plurality of frontside trenches in the frontside surface of the sensor layer, and implanting oxygen into the sensor layer through the plurality of frontside trenches. The method further includes annealing the implanted oxygen to form a plurality of first silicon oxide blocks in the sensor layer, wherein each first silicon oxide block is disposed substantially adjacent a respective frontside trench to form an isolation feature. A semiconductor device fabricated by such a method is also disclosed.

Owner:TAIWAN SEMICON MFG CO LTD

Packaging structure and packaging method of back-illuminated cmos sensor

ActiveCN107425031BImprove reliabilityReduce package sizeSolid-state devicesRadiation controlled devicesCMOS sensorElectrical connection

The invention provides a packaging structure and packaging method of a back-illuminated CMOS sensor, comprising: a rewiring layer; a back-illuminated CMOS sensor structure fixedly connected to the second surface of the rewiring layer; a logic chip arranged on the The first surface of the rewiring layer; packaging material, covering the logic chip; perforation, formed in the packaging material; metal lead structure, made in the through hole, so as to realize the rewiring layer, the The back-illuminated CMOS sensor structure is electrically derived from the logic chip. The present invention adopts the method of rewiring layer to realize the electrical connection between the back-illuminated CMOS sensor, the logic chip and the metal lead structure, and has the advantages of small packaging volume, high sensing performance and device reliability; The electrical extraction of the rewiring layer can be achieved by opening holes in the packaging material, without the need for silicon through holes and other processes, which can greatly save process costs.

Owner:SJ SEMICON JIANGYIN CORP

Method of making a back-illuminated radiation sensor and a back-illuminated radiation sensor

A backside illuminated sensor comprising a supporting substrate, a semiconductor layer which comprises a photodiode comprising a region of n-doped semiconductor provided at a first surface of the semiconductor layer, and a region of p-doped semiconductor, wherein a depletion region is formed between the region of n-doped semiconductor and the region of p-doped semiconductor, and a layer of p-doping protective material provided on a second surface of the semiconductor layer, wherein the first surface of the semiconductor layer is fixed to a surface of the supporting substrate.

Owner:ASML NETHERLANDS BV

Method for fabricating backside-illuminated sensors

InactiveUS8871608B2Solid-state devicesSemiconductor/solid-state device manufacturingElectrical connectionBack-illuminated sensor

A method for fabricating a backside-illuminated sensor includes providing a thin film semiconductor lamina having a first conductivity, and forming a doped region having a second conductivity within the lamina and at a front surface of the lamina. The lamina may be provided as a free-standing lamina, or may be provided as a semiconductor donor body from which the lamina is cleaved. An electrical connection is formed to the doped region. A temporary carrier is contacted to the back surface of the semiconductor and later removed. A backside-illuminated sensor is fabricated from the semiconductor lamina, in which the thickness of the semiconductor lamina remains substantially unchanged during the fabrication process.

Owner:NEUTRON THERAPEUTICS LLC

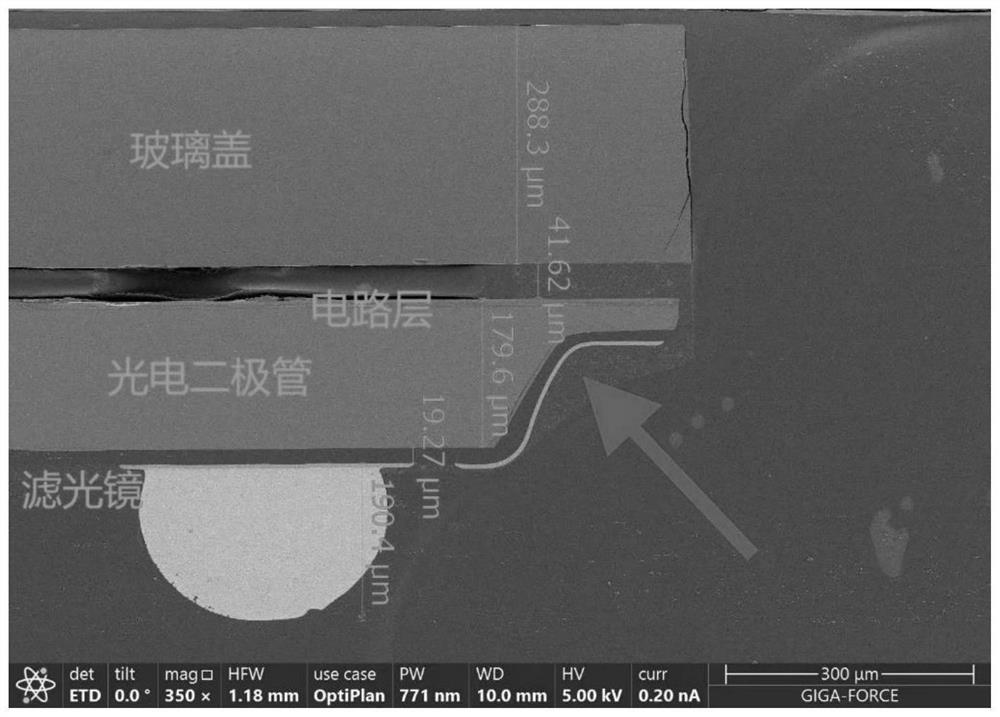

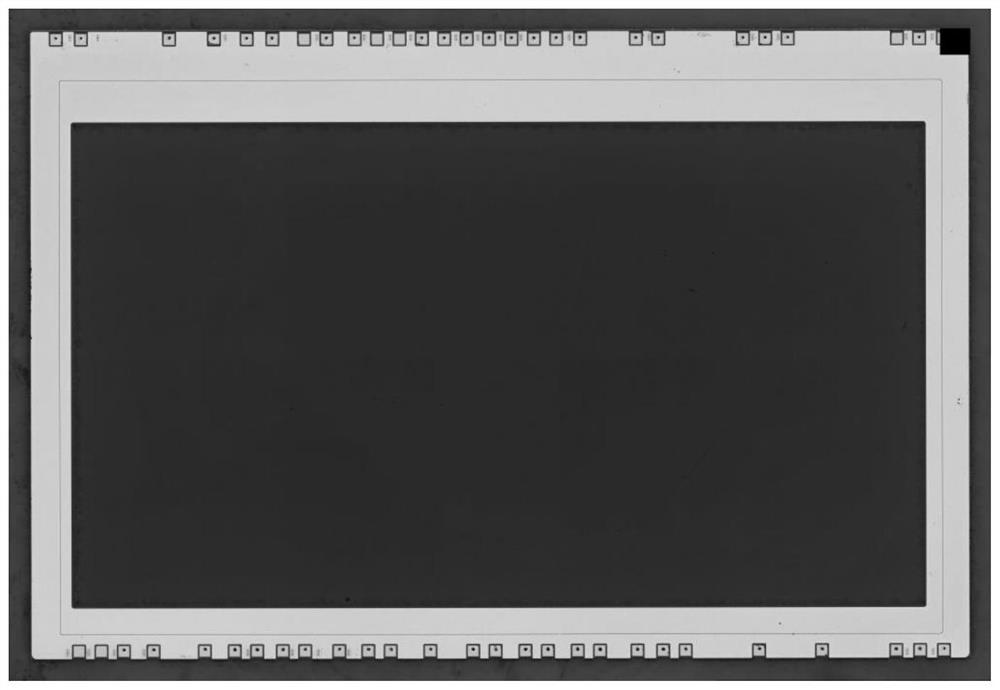

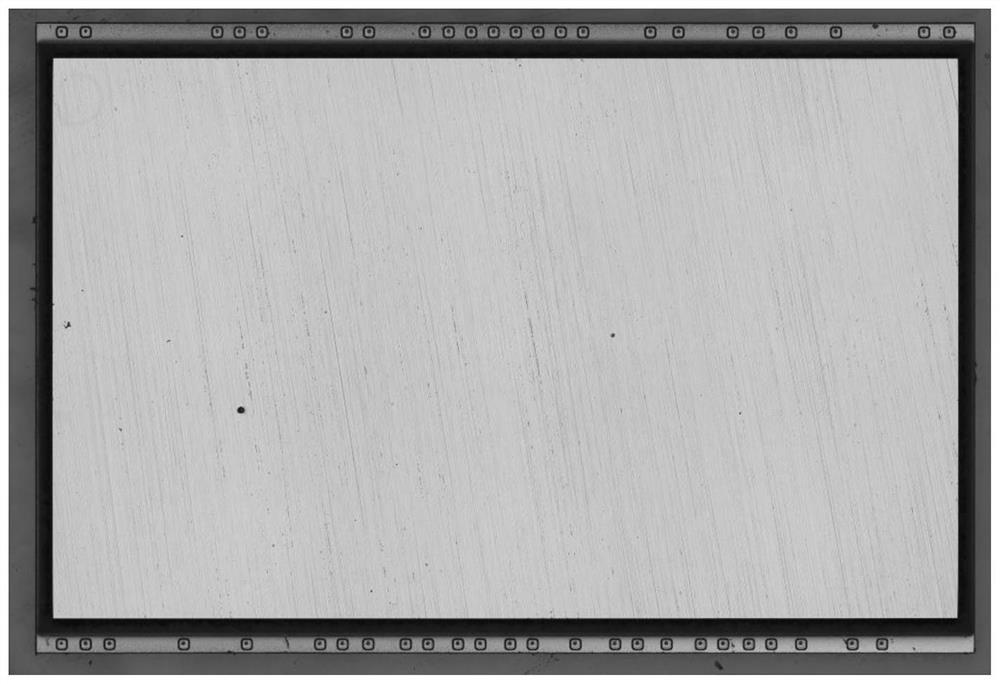

Method for taking crystal grains from backside illuminated CMOS (complementary metal oxide semiconductor) sensor and application

PendingCN114486439AAffect the extraction situationGuaranteed flatnessPreparing sample for investigationFinal product manufactureCMOS sensorHemt circuits

The invention provides a method for taking crystal grains from a backside illuminated CMOS sensor and application, and relates to the technical field of CMOS sensors. The method comprises the following steps: firstly, carrying out mixed acid treatment on the back-illuminated CMOS sensor, flatly fixing one side, close to a circuit layer, of an obtained pretreated crystal grain on a silicon wafer, and carrying out optional primary grinding on one side, far away from the circuit layer, of the pretreated crystal grain so as to remove a possibly residual packaging material; then reactive ion etching and secondary grinding are carried out to enable the circuit layer to be completely exposed and keep certain flatness, and crystal grains are obtained; wherein the pretreated crystal grains are flatly fixed on the silicon wafer, and the silicon wafer can provide a supporting effect for the circuit layer, so that the problems of falling or layering of the circuit layer and the like cannot occur in the subsequent extraction process, thereby realizing complete and intact extraction of the crystal grains, and providing a basis for subsequent failure analysis work. The invention further provides a failure analysis method of the backside illuminated CMOS sensor.

Owner:GIGA FORCE ELECTRONICS CO LTD

Back-illuminated sensor with bonding pad structure and manufacturing method thereof

ActiveCN102867832BSemiconductor/solid-state device detailsSolid-state devicesDielectricSemiconductor structure

Owner:TAIWAN SEMICON MFG CO LTD

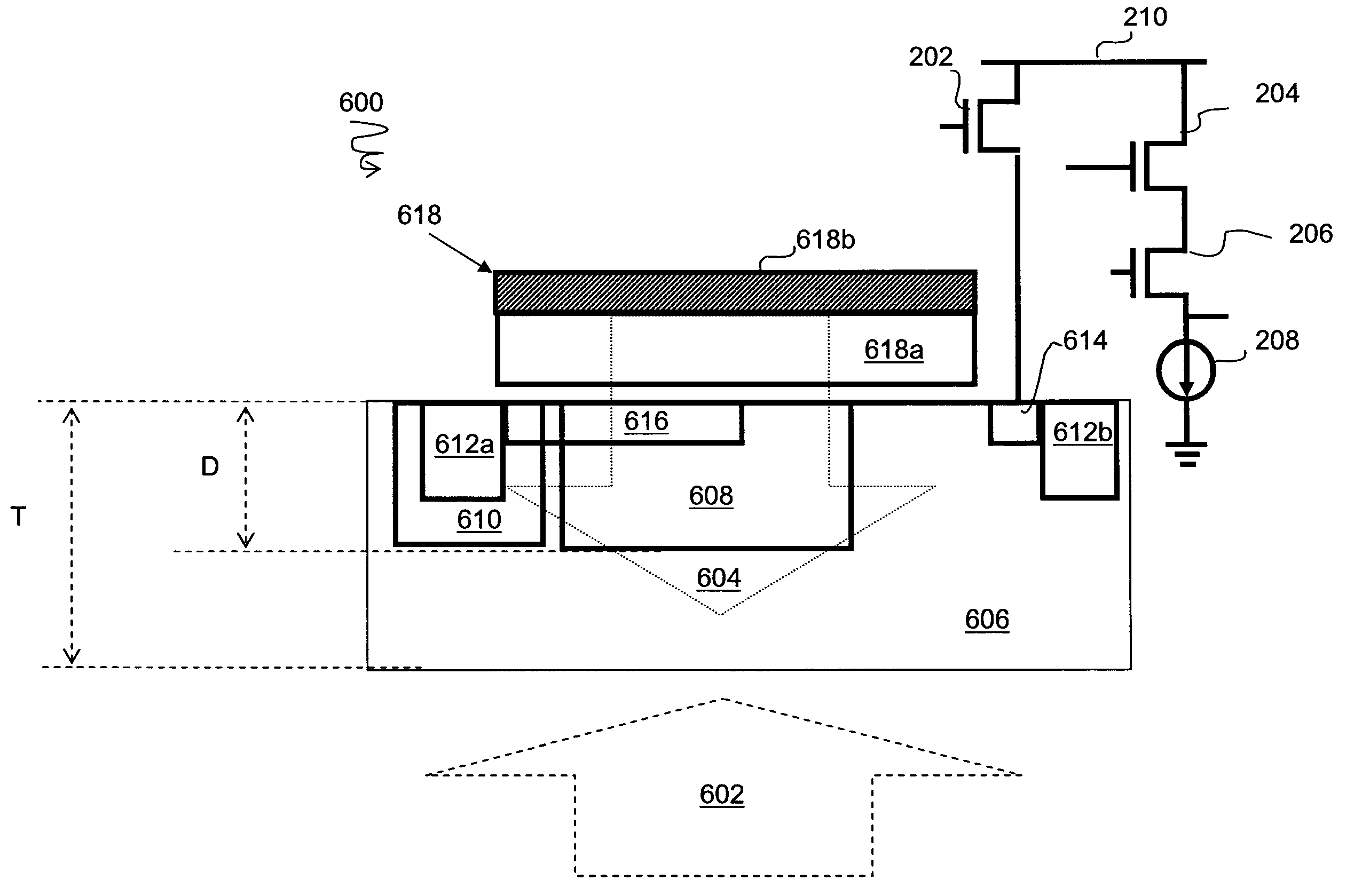

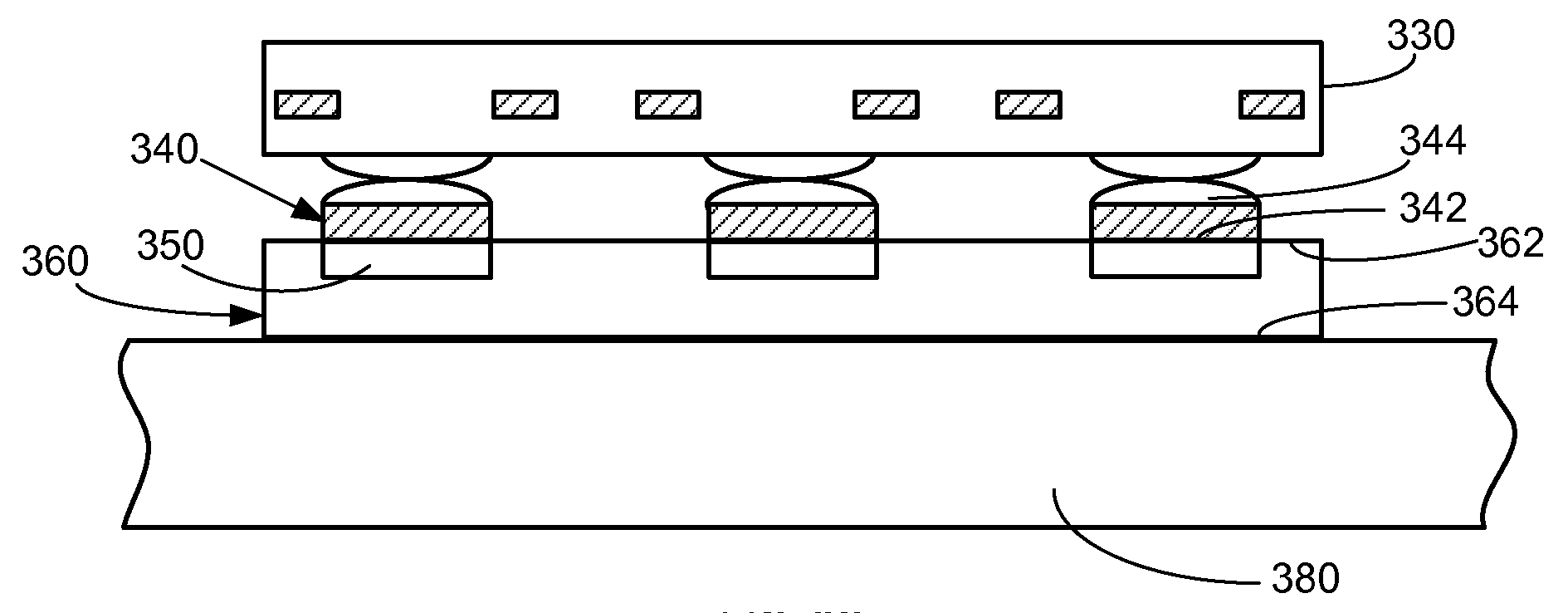

Back-Illuminated Sensor Chips

ActiveUS20160315110A1Solve the real problemUniform Image QualitySolid-state devicesDiodeComputer visionBack-illuminated sensor

A back-illuminated sensor chip is disclosed, which includes one or more pixel areas each including a plurality of pixels located in a plane and arranged in a matrix. Each pixel area includes: a central portion consisting of a plurality of first pixels located in vicinity of a center of the pixel area; and a peripheral portion surrounding the central portion and consisting of the other pixels in the pixel area than the first pixels. The plurality of first pixels have a first height in a vertical direction perpendicular to the plane, and the pixels in the peripheral portion have a second height in the vertical direction that is greater than the first height so that the peripheral portion protrudes outward beyond the central portion and is thus located nearer to a light source during imaging than the central portion. As a result, light sensibility of the peripheral portion is increased.

Owner:OMNIVISION TECH (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com