Method for taking crystal grains from backside illuminated CMOS (complementary metal oxide semiconductor) sensor and application

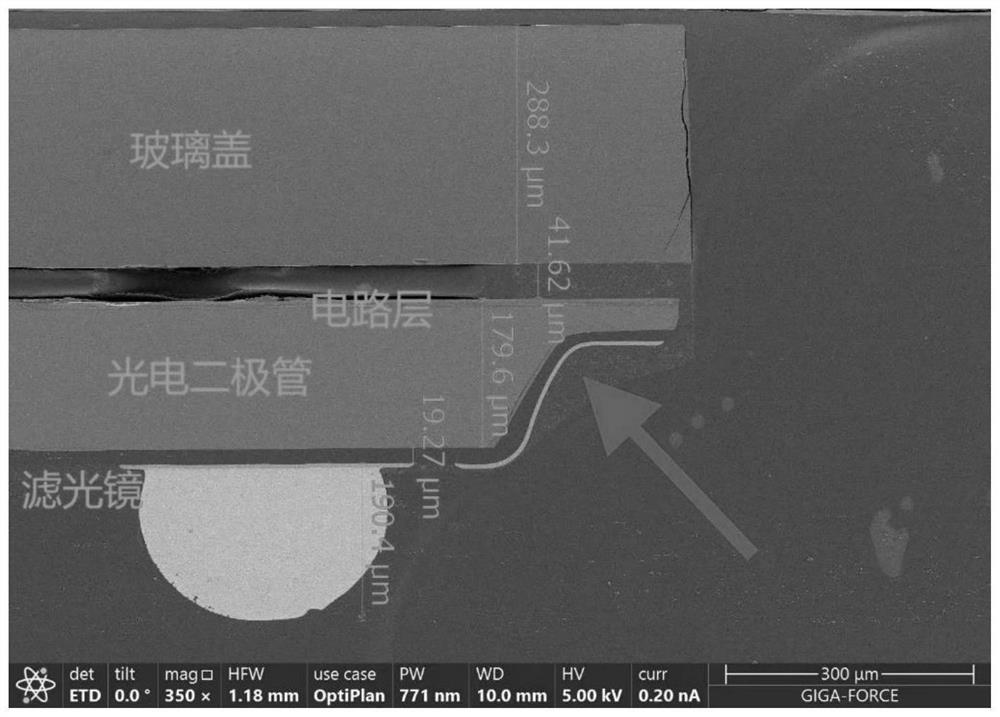

A CMOS sensor, back-illuminated technology, applied in the field of CMOS sensors, can solve the problem of not being able to take a complete grain, and achieve the effect of improving imaging quality, increasing speed, high sensitivity and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

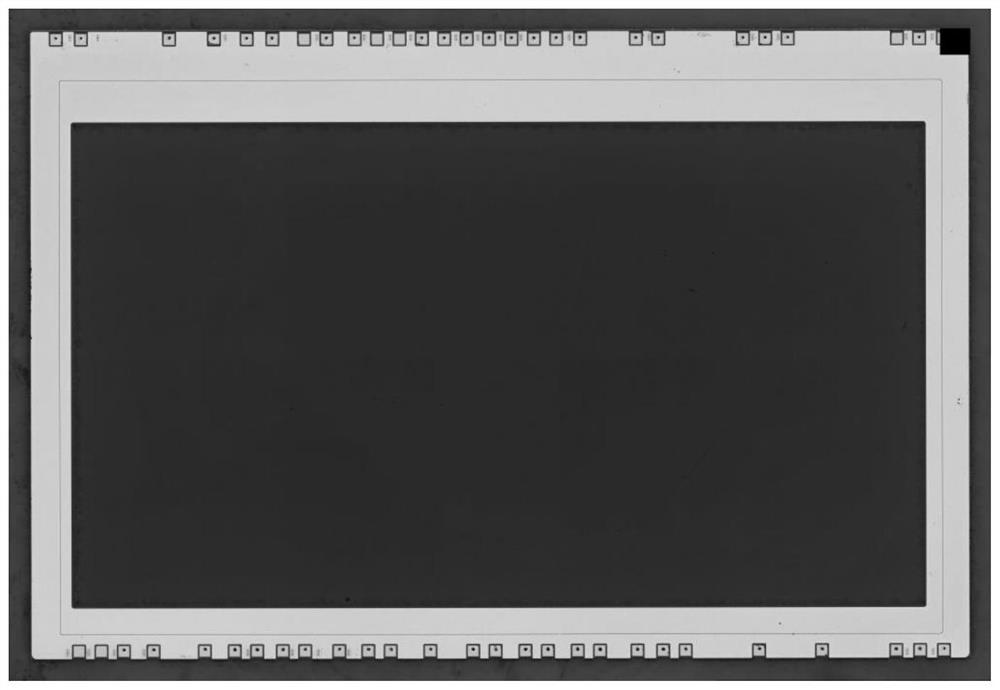

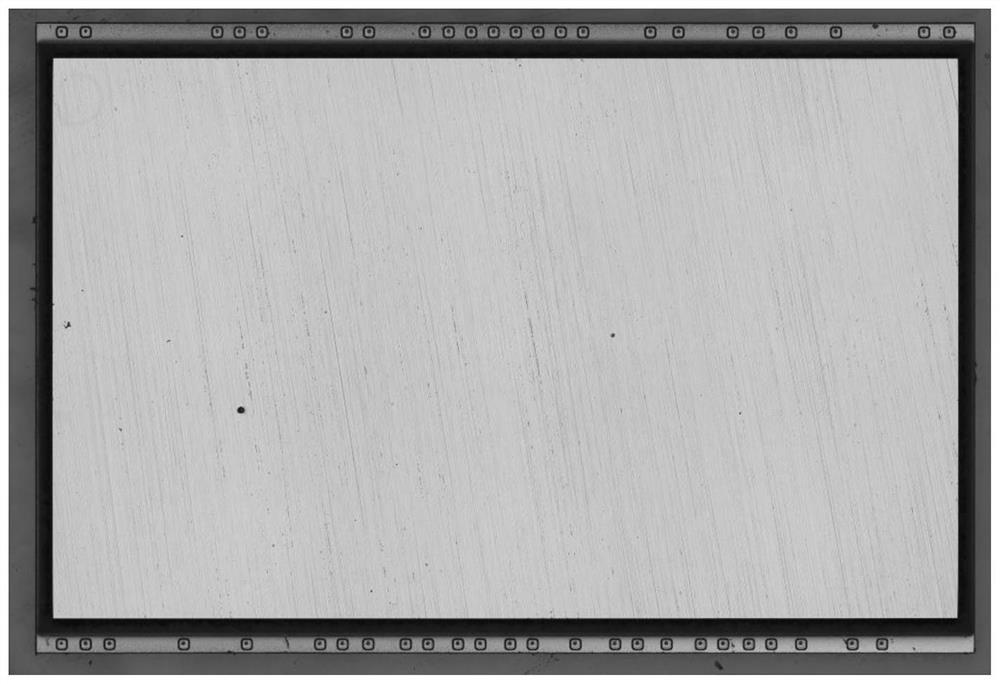

Image

Examples

Embodiment 1

[0096] This embodiment provides a method for taking crystal grains in a back-illuminated CMOS sensor, comprising the following steps:

[0097] (a) placing the back-illuminated CMOS sensor in mixed acid for treatment to remove at least most of the packaging material on the surface of the grain, and taking it out to obtain a pre-treated grain;

[0098] Wherein, the mixed acid includes sulfuric acid and nitric acid, the mass fraction of sulfuric acid is 98%, the mass fraction of nitric acid is 68%, the volume ratio of sulfuric acid and nitric acid is 5:1, the treatment temperature is 150°C, and the treatment time is 1h;

[0099] (b) Apply glue (AB glue for preparing metal pattern samples, high temperature resistance temperature is 220°C) on the silicon wafer, and fix the side of the pretreated grain close to the circuit layer on the silicon wafer (can be used at 100°C Bake for 40 minutes to solidify), to ensure that there are no air bubbles between the pre-treated grains and the ...

Embodiment 2

[0105] This embodiment provides a method for obtaining crystal grains in a back-illuminated CMOS sensor. Except that the volume ratio of sulfuric acid and nitric acid in the mixed acid in step (a) is 4.5:1, the remaining steps and process parameters are the same as in Embodiment 1.

Embodiment 3

[0107] This embodiment provides a method for obtaining crystal grains in a back-illuminated CMOS sensor. Except that the volume ratio of sulfuric acid and nitric acid in the mixed acid in step (a) is 4:1, the remaining steps and process parameters are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| High temperature resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com