Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Vulcanization rate is slow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

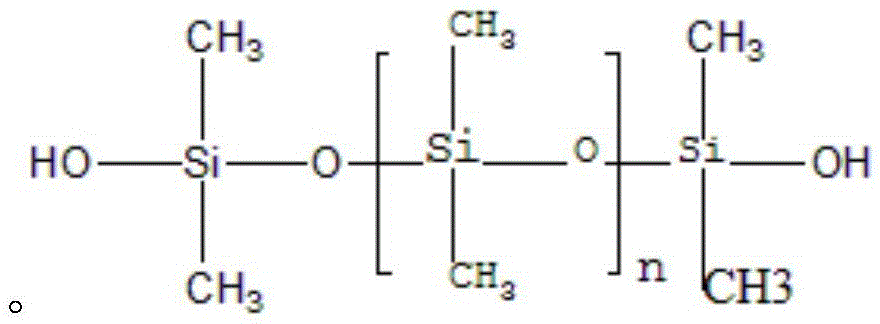

Silicone Materials Which Crosslink By Condensation At Room Temperature

ActiveUS20110028647A1Fast cross-linkingVulcanization rate is slowCoatingsAdhesivesRoom temperatureInorganic acids

Materials crosslinkable at room temperature by condensation, based on organosilicon compounds which cure to give permanently resilient materials, are catalyzed by a compound of the main or subgroups I and II in conjunction with an inorganic acid as a catalyst.

Owner:WACKER CHEM GMBH

Condensation-Crosslinking Silicone Materials

Materials crosslinkable at room temperature by condensation are based on organosilicon compounds which cure to give permanently resilient materials, and which employ one or more compounds of the metals Li, Na, K, Mg, Ca, or Sr as catalyst.

Owner:WACKER CHEM GMBH

High-strength tear-resistant modified cable material and preparation method thereof

The invention discloses a high-strength tear-resistant modified cable material. The high-strength tear-resistant modified cable material comprises the following raw materials in part by weight: 36-42 parts of polyurethane rubber, 52-56 parts of butadiene-vinylpyridine rubber, 6-9 parts of hydrogenated nitrile rubber, 10-13 parts of nano-cellulose whisker, 1.8-2.2 parts of silane coupling agent A-151, 2-2.5 parts of sulphur, 1.1-1.4 parts of accelerant TMTD (tetramethyl thiuram disulfide), 1.5-1.8 parts of accelerant AC, 7-8 parts of light calcium carbonate, 5-6 parts of modified graphene, 24-28 parts of hard clay, 20-23 parts of mica powder, 2-3 parts of diethyl phthalate DEP, 3-5 parts of epoxy butyl oleate, 2-3 parts of pentaerythritol fatty acid ester, 2.3-2.6 parts of melamine phosphate, 8-11 parts of microencapsulated red phosphorus, 11-14 parts of zinc borate, 1.5-1.8 parts of anti-aging agent ODA and 0.9-1.2 parts of anti-aging agent DFC-34. The invention discloses a preparation method of the high-strength tear-resistant modified cable material.

Owner:ANHUI ELECTRIC GRP SHARES

Degradable highly-elastic sponge and preparation technology thereof

The invention relates to degradable highly-elastic sponge and a preparation technology thereof. The degradable highly-elastic sponge and the preparation technology thereof have the advantages that thedegradable highly-elastic sponge is made of green, natural and healthy materials according to the environment-friendly preparation technology, harmless to human bodies and capable of avoiding resource waste and environment pollution, and its mechanical properties including rebound resilience and compression set value are in compliance with the international standards; through adoption of recyclable pineapple fibers, resource waste is reduced and physical properties of low-density sponge with natural latex matrixes are improved to comply with the international standards; sodium alcohol ether sulphate and sodium lauryl sulfate which serve as foaming agents substitute for traditional pollutional ones to further avoid pollution; the high-performance low-density sponge with the excellent mechanical properties can be produced at a low preparation cost; the preparation technology is safe, simple and environment friendly.

Owner:德清舒华泡沫座椅有限公司

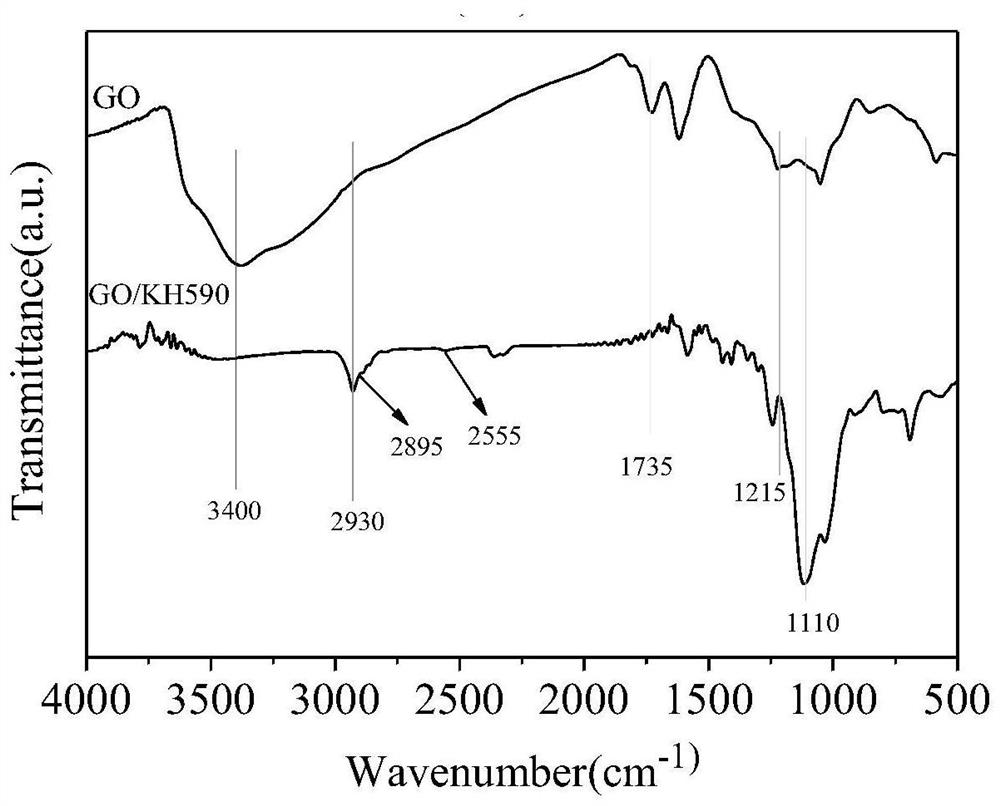

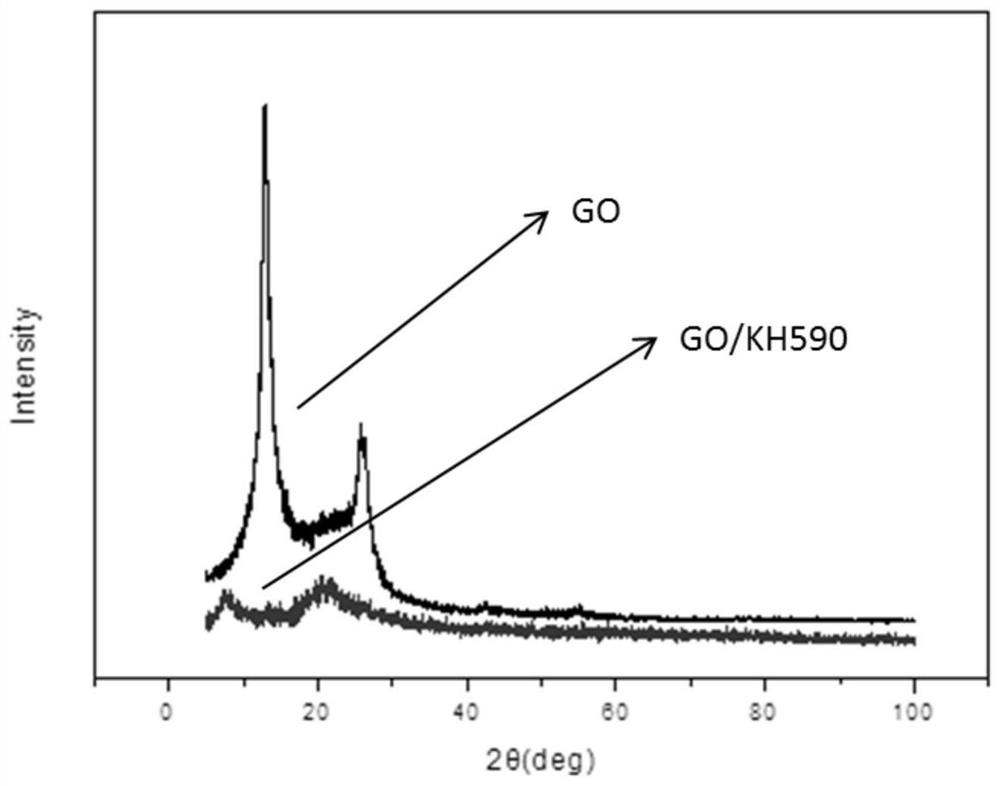

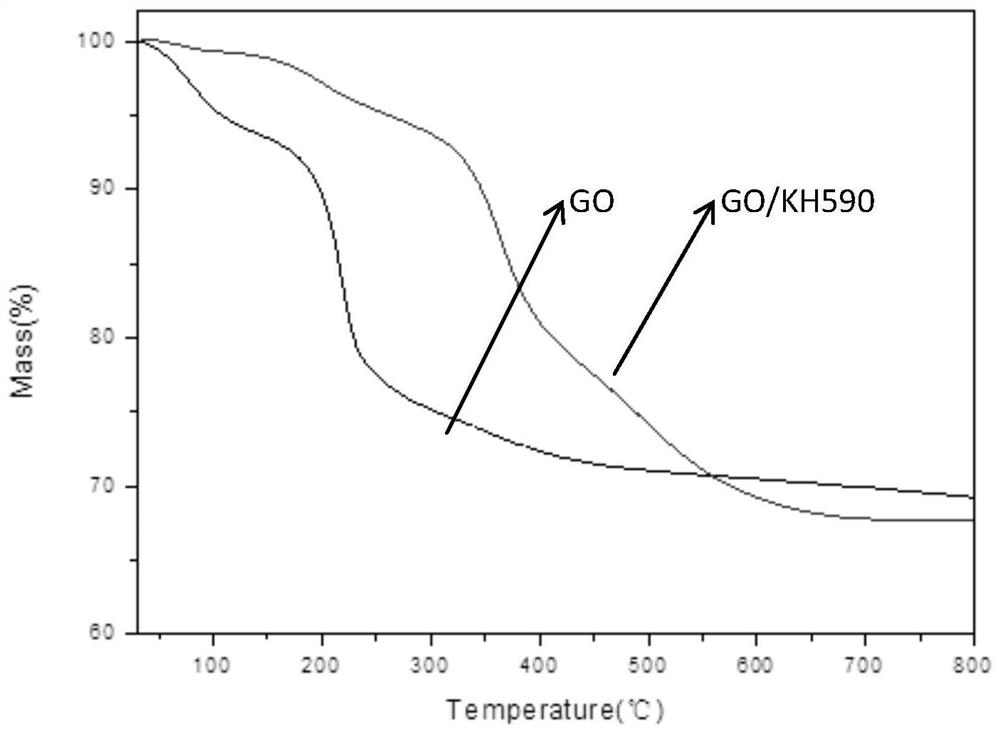

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

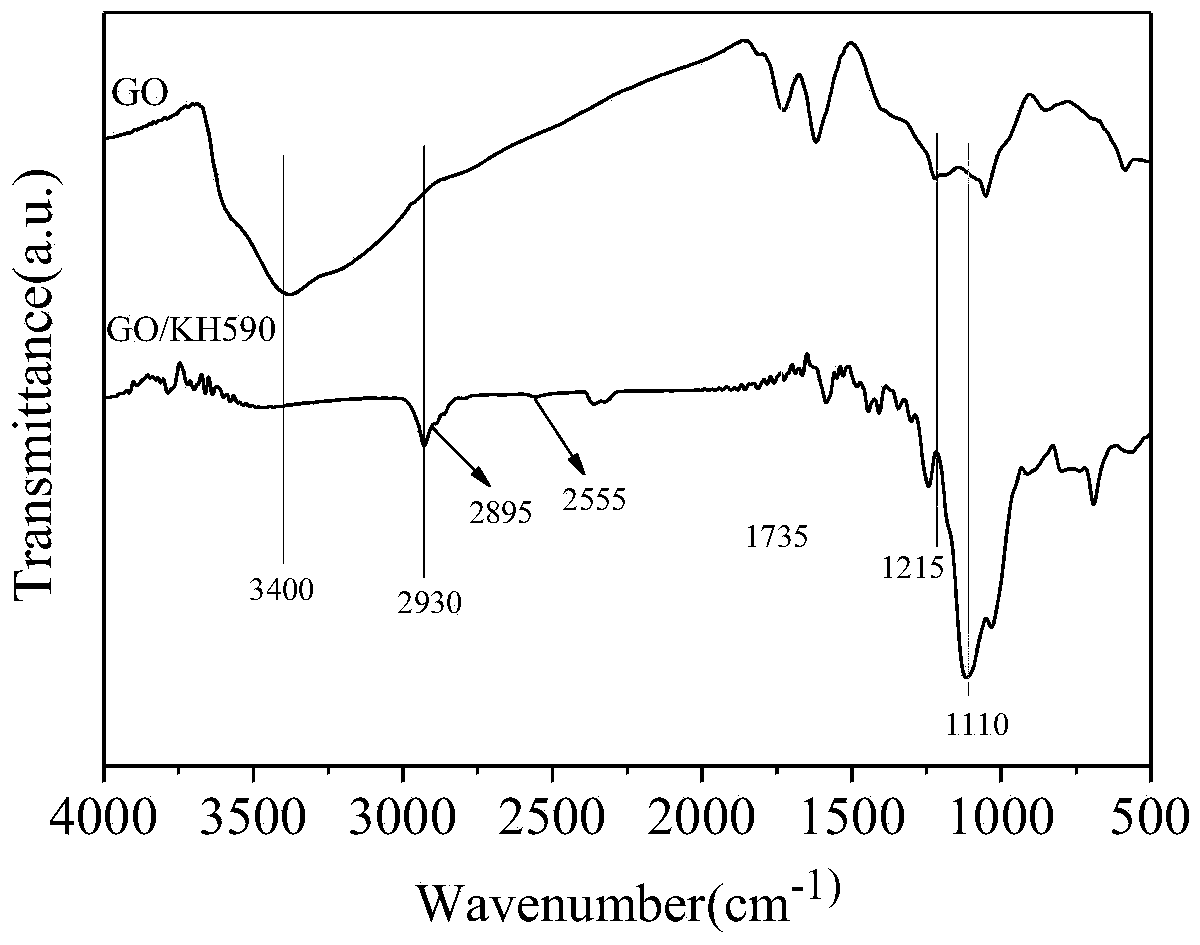

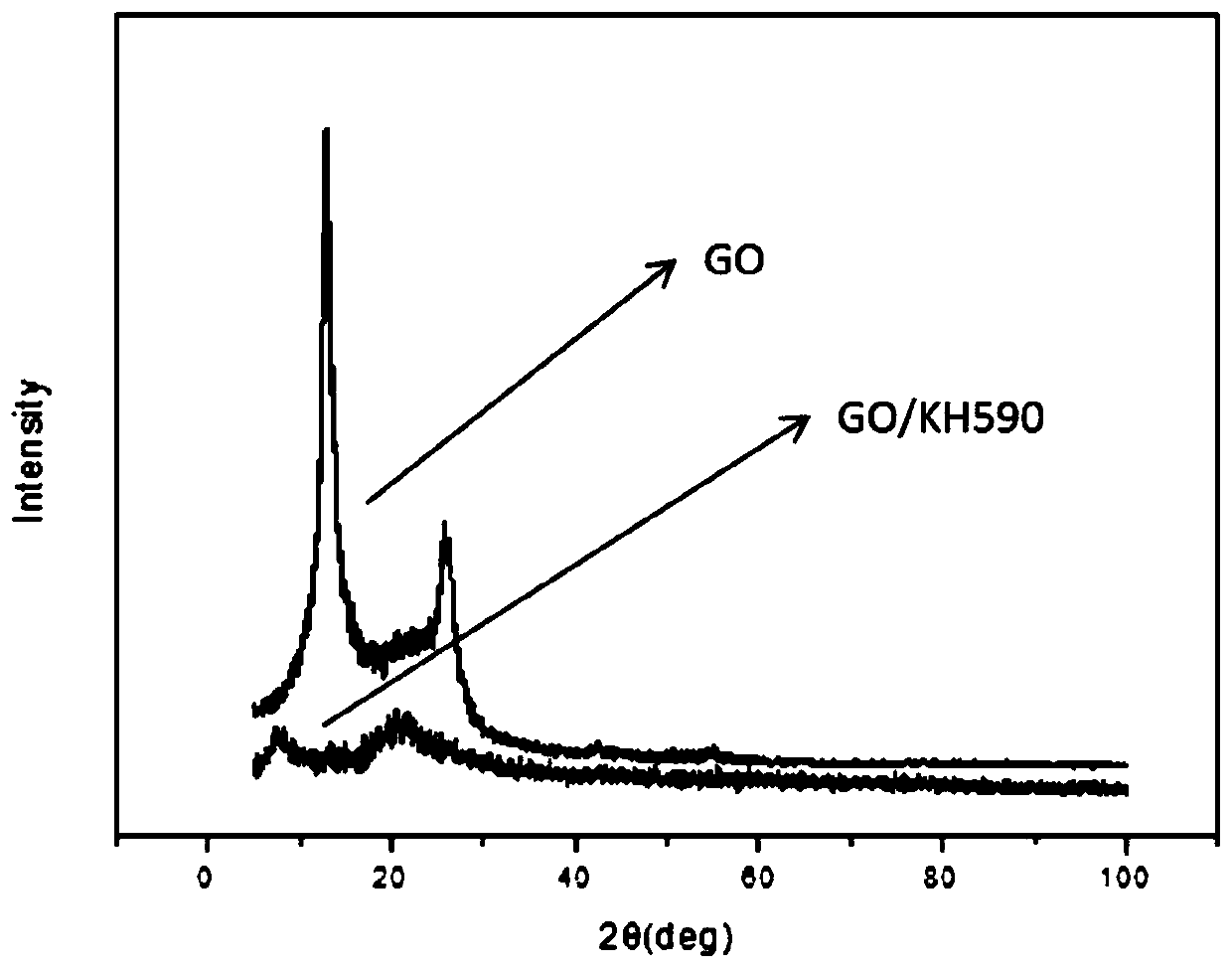

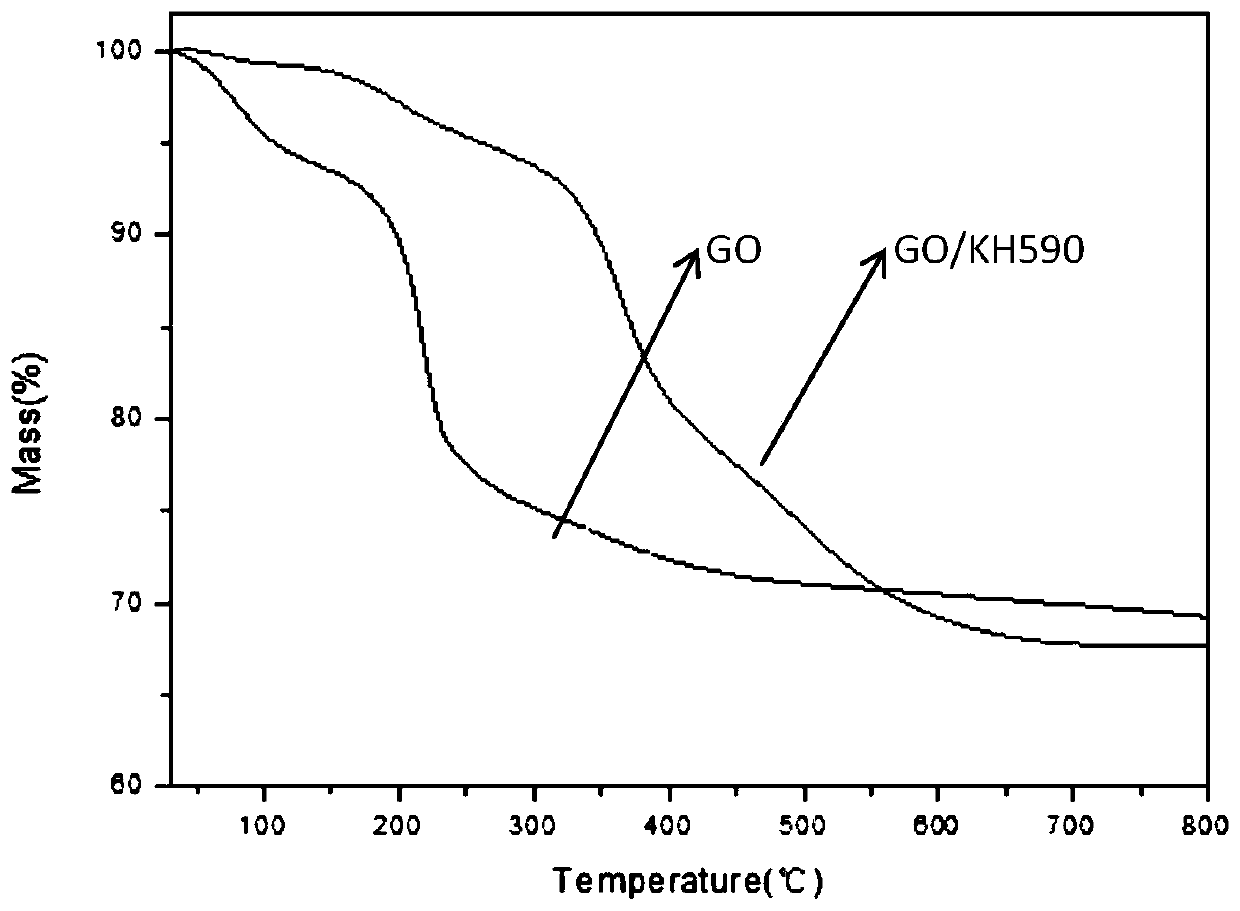

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

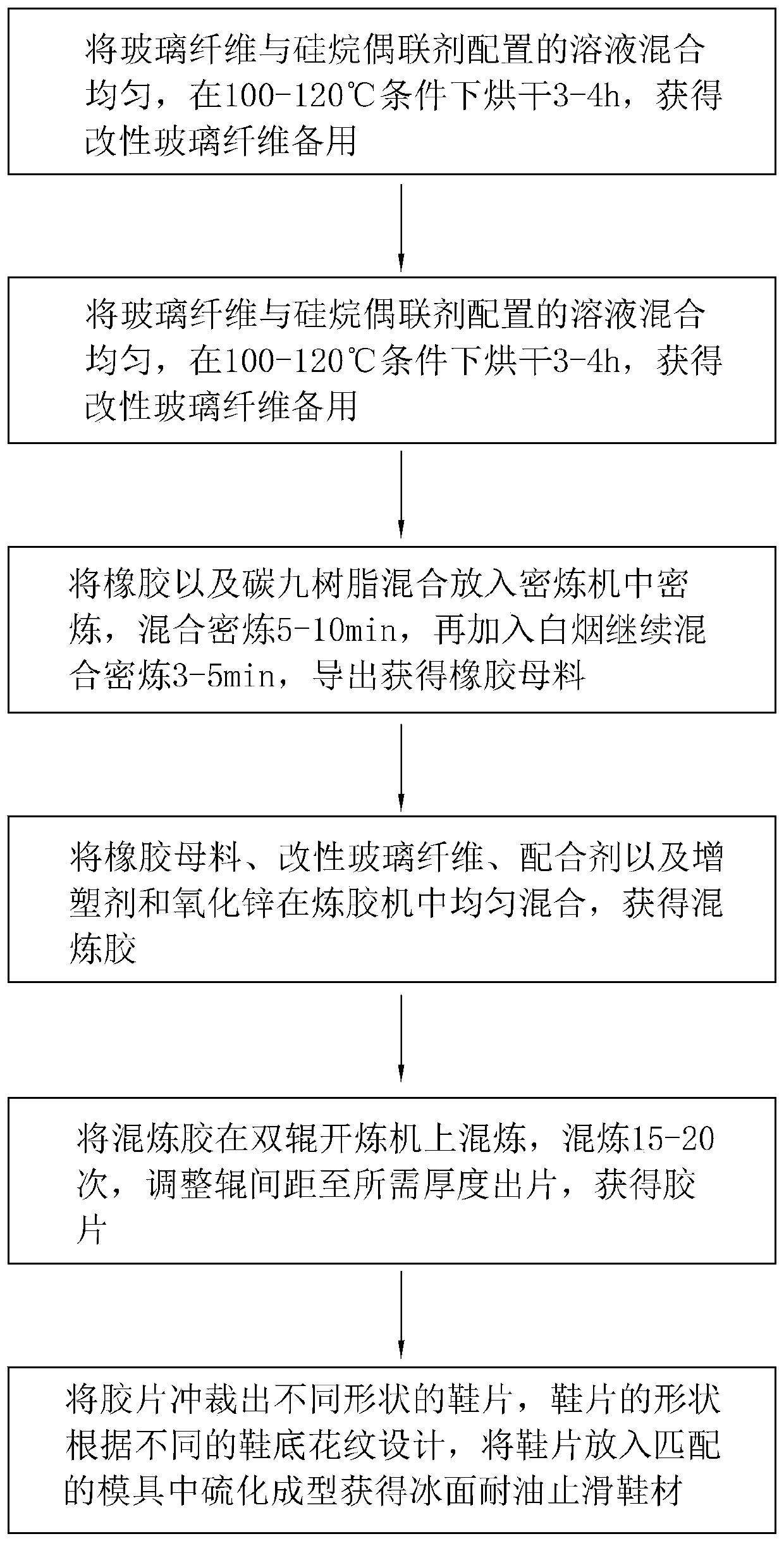

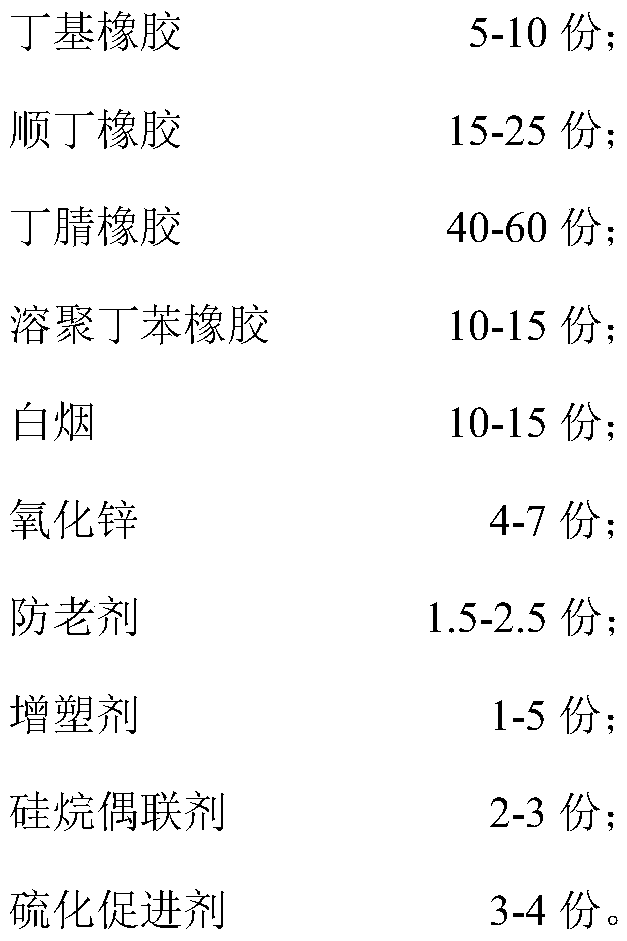

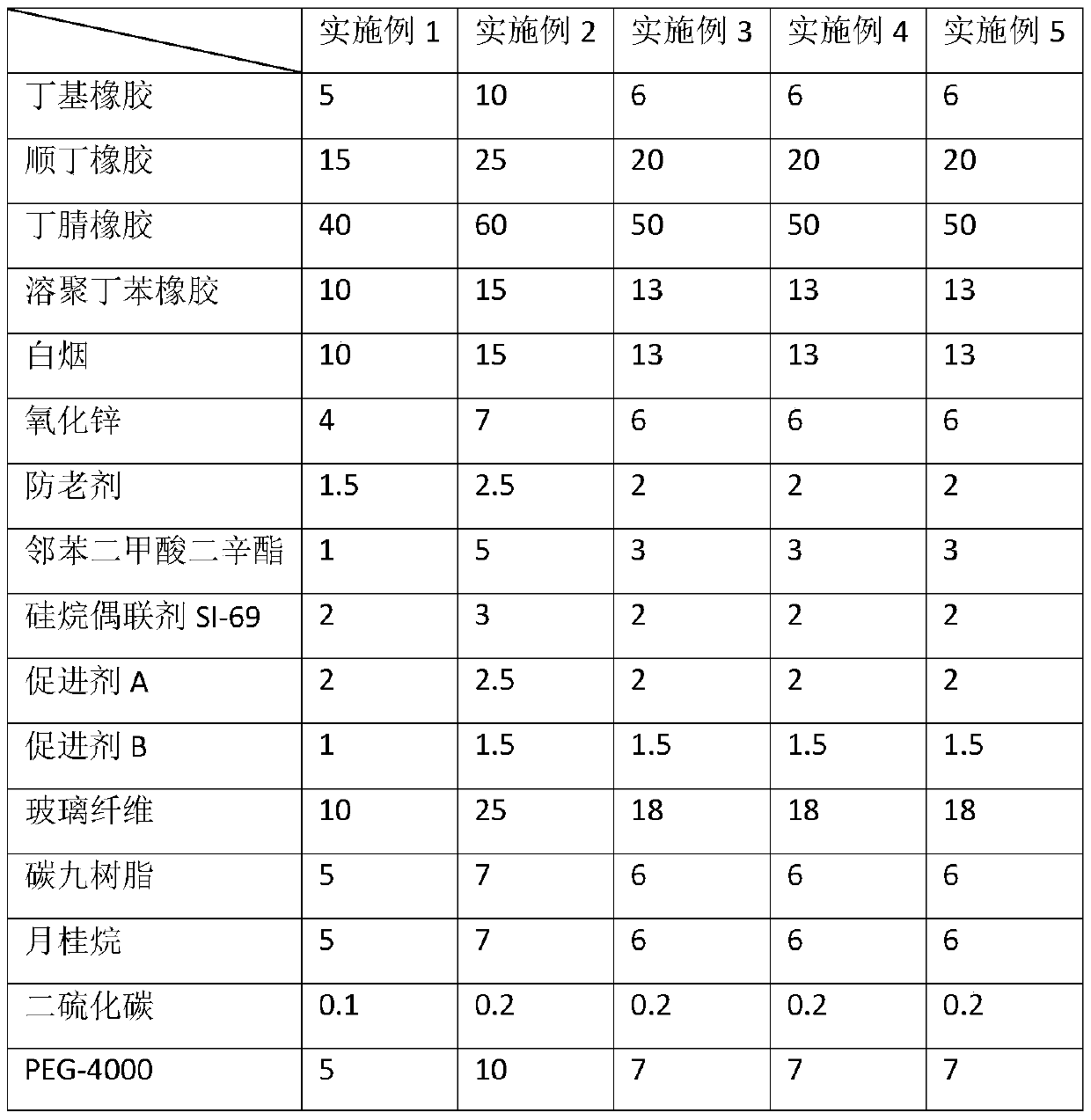

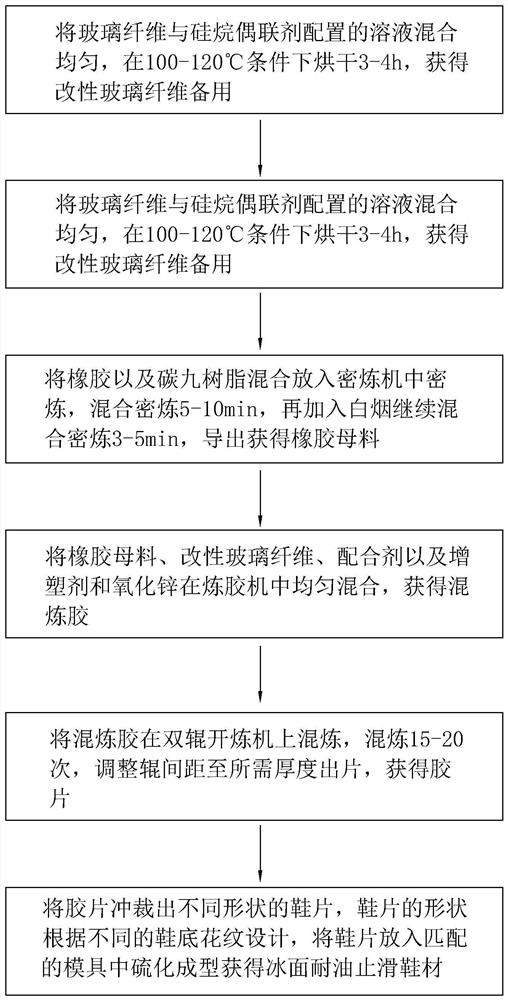

Ice-surface oil-resistant non-slip shoe material and preparation method thereof

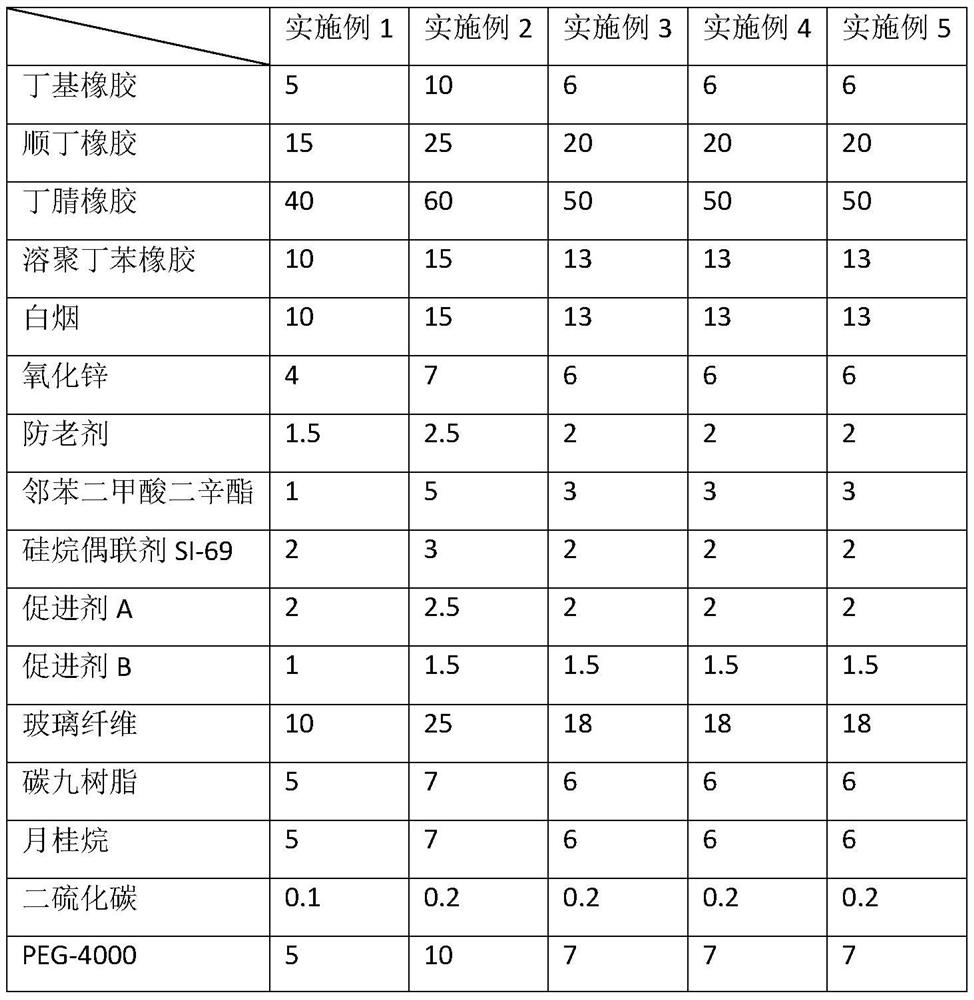

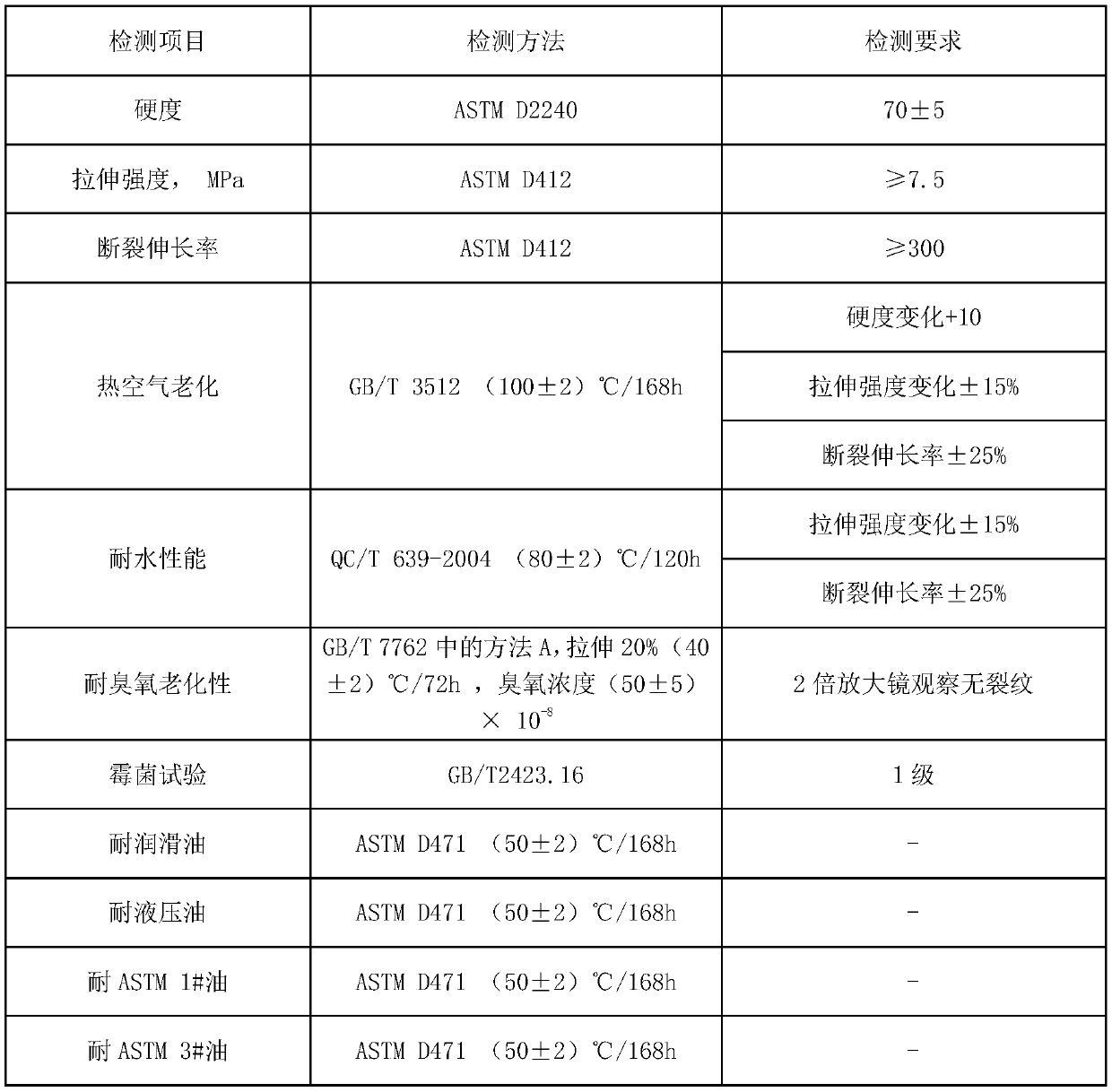

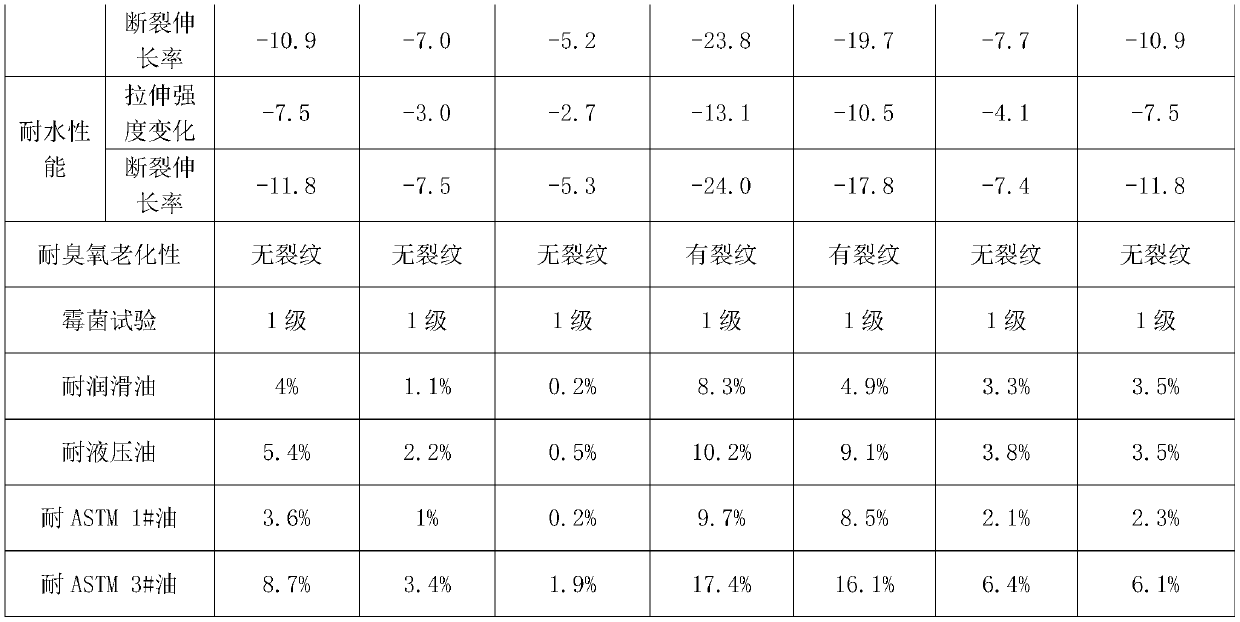

The invention discloses an ice-surface oil-resistant non-slip shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The shoe material is prepared from butyl rubber, butadiene rubber, nitrile rubber, solution polymerized styrene-butadiene rubber, white smoke, zinc oxide, an anti-ageing agent, a plasticizer, a silane coupling agent and a vulcanizationaccelerator. The shoe material prepared through the formula is combined with the specific pattern of an outsole and integrally formed or adhered to the outsole, and the obtained sole has the advantages of being resistant to oil and slip, good in mechanical performance, free of fog return and the like. The anti-slip performance is excellent, and the shoe material is suitable for being used on the ice and snow ground.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

Self-lubricating fluorinated silicone rubber seal ring

A self-lubricating fluorinated silicone rubber seal ring relates to the technical field of seal rings, and is characterized by comprising fluorinated silicone rubber, and a PTFE (Polytetrafluoroethylene) thin film arranged on the surface layer of the fluorinated silicone rubber. The invention further provides a production method of the fluorinated silicone rubber seal ring. The production method is characterized by comprising the following steps: injection molding, bonding, hot-forming, cutting and punching. The self-lubricating fluorinated silicone rubber seal ring has the excellent properties of abrasion resistance, pressure resistance and the like, and can be used in complex or bad environments requiring relatively high requirements. The production method has the advantages that the problem of difficulty in bonding polytetrafluoroethylene with fluorinated silicone rubber is solved; the production speed is fast; the machining quality is high.

Owner:宁国市格斯特密封件有限公司

Acrylate rubber raw material composition for crankcase ventilation hose

The present invention makes public a type of acrylate rubber materials used in crankcase ventilation pipes, which belongs to the technological field of rubber and has the following characteristic qualities: acrylate rubber PA 402L, 40-70; acrylate rubber PA 402H, 30-60; stearic acid, 1-2; age resister Dusantox 86, 2-3; processing agent Vanfre VAM, 1-2; carbon black N330, 25-45; carbon black N550, 10-30; potassium stearate, 0.2-0.5; sodium stearate, 1-4; brimstone, 0.1-0.3. The oil resistance of this acrylate rubber made by the above mentioned materials is superior than the now commonly used acrylate rubber's, its heat resistance corresponds to ethylene acrylate rubber's and its cost is cheaper.

Owner:ZHANG LEI

Silicone materials which crosslink by condensation at room temperature

ActiveUS8247513B2Fast cross-linkingVulcanization rate is slowCoatingsAdhesivesRoom temperatureCompound (substance)

Owner:WACKER CHEM GMBH

Condensation-crosslinking silicone materials

Materials crosslinkable at room temperature by condensation are based on organosilicon compounds which cure to give permanently resilient materials, and which employ one or more compounds of the metals Li, Na, K, Mg, Ca, or Sr as catalyst.

Owner:WACKER CHEM GMBH

Rubber composition

InactiveUS8445572B2Excellent characteristicsImprove workabilityLayered productsSpecial tyresPolymer scienceSilicic acid

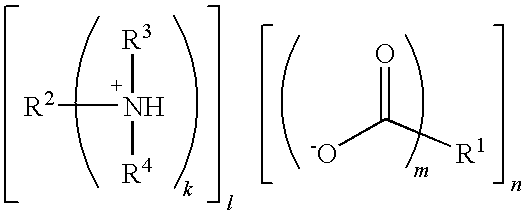

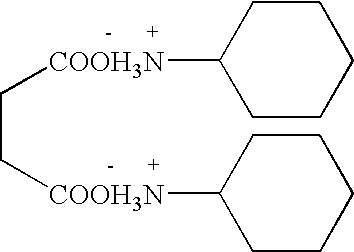

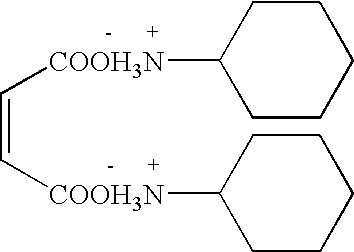

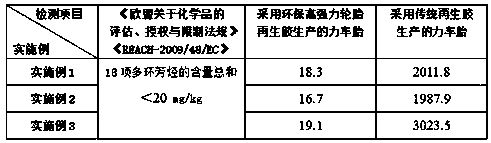

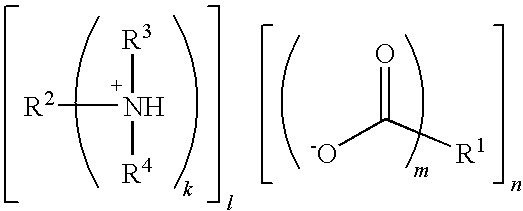

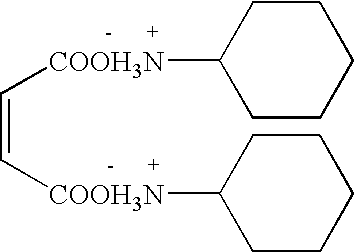

Disclosed is a rubber composition containing (A) a natural rubber, a diene synthetic rubber or a combination of them and (B) 50-120 parts by weight of a silicic acid-based or silicate-based inorganic filler per 100 parts by weight of the component (A). This rubber composition is characterized by further containing (C) 0.2-20 parts by weight of a certain amine salt per 100 parts by weight of the component (A).

Owner:THE YOKOHAMA RUBBER CO LTD

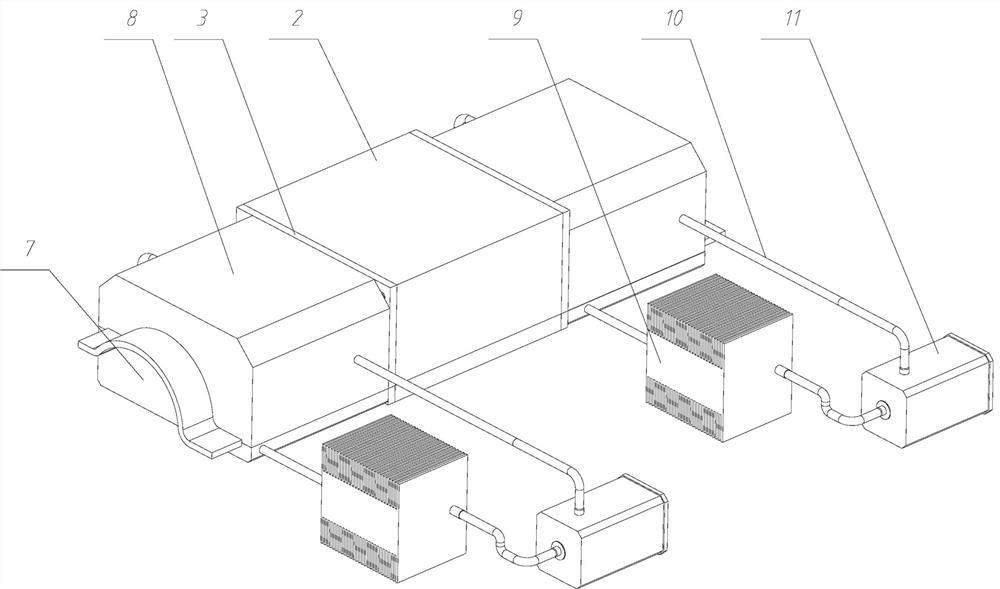

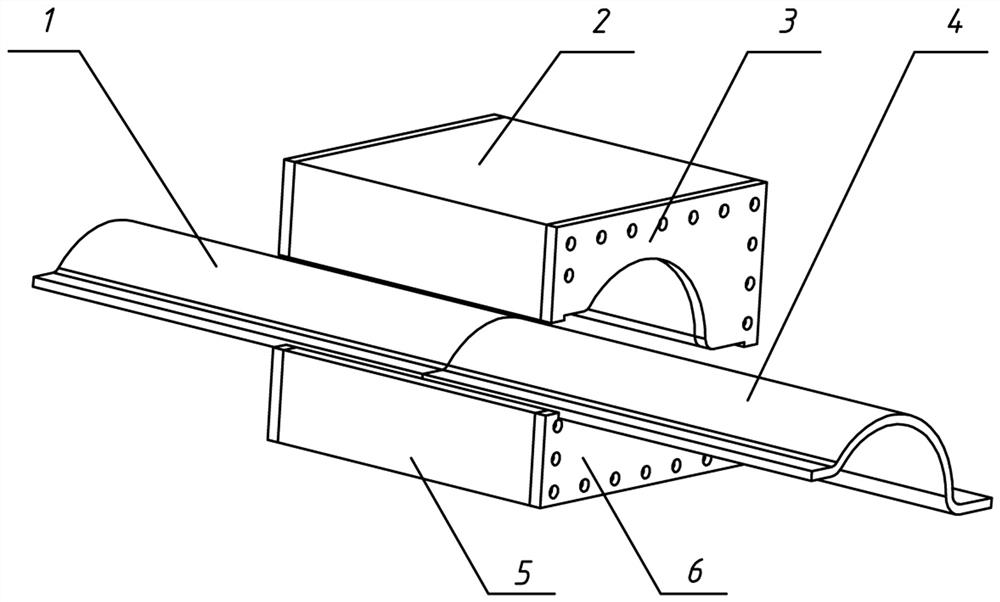

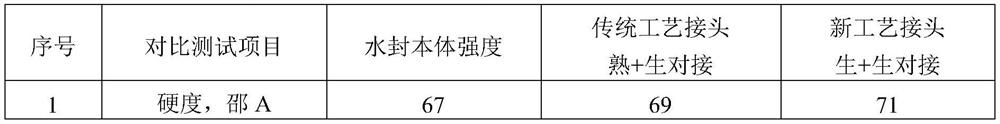

Rubber material for rubber water seal and preparation forming method and equipment thereof

The invention discloses a rubber material for a rubber water seal as well as a preparation forming method and equipment thereof. The rubber material comprises the following components in parts by weight: 100 parts of No.3 smoke sheet rubber; 14.6 to 15.0 parts of Fast extruding furnace black; 34.5 to 34.8 parts of high-wear-resistance carbon black; 14.6 to 15.0 parts of gas-mixture carbon black; 4.1-4.5 parts of zinc oxide, 2.0-2.2 parts of stearic acid, 1.8-2.1 parts of paraffin, 1.0 to 1.1 parts of an anti-aging agent RD; 2.8 to 3.1 parts of Vaseline, 0.6 to 0.8 part of an accelerant NOBS, 0.05 to 0.15 part of an accelerant D, 0.9 to 1.3 parts of an anti-aging agent 4010NA, 0.2 to 0.4 part of an anti-scorching agent CTP, 2.3 to 2.7 parts of sulfur S-80 and 19.5 to 22.0 parts of ethylenepropylene diene monomer rubber. During preparation and forming, the rubber material is preformed firstly, then a vulcanization mold is filled with the preformed rubber material, meanwhile, extension parts are arranged at one end or two ends of the vulcanization mold, only part of the vulcanization mold is vulcanized during vulcanization, and the extension parts are not vulcanized, so that vulcanization between raw rubber and raw rubber can be realized through vulcanization of a later joint part; and the vulcanization bonding strength of a rubber water seal joint is improved.

Owner:THREE GORNAVIGATION AUTHORITY

Radial tire belt compound for small rough terrain lift trucks and preparation method of radial tire belt compound

InactiveCN104448414AMeet the conditions of poor working environmentIncrease production capacitySpecial tyresTerrainEngineering

The invention belongs to the technical field of tire rubber, and particularly relates to a radial tire belt compound for small rough terrain lift trucks and a preparation method of the radial tire belt compound. The radial tire belt compound for small rough terrain lift trucks is prepared from the following raw materials in parts by weight: 100 parts of SMR20, 53-58 parts of carbon black 326, 8-11 parts of zinc oxide, 0.4-0.6 part of stearic acid, 1.4-2.2 parts of petroleum resin, 0.3-0.6 part of anti-aging agent RD, 0.2-0.5 part of cobalt canoic acid, 0.2-0.4 part of a scorch retarder CTP, 3-3.5 parts of tert-butyl-phenolic curing resin, 1.2-1.5 parts of sulfur and 0.8-1 part of an accelerant NOBS. The radial tire belt compound is matched with the performance of the small rough terrain lift trucks, and adapts to the working environment of the rough terrain lift trucks; the processing safety of the belt compound is improved; the bonding performance of a sizing material and an all-steel cord is improved; and the yield and quality of the tire are improved.

Owner:SHANDONG YONGTAI CHEM GROUP

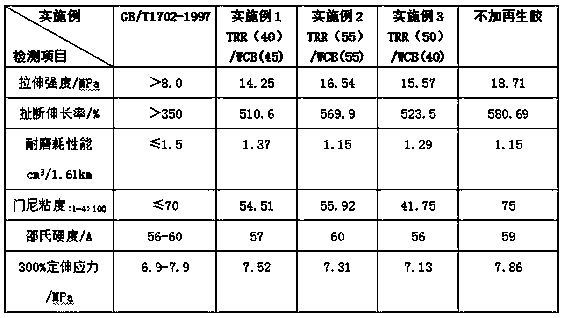

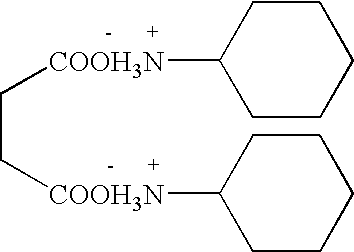

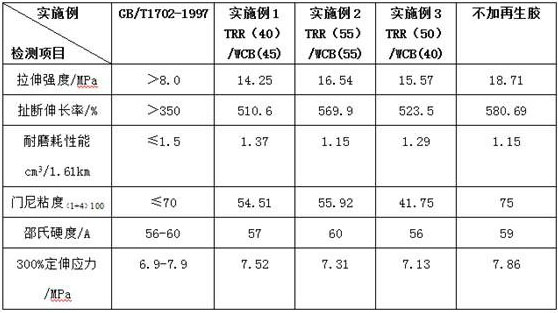

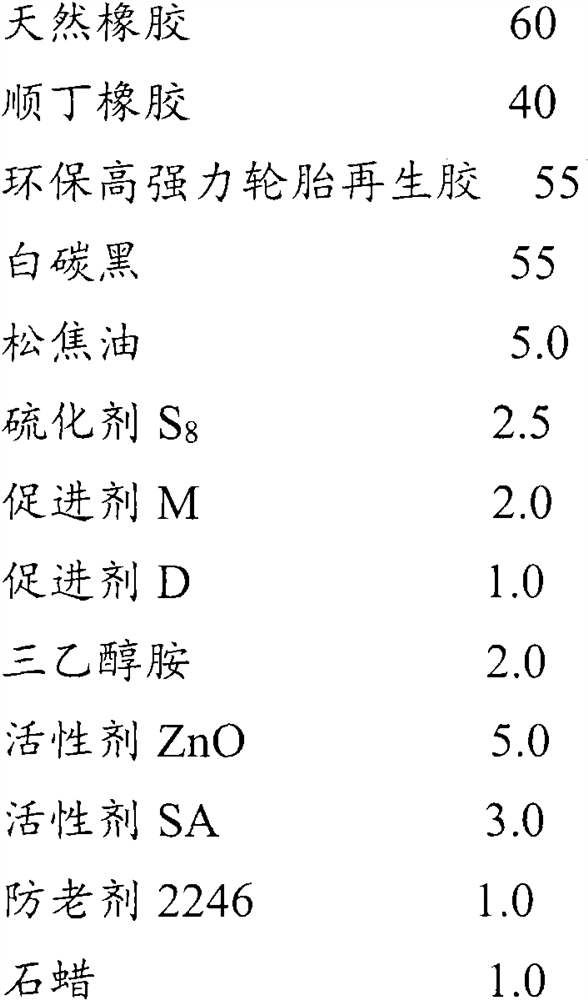

Preparation method of colorful cycle tire tread rubber made of high-filling environment-friendly high-strength tire reclaimed rubber

The invention discloses a preparation method of colorful cycle tire tread rubber made of high-filling environment-friendly high-strength tire reclaimed rubber, wherein the use amount of the high-filling environment-friendly high-strength tire reclaimed rubber is 40-55 parts, the preparation method comprises the following steps: an open mill or an internal mixer is adopted to plasticize NR and BR respectively, the NR and BR plasticated rubber are combined and pressed, and reclaimed rubber is added to enable the rubber material to be uniform in texture; a vulcanization accelerator and triethanolamine are respectively added into the rubber material, and uniformly mixed, then white carbon black and pine tar are alternately added, finally sulfur is added, rolling and triangular packaging are performed until various materials are uniformly dispersed, plastifying and mixing time is totally about 25-30 minutes, then performance detection is performed according to GB / T1702-1997, the tensile strength is 16.54 MPa, the elongation at break is 569.9%, and the mechanical property of the cycle tire tread rubber can be well met; the tire performance can be improved, the pollution can be reduced, and the cost of a cycle tire can be reduced by 10-30%.

Owner:XUZHOU COLLEGE OF INDAL TECH

Radial-tire belt compound applied to cross-country fork truck with load of 5.8 t and preparation method thereof

InactiveCN104497370AMeet the conditions of poor working environmentVulcanization rate is slowSpecial tyresEngineeringStearic acid

The invention belongs to the technical field of tyre rubber, and concretely relates to a radial-tire belt compound applied to a cross-country fork truck with load of 5.8 t and a preparation method thereof. The radial-tire belt compound applied to a cross-country fork truck with load of 5.8 t is composed of the following raw materials in parts by weight: 100 parts of IR, 40-44 parts of carbon black N326, 25-27 parts of ISAF, 9-11 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 1.5-2.5 parts of petroleum resin, 0.4-0.7 part of anti-ageing agent RD, 0.2-0.4 part of cobaltous naphthenate, 0.3-0.5 parts of anti-scorching agent CTP, 2.4-3.1 parts of third vacuum side distillate oil, 4.3-5.2 parts of tert-butyl-phenolic curing resin, 2.1-2.4 parts of sulfur, and 0.8-1 parts of promoter NOBS. The radial-tire belt compound is matched with the performances of the cross-country fork truck with load of 5.8 t, and is adaptive to the work environment of cross-country fork trucks. The processing safety of the belt compound is improved, the bonding performance of the belt compound material with a steel cord is improved, and the yield and the quality of a tyre are improved.

Owner:SHANDONG YONGTAI CHEM GROUP

Radial tire belt ply rubber for 5.8-ton off-road forklifts and preparation method of rubber

The invention belongs to the technical field of tire rubber, and particularly relates to radial tire belt ply rubber for 5.8-ton off-road forklifts and a preparation method of the rubber. The radial tire belt ply rubber for the 5.8-ton off-road forklifts comprises raw materials in parts by weight as follows: 100 parts of SMR20, 40-44 parts of carbon black N326, 25-27 parts of carbon black N660, 9-11 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 1.5-2.5 parts of petroleum resin, 0.4-0.7 parts of an anti-aging agent RD, 0.2-0.4 parts of cobalt boroacylate, 0.3-0.5 parts of an anti-scorching agent CTP, 2.4-3.1 parts of resorcinol-80, 4.3-5.2 parts of tert-butyl phenolic curing resin, 2.1-2.4 parts of sulfur and 0.8-1 part of an accelerant NOBS. The radial tire belt ply rubber is matched with the off-road forklifts in performance and adapted to working environments of the off-road forklifts; the machining safety of the belt ply rubber is improved, the bonding performance of the rubber to steel cords is improved, the yield of tires is increased, and the quality of the tires is improved.

Owner:SHANDONG YONGTAI CHEM GROUP

Rubber composition

InactiveUS20100222478A1Excellent characteristicsImprove workabilityLayered productsSpecial tyresPolymer scienceSilicic acid

Disclosed is a rubber composition containing (A) a natural rubber, a diene synthetic rubber or a combination of them and (B) 50-120 parts by weight of a silicic acid-based or silicate-based inorganic filler per 100 parts by weight of the component (A). This rubber composition is characterized by further containing (C) 0.2-20 parts by ht of a certain amine salt per 100 parts by weight of the component (A).

Owner:YOKOHAMA RUBBER CO LTD

Single-component rubber shoe foxing dispersant

InactiveCN104725680AQuality assuranceHigh temperature critical pointNatural rubber adhesivesNon-macromolecular adhesive additivesThiazolePolymer science

The invention relates to the technical field of rubber shoe foxing adhesion, in particular to a single-component rubber shoe foxing dispersant. The dispersant is characterized by comprising the following components by dry weight: 100 parts of natural rubber latex, 0.1-5 parts of a thiazole accelerator, 0.05-2 parts of a thiuram accelerator, 1 part of an emulsifier, 1 part of sulfur, 1 part of zinc oxide, 2 parts of an antioxidant, 1 part of an osmotic agent, 1 part of a stabilizer and a proper amount of deionized water. The dispersant does not have sulfuration conditions at room temperature, and can be stored at room temperature for more than 180 days, so as to ensure product quality, reduce waste in the production, improve production efficiency and save time and resources.

Owner:FOSHAN NANHAI HONGMING ADHESIVES

Clean synthesis process for synthesizing vulcanization accelerators CBBS by using 2-mercaptobenzothiazole and cyclohexane as raw materials

The invention relates to a clean synthesis process for synthesizing vulcanization accelerators CBBS by using 2-mercaptobenzothiazole and cyclohexane as raw materials. The process comprises the following steps of (1) generating intermediate products; (2) generating an M-Na salt solution; (3) synthesizing CBBS. Compared with the synthesis process in the prior art, the clean synthesis process for synthesizing vulcanization accelerators CBBS by using 2-mercaptobenzothiazole and cyclohexane as raw materials has the advantages that the cost is reduced; the whole yield is as high as 90 percent or higher; the purity of the product CBBS can reach 96 percent through HPLC test; less waste water is generated in the synthesis; the waste water can be easily treated; in the industrialization process, theinfluence on the environment is small; the large-scale industrialized popularization is easy.

Owner:KEMAI CHEM

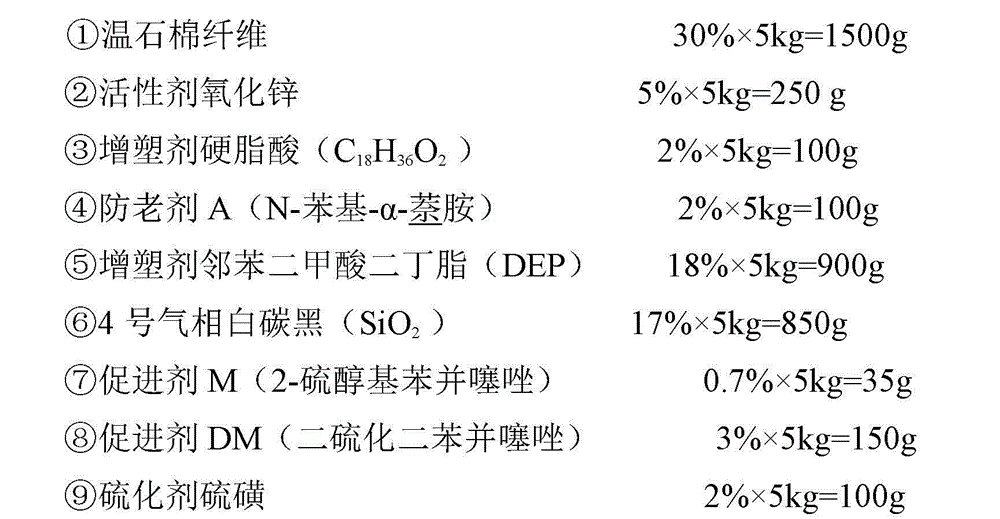

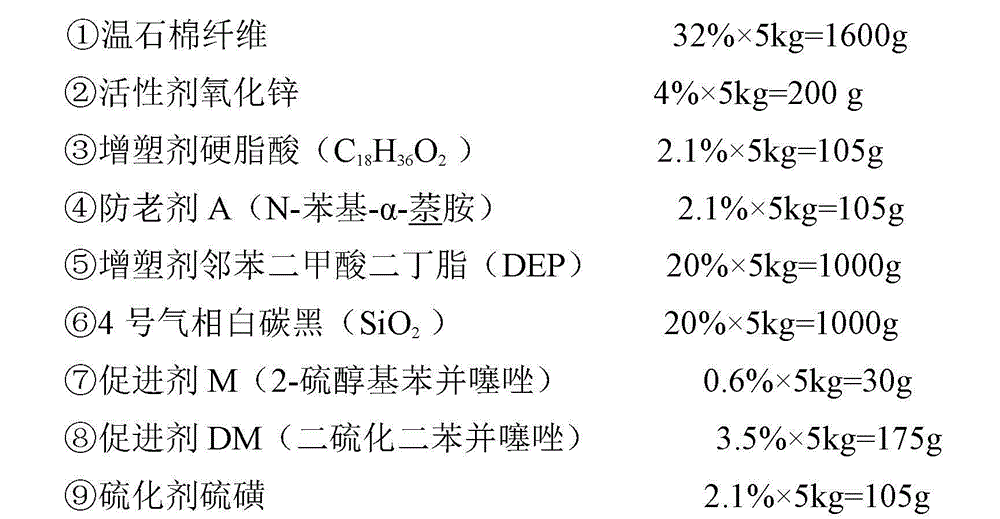

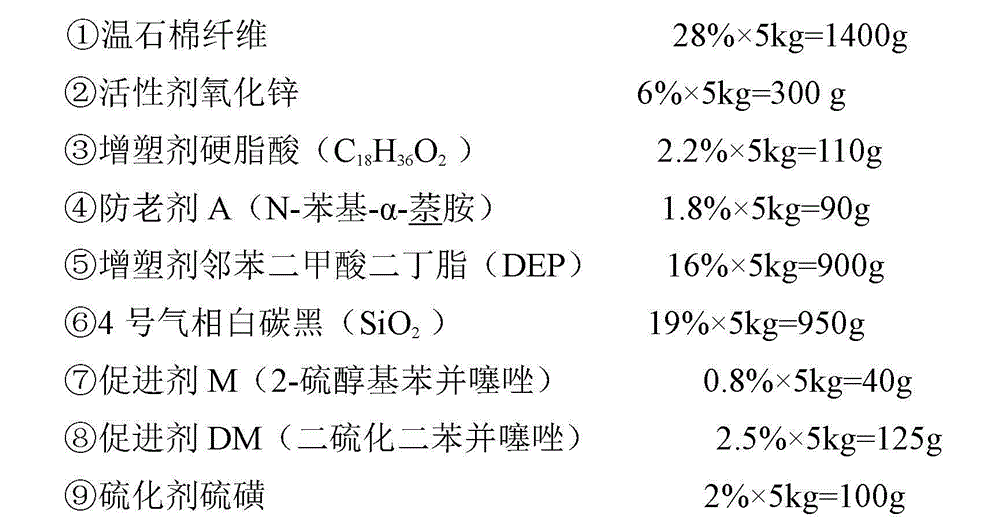

Styrene-butadiene asbestos heat-resisting composite rubber and preparation method thereof

The invention discloses styrene-butadiene asbestos heat-resisting composite rubber and a preparation method thereof. The styrene-butadiene asbestos heat-resisting composite rubber is prepared by styrene-butadiene rubber, chrysotile fiber and compounding agent as raw materials, wherein when the styrene-butadiene rubber is computed according to the mass m, the chrysotile fiber is 25-32%m; and the compounding agent comprises 4-6%m of zinc oxide, 1.8-2.2%m of stearic acid, 16-20%m of dibutyl phthalate, 1.8-2.2%m of N-phenyl-alpha-naphthylamine, 15-20m% of fumed silica, 0.6-0.8%m of 2- mercaptobenzothiazole, 2.5-3.5%m of dibenzothiazyl disulfide and 1.9-2.1%m of sulphur. The styrene-butadiene asbestos heat-releasing compound rubber can be obtained after plastifying, mixing and the like. The rubber has excellent aging resistance, ablation resistance and mechanical property; meanwhile, the preparation method is simple in operation so as to be suitable for mass production.

Owner:AEROSPACE SCI & IND KET TECH CO LTD

Radial tire belt compound for forklift trucks with carrying capacity of 4.8t, and preparation method thereof

The invention belongs to the technical field of tire rubber, and concretely relates to a radial tire belt compound for forklift trucks with the carrying capacity of 4.8t, and a preparation method thereof. The radial tire belt compound for s forklift trucks with the carrying capacity of 4.8t comprises, by weight, 100 parts of BR, 38-44 parts of a medium super abrasion furnace black strengthening agent, 22-27 parts of carbon black N660, 8-11 parts of zinc oxide, 0.4-0.6 parts of stearic acid, 1.4-2.2 parts of petroleum resin, 0.3-0.6 parts of an antioxidant RD, 0.2-0.5 parts of polyethylene glycol, 0.2-0.4 parts of an anti-scorching agent CTP, 2.4-3.1 parts of resorcinol-80, 4.3-5.2 parts of pine tar, 1.2-1.5 parts of sulfur and 0.8-1 part of an accelerant CZ. The radial tire belt compound matches with the small forklift trucks in performances, is adapted to the work environment of the small forklift trucks, has increased processing safety, improves the bonding performance of a rubber compound with steel wire cords, and improves the output and the quality of tires.

Owner:SHANDONG YONGTAI CHEM GROUP

Studless tire rubber composition and studless tire using same

PendingUS20220289949A1Improve performanceVulcanization rate is slowSpecial tyresPolymer chemistryFiber

In a studless tire rubber composition, per 100 parts by mass of a diene rubber containing 30 parts by mass or more of a polybutadiene rubber, 20 parts by mass or more of an inorganic filler and from 10 to 40 mass %, with respect to the inorganic filler, of basic magnesium sulfate inorganic fibers having an average diameter of less than 1 μm are blended.

Owner:YOKOHAMA RUBBER CO LTD

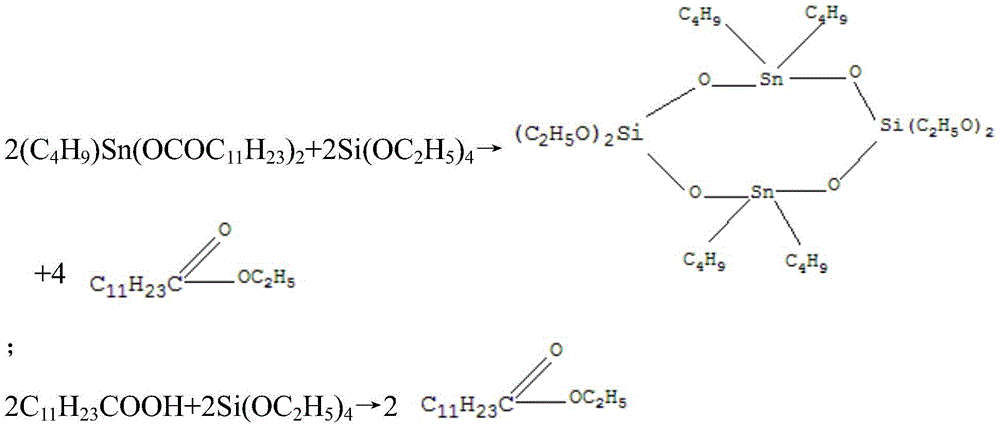

A kind of preparation method of two-component condensation type room temperature vulcanization silicone rubber curing agent

InactiveCN103554915BWill not cause excessiveSlight hydrolysis reactionTin organic compoundsDibutyl tin dilaurateStrong acids

The invention provides a preparation method of a two-component condensed type room temperature vulcanized silicone rubber curing agent. The curing agent is prepared by reacting tetraethoxysilane and dibutyltin dilaurate under the catalysis of macroreticular strong-acid cation exchange resin. The curing agent prepared by the method has the advantages of good stability and proper heavy metal content, and the method is simple to operate.

Owner:深圳市红叶杰科技有限公司

A kind of high rigidity TPV toughened polypropylene composition and preparation method thereof

Owner:PETROCHINA CO LTD

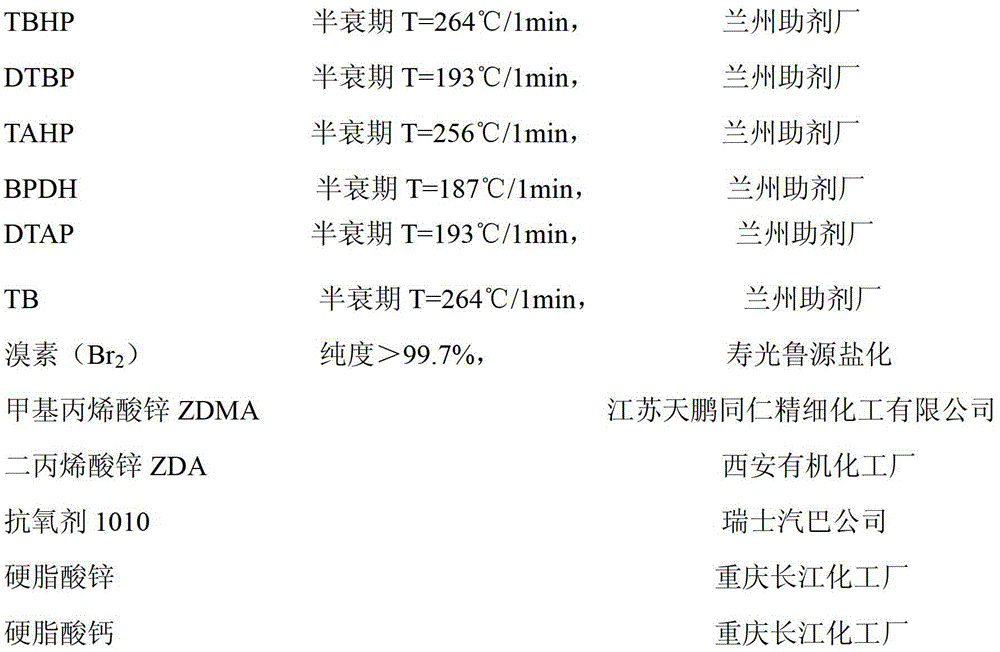

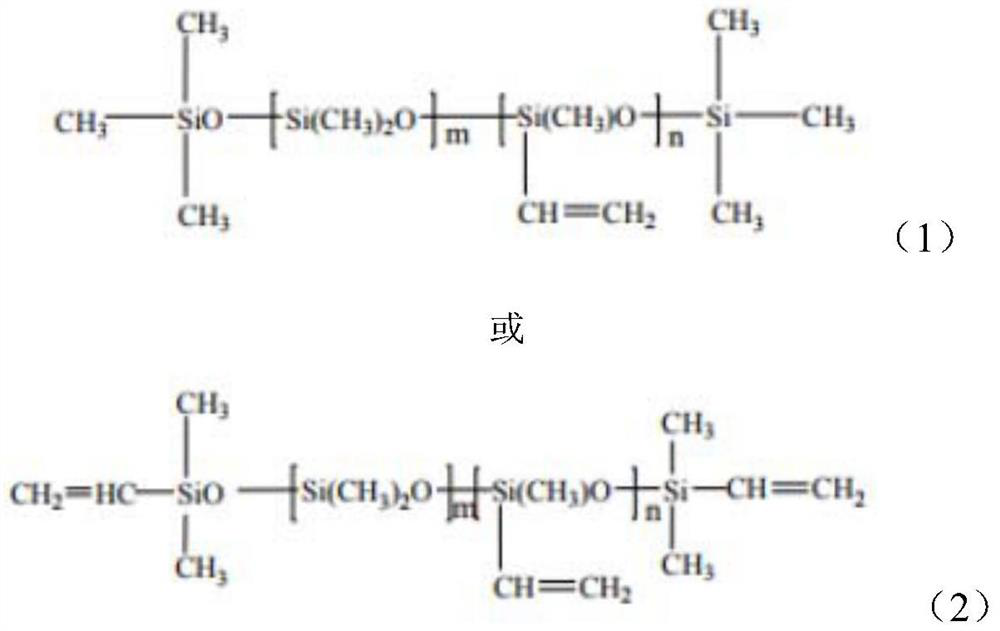

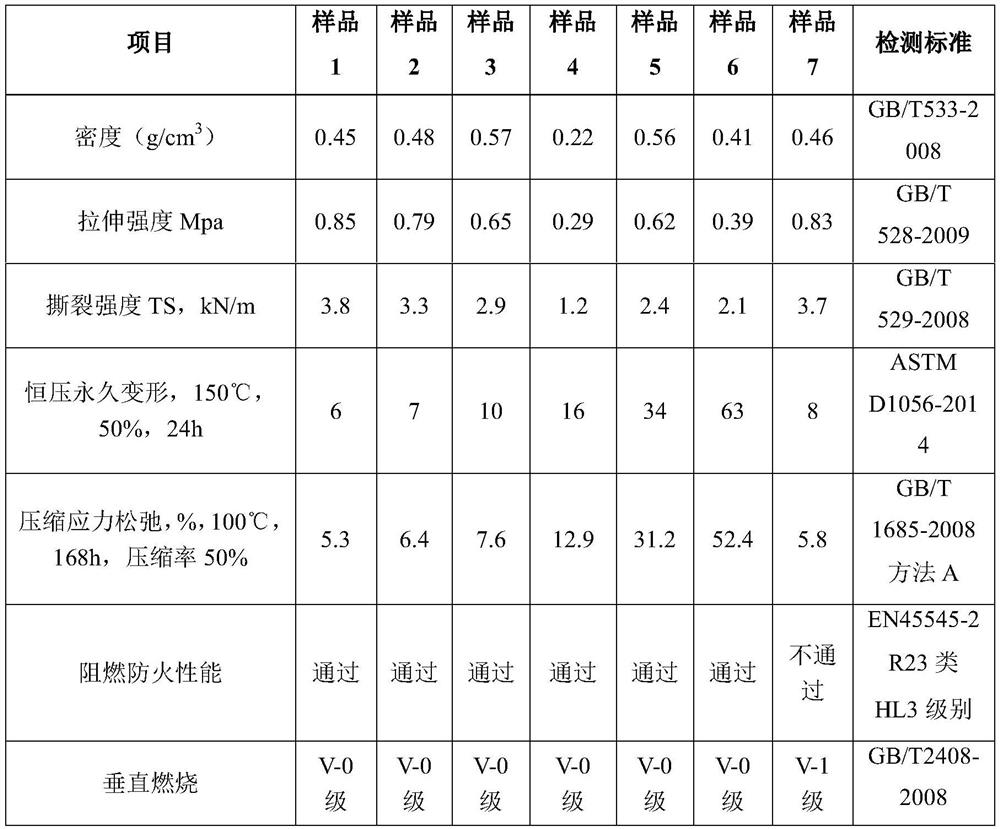

Silicone rubber foaming sealing material and preparation method thereof

The invention relates to a silicone rubber foaming sealing material and a preparation method thereof. The silicone rubber foaming sealing material comprises 100 parts of silicone rubber, 1-8 parts of vinyl silicone oil, 1-6 parts of vinyl MQ silicone resin, 1-10 parts of a foaming agent, 1-5 parts of a composite vulcanizing agent and 20.5-102 parts of a composite flame retardant. The composite flame retardant is prepared from 20 to 100 parts of flame-retardant filler and 0.5 to 2 parts of platinum flame retardant; the invention also discloses a preparation method of the silicone rubber foaming sealing material. The silicone rubber sealing material prepared by the invention has the advantages of excellent flame retardant property, low compression set at high temperature, good compressive stress relaxation resistance and excellent long-time sealing protection performance.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A kind of ice surface oil resistant anti-slip shoe material and preparation method thereof

The invention discloses an ice-surface oil-resistant anti-skid shoe material and a preparation method thereof, and relates to the technical field of shoe materials. The raw materials include butyl rubber; butadiene rubber; nitrile rubber; dissolved polystyrene butadiene rubber; white smoke; zinc oxide ; Antiaging agent; Plasticizer; Silane coupling agent; Vulcanization accelerator. The shoe material prepared by this formula is integrated with the specific pattern of the outsole, or is pasted on the outsole. The obtained shoe sole has the advantages of oil resistance and anti-skid, good mechanical properties, and no return of fog. Excellent anti-skid performance, suitable for use on ice and snow.

Owner:WENZHOU YIHE SHOE MATERIAL CO LTD

Intermediate rubber for aviation retreaded tire and preparation method thereof

The invention relates to an intermediate rubber for an aviation retreaded tire and a preparation method thereof. The preparation method is characterized by comprising the following steps: mixing natural bacon rubber NR1, carbon black N330, aromatic hydrocarbon oil, anti-aging agent 4020, anti-aging agent RD, rubber adhesive RF-90, stearic acid SA, tackifying resin TKM-M, cure activator Z311 and zinc oxide to obtain a primary rubber; refining the primary rubber into a secondary rubber; adding adhesive CS-964, scorch retarder CPT, insoluble sulfur IS-6005, accelerator MOR and accelerator TT into the secondary rubber, and carrying out secondary refining to obtain a tertiary rubber; and cooling the tertiary rubber, rubberizing, and discharging to obtain the intermediate rubber for an aviationretreaded tire. The intermediate rubber is prepared by using the TKM-M adhesive in the super tackifier TKM series as well as other novel materials, thereby enhancing the adhesive strength between theoriginal tire body and retreaded tire surface of the aviation retreaded tire, so that the adhesive strength is more than 13.66 KN / m and is more than twice of the standard specified by GB13651 in China and AC-145 in America.

Owner:无锡翼龙航空设备有限公司

Sealing strip composite material and preparation method thereof

The invention provides a sealing strip composite material and a preparation method thereof and relates to the technical field of high polymer materials. The sealing strip composite material comprisesethylene propylene diene monomers, nitrile-butadiene rubber, a rubber modifier, N550 carbon black, N774 carbon black, nano calcium carbonate, plasticizer, zinc oxide, stearic acid, a protecting agent,a vulcanizing agent, a moisture absorbent, polyethylene glycol dialkyl ether and vitamin E polyethylene glycol succinate. The sealing strip composite material is excellent in hardness, tensile strength, aging resistance, water resistance, oil resistance and mildew resistance and widely applicable to multiple fields such as cars, doors and windows, buildings and rail transit. The preparation method is stable, controllable, easy to operate and suitable for large-scale production.

Owner:柳州宏桂汽车零部件有限公司

A kind of preparation method of the colored rickshaw tread rubber of high-fill environment-friendly high-strength tire reclaimed rubber

The invention discloses a preparation method of colored tire tread rubber highly filled with environmentally friendly and high-strength tire reclaimed rubber, wherein the amount of environmentally friendly and high-strength tire reclaimed rubber is 40-55 parts; the preparation method is as follows: firstly, an open mill or The internal mixer plasticizes NR and BR respectively, and then combines the plasticized rubbers of NR and BR for compaction, and adds reclaimed rubber to make the rubber material uniform; add vulcanization accelerator and triethanolamine to the above rubber materials and mix evenly, and then Add white carbon black, pine tar, and finally add sulfur, roll and triangular bag, until the various materials are evenly dispersed with each other, the plasticizing and mixing time is about 25-30min, and then perform performance testing according to GB / T1702-1997, pull The tensile strength is 16.54 MPa, and the elongation at break is 569.9%, which can better meet the needs of the mechanical properties of tire tread rubber; improve tire performance, reduce pollution, and reduce the cost of tires by 10‑30%.

Owner:XUZHOU COLLEGE OF INDAL TECH

A kind of graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299BSolve the problem of poor high and low temperature resistanceImprove mechanical propertiesPolymer scienceVulcanization

The invention belongs to the technical field of graphene rubber composite materials, and proposes a graphene modified nitrile rubber and a preparation method thereof. A graphene-modified nitrile rubber, comprising the following components by weight: 70-90 parts of nitrile rubber, 10-30 parts of modified graphene oxide carboxylated nitrile-butadiene rubber masterbatch, 1.5-2 parts of vulcanizing agent, 0.5-2.0 parts of vulcanization accelerator, 3-5 parts of vulcanization activator, 1-3 parts of plasticizer, 1-2 parts of anti-aging agent, 20-30 parts of filler, modified graphene oxide-carboxylated nitrile rubber masterbatch includes The modified graphene oxide also includes carboxylated nitrile latex, wherein the modified graphene oxide is obtained by dehydrating and condensing graphene oxide after hydrolysis of mercaptosiloxane. Through the above technical scheme, the problem of poor high and low temperature resistance of nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com