Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Uniform grinding force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

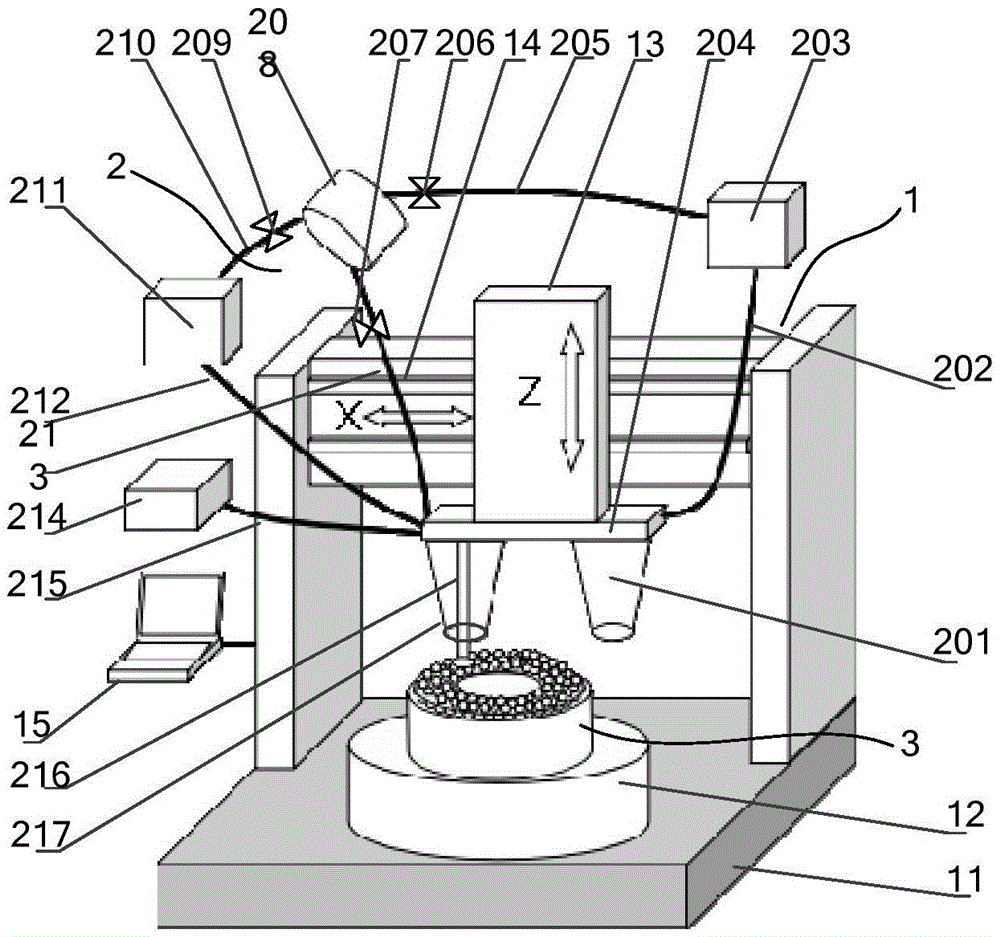

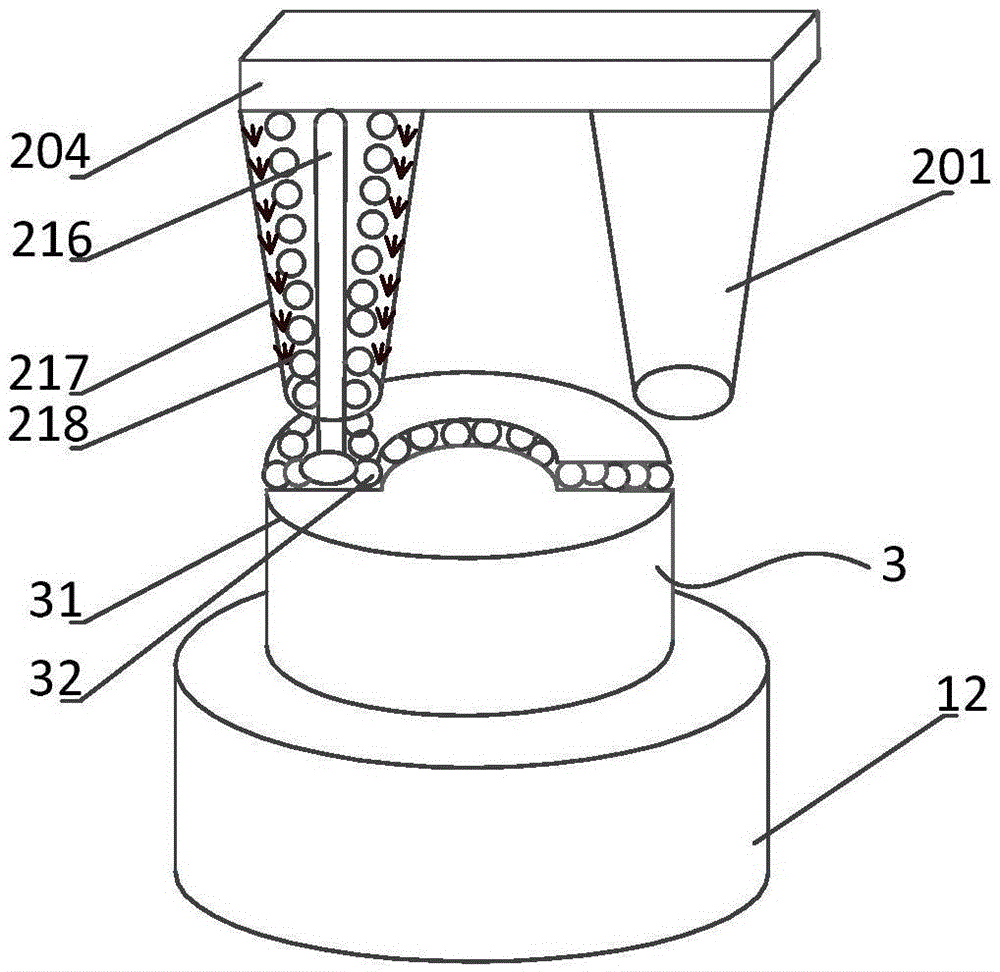

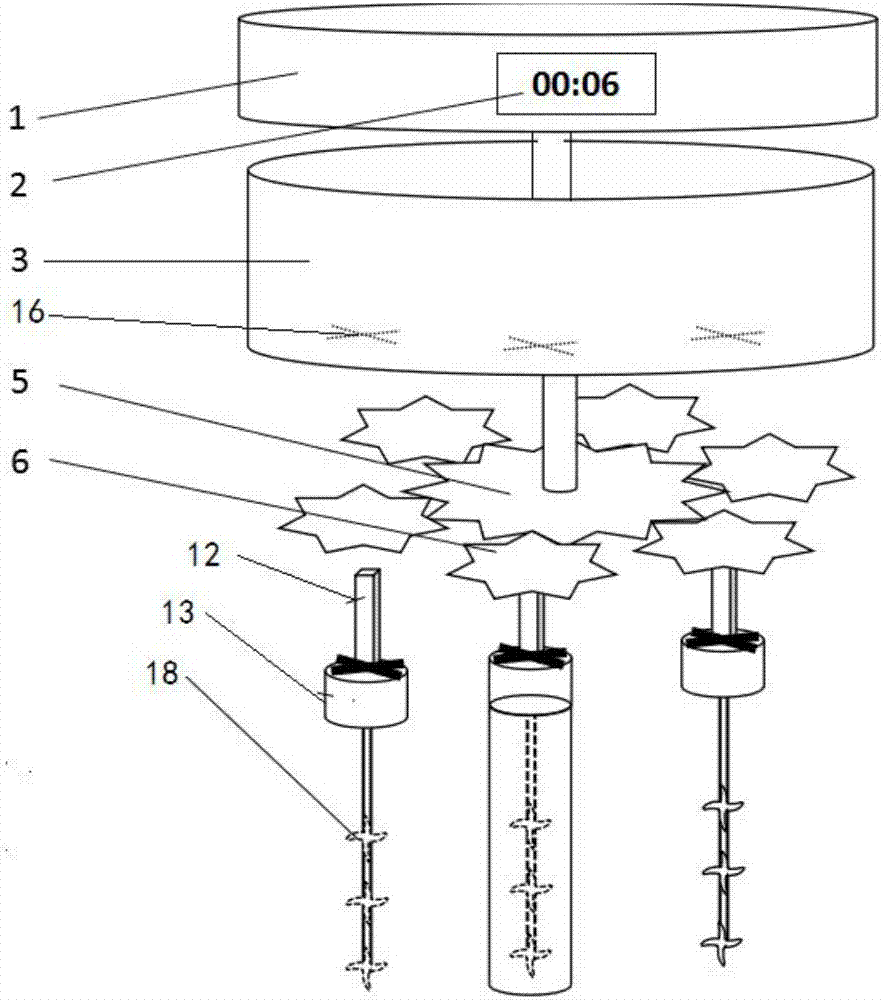

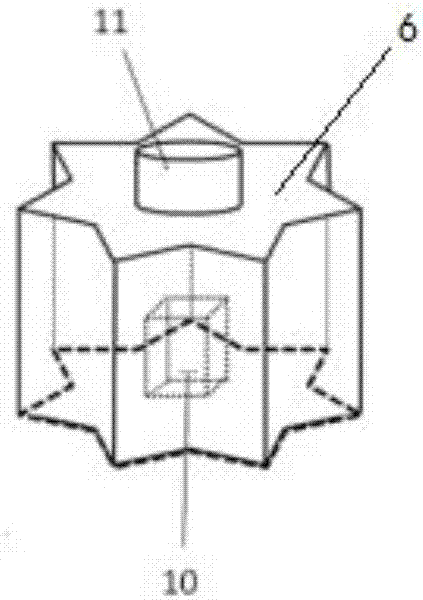

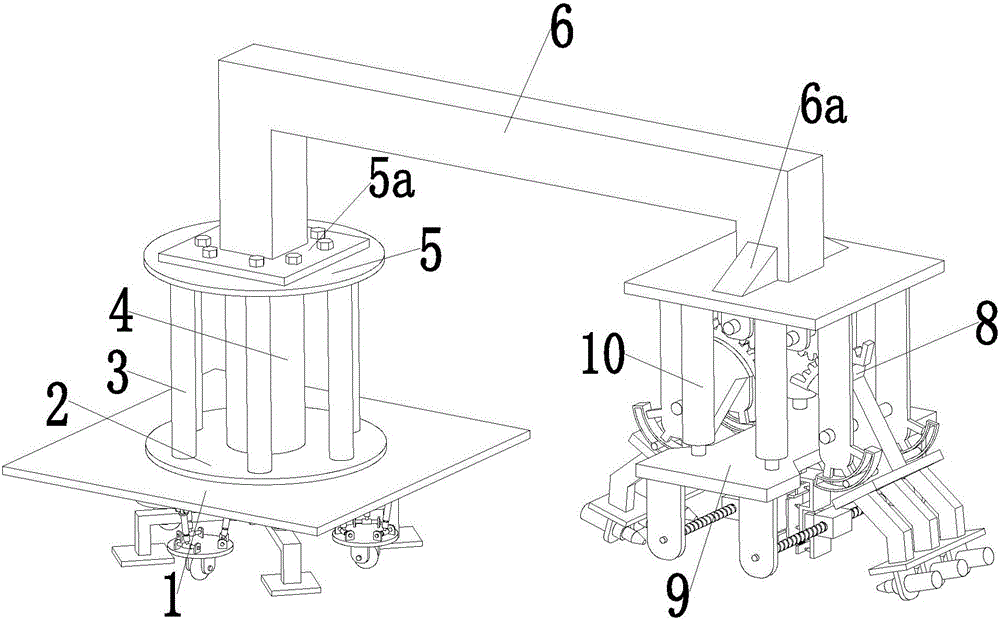

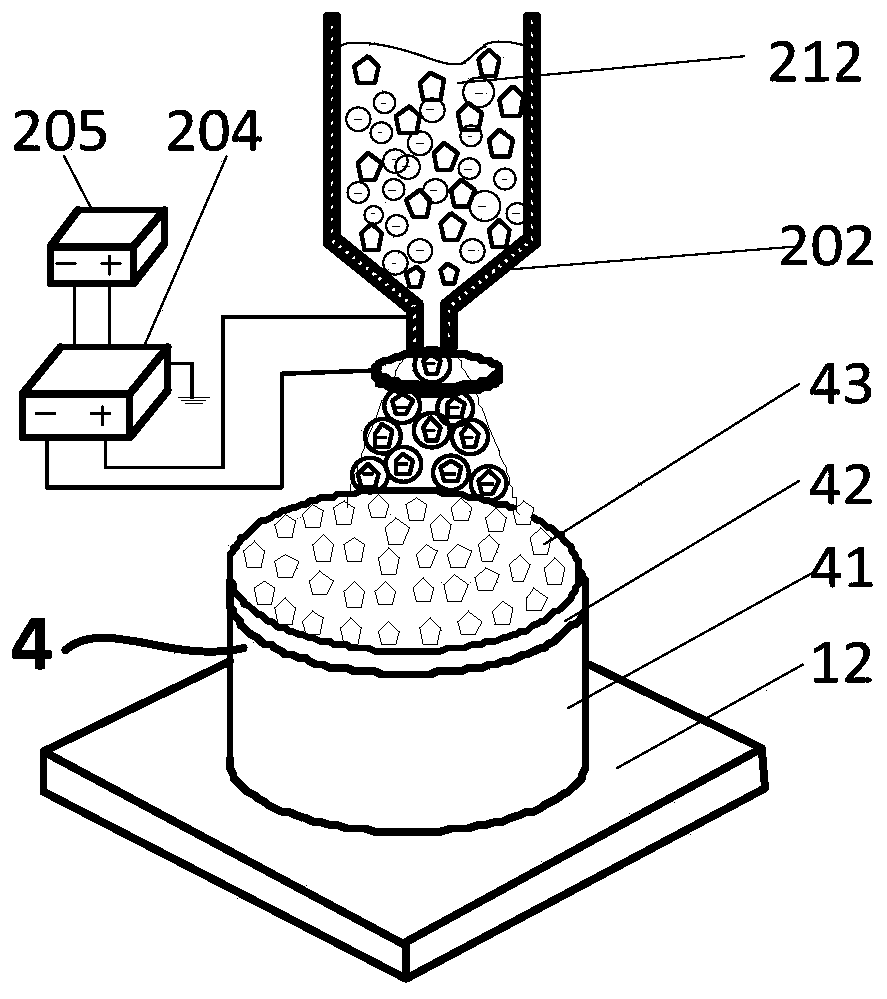

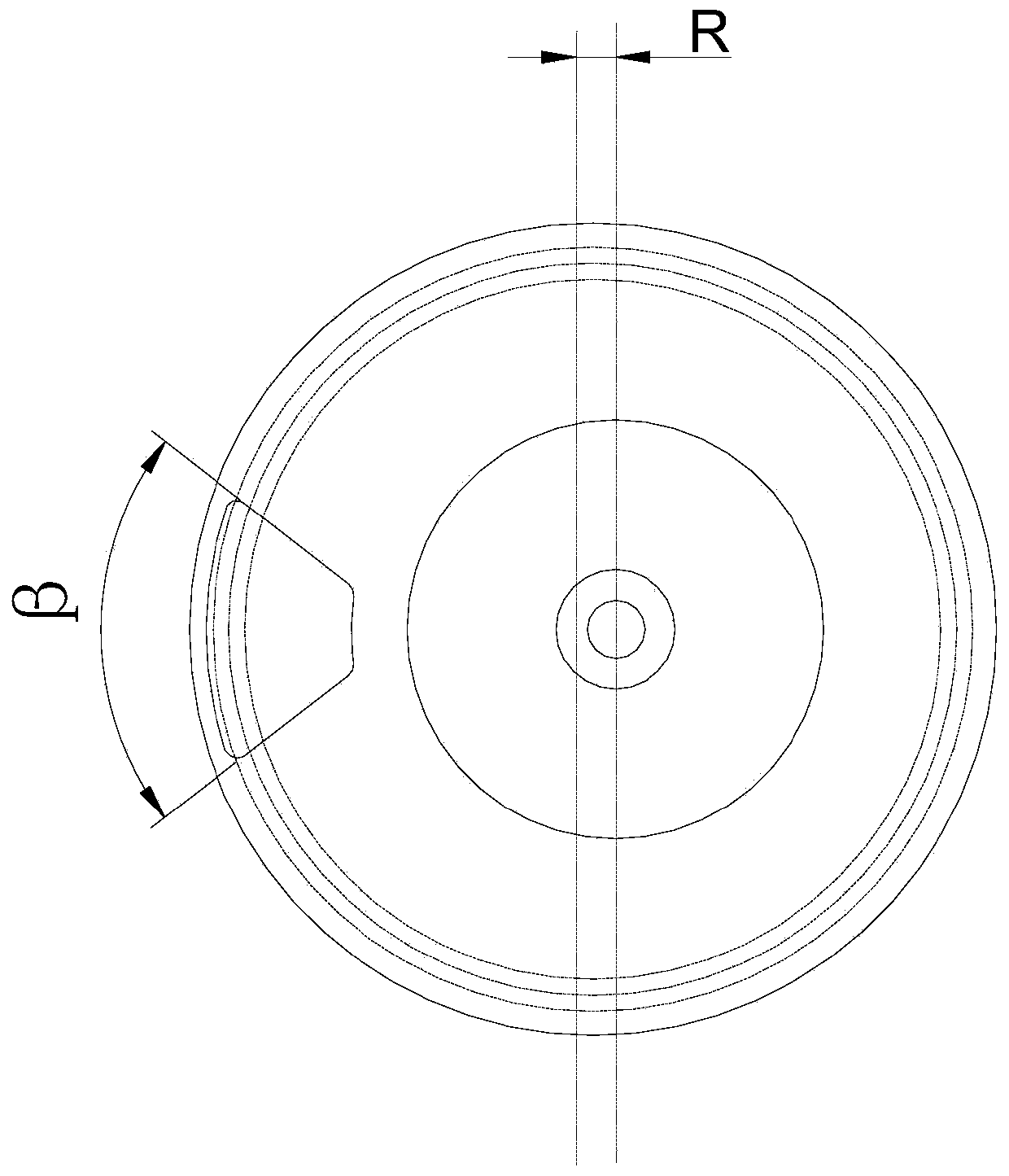

Manufacturing method for 3D printing diamond grinding wheel with abrasive particles arranged regularly

ActiveCN105415216AImprove grinding efficiencyUniform grinding forceGrinding devicesManufacturing technologyMachined surface

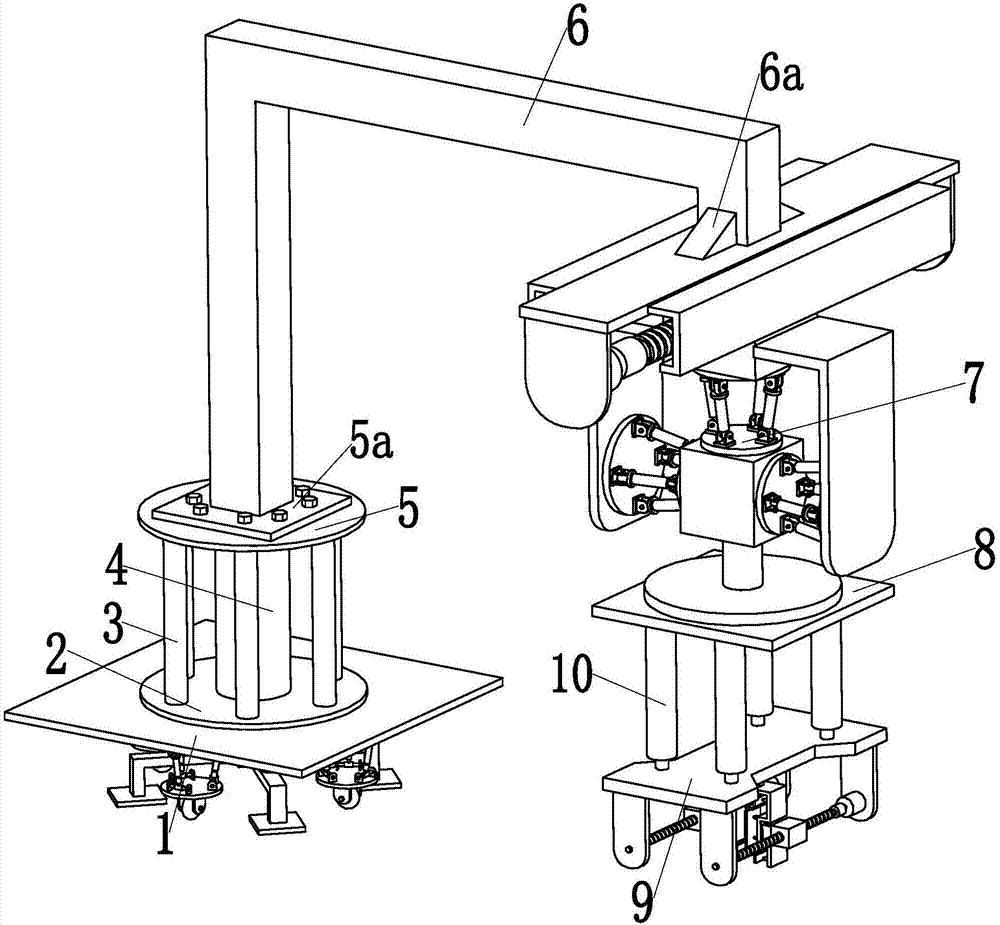

The invention belongs to the technical field of grinding machining and 3D printing and relates to a manufacturing method for a diamond grinding wheel with abrasive particles arranged regularly. Related devices mainly comprise a movement control platform, a grinding wheel printing system and a 3D printing grinding wheel. The movement control platform comprises a base, a rotation movement table, a lifting platform, a horizontal-moving platform, a movement control device and a supporting frame. The grinding wheel printing system comprises a diamond abrasive particle nozzle, a conveying pipe I, a diamond abrasive particle box, a nozzle supporting plate, an air pipe I, an air valve I, an air valve III, an air source, an air valve II, an air pipe II, a metal bonding agent powder box, a conveying pipe II, an air pipe III, a laser source, a laser optical path, a laser beam, a bonding agent nozzle and airflow. The 3D printing grinding wheel comprises a grinding wheel base body, a metal bonding agent and the diamond abrasive particles. The abrasive particles can be regularly arranged in the grinding wheel, when the grinding wheel of this kind is ground, the machined surface is high in quality, grinding efficiency is high, grinding force is even, and the service life of the grinding wheel is prolonged. Thus, the manufacturing technology of the special-shaped grinding wheel is simplified, platform constructing is convenient, and operation is easy and convenient.

Owner:HUNAN UNIV

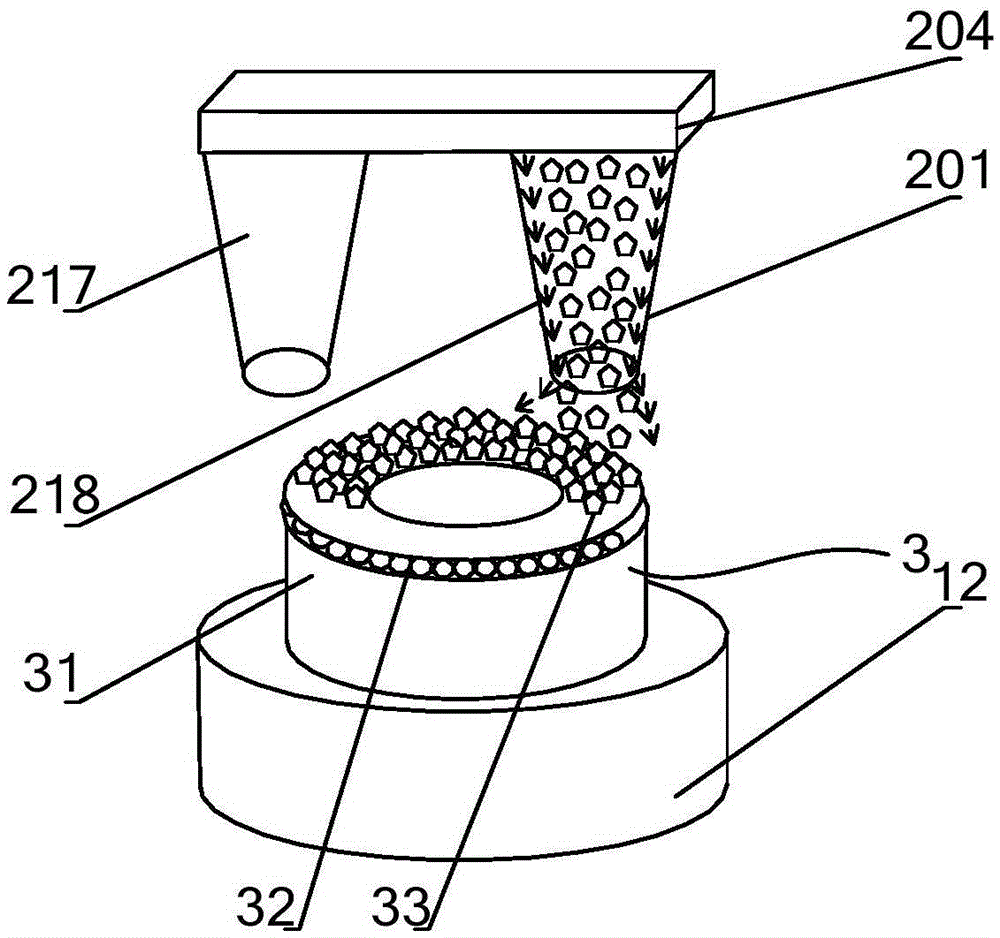

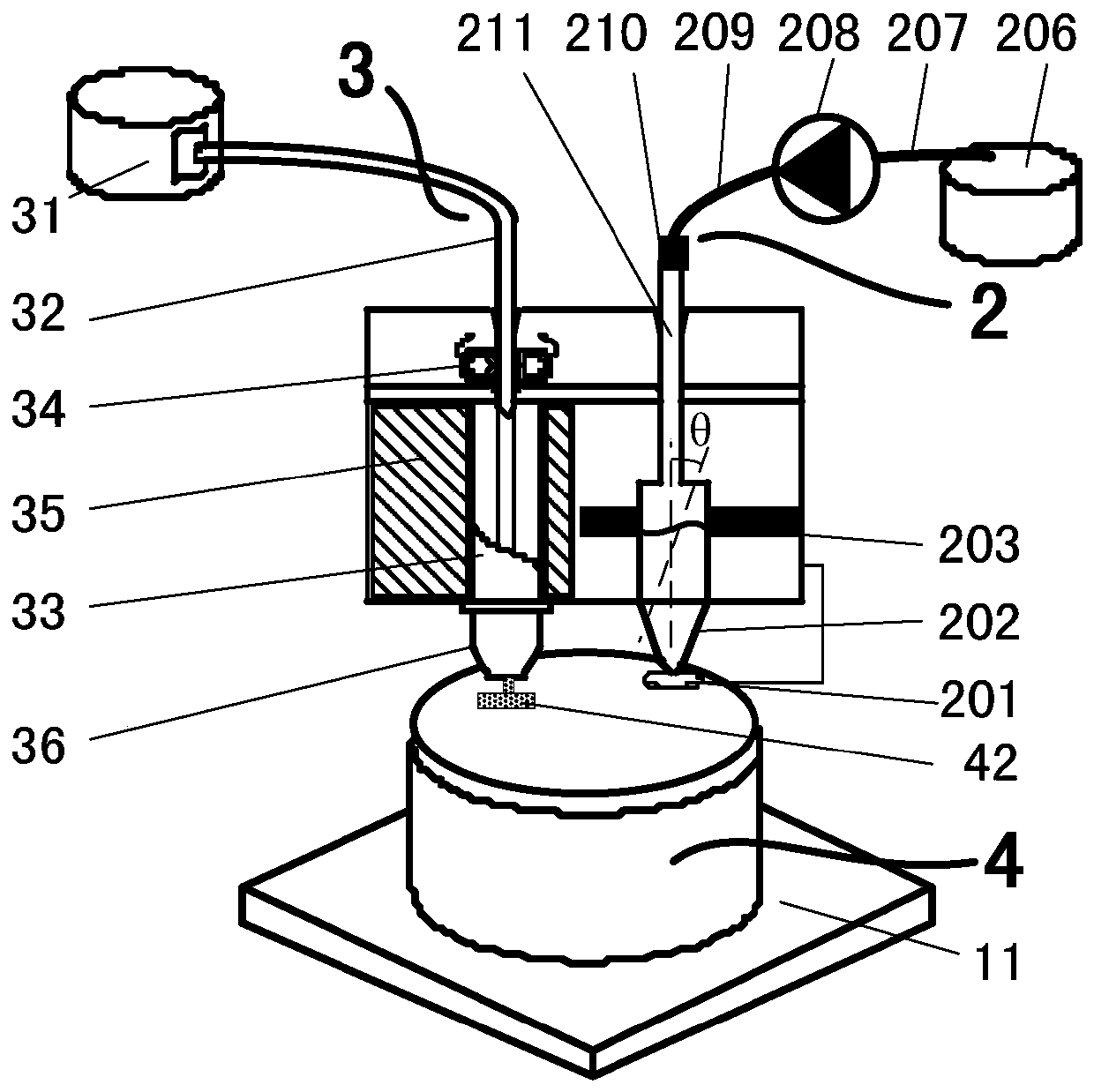

Manufacturing device and method of diamond resin abrasive wheel

ActiveCN106553137AImprove grinding efficiencyUniform grinding forceGrinding devicesMovement controlResin bonding

The invention belongs to the technical field of electrostatic atomization and heat fused deposition modeling, and relates to a manufacturing device and method of a diamond resin abrasive wheel with uniformly-distributed abrasive particles. The device mainly comprises a movement control platform, an electrostatic atomization system, an abrasive wheel printing system and a printed abrasive wheel. The movement control platform comprises a basic platform, a lifting platform, a horizontal movement platform, a movement control device and a supporting frame. The electrostatic atomization system comprises an annular electrode, an electrostatic nozzle, a supporting block, a high-voltage electrostatic generator, a power source, an electrostatic liquid container, connecting pipes, an injection pump and a connector. The abrasive wheel printing system comprises a wire material box, a resin bond wire material, a sleeve, a wire feeding mechanism, a heating mechanism and a forming nozzle. The printed abrasive wheel comprises an abrasive wheel basic body, a resin bonding agent and diamond abrasive particles. The abrasive particles are uniformly distributed in the abrasive wheel. When the abrasive wheel conducts grinding operation, the processed surface quality is high, the grinding force is uniform, the grinding efficiency is high, and a certain polishing effect is achieved.

Owner:HUNAN UNIV

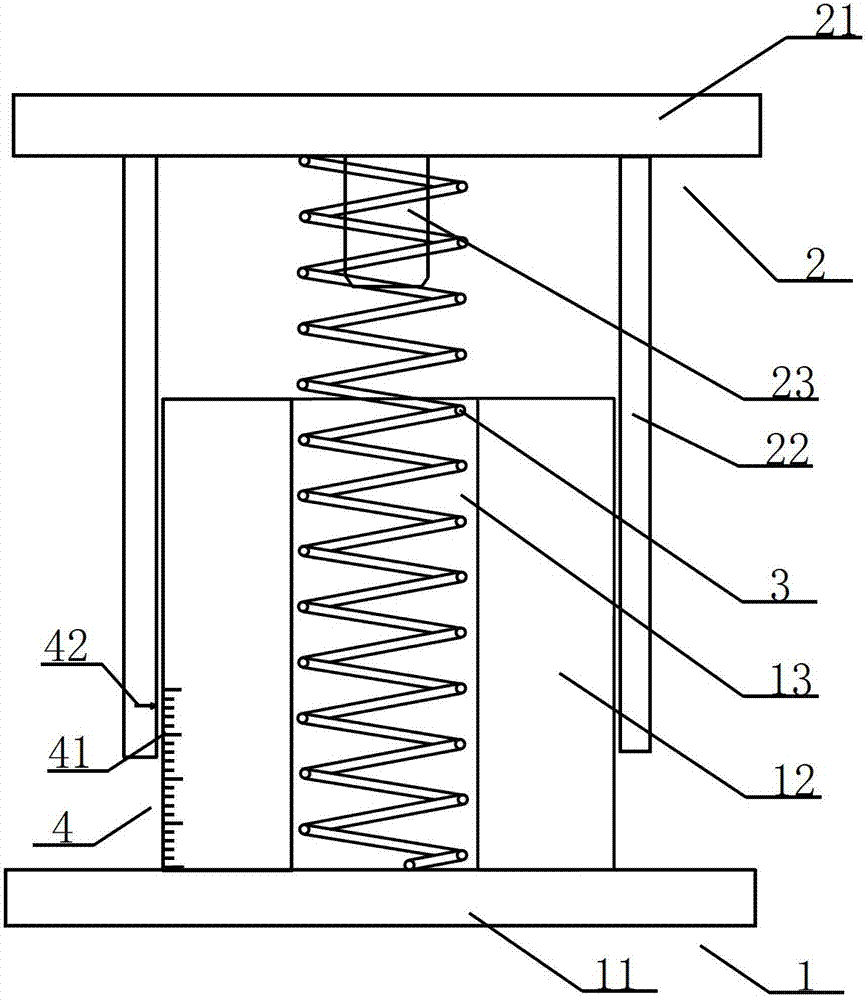

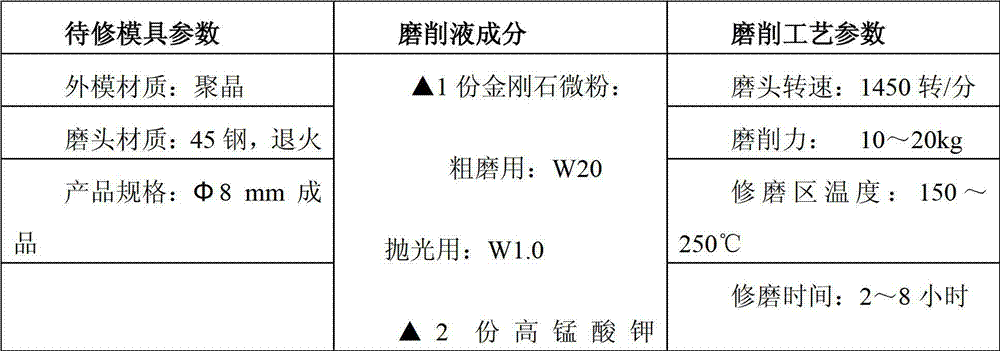

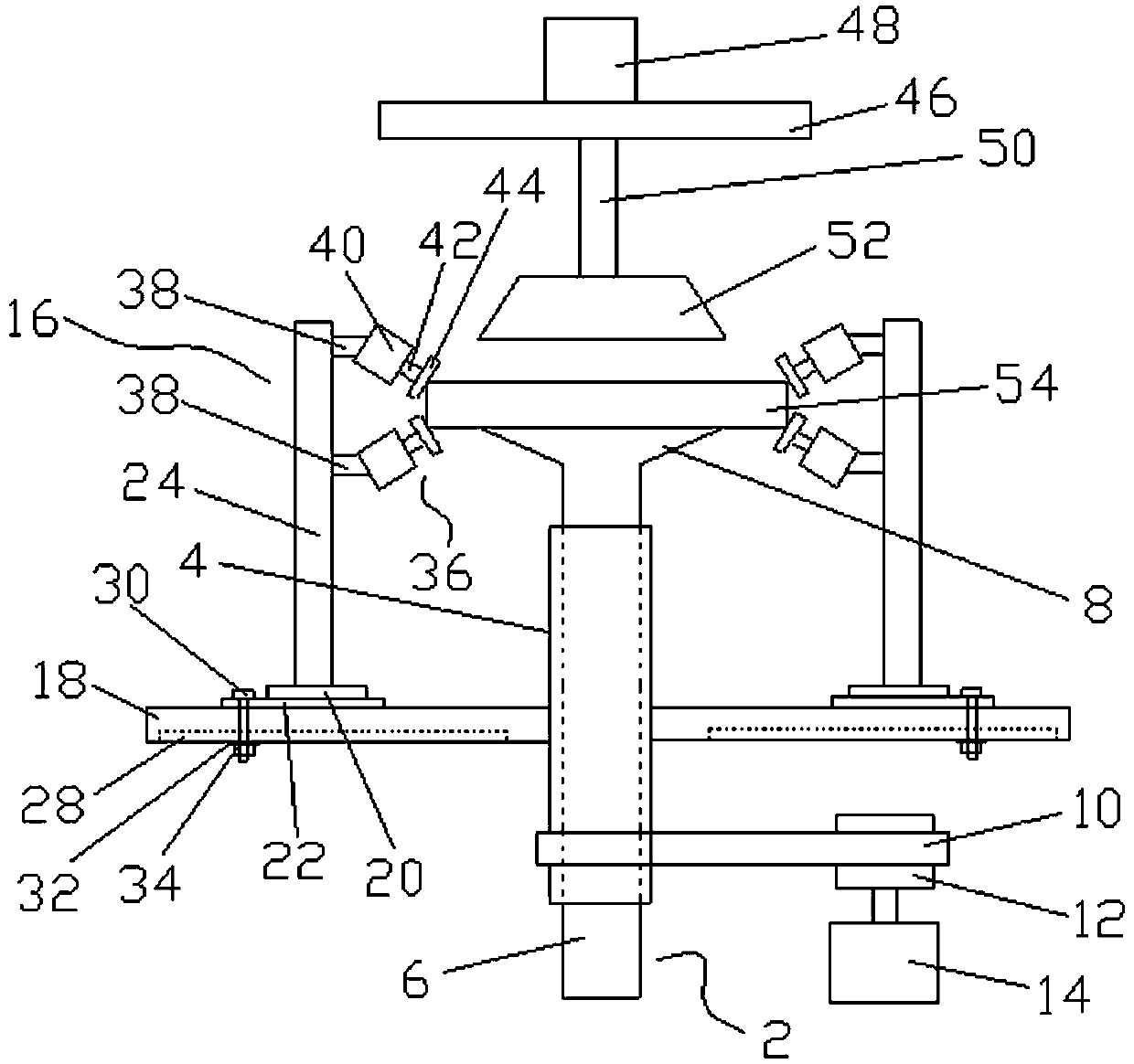

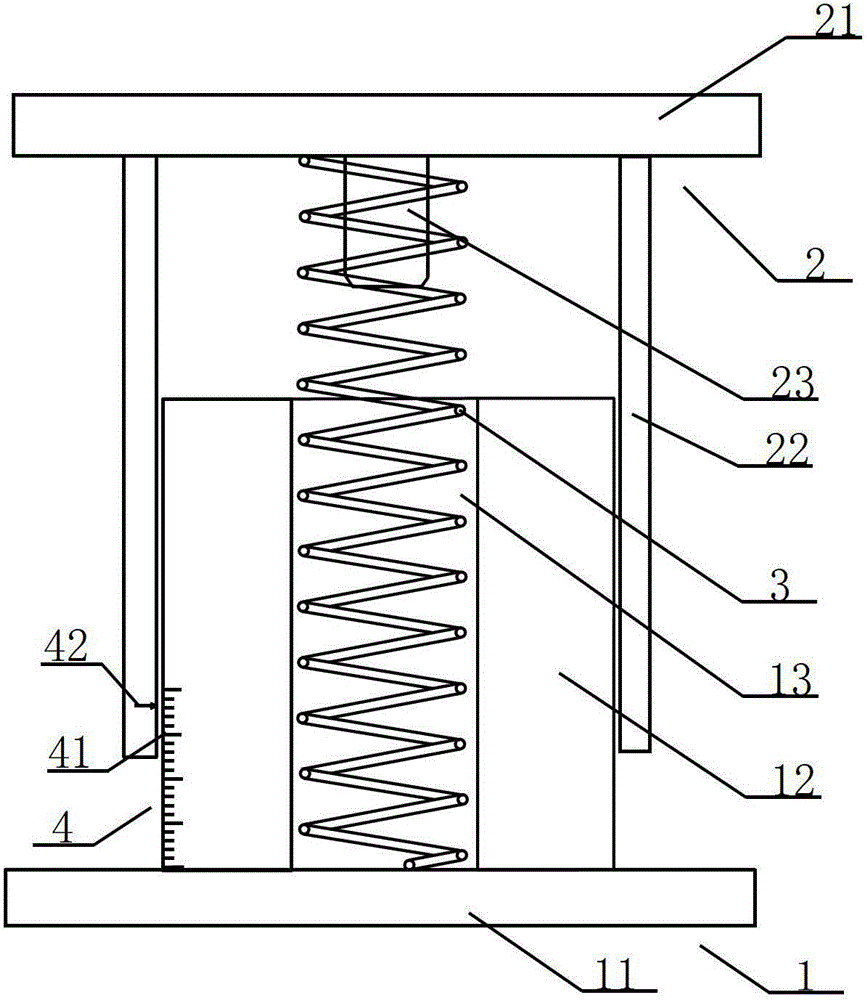

Device and method for grinding cold-drawing die

The invention discloses a device and method for grinding a cold-drawing die. The device comprises a rack, a floating platform and an elastic compression spring, wherein the rack comprises a base and a vertical column which is fixed on the base; an inner hole is formed in the middle of the vertical column; the floating platform comprises a working platform and a sleeve which is fixed on the working platform; the sleeve is in clearance fit with the vertical column; a positioning pin is fixed at the middle of the sleeve; the elastic compression spring is arranged inside the inner hole of the vertical column; and one end of the elastic compression spring is sleeved on the positioning pin. The device has the beneficial effects that as the die to be polished on the device can float on the water level when being put on the floating platform, and the axis of a working die hole can be automatically aligned and overlapped with the axis of a grinding head in the grinding process, thereby ensuring that the grinding force is uniformly distributed on a whole grinding plane; and moreover the grinding force can be judged according to the die material, the damage degree and the grinding material performance so as to be effectively adjusted and controlled, the grinding efficiency and the grinding quality are greatly improved with high grinding precision.

Owner:上海奉贤钢管厂有限公司

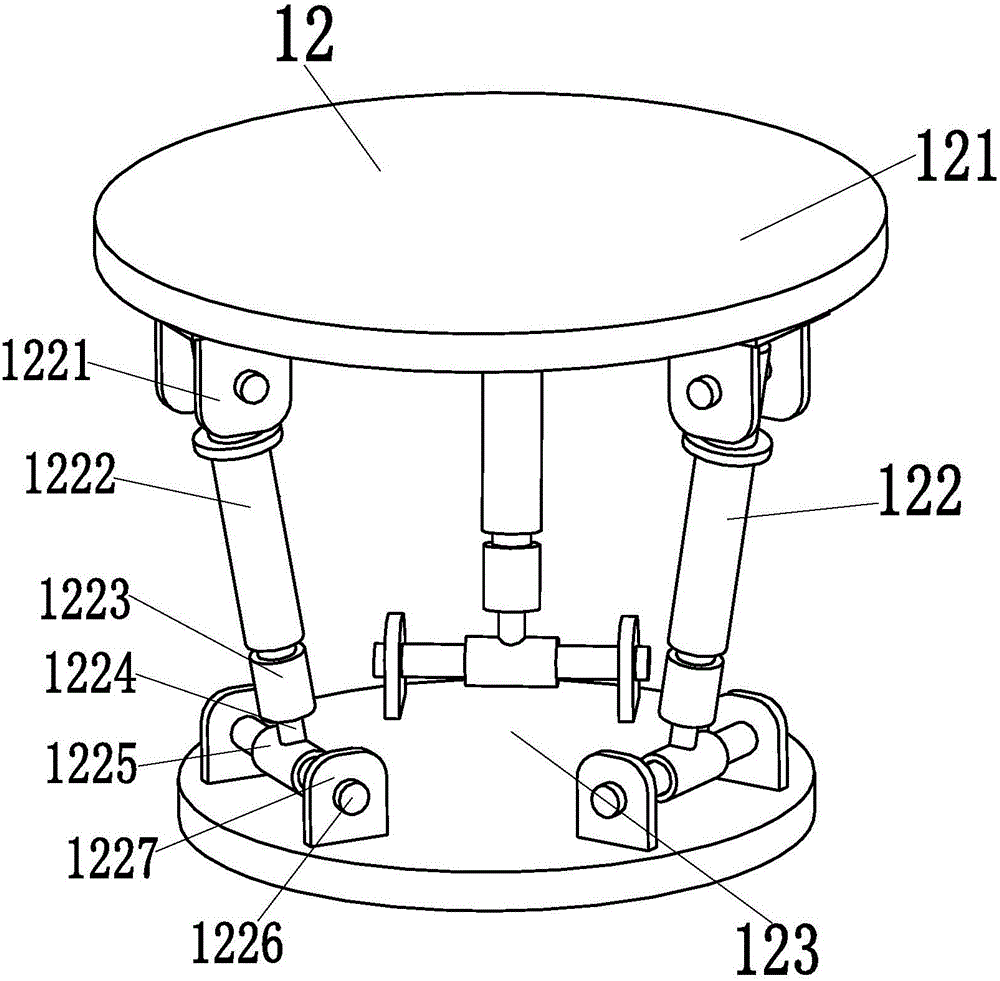

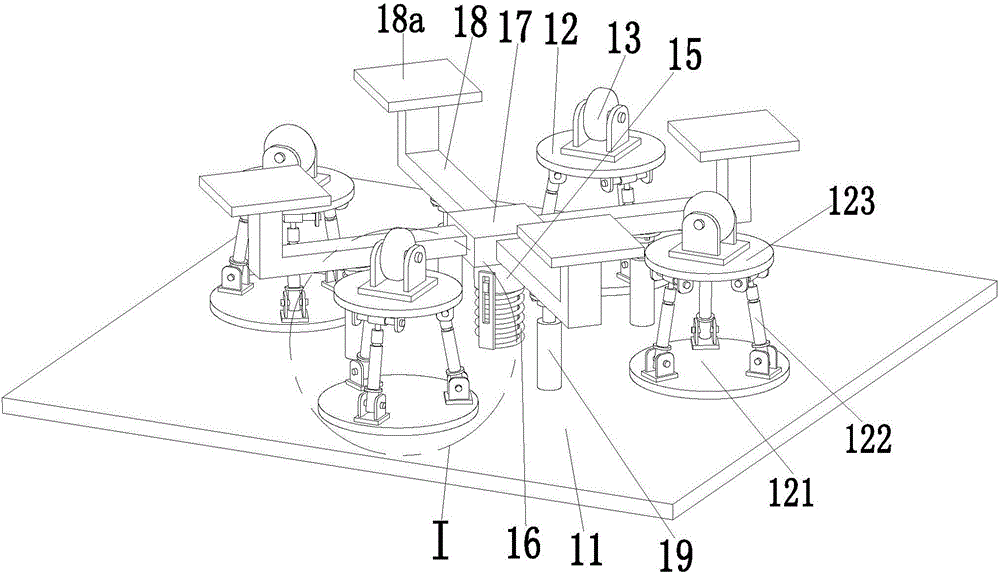

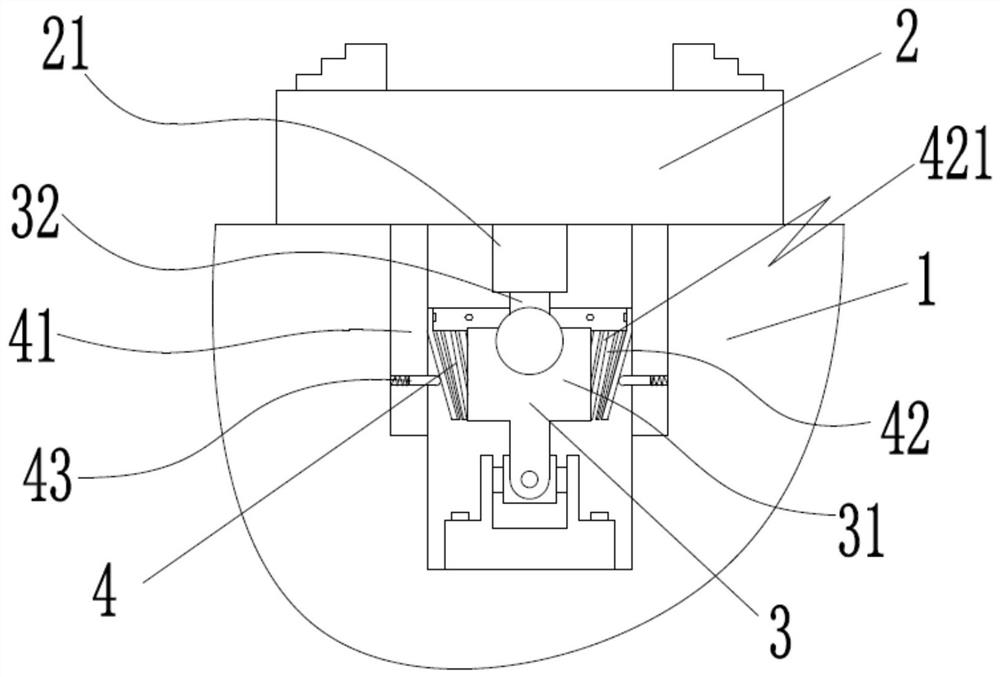

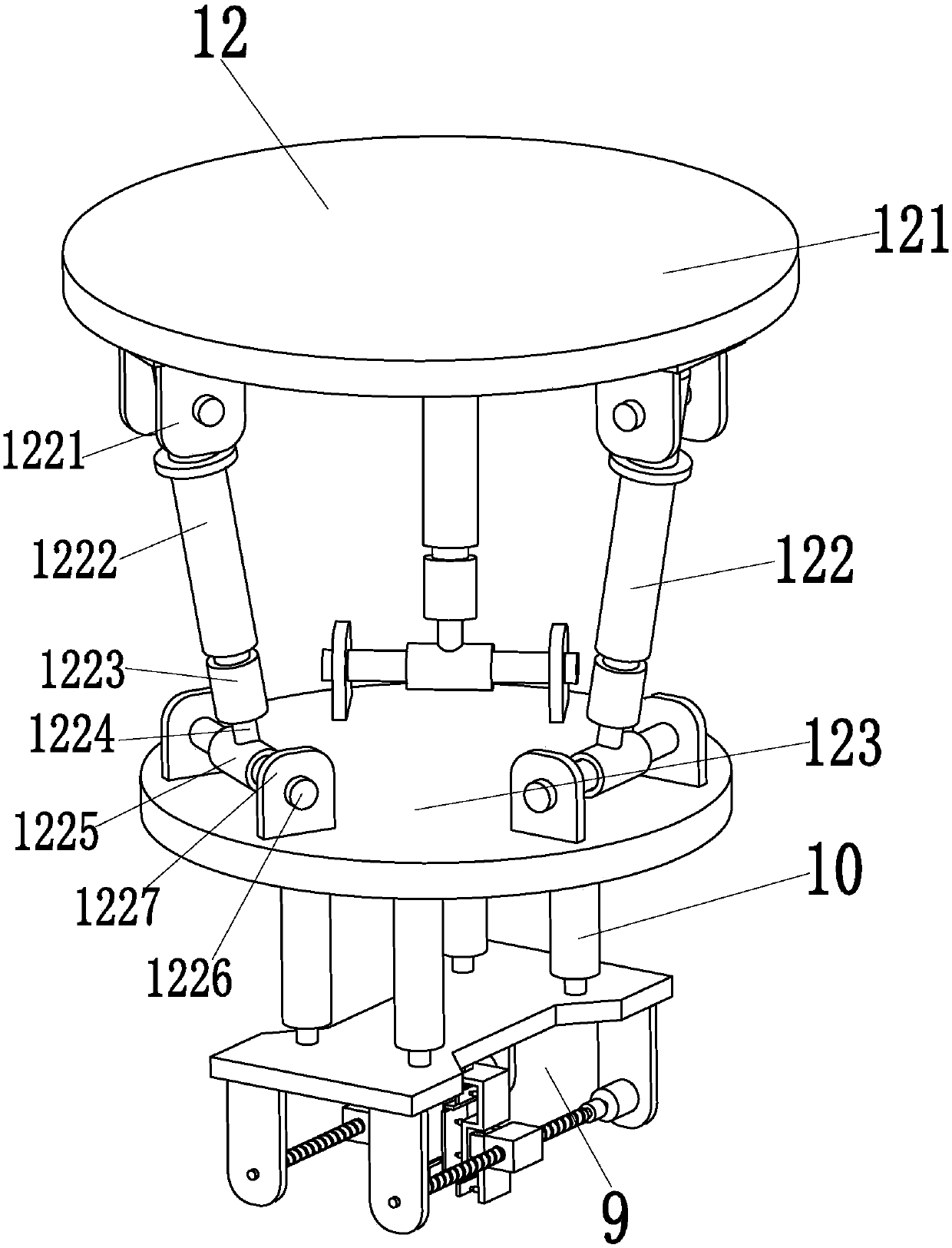

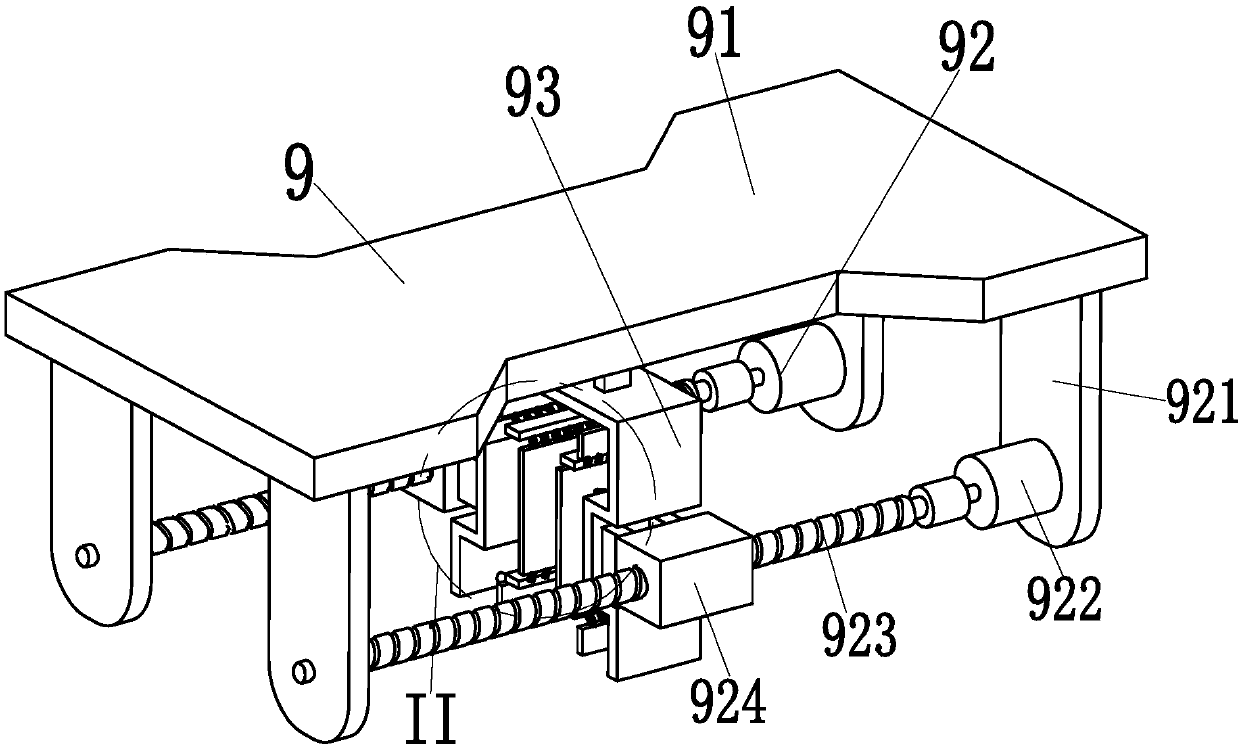

Circular workpiece polishing device

InactiveCN107900875AEasy to polishGrinding is easy to applyEdge grinding machinesGrinding drivesElectric machinerySprocket

The invention relates to a circular workpiece polishing device. The circular workpiece polishing device comprises a positioning assembly and a rotary sleeve. The positioning assembly comprises a rod body and a first suction cup connected with the rod body, the rotary sleeve is arranged on the rod body in a sleeving mode, the rotary sleeve is connected with a chain, the chain is engaged with a chain wheel, and the chain wheel is driven by a first motor; and three supporting frames are evenly installed on the peripheral surface of the rotary sleeve in the circumferential direction at intervals,and a polishing assembly is fixed to each supporting frame. According to the circular workpiece polishing device, the structure is simple, using is convenient, the polishing assemblies are supported by the three supporting frames correspondingly, polishing force of each polishing assembly to a to-be-polished circular workpiece is even, the circular workpiece is stably positioned, and cannot shake,and the polishing quality of the circular workpiece is good, the positions of the supporting frames can be adjusted along a guide rail, the circular workpiece polishing device can be conveniently used for polishing circular workpieces with different diameters, and the cost is reduced.

Owner:SUZHOU BOLAIXI ELECTRICAL APPLIANCE CO LTD

Grinding machine for wind power blade

PendingCN110625483AAvoid damageEasy to flyGrinding drivesGrinding feed controlElectricitySlide plate

The invention discloses a grinding machine for a wind power blade. The grinding machine comprises an AGV (automatic guided vehicle), wherein two stand columns are arranged on the AGV side by side; a sliding plate is movably arranged on the two stand columns in a vertical direction; a telescopic table is movably arranged on the sliding plate in a penetrating manner in a horizontal direction; the end part of one end, close to the wind power blade to be ground, of the telescopic table is connected to a grinding mechanism; and the grinding mechanism can be adjusted according to the inclination angle of the surface of the wind power blade to be ground to ensure that the grinding mechanism and the surface of the wind power blade to be ground are in vertical contact during working. As the grinding mechanism can be adjusted according to the inclination angle of the surface of the wind power blade to be ground in the grinding process, the grinding mechanism and the surface of the wind power blade are always in vertical contact, and the grinding efficiency and the grinding quality are improved.

Owner:CHONGQING MACHINE TOOL GROUP

Biological tissue grinding device

The invention discloses a biological tissue grinding device. The biological tissue grinding device comprises an airtight shell, a power unit, a transmission unit and an execution unit, wherein the airtight shell enables the whole grinding process to be conducted in an airtight space, so that biological tissue is prevented from being polluted, and the power unit, the transmission unit and the execution unit are arranged in the airtight shell; the power unit comprises a motor, the transmission unit comprises a main drive gear connected to the motor and at least two driven gears which are symmetrically arranged around the main drive gear and engaged with the main drive gear, and the execution unit comprises a sample cell and a plurality of grinding rods used for grinding the biological tissuein the sample cell; the sample cell is detachably connected to the airtight shell, the grinding rods are detachably connected to the driven gears, and a biological tissue sample can be simultaneouslygrinded by the multiple grinding rods through gear transmission; and the grinding efficiency is improved, the grinding rods are detachably connected to the driven gears, and mounting and dismountingof the grinding rods are facilitated.

Owner:CHENGDU MILITARY GENERAL HOSPITAL OF PLA

Intelligent polishing and cleaning integrated machine special for railway track

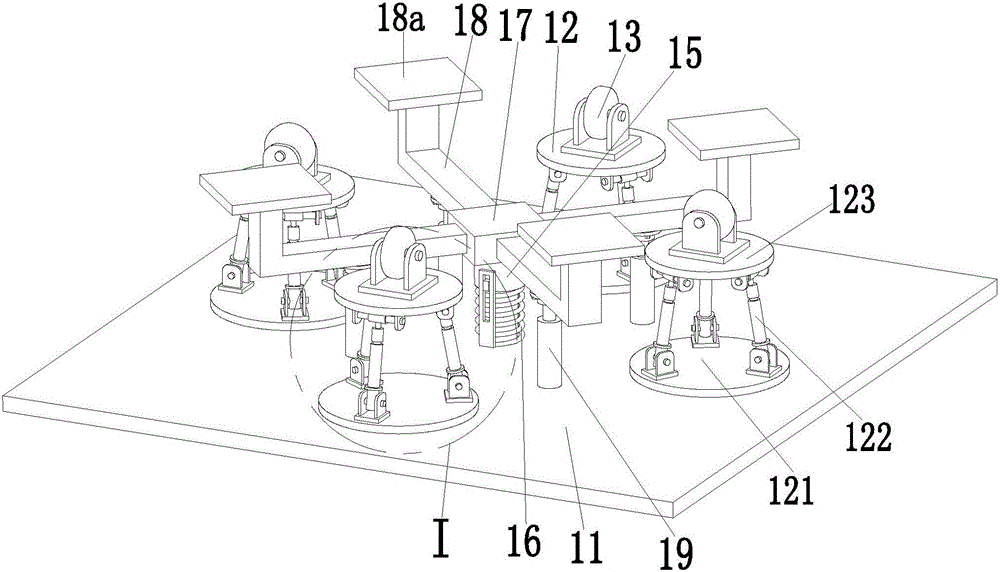

ActiveCN106120495AGood dynamic responseIncrease stiffnessRailway track constructionRailway cleaningHydraulic cylinderEngineering

The invention relates to an intelligent polishing and cleaning integrated machine special for a railway track. The intelligent polishing and cleaning integrated machine comprises a parallel-connection supporting mechanism, and the parallel-connection supporting mechanism comprises a fixed platform. Three parallel-connection branch chains are evenly installed on the lower end face of the fixed platform in the axis direction. The top ends of the three parallel-connection branch chains are all installed on a movable platform. A self-stabilizing mobile device is welded to the lower end face of the movable platform, and the self-stabilizing mobile device can achieve stable self-adjustment of the polishing direction according to the bending shape of the railway track. A variable high-pressure cleaning device is installed on the lower end face of the self-stabilizing mobile device, can quickly remove residual polishing scrap iron and unremoved dust adhering to the railway track based on the working principle of high-pressure water jetting, and has a good high-pressure cleaning effect. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the variable high-pressure cleaning device. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The adjustable polishing device can carry out polishing back and forth by being completely attached to the surface of the railway track. The intelligent polishing and cleaning integrated machine can achieve the full-automatic railway track polishing and cleaning functions, is free of manual operation and is high in degree of automation.

Owner:盐城华依鑫机械科技有限公司

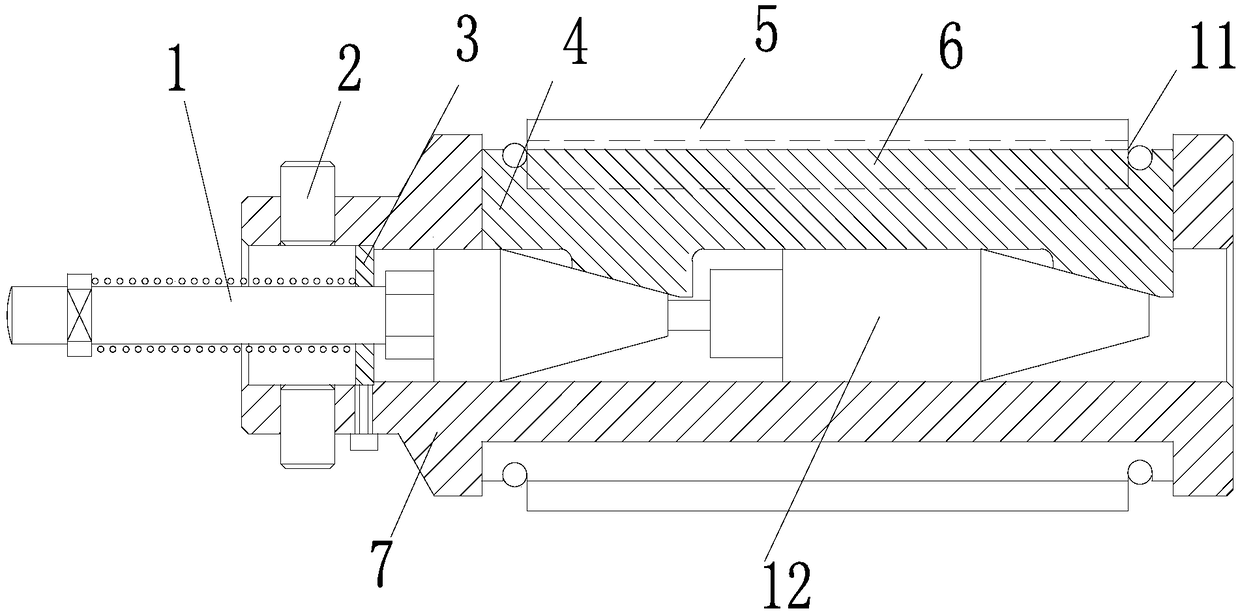

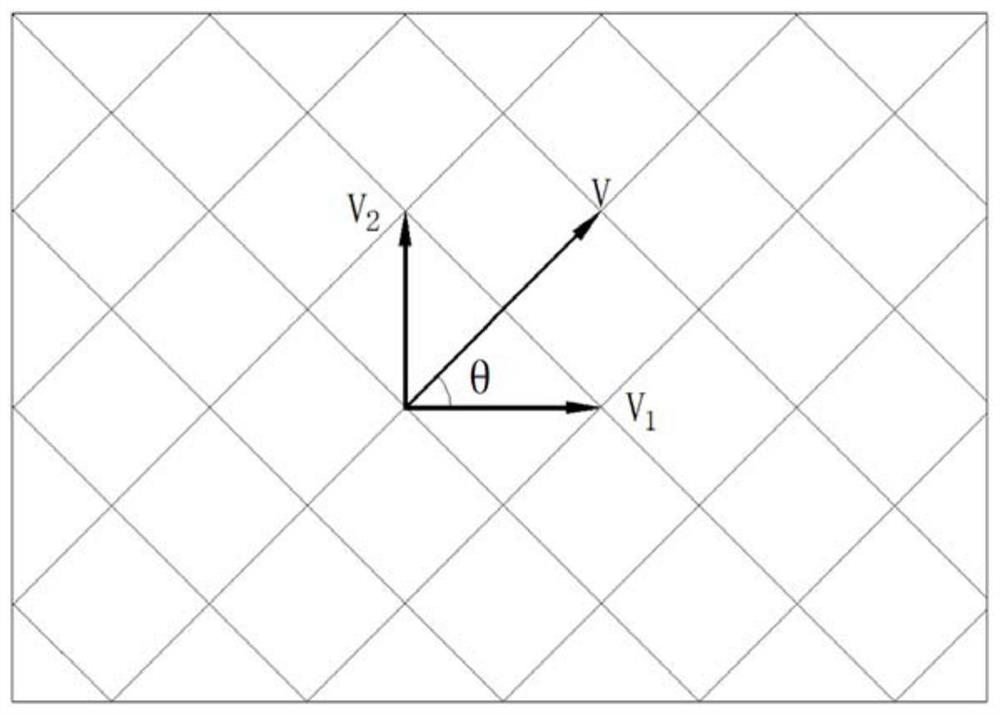

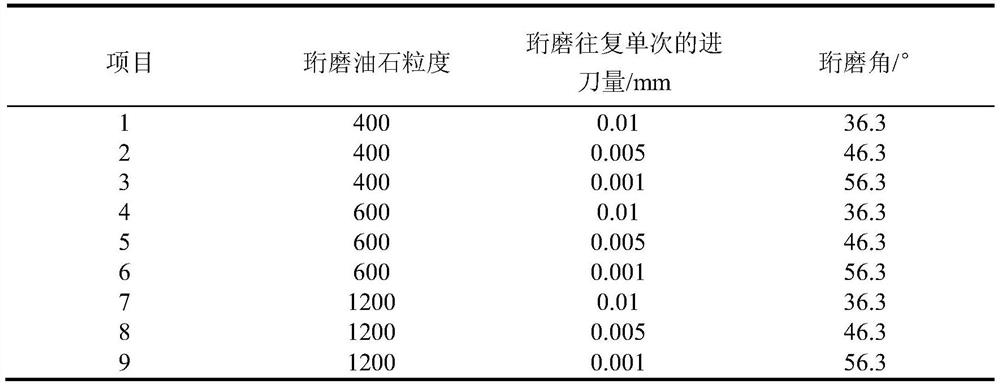

Honing machining method for carburizing hole of tappet guide sleeve of aero-engine

ActiveCN112743442AUniform grinding forceHigh cooling frequencyGrinding drivesGrinding feed controlNumerical controlEngineering

The invention discloses a honing machining method for a carburizing hole of a tappet guide sleeve of an aero-engine. The honing machining method comprises the following steps that the carburizing hole of the tappet guide sleeve is machined by adopting a numerical control boring cutter to remove the allowance to 0.2-0.3 mm, the tappet guide sleeve is mounted on a honing machine, the carburizing hole of the tappet guide sleeve is aligned, the carburizing hole is honed for four times until the surface smoothness Ra of the carburizing hole is less than or equal to 0.02, the four times of honing machining comprise rough honing machining, semi-fine honing machining, fine honing machining and super-fine honing machining, and honing machining parameters are optimized, so that the carburizing hole of the tappet guide sleeve does not have burn and crack defects, and the internal surface smoothness of the carburizing hole of the tappet guide sleeve is close to the level of a mirror surface. The honing machining method for the carburizing hole of the tappet guide sleeve of the aero-engine has the advantages of being high in machining efficiency, even in grinding force, high in cooling frequency, sufficient in cooling and free of burn and crack defects, and the surface smoothness of the inner hole is close to the level of a mirror surface.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

Plug valve sealing grinding machine

The invention discloses a plug valve sealing grinding machine which comprises a workbench, and at least one stand column is arranged on the workbench. The plug valve sealing grinding machine further comprises a gear box which is arranged on the stand column in a lifting manner, a universal mechanism which is arranged in the workbench, a fixed clamping base which is placed on the workbench and used for fixing a valve seat and a clamping mechanism which is arranged on the workbench and used for fixing the fixed clamping base, and an input shaft of the gear box is fixedly connected with a hydraulic motor; and a plug body is fixedly connected with an output shaft of the gear box through a telescopic mechanism, wherein the universal mechanism comprises a universal joint and a guide rod, one end of the universal joint is fixedly connected with the bottom of a containing hole located in the workbench, the guide rod is connected to the other end of the universal joint through a knuckle bearing, and the guide rod is connected with a guide sleeve of the fixed clamping base in a sliding fit manner. In the working process of the plug valve sealing grinding machine, the phenomena of meshing and jamming are avoided, a valve body and the plug body are stressed in a balanced manner, and the machining precision is high.

Owner:浙江优机机械科技有限公司

A kind of preparation method of 3D printing diamond grinding wheel with regular arrangement of abrasive grains

ActiveCN105415216BImprove grinding efficiencyUniform grinding forceGrinding devicesManufacturing technologyMachined surface

The invention belongs to the technical field of grinding machining and 3D printing and relates to a manufacturing method for a diamond grinding wheel with abrasive particles arranged regularly. Related devices mainly comprise a movement control platform, a grinding wheel printing system and a 3D printing grinding wheel. The movement control platform comprises a base, a rotation movement table, a lifting platform, a horizontal-moving platform, a movement control device and a supporting frame. The grinding wheel printing system comprises a diamond abrasive particle nozzle, a conveying pipe I, a diamond abrasive particle box, a nozzle supporting plate, an air pipe I, an air valve I, an air valve III, an air source, an air valve II, an air pipe II, a metal bonding agent powder box, a conveying pipe II, an air pipe III, a laser source, a laser optical path, a laser beam, a bonding agent nozzle and airflow. The 3D printing grinding wheel comprises a grinding wheel base body, a metal bonding agent and the diamond abrasive particles. The abrasive particles can be regularly arranged in the grinding wheel, when the grinding wheel of this kind is ground, the machined surface is high in quality, grinding efficiency is high, grinding force is even, and the service life of the grinding wheel is prolonged. Thus, the manufacturing technology of the special-shaped grinding wheel is simplified, platform constructing is convenient, and operation is easy and convenient.

Owner:HUNAN UNIV

Intelligent polishing and cleaning equipment for high-speed rail track

ActiveCN106120496APrecise adjustment of high pressure cleaning angleHigh pressure cleaning effect is goodRailway track constructionRailway cleaningHydraulic cylinderEngineering

The invention relates to intelligent polishing and cleaning equipment for a high-speed rail track. The intelligent polishing and cleaning equipment for the high-speed rail track comprises a self-stabilizing traveling device. A lower supporting circular truncated cone is welded to the middle of the upper end face of the self-stabilizing traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular truncated cone in the axis direction. A supporting stand column is welded to the middle of the upper end face of the lower supporting circular truncated cone. An upper supporting circular truncated cone is welded to the upper end faces of the supporting stand column and the six supporting cylinders. A connecting piece is installed on the upper end face of the upper supporting circular truncated cone through screws, and a supporting curved boom is welded to the middle of the upper end face of the connecting piece. A variable high-pressure cleaning device is welded to the tail end of the supporting curved boom. Two ribbed blocks are welded between the two sides of the tail end of the supporting curved boom and the variable high-pressure cleaning device correspondingly. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the variable high-pressure cleaning device. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The intelligent polishing and cleaning equipment can achieve the full-automatic railway track polishing and cleaning functions, shaking in the operation process of the equipment is eliminated, and the equipment has good stability performance and fixation performance.

Owner:SHIJIAZHUANG TIEDAO UNIV

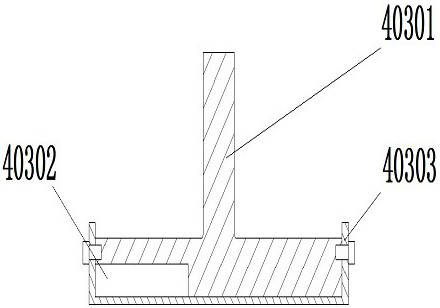

Tile type key groove hole honing head

The invention discloses a tile type key groove hole honing head. The tile type key groove hole honing head comprises a honing head body and a push rod, wherein a through hole is formed in the middle of the honing head body, a harmomegathus cone is arranged in the through hole, the push rod is in connected to the left end of the harmomegathus cone in a threaded mode, a backup ring sleeves on the right part of the push rod, a sleeving ring is connected to the left part of the push rod in a threaded mode, a spring sleeves on the push rod, and the spring is located between the sleeing ring and thebackup ring. The tile type key groove hole honing head is reasonable in structural design, when the tile type key groove hole honing head is machined, oilstone seat rises, when an oilstone sharp corner and a key groove sharp corner are in contract and stressed, and other oilstone on the same oilstone seat is in contract with the inner wall of a workpiece to play a supporting role; the structure is not prone to breaking the oilstone, when a tile type oilstone installation piece and a harmomegathus piece rise, grinding force at a key groove is uniform due to the fact that the oilstone away fromthe key groove plays a supporting role, the precision of roundness of the workpiece is higher after honing, more quantities of the oilstone can be installed by the tile type oilstone installation piece, and the honing efficiency can be effectively improved.

Owner:昆山昆江数控机床有限公司

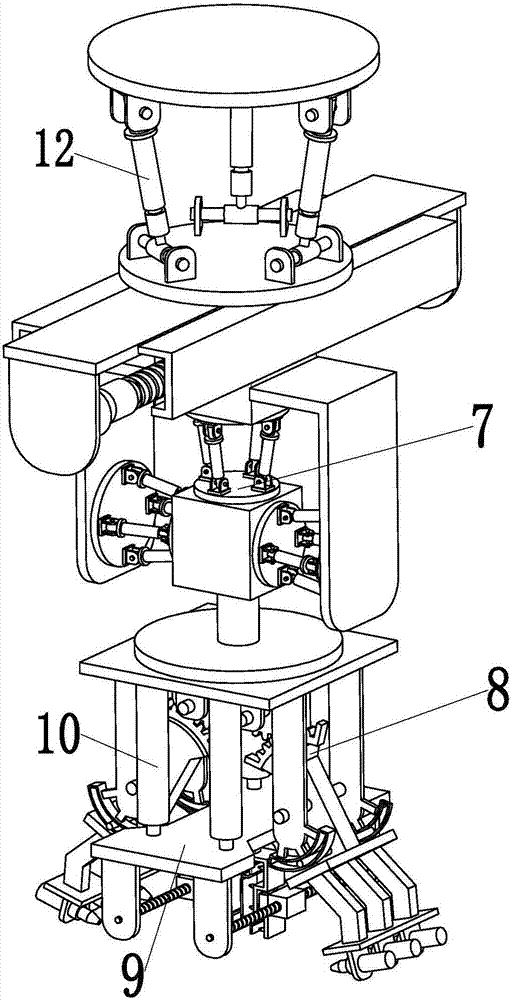

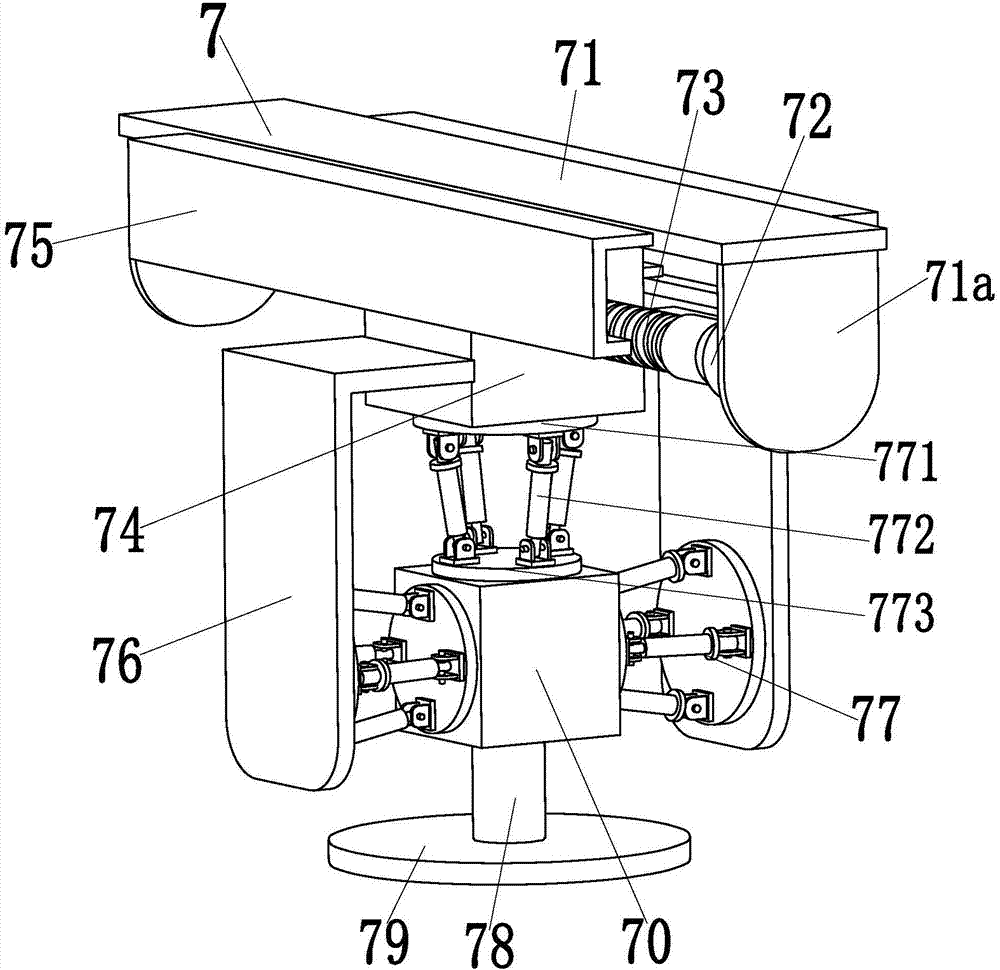

Intelligent polishing machine for train tracks

ActiveCN106120493AGood dynamic responseIncrease stiffnessRailway track constructionHydraulic cylinderSelf-stabilization

The invention relates to an intelligent polishing machine for train tracks. The intelligent polishing machine for train tracks comprises a self-stabilization traveling device. A lower supporting circular platform is welded to the middle of the upper end face of the self-stabilization traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular platform in the axis direction. A supporting stand column is welded to the middle of the upper end face of the lower supporting circular platform. An upper supporting circular platform is welded to the upper end faces of the supporting stand column and the six supporting cylinders. A connecting piece is installed on the upper end face of the upper supporting circular platform through screws. A supporting bent arm is welded to the middle of the upper end face of the connecting piece. A polishing bottom plate is welded to the tail end of the supporting bent arm, and two rib blocks are welded between the two sides of the tail end of the supporting bent arm and the polishing bottom plate. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the polishing bottom plate. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The intelligent polishing machine for train tracks can achieve the function of fully automatically polishing tracks, does not need manual operation and is high in automation degree, a shaking condition in the working process of equipment is eliminated, and the stability performance of the equipment is good.

Owner:中铁物总运维科技有限公司

Non-resonant vibration auxiliary magneto-rheological polishing device and method for machining optical element

The invention relates to a non-resonant vibration auxiliary magneto-rheological polishing device and method for machining an optical element, and belongs to the field of ultra-precision machining. AnX-direction air floatation guide rail and a Y-direction air floatation guide rail are installed on a machine tool frame and drive an element to move in the X-direction and the Y-direction; an Z-direction air floatation guide rail and the Y-direction air floatation guide rail are connected through screws, so that a polishing tool bit moving platform fixed at the bottom end of the Z-direction air floatation guide rail moves in the Z direction; a magnet rotating table is fixed to the machine tool frame, and a generated dynamic magnetic field enables magnetorheological fluid to be subjected to a magnetization reaction to form a magnetic cluster; and a vibration device is installed on the magnet rotating table and drives the element to vibrate in a two-dimensional mode. According to the non-resonant vibration auxiliary magneto-rheological polishing method provided by the invention,a rotary magnetic brush is combined with two-dimensional vibration, so that an abrasive material makes full contact with a surface microstructure of the element, the abrasive material effectively removes scratches, burrs and cracks on the surface of the element through composite motion of the rotary magnetic brush and the two-dimensional vibration, and the polishing efficiency is improved, and the shape precision of the element is better reserved.

Owner:CHANGCHUN UNIV OF TECH

Intelligent polishing integrated machine for bullet train track

ActiveCN106120494AGood dynamic responseIncrease stiffnessRailway track constructionHydraulic cylinderEngineering

The invention relates to an intelligent polishing integrated machine for a bullet train track. The intelligent polishing integrated machine comprises a self-stabilizing traveling device. A lower supporting circular truncated cone is welded to the center of the upper end face of the self-stabilizing traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular truncated cone in the axis direction. A supporting stand column is welded to the center of the upper end face of the lower supporting circular truncated cone. An upper supporting circular truncated cone is welded to the upper end face of the supporting stand column and the upper end faces of the six supporting cylinders. A connection piece is installed on the upper end face of the upper supporting circular truncated cone through screws. A bent supporting arm is welded to the center of the upper end face of the connection piece. A self-stabilizing moving device is welded to the tail end of the bent supporting arm, and two ribbed blocks are welded between the two sides of the tail end of the bent supporting arm and the self-stabilizing moving device. A polishing bottom plate is installed on the lower end face of the self-stabilizing moving device. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the polishing bottom plate. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. According to the intelligent polishing integrated machine, a full-automatic track polishing function can be achieved, manual operation is not needed, and the automation degree is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

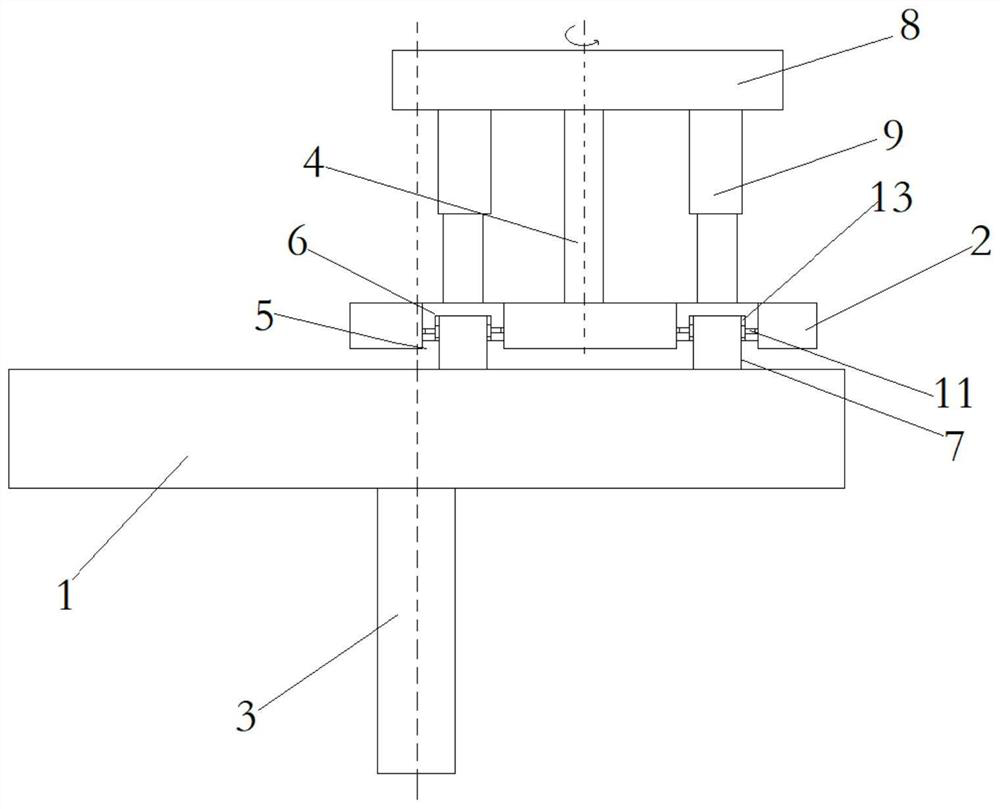

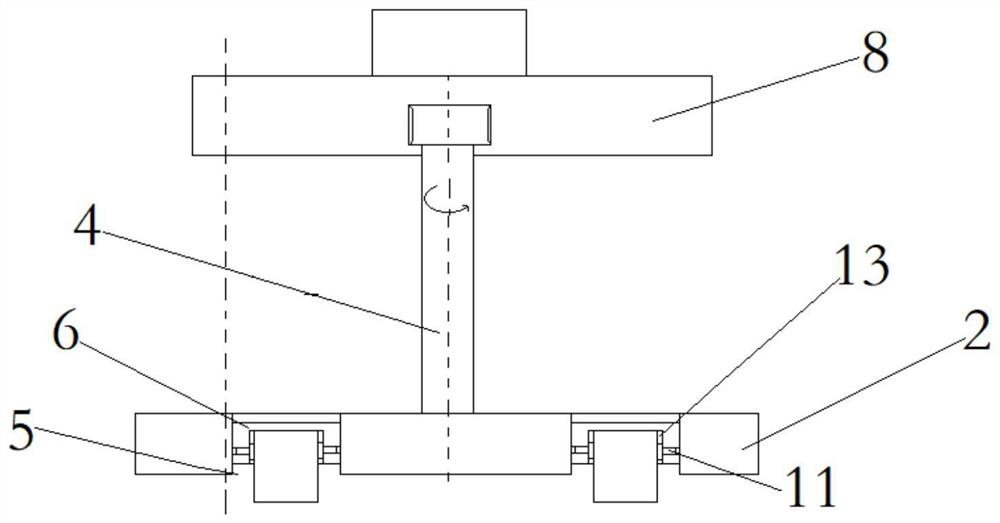

Planetary grinding device and grinding method for planar optical element

ActiveCN111702653AGrinding speed is fastGuaranteed flatnessOptical surface grinding machinesLapping machinesEngineeringMachining process

The invention discloses a planetary grinding device and a grinding method for a planar optical element. According to the planetary grinding device and method for the planar optical element, the lowerend face of a workpiece disc and the upper end face of a grinding table are arranged in parallel, the grinding table and the workpiece disc can rotate in a mutually non-coaxial mode, a plurality of clamp positioning holes are formed in the workpiece disc, the multiple clamp positioning holes are circumferentially arrayed with the axis of a driving shaft of the workpiece disc as the center, the to-be-machined optical element is clamped through a clamp, the to-be-ground end face of the to-be-machined optical element makes contact with the upper grinding end face after being limited through the workpiece disc, and finally the pressure between the to-be-machined optical element and the grinding table is adjusted through a pressure applying device, and the contact stability between the to-be-machined optical element and the grinding table is ensured. The device is simple in structure, the grinding speed of the planar optical element is greatly increased through mutual rotation of the grinding disc and the workpiece disc in a planetary motion mode, the same pressure is kept in real time through the pressure applying device in the grinding process, the flatness of workpiece machining is guaranteed, and the machining efficiency of the whole machining technology is improved.

Owner:XI AN JIAOTONG UNIV

Method for increasing grinding wafer flatness

InactiveCN101357451AUniform grinding forceImprove flatnessSemiconductor/solid-state device manufacturingLapping machinesMotion rangeEngineering

The invention provides a method for improving the planeness of a ground wafer; the method is applied on a grinding machine which comprises a grinding head and a grinding disc; the grinding head is used for adsorbing and fixing the wafer; the grinding disc is used with the grinding head and used for grinding the wafer, wherein, the motion range of the grinding head does not exceed the surface of the grinding disc; the brim of the bottom of the grinding head is provided with a fixing ring which is used for fixing the wafer and is contacted with the grinding disc completely. Compared with the prior art, the even grinding force exerted on the wafer can improve the planeness of the wafer surface in one grinding process and can improve the production efficiency and the yield of the wafer simultaneously.

Owner:SEMICON MFG INT (SHANGHAI) CORP

A cold drawing die grinding device and method

The invention discloses a device and method for grinding a cold-drawing die. The device comprises a rack, a floating platform and an elastic compression spring, wherein the rack comprises a base and a vertical column which is fixed on the base; an inner hole is formed in the middle of the vertical column; the floating platform comprises a working platform and a sleeve which is fixed on the working platform; the sleeve is in clearance fit with the vertical column; a positioning pin is fixed at the middle of the sleeve; the elastic compression spring is arranged inside the inner hole of the vertical column; and one end of the elastic compression spring is sleeved on the positioning pin. The device has the beneficial effects that as the die to be polished on the device can float on the water level when being put on the floating platform, and the axis of a working die hole can be automatically aligned and overlapped with the axis of a grinding head in the grinding process, thereby ensuring that the grinding force is uniformly distributed on a whole grinding plane; and moreover the grinding force can be judged according to the die material, the damage degree and the grinding material performance so as to be effectively adjusted and controlled, the grinding efficiency and the grinding quality are greatly improved with high grinding precision.

Owner:上海奉贤钢管厂有限公司

A kind of preparation method of diamond resin grinding wheel

ActiveCN106553137BImprove grinding efficiencyUniform grinding forceGrinding devicesMovement controlResin bonding

The invention belongs to the technical field of electrostatic atomization and heat fused deposition modeling, and relates to a manufacturing device and method of a diamond resin abrasive wheel with uniformly-distributed abrasive particles. The device mainly comprises a movement control platform, an electrostatic atomization system, an abrasive wheel printing system and a printed abrasive wheel. The movement control platform comprises a basic platform, a lifting platform, a horizontal movement platform, a movement control device and a supporting frame. The electrostatic atomization system comprises an annular electrode, an electrostatic nozzle, a supporting block, a high-voltage electrostatic generator, a power source, an electrostatic liquid container, connecting pipes, an injection pump and a connector. The abrasive wheel printing system comprises a wire material box, a resin bond wire material, a sleeve, a wire feeding mechanism, a heating mechanism and a forming nozzle. The printed abrasive wheel comprises an abrasive wheel basic body, a resin bonding agent and diamond abrasive particles. The abrasive particles are uniformly distributed in the abrasive wheel. When the abrasive wheel conducts grinding operation, the processed surface quality is high, the grinding force is uniform, the grinding efficiency is high, and a certain polishing effect is achieved.

Owner:HUNAN UNIV

A train track intelligent grinding machine

ActiveCN106120493BGood dynamic responseIncrease stiffnessRailway track constructionHydraulic cylinderEngineering

The invention relates to an intelligent polishing machine for train tracks. The intelligent polishing machine for train tracks comprises a self-stabilization traveling device. A lower supporting circular platform is welded to the middle of the upper end face of the self-stabilization traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular platform in the axis direction. A supporting stand column is welded to the middle of the upper end face of the lower supporting circular platform. An upper supporting circular platform is welded to the upper end faces of the supporting stand column and the six supporting cylinders. A connecting piece is installed on the upper end face of the upper supporting circular platform through screws. A supporting bent arm is welded to the middle of the upper end face of the connecting piece. A polishing bottom plate is welded to the tail end of the supporting bent arm, and two rib blocks are welded between the two sides of the tail end of the supporting bent arm and the polishing bottom plate. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the polishing bottom plate. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The intelligent polishing machine for train tracks can achieve the function of fully automatically polishing tracks, does not need manual operation and is high in automation degree, a shaking condition in the working process of equipment is eliminated, and the stability performance of the equipment is good.

Owner:中铁物总运维科技有限公司

An intelligent grinding and cleaning equipment for high-speed rail tracks

ActiveCN106120496BGood dynamic responseIncrease stiffnessRailway track constructionRailway cleaningHydraulic cylinderEngineering

The invention relates to intelligent polishing and cleaning equipment for a high-speed rail track. The intelligent polishing and cleaning equipment for the high-speed rail track comprises a self-stabilizing traveling device. A lower supporting circular truncated cone is welded to the middle of the upper end face of the self-stabilizing traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular truncated cone in the axis direction. A supporting stand column is welded to the middle of the upper end face of the lower supporting circular truncated cone. An upper supporting circular truncated cone is welded to the upper end faces of the supporting stand column and the six supporting cylinders. A connecting piece is installed on the upper end face of the upper supporting circular truncated cone through screws, and a supporting curved boom is welded to the middle of the upper end face of the connecting piece. A variable high-pressure cleaning device is welded to the tail end of the supporting curved boom. Two ribbed blocks are welded between the two sides of the tail end of the supporting curved boom and the variable high-pressure cleaning device correspondingly. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the variable high-pressure cleaning device. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. The intelligent polishing and cleaning equipment can achieve the full-automatic railway track polishing and cleaning functions, shaking in the operation process of the equipment is eliminated, and the equipment has good stability performance and fixation performance.

Owner:SHIJIAZHUANG TIEDAO UNIV

Planetary plate type ball mill

PendingCN111283549APlay limitPlay the role of grindingLapping machinesLapping toolsEngineeringMechanical engineering

The invention discloses an upper grinding disc for a disc ball mill. V-shaped grooves distributed in the circumferential direction are formed in the lower surface of the upper grinding disc, and the lower surface of the upper grinding disc is used for being matched with the upper surface of a lower grinding disc; and the upper grinding disc is used for being connected with a floating part and is used as a floating grinding disc. According to the upper grinding disc for the disc ball mill, the V-shaped grooves are formed in the upper grinding disc to limit and grind micro balls, and the upper grinding disc is adopted as the floating grinding disc, so that the limiting effect on the micro balls in the grinding process is weakened, it is guaranteed that the micro balls can effectively rotatereversely, the rolling randomness of ball bodies in the disc ball mill is favorably improved, uniform stress of the ball bodies at all angles is guaranteed, and the grinding quality is improved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A plug valve seal grinding machine

Owner:浙江优机机械科技有限公司

Brush wheel resin grinding sheet for grinding printed circuit board and manufacturing method thereof

InactiveCN107263342BExtended service lifeNot easy to cause scratchesAbrasion apparatusGrinding devicesEpoxyEngineering

The invention discloses a brush wheel resin grinding disc for grinding a printed circuit board and a manufacturing method thereof. The brush wheel resin grinding disc is prepared from the following raw materials in parts by weight: 10 to 25 parts of phenolic resin, 10 to 20 parts of epoxy resin, 10 to 15 parts of vinylite, 30 to 70 parts of green silicon carbide, 2 to 5 parts of AC foaming agent, 8 to 18 parts of polyamide resin, 13 to 17 parts of ethyl ester, 1 to 2 parts of silicone oil, 1 to 6 parts of silicon carbide whisker, 2 to 6 parts of aluminium borate whisker, 1 to 2 parts of starch, and 1 to 2 parts of dextrin. The brush wheel resin grinding disc for grinding the printed circuit board is long in service life, has favorable traceability for grinding materials during grinding, cannot scratch a grinding surface, is uniform in grinding force, can be used for getting a favorable and uniform grinding surface, and is cost-saving, high in production efficiency, and free of toxicity.

Owner:广州捷骏电子科技有限公司

An intelligent grinding all-in-one machine for train tracks

ActiveCN106120494BGood dynamic responseIncrease stiffnessRailway track constructionHydraulic cylinderEngineering

The invention relates to an intelligent polishing integrated machine for a bullet train track. The intelligent polishing integrated machine comprises a self-stabilizing traveling device. A lower supporting circular truncated cone is welded to the center of the upper end face of the self-stabilizing traveling device. Six supporting cylinders are evenly welded to the upper end face of the lower supporting circular truncated cone in the axis direction. A supporting stand column is welded to the center of the upper end face of the lower supporting circular truncated cone. An upper supporting circular truncated cone is welded to the upper end face of the supporting stand column and the upper end faces of the six supporting cylinders. A connection piece is installed on the upper end face of the upper supporting circular truncated cone through screws. A bent supporting arm is welded to the center of the upper end face of the connection piece. A self-stabilizing moving device is welded to the tail end of the bent supporting arm, and two ribbed blocks are welded between the two sides of the tail end of the bent supporting arm and the self-stabilizing moving device. A polishing bottom plate is installed on the lower end face of the self-stabilizing moving device. Four fourth hydraulic cylinders are symmetrically installed at the lower end of the polishing bottom plate. An adjustable polishing device is installed at the top ends of the four fourth hydraulic cylinders. According to the intelligent polishing integrated machine, a full-automatic track polishing function can be achieved, manual operation is not needed, and the automation degree is high.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

A planetary grinding device and grinding method for a plane optical element

ActiveCN111702653BGrinding speed is fastGuaranteed flatnessOptical surface grinding machinesLapping machinesPhysicsGrinding process

The invention discloses a planetary grinding device and a grinding method for a plane optical element. By arranging the lower end surface of the workpiece disk parallel to the upper end surface of the grinding table, the grinding table and the workpiece disk can rotate differently from each other. A plurality of fixture positioning holes, a plurality of fixture positioning holes are arrayed around the axis of the drive shaft of the workpiece disc, and the optical element to be processed is clamped by the fixture, and the end surface to be polished of the optical element to be processed is aligned with the grinding surface after being limited by the workpiece disc. End surface contact, and finally adjust the pressure between the optical element to be processed and the grinding table through the pressure device to ensure the contact stability between the optical element to be processed and the grinding table. The structure of this device is simple. The movement mode rotates with each other, which greatly improves the grinding speed of the planar optical element. During the grinding process, the same pressure is maintained in real time by the pressure device, which ensures the flatness of the workpiece processing and improves the processing efficiency of the entire processing process.

Owner:XI AN JIAOTONG UNIV

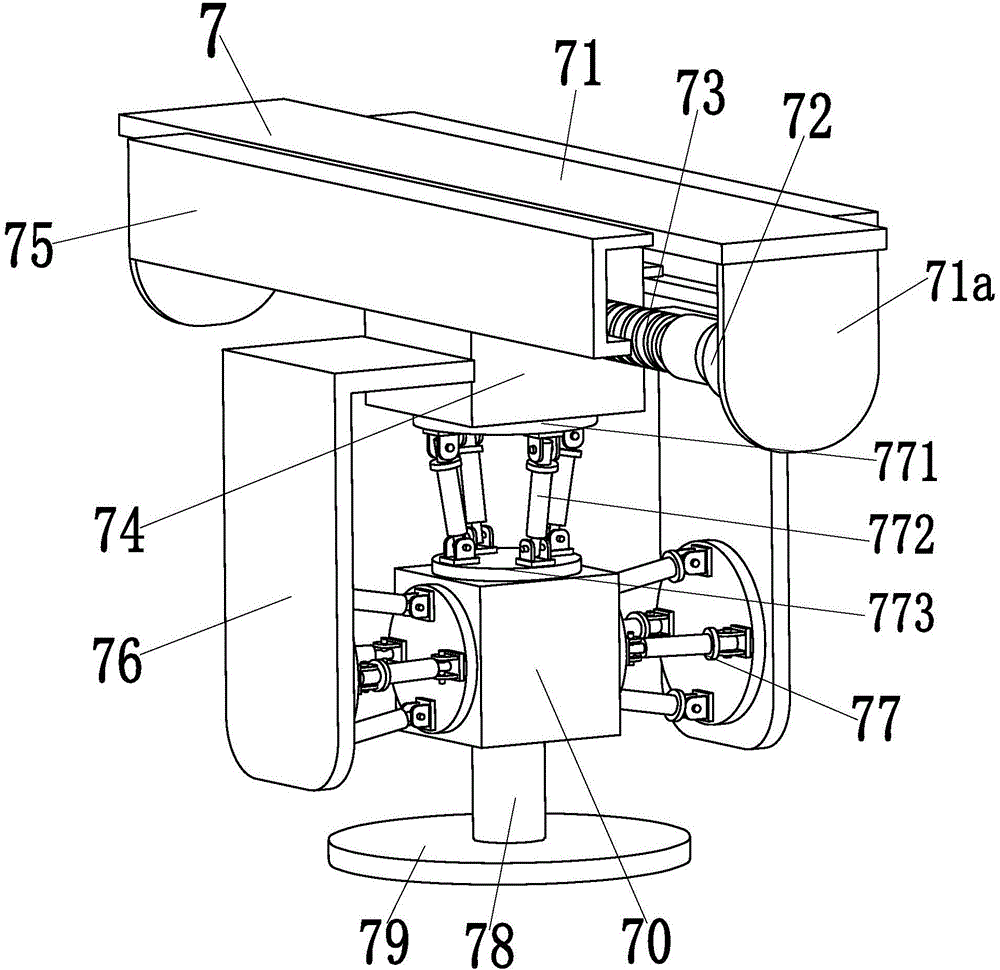

A parallel intelligent grinding robot arm for high-speed railway tracks

ActiveCN106078682BGood dynamic responseIncrease stiffnessProgramme-controlled manipulatorGrinding machine componentsHydraulic cylinderTerrain

The invention relates to an intelligent grinding mechanical arm for a railway special for parallel high-speed trains. The intelligent grinding mechanical arm comprises a parallel supporting mechanism, wherein the parallel supporting mechanism comprises a fixed platform; three parallel supporting chains are uniformly mounted on the lower end surface of the fixed platform along the axial direction; the top ends of the three parallel supporting chains are mounted on a movable platform; four hydraulic cylinders IV are symmetrically mounted at the lower end of the movable platform; adjustable grinding devices are mounted at the top ends of the four hydraulic cylinders IV; the four hydraulic cylinders IV can adjust the grinding height of the intelligent grinding mechanical arm, so that the intelligent grinding mechanical arm can be applied to the grinding operation of railways at different terrain heights; and the adjustable grinding devices can be completely and closely fitted to the surface of the railway for grinding back and forth, and are large in grinding range, good in grinding effect and high in working efficiency. The intelligent grinding mechanical arm can realize a full-automatic grinding function for the railway, does not need manual operation, and is high in automation degree; shakes of equipment in a working process are eliminated, and the equipment is high in stability.

Owner:华粹智能装备有限公司

grinding table

ActiveCN104959909BThe size of the support force can be adjustedWide applicabilityLapping machinesEngineeringLarge size

The invention discloses a grinding workbench. The grinding workbench comprises a base (1), a push rod (4) and a platform seat (7) arranged at the upper end of the push rod (4). The lower end of the push rod (4) is provided with a first magnetic patch (9). A second magnetic patch (10) is arranged below the first magnetic patch (9) and has magnetism opposite to the first magnetic patch. A secondary support part used for providing a thrust supporting effect is arranged below the second magnetic patch (10).The grinding workbench has following beneficial effects: due to a simple structure and low weight, the grinding workbench is adapted to a wire-drawing die in the larger size range for grinding and polishing so that border applicability is obtained and convenience is achieved so that working efficiency is improved and working cost is reduced.

Owner:旌德县小春机械厂

A kind of railway track special grinding and cleaning intelligent all-in-one machine

ActiveCN106120495BGood dynamic responseIncrease stiffnessRailway track constructionRailway cleaningHydraulic cylinderEngineering

Owner:盐城华依鑫机械科技有限公司

The Honing Machining Method of Carburizing Holes of Aero-engine Tappet Guide Sleeves

ActiveCN112743442BUniform grinding forceHigh cooling frequencyGrinding drivesGrinding feed controlNumerical controlSurface finish

The invention discloses a method for honing a carburized hole of a lifter guide sleeve of an aero-engine. A numerical control boring tool is used to process the carburized hole of a lifter guide sleeve to remove the allowance to 0.2 mm to 0.3 mm, and the lifter guide sleeve is installed on the On the honing machine, align the carburized hole of the tappet guide bush, and process the carburized hole four times until the surface finish of the carburized hole is Ra≤0.02. The four honing processes include rough honing, semi-finishing honing, and fine honing Processing and ultra-fine honing processing, and the honing process parameters are optimized, so that there is no burn or crack defect in the carburized hole of the tappet guide bush, and the internal surface finish of the carburized hole of the tappet guide bush is close to the mirror level. The honing method of the carburized hole of the tappet guide sleeve of the aero-engine has high processing efficiency, uniform grinding force, high cooling frequency, sufficient cooling, no burns and crack defects, and the surface finish of the inner hole is close to the mirror surface level.

Owner:AVIC POWER ZHUZHOU AVIATION PARTS MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com