The Honing Machining Method of Carburizing Holes of Aero-engine Tappet Guide Sleeves

A technology for aero-engine and honing processing, which is applied to honing machine tools, metal processing equipment, and parts of grinding machine tools. It can solve problems such as unevenness, large grinding force, and low efficiency of carburizing holes in aero-engine tappet guide sleeves. , to achieve the effect of uniform grinding force, high processing efficiency and high cooling frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

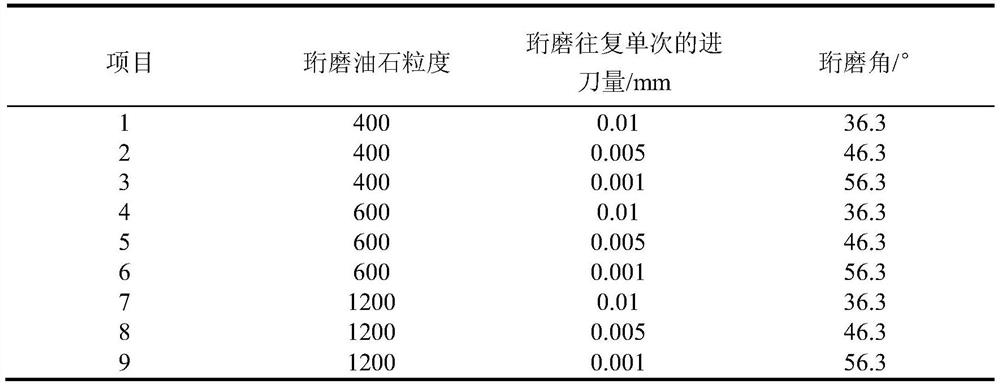

[0060] The honing method of the carburizing hole of the lifter guide sleeve of the aero-engine uses the CNC machining boring tool to grind the carburizing hole of the lifter guide sleeve to 0.215mm, install the lifter guide sleeve on the honing machine, and align the lifter For the carburized hole of the guide sleeve, the carburized hole is divided into four honing processes until the surface finish of the carburized hole is Ra≤0.02. The four honing processes include rough honing, semi-finishing honing, fine honing and super-finishing honing. And optimize the honing processing parameters, so that there is no burn or crack defect in the carburized hole of the tappet guide bush, and the internal surface finish of the carburized hole of the tappet guide bush is close to the mirror level;

[0061] The four-pass honing process includes the following steps:

[0062] S1: Carry out rough honing processing, the removal allowance is 0.15mm, the reciprocating single feed rate is 0.01mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com