Planetary plate type ball mill

A ball mill and planetary disc technology, which is applied to grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of poor surface roughness, sphericity and other index parameters, poor randomness, etc., to improve polishing accuracy, uniform force, The effect of improving the uniformity of the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

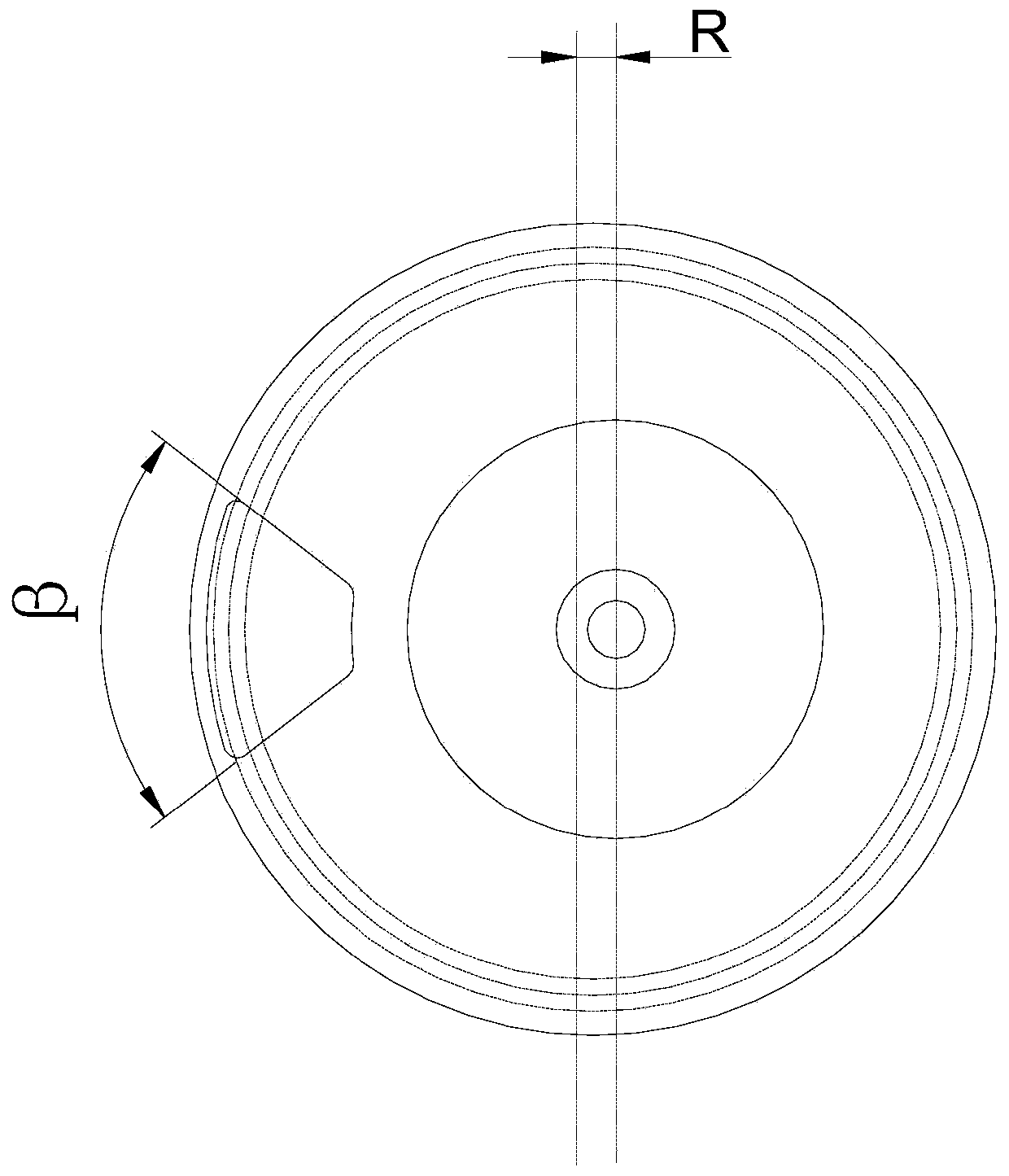

[0044] This embodiment provides an upper grinding disc for a disc ball mill. The lower surface of the upper grinding disc 1 is provided with a V-shaped groove 4 distributed along the circumferential direction near the outer edge. It is adapted to the upper surface of the lower grinding disc 2; the upper grinding disc 1 is used for connecting with a floating part and used as a floating grinding disc. The angle of the V-groove 4 is 90°. The V-shaped groove 4 is used to accommodate the microspheres. The size of the V-shaped groove 4 is set according to the diameter of the grinding microspheres. For example, the diameter of the microspheres that can be processed: 0.7mm~3mm, a symmetrical right-angle "V"-shaped groove is used, and three kinds of grooves are provided. The "V" grooves are: the microspheres with a diameter of 0.7mm correspond to a groove width of 1.12mm; the microspheres with a diameter of 2.0mm correspond to a groove width of 3.16mm, and the microspheres with a diame...

Embodiment 2

[0048] This embodiment provides an upper grinding part for a disc ball mill, including the upper grinding disc for a disc ball mill provided in Embodiment 1; and a floating part, which drives the upper grinding disc 1 to float up and down. The floating part includes an elastic piece and a pressure plate 6, one end of the elastic piece is connected with the pressure plate 6, the pressure plate is connected with the upper grinding disc 1 through the mounting piece, the elastic grinding pressure is applied through the elastic piece, and the elastic grinding pressure is applied by the pressure plate 6 and the mounting piece. Transfer to upper grinding disc 1. A load cell 7 is also provided between the pressing plate 6 and the mounting piece.

[0049] Regarding the specific structure of the elastic member, a structure with a spring as the main body can be adopted. like Figure 4 As shown, the mount includes an upper grinding disc mount 81 , ball splines 82 , an upper grinding dis...

Embodiment 3

[0052] This embodiment provides a planetary disc ball milling mechanism, including a lower grinding disc 2, and also includes an upper grinding disc provided in Embodiment 1 for a disc ball mill, or a disc ball mill provided in Embodiment 2. of the upper grinding part. The upper surface of the lower grinding disc 2 is adapted to fit the lower surface of the upper grinding disc 1 , and the upper surface of the lower grinding disc 2 is a smooth plane structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com