Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Suppress and prevent generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

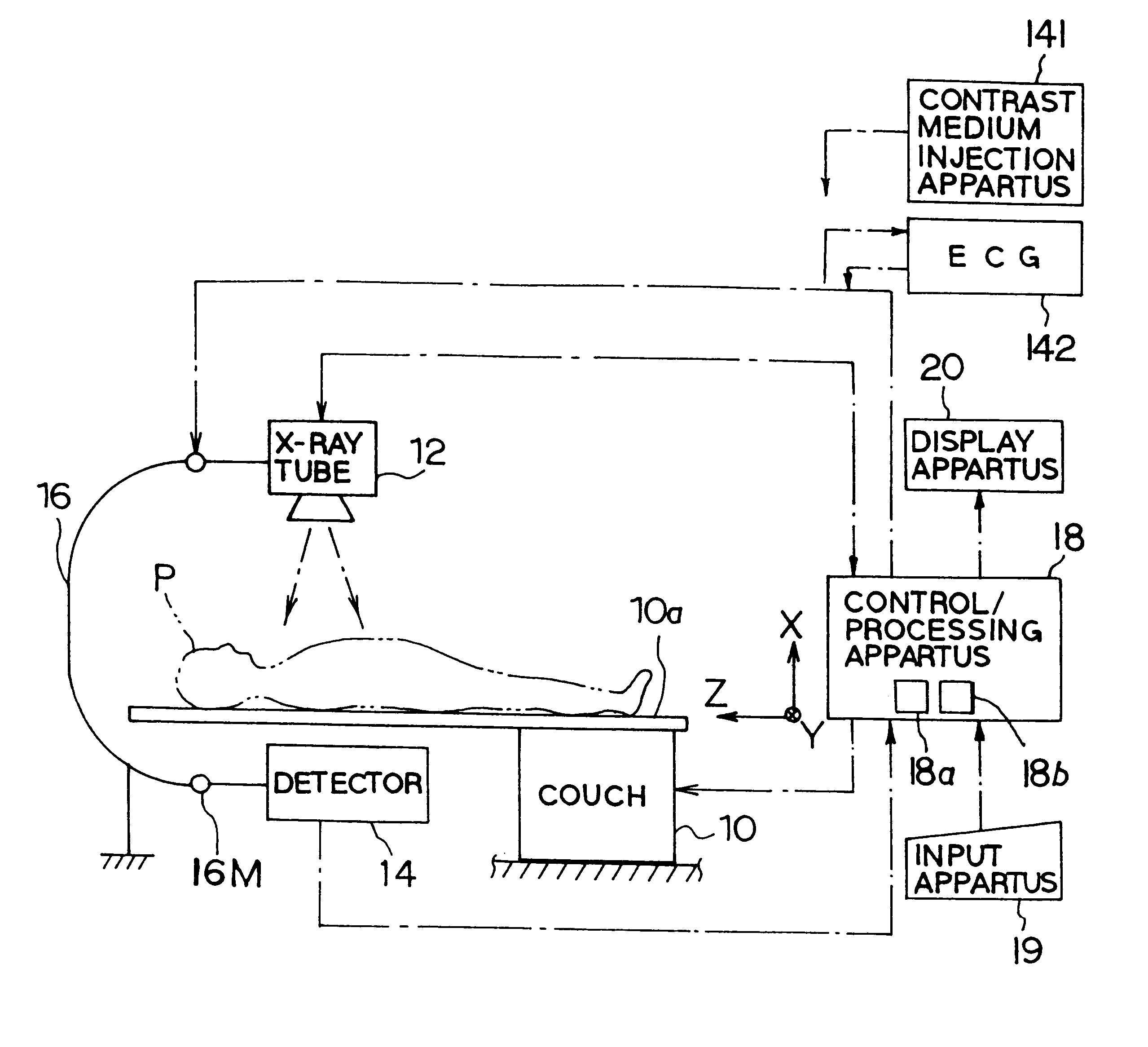

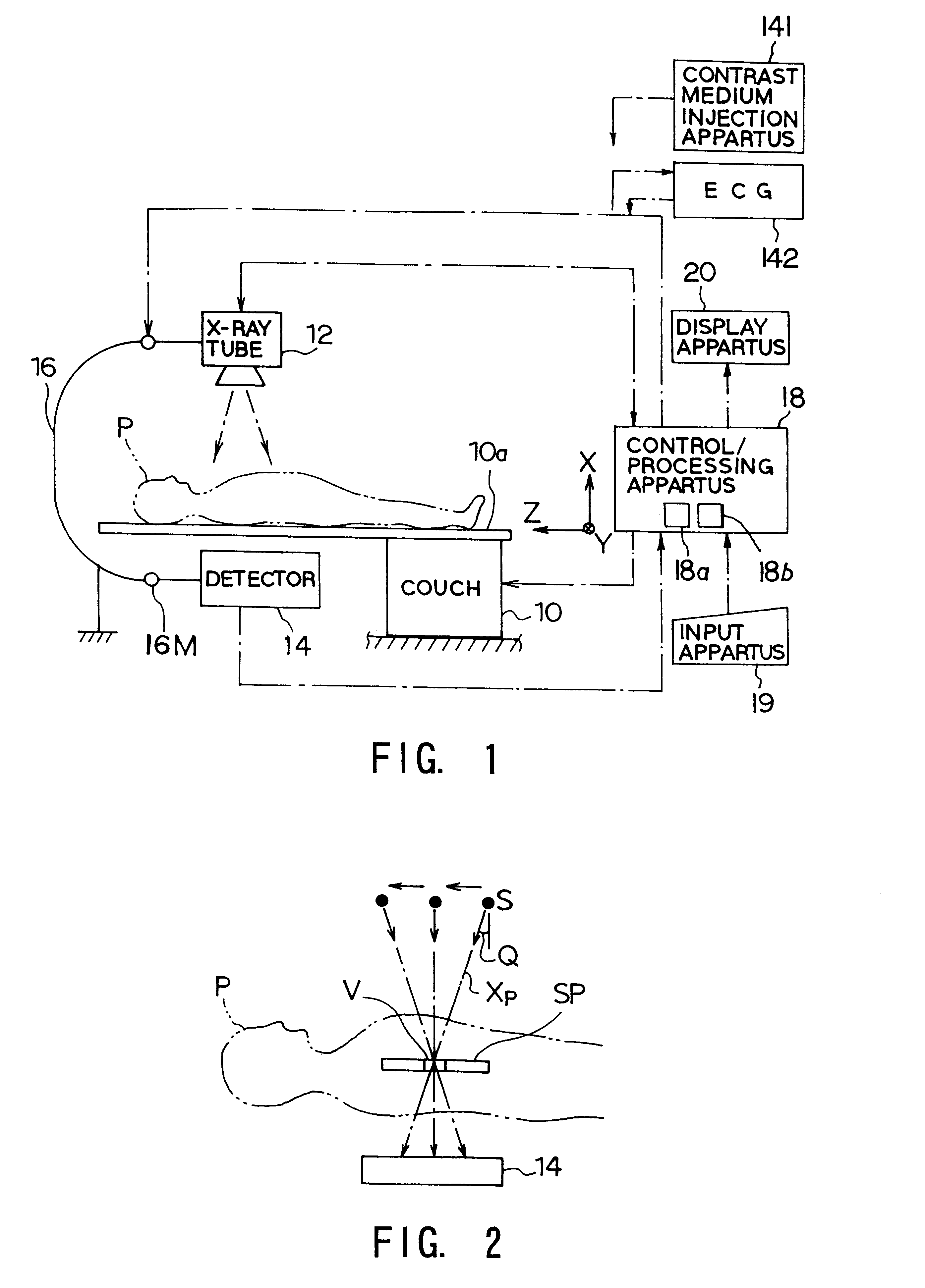

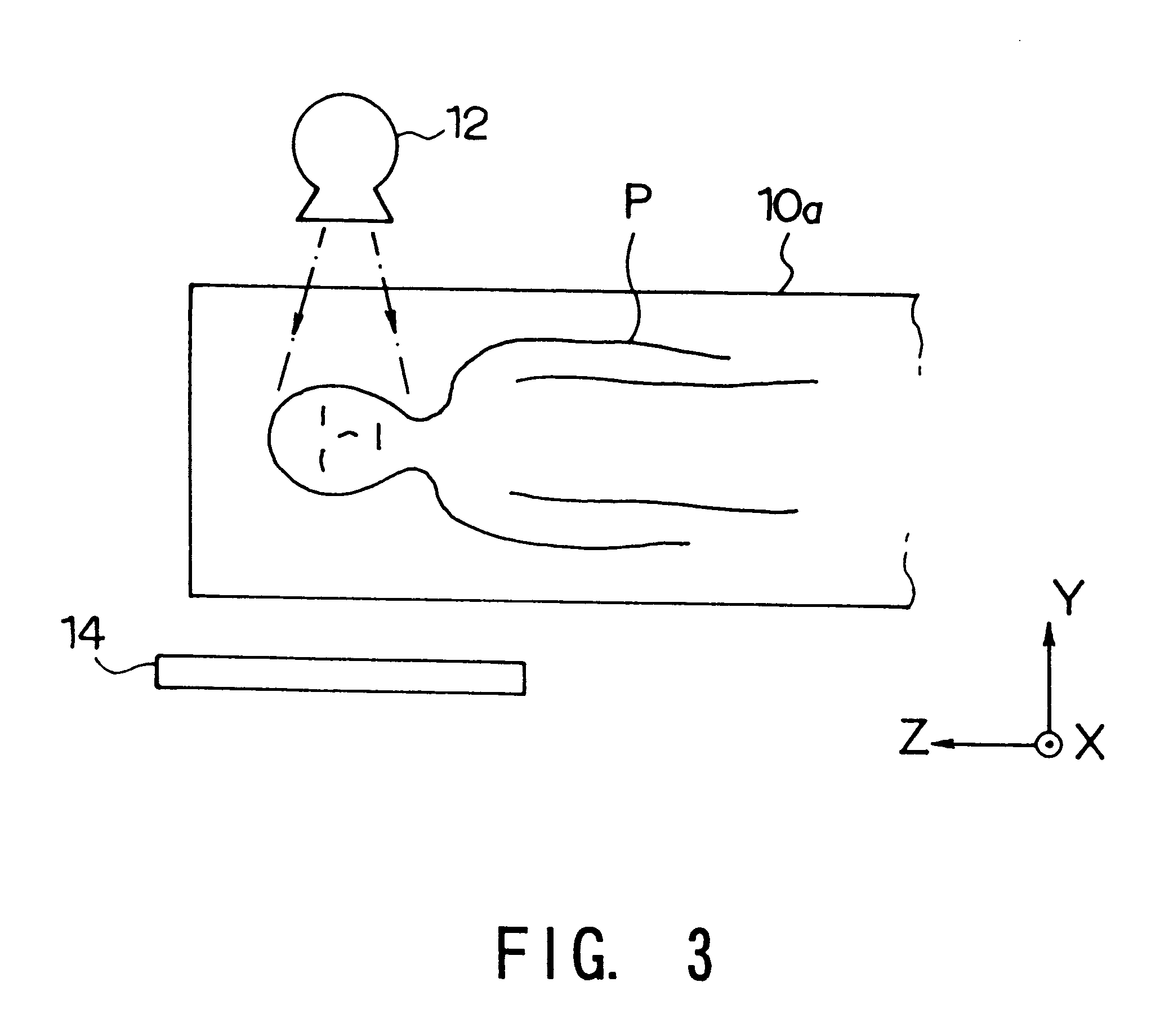

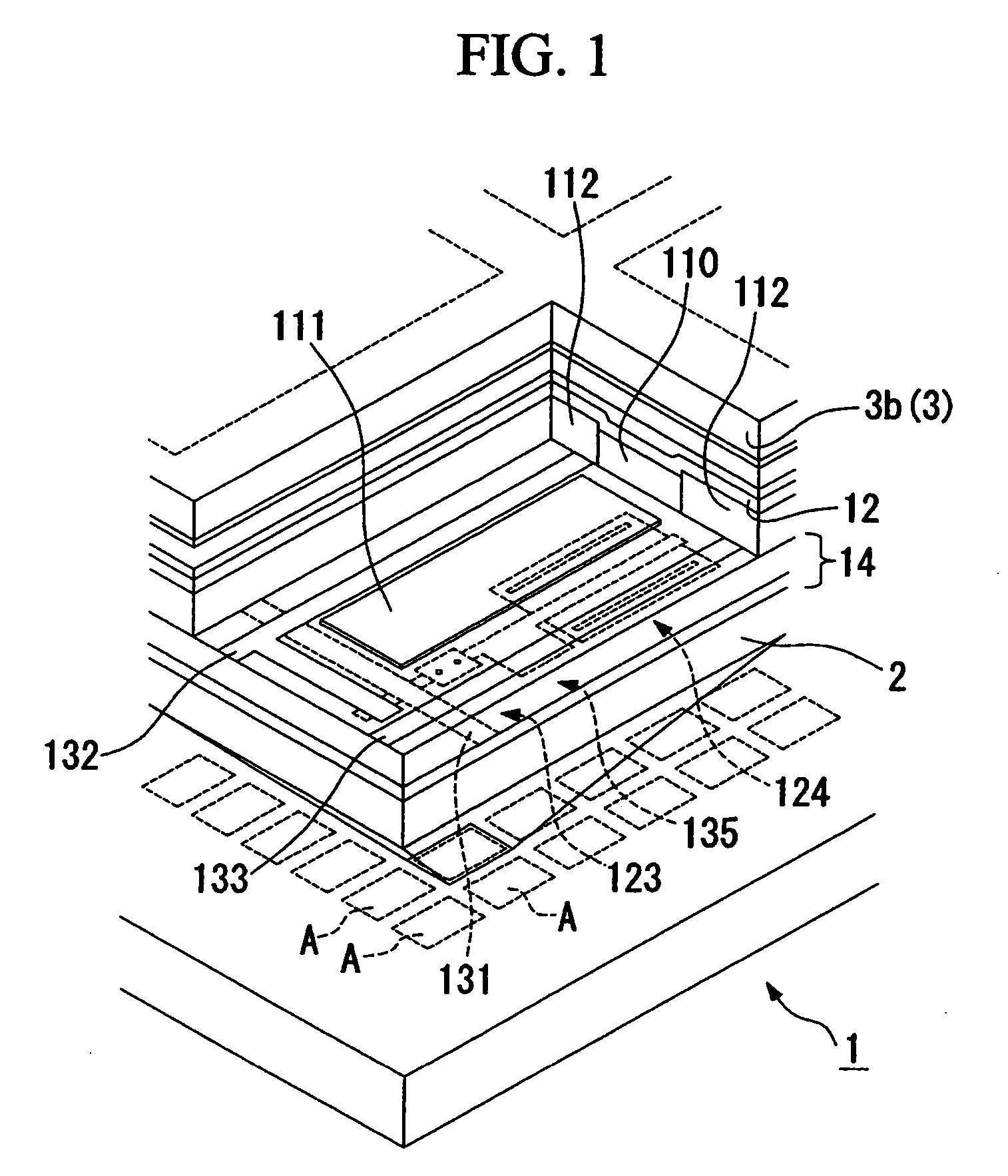

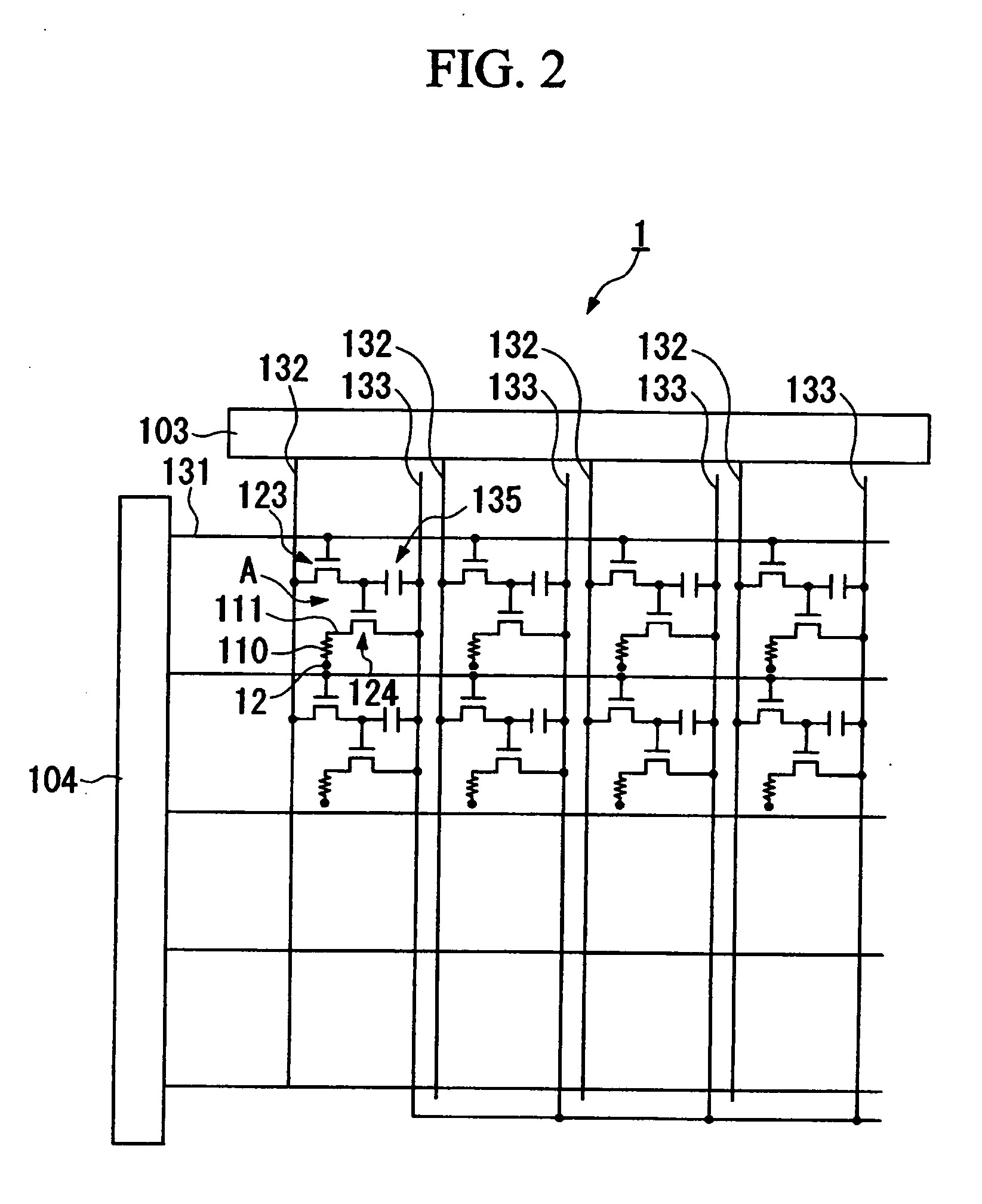

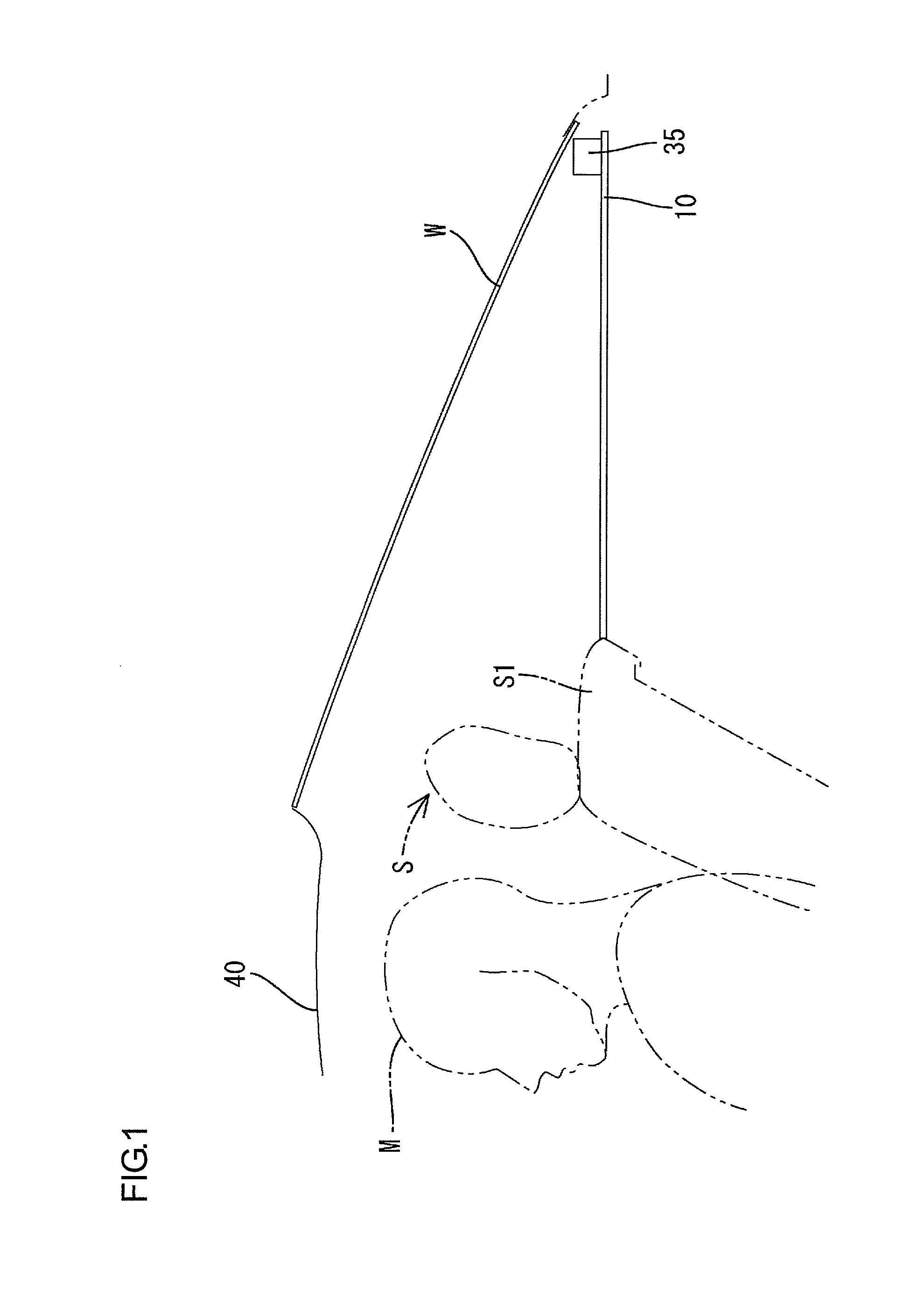

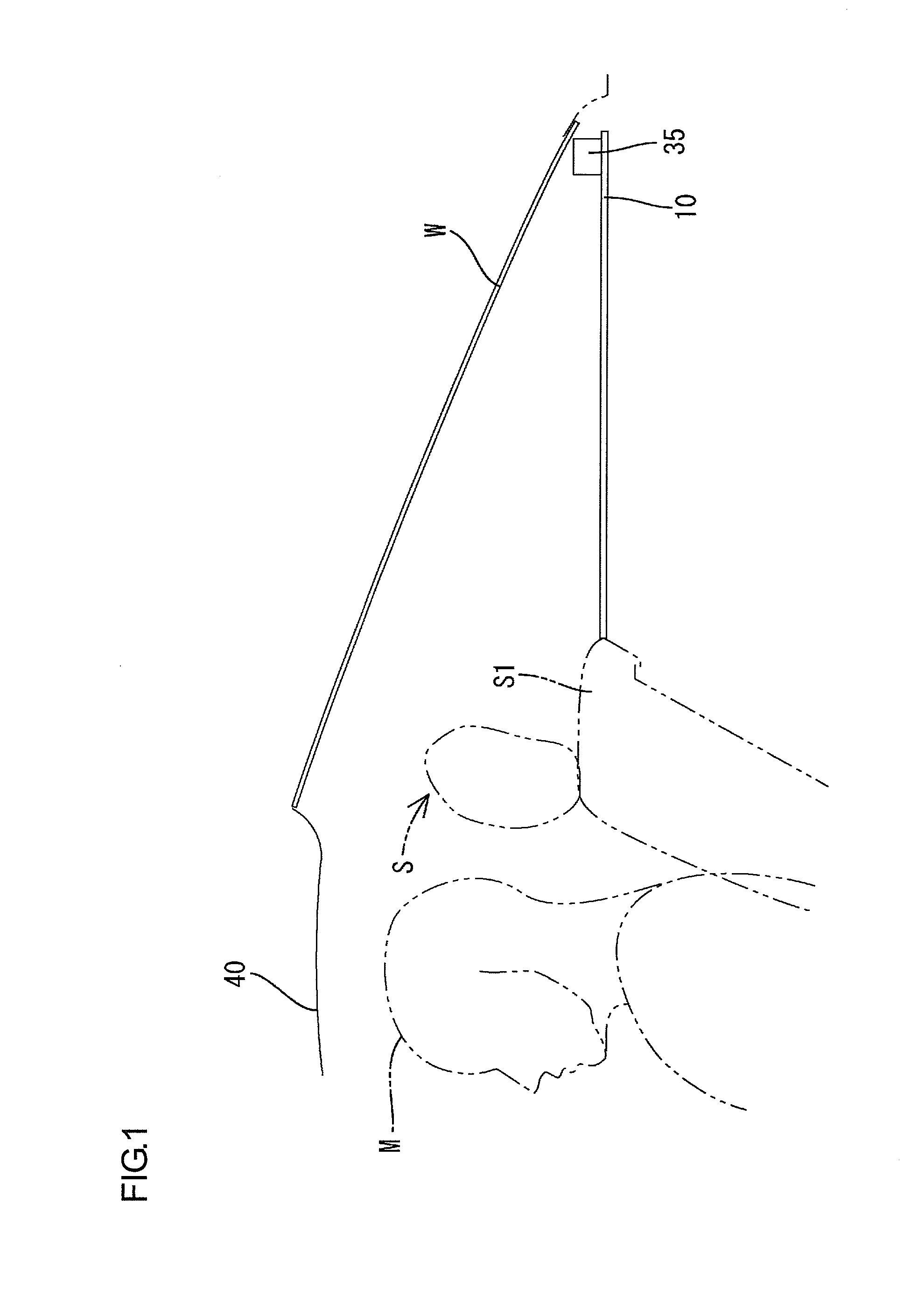

X-ray diagnostic system preferable to two dimensional x-ray detection

InactiveUS6196715B1Suppress and prevent generationImprove image qualityTelevision system detailsRadiation/particle handlingTomosynthesisX-ray generator

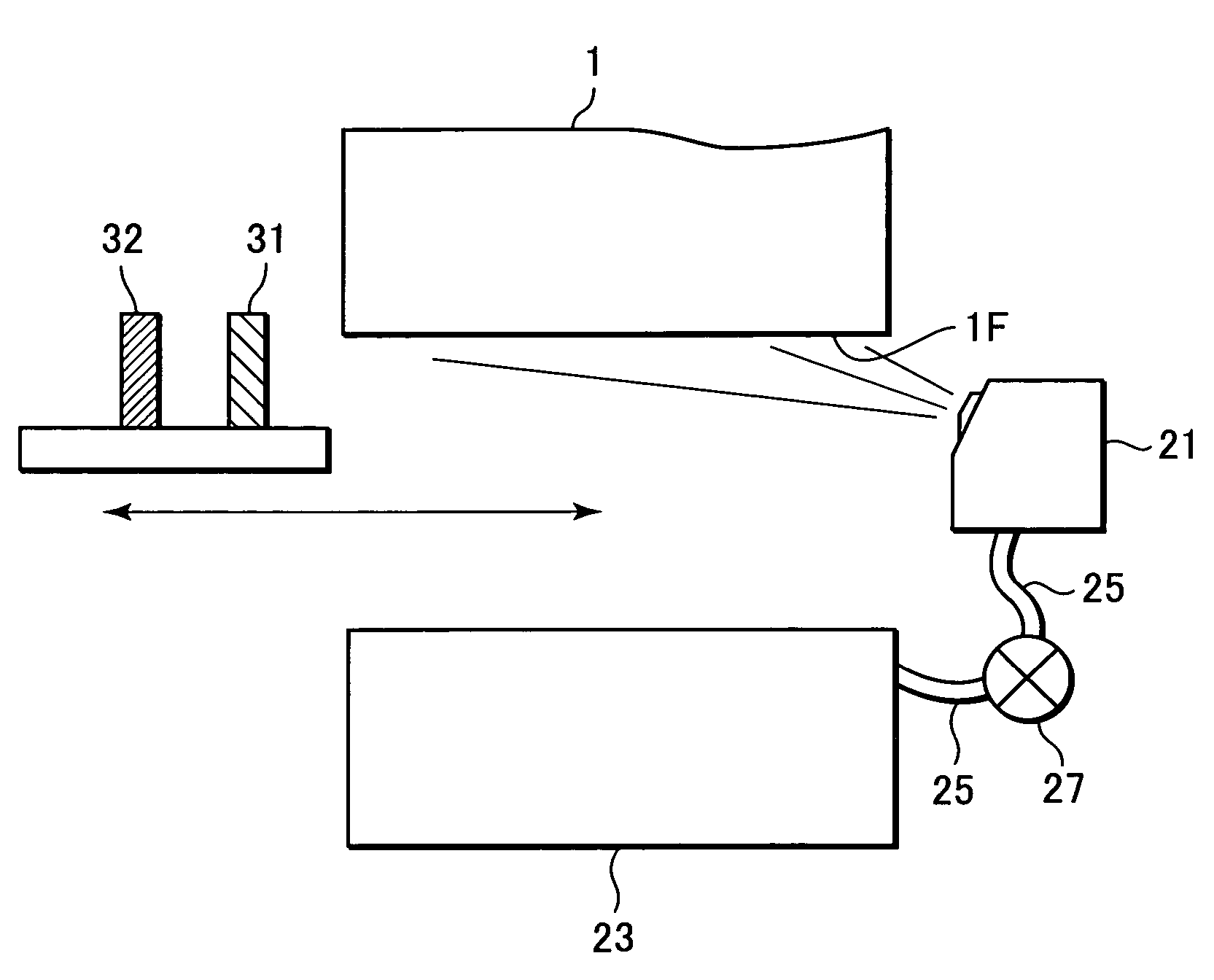

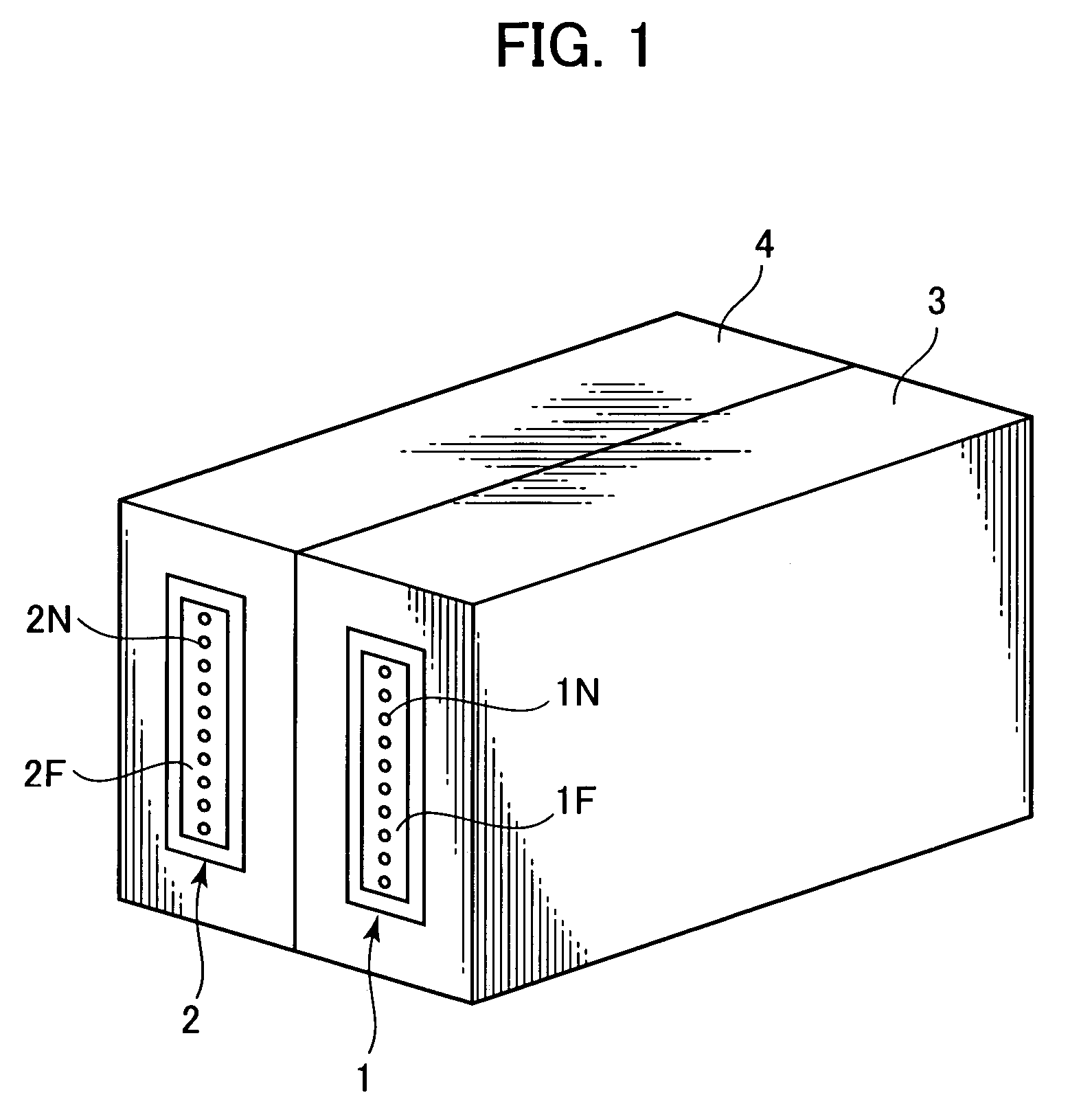

An X-ray tomosynthesis system as an X-ray diagnostic system is provided. The system comprises an X-ray generator irradiating an X-ray toward a subject, and a planar-type X-ray detector detecting the X-ray passing through the subject and outputting two dimensional imaging signals based on the detected X-ray. The system comprises a supporting / moving mechanism supporting at least one of the X-ray generator and the X-ray detector so that the at least one is moved relatively to the subject. The system also comprises an element setting a ROI position of the subject, an element for obtaining a plurality of three dimensional coordinates of pixels included in the ROI, a calculating element obtaining two dimensional coordinates of data in the two dimensional imaging signals for each of the two dimensional imaging signals detected by the X-ray detector, the data being necessary for obtaining pixel values of the three dimensional coordinates; and an element for obtaining the pixel value of each of the three dimensional coordinates by extracting the corresponding data of the two dimensional coordinates from the detected two dimensional imaging signals and adding the extracting data.

Owner:KK TOSHIBA

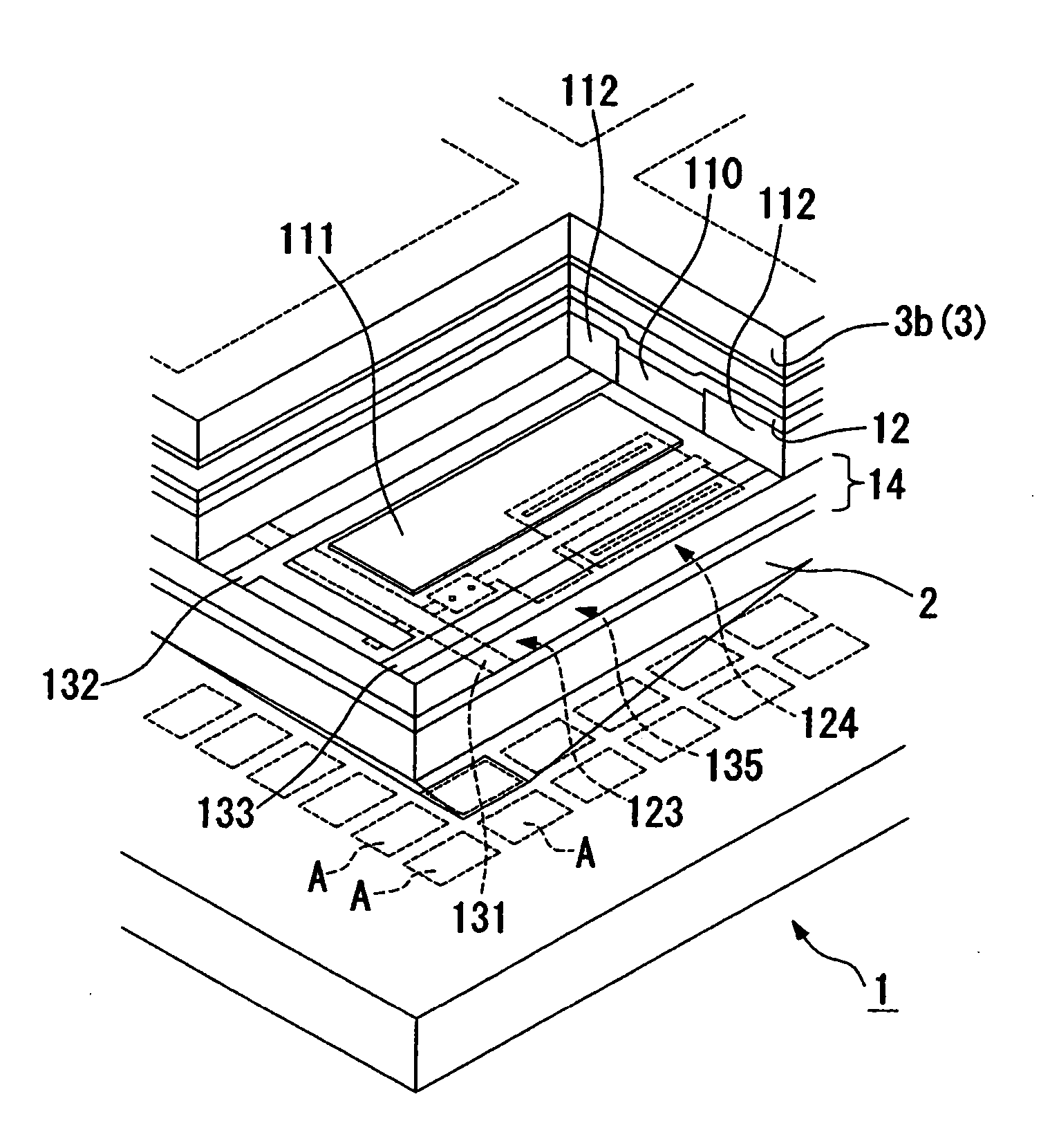

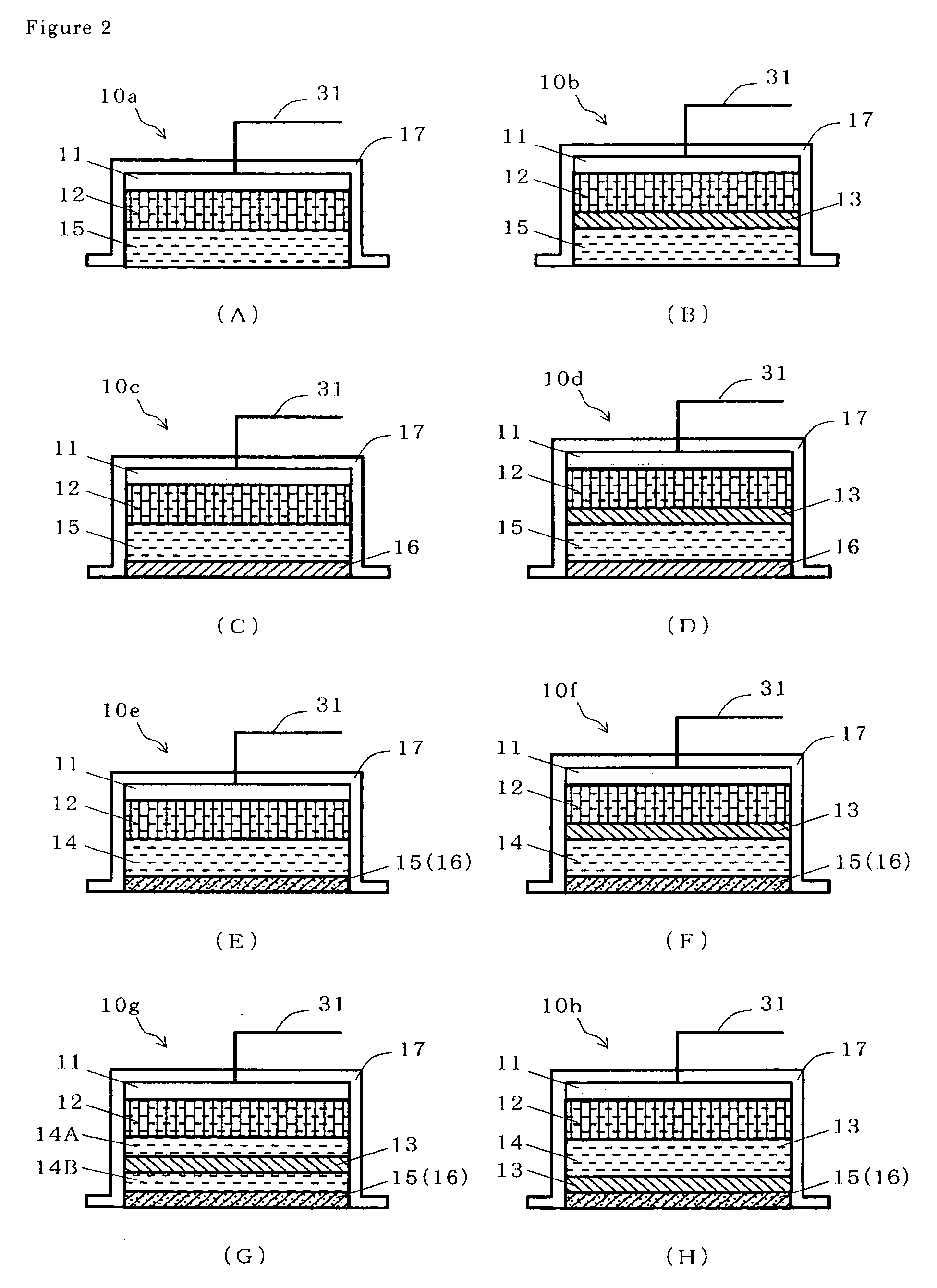

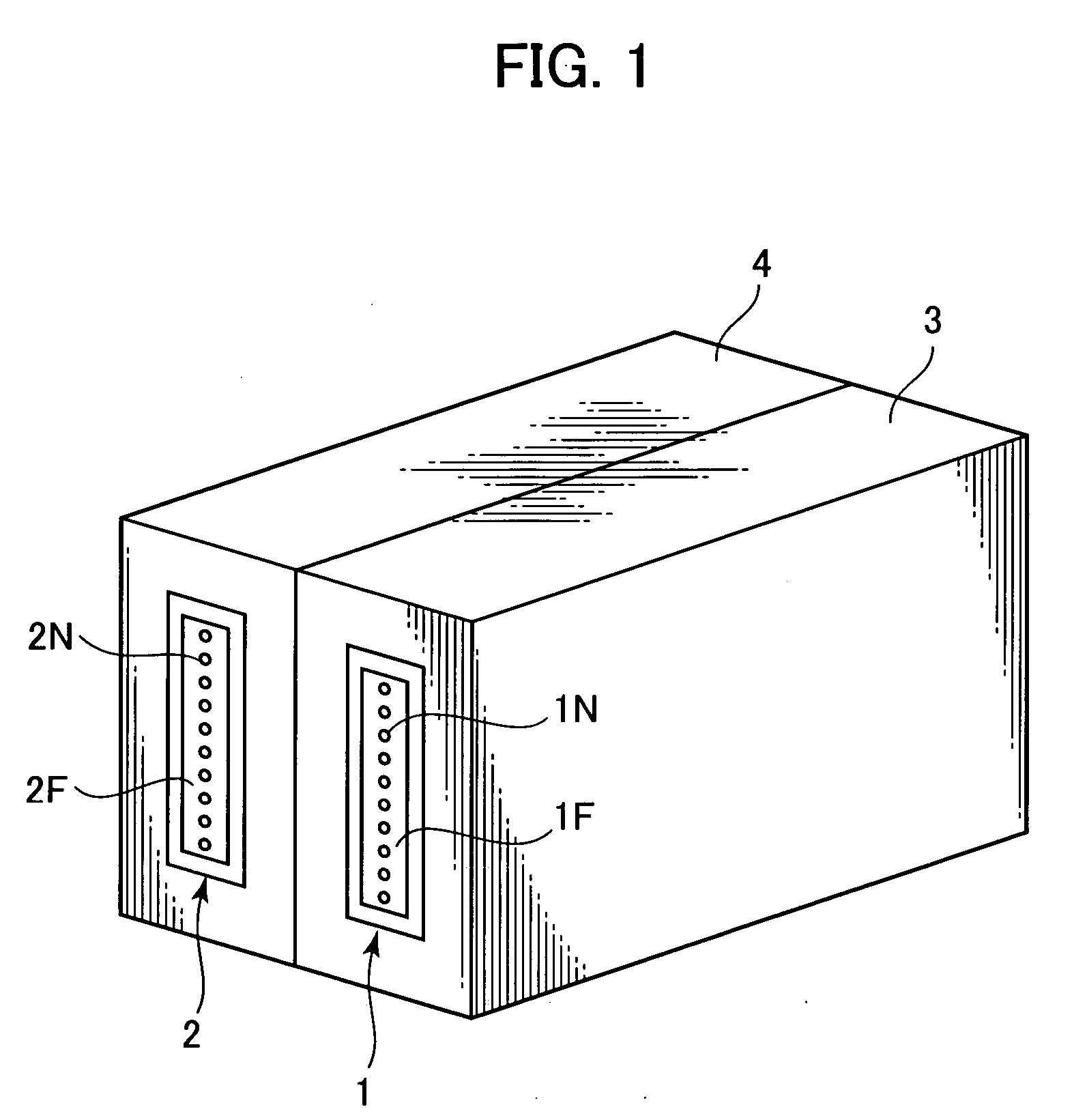

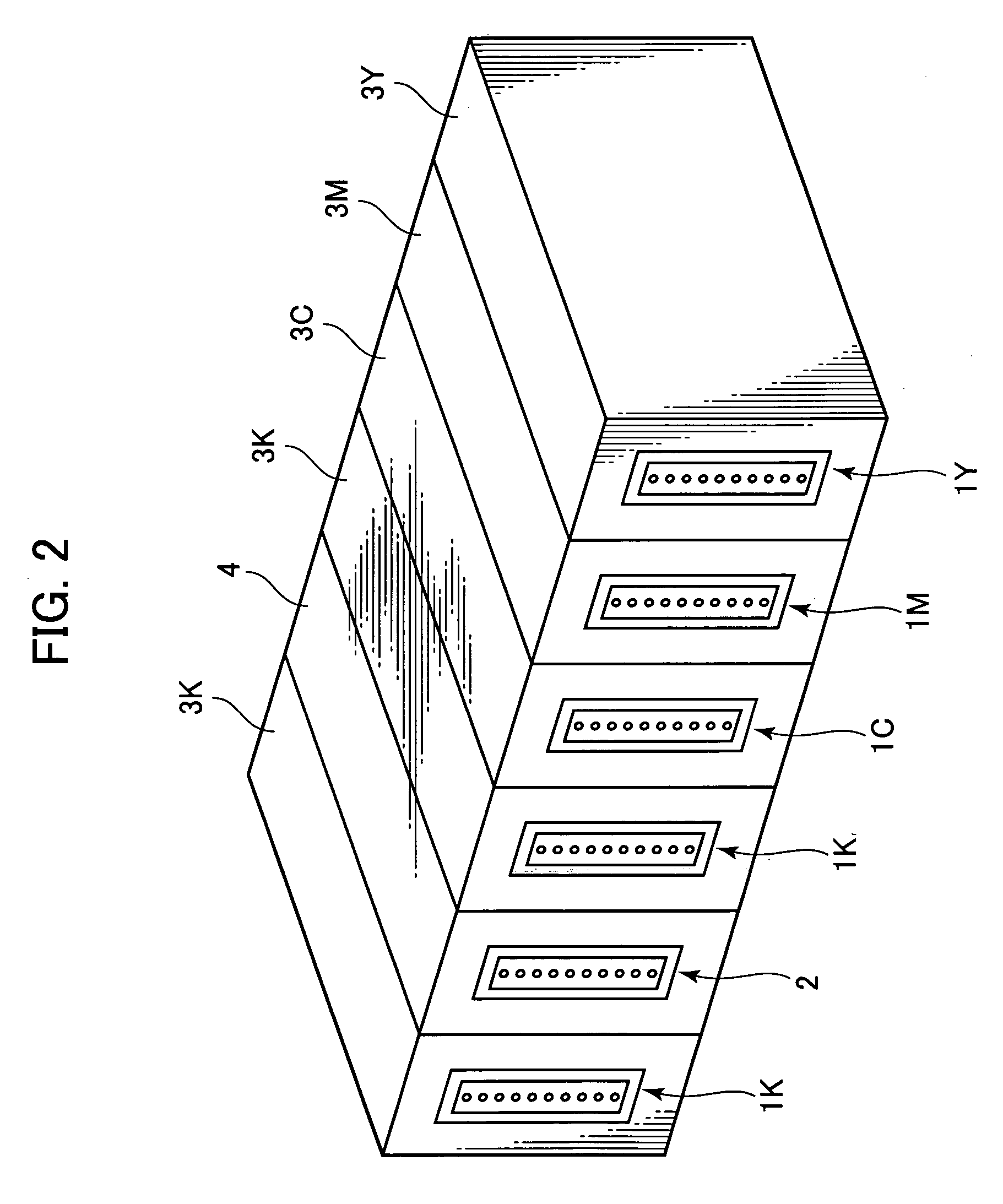

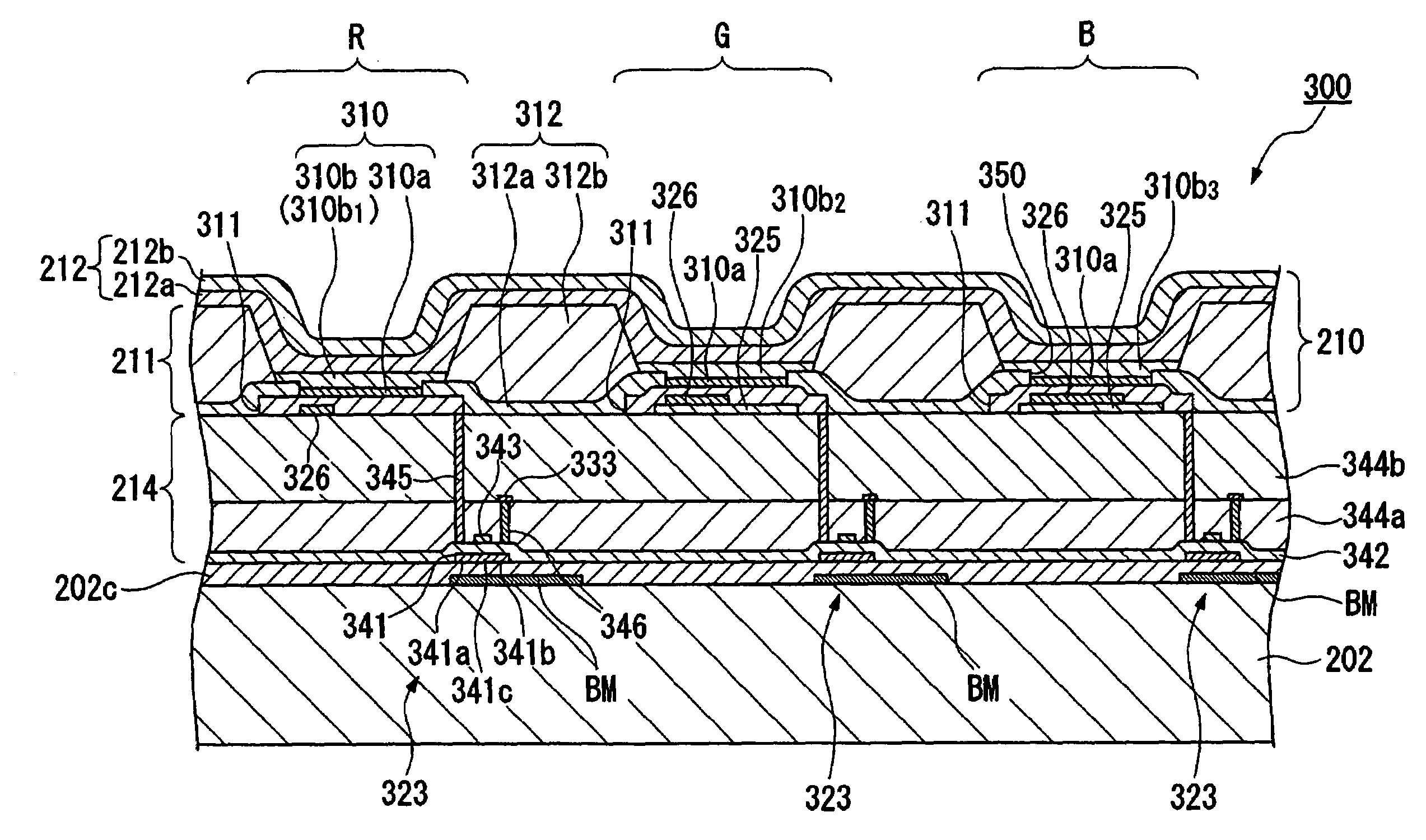

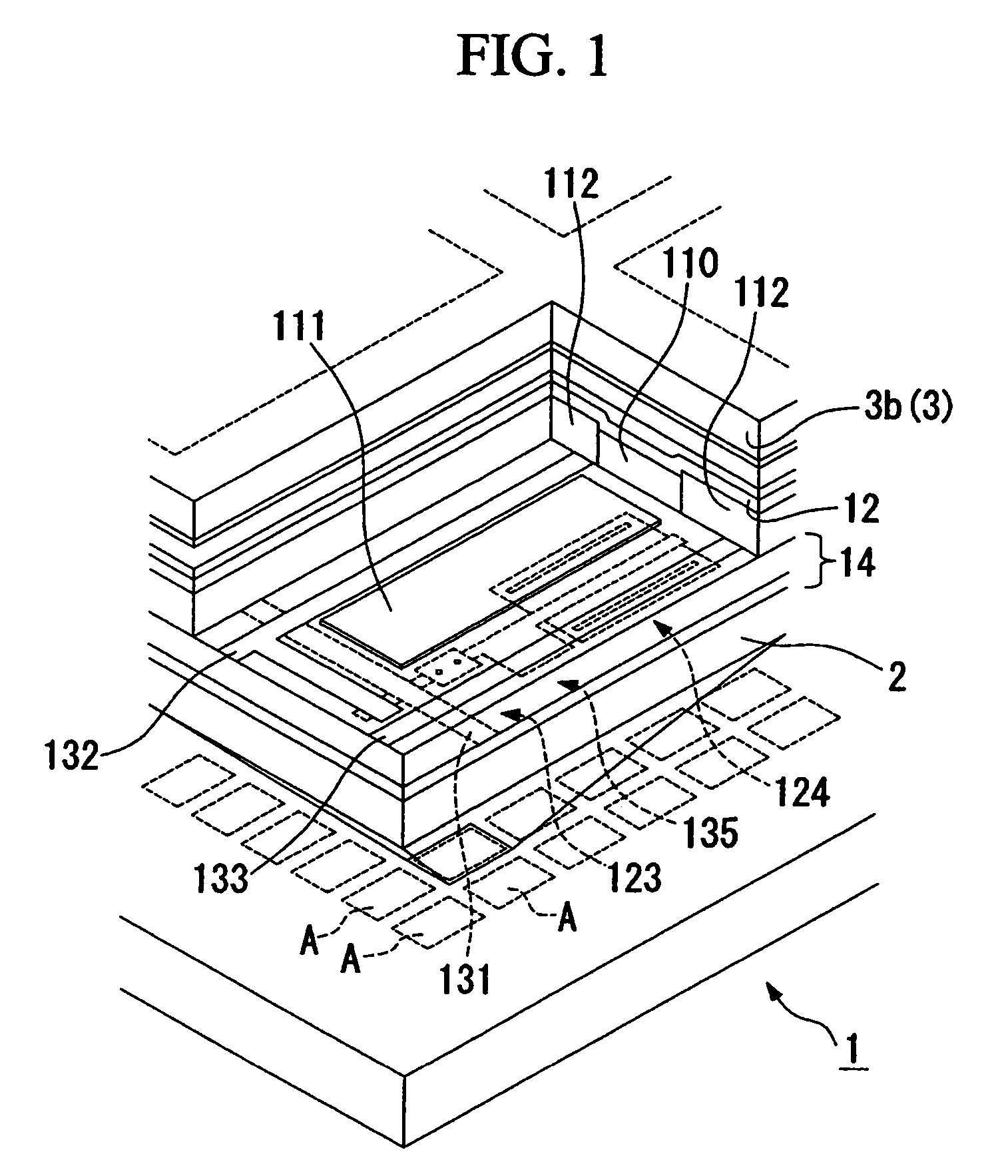

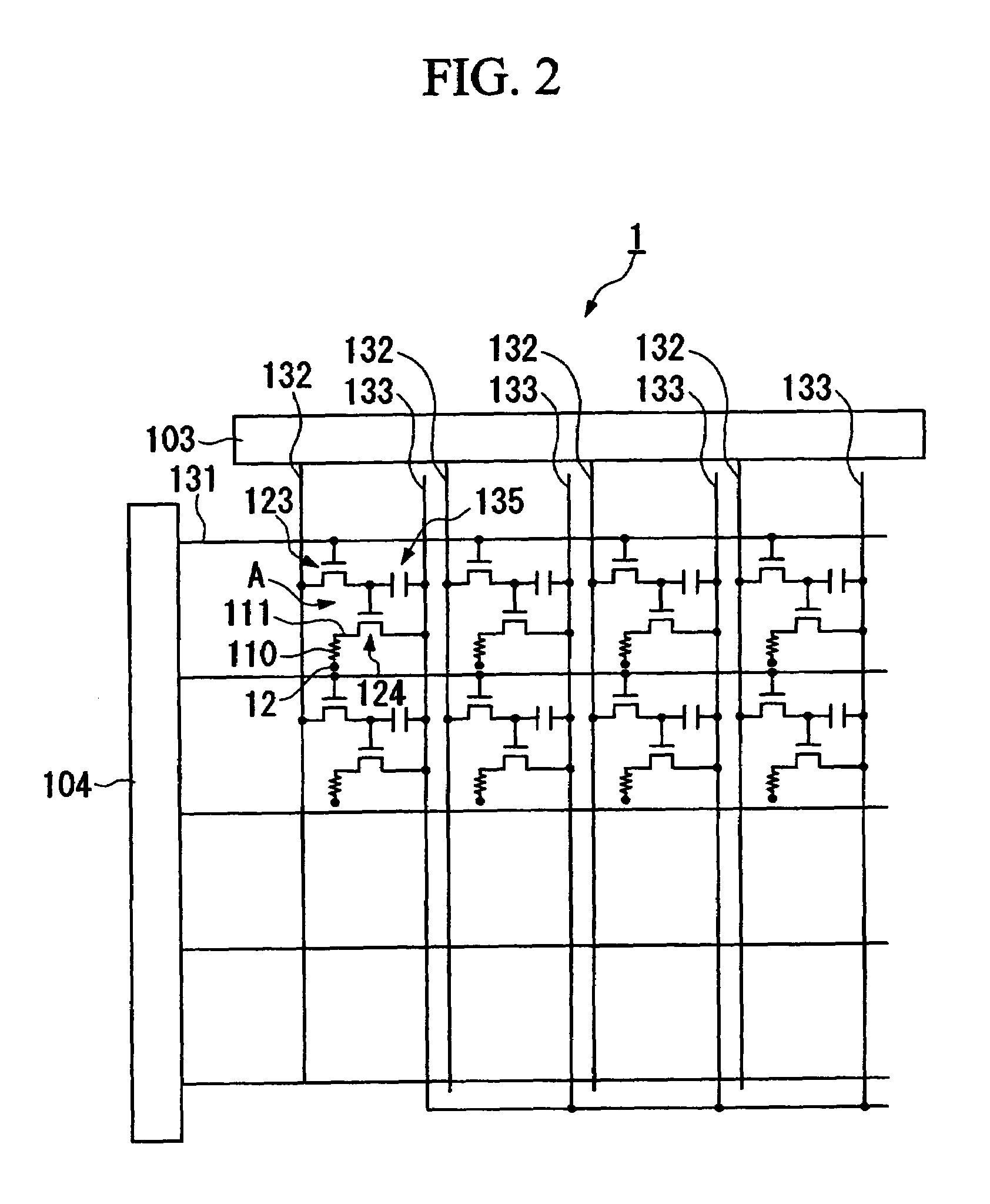

Organic EL device and electronic apparatus

ActiveUS20050269947A1High color purityIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsTransmitted light

An organic EL device includes light-reflective electrodes; light-transmissive electrodes; organic EL layers that are respectively provided between the light-reflective electrodes and the light-transmissive electrodes to emit a plurality of color light components, the organic EL layer emitting a different color light component in each pixel; and transflective layers that are selectively provide in predetermined color pixels to reflect or transmit light emitted from the organic EL layers, respectively, each transflective layer being opposite to the light-reflective electrode with the organic EL layer interposed therebetween.

Owner:INTELLECTUAL KEYSTONE TECH LLC

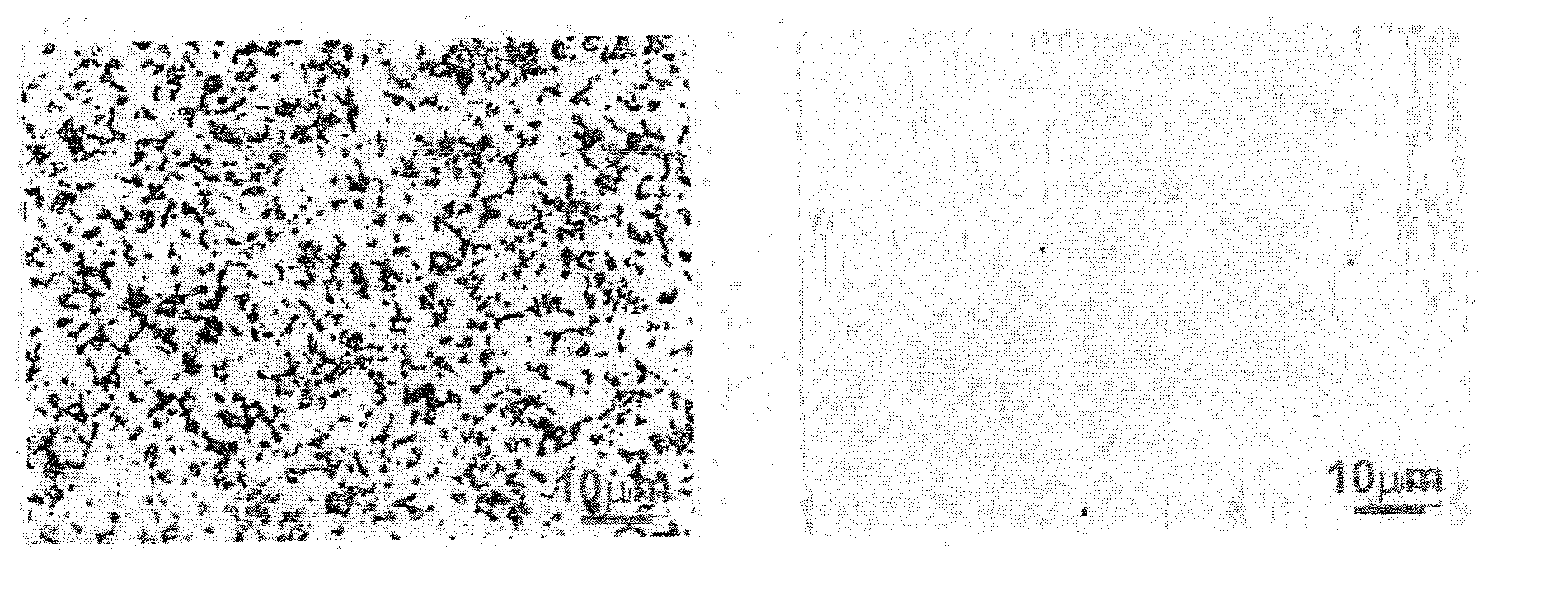

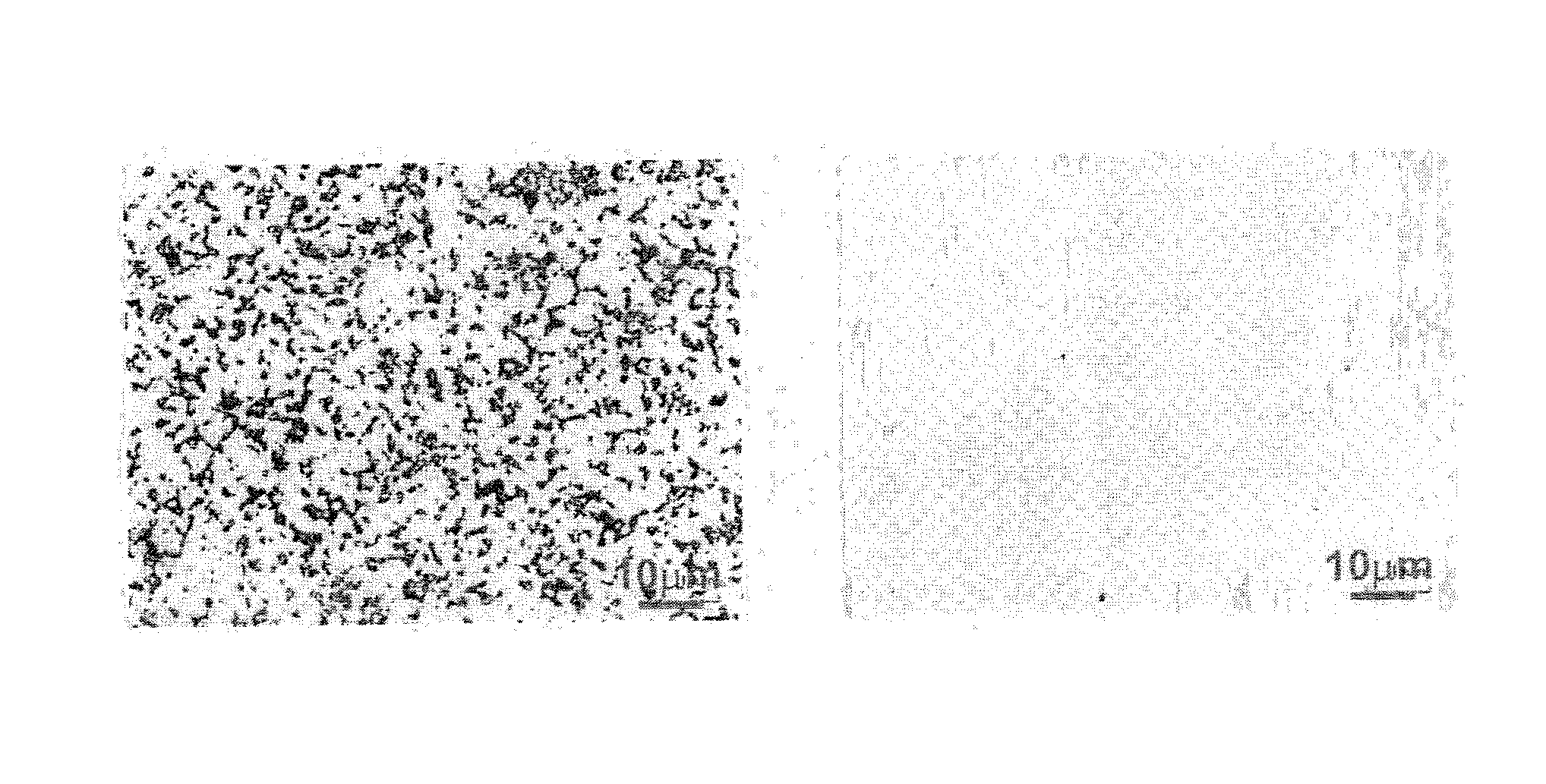

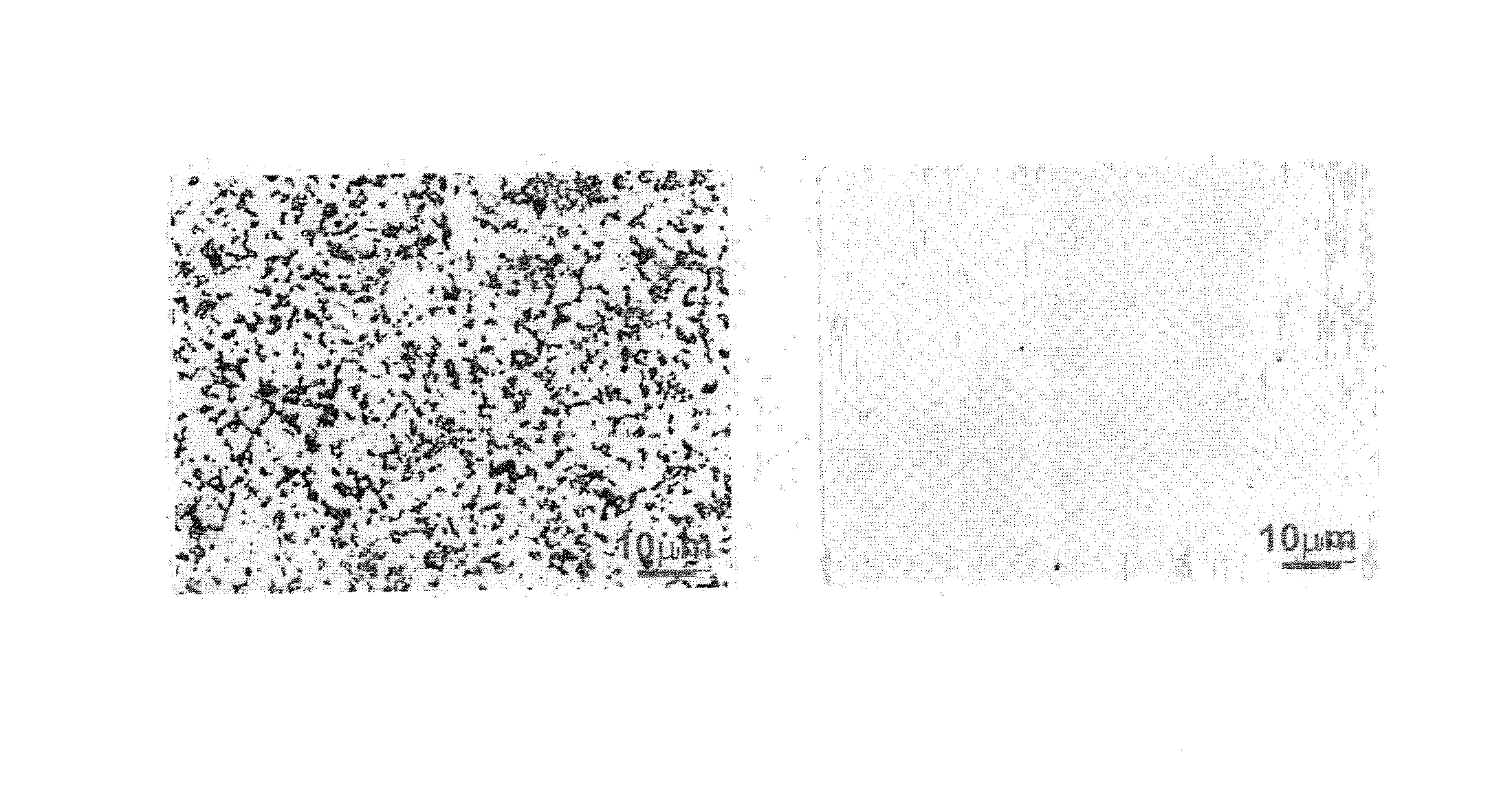

Sputtering target with few surface defects, and surface processing method thereof

ActiveUS7909949B2Suppress and prevent generationFine surfaceCellsMetal rolling stand detailsTarget surfaceCarbide

Provided is a surface processing method of a sputtering target, wherein a target surface in which intermetallic compounds, oxides, carbides, carbonitrides and other substances without ductility exist in a highly ductile matrix phase at a volume ratio of 1 to 50% is preliminarily subject to the primary processing of cutting work, then subsequently subject to finish processing via polishing. The sputtering target subject to this surface processing method is able to improve the target surface having numerous substances without ductility, and prevent or suppress the generation of nodules and particles upon sputtering.

Owner:JX NIPPON MINING & METALS CORP

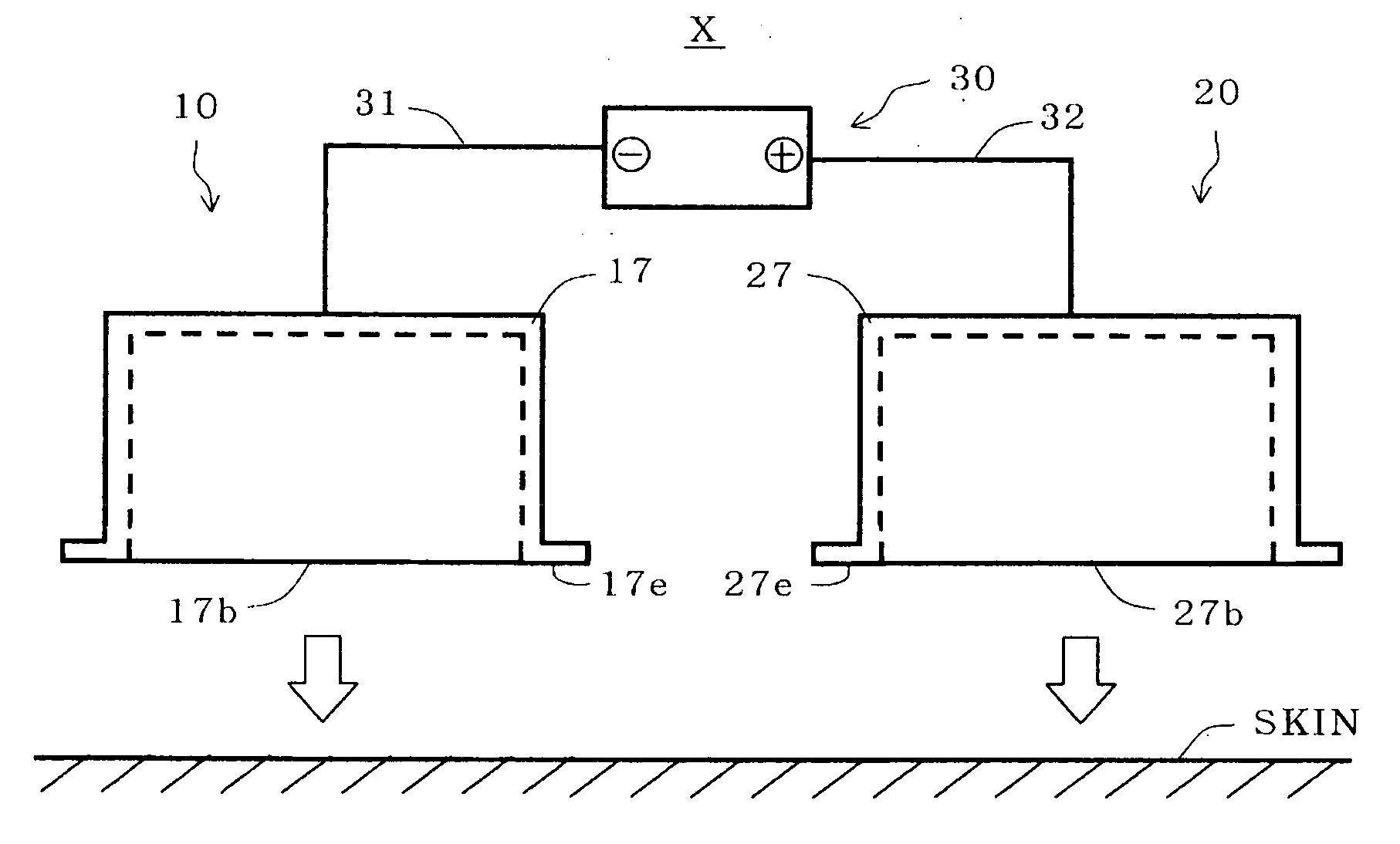

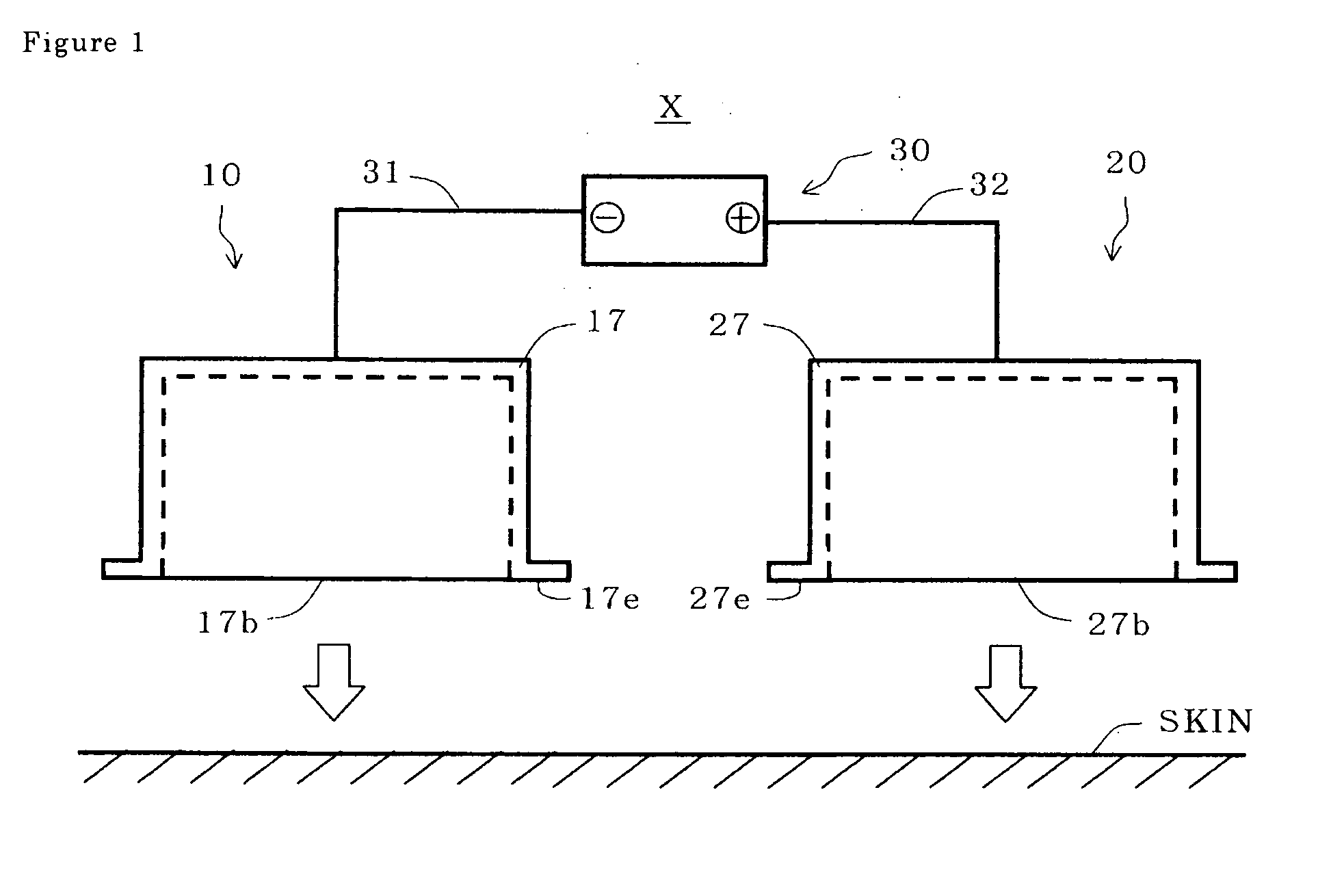

Iontophoresis device

InactiveUS20070112294A1Suppress and prevent generationPreventing and suppressing alterationElectrotherapyMethane sulfonateActive agent

An iontophoresis device may be capable of preventing the generation of gas or ions upon energization, and / or may be capable of preventing the alteration of active agent ions due to an electrode reaction. Energization from an electrode to an active agent reservoir may be performed through an ionic liquid. The ionic liquid may include an anion such as PF6-, BF4-, AlCl4-, ClO4-, a hydrogen sulfate ion, bis-trifluoro-alkyl-sulfonyl-imide, or trifluoro-methane-sulfonate, and a cation such as an imidazolium derivative, a pyridinium derivative, a piperidinium derivative, a pyrolidinium derivative, and a tetra-alkyl-ammonium derivative.

Owner:TITI ELLEBEAU INC

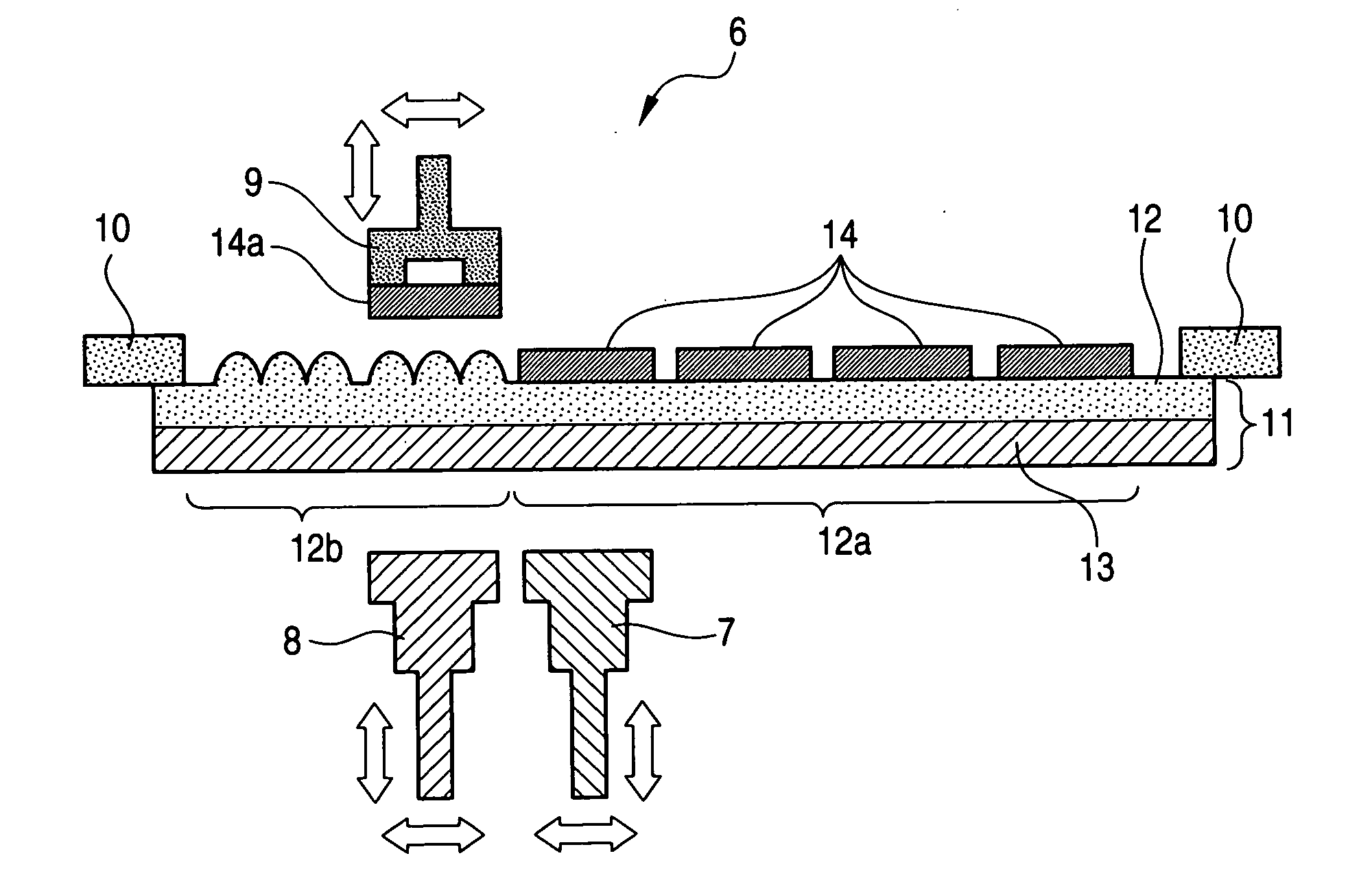

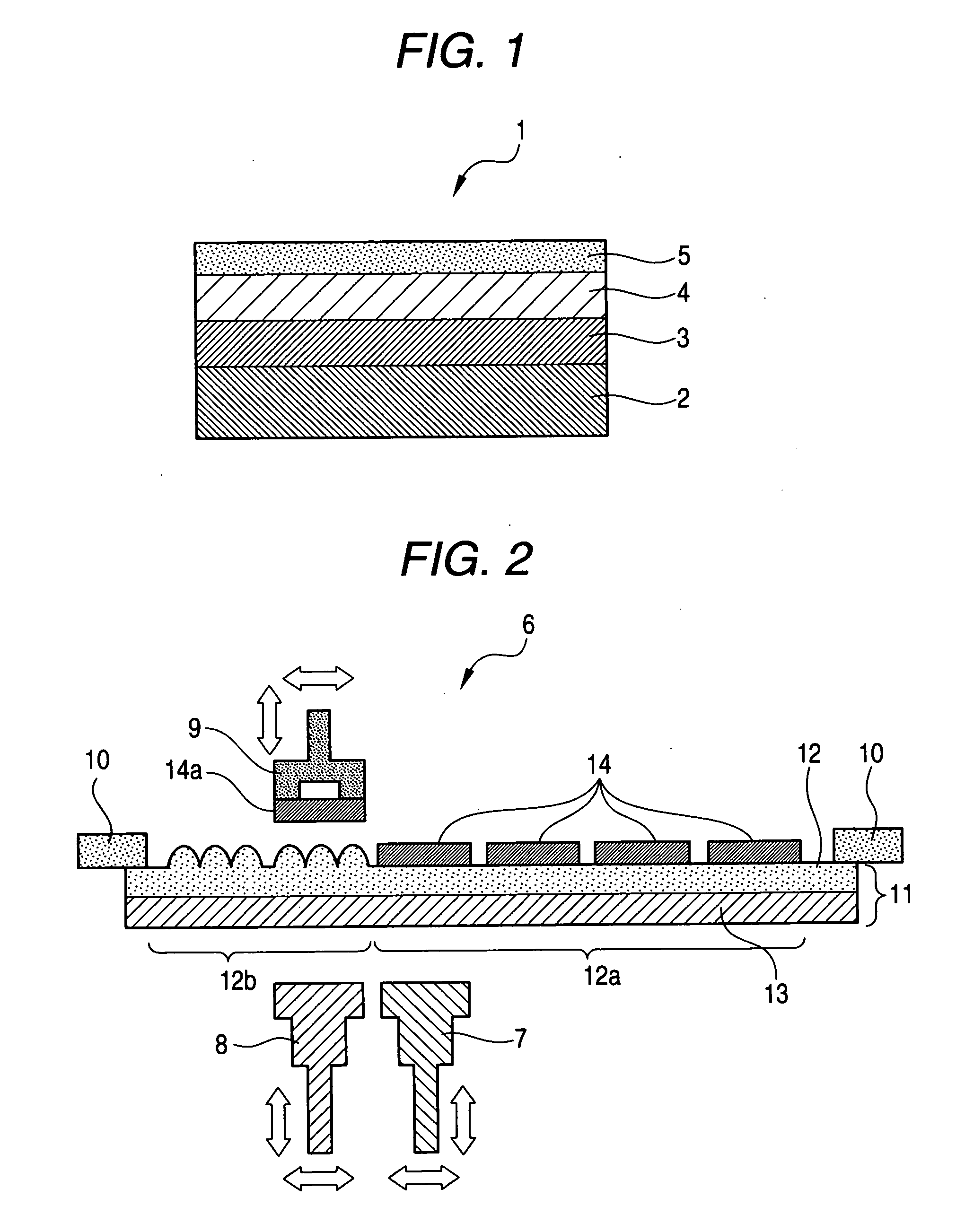

Method of thermal adherend release and apparatus for thermal adherend release

InactiveUS20060124241A1Separated easily and moreGood precisionAdhesive processesLamination ancillary operationsFoaming agentEngineering

A method of thermal adherend release, wherein a part of adherends adherent to a heat-peelable pressure-sensitive adhesive sheet having a heat-expandable layer containing a foaming agent are selectively released from the pressure-sensitive adhesive sheet by partly heating the heat-peelable pressure-sensitive adhesive sheet, wherein the method comprises previously heating a sticking site of an adherend to be released at a temperature at which the heat-expandable layer of the heat-peelable pressure-sensitive adhesive sheet does not expand and then heating the sticking site of the adherend in the heat-peelable pressure-sensitive adhesive sheet at a temperature at which the heat-expandable layer expands to thereby selectively releasing the adherend.

Owner:NITTO DENKO CORP

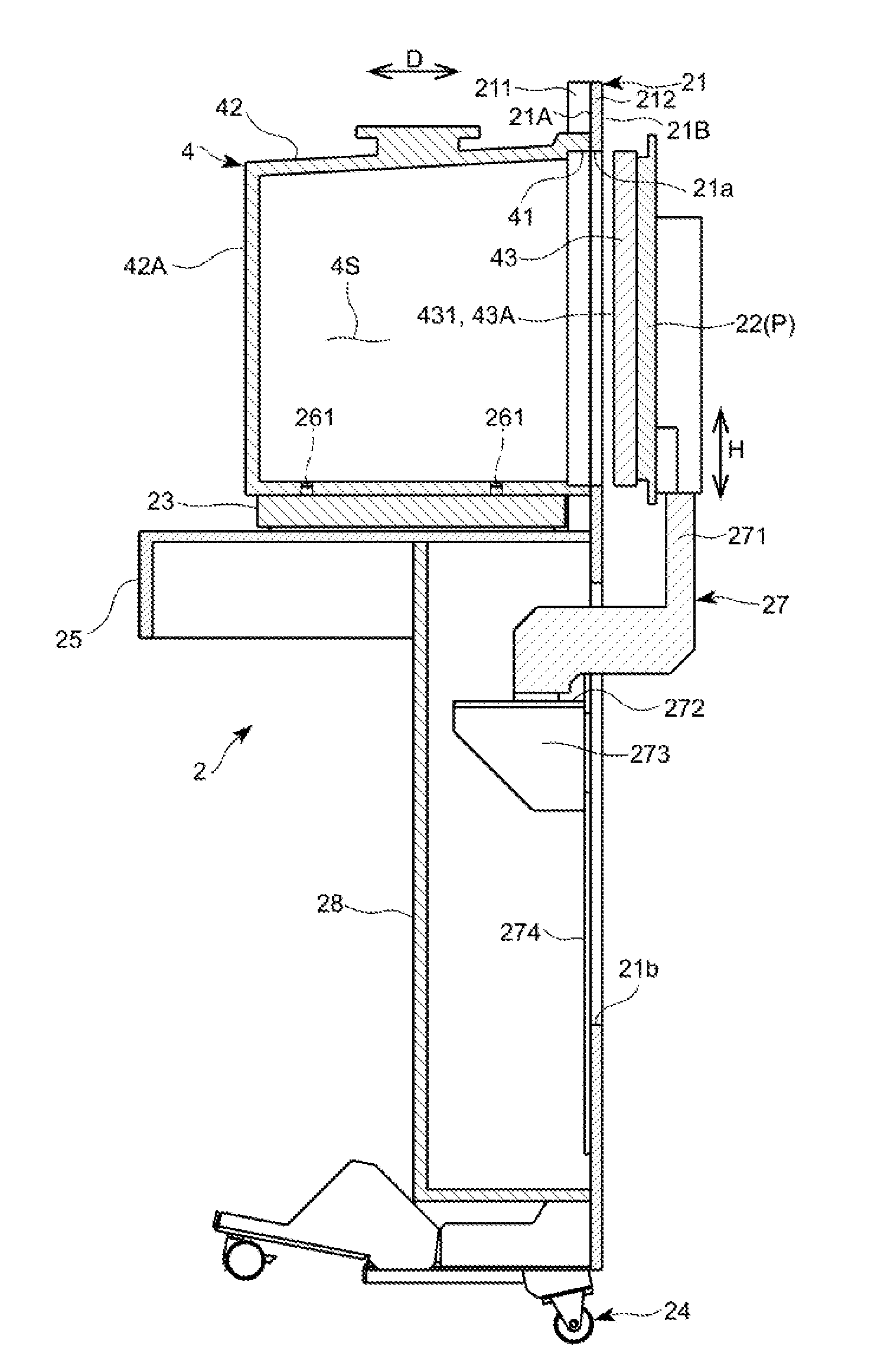

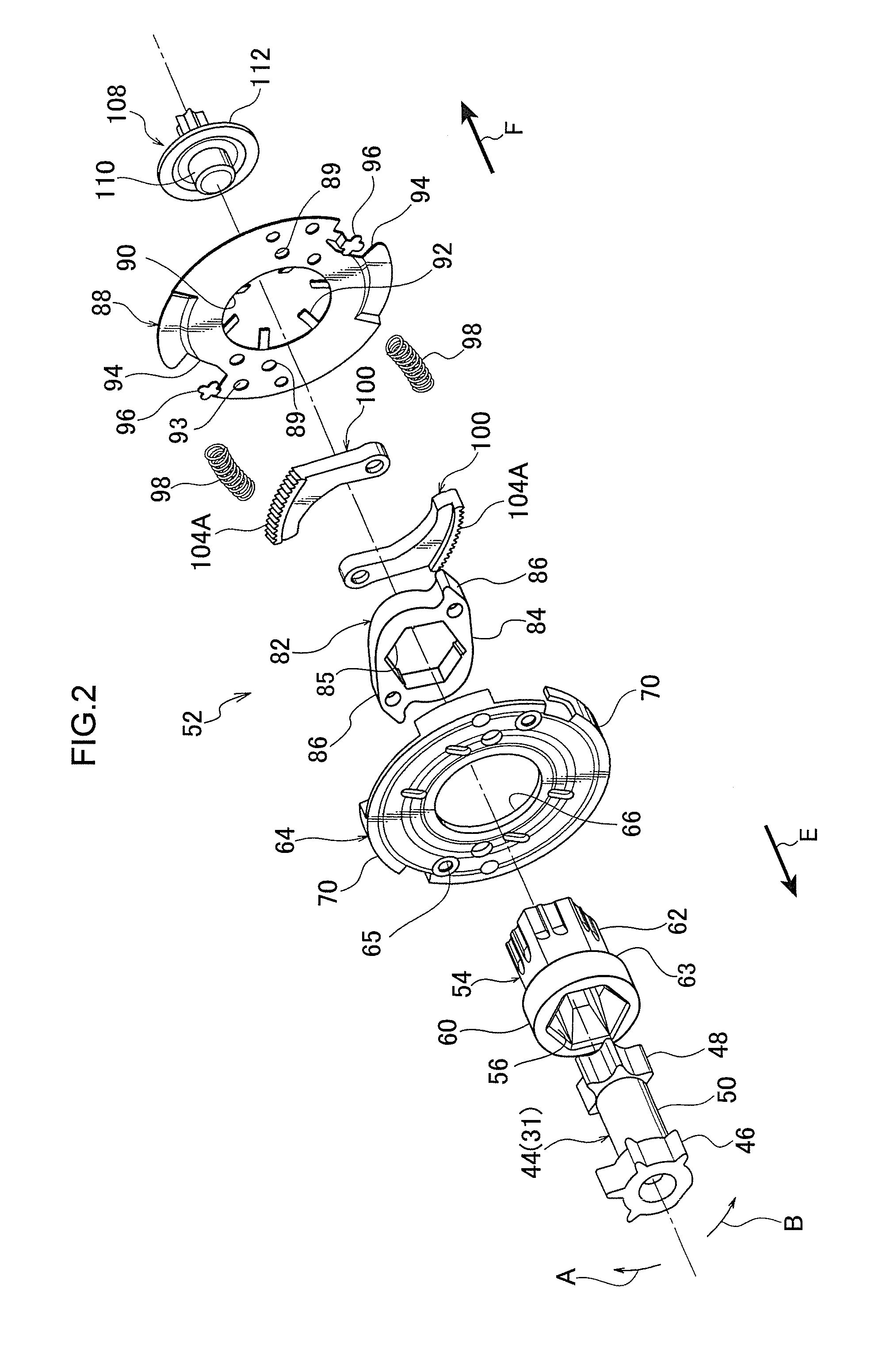

Door opening and closing apparatus

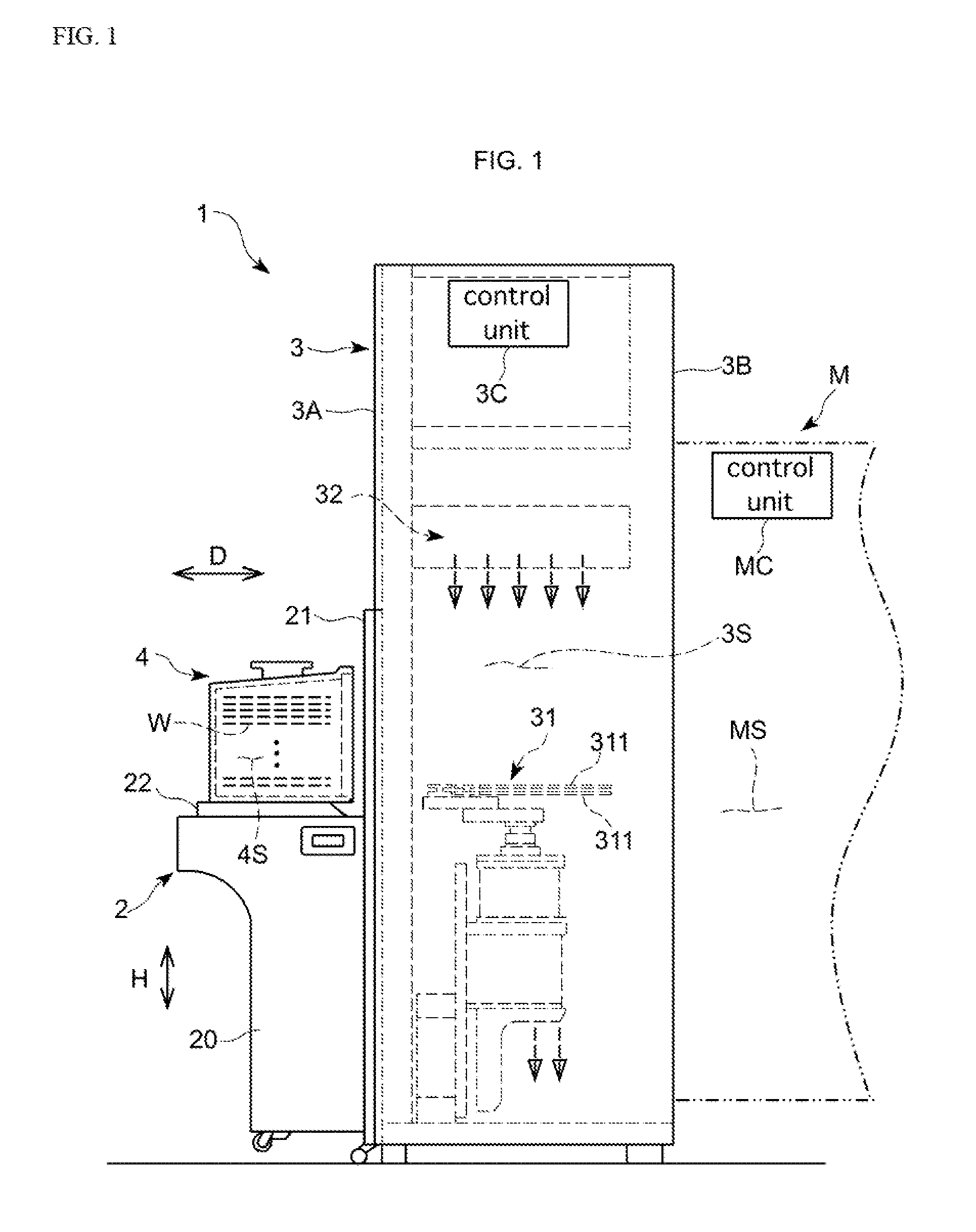

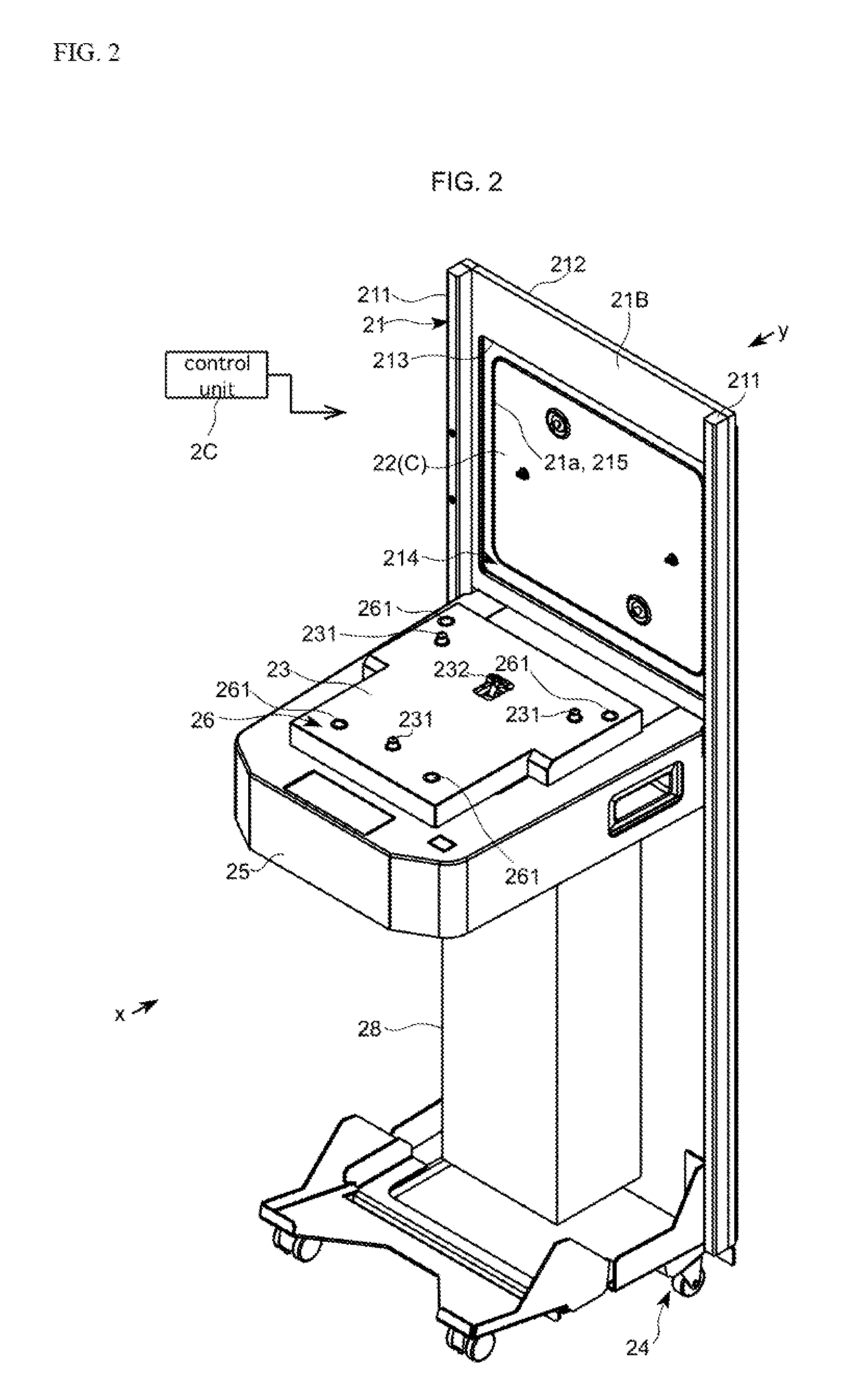

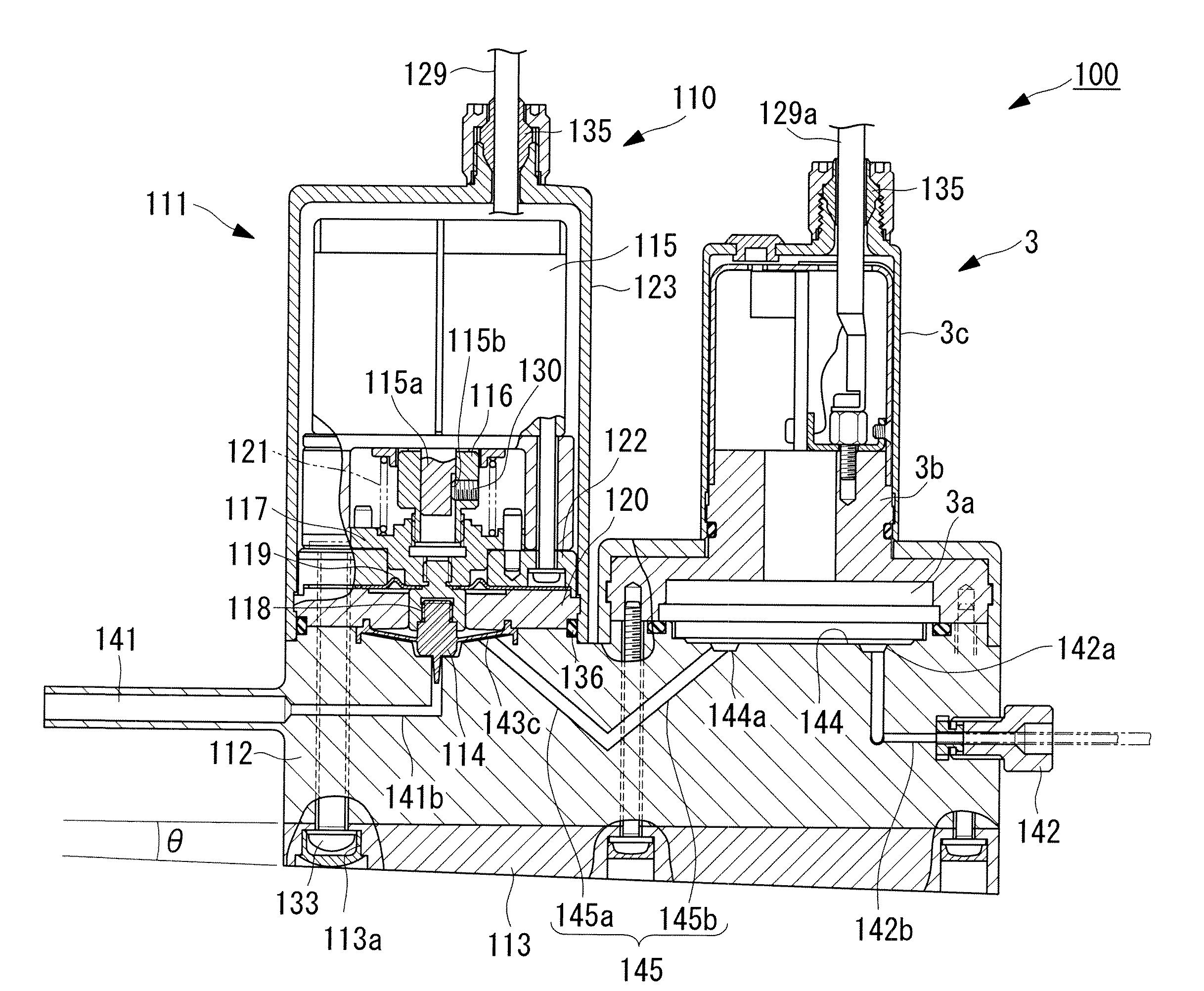

InactiveUS20160260628A1Improve purge efficiencyIncrease costSemiconductor/solid-state device manufacturingPower-operated mechanismEngineeringMechanical engineering

A door opening and closing apparatus shifts a door part holding a lid part of a storage container between a totally closed position where the inner space of the storage container body is sealed and a totally open position where the inner space of the storage container body is totally opened frontward, for putting in and taking out transfer target objects between the storage container and a transfer room. The door opening and closing apparatus puts the door part on standby at the predetermined halfway stop position every time a single access operation of a transfer robot to the storage container ends and until next access operation of the transfer robot to the storage container is performed.

Owner:SINFONIA TECHNOLOGY CO LTD

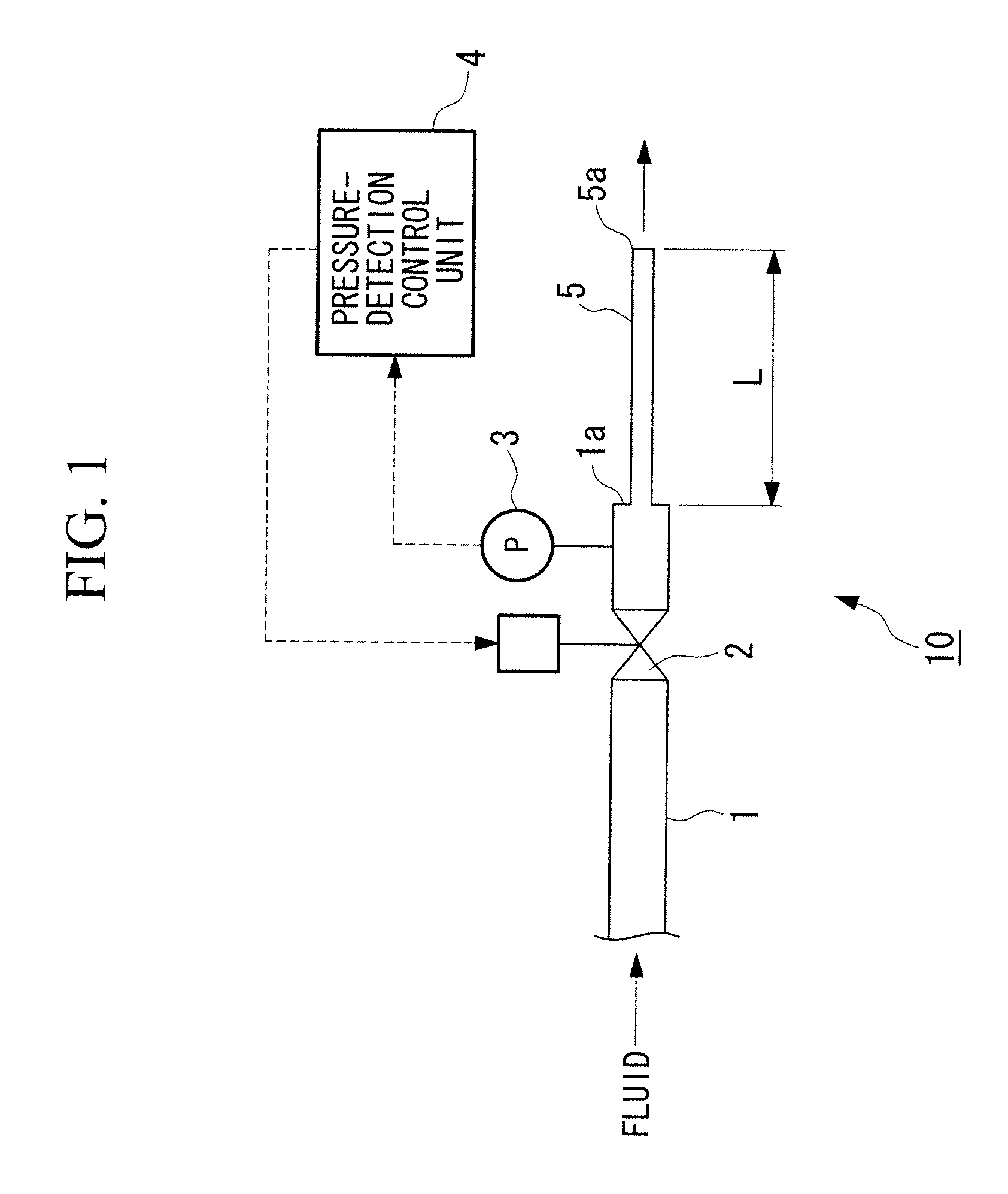

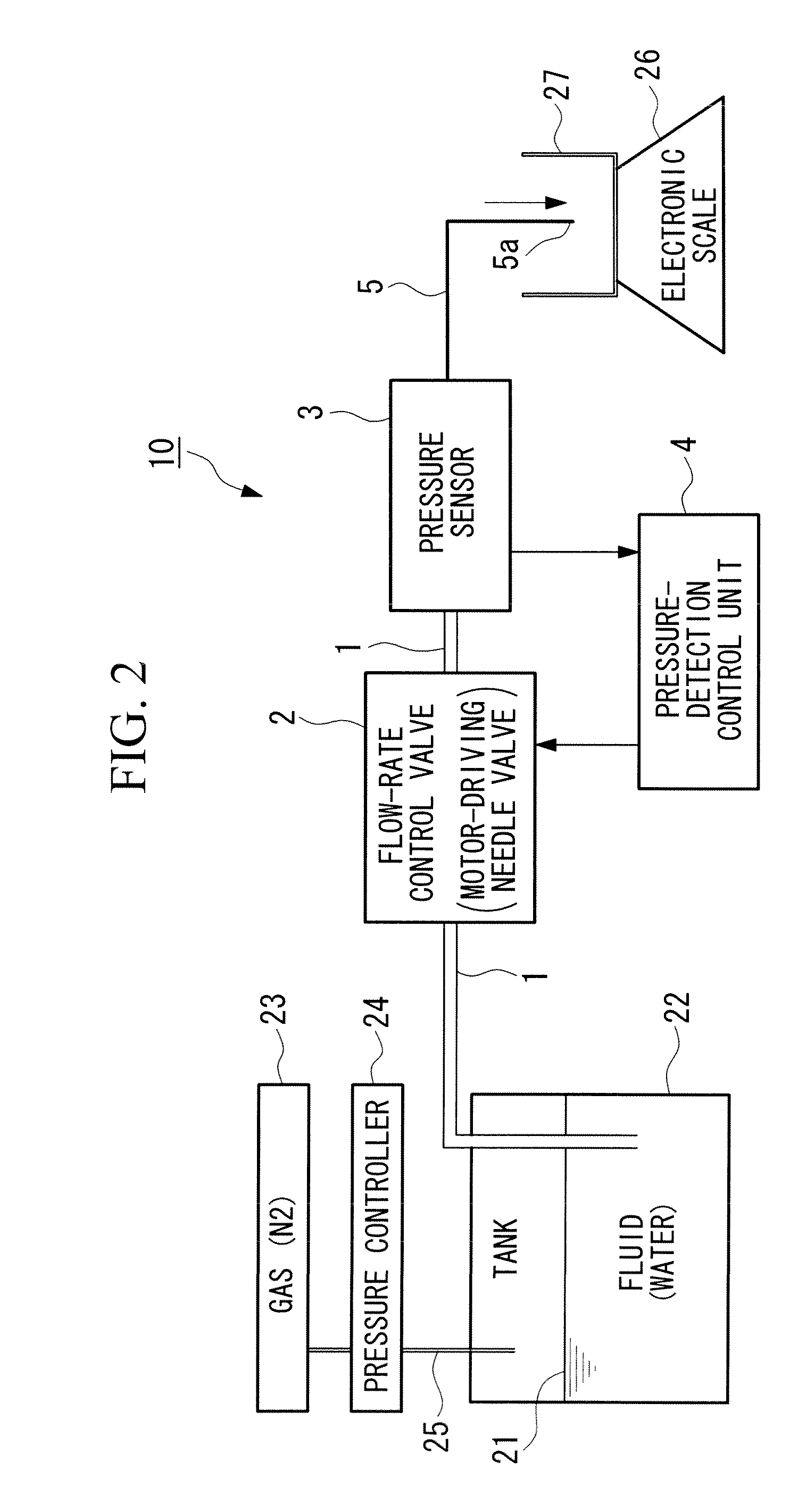

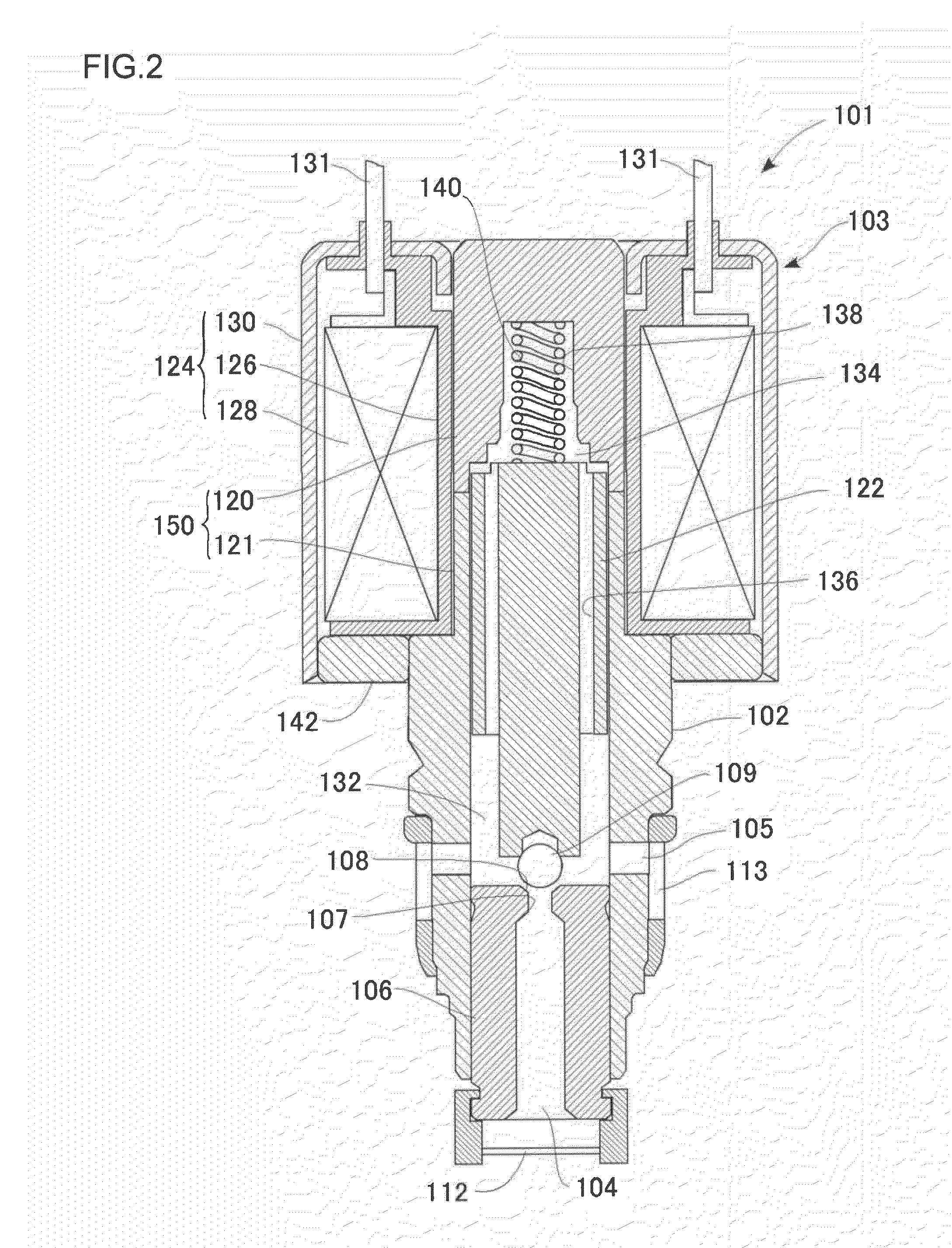

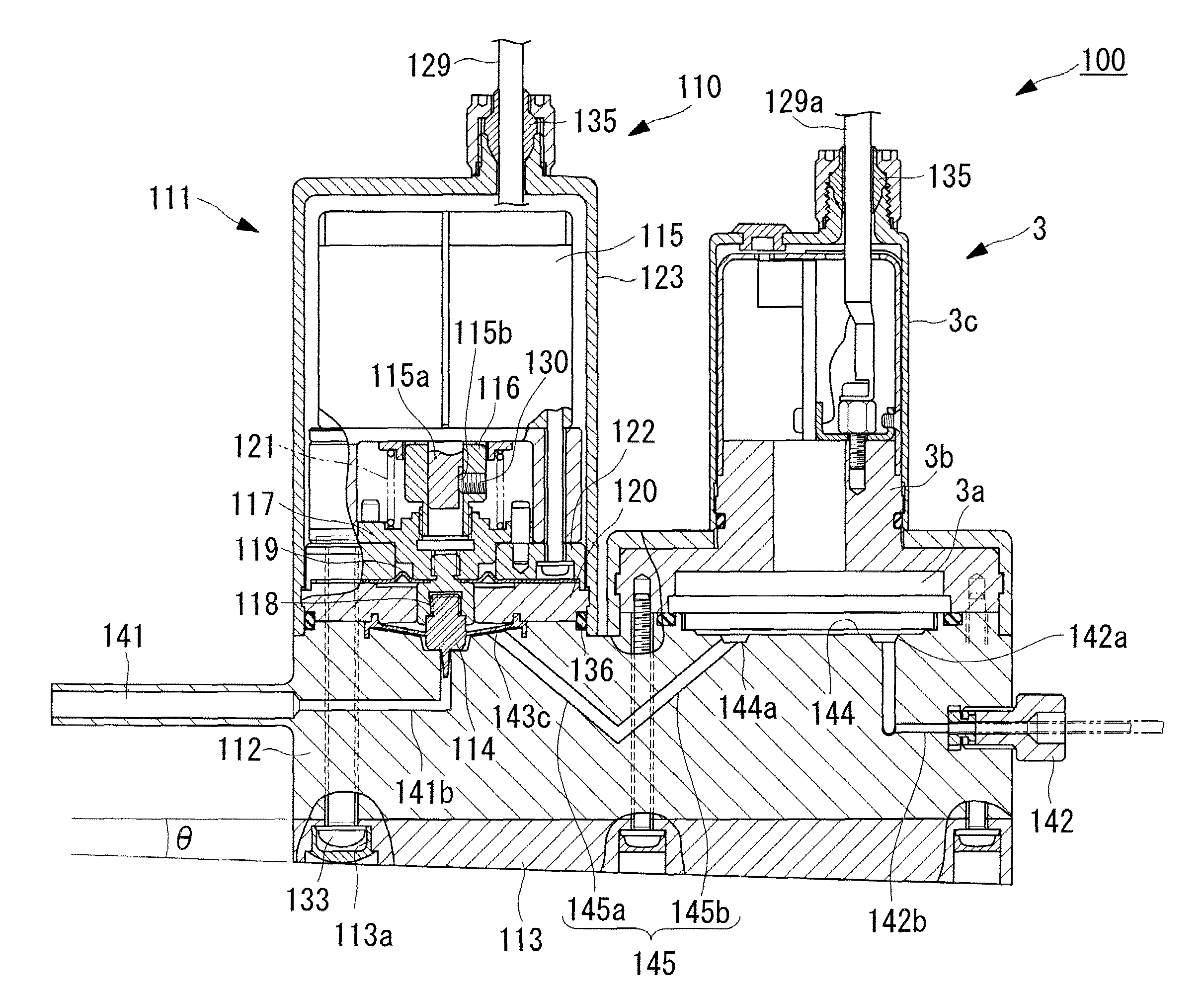

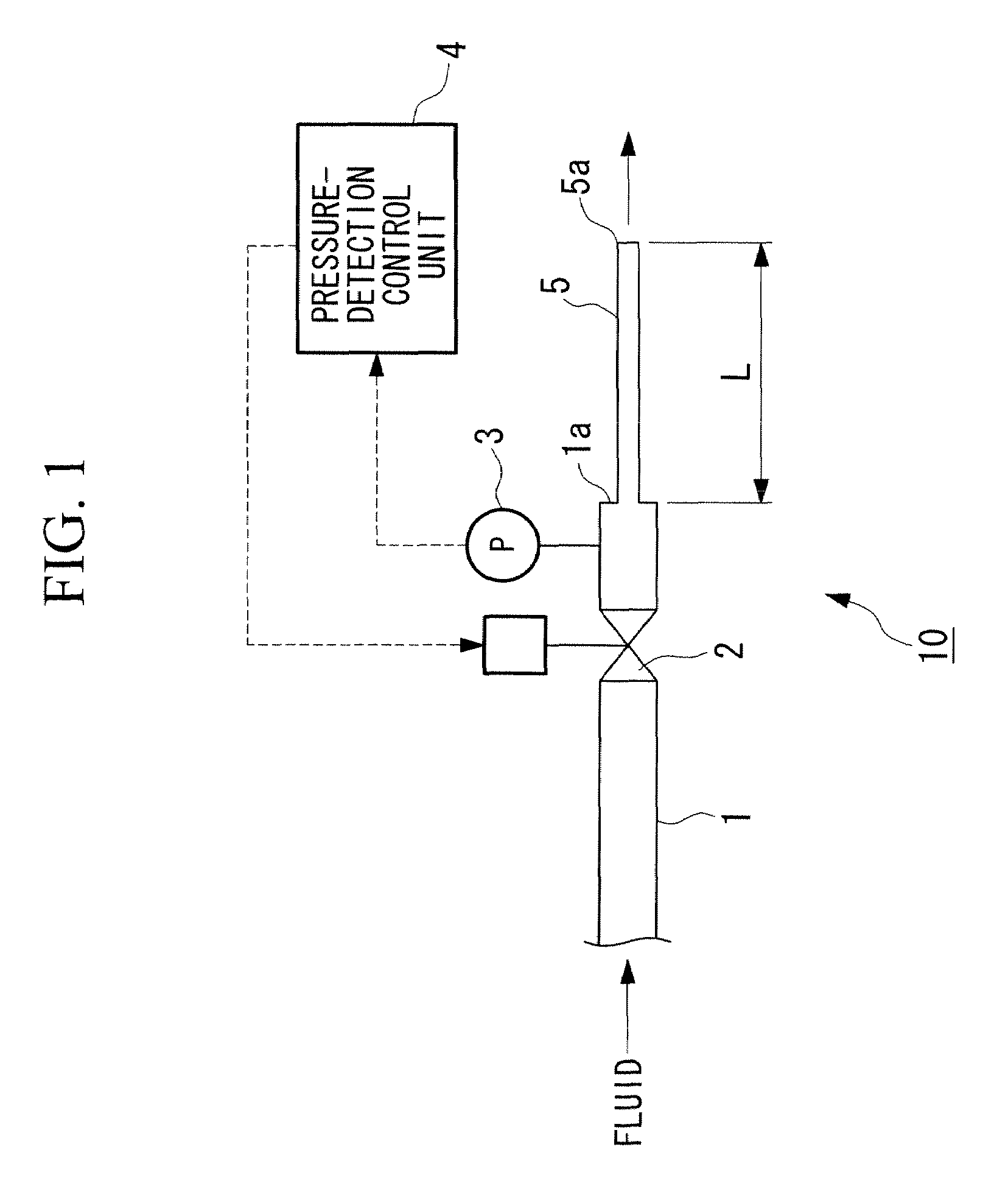

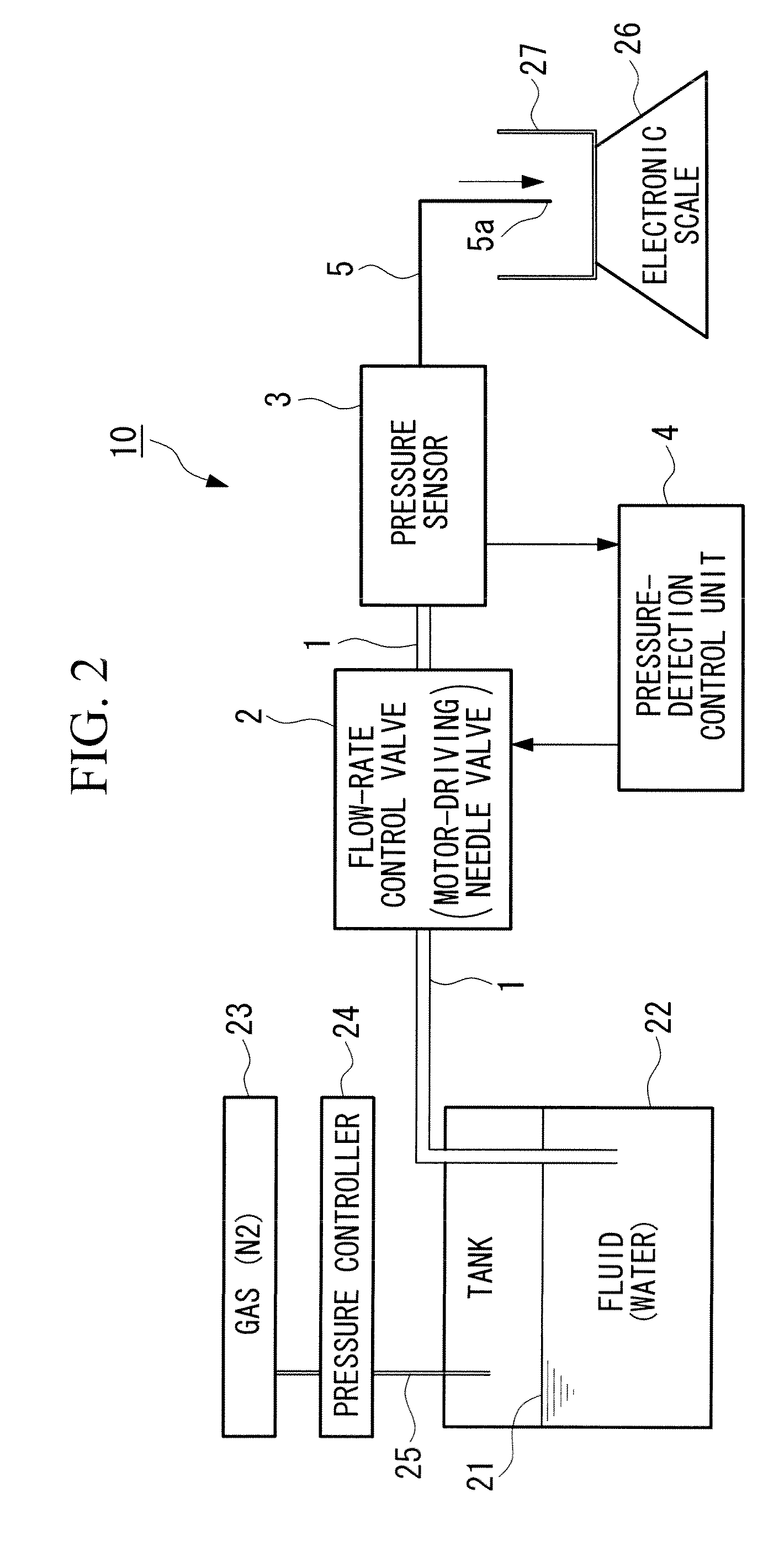

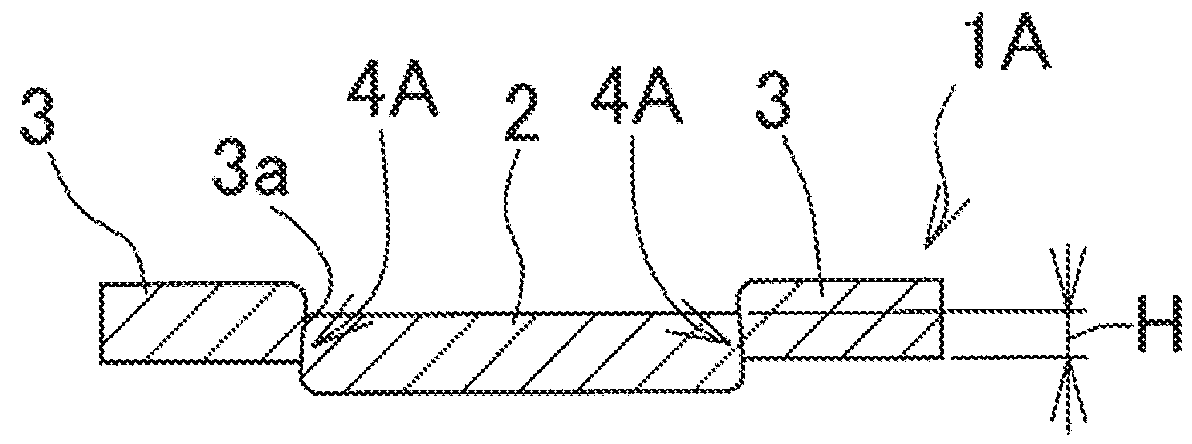

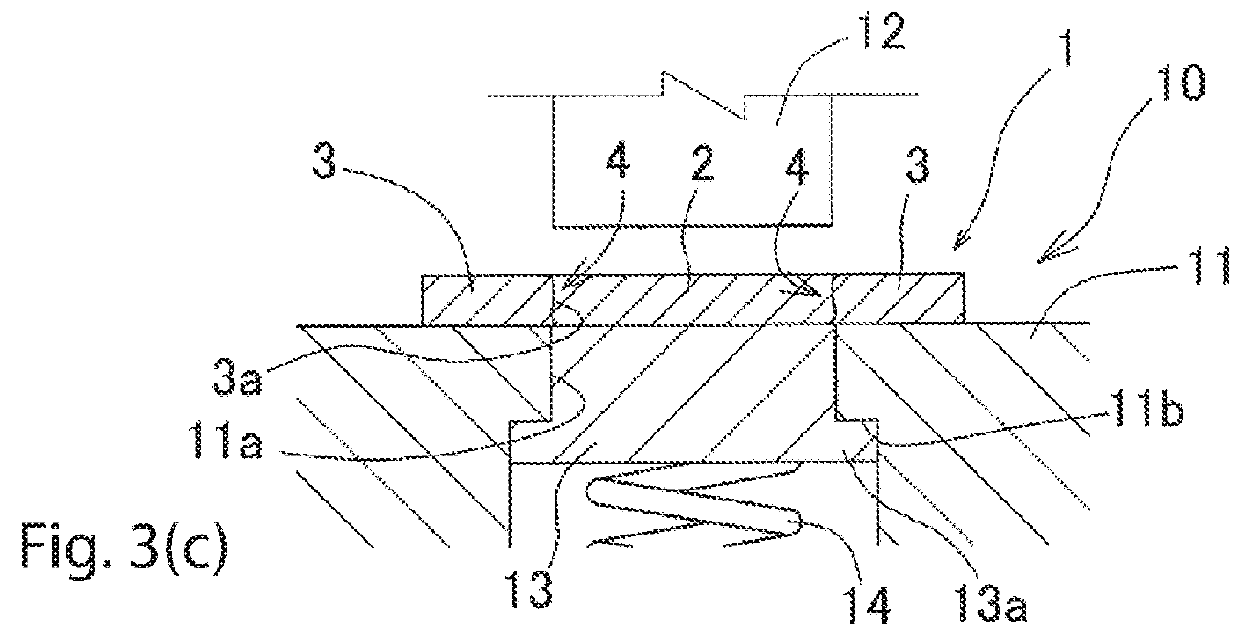

Flow meter and flow-regulating system using the same

ActiveUS20090078038A1Reduce loadHigh precision measurementOperating means/releasing devices for valvesFlow control using electric meansEngineeringDischarge measurements

Provided are a flow meter and a flow-rate control system using the same that is capable of measuring a flow rate in a minute flow-rate region with excellent measurement accuracy by preventing or suppressing the generation of bubbles and in which accumulation of the fluid and the bubbles is less likely to occur. The flow meter is for measuring a minute flow rate of a fluid flowing through a fluid channel whose outlet environment is set to constant pressure, the flow meter including a flow-rate measurement conduit portion having a predetermined length connected to an outlet-side end of the fluid channel 1 and whose outlet environment is set to constant pressure by setting the cross-sectional area of a channel smaller than the fluid channel; a pressure sensor for detecting the pressure of the fluid at the upstream side of the flow-rate measurement conduit portion by being disposed near an outlet of the fluid channel 1; and a pressure-detection control unit 4 for calculating a flow rate from a fluid pressure detected at the pressure detection part.

Owner:SURPASS IND

Ink jet printing apparatus

An ink jet printing apparatus can prevent or suppress the generation, by a reaction liquid and ink, of a reaction product on the face surface of a discharge head, and can remove the ink, the reaction liquid or the reaction product adhering to the face surface so as to constantly maintain a stable printing quality. Immediately before a printing operation is initiated, an anti-coagulation liquid is sprayed on the face surface of a discharge head, and the discharge head performs the discharge operation (printing operation) with the anti-coagulation liquid applied to the face surface. When the printing operation has been completed, or when the printing of a predetermined amount of data has been performed, the face surface of the discharge head is wiped by blades to remove the ink and the reaction liquid. Since the anti-coagulation liquid is applied to the face surface in advance, the generation of the reaction product on the face surface is prevented or suppressed. Furthermore, even when a reaction product is adhered to the face surface, the coagulation of this product on the face surface can be prevented.

Owner:CANON KK

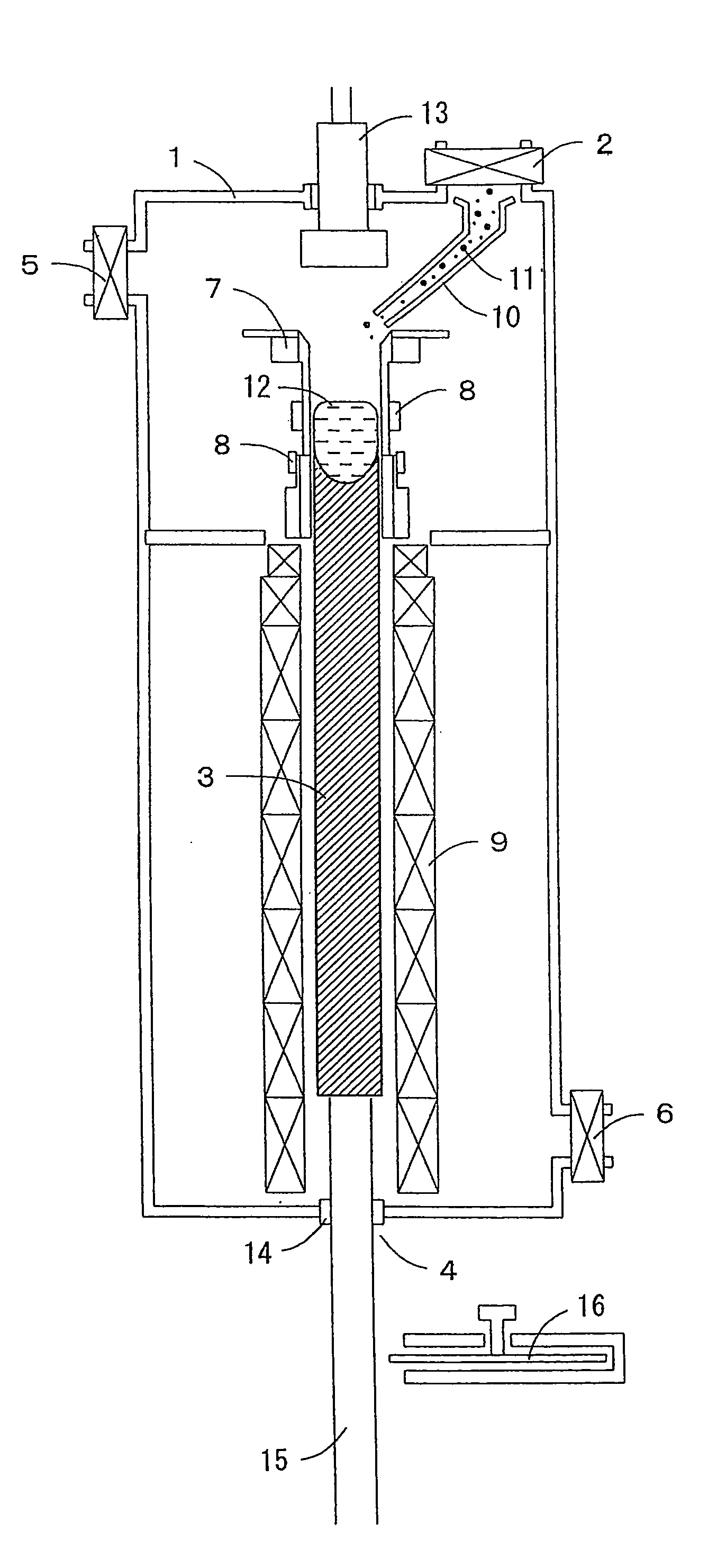

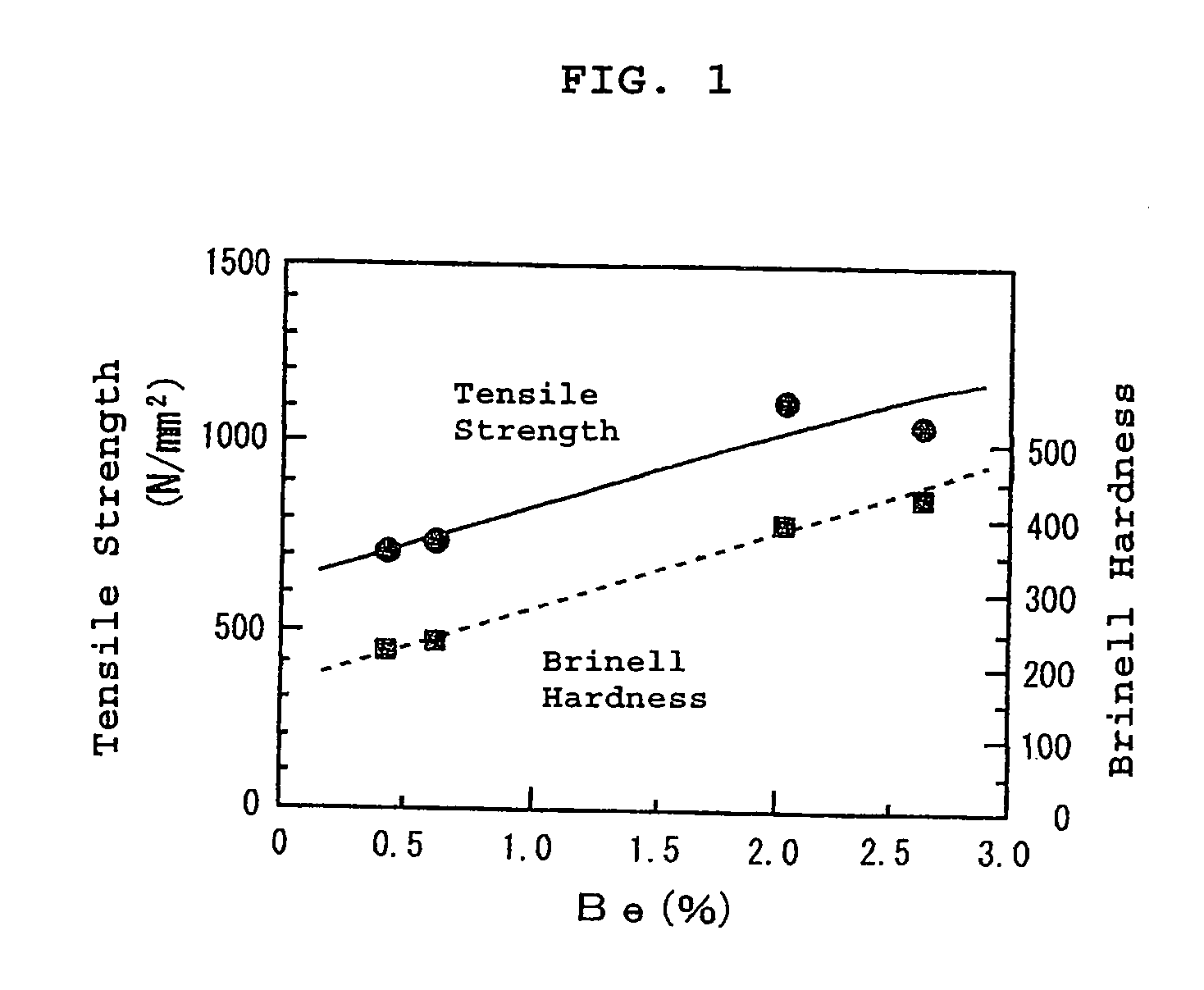

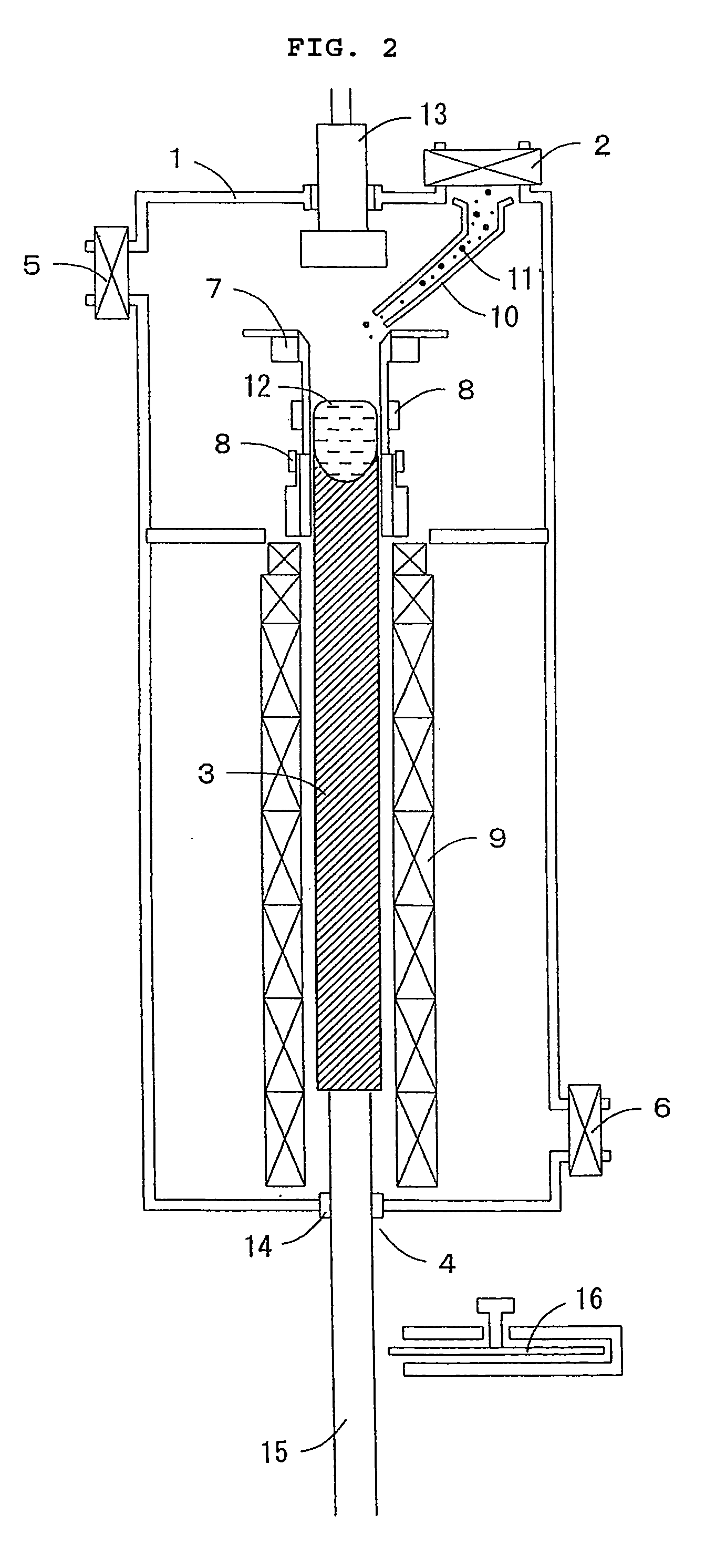

Silicon casting apparatus

InactiveUS20090044926A1Prevent effectively generationReduce facility costsPolycrystalline material growthFrom frozen solutionsElectromagnetic castingElectric discharge

In a silicon casting apparatus according to the present invention, silicon melted by electromagnetic induction heating is continuously solidified using an electrically-conductive bottomless cold crucible and an induction coil surrounding the cold crucible. The cold crucible is made of copper alloy containing beryllium (desirably containing beryllium of 0.1 to 5 mass %), whereby the generation of electric-discharge flaw can be effectively prevented in performing electromagnetic casting. The use of the silicon casting apparatus according to the present invention can greatly extend a crucible life to reduce facility costs. Additionally, a solar-cell silicon ingot can be produced with high quality.

Owner:SUMCO SOLAR CORP

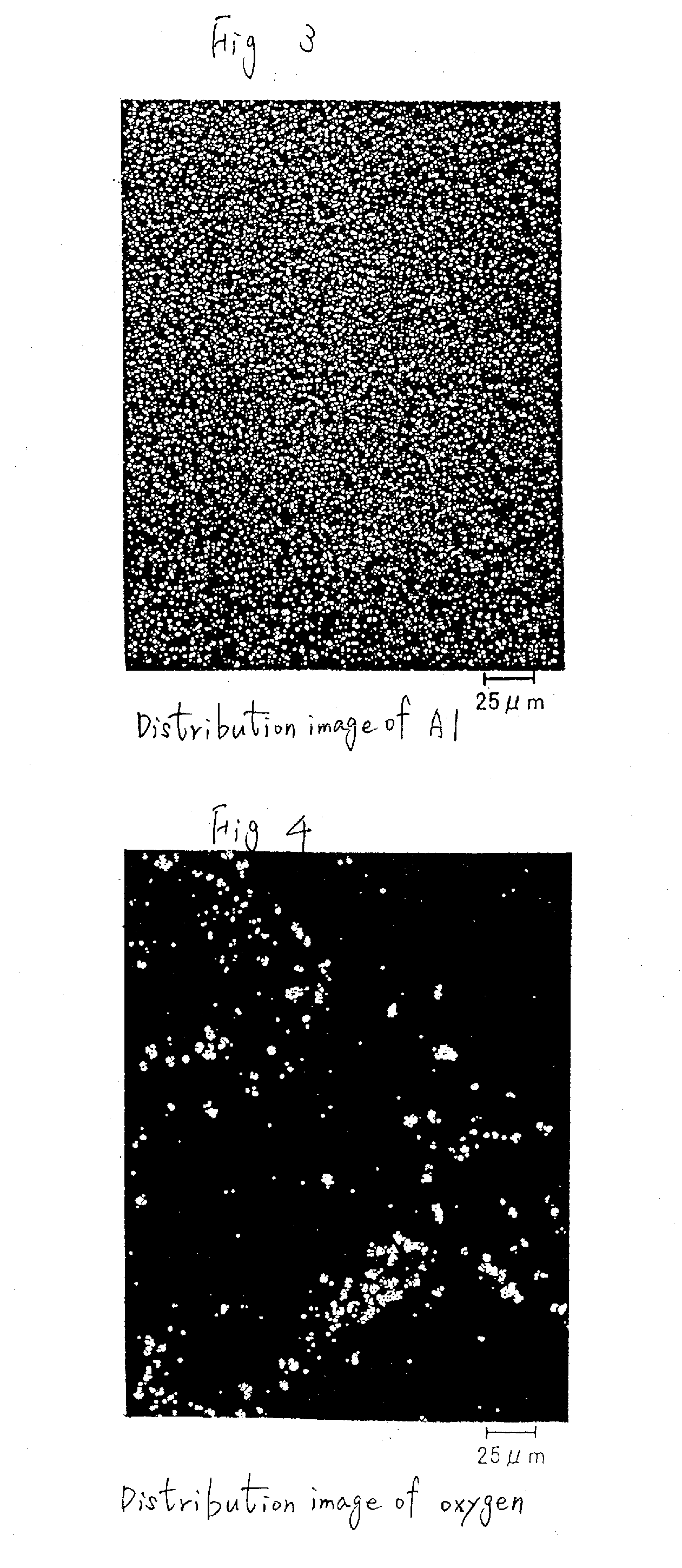

Sputtering Target and Process for Producing Same

ActiveUS20110162971A1Excellent surface characteristicGood effectCellsVacuum evaporation coatingDuctilityOxide

A sputtering target with low generation of particles in which oxides, carbides, nitrides, borides, intermetallic compounds, carbonitrides, and other substances without ductility exist in a matrix phase made of a highly ductile substance at a volume ratio of 1 to 50%, wherein a highly ductile and conductive metal coating layer is formed on an outermost surface of the target. Provided are a sputtering target capable of improving the target surface in which numerous substances without ductility exist and preventing or inhibiting the generation of nodules and particles during sputtering, and a method of producing such a sputtering

Owner:JX NIPPON MINING& METALS CORP

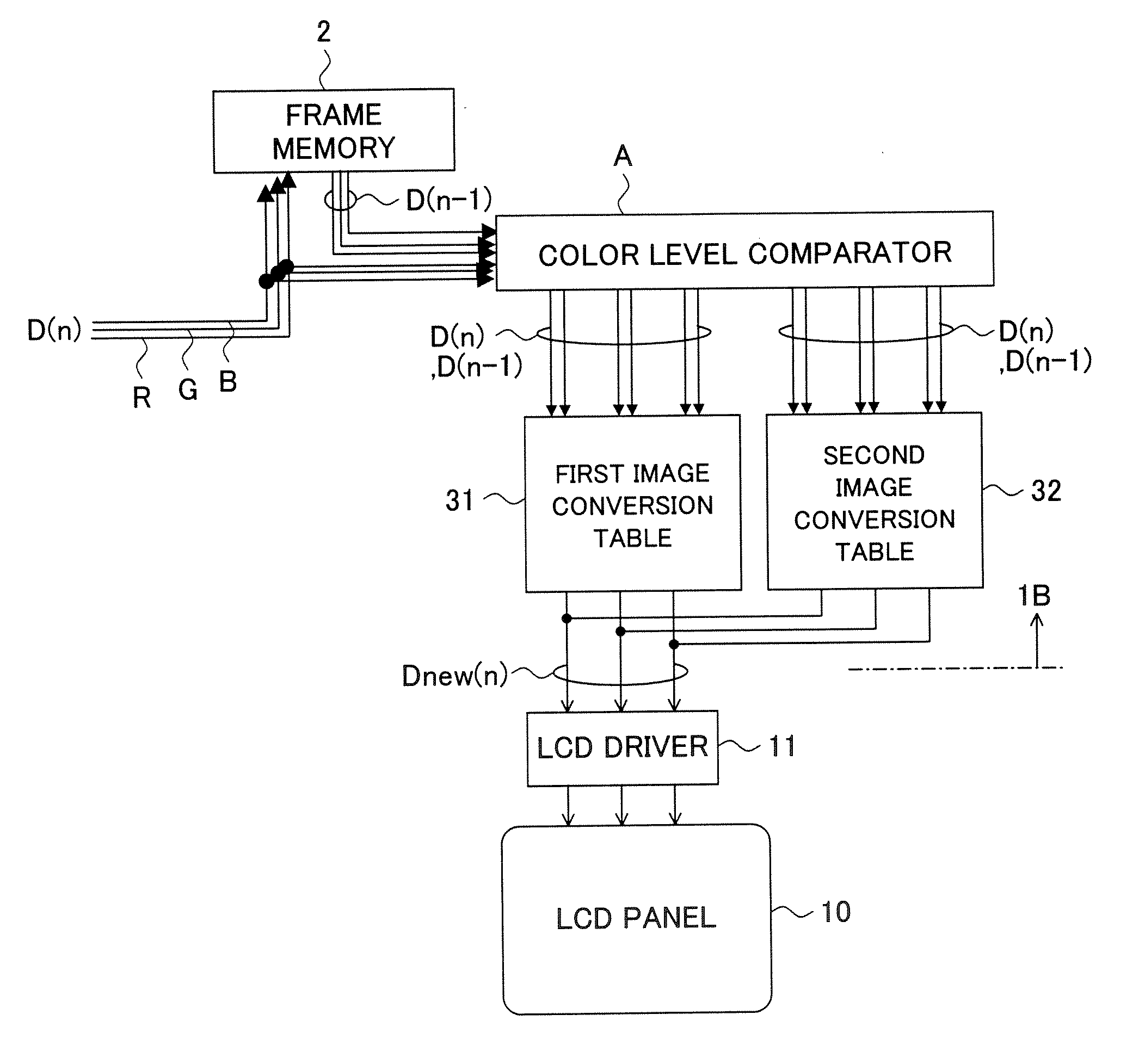

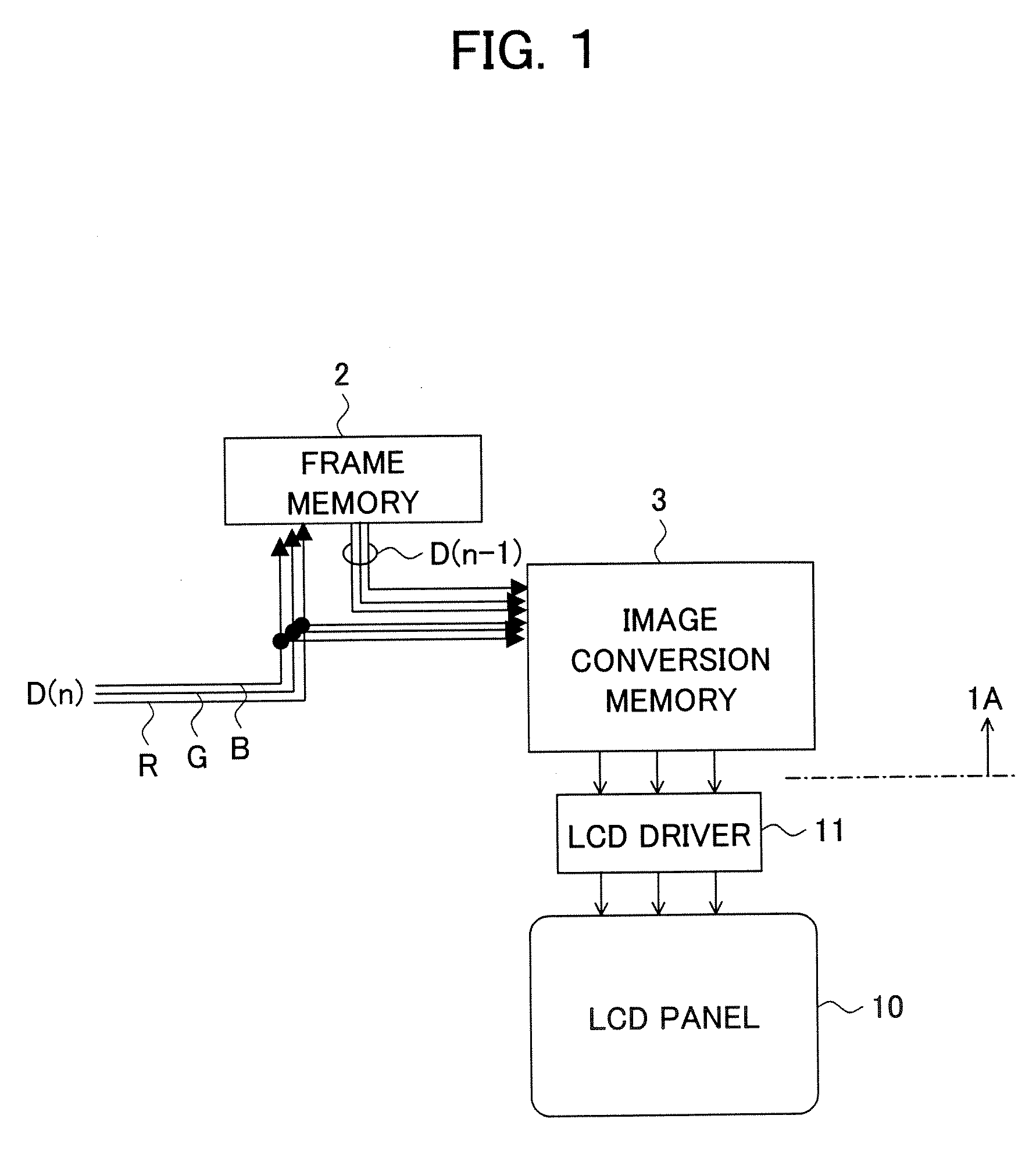

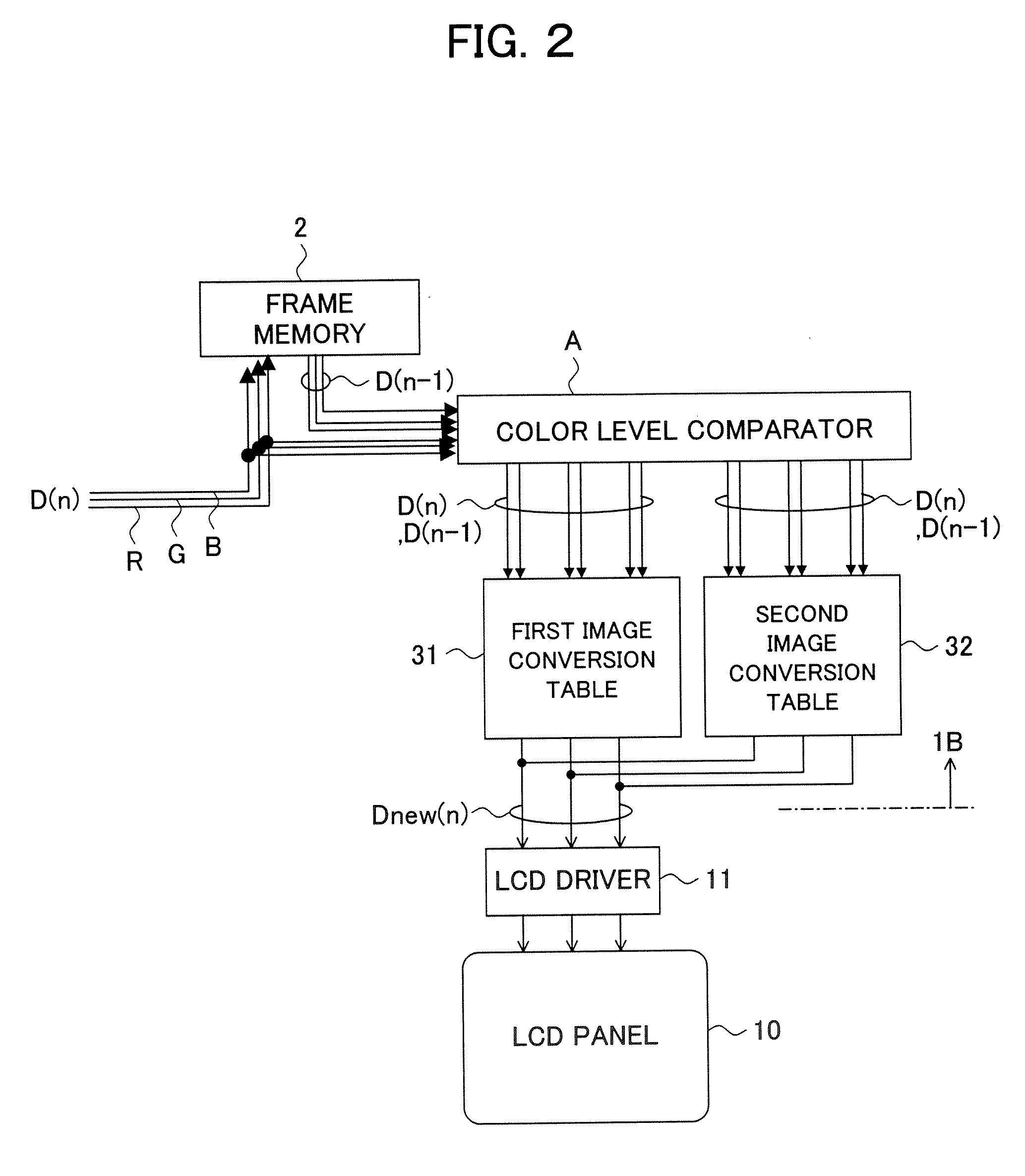

Image processing apparatus, liquid crystal display apparatus, and color correction method

InactiveUS20060274162A1Improve responseSuppress and prevent generationTelevision system detailsStatic indicating devicesLiquid-crystal displayLiquid crystal

An image processing apparatus has: a frame memory storing a signal of a previous image in a previous one frame, and a correction processing unit configured to receive signals of the previous image and a current image, correct a signal level of the current image based on a difference of signal levels between the previous and current images, execute the correction by applying a first correction mode where a relationship between the signal level of the previous image and an amount of correction of the signal level of the current image is common to three primary colors or a second correction mode for correcting the current image by applying another amount of correction so as to complete an optical response of liquid crystal in the entire primary colors within one frame display period when an input image transits from the previous image to the current image.

Owner:SONY CORP

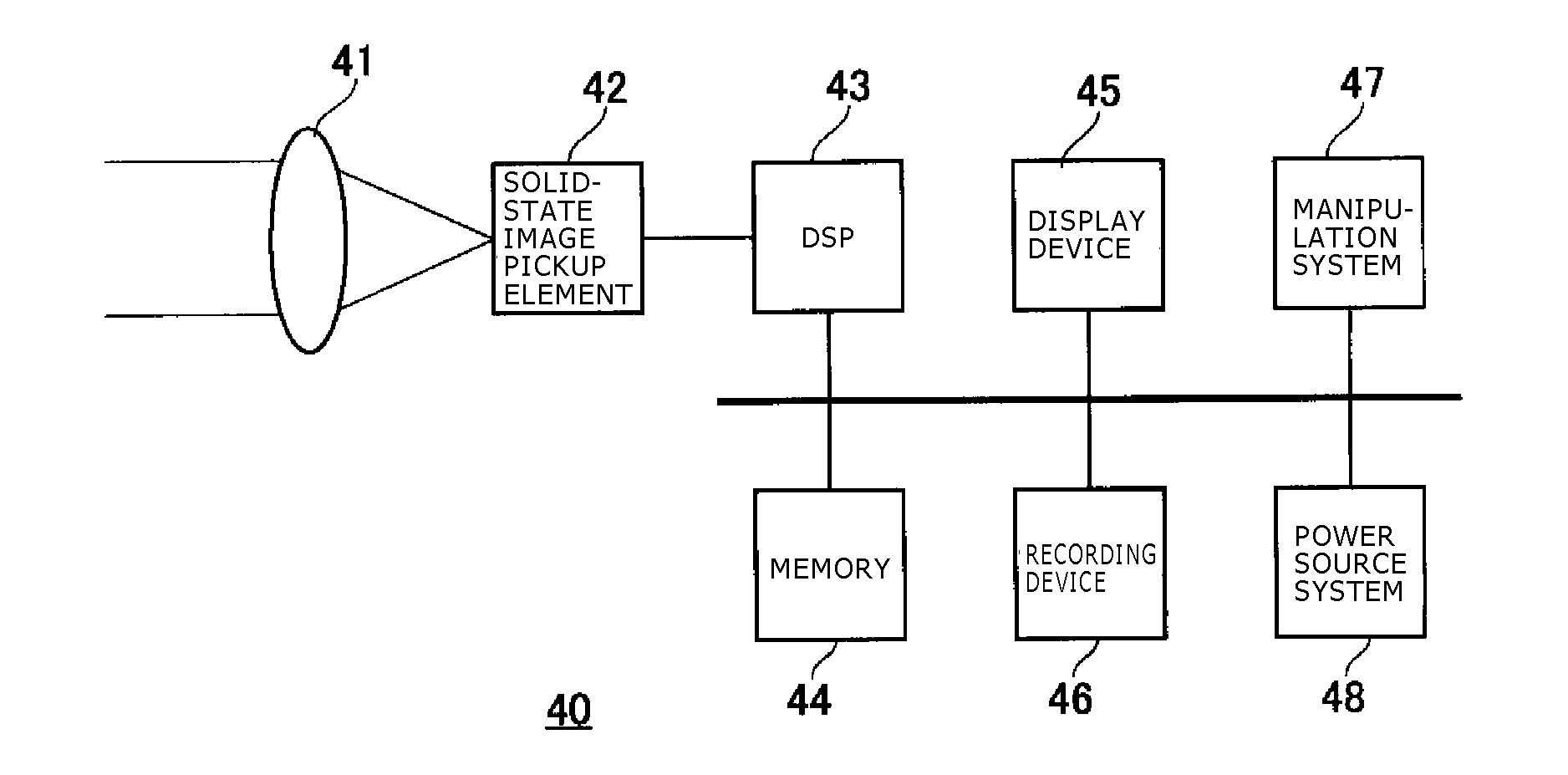

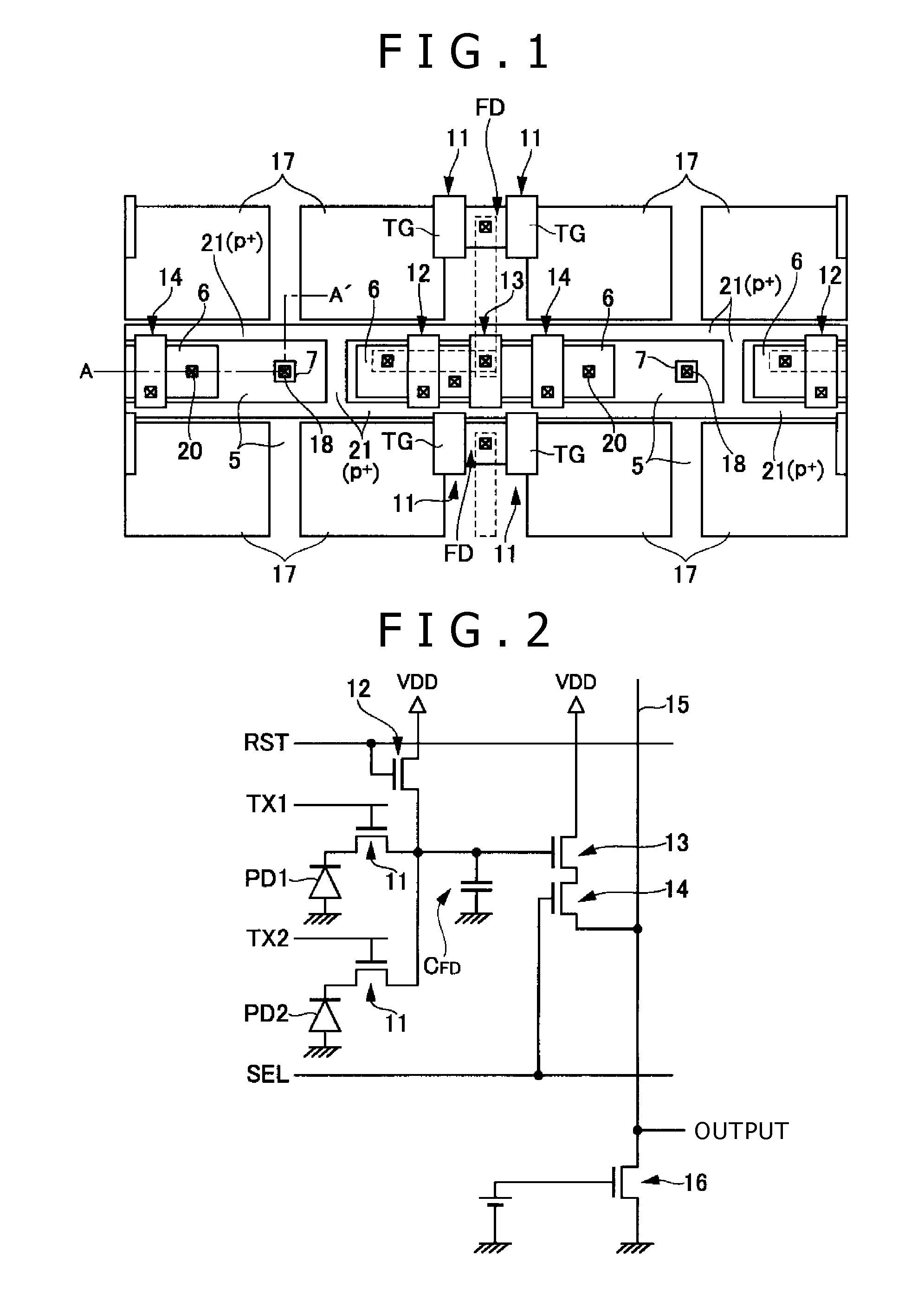

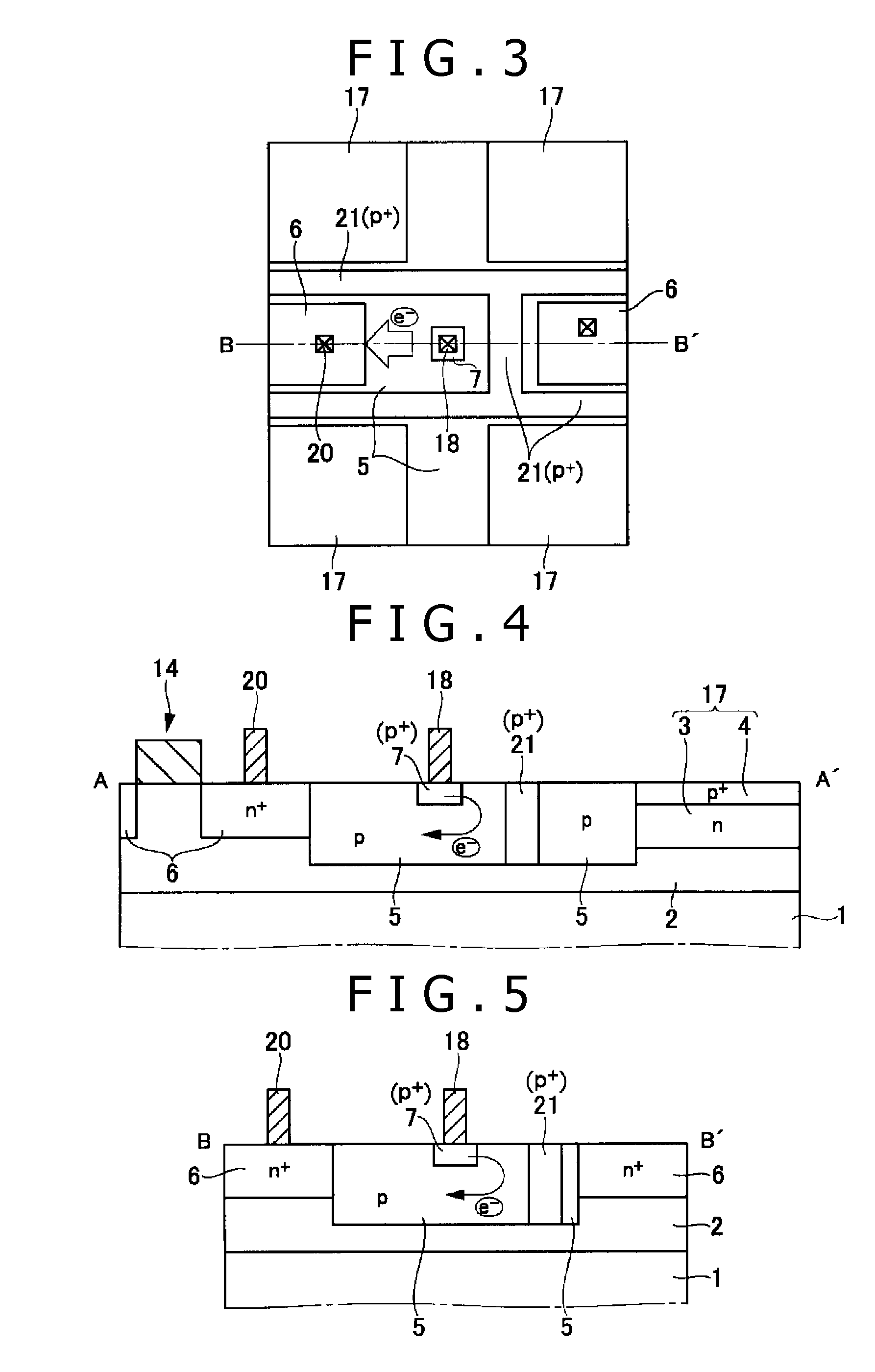

Solid-state image pickup element and image pickup apparatus

ActiveUS20110234873A1Suppress and prevent flowingSuppress and prevent generationTransistorTelevision system detailsEngineeringPhotoelectric conversion

Disclosed herein is a solid-state image pickup element, including: a photoelectric conversion region; a transistor; an isolation region of a first conductivity type configured to isolate the photoelectric conversion region and the transistor from each other; a well region of the first conductivity type having the photoelectric conversion region, the transistor, and the isolation region of the first conductivity type formed therein; a contact portion configured to supply an electric potential used to fix the well region to a given electric potential; and an impurity region of the first conductivity type formed so as to extend in a depth direction from a surface of the isolation region of the first conductivity type in the isolation region of the first conductivity type between the contact portion and the photoelectric conversion region, and having a sufficiently higher impurity concentration than that of the isolation region of the first conductivity type.

Owner:SONY CORP

Organic EL device having a transflective layer and a light-reflective electrode constituting an optical resonator

ActiveUS7573191B2High color purityIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesTransmitted lightResonator

An organic EL device includes light-reflective electrodes; light-transmissive electrodes; organic EL layers that are respectively provided between the light-reflective electrodes and the light-transmissive electrodes to emit a plurality of color light components, the organic EL layer emitting a different color light component in each pixel; and transflective layers that are selectively provide in predetermined color pixels to reflect or transmit light emitted from the organic EL layers, respectively, each transflective layer being opposite to the light-reflective electrode with the organic EL layer interposed therebetween.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Sputtering target with few surface defects, and surface processing method thereof

ActiveUS20070125645A1Increase heightSuppress and prevent generationCellsMetal rolling stand detailsTarget surfaceCarbide

Provided is a surface processing method of a sputtering target, wherein a target surface in which intermetallic compounds, oxides, carbides, carbonitrides and other substances without ductility exist in a highly ductile matrix phase at a volume ratio of 1 to 50% is preliminarily subject to the primary processing of cutting work, then subsequently subject to finish processing via polishing. The sputtering target subject to this surface processing method is able to improve the target surface having numerous substances without ductility, and prevent or suppress the generation of nodules and particles upon sputtering.

Owner:JX NIPPON MINING& METALS CORP

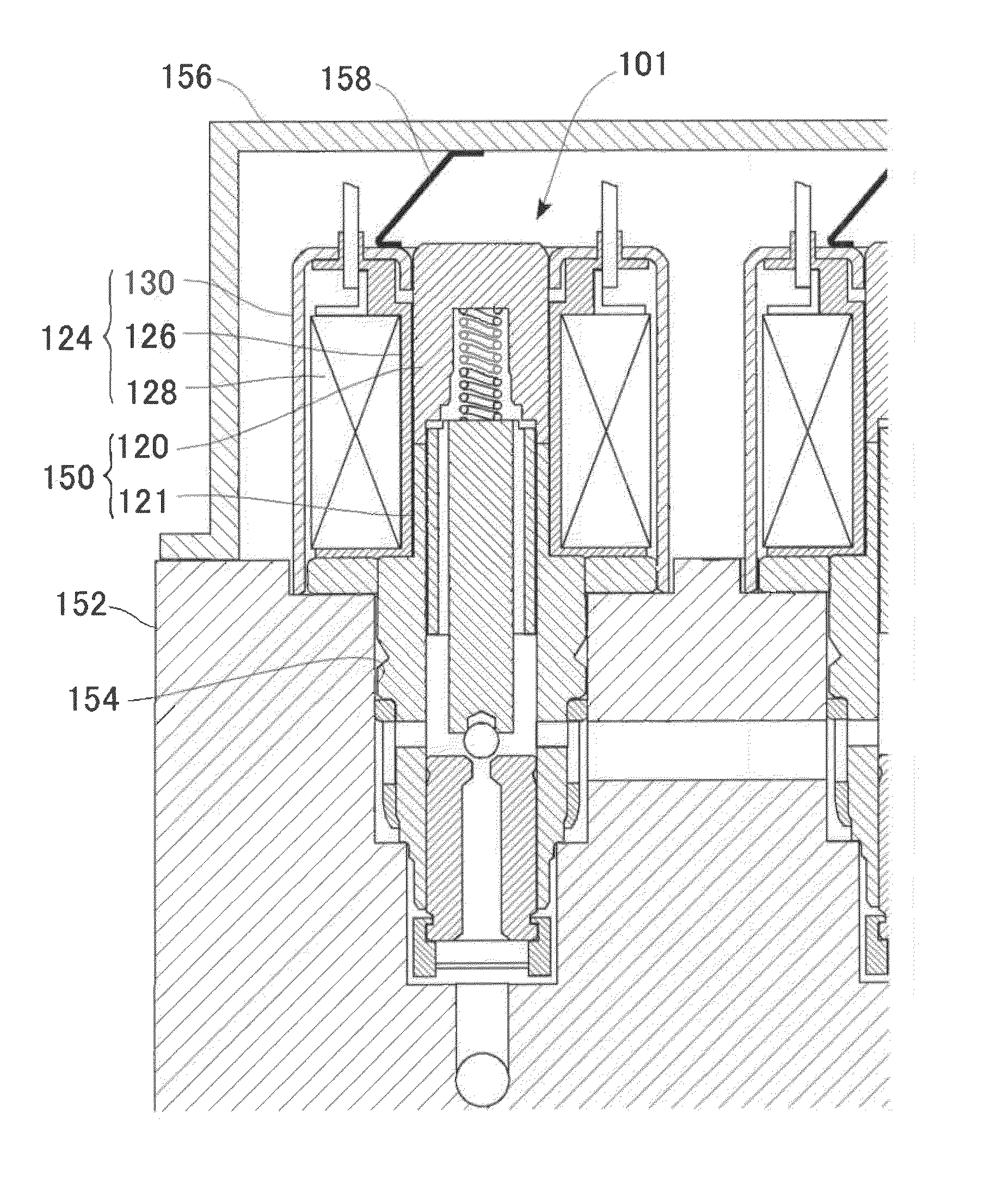

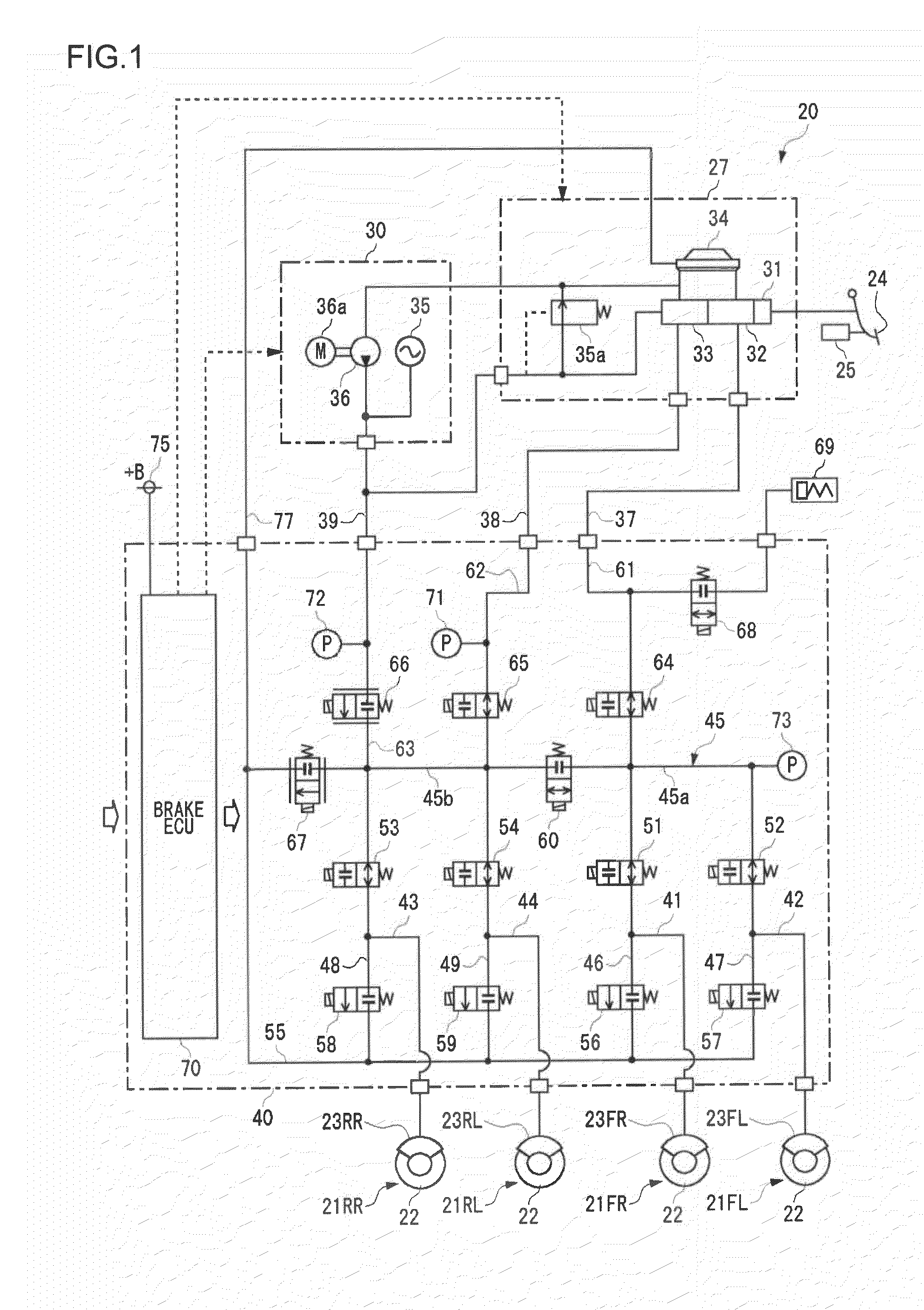

Solenoid valve control apparatus and actuator

InactiveUS8128059B2Suppress and prevent generationOperating means/releasing devices for valvesServomotor componentsSolenoid valveEngineering

In a certain brake control apparatus, a valve main body of a hydraulic control valve and a coil unit are separately formed, are assembled with each other, and are mounted on an actuator block. Further, bias current is secured even though the supply of current is temporarily unnecessary depending on a control state and a period between the termination and the start of the driving of the hydraulic control valve. Accordingly, it may be possible to maintain a contact state between the inner peripheral surface of the coil unit and the outer peripheral surface of the valve main body during the driving control period.

Owner:TOYOTA JIDOSHA KK

Flow meter and flow-regulating system using the same

ActiveUS7637152B2Suppress and prevent generationHigh measurement accuracyOperating means/releasing devices for valvesFlow control using electric meansControl systemEngineering

Owner:SURPASS IND

Ink jet printing apparatus

InactiveUS7314267B2Suppress and prevent generationImprove printing qualityPrintingEngineeringElectrical and Electronics engineering

An ink jet printing apparatus can prevent or suppress the generation, by a reaction liquid and ink, of a reaction product on the face surface of a discharge head, and can remove the ink, the reaction liquid or the reaction product adhering to the face surface so as to constantly maintain a stable printing quality. Immediately before a printing operation is initiated, an anti-coagulation liquid is sprayed on the face surface of a discharge head, and the discharge head performs the discharge operation (printing operation) with the anti-coagulation liquid applied to the face surface. When the printing operation has been completed, or when the printing of a predetermined amount of data has been performed, the face surface of the discharge head is wiped by blades to remove the ink and the reaction liquid. Since the anti-coagulation liquid is applied to the face surface in advance, the generation of the reaction product on the face surface is prevented or suppressed. Furthermore, even when a reaction product is adhered to the face surface, the coagulation of this product on the face surface can be prevented.

Owner:CANON KK

Metal plate molded article, noise-reduction brake disc using the same, and manufacturing method of metal plate molded article

InactiveUS20180094680A1Suppress prevent generationReduce vibrationNoise/vibration controlBraking discsEngineeringNoise reduction

To provide a metal plate molded article with high vibration damping functionality, a noise-reduction brake disc using the same, and a manufacturing method of a metal plate molded article.A brake disc 20 is composed of a metal plate molded article including an inner member 31 composed of a metal plate and an outer member 32 composed of a metal plate and fitted onto the inner member 31, wherein a friction damping surface 30 is formed in press-contact with fitted surfaces of the inner member 31 and the outer member 32. The brake disc 20 includes a hub part 22 with a plurality of attachment holes 29 into which attachment bolts to a wheel are inserted, and an annular sliding part 21 with a sliding surface 21a with which a brake pad BP is brought into press-contact. The friction damping surface 30 is provided to surround the attachment holes 29 individually or collectively. The inner member 31 and the outer member 32 are formed inside and outside the friction damping surface 30.

Owner:SUNSTAR SINGAPORE

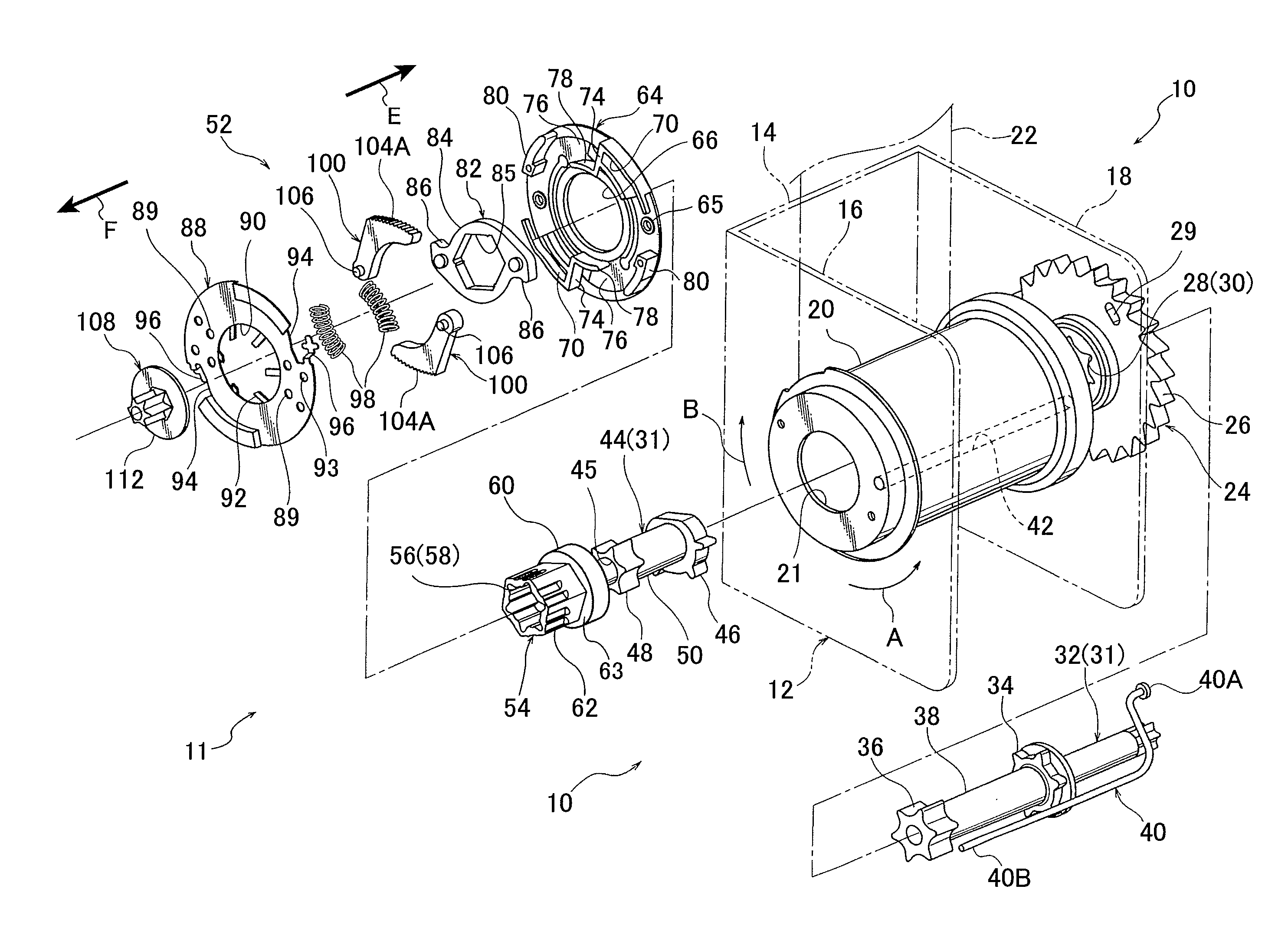

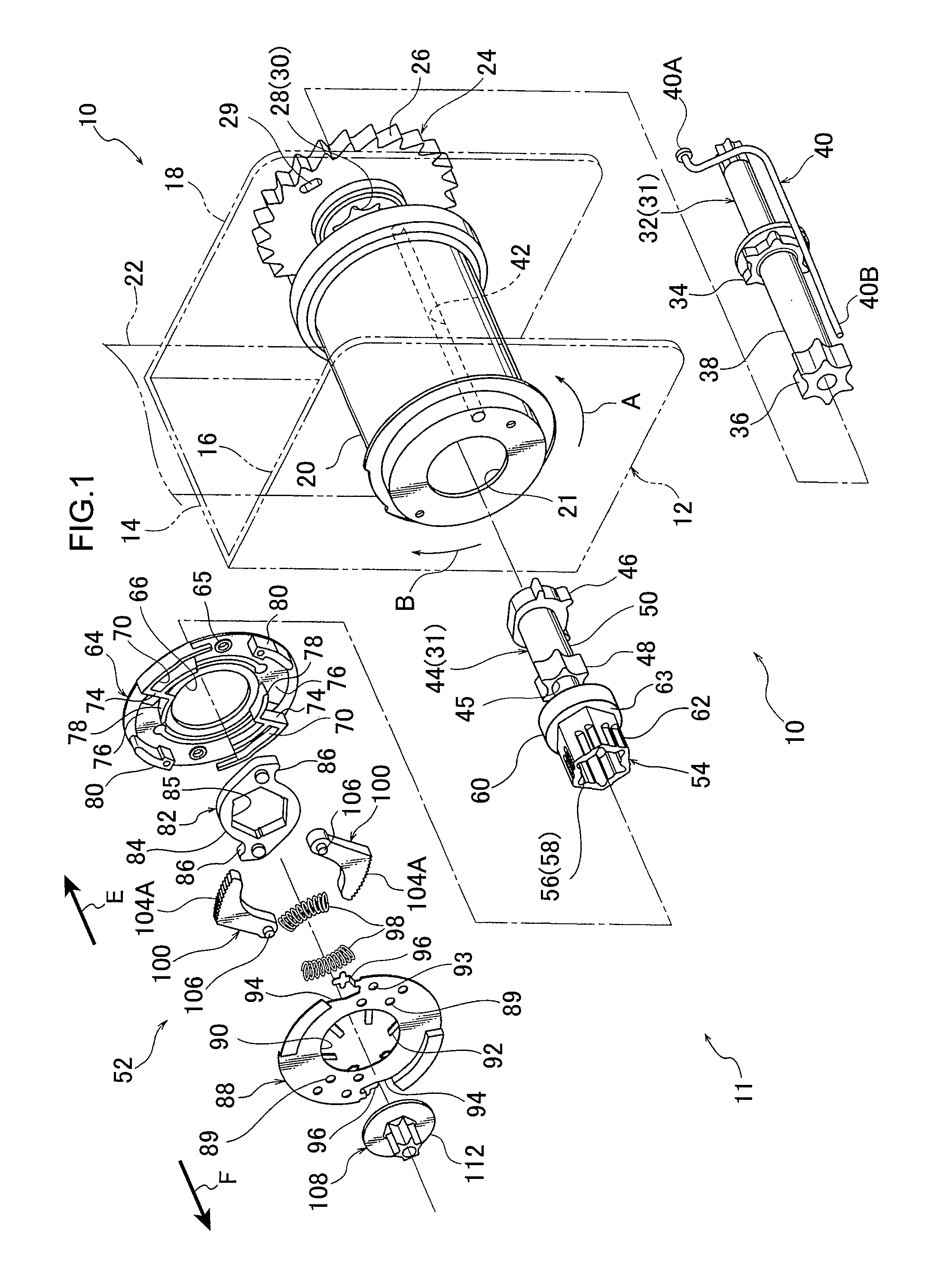

Webbing retractor

In a webbing retractor, a press insertion portion of a sleeve provided to a webbing take-up shaft is press-inserted into a press insertion hole of a clutch base. Ribs are provided to an inner peripheral face of the press insertion hole, thereby enabling rattling between the sleeve and the clutch base to be suppressed. An end face of each rib on the opposite side to the press insertion direction of the press insertion portion is configured with a sloping faces that slopes along the press insertion direction, and so the sloping face makes sliding contact with the press insertion portion when the press insertion portion is being press-inserted into the press insertion hole. Burrs due to the press insertion portion being cut by the ribs can accordingly be prevented or suppressed from generating.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Humor sampling implement and method of humor sampling

InactiveUS20060212021A1Sample humor more securely and speedilyImprove efficiencyMedical devicesSensorsBlood inflowGlucose polymers

A humor sampling implement includes a detection unit having a main frame part possessing a blood transfer channel to collect blood through a blood inflow port and transfer the blood to a blood outflow port, and a test paper for detecting glucose in the blood transferred through the blood transfer channel. The main frame part is furnished with a projection protruding in the blood transfer channel toward the blood outflow port. The blood transfer channel can be configured to include a first blood transfer channel opening to the blood inflow port and a second blood transfer channel connected to the first blood transfer channel, wherein the direction of blood transfer is different from that in the first blood transfer channel, and the projection is provided at an end portion of the first blood transfer channel on blood outflow port side so as to protrude in the second blood transfer channel.

Owner:TERUMO KK

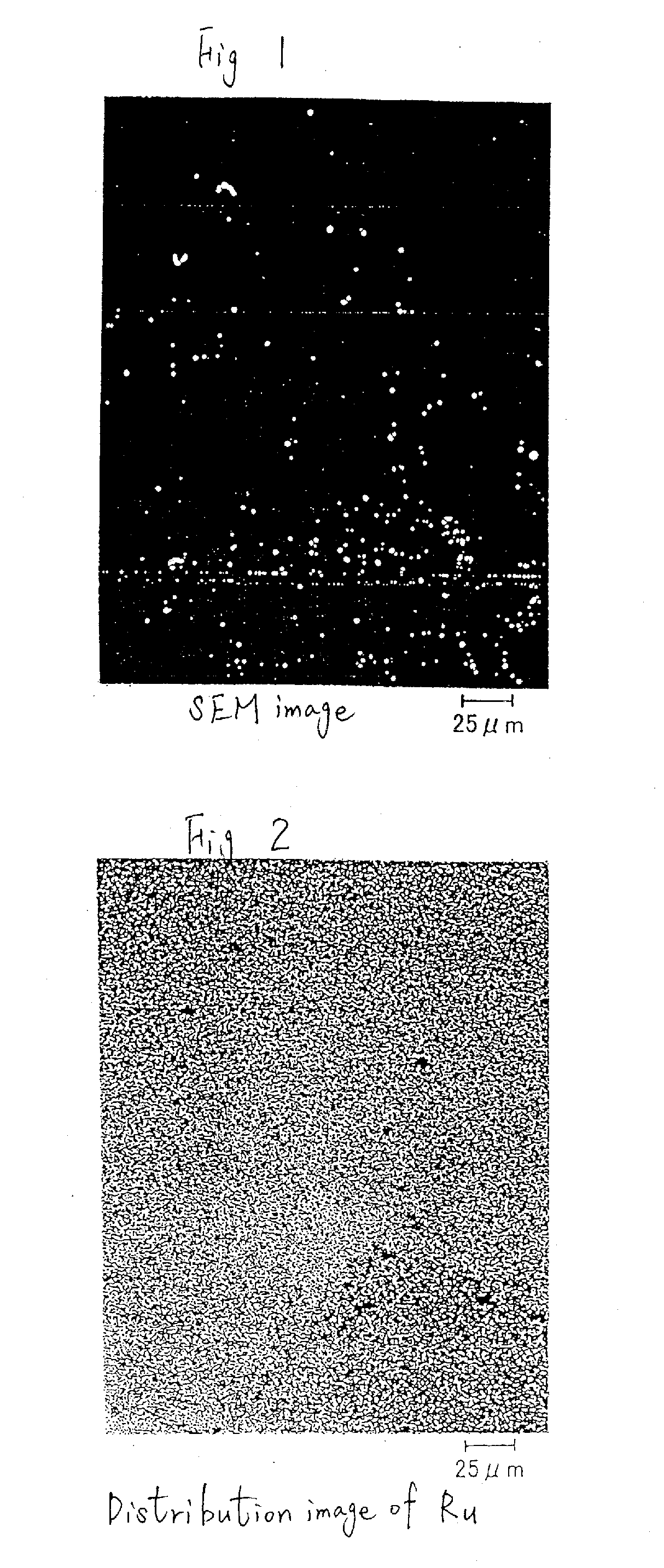

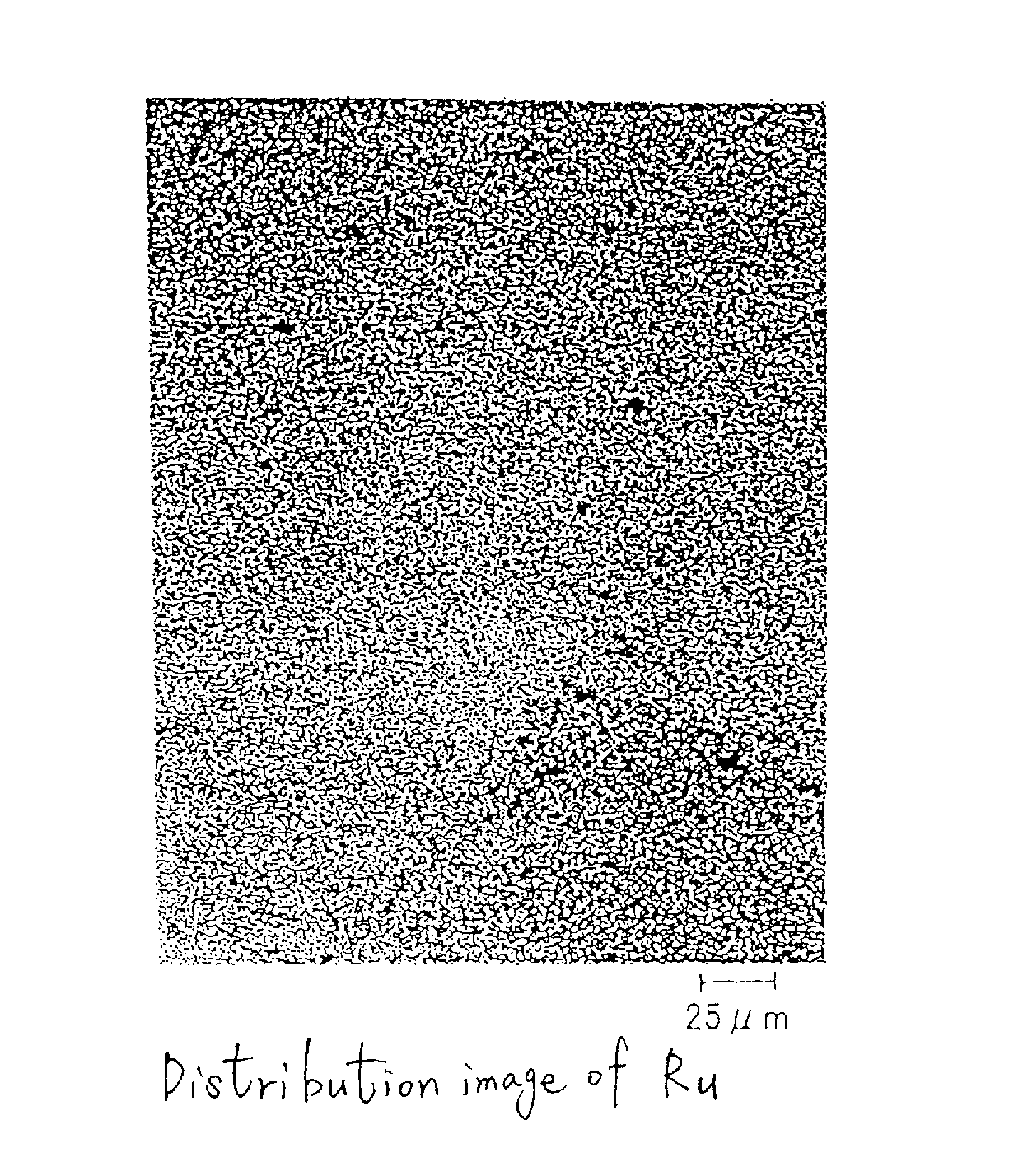

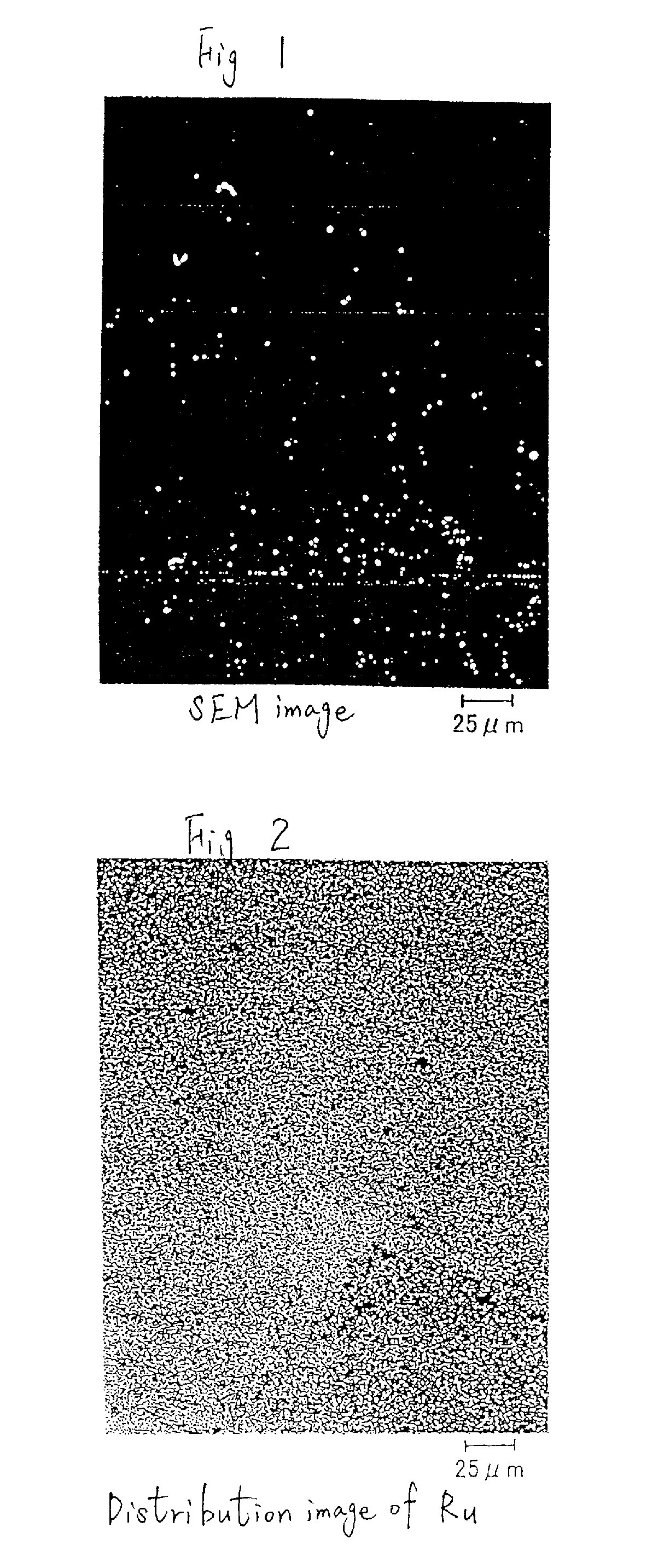

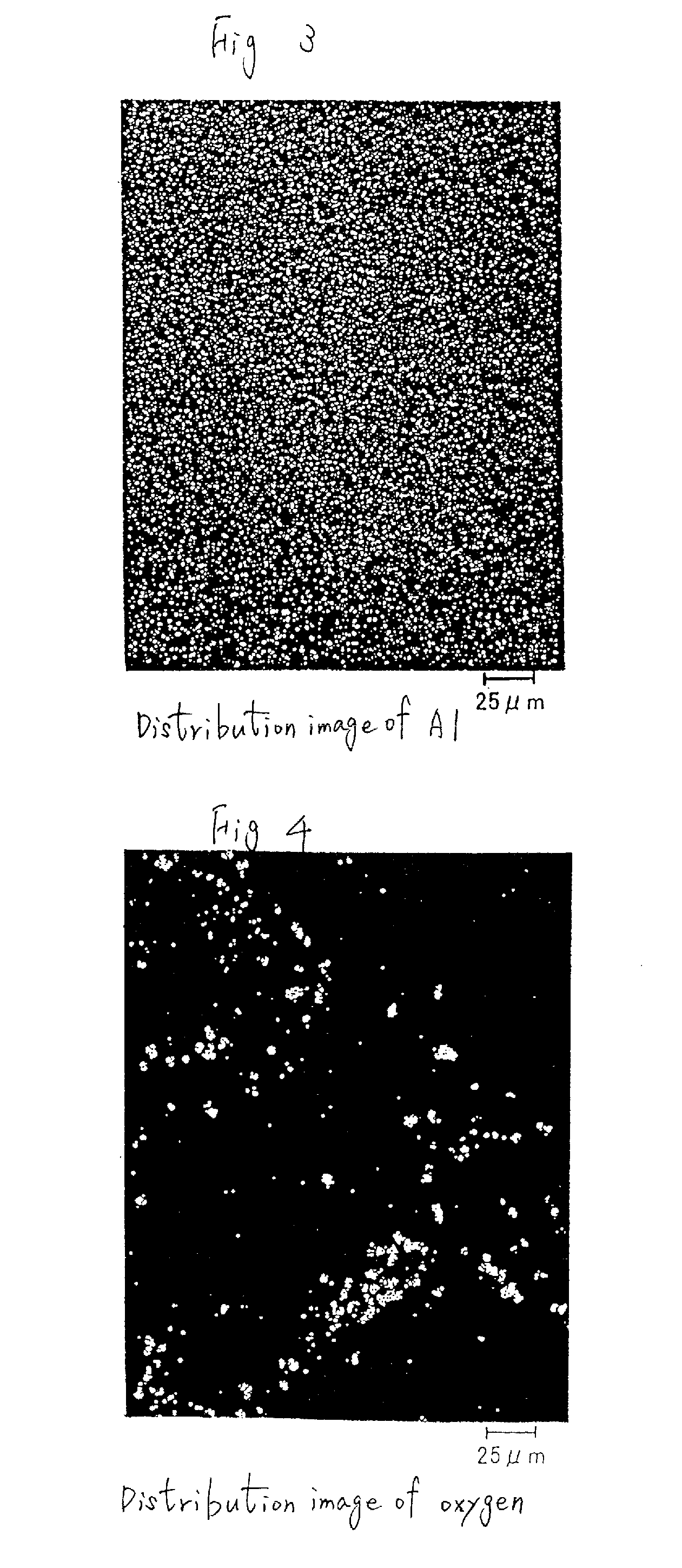

AlRu Sputtering Target and Manufacturing Method thereof

InactiveUS20070175753A1Stable and low-cost manufactureReduce oxygenCellsVacuum evaporation coatingYield ratioOxygen

An AlRu sputtering target that is a sintered body composed of an AlRu intermetallic compound of 95 vol.% or more is provided. It is manufactured by a stable and low-cost method that provides it with an even texture, significantly reduces oxygen, prevents or suppresses the generation of particles, and improves the yield ratio of deposition goods.

Owner:JX NIPPON MINING & METALS CO LTD

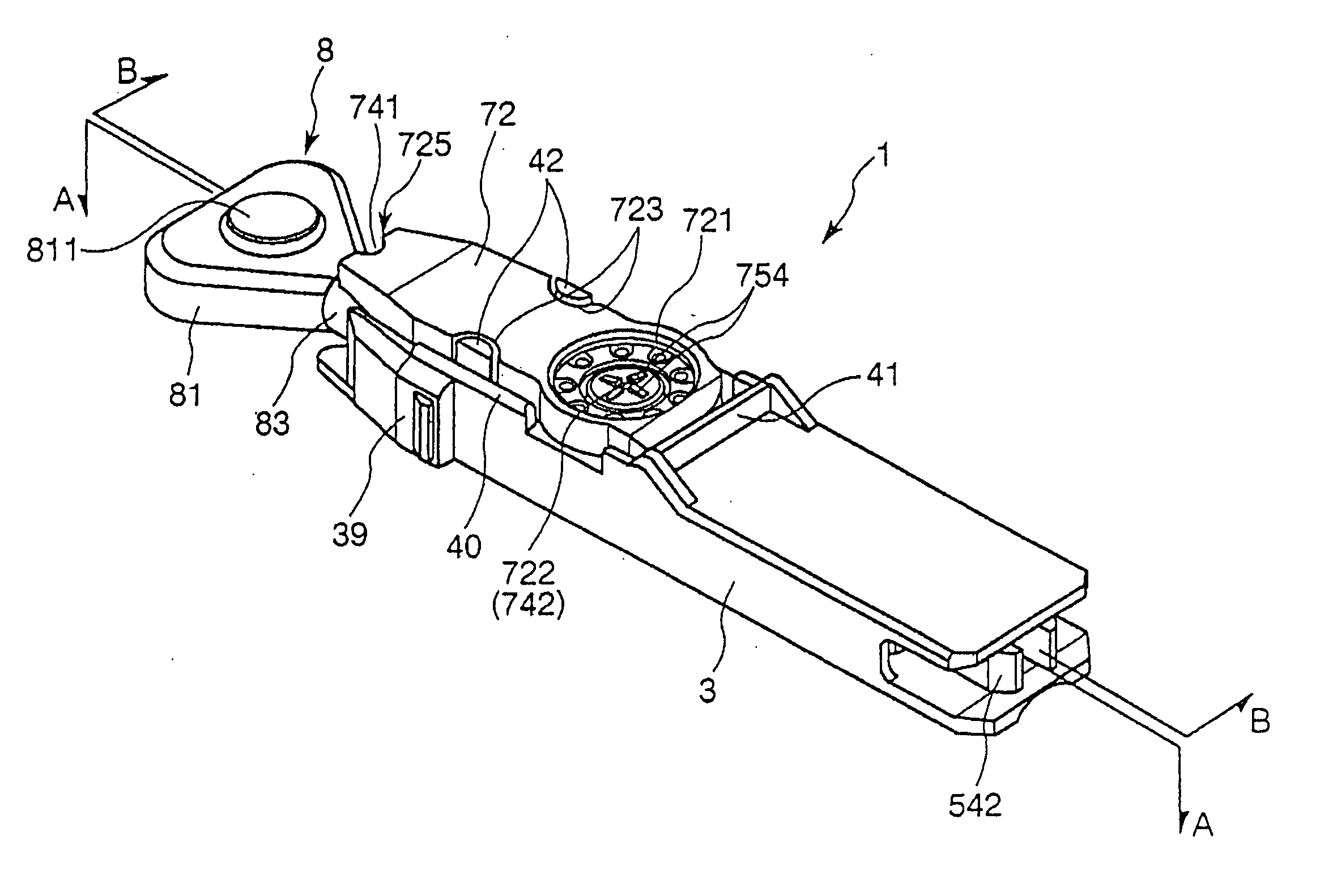

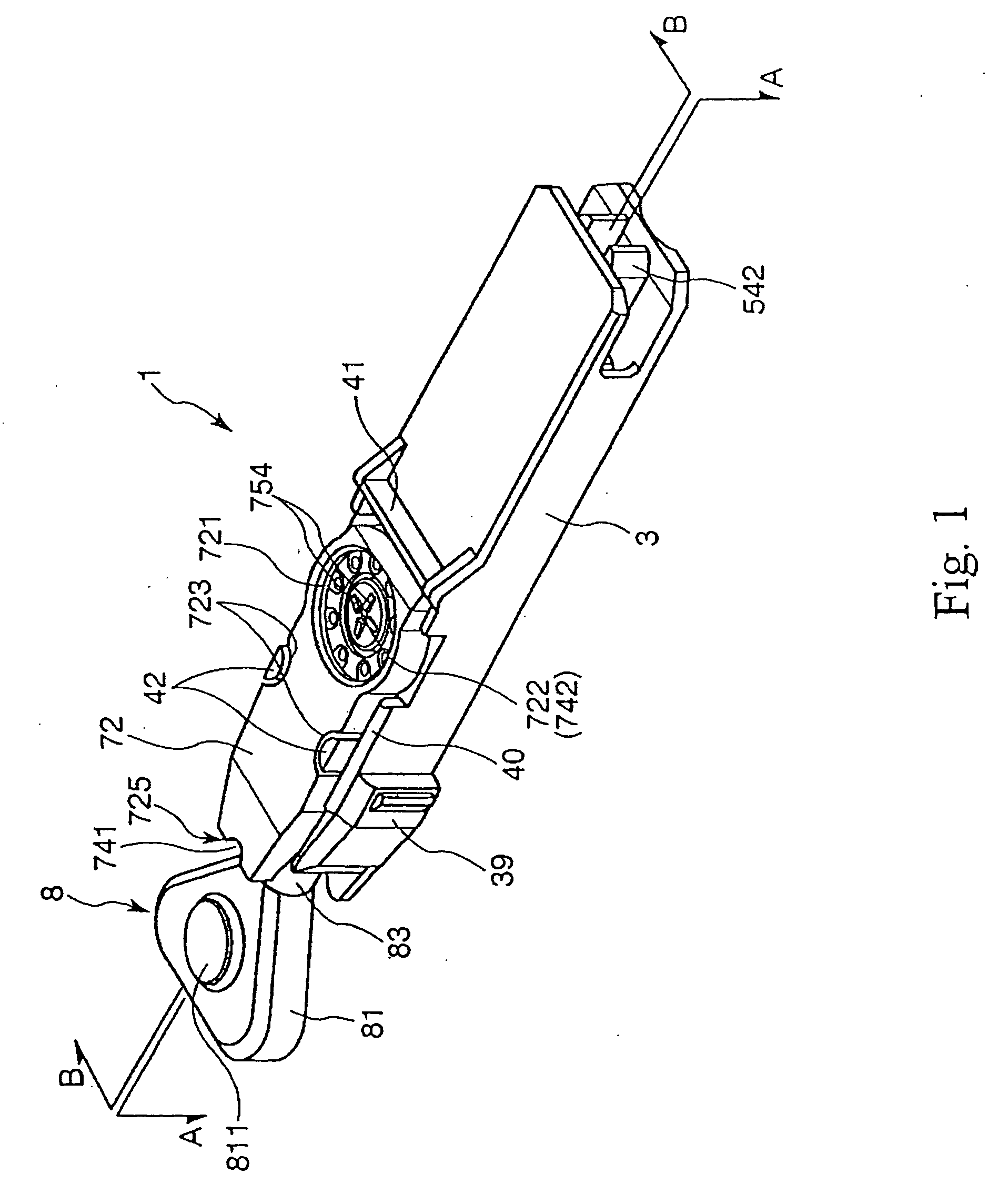

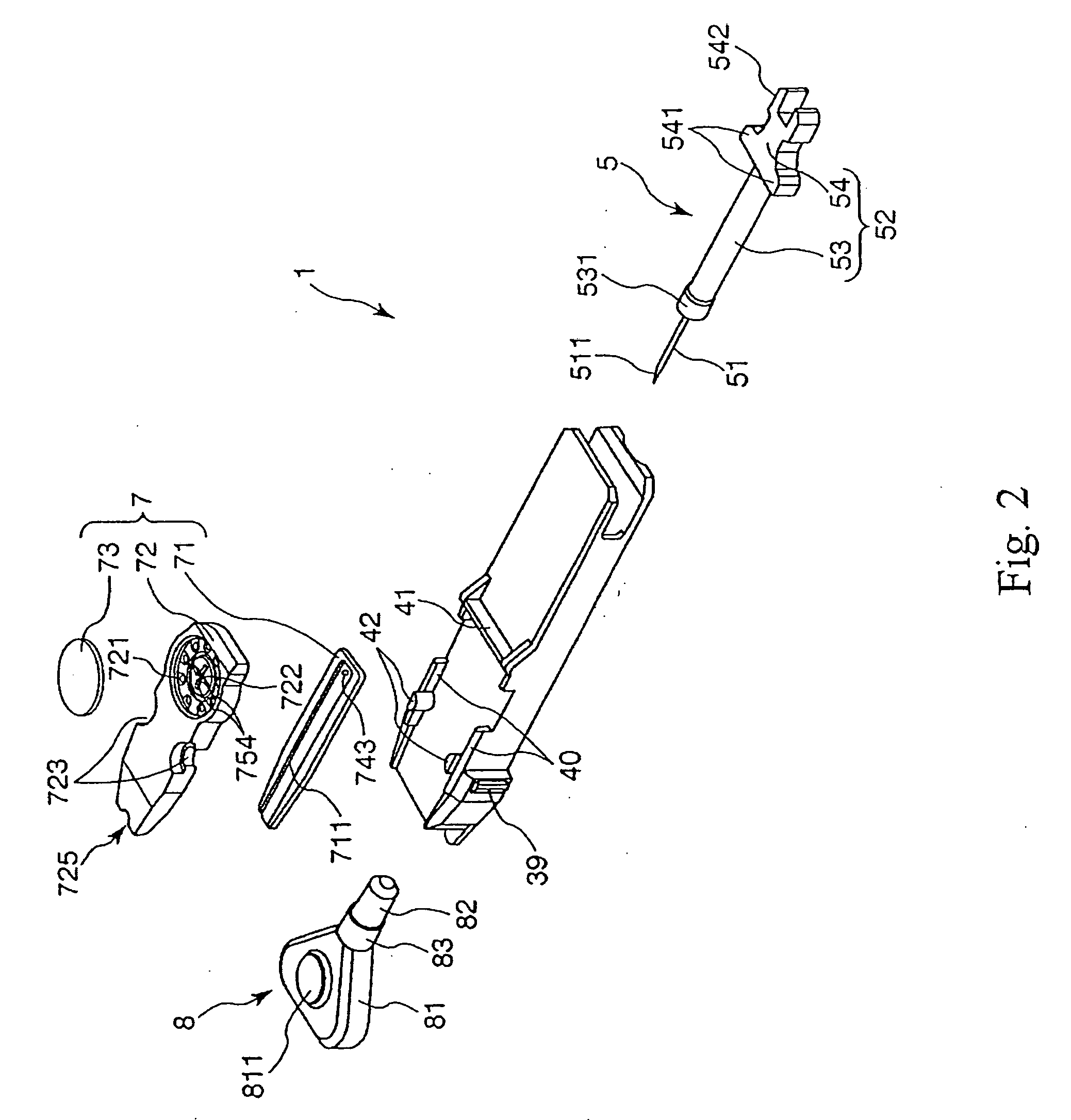

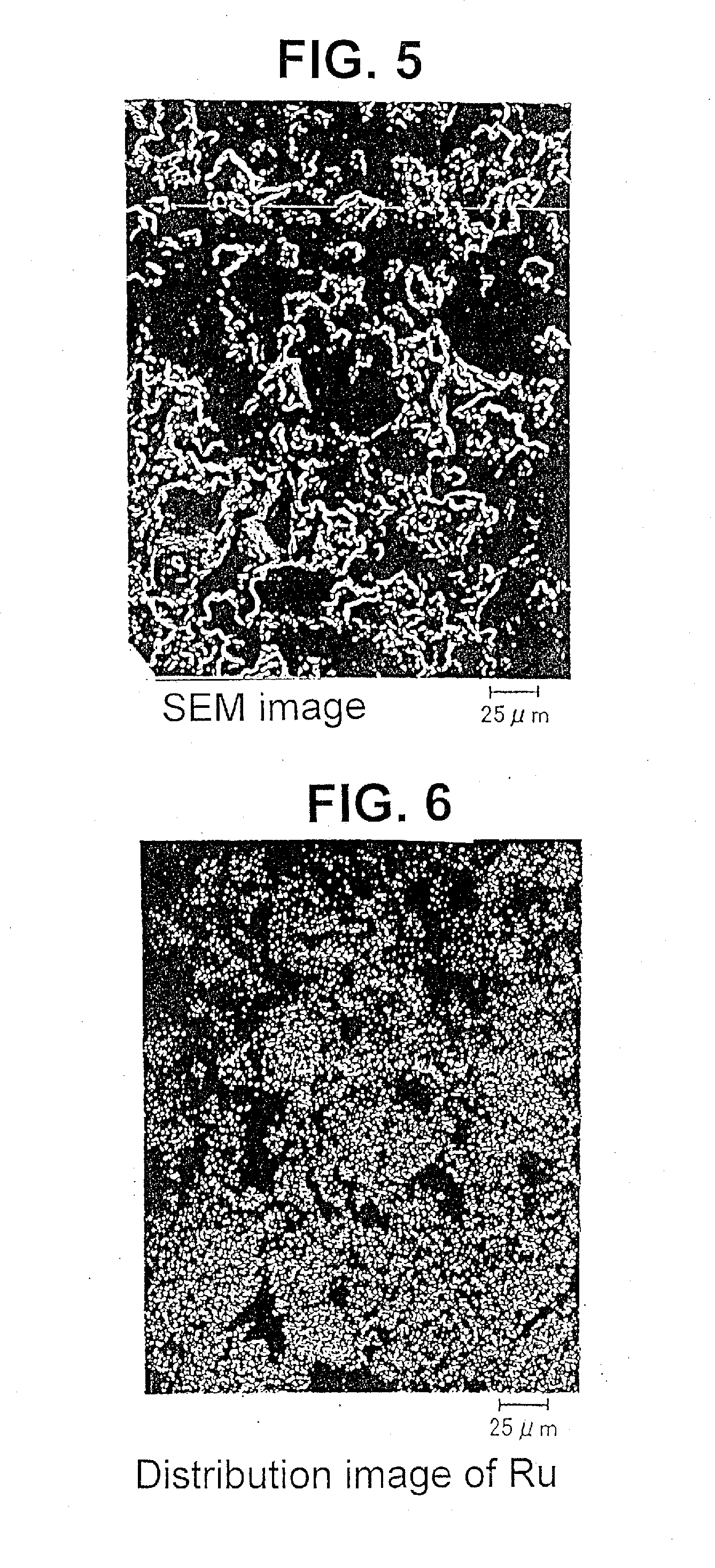

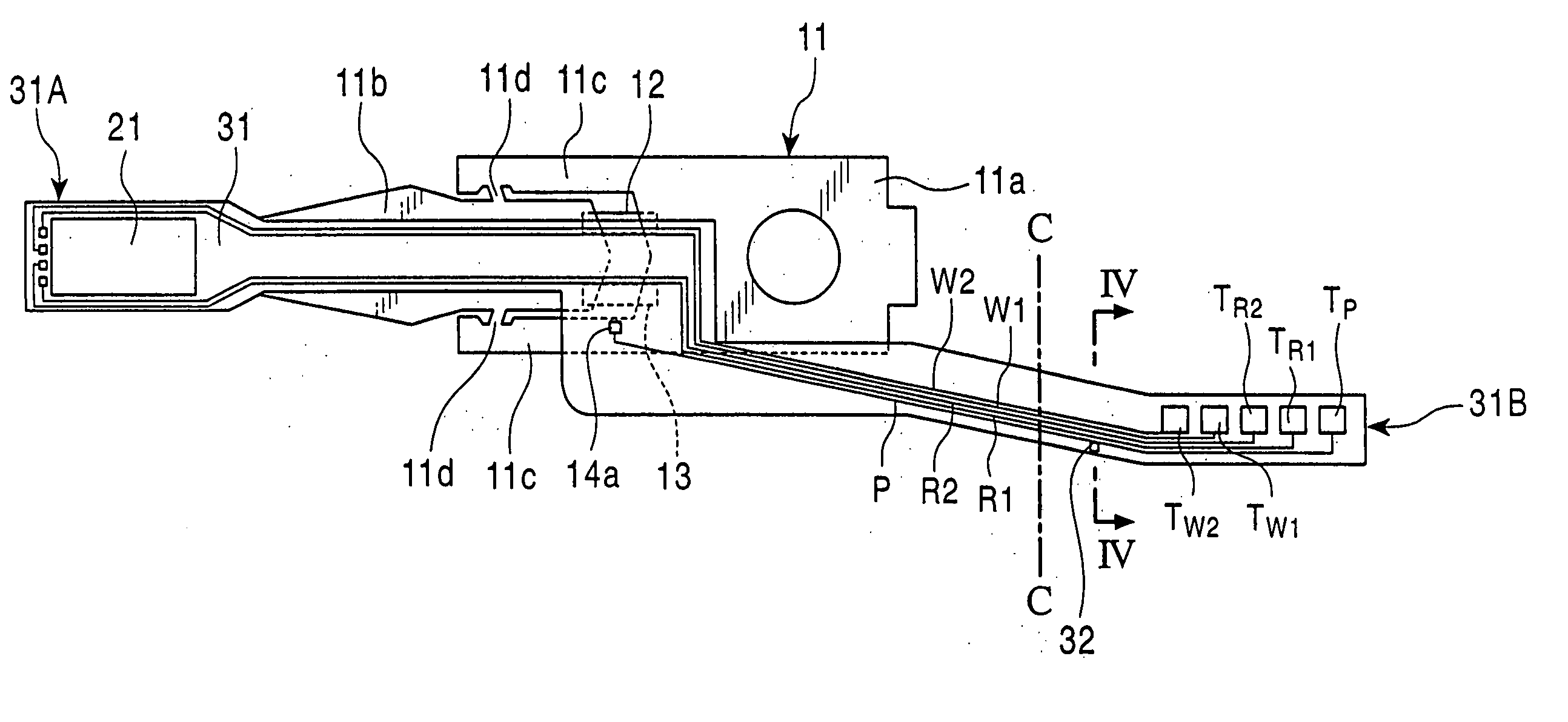

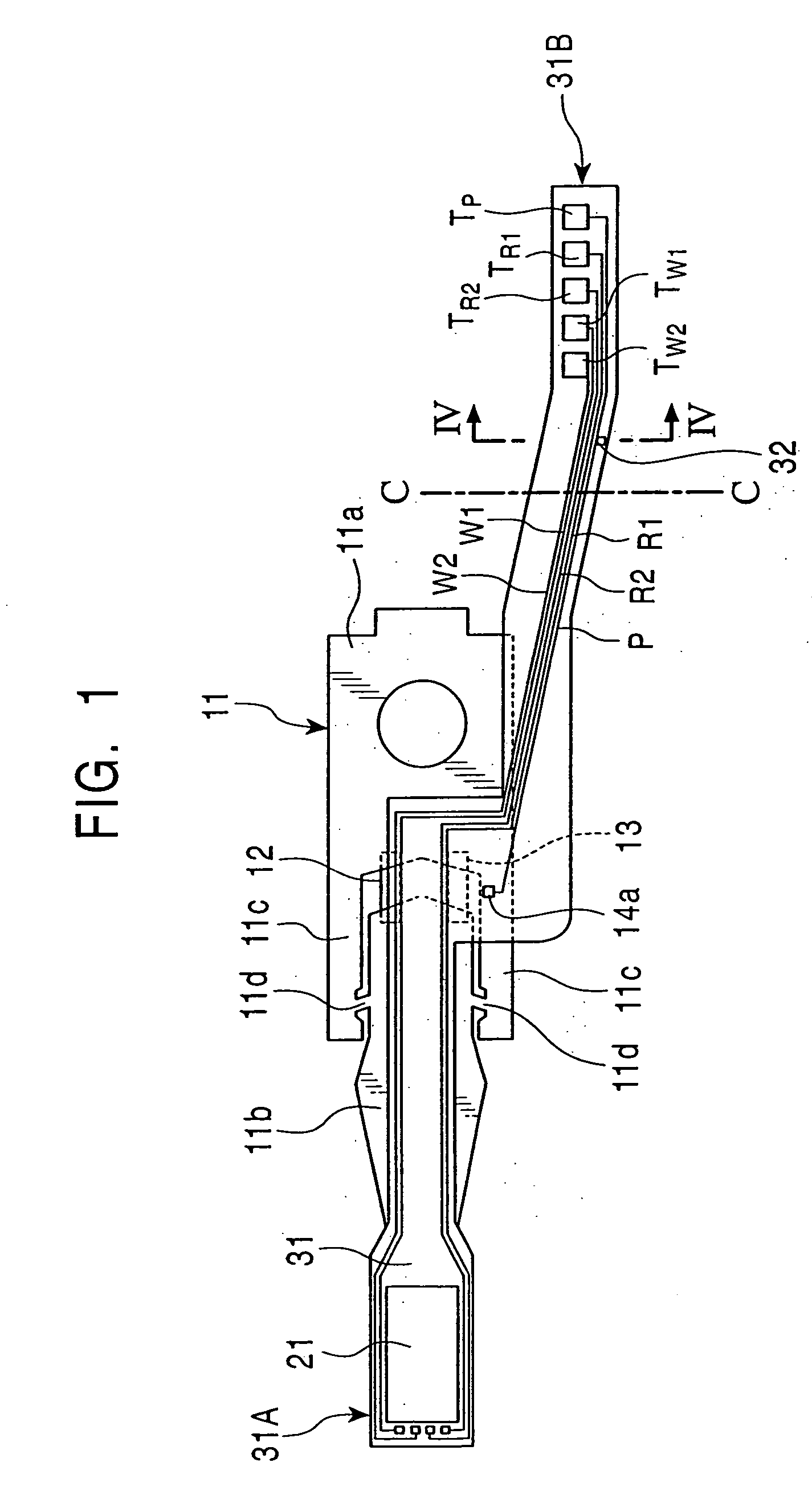

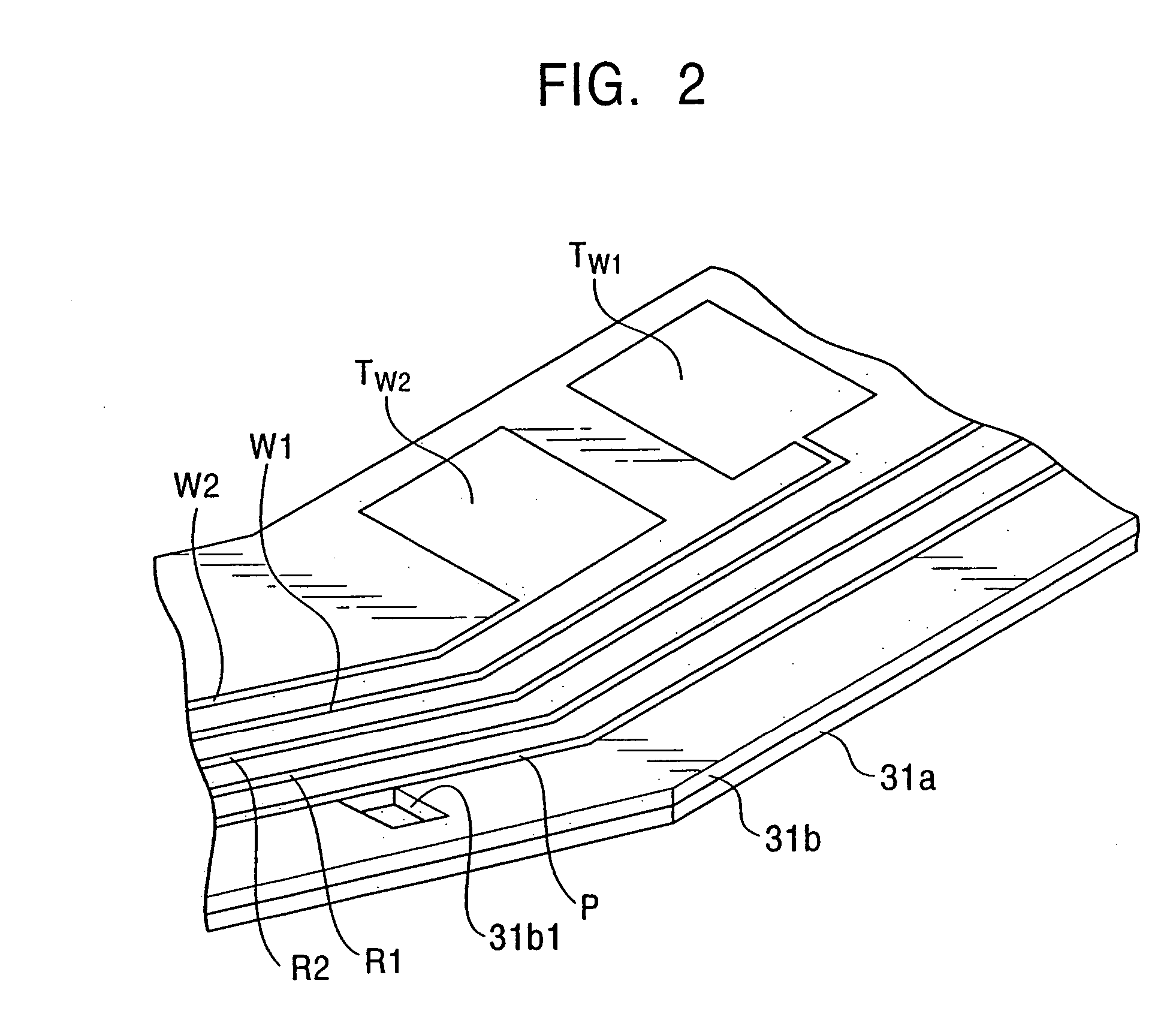

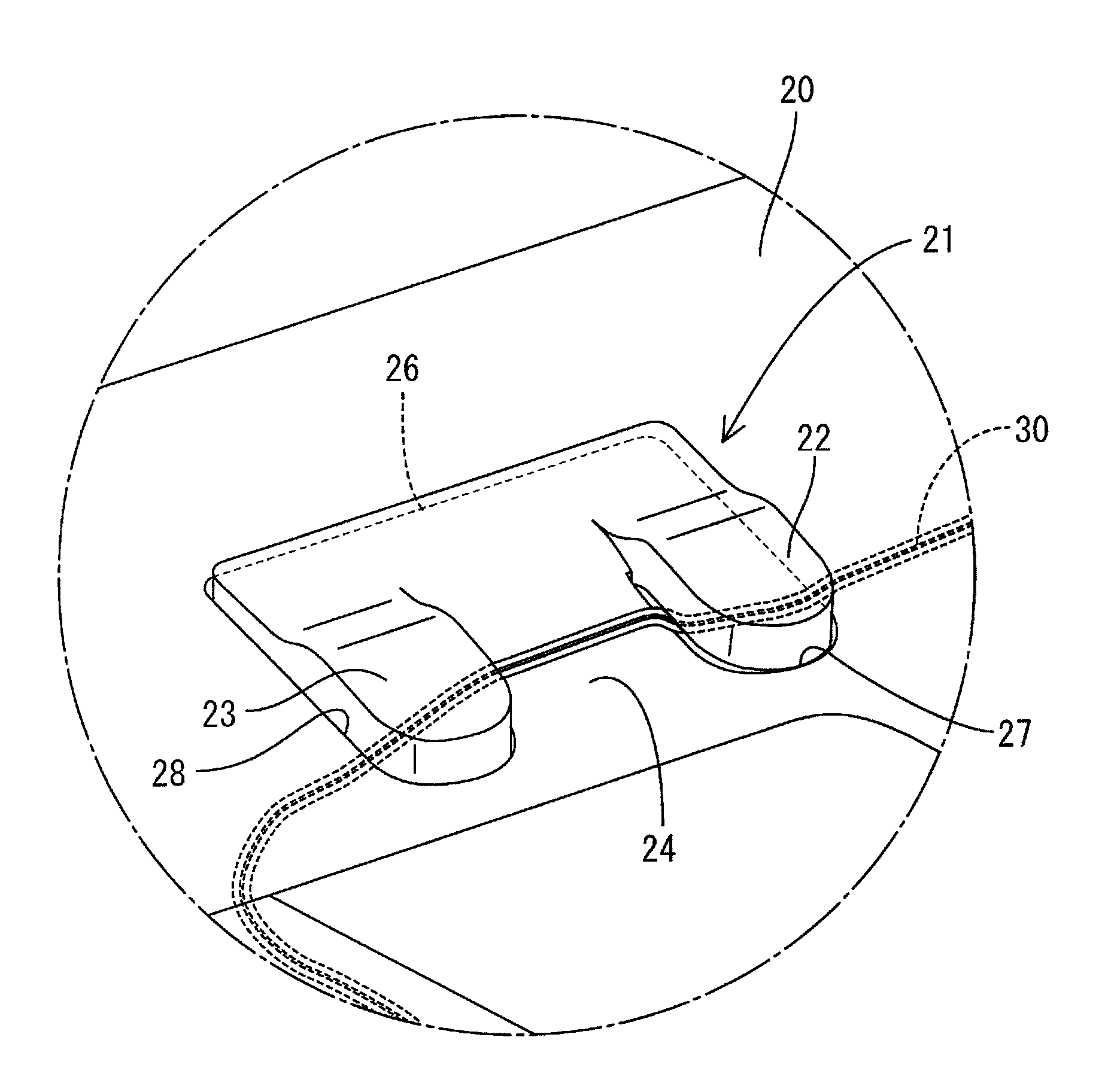

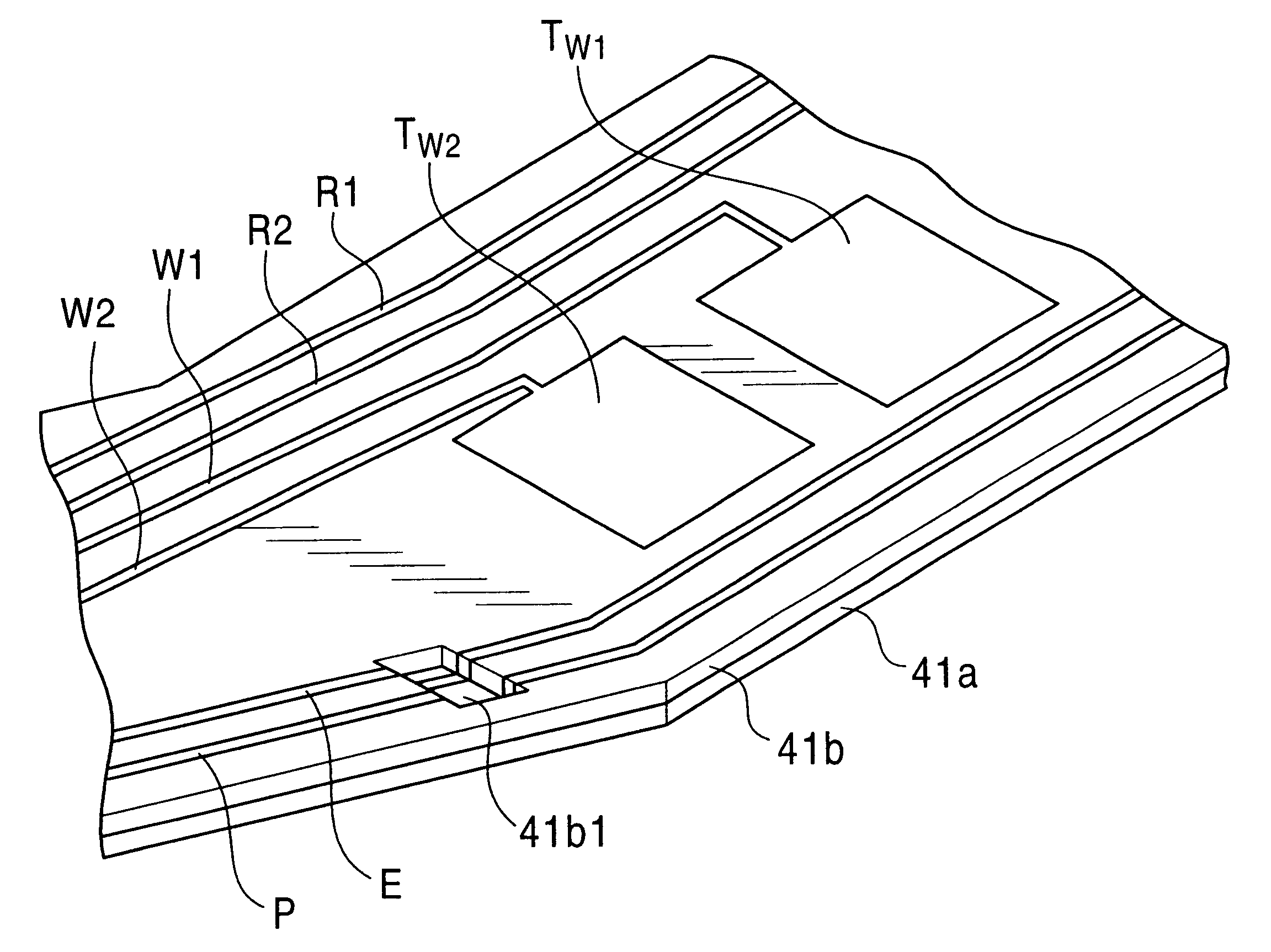

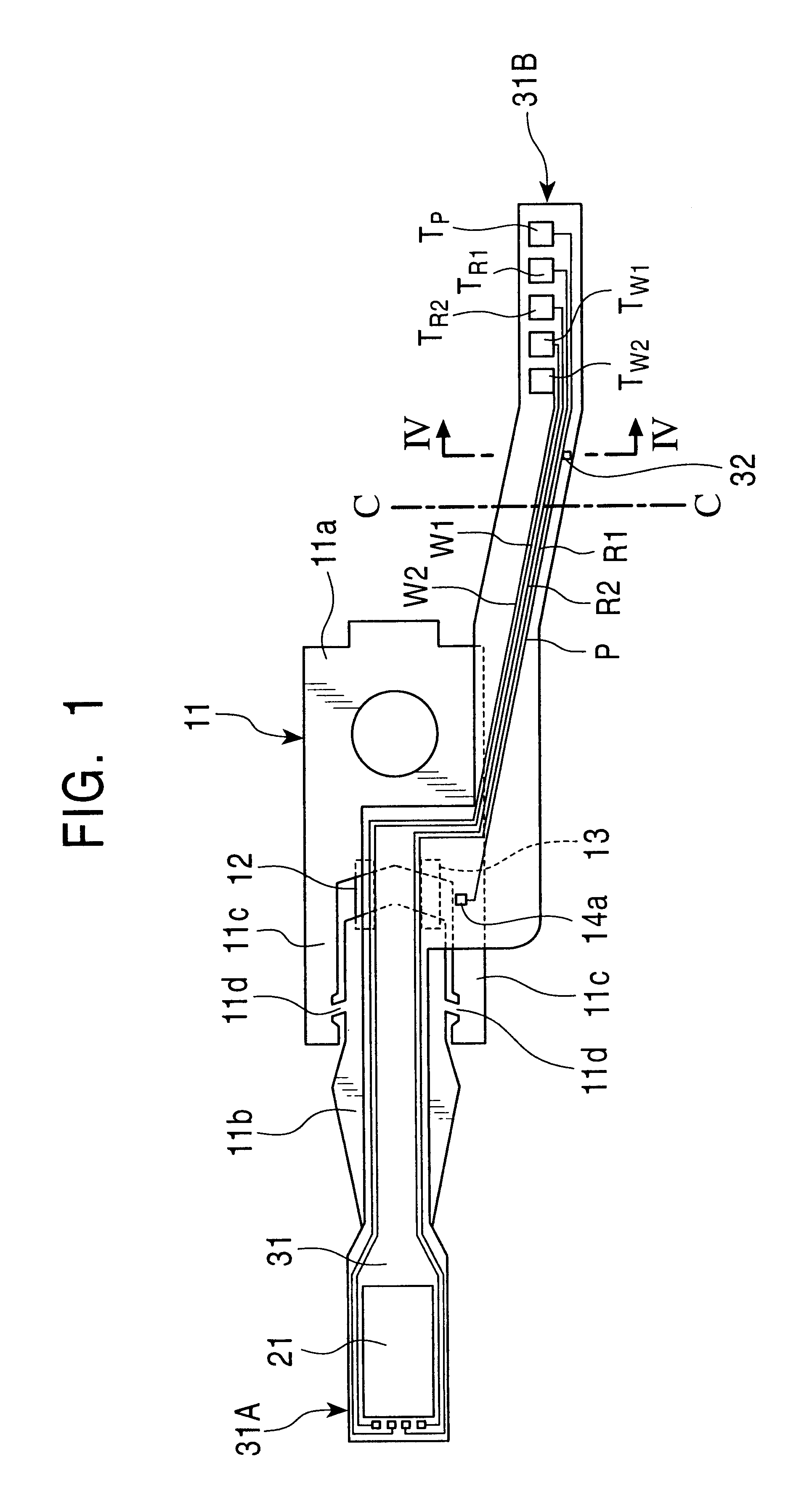

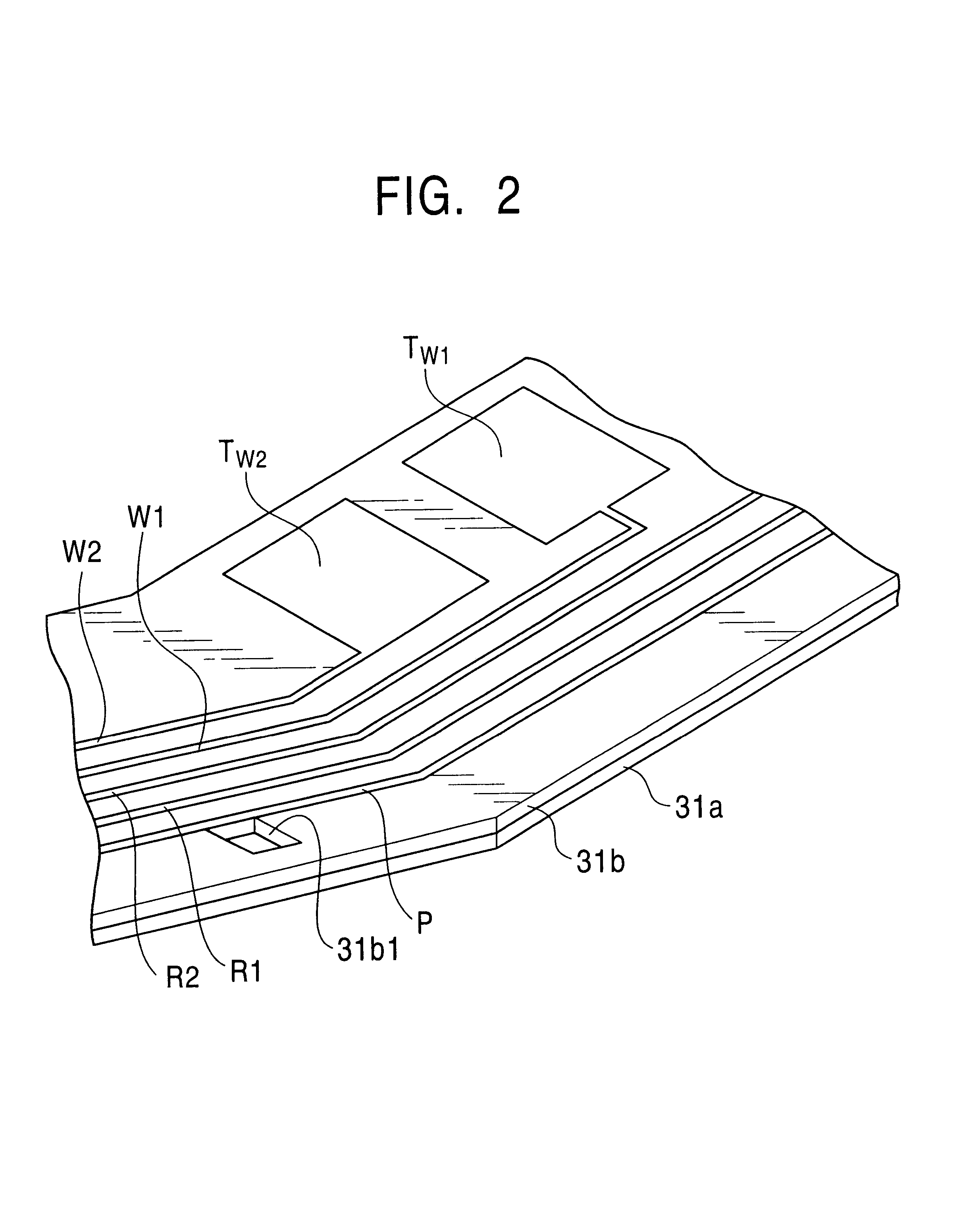

Magnetic-head apparatus with microactuator having function of short-circuiting both electrodes of epiezoelectric elements and method of manufacturing the same

InactiveUS20060039085A1Reduce harmSuppress and prevent generationElectrical connection between head and armTrack finding/aligningElectricityMegasonic cleaning

The supersonic cleaning of a magnetic head apparatus is executed while the control conductive pattern and the conductive leaf spring are electrically connected by means of soldering, and the conductive leaf spring is grounded. This makes it possible to prevent the accumulation of electrostatic charges in the piezoelectric elements on the magnetic head apparatus, thereby preventing the development of surge current or reducing the intensity thereof, and reducing the damage to the reproducing elements and the recording element mounted on the slider of the magnetic head apparatus.

Owner:TDK CORPARATION

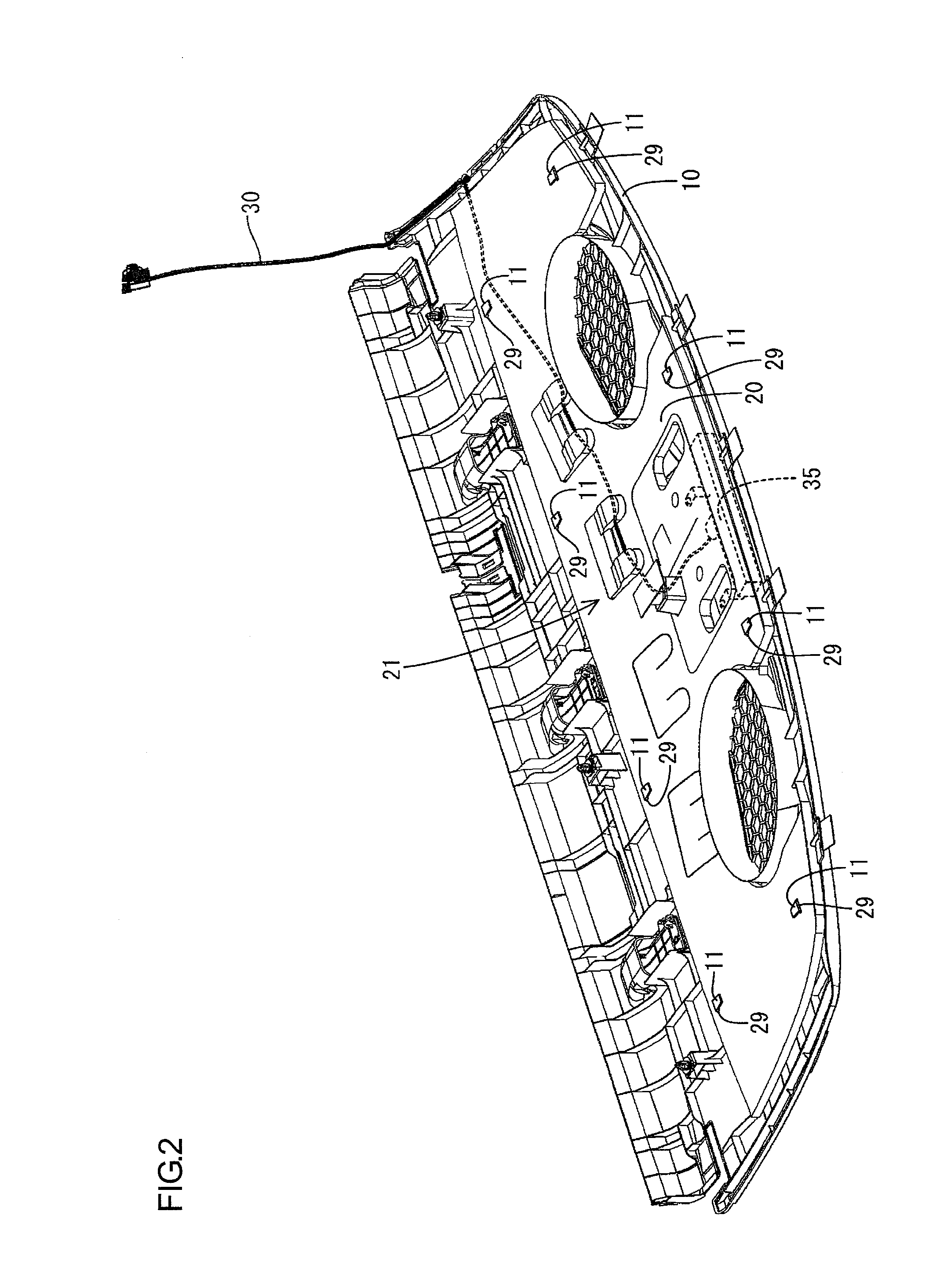

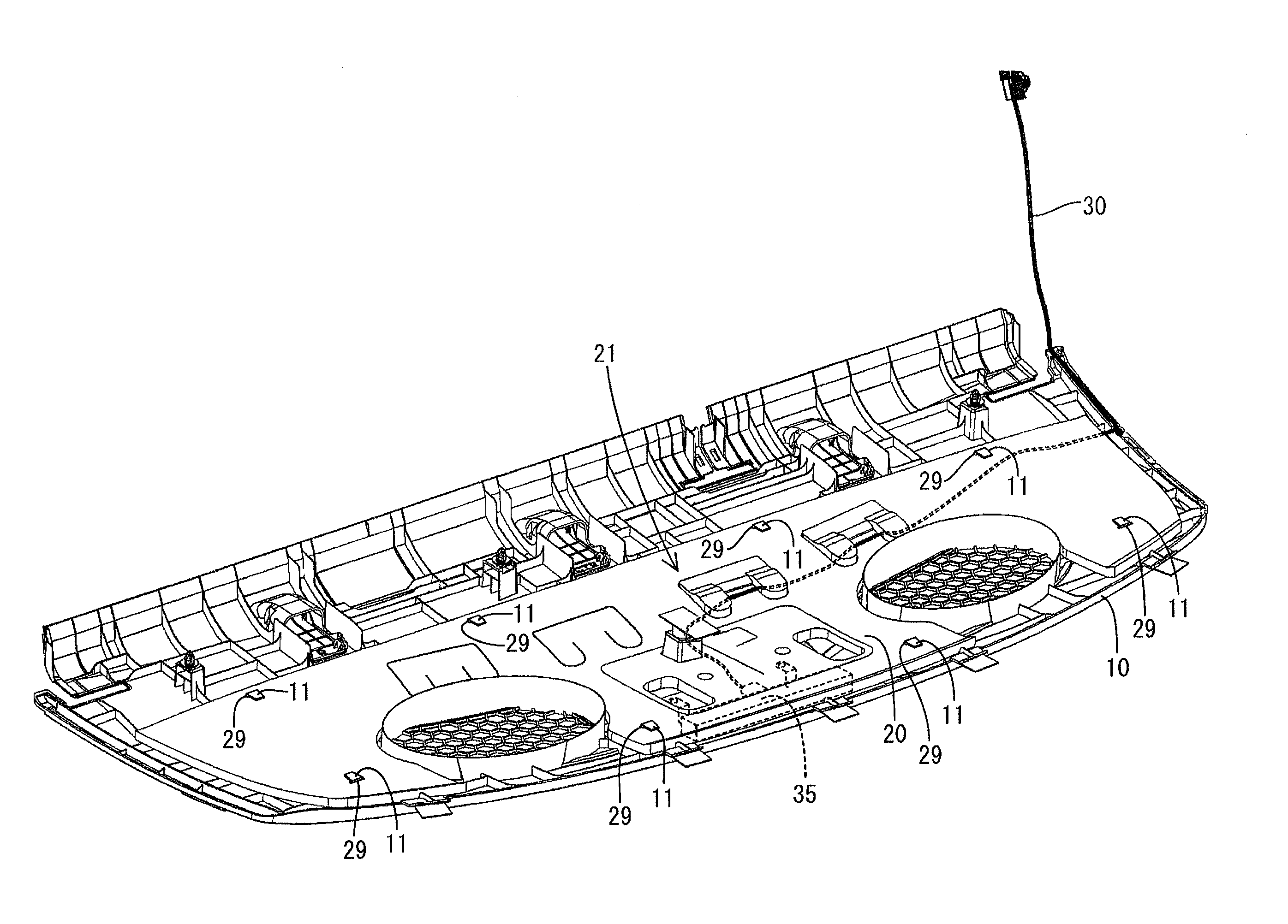

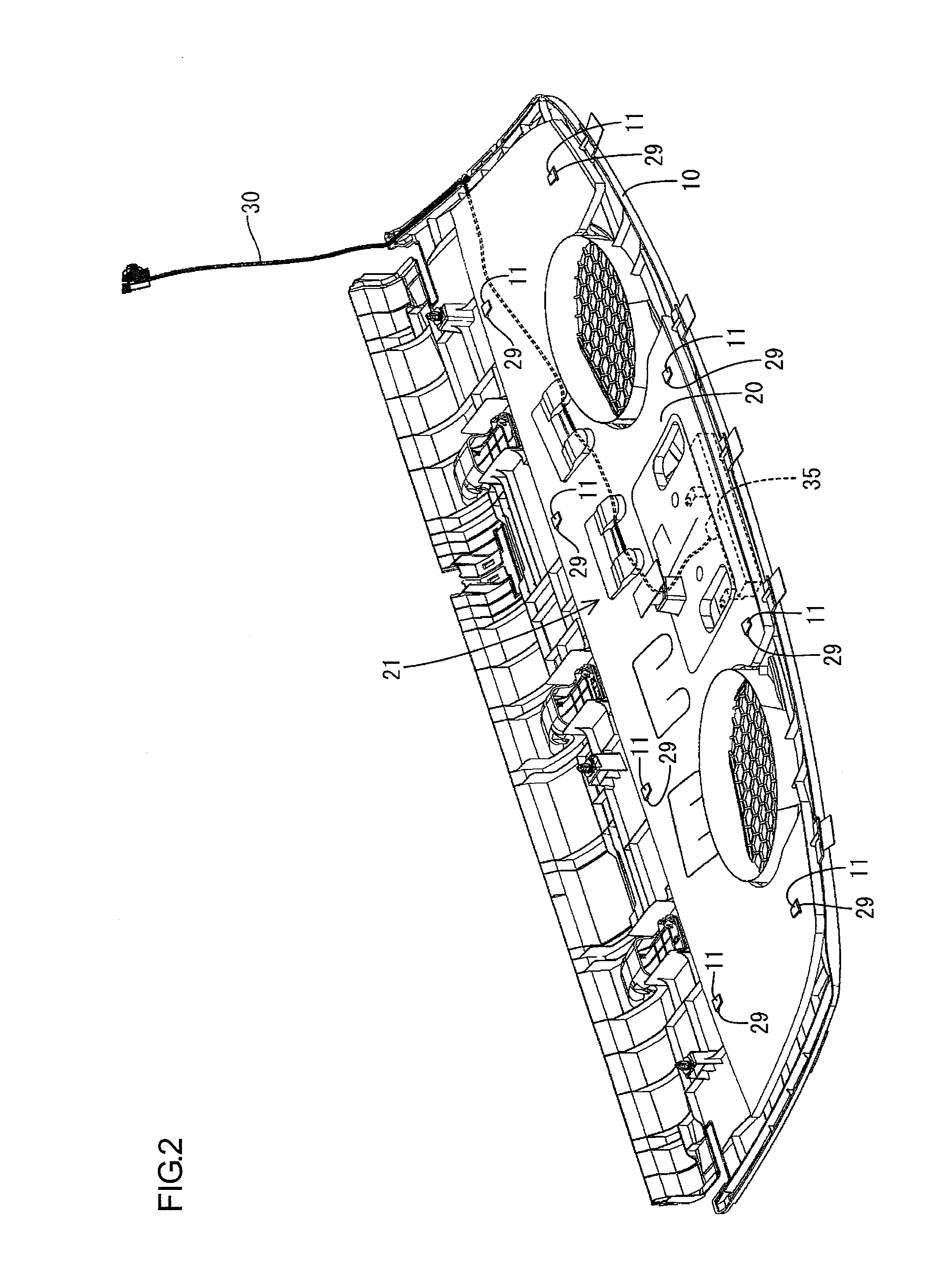

Fixing structure of wire harness

ActiveUS8123178B2Avoid it happening againSuppress and prevent generationInsulated cablesFurniture partsEngineeringMechanical engineering

Owner:TOYOTA BOSHOKU KK

Magnetic head apparatus with microactuator having function of short-circuiting both electrodes of epiezoelectric elements and method of manufacturing the same

InactiveUS6987649B2Avoid Static Charge BuildupReduce harmElectrical connection between head and armTrack finding/aligningElectricitySoldering

The supersonic cleaning of a magnetic head apparatus is executed while the control conductive pattern and the conductive leaf spring are electrically connected by means of soldering, and the conductive leaf spring is grounded. This makes it possible to prevent the accumulation of electrostatic charges in the piezoelectric elements on the magnetic head apparatus, thereby preventing the development of surge current or reducing the intensity thereof, and reducing the damage to the reproducing elements and the recording element mounted on the slider of the magnetic head apparatus.

Owner:TDK CORPARATION

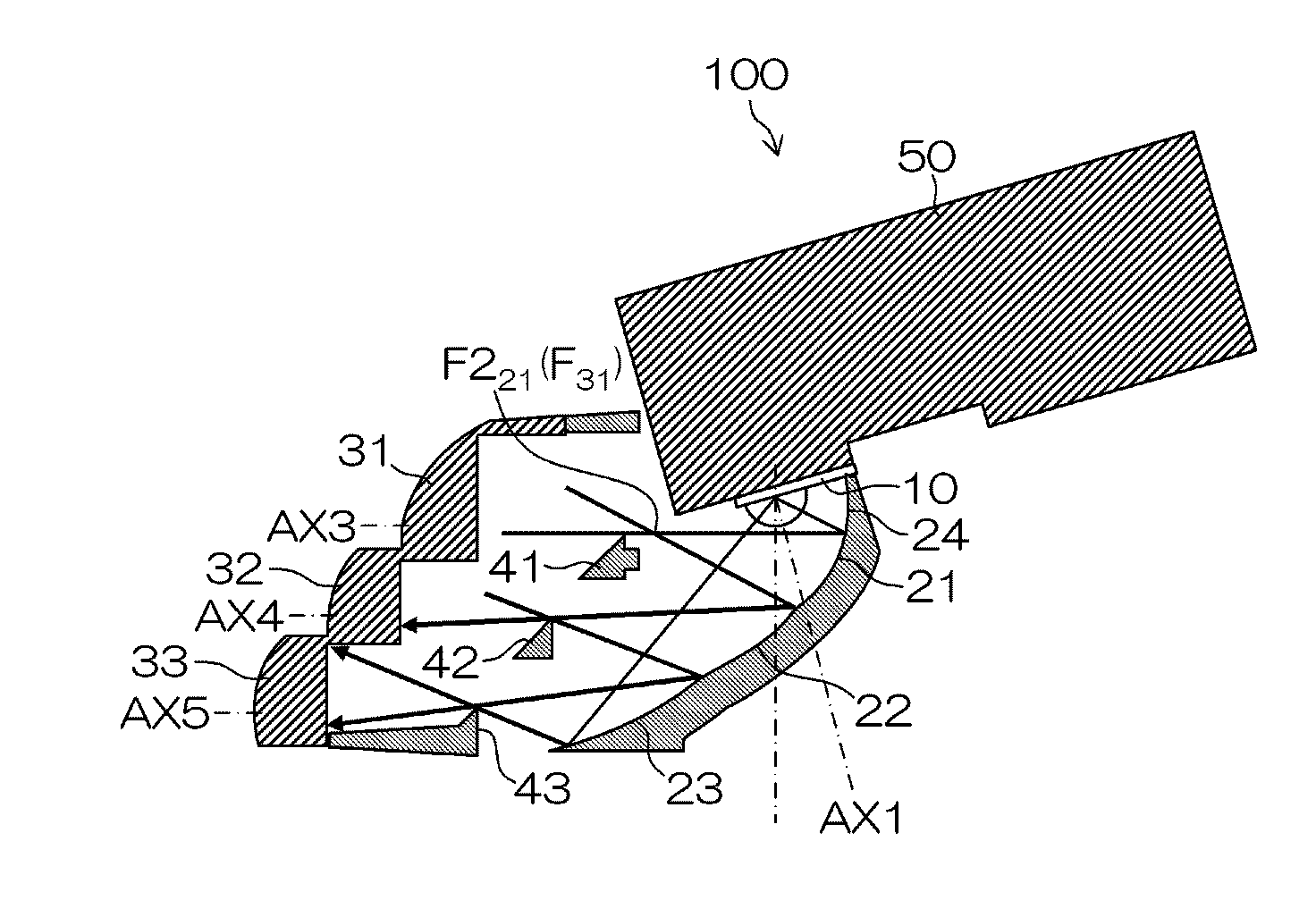

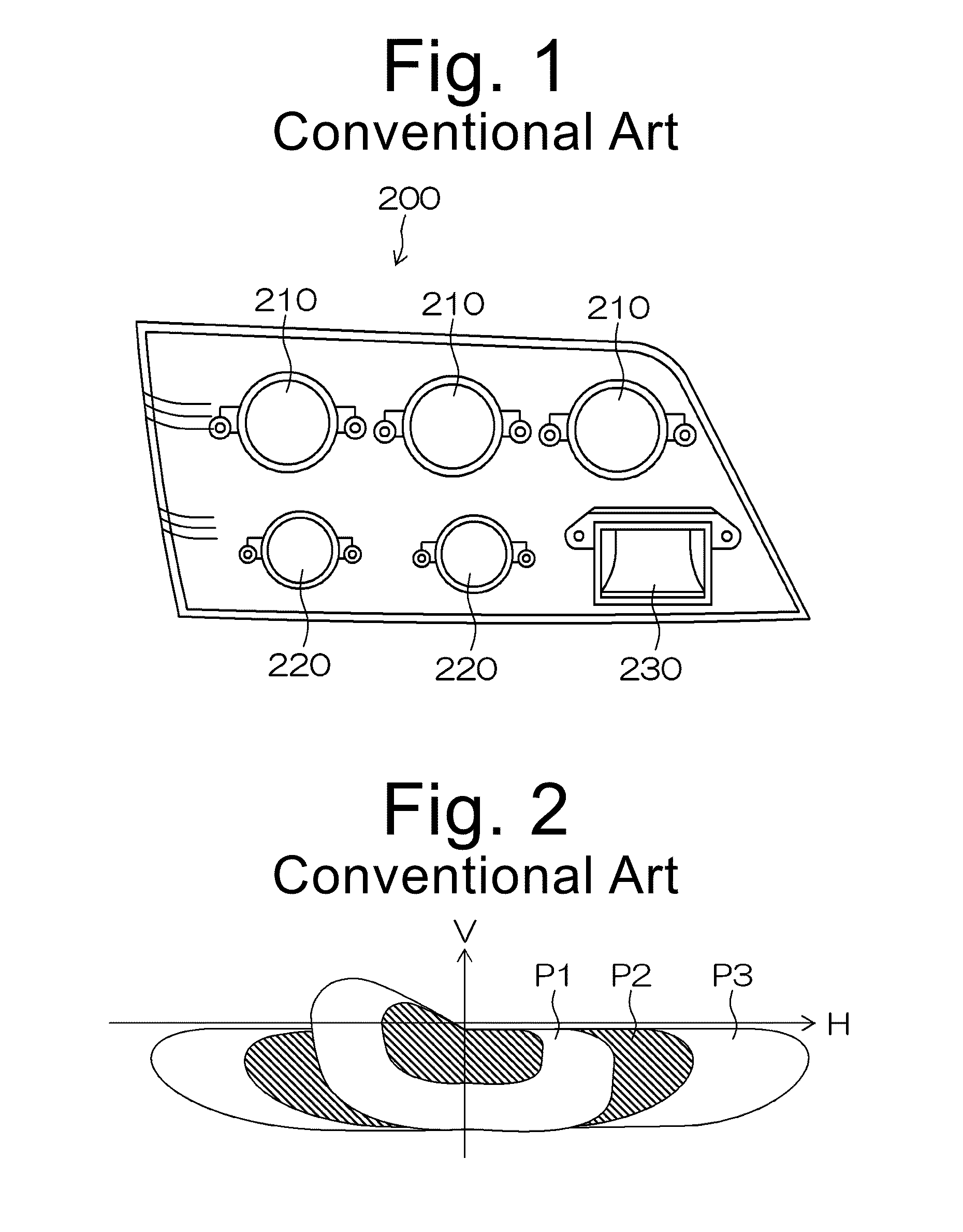

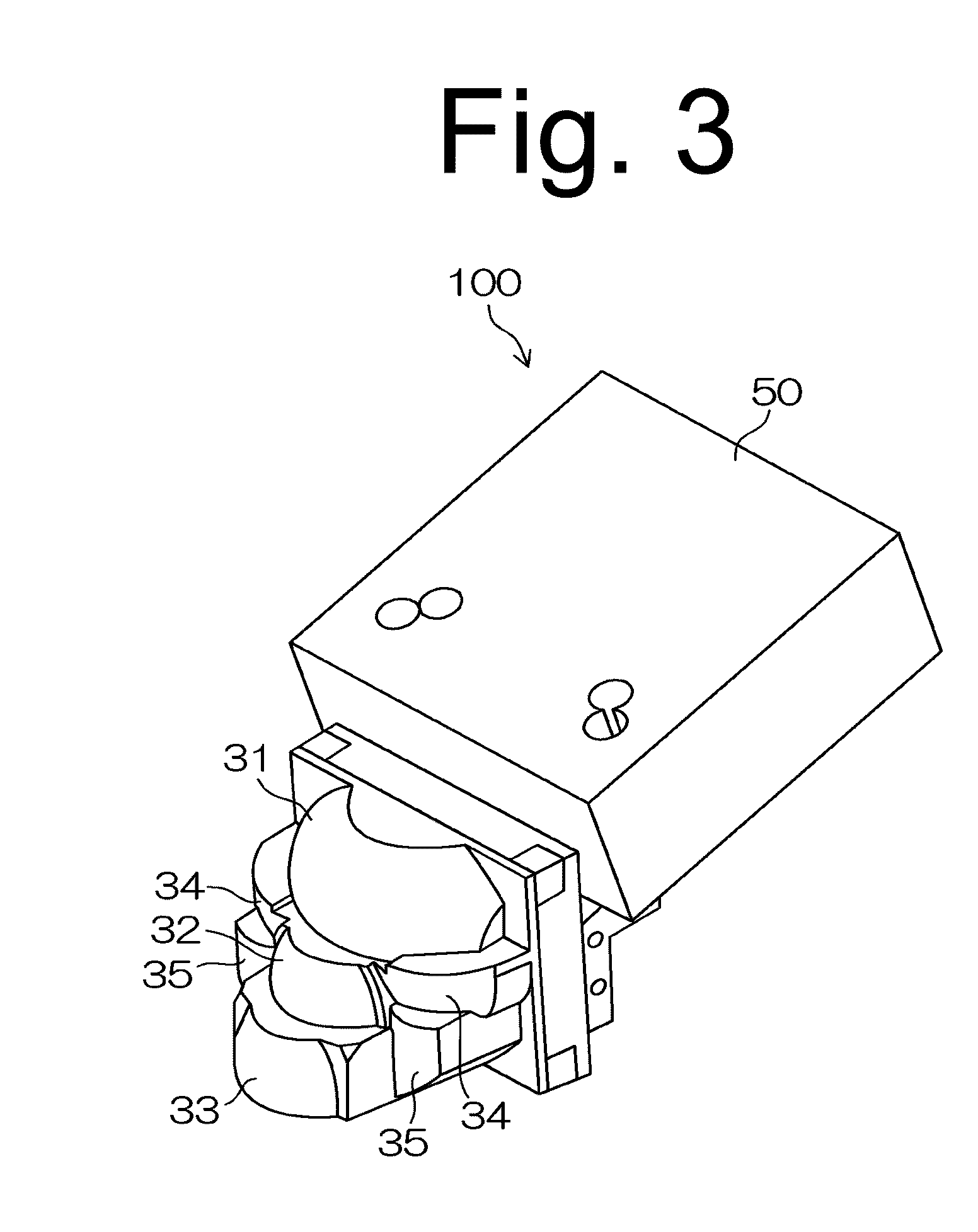

Vehicle light with LED light source

InactiveUS8517581B2Low costSuppress and prevent generationVehicle headlampsPoint-like light sourceOptical axisLight beam

Owner:STANLEY ELECTRIC CO LTD

Fixing structure of wire harness

ActiveUS20100148014A1Avoid it happening againLow costInsulated cablesFurniture partsEngineeringMechanical engineering

The present invention provides a hard-to-fall fixing structure of wire harness contributive to cost reduction in which VOC is not generated and flapping sound (noise) of wire harness is hard to occur. In the fixing structure of a wire harness to a vehicle interior material according to the present invention, a silencer pad (acoustical material) is fixed to the vehicle interior material, and the silencer pad is provided with a latching piece formed by cutting a portion of the present silencer pad, and the wire harness is latched to the latching piece.

Owner:TOYOTA BOSHOKU KK

AlRu sputtering target and manufacturing method thereof

InactiveUS7767139B2Stable and low-cost manufacturePrevent and suppress generation of particleCellsVacuum evaporation coatingOxygenYield ratio

An AlRu sputtering target that is a sintered body composed of an AlRu intermetallic compound of 95 vol. % or more is provided. It is manufactured by a stable and low-cost method that provides it with an even texture, significantly reduces oxygen, prevents or suppresses the generation of particles, and improves the yield ratio of deposition goods.

Owner:JX NIPPON MINING & METALS CORP

Sputtering target and process for producing same

ActiveUS9034154B2Improve featuresSuppress and prevent generationCellsVacuum evaporation coatingBorideTarget surface

A sputtering target with low generation of particles in which oxides, carbides, nitrides, borides, intermetallic compounds, carbonitrides, and other substances without ductility exist in a matrix phase made of a highly ductile substance at a volume ratio of 1 to 50%, wherein a highly ductile and conductive metal coating layer is formed on an outermost surface of the target. Provided are a sputtering target capable of improving the target surface in which numerous substances without ductility exist and preventing or inhibiting the generation of nodules and particles during sputtering, and a method of producing such a sputtering target.

Owner:JX NIPPON MINING & METALS CORP

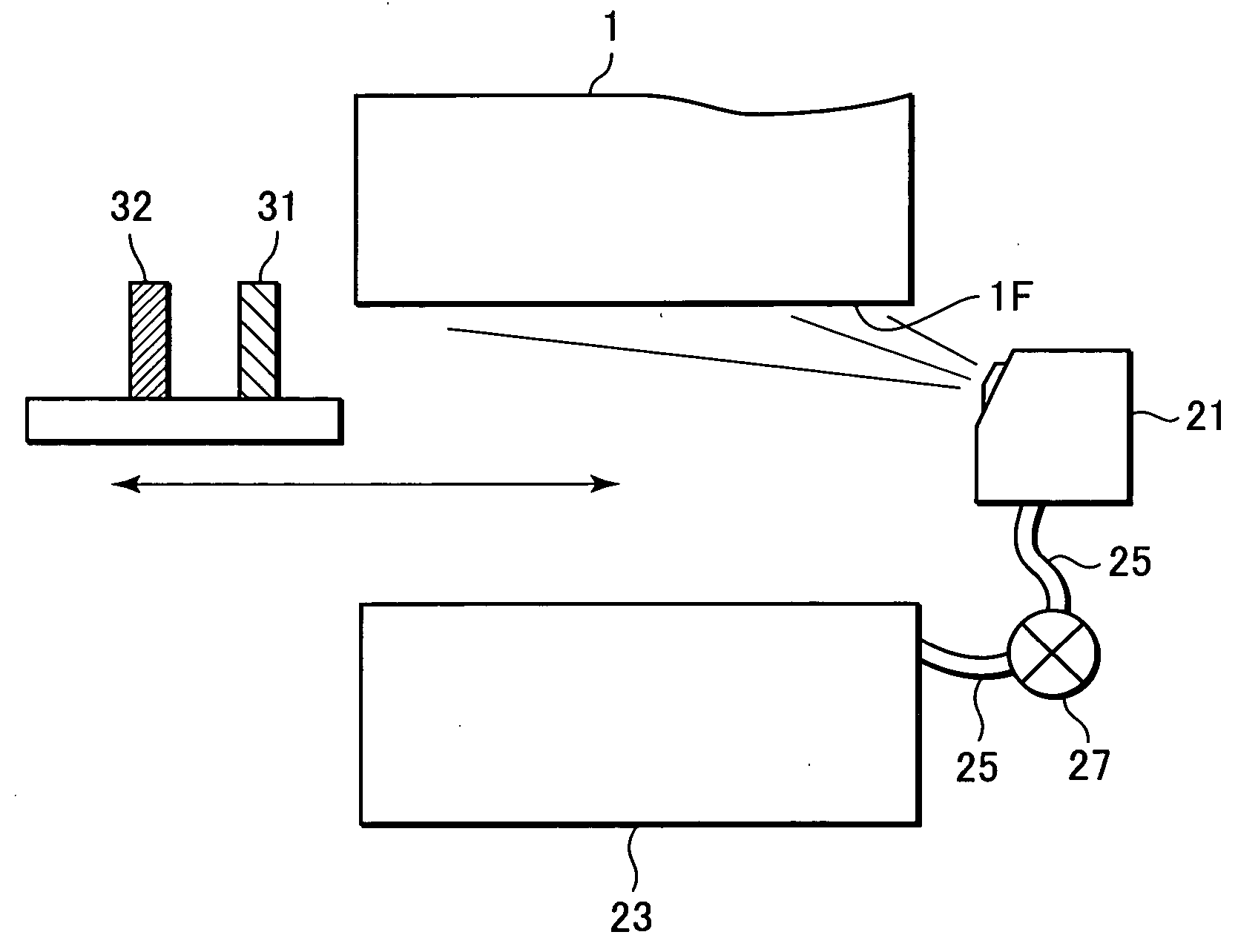

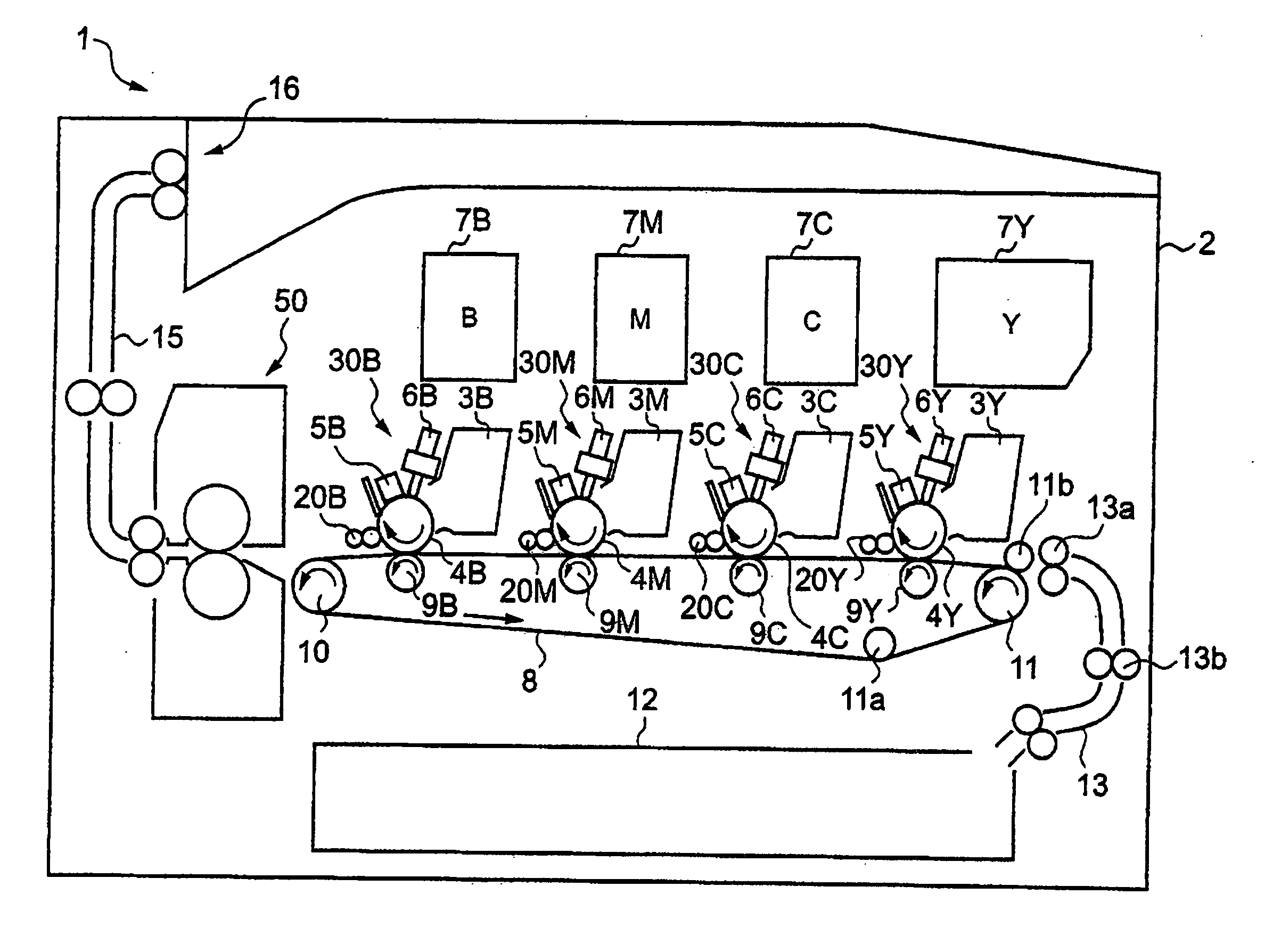

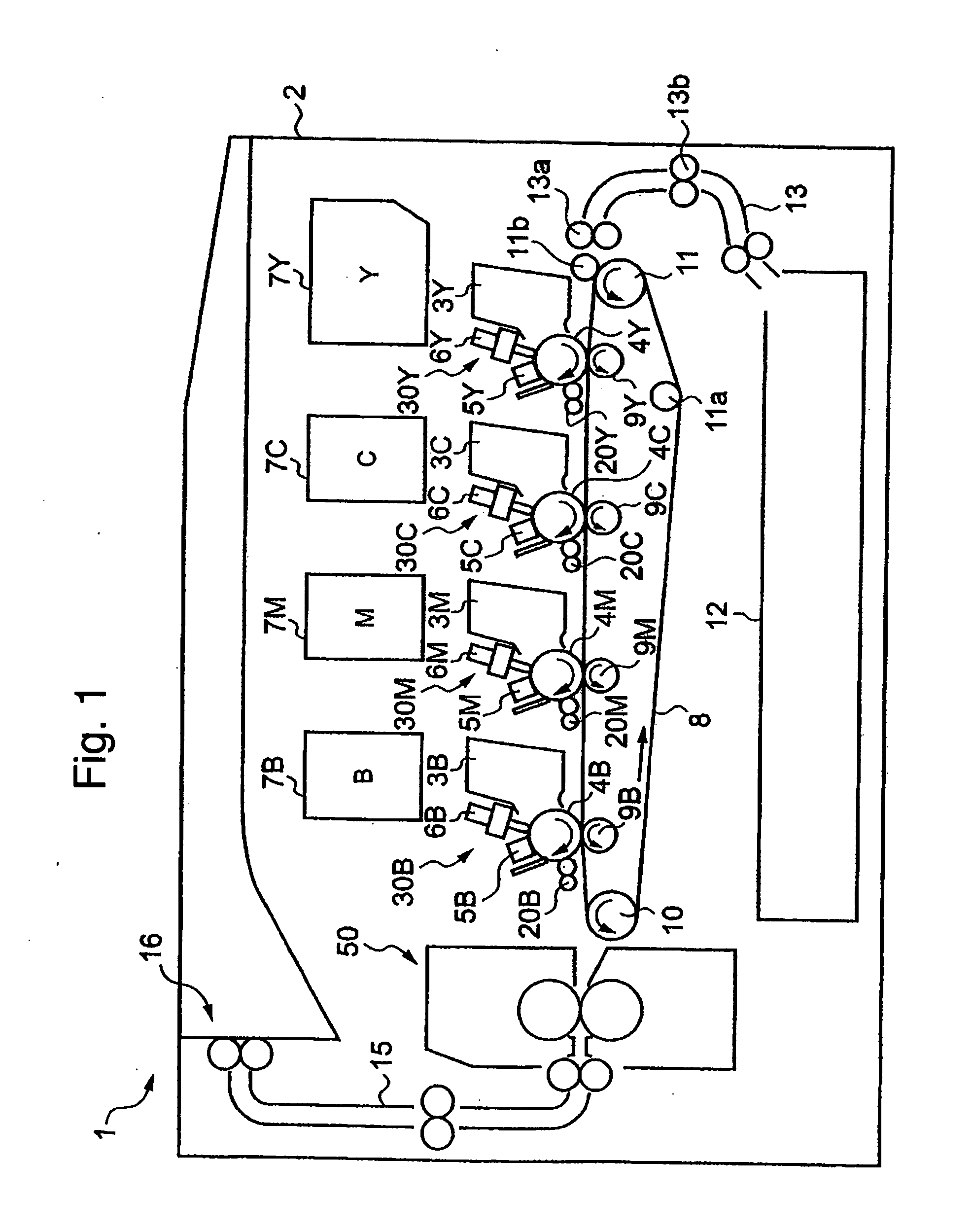

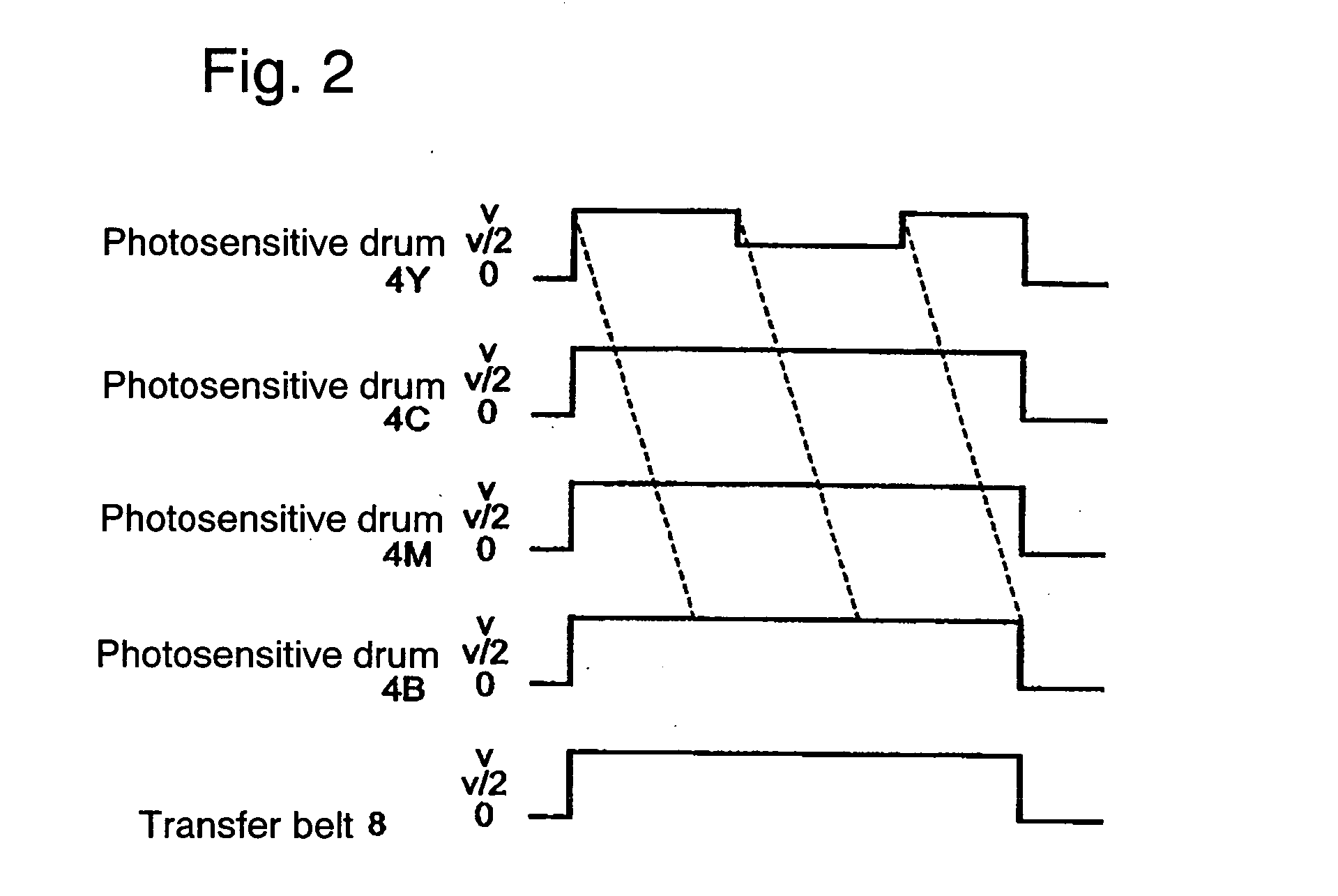

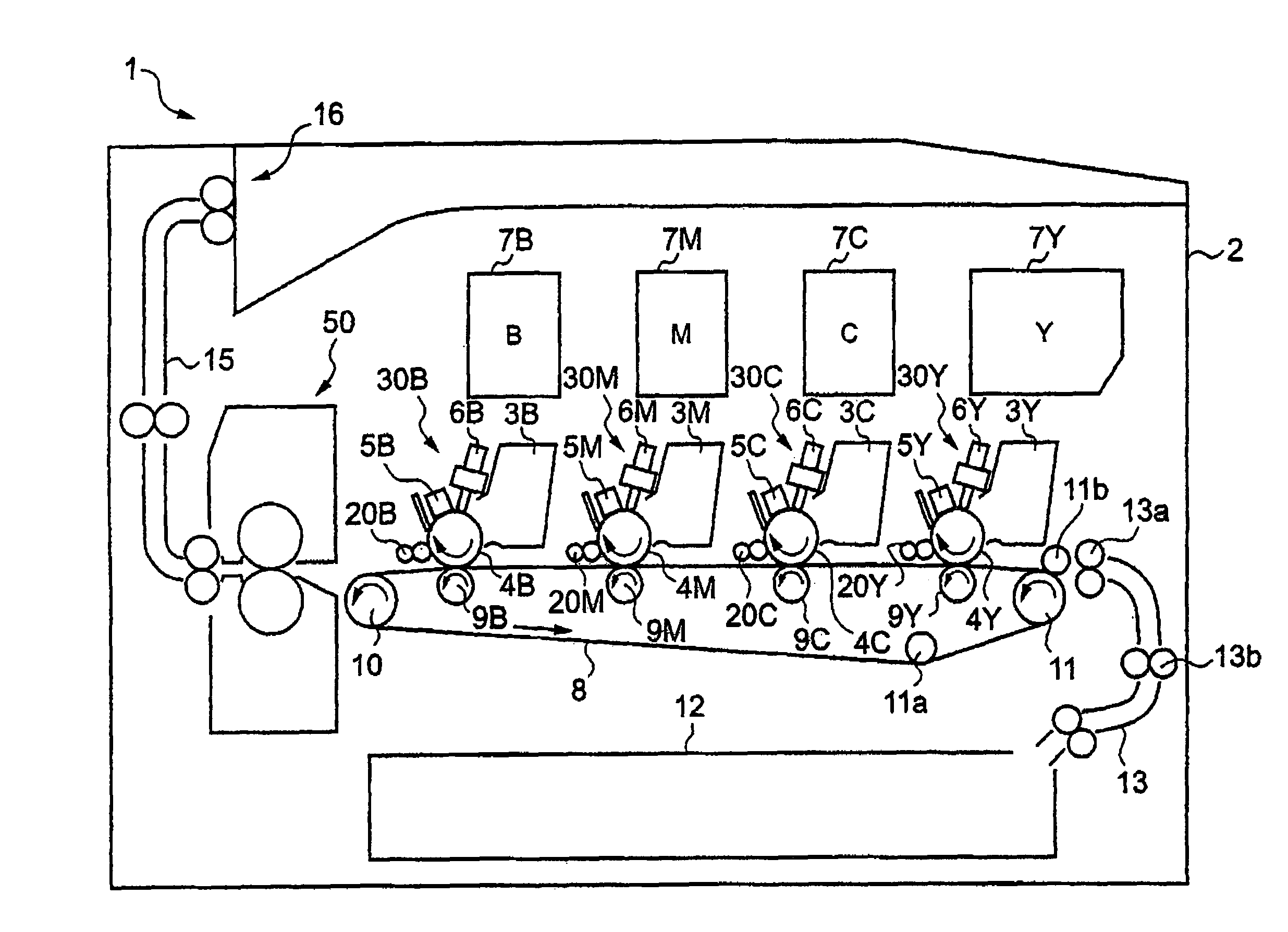

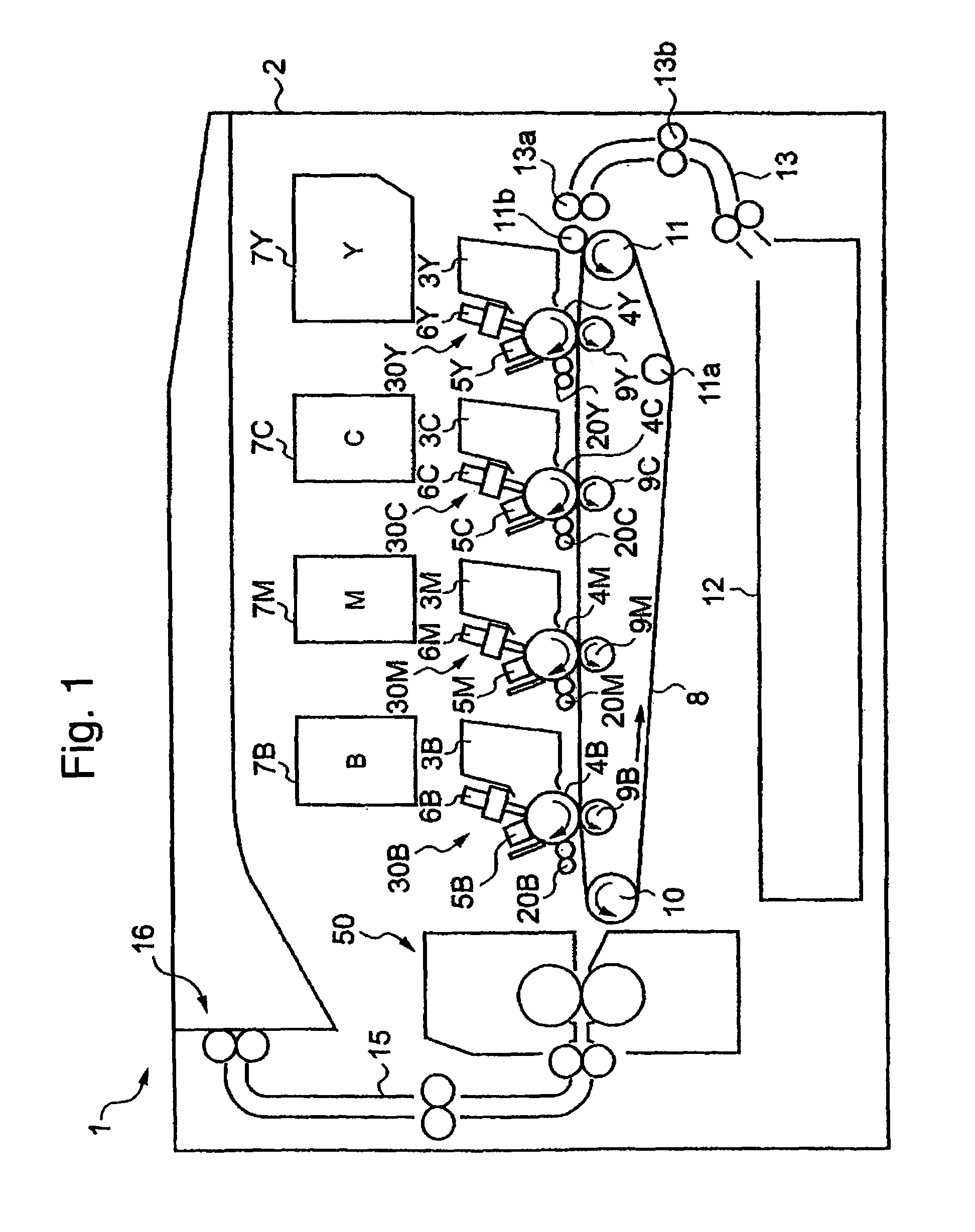

Image forming method and image forming apparatus

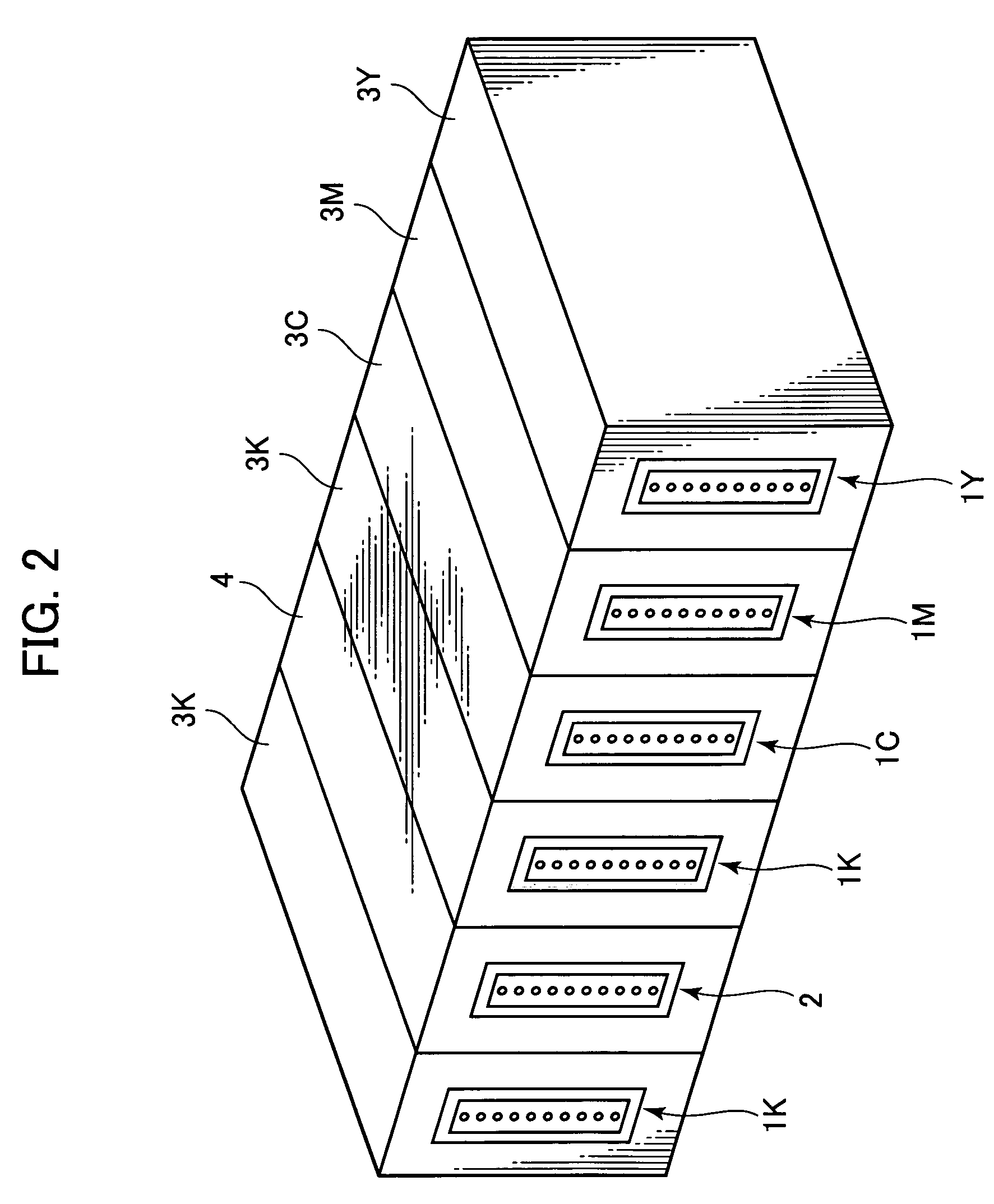

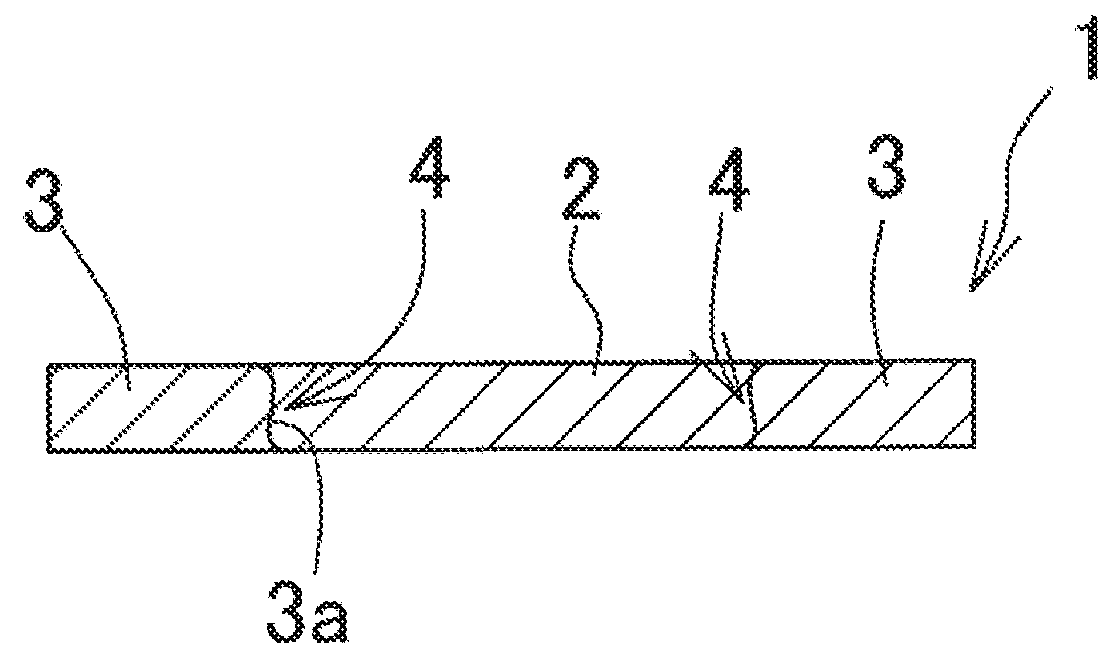

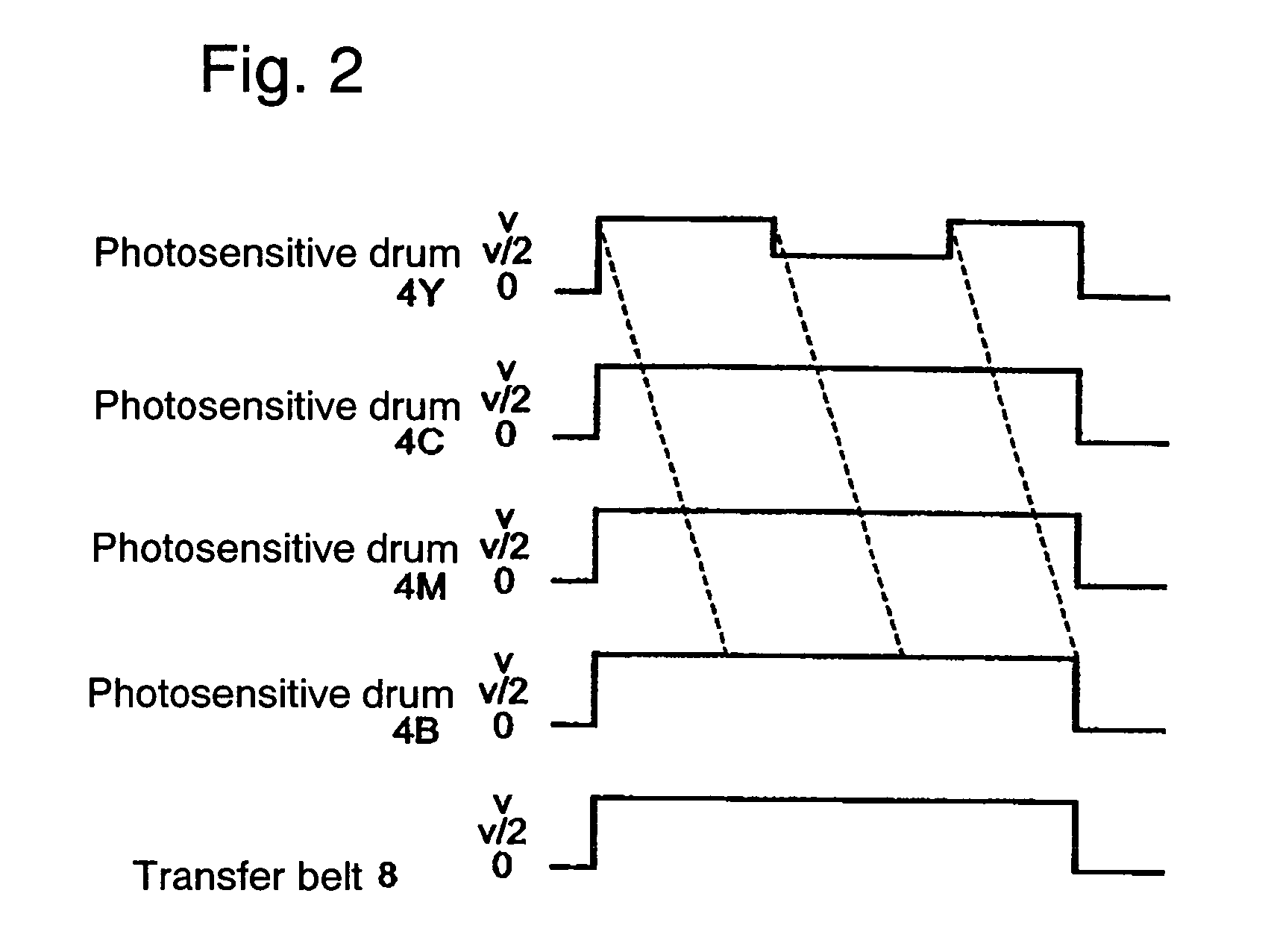

ActiveUS20050123325A1Easy to cleanHigh spectroreflectivityElectrographic process apparatusForeign matterImage transfer

An image transfer method and apparatus are provided, with which, even if scratches are produced due to entrainment of foreign matter on the surface of the image carrying body on which a toner image of which the spectroreflectivity at wavelength of 550 nm is the highest is to be formed, the image transferred to a recording medium is not perceived to have a flaw, for the image formed with the toner of which the spectroreflectivity at wavelength of 550 nm is the highest is difficult for human eyes to discern when it is printed on a white recording medium. When cleaning off the toner remaining on the sheet transfer belt 8 or intermediate transfer belt 8a, reverse bias voltage is applied to at least one of the transfer rollers 9Y˜9B, the peripheral velocity of the photosensitive drum 4Y on which a yellow toner image of which the spectroreflectivity at wavelength of 550 nm is the highest is to be formed is allowed to be different from the transfer velocity of the sheet transfer belt 8 or intermediate transfer belt 8a, and at least the photosensitive drum 4Y on which said yellow toner image of which the spectroreflectivity at wavelength of 550 nm is the highest is to be formed is detached from the sheet transfer belt 8 or intermediate transfer belt 8a.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Color image forming method and apparatus with image flaw reducing speed control of toner image carrier peripheral velocity

ActiveUS7123869B2High spectroreflectivitySuppress and prevent generationElectrographic process apparatusColor imageImage transfer

Owner:KYOCERA DOCUMENT SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com