Silicon casting apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

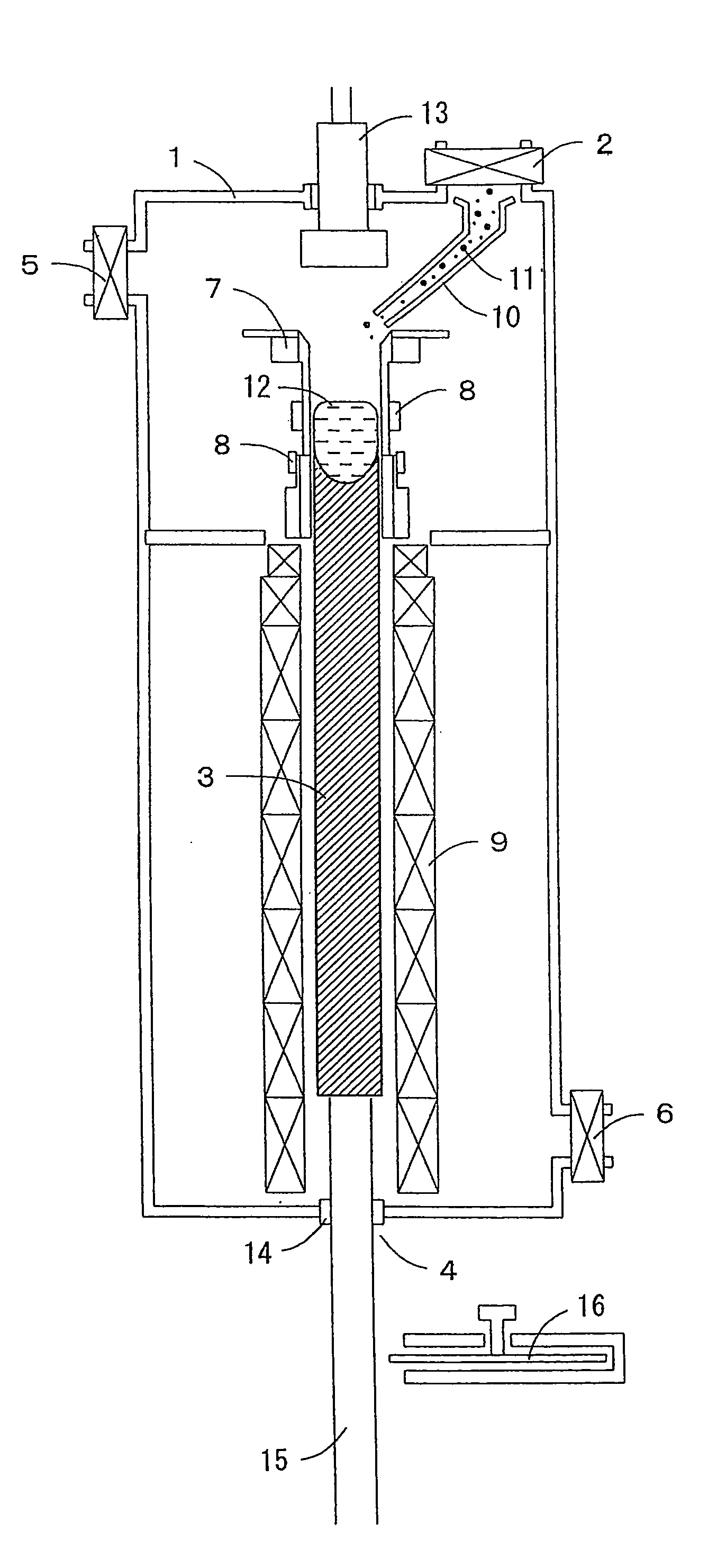

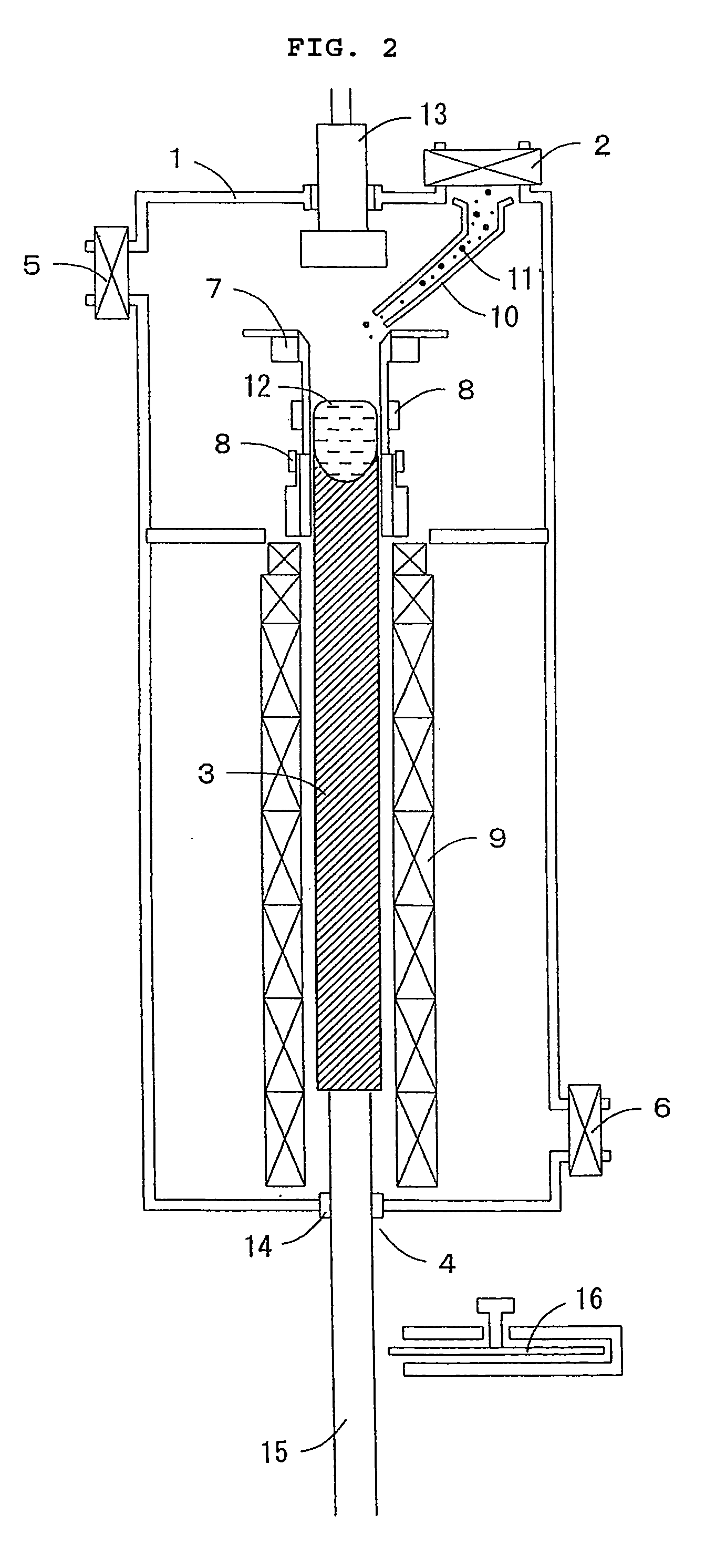

[0050]The electromagnetic casting was performed using the silicon casting apparatus of the present invention having the schematic configuration of FIG. 2, and the state of the slit deterioration associated with the repetitive use of the cooled mold and the mold life were investigated. Given that the use of the mold from the start to the end in the continuous casting is deemed to be one (1) time in the frequency of use, the mold life was evaluated in terms of the frequency of use in the casting.

[0051]The crucible made of beryllium copper equivalent defined in JIS H 3270 was used as the cold crucible made of copper alloy containing beryllium.

[0052]FIGS. 3A to 3C illustrate the progression of the deterioration of the slit portion in the copper cold crucible which is used for the purpose of comparison. FIG. 3A shows the normal slit portion before casting is performed, and FIGS. 3B and 3C show the slit portions after being used 6 and 8 times in the casting. The deterioration aggravates c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com