Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Suitable for industrial mass production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/molybdenum disulfide composite electrode material and preparation method thereof

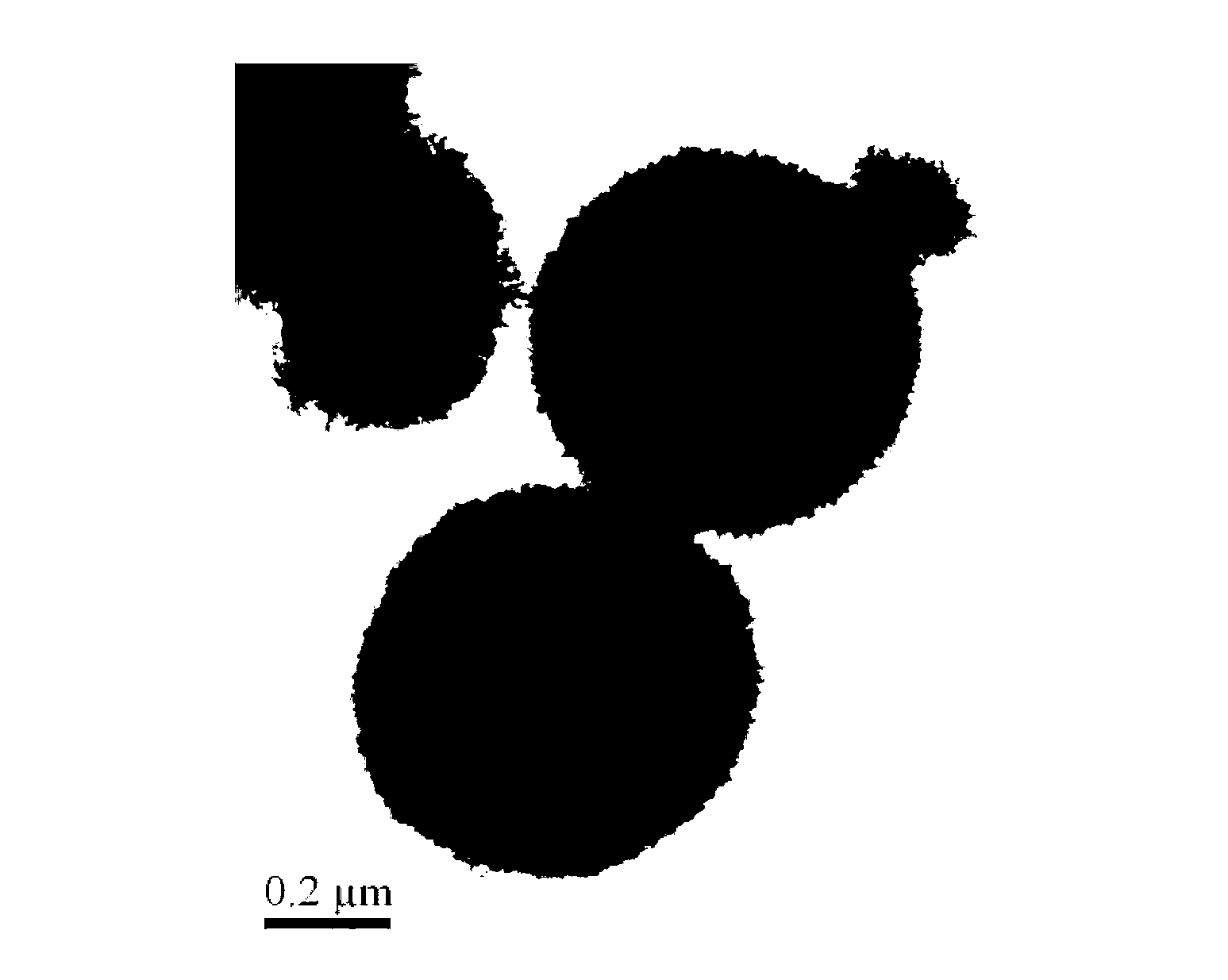

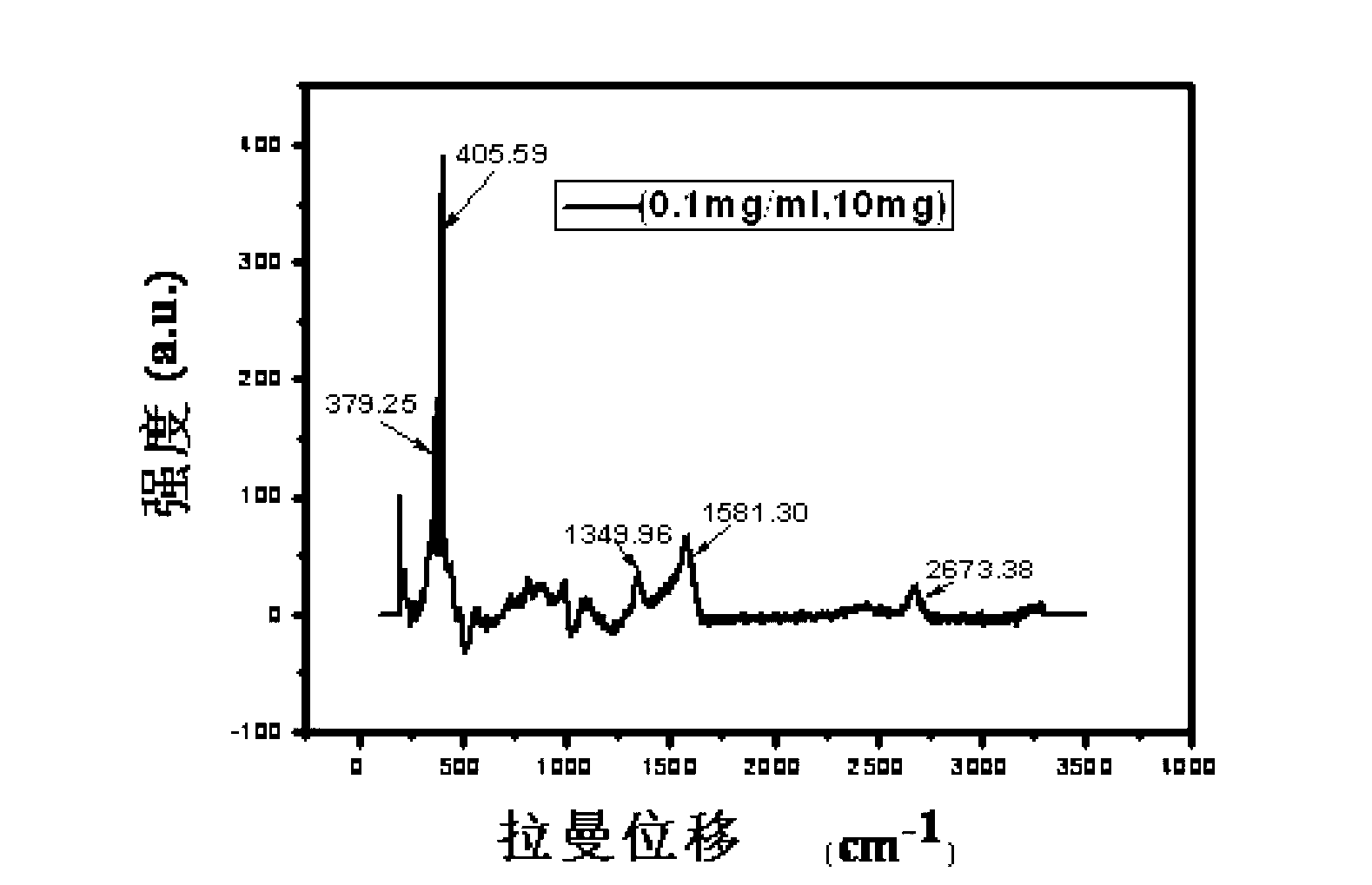

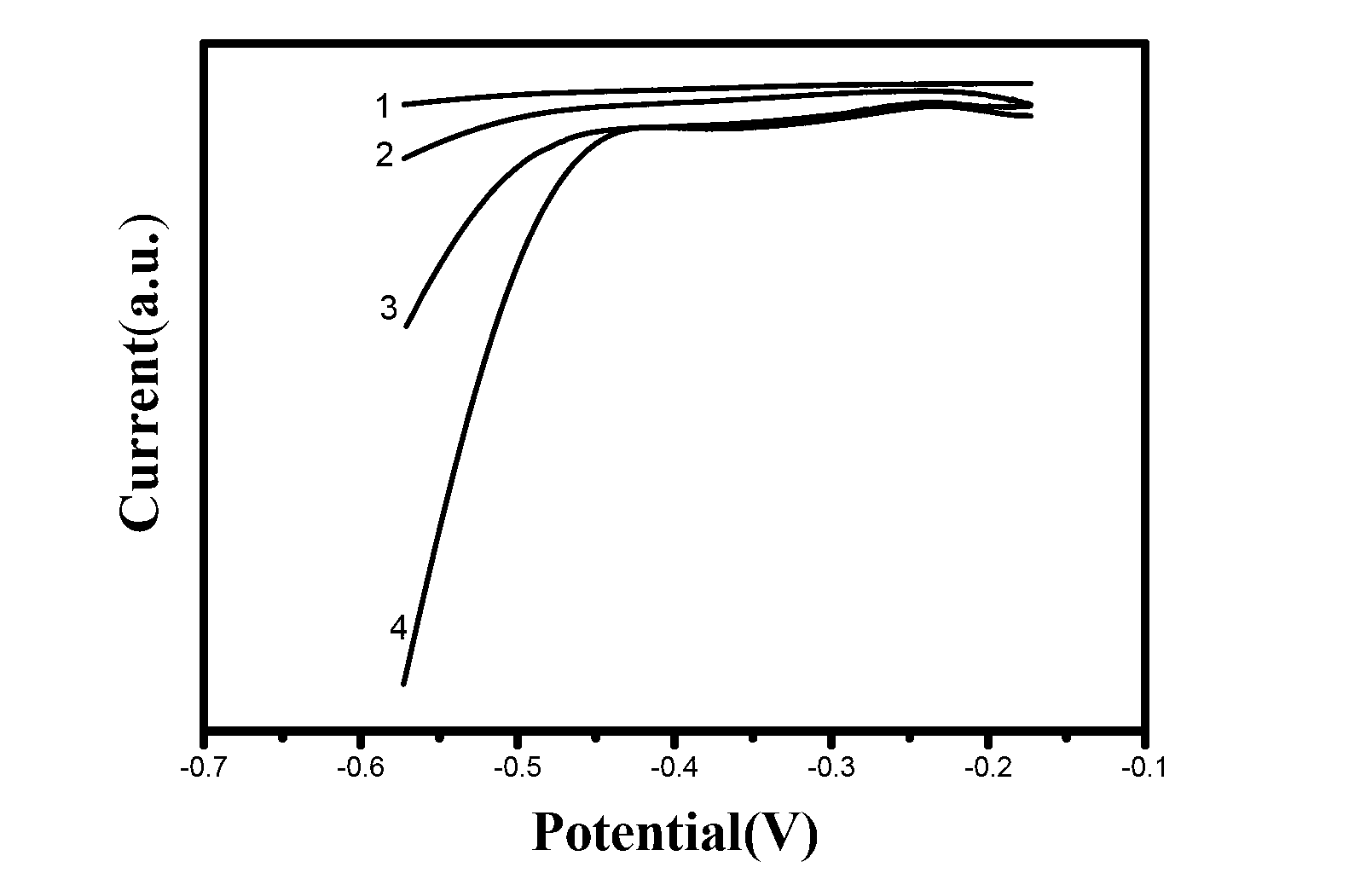

The invention relates to the fields of a novel chemical electric power source and a new energy material, and particularly discloses a graphene / molybdenum disulfide composite electrode material and a preparation method of the composite electrode material. The preparation method comprises the steps of: (1) preparing graphite oxide from graphite as a raw material by an oxidation and intercalation method; (2) dissolving prepared graphite oxide with deionized water, carrying out ultrasonic stripping to obtain a graphene oxide solution, then adding DMF (dimethyl formamide) and molybdate, finally adding a reducing agent, and dispersing uniformly to obtain a mixed solution; and (3) transferring the mixed solution to a reaction kettle, keeping the temperature in the temperature condition of greater than or equal to 180 DEG C for 5-10h, centrifuging and washing the product to remove DMF, and drying to obtain the graphene / molybdenum disulfide composite electrode material product. The preparation method of the graphene / molybdenum disulfide composite electrode material is simple, uniform in reaction system and low in production cost, and is particularly suitable for requirements of industrial large scale production; and the prepared product graphene / molybdenum disulfide composite electrode material has better electrochemical performances.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

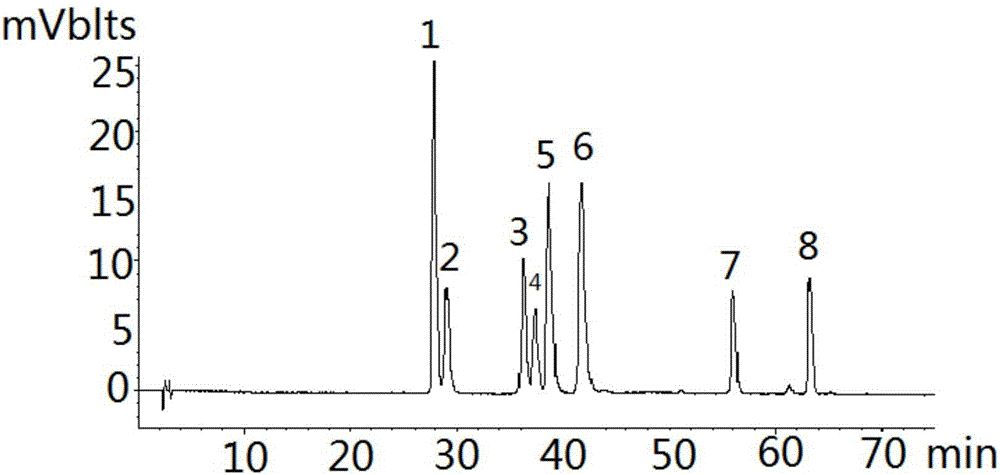

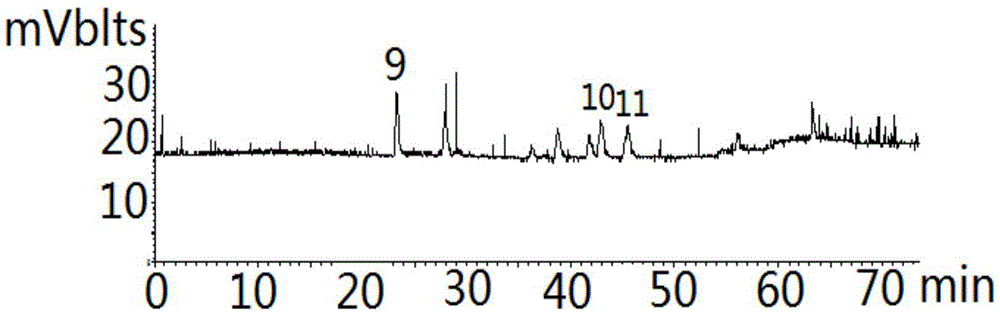

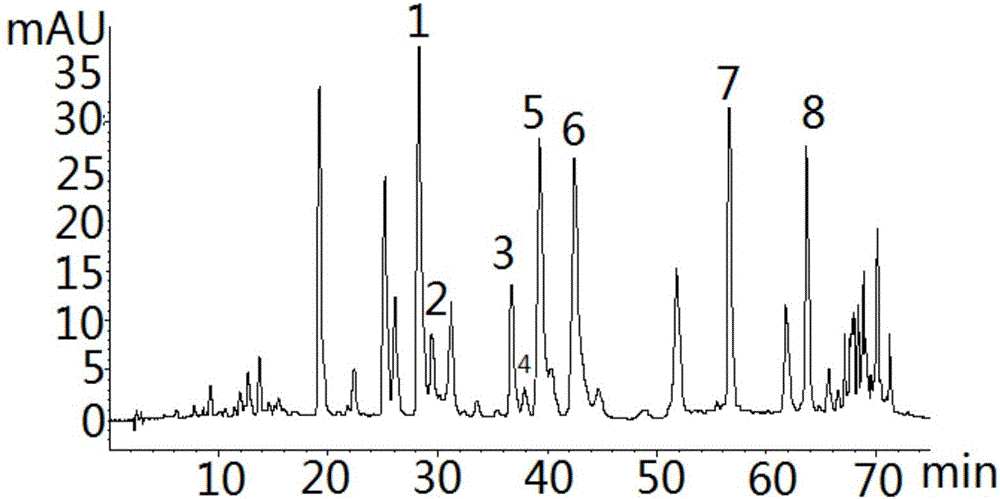

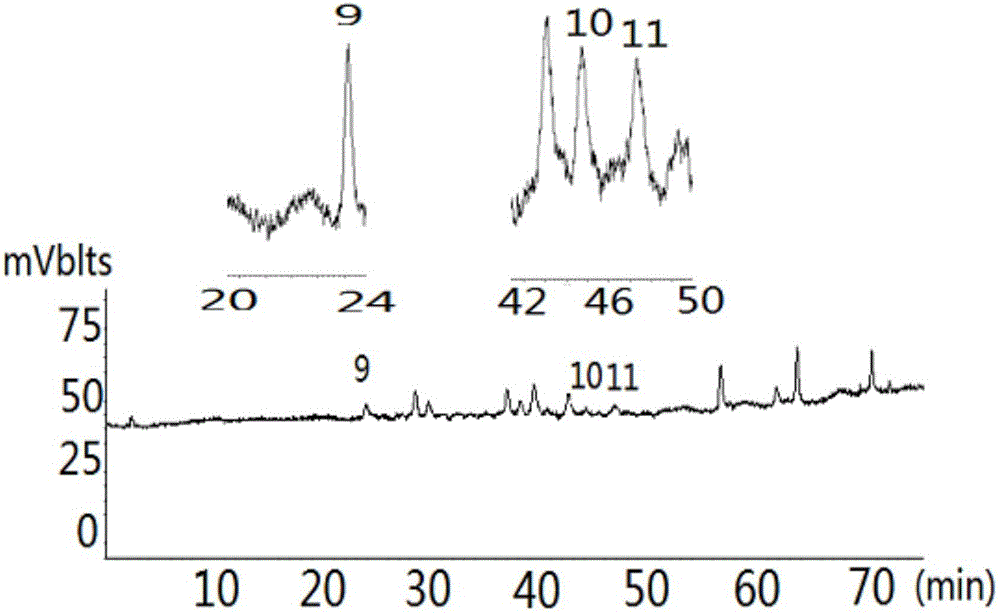

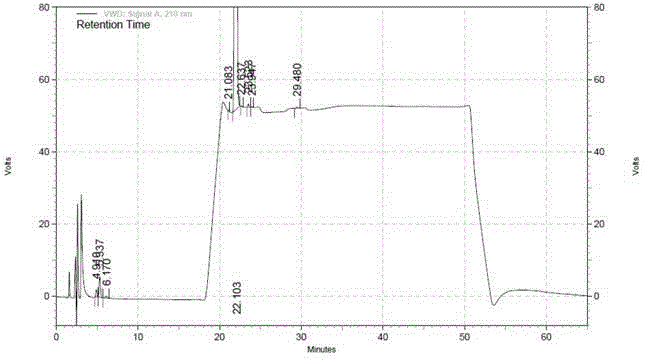

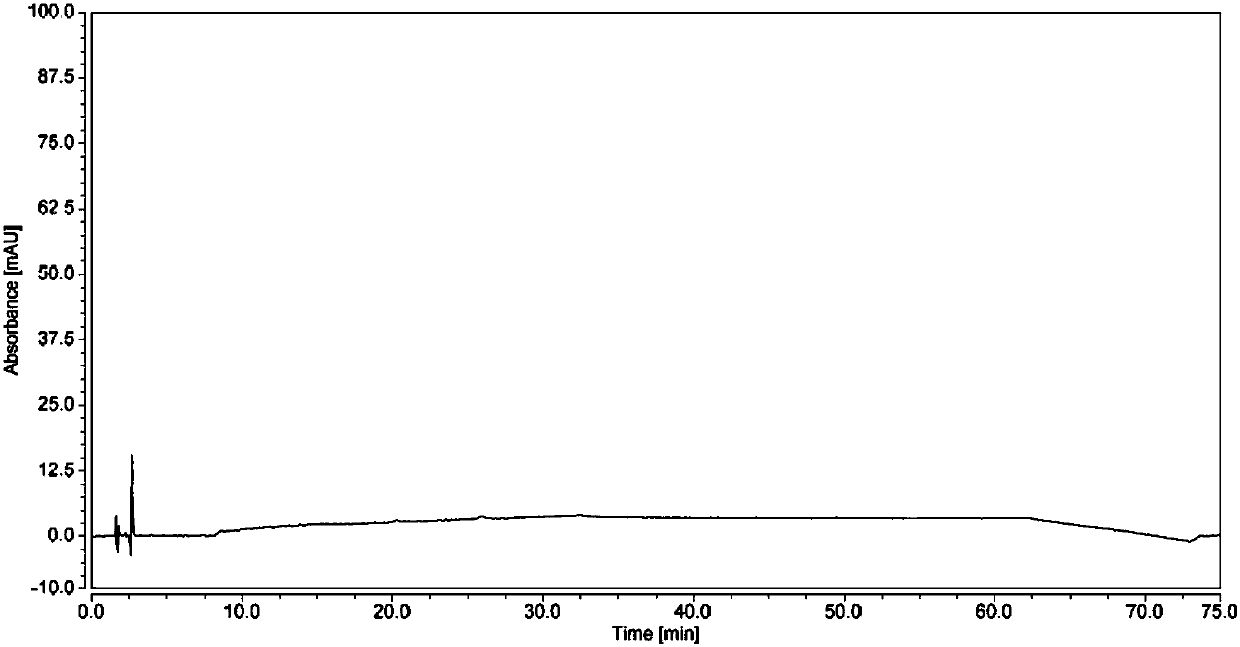

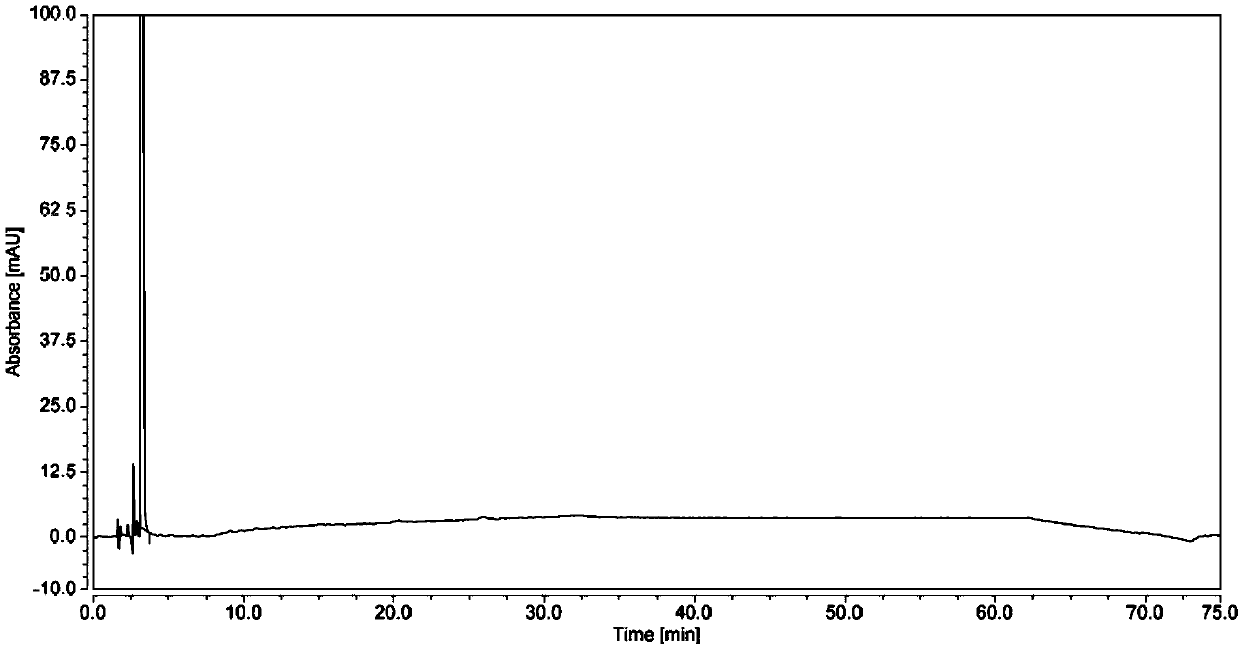

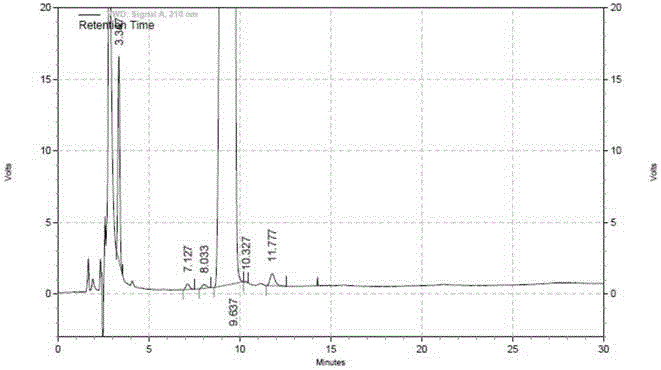

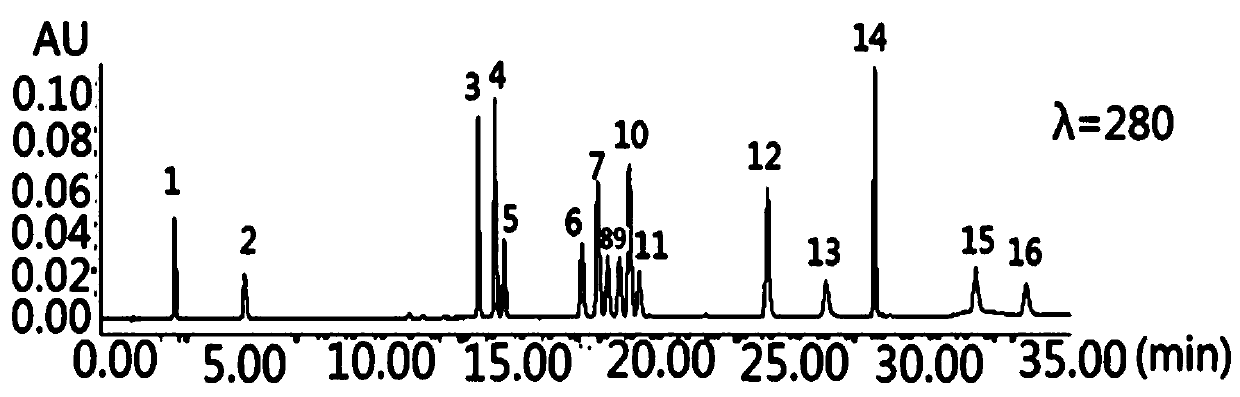

Detecting method for measuring content of flavonoid compounds and terpene lactone compounds in ginkgo leaf extract or preparations of ginkgo leaf extract at same time

ActiveCN105891355AAvoid frequent replacementImprove work efficiencyComponent separationGinkgo leaf extractAnalysis method

The invention relates to the field of medicine detection, in particular to a high-performance liquid chromatography detecting method for measuring the content of flavonoid compounds and terpene lactone compounds in ginkgo leaves (or ginkgo leaf extract) or preparations of the ginkgo leaves at the same time. The HPLC-DAD-ELSD method is set up, the method can measure the eight flavonoid compounds and three terpene lactone compounds in the ginkgo leaves (or the leaf extract) or preparations of the ginkgo leaves at the same time, the measurement result is analyzed, and a new analysis method and a basis are provided for quality control over the ginkgo leaf extract and the preparations of the ginkgo leaf extract.

Owner:HEBEI SHINEWAY PHARMA +2

Detecting method for measuring content of flavonoid compounds and terpene lactone compounds in ginkgo bioba leaf extract at same time

ActiveCN105891356AAvoid frequent replacementImprove work efficiencyComponent separationGinkgo leaf extractAnalysis method

The invention relates to the field of medicine detection, in particular to a high-performance liquid chromatography detecting method for measuring the content of flavonoid compounds and terpene lactone compounds in ginkgo leaves (or ginkgo leaf extract) or preparations of the ginkgo leaves at the same time. The HPLC-DAD-ELSD method is set up, the method can measure the eight flavonoid compounds and three terpene lactone compounds in the ginkgo leaves (or the ginkgo leaf extract) or preparations of the ginkgo leaves at the same time, the measurement result is analyzed, and a new analysis method and a basis are provided for quality control over the ginkgo leaf extract and the preparations of the ginkgo leaf extract.

Owner:HEBEI SHINEWAY PHARMA +1

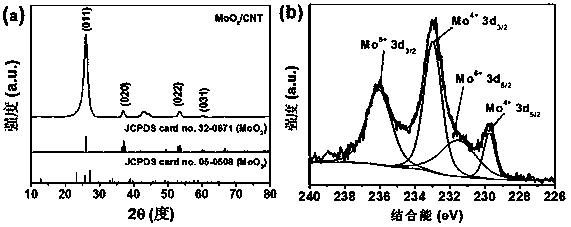

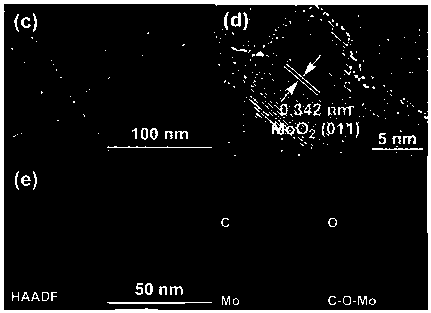

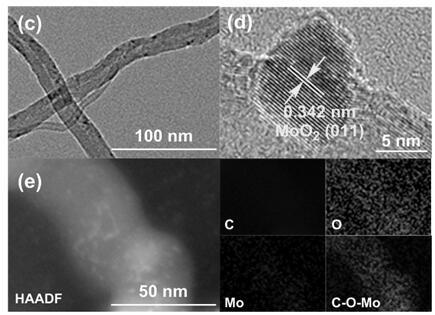

Preparation method for supported molybdenum oxide catalyst and application thereof

ActiveCN107597097AFacilitated DiffusionIncrease exposureMolecular sieve catalystsOrganic compound preparationDepolymerizationEvaporation

The invention discloses a preparation method for a supported molybdenum oxide catalyst and an application thereof. The preparation method comprises the following steps: firstly preparing a molybdenumdichloride hydrate precursor, dissolving the obtained molybdenum dichloride hydrate precursor into methanol or ethanol, slowly adding the obtained liquid into a carrier dropwise after the precursor iscompletely dissolved, allowing the obtained mixture to stand, performing evaporation, and performing roasting under an inert gas atmosphere to obtain the supported molybdenum oxide catalyst. The application of the supported molybdenum oxide catalyst including that the supported molybdenum oxide catalyst is used for hydrogenation depolymerization of lignin, is used for preparing aniline from nitrobenzene and is used as a composite electrode material. The catalyst provided by the invention has the advantages of having small particles and a large specific surface area, being beneficial for reactant diffusion and active site exposure and the like, and meanwhile the catalyst has similar noble-metal catalytic performance, and can be widely applied to the fields such as biomass catalytic conversion and electrode materials.

Owner:BEIJING FORESTRY UNIVERSITY

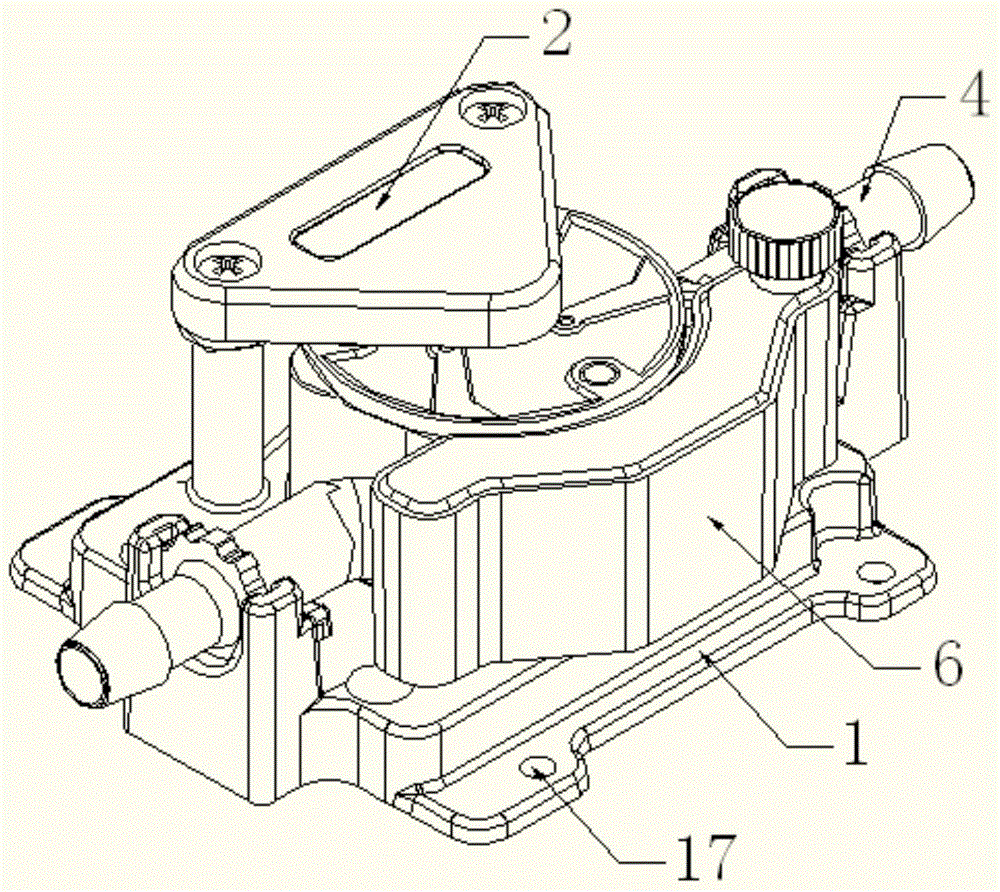

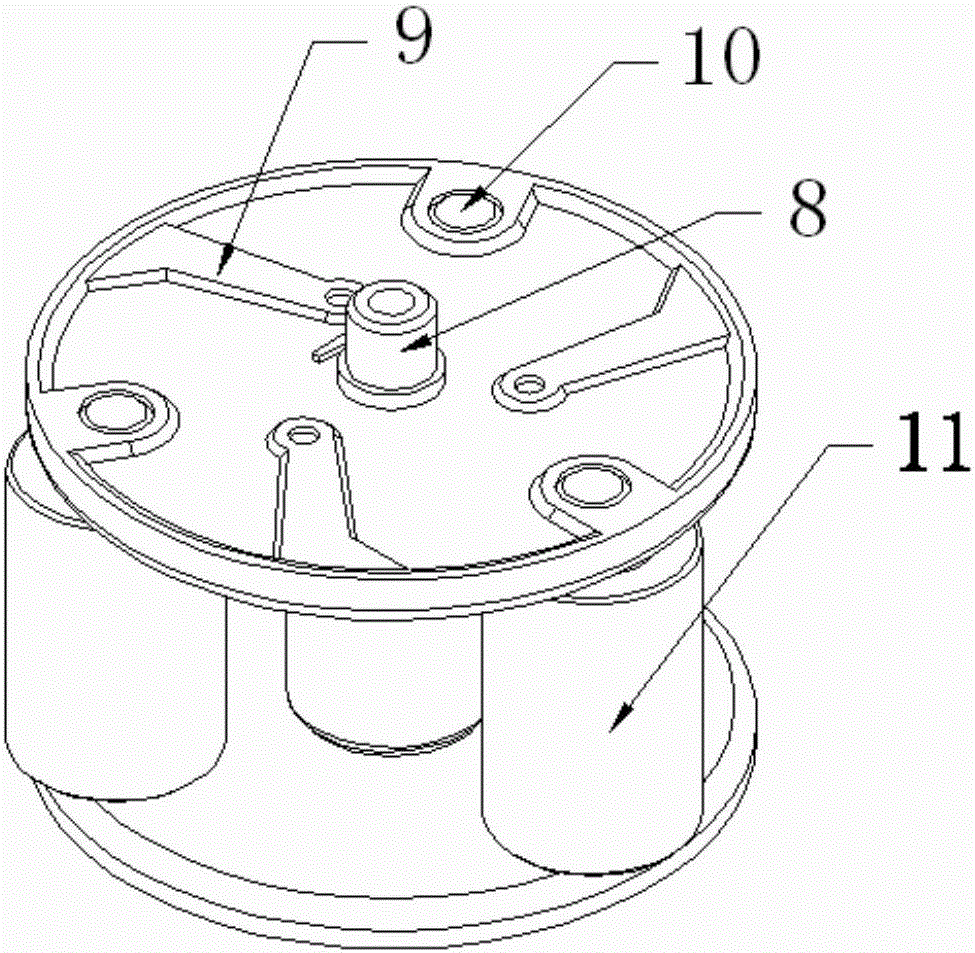

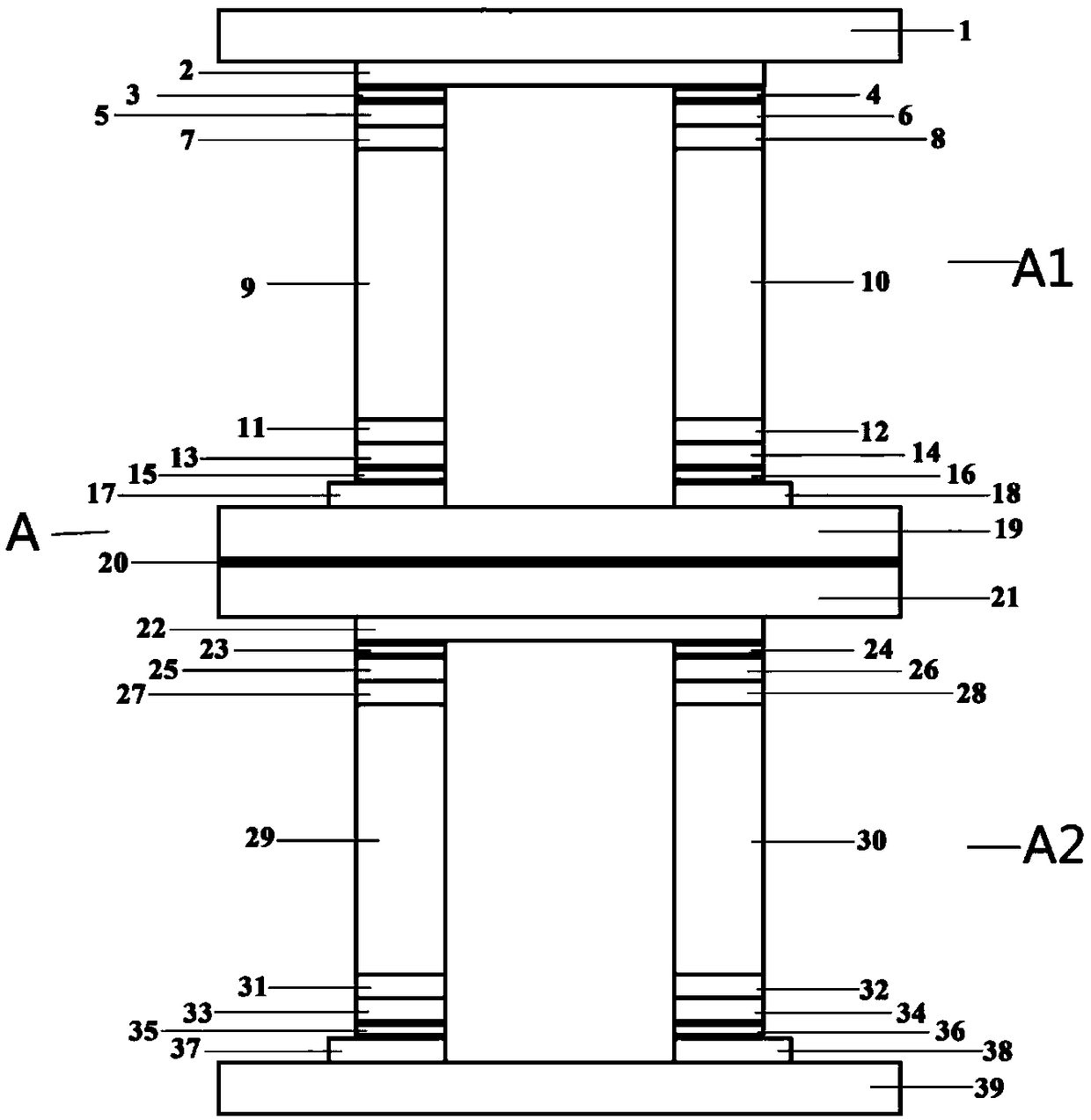

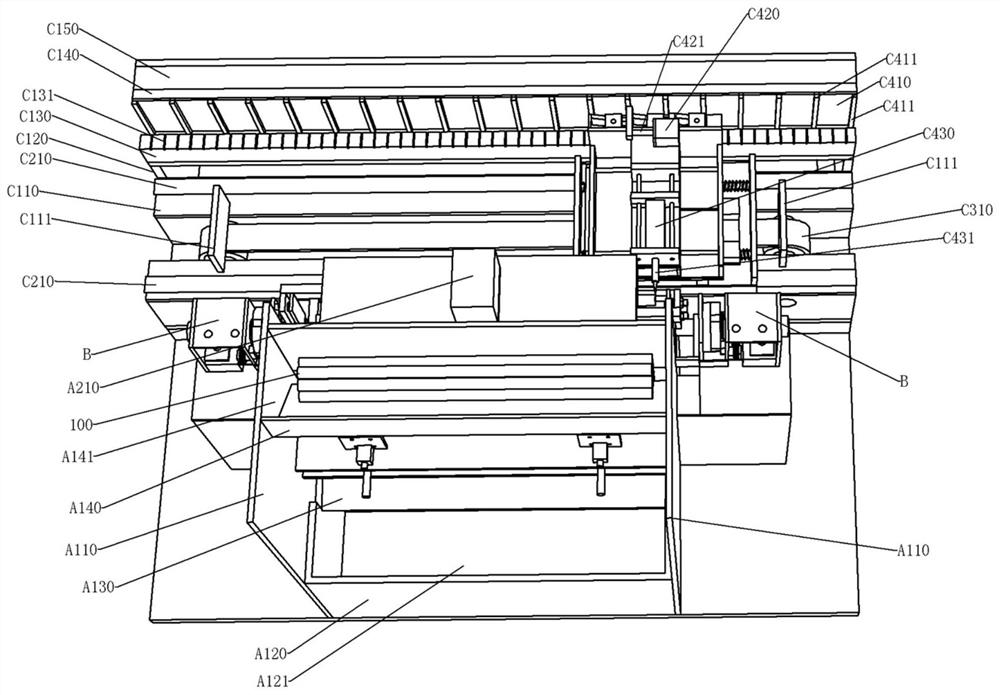

Linear type fast-assembling peristaltic pump assembly

InactiveCN105697343ASave installation spaceShort flow distancePositive displacement pump componentsFlexible member pumpsPeristaltic pumpInterference fit

The invention discloses a linear type fast-assembling peristaltic pump assembly. The linear type fast-assembling peristaltic pump assembly comprises a base, an extrusion roller assembly fixed to the base, and an upper support covering the extrusion roller assembly. Mounting grooves are fixed to the left and right edges of the base correspondingly, hoses with connectors are mounted in the mounting grooves, and the inner side faces of the hoses are in interference fit with the extrusion face of the extrusion roller assembly. The two ends of each hose are located on the same straight line. A locating column is further fixed to the base and rotatably connected to one end of a pressing block, and the other end of the pressing block is fixedly connected with the base through a hand screw. The hoses are covered by the pressing block, and the inner side wall of the pressing block makes contact with the outer walls of the hoses. The linear type fast-assembling peristaltic pump assembly has the remarkable effects that an inlet and an outlet of each hose are located on the same straight line, multiple special requirements can be met, a mounting space of a user is saved, the flowing distance is reduced, and the staying time is shortened; operation is simple, convenient and quick.

Owner:CHONGQING JIEHENG PERISTALTIC PUMP

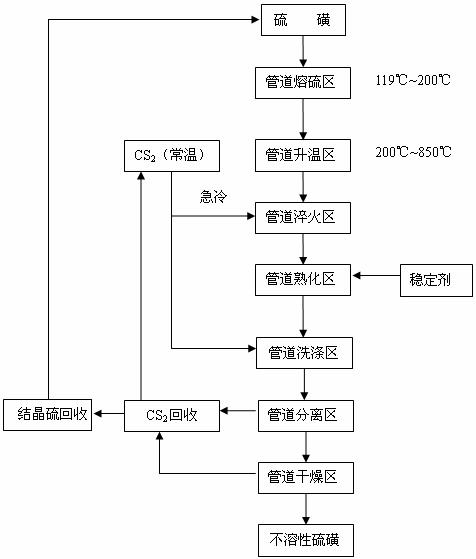

Process for continuously producing insoluble sulfur by pipeline

InactiveCN102009962AIncrease contentImprove thermal stabilitySulfur preparation/purificationPhysical chemistryProcess engineering

The invention discloses a process for continuously producing insoluble sulfur by a pipeline. In the process, the insoluble sulfur is produced by adopting the sealed pipeline, steps forming a flow for producing the insoluble sulfur are sequentially performed on each section of the pipeline and corresponding process conditions are provided for materials of each section of pipeline so as to realize the pipeline type continuous production of the insoluble sulfur. The pipeline for producing the insoluble sulfur is divided into a pipeline sulfur melting section, a pipeline heating section, a pipeline quenching section, a pipeline curing section, a pipeline washing section, a pipeline separation section and a pipeline drying section. A sulfur raw material enters the pipeline sulfur melting section, and is sequentially subjected to sulfur melting, heating, quenching, curing, washing, separation and drying, and finally, the insoluble sulfur is automatically discharged from the pipeline drying section. The process is used for producing the insoluble sulfur, has the advantages of high quality of product, low cost, energy saving, environmental friendliness, safety and the like, and is applied to the continuous mass production of the insoluble sulfur.

Owner:江西恒兴源化工有限公司

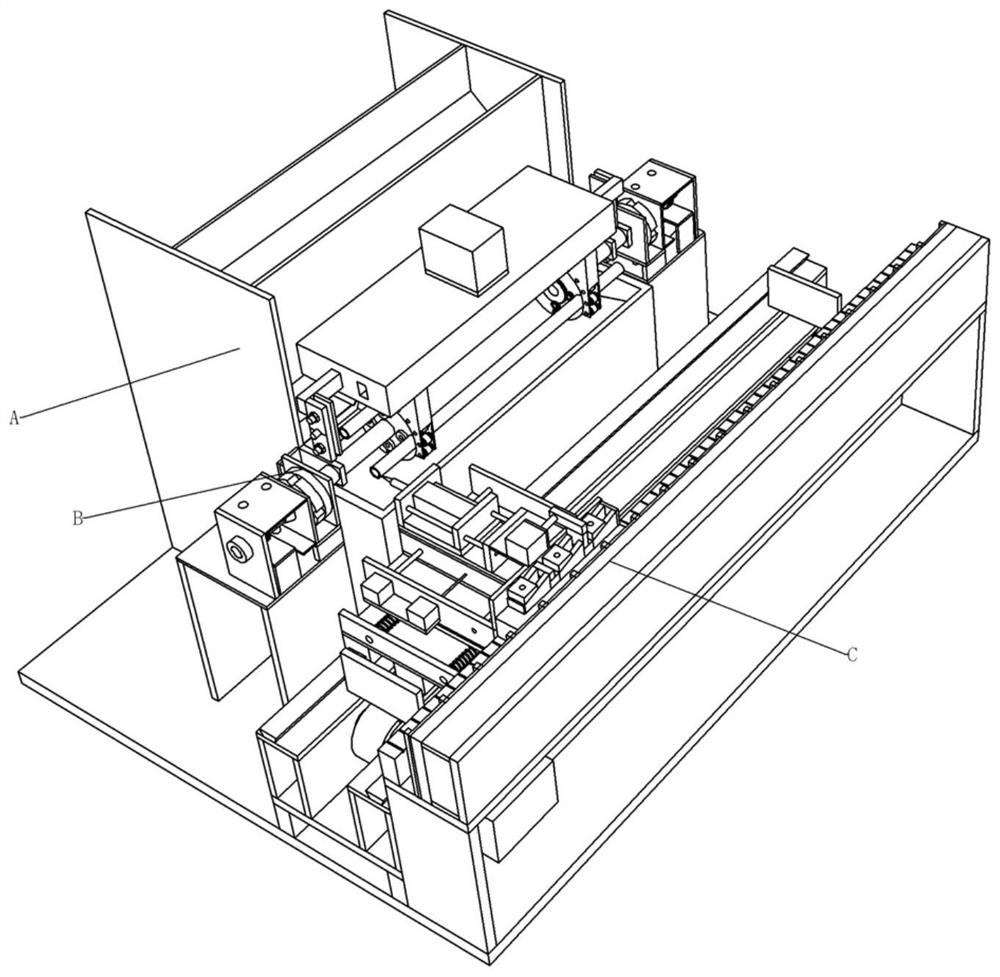

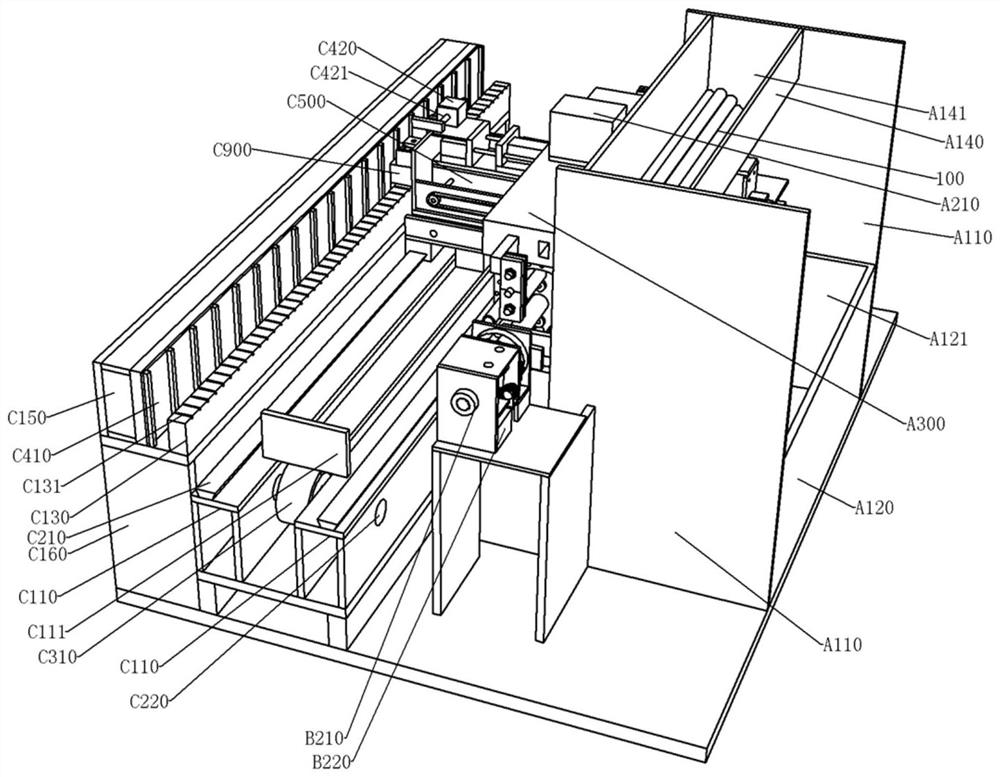

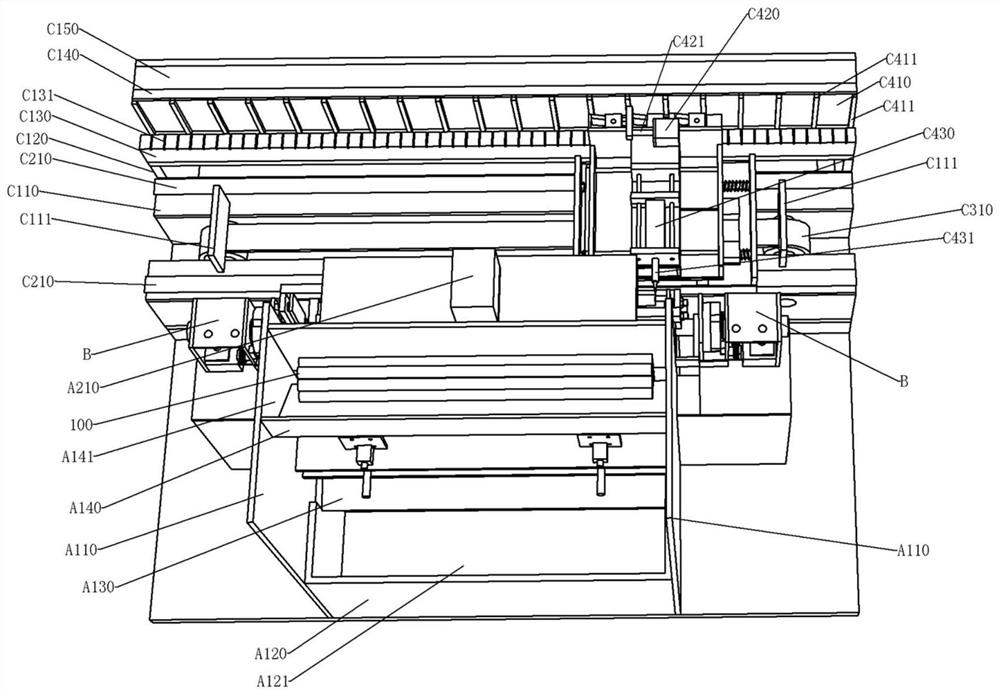

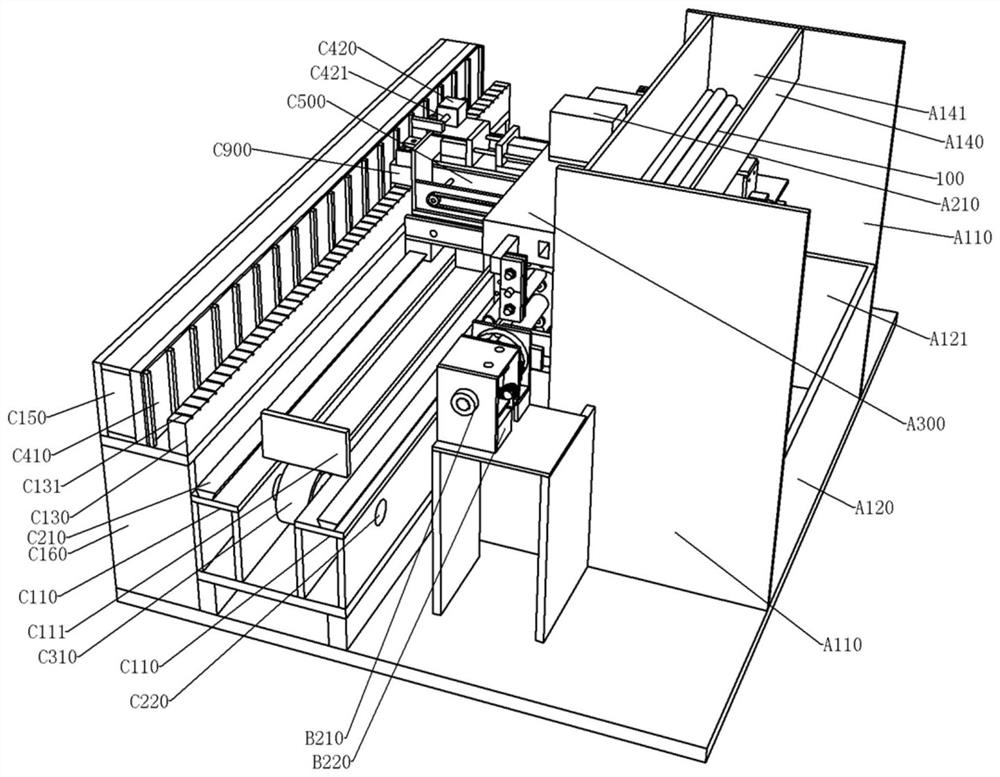

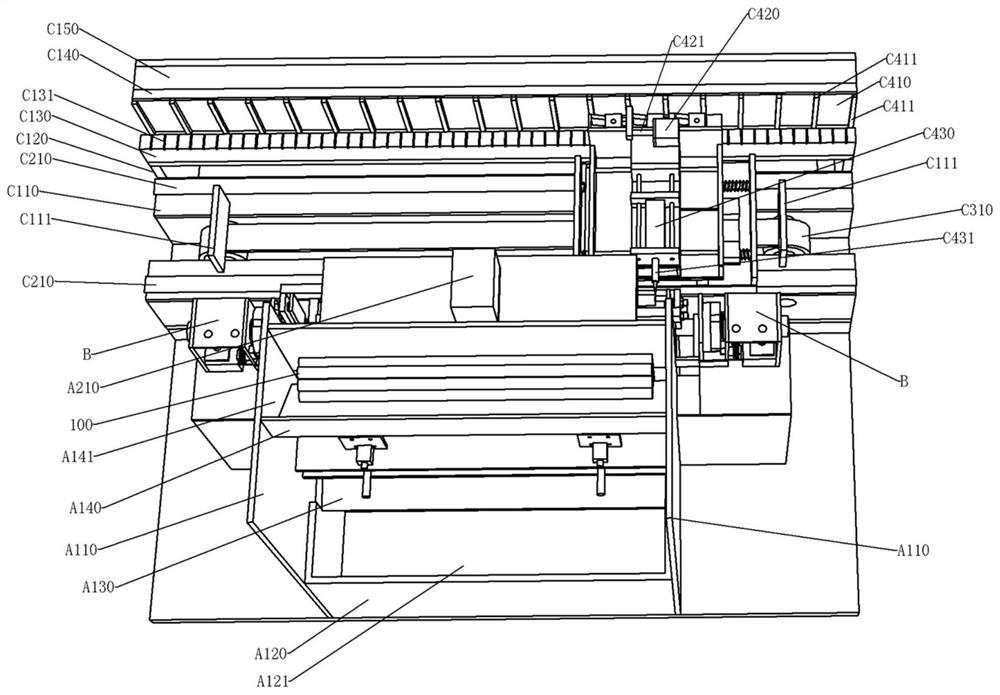

Material pushing mechanism and full-automatic laser pipe cutting machine

ActiveCN112207459ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a material pushing module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, a power module and a cutting module, wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes through laser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved, so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipe cutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

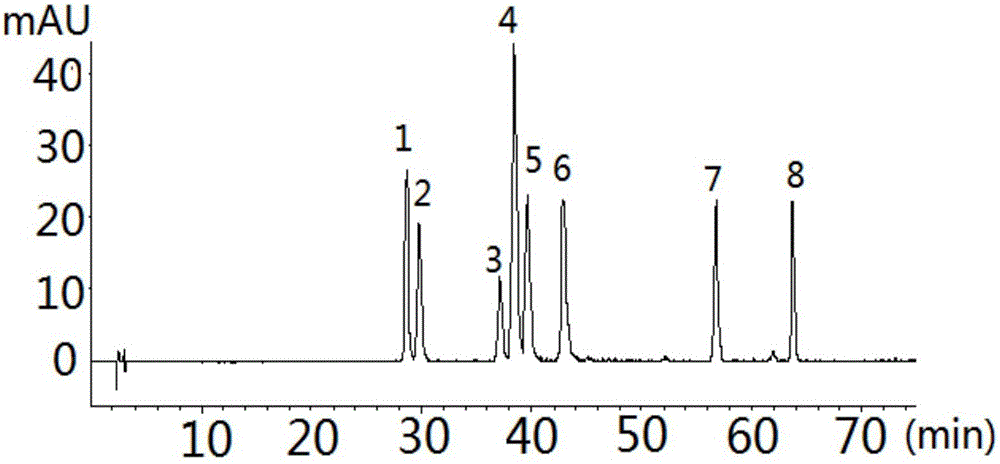

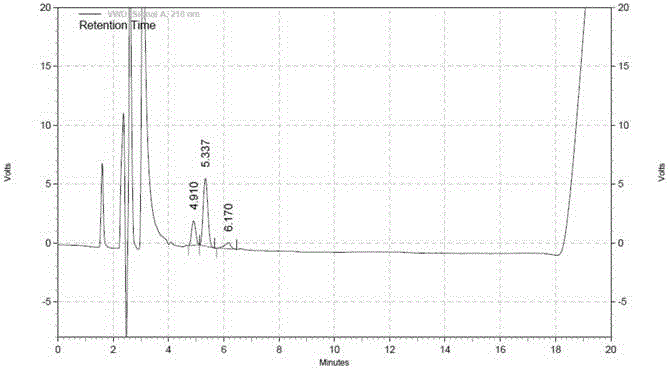

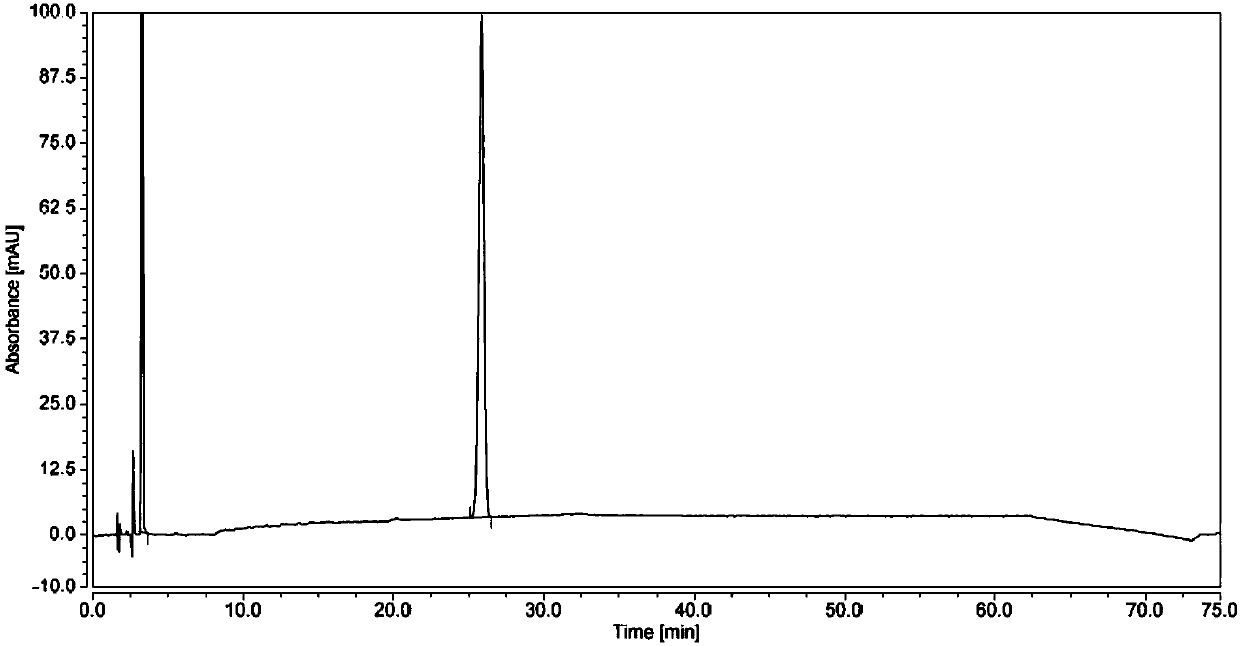

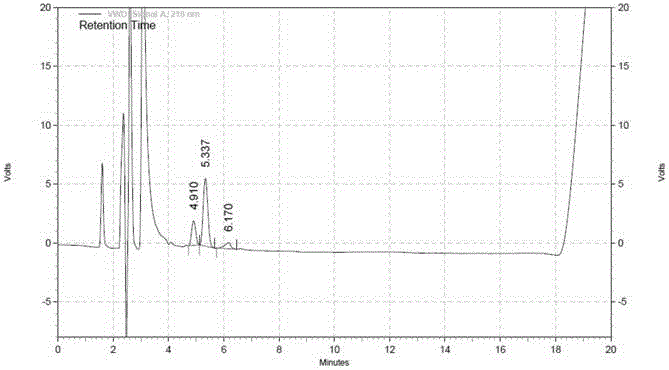

Method for measuring fat-soluble platinum complex and preparation related substances thereof

ActiveCN104597157AAvoid frequent replacementImprove work efficiencyComponent separationMiriplatinGradient elution

The invention relates to a method for measuring fat-soluble platinum complex and preparation related substances thereof. The detection method refers to a high performance liquid chromatography method. The chromatographic conditions are that the chromatographic column refers to an octadecylsilane chemically bonded silica (C18) chromatographic column; the phase A refers to a methanol-ethanol mixed solvent; the phase B refers to a mixed solvent of water and methanol or ethanol, and gradient elution is performed; the column temperature is 38-42 DEG C; the detection wavelength is 208-215nm; and the flow velocity is 0.5-2.0ml / min. With the adoption of the high performance liquid chromatography method disclosed by the invention, the content of impurities A and the content of other unknown impurities in the sample can be accurately determined, the separation degree of each impurity is high in the analysis process, the reproducibility of the analysis result is high, and a simple and reliable method is provided for quality control and analysis of miriplatin and preparations thereof.

Owner:SHINEWAY PHARMA GRP LTD

Power module and full-automatic laser pipe cutting machine

ActiveCN112207457ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusLaser cuttingErbium lasers

The invention discloses a power module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, the power module and a cutting module,wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes throughlaser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved, so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipe cutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

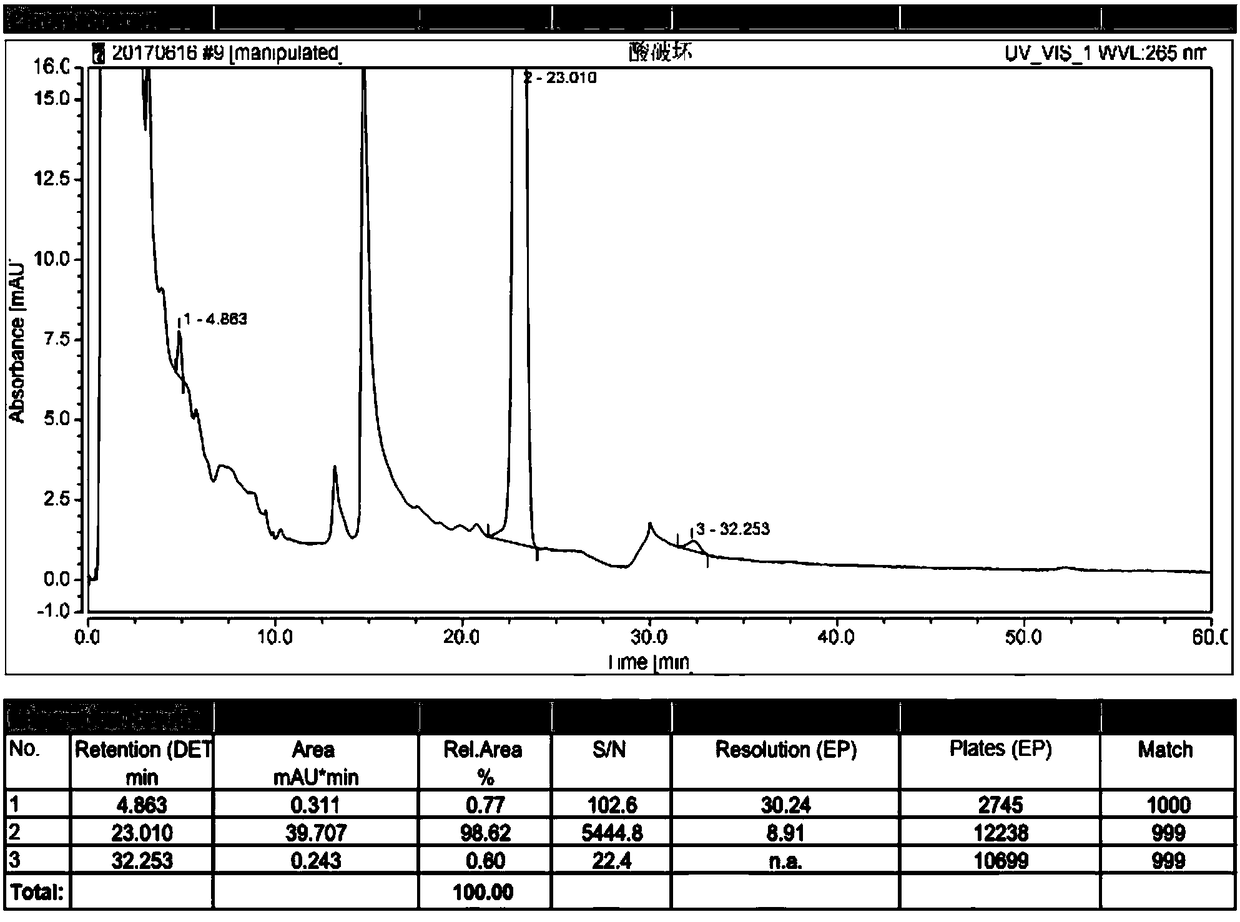

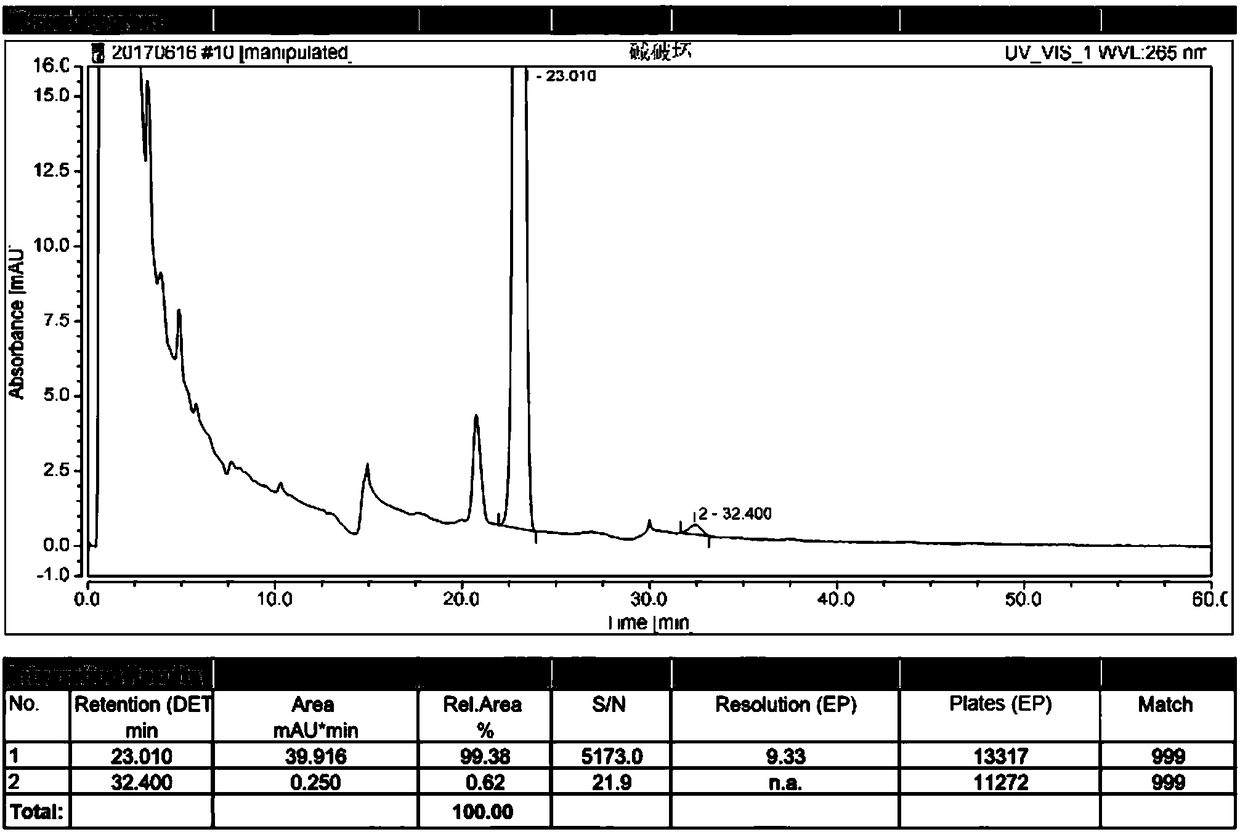

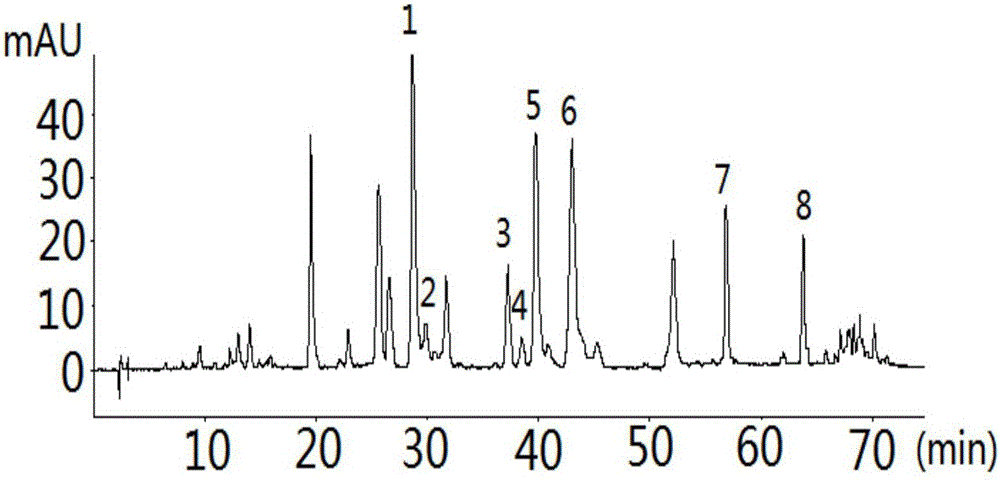

Inspection method for alfacalcidol tablet related substances

ActiveCN108663442AReliable impurity profile referenceHigh probability of degradationComponent separationSilica gelImpurity

The invention discloses a high performance liquid chromatography method for alfacalcidol tablet related substances. A sample solution and a control solution are obtained by adopting octadecylsilane bonded silica as a filler and an acetonitrile-water mixed solution as a mobile phase, adopting an ultraviolet detector for a wavelength of 265 nm and especially adopting a vortex-extraction-concentration way, so the detection of an extremely low dose of a drug in the above tablet and related substances thereof is greatly ensured. The method be used to simultaneously analyze all known impurities in the alfacalcidol tablet, and allows the content of each known impurity to be effectively controlled by a main component self-contrasted technology with a correction factor, the resolution among all impurity peaks and the resolution between a main peak and the adjacent impurity peak are respectively greater than 1.5, and the peak purities of the main peak and all the impurity peaks are respectivelymore than 1.0. The high performance liquid chromatography method is a simple and reliable analysis method for the quality control of the alfacalcidol tablet.

Owner:NANJING HERON PHARM CO LTD

Cutting module and full-automatic laser pipe cutting machine

ActiveCN112207456ARealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a cutting module and a full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises a feeding module, a power module and the cutting module, wherein the feeding module is used for loading pipes to be cut into pipe grooves of a feeding wheel one by one, and then the feeding wheel rotates to enable the pipes to be cut to be sequentially subjected to the procedures of feeding, centering, clamping, section cutting and discharging; the power module is used for driving the pipes at the section cutting procedure to rotate so as to ensure that the whole circles of the pipes are cut off, and intermittently driving the feeding wheel to rotate so as to complete procedure switching; and the cutting module is used for cutting the pipes through laser emitted by a laser device, the pipes are relatively fixed in the axial direction, and laser cutting heads move in the axial direction of the pipes and positioning is carried out, so that accurate cutting of the pipes is completed. Automatic feeding can be achieved, and the five procedures of feeding, clamping, axial alignment, section cutting and discharging can be synchronously achieved,so that the production efficiency is improved by at least two times or above. In addition, the mode that the laser device moves while the pipes are fixed is adopted, and the full-automatic laser pipecutting machine can adapt to pipes with more lengths.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Synthetic method of rilpivirine intermediate

ActiveCN111333543AIncrease profitHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystCyanoacetic acid

The invention provides a synthetic method of a rilpivirine intermediate. The synthesis method includes: taking 2, 4, 6-trimethylaniline as the raw material to react with 2, 3-dichloro-5, 6-dicyanobenzoquinone (DDQ) in a diluted hydrochloric acid solution to obtain 4-amino-3, 5-dimethyl benzaldehyde, then carrying out Knoevenagel reaction with cyanoacetic acid under the condition that organic alkali serves as the catalyst to obtain 3-(4-amino-3, 5-dimethylphenyl)2-cyanoacrylate, and then carrying out decarboxylation reaction to obtain the intermediate (E)-3-(4-amino-3, 5-dimethylphenyl)acrylonitrile. According to the invention, the raw materials used in the whole synthesis process are cheap and easily available, the raw material utilization rate is high, the synthesis process is simple, thereaction conditions are mild, the intermediate yield is high, and the method is suitable for the requirements of industrial large-scale production. In addition, compared with an original synthetic route, the reagents used in the method are low in toxicity, therefore the method has good environmental protection benefits.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Production process of sodium hyaluronate

ActiveCN106434443AHigh yieldHigh purityBacteriaMicroorganism based processesHyaluronic acidFermentation

The invention discloses a production process of sodium hyaluronate. A strain high in hyaluronic acid yield is screened out, improved fermentation technology is combined, production period is short, and the production process is simple; raw and auxiliary materials are common and easy to get, production is easy to control, impurity content is lower, the production process is suitable for industrial large-scale production requirements and high in yield, and production cost is lowered greatly.

Owner:DONGYING FIRST BIOCHEM IND CO LTD

Graphene/molybdenum disulfide composite electrode material and preparation method thereof

The invention relates to the fields of a novel chemical electric power source and a new energy material, and particularly discloses a graphene / molybdenum disulfide composite electrode material and a preparation method of the composite electrode material. The preparation method comprises the steps of: (1) preparing graphite oxide from graphite as a raw material by an oxidation and intercalation method; (2) dissolving prepared graphite oxide with deionized water, carrying out ultrasonic stripping to obtain a graphene oxide solution, then adding DMF (dimethyl formamide) and molybdate, finally adding a reducing agent, and dispersing uniformly to obtain a mixed solution; and (3) transferring the mixed solution to a reaction kettle, keeping the temperature in the temperature condition of greater than or equal to 180 DEG C for 5-10h, centrifuging and washing the product to remove DMF, and drying to obtain the graphene / molybdenum disulfide composite electrode material product. The preparation method of the graphene / molybdenum disulfide composite electrode material is simple, uniform in reaction system and low in production cost, and is particularly suitable for requirements of industrial large scale production; and the prepared product graphene / molybdenum disulfide composite electrode material has better electrochemical performances.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Double-layer/multilayer thermoelectric device and preparation method thereof

ActiveCN109449277AWeld firmlyCooperate wellThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsRoom temperature

The invention relates to a double-layer / multilayer thermoelectric device and belongs to the technical field of thermoelectric conversion. The double-layer / multilayer thermoelectric device at least comprises thermoelectric sub-modules corresponding to two different temperature segments and an insulating material layer located in front of the thermoelectric sub-modules; the at least one thermoelectric sub-module comprises a thermoelectric material with low low-temperature electric conductivity and high high-temperature electric conductivity, namely a high-temperature ZT value is more than 10 times higher than a low-temperature ZT value; the thermoelectric material with low room temperature electric conductivity and high high-temperature electric conductivity corresponds to the high-temperature segment thermoelectric sub-module; each thermoelectric sub-module comprises a plurality of pairs of n-type and / or p-type thermoelectric arms, wherein the internal structure of each thermoelectric arm is five layers of a high-melting-point metal layer, a metallization layer, a thermoelectric material, a metallization layer and a high-melting-point metal layer from top to bottom. The obtained double-layer / multilayer thermoelectric material device can still keep the maximum conversion efficiency Eta max to be not less than 3% even when the temperature difference is only less than 300k. The device and the method in the invention are not high to the requirement of the sintering process, are lower to the requirement on equipment, are low in production cost, and are more suitable for the requirement of industrial large-scale production.

Owner:UNIV OF SCI & TECH BEIJING +1

A kind of preparation method and application of supported molybdenum oxide catalyst

ActiveCN107597097BFacilitated DiffusionIncrease exposureMolecular sieve catalystsOrganic compound preparationPtru catalystDepolymerization

The invention discloses a preparation method for a supported molybdenum oxide catalyst and an application thereof. The preparation method comprises the following steps: firstly preparing a molybdenumdichloride hydrate precursor, dissolving the obtained molybdenum dichloride hydrate precursor into methanol or ethanol, slowly adding the obtained liquid into a carrier dropwise after the precursor iscompletely dissolved, allowing the obtained mixture to stand, performing evaporation, and performing roasting under an inert gas atmosphere to obtain the supported molybdenum oxide catalyst. The application of the supported molybdenum oxide catalyst including that the supported molybdenum oxide catalyst is used for hydrogenation depolymerization of lignin, is used for preparing aniline from nitrobenzene and is used as a composite electrode material. The catalyst provided by the invention has the advantages of having small particles and a large specific surface area, being beneficial for reactant diffusion and active site exposure and the like, and meanwhile the catalyst has similar noble-metal catalytic performance, and can be widely applied to the fields such as biomass catalytic conversion and electrode materials.

Owner:BEIJING FORESTRY UNIVERSITY

Detection method of ACEI-containing composition and related substances

PendingCN110320289AGood injection precisionSystem Suitability Solution StabilityComponent separationChemistryFolic acid

The invention provides an analysis and detection method for simultaneously measuring enalapril maleate folic acid and related substances, a high performance liquid chromatograph is adopted, octyl-bonded silica gel is used as a filler, a phosphate buffer solution with pH of 2-3 and acetonitrile are used as mobile phases, gradient elution is carried out, the detection wavelength is 210 nm to 220 nm,and the column temperature is 48-52 DEG C. According to the analysis and detection method provided by the invention, the effective separation of impurities is achieved by using gradient elution, theseparation degree of each absorption peak is greater than 1.5, the sample introduction precision is good, the system suitability solution is stable, and the method has good durability.

Owner:NANJING YOUKE BIOLOGICAL MEDICAL RES +3

High performance liquid chromatography analysis method for alvimopan or its related substances

InactiveCN103575813BAvoid frequent replacementSimple methodComponent separationResponse factorHplc method

The invention provides a high-performance liquid chromatography analysis method for alvimopan or its related substances. The method of the present invention is a method for component analysis of a mixture containing alvimopan and / or related substances of alvimopan by high performance liquid chromatography. Compared with the prior art, the method of the present invention has the following advantages and positive effects: the method is simple and fast, can effectively detect each known related substance, and can accurately detect the content of the known related substance according to its response factor , can comprehensively control related substances in alvimopan and its preparations, improve drug safety, and provide a basis for formulating quality standards for alvimopan raw materials and preparations.

Owner:NEW FOUNDER HLDG DEV LLC +2

A fully automatic laser pipe cutting machine

ActiveCN112207459BRealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a material pushing mechanism and a fully automatic laser pipe cutting machine thereof. The fully automatic laser pipe cutting machine comprises: a feeding module for loading the pipes to be cut into the pipe grooves of the feeding wheel one by one, and then the upper The material wheel rotates so that the pipes to be cut go through the processes of feeding, centering, clamping, cutting, and discharging in sequence; the power module is used to drive the rotation of the pipes at the cutting process to ensure that the pipes are cut in one circle, and at the same time, the The feeding wheel is driven to rotate to complete the process switching; the cutting module is used to cut the pipe through the laser emitted by the laser, and the pipe is relatively fixed in the axial direction, and the laser cutting head moves and positions along the axial direction of the pipe to complete the pipe cutting precise cutting. The invention can realize automatic feeding, and the five processes of feeding, clamping, axial alignment, section cutting, and discharging can be synchronized to realize at least twice or more increase in production efficiency. In addition, the method of moving the laser and fixing the pipe can be adapted to more lengths of pipe.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

A detection method for simultaneously determining the content of flavonoids and terpene lactones in ginkgo biloba extract and its preparations

ActiveCN105891355BAvoid frequent replacementImprove work efficiencyComponent separationGinkgo leaf extractAnalysis method

The invention relates to the field of medicine detection, in particular to a high-performance liquid chromatography detecting method for measuring the content of flavonoid compounds and terpene lactone compounds in ginkgo leaves (or ginkgo leaf extract) or preparations of the ginkgo leaves at the same time. The HPLC-DAD-ELSD method is set up, the method can measure the eight flavonoid compounds and three terpene lactone compounds in the ginkgo leaves (or the leaf extract) or preparations of the ginkgo leaves at the same time, the measurement result is analyzed, and a new analysis method and a basis are provided for quality control over the ginkgo leaf extract and the preparations of the ginkgo leaf extract.

Owner:HEBEI SHINEWAY PHARMA +2

A power module and its automatic laser pipe cutting machine

ActiveCN112207457BRealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusLaser cuttingErbium lasers

The invention discloses a power module and its full-automatic laser pipe cutting machine. The full-automatic laser pipe cutting machine comprises: a feeding module, which is used to load the pipes to be cut into the pipe grooves of the feeding wheel one by one, and then the feeding The wheel rotates so that the pipes to be cut go through the processes of feeding, centering, clamping, cutting, and discharging in sequence; the power module is used to drive the rotation of the pipes at the cutting process to ensure that the pipes are cut off in one circle, and at the same time intermittently Drive the feeding wheel to rotate to complete the process switching; the cutting module is used to cut the pipe through the laser emitted by the laser, and the pipe is relatively fixed in the axial direction, and the laser cutting head moves and positions along the axial direction of the pipe to complete the cutting of the pipe Precise cut. The invention can realize automatic feeding, and the five processes of feeding, clamping, axial alignment, section cutting, and discharging can be synchronized to realize at least twice or more increase in production efficiency. In addition, the method of moving the laser and fixing the pipe can be adapted to more lengths of pipe.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

A method for checking related substances of tacalcitol ointment

ActiveCN108663441BReliable impurity profile referenceHigh probability of degradationComponent separationFluid phaseAlcohol

The invention discloses a high performance liquid chromatography method for tacalcitol ointment related substances. Octadecylsilane bonded silica is used as a filler, an acetonitrile-water mixed solution is used as a mobile phase, and a sample solution and a control solution are obtained in a vortex-extraction-concentration manner, so the detection of an extremely low dose of a drug in the above ointment and related substances thereof is greatly ensured, and the solvent system for dissolving and concentrating to form dry residues is optimized, thereby the shape of peaks is sharp, and the reproducibility is good. The method can be used to simultaneously analyze all known impurities in the tacalcitol ointment , and allows the content of each known impurity to be effectively controlled by a main component self-contrasted technology with a correction factor, the resolution among all impurity peaks and the resolution between a main peak and the adjacent impurity peak are respectively greater than 1.5, and the peak purities of the main peak and all the impurity peaks are respectively more than 1.0. The method is a simple and reliable analysis method for the quality control of the tacalcitol ointment.

Owner:NANJING HERON PHARM CO LTD

A kind of determination method of fat-soluble platinum complex and its preparation related substances

ActiveCN104597157BAvoid frequent replacementImprove work efficiencyComponent separationMiriplatinGradient elution

The invention relates to a method for measuring fat-soluble platinum complex and preparation related substances thereof. The detection method refers to a high performance liquid chromatography method. The chromatographic conditions are that the chromatographic column refers to an octadecylsilane chemically bonded silica (C18) chromatographic column; the phase A refers to a methanol-ethanol mixed solvent; the phase B refers to a mixed solvent of water and methanol or ethanol, and gradient elution is performed; the column temperature is 38-42 DEG C; the detection wavelength is 208-215nm; and the flow velocity is 0.5-2.0ml / min. With the adoption of the high performance liquid chromatography method disclosed by the invention, the content of impurities A and the content of other unknown impurities in the sample can be accurately determined, the separation degree of each impurity is high in the analysis process, the reproducibility of the analysis result is high, and a simple and reliable method is provided for quality control and analysis of miriplatin and preparations thereof.

Owner:SHINEWAY PHARMA GRP LTD

A method for simultaneous determination of multi-component content in Shuxuening injection

ActiveCN106706809BAvoid frequent replacementImprove work efficiencyComponent separationQuality controlFlavonoid glycosides

The invention relates to the field of medicine detection, in particular to a method for simultaneously determining the contents of multiple components in a Shuxuening injection. By adopting the method, the contents of 14 flavonoid glycoside compounds and 2 phenolic acid compounds in the Shuxuening injection can be simultaneously determined, and the new analysis method and a basis are provided for quality control of commercially available Shuxuening injections.

Owner:HEBEI SHINEWAY PHARMA +1

Process for continuously producing insoluble sulfur by pipeline

InactiveCN102009962BIncrease contentImprove thermal stabilitySulfur preparation/purificationPhysical chemistryProcess engineering

Owner:江西恒兴源化工有限公司

A kind of production technology of sodium hyaluronate

ActiveCN106434443BHigh yieldHigh purityBacteriaMicroorganism based processesHyaluronic acidFermentation

Owner:DONGYING FIRST BIOCHEM IND CO LTD

A method for simultaneous determination of butylphthalide and its related substances

ActiveCN106093238BAvoid frequent replacementImprove work efficiencyComponent separationPhosphateButylphthalide

Owner:NANJING YOKO PHARMA +2

A detection method for simultaneously determining the contents of flavonoids and terpene lactones in Shuxuening

ActiveCN105891356BAvoid frequent replacementImprove work efficiencyComponent separationQuality controlGinkgo leaf extract

The invention relates to the field of medicine detection, in particular to a high-performance liquid chromatography detecting method for measuring the content of flavonoid compounds and terpene lactone compounds in ginkgo leaves (or ginkgo leaf extract) or preparations of the ginkgo leaves at the same time. The HPLC-DAD-ELSD method is set up, the method can measure the eight flavonoid compounds and three terpene lactone compounds in the ginkgo leaves (or the ginkgo leaf extract) or preparations of the ginkgo leaves at the same time, the measurement result is analyzed, and a new analysis method and a basis are provided for quality control over the ginkgo leaf extract and the preparations of the ginkgo leaf extract.

Owner:HEBEI SHINEWAY PHARMA +1

A method for simultaneous determination of multi-component content in ginkgo biloba extract and its preparation

ActiveCN106770828BAvoid frequent replacementImprove work efficiencyComponent separationMedicineQuality control

The invention relates to the field of medicament detection, and more specifically relates to a high performance liquid chromatography for simultaneously measuring the contents of gingko leaves (or extracts thereof) and multiple components in a preparation thereof. The method can be used for simultaneously measuring the contents of gingko leaves (or extracts thereof) as well as 14 flavonoid compounds and 2 phenolic acid compounds in a preparation thereof, and a new analysis method and basis are thus provided for quality control of commercial gingko leaf preparations.

Owner:HEBEI SHINEWAY PHARMA +2

A feeding module and its automatic laser pipe cutting machine

ActiveCN112207453BRealize automatic feeding processRealize automated productionMetal working apparatusLaser beam welding apparatusEngineeringLaser cutting

The invention discloses a feeding module and a full-automatic laser pipe cutting machine thereof. The full-automatic laser pipe cutting machine comprises: a feeding module, which is used to load the pipes to be cut into the pipe grooves of the feeding wheel one by one, and then the upper The material wheel rotates so that the pipes to be cut go through the processes of feeding, centering, clamping, cutting, and discharging in sequence; the power module is used to drive the rotation of the pipes at the cutting process to ensure that the pipes are cut in one circle, and at the same time, the The feeding wheel is driven to rotate to complete the process switching; the cutting module is used to cut the pipe through the laser emitted by the laser, and the pipe is relatively fixed in the axial direction, and the laser cutting head moves and positions along the axial direction of the pipe to complete the pipe cutting precise cutting. The invention can realize automatic feeding, and the five processes of feeding, clamping, axial alignment, section cutting, and discharging can be synchronized to realize at least twice or more increase in production efficiency. In addition, the method of moving the laser and fixing the pipe can be adapted to more lengths of pipe.

Owner:CHONGQING WANCHONGSHAN INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com