Graphene/molybdenum disulfide composite electrode material and preparation method thereof

A molybdenum disulfide, composite electrode technology, applied in electrodes, electrolysis process, electrolysis components and other directions, can solve the problems of expensive organic solvent, uneconomical post-processing, difficult to uniform products, etc., to reduce the use of expensive organic solvent DMF, Low production cost and uniform reaction system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Experimental method

[0048] Graphite oxide was prepared by the Staudenmair method: the reaction temperature was 5°C, the natural flake graphite was added to the mixed solution of nitric acid and sulfuric acid, stirred and cooled for half an hour, then sodium chlorate was added, reacted at 5°C for 12 hours, and precipitated with water for at least 5 times to remove the acid, and then centrifuged; dried at 65°C to obtain graphite oxide.

[0049] Weigh 1 mg of graphite oxide and add it into 10 ml of deionized water, and ultrasonically strip it for 5 minutes to obtain a graphene oxide solution. Add 10ml of DMF. Weigh 22 mg of ammonium tetrathiomolybdate, add it into the solution, and sonicate for 10 minutes, and the solution turns blood red at this time; then add 1 ml of hydrazine hydrate, and sonicate for 30 minutes. Transfer the above solution to a 100ml reaction kettle, raise the temperature to 200°C, and keep the temperature for 10 hours. A graphene / molybdenum di...

Embodiment 2

[0052] 1. Experimental method

[0053] The preparation method of graphite oxide was the same as that in Example 1, and 10 mg of graphite oxide was weighed and added into 10 ml of deionized water, and ultrasonically peeled for 20 minutes to obtain a graphene oxide solution. Add 10ml of DMF, weigh 22mg of ammonium tetrathiomolybdate, add it to the reaction solution, and ultrasonicate for 10 minutes. At this time, the solution is blood red; then add 1ml of hydrazine hydrate, and ultrasonicate for 40 minutes; transfer the above solution to a 100ml reaction kettle In the process, the temperature was raised to 300°C, and the temperature was kept for 5 hours. A graphene / molybdenum disulfide composite material in which the ratio of graphene to molybdenum disulfide is 1:1 is obtained.

[0054] 2. Experimental results

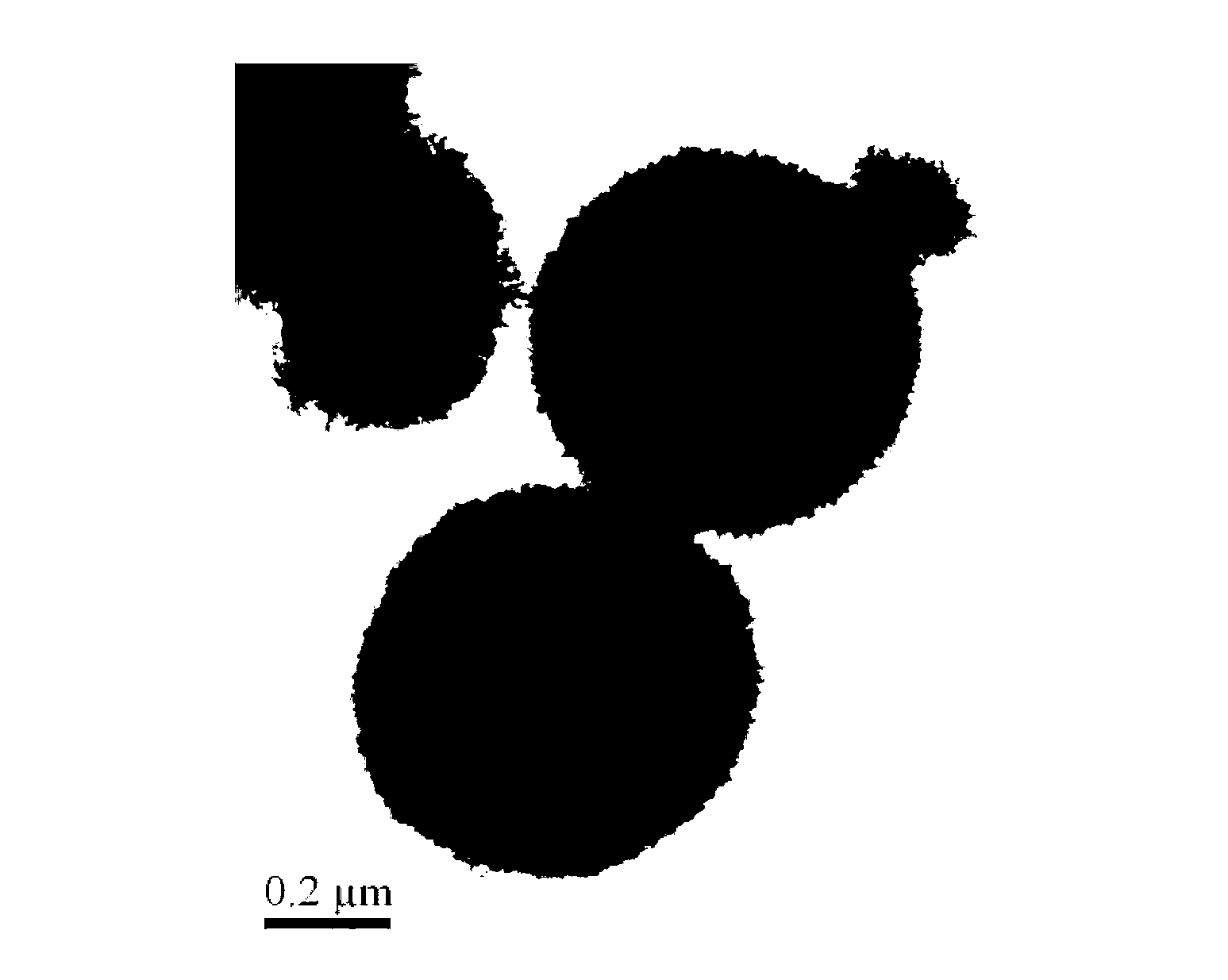

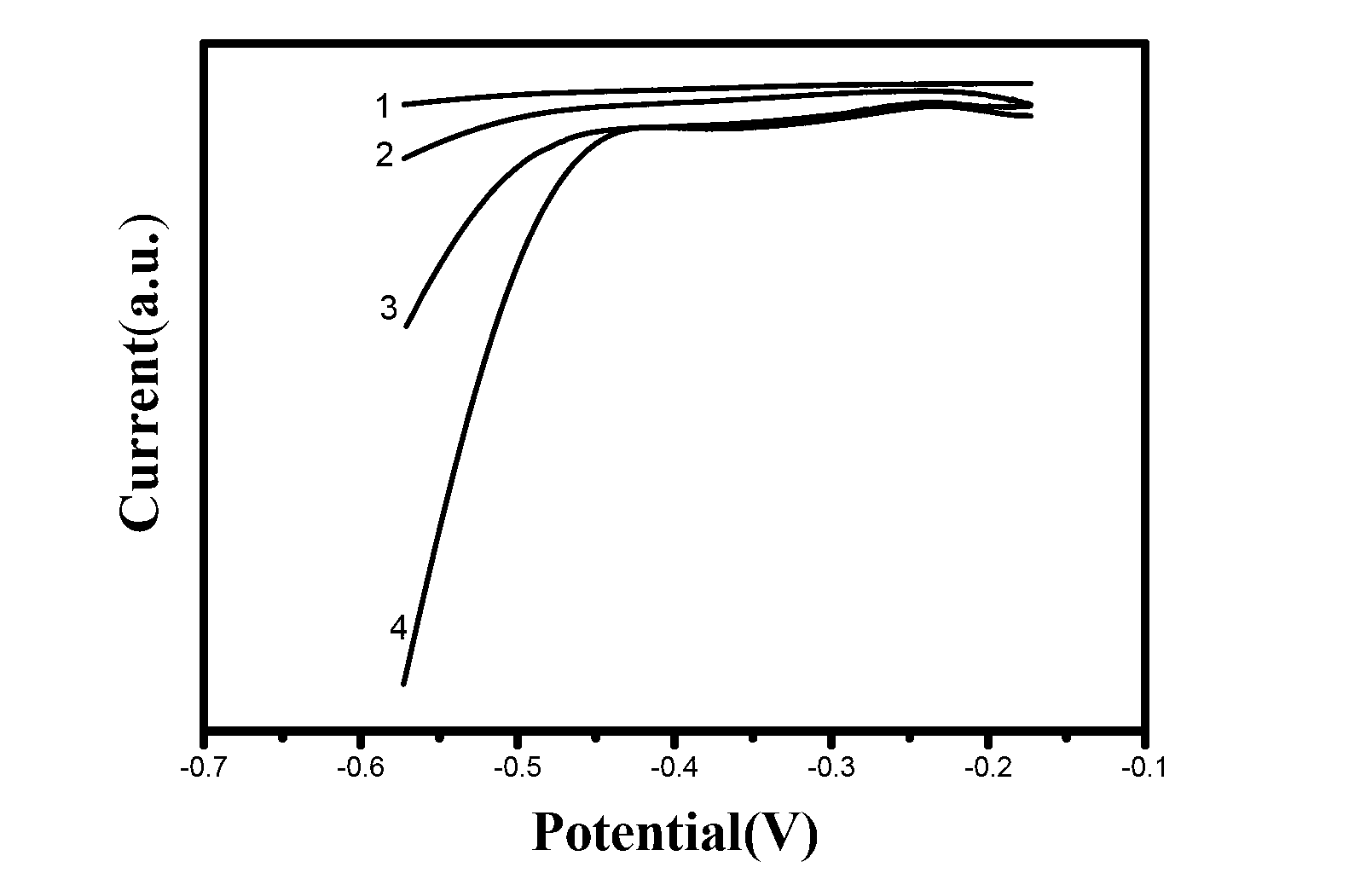

[0055] Figure 4 For the TEM figure of the graphene / molybdenum disulfide composite material prepared according to Example 2, the TEM test shows that the composite mat...

Embodiment 3

[0057] 1. Experimental method

[0058] The preparation method of graphite oxide was the same as that in Example 1. Weighed 44 mg of graphite oxide and added it to 20 ml of deionized water, and ultrasonically stripped it for 20 minutes to obtain a graphene oxide solution. Add 10ml of DMF, weigh 22mg of ammonium tetrathiomolybdate, add to it, ultrasonic for 10 minutes, the solution is blood red at this time; then add 1ml of hydrazine hydrate, and ultrasonic for 10 minutes;

[0059] Transfer the above solution to a 100ml reaction kettle, raise the temperature to 180°C, and keep the temperature for 10 hours. A graphene / molybdenum disulfide composite material with a material ratio of graphene to molybdenum disulfide of 2:1 is obtained.

[0060] 2. Experimental results

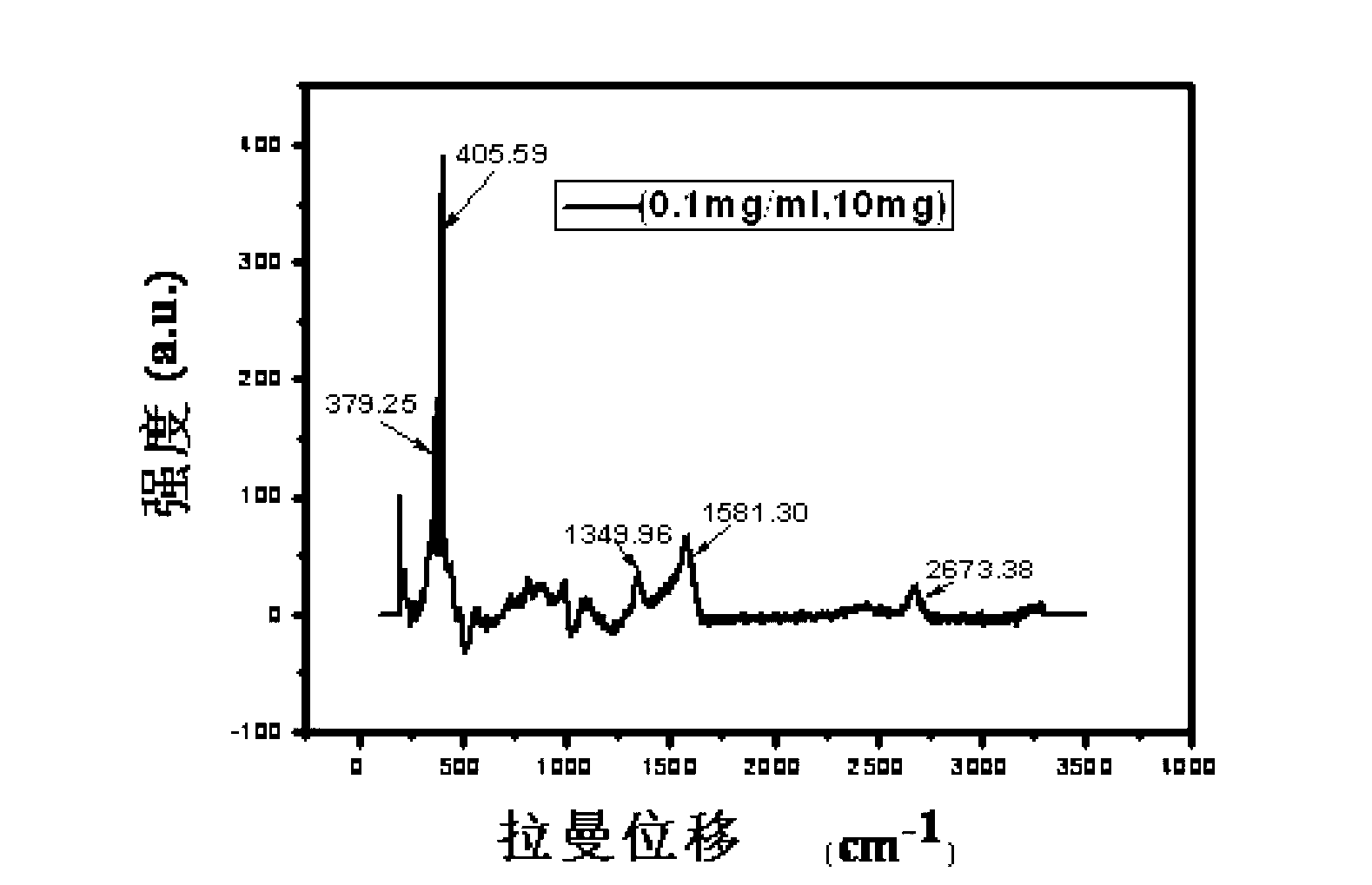

[0061] Such as Figure 6 It is the TEM figure of the graphene / molybdenum disulfide composite material prepared according to embodiment 3; Figure 7 It is the Raman diagram of the material. The test shows that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com