Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Smooth and precise movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

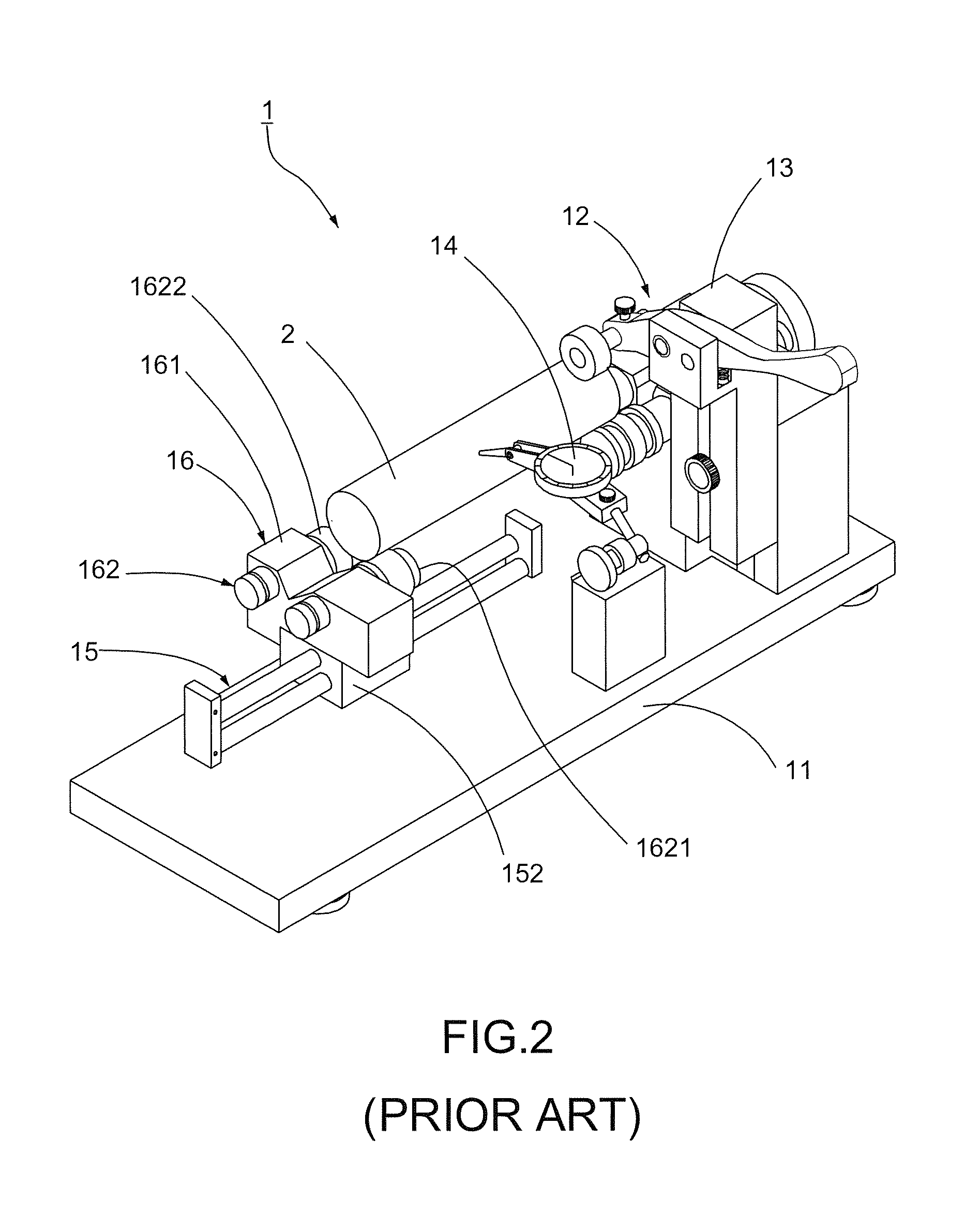

Tool system

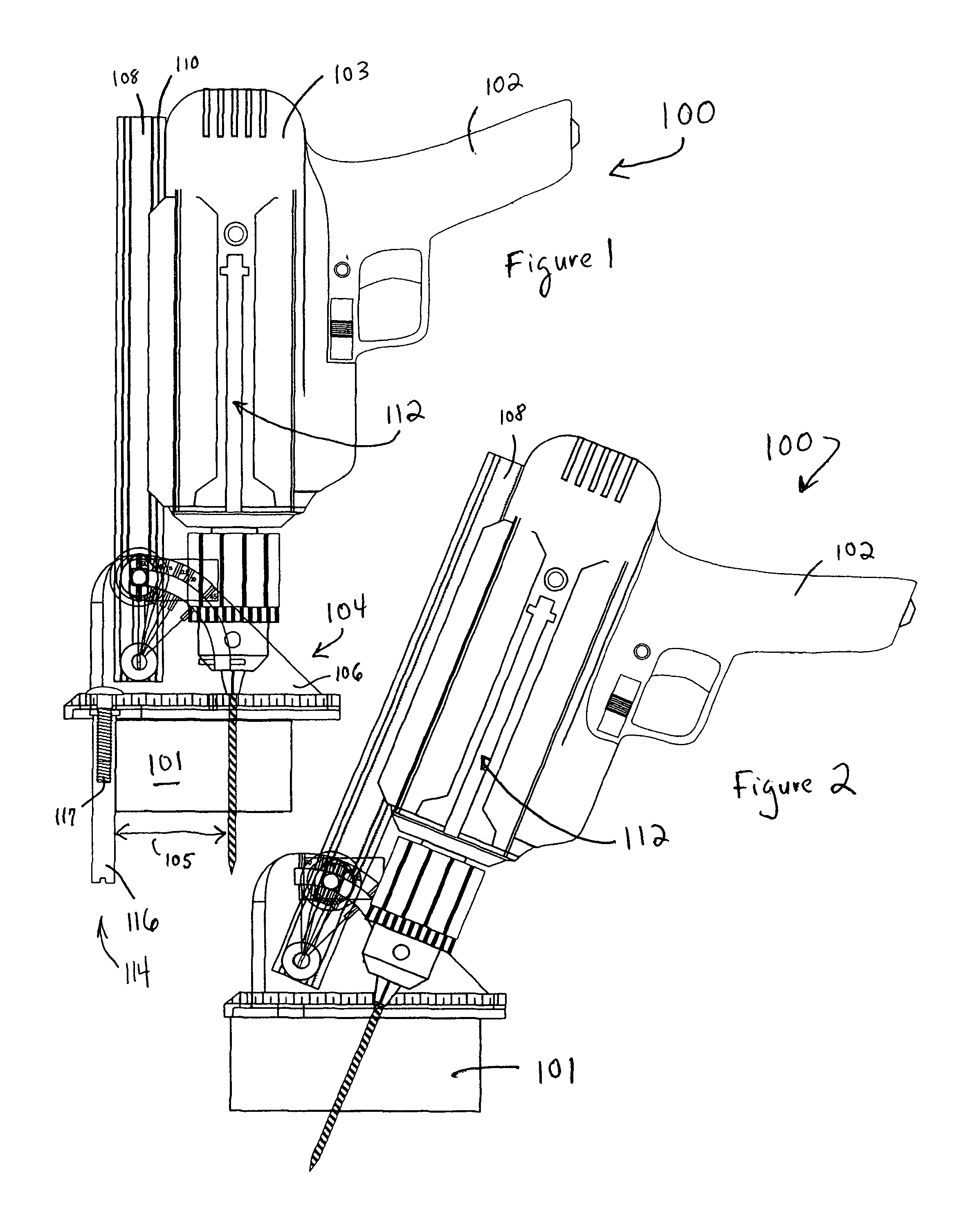

ActiveUS8375541B1Facilitate smooth and precise movementEasy to storeDrilling/boring measurement devicesThread cutting machinesClassical mechanicsElectric machinery

One embodiment of the present invention is a drill motor assembly (100) including a drill motor (102) and a housing guide assembly (104). The housing guide assembly in turn includes a base (106) and a mast (108) pivotally and adjustably attached thereto. A male slide (110) on the mast (108) slidably and precisely engages a female slide (112) on the drill motor (102). To drill a precise hole using the drill motor assembly (100), the operator simply adjusts the mast (108) to the desired angle relative to the base (106), engages the slides (110) and (112), activates the drill motor (102), and moves the drill motor (102) along the mast (108) until the drilling operation is completed. The present invention also includes a wide variety of accessories that can be connected to, and in some cases powered by, the drill motor (102); and a wide variety of storage options as well; and all of the attachments and storage options use the slides on the tool and accessories to facilitate use and / or storage of the various devices and components of the present invention.

Owner:BEACHY ROBERT WISLER +2

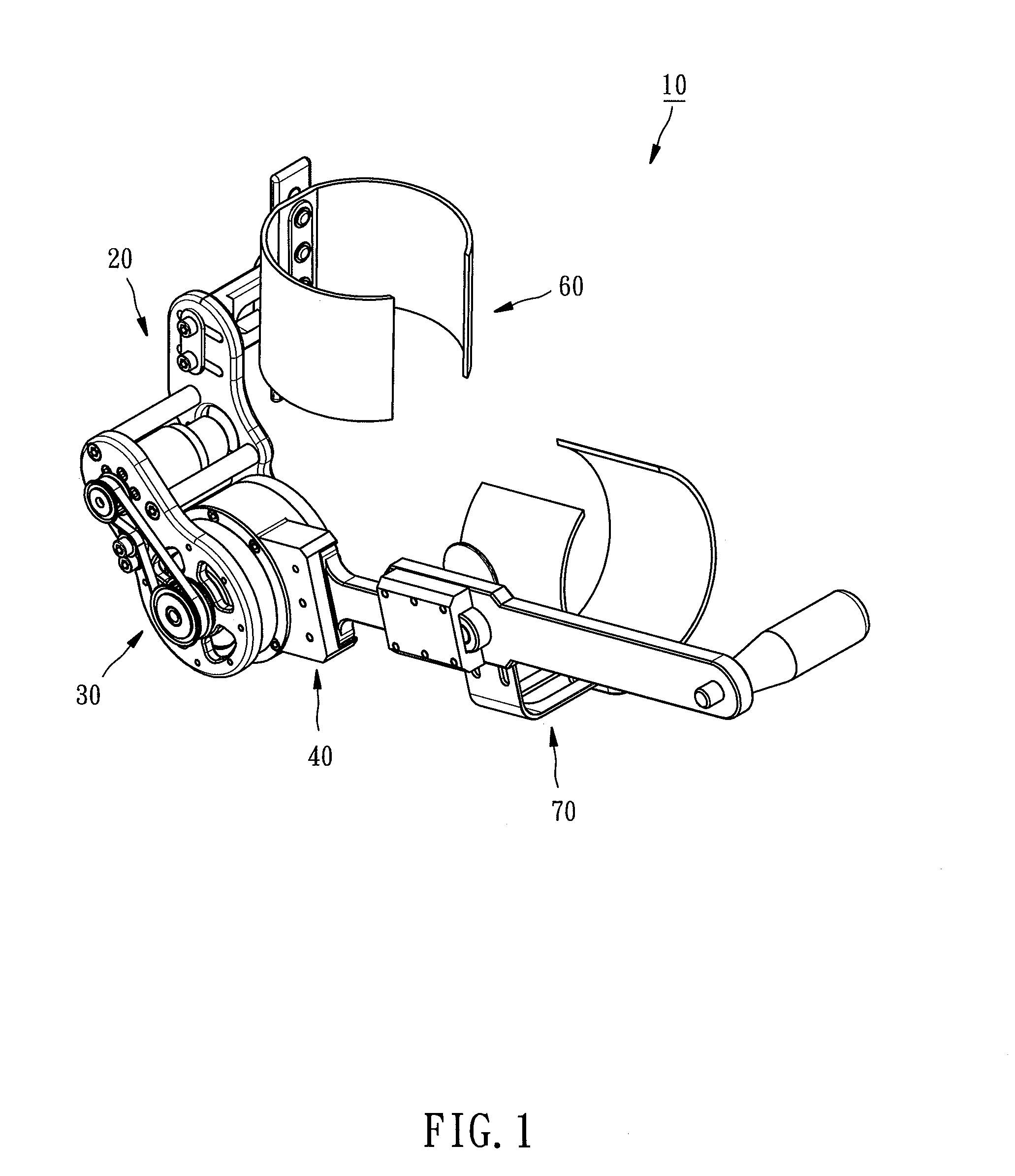

Force feedback type complaint orthotic device

ActiveUS20150173992A1Easy to operateRapid responseDiagnosticsChiropractic devicesEngineeringOrthotic device

A Force feedback type compliant orthotic device includes a fixing base, driving unit, first limb supporting unit, and second limb supporting unit. The driving unit has a motor disposed at the fixing base and an output shaft connected to the motor. The output shaft is inserted into a joint base to connect with a resilience unit. The first limb supporting unit has a first supporting element fixed at the fixing base and a first electromyographic signal sensor disposed at the first supporting element. The second limb supporting unit has a second supporting element disposed at the joint base and a second electromyographic signal sensor disposed at the second supporting element. The motor generates appropriate auxiliary power according to the sensing result of the first and second electromyographic signal sensors, such that the first and second supporting elements move relative to each other precisely.

Owner:HIWIN TECH

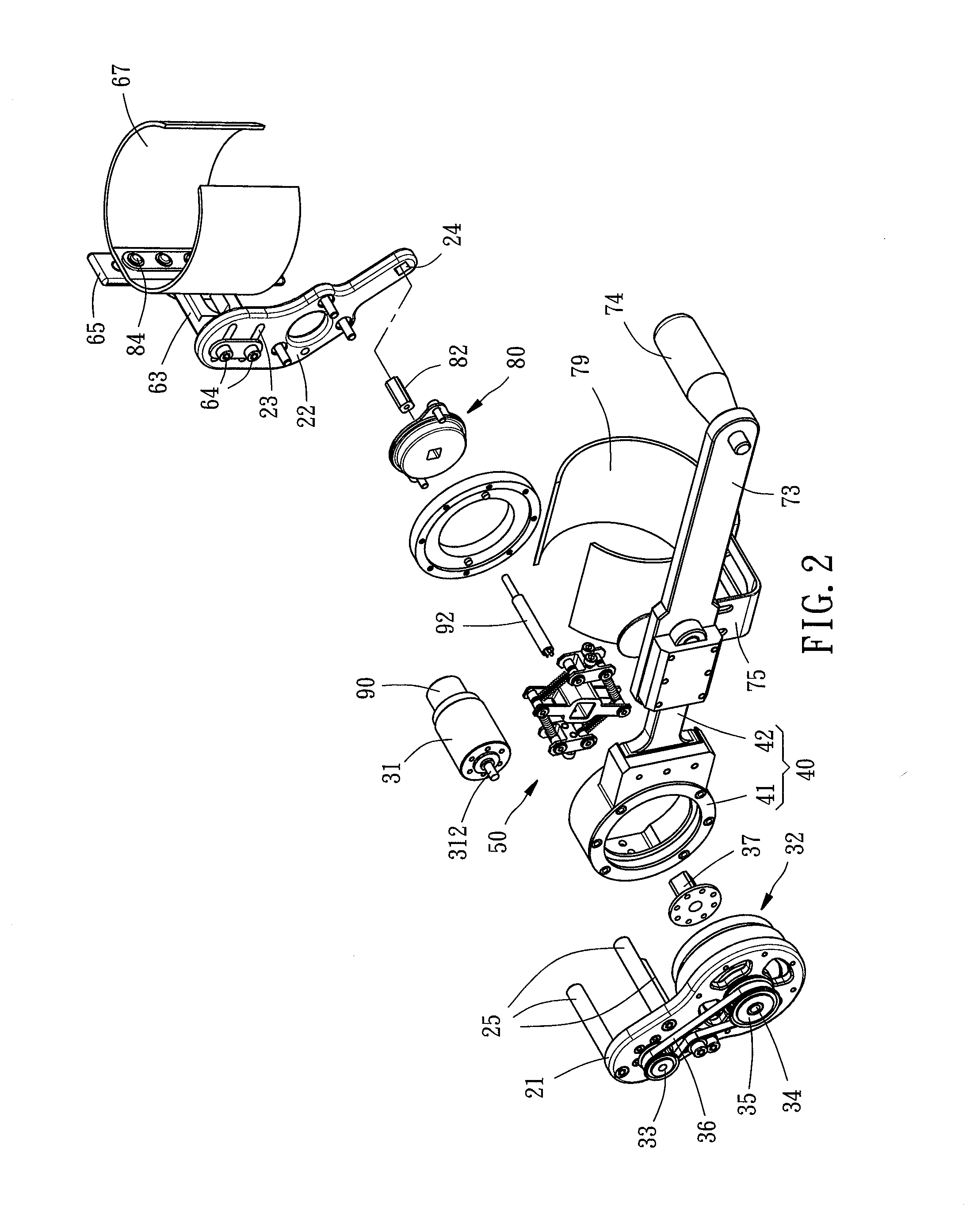

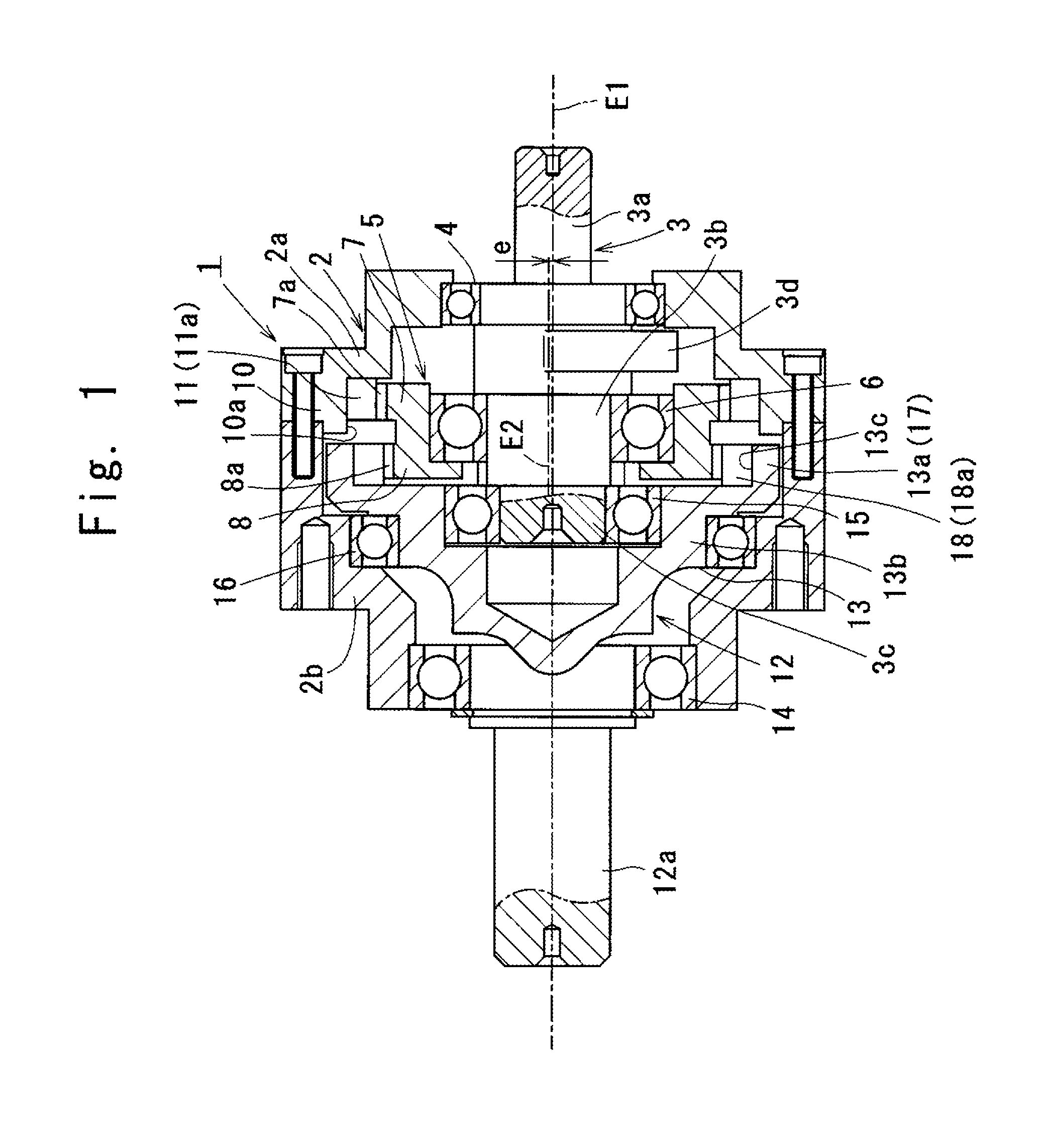

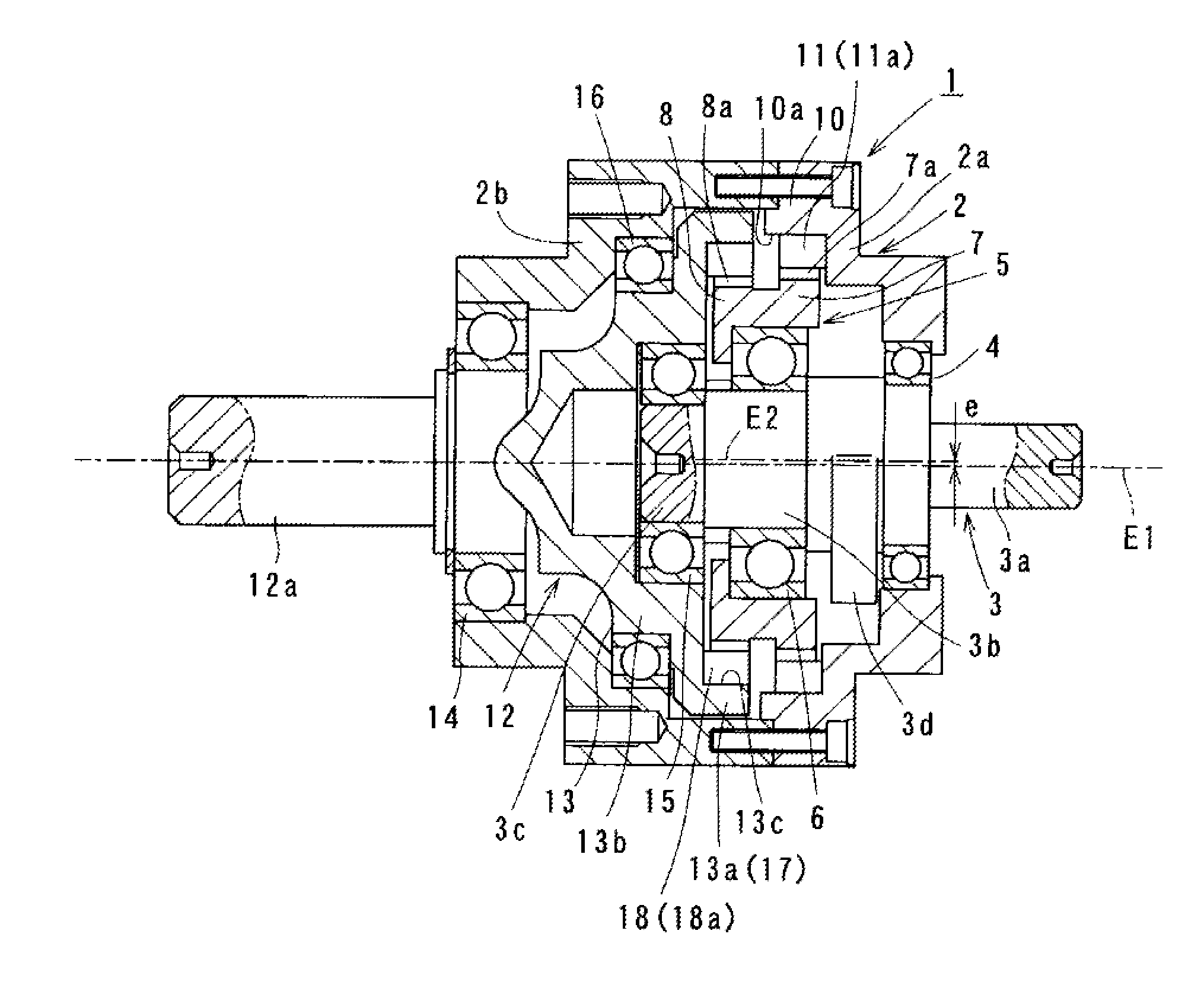

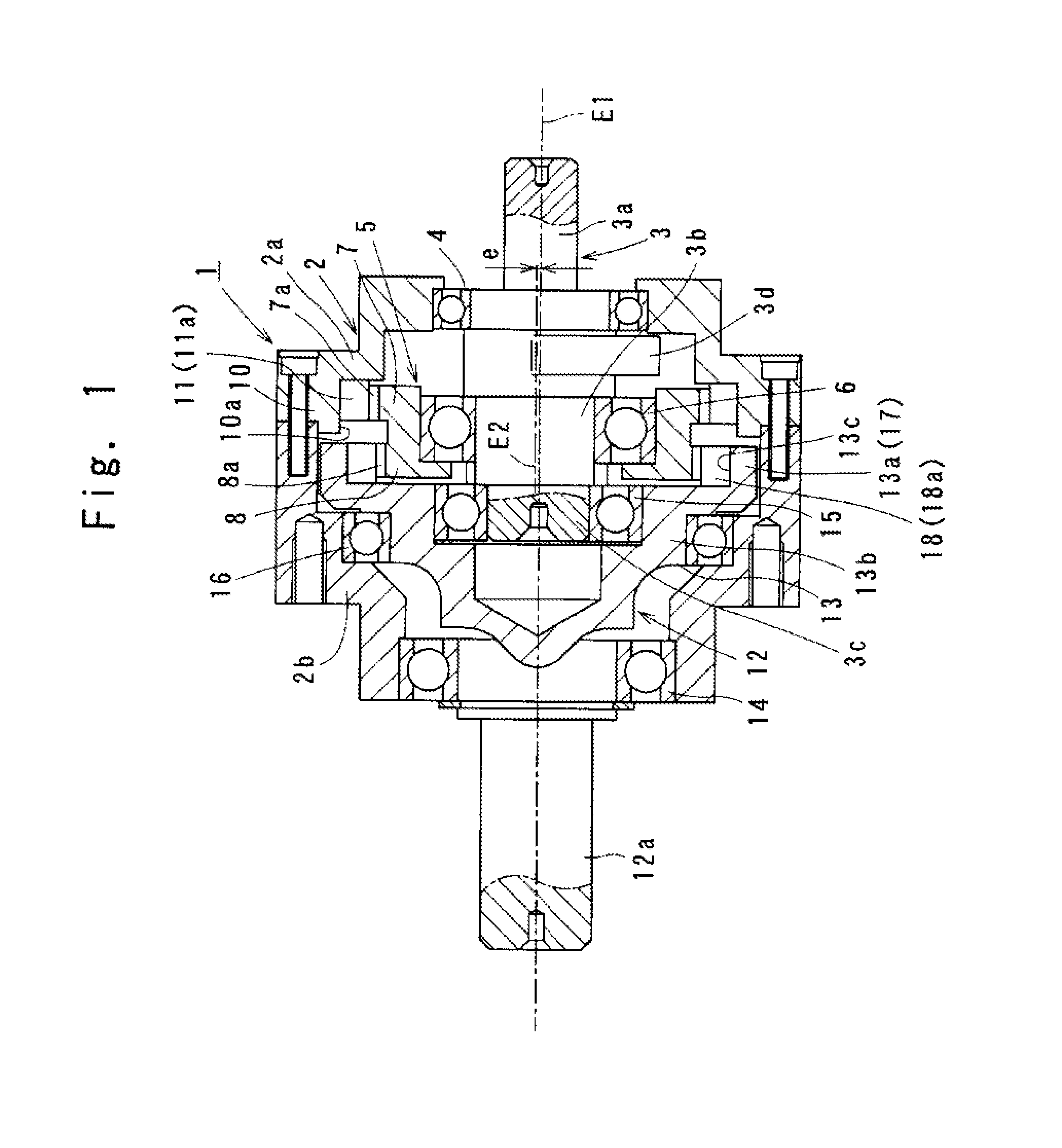

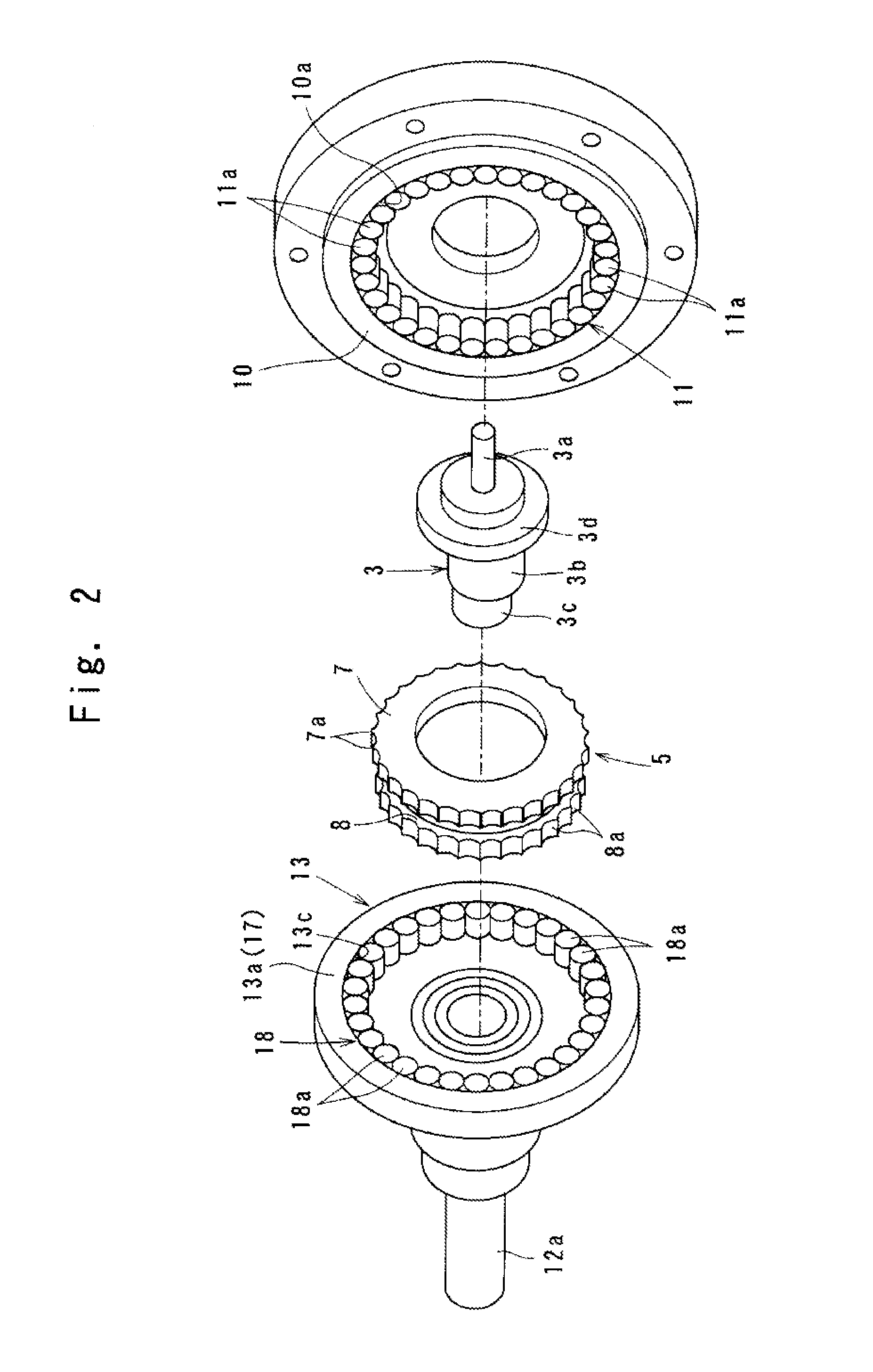

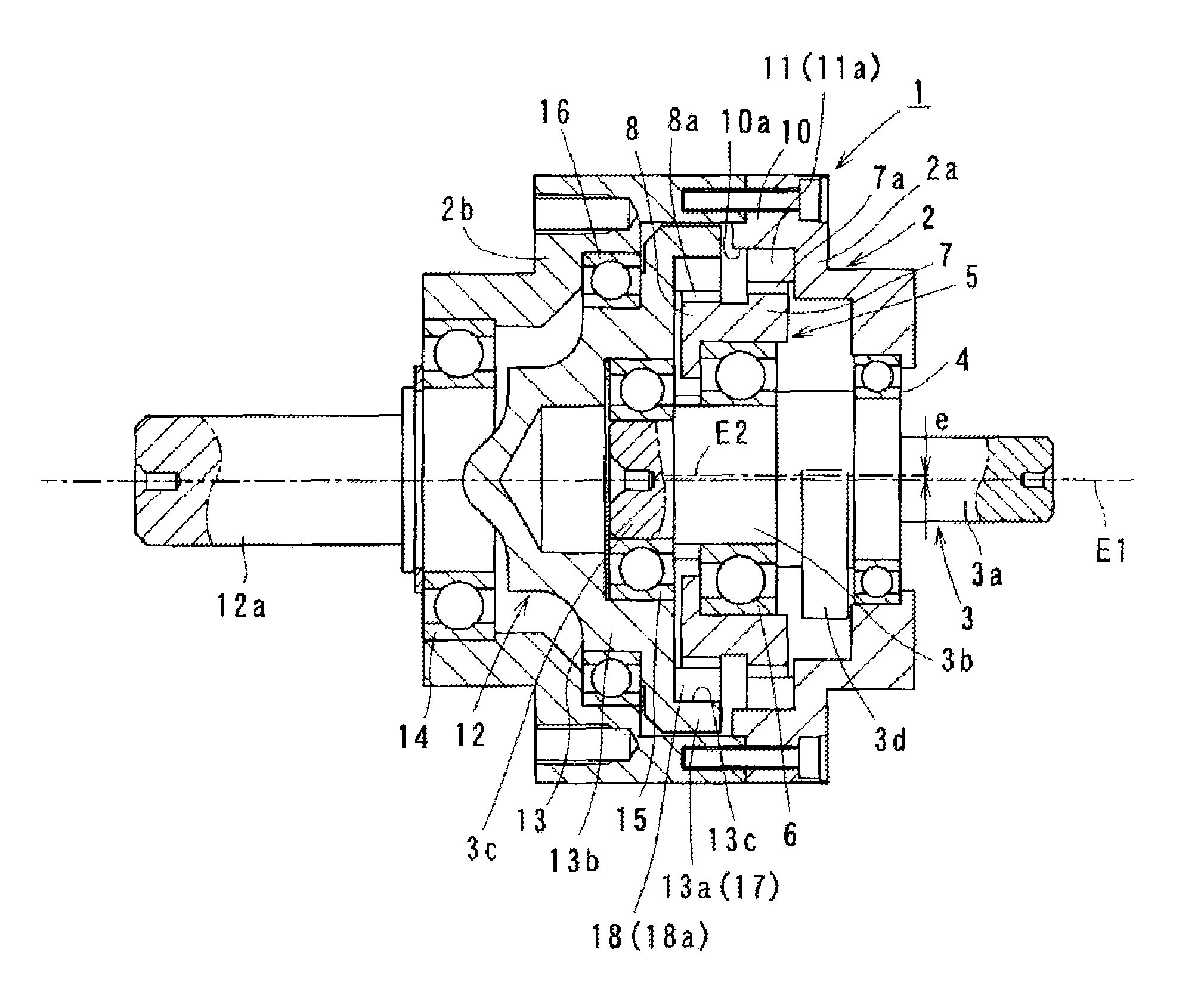

Roller type transmission device

InactiveUS20110319217A1Readily profiledAccurate distanceGearboxesToothed gearingsSurface roughnessEngineering

In a roller type transmission device 1, an array 11 of transmission pin rollers is press fit circularly into an inner side surface 10a of a stationary ring 10, and an array 18 of controllable pin rollers is press fit circularly into an inner side surface 13c of a rotational ring 13. To pin rollers 11a, 18a, employed are high precision cylindrical rollers or needle rollers which are usually used for a roller bearing or the like. Such is the structure that the array 11 of transmission pin rollers and the array 18 of controllable pin rollers work as inner teeth to make a backlash phenomenon minimum, rendering a pitch distance precise between the pin rollers, maintaining a uniform tooth profile with a high precision, equalizing a surface roughness and improving a meshing precision between the pin rollers 11a, 18a and the teeth 7a, 8a.

Owner:KAMOSEIKO

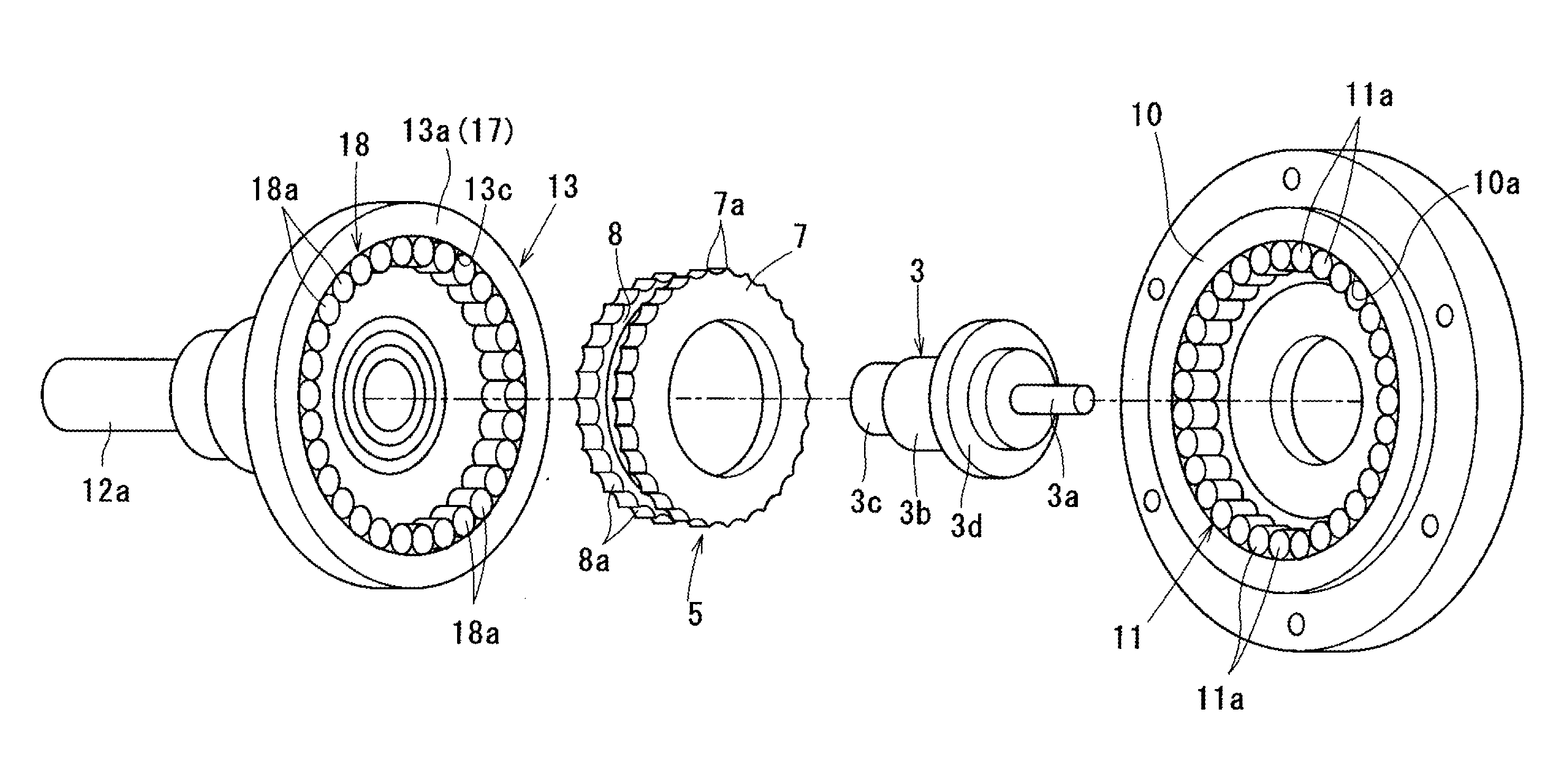

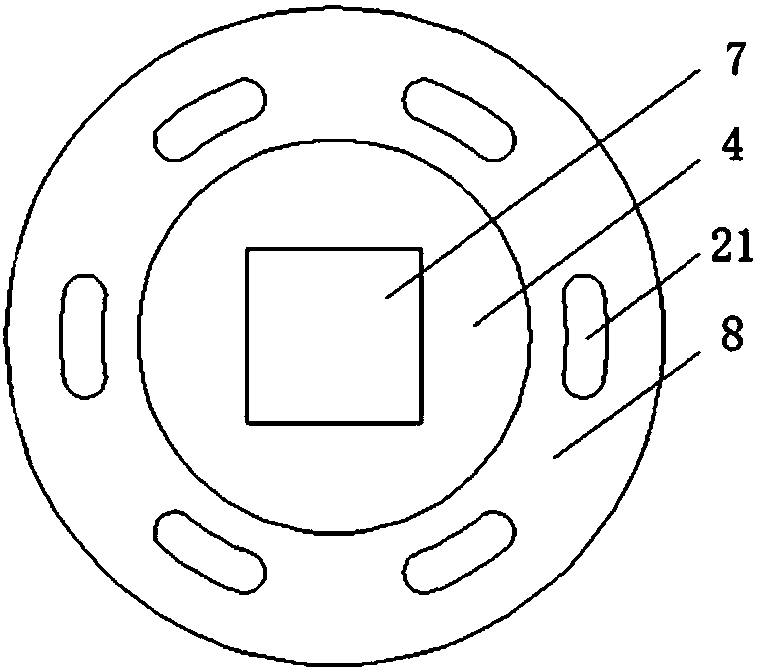

Compact wafer handling system with single axis robotic arm and prealigner-cassette elevator

InactiveUS20050111944A1Easy to optimizeSmooth and precise angular effector movementSemiconductor/solid-state device manufacturingArticle unpackingRobotic armEngineering

A robotic single axis system includes an effector moveable around a single rotating axis. The system is substantially concentrically arranged and mounted adjacent a wafer chuck of a precision stage. The robotic effector has a tangential distal end with a carrying face for positioning the wafer between concentric pinlifters raising from the wafer chuck. The pinlifters load and unload the wafer from the effector. The effector reaches with addition of the stage's travel into a cassette and alternating into a prealigner positioned on top of each other on an adjacent elevator. The elevator provides Z-axis movement so that the effector may load and unload wafers from the cassette, and alternating inserts a carried wafer into the prealigner.

Owner:N & K TECH

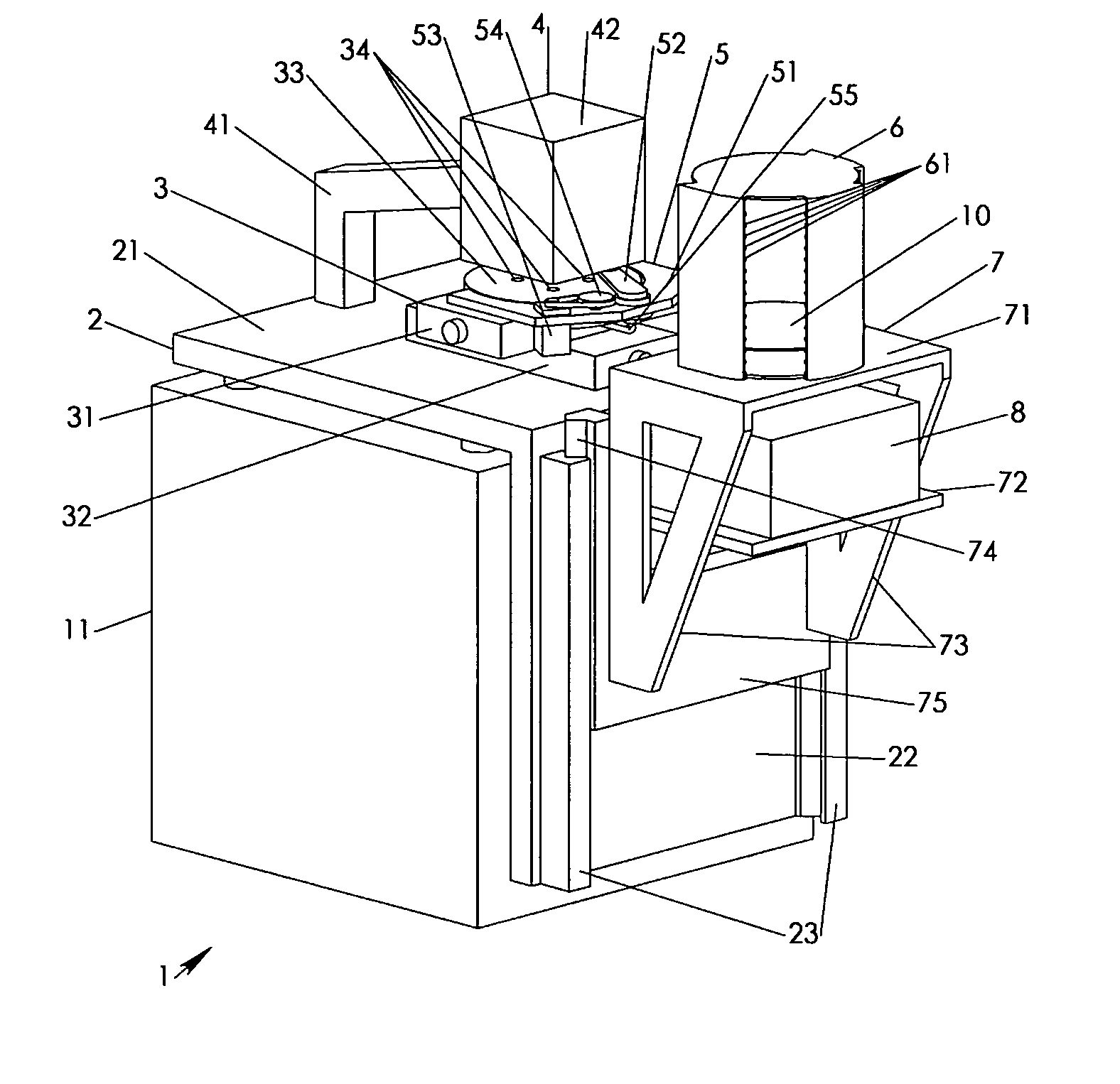

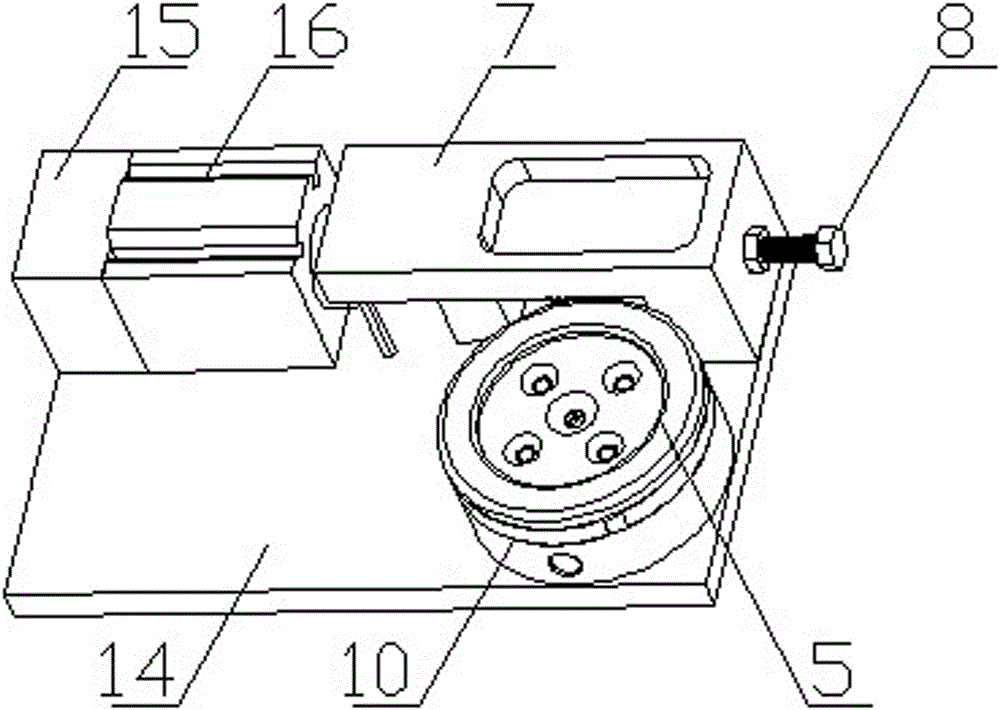

Device for automatically assembling snap spring on engine rotor

ActiveCN106271549AGuaranteed tightGuaranteed fixed effectMetal working apparatusEngineeringMechanical engineering

Owner:安徽创研新材料有限公司

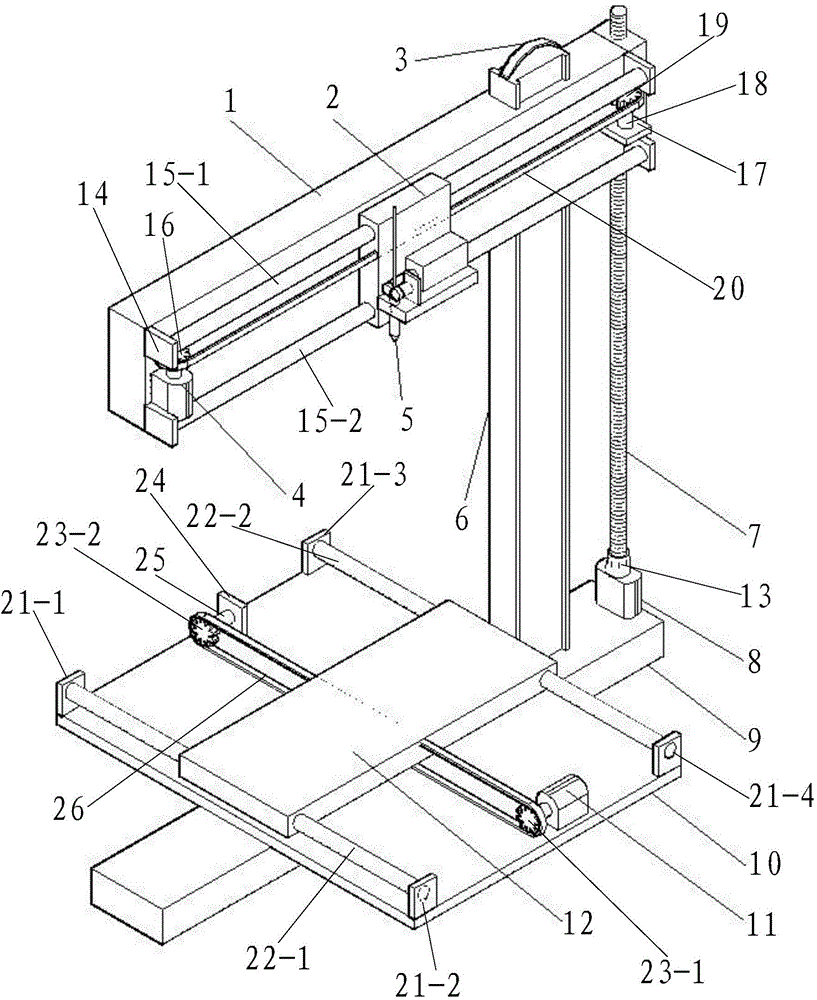

Hand-held small-sized 3D printer

The invention discloses a hand-held small-sized 3D printer which comprises a base, a printing platform and a lifting bracket, wherein the Z-axis lifting motor and a lifting guide rail are arranged at the top of the base; the Z-axis lifting motor is connected with a lifting screw, the lifting guide rail and the lifting screw both penetrate through the lifting bracket, a handle is arranged at the top of the lifting guide rail, the lifting bracket is connected with a first horizontal support rod, a second horizontal support rod, a mobile plate, an X-axis mobile motor, a horizontal support plate and a first annular gear driving belt, one edge of the first annular gear driving belt penetrates through the mobile plate, and the mobile plate is provided with a vertically arranged printing head; the printing platform comprises a bottom plate; and the bottom plate is connected with a first polished rod, a second polished rod, the printing platform, a Y-axis mobile motor and a second annular gear driving belt, and the upper edge of the second annular gear driving belt is arranged in the printing platform in an embedded manner. The hand-held small-sized 3D printer disclosed by the invention has the advantages of compact structure, small size, portability, convenience for carrying and high accuracy of Z-axis direction lifting and X-axis direction motion of the printing head.

Owner:XIAN ZHONGKEMAITE ELECTRONICS TECH EQUIP

Roller type transmission device

InactiveUS20110319218A1Accurate distanceUniform tooth profileYielding couplingToothed gearingsSurface roughnessEngineering

In a roller type transmission device 1, an array 11 of transmission pin rollers is press fit circularly into an inner side surface 10a of a stationary ring 10, and an array 18 of controllable pin rollers is press fit circularly into an inner side surface 13c of a rotational ring 13. To pin rollers 11a, 18a, employed are high precision cylindrical rollers or needle rollers which are usually used for a roller bearing or the like. Such is the structure that the array 11 of transmission pin rollers and the array 18 of controllable pin rollers work as inner teeth to make a backlash phenomenon minimum, rendering a pitch distance precise between the pin rollers, maintaining a uniform tooth profile with a high precision, equalizing a surface roughness and improving a meshing precision between the pin rollers 11a, 18a and the teeth 7a, 8a.

Owner:KAMOSEIKO

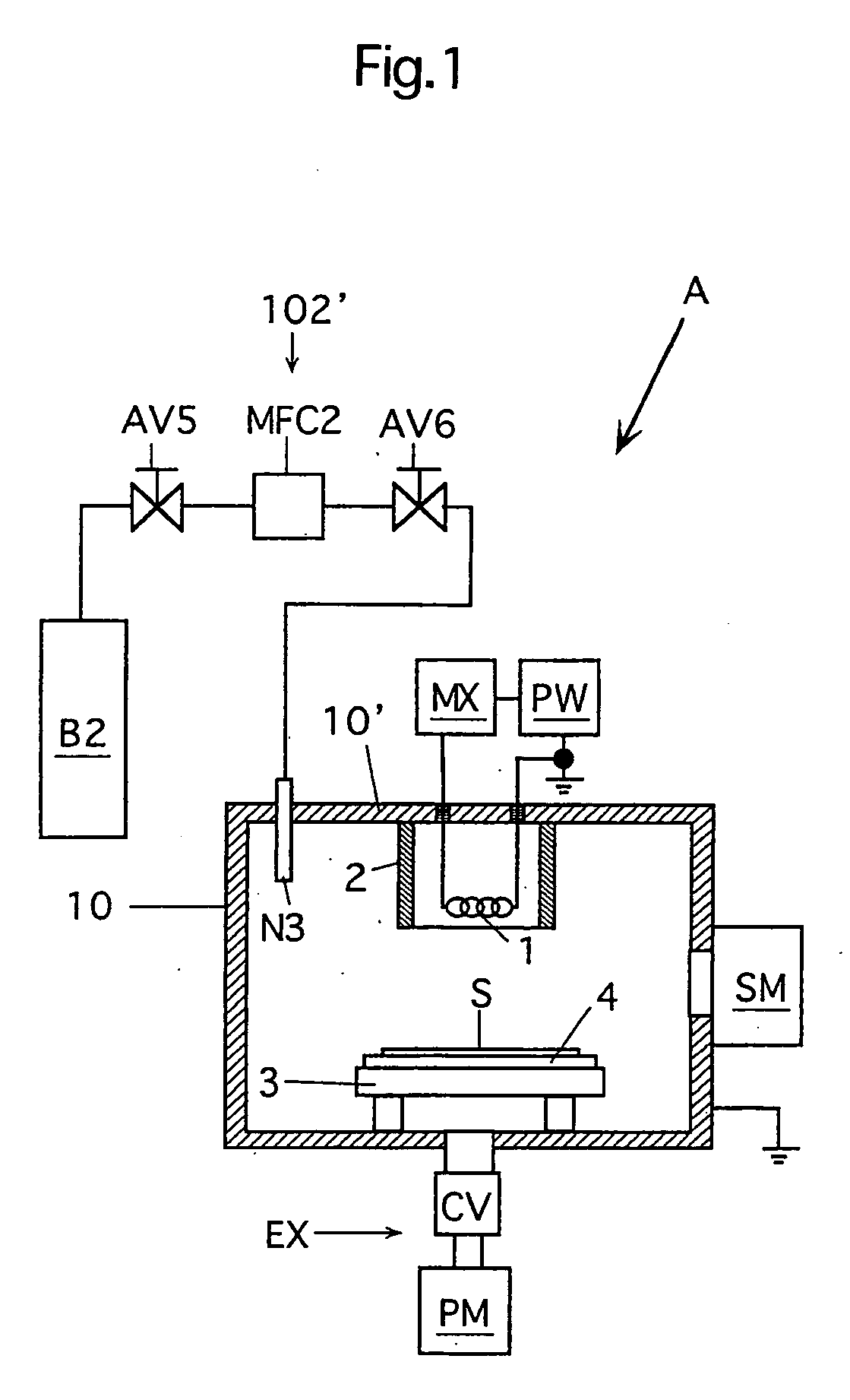

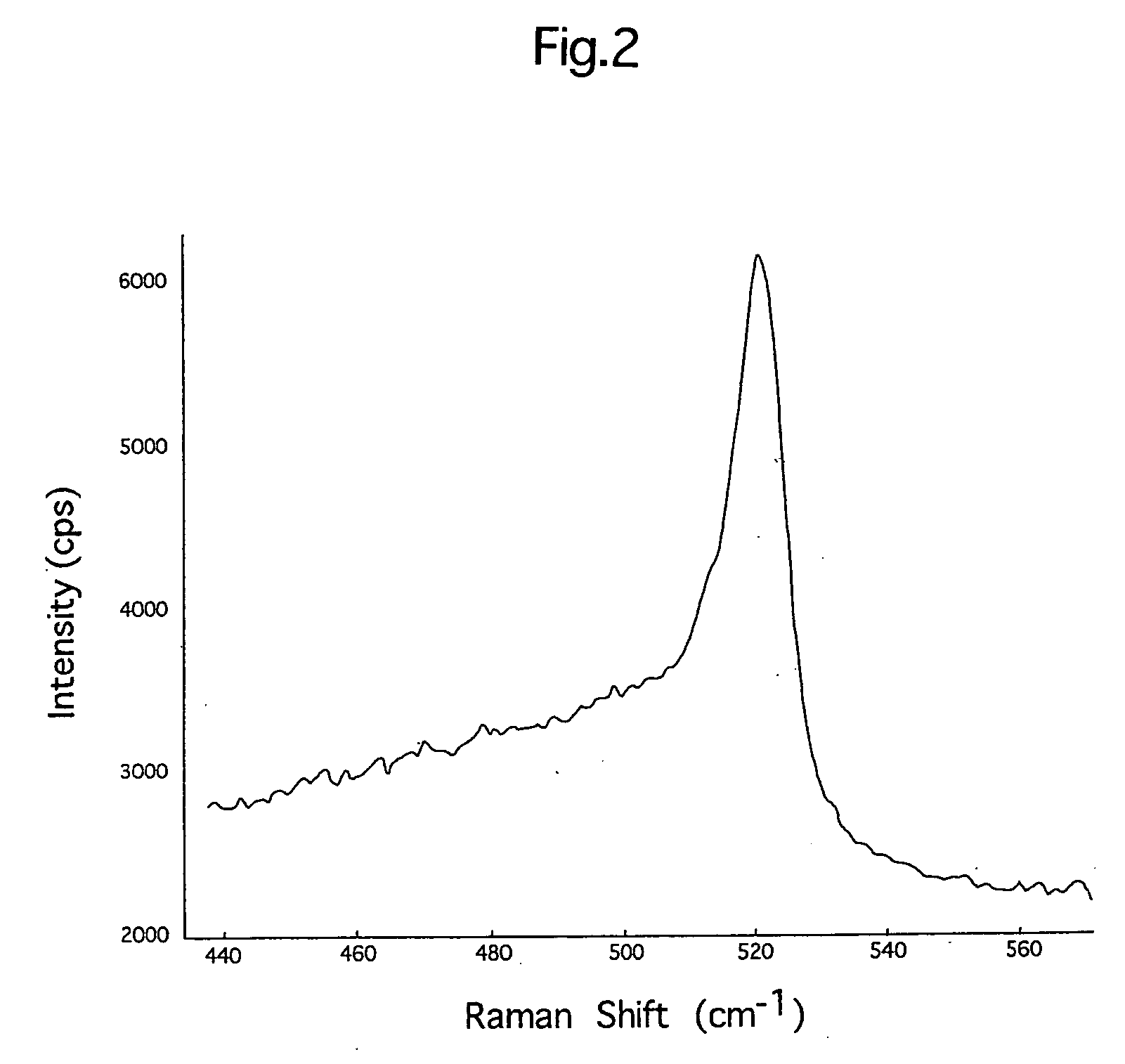

Silicon film forming apparatus

InactiveUS20070007128A1Reduce the temperatureSmooth and precise movementCellsElectric discharge tubesSputteringHigh frequency power

A silicon film forming apparatus includes a deposition chamber (10), a silicon sputter target (2) arranged in the chamber, a hydrogen gas supply circuit (102 or 102′) supplying a hydrogen gas into the chamber, and a high-frequency power applying device (antenna 1, 1′, power source PW and others) generating inductively coupled plasma by applying high-frequency power to the gas supplied into the deposition chamber (10). Chemical sputtering is effected on the target (2) by the plasma to form a silicon film on a substrate S. A silane gas may be used. A silane gas supply circuit (101) may be provided with a gas reservoir unit (GR). The silicon film can be formed inexpensively and fast at a relatively low temperature.

Owner:NISSIN ELECTRIC CO LTD +1

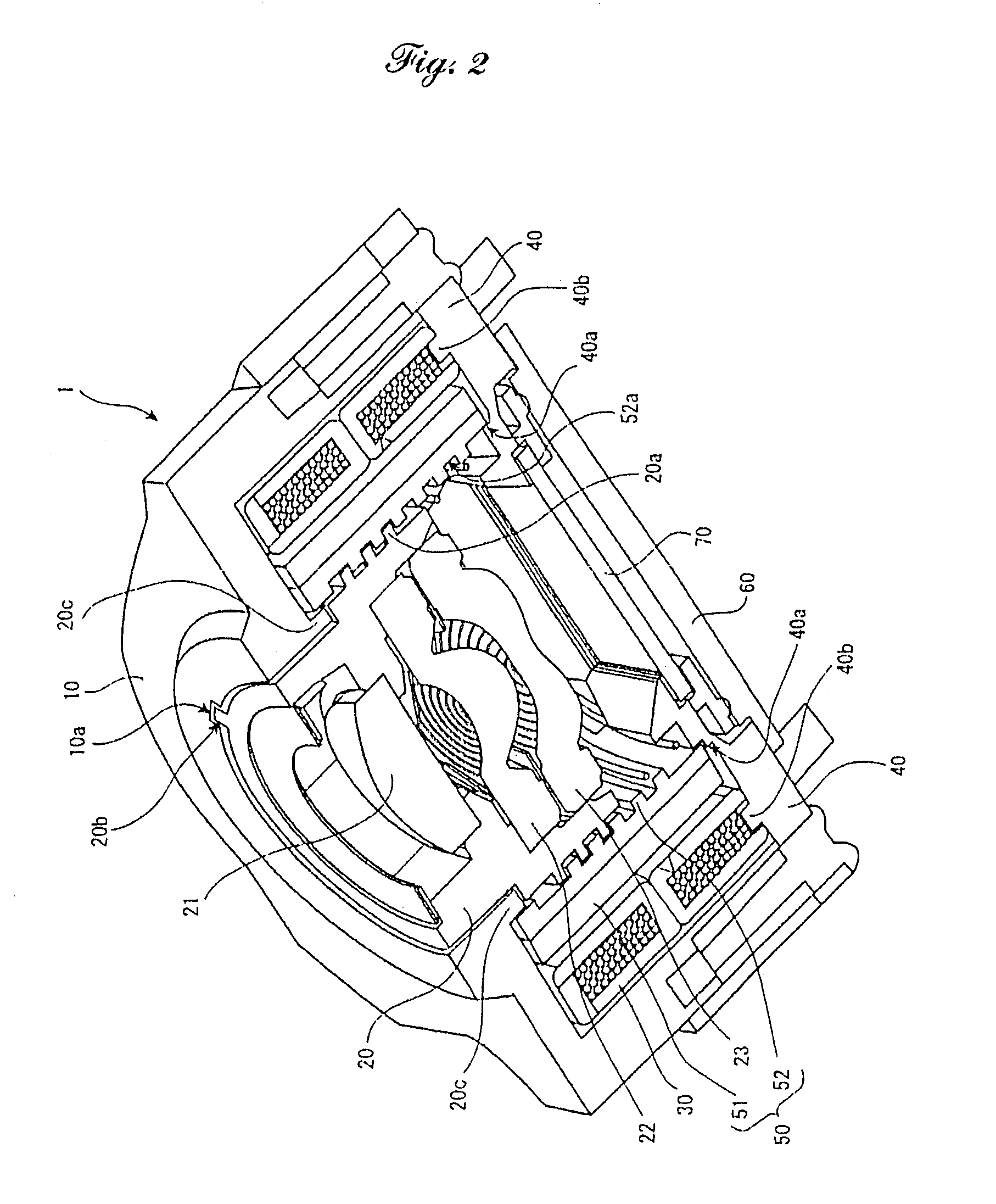

Drive unit and image pickup unit equipped with the drive unit

InactiveUS7274120B2Prevent movementReduce necessityMagnetic circuit stationary partsMechanical energy handlingLinear motionEngineering

A drive unit for performing precise linear movement of a driven object comprises a motor having a cylindrical stator and a cylindrical rotor that is coaxially put in the cylindrical stator and capable of rotating relatively to the cylindrical stator, a movable barrel for holding a driven object mounted for rotation in the cylindrical rotor, a motion transformation mechanism comprising an internal helical groove formed in the cylindrical rotor and an external helical thread formed on the movable barrel which engage with each other so as to cause relative rotation between the cylindrical rotor and the movable barrel when the cylindrical rotor rotates, thereby transforming rotational movement of the rotor into a linear movement of the movable barrel, and a head-on striking structure provided between the helical groove and the helical thread to restrict the relative rotation at an intended extreme end of an axial path of the movable barrel.

Owner:FUJI PHOTO OPTICAL CO LTD

Packing and stacking device for smoke alarm assembly production line

PendingCN106742421AFast packFast palletizingConveyorsStacking articlesMechanical equipmentEngineering

The invention discloses a packing and stacking device for a smoke alarm assembly production line, belonging to the field of product assembly equipment. The packing and stacking device comprises a packing box feeding device, a grabbing and packing device, a conveying device and a stacking device, wherein the conveying device is arranged between the packing box feeding device and the stacking device; the packing box feeding device comprises a package pushing and conveying mechanism and a baffling mechanism; the package pushing and conveying mechanism and the baffling mechanism are arranged on one end of the conveying device; the grabbing and packing device stretches over the conveying device and the product assembly line; the stacking device comprises a stacking pushing and conveying mechanism, a stacking pushing-out mechanism and a lifting stacking mechanism; the stacking pushing and conveying mechanism is arranged on one side of the conveying device; the lifting stacking mechanism is arranged on the other side of the conveying device; and the stacking pushing-out mechanism is arranged on one side of the lifting stacking mechanism. According to the packing and stacking device, manual packing and stacking work is replaced by mechanical equipment, so that packing and stacking efficiency for smoke alarms is greatly improved; and manual labor intensity and labor cost are lowered.

Owner:常州赛凯电器设备有限公司

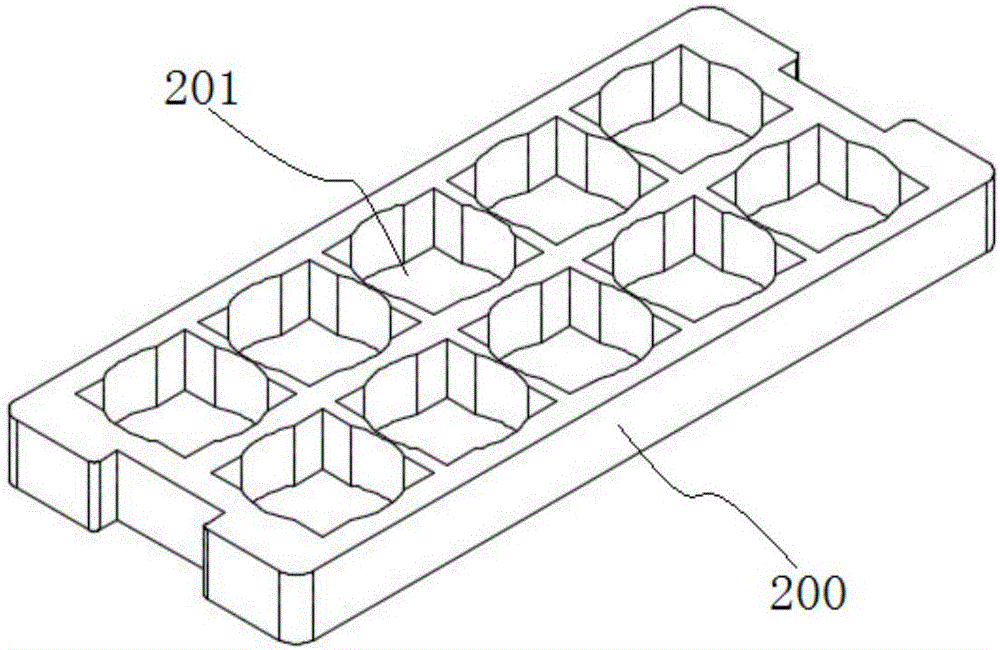

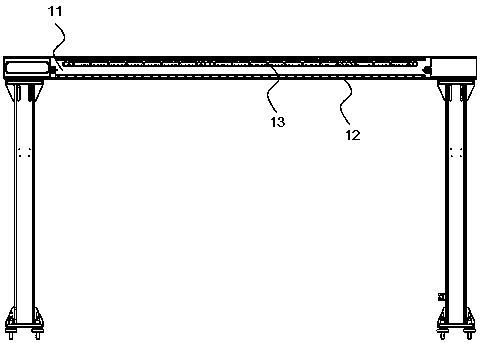

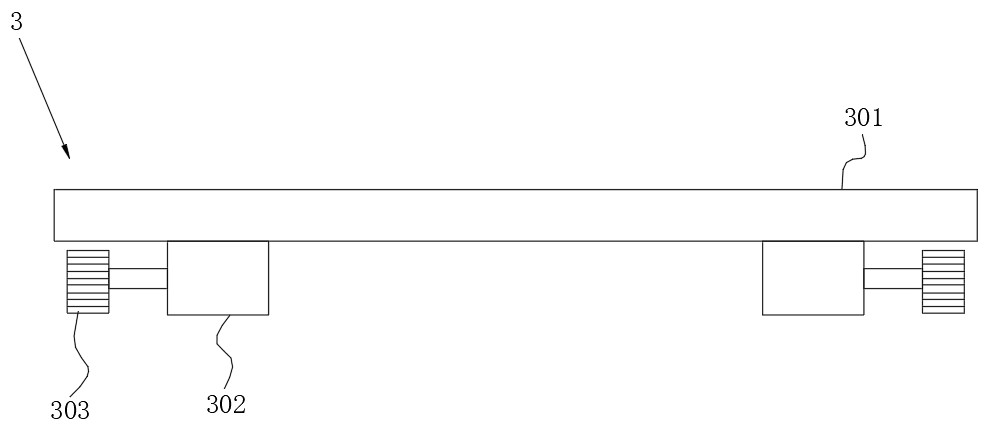

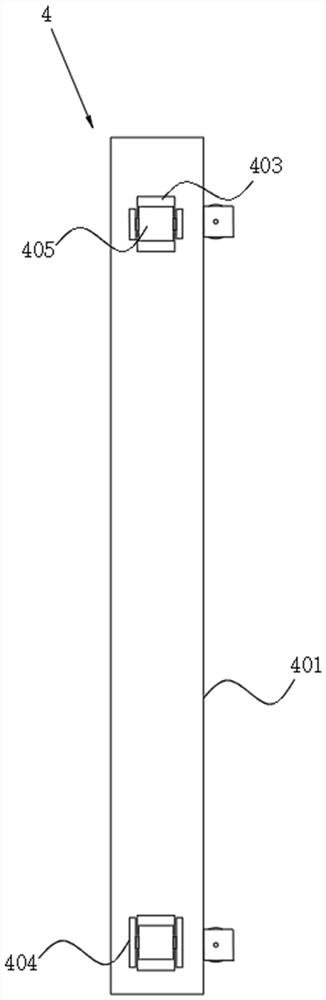

Loading and unloading mechanism for small-module bevel gears

PendingCN111439574ARealize loading and unloadingSmooth feedingDe-stacking articlesGear-cutting machinesGear wheelBevel gear

The invention belongs to the field of gear machining, and discloses a loading and unloading mechanism for small-module bevel gears. The loading and unloading mechanism comprises a portal truss, a feeding mechanism and a storing mechanism; the portal truss comprises a cross beam; double guiding rails A are fixed to one side of the cross beam; a rack is arranged between the double guiding rails A; the feeding mechanism is arranged on the cross beam and comprises internal expansion fixtures, the internal expansion fixtures realize three-dimensional actions of the space through driving mechanisms,and the driving mechanisms are connected onto the double guiding rails A; the storing mechanism is arranged below the cross beam and comprises a group of bases used for loading and unloading respectively, rotating disk mechanisms are arranged above the bases, and clamping mechanisms A are arranged beside the rotating disk mechanisms. By the aid of the loading and unloading mechanism, the problemsof difficulty in clamping, relatively slow loading and unloading of products and the like during machining of the small-module bevel gears are solved.

Owner:江苏双环齿轮有限公司

Traffic signal device convenient to use

ActiveCN103531034ASimple structureIngenious designRoad vehicles traffic controlTraffic signalEngineering

A traffic signal device convenient to use comprises an upright mounting column and a display framework assembled at the top of the upright mounting column, wherein the display framework comprises a frame body, a plurality of rotating shafts assembled on the frame body and a drive device driving the rotating shafts to rotate; each rotating shaft is sleeved with a regular triangular prism; each regular triangular prism is provided with a first display surface, a second display surface and a third display surface; a plurality of first display surfaces jointly form a red light signal indication surface; a plurality of second display surfaces jointly form a yellow light signal indication surface; and a plurality of third display surfaces jointly form a green light signal indication surface. With the adoption of the traffic signal device, traffic signals can be switched among the red light indication surface, the yellow light indication surface and the green light indication surface which are jointly formed on the three display surfaces respectively through synchronous rotation of each regular triangular prism, so that a traffic indication function can be achieved without luminescence, the electric energy can be saved, a traffic signal controller is not required, and accordingly, the cost is greatly saved.

Owner:SUZHOU JINCHUANG INTERNET TECH CO LTD

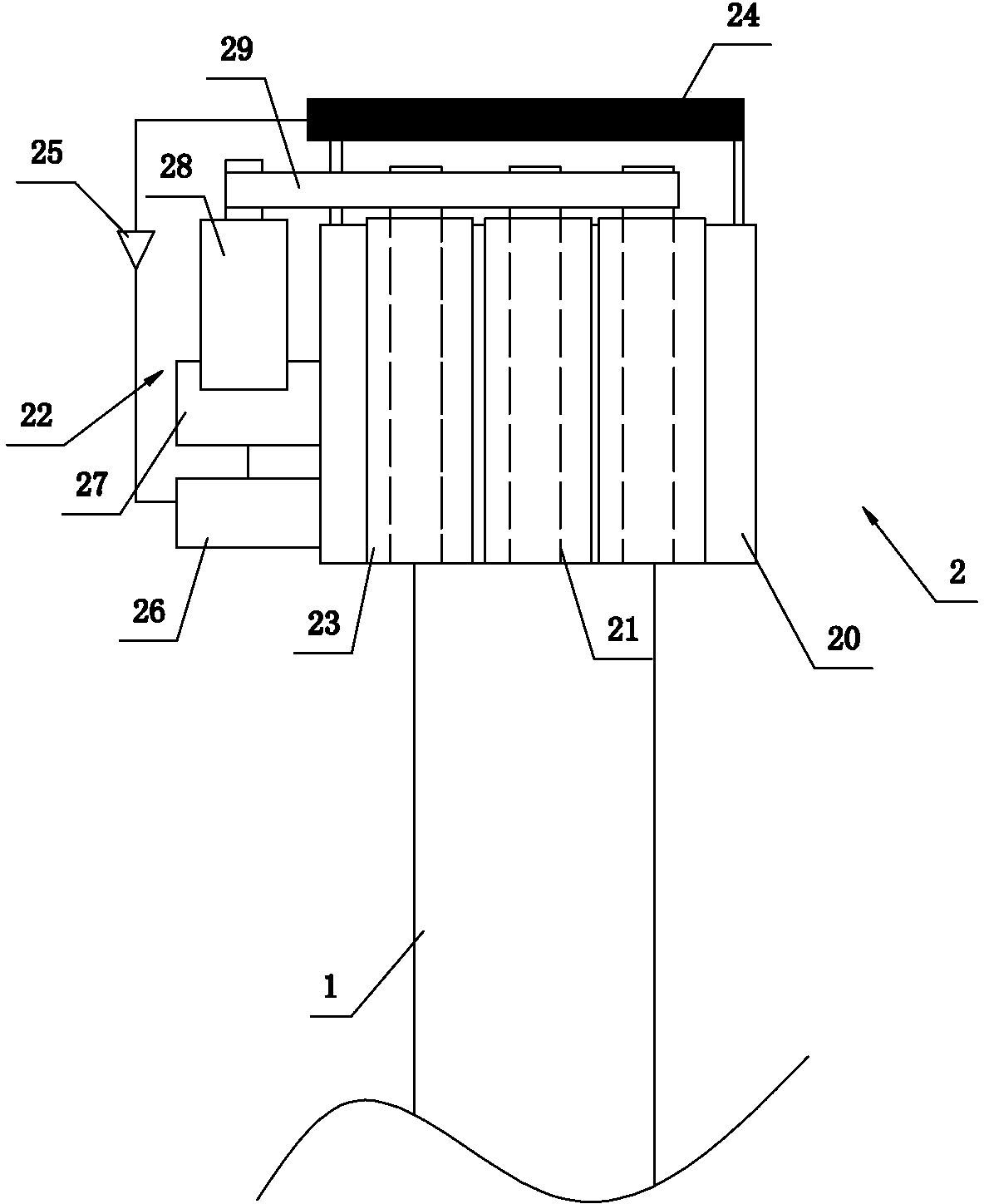

Underwater bridge pier detection device and method thereof

InactiveCN113109445AEasy to holdEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic wave reradiationContinuous scanningMarine engineering

The invention provides an underwater bridge pier detection device and method thereof. The device is applied to a bridge pier. The device comprises an overwater frame and an underwater frame which are oppositely arranged on the periphery of the bridge pier, and a movable guide rod assembly and a lifting traction piece which are arranged between the two frames; annular driving pieces are arranged at the opposite ends of the overwater frame and the underwater frame correspondingly, the upper end and the lower end of the movable guide rod assembly are in transmission connection with the two annular driving pieces correspondingly and used for driving the movable guide rod assembly to rotate around the periphery of a pier, and the upper end and the lower end of the lifting traction piece are connected with the overwater frame and the underwater frame correspondingly for pulling the underwater frame to lift. The device also comprises a detection trolley which is arranged on the movable guide rod assembly in a sleeving mode and moves up and down, and the detection trolley is used for detecting the diseased part of the bridge pier. The device is suitable for piers in various shapes, can continuously scan the complete surface of the pier, and is high in working efficiency.

Owner:郑德粮

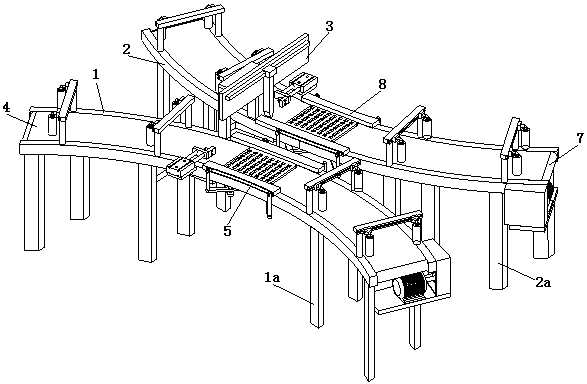

Pot seedling transplanter

The invention relates to the field of automatic transplanting in fertility agriculture, and particularly relates to a pot seedling transplanter. The pot seedling transplanter comprises a first transfer belt, a second transfer belt and a pot seedling transplanting mechanism, wherein a seedling tray conveying mechanism and a seedling tray positioning mechanism are arranged on the first transfer belt; the seedling tray conveying mechanism comprises a seedling guiding device; the seedling tray positioning mechanism comprises a first connecting rod positioning device; a seedling supply tray conveying mechanism and a seedling supply tray positioning mechanism are arranged on the second transfer belt; the seedling supply tray conveying mechanism comprises a plurality of seedling supply tray guiding devices; the seedling supply tray positioning mechanism comprises a second connecting rod positioning device; the pot seedling transplanting mechanism is erected on the first and second transfer belts; and the pot seedling transplanting mechanism comprises a clamping device. The pot seedling transplanter can solve the inaccuracy of seedling tray and seedling supply tray moving positions by adopting the design, can be used for accurately transferring seedling trays to the transplanting position, so that the work efficiency of plug pot seedling transplanting can be improved.

Owner:SUZHOU SIFANG PRECISION IND MACHINERY MFG

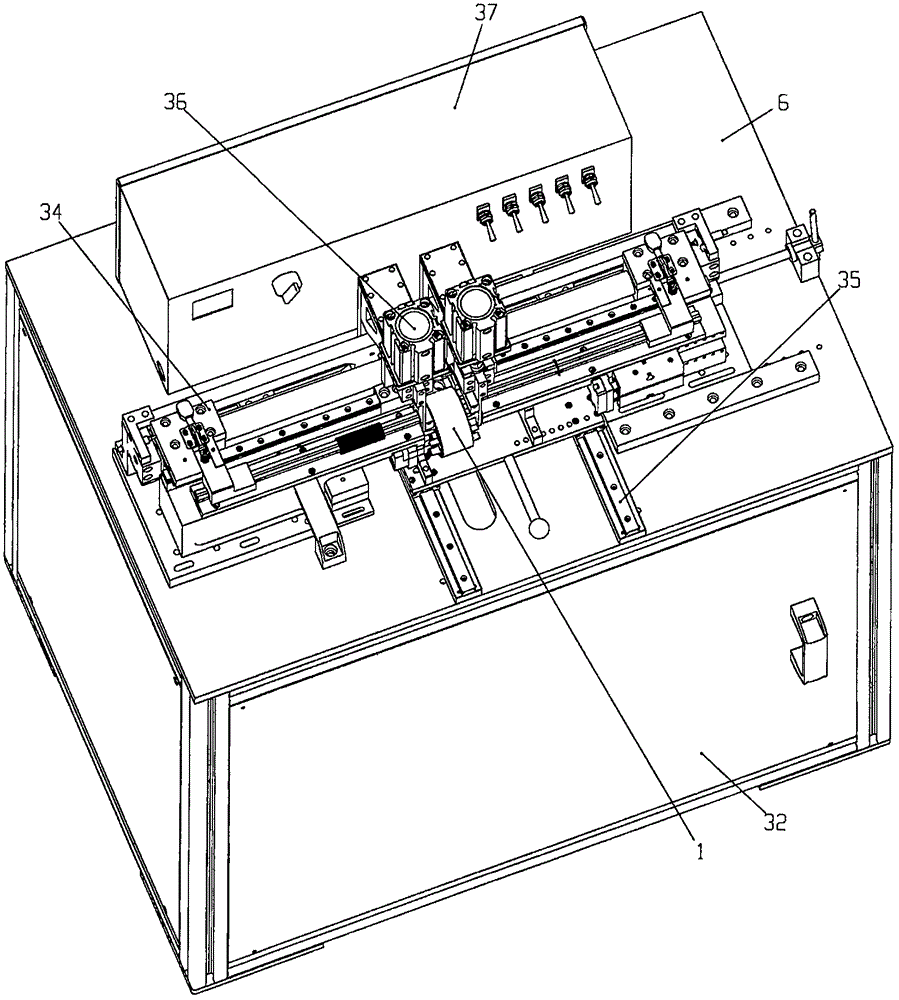

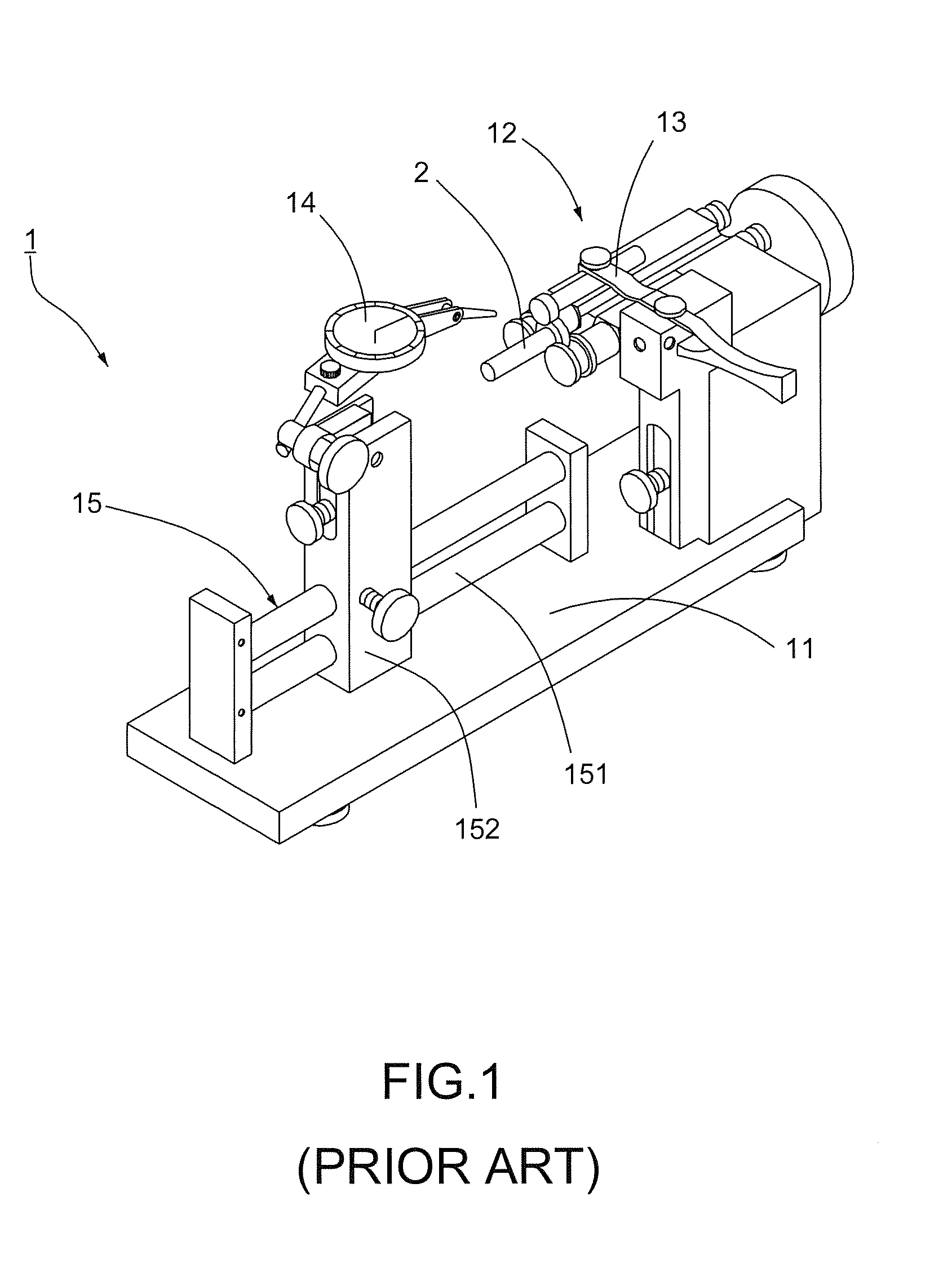

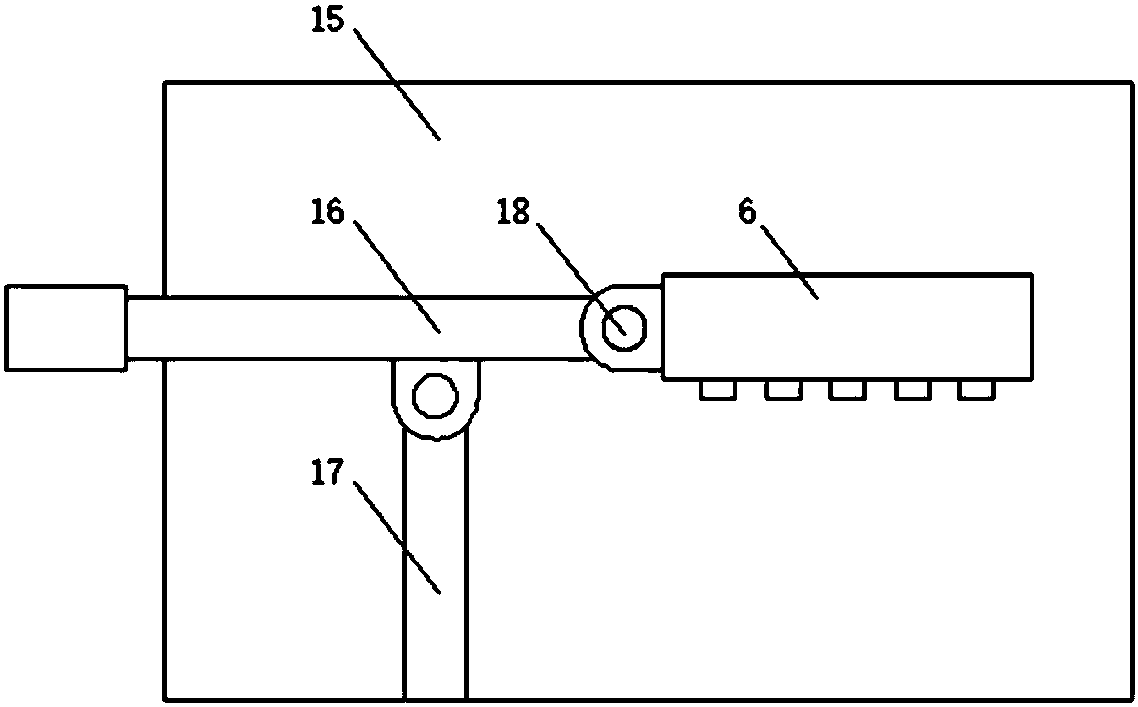

Detecting gauge with high accuracy

ActiveUS20140196297A1Improve accuracySmooth and precise movementMechanical measuring arrangementsComputer engineering

A detecting gauge with high accuracy mainly comprises a machine table, a detecting set, a clamping apparatus, a detecting apparatus, and a sliding apparatus. Particularly, the sliding apparatus includes a sliding rail disposed on a machine table and a sliding base slidably disposed on said sliding rail. A sliding groove is disposed on both sides of the sliding rail, an embedding portion is formed on the sliding base for matching the sliding groove, and a plurality of rollers are embedded on a surface of said embedding portion which is in contact with said sliding groove. By matching the embedding portion with the sliding groove, the sliding base can be slid and moved precisely and smoothly on the sliding rail, and a target to be detected can be stably held by the clamping apparatus, whereby the detecting apparatus can obtain the measurement with high accuracy.

Owner:SHENG KUO MACHINERY

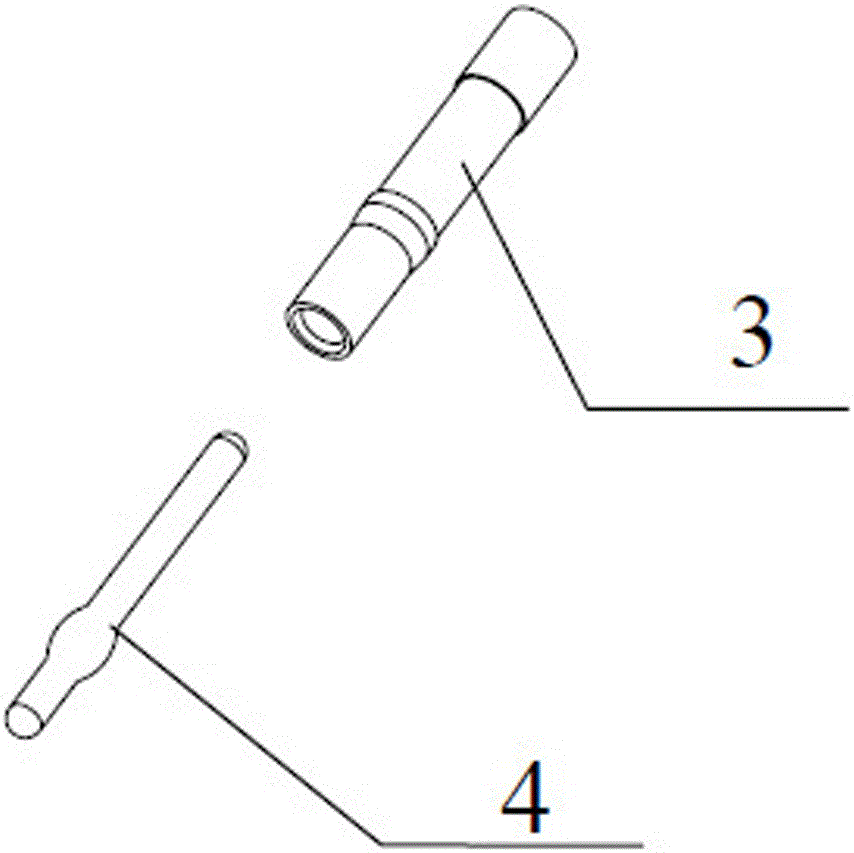

Contact rear sleeve riveting tool

The invention relates to a contact rear sleeve riveting tool comprising a base. A cylinder and a riveting device are mounted on the base. The riveting device comprises a slide block circular seat; the center of the slide block circular seat is provided with a positioning through hole; the top surface of the slide block circular seat is provided with a cylinder boss coaxial with the slide block circular seat; the cylinder boss is provided with horizontal cross recess penetrating the cylinder boss; the center of the cross recess is communicated with the positioning through hole; and four slide blocks in a cross structure are placed in the cross recess. The head of each slide block has a steeple top; the tail of each slide block has an arc surface; and the tail of each slide block extends from the outer side of the cylinder boss. A pressure spring arranged in the direction of the cross recess is arranged at the bottom of each slide block; one end of the pressure spring is connected to the corresponding slide block; and the other end of the pressure spring is fixedly connected to the slide block circular seat. The slide blocks simultaneously press a contact rear sleeve located in the positioning through hole of the slide block circular seat after the slide blocks move toward the center in the cross recess, and then the riveting is completed.

Owner:CHINA NORTH IND GRP HANGLIAN TECH CO LTD

Apparatus for forward and backward movement of sewing machine

InactiveUS8146522B2Ensure fast and accurate movementIncrease productivityTufting apparatusSewing-machine control devicesEngineeringSewing machine

Forward and backward movement apparatus for main body of sewing machine according to this invention comprises, in sewing machine comprising Main Body movable forward and backward and supported on both sides of a Base and Heads movable left and right and supported on the Main Body; Frame mounted on the Base; Timing Gears installed in the front and rear Fixed Frame of the Frame in multiple rows; Connecting Shat which connects Timing Gears beneath Front Fixed Frame; Forward and Backward Movement Frames is movable forward and backward on the Frame and connected to the Main Body; Rollers are installed in the Forward and Backward Movement Frames in multiple rows to correspond to the Timing Gears; Timing Belt which zigzags through Timing Gear and Roller and Timing Gear and Roller, and both ends of which are connected to the top of Front and Rear Fixed Frames; and electric motor which drives the Connecting Shat in forward and reverse directions.

Owner:DAE HUNG HITECH +1

Tapping machine

InactiveCN103157856AHigh degree of automationImprove work efficiencyThread cutting feeding devicesPrecision positioning equipmentRotary engineEngineering

The invention disclose a tapping machine which comprises a machine frame, a delivering device, a tapping device, a material taking device and tapping smelting tools. The delivering device, the tapping device and the material taking device are respectively placed on the machine frame. The delivering device comprises a positioning rotary plate, a rotary decollator and a motor, wherein the rotary decollator is used for controlling rotary angles of the positioning rotary plate, the positioning rotary plate is placed on an output shaft of the rotary decollator, and the motor is connected with the rotary decollator in a transmission mode. The tapping device is placed at a tapping station of the delivering device, the material taking device is arranged at a material taking station of the delivering device, the tapping melting tools are placed on the positioning rotary plate, and the number of the tapping melting tools is at least three. The tapping machine has the advantages that materials are taken automatically and the materials are placed manually while tapping is carried out, degree of automation is improved, simultaneously, work efficiency is effectively improved, and product quality is guaranteed.

Owner:YIHE PRECISION IND SUZHOU

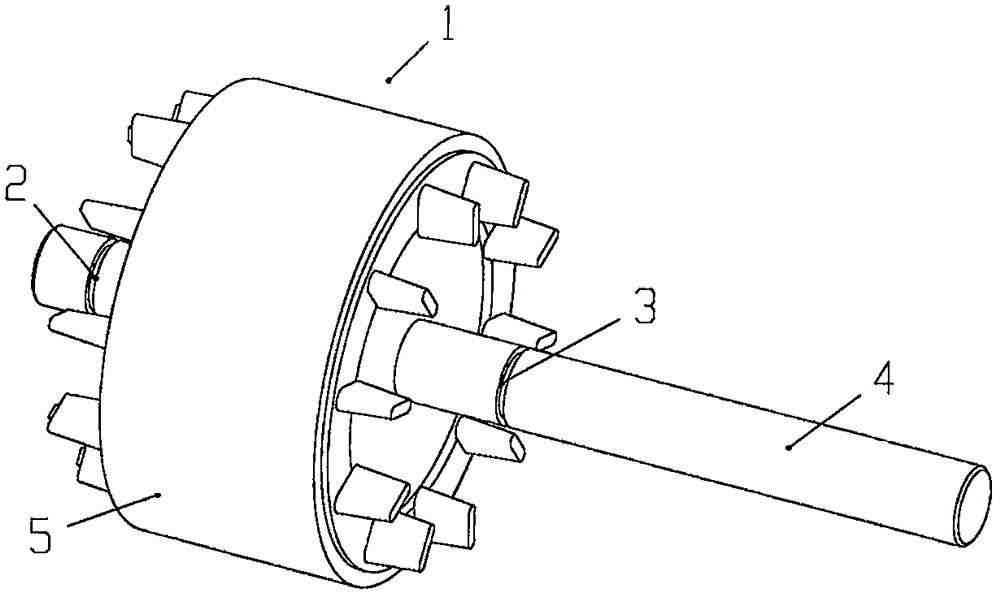

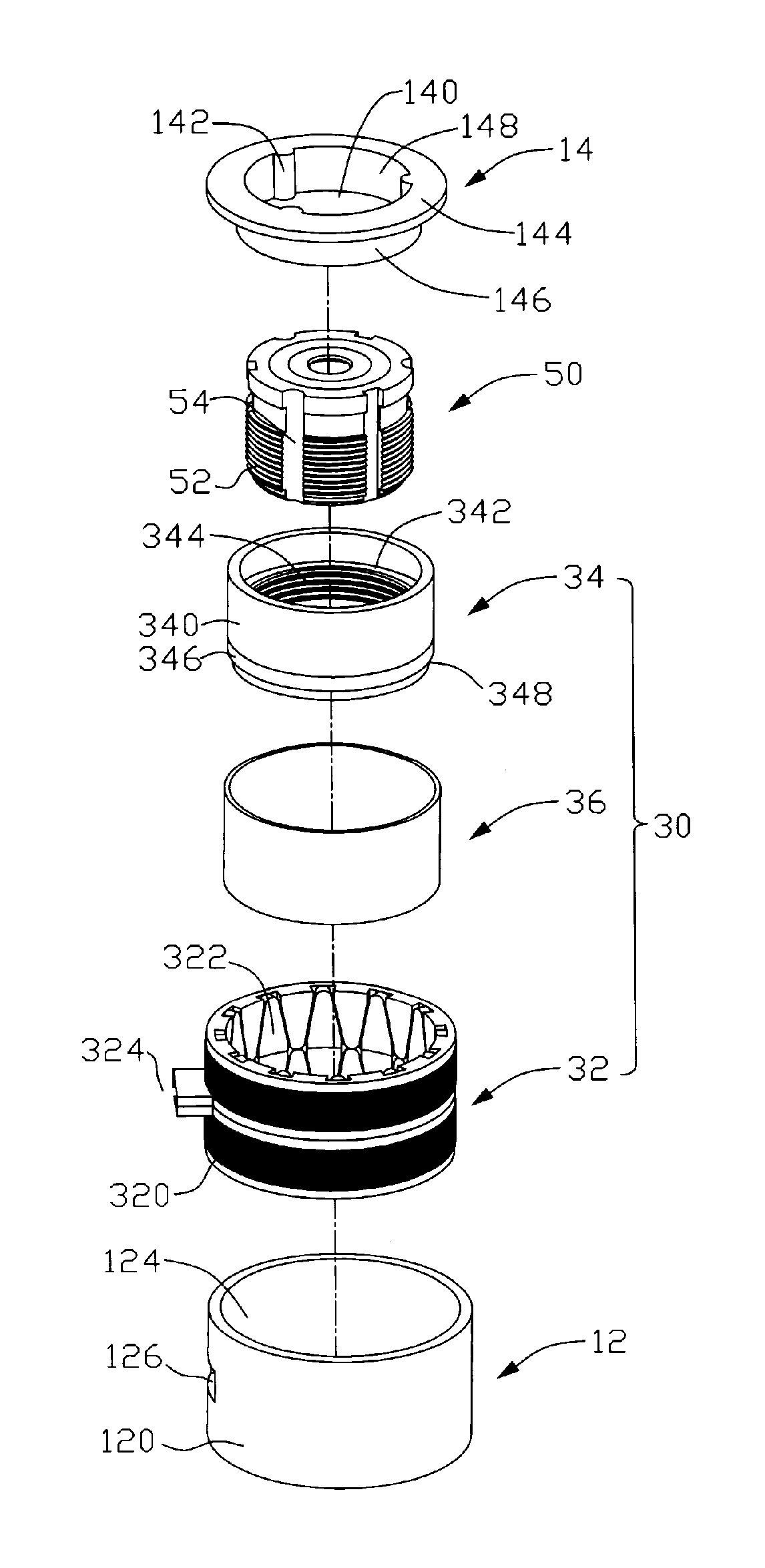

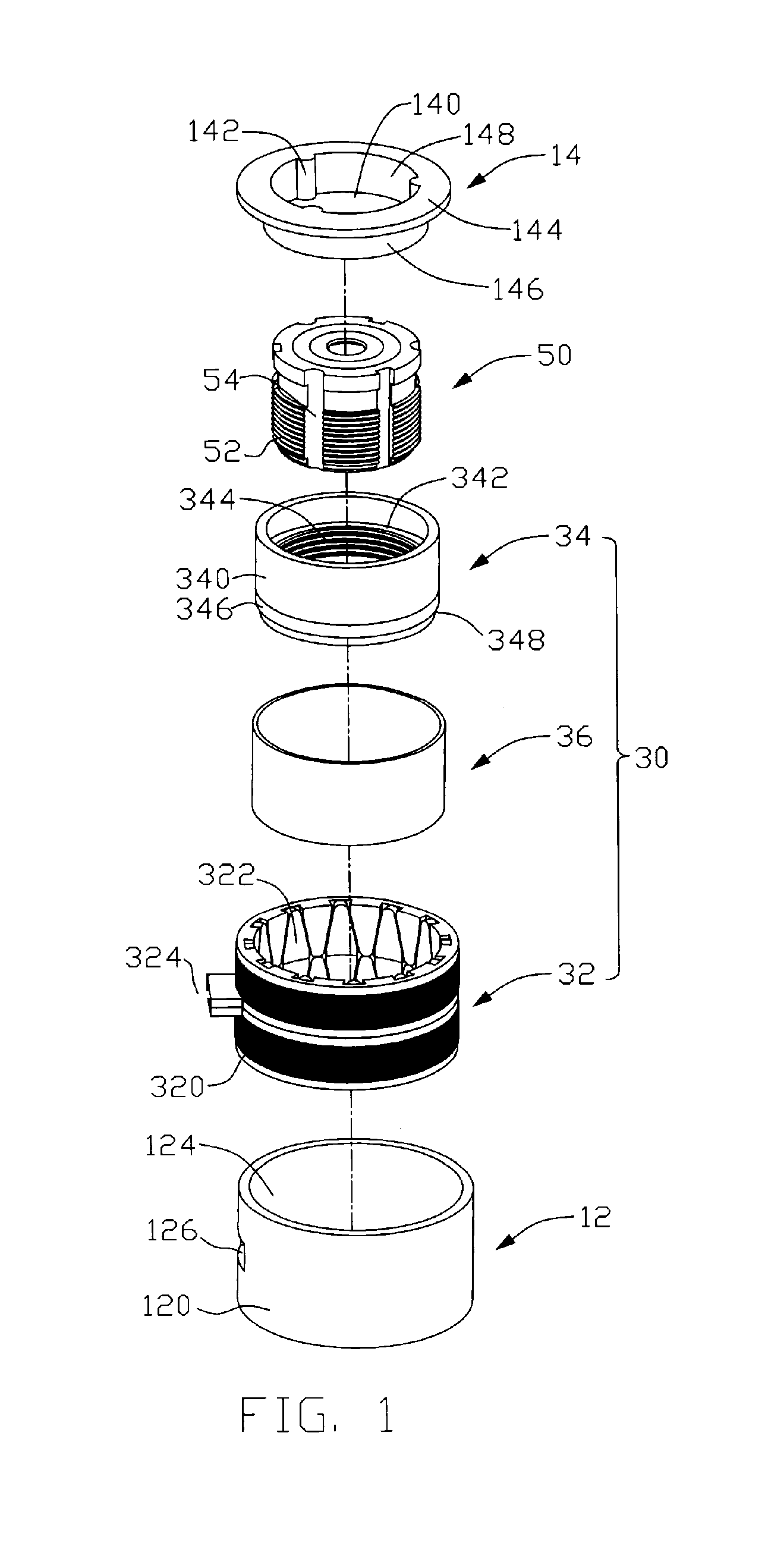

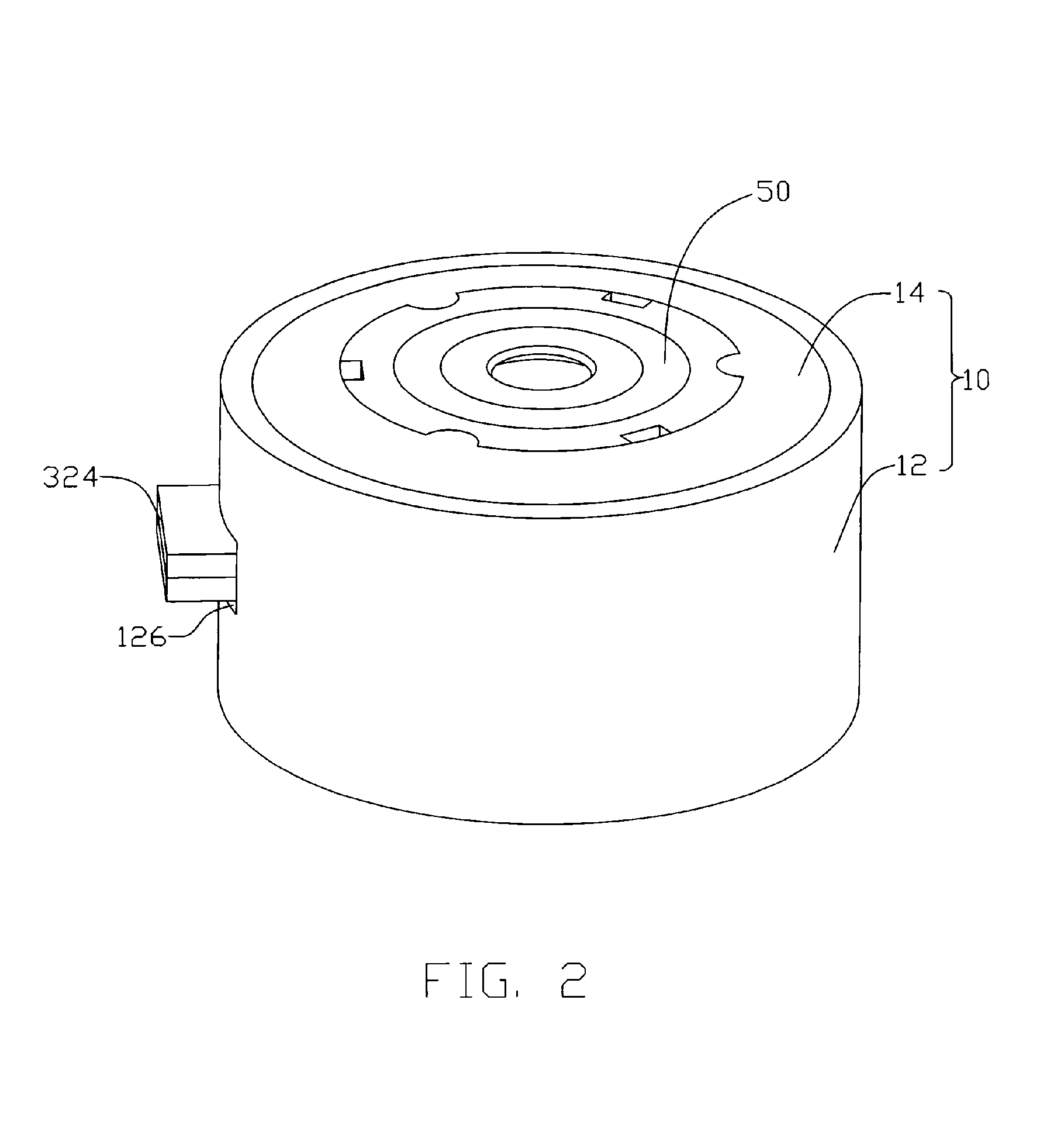

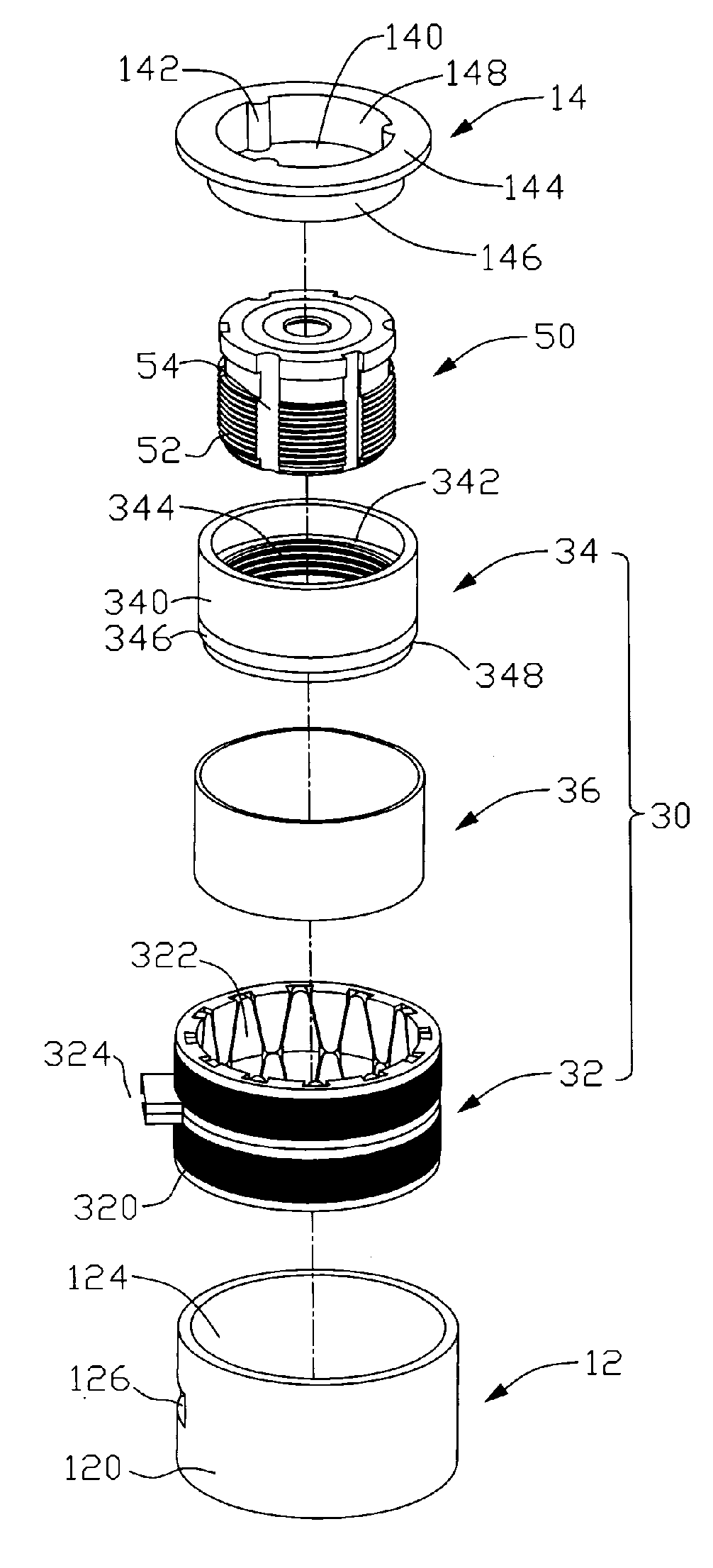

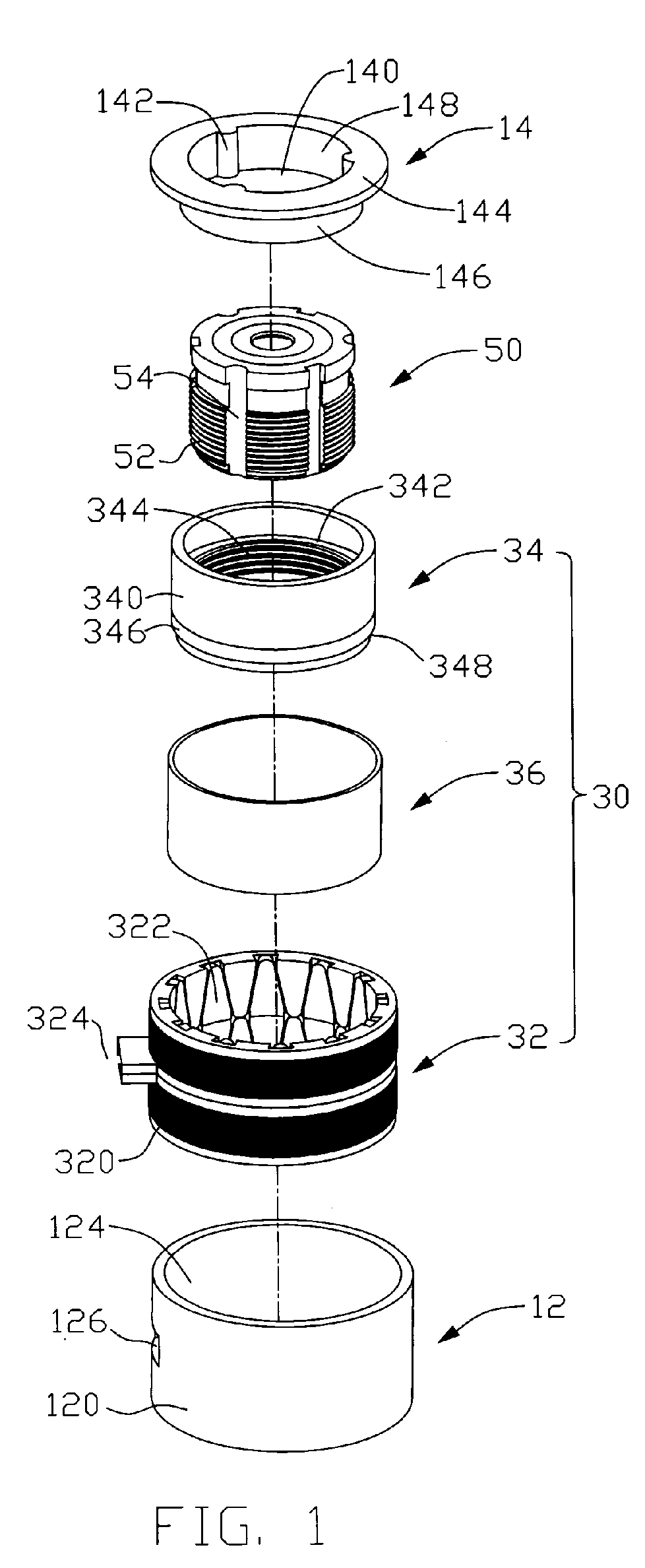

Motor structure with built-in lens

InactiveUS7599615B2Smooth and precise movementEasy to wearProjector focusing arrangementCamera focusing arrangementCamera lensEngineering

Owner:HON HAI PRECISION IND CO LTD

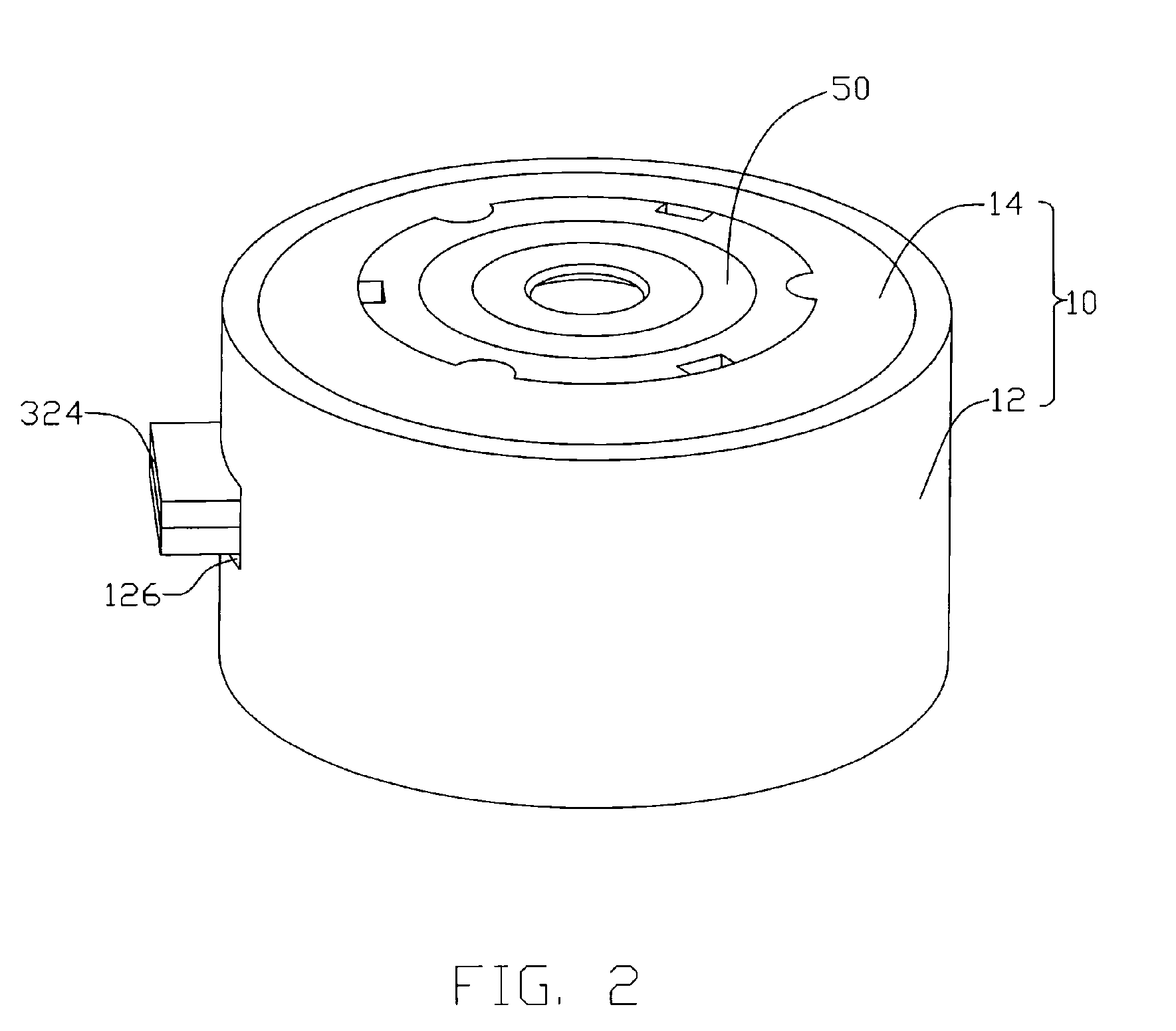

Motor structure with built-in lens

InactiveUS7443618B2Smooth and precise movementPrevent rotationMountingsCamera body detailsCamera lensEngineering

A motor structure with a built-in lens includes a lens mount (10), a motor (30) received in the lens mount, and a lens unit (50) received in the lens mount. The lens unit is drove by the motor to telescopically move along an axial thereof when a rotor (34) of the motor is rotated. A guiding member (70) arranged on an end of the motor for preventing an axial movement of the motor. The guiding member includes at least a leg (78) extending along an axial direction therefrom for guiding the axial movement of the lens unit.

Owner:HON HAI PRECISION IND CO LTD

Motor structure with built-in lens

InactiveUS20070110421A1Smooth and precise movementEasy to wearProjector focusing arrangementCamera focusing arrangementEngineeringNarrow gap

A motor structure with a built-in lens includes a lens mount (10), a motor (30) received in the lens mount, and a lens unit (50) received in the lens mount and driven by the motor to telescopically move along an axial thereof. The motor includes a stator (32) and a rotor (34) being rotatably received in the stator. A narrow gap is defined between an inner surface of the stator and an outer surface of the rotor. A bearing layer (36) is filled in the gap of the motor to avoid swing of the rotor during rotation thereof. The lens unit threadedly engages with the rotor, whereby when the rotor rotates, the lens unit has a linearly telescopic movement relative to the lens mount.

Owner:HON HAI PRECISION IND CO LTD

Roller type transmission device

InactiveUS8460146B2Accurate distanceUniform tooth profileYielding couplingToothed gearingsSurface roughnessEngineering

In a roller type transmission device 1, an array 11 of transmission pin rollers is press fit circularly into an inner side surface 10a of a stationary ring 10, and an array 18 of controllable pin rollers is press fit circularly into an inner side surface 13c of a rotational ring 13. To pin rollers 11a, 18a, employed are high precision cylindrical rollers or needle rollers which are usually used for a roller bearing or the like. Such is the structure that the array 11 of transmission pin rollers and the array 18 of controllable pin rollers work as inner teeth to make a backlash phenomenon minimum, rendering a pitch distance precise between the pin rollers, maintaining a uniform tooth profile with a high precision, equalizing a surface roughness and improving a meshing precision between the pin rollers 11a, 18a and the teeth 7a, 8a.

Owner:KAMOSEIKO

Switching device for ratchet wrench

A ratchet wrench includes a head with a driving member located in a first room thereof. A clip is engaged with a first groove in the first room and a second groove in the driving member to retain the driving member in the first room. A pawl is received in a second room defined in the inside of the first room and engaged with the driving member. The pawl has a lip on the rear side thereof. A switching device is located in a third room communicating with the second room and outside of the wrench. The lip is inserted in a slot in the switching device. The switching device has a board which is rested on the lip and pushes either one of the two inclined faces of the recess in the rear side of the pawl to change the ratcheting engagement between the pawl and the driving member.

Owner:CHI YEN JU

Stacker crane with an improved sliding mechanism

ActiveUS20170267451A1Less exposed to wear and friction and to mechanical stressWithout riskLifting devicesStorage devicesEngineeringBiological materials

The present invention relates to a stacker crane (2) for transporting, inserting and picking containers of biological material test tubes in / from locations (3) of a plurality of shelves (4) of a warehouse (1) for storing containers of biological material test tubes. The stacker crane (2) is able to move the containers of biological material test tubes in the three Cartesian directions x, y and z, so as to reach the locations (3), wherein the stacker (2) comprises a first carriage (21) and a second carriage (22) able to slide independently of, and to be released from, the first carriage (21) in direction y.

Owner:INPECO

Internal-pulling type ultrahigh-pressure hydraulic pressure testing machine for large-diameter steel pipe and hydraulic system of hydraulic pressure testing machine

InactiveCN104865132AReduce configurationIncrease motivationMaterial strength using tensile/compressive forcesFluid-pressure actuator componentsClosed loopHigh pressure water

The invention relates to an ultrahigh-pressure hydraulic testing machine for a steel pipe, in particular to an internal type ultrahigh-pressure hydraulic pressure testing machine for a large-diameter steel pipe and a hydraulic system of the hydraulic pressure testing machine. The hydraulic testing machine comprises a piston cylinder body, a front cover, a rear cover, a piston, a piston rod, a rear-end zigzag nut, a front-end zigzag nut, an internal sealing mold and an external sealing mold, wherein the front cover and the rear cover are located at two ends of the piston cylinder body; the piston and the piston rod are located in the cylinder body; the rear-end zigzag nut is used for fixing the piton rod; the front-end zigzag nut is used for transmitting force to a tested steel pipe; the internal sealing mold and the external sealing mold are used for sealing and fixing the tested steel pipe; an inner cavity of the cylinder body is divided into a rodless cavity body and a rod cavity by the piston. The hydraulic system comprises a low-pressure oil power system, an electrical-hydraulic closed-loop control system, a high-pressure water pump accumulator power system, a low-pressure water supply system and an oil pressure driving device. According to the hydraulic testing machine and the hydraulic system, cylindrical closed space is formed in the tested steel pipe, and an ultrahigh-pressure hydraulic test can be performed on the tested steel pipe without any other external force; the hydraulic testing machine and the hydraulic system are suitable for the ultrahigh-pressure hydraulic test of the large-diameter steel pipe, the equipment weight can be greatly reduced, and the investment can be reduced by times.

Owner:XIAN TIANYU HEAVY IND

Bar material blank processing device

ActiveCN103521784ASolve the inconvenience of clampingSmooth transmissionTailstocks/centresFeeding apparatusLinear motionBall screw

The invention discloses a bar material blank processing device which comprises a cutter holder, a cutter holder seat, a linear ball guide rail, a ball screw, a column, an upper servo motor and a lower servo motor. The cutter holder and the cutter holder seat are used for fixing an external circle turning tool, the linear ball guide rail is fixed on the column, the ball screw is arranged in the longitudinal direction of the linear ball guide rail and parallel to the linear ball guide rail, the cutter holder seat is connected with a nut seat of the ball screw, the two sides of the cutter holder seat are arranged in slide grooves on the two sides of the linear ball guide rail, the upper end of the ball screw is connected with an output shaft of the upper servo motor through a coupling, the upper end of an upper thimble is connected a clamping and adjusting device which can adjust the vertical position of the upper thimble, the clamping and adjusting device is fixed on the column, and a lower thimble is connected with an output shaft of the lower servo motor to achieve rotation of bar material blanks. The rotation motion of the ball screw is converted into the linear motion of the nut seat to drive the cutter holder seat to slide along the linear ball guide rail, so that external circles of the bar material blanks can be longitudinally turned. By means of the bar material blank processing device, the problems that bar material blanks are inconvenient to clamp, prone to being broken in transmission and the like are solved. Furthermore, a pre-sintering link is removed.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Welding robot fixing device having positioning function

InactiveCN107717290ASmooth motionSmooth and precise movementWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringLaser

The invention discloses a welding robot fixing device with a positioning function, which comprises a base, a bearing is installed on the top of the base, a mounting groove is arranged inside the base, racks are installed on both sides of the mounting groove, and inside the bearing Bearing rollers are installed, a mounting column is installed in the mounting groove, a mounting seat is installed on the top of the mounting column, a laser is installed on one side of the mounting seat, a motor is installed in the mounting column, and the rotating shaft of the motor A reducer is installed on the reducer, a rotating shaft is connected to the reducer, a driving gear is installed on the rotating shaft, mounting frames are installed on both sides of the mounting column, and a brake wheel is installed on one of the mounting frames And driven gear, auxiliary gear is installed on the other in the said mounting frame, a connection block is installed on one side of the brake wheel, and a toggle lever is connected on the connection block. The invention can accurately locate the welding position and is more convenient to use.

Owner:GUANGXI UNIV +1

Forage bundle loading lifting equipment for livestock breeding and using method of forage bundle loading lifting equipment

InactiveCN113200458AStable and precise movementPrevent slippingTrolley cranesTravelling gearAnimal scienceAgricultural science

The invention relates to the technical field of livestock breeding, in particular to forage bundle loading lifting equipment for livestock breeding and a using method of the forage bundle loading lifting equipment. The equipment comprises a supporting frame, a moving assembly, a sliding cylinder and a loading and unloading assembly. The height of a lifting plate can be adjusted up and down, so that the equipment can lift forage bundles at different height positions, the application scene of the equipment is increased, and the use range of the equipment is widened; the forage bundles are shoveled by moving the lifting plate left and right, so that the equipment achieves an automatic feeding function for lifting the forage bundles, the labor burden is reduced, the speed of loading of forage bundles for livestock breeding is increased, and the use efficiency of the equipment is improved; and the forage bundles are shoveled by moving the lifting plate up and down and moving the lifting plate left and right, so that the equipment can also automatically feed and lift the stacked forage bundles, and the use range of the equipment is further widened.

Owner:淮北市三石磊牧业有限公司

Tracking and positioning system of ground chain conveying chain

ActiveCN104176494ASmooth and precise movementTracking locator is stableLiquid surface applicatorsControl devices for conveyorsDetentControl engineering

The invention provides a tracking and positioning system of a ground chain conveying chain. The tracking and positioning system comprises a follow positioning mechanism, a robotic gripper mechanism, a ground chain conveying system and a control mechanism, wherein the follow positioning mechanism and the robotic gripper mechanism are arranged in two different initial positions respectively; when the positioning mechanism detects a jig, the control mechanism controls the positioning mechanism to position the jig and keep the jig in a fixed gesture, and the robotic gripper mechanism grips a workpiece on the jig and transfers the workpiece to a jig on another conveying line under the control of the control mechanism; and the positioning mechanism and the robotic gripper mechanism return to the respective initial positions, and workpiece transfer between conveying lines is finished. According to the system, a jig rod is gripped more firmly, so that the jig is vertical without inclination; internal force is not formed during gripping, and accordingly, a conveying chain tracking and positioning device is more stable; and the linear guideway movement is more stable and accurate.

Owner:ANQING LIUXI IND EQUIP

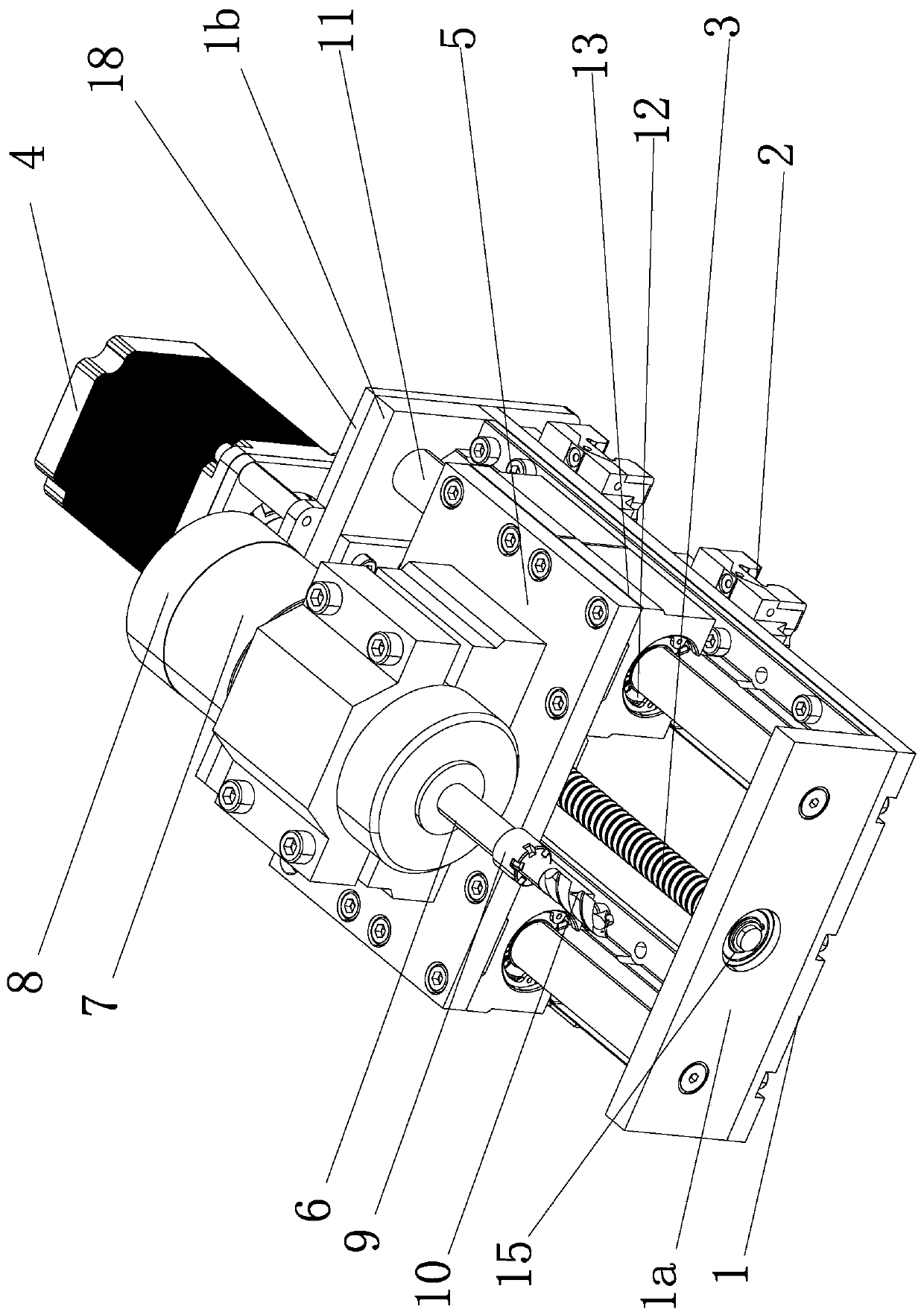

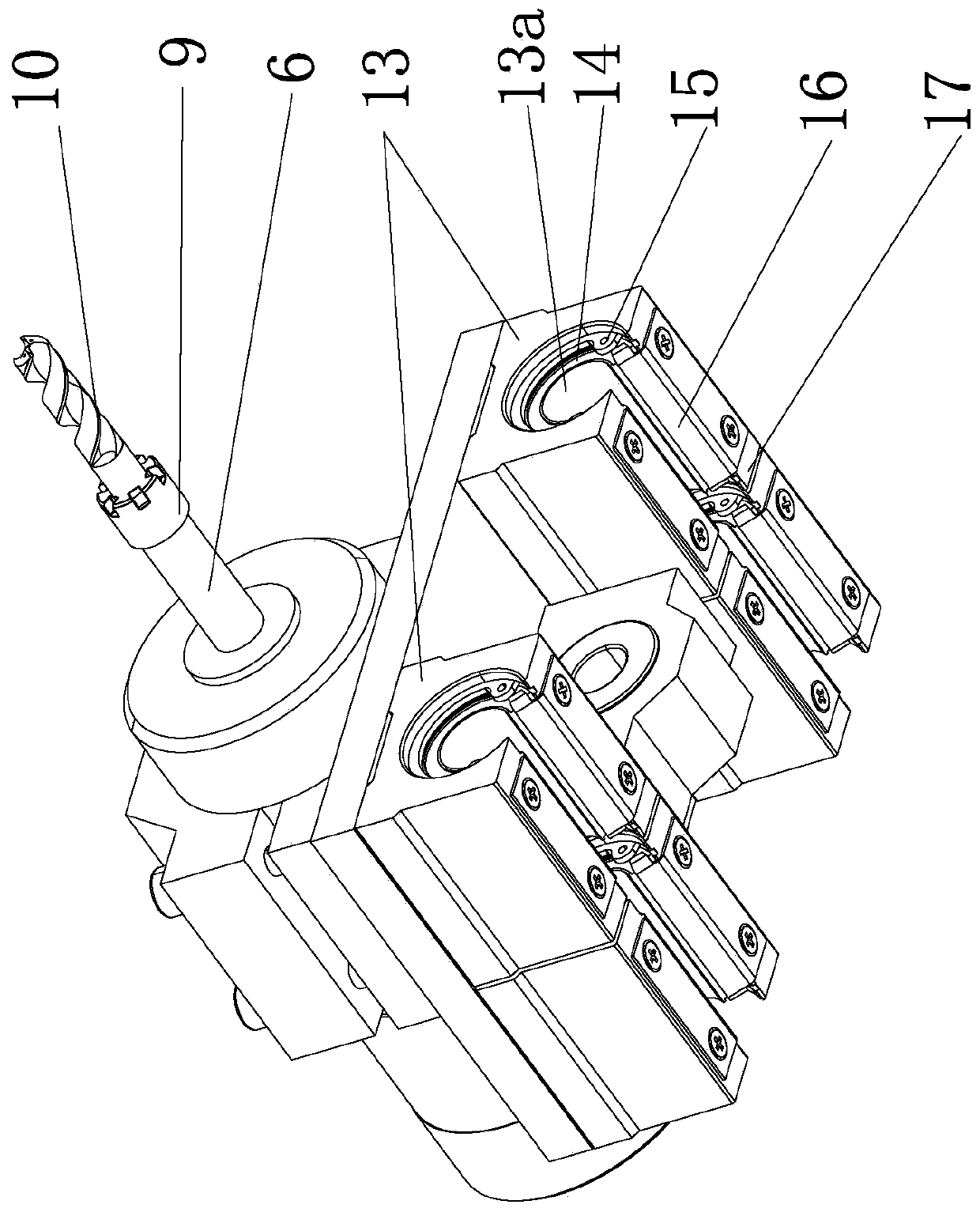

Detachable type Z-direction cutter assembly on machine tool

PendingCN110303354AEasy to transformImprove efficiencyFeeding apparatusPositioning apparatusDrive motorEngineering

The invention provides a detachable type Z-direction cutter assembly on a machine tool and belongs to the technical field of machine tool equipment. By means of the detachable type Z-direction cutterassembly on the machine tool, the technical problem that the Z-direction cutter assembly on an existing machine tool is high in the cost and inconvenient to use is solved. The Z-direction cutter assembly comprises a base. Fixing block assemblies are fixedly arranged on one side of the base. A rotatable screw is arranged on the other side of the base. A servo motor by which the screw can be drivento rotate is fixedly arranged at one end of the base. A sliding base is in threaded connection with the screw. A cutter fixing sleeve and a driving motor by which the cutter fixing sleeve is driven torotate are arranged on the sliding base. A synchronizing wheel is further arranged on the output shaft of the driving motor. A cutter is fixed to an end of the cutter fixing sleeve through a cutter fixing lock. The axis direction of the screw is consistent with the axis direction of the cutter fixing sleeve. By means of the detachable type Z-direction cutter assembly on the machine tool, existingmachine tool equipment can be conveniently reformed; multiple Z-direction cutter assemblies can also be used simultaneously; the Z-direction cutter assembly is relatively flexible, convenient to assemble and high in universality; and the cost is saved.

Owner:SANMEN TONGSHUN RIVET

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com