Detachable type Z-direction cutter assembly on machine tool

A dismantling and cutting tool technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems such as the inability to comprehensively use the precision transformation of machine tools, reduce or increase the Z-axis structure, and the belt is easily distorted and deformed. Processing performance and processing accuracy, high versatility, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

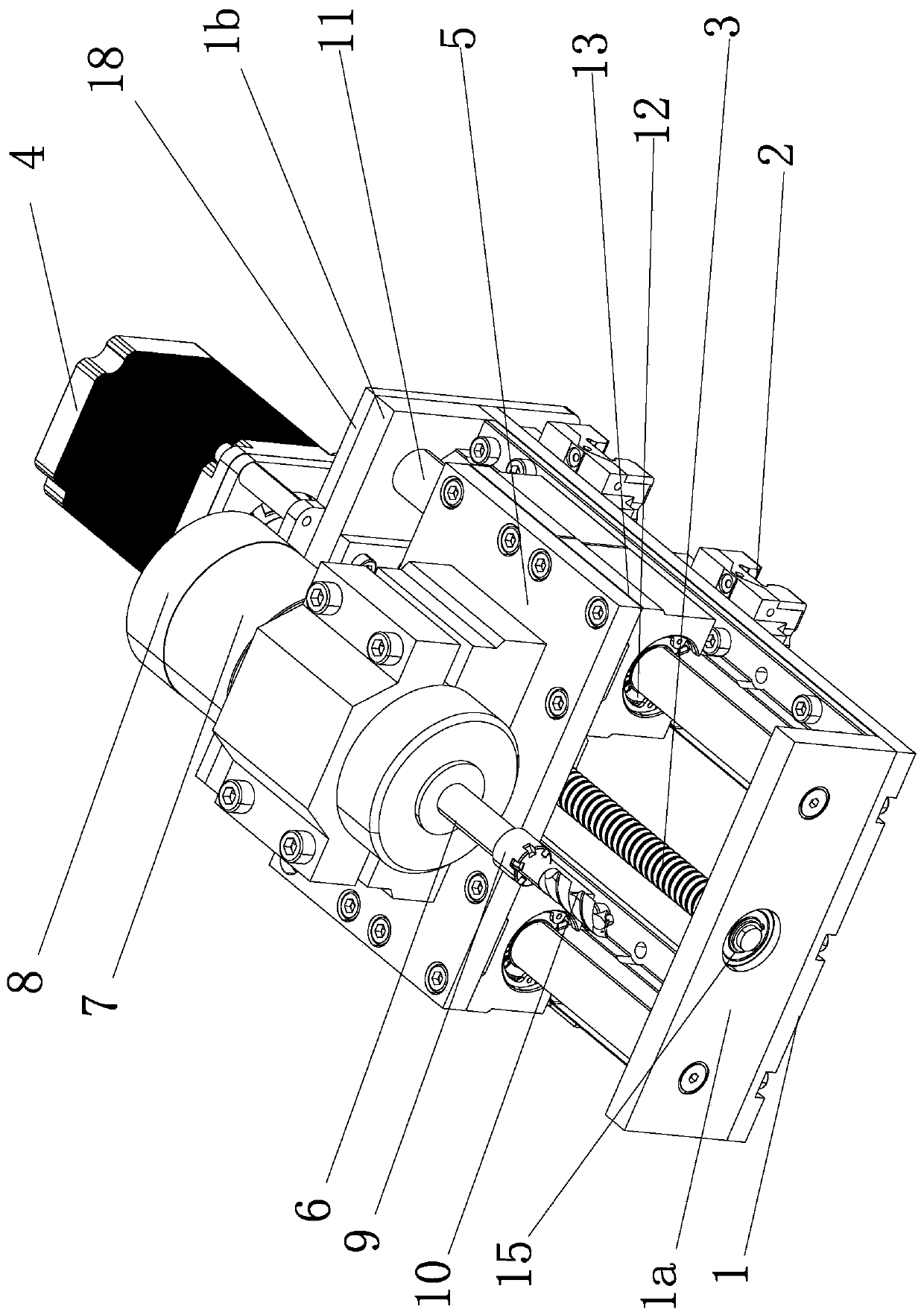

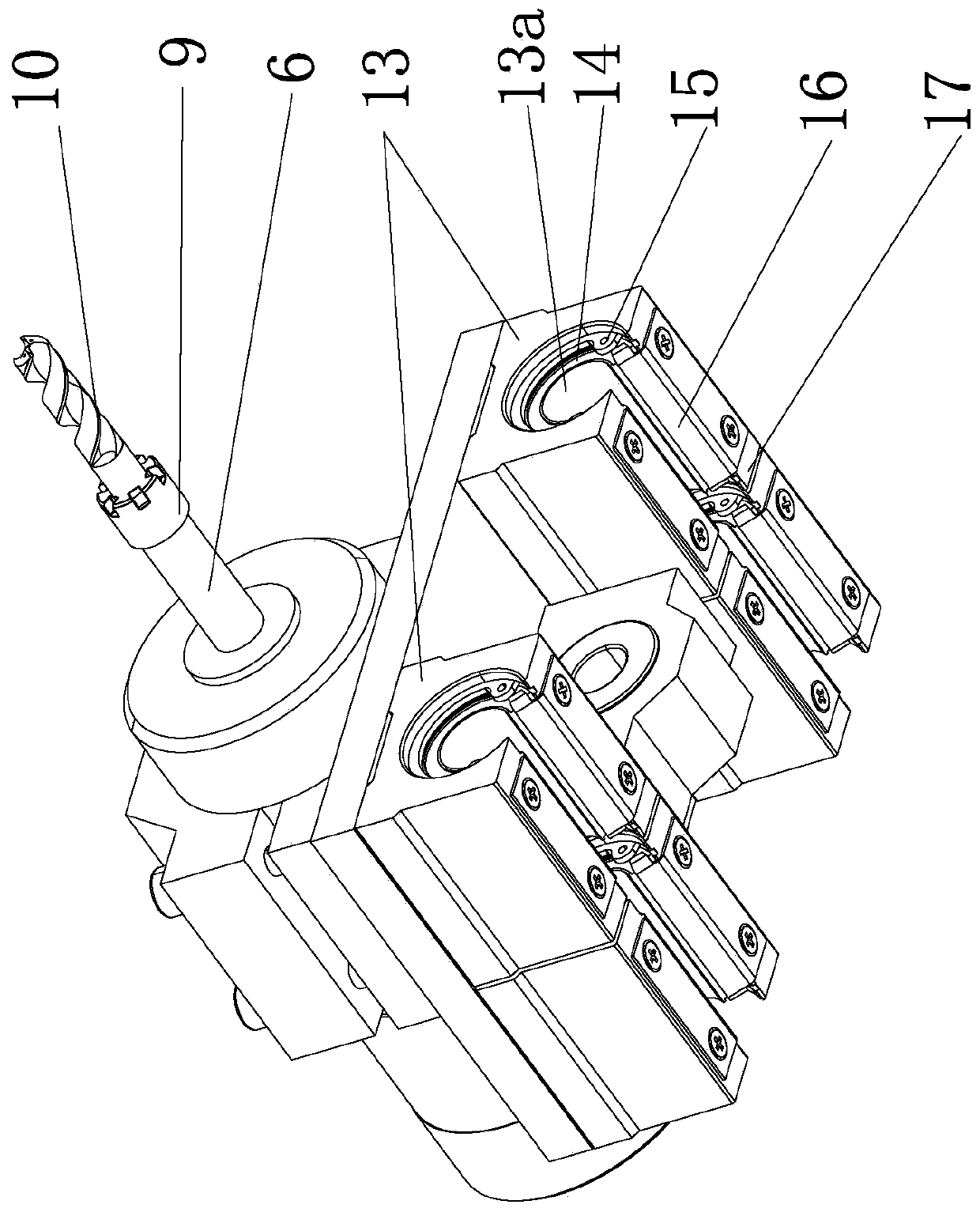

[0036] Such as Figure 1 to Figure 5 As shown, the detachable Z-direction tool assembly on this machine tool includes a base 1, and a fixed block assembly 2 is fixed on one side of the base 1; the fixed block assembly 2 includes a fixed seat 21 fixed on the side of the base 1 and a fixed On the cross rib plate fixing block 22 on the fixed seat 21, a wedge-shaped groove 22a is provided on the side of the cross rib plate fixing block 22; the other side of the base 1 is provided with a rotatable screw 3, and one end of the base 1 is fixed with A servo motor 4 capable of driving the lead screw 3 to rotate, the lead screw 3 is threadedly connected with a slide seat 5, the slide seat 5 is provided with a tool holder 6 and a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com