Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Simple production process requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zymophyte liquid, liquid spirit stillage fermented feed and fermentation method of liquid spirit stillage fermented feed

InactiveCN103074284AGrowth inhibitionMaintain balanceFungiBacteriaBacillus subtilis var. nattoBacilli

The invention discloses a zymophyte liquid, a liquid spirit stillage fermented feed and a fermentation method of the liquid spirit stillage fermented feed. The zymophyte liquid is prepared by mixing, at a preset proportion, liquids of lactobacillus, bacillus subtilis, bacillus natto and candida utilis bacteria which are obtained by enlarged culture. The fermented feed is prepared by fermenting a liquid complete feed with the zymophyte liquid. The fermentation method comprises the steps of inoculating the zymophyte liquid with the liquid complete feed at 3-5%wt, adjusting the moisture content to be 68-72%, sufficiently mixing into a liquid, and loading into a sealer for sealing and fermentation. The shelf life of the liquid spirit stillage fermented feed fermented by the zymophyte liquid is over 6 months at a room temperature. The liquid spirit stillage fermented feed is easier to digest, low in thallus activity loss and ideal in using effect, a culture proportion and a complete feed formula balance essential amino acid, and the liquid spirit stillage fermented feed is suitable for a whole postweaning growth stage of a commercial pig.

Owner:四川国凤生物科技有限公司

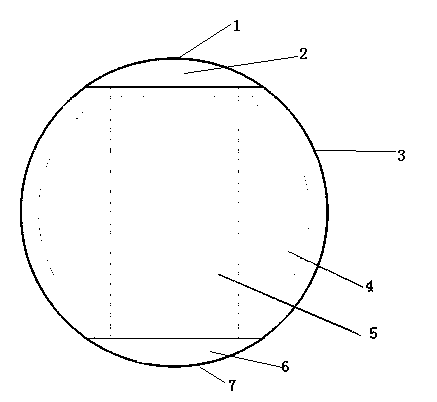

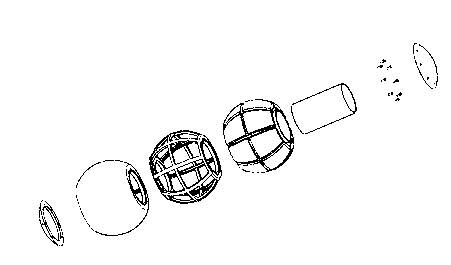

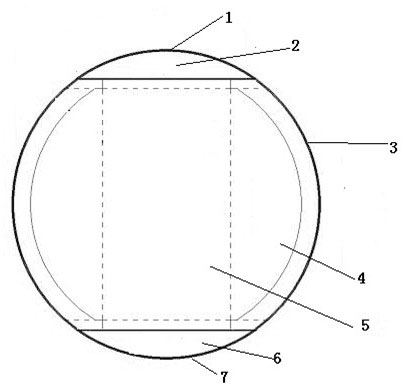

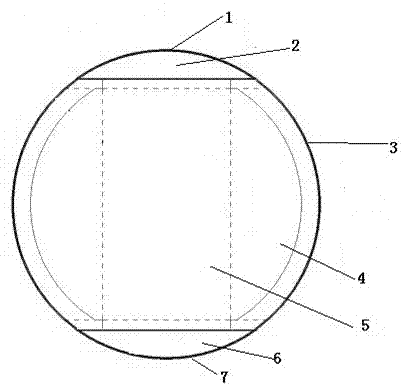

Spherical buoy and manufacturing method thereof

InactiveCN102700684AReduce non-uniform impactImprove and ensure posture stabilityWaterborne vesselsBuoysEngineeringBuoy

The invention discloses a spherical buoy and a manufacturing method thereof. The spherical buoy comprises a spherical buoy body. The spherical buoy is characterized in that the periphery of the spherical buoy body is smooth, the spherical buoy body is provided with an upper top cover and a lower bottom cover, the upper top cover, the lower bottom cover and the spherical buoy body form three cavities from top to bottom, i.e. a first cavity, a spherical buoy body cavity and a second cavity, the spherical buoy body cavity is a cylindrical cavity, and a foam body is arranged at the periphery of the cylindrical cavity. The spherical buoy has the advantages of good gesture stability, simple structure and low cost.

Owner:周涛

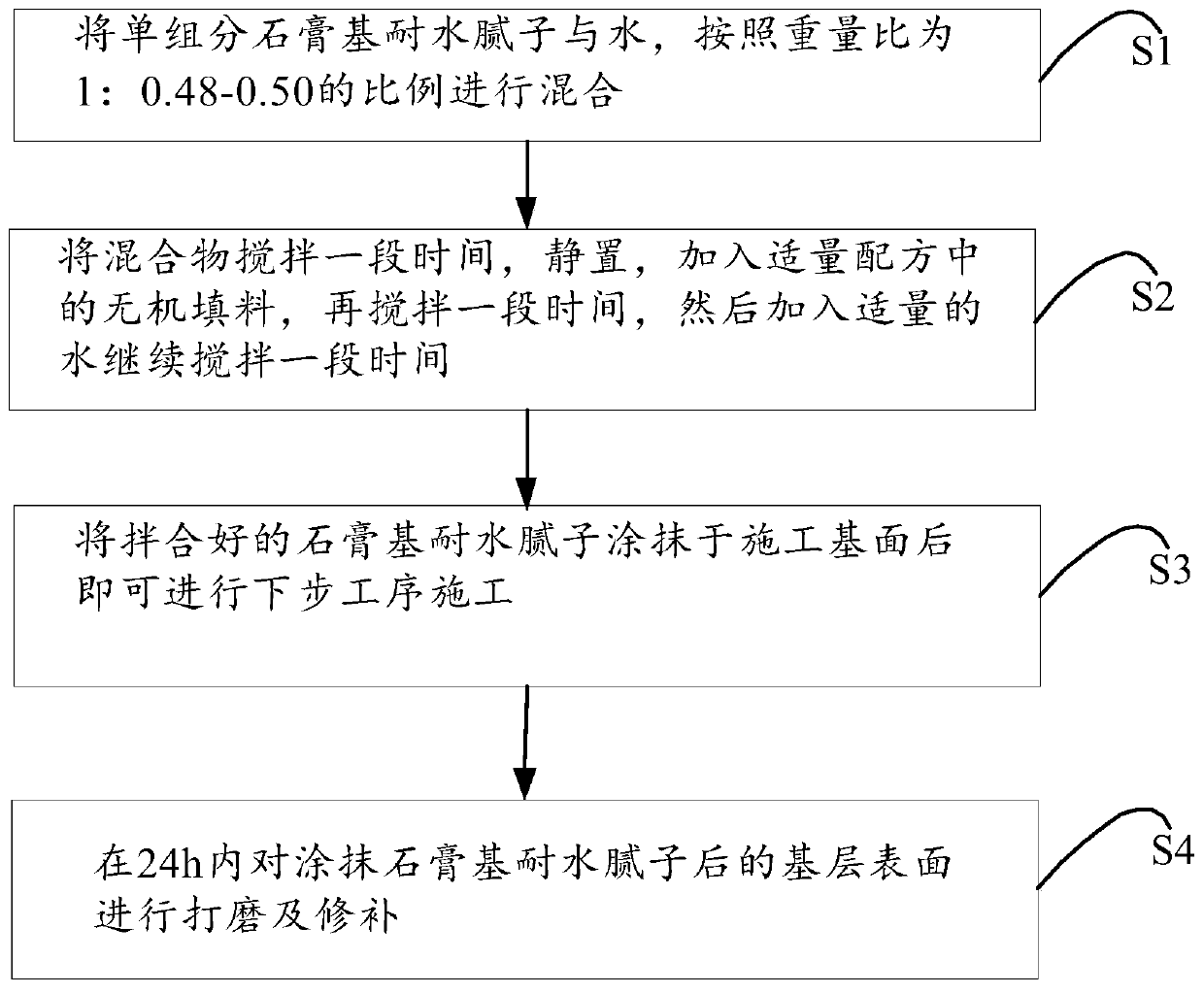

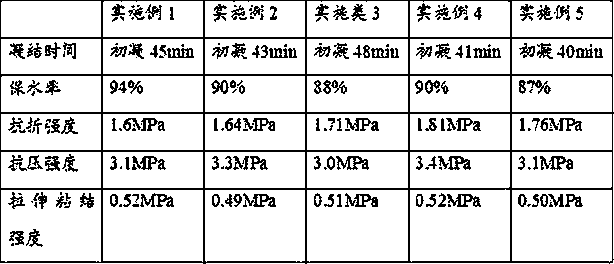

Single-component gypsum-based water-resistant putty and construction method thereof

InactiveCN109810556AImprove workabilityGood flexibilityCovering/liningsFilling pastesWater resistantGypsum

The invention provides single-component gypsum-based water-resistant putty and a construction method thereof. The single-component gypsum-based water-resistant putty adopts powder packaging and is prepared from the components in percentage by weight: 30-35% of desulfurized gypsum, 3-5% of white cement, 36.05-58.38% of an organic filler, 5-10% of an inorganic filler, 3.62-7.0% of an additive, 0.15-0.40% of a water-retaining thickener, 0.01-0.05% of an expanding agent, 0.1-0.2% of an anti-settling agent, and 0.015-0.04% of a thickening starch agent. The single-component gypsum-based water-resistant putty is mixed through a stirrer and then discharged to be packaged into powder products, and packaging and transporting are convenient; and the single-component gypsum-based water-resistant puttyhas the advantages of being quickly dried within two hours, and being easy to smear in batches, low in cost, single in component, easy to construct, moderate in strength, capable of being applied inbatches in a thick-layer mode, good in water resistance, high in anti-crack capacity and the like.

Owner:ZHEJIANG ZHIQIANG PAINT

Mechanical sand blasting process for appearance pattern of ceramic

InactiveCN101333119AImprove the artistic effectSimple production process requirementsClay processing apparatusMetallurgySand blasting

The invention discloses a ceramic external pattern surface mechanical sandblasting treatment process, which makes the ceramic blanks into finished products through molding, drying, glazing, firing, soft material pattern surface layout, mechanical sandblasting and other steps. The treatment process disclosed in the invention enables the ceramic products to form diversified artistic effects, and has simple requirements on production technology and is easy to operate; meanwhile, the ceramic external pattern surface mechanical sandblasting treatment process saves costs and can achieve batched semi-mechanical production.

Owner:陈振奎 +3

Method for producing composite layer substrate of trunk ornamental plate for automobile

InactiveCN101659240ASimple production process and equipment requirementsAvoid investment establishmentVehicle componentsMetal working apparatusWork in processEngineering

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

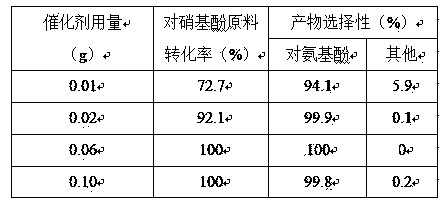

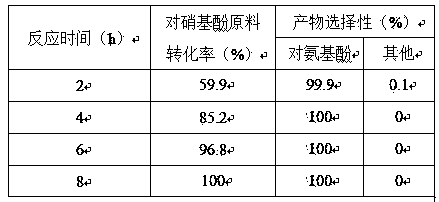

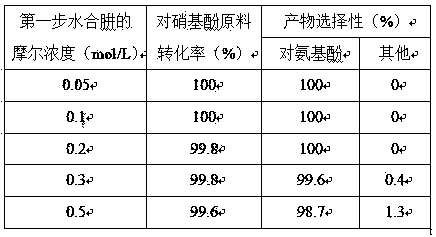

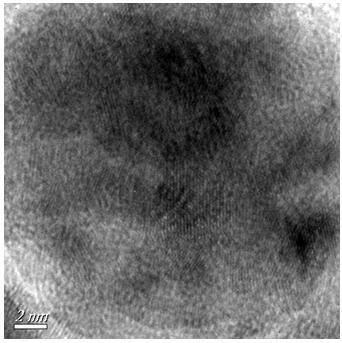

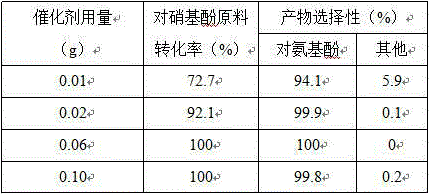

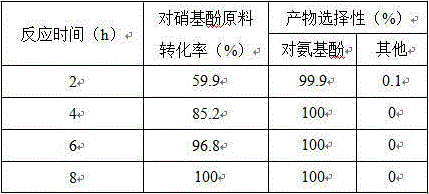

Preparation and application of nano-nickel/silver/copper (Ni/Ag/Cu) composite catalyst

InactiveCN103638949AHigh selectivityHigh catalytic activityOrganic compound preparationNanotechnologyNano catalystPtru catalyst

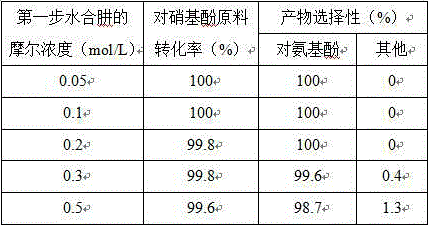

The invention relates to the preparation and application of a nano-nickel / silver / copper (Ni / Ag / Cu) composite catalyst and belongs to the field of nano-catalyst preparation and catalytic research. The preparation comprises the following steps: preparing a hollow Ni / Ag / Cu composite nano-catalyst by using copper nitrate, silver nitrate and nickel nitrate as raw materials; performing reaction through the catalyst by using p-nitrophenol and absolute ethyl alcohol as the raw materials to raise the reaction temperature to 80-160 DEG C, maintaining the temperature, and reacting for 2-8h to obtain high-purity p-aminophenol. The hollow Ni / Ag / Cu composite nano-catalyst is in a spherical particle shape, is small in dosage and is high in catalytic activity and stability. A method for preparing the p-aminophenol through the nano-Ni / Ag / Cu composite catalyst is simple in process requirement and meets an industrialization requirement.

Owner:JIANGSU UNIV

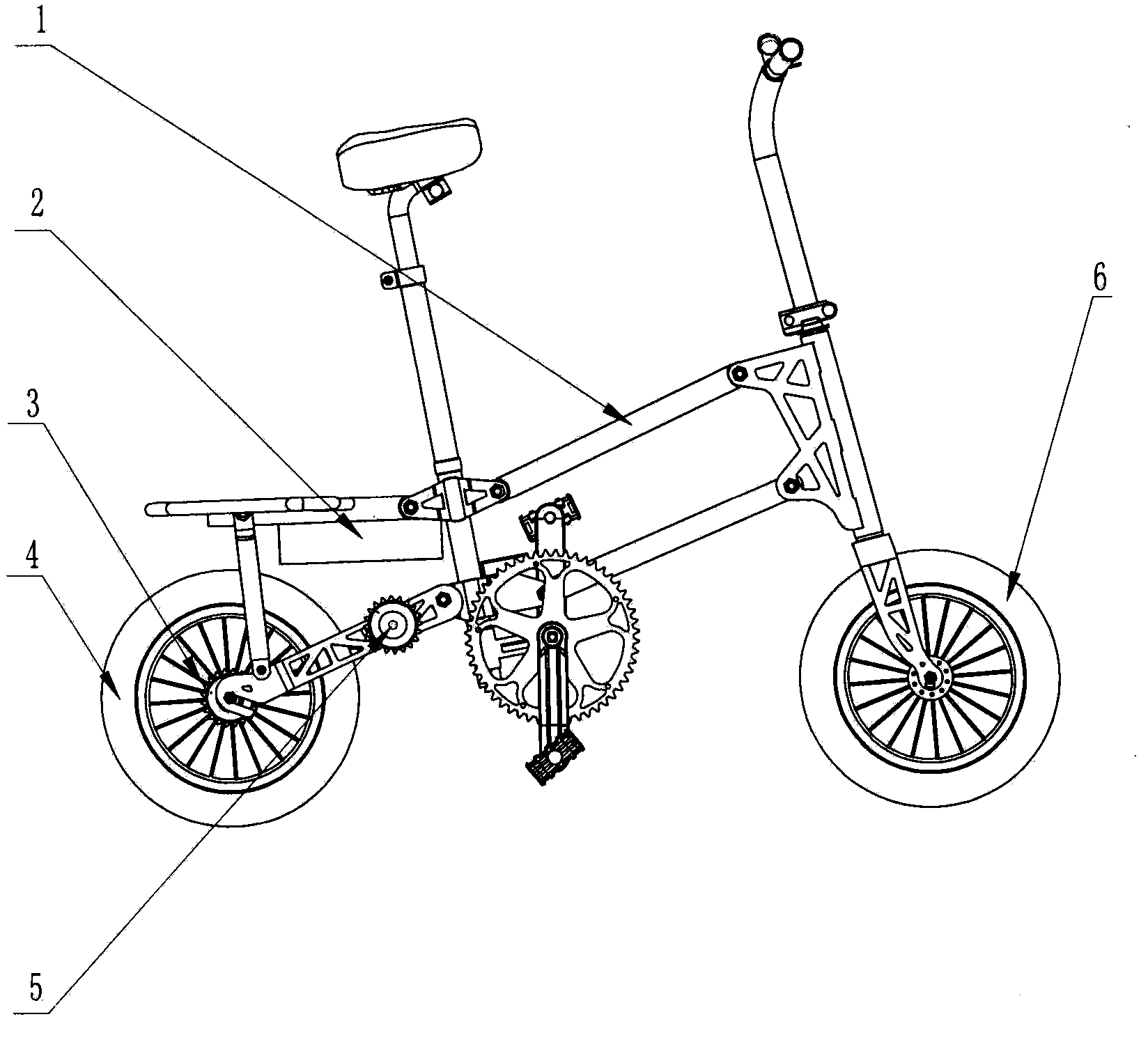

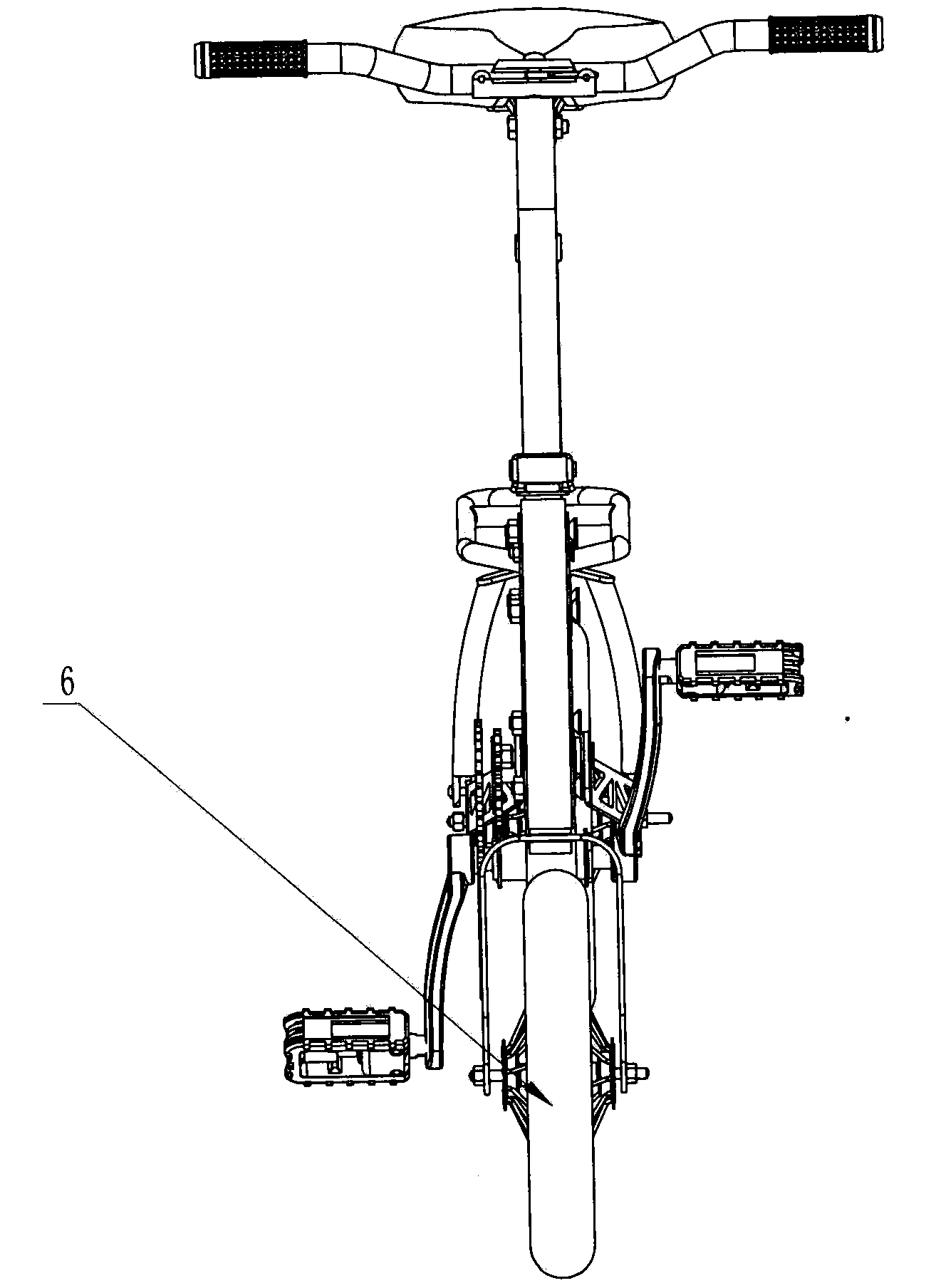

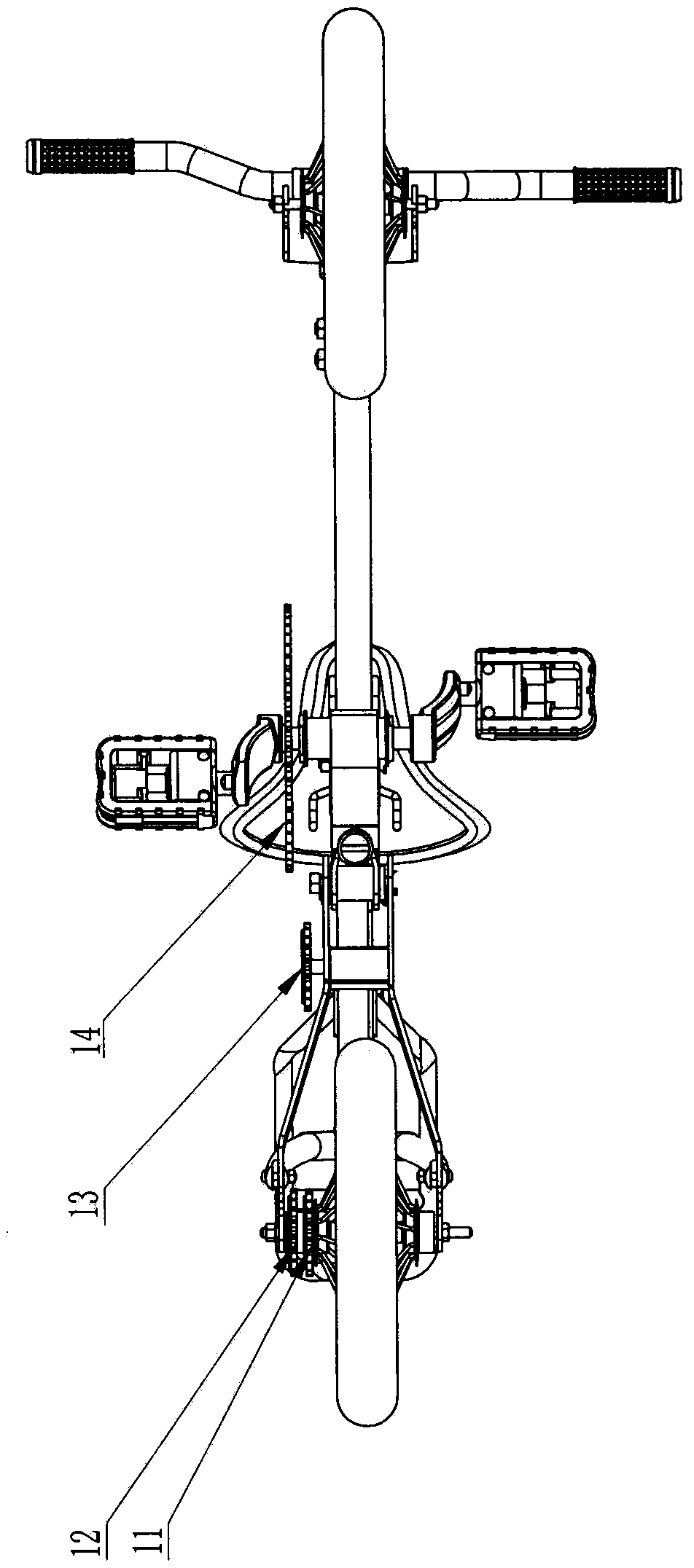

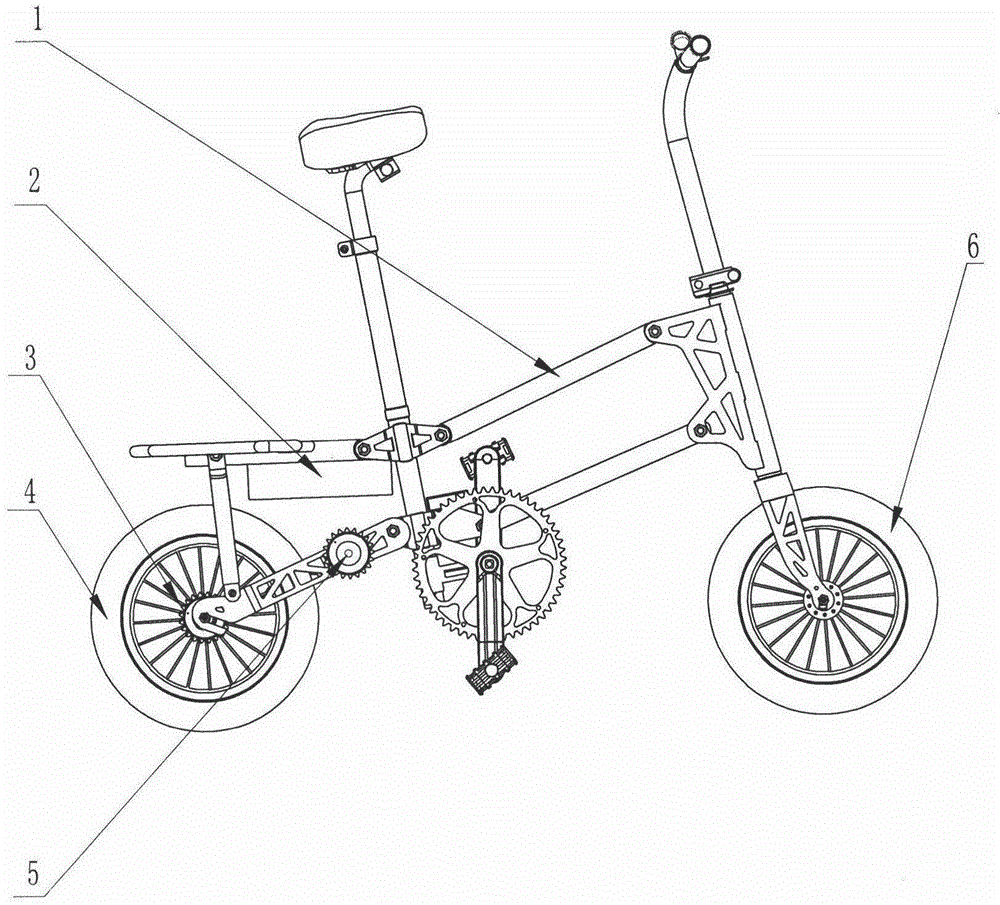

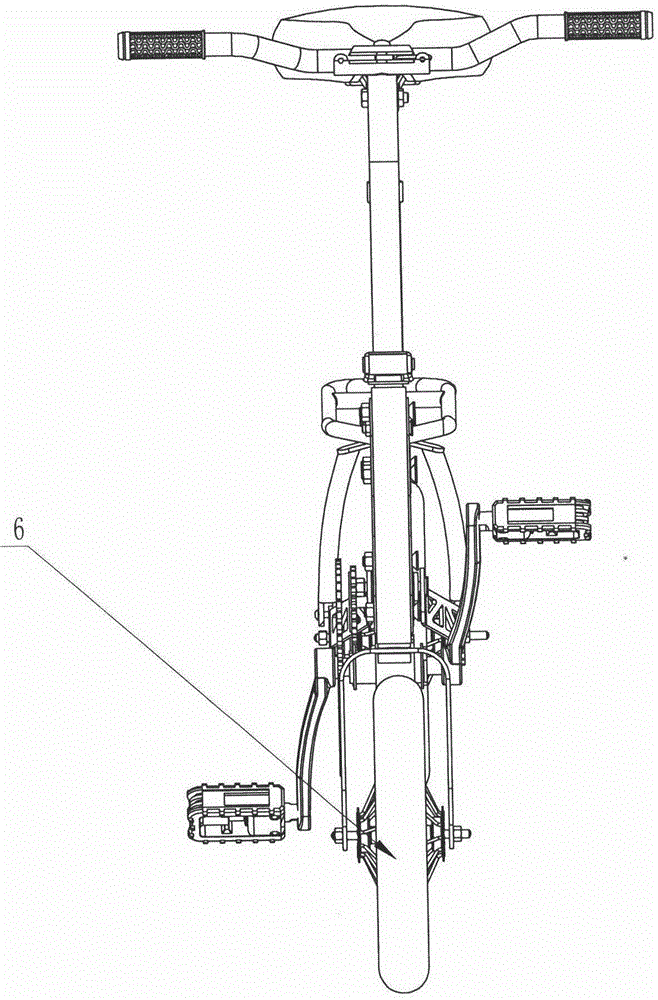

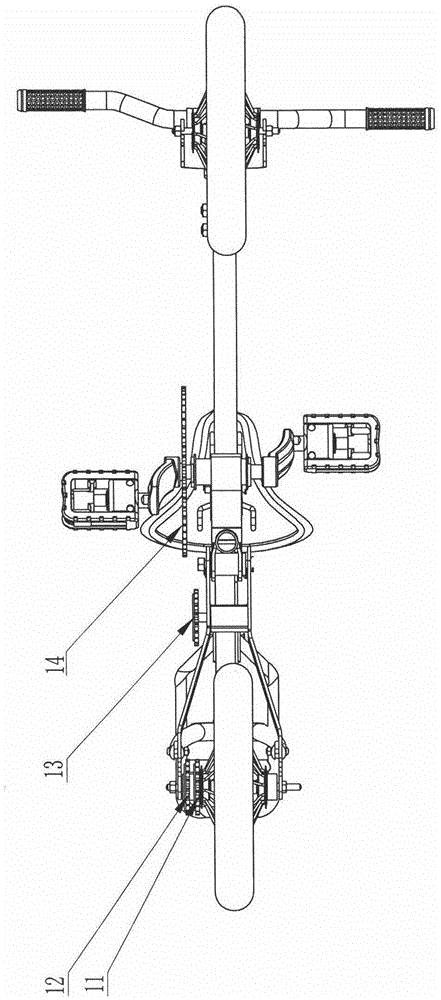

Intelligent uniform-force pedal moped

ActiveCN104276249AThe production process and processing requirements are simpleEasy to installFoldable cyclesRider propulsionFlywheelTransmission system

Disclosed is an intelligent uniform-force pedal moped which comprises a body system, a motor drive system, a flywheel chain plate transmission system, a control system, a pedal force measurement driving system and a brake system. The intelligent uniform-force pedal moped is characterized in that according to the body system, a front fork is mounted at the front end of a frame, and wheels are mounted on the front and the front fork; according to the motor drive system, a battery is fixed on the frame, and a motor is fixed on the frame through bolts; according to the flywheel chain plate transmission system, a first flywheel and a second flywheel which are concentric with the rear wheel are fixedly connected to the rear wheel and on one side of the rear wheel, and a motor flywheel is fixed on a shaft of the motor; according to the pedal force measurement driving system, one ends of N force transducers are fixed on the frame while the other ends are fixedly connected with a middle axle fixing block, and a middle axle is rotationally mounted in a hole of the middle axle fixing block through a headset; according to the brake system, brake mechanisms are mounted on the front and rear wheels respectively.

Owner:HAIMEN THE YUECAI TEXTILE TECH CO LTD

Skyhigh nitrile crosslinking type powdery butadiene-acrylonitrile rubber and preparation method thereof

ActiveCN109320655AEvenly distributedSimple production process requirementsPotassium persulfateAcrylonitrile

The invention discloses a preparation method of skyhigh nitrile crosslinking type powdery butadiene-acrylonitrile rubber. The preparation method comprises the following steps that firstly butadiene and acrylonitrile serve as monomers to synthesize butadiene-acrylonitrile latex through emulsion polymerization; then the butadiene-acrylonitrile latex is agglomerated into powder and subjected to centrifugal dehydration and drying, and the skyhigh nitrile crosslinking type powdery butadiene-acrylonitrile rubber is obtained. At the synthesis stage of the butadiene-acrylonitrile latex, the butadiene-acrylonitrile latex is prepared from 40-50 parts of acrylonitrile and 20-30 parts of butadiene; one of ammonium persulfate, potassium persulfate or diisopropylbenzene hydroperoxide is added into sodium formaldehyde sulfoxylate, ferrous sulfate, EDTA (ethylenediaminetetraacetic acid) tetrasodium and EDTA ferrisodium at the weight ratio of 1 to 0.5 to 0.25 to 0.1 to 0.1 to form a compound which serves as an initiator. The invention further discloses skyhigh nitrile crosslinking type powdery butadiene-acrylonitrile rubber prepared by adopting the method. The preparation method has the advantagesthat the polymerization reaction technology with high and mediate temperature combining is adopted; polymerization conversion rate is high, and no acrylonitrile and butadiene recycling devices are needed; the monomers react completely, and the cost is low; product quality stability is effectively improved, and oil resistance is better; the crosslinking of molecular chains is effectively completed,and the abrasion resistance and the heat resistance of the product are better.

Owner:安庆华兰科技有限公司

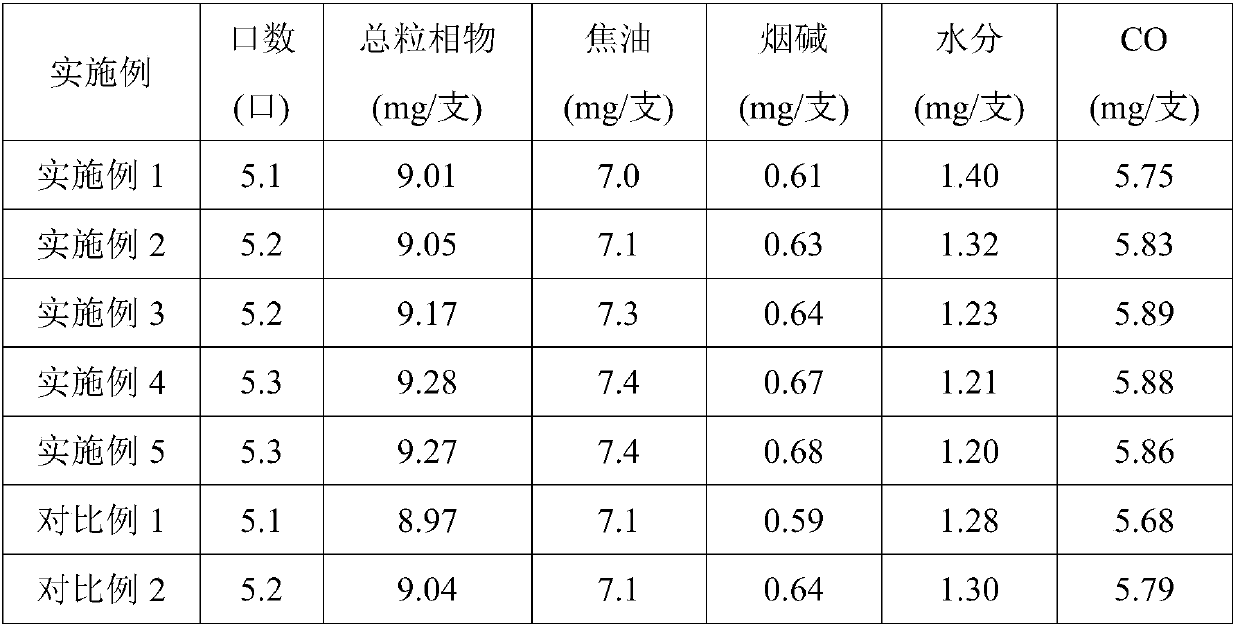

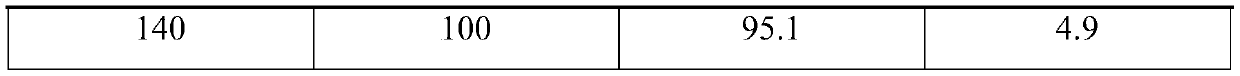

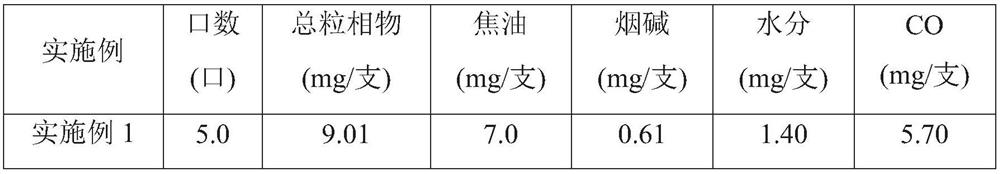

Flame retardant for thin cigarettes, preparation method and applications thereof

InactiveCN110924221AReduce burn rateImprove sensory qualityNatural cellulose pulp/paperPaper coatingFire retardant

The invention discloses a flame retardant for thin cigarettes, wherein the flame retardant comprises aluminum dihydrogen phosphate and PEG. The invention further discloses applications of the flame retardant, wherein the flame retardant is applied to preparation of fin cigarette paper. The invention further discloses applications of the thin cigarette paper, wherein the thin cigarette paper is applied to preparation of thin cigarette paper capable of regulating the combustion rate of a thin cigarette. The invention further discloses a preparation method of the thin cigarette paper capable of regulating the combustion rate of the thin cigarette. By using the thin cigarette paper capable of regulating the combustion rate of the thin cigarette, the combustion rate of a thin cigarette can be effectively regulated, the phenomenon of cigarette end falling caused by overlong combustion cone is reduced, irritation can be remarkably reduced, the ash wrapping effect after cigarette combustion isimproved, and the combustion quality and the consumption experience of thin cigarettes are effectively improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

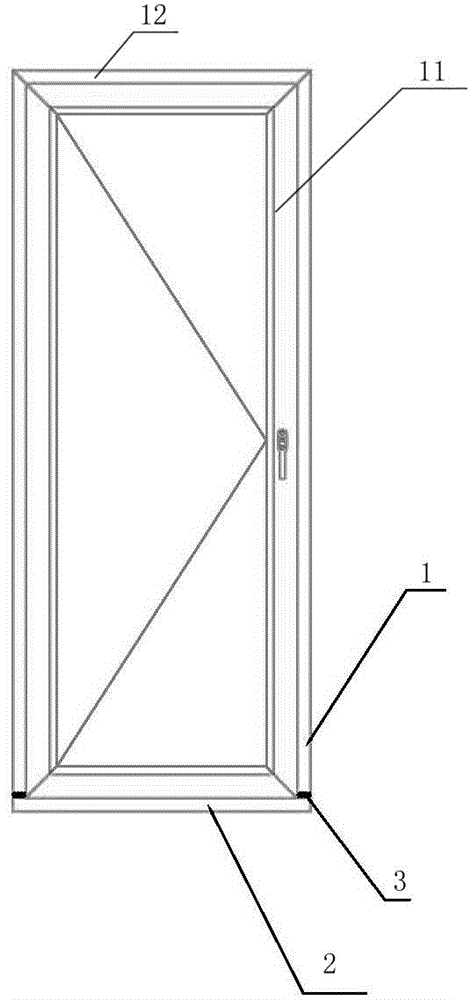

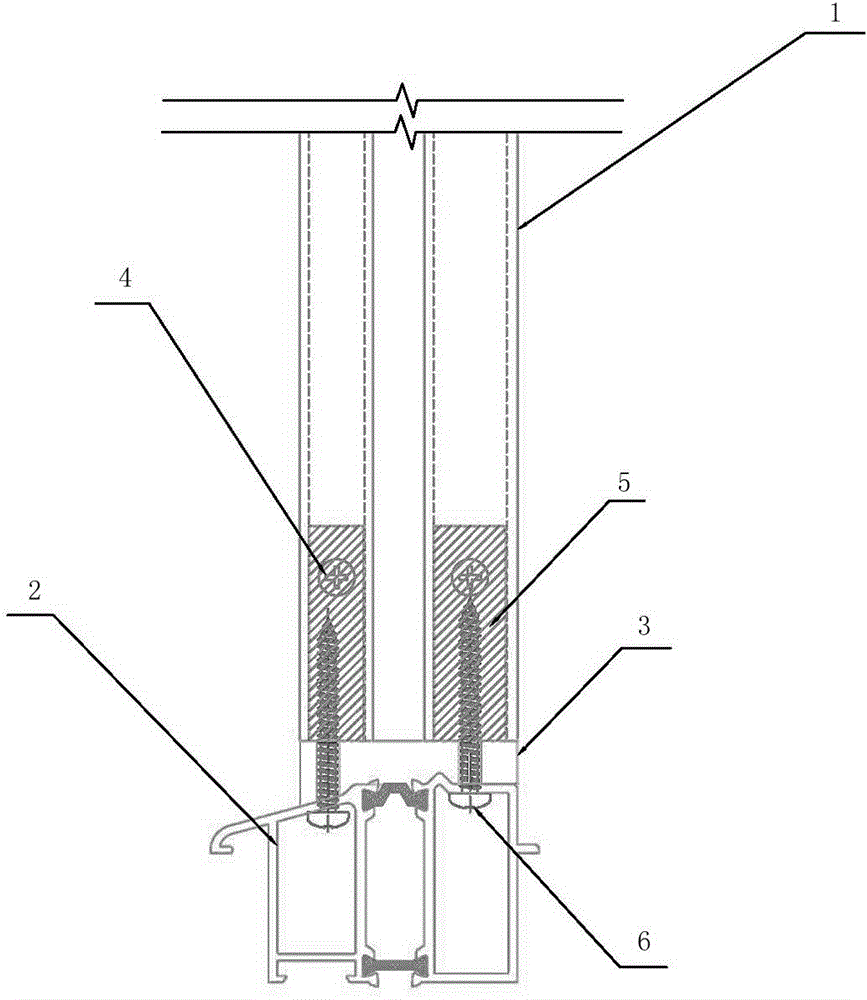

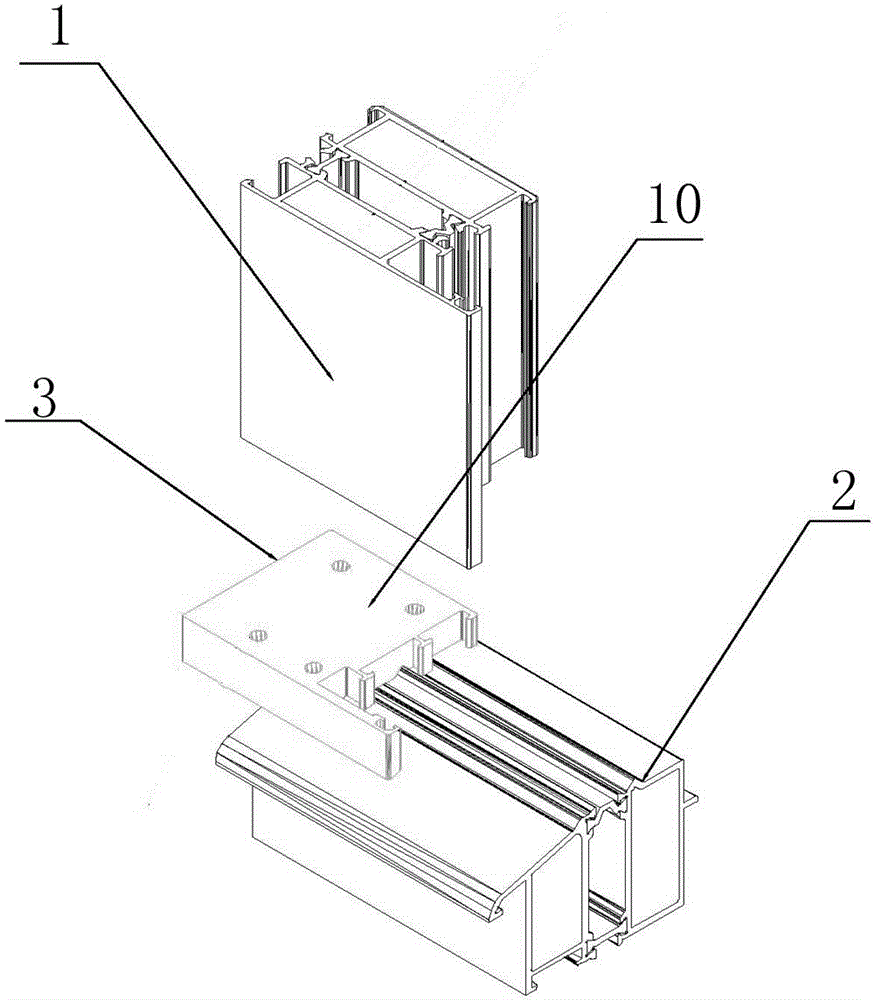

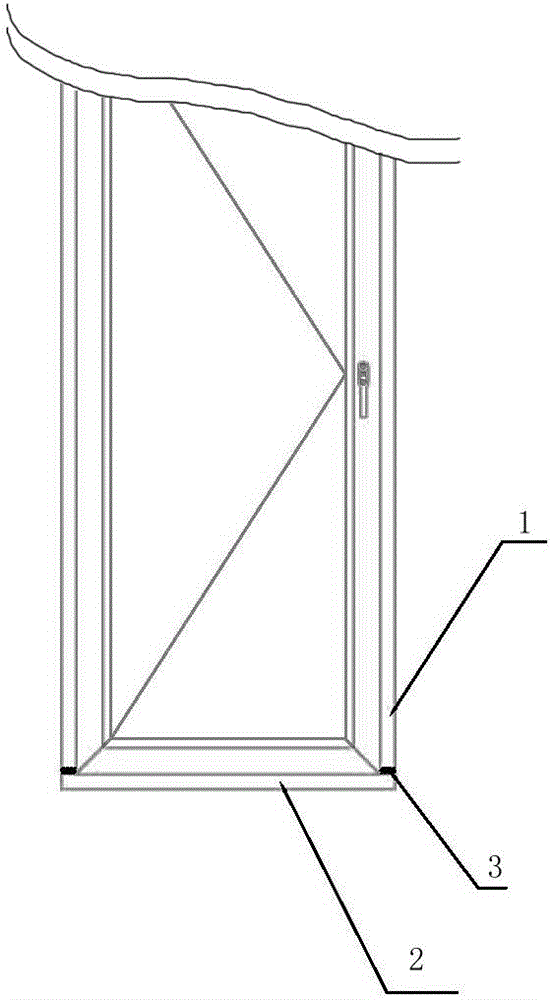

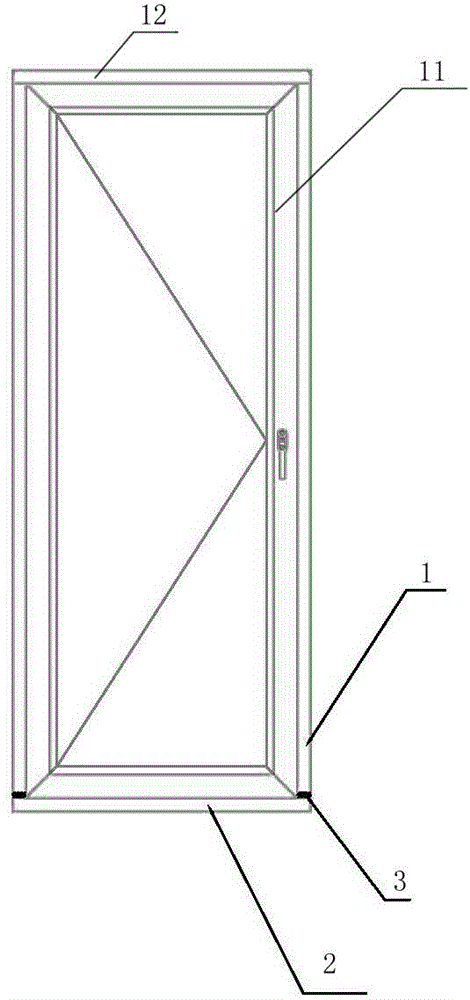

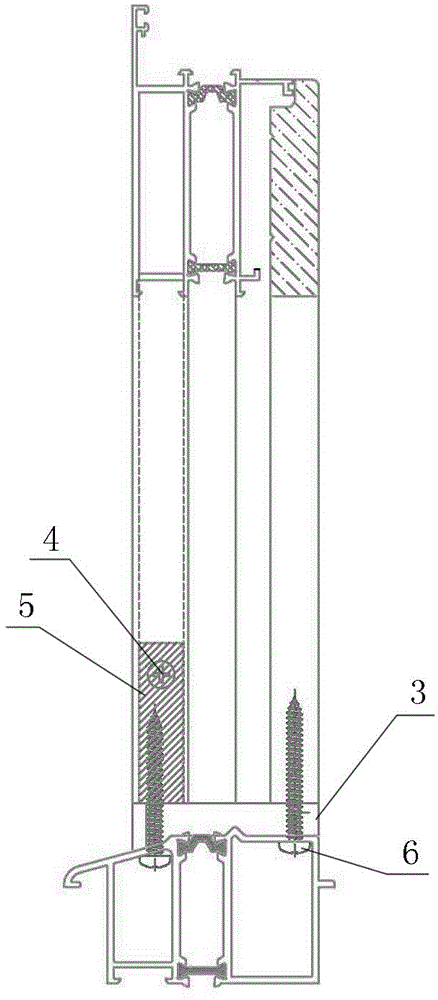

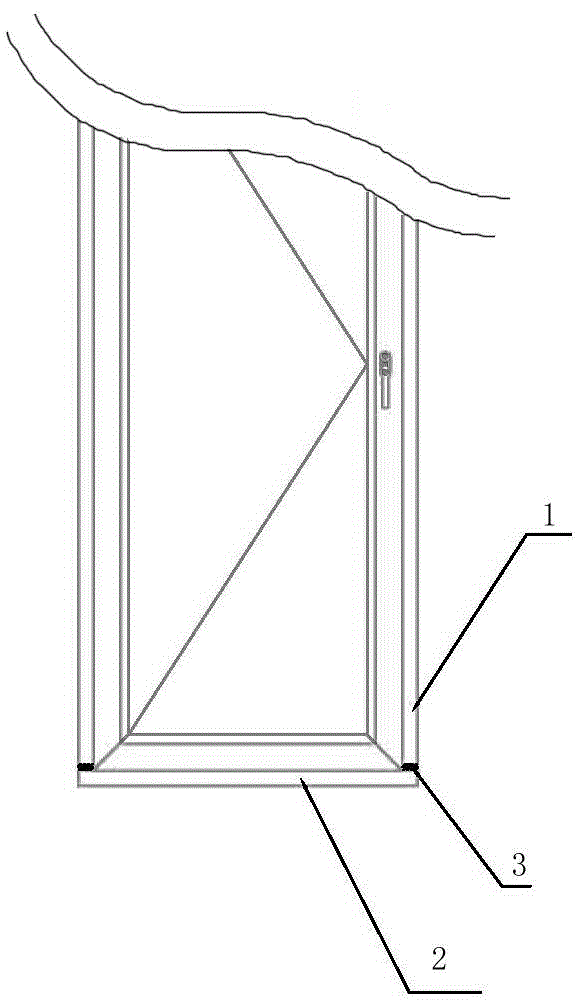

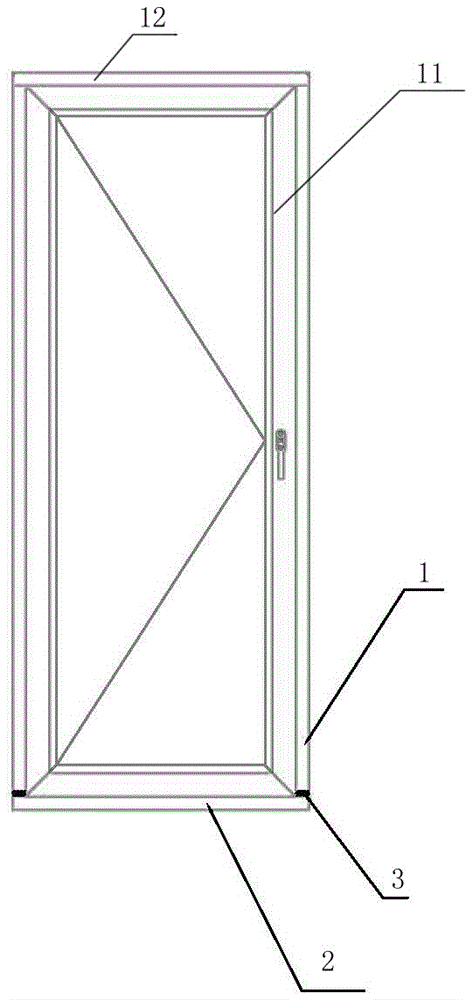

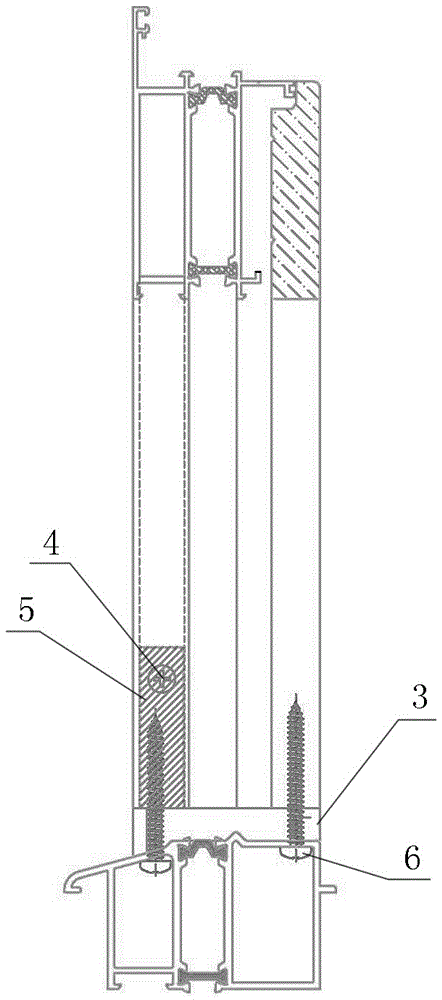

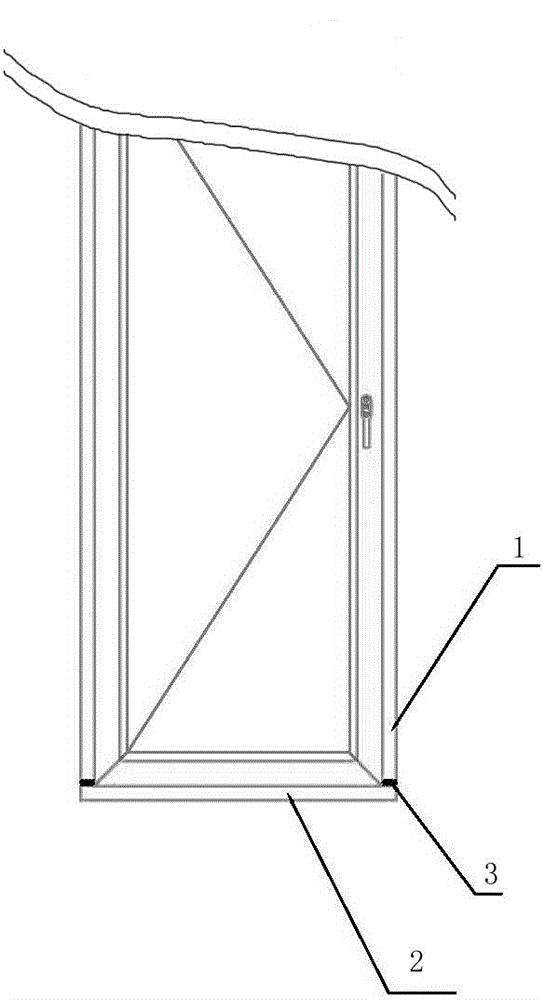

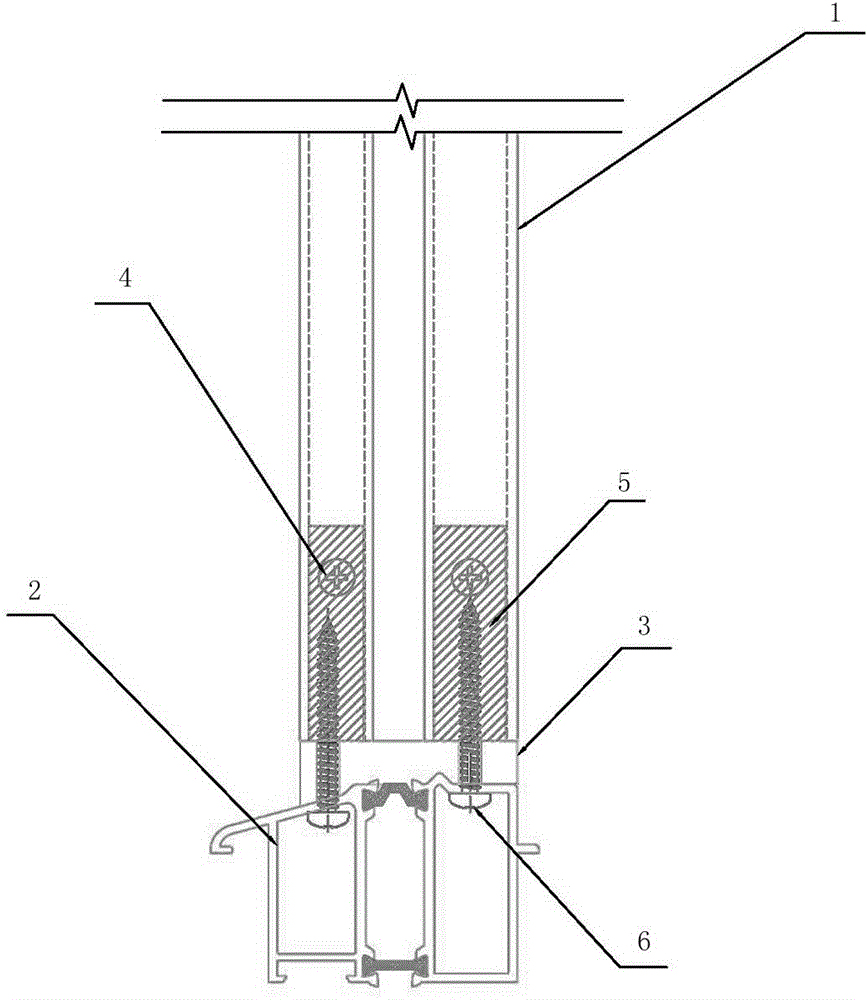

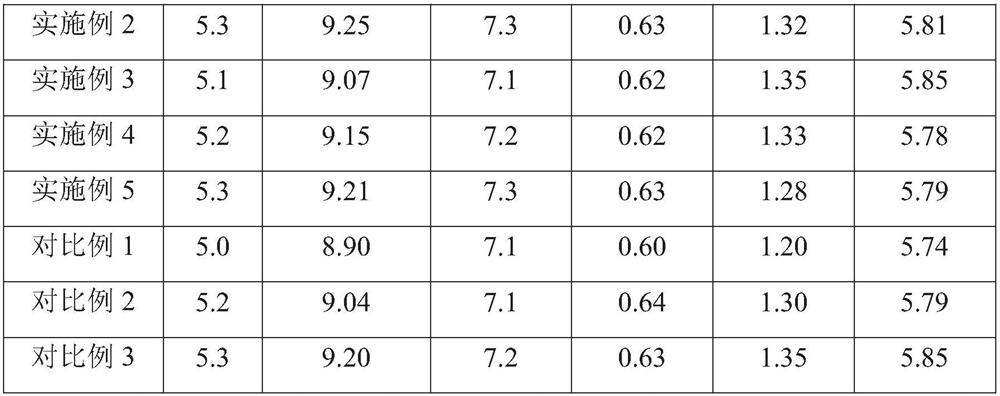

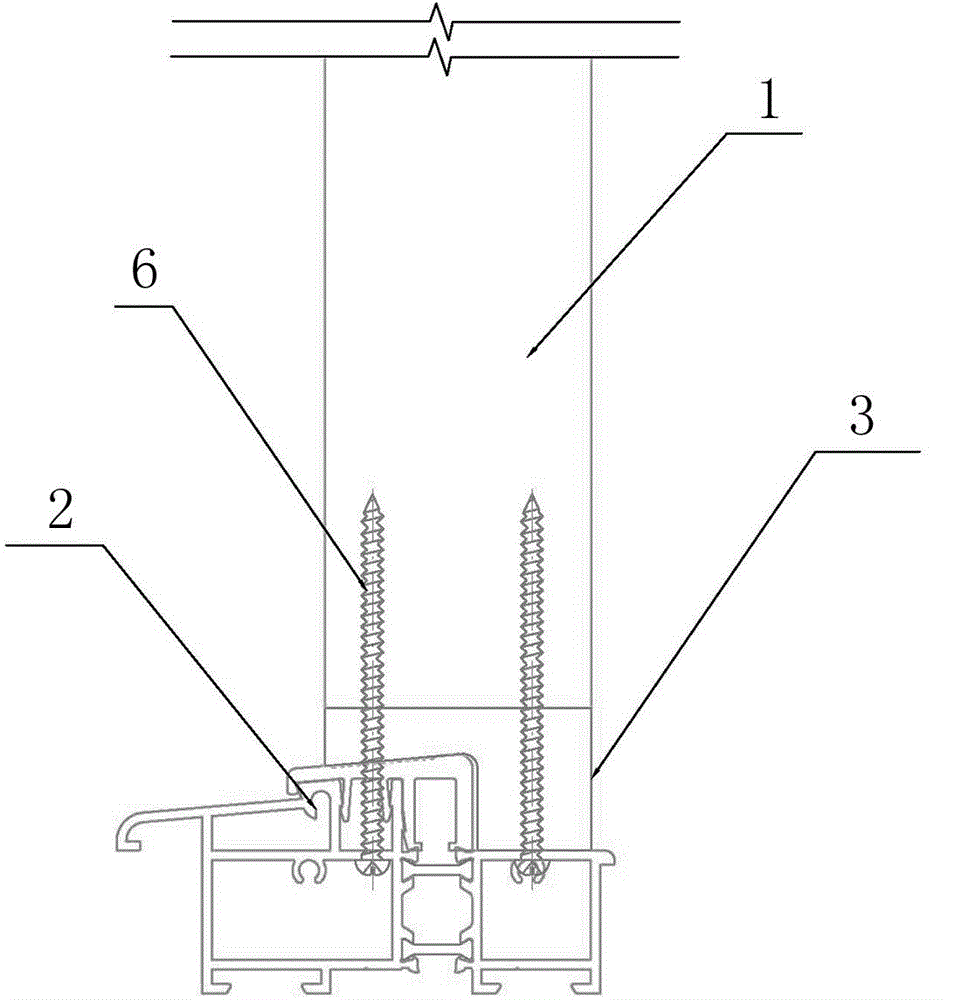

Aluminium alloy outer frame framing structure for threshold-free door window

InactiveCN104088555AGuaranteed tightnessSimplified group box formWindow/door framesEngineeringAir tightness

The invention discloses an aluminium alloy outer frame framing structure for a threshold-free door window. An outer frame is formed by assembling left and right vertical frames, an upper door frame and a lower door frame; the lower door frame is a threshold-free door frame; the lower end parts of the left and the right vertical frames are placed at the upper parts of the two ends of the threshold-free door frame, and the lower end sides of the vertical frame are connected together with the upper side of the end part of the threshold-free door frame at least through one threshold-free door cushion block; the two ends of the upper door frame are respectively connected together with the upper end parts of the left and the right vertical frames at an angle of 45 degrees or 90 degrees; the two vertical frames and the threshold-free door frame are aluminium alloy frames, vertical cushion blocks are positioned and fastened inside the lower end cavities of the vertical frames through fastening bolts, and the upper sides of the two ends of the threshold-free door frame are fixedly connected together with the lower end sides of the left and the right vertical frames through threshold-free door cushion blocks and the vertical cushion blocks. The framing form between the vertical frames and the threshold-free door frame is simplified, the manufacture process requirements are simplified, and moreover the integral air tightness of the threshold-free door corners is ensured.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

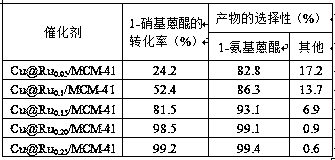

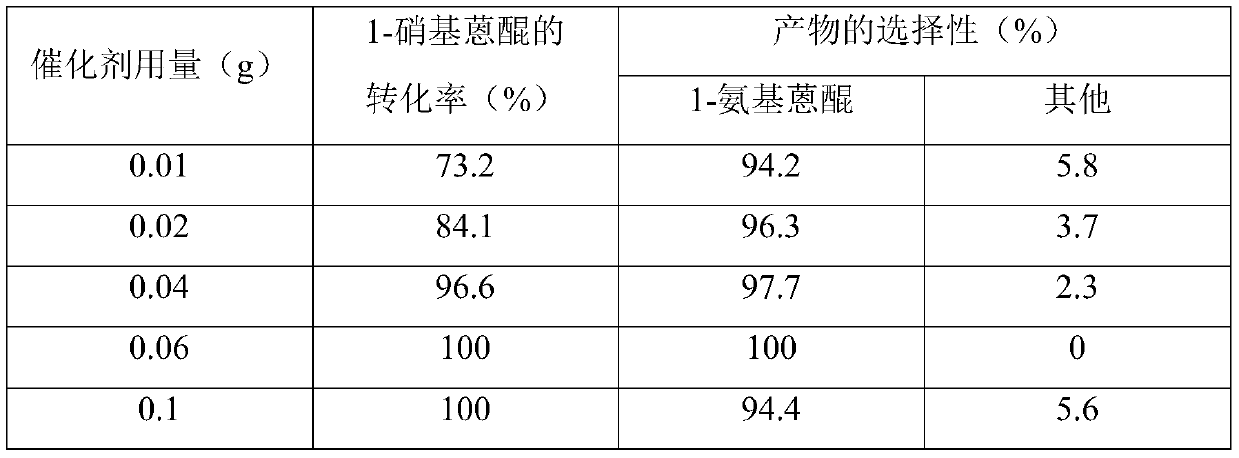

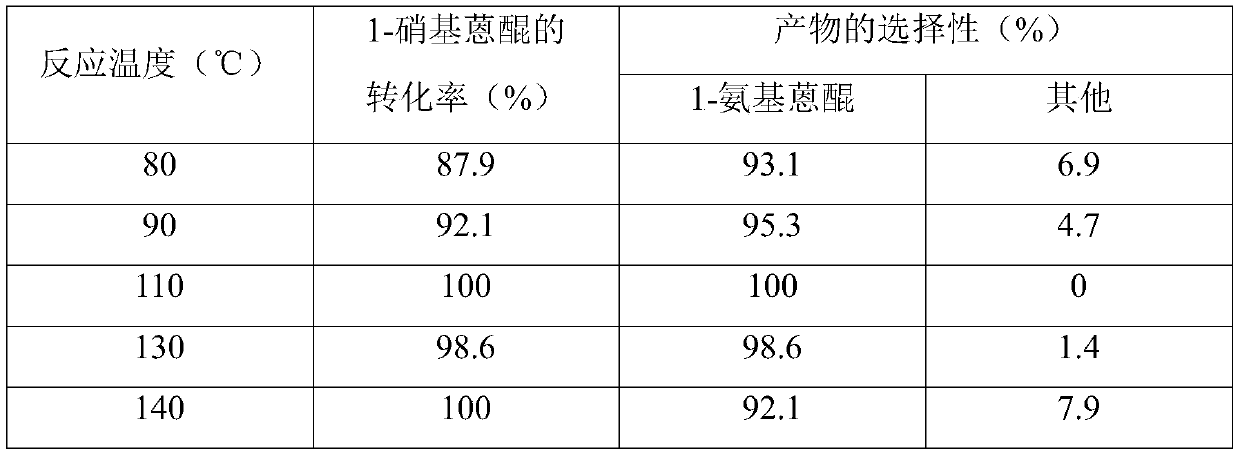

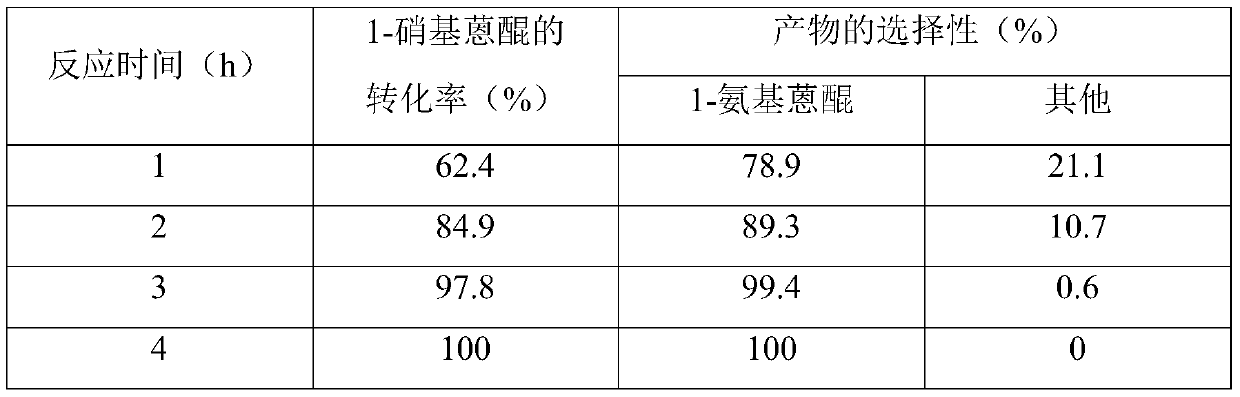

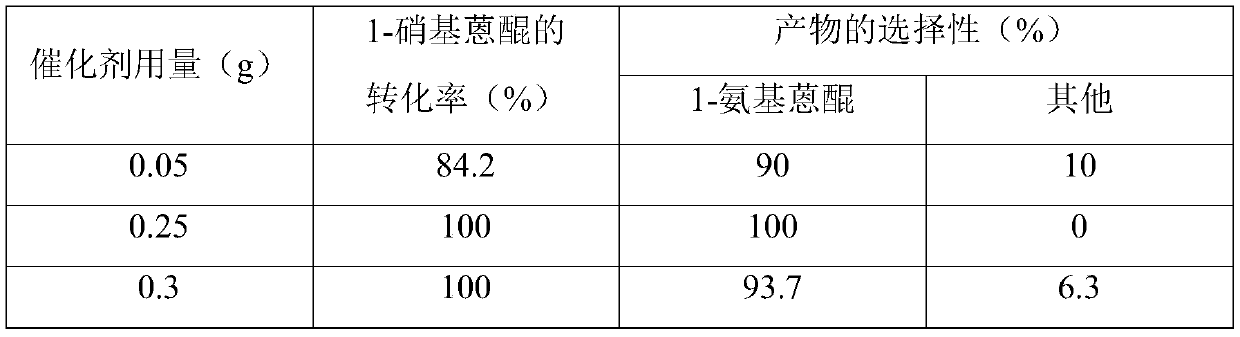

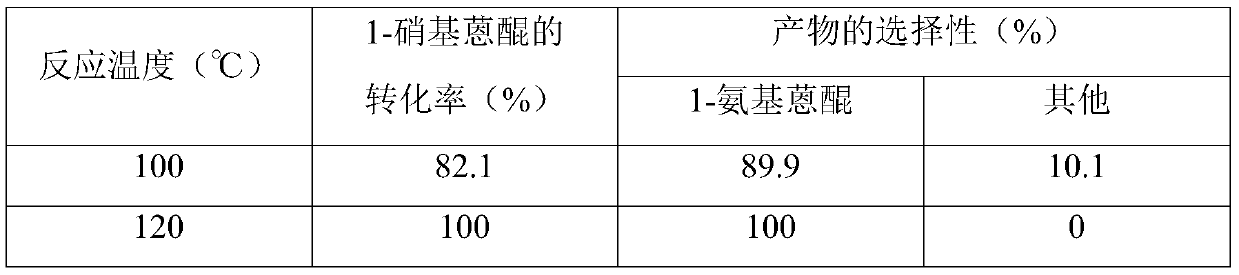

Cu@Ru/MCM-41 nanocatalyst, and preparation method and application thereof

InactiveCN110252383AReduce dosageHigh catalytic activityMaterial nanotechnologyOrganic chemistryHeterojunctionNano catalyst

The invention relates to a Cu@Ru / MCM-41 nanocatalyst, and a preparation method and an application thereof, and belongs to the field of nanocatalyst studies. A full-silicon MCM-41 mesoporous molecular sieve and nano-Cu particles are synthesized, and the Cu@Ru / MCM-41 nanocatalyst is prepared in the presence of an organic modifier. The surface of large-grain nano-Cu is wrapped with nano-Ru to form a heterojunction type Cu@Ru shell-core structure, and the Cu@Ru shell-core structure is loaded on a porous component MCM-41, so the dispersiveness of the active component Ru is greatly increased, thereby the active component Ru exposes many active sites, and the catalyst has a good hydrogenation performance; the Cu@Ru / MCM-41 nanocatalyst prepared in the invention has high catalytic activity and stability when catalyzing the hydrogenation of 1-nitroanthraquinone to produce 1-aminoanthraquinone; and the preparation method has the advantages of simple process route, small dosage of the catalyst, greenness and environmental friendliness, and meets industrialization requirements.

Owner:JIANGSU UNIV

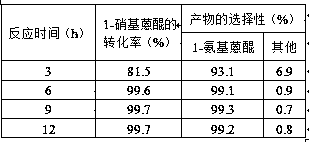

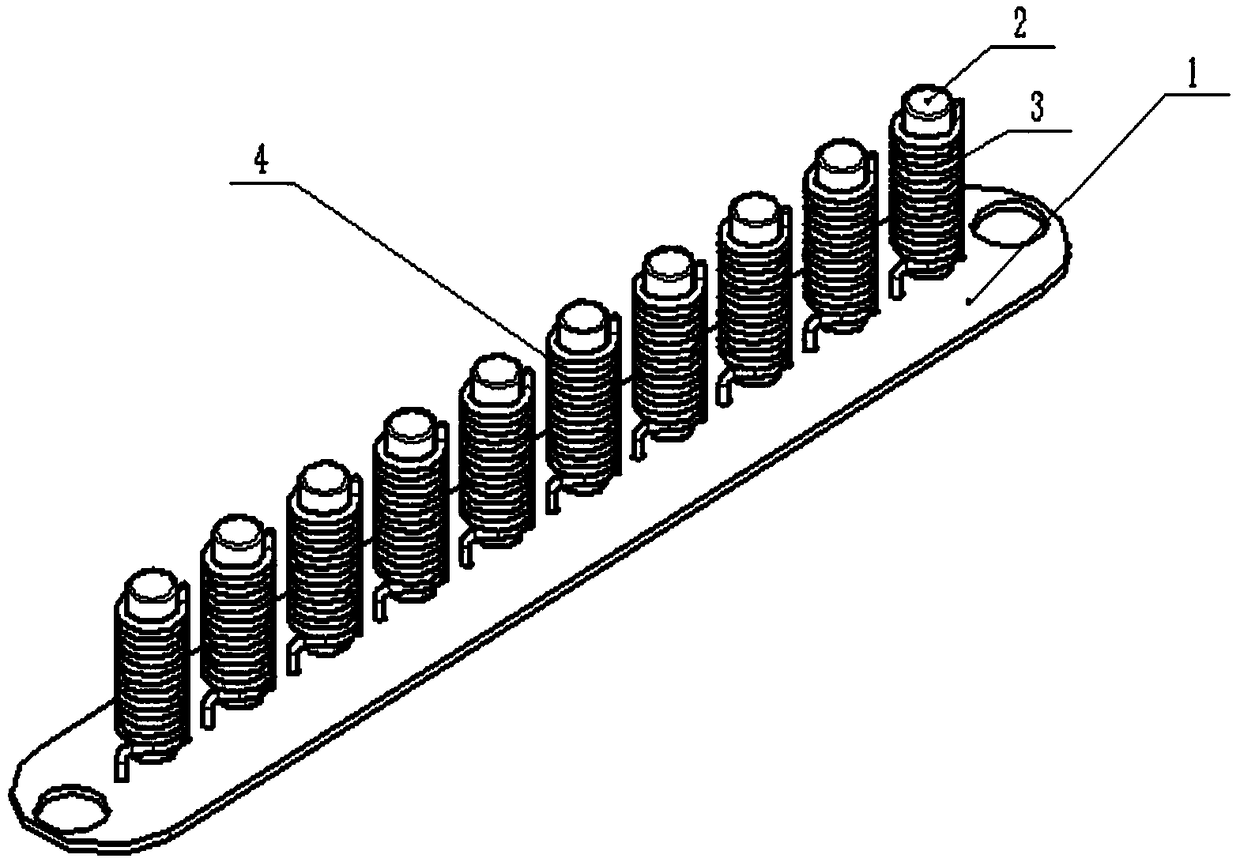

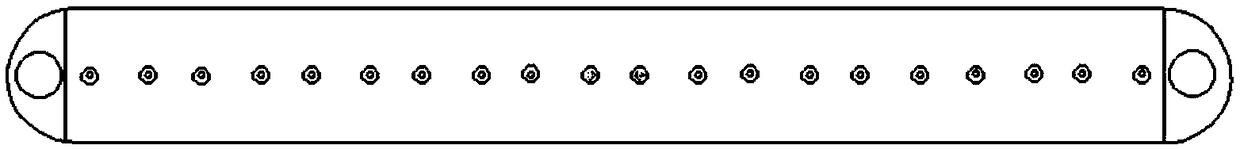

Vehicle-mounted electromagnetic oscillation signal receiving device

The invention discloses a vehicle-mounted electromagnetic oscillation signal receiving device. The device comprises magnetic rod core inductors and a substrate arranged at the bottom portion. The leftand right two ends of the substrate are signal output ports respectively. Frequency signals mainly received by the different magnetic rod core inductors in the device are different; and the receivedfrequency signals are input to vehicle-mounted communication and entertainment equipment from the signal output ports of the substrate through signal transmission lines. The device reduces use of antennas; and by designing reception of the different vehicle-mounted communication and entertainment equipment signals in one electromagnetic oscillation signal receiving device, and using the magnetic rod core inductors to receive the signals, the device is not only beautiful but also very practical.

Owner:赵东方

Solid wood combined outer frame end opening framing structure for threshold-free door window

The invention relates to a solid wood combined outer frame end opening framing structure for a threshold-free door window. An outer frame end opening is formed by assembling left and right vertical frames and a lower door frame; the lower door frame is a threshold-free door frame; the lower ends of the left and the right vertical frames are placed at the upper parts of the two ends of the threshold-free door frame, and the lower end sides of the vertical frames are connected together with the upper side of the end part of the threshold-free door frame through threshold-free door cushion blocks; the two vertical frames are solid wood profile frames, and the threshold-free door frame is an aluminium alloy frame; the upper sides of the two end parts of the threshold-free door frame are fixedly connected together with the lower end sides of the left and the right vertical frames through the threshold-free door cushion blocks; the shapes of the upper surfaces and the lower surfaces of the threshold-free door cushion blocks respectively correspond to and are in accordance with the shapes of the lower end sides of the vertical frames of which the upper surfaces are connected and the shapes of the upper surfaces of the two end parts of the threshold-free door frame of which the low surfaces are connected; the threshold-free door frame and the threshold-free door cushion blocks are fixedly connected with the vertical frames thereon through fastening bolts, and a sealant is applied between the threshold-free door frame cushion blocks and the vertical frames and between the threshold-free door frame cushion blocks and the threshold-free door frame.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

Spherical buoy and manufacturing method thereof

InactiveCN102700684BReduce non-uniform impactImprove and ensure posture stabilityWaterborne vesselsBuoysEngineeringBuoy

The invention discloses a spherical buoy and a manufacturing method thereof. The spherical buoy comprises a spherical buoy body. The spherical buoy is characterized in that the periphery of the spherical buoy body is smooth, the spherical buoy body is provided with an upper top cover and a lower bottom cover, the upper top cover, the lower bottom cover and the spherical buoy body form three cavities from top to bottom, i.e. a first cavity, a spherical buoy body cavity and a second cavity, the spherical buoy body cavity is a cylindrical cavity, and a foam body is arranged at the periphery of the cylindrical cavity. The spherical buoy has the advantages of good gesture stability, simple structure and low cost.

Owner:周涛

A kind of preparation method and application of palladium/silver alloy nano catalyst

ActiveCN107497426BHigh selectivityHigh catalytic activityOrganic chemistryOrganic compound preparationNano catalystPtru catalyst

The invention provides a preparation method and application of a palladium / silver alloy nanocatalyst. The preparation method comprises the following steps: weighing a certain amount of Pd and Ag metal precursors, dissolving the Pd and Ag metal precursors into an absolute ethanol solution respectively, stirring, mixing, adding an alcohol solution of an organic modifier, mixing and stirring for 20 min at 30-60 DEG C, adjusting the pH value of a reaction solution with an ethanol solution of NaOH, raising the temperature to 70 DEG C, dropwise adding an ethanol solution of hydrazine hydrate / ascorbic acid with a certain concentration into the reaction solution, reacting for 4-8 h, washing for multiple times with absolute ethanol, and performing vacuum drying to obtain the palladium / silver alloy nanocatalyst. The palladium / silver alloy nanocatalyst prepared by the preparation method provided by the invention is applied to a reaction for preparing 1-aminoanthraquinone through catalytic hydrogenation of 1-nitroanthraquinone, and shows high catalytic activity and stability; in addition, by a method for preparing 1-aminoanthraquinone by using the palladium / silver alloy nanocatalyst, a process requirement is simple, the using amount of the catalyst is small, environment friendliness is achieved, and industrial requirements are met.

Owner:JIANGSU UNIV

Composite sectional-bar outer frame framing structure of threshold-free door-window

The invention relates to a composite sectional-bar outer frame framing structure of a threshold-free door-window. An outer frame is formed by assembling a left vertical frame, a right vertical frame, an upper door frame and a lower door frame, wherein the lower door frame is a threshold-free door frame, the lower end parts of the left vertical frame and the right vertical frame are arranged on the upper parts of the two ends of the threshold-free door frame, and the lower end of each vertical frame is connected with the upper edge of the end part of threshold-free door frame through at least one threshold-free cushion block; two ends of the upper door frame are respectively connected with the upper end parts of the left vertical frame and the right vertical frame by adopting a 45-DEG angular connection way or a 90-DEG angular connection way. By adopting the composite sectional-bar outer-frame framing structure of the threshold-free door-window, the framing form can be simplified, the production technological requirement can be simplified, the direct contact between the vertical frames and the threshold-free door frame can be avoided in the existence of the cushion block, and lumber of a lower opening of the vertical frame is prevented from being corroded by the invasion of the moisture.

Owner:浙江瑞明节能门窗技术有限公司

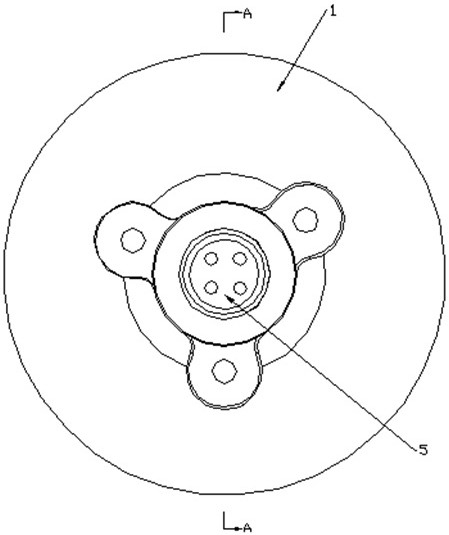

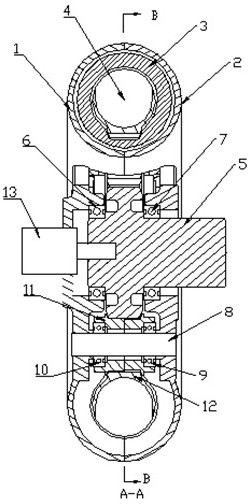

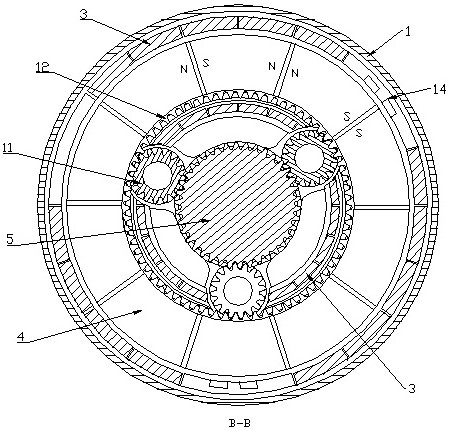

Planetary gear type novel motor

InactiveCN113346672AImprove efficiencySimple structureToothed gearingsMechanical energy handlingGear wheelElectric machinery

The invention discloses a planetary gear type novel motor. The planetary gear type novel motor structurally comprises a sun gear, a planetary gear, an outer gear ring, a gear ring provided with an annular magnet, an annular coil, a bearing supported by the sun gear and the planetary gear, an encoder and a sensor accessory. According to the gear ring embedded with the annular magnet, the south polarity and the north polarity of the annular magnet are arranged in a crossed mode in the circumferential direction, inner teeth of the gear ring provided with the magnet and the planetary gear are in combined transmission, the planetary gear with the two ends supported by bearings and a sun gear with the two ends supported by bearings are in combined transmission, and an output flange is arranged on a sun gear. The annular coil sleeves the outside of the gear ring in a planet wheel transmission structure, and winding on the annular coil is performed in a segmented and crossed manner in different winding directions, so that the annular coil interacts with the annular magnet through magnetic force during electrification.

Owner:包戴远

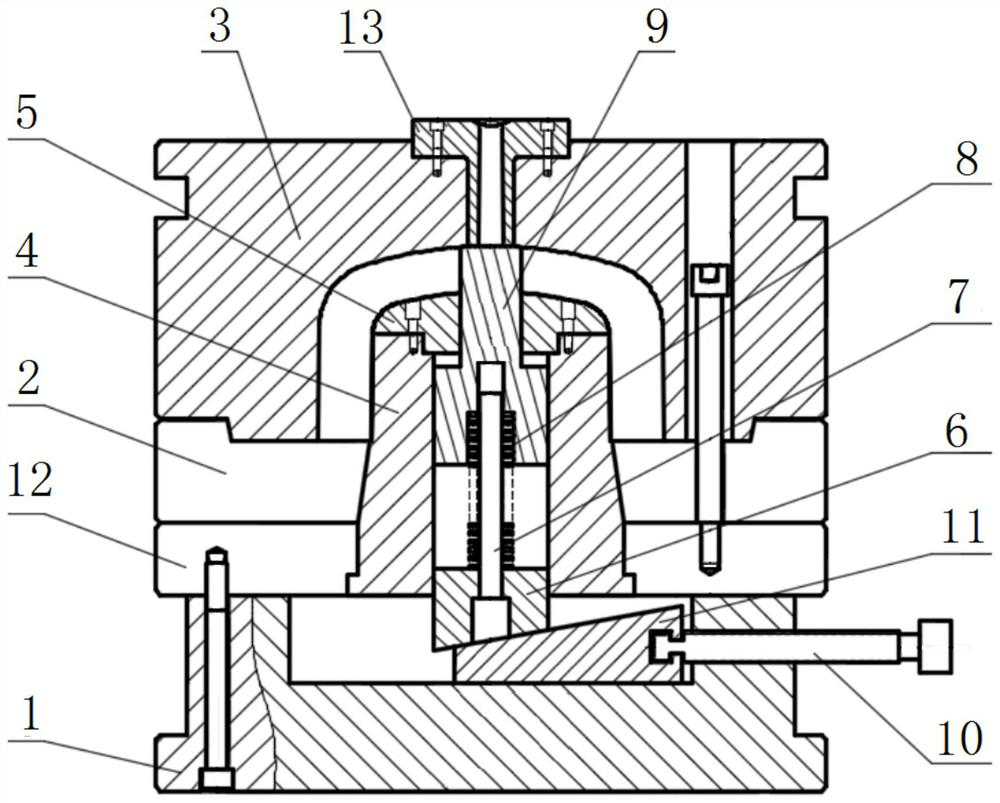

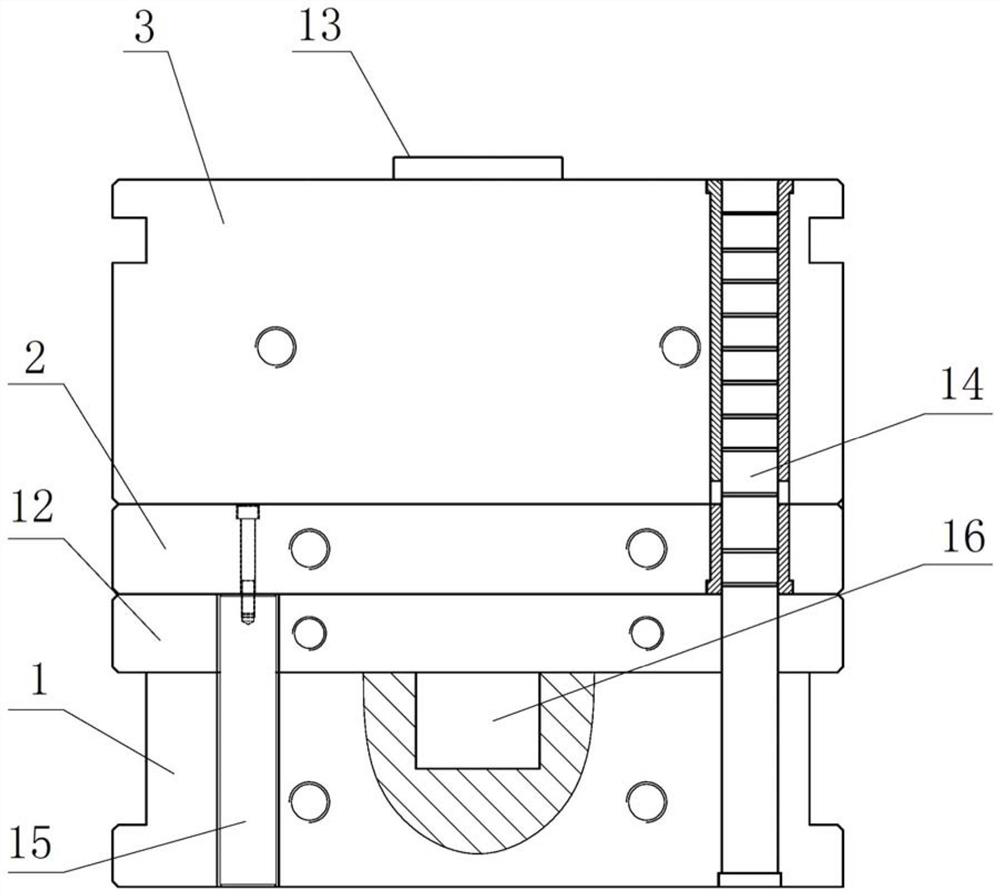

Mold capable of adjusting elasticity on line

PendingCN112810071AEffective dispersionAvoid formingTubular articlesMechanical engineeringIndustrial engineering

The invention relates to the technical field of mold production and application, in particular to a mold capable of adjusting elasticity online, which comprises a support, a push plate, a fixed mold plate, a mold core and a mold core cover, the push plate is arranged on the support, the fixed mold plate is arranged on the push plate, the mold core is arranged on the support, the mold core cover is arranged in a mold cavity of the push plate and the fixed mold plate, the mold core penetrates through the push plate to be connected with the mold core cover, the interior of the mold core is of a hollow structure, an elastic mechanism is arranged inside the mold core, an adjusting mechanism matched with the elastic mechanism is arranged on the support, a sprue bush is arranged above the fixed mold plate, one end of the elastic mechanism abuts against the adjusting mechanism, and the other end of the elastic mechanism abuts against the interior of a glue inlet of the sprue bush. According to the mold capable of adjusting the elasticity online, the problem of flow lines on the surface of a product is effectively solved, the application range is wide, the effect is stable, and operation is easy.

Owner:GUANGDONG LIANSU TECH INDAL

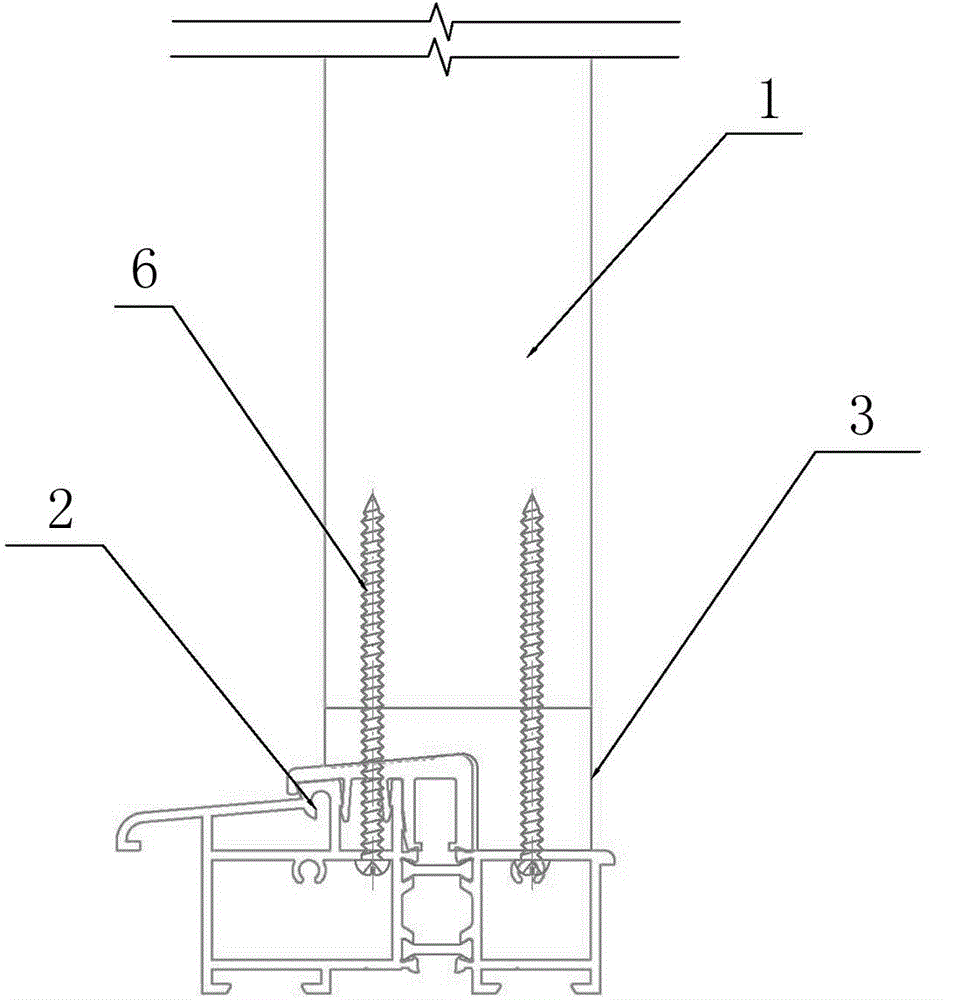

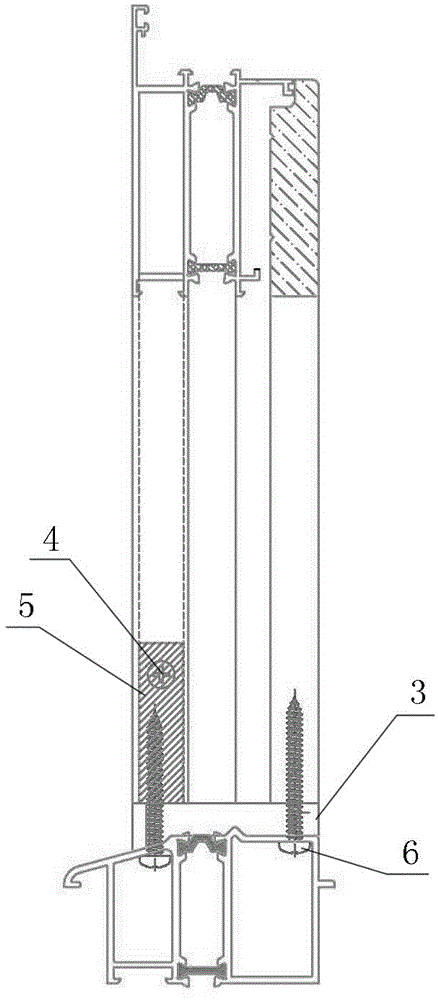

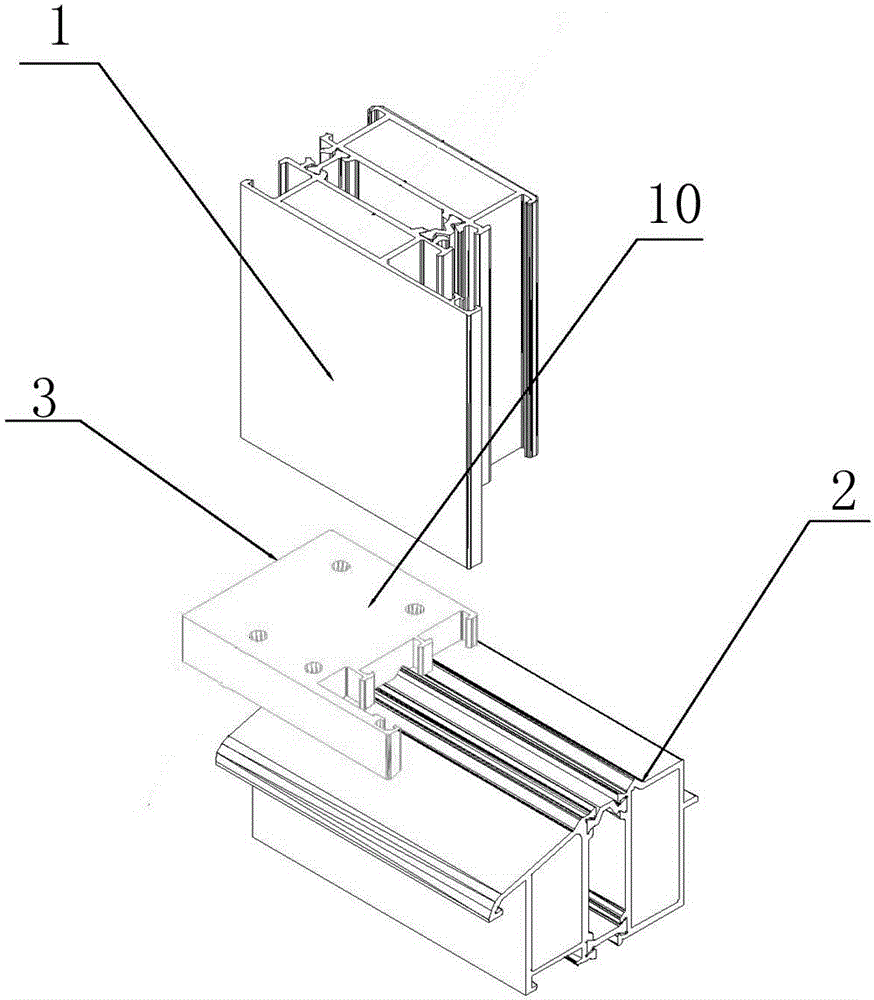

Composite profile outer frame end opening framing structure for threshold-free door window

The invention relates to a composite profile outer frame end opening framing structure for a threshold-free door window. An outer frame end opening is formed by assembling left and right vertical frames and a lower door frame; the lower door frame adopts a threshold-free door frame; the lower ends of the left and the right vertical frames are placed at the upper parts of the two ends of the threshold-free door frame, and the lower end sides of the vertical frames are connected together with the upper edge of the end part of the threshold-free door frame through threshold-free door cushion blocks; the vertical frames are aluminum wood composite frames comprising outer aluminium alloy profiles and inner wooden battens, and the threshold-free door frame adopts an aluminium alloy frame; vertical cushion blocks are positioned and fastened inside an aluminium alloy profile lower end cavities of the vertical frames through tightening screw; the upper sides of the two ends of the threshold-free door frame are fixedly connected together with the lower end edges of the left and the right vertical frames through the threshold-free door cushion blocks, the vertical cushion blocks and the inner wooden battens; according to the composite profile outer frame end opening framing structure provided by the invention, the framing form between the vertical frames and the threshold-free door frame is simplified and the manufacture process requirements are simplified through a way of mounting the cushion blocks between the vertical frames and the threshold-free door frame; moreover, through the effects of the cushion blocks, the vertical frames are prevented from being in direct contact with the threshold-free door frame, and the wood of the end openings of the vertical frames is protected from being attacked and corroded by water.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

A Composite Profile Outer Frame Structure for Sillless Doors and Windows

A composite profile outer frame group frame structure for doors and windows without sills, the outer frame is assembled from left and right vertical frames, an upper door frame and a lower door frame, the lower door frame is a door frame without sills, and the left and right vertical frames are assembled. The lower end of the frame is placed on the upper part of the two ends of the door frame without sill, and the lower end of the vertical frame and the upper edge of the end of the door frame without sill are connected together by at least a door pad without sill; the two ends of the upper door frame are respectively It is connected with the upper ends of the left and right vertical frames by a 45-degree angle or a 90-degree connection; it simplifies the form of the frame between the two and simplifies the production process requirements. The direct contact between the vertical frame and the door frame without sills protects the wood at the bottom of the vertical frame from being attacked and corroded by moisture.

Owner:浙江瑞明节能门窗技术有限公司

Preparation and application of a nano-nickel/silver/copper composite catalyst

InactiveCN103638949BHigh selectivityHigh catalytic activityOrganic compound preparationNanotechnologyNano catalystPtru catalyst

The invention relates to the preparation and application of a nano-nickel / silver / copper (Ni / Ag / Cu) composite catalyst and belongs to the field of nano-catalyst preparation and catalytic research. The preparation comprises the following steps: preparing a hollow Ni / Ag / Cu composite nano-catalyst by using copper nitrate, silver nitrate and nickel nitrate as raw materials; performing reaction through the catalyst by using p-nitrophenol and absolute ethyl alcohol as the raw materials to raise the reaction temperature to 80-160 DEG C, maintaining the temperature, and reacting for 2-8h to obtain high-purity p-aminophenol. The hollow Ni / Ag / Cu composite nano-catalyst is in a spherical particle shape, is small in dosage and is high in catalytic activity and stability. A method for preparing the p-aminophenol through the nano-Ni / Ag / Cu composite catalyst is simple in process requirement and meets an industrialization requirement.

Owner:JIANGSU UNIV

Outer frame end opening framing structure for threshold-free door window

InactiveCN104088554AGuaranteed tightnessSimplified group box formWindow/door framesEngineeringAir tightness

The invention relates to an outer frame end opening framing structure for a threshold-free door window. An outer frame end opening is formed by assembling left and right vertical frames and a lower door frame; the lower door frame adopts a threshold-free door frame; the two ends of the threshold-free door frame are respectively in direct or indirect connection with the lower end parts of the left and the right vertical frames fixedly; the lower end parts of the left and the right vertical frames are placed at the upper parts of the two ends of the threshold-free door frame, and the lower end sides of the vertical frames are connected together with the upper side of the end part of the threshold-free door frame through threshold-free door cushion blocks; the left and the right vertical frames and the threshold-free door frame are all aluminium alloy frames, vertical cushion blocks are positioned and fastened inside the lower end cavities of the vertical frames through fastening bolts, and upper sides of the two end parts of the threshold-free door frame are fixedly connected together with the lower end sides of the left and the right vertical frames through the threshold-free door frame cushion blocks and the vertical cushion blocks; the outer frame end opening framing structure provided by the invention mainly adopts a way of mounting cushion blocks between the vertical frames and the threshold-free door frame, so that the framing form between the vertical frames and the threshold-free door frame is simplified, and the manufacture process requirements are simplified. Moreover, the entire air tightness of the corners of a threshold-free door is ensured.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

Method for producing composite layer base material of carpet sound insulating mat for automobile

InactiveCN108891118AAvoid investment establishmentAvoid investmentVehicle arrangementsLamination ancillary operationsHigh resistanceAging resistance

The invention relates to a method for producing a composite layer base material of a carpet sound insulating mat for an automobile, in particular to a composite layer base material which can be applied to a composite layer for producing the carpet sound insulating mat for the automobile. The method is characterized by comprising the following steps: taking an ethylene-propylene-diene monomer (EPDM) rubber blanket as a bonding base material, and embossing in a bonding area on the surface of the EPDM rubber blanket; uniformly coating a neoprene solution on embossed lines, and adhering two EPDM rubber blankets with surfaces coated with the neoprene solution after airing; placing the two EPDM rubber blankets into a press for pressing; and then placing the two EPDM rubber blankets into a dryingoven for heating and warming, and taking out; and cooling and molding the two EPDM rubber blankets to obtain a finished product. The method provided by the invention is low in production process andequipment requirements, and avoids investment and establishment for large equipment, and investment in repeated modification of molds. The finished product has very high resistance to high and low temperatures, aging resistance, and good bending resistance, the bonding strength is greatly improved, and the maximum peel strength can be 15 times an original value.

Owner:陈卫

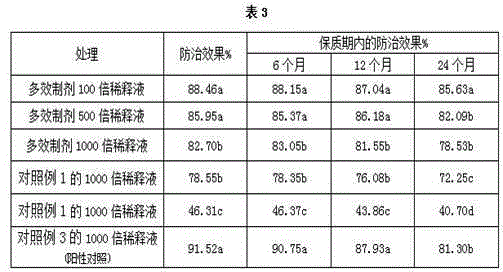

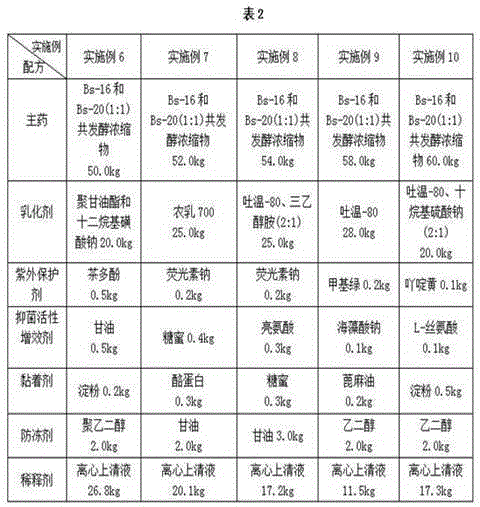

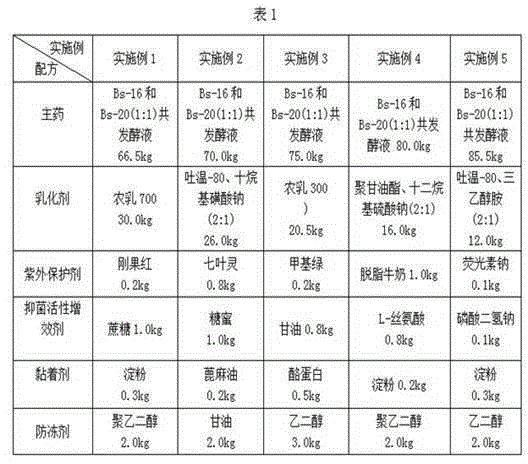

A kind of biocontrol bacteria multi-effect compound preparation for disease resistance and production increase and preparation method thereof

ActiveCN103783085BGray mold obviousExpand the antibacterial spectrumBiocidePlant growth regulatorsBiotechnologyDisease

The invention discloses a multi-effect compound preparation of biocontrol bacteria for disease resistance and production increase and a preparation method thereof. The compound fermentation liquid of two biocontrol strains of Bacillus subtilis is used as the main active ingredient, and contains an emulsifier, an ultraviolet protective agent, Synergist, antifreeze, adhesive. The preparation method is that the emulsifier and the main drug are placed together in an emulsifying machine to stir and emulsify, and then add auxiliary agents successively to continue stirring and emulsifying to obtain the finished product of bacillus subtilis emulsion. The product can be quickly and evenly dispersed in water, has a wide antibacterial spectrum, has a remarkable effect of increasing production, and has a wide range of applications.

Owner:GANSU ACAD OF SCI INST OF BIOLOGY

Zymophyte liquid, liquid spirit stillage fermented feed and fermentation method of liquid spirit stillage fermented feed

InactiveCN103074284BGrowth inhibitionMaintain balanceBacteriaFood processingBacillus subtilis var. nattoBacilli

Owner:四川国凤生物科技有限公司

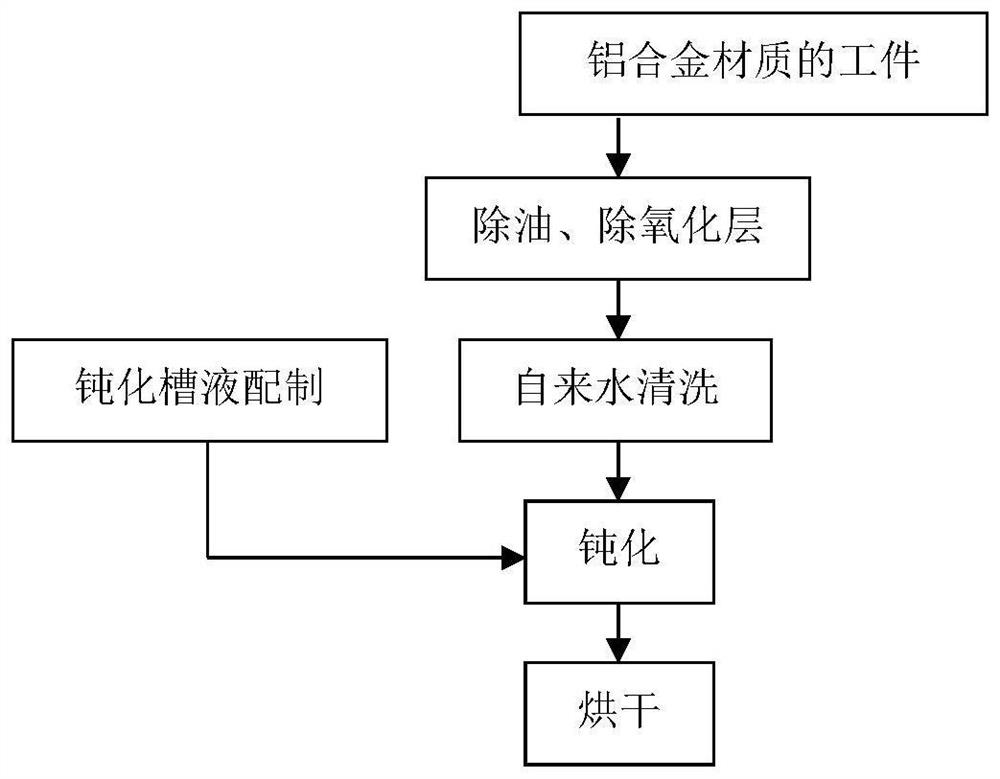

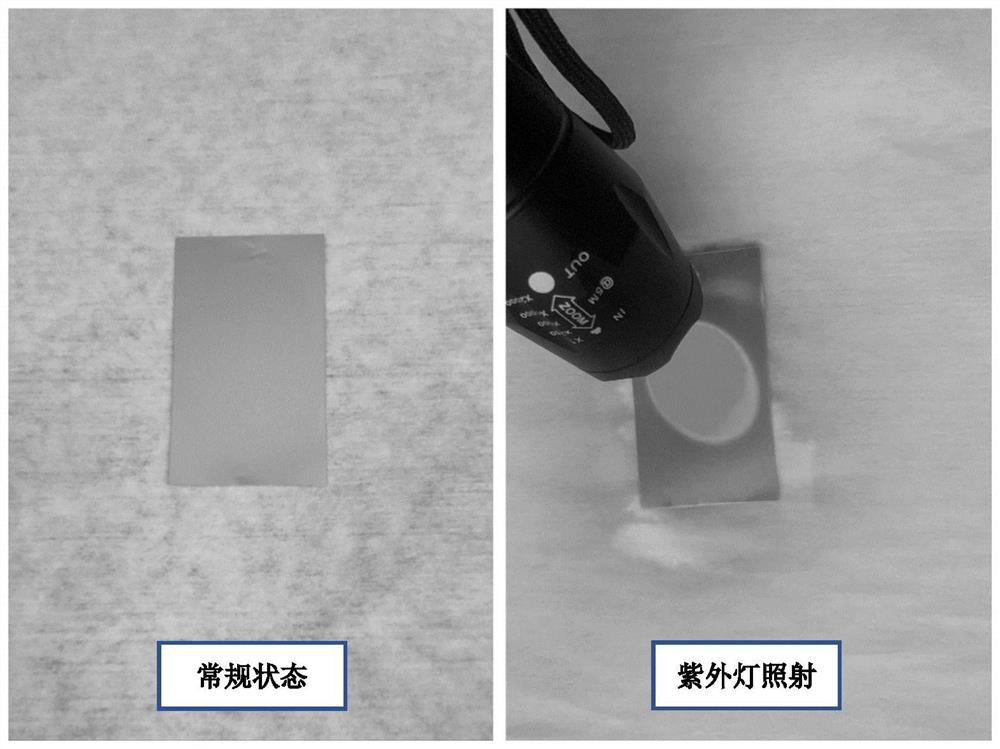

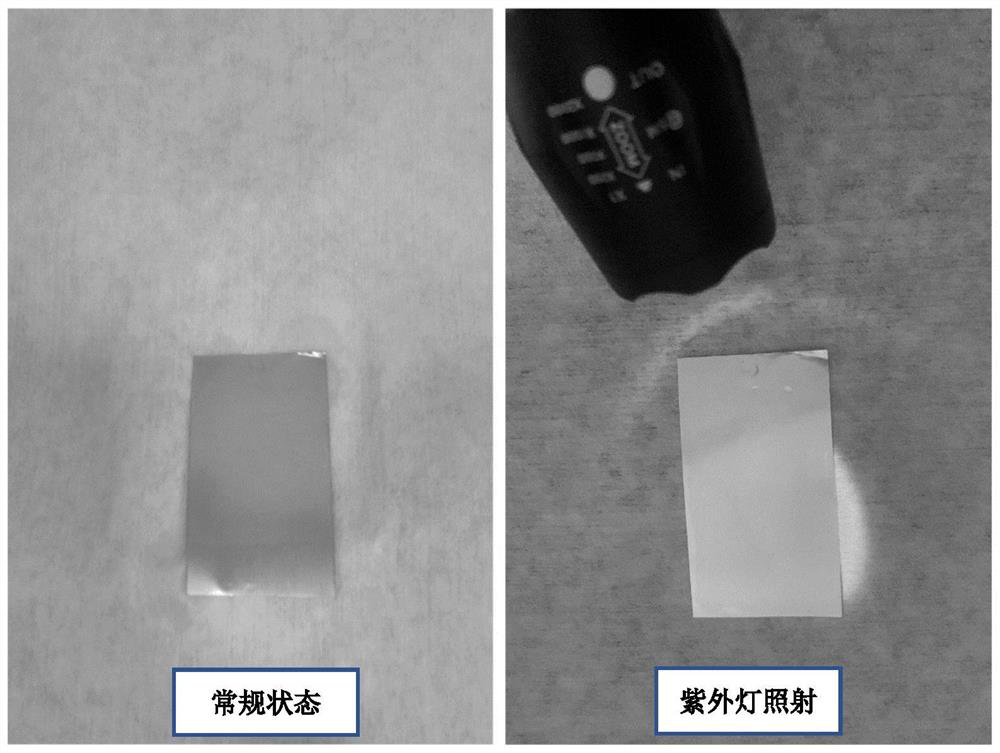

Aluminum alloy chromate-free passivation agent containing fluorescent agent as well as preparation method and use method of aluminum alloy chromate-free passivation agent

PendingCN114774904ASimple and convenient online identificationSimple and convenient judgmentMetallic material coating processesFluorescenceMetal

The invention discloses an aluminum alloy chromate-free passivation agent containing a fluorescent agent as well as a preparation method and a use method of the aluminum alloy chromate-free passivation agent, and belongs to the field of metal surface treatment. The invention discloses an aluminum alloy chromium-free passivation agent containing a fluorescent agent. The aluminum alloy chromium-free passivation agent comprises the following components in percentage by weight: 30%-90% of deionized water, 1%-10% of inorganic acid, 1%-10% of a film-forming main agent, 1%-10% of the fluorescent agent, 1%-10% of an accelerant, 1%-10% of a complexing agent and 1%-10% of a corrosion inhibitor.

Owner:安徽光铧帝业化学有限公司

A kind of preparation method and application of ruthenium/nickel alloy nano catalyst

ActiveCN107570172BHigh selectivityHigh catalytic activityOrganic chemistryOrganic compound preparationNano catalystPtru catalyst

The invention relates to a preparation method and application of a ruthenium / nickel alloy nanocatalyst. The preparation method comprises the following steps: weighing metal precursors of Ru and Ni, dissolving in an absolute ethanol solution respectively, stirring and mixing, adding an alcohol solution of an organic modifier, mixing and stirring for 20 min at 30-60 DEG C, adjusting the pH value ofa reaction solution by using an ethanol solution of NaOH, raising the temperature to 70 DEG C, dropwise adding a hydrogen peroxide and lithium aluminum hydride containing ethanol solution with a certain concentration into the reaction solution, carrying out a reaction for 4-8h, washing for several times by using anhydrous ethanol, and drying in vacuum to obtain the ruthenium / nickel alloy nanocatalyst. The ruthenium / nickel alloy nanocatalyst prepared according to the preparation method provided by the invention shows high catalytic activity and stability in a reaction for preparing 1-aminoanthraquinone through catalytic hydrogenation of 1-nitroanthraquinone; the technical route is simple, the using amount of the catalyst is low, the environmental friendliness is high, and industrializationrequirements are met.

Owner:JIANGSU UNIV

Composite combustion regulator, flame retardant additive and cigarette paper and slim cigarette made therefrom

ActiveCN111021144BReduce burn rateU-turn rate downFlexible coversWrappersPhosphoric acidProcess engineering

The invention belongs to the technical field of cigarettes, and specifically discloses a composite combustion regulator for slim cigarette paper, which comprises monobutyltin trilaurate, calcium stearate and aluminum dihydrogen phosphate. The invention also provides a flame retardant additive comprising a filler and the composite combustion regulator. The present invention further provides the slim cigarette paper added with the flame retardant additive and the slim cigarette obtained from the cigarette paper. After using the cigarette paper to roll slim cigarettes, it can effectively control the burning rate of slim cigarettes, reduce the turning phenomenon caused by excessively long combustion cones, reduce irritation, improve the ash-coating effect of cigarettes after burning, and effectively improve Combustion quality and consumption experience of slim cigarettes.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Solid wood combined outer frame framing structure for threshold-free door window

The invention relates to a solid wood combined outer frame framing structure for a threshold-free door window. An outer frame is formed by assembling left and right vertical frames, an upper door frame and a lower door frame; the lower door frame adopts a threshold-free door frame; the lower end parts of the left and the right vertical frames are placed at the upper parts of the two ends of the threshold-free door frame, and the lower end sides of the vertical frames are connected together with the upper side of the end part of the threshold-free door frame at least through a threshold-free door cushion block; the two ends of the upper door frame are respectively connected together with the upper ends of the left and the right frames by adopting a 45-degree angle or 90-degree angle connecting way; the two vertical frames are solid wood profile frames, and the threshold-free door frame is an aluminium alloy frame; the upper sides of the two end parts of the threshold-free door frame are fixedly connected together with the lower end sides of the left and the right frames through threshold-free door cushion blocks; the solid wood combined outer frame framing structure mainly adopts a way of mounting the cushion blocks between the vertical frames and the threshold-free door frame, so that the framing form between the vertical frames and the threshold-free door frame is simplified, and the manufacture process requirements are simplified; moreover, through the effects of the cushion blocks, direct contact between the vertical frames and the threshold-free door frame is avoided, the wood of the vertical frame end opening is prevented from being attacked and corroded by water.

Owner:ZHEJIANG ROOMEYE ENERGY SAVING TECH CO LTD

Smart Uniform Pedal Moped

ActiveCN104276249BSolve the problem of riding convenienceSimple production process requirementsFoldable cyclesRider propulsionFreewheelMotor drive

Disclosed is an intelligent uniform-force pedal moped which comprises a body system, a motor drive system, a flywheel chain plate transmission system, a control system, a pedal force measurement driving system and a brake system. The intelligent uniform-force pedal moped is characterized in that according to the body system, a front fork is mounted at the front end of a frame, and wheels are mounted on the front and the front fork; according to the motor drive system, a battery is fixed on the frame, and a motor is fixed on the frame through bolts; according to the flywheel chain plate transmission system, a first flywheel and a second flywheel which are concentric with the rear wheel are fixedly connected to the rear wheel and on one side of the rear wheel, and a motor flywheel is fixed on a shaft of the motor; according to the pedal force measurement driving system, one ends of N force transducers are fixed on the frame while the other ends are fixedly connected with a middle axle fixing block, and a middle axle is rotationally mounted in a hole of the middle axle fixing block through a headset; according to the brake system, brake mechanisms are mounted on the front and rear wheels respectively.

Owner:HAIMEN THE YUECAI TEXTILE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com