Cu@Ru/MCM-41 nanocatalyst, and preparation method and application thereof

A technology of MCM-41 and nano-catalyst, which is applied in the field of nano-catalyst research, can solve the problems of high impurity content in products and difficulty in treating waste water, etc., and achieve the effects of improving catalytic activity, no three wastes, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

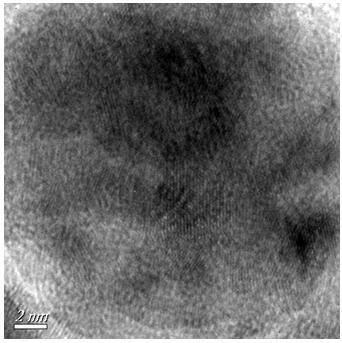

Image

Examples

Embodiment 1

[0038] (1) Preparation of catalyst:

[0039] Using sodium silicate as silicon source and di-n-propylamine (DPA) as template to control the channels of MCM-41, all-silicon MCM-41 mesoporous molecular sieves were synthesized by hydrothermal method in alkaline medium. Cu@Ru / MCM- 41 nanometer catalyst, in which the molar ratio of Ru and Cu is 0.15:1, and the Cu@Ru loading is 15wt%, that is, the mass of Cu@Ru accounts for 15% of the total catalyst mass.

[0040] Preparation of all-silicon MCM-41 mesoporous molecular sieve: Dissolve 40 g of sodium silicate in a beaker with 160 mL of distilled water, heat and dissolve 8 g of di-n-propylamine in 80 mL of distilled water, cool to room temperature, stir for 15 min after mixing, and use Sulfuric acid solution (3moL / L) adjusted the pH value of the mixture to 8, and continued stirring for 1 h to make the solution into a viscous transparent gel. Then pack into a 500ml stainless steel hydrothermal kettle with a polytetrafluoroethylene line...

Embodiment 2

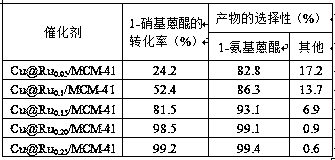

[0049] Same as in Example 1, only changing the amount of catalyst: 0.07 g, 0.14 g, 0.28 g, 0.35 g, 0.45 g to carry out the selective hydrogenation reaction of 1-nitroanthraquinone. The product selectivity and raw material conversion rate obtained are shown in Table 1.

[0050] Table 1. Different amounts of Cu@Ru 0.15 / MCM-41 Nanocatalyst Selectively Catalyzes the Hydrogenation of 1-Nitroanthraquinone

[0051]

[0052] It can be found that in Cu@Ru 0.15 In the hydrogenation reaction of 1-nitroanthraquinone selectively catalyzed by / MCM-41 nano-catalyst, with the increase of catalyst dosage, the conversion rate of 1-nitroanthraquinone and the selectivity of the target product will increase.

Embodiment 3

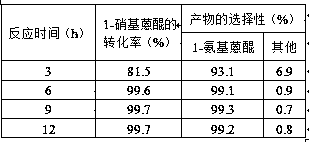

[0054] With embodiment 1, only changing the temperature of reactor is: 70 o C. 110 o C. 130 o C, 150 o C carries out the selective hydrogenation reaction of 1-nitroanthraquinone. The resulting product selectivity and feedstock conversion are shown in Table 2.

[0055] Table 2. Cu@Ru at different reaction temperatures 0.15 / MCM-41 Nanocatalyst Selectively Catalyzes the Hydrogenation of 1-Nitroanthraquinone

[0056]

[0057] It can be found that in Cu@Ru 0.15 / MCM-41 nano-catalyst selectively catalyzes the hydrogenation reaction of 1-nitroanthraquinone. The increase of reaction temperature is beneficial to the conversion of 1-nitroanthraquinone into the target product 1-aminoanthraquinone. The reaction temperature is 130°C At that time, the conversion rate of 1-nitroanthraquinone to target product 1-aminoanthraquinone was 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com