Preparation and application of a nano-nickel/silver/copper composite catalyst

A composite catalyst and nano-nickel technology, which is applied in the preparation of organic compounds, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of reducing the purity of the main product and producing by-products , to avoid high temperature and high pressure reaction, increase profit value, and achieve high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Catalyst preparation:

[0032] In the presence of organic modifier dihydrate bis(p-sulfonylphenyl)phenyl phosphine dipotassium salt, using copper nitrate, silver nitrate, nickel oxalate, hydrazine hydrate, absolute ethanol, etc. as raw materials, through wet Nano-nickel / silver / copper composite catalysts were prepared by combining chemical reduction method and template method. In the first step, at room temperature, 0.1 g of organic modifier was dissolved in 20 mL of absolute ethanol solution and 20 mL of poly(styrene / methacrylic acid) solution were mixed with each other. Under magnetic stirring, 20 mL of copper nitrate (0.05 mol / L) ethanol solution was added dropwise to the above mixture, and stirred for 1 h. 20 mL of hydrazine hydrate aqueous solution (0.05 mol / L) was added dropwise to the above mixture, and reacted at 40° C. for 10 h. In the second step, 20 mL of silver nitrate (0.05 mol / L) was added dropwise to the above mixed solution, and after magnetic stirri...

Embodiment 2

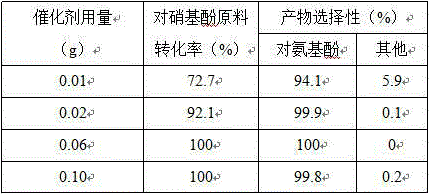

[0038]Same as in Example 1, only changing the amount of catalyst: 0.01, 0.02, 0.06, 0.1g, to carry out the selective hydrogenation reaction of p-nitrophenol. The product selectivity and raw material conversion rate obtained are shown in Table 1.

[0039] Table 1. At 0.8MPH 2 The reaction temperature is 120°C, and the reaction time is 8 hours under heat preservation. When the amount of catalyst is different, the selectivity of p-aminophenol and the conversion rate of the raw material of the hydrogenation reaction product of p-nitrophenol are selectively catalyzed by the nano-nickel / silver / copper composite catalyst.

[0040]

Embodiment 3

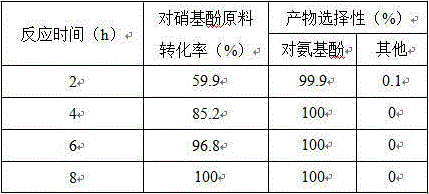

[0042] Same as Example 1, only changing the temperature of the reactor to 80°C, 100°C, 120°C, 140°C, and 160°C respectively, and carrying out the selective hydrogenation reaction of p-nitrophenol, the results obtained are shown in Table 2.

[0043] Table 2. At 0.8MPH 2 When the amount of catalyst is 0.08g, under different reaction temperatures, under heat preservation for 8 hours, the nano-nickel / silver / copper composite catalyst selectively catalyzes the selectivity of p-aminophenol hydrogenation reaction product of p-nitrophenol and the conversion rate of raw materials

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com