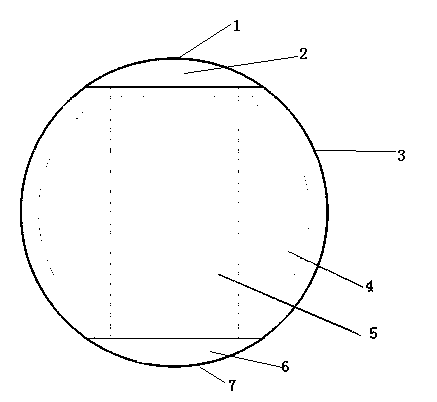

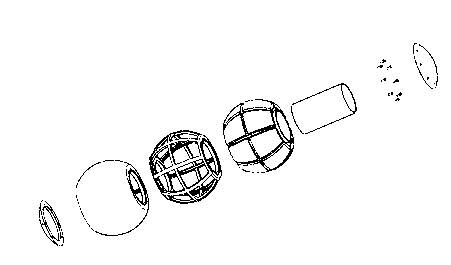

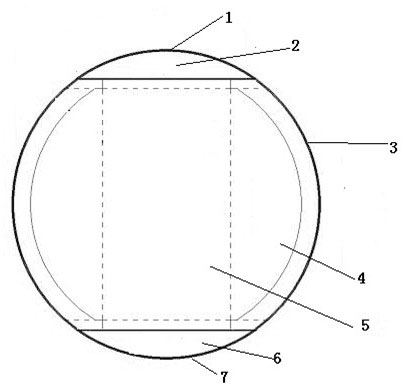

Spherical buoy and manufacturing method thereof

A manufacturing method and technology of buoys, which are applied to buoys, special-purpose ships, ships, etc., can solve the problems of increasing non-uniform impact of buoys, sinking of buoys, and reduction of carrying capacity, so as to optimize inner cavity space and function design, and simplify production process Requirements, the effect of reducing non-uniform impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A GPRS communication module and a warning light are arranged in the first cavity of the spherical buoy, a six-axis acceleration sensor is arranged in the cavity of the spherical buoy body, a data acquisition module, a microprocessor and a battery are arranged in the second cavity, and the lower bottom cover is outside Set the rope pull ring to form an anchored wave buoy. The data acquisition module is a water pressure sensor, a direction sensor, etc. The data acquisition module sends the collected information to the microprocessor for processing and then sends it to the control platform through the GPRS communication module, which can be fixed. Real-time monitoring of marine dynamic environmental parameters such as ocean wave height, wave direction and wave period.

Embodiment 2

[0038] A Beidou (BD) antenna and warning light are installed in the first cavity of the spherical buoy, a six-axis acceleration sensor is installed in the cavity of the spherical buoy body, and a BD positioning communication host, data acquisition module, and microprocessor are installed in the second cavity. And the battery form a wave drifting buoy. The data collection module is a water pressure sensor, a direction sensor, etc., which can be drifted and moved to monitor the sea dynamic environment parameters such as wave height, wave direction, wave period, flow rate, and flow direction in real time.

Embodiment 3

[0040] The Beidou (BD) antenna and warning lights are installed in the first cavity of the spherical buoy, and the BD positioning communication host, signal acquisition and processing module and battery are installed in the cavity of the spherical buoy body and the second cavity to form a drifting buoy. Drifting and moving real-time monitoring of marine dynamic environmental parameters such as flow velocity and direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com