Single-component gypsum-based water-resistant putty and construction method thereof

A technology of water-resistant putty and construction method, used in filling slurry, covering/lining, construction, etc., can solve problems such as easy cracking and water resistance, and achieve the effects of good water resistance, convenient grinding and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

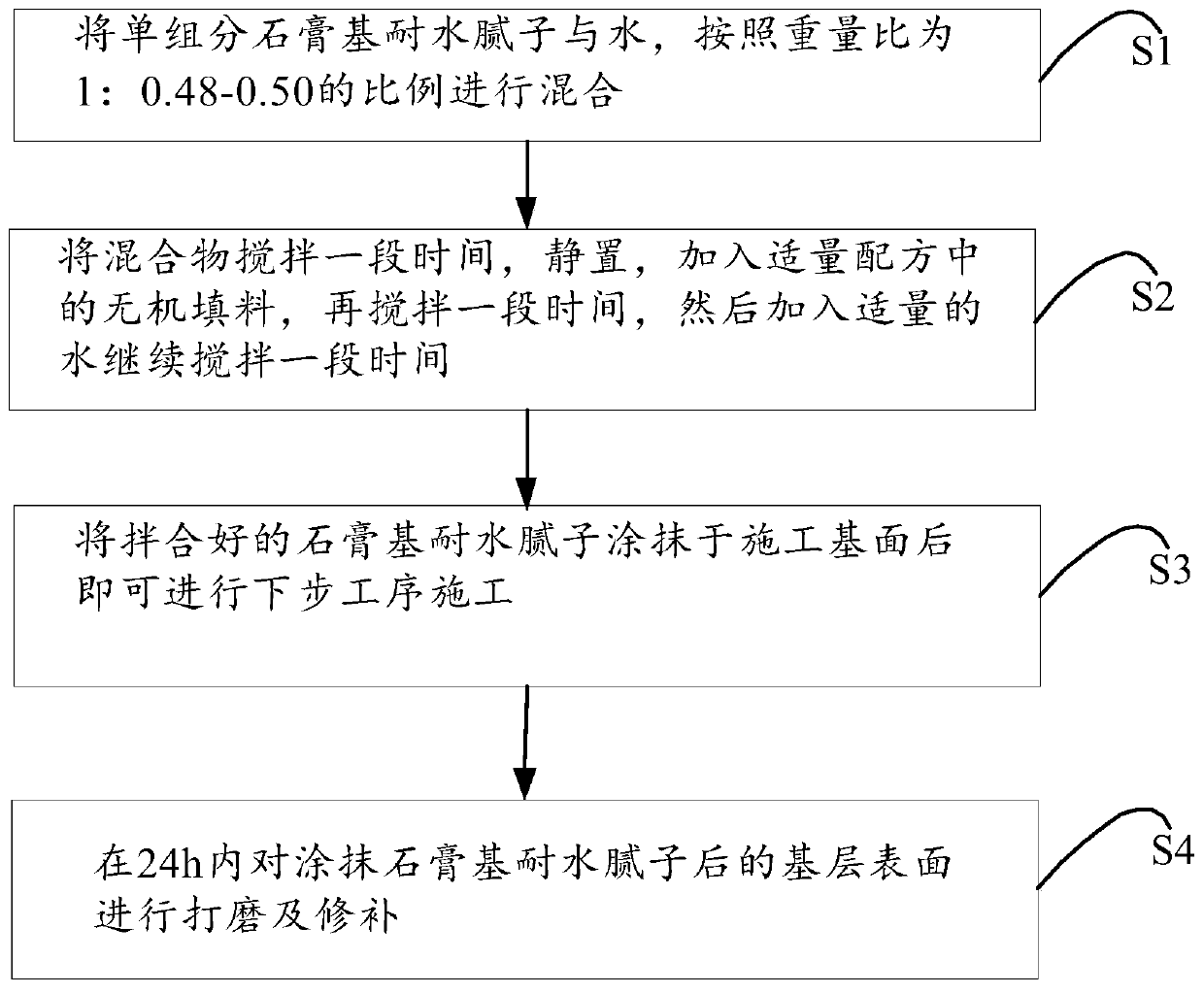

Method used

Image

Examples

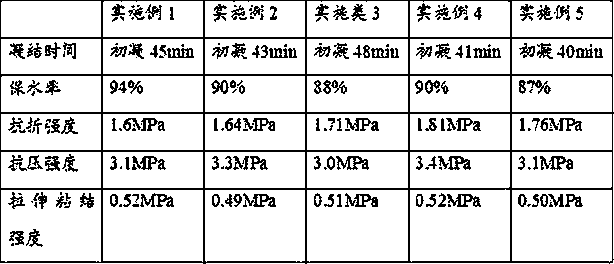

Embodiment 1

[0085] Take 30g of desulfurized gypsum, 3g of white cement, 36.05g of organic fillers, 8g of inorganic fillers and 5g of additives, stir and mix for a period of time, pack and pack to obtain powdery finished products;

[0086] Mix the powdery one-component gypsum-based water-resistant putty with water at a weight ratio of 1:0.48;

[0087] Stir the mixture for 5 minutes, let it stand for 3 minutes, add 5% inorganic filler accounting for the weight of the total mixture, stir for a while, then add water accounting for 8% of the weight of the total mixture and continue stirring for a period of time;

[0088] Apply the mixed gypsum-based water-resistant putty on the surface of the mortar or concrete base with a batch scraper. Depending on the flatness of the base, control the thickness of the application between 2-5mm, and perform grinding and repairing within 24 hours. After the repair is completed, the next step of construction can be carried out.

Embodiment 2

[0090] Take 35g of desulfurized gypsum, 5g of white cement, 36.05g of organic fillers, 5g of inorganic fillers and 7g of additives, stir and mix for a period of time, pack and pack to obtain powdery finished products;

[0091] Mix the powdery one-component gypsum-based water-resistant putty with water at a weight ratio of 1:0.48;

[0092] Stir the mixture for 6 minutes, let it stand for 3 minutes, add 3% inorganic filler accounting for the weight of the total mixture, stir for a while, then add water accounting for 6% of the weight of the total mixture and continue stirring for a period of time;

[0093] Apply the mixed gypsum-based water-resistant putty on the surface of the mortar or concrete base with a batch scraper. Depending on the flatness of the base, control the thickness of the application between 2-5mm, and perform grinding and repairing within 24 hours. After the repair is completed, the next step of construction can be carried out.

Embodiment 3

[0095] Take 32g of desulfurized gypsum, 4g of white cement, 45g of organic filler, 5g of inorganic filler and 3.62g of additives, stir and mix for a period of time, pack and pack to obtain a powdery finished product;

[0096] Mix the powdery one-component gypsum-based water-resistant putty with water at a weight ratio of 1:0.48;

[0097] Stir the mixture for 5 minutes, let it stand for 3 minutes, add 5% inorganic filler accounting for the weight of the total mixture, stir for a while, then add water accounting for 8% of the weight of the total mixture and continue stirring for a period of time;

[0098] Apply the mixed gypsum-based water-resistant putty on the surface of the mortar or concrete base with a batch scraper. Depending on the flatness of the base, control the thickness of the application between 2-5mm, and perform grinding and repairing within 24 hours. After the repair is completed, the next step of construction can be carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com