A kind of preparation method and application of palladium/silver alloy nano catalyst

An alloy catalyst and silver nanotechnology, applied in the field of nanocatalyst research, can solve the problems of reducing product purity and producing by-products, and achieve the effects of avoiding by-products, no three wastes, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of catalyst:

[0023] Using palladium nitrate and silver nitrate as raw materials and ascorbic acid as reducing agent, palladium / silver alloy nano-catalysts are prepared in the presence of organic modifiers.

[0024] When palladium, silver molar ratio is 0.03:1, palladium / silver alloy nanocatalyst (Pd 0.03 Ag) preparation: respectively weigh 0.0799g of Pd (NO 3 ) 2 2H 2 O, 1.6987g of AgNO 3 and 0.1779g of KH570 silane coupling agent were dissolved in 40mL, 70mL and 10mL of anhydrous ethanol respectively by ultra-dispersion, and stirred and mixed at 50°C for 20min. Use 1.0mol / L NaOH ethanol solution to adjust the pH to 10, add 0.65mol / L ascorbic acid absolute ethanol solution dropwise to the above reaction solution, react at 70°C for 6h, the product is washed with alcohol several times, vacuum After drying, the Pd 0.03 Ag alloy nanocatalysts.

[0025] 2.1-Nitroanthraquinone selective catalytic hydrogenation to prepare 1-aminoanthraquinone reaction: ...

Embodiment 2

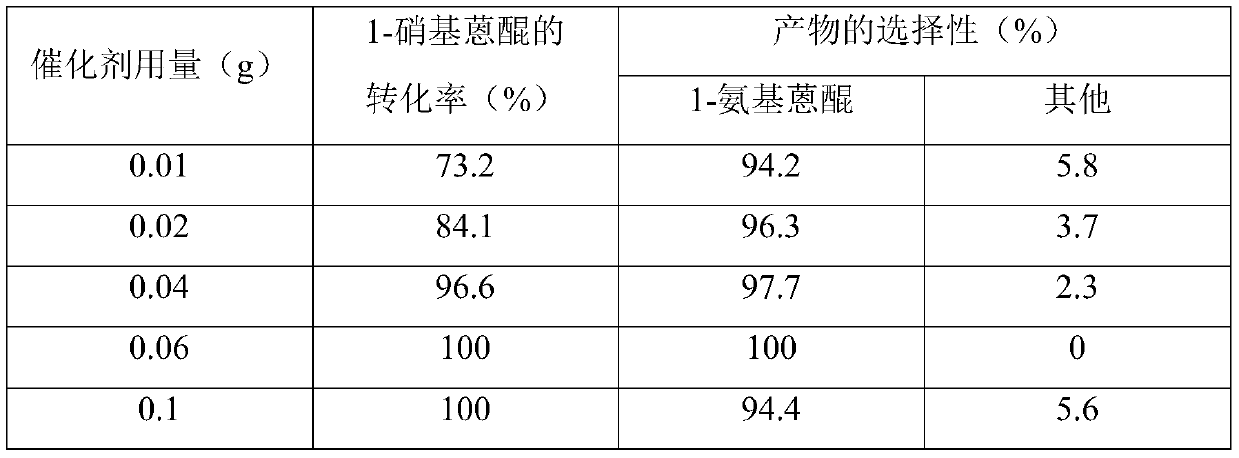

[0028] Same as in Example 1, only changing the amount of catalyst: 0.01g, 0.02g, 0.04g, 0.06g, 0.1g, to carry out selective hydrogenation reaction of 1-nitroanthraquinone. The product selectivity and raw material conversion rate obtained are shown in Table 1.

[0029] Table 1 at 1.0MPa H 2 The reaction temperature is 110°C, and the reaction time is 4 hours under heat preservation. When the amount of catalyst is different, the selectivity of the palladium / silver alloy nanocatalyst to catalyze the hydrogenation reaction of 1-nitroanthraquinone to produce 1-aminoanthraquinone and the conversion rate of raw materials

[0030]

Embodiment 3

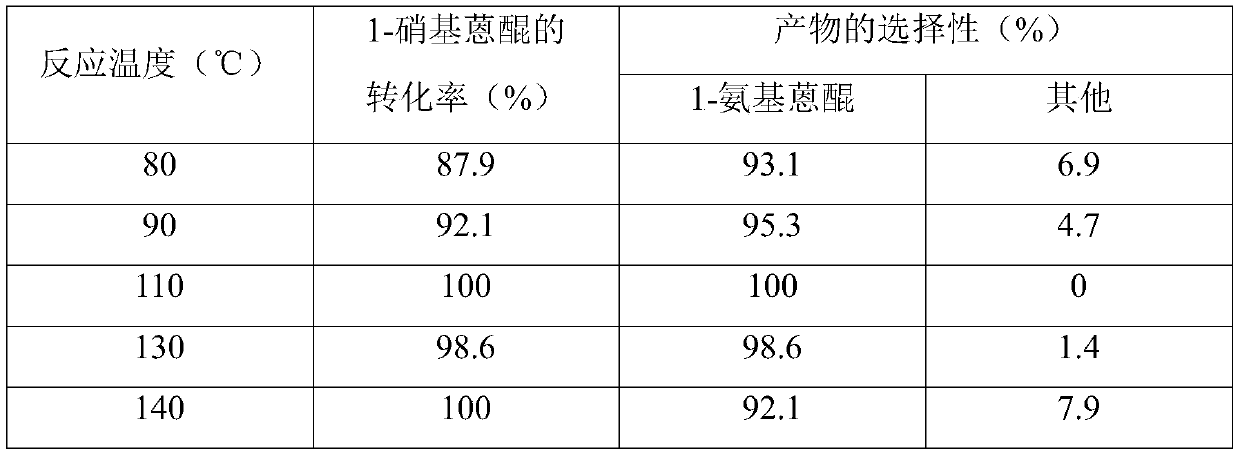

[0032] Same as in Example 1, only changing the temperature of the reactor to 80°C, 90°C, 110°C, 130°C, 140°C to carry out the selective hydrogenation reaction of 1-nitroanthraquinone. The resulting product selectivity and feedstock conversion are shown in Table 2.

[0033] Table 2 at 1.0MPa H 2 Under pressure, when the amount of catalyst is 0.06g, under different reaction temperatures, under heat preservation for 4 hours, the palladium / silver alloy nano-catalyst selectively catalyzes the selectivity of 1-aminoanthraquinone hydrogenation reaction product 1-aminoanthraquinone and the conversion of raw materials Rate

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com