Aluminum alloy chromate-free passivation agent containing fluorescent agent as well as preparation method and use method of aluminum alloy chromate-free passivation agent

A chromium-free passivation and aluminum alloy technology, applied in the coating process of metal materials, etc., can solve problems such as failure to meet customer requirements, difficulty in online identification, and damage to aluminum products, and meet the requirements of production equipment and production technology. Simple, adhesion-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

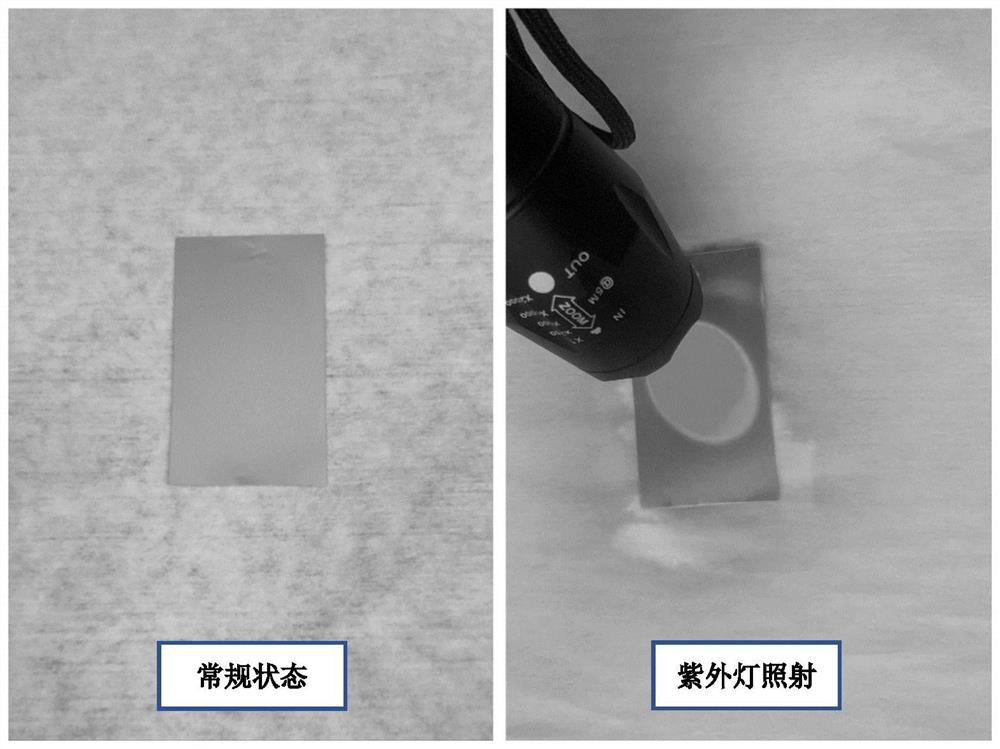

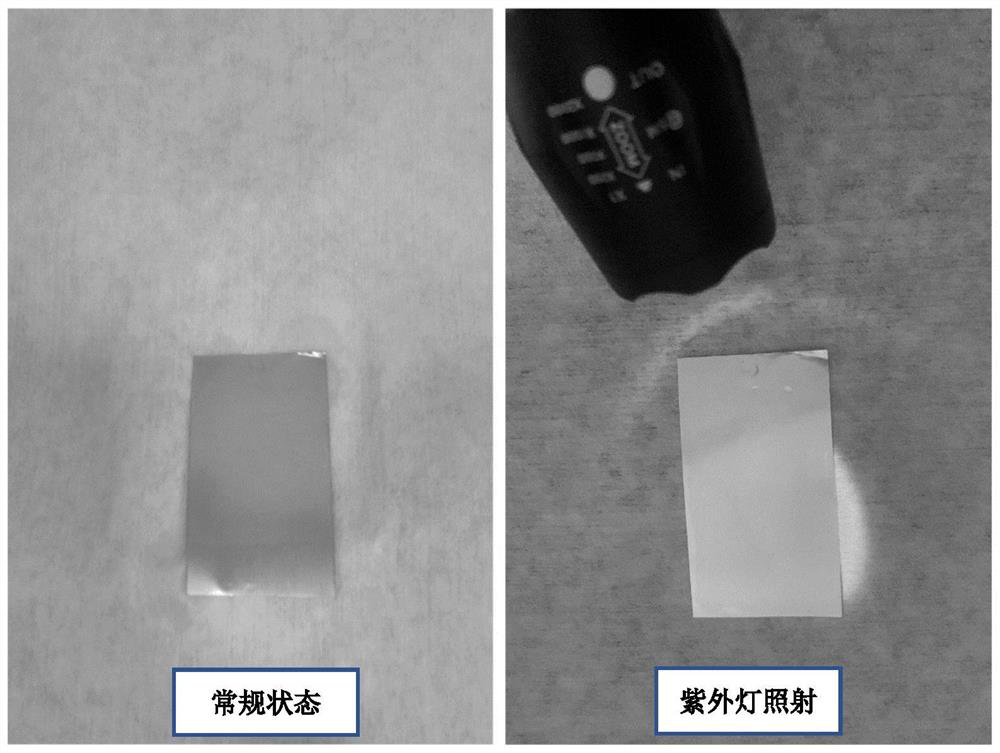

Examples

Embodiment 1

[0030] An aluminum alloy chromium-free passivation agent containing a fluorescent agent contains the following components:

[0031] paint remover ingredients weight percentage Deionized water 74% Hydrofluoric acid 5% Basic zirconium carbonate 2% Optical Brightener BBU 5% water-based acrylic resin 10% Sodium Gluconate 3% Triethanolamine 1%

[0032] The preparation method of above-mentioned embodiment 1 chromium-free passivation agent comprises the steps:

[0033] First dissolve hydrofluoric acid in deionized water to form an acid base solution, then add basic zirconium carbonate, optical brightener BBU, water-based acrylic resin, sodium gluconate and triethanolamine in sequence, and stir to completely dissolve all components to obtain the Described chromium-free passivation agent.

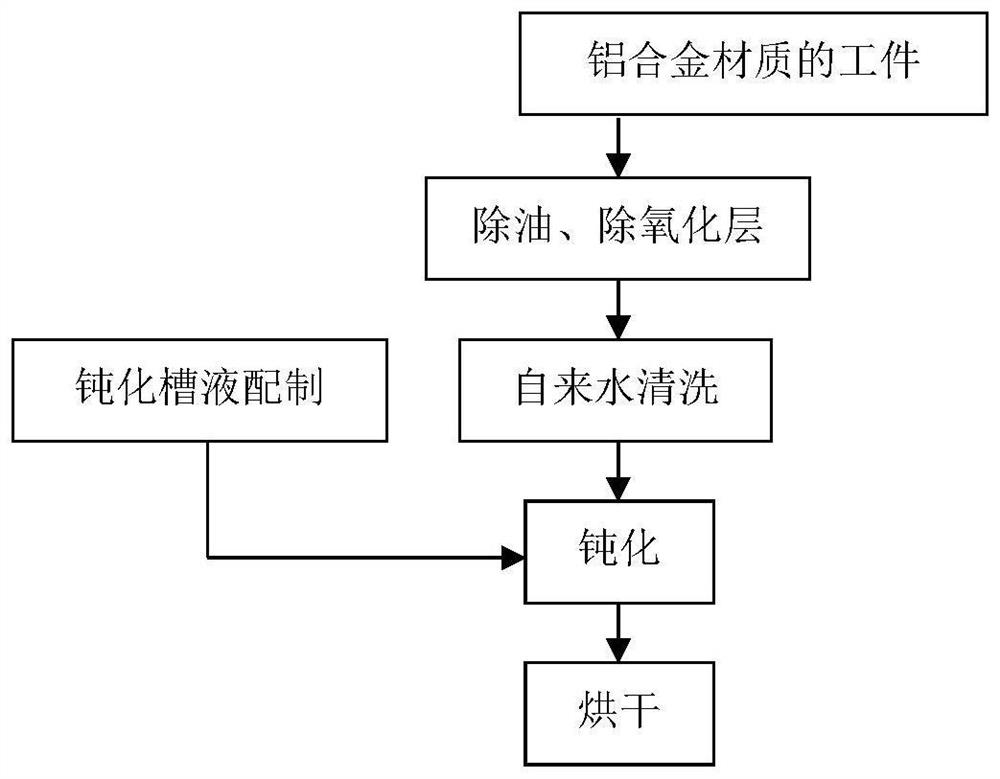

[0034] The using method of above-mentioned embodiment 1 chromium-free passivation agent, may further comprise the steps:

[0035] (1) Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com