Can negative pressure detection device

A negative pressure detection device and canned food technology, which is applied in the direction of testing the fluid tightness by detecting the dimensional change of the structural parts to be tested, and using liquid/vacuum degree for liquid tightness measurement, etc., which can solve the problem of food and air contact, easy to be corrupted, and shelf life. Shorten and increase the cost of canned food inspection, etc., to achieve simple and convenient judgment, reduce inspection cost, and improve resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

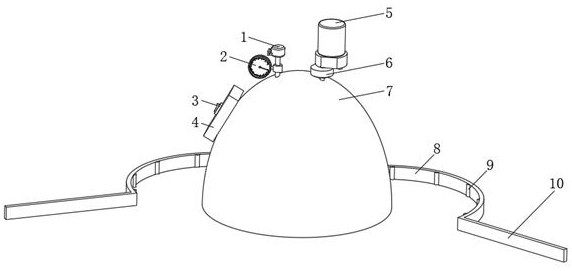

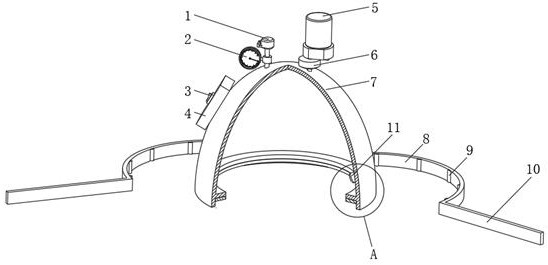

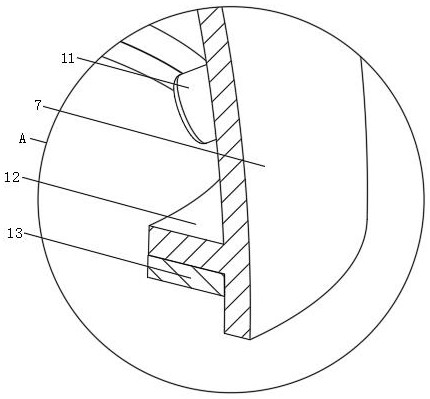

[0037] Example 1: Please refer to Figure 1-6 , the present embodiment discloses a negative pressure detection device for cans, which includes an observation cover 7 with an opening at one end, a fixing ring 12 is provided on the inner wall of the observation cover 7 close to the opening, and an elastic ring piece is fixed on the side of the fixing ring 12 facing the opening of the observation cover 7 13. The observation cover 7 is provided with an air inlet and an air outlet connected to the inside and outside of the observation cover. The air inlet of the observation cover 7 is connected to a port of the valve 1. The air outlet of the first one-way valve 6 is connected with the air inlet of the negative pressure pump 5 .

[0038] This embodiment also includes a clamping piece, the clamping piece includes two oppositely arranged arc-shaped plates 8, the arc-shaped plates 8 include a first end and a second end of the plate body, and the first ends of the two arc-shaped plates ...

Embodiment 2

[0056] Embodiment two: if figure 2 with image 3 As shown, this embodiment discloses a negative pressure detection device for cans, the structure of which is roughly the same as that of Embodiment 1, the difference is that a laser generator 11 is fixed on the inner wall of the observation cover 7 of this embodiment;

[0057] Wherein, the inline laser beam irradiated by the inline laser generator 11 passes through the position near the center outside the cover.

[0058] It also includes a control switch 3 and a battery 4 located outside the observation cover 7, the output terminal of the battery 4 is electrically connected to the input terminal of the control switch 3, and the output terminal of the control switch 3 is respectively connected to the input terminal of the negative pressure pump 5 and the laser generator. The input end of the device 11 is electrically connected.

[0059] Preferably, the control switch 3 is provided with control buttons for respectively controll...

Embodiment 3

[0065] Embodiment three: as figure 1 with figure 2 As shown, this embodiment discloses a negative pressure detection device for canned food. On the basis of Embodiment 1 or Embodiment 2, this embodiment also includes a negative pressure gauge 2 and a three-way pipe. The three ports of the three-way pipe are respectively It is connected with the air inlet of observation cover 7, a port of valve 1, and the port of negative pressure gauge 2.

[0066] The valve 1 includes two ports, the two ports are in a connected state when the valve 1 is open, and the two ports are in a closed state when the valve 1 is closed.

[0067] The working process and principle of this embodiment are:

[0068] The air pressure in cans of the same specification is similar, measure the air pressure in one of the cans.

[0069] The can negative pressure detection device is installed on the lid of the can. The negative pressure pump 5 works to reduce the air pressure in the observation cover 7. The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com