Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Simple mechanics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

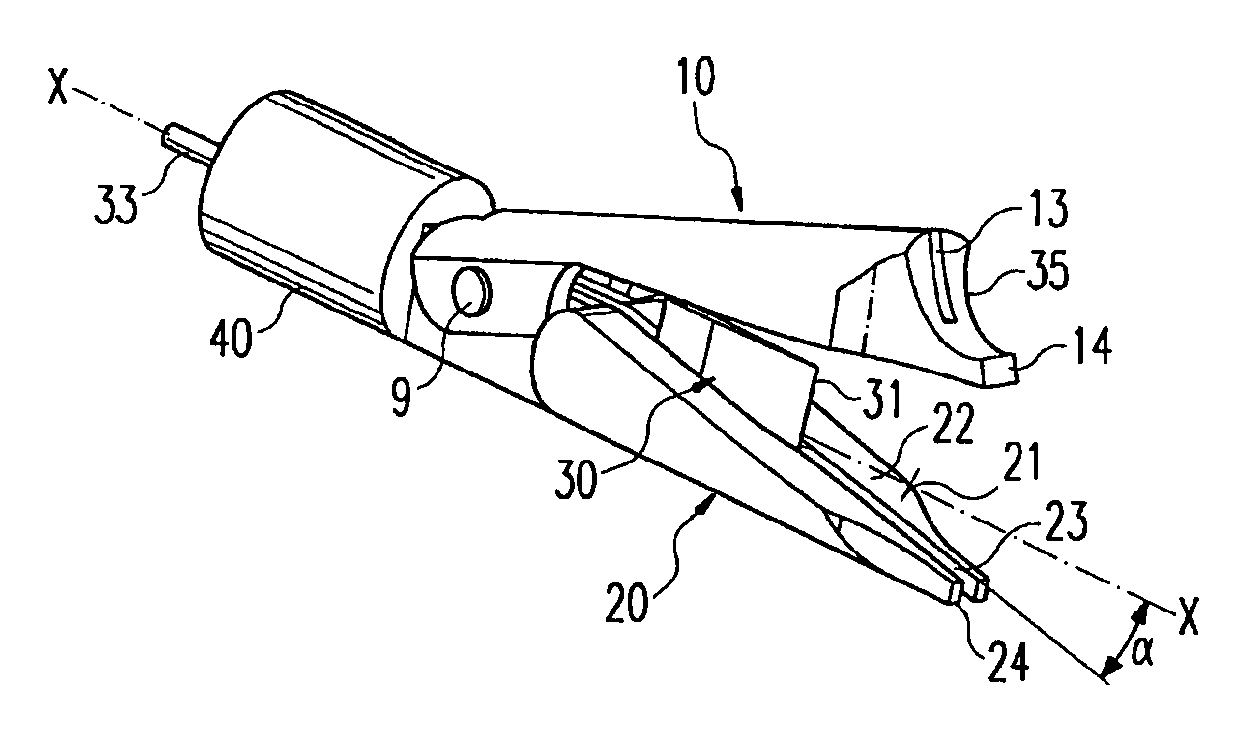

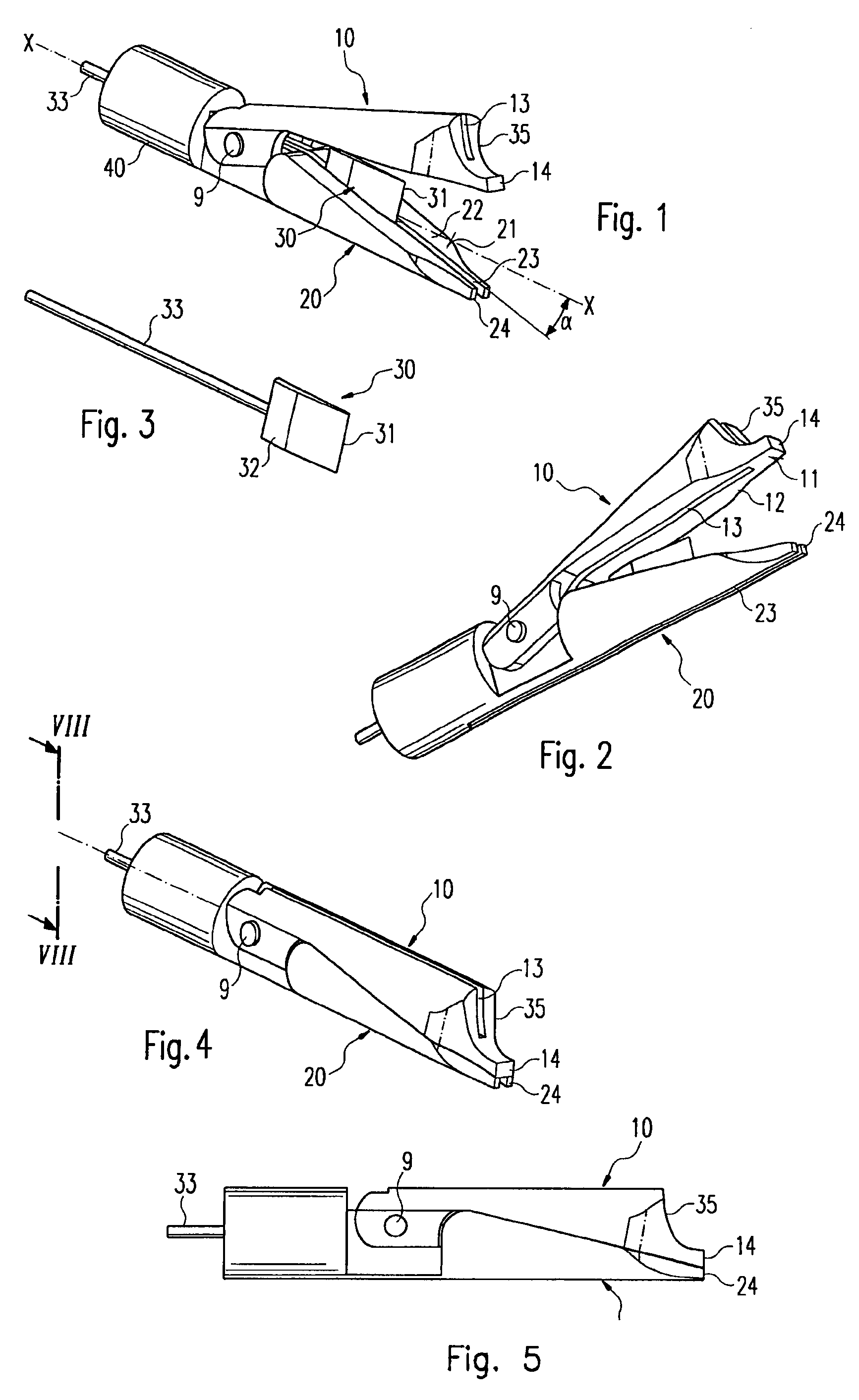

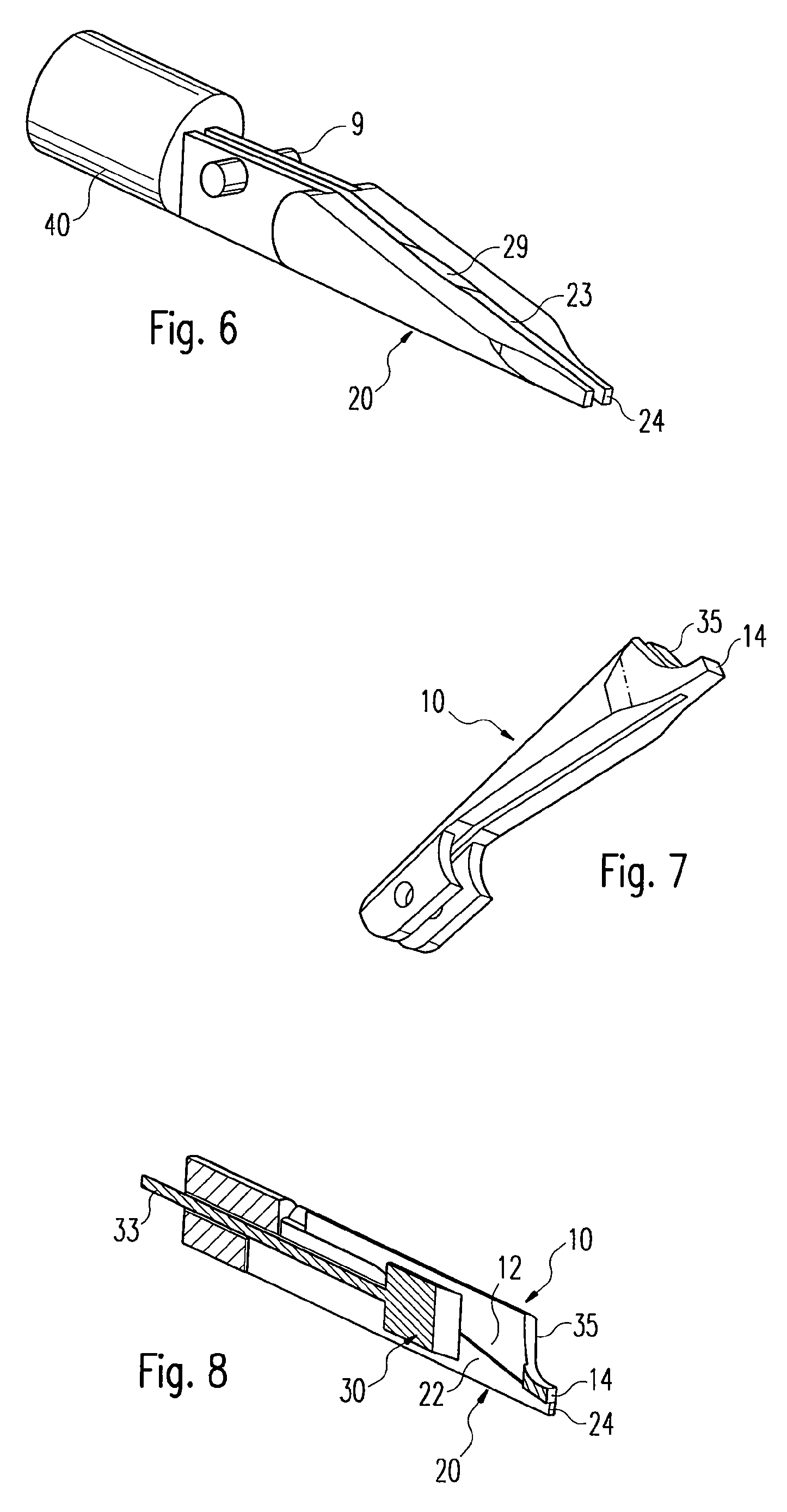

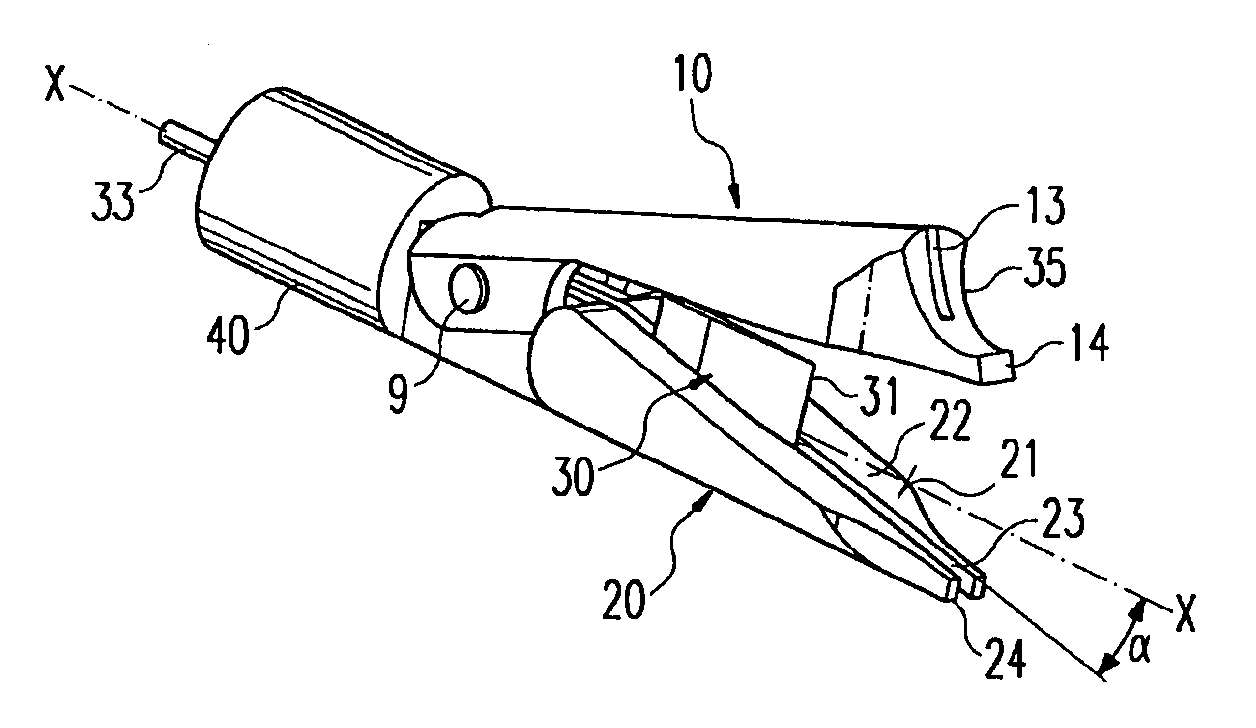

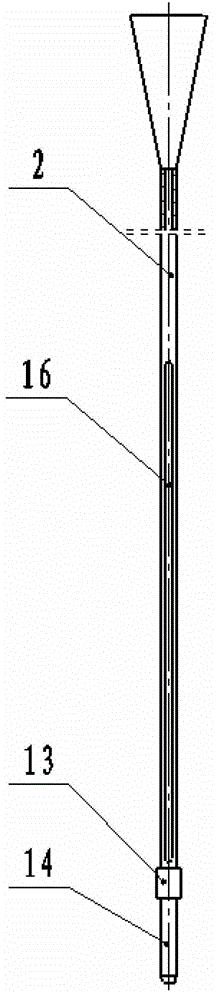

Surgical instrument

InactiveUS8992526B2Good and safe operabilityEasy to operateSurgical instruments for heatingSurgical forcepsLess invasive surgeryPERITONEOSCOPE

Surgical instruments are provided for performing laparoscopic or similar minimally invasive operations, including two clamping parts, which can move towards one another and which have clamping surfaces for gripping tissue when they are closed. A cutting device has a cutting edge that, in a cutting direction, can be displaced relative to the clamping parts for cutting the gripped tissue. In such an instrument the cutting direction extends at an acute angle to the clamping surfaces when they are closed.

Owner:ERBE ELEKTROMEDIZIN GMBH

Surgical instrument

InactiveUS20090043305A1Improve cutting performanceGood and safe operabilitySurgical instruments for heatingSurgical forcepsLess invasive surgeryAcute angle

Surgical instruments are provided for performing laparoscopic or similar minimally invasive operations, including two clamping parts, which can move towards one another and which have clamping surfaces for gripping tissue when they are closed. A cutting device has a cutting edge that, in a cutting direction, can be displaced relative to the clamping parts for cutting the gripped tissue. In such an instrument the cutting direction extends at an acute angle to the clamping surfaces when they are closed.

Owner:ERBE ELEKTROMEDIZIN GMBH

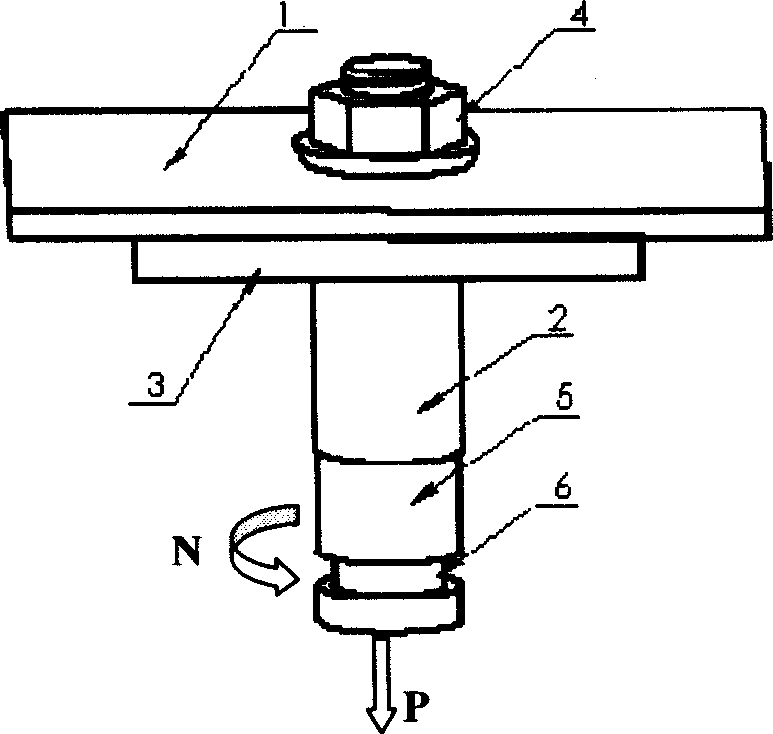

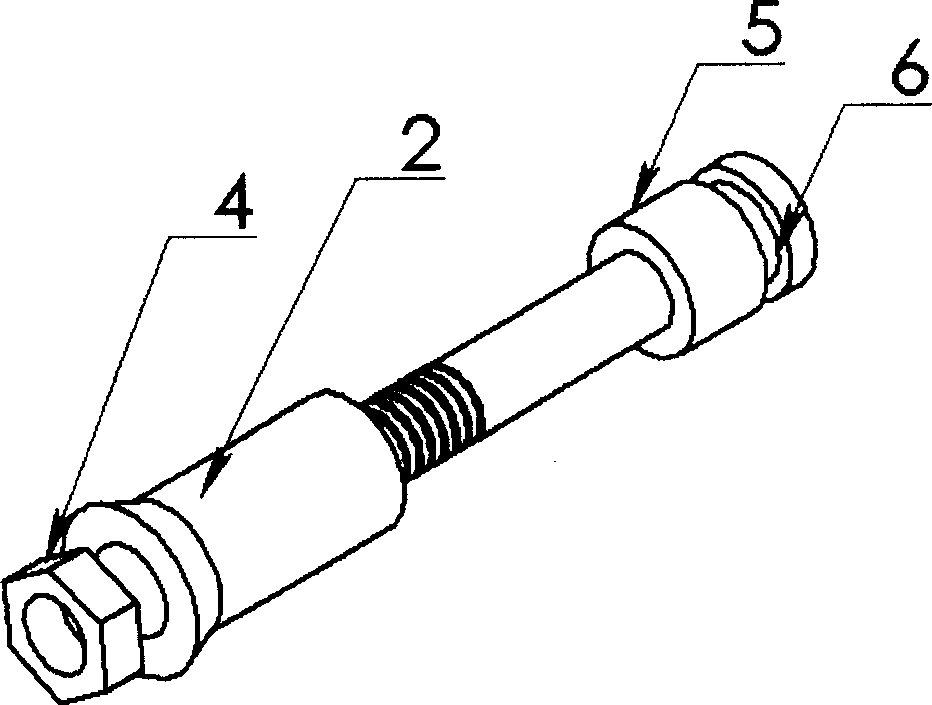

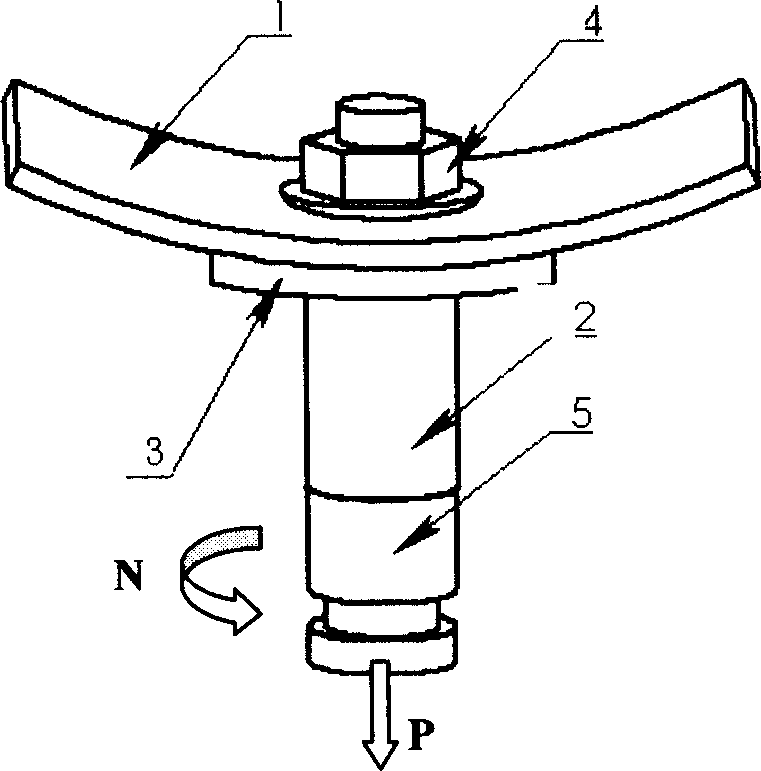

Tube sheet friction welding method

ActiveCN1876307APrecise control of welding parametersImprove processing stabilityNon-electric welding apparatusFriction weldingNonferrous metal

Owner:CAPITAL AEROSPACE MACHINERY

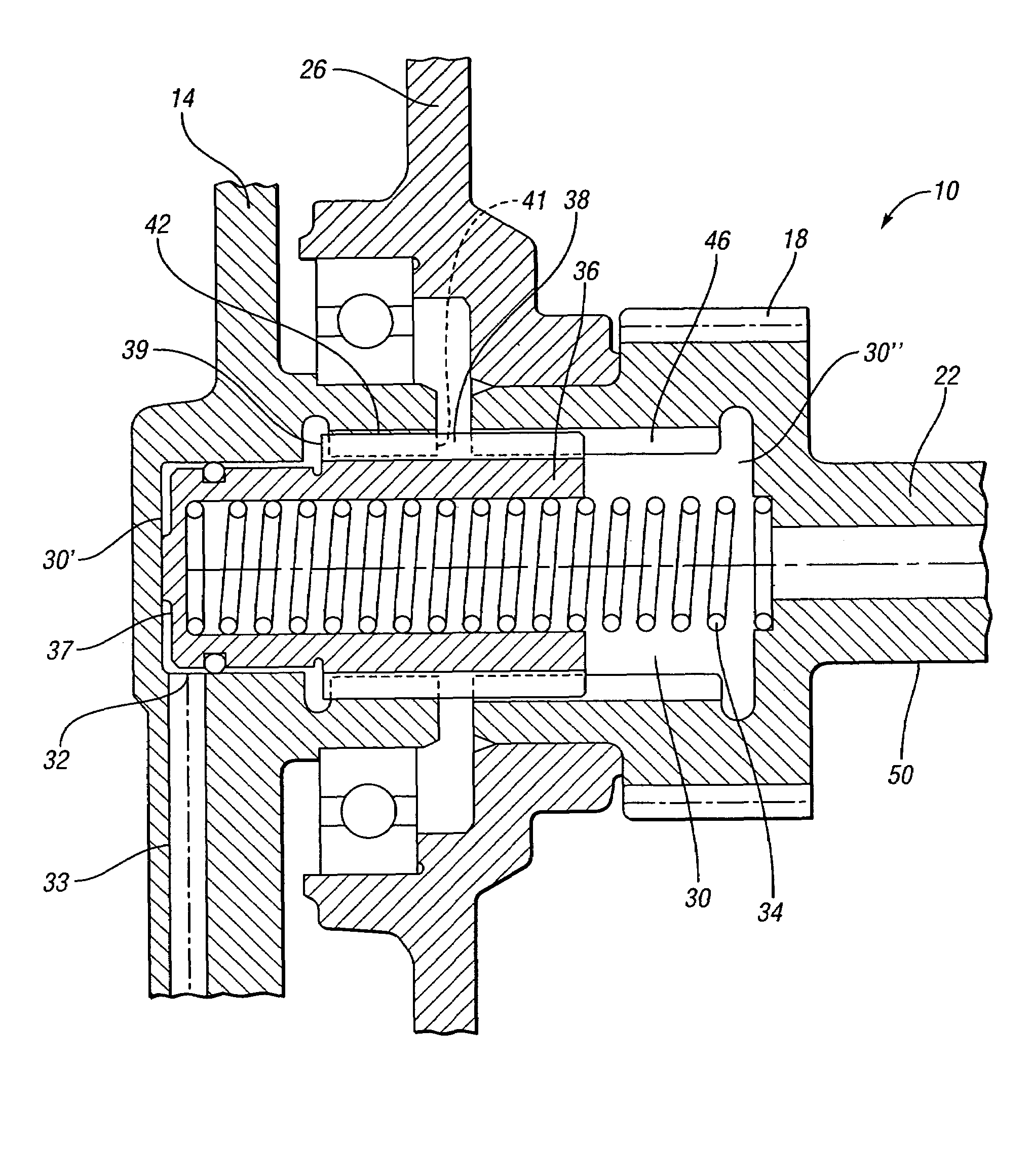

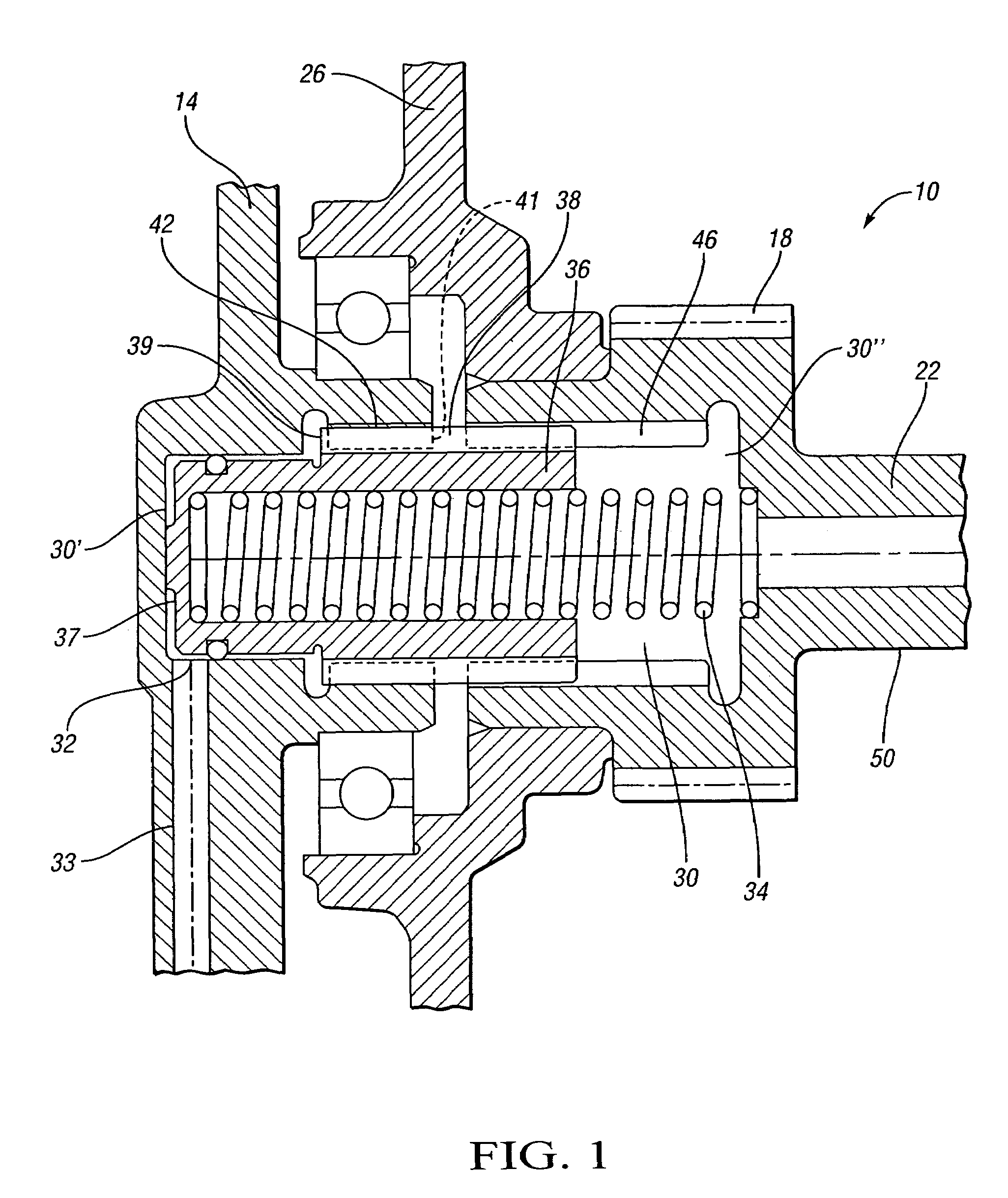

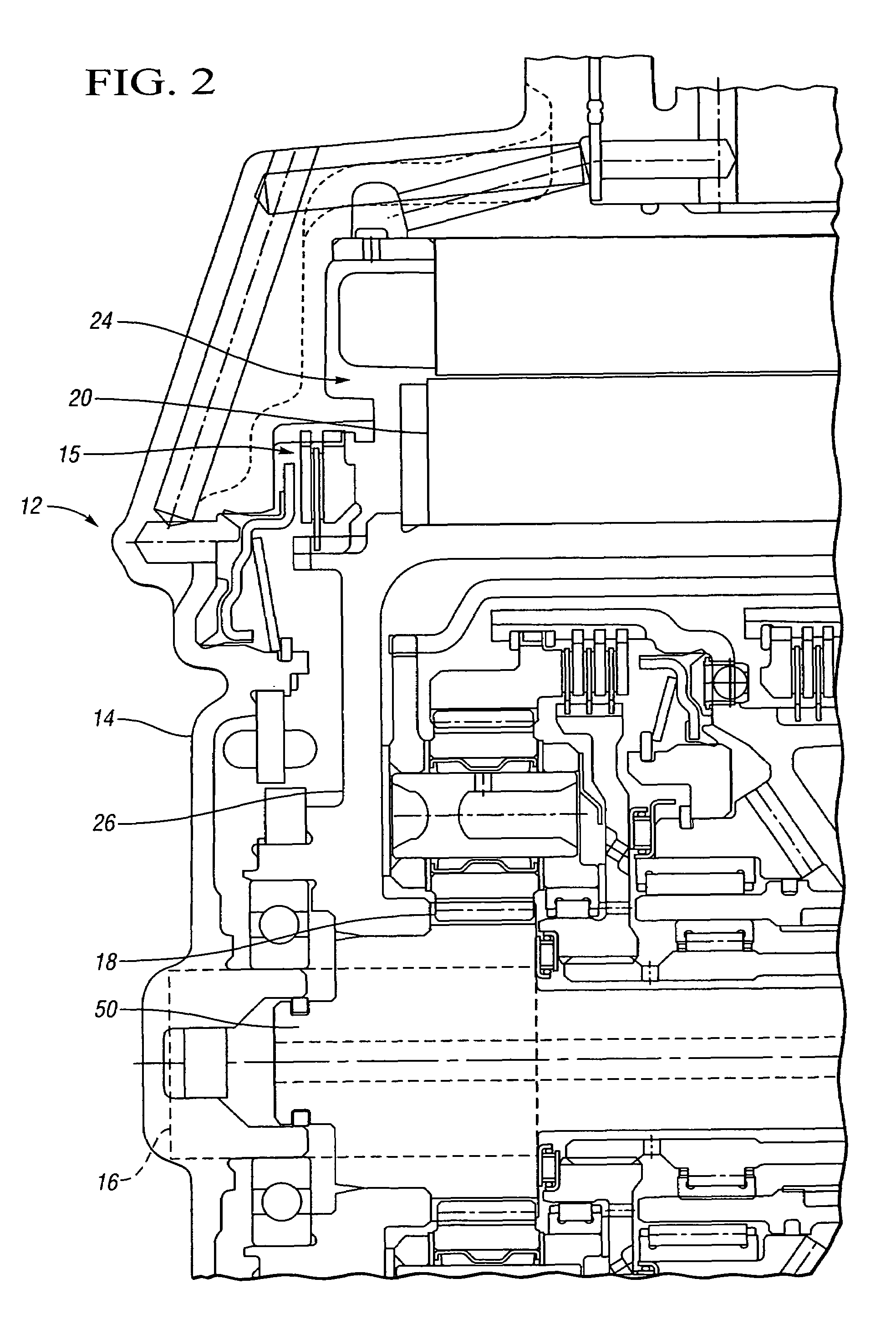

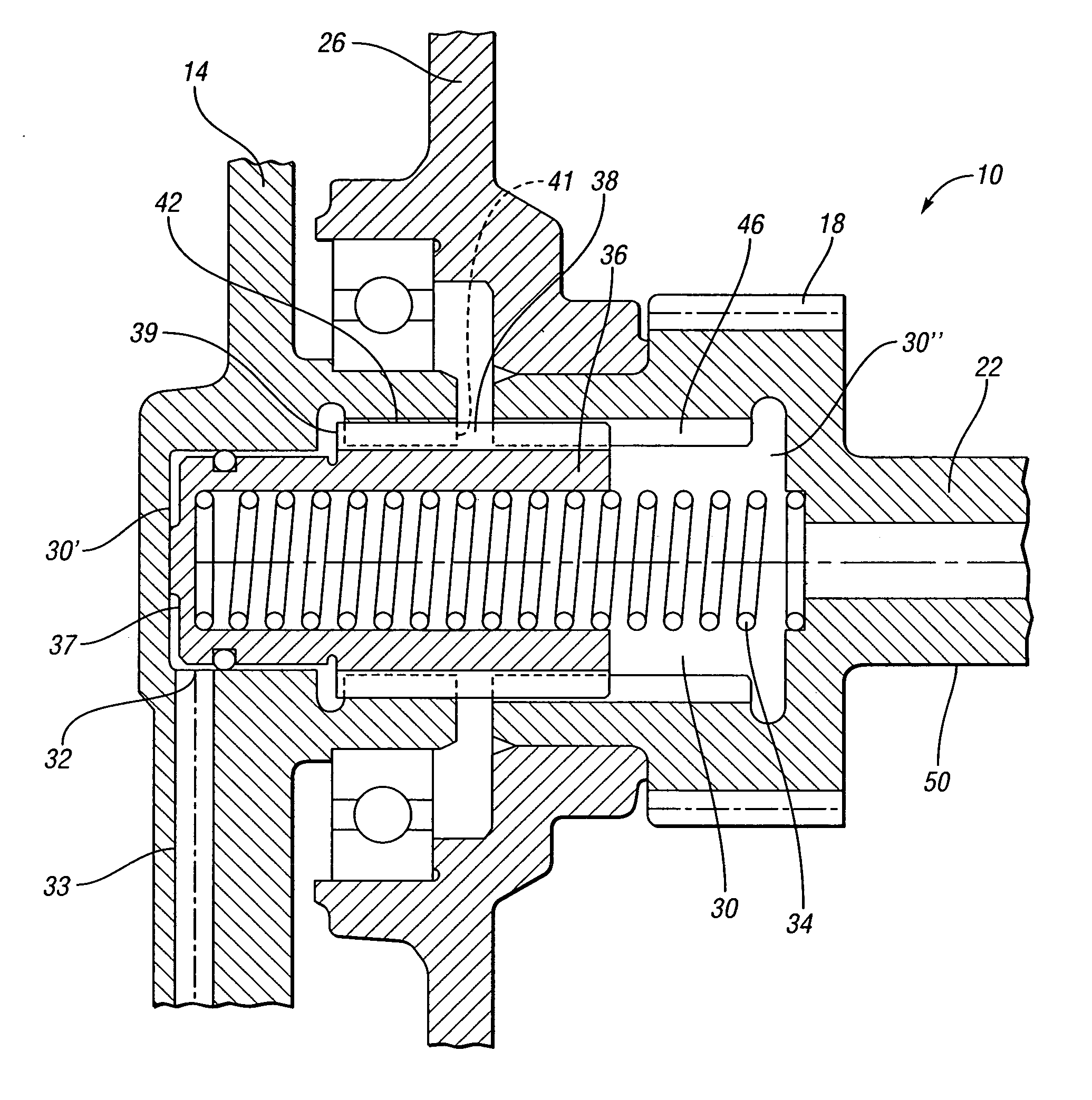

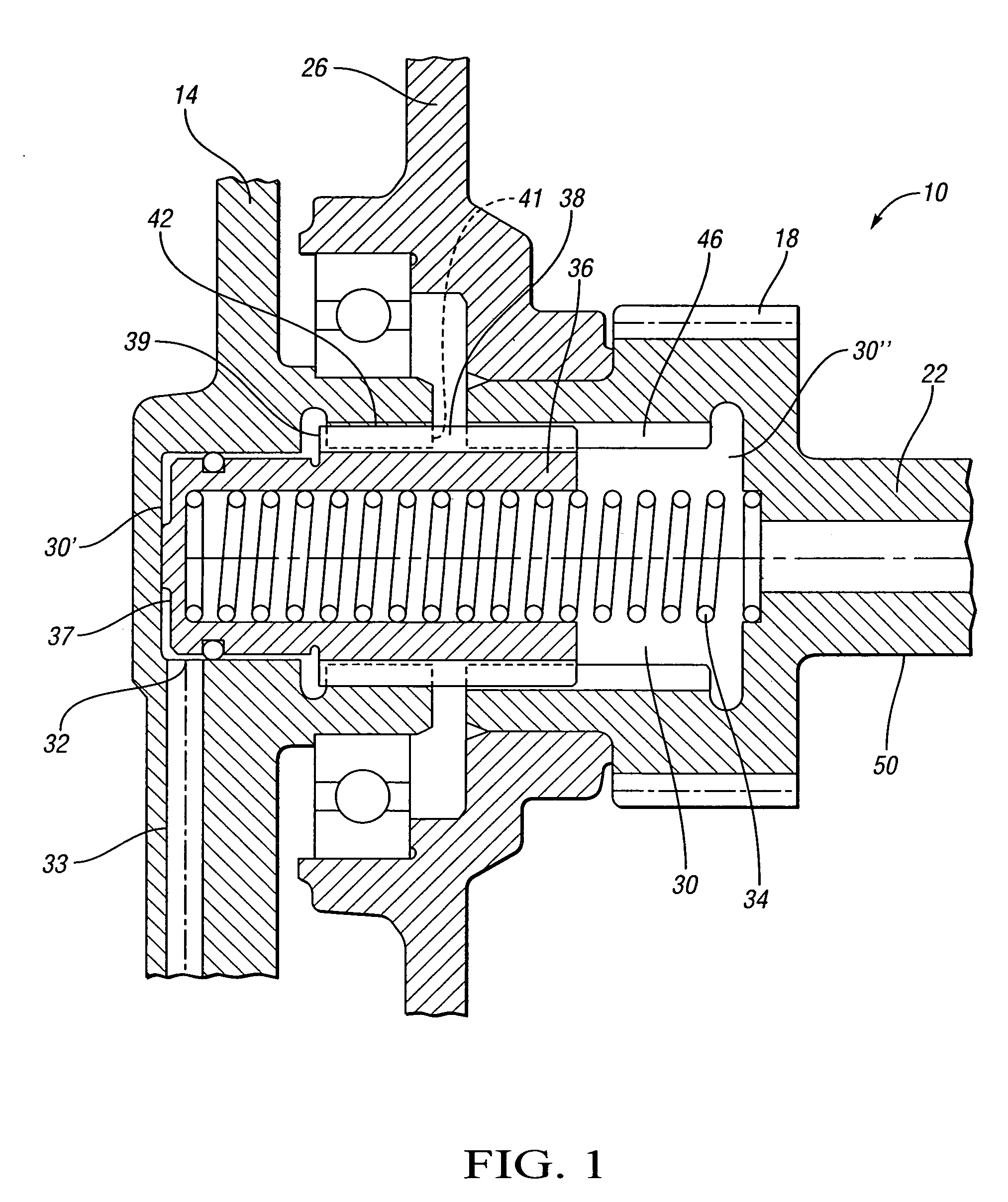

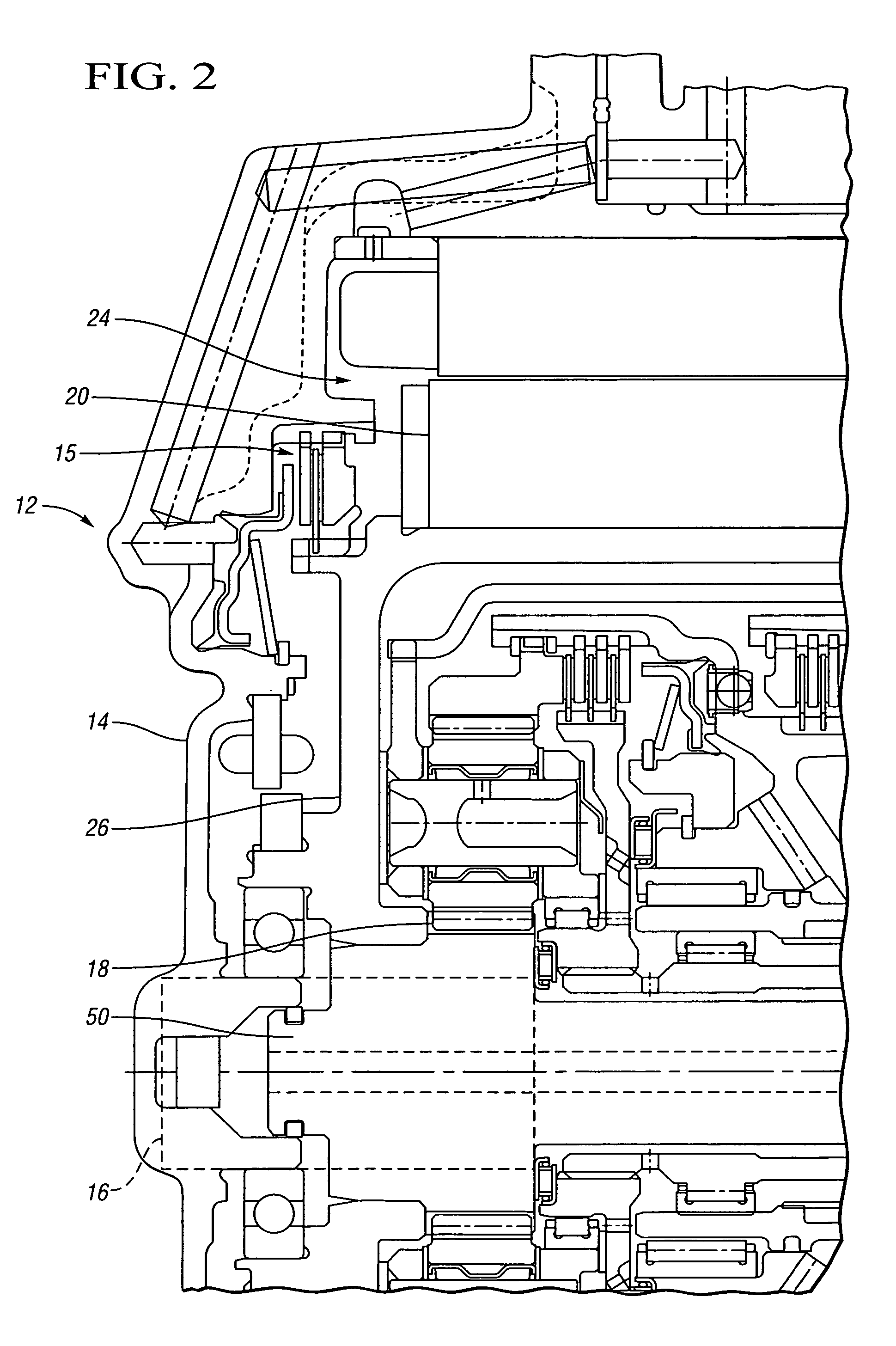

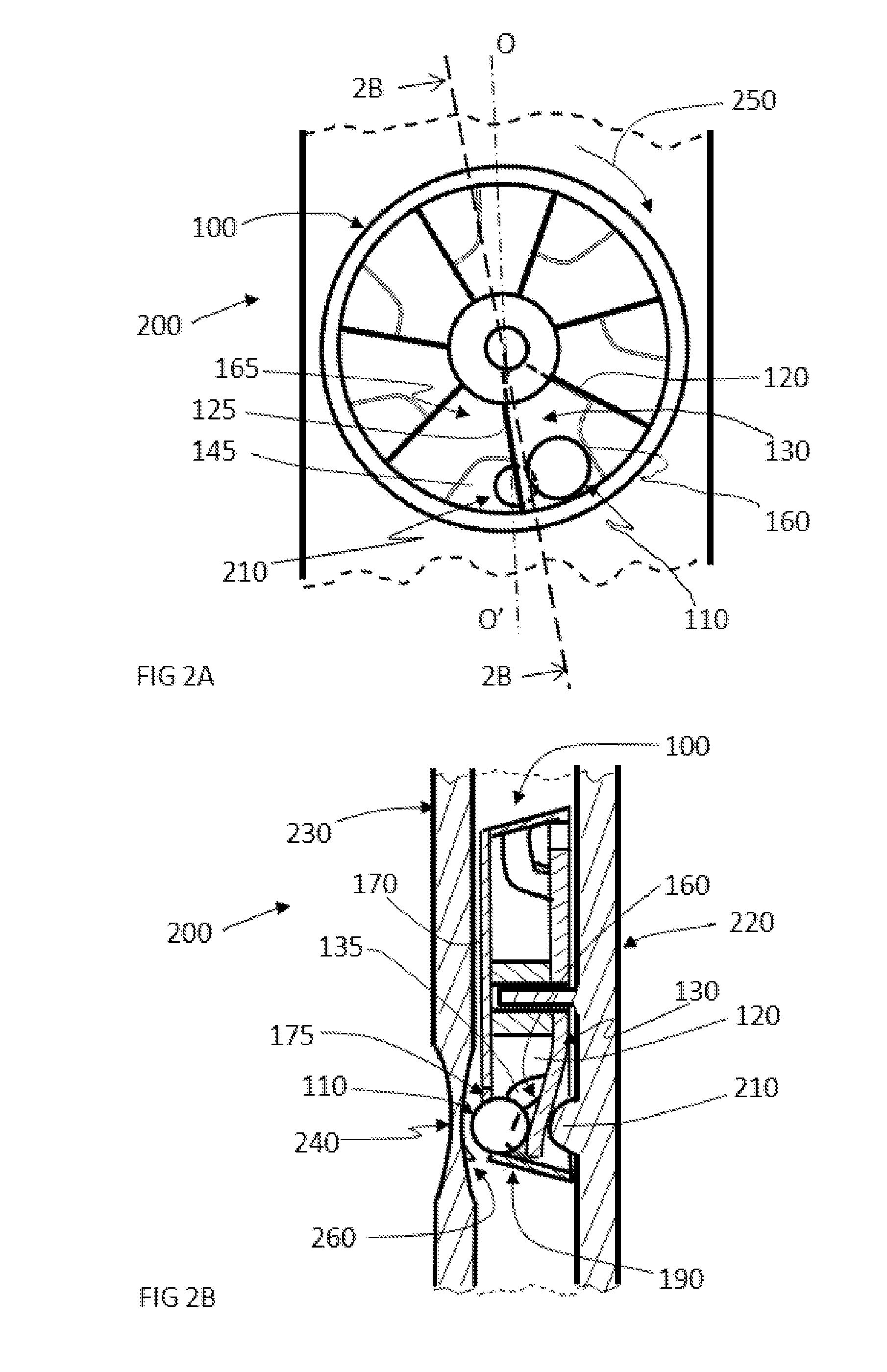

Dog clutch and method for overdrive

A hydraulically-actuatable clutch and method is operable as an overdrive clutch in a transmission system having a transmission main shaft portion. The clutch is engageable between a transmission housing and a sun gear and rotor hub to provide for grounding of the sun gear and rotor hub to the transmission housing. The clutch may either be engaged or disengaged from the transmission housing. The clutch does not allow the rotor and sun gear to rotatably slip with respect to the transmission housing when the clutch is engaged to ground the rotor and sun gear to the transmission housing. When the clutch is disengaged, the rotor and sun gear may rotate with the transmission main shaft portion.

Owner:GM GLOBAL TECH OPERATIONS LLC

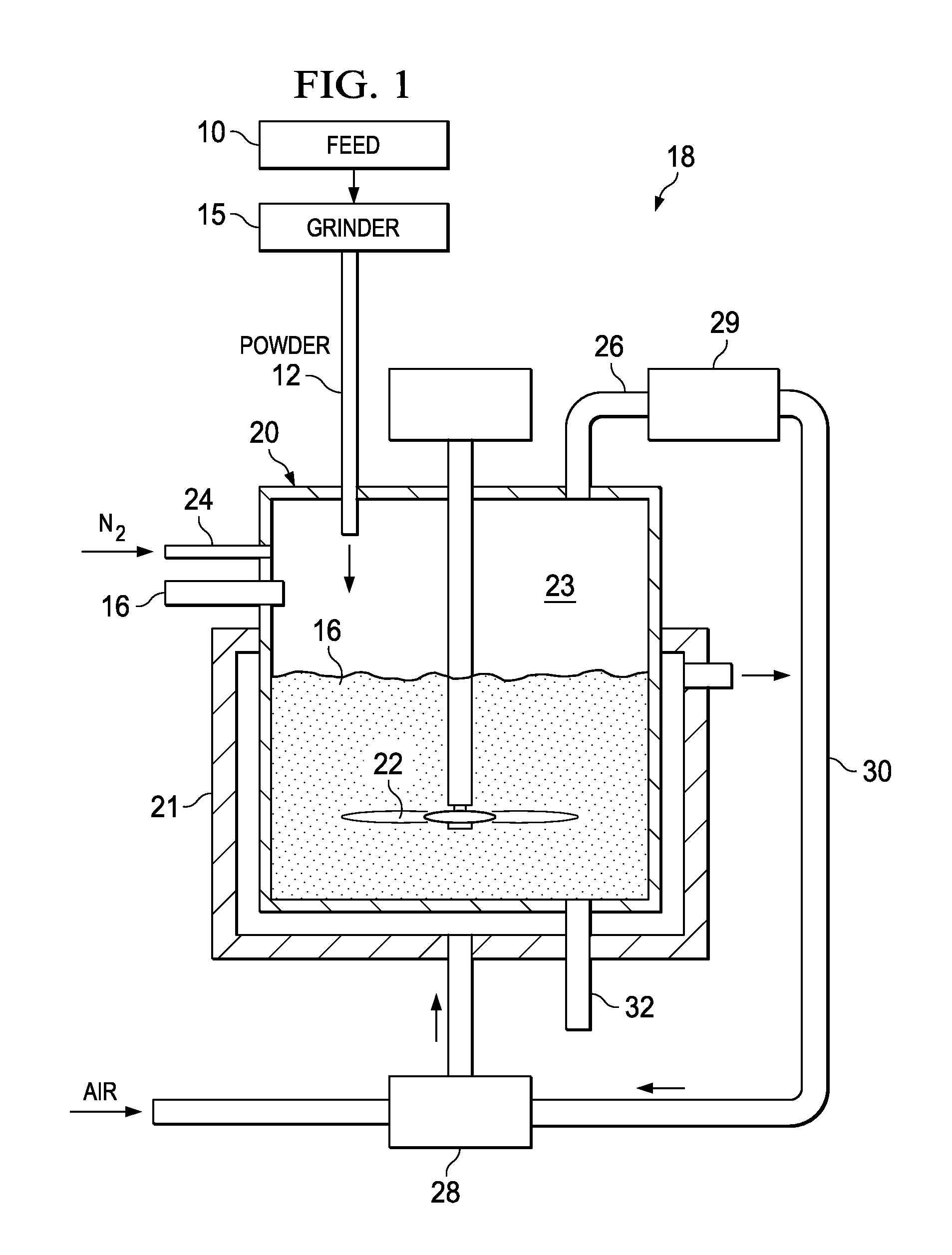

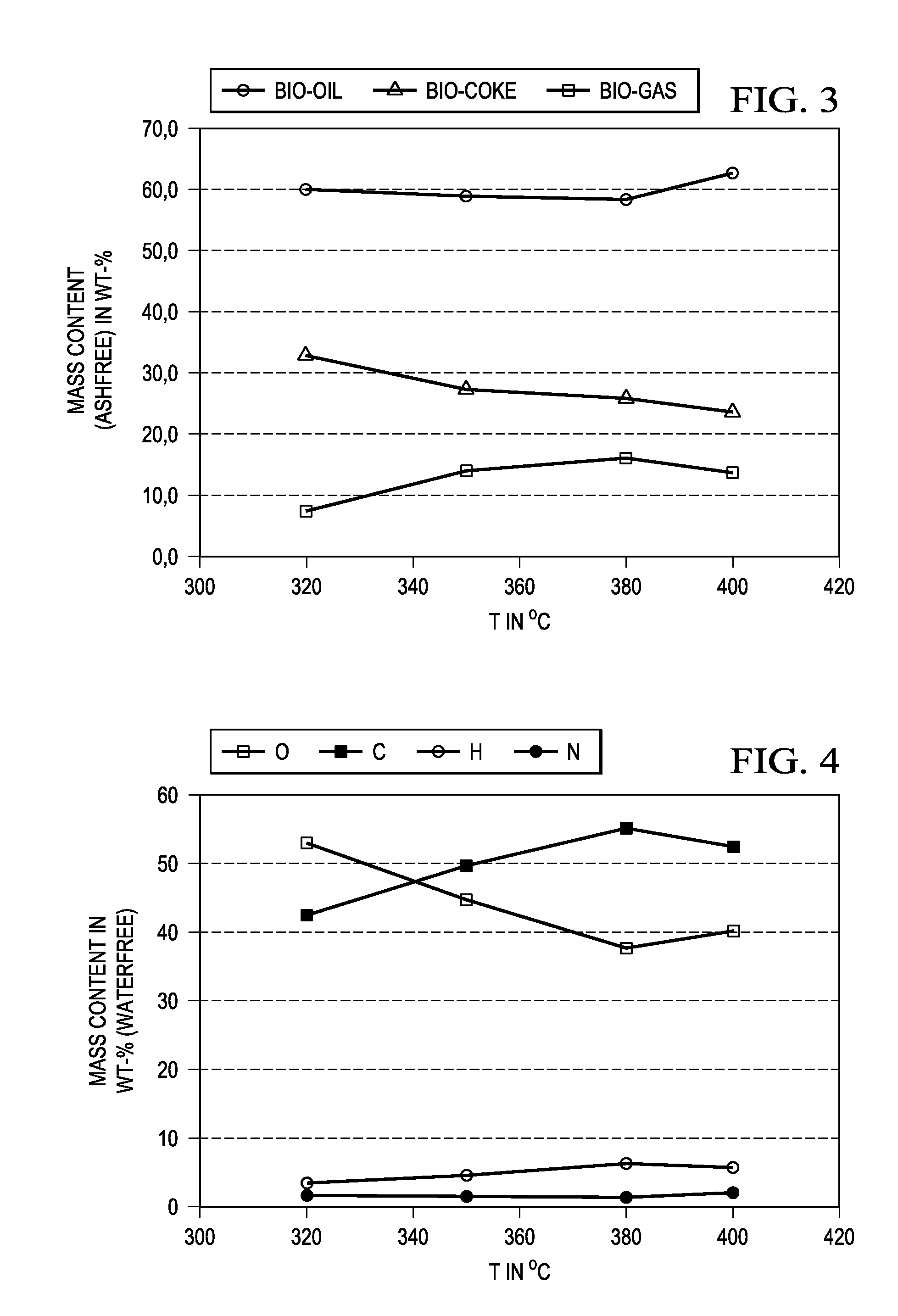

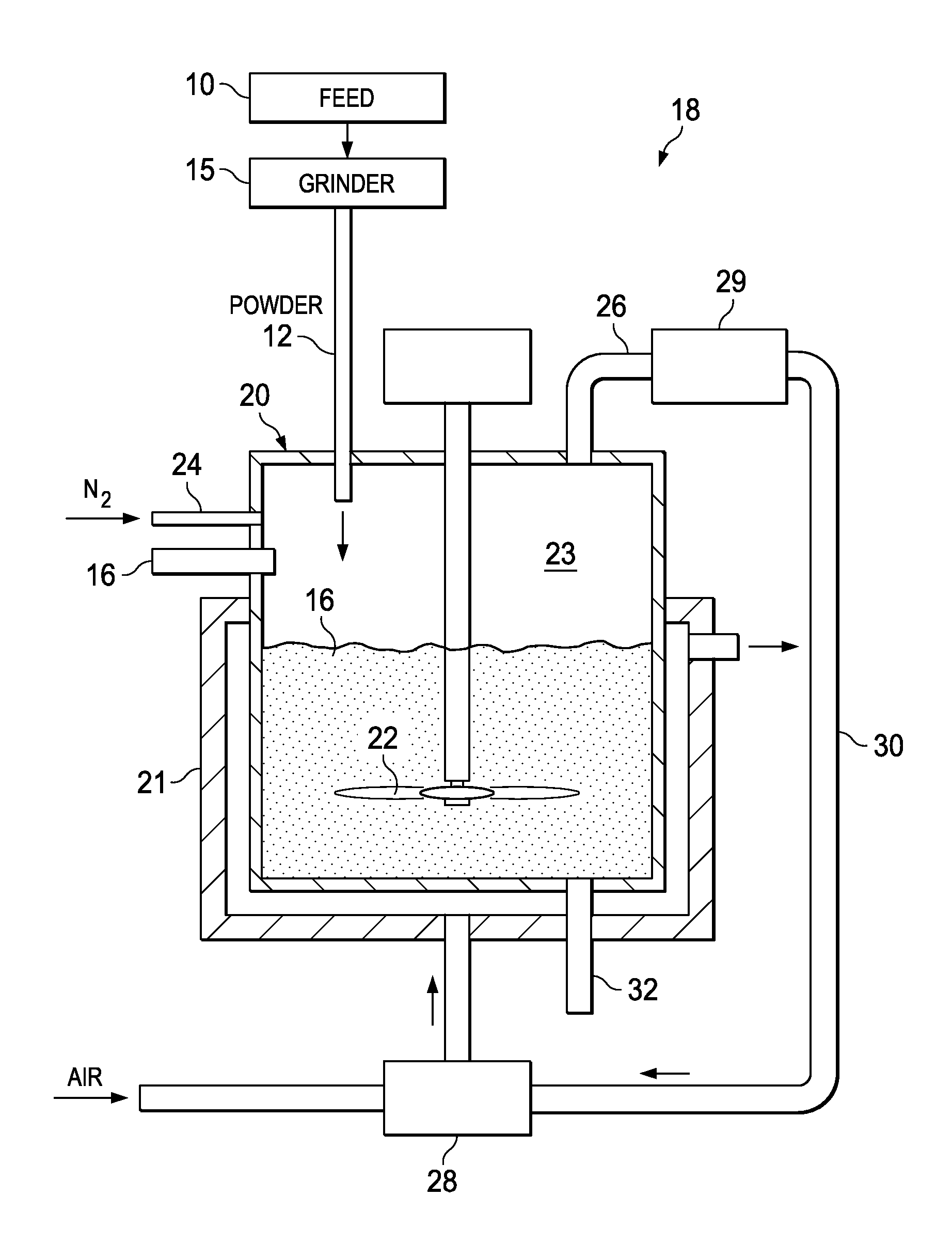

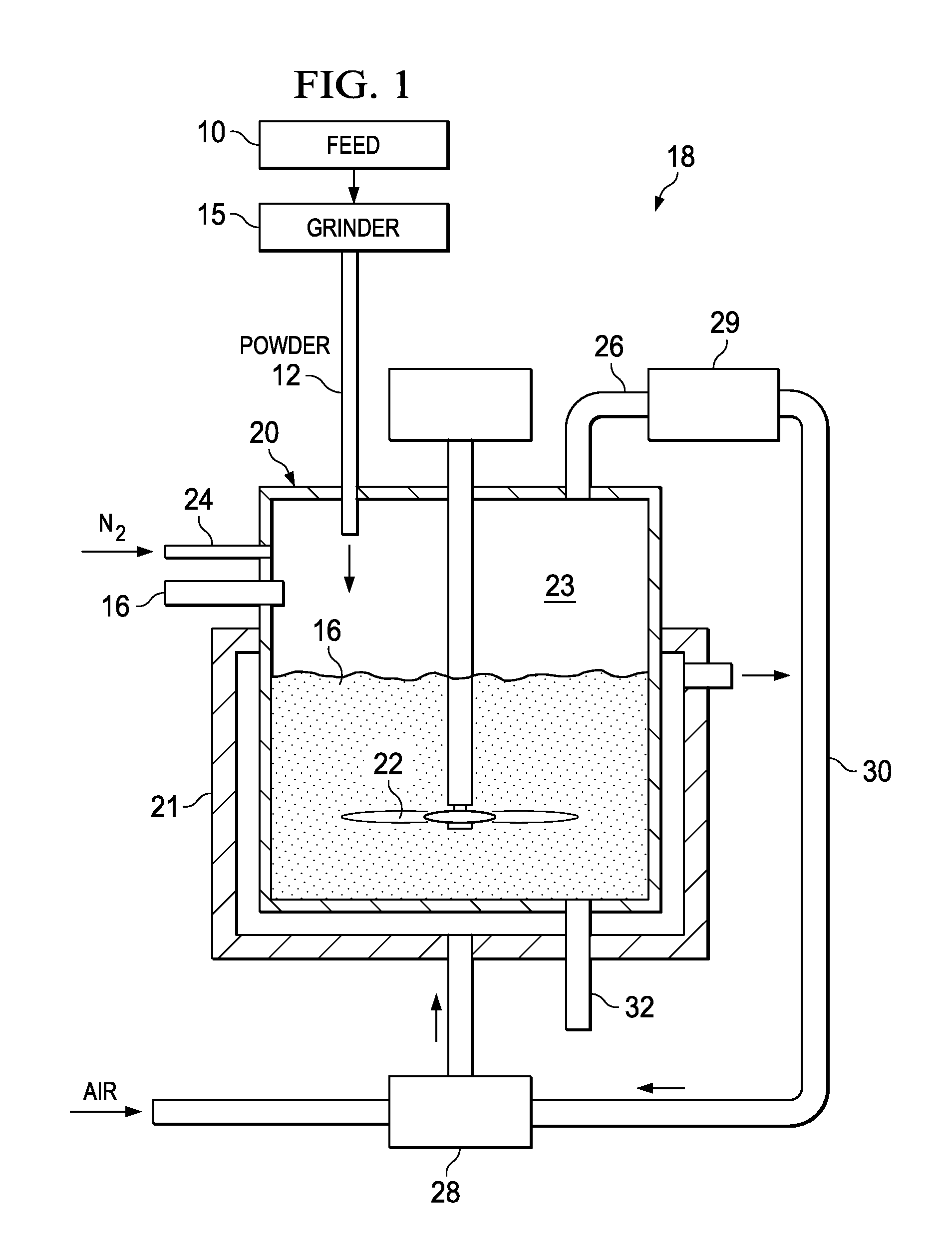

Biomass pyrolysis in refinery feedstock

ActiveUS20110184215A1Accelerated pyrolysisIncrease costPreheating coke ovensDirect heating destructive distillationHot liquidsBiomass

This invention relates to biomass pyrolysis through the use of a hot liquid refinery feedstock as a heat transfer medium, preferably a vacuum gas oil feedstock.

Owner:PHILLIPS 66 CO

Dog clutch and method for overdrive

InactiveUS20060037830A1Simple mechanicsFluid actuated clutchesToothed gearingsVariatorTransmission system

A hydraulically-actuatable clutch and method is operable as an overdrive clutch in a transmission system having a transmission main shaft portion. The clutch is engageable between a transmission housing and a sun gear and rotor hub to provide for grounding of the sun gear and rotor hub to the transmission housing. The clutch may either be engaged or disengaged from the transmission housing. The clutch does not allow the rotor and sun gear to rotatably slip with respect to the transmission housing when the clutch is engaged to ground the rotor and sun gear to the transmission housing. When the clutch is disengaged, the rotor and sun gear may rotate with the transmission main shaft portion.

Owner:GM GLOBAL TECH OPERATIONS LLC

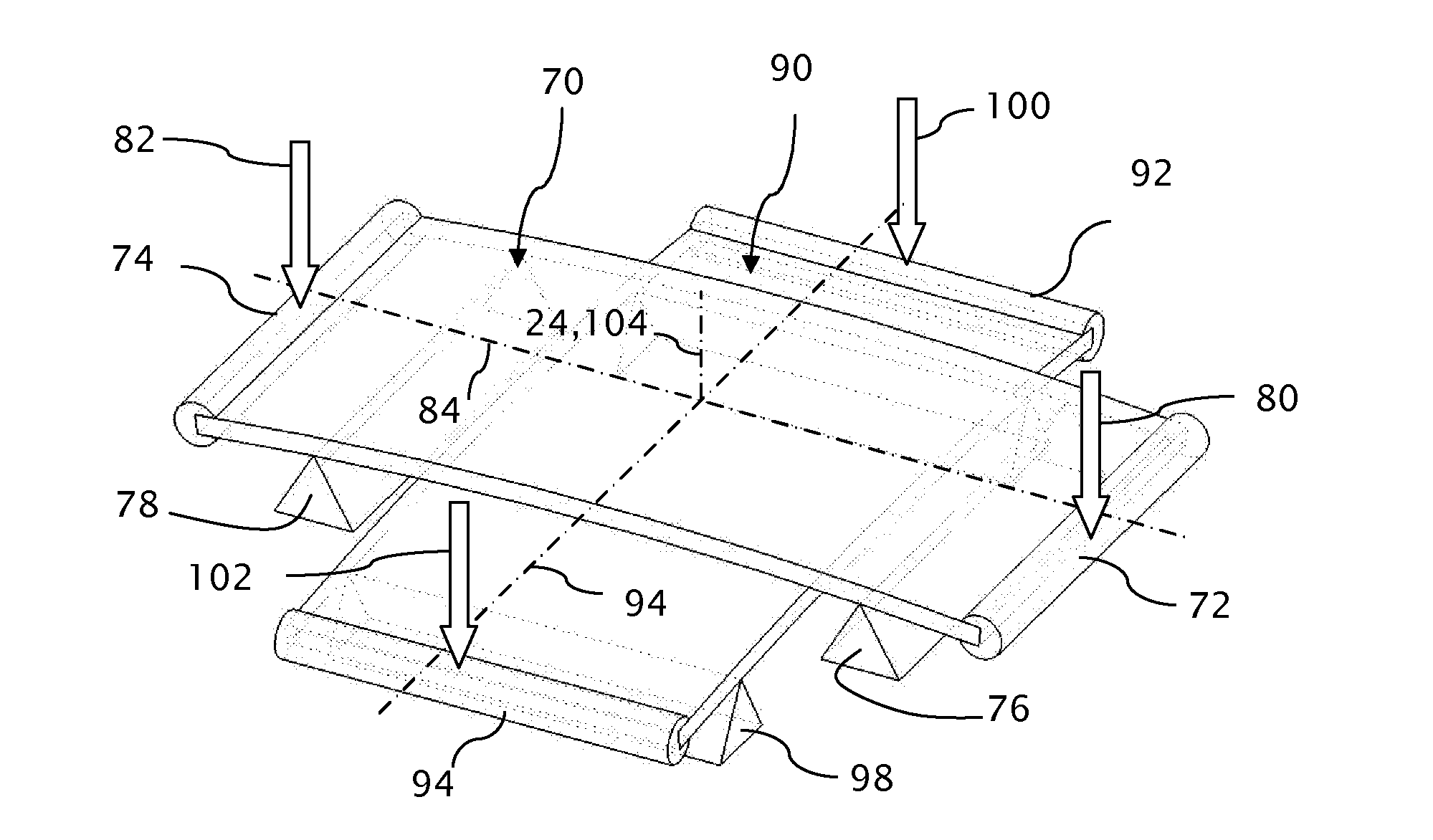

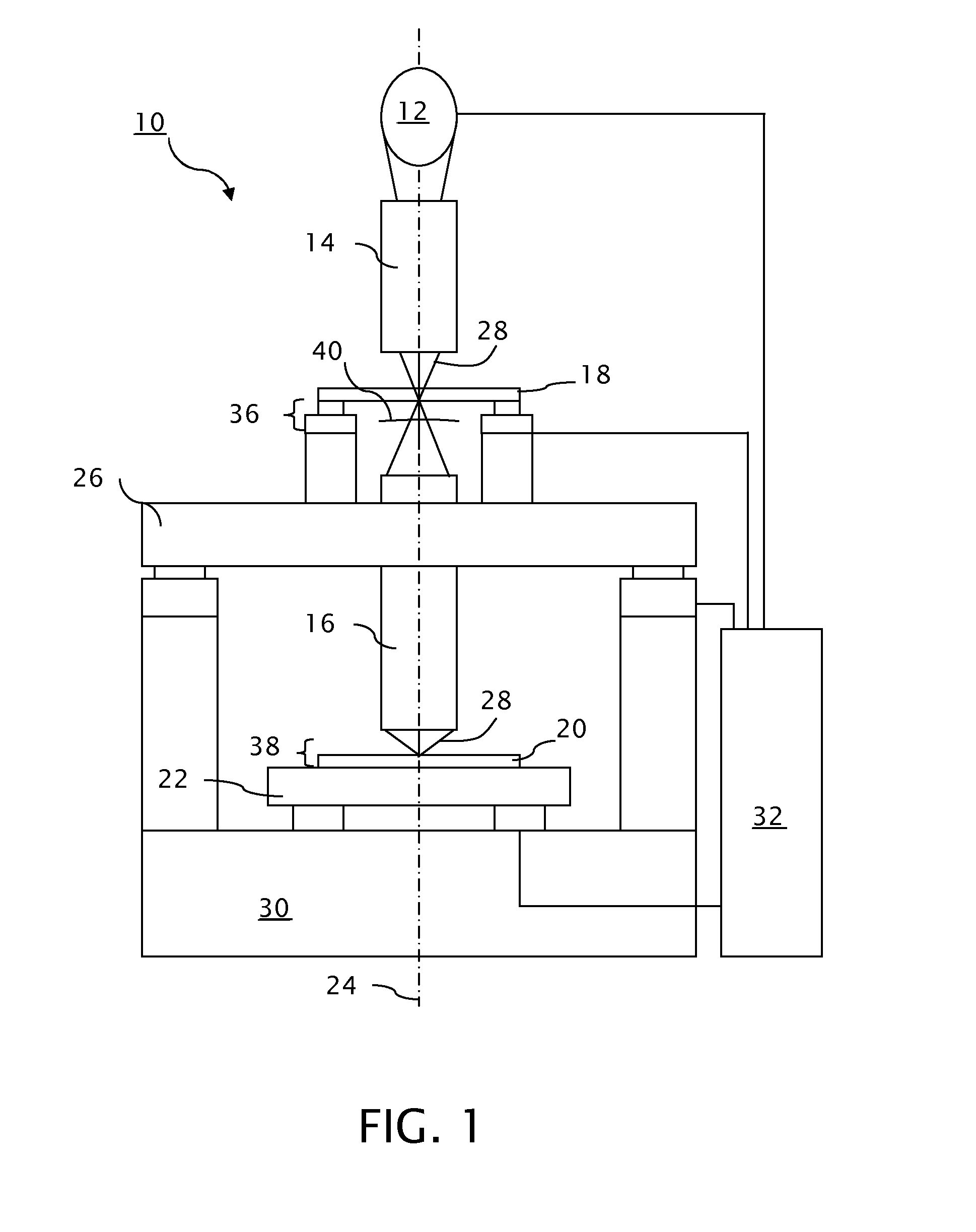

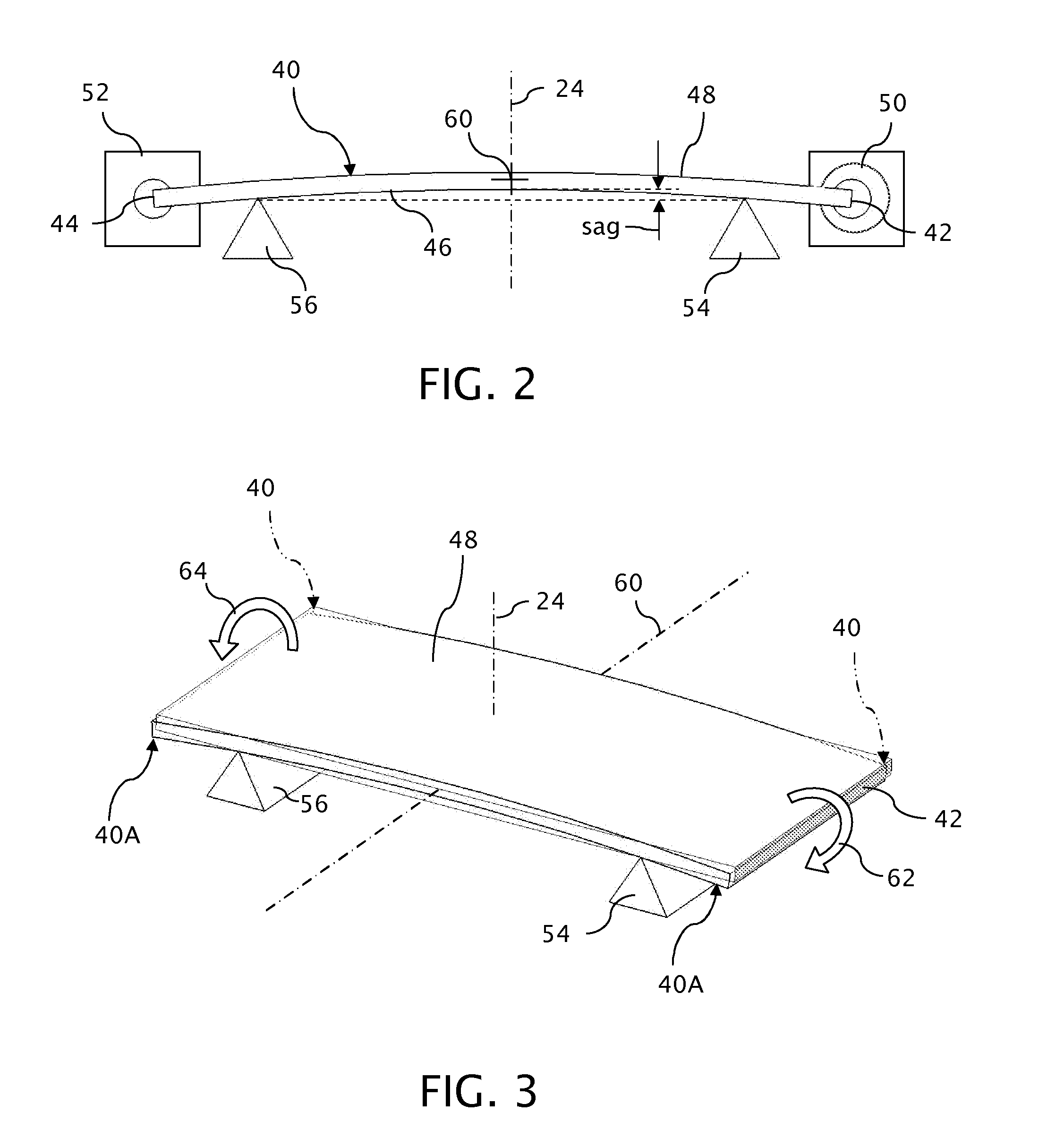

Magnification control for lithographic imaging system

ActiveUS20110122383A1Minimal impactSimple mechanicsPhotomechanical apparatusPhotographic printingProjection systemPhotolithography

In a lithographic projection system, a corrective optic in the form of one or more deformable plates is mounted within telecentric image or object space for making one-dimensional or two-dimensional adjustments to magnification. The deformable plate, which can be initially bent under the influence of a preload, contributes weak magnification power that influences the magnification of the projection system by changing the effective focal length in object or image space. An actuator adjusts the amount of curvature through which the deformable plate is bent for regulating the amount of magnification imparted by the deformable plate.

Owner:CORNING INC

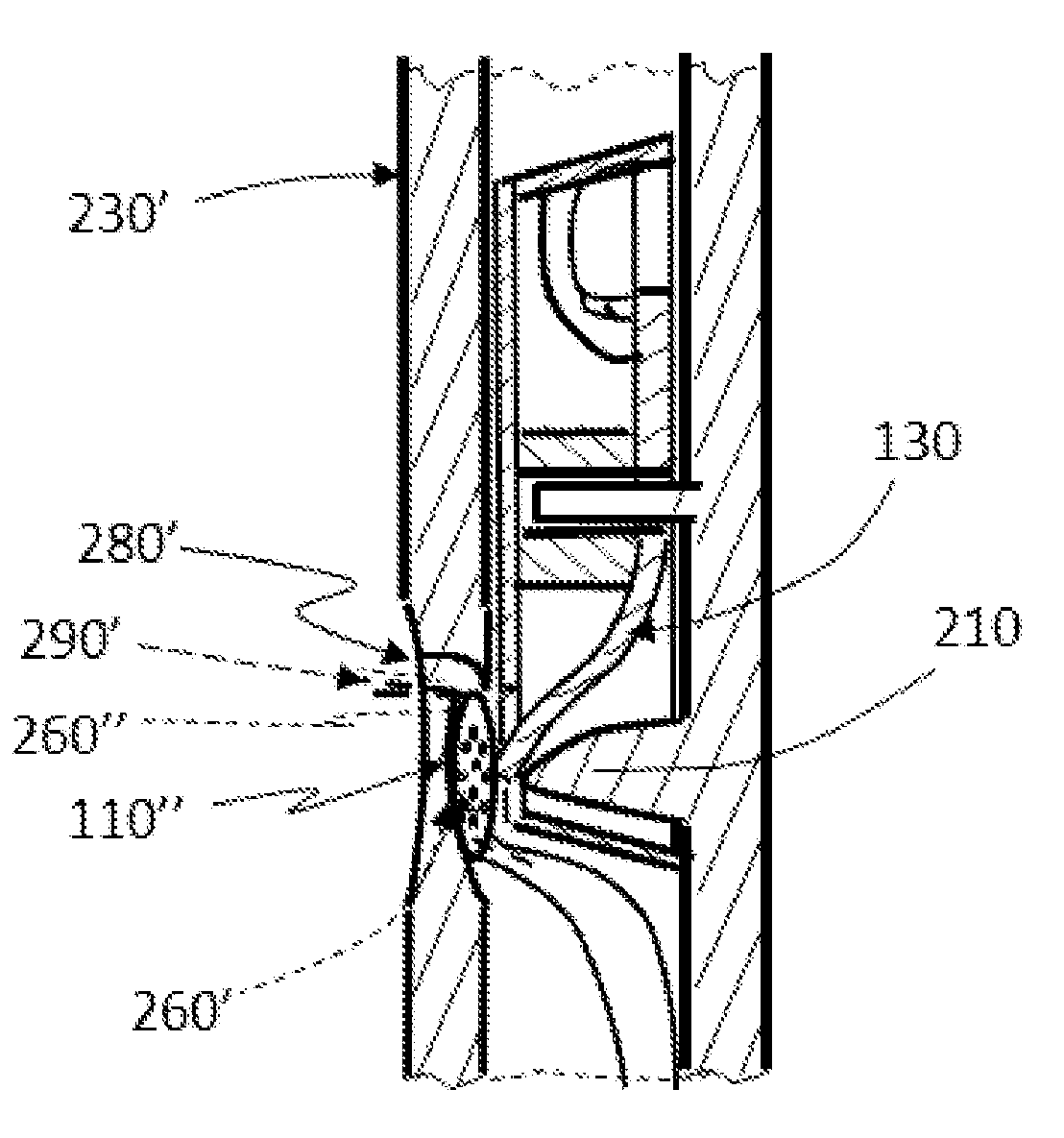

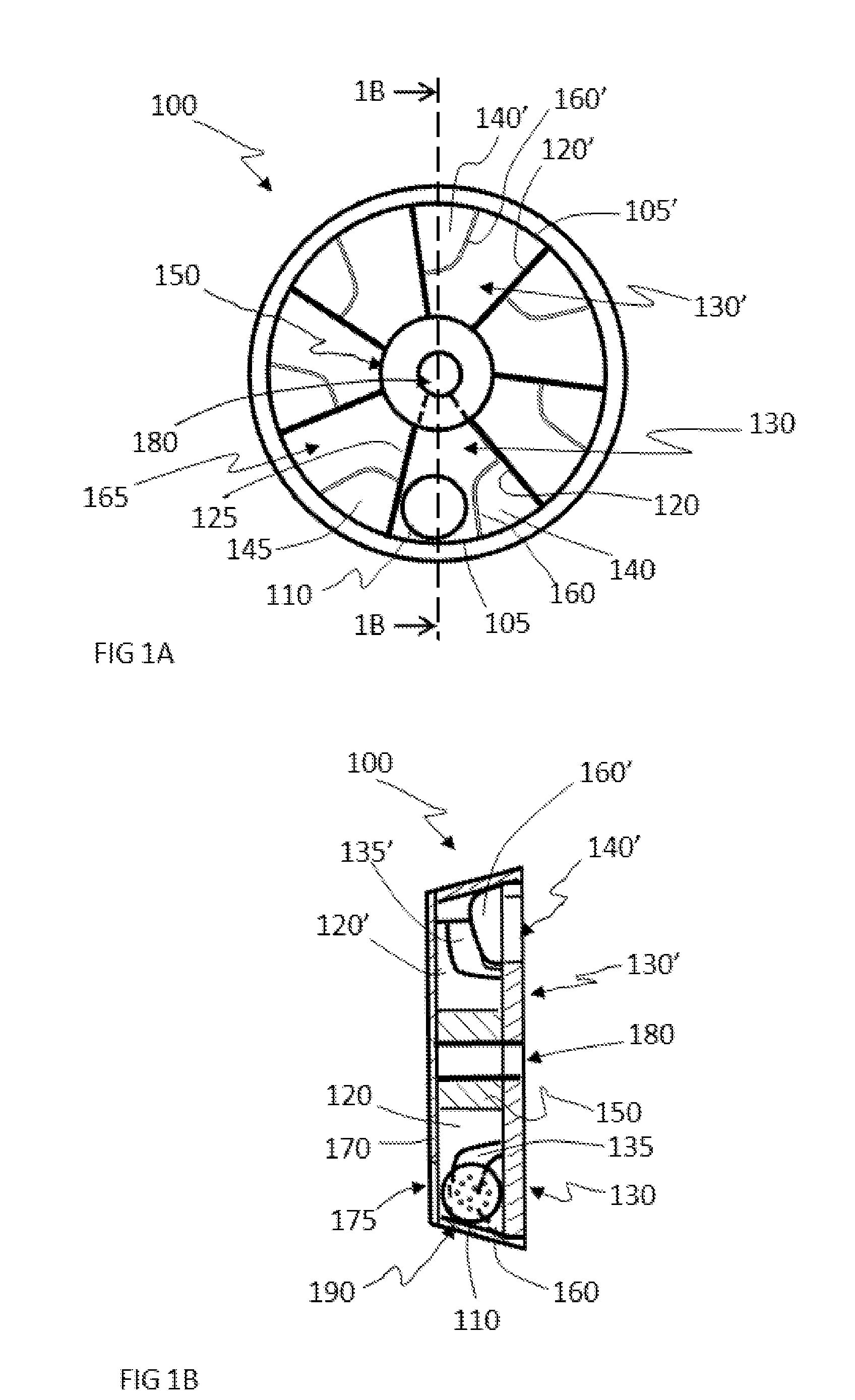

Capsular medication delivery and inhalation device

A method and capsular medication delivery and inhalation device is used with a medication capsule. The capsule is free-standing in a capsule chamber and not secured in a fixed position. The capsule is moved with a moveable back wall and other cooperative structure into an opener which releases the medication inside the capsule. The device may include an aerosol stream for facilitating medication delivery. The device works with capsules of varying sizes and shapes.

Owner:PORTNEY NATHANIEL GERALD

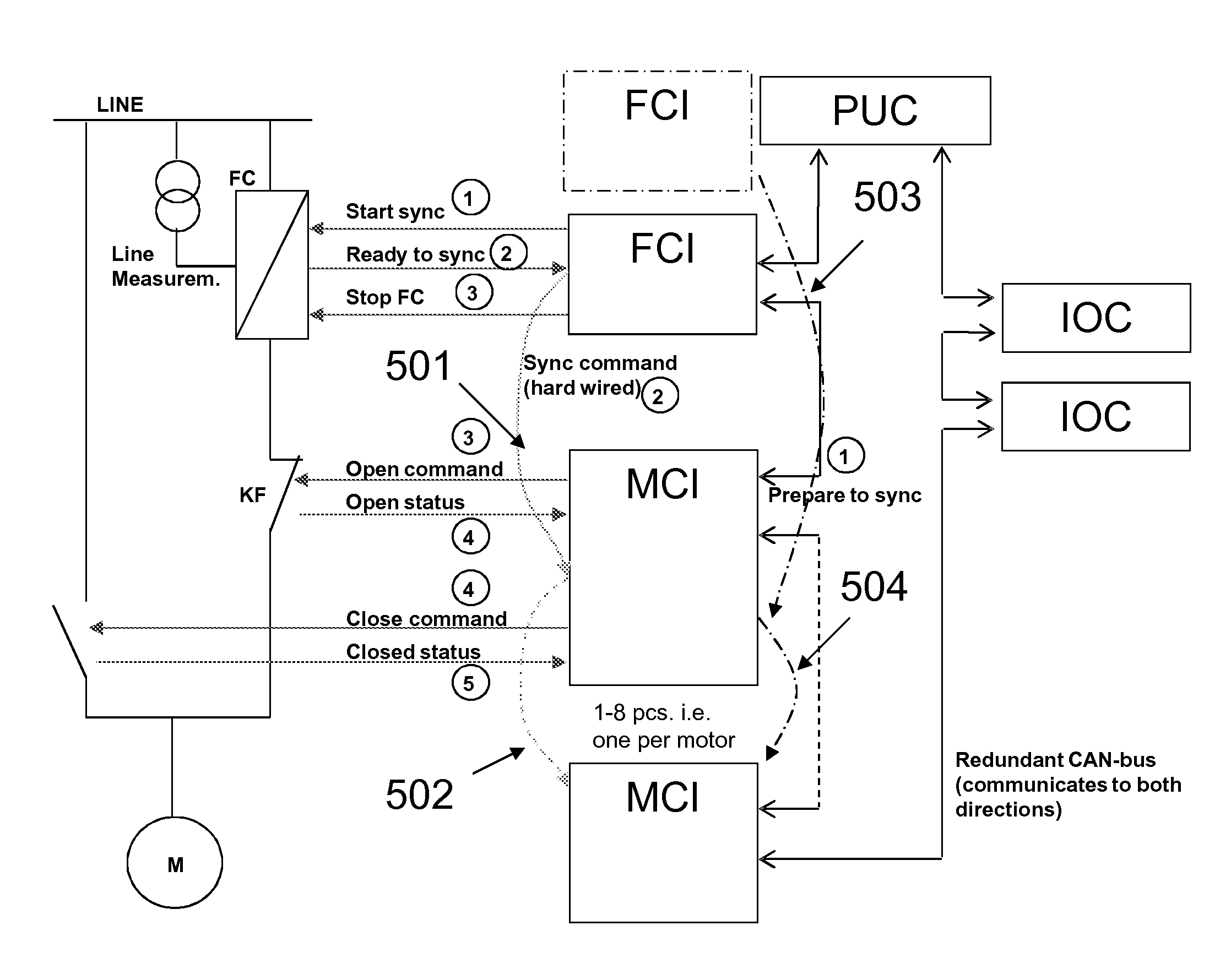

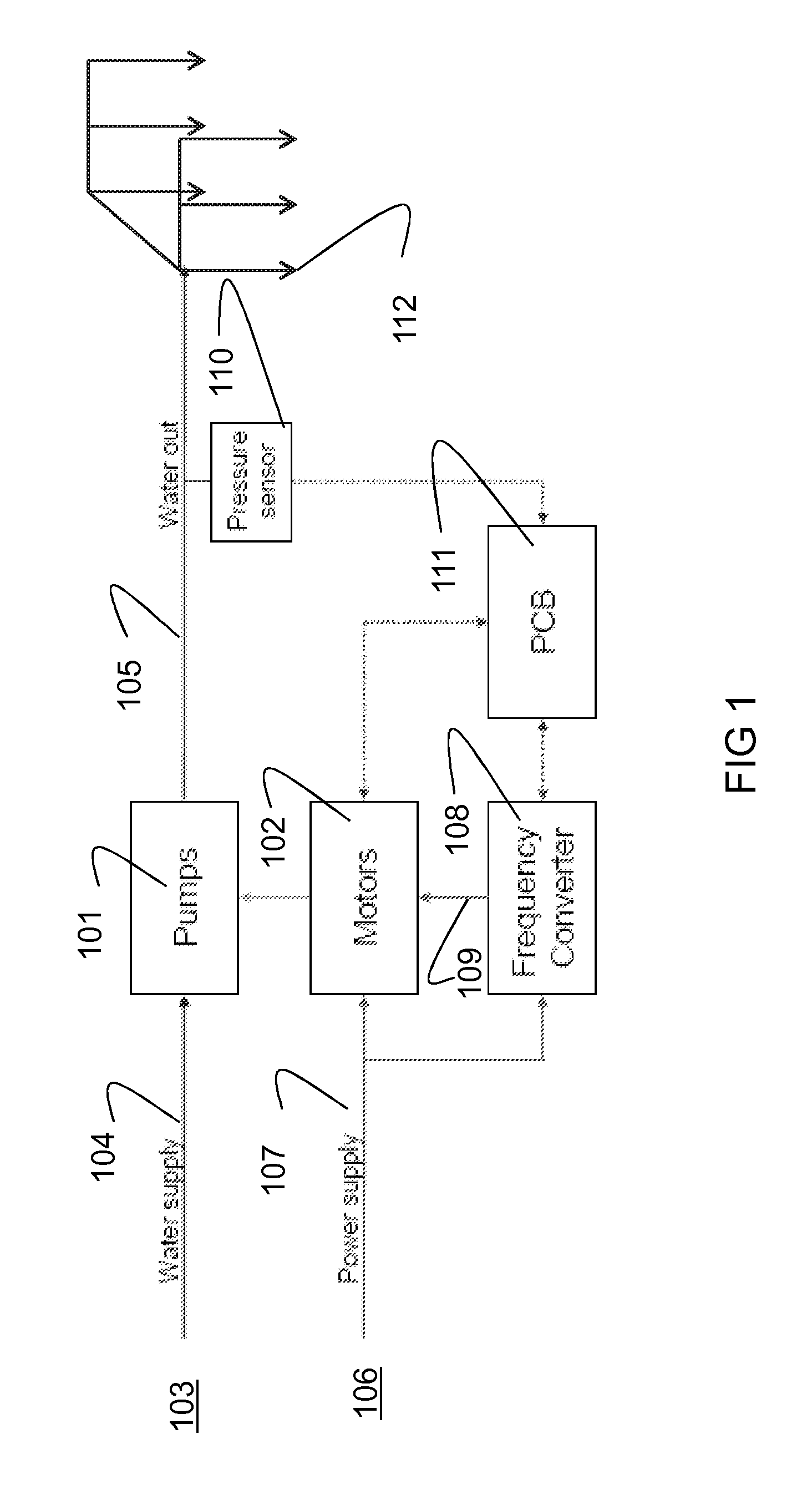

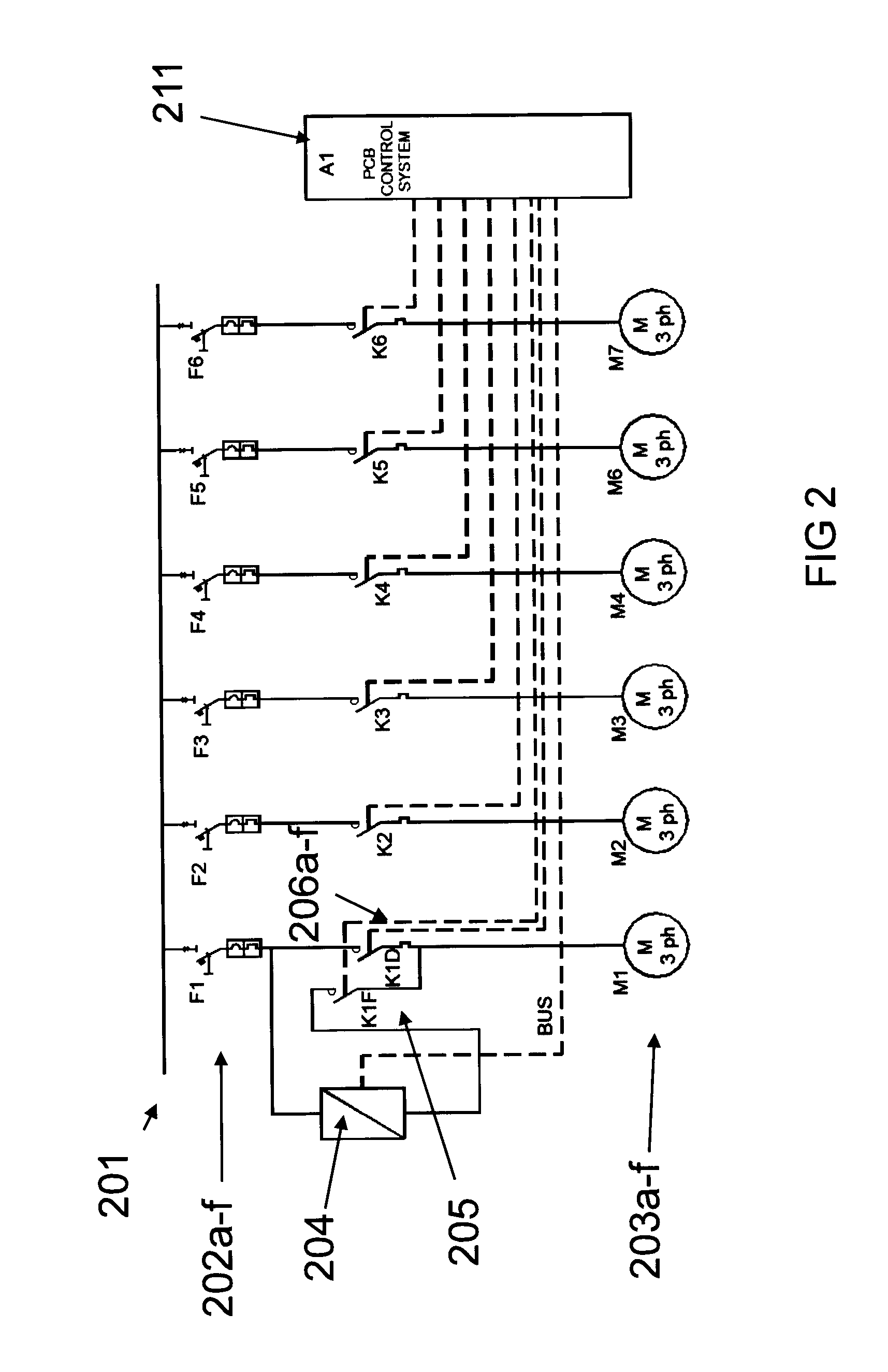

Control of the Electric Motors of a Pump Unit of a Fire Protection System

ActiveUS20130228345A1Minimizing the starting-current peaks of the electric motorsCost-effective constructionFluid parameterMotor parameterFrequency changerAC motor

Control method and control apparatus of the electric motors of a pump unit of a fire protection system, which fire protection system comprises spray nozzles (112), a pump unit, a control system with pressure-measuring means, and piping (105) for conducting extinguishing medium from the pump unit to the spray nozzles, which pump unit comprises pump drives, each of which comprises a pump (101) and an AC electric motor (102, 203a-203f) rotating it, which AC motor can be connected to an AC electricity network via a contactor device (206a-f), in which pump unit the AC electric motors are controlled on the basis of the pressure to be measured in the piping, and in which one of the electric motors (102, 203a-203f) at a time is controlled by means of a frequency converter (108, 204) such that the motor to be controlled with the frequency converter operates as a motor that under the control of the frequency converter steplessly adjusts pressure and the others are started up into the network as steplessly adjusting motors.

Owner:MARIOFF CORP OY

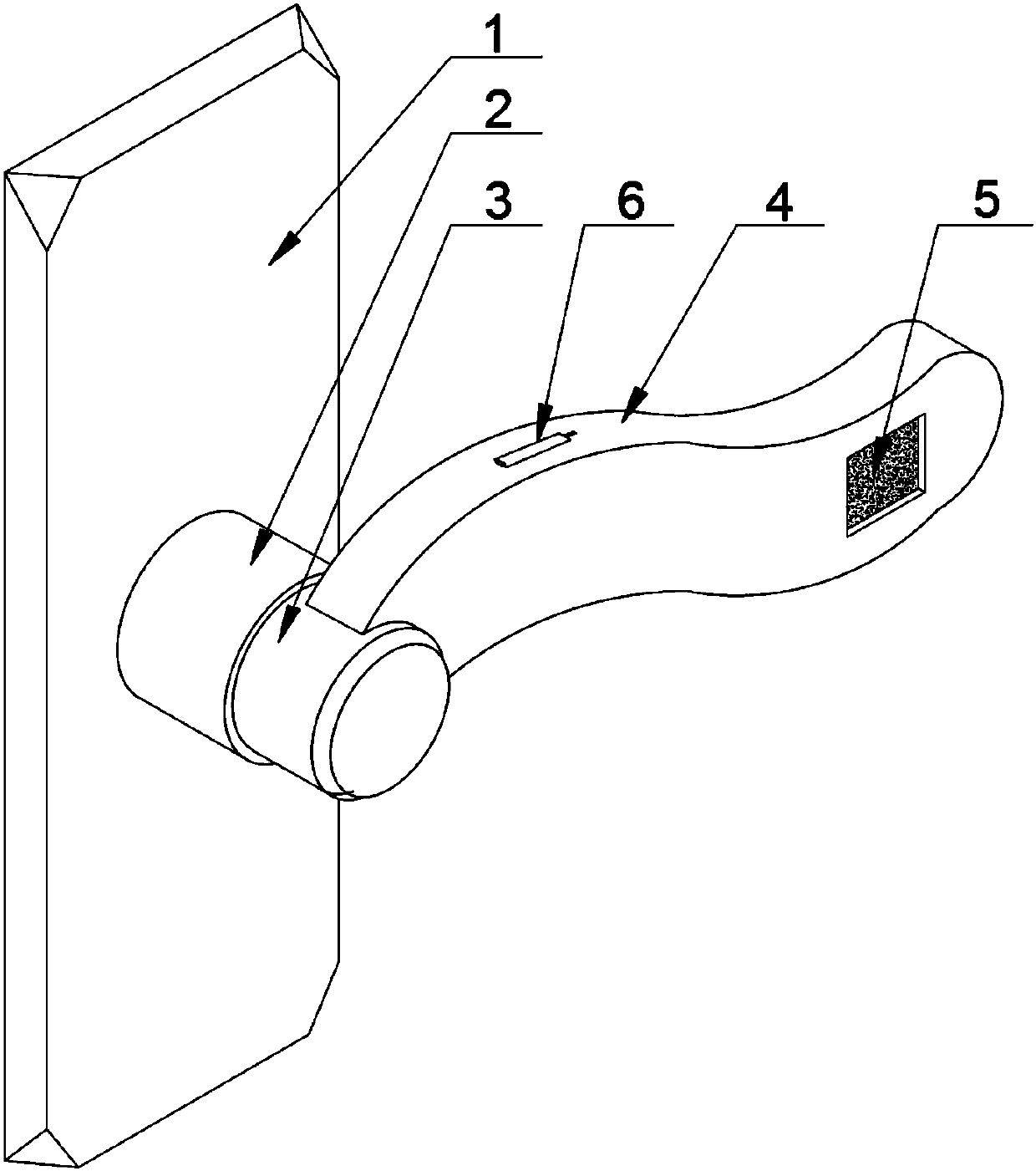

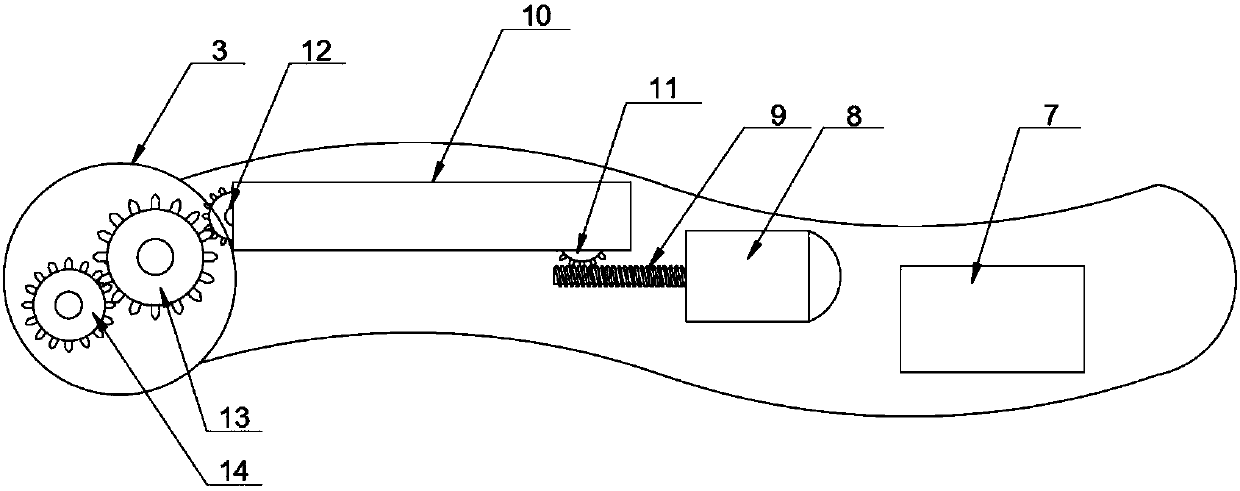

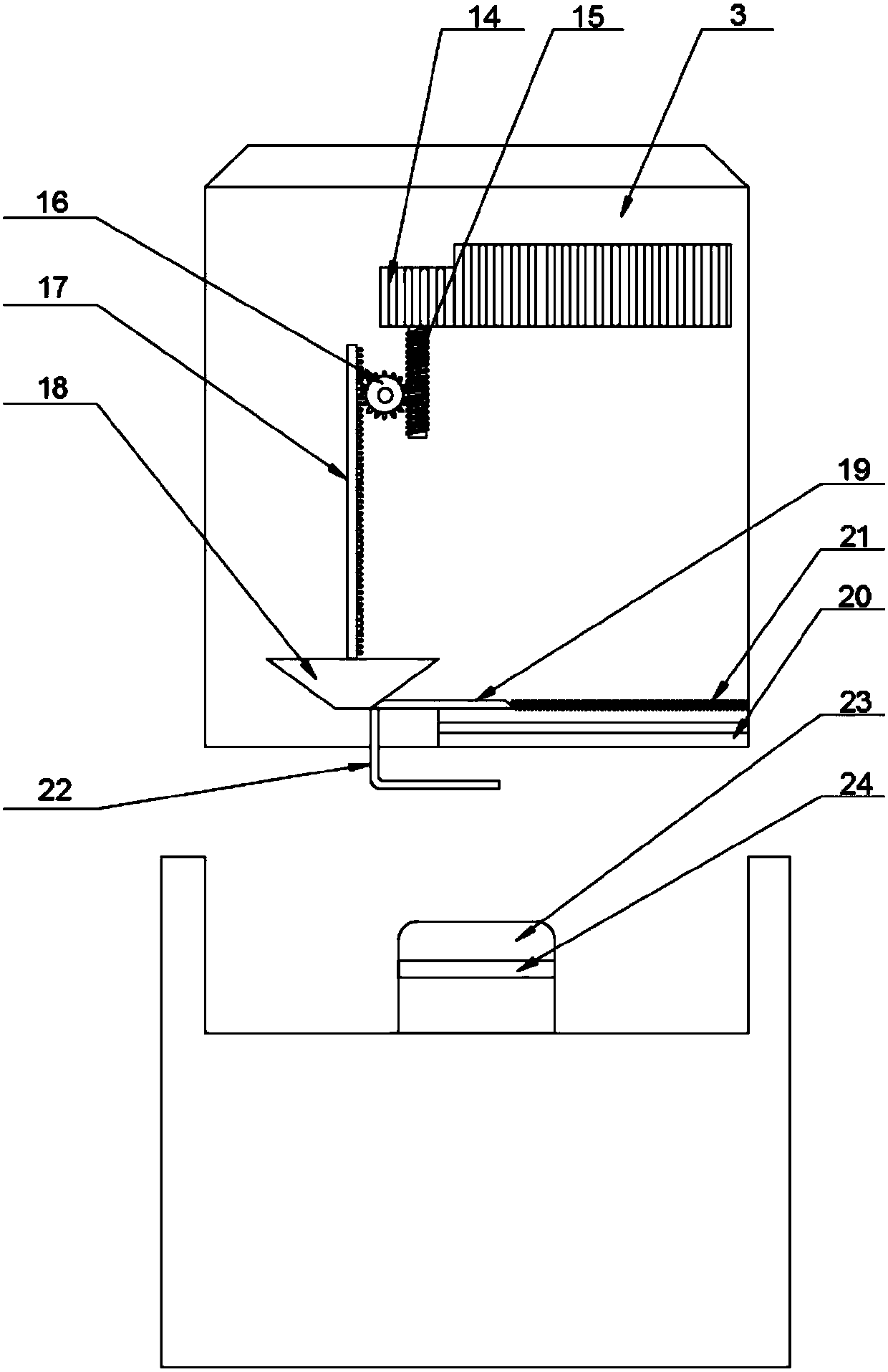

Handle and handle head connection method of intelligent door lock

PendingCN107675943AAvoid enteringAccurate identificationElectric permutation locksIndividual entry/exit registersGear wheelReduction drive

The invention discloses a method for connecting handles and handles of an intelligent door lock, which comprises an outer panel, a handle is fixed on the surface of the outer panel, one end of the handle is provided with a handle connecting part, and one side of the handle connecting part is There is a fixed handle, and a circuit board is arranged inside the handle, and a motor is arranged on one side of the circuit board. The first gear meshes with the first lead screw, the reducer meshes with the third gear in the connection part of the handle through the second gear, the third gear meshes with the fourth gear on one side, and the bottom end of the fourth gear is coaxially fixed with a The second lead screw, the second lead screw meshes with the fifth gear on one side, and the fifth gear meshes with the rack on one side. The invention ensures the accuracy of unlocking and prevents others from entering the door, and the mechanical principle is simple. The manufacturing process saves time and labor, and the cost is not high, and has good market competitiveness.

Owner:陈佳

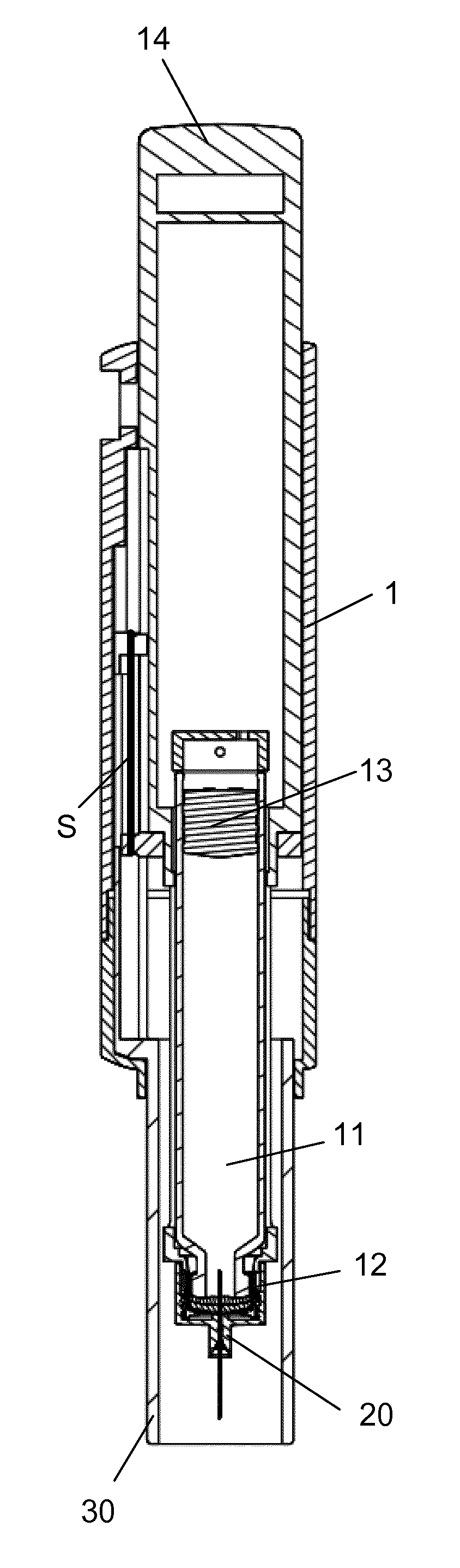

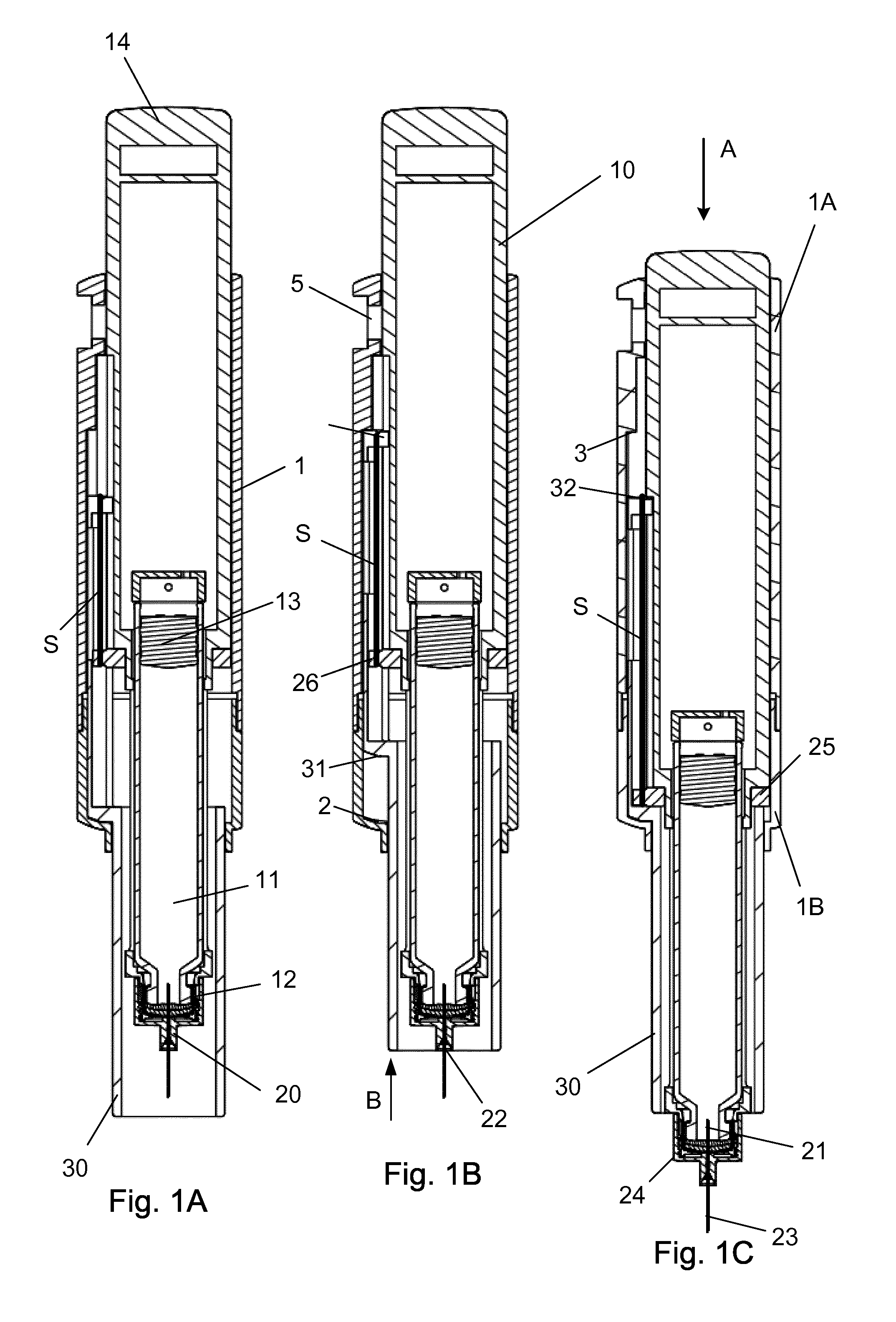

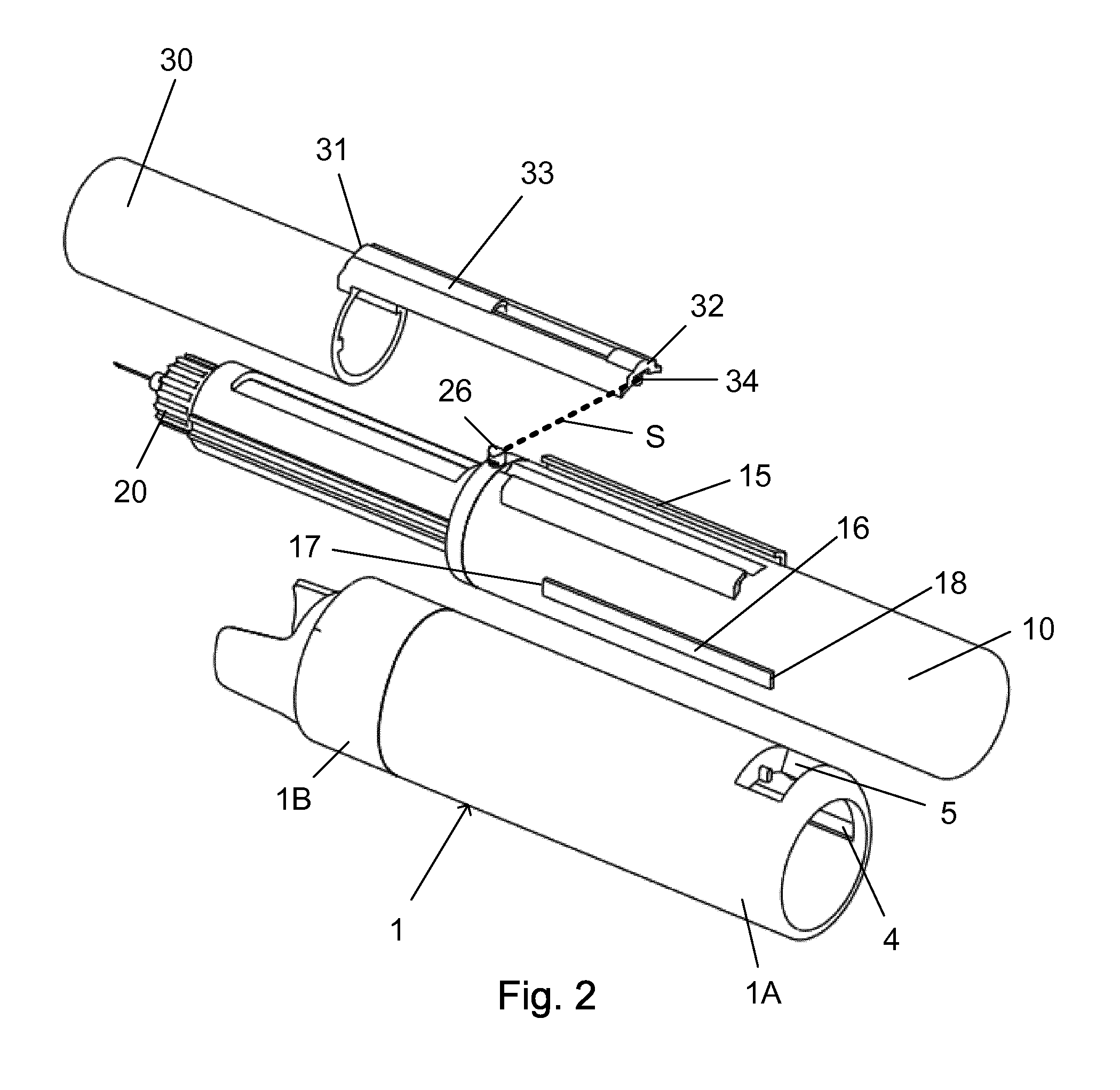

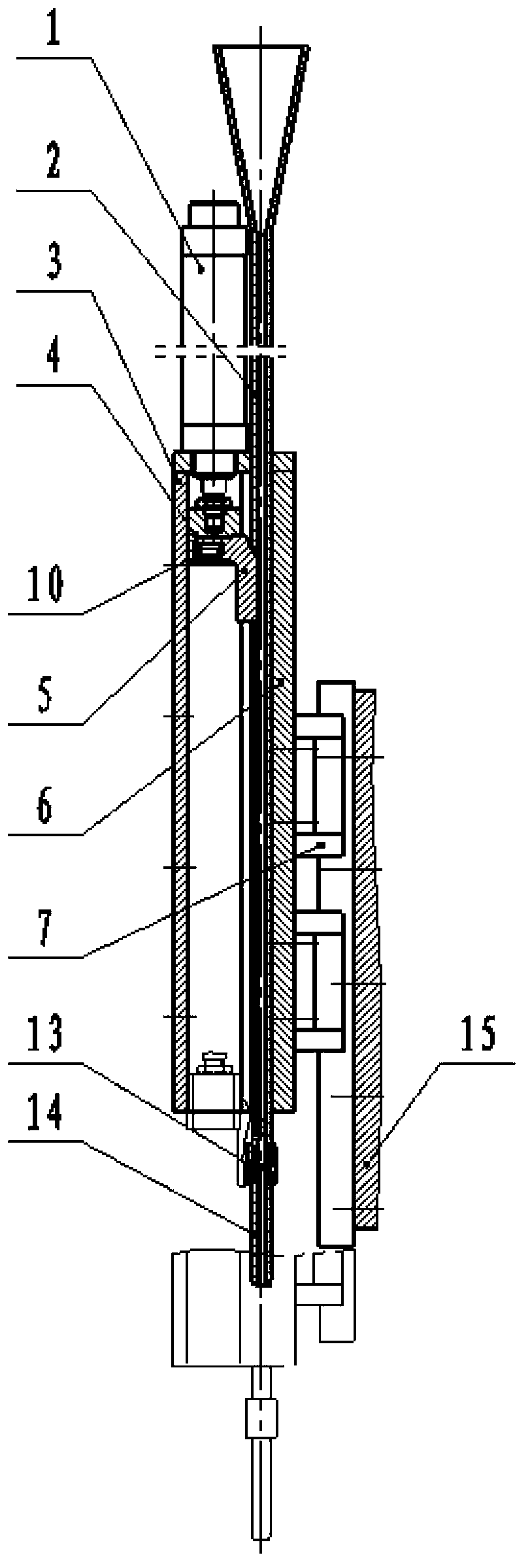

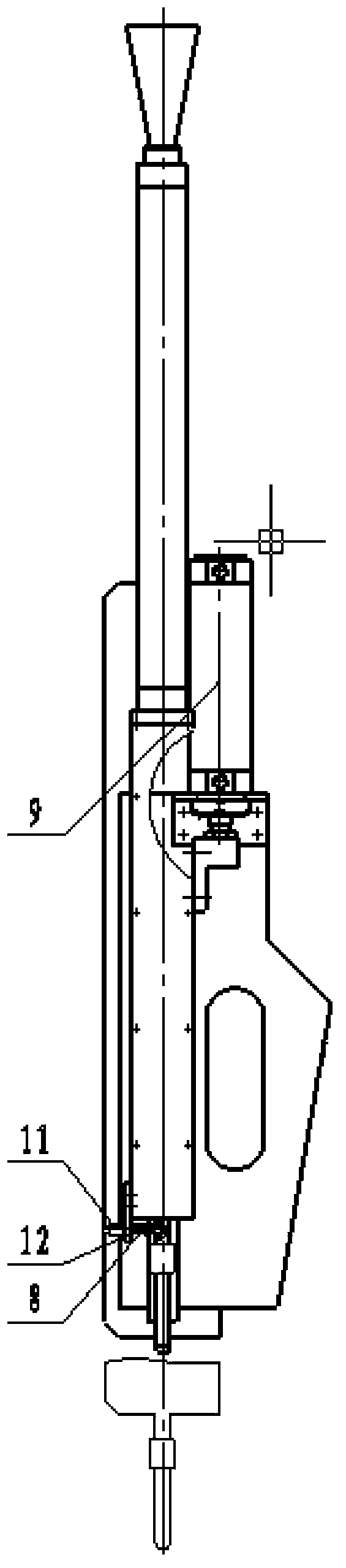

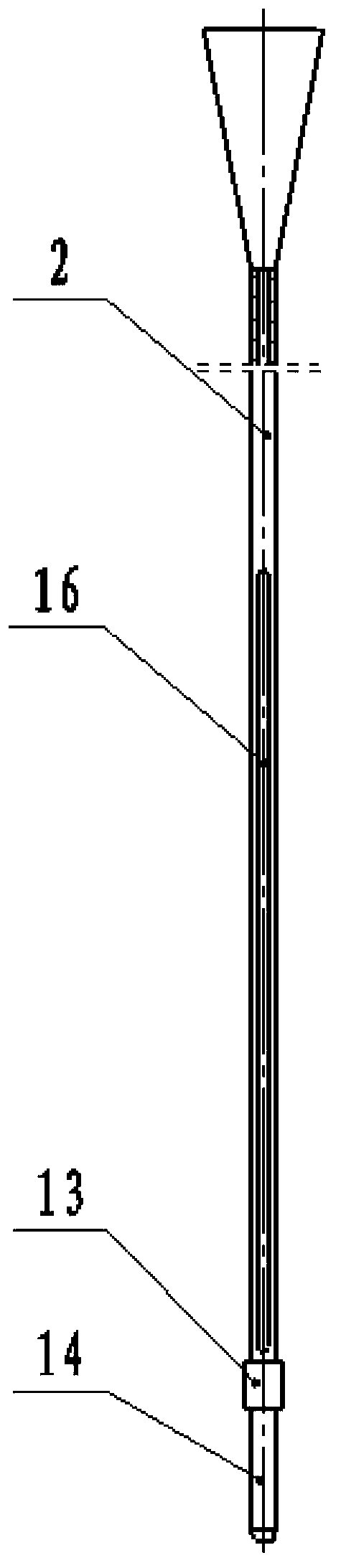

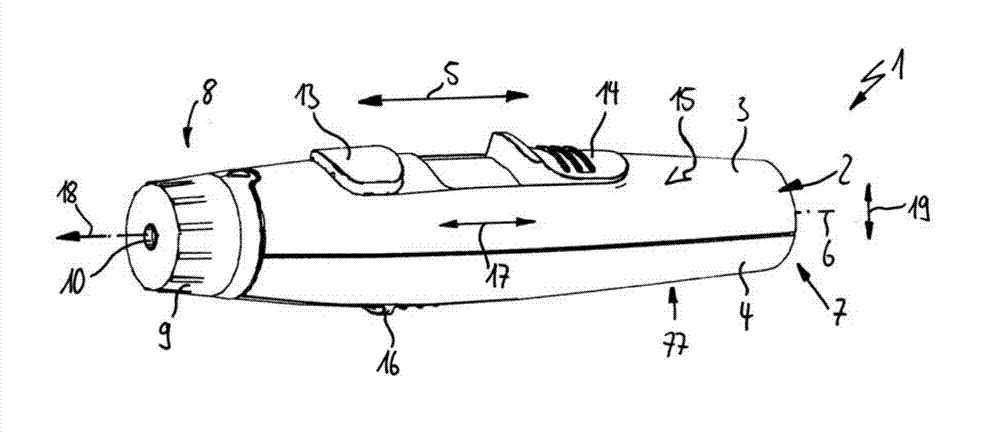

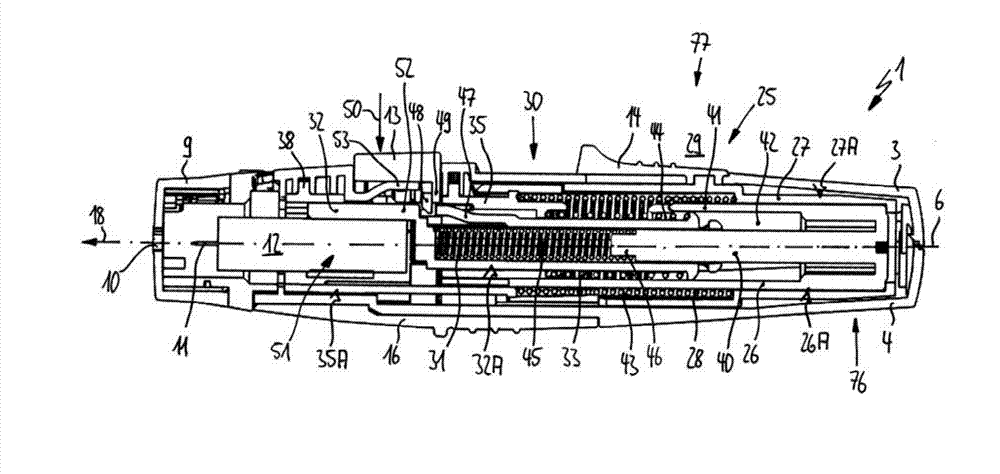

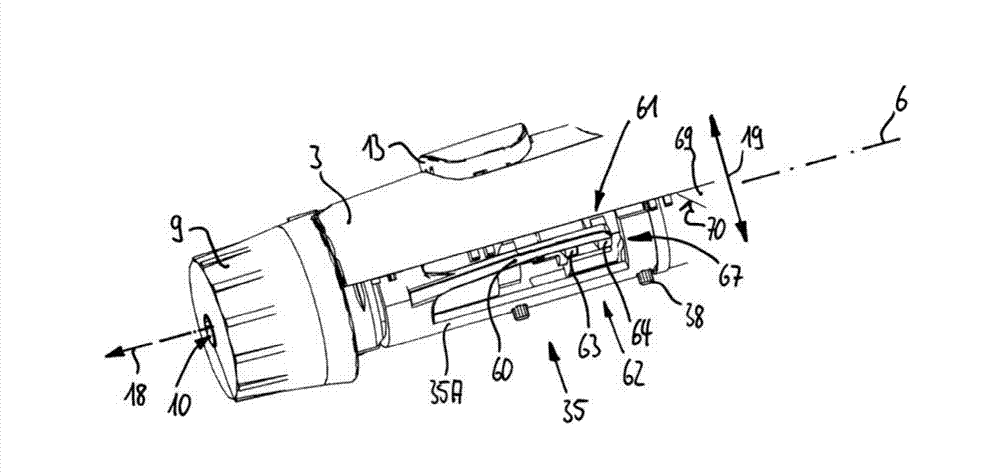

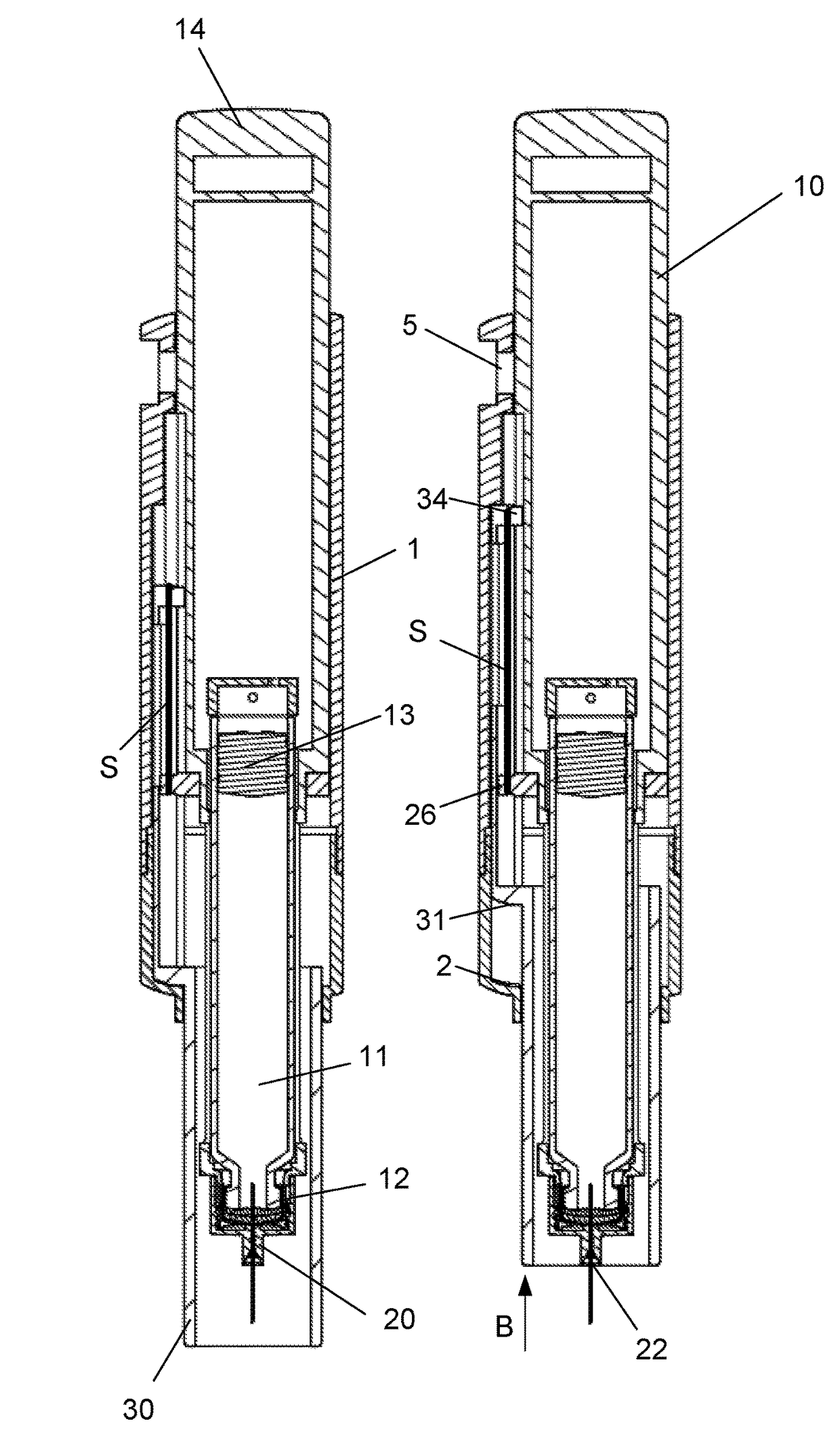

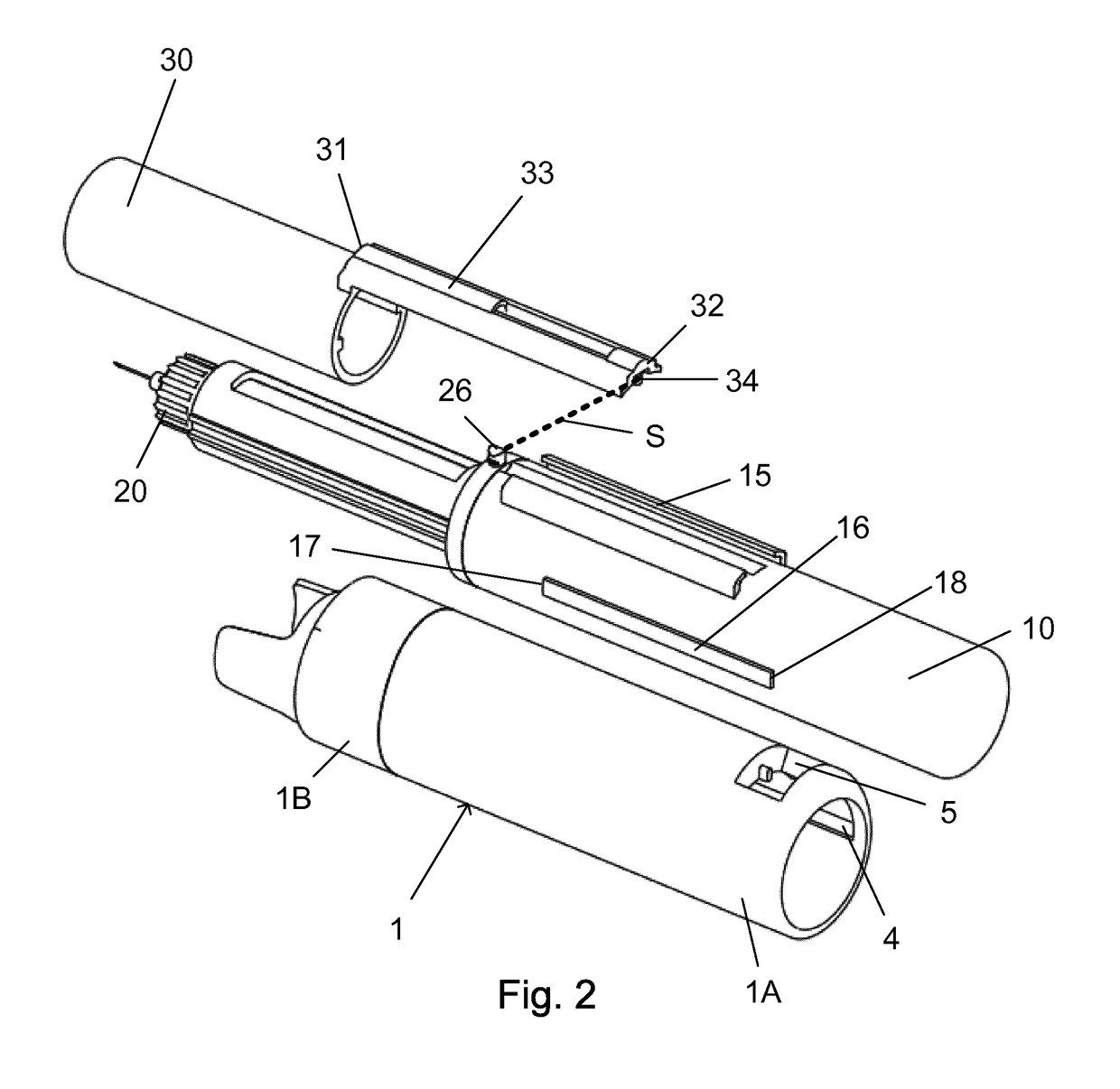

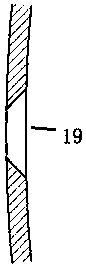

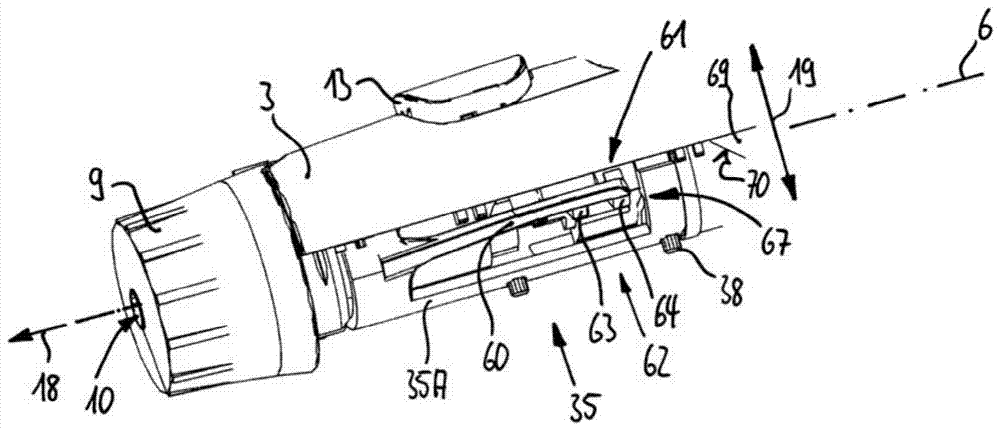

Injection Device with Integrated Needle Shield

InactiveUS20150320939A1Easy to changeSimple mechanicsAutomatic syringesInfusion needlesEngineeringBiomedical engineering

The invention relates to injection device, which device comprises an outer housing (1), a syringe body (10) and a needle shield (30). Both the syringe body (10) and the needle shield (30) are telescopically movable mounted to the housing (1) such that the needle shield (30) is movable relatively to the housing (1) between a first position and a second position, and the syringe body (10) is movable in relation to the housing (1) between an extended position and a retracted position.

Owner:NOVO NORDISK AS

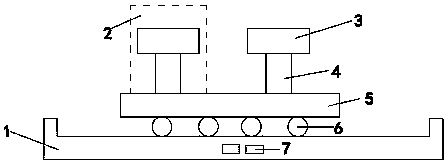

Clamping device for plate cutting

InactiveCN107971780ASimple mechanicsSave human effortPositioning apparatusMetal-working holdersCircular discElectric machinery

The invention discloses a clamping device for plate cutting. The clamping device comprises a base. Rectangular openings are machined in the two ends of the upper surface of the outer portion of the base correspondingly, a set of clamping blocks capable of moving in each rectangular opening is movably installed in the rectangular opening in an embedded mode, supports are fixedly welded to the positions, located below the rectangular openings, of the two ends of the lower surface of the interior of the base correspondingly, N-shaped frames are installed on the upper surfaces of the outer portions of the supports in a bolted mode correspondingly, and rotating motors are fixedly installed in the N-shaped frames correspondingly; circular openings are machined in cross beams of the N-shaped frames correspondingly, bearings are fixedly installed in the circular openings in an embedded mode correspondingly, circular discs are fixedly installed at the rotating ends of the rotating motors correspondingly, and cylinders are fixedly welded to the opposite tangent points of the circumferential faces of the circular discs correspondingly; and rotating rods are fixedly installed on the cylindersin a sleeving mode correspondingly, the other ends of the rotating rods are connected with the lower surfaces of the clamping blocks through hinge pins correspondingly, a controller is fixedly installed on one side of the base, and the controller is electrically connected with the set of rotating motors. The clamping device has the beneficial effects that the structure is simple, and the practicability is high.

Owner:陕西再造故乡文化发展有限公司

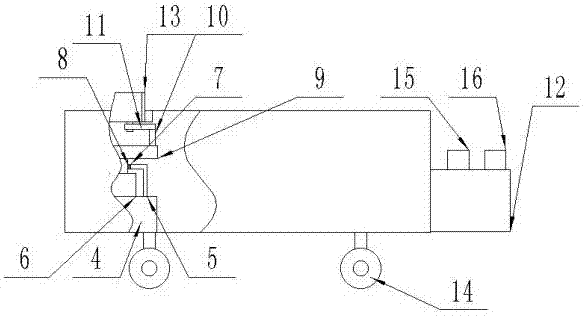

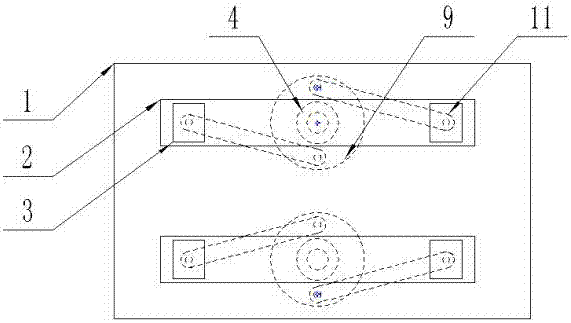

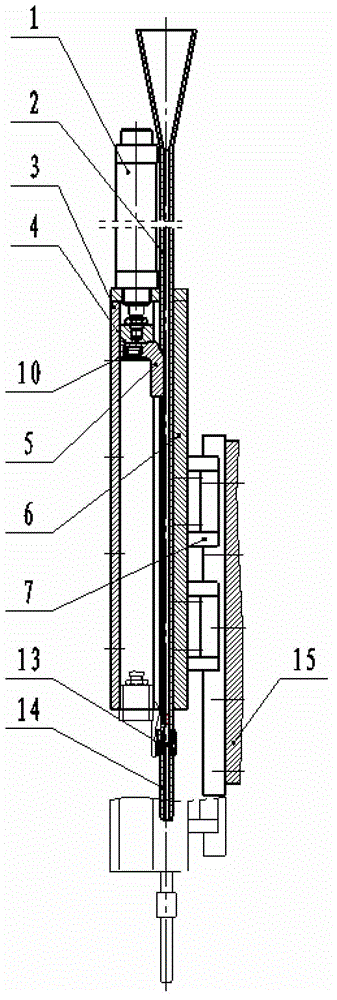

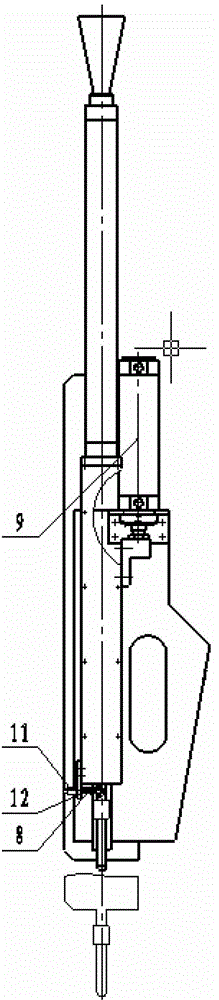

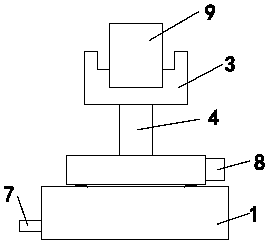

Mechanical and automatic wire inserting mechanism

ActiveCN103358064ARealize mechanized production operationsSimple mechanicsWelding/cutting auxillary devicesAuxillary welding devicesFixed frameGuide tube

The invention relates to a mechanical and automatic wire inserting mechanism, and belongs to the field of welding machinery or equipment. The mechanical and automatic wire inserting mechanism comprises a wire inserting air cylinder and a guide tube, parallelly arranged, a guide seat fixing the wire inserting air cylinder and the guide tube together and a guided plate playing a supporting role, wherein a guide sliding block is arranged on the inserting air cylinder; a push rod and a push rod spring are arranged on the guide sliding block; the guide sliding block carries out a reciprocating rectilinear motion along a sliding block guide groove in the guide seat under the drive of the wire inserting air cylinder to form a wire inserting unit; a displacement air cylinder is also arranged on the guide seat, and is connected with a fix frame of the whole equipment through a straight guide rail pair. The invention aims to the web bar wire inserting during the CL (composite light) net rack plate welding process, discloses a specially designed mechanical and automatic wire inserting mechanism and wire inserting method truncating the steel wire first then feeding wire one by one to weld, and can realize mechanized production operation of the CL net rack plate web bar wire inserting.

Owner:石家庄晶达建筑体系有限公司

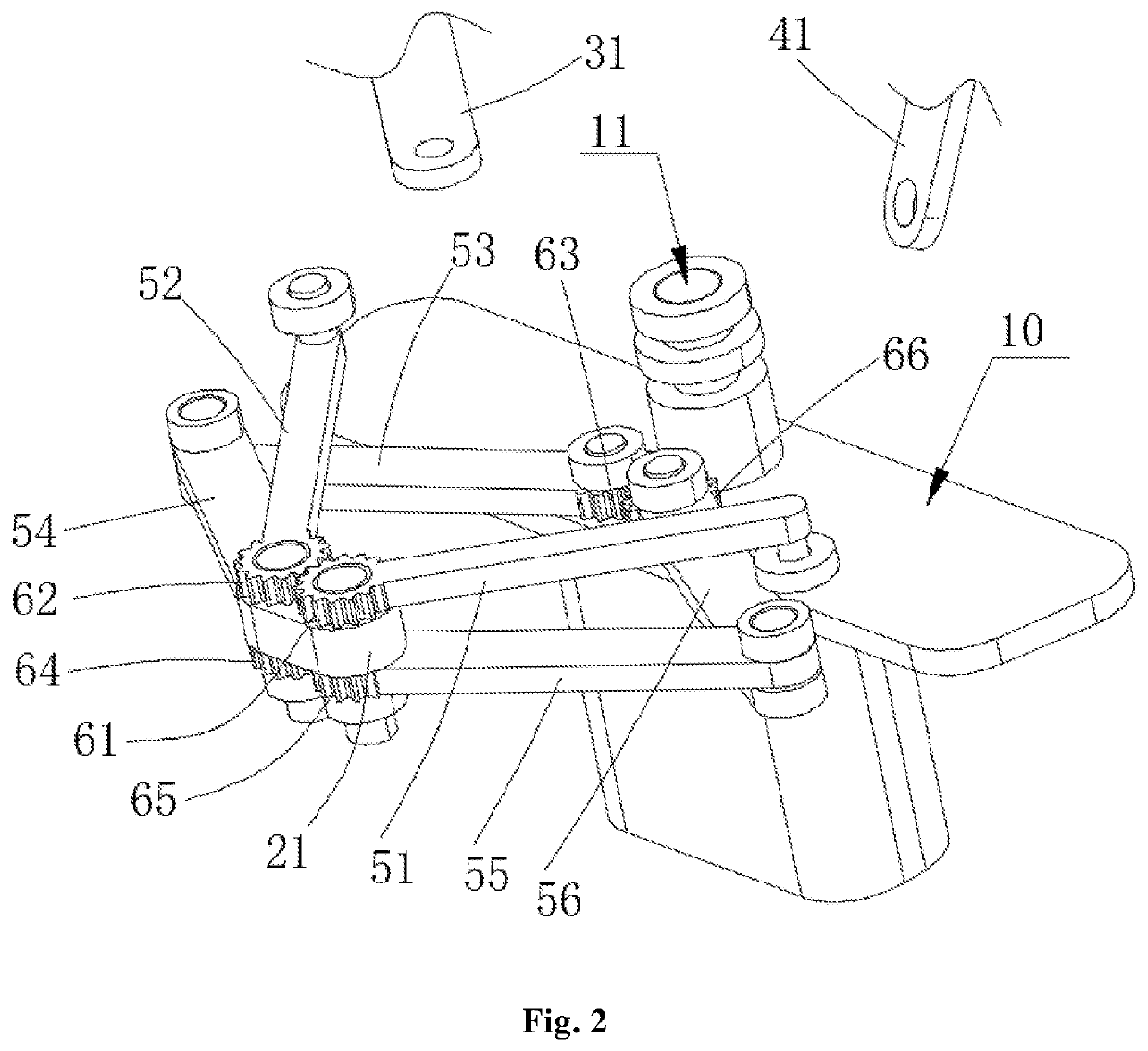

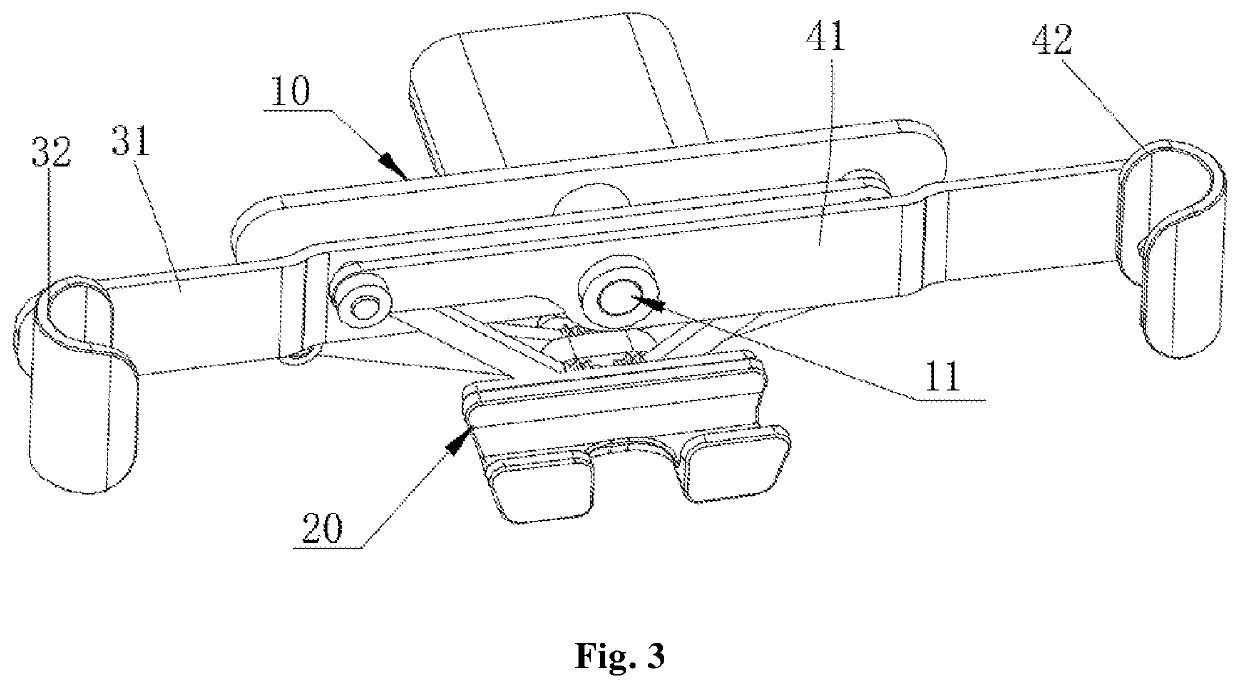

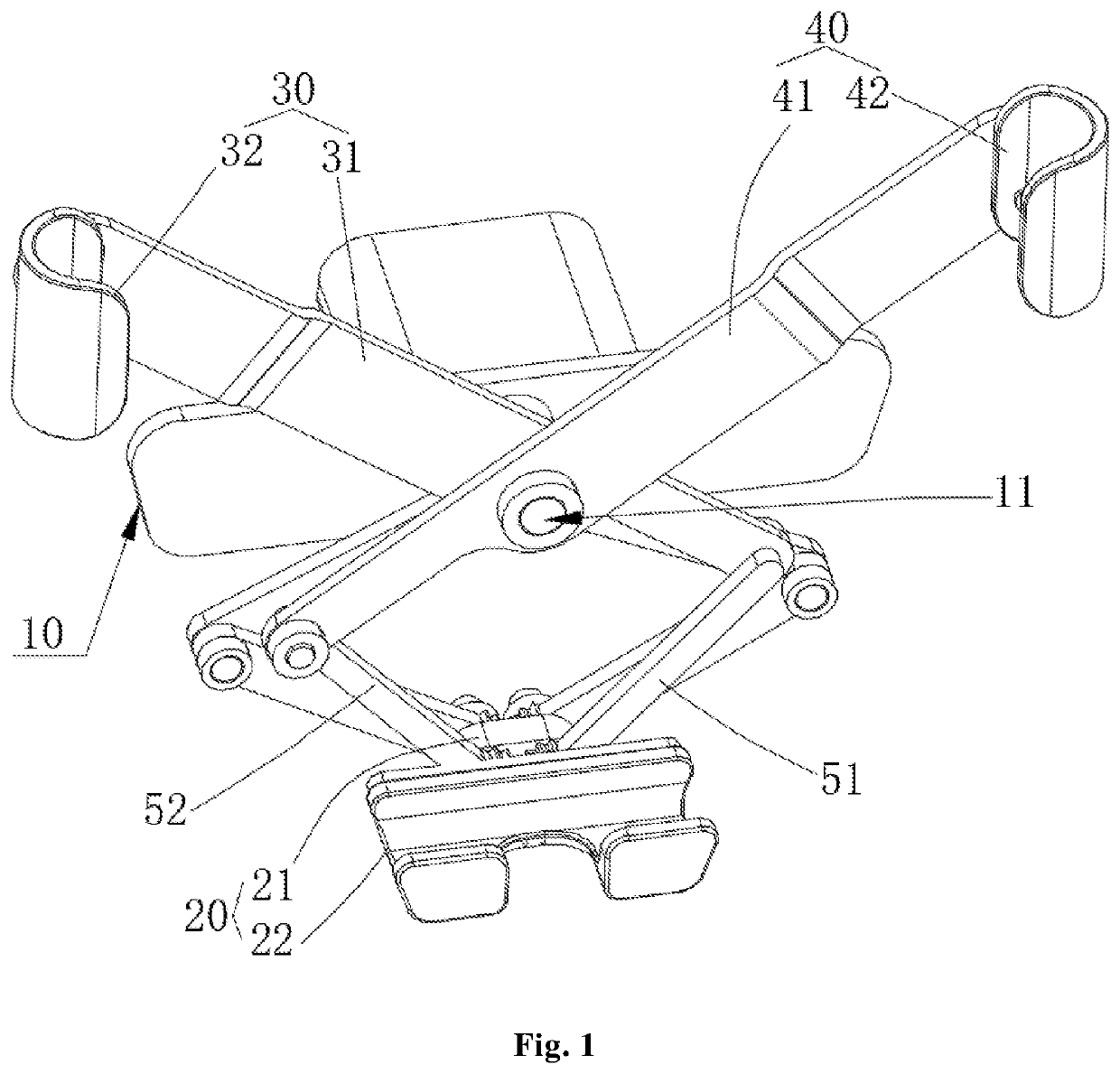

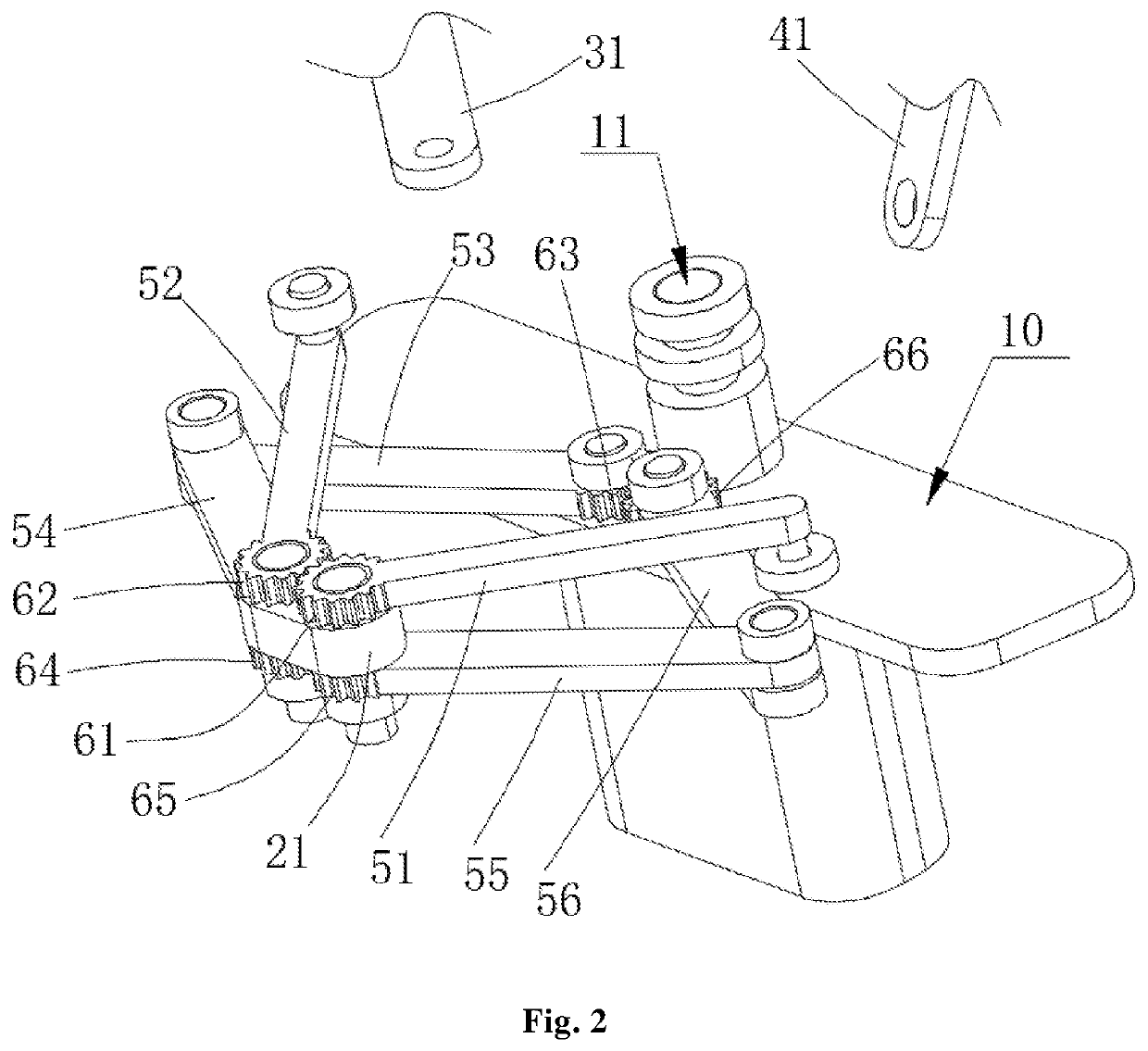

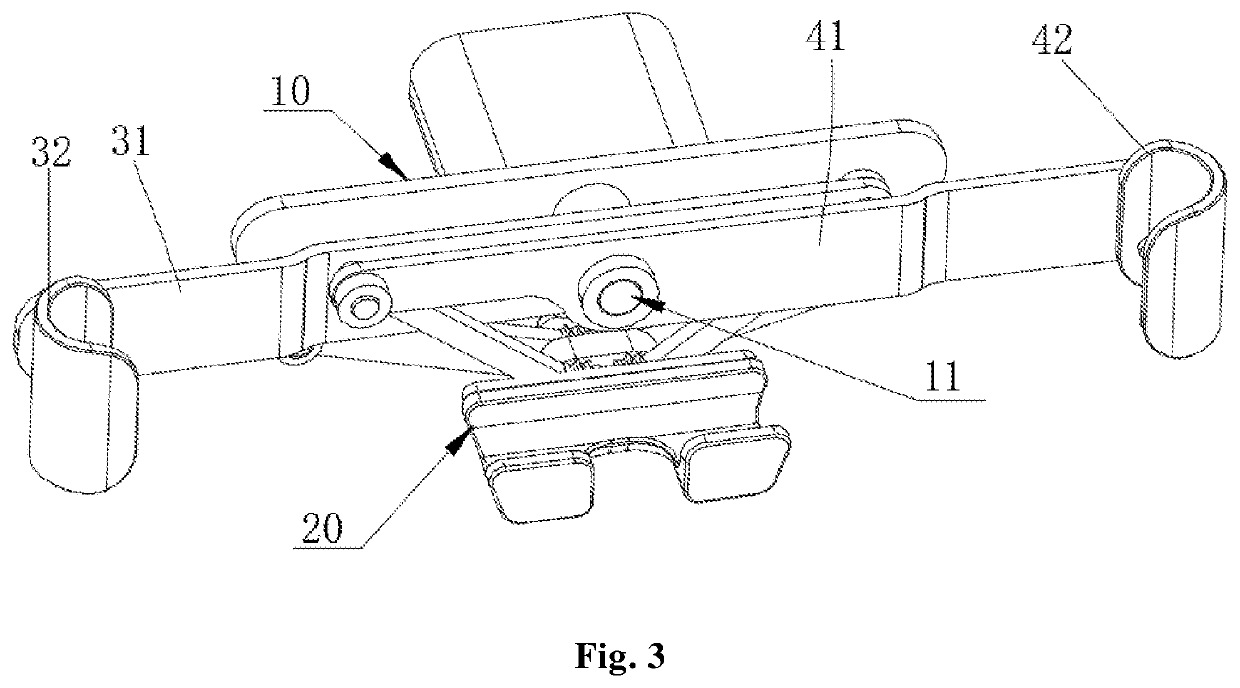

Phone gravity holder

ActiveUS20210367638A1Simple structureLow production costStands/trestlesTransmissionPhysical medicine and rehabilitationEngineering

A phone gravity holder comprises a base, a pull rod configured to hold the phone, and a left clamping arm and a right clamping arm configured to clamp the phone, wherein the base is provided with a positioning shaft, the left clamping arm and the right clamping arm are both mounted on the positioning shaft in a rotatable manner, and the pull rod is respectively in transmission connection with the left clamping arm and the right clamping arm, respectively. When the phone is used, the phone is directly placed on the pull rod, and under the gravity effect of the phone, the pull rod drives the left clamping arm and the right clamping arm to rotate in reverse to clamp the phone. The phone can be clamped automatically by utilizing the gravity of the phone and simple mechanical principles, the structure is simple, and the production cost is greatly reduced.

Owner:SHENZHEN DIVI ELECTRONICS CO LTD

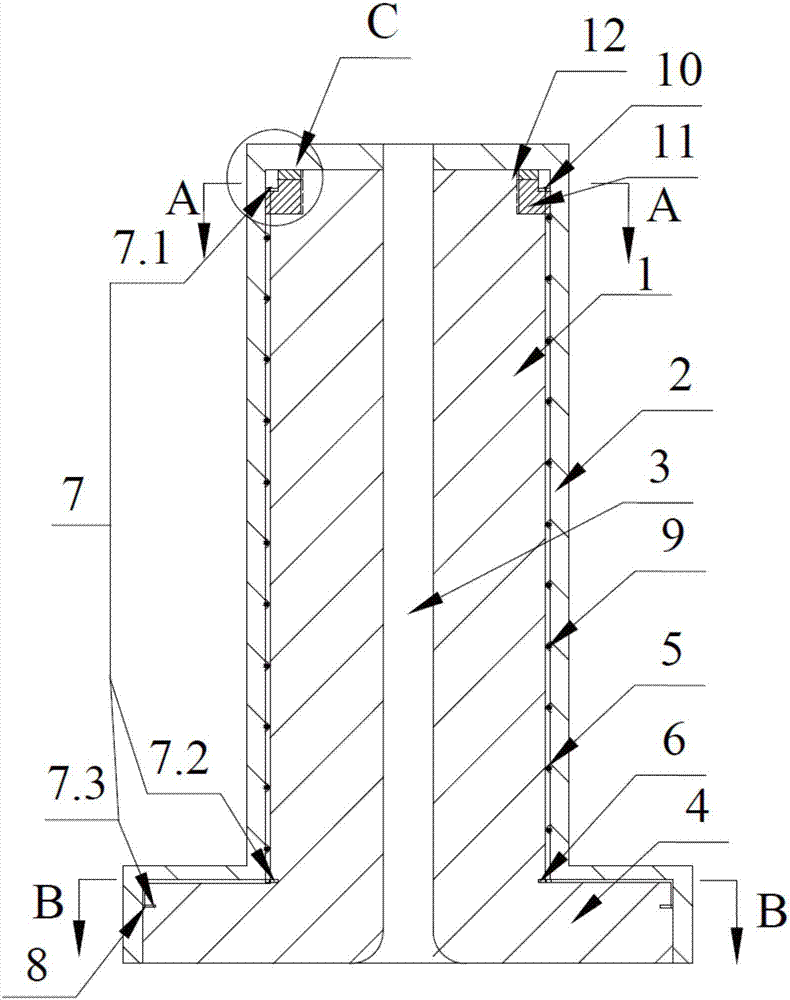

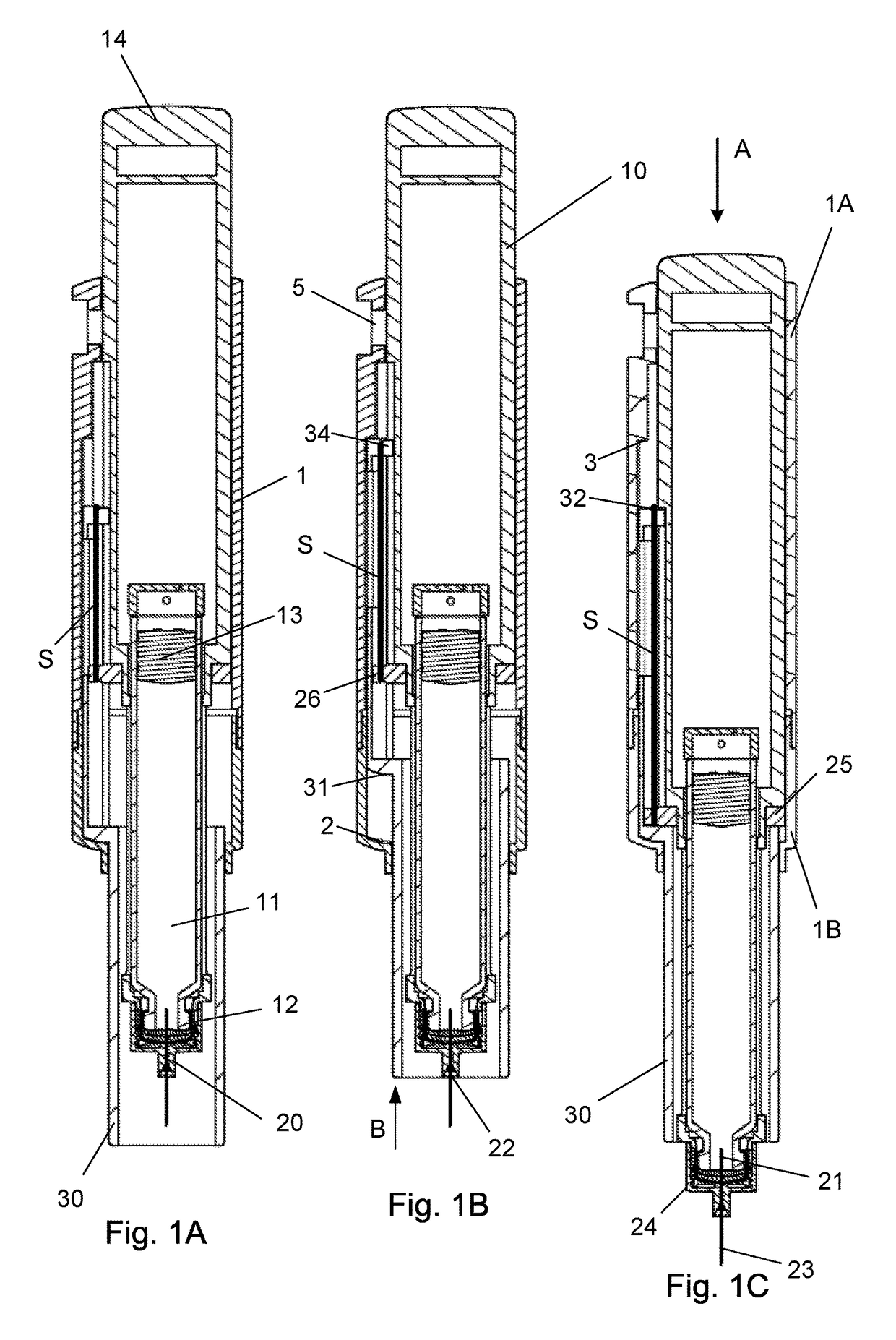

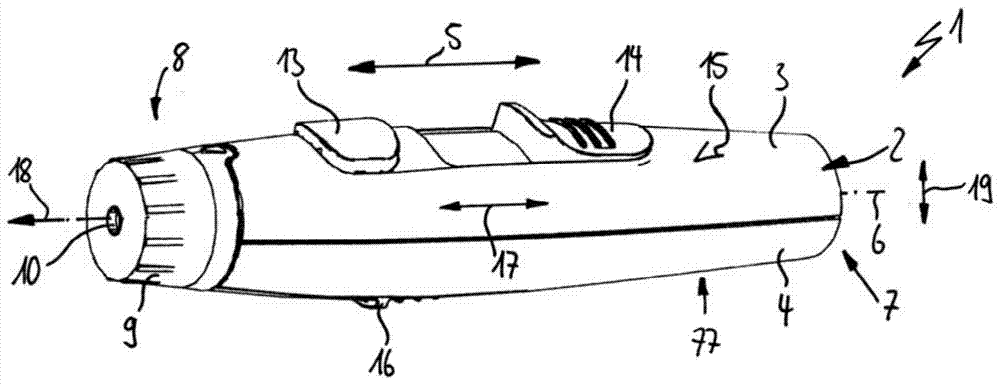

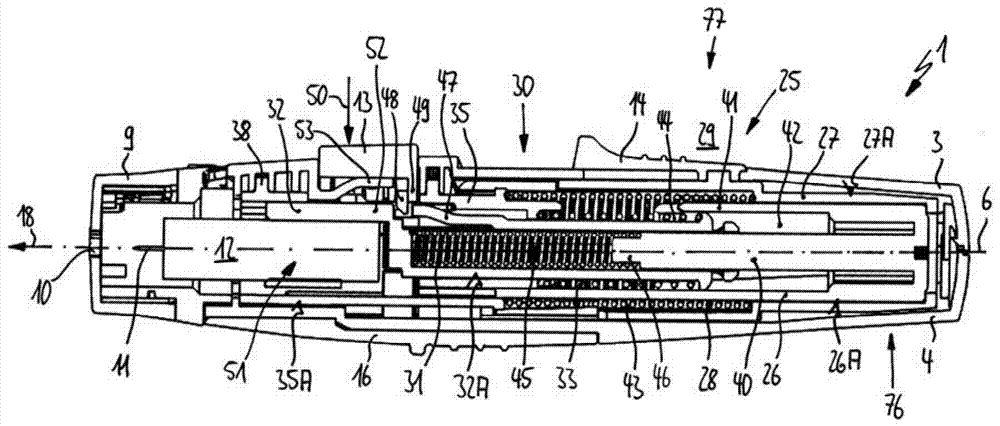

Lancing device for taking blood samples

ActiveCN103705251ASimplify mechanical designEasy to operateCatheterDiagnostic recording/measuringEngineeringLance device

Owner:GERRESHEIMER REGENSBURG GMBH

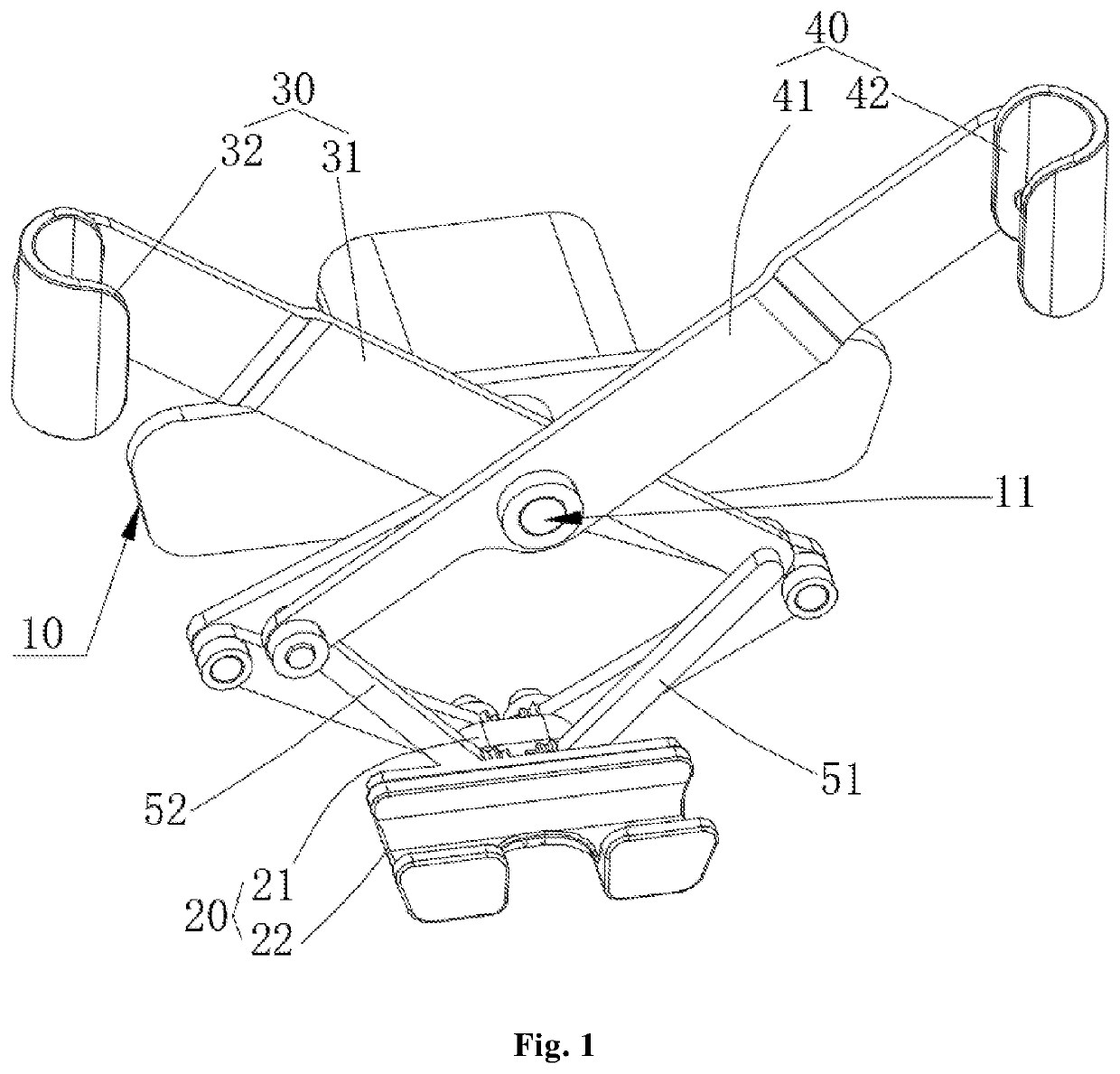

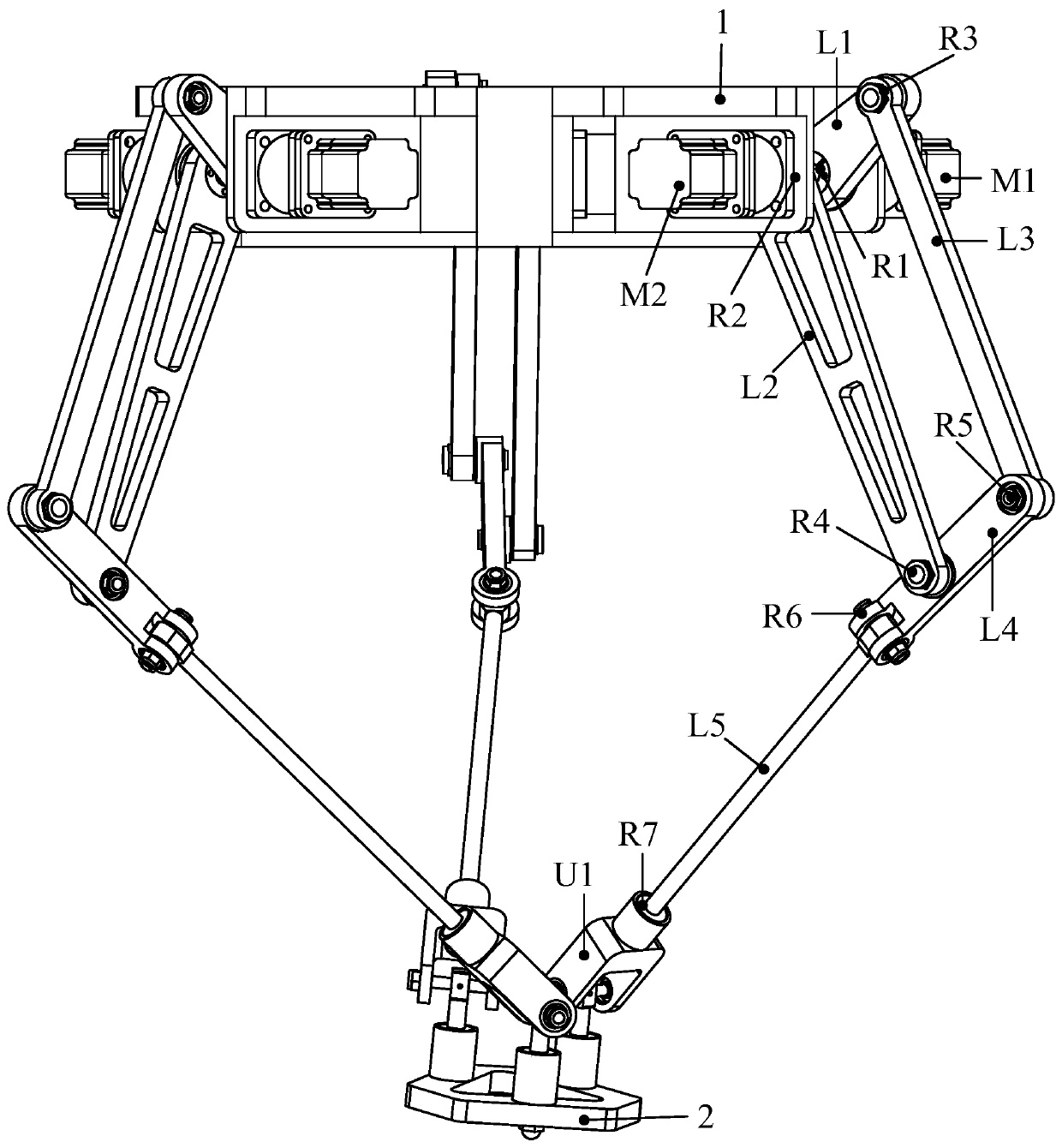

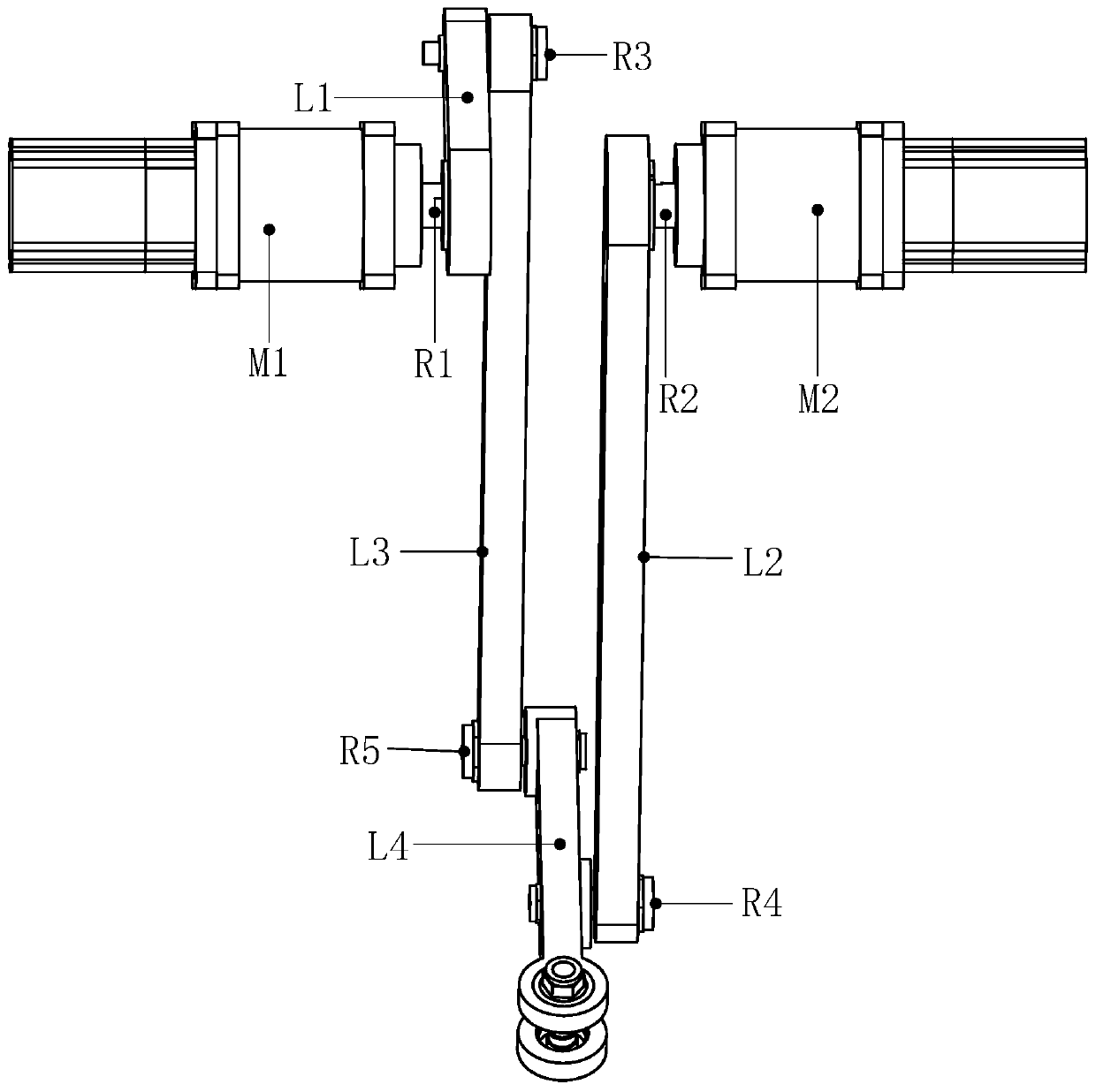

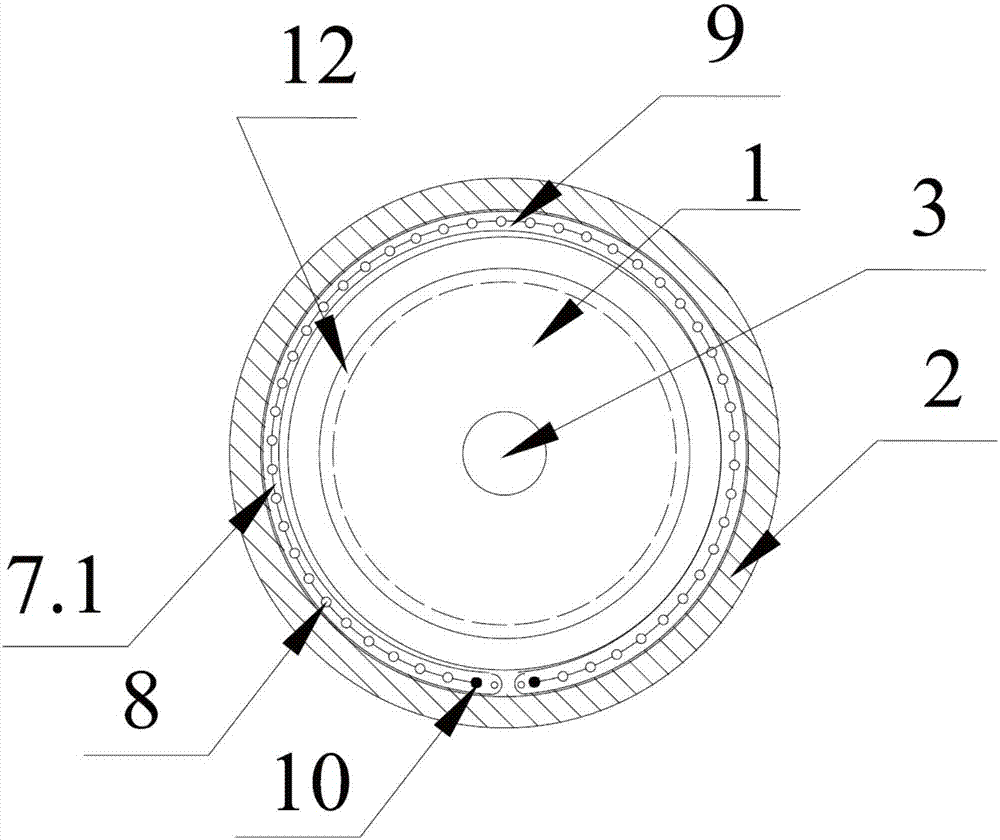

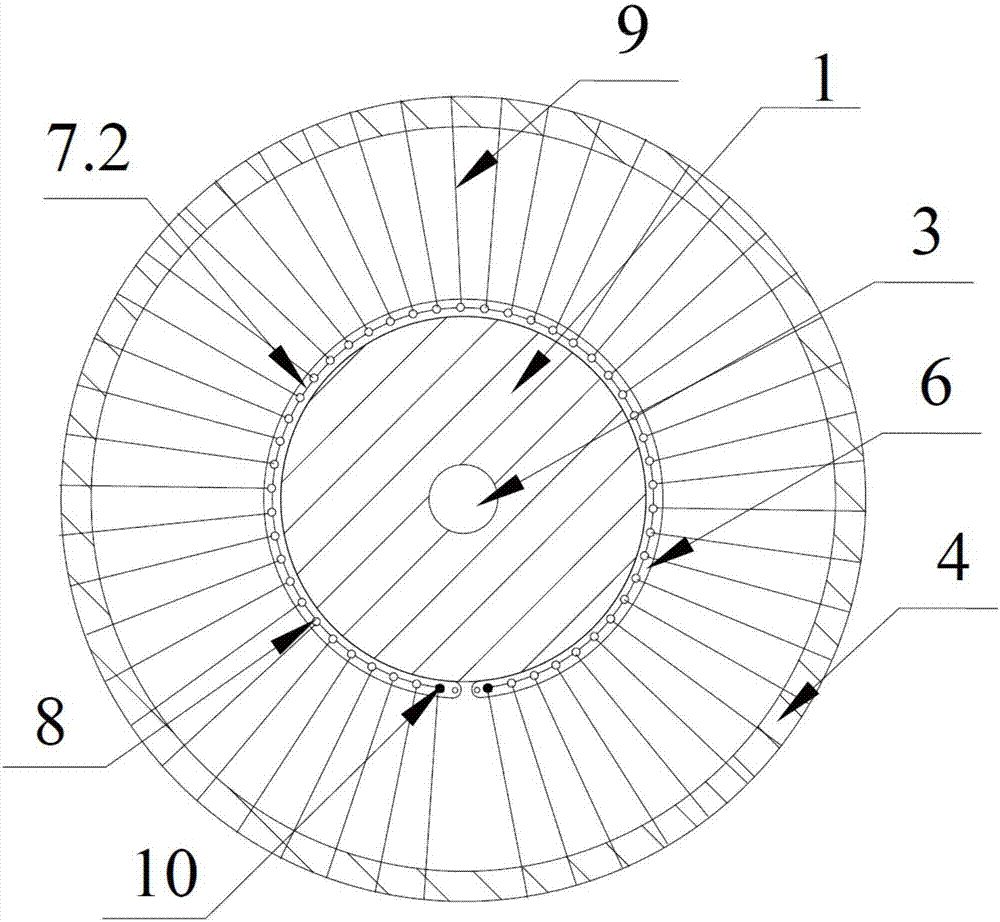

Parallel robot with large working space and low inertia

PendingCN110653800ALarge operating angleSimple KinematicsProgramme-controlled manipulatorJointsCouplingControl engineering

The invention discloses a parallel robot with a large working space and low inertia. The robot comprises a rack, a dynamic operation table, and three same branches connected between the rack and the dynamic operation table and uniformly and circumferentially distributed along a central axis of the rack, wherein each branch sequentially comprises a parallelogram coupling drive assembly, a sixth rotational joint assembly, a driven rod piece, a seventh rotational joint assembly and a universal hinge from the rack to the dynamic operation table. The parallel robot with the large working space andthe low inertia provided by the invention has the advantages that six drive motors are arranged on the rack and have no follow-up movement, and each branch is concise and compact in structure, so thatthe mechanism has the characteristics of low inertia, light weight, large working space, easiness in processing and manufacturing and the like, and has a favorable application prospect.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Wind power main shaft provided with strengthening layer and machining technology of wind power main shaft

The invention discloses a wind power main shaft provided with a strengthening layer. The wind power main shaft comprises a core shaft and a sleeve shaft; a carbon fiber die sleeve layer or a carbon fiber mesh layer is arranged between the core shaft and the sleeve shaft; the wind power main shaft is provided with an axial center hole; and a flange plate is arranged at one end of the wind power main shaft. A machining technology of the wind power main shaft comprises the steps that the core shaft and the sleeve shaft are machined according to designed sizes, an axial groove or a spiral groove into which a carbon fiber is inserted and a spring expansion ring for being embedded into an annular groove are machined in the surface of the core shaft, a threading hole through which the carbon fiber is penetrated is machined in the spring expansion ring, the carbon fiber embedded into the groove generates pretightening force through an adjusting nut, the core shaft embedded with the carbon fiber is put in a refrigeration warehouse for refrigeration, the sleeve shaft is put in a heating furnace for heating, the refrigerated core shaft and the heated sleeve shaft are arranged in a sleeving manner, and after the sleeved wind power main shaft reaches the normal temperature, the wind power main shaft can be used for subsequent machining. With the adoption of the structure and the machining technology, the structural size of the wind power main shaft of a wind power generator can be reduced substantially, and the strength of the wind power main shaft can be improved.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Injection device with integrated needle shield

InactiveUS9649451B2Easy to changeSimple mechanicsAutomatic syringesInfusion needlesInjection deviceBiomedical engineering

The invention relates to injection device, which device comprises an outer housing (1), a syringe body (10) and a needle shield (30). Both the syringe body (10) and the needle shield (30) are telescopically movable mounted to the housing (1) such that the needle shield (30) is movable relatively to the housing (1) between a first position and a second position, and the syringe body (10) is movable in relation to the housing (1) between an extended position and a retracted position.

Owner:NOVO NORDISK AS

Phone gravity holder

ActiveUS11349517B2Simple mechanicsSimple structureStands/trestlesTransmissionPhysical medicine and rehabilitationEngineering

Owner:SHENZHEN DIVI ELECTRONICS CO LTD

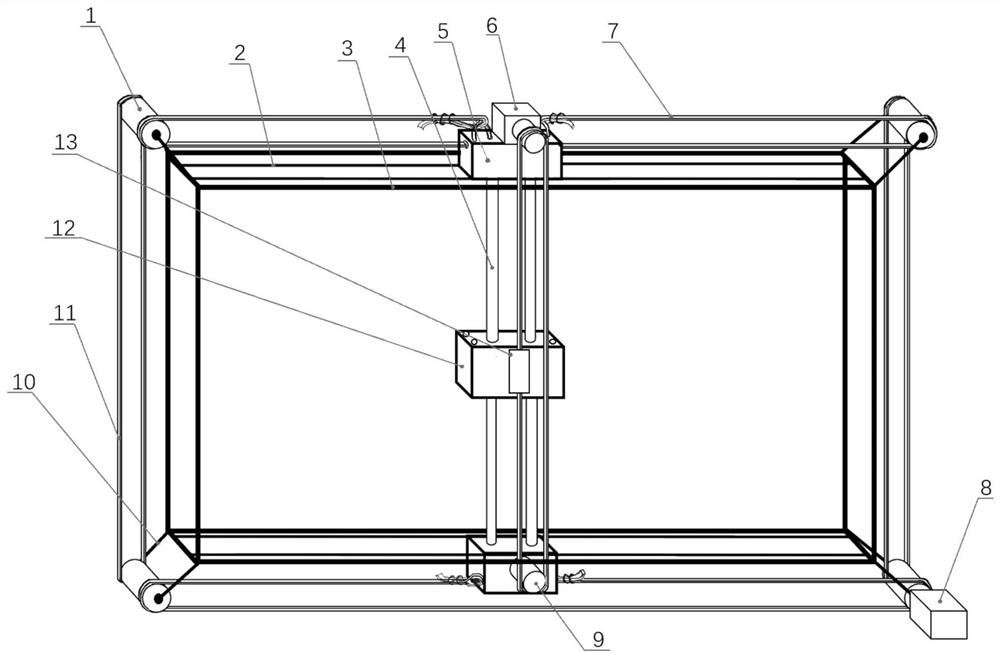

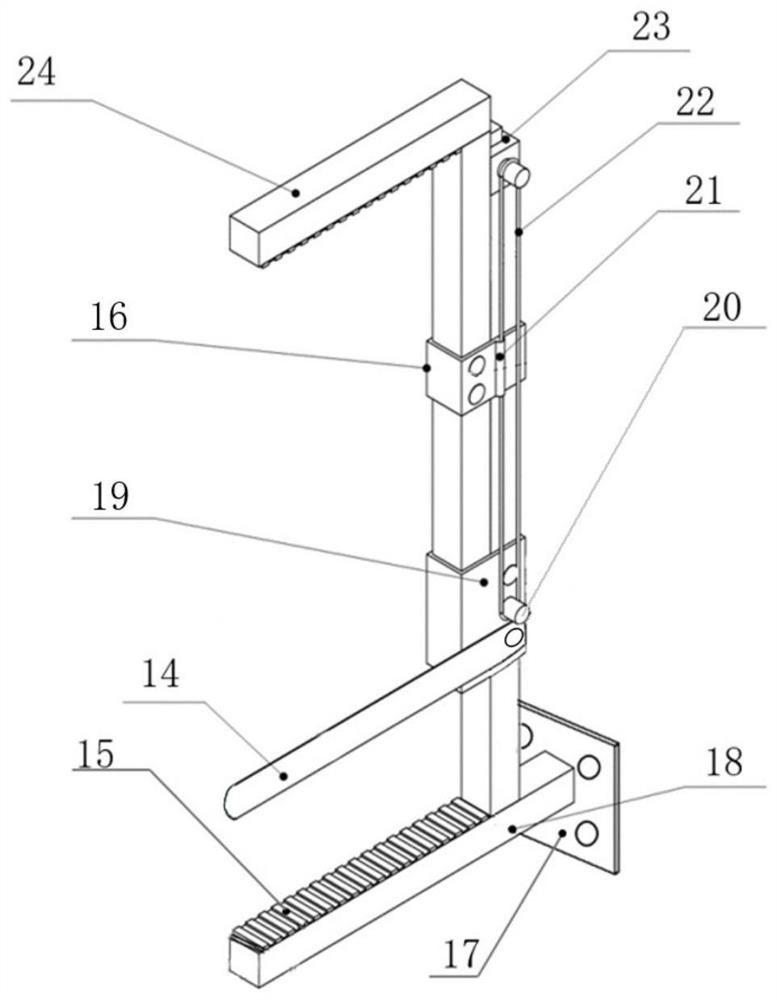

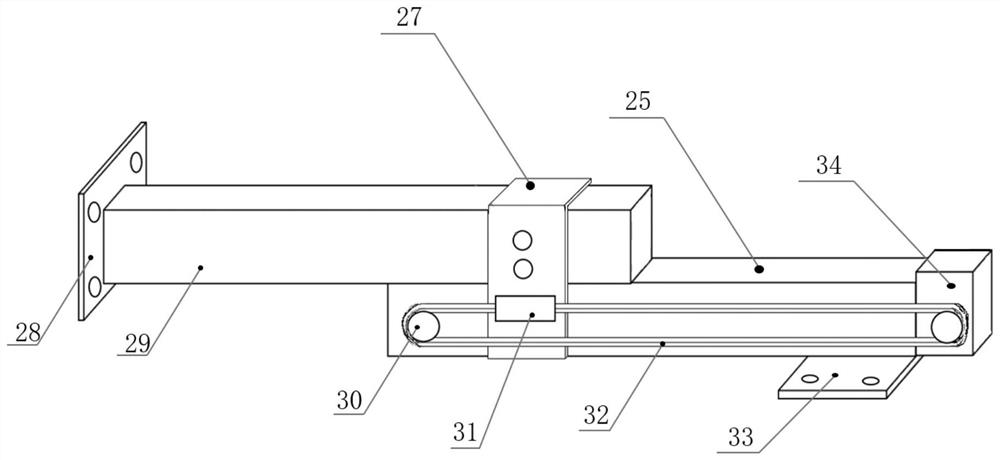

Automatic book taking and returning manipulator device for intelligent bookshelf

The invention discloses an automatic book taking and returning manipulator device for an intelligent bookshelf. The automatic book taking and returning manipulator device comprises a manipulator moving device, a manipulator grabbing device and a manipulator telescopic device, wherein the manipulator moving device comprises a support frame; the upper end surface and lower end surface of the outer side of the support frame are respectively and fixedly connected with a transverse guide rail; each transverse guide rail is slidably connected with a transverse sliding block; vertical optical axis guide rails are fixedly connected between the transverse sliding blocks; a vertical sliding block is slidably connected on the vertical optical axis guide rails; the manipulator grabbing device comprises an upper frame and a lower frame; a sliding rod of the upper frame is slidably connected with a sliding rod of the lower frame through a first metal sleeve and a second metal sleeve; the manipulatortelescopic device comprises a first sliding rod and a second sliding rod; the first sliding rod is slidably connected with the second sliding rod through a third metal sleeve; and the third metal sleeve is fixedly connected with the second sliding rod. The automatic book taking and returning manipulator device is low in manufacturing cost, high in reliability, stability and automation level, andcapable of providing the reliable mechanical device for the intelligent bookshelf.

Owner:NANHUA UNIV

A drawing type inertial friction welding method and device

ActiveCN107803583BImprove performanceSmall heat affected zoneNon-electric welding apparatusHeat-affected zoneEngineering

The invention belongs to the technical field of inertial friction welding, and particularly relates to a drawing type inertial friction welding method and device. The drawing type inertial friction welding method and device are suitable for welding of plates and bars and repairing of point-shaped defects. According to the technical scheme of the drawing type inertial friction welding method and device, a solid phase welding technology is adopted, base metal melting is not required, defects such as cracks and pores generated by fusion welding do not occur, the heat-affected zone of a joint is narrow, residual stress of repairing of a welding seam is low, welding deformation is small, and comprehensive performance of the joint is high; meanwhile, mechanical properties, the fatigue strength,the fracture toughness and the joint plasticity of the welding seam can further be improved; meanwhile, by adopting thinking of inertial friction welding, energy required by welding is provided by a main shaft and an inertia welding flywheel, welding heat input quantity is stable and consistent, and control parameters of a welding technology are less so that precise control of the parameters can be realized; therefore, the welding process is stable and reliable, stability of quality of the welding joint is good; and the mechanical principle of the device is simple, the energy utilization rateis high, and the welding process does not produce smoke, so that the green and environmentally friendly effects are achieved.

Owner:CAPITAL AEROSPACE MACHINERY +1

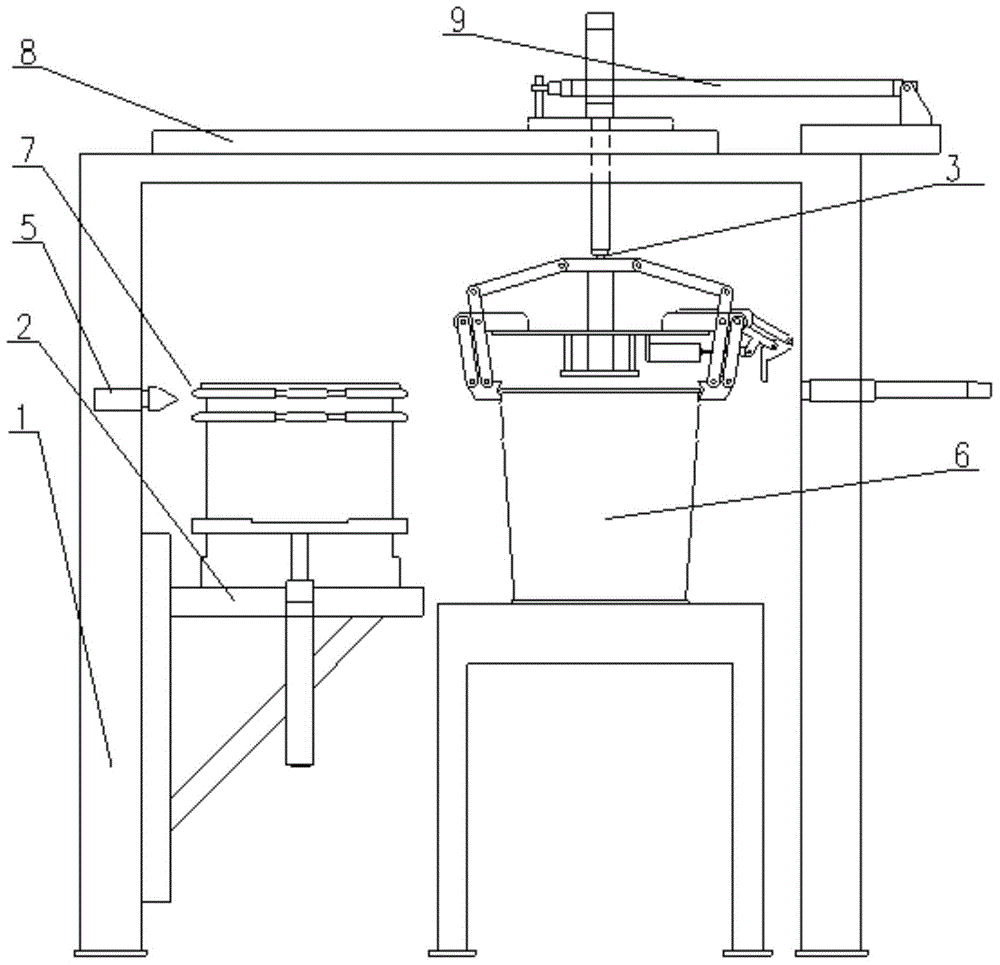

Packaging barrel automatic buckle device

ActiveCN103863615BReduce intensityEnsure safetyWrapper twisting/gatheringEngineeringMechanical engineering

The invention aims at providing an automatic hoop fastening device for a packaging barrel. In the device, a barrel hoop bank is fixedly arranged left below a rack through bolts, a guide rail is fixedly arranged at the top of the rack, and a barrel hoop clamping device is fixedly arranged on the guide rail and is driven to slide on the guide rail through an air cylinder; a hoop limiting device is installed on the left side of the rack and a barrel hoop locking device is arranged on the right side of the rack; the barrel hoop bank is used for providing barrel hoops for the device; the barrel hoop clamping device has two stations; the barrel hoop clamping device picks out the barrel hoops from the barrel hoop bank at a hoop picking station, is driven by the air cylinder to move to a hoop fastening station along the guide rail and places the barrel hoops onto material barrels on which the hoops are to be fastened; the hoop locking device fastens the barrel hoops to realize locking and sealing. The automatic hoop fastening device for the packaging barrel has the advantages that the occupied space is small, the action accuracy is high and the effect of long-time uninterrupted high-efficiency working can be realized.

Owner:BEIJING AEROSPACE PROPULSION INST

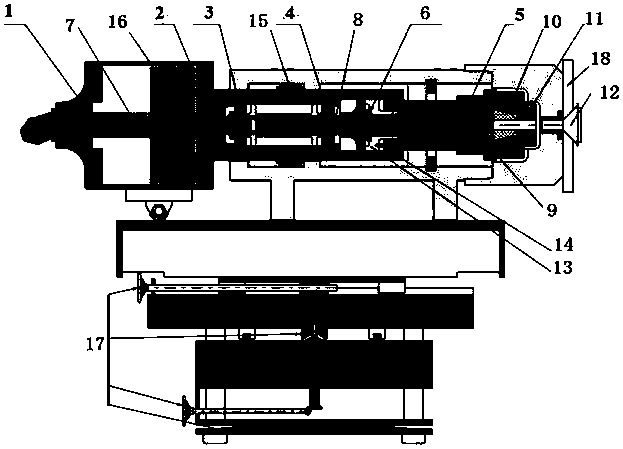

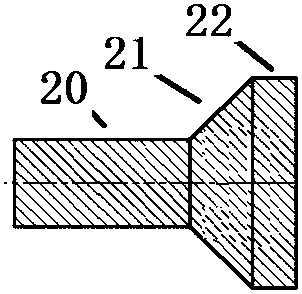

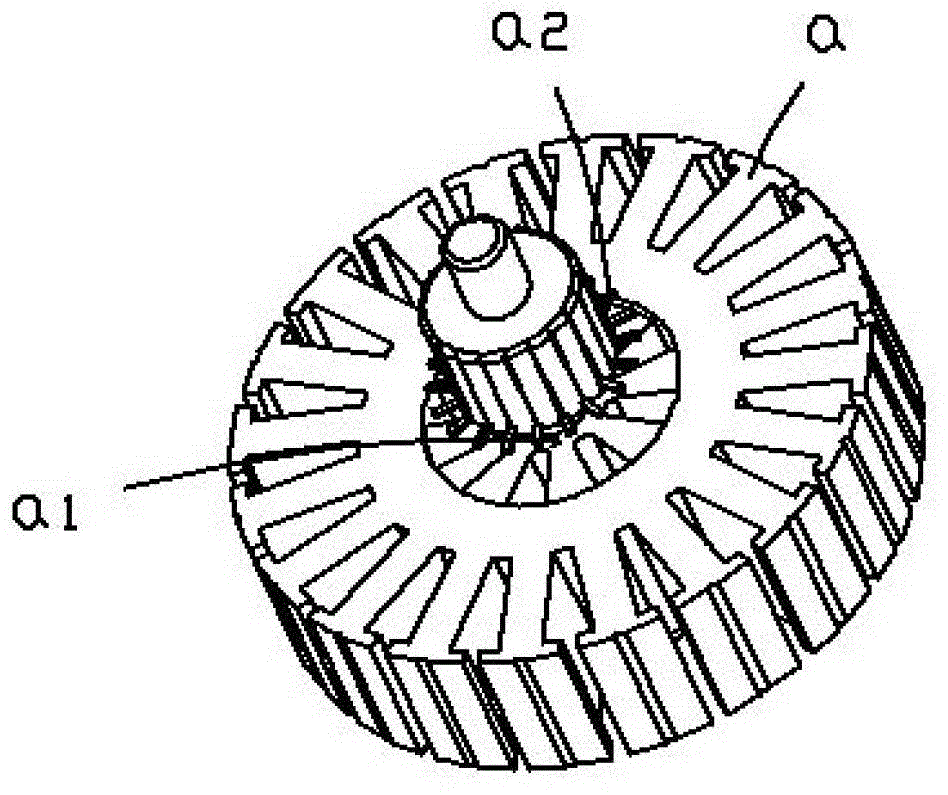

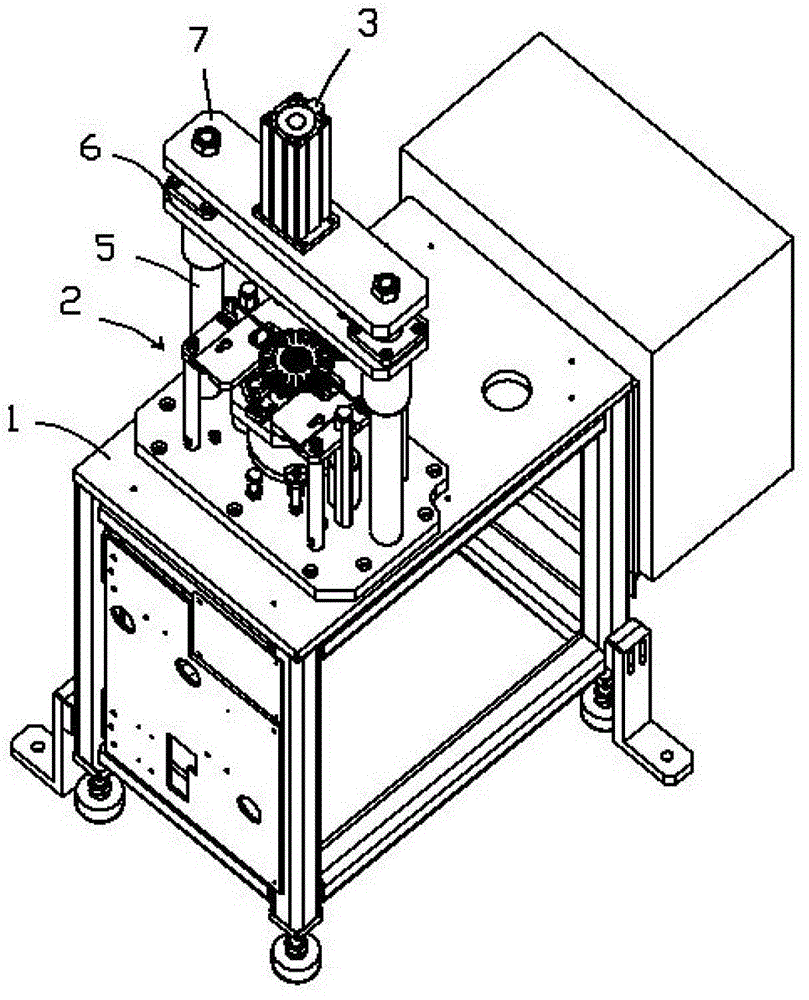

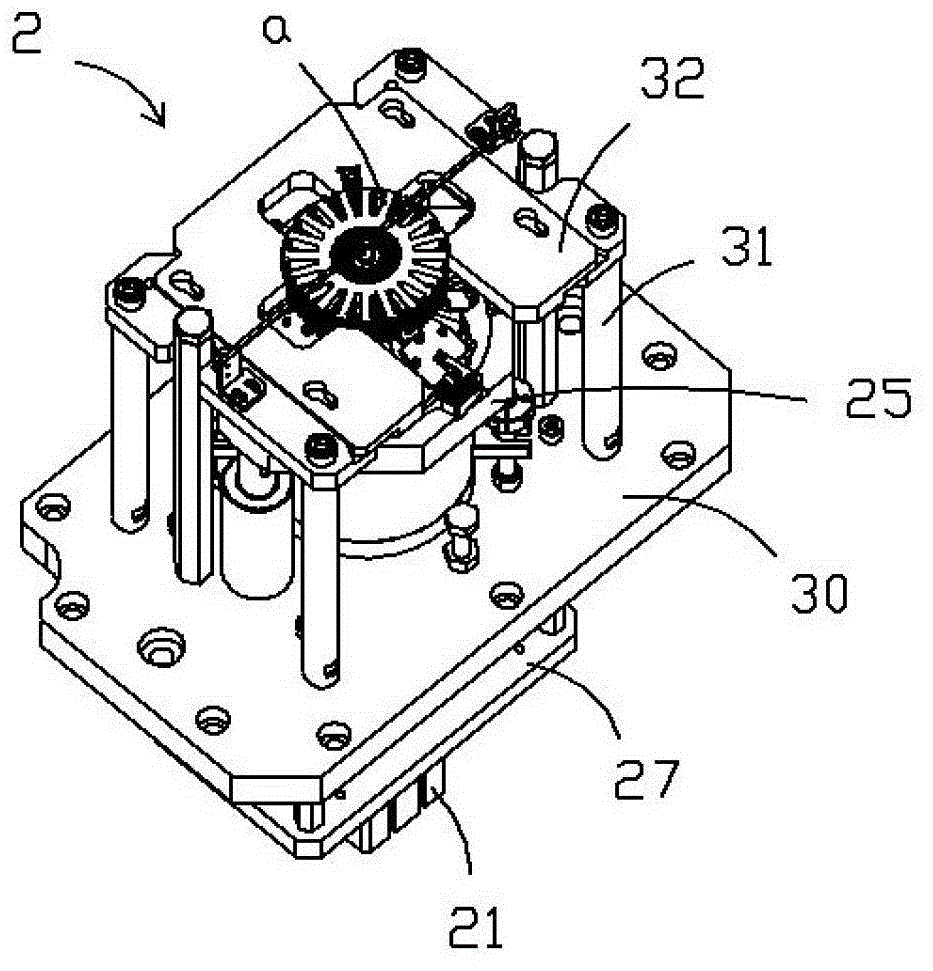

A motor rotor winding shaping machine

ActiveCN103401365BSimple mechanicsSimple structureManufacturing dynamo-electric machinesEngineeringPiston rod

The invention discloses a motor rotor winding shaping machine, which comprises a rack, wherein the rack is provided with a pressure head which can move up and down under the driving of a first cylinder, and the rack below the pressure head is provided with a wire shaping mechanism; and the wire shaping mechanism structurally comprises an inner core body, a telescopic disc is sleeved in the inner core body, an outer conical surface is molded on the inner core body, an inner conical surface is molded on the telescopic disc, a shaping plate is arranged on the outer conical surface, the rear end of the shaping plate is pressed against the inner conical surface, the outer conical surface is provided with a notch, a spring is arranged in the notch, one end of spring applies a force to the notch wall, the other end applies a force to the shaping plate, the shaping plate is provided with a gap portion, a front end hook portion of a pressing claw installed on the telescopic disc is arranged in the gap portion, an elastic telescopic rod is installed in a center hole of the inner core body, and the telescopic disc is connected with a piston rod of a second cylinder. The motor rotor winding shaping machine disclosed by the invention can reduce the production cost greatly, and improve the production efficiency.

Owner:XIONG HUA MACHINERY SUZHOU CO LTD

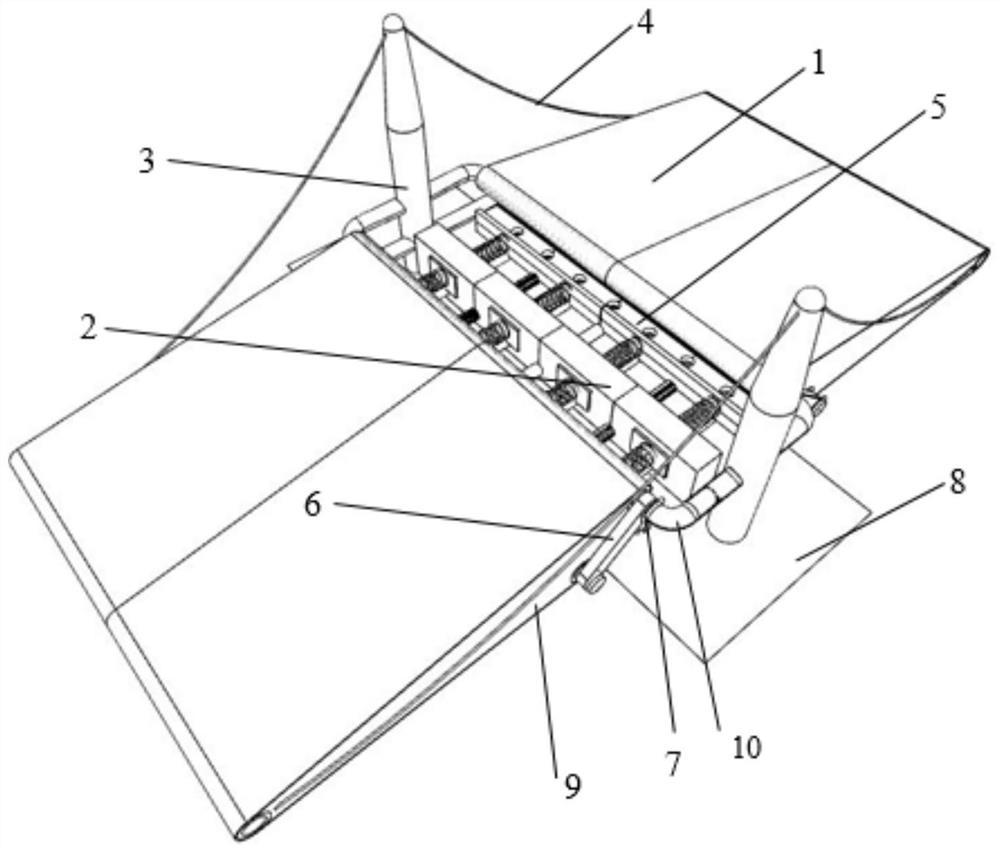

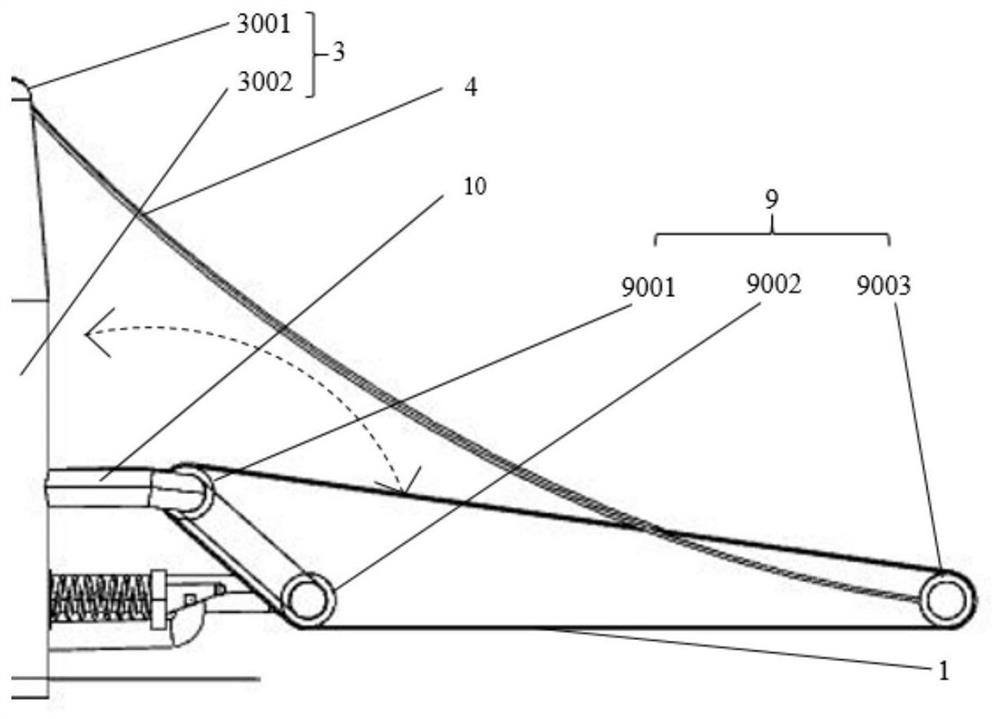

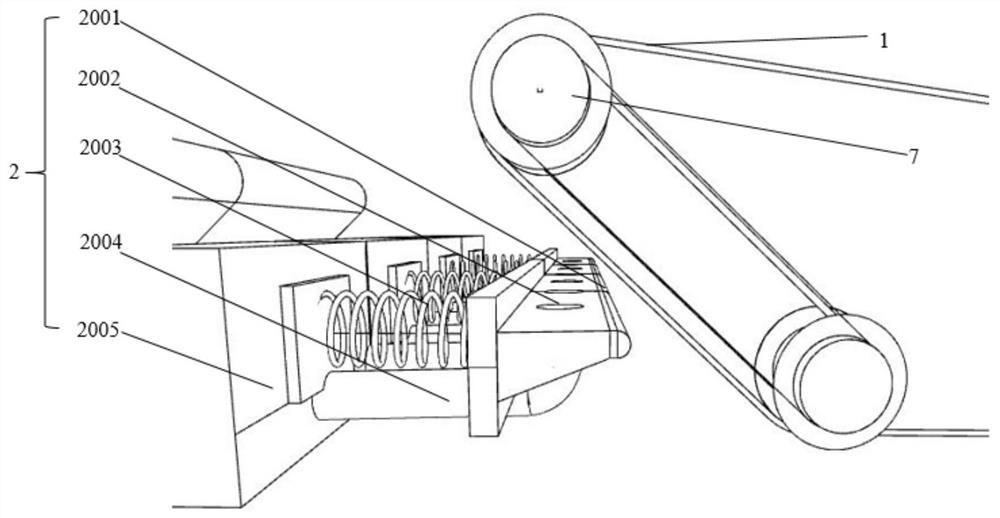

Marine crawler-type sump oil recovery device

InactiveCN112900388AImprove efficiencyImprove mobilityWater cleaningWaterborne vesselsMarine engineeringCrude oil

The invention discloses a marine crawler-type sump oil recovery device. The marine crawler-type sump oil recovery device involves a deck, the deck is connected to a turnover crawler structure through a supporting device, the crawler structure is of a triangular structure, crawler strips are laid on the crawler structure, a layer of lipophilic hydrophobic oil absorption cotton is arranged on the outer surface of each crawler strip, a recovery device body used for collecting, storing and transporting sump oil is arranged on one side of the crawler structure and comprises an extrusion head used for collecting the sump oil on the crawler strips and a sump oil storage cabinet used for storing the sump oil collected by the extrusion head, one side of the extrusion head abuts against the oil absorption cotton on the crawler strips, the crawler strips are connected to a driving device driving the crawler strips to rotate, and a stretching device for lifting the crawler structure is arranged on the supporting device. The marine crawler-type sump oil recovery device is simple in principle and high in economical efficiency, benefits from a crawler structure, is high in operation efficiency, integrates sump oil collection, storage and transportation, has both maneuverability and economical efficiency, and is very suitable for rapid collection of the ocean sump oil caused by offshore crude oil leakage.

Owner:708TH RES INST OF CSSC

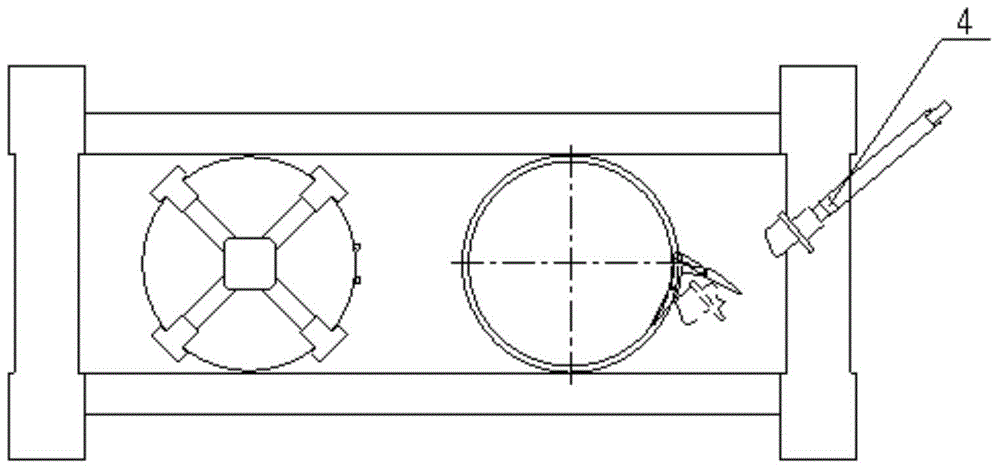

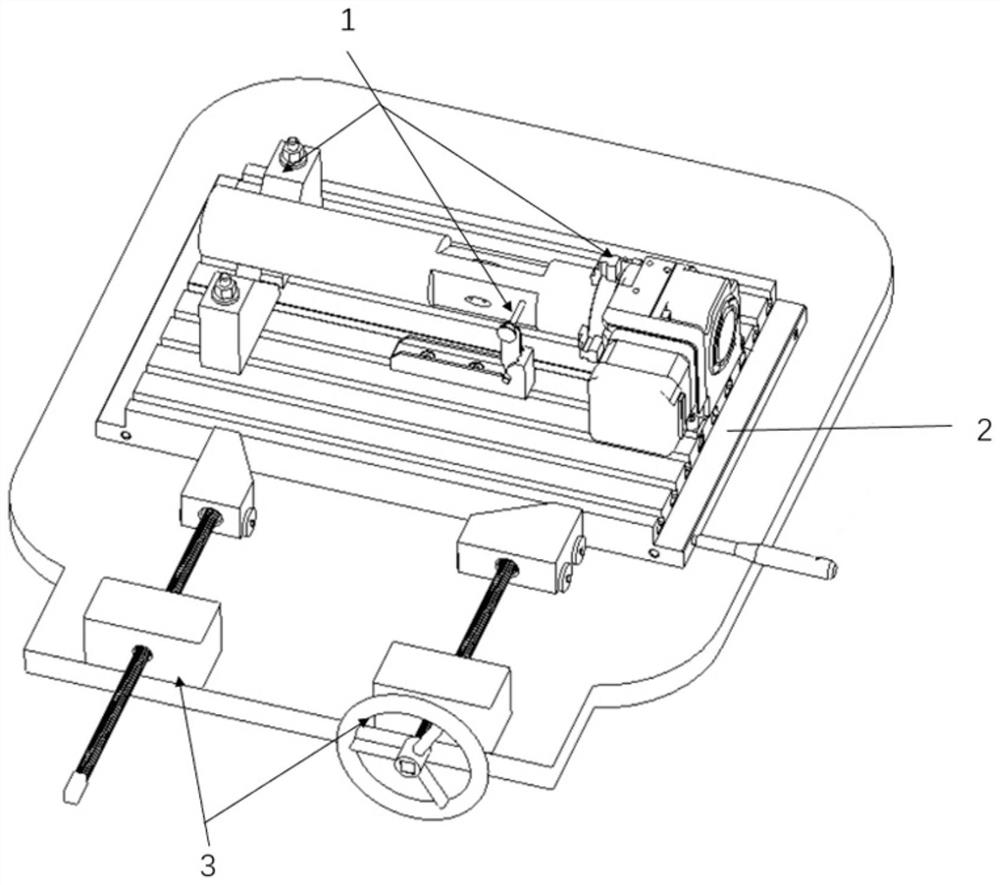

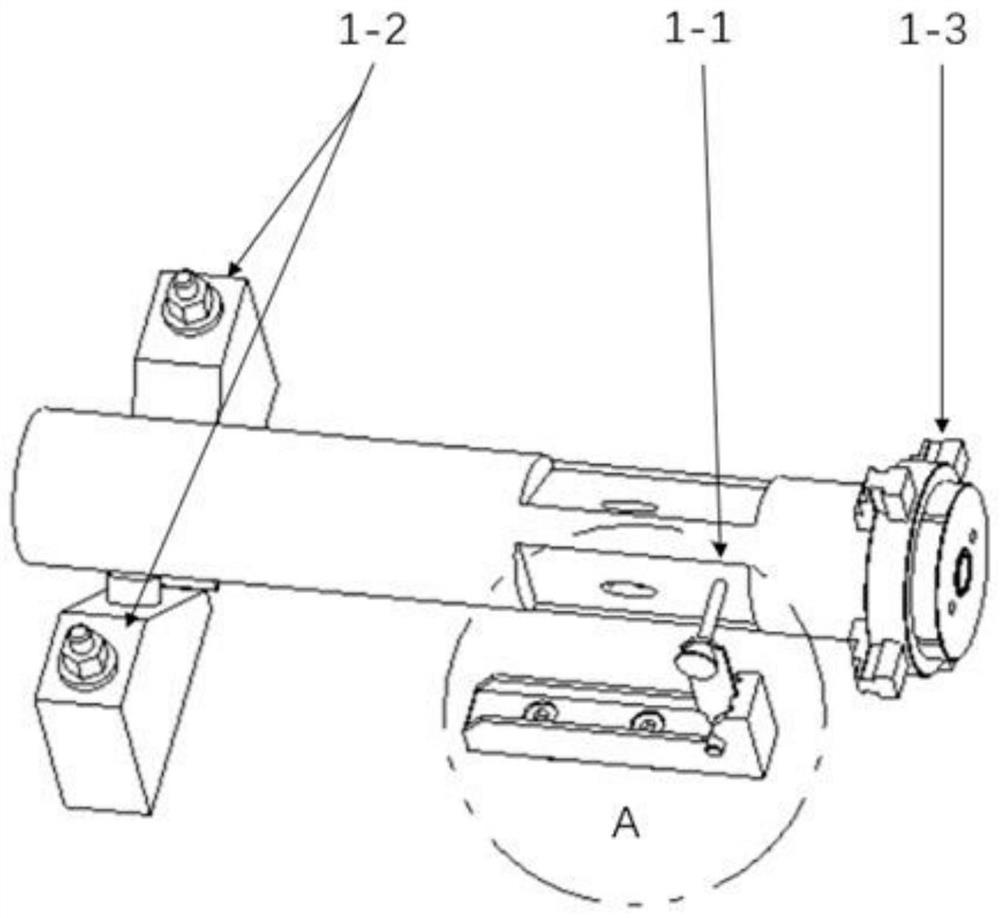

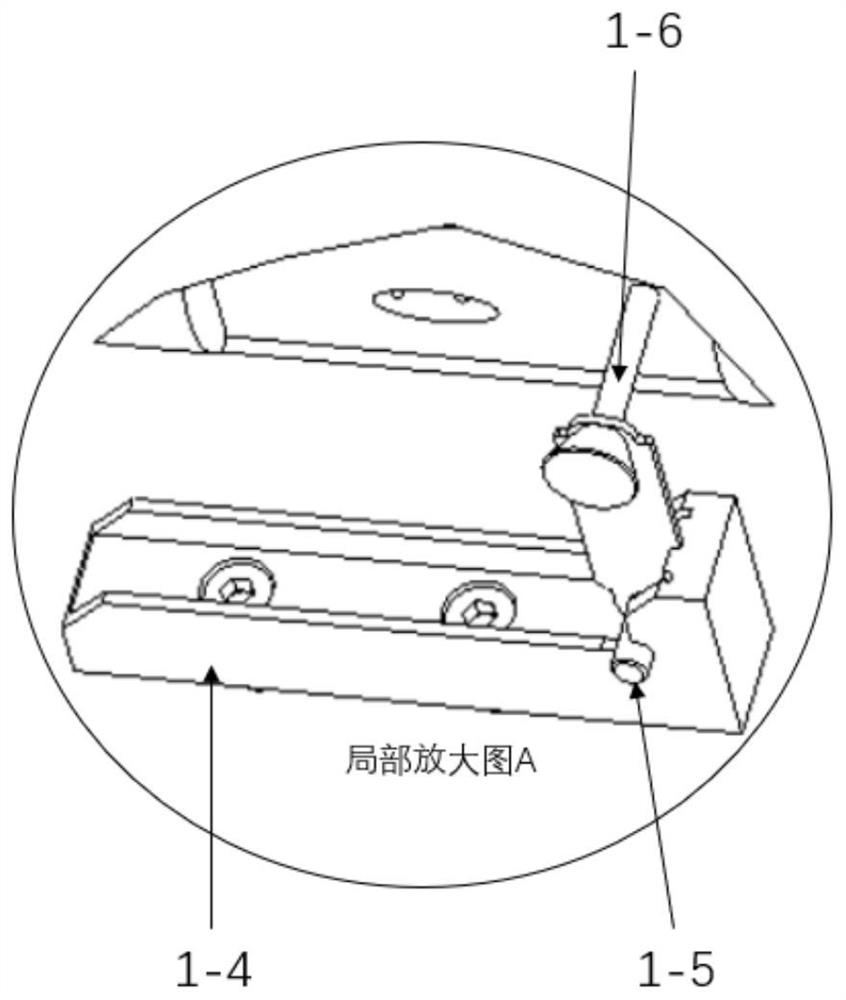

Fixtures for making offset pipe bodies for well completions

ActiveCN111390576BEasy to operateReduce manufacturing costFeeding apparatusLarge fixed membersControl engineeringPipe

The tooling and fixture used to manufacture the offset pipe body of the completion device. The clamping system includes a V-shaped support block for placing the pipe body; the indexing system includes: X-axis rotary positioning mechanism, which controls the pipe body by driving a four-jaw chuck Rotate around the central axis; and the Z-axis rotary positioning mechanism controls the rotation of the tube body around the vertical central axis through the rotating shaft; the limit system includes several locking mechanisms to limit the position after the Z-axis rotary positioning mechanism rotates. The invention can flexibly adjust the angle between the pipe body and the fixed tool. In the operation of processing multiple inclined holes or straight holes, the original two or more processes are combined into one, the operation is simplified, the processing efficiency is improved, and the production cost.

Owner:SHANGHAI GENIE ROBOT AUTOMATIC

Mechanical and automatic wire inserting mechanism

ActiveCN103358064BRealize mechanized production operationsSimple mechanicsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringGuide tube

The invention relates to a mechanical and automatic wire inserting mechanism, and belongs to the field of welding machinery or equipment. The mechanical and automatic wire inserting mechanism comprises a wire inserting air cylinder and a guide tube, parallelly arranged, a guide seat fixing the wire inserting air cylinder and the guide tube together and a guided plate playing a supporting role, wherein a guide sliding block is arranged on the inserting air cylinder; a push rod and a push rod spring are arranged on the guide sliding block; the guide sliding block carries out a reciprocating rectilinear motion along a sliding block guide groove in the guide seat under the drive of the wire inserting air cylinder to form a wire inserting unit; a displacement air cylinder is also arranged on the guide seat, and is connected with a fix frame of the whole equipment through a straight guide rail pair. The invention aims to the web bar wire inserting during the CL (composite light) net rack plate welding process, discloses a specially designed mechanical and automatic wire inserting mechanism and wire inserting method truncating the steel wire first then feeding wire one by one to weld, and can realize mechanized production operation of the CL net rack plate web bar wire inserting.

Owner:石家庄晶达建筑体系有限公司

Biomass pyrolysis in refinery feedstock

ActiveUS8287723B2Well mixedSimple mechanicsPreheating coke ovensDirect heating destructive distillationHot liquidsOil refinery

This invention relates to biomass pyrolysis through the use of a hot liquid refinery feedstock as a heat transfer medium, preferably a vacuum gas oil feedstock.

Owner:PHILLIPS 66 CO

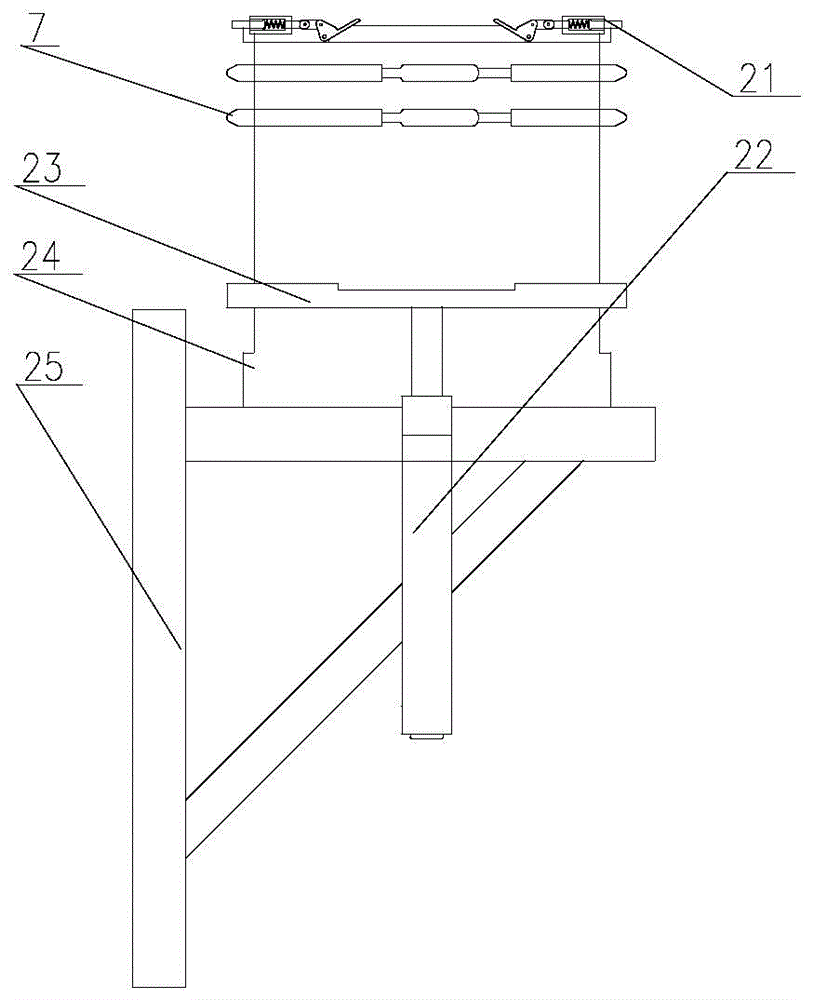

Singeing machine burner assembling support

The invention discloses a singeing machine burner assembling support. The singeing machine burner assembling support comprises a base, a moving rack and an adjusting device and is characterized in that two slide grooves are arranged in the base; a plurality of moving wheels are arranged below the moving rack and located in the slide grooves; the moving rack further comprises a bottom plate, two supports and a motor; the adjusting device comprises two footboards respectively used for controlling the moving rack to move leftwards and rightwards; each support comprises a support plate, grooves are formed in the support plate, the cross sections of the grooves form an inverted-T shape in one direction, that is to say, the upper surface of each support plate is downwardly recessed to form two first grooves and one second groove, and the depth of the second groove is larger than that of the first grooves. The singeing machine burner assembling support has the advantages that a semi-finishedburner can be horizontally moved by treading the footboards, a worker does not need to walk to to-be-assembled parts, time and manpower are saved, and the support is simple to operate and capable of increasing work efficiency.

Owner:泰州印染机械有限公司

Blood collection device for collecting blood samples

ActiveCN103705251BSimple structural designSimple structureCatheterDiagnostic recording/measuringBiomedical engineeringLance device

The apparatus (1) has an axially displaceable lancet holder element (32) for holding a replaceable lancet (12). A drive unit (12) comprises a lancing spring element (31) for driving the axially displaceable lancet holder element in lancing direction (18). A tensioning carriage part (26) is fixed in a clamping position for tensioning the lancing spring element. The tensioning carriage part is temporarily fixed in the clamping position by using a snap-locking unit (35) that is engaged with the axially displaceable lancet holder element.

Owner:GERRESHEIMER REGENSBURG GMBH

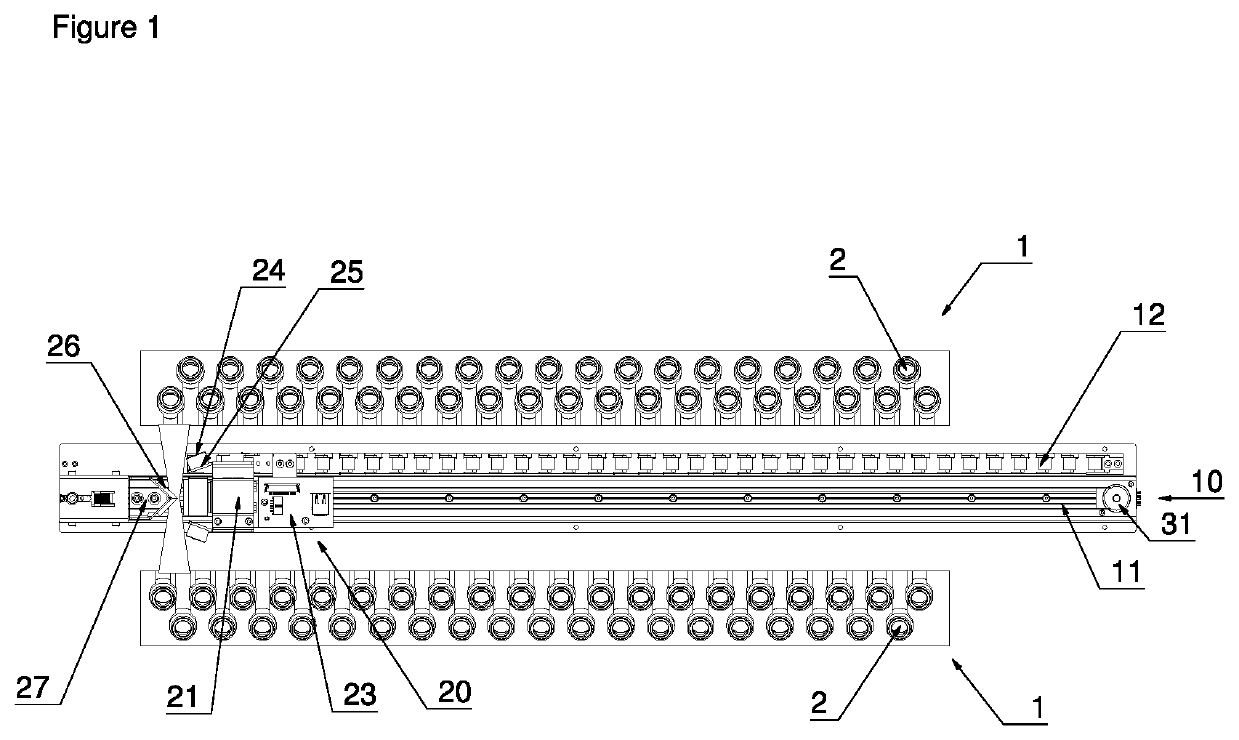

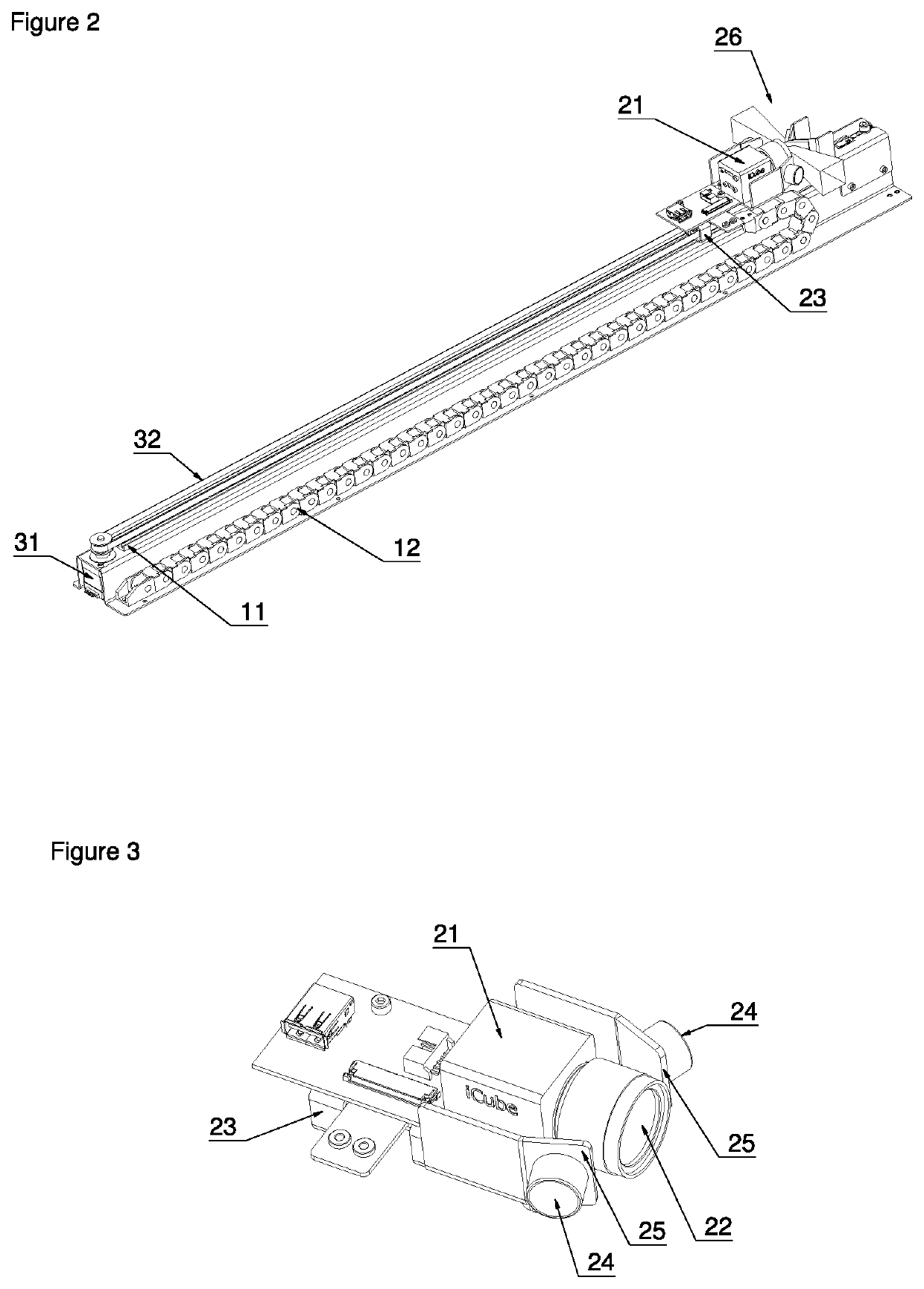

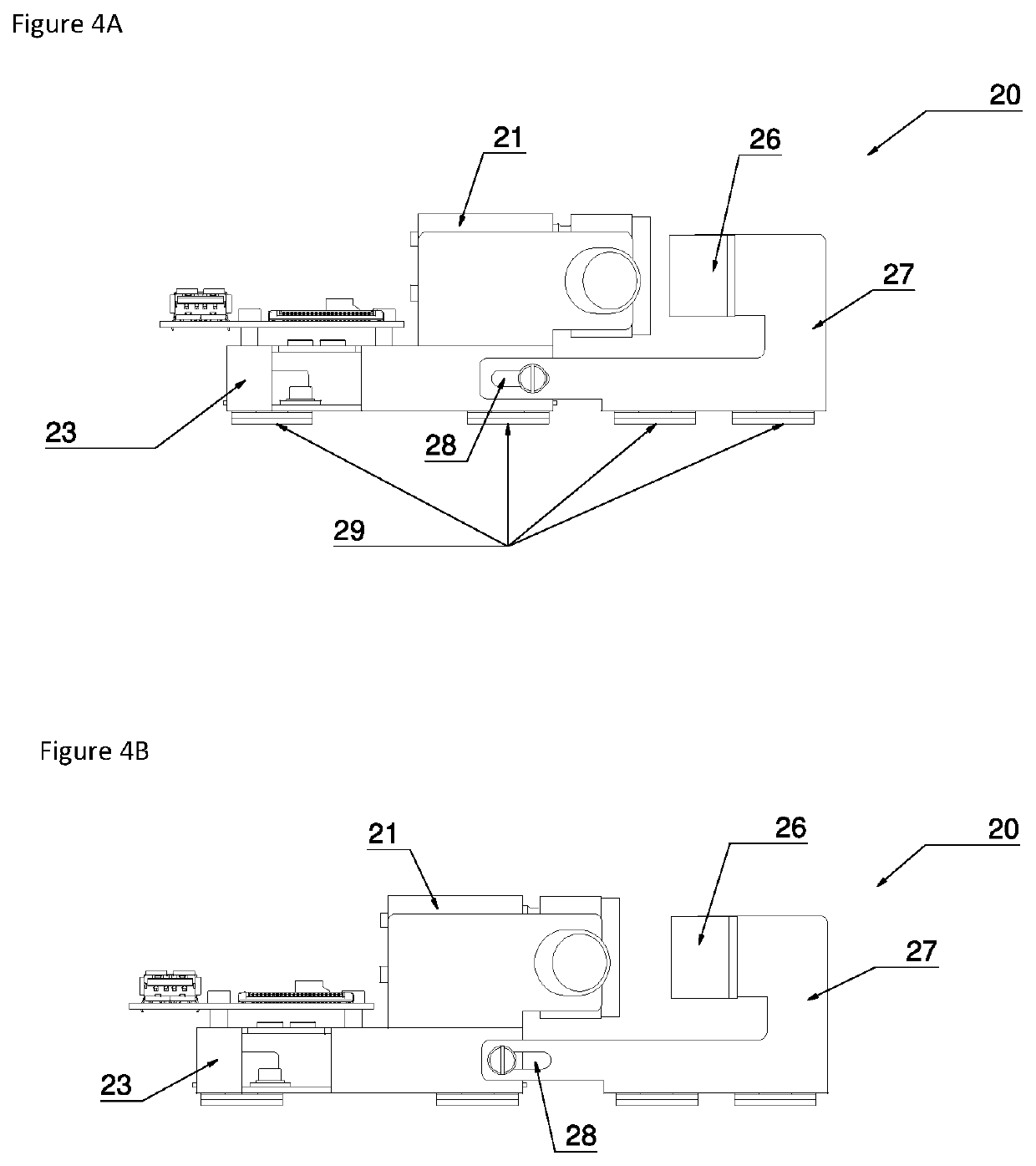

Scanning device and method for use in an automated analyser

ActiveUS10970500B2Simple mechanicsMountingsSensing by electromagnetic radiationEngineeringComputational physics

A scanning method with simple mechanics for use in an automated analyser to scan objects or codes on objects. The invention enables one to move a scanning unit comprising a camera and two deflection mirrors and to set two different focus levels with one and the same drive unit.

Owner:STRATEC BIOMEDICAL AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com