Wind power main shaft provided with strengthening layer and machining technology of wind power main shaft

A wind power main shaft and processing technology technology, applied in the directions of shafts, bearings, shafts and bearings, etc., can solve the problems of increasing the shaft diameter of the fan main shaft, difficult forging process of the crankshaft, and radial runout of the main shaft, so as to reduce the weight and improve the strength of the main shaft. , the effect of reducing the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

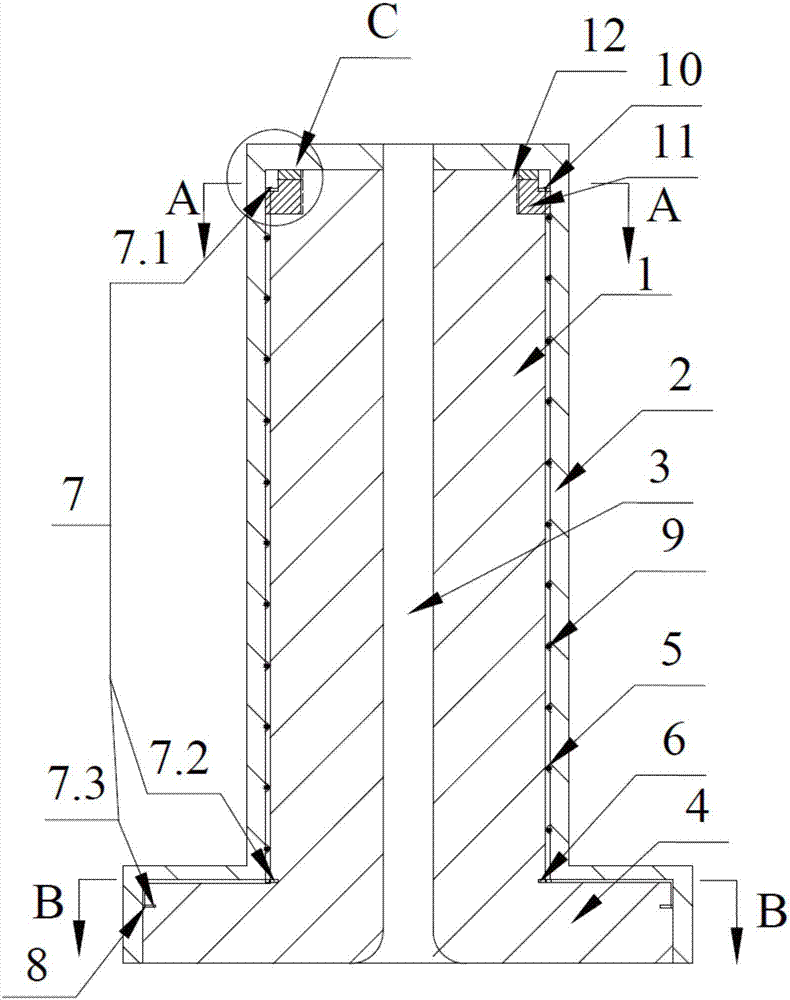

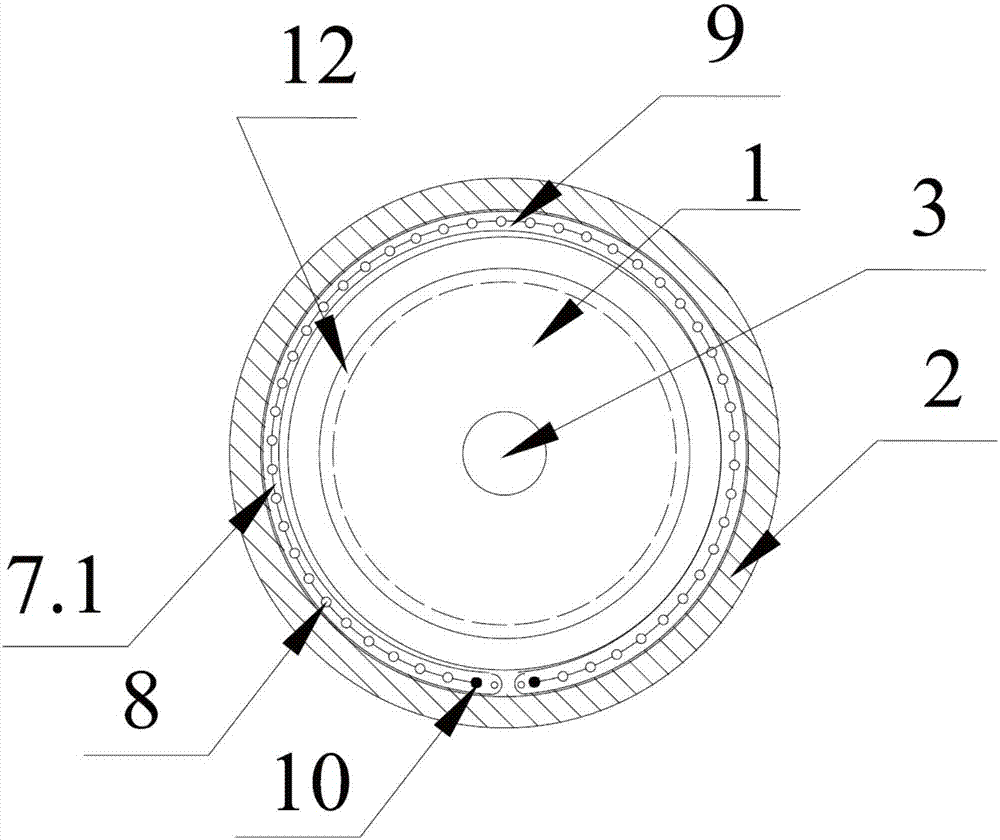

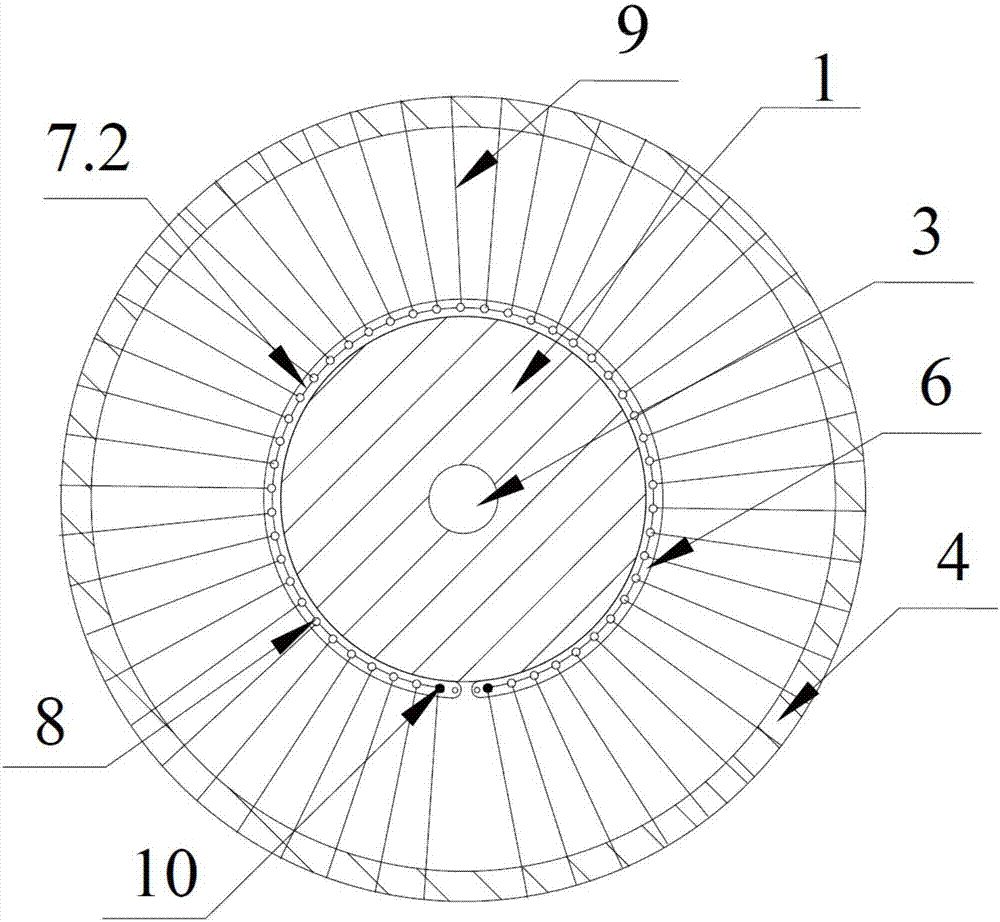

[0035] Such as Figure 1~5 As shown, the present invention is a wind power main shaft provided with a reinforcement layer. The wind power main shaft includes a mandrel 1 and a sleeve shaft 2, and a carbon fiber mold sleeve layer or a carbon fiber mesh layer is arranged between the mandrel 1 and the sleeve shaft 2. The wind power main shaft is provided with an axial center hole 3 , and one end of the wind power main shaft is provided with a flange 4 .

[0036] In order to facilitate the clamping of carbon fiber filaments or carbon fiber membranes inside the wind power main shaft so that it forms an integral structure with the wind power main shaft, a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com