Clamping device for plate cutting

A technology of clamping device and plate, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of unfavorable company benefits, plate damage, plate falling off, etc., and achieve the effect of reducing manpower and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

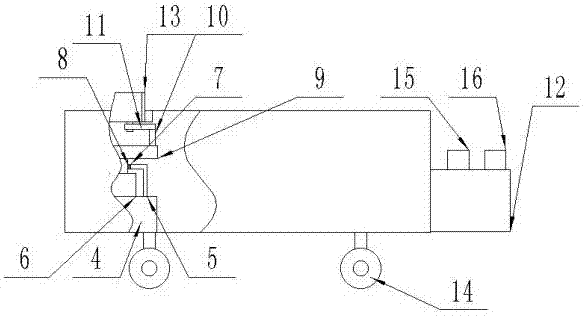

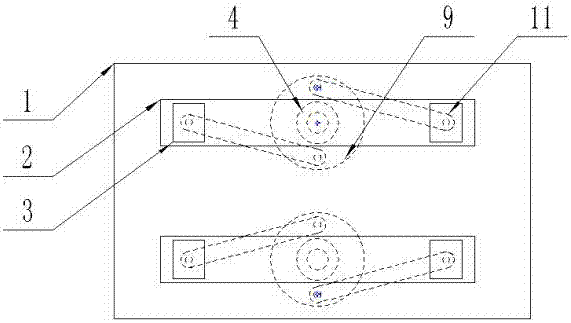

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-2 As shown in the figure, a clamping device for sheet material cutting includes a base (1), and both ends of the outer upper surface of the base (1) are processed with rectangular openings (2), and the inside of the rectangular opening (2) is movable A set of clamping blocks (3) that can move inside it is embedded, and brackets (4) are fixedly welded at both ends of the inner lower surface of the base (1) and below the rectangular opening (2), and the brackets ( 4) The N-shaped frame (5) is installed with bolts on the outer upper surface, and the rotating motor (6) is fixedly installed inside the N-shaped frame (5), and the beams of the N-shaped frame (5) are all processed with circular Openings (7), the circular openings (7) are fixedly embedded with bearings (8), the rotating end of the rotating motor (6) is fixedly equipped with a disc (9), and the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com