Singeing machine burner assembling support

A technology for assembling a bracket and a singeing machine, which is applied in the directions of singeing, textile and papermaking, fabric surface trimming, etc., can solve the problems of fast physical exertion, time-consuming, and large workload, and achieves improved work efficiency, reduced production costs, and practical strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

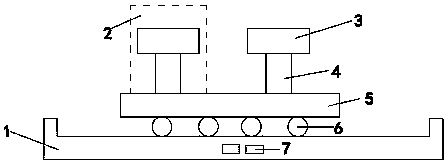

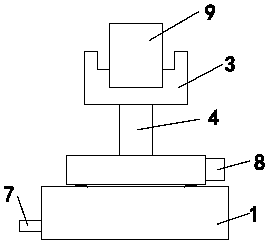

[0016] A burner assembly support for a singeing machine, comprising a base 1, a moving frame, and an adjusting device.

[0017] The base 1 includes two sliding slots.

[0018] The moving frame includes a base plate 5, two supports 2, a motor 8, and several running wheels 6.

[0019] The regulating device is two foot pedals 7, which control the moving frame to move left and right respectively.

[0020] The upper surface of the base 1 is provided with two parallel sliding grooves. Several running wheels 6 are connected with the base plate 5, and the running wheels 6 are located in the chute. The motor 8 is connected with the adjusting device and the bottom plate 5 . Each of the brackets 2 includes a support plate 3 with a groove on the support plate 3, and the cross section of the groove on a certain side is "convex", that is, each of the support plates 3 has an upper surface and a lower surface. Concave, forming two first grooves and one second groove, the depth of the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com