Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduced horizontal footprint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

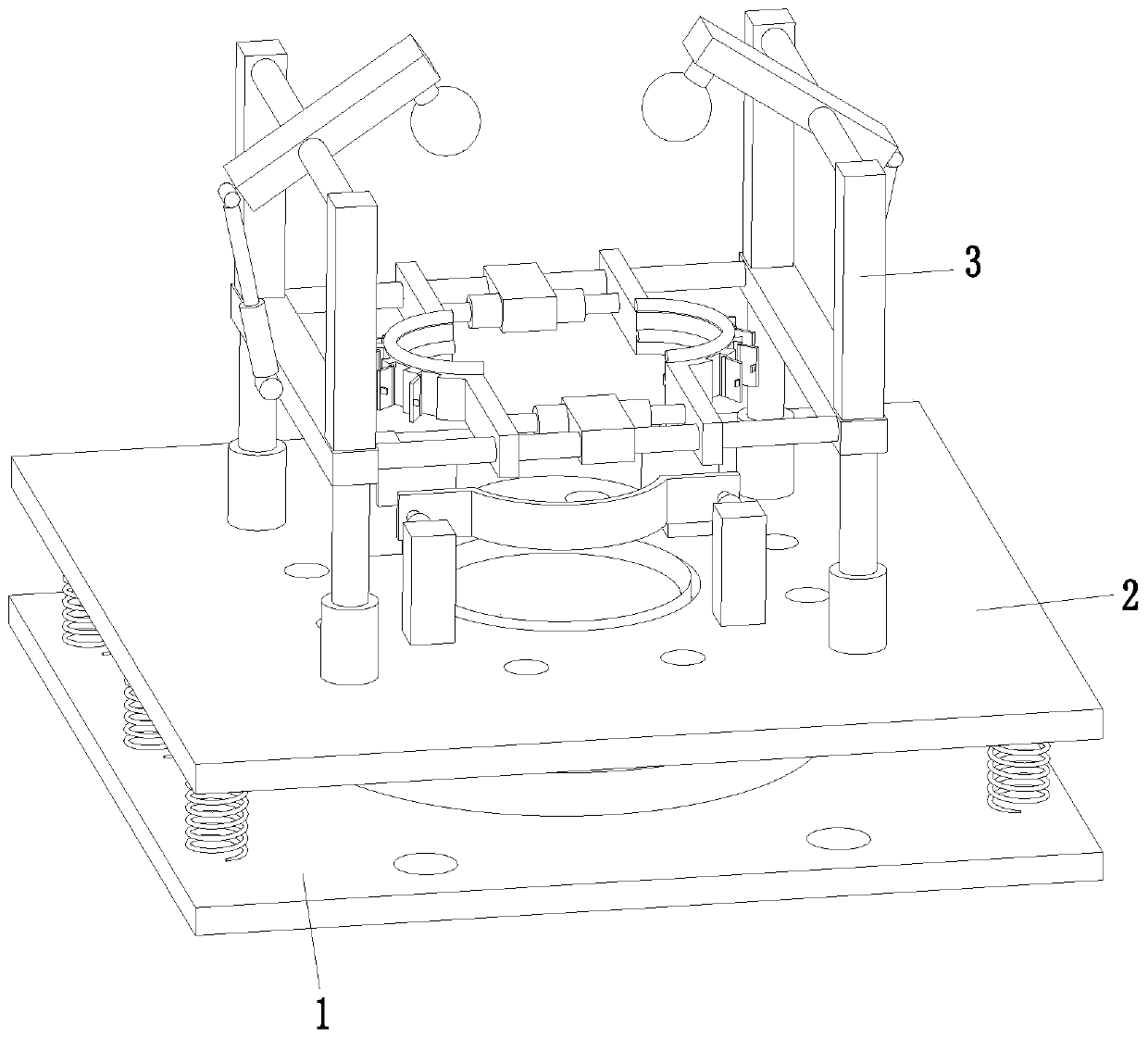

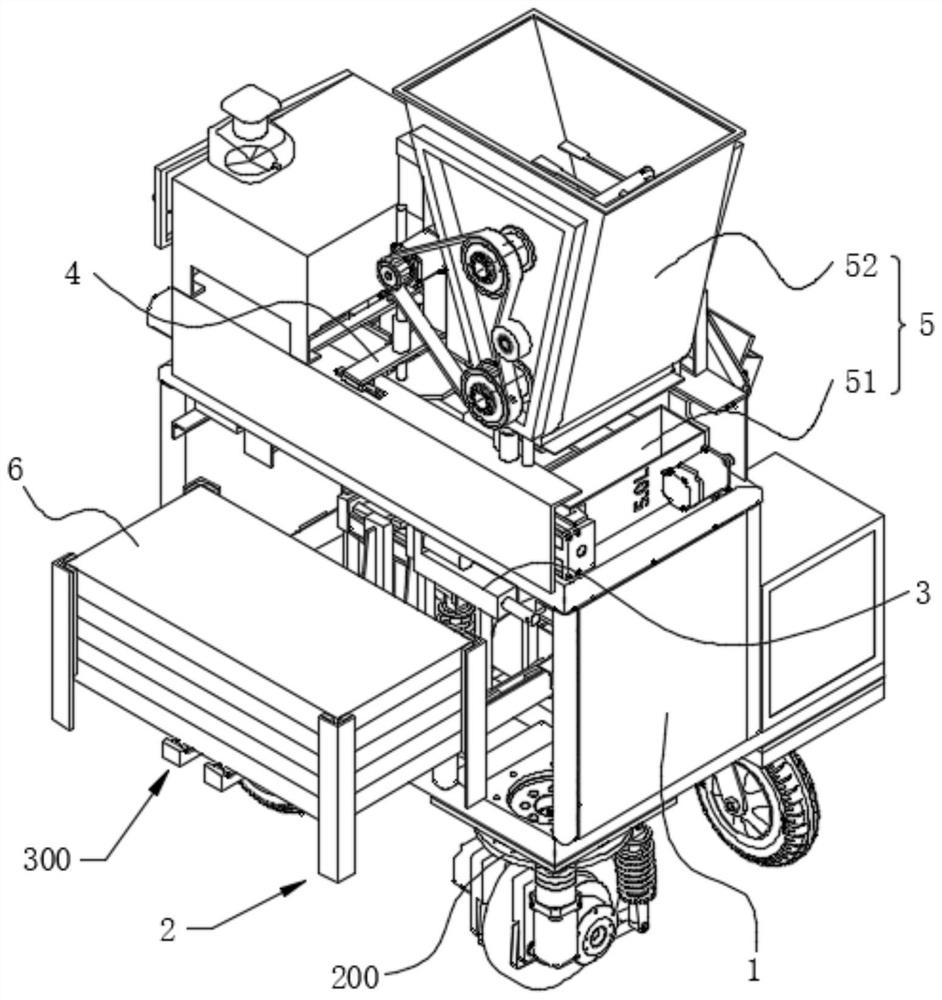

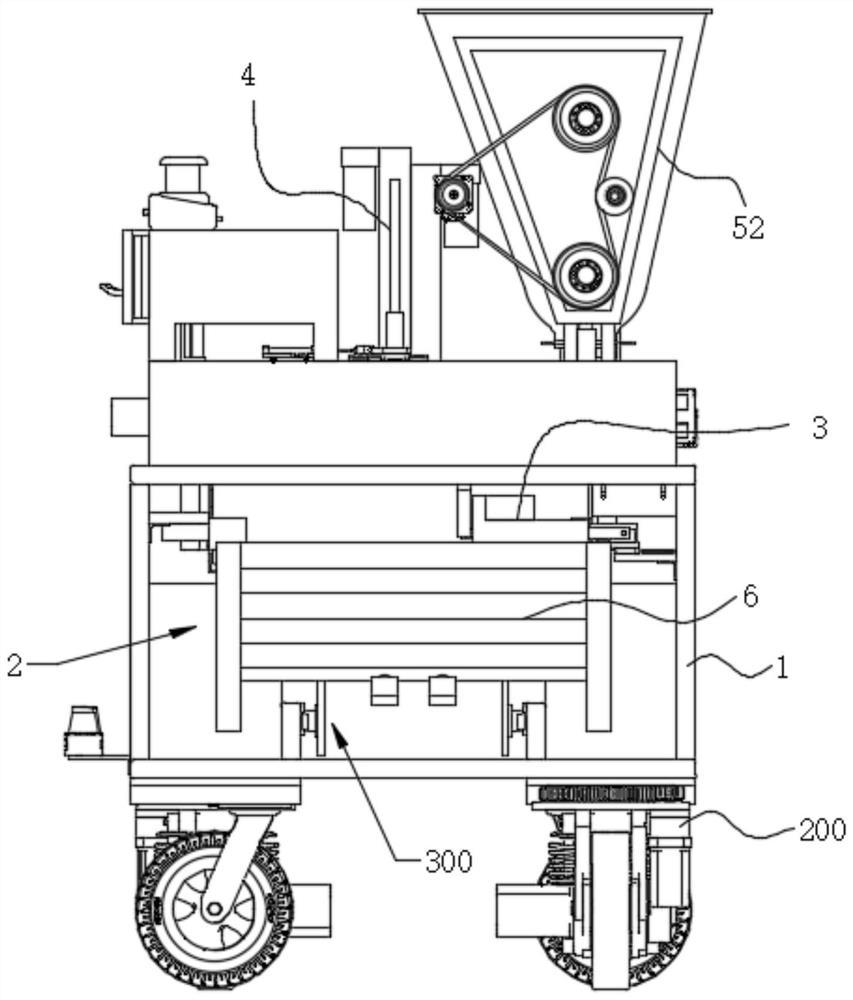

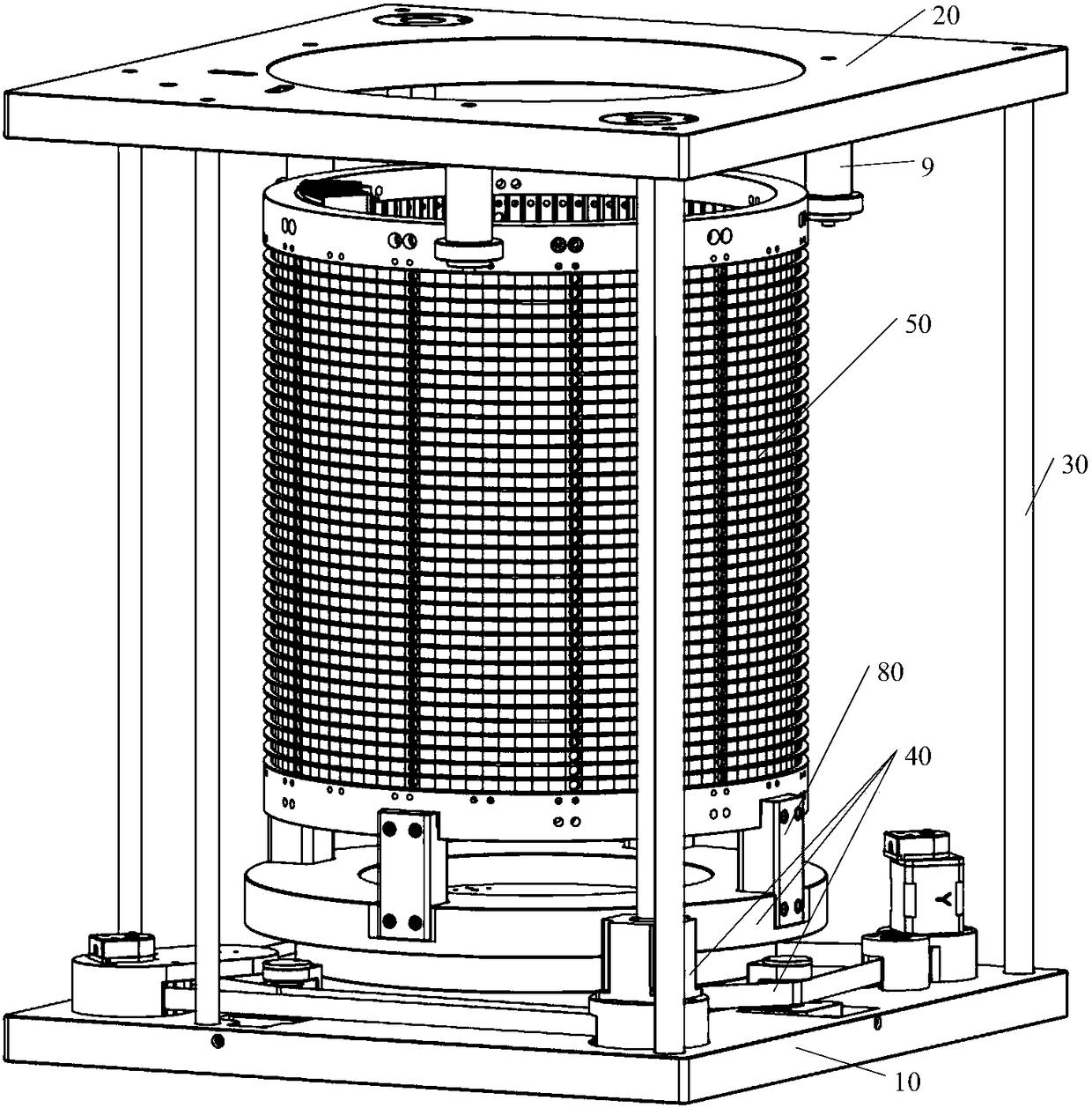

Ceramic tile gluing device and method and paving and pasting equipment

ActiveCN111760747AFully automatedTake advantage ofLiquid surface applicatorsFinal product manufactureStructural engineeringMechanical engineering

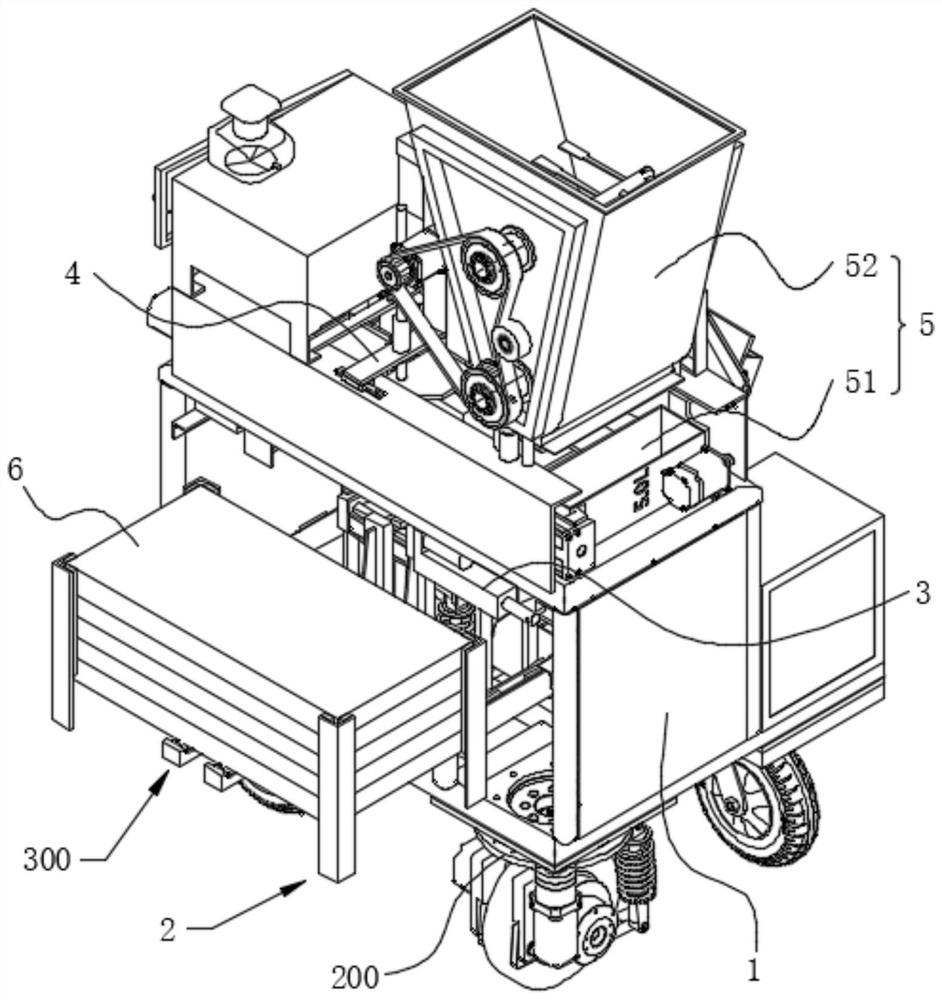

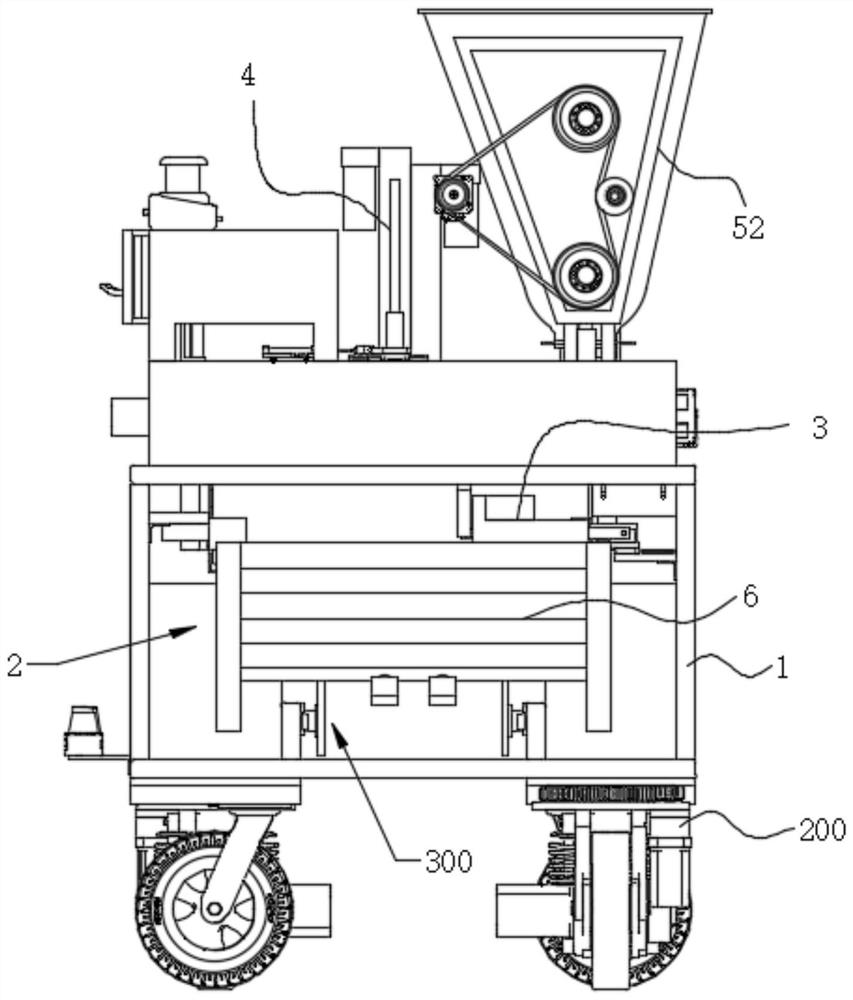

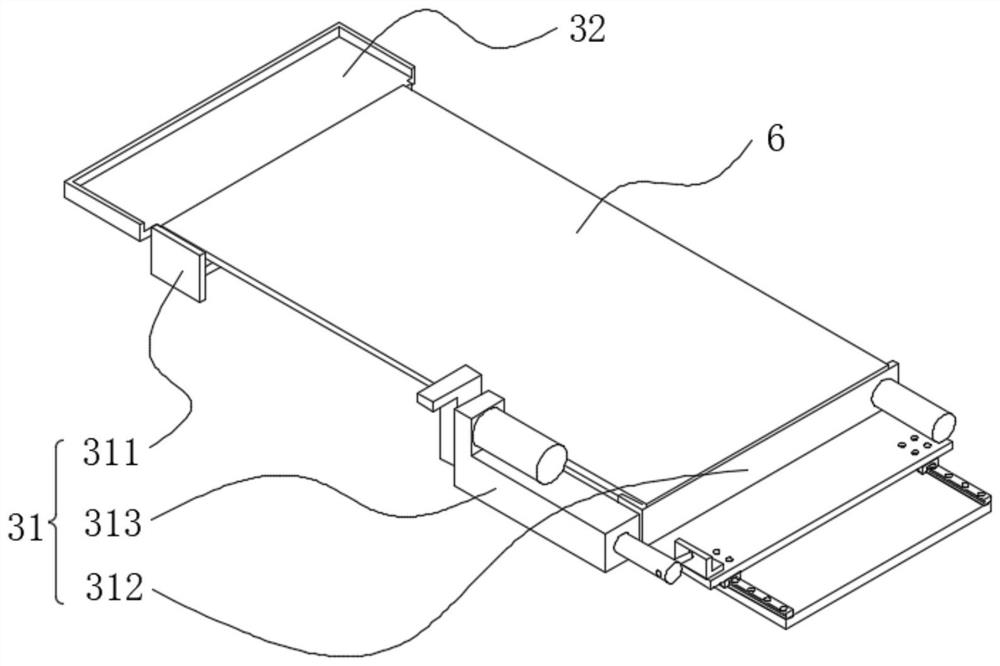

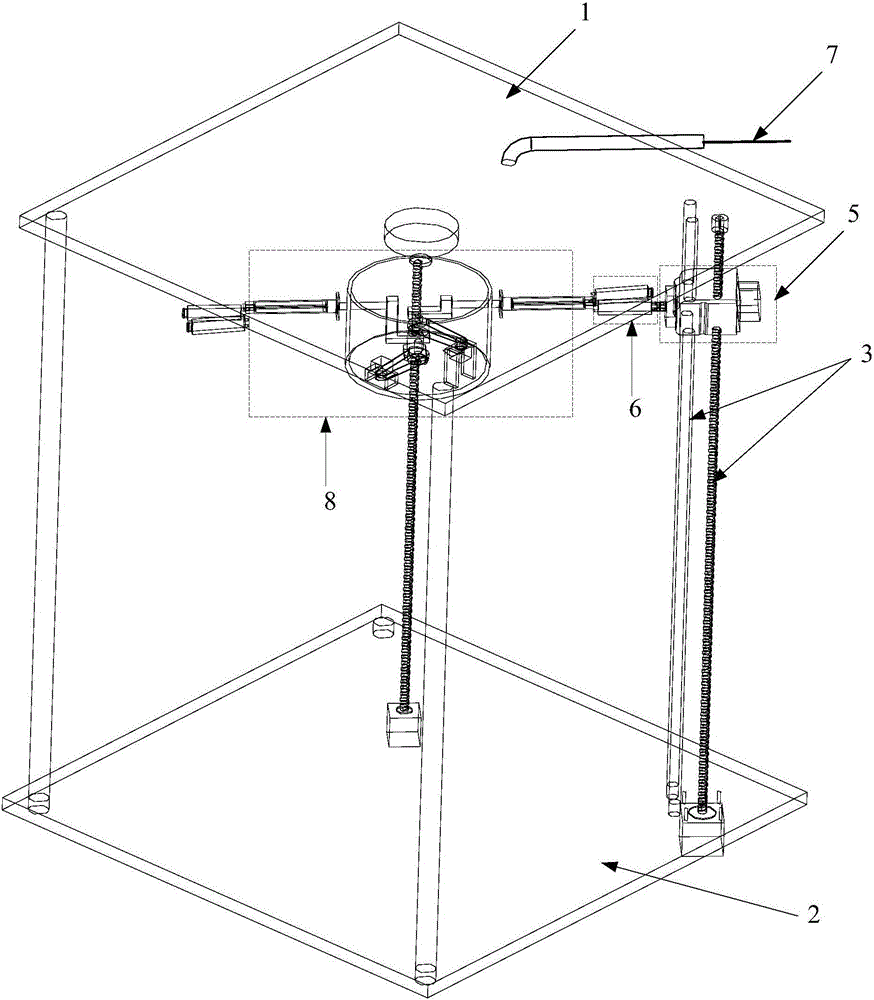

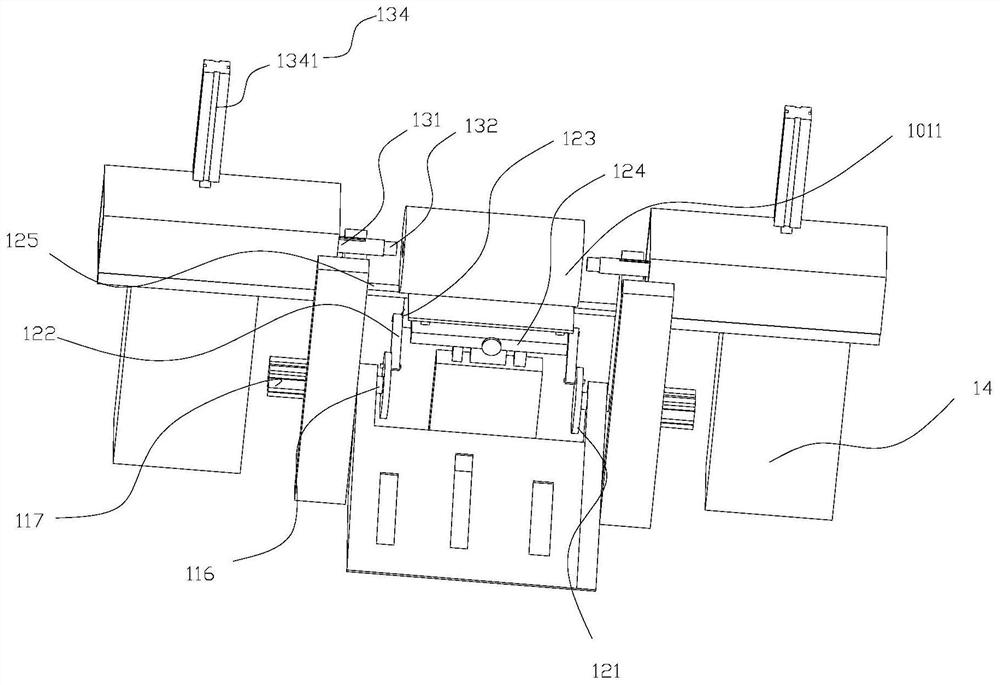

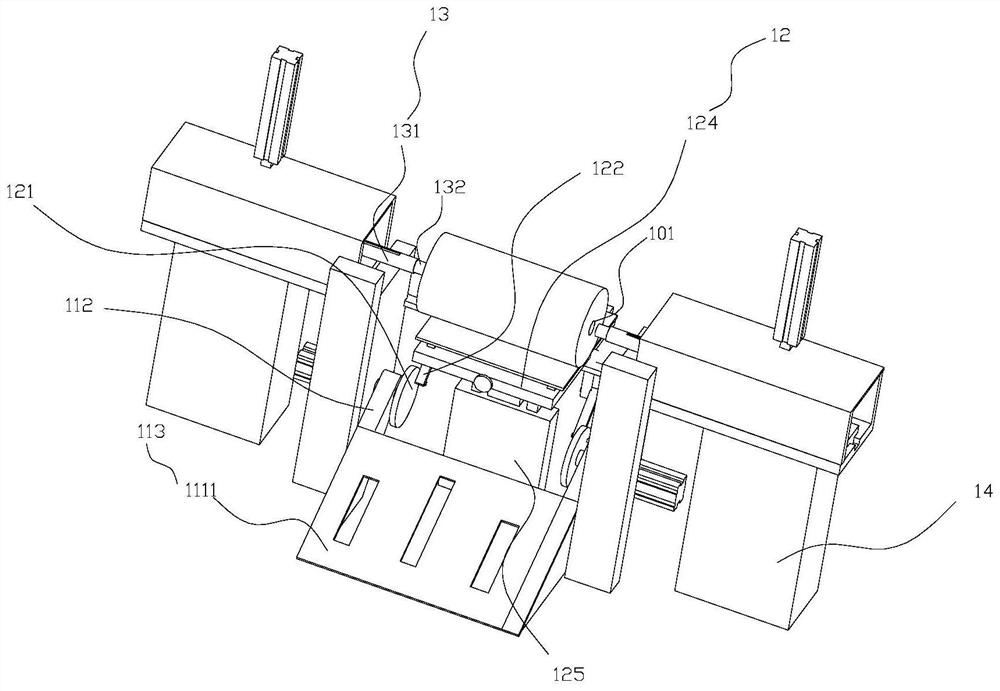

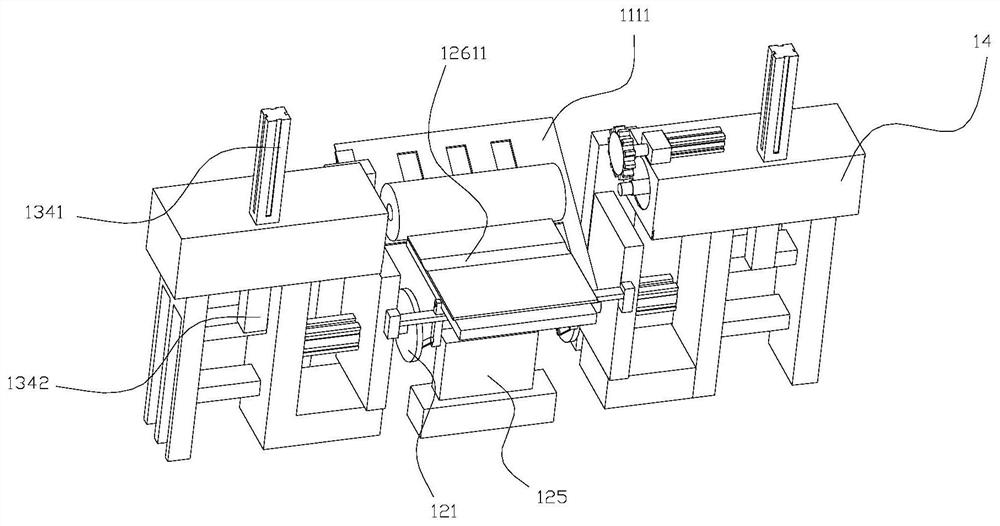

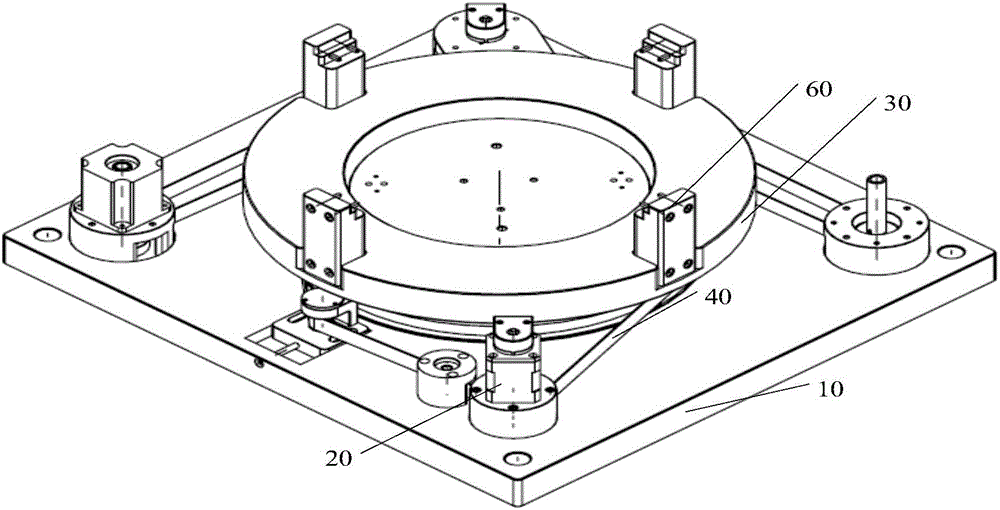

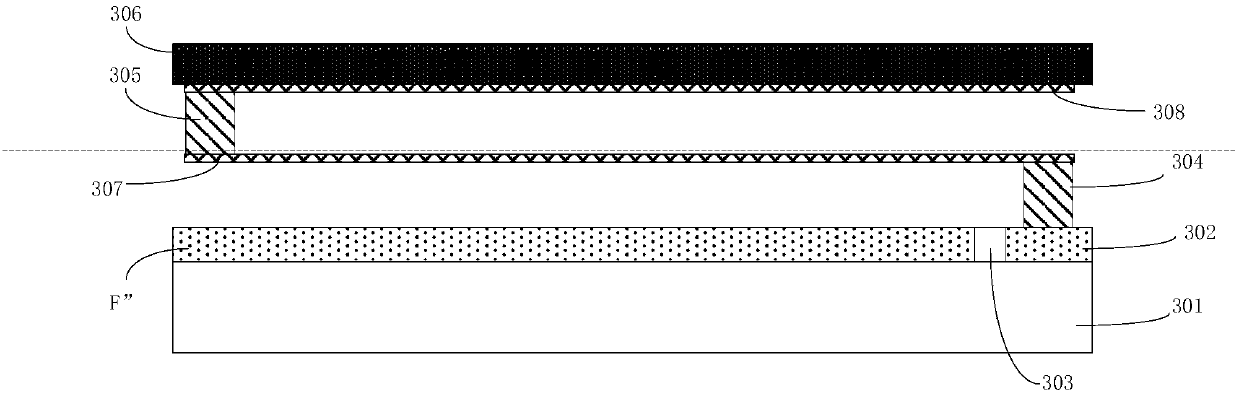

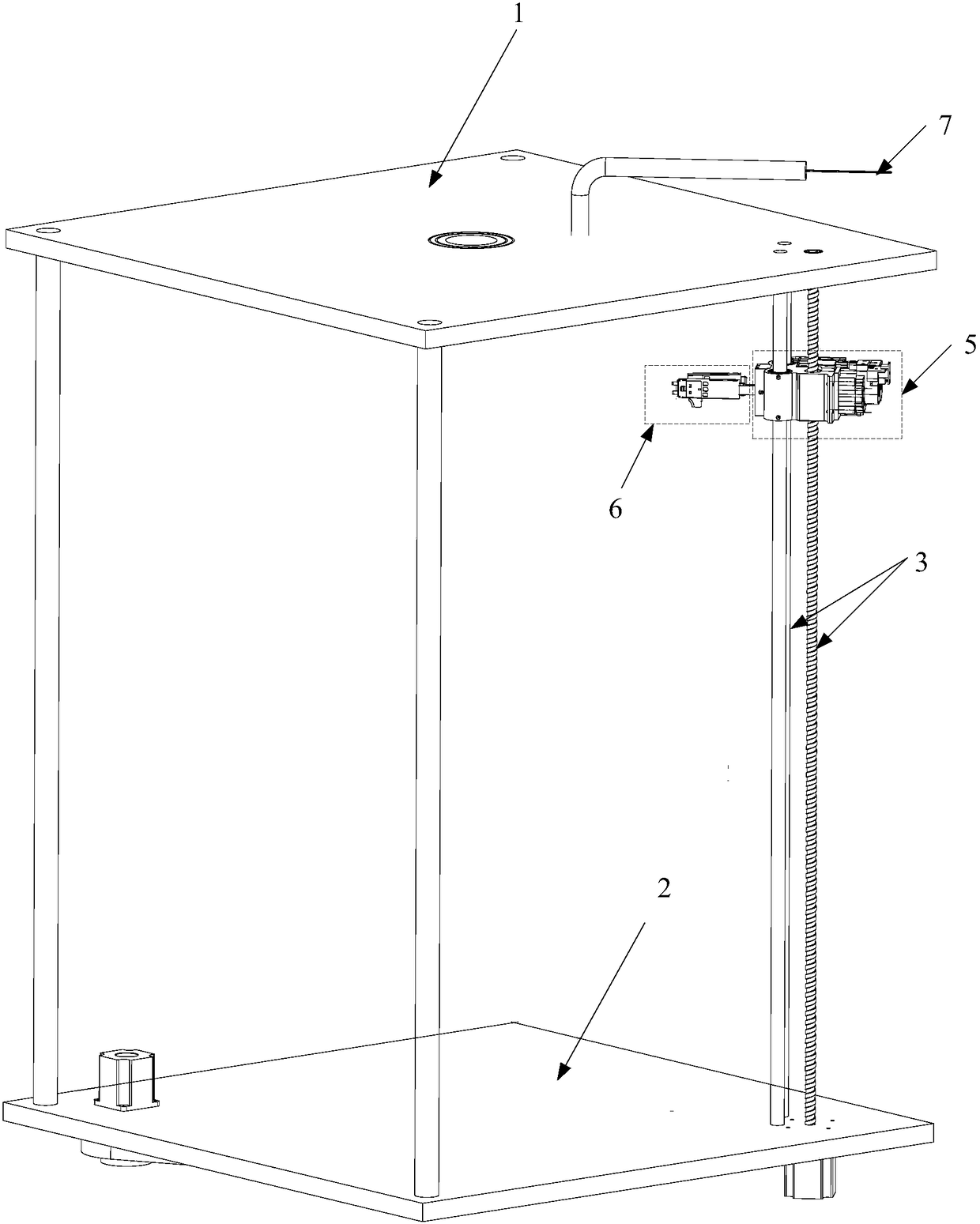

The invention belongs to the technical field of building robots, and discloses a ceramic tile gluing device. The device comprises a rack, and the rack is provided with a ceramic tile storage area. A bearing conveying mechanism is located above the ceramic tile storage area. A bearing clamping platform of the bearing conveying mechanism comprises two clamping plates for bearing and limiting a to-be-glued ceramic tile, an opening is formed between the two clamping plates, and at least one clamping plate can move relative to the other clamping plate. A lifting grabbing mechanism is arranged on the rack and used for grabbing the ceramic tile from the ceramic tile storage area and placing the ceramic tile on the bearing clamping platform. A gluing mechanism is arranged on the rack and located above the bearing conveying mechanism, and the gluing mechanism is used for gluing the ceramic tile placed on the bearing clamping platform. The invention further discloses a gluing method and paving and pasting equipment with the gluing device. The gluing device can utilize space in the height direction, the horizontal occupied area is reduced, and operation of the device in the narrow space is facilitated.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

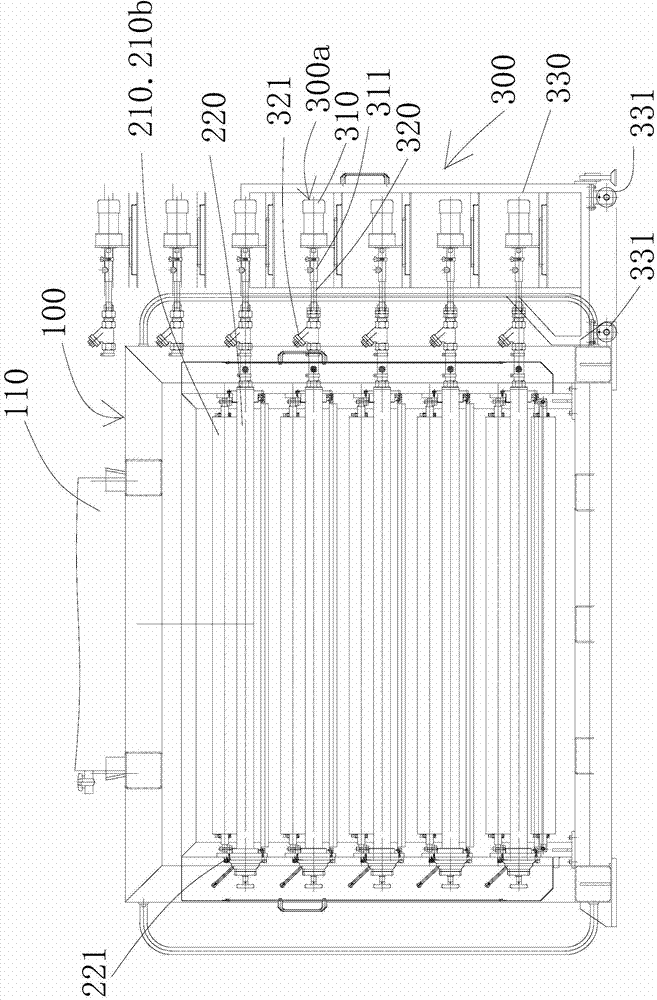

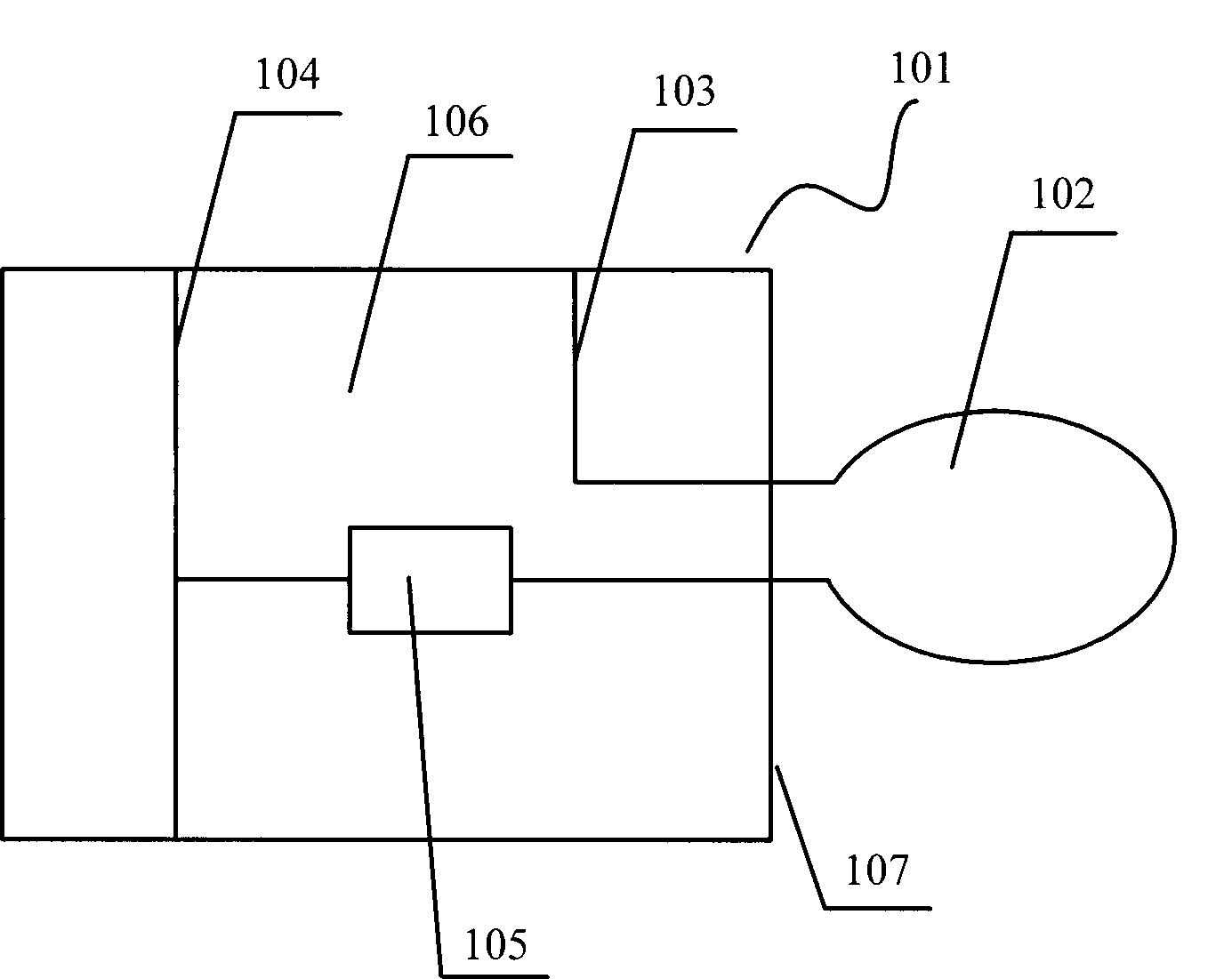

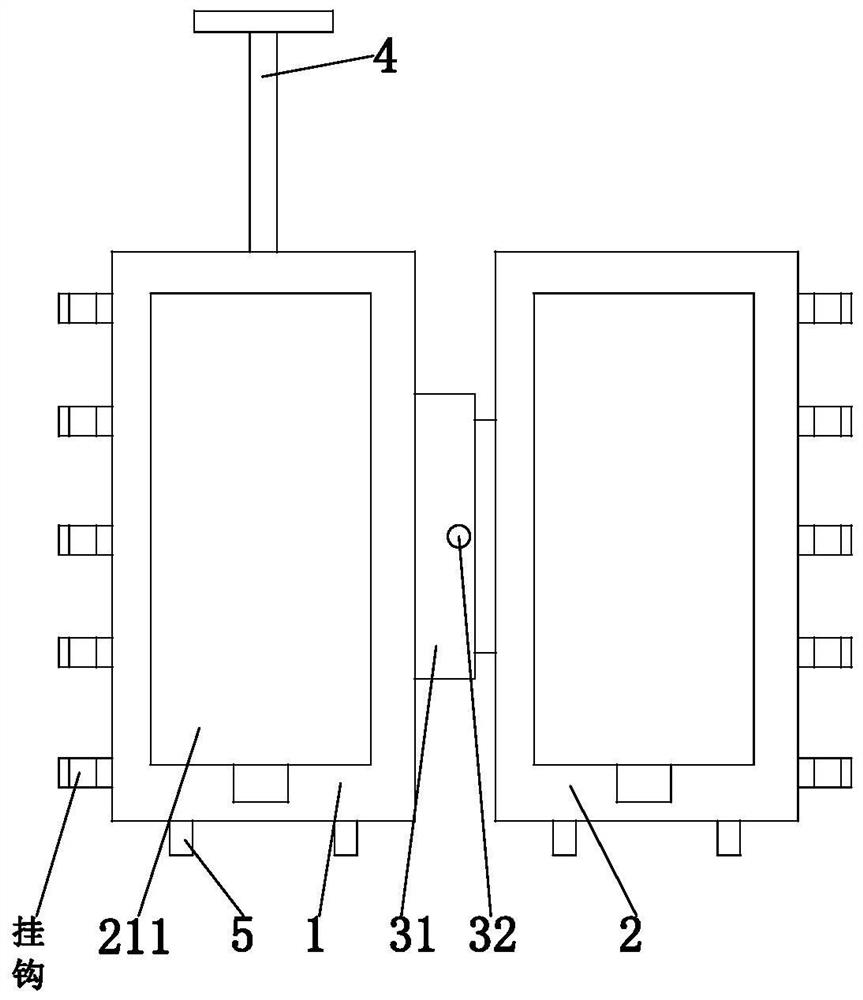

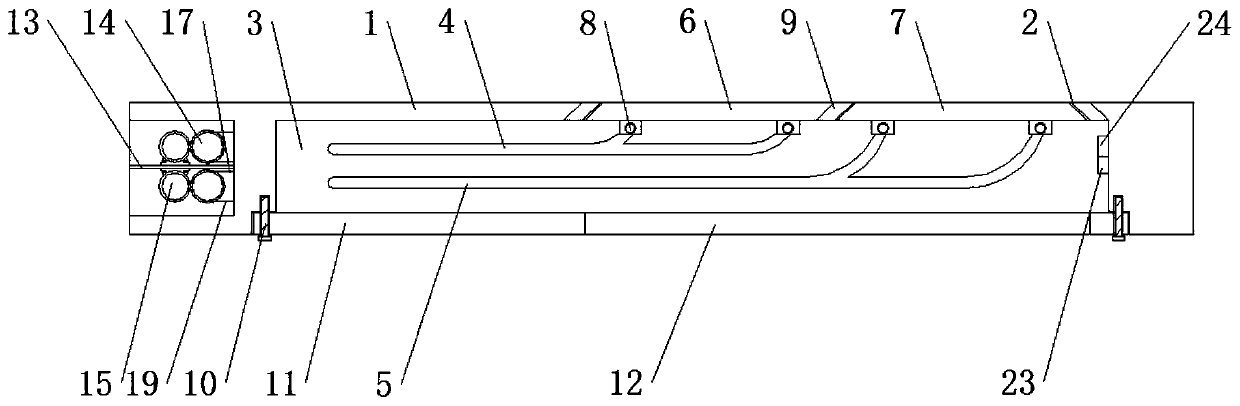

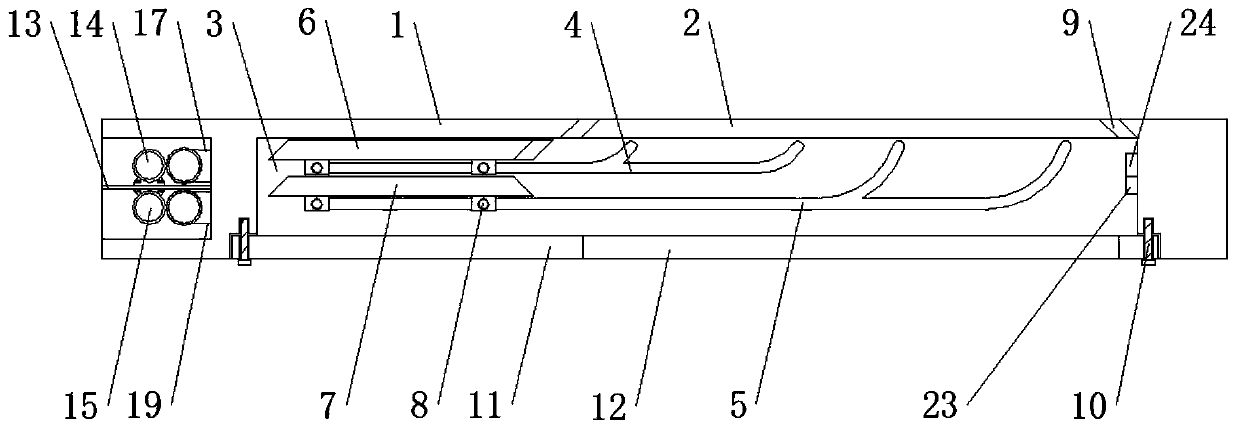

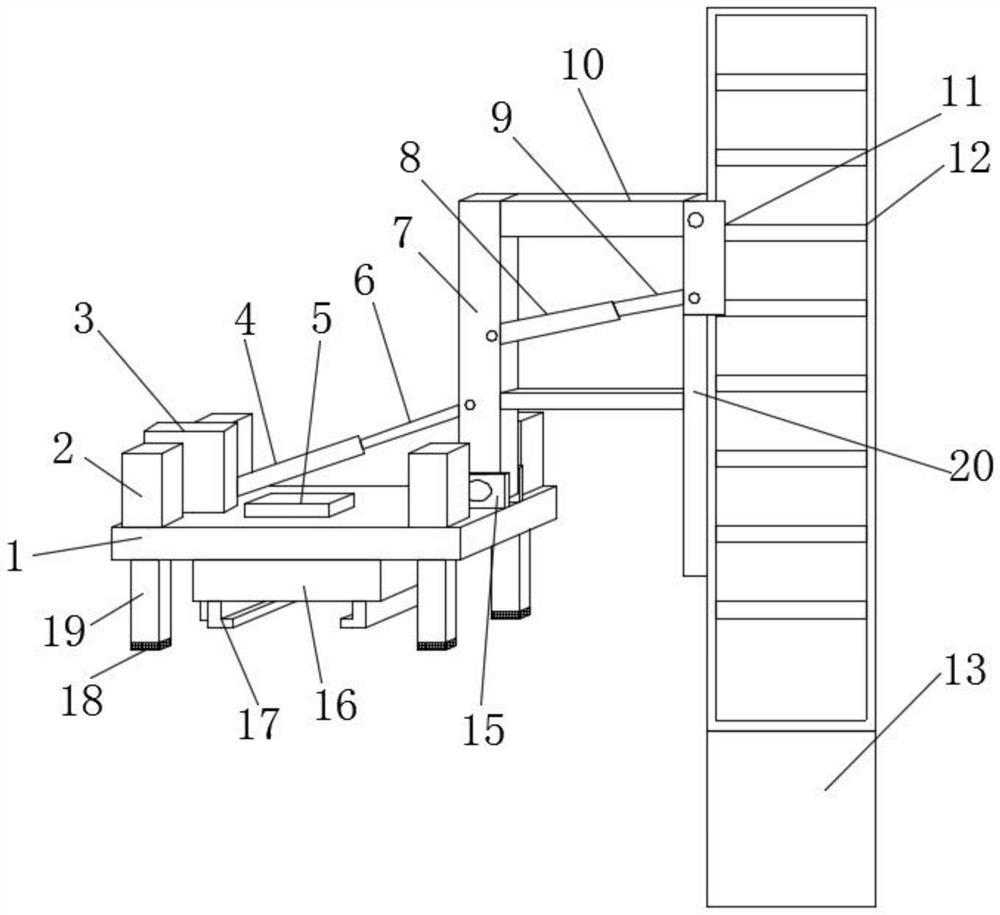

Optical fiber splicing device

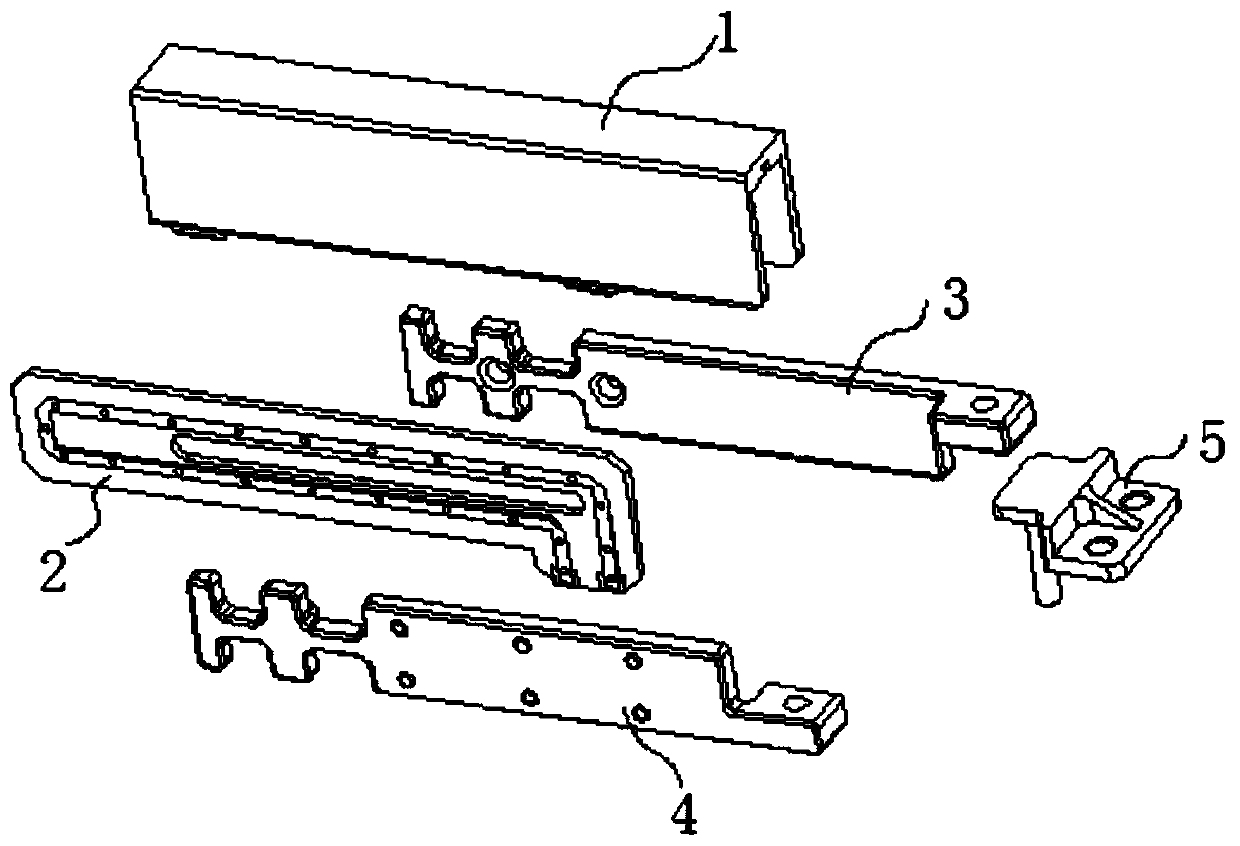

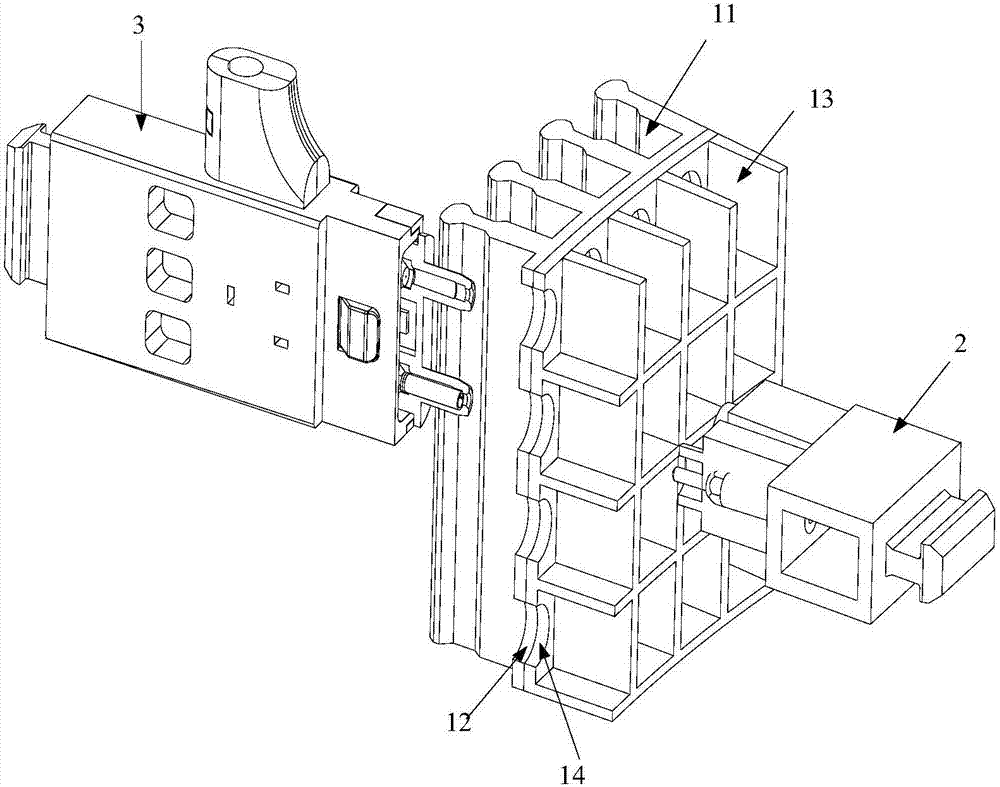

ActiveCN105739027ARealize automatic dockingReduced horizontal footprintCoupling light guidesEngineeringManipulator

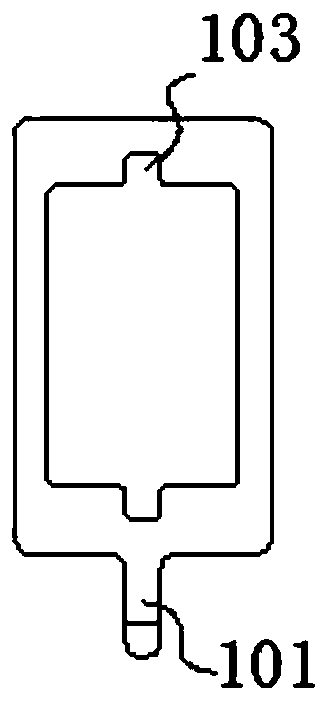

An embodiment of the invention discloses an optical fiber splicing device which comprises the components of a first fixing board and a second fixing board which are arranged in a manner of facing each other; a plurality of slide bars which are arranged between the first fixed board and the second fixed board and are fixedly connected with the first fixed board and the second fixed board; a splicing matrix structure in a space which is composed of the first fixing board, the second fixing board and the plurality of slide bars; at least one manipulator which is movably connected with the slide bar and can move along the slide bar; an optical fiber core splicing device which is used for fixing outer optical cores and is driven by the manipulator to move along a preset direction; and a cord connecting structure which is arranged in the chamber of the splicing matrix structure, wherein the cord connecting structure comprises a first cord connector, a second cord connector and a cord fixing member which is fixedly connected with the first cord connector and the second cord connector. The optical fiber splicing device has advantages of realizing automatic splicing of multiple optical fiber cores, greatly reducing labor and saving a large amount of labor and physical resource.

Owner:NINGBO YINGMING ELECTRIC TECH

Ground cleaning equipment

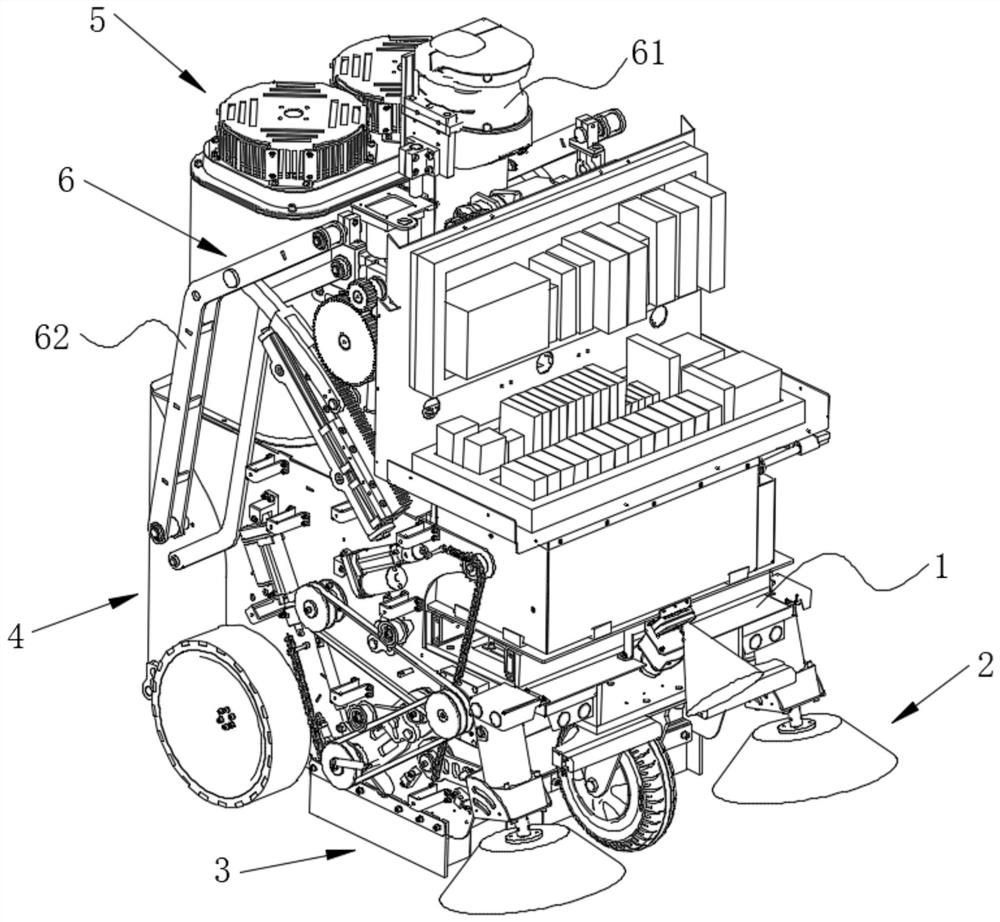

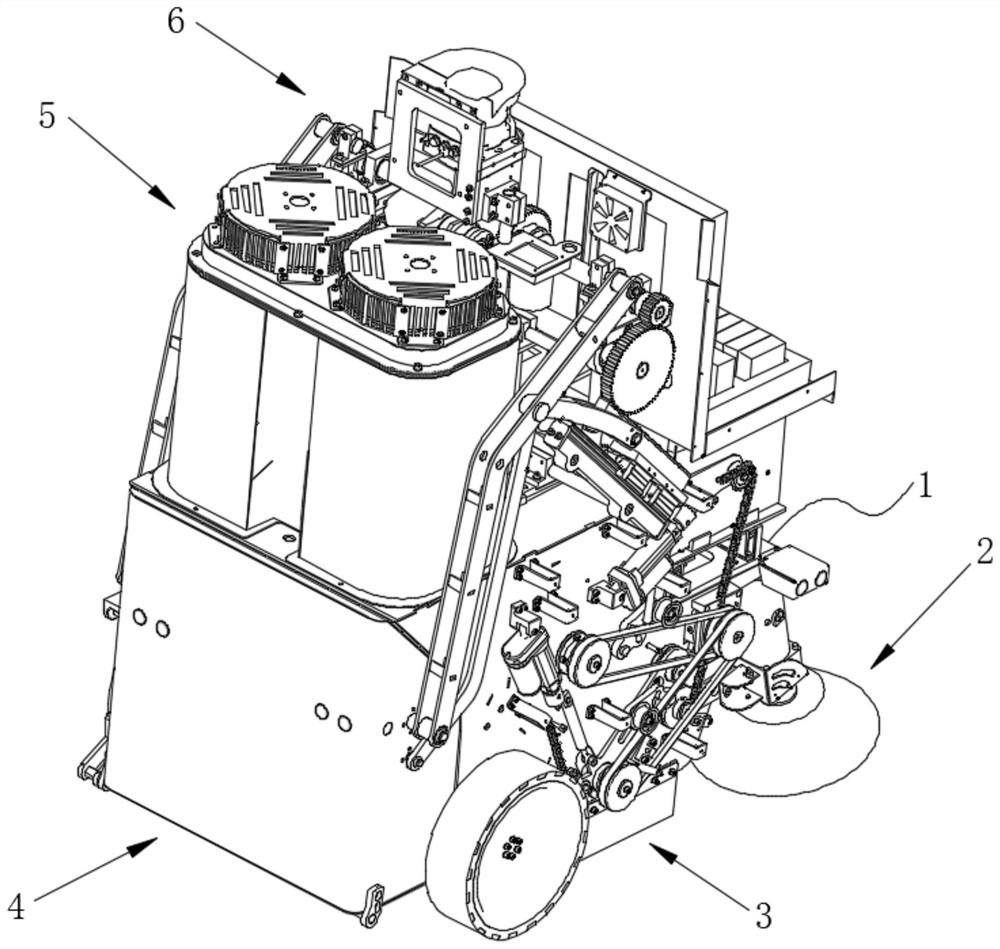

PendingCN112120604AImprove dust collection abilityReduce front and rear distance dimensionsCarpet cleanersFloor cleanersBrush deviceStructural engineering

The invention belongs to the technical field of buildings, and discloses ground cleaning equipment which is characterized in that a side brush device is mounted below the front part of a frame, a rolling brush device is mounted below the middle part of the frame, a garbage can is mounted below the rear part of the frame, the garbage can is communicated with the rolling brush device, and a negativepressure device is mounted above the rear part of the frame; the negative pressure device comprises a filter element mechanism and a draught fan mechanism, the filter element mechanism comprises a shell and at least two filter elements, the filter elements are vertically arranged side by side in the direction perpendicular to the advancing direction of the frame, the upper end of the shell is connected with the periphery of the draught fan mechanism in a sealed mode, and an air outlet channel communicated with the draught fan mechanism is formed in each filter element. An air inlet channel isformed between the filter element and the shell, the axial lower end of the filter element is closed, an opening is formed in the lower end of the shell, and an air inlet is formed between the edge of the opening and the filter element and communicated with the rolling brush device and the side brush device. The horizontal occupied area of the equipment can be reduced, and then the operation capacity of the equipment in a narrow space is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Trailing vine plant transportation fixed frame

InactiveCN109703875ASufficient lightingPromote photosynthesisLiving organism packagingContainers to prevent mechanical damageGrowth plantFixed frame

The invention provides a trailing vine plant transportation fixed frame. The trailing vine plant transportation fixed frame comprises a base plate, a flowerpot fixing device and a trailing vine fixingdevice. The trailing vine plant transportation fixed frame can solve such difficulties as the peeling phenomenon caused by extrusion friction between main poles and branched stems of trailing vine plants easily caused by complicated transportation road sections in the trailing vine plane transportation process, influence on the growth of the trailing vine plants by insufficient illumination in long-time transportation process, influence on original structural forms of flowers and bad influence on the living due to easy breakage in the transportation process and large occupied transportation space caused by verdant growth, larger size and longer training vines of the trailing vine plants, and drying death of the plants easily caused by insufficient water in the plants due to long-time transportation. The trailing vine plant transportation fixed frame can realize fixed transportation of vines of the trailing vine plants, and provides proper illumination and environmental humidity for full photosynthesis on the plants to promote the plant growth function.

Owner:西安科技成果转化工程有限公司

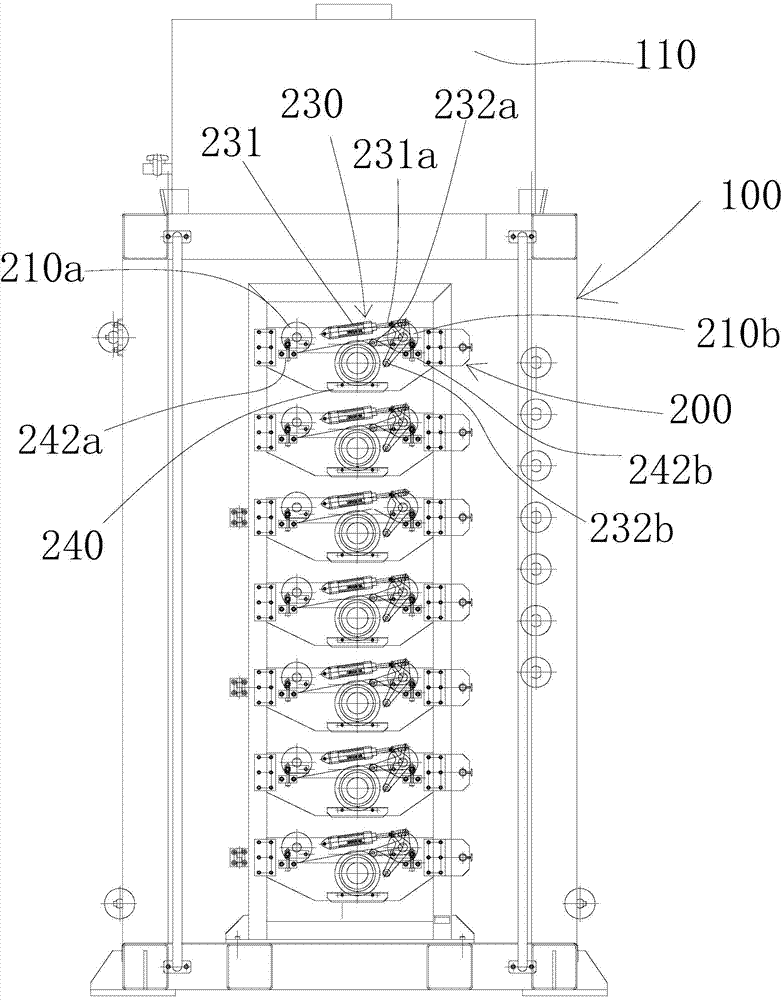

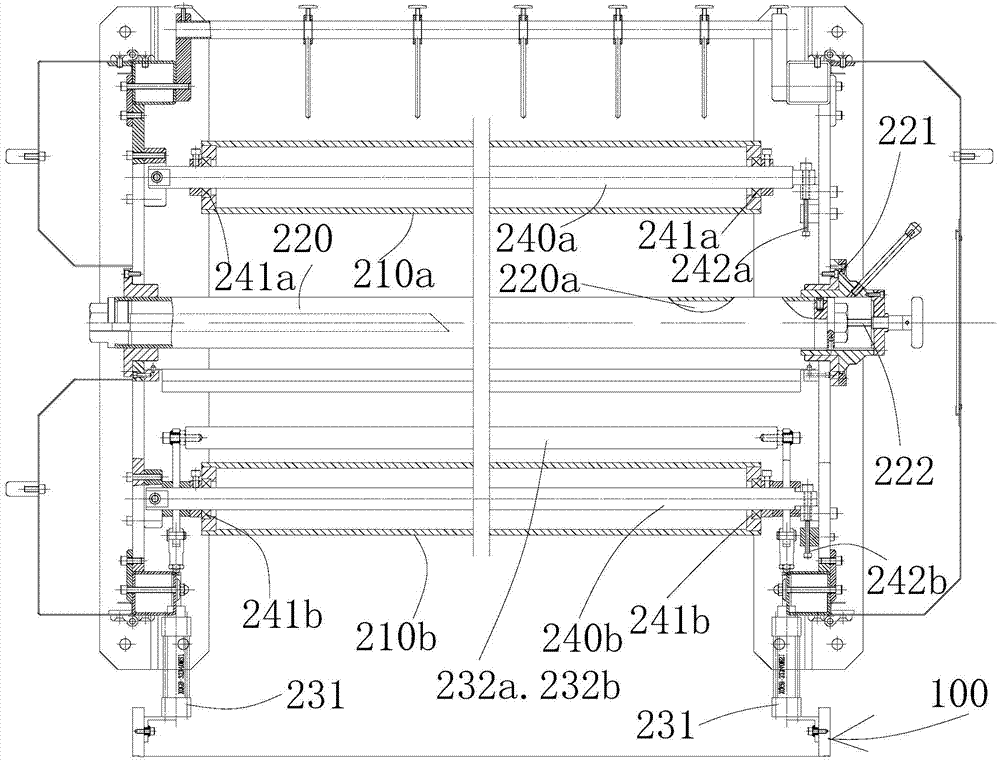

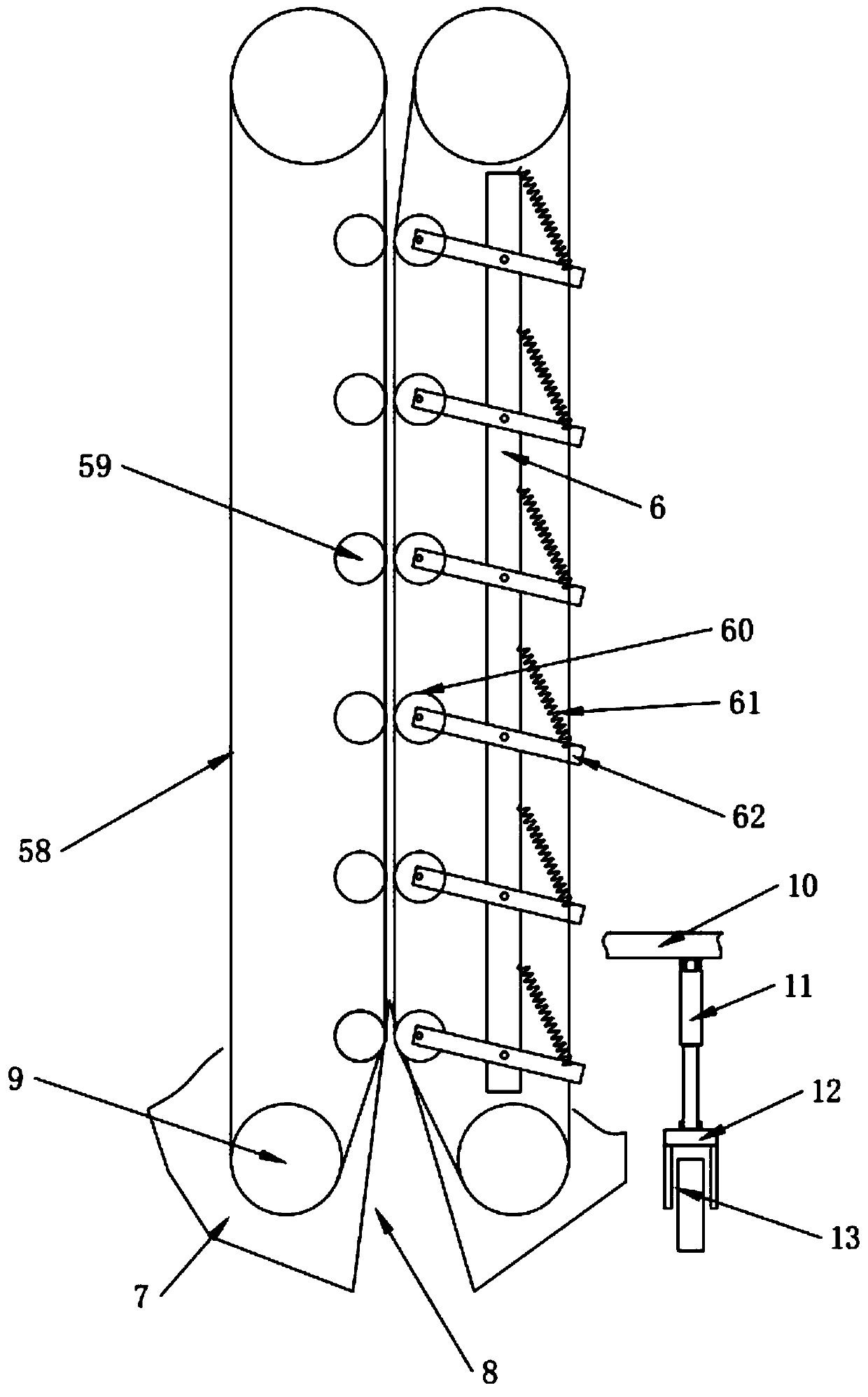

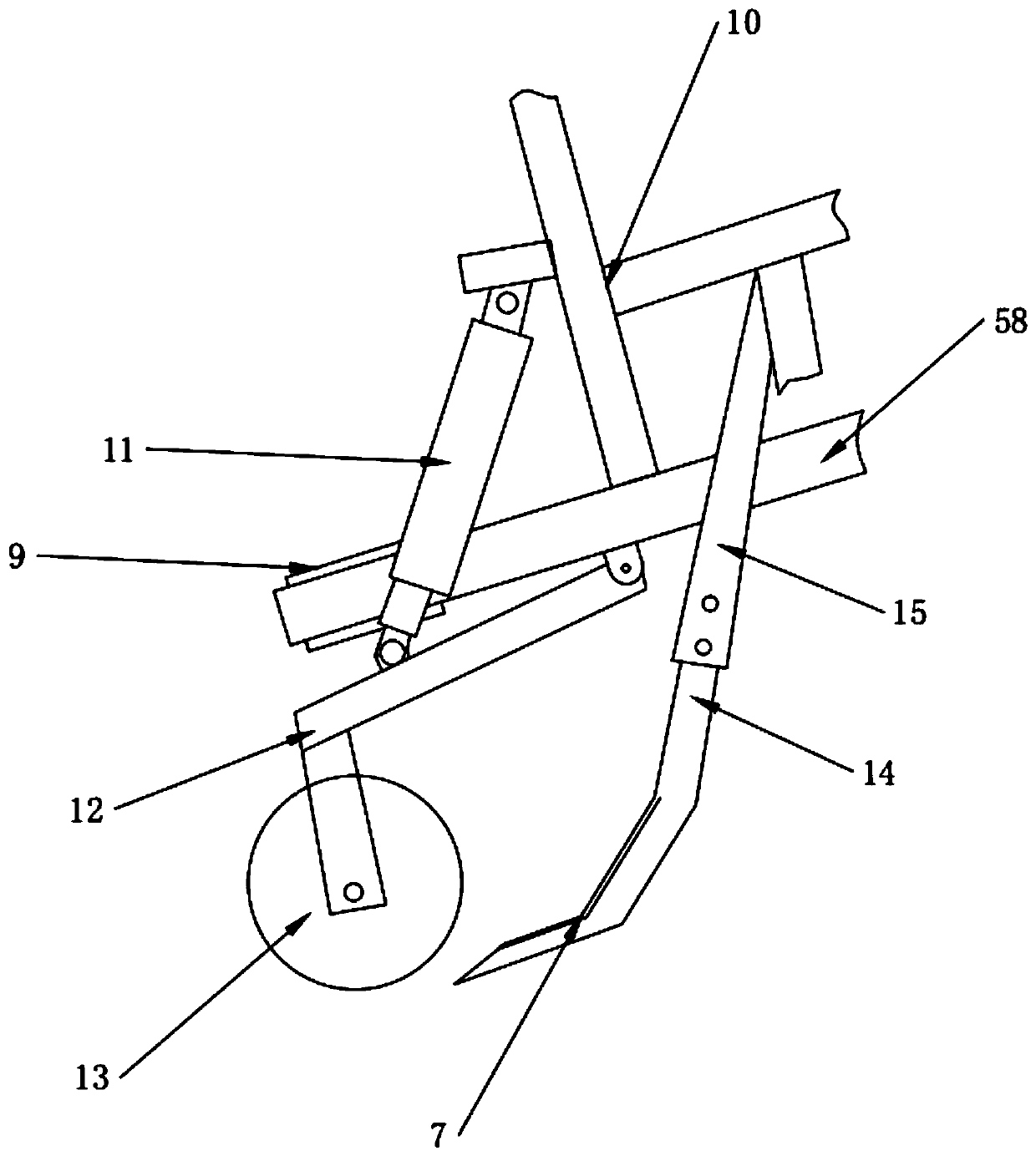

Glue filling machine for high-speed continuous production line of honeycomb paper core

InactiveCN103495518AReduced horizontal footprintImprove gluing effectLiquid surface applicatorsPaper/cardboard articlesHoneycombCardboard

The invention discloses a glue filling machine for a high-speed continuous production line of a honeycomb paper core. The glue filling machine comprises a rack, a glue barrel arranged on the rack, a plurality of glue coating unit mechanisms which are arranged on the rack and are used for carrying glue coating on a paper plate, and a glue filling mechanism which is arranged on one side of the rack and is used for filling glue in the plurality of glue coating unit mechanisms, wherein the plurality of glue coating unit mechanisms are arranged on the rack from top to bottom in a vertical structure manner. The glue filling machine provided by the invention has the advantages that the plurality of glue coating unit mechanisms are arranged from top to bottom in the vertical structure manner, a horizontal floor space of equipment is greatly reduced, the glue coating effect is improved, and the disassembly, the cleaning and the maintenance are convenient.

Owner:SHANGHAI LVSHUN PACKAGING MACHINERY

LED unit and LED apparatus

InactiveCN101368700AReduced horizontal footprintBeautiful viewing surfacePoint-like light sourceElectric circuit arrangementsEngineering

Owner:BEIJING ZHONGQING MICRO ELECTRIC TECH

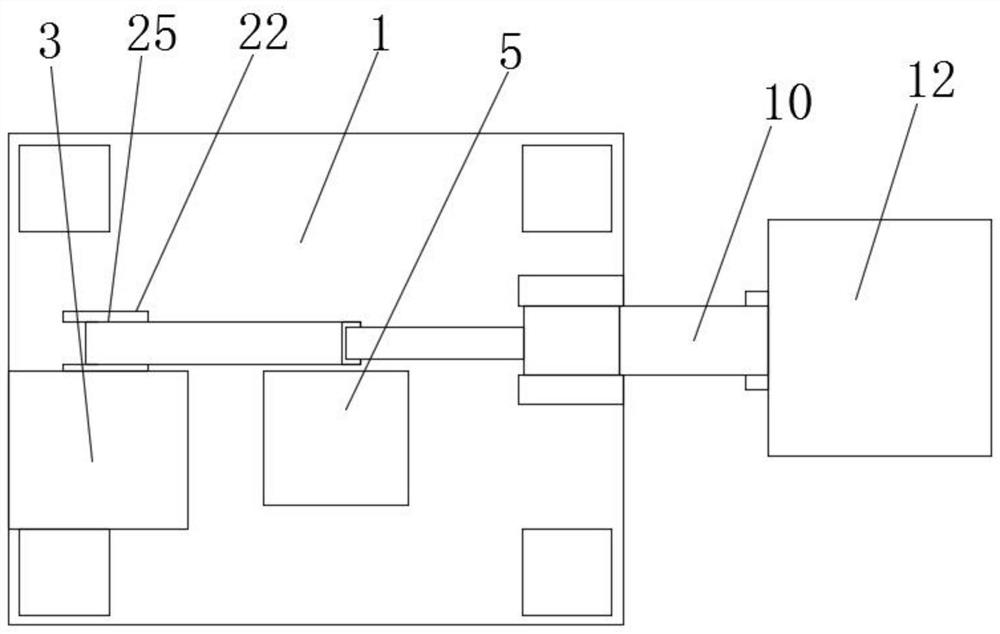

Functional composite non-woven fabric preparation method and feeding method and device

ActiveCN112537678AHeight fine-tuningReduce frictionLiquid surface applicatorsCoatingsEngineeringStructural engineering

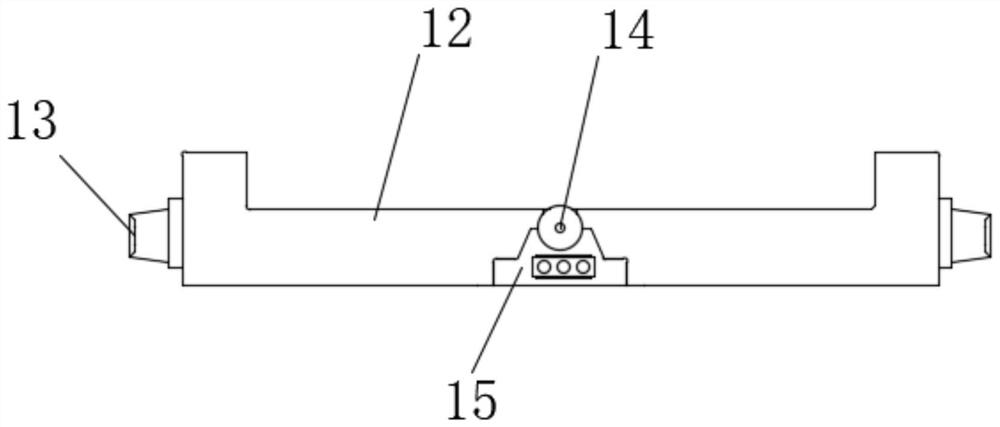

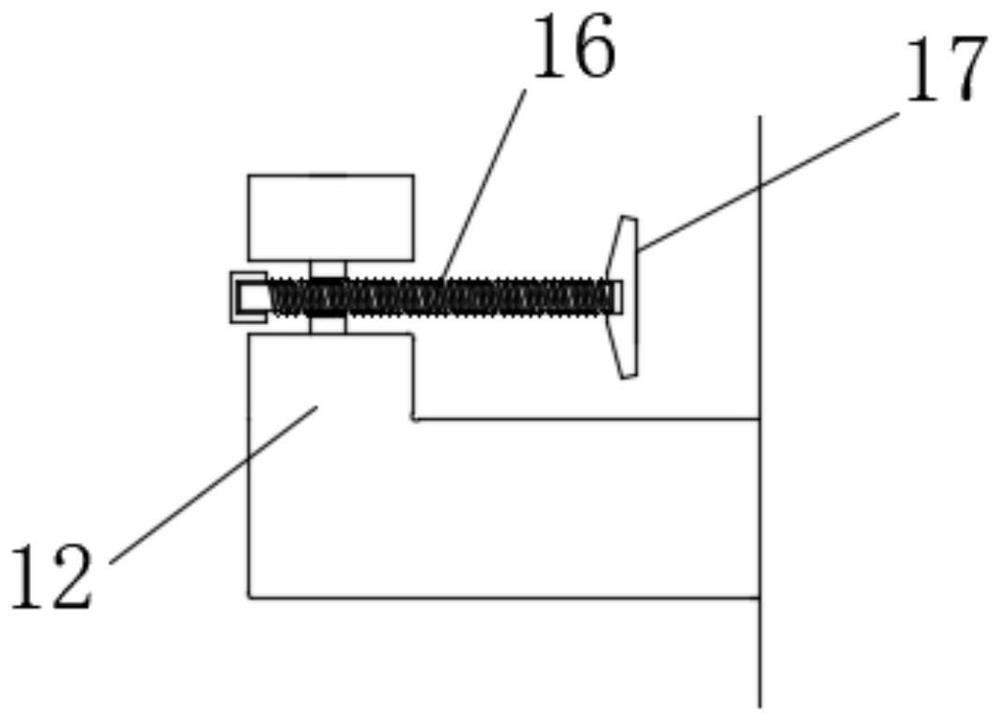

The invention discloses an inclined fastening feeding device. The top of a turnover feeding platform is a placing surface, the turnover feeding platform is rotated towards a lifting platform so that the lifting platform can move downwards, and a cloth roll on the placing surface can fall to the top of the lifting platform; the turnover feeding platform is rotated back to the lifting platform so that the lifting platform can move upwards until the cloth roll on the top of the lifting platform is opposite to aligning and fastening devices; and the two aligning and fastening devices are symmetrically distributed on two sides of the lifting platform, when two aligning roller bodies extend out to be aligned oppositely, two extrusion movable blocks extrude each other to move into inner cavitiesof the corresponding aligning roller bodies, and thus, a fastener partially extends out of the aligning roller bodies and abuts against the inner wall of a paper tube. The invention further disclosesa functional composite non-woven fabric preparation method, a feeding method and a feeding and conveying device. The inclined fastening feeding device has the advantage of improving the cloth production and processing efficiency.

Owner:福建智罗科技有限公司

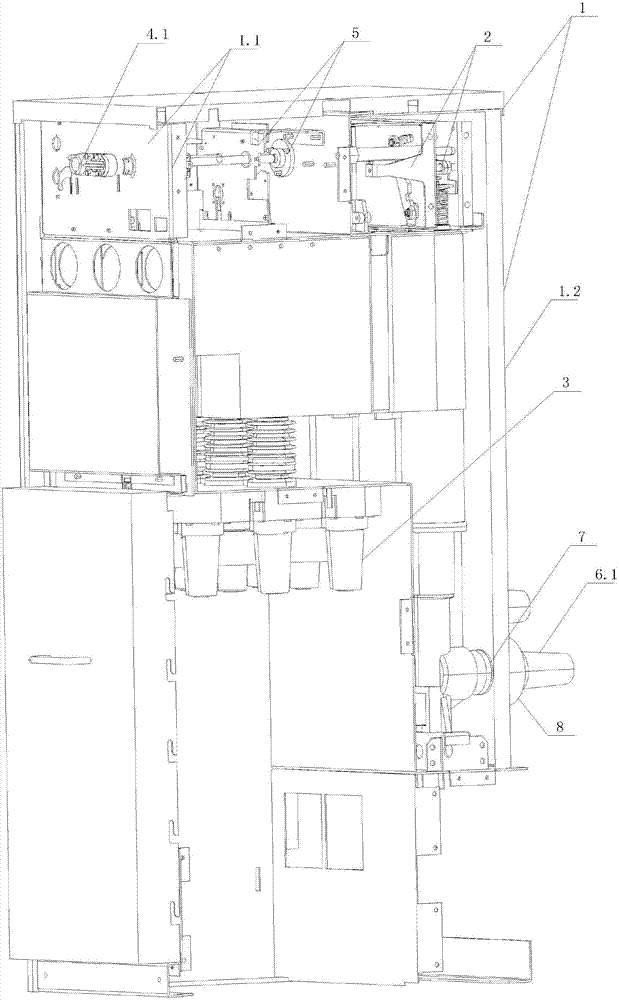

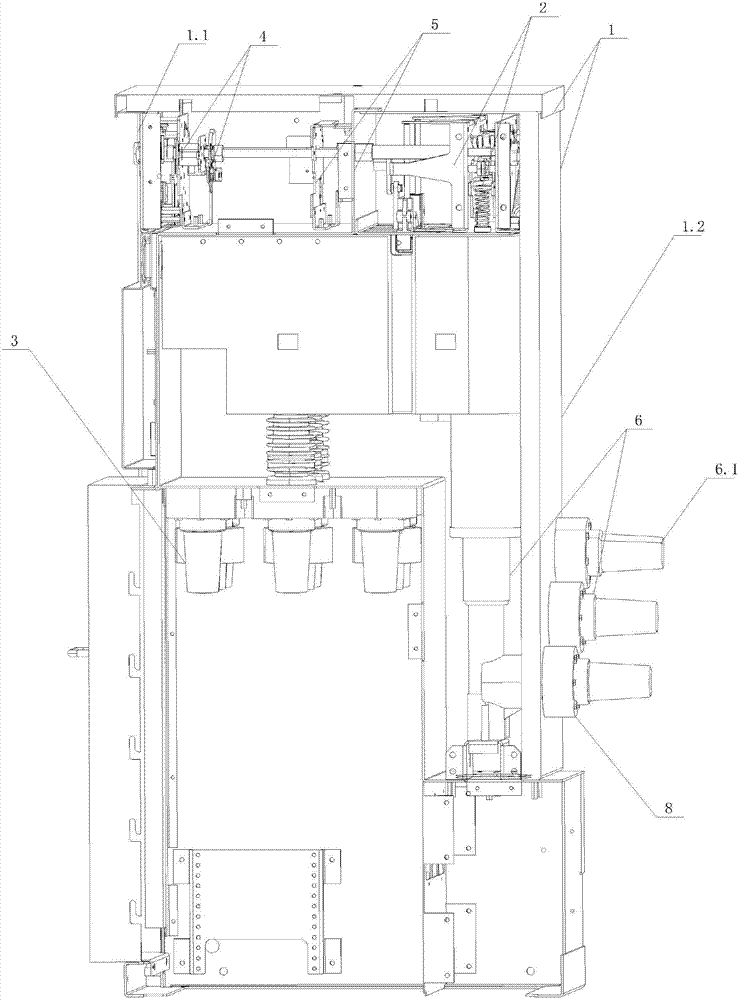

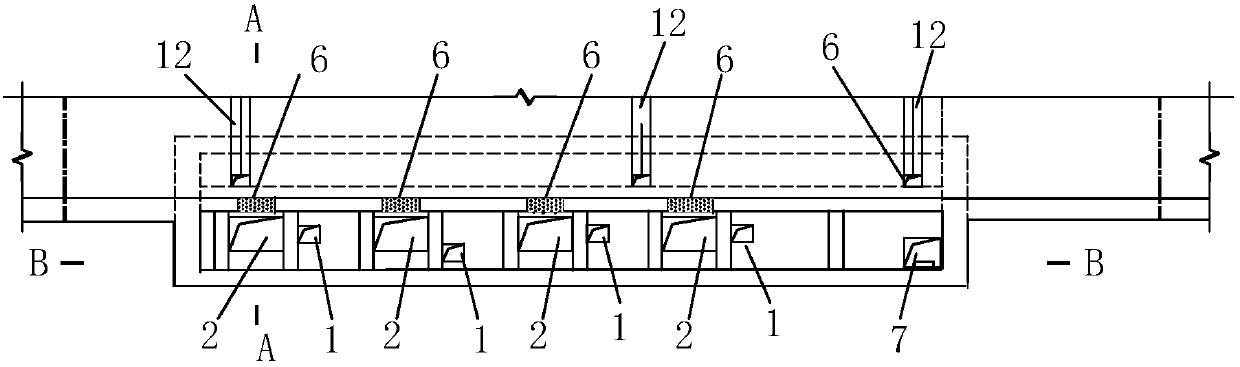

Small-sized vacuum ring main unit

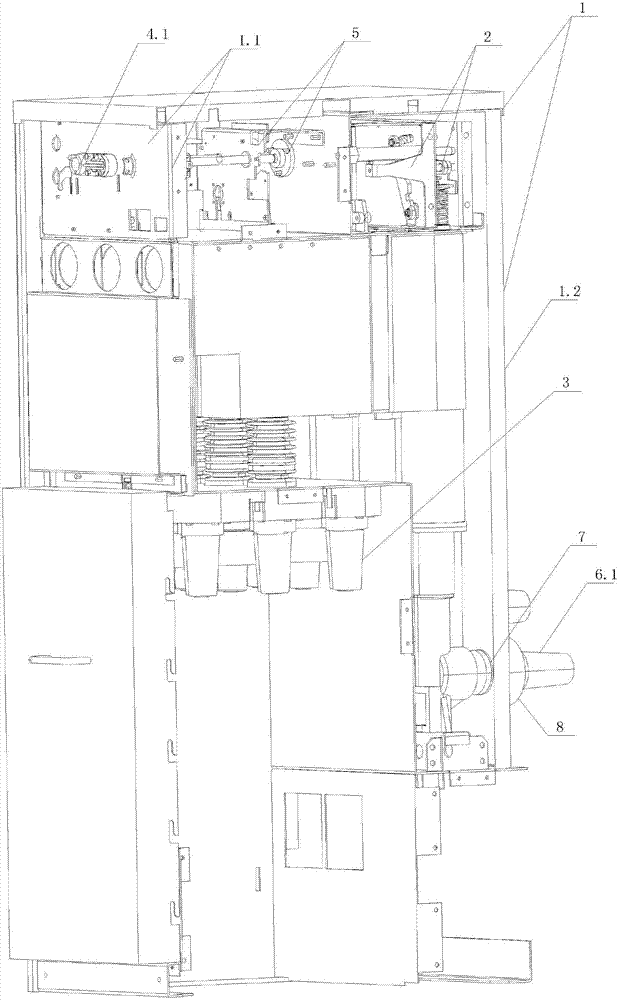

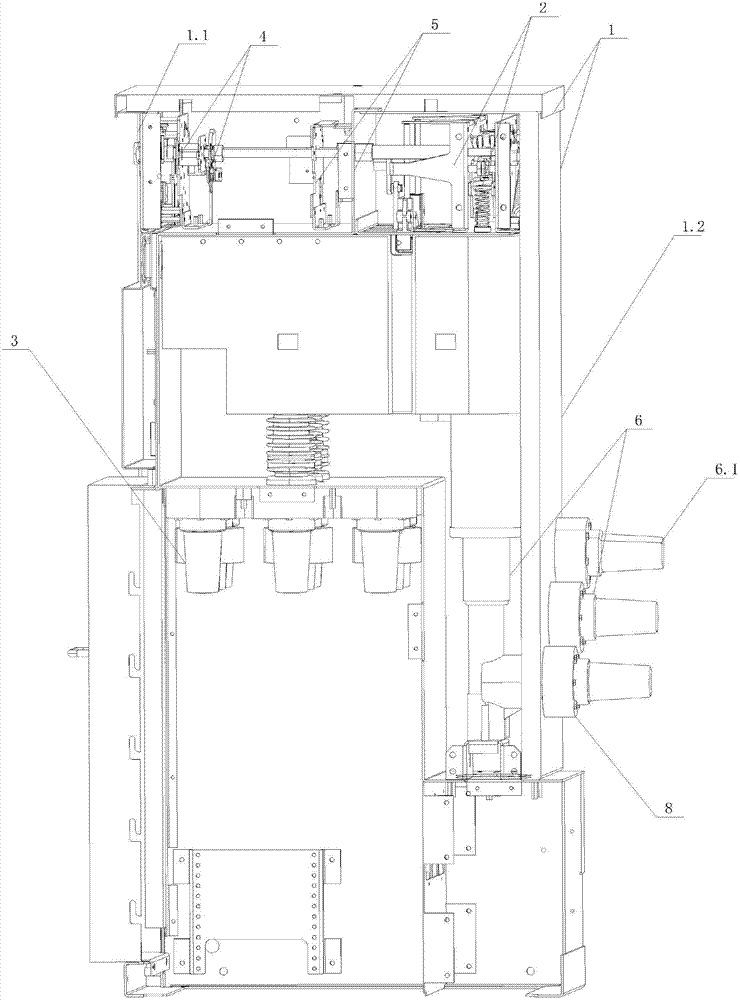

ActiveCN102780171AGuaranteed to workHigh working reliabilityBus-bar/wiring layoutsSwitchgear arrangementsElectrical and Electronics engineeringEngineering

The invention discloses a small-sized vacuum ring main unit. A three-position disconnecting switch (4), a mechanical interlocking assembly (5) and a spring operating mechanism (2) are arranged at the upper part of a casing (1) and are sequentially connected; an operation button (4.1) of the three-position disconnecting switch (4) is arranged outside the casing (1); an insulated bus (6) is arranged below the spring operating mechanism (2); the upper end of the insulated bus (6) is connected with the spring operating mechanism (2); an arcing chamber pole column (3) is arranged below the three-position disconnecting switch (4) in the casing (1), the arcing chamber pole column (3) is connected to the insulated bus (6), and a wiring terminal (6.1) of the insulated bus (6) is arranged outside the casing (1); the casing (1) is a closed casing; and the spring operating mechanism (2), the three-position disconnecting switch (4) and the mechanical interlocking assembly (5) are arranged in the closed casing. The small-sized vacuum ring main unit is small in size and high in work reliability.

Owner:SUNRISE GRP CO LTD

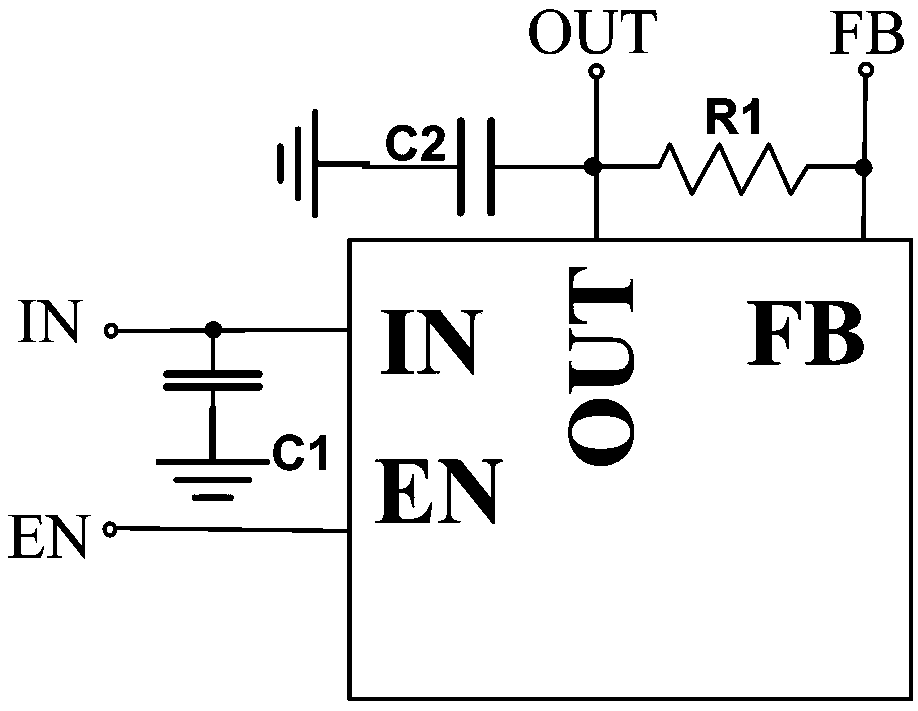

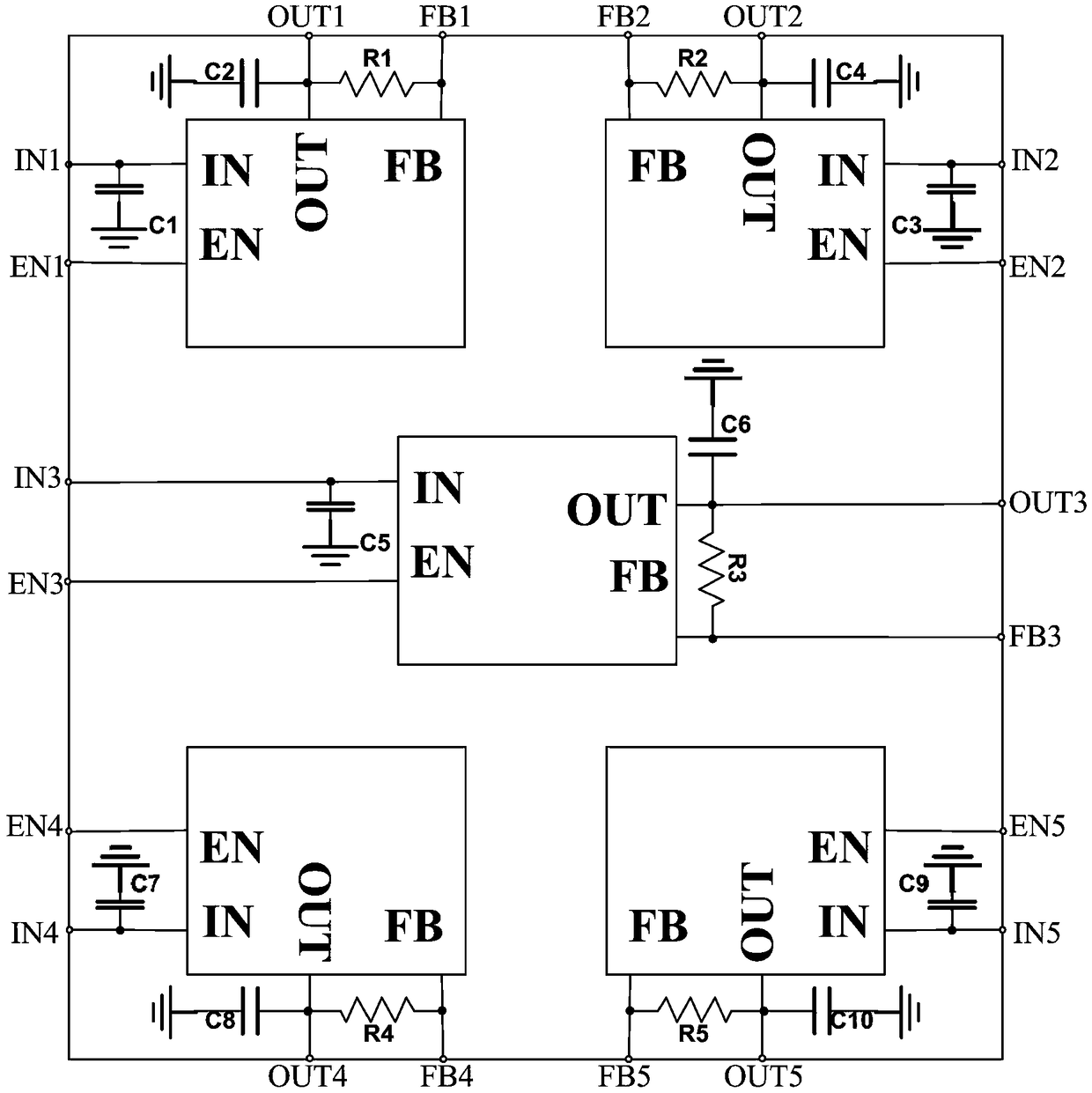

Multi-channel voltage converter based on integral packaging

InactiveCN108880195AImprove stabilityIncrease the effective cooling surfacePrinted circuit board receptaclesCooling/ventilation/heating modificationsVoltage converterCapacitance

The invention provides a multi-channel voltage converter based on integral packaging. The multi-channel voltage converter comprises a plurality of mutually independent voltage conversion units packaged inside an integral shell; each voltage conversion unit comprises a voltage conversion unpacked chip, the input end of each voltage conversion unpacked chip is grounded through a corresponding firstcapacitor, the output end of each voltage conversion unpacked chip is grounded through a corresponding second capacitor and is connected to an output voltage adjusting end of the voltage conversion unpacked chip through a corresponding resistor, the output voltage adjusting end of each voltage conversion unpacked chip is externally connected to an adjustable resistor, the output voltage of each voltage conversion unpacked chip is adjusted by adjusting the resistance value of the corresponding adjustable resistor, and pins correspondingly connected with the input end, output end, output voltageadjusting end and enabled end of each voltage conversion unpacked chip are led out from one side of the integral shell. According to the multi-channel voltage converter, the multi-channel integrationof the power device is realized by using the integral packaging, so that the size of circuit packaging is reduced, the heat dissipation effect is preferable, and the operating temperature range is wide.

Owner:NO 24 RES INST OF CETC

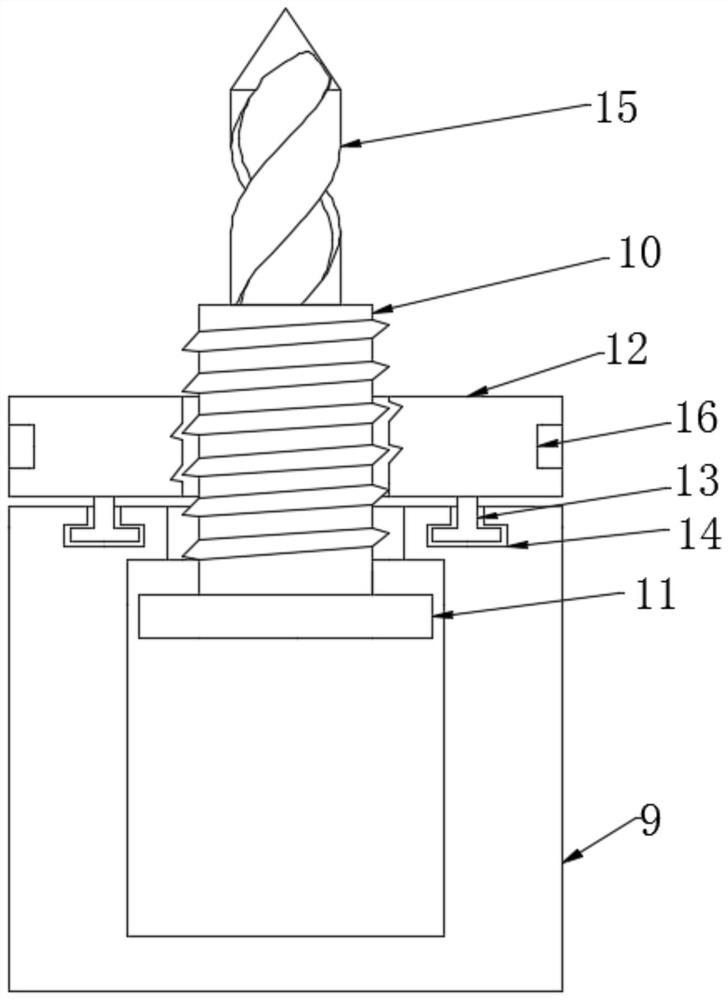

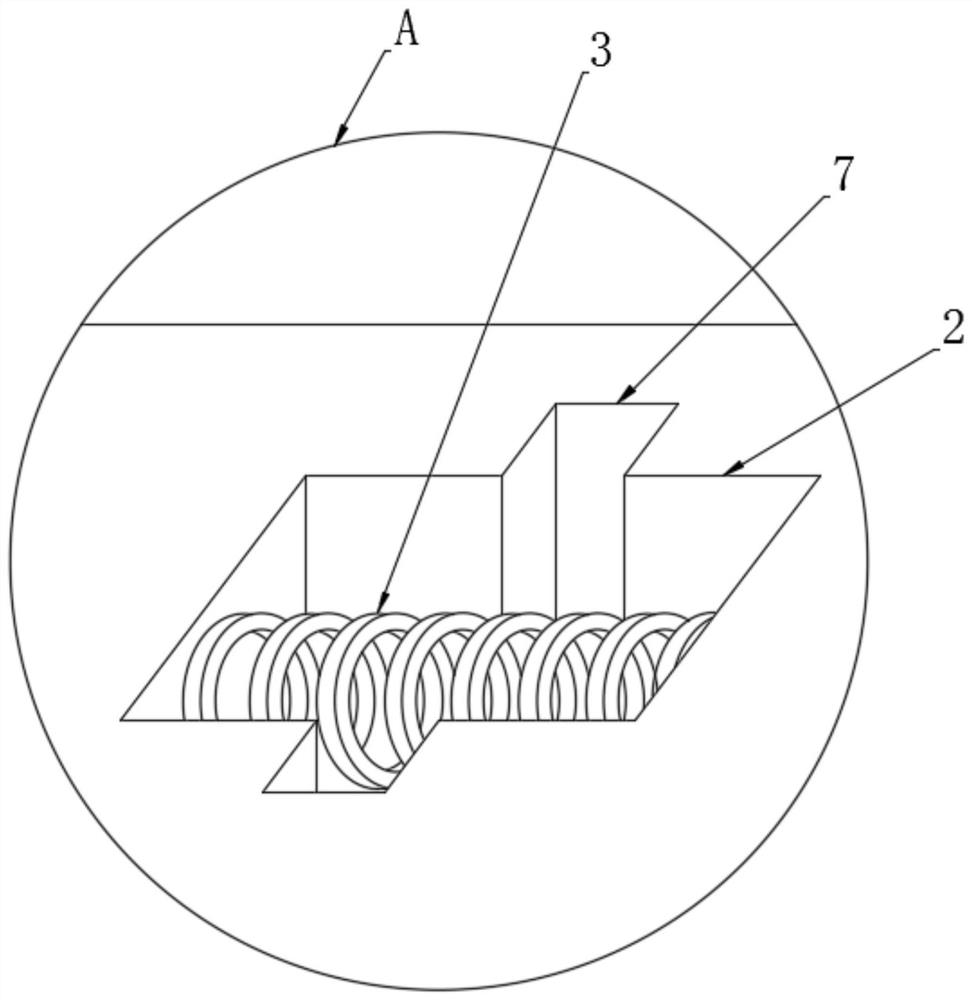

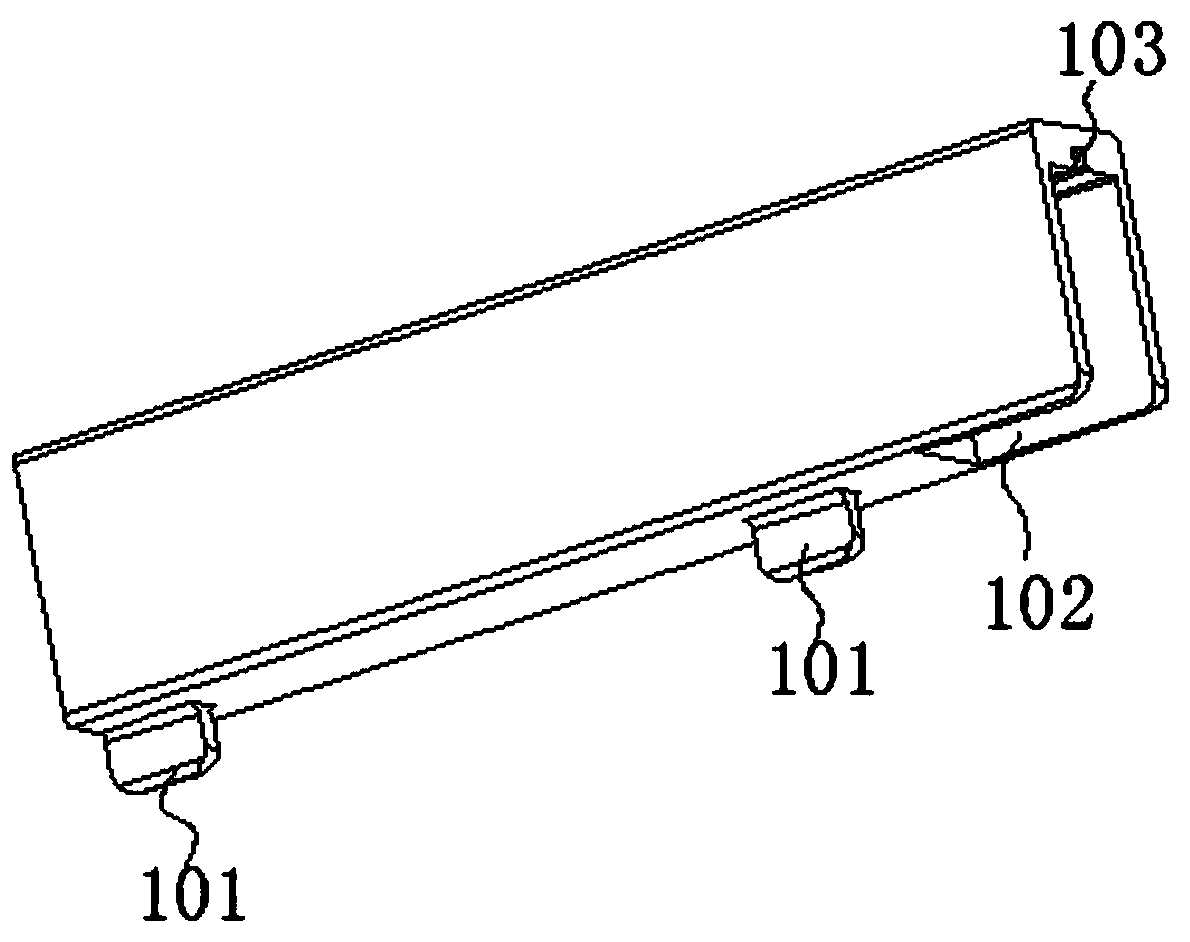

Precise temperature control intelligent slow cooker circuit board

InactiveCN112601350AReduce horizontal sizeReduced horizontal footprintCooking vesselsPrinted circuits structural associationsTemperature controlControl system

The invention relates to the technical field of circuit boards, in particular to a precise temperature control intelligent slow cooker circuit board. The circuit board comprises a first circuit board,a second circuit board, a screw rod and a control system, a through notch is formed in the surface of the first circuit board, a cushioning spring is bonded to the inner wall of the through notch, the outer side of the cushioning spring is sleeved with a pressing cylinder, a butt-joint insertion rod is bonded to the surface of the pressing cylinder, an occlusion strip is bonded to the surface ofthe butt-joint insertion rod, the occlusion strip is slidably connected to the interior of an occlusion groove, the occlusion groove is formed in the inner wall of a through notch, the butt-joint insertion rod is bonded to the bottom surface of the second circuit board, and a sleeve is bonded to the side wall of the first circuit board. The slow cooker circuit board has the beneficial effects that: according to the precise temperature control intelligent slow cooker circuit board, double layers of circuit boards are vertically stacked, so that the horizontal occupied area of the circuit boardsis reduced, the horizontal size of a slow cooker head is conveniently reduced, and storage is convenient.

Owner:中山市兴杰电器有限公司

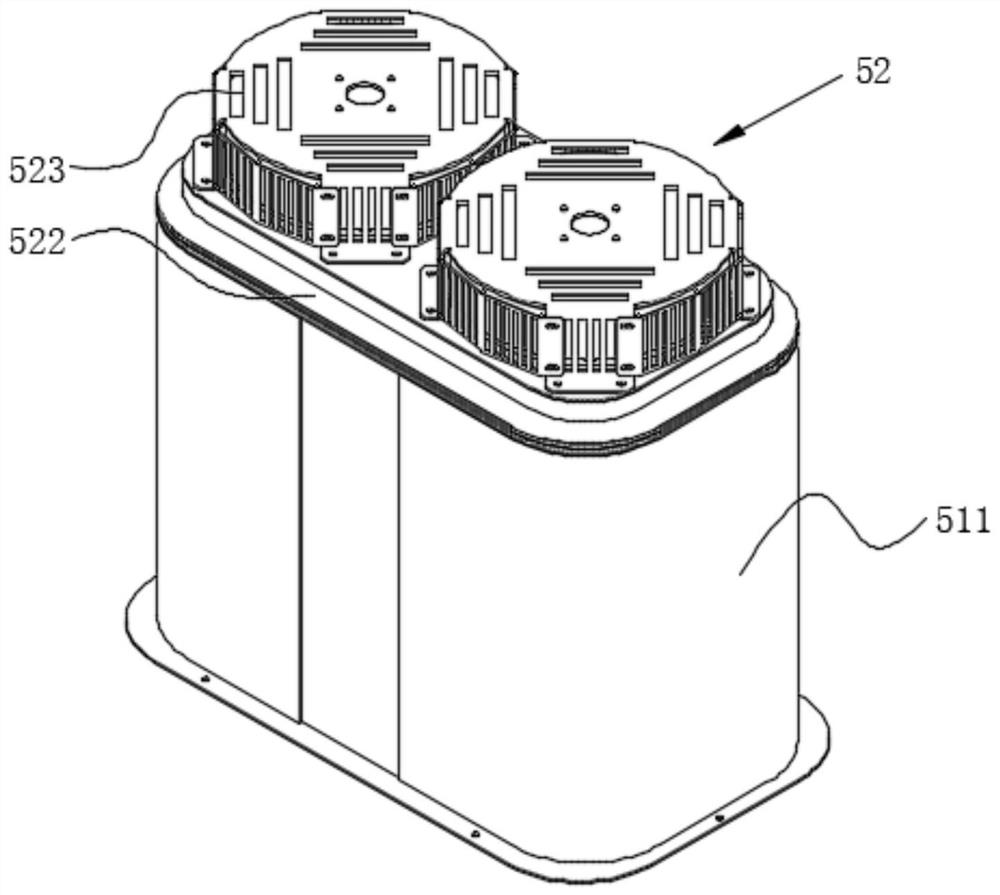

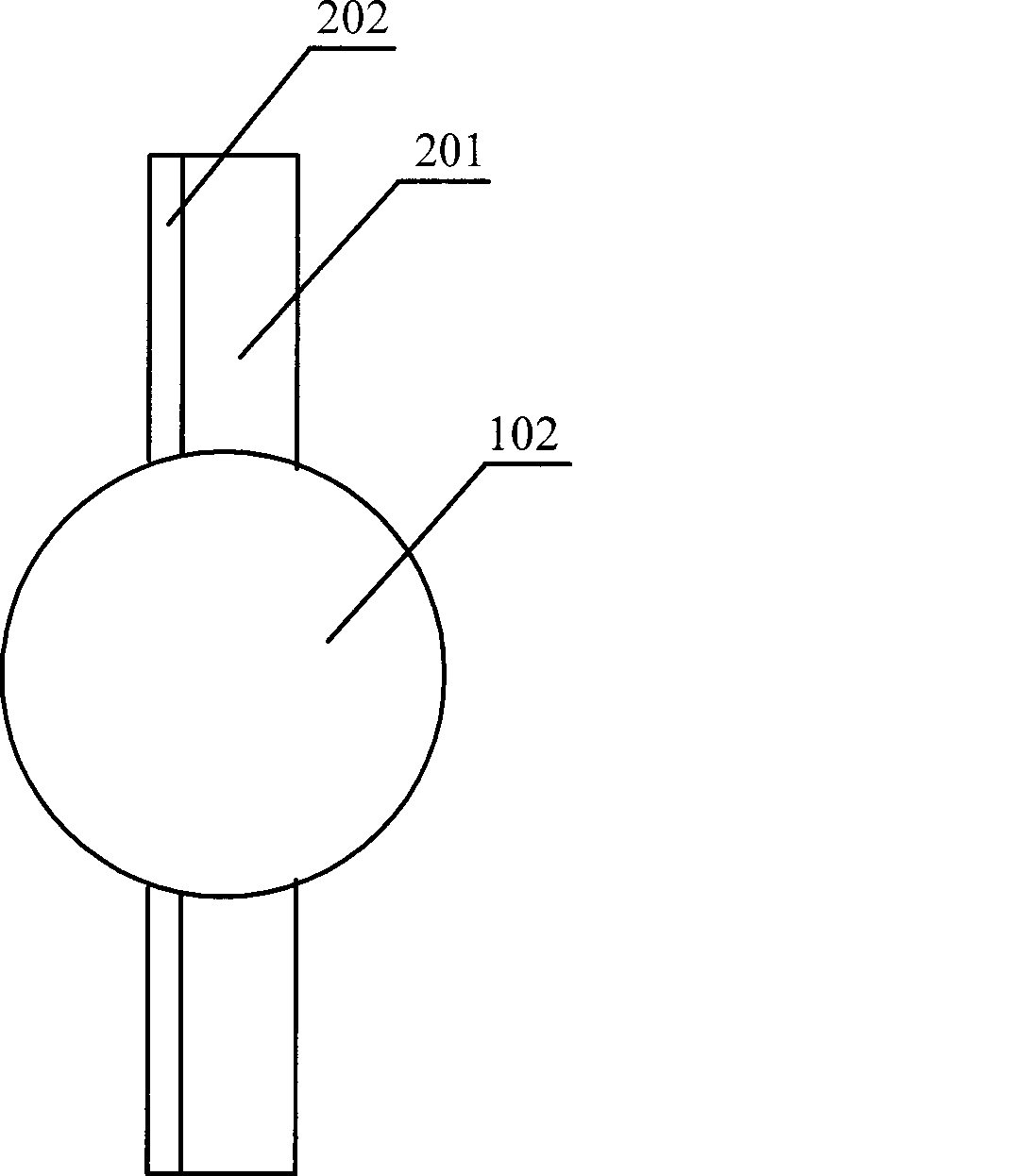

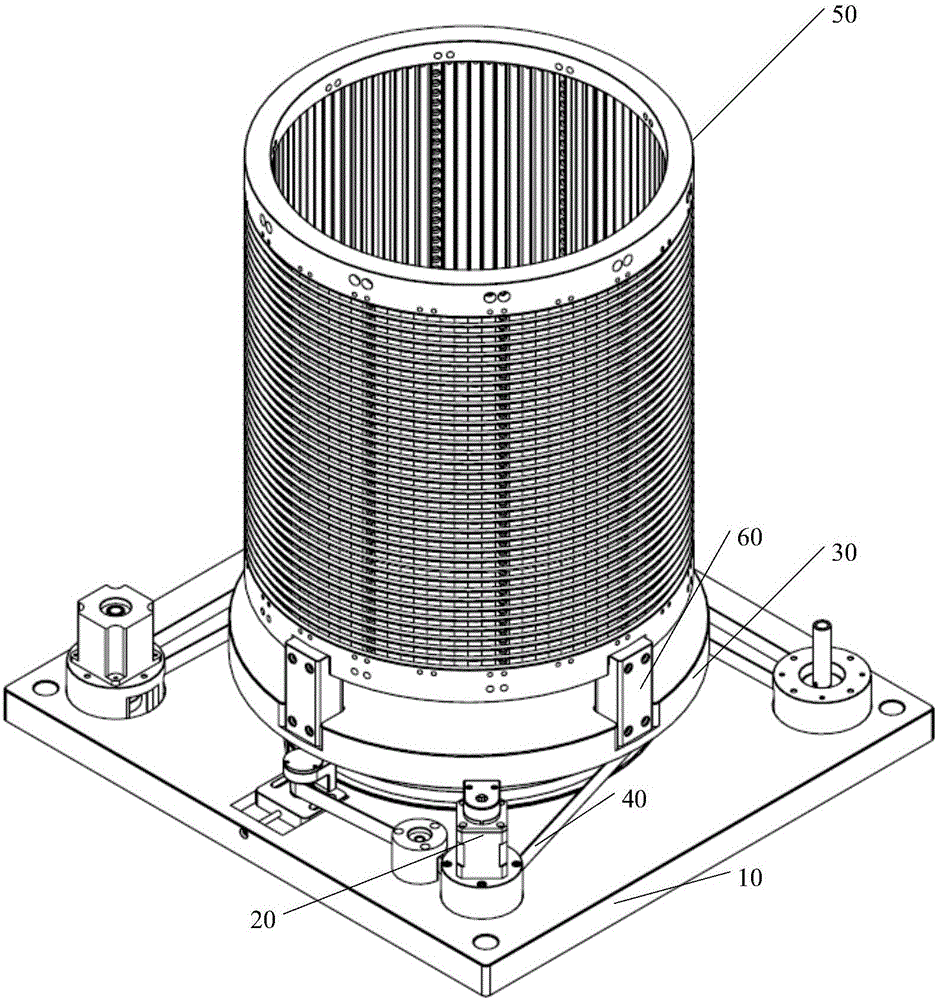

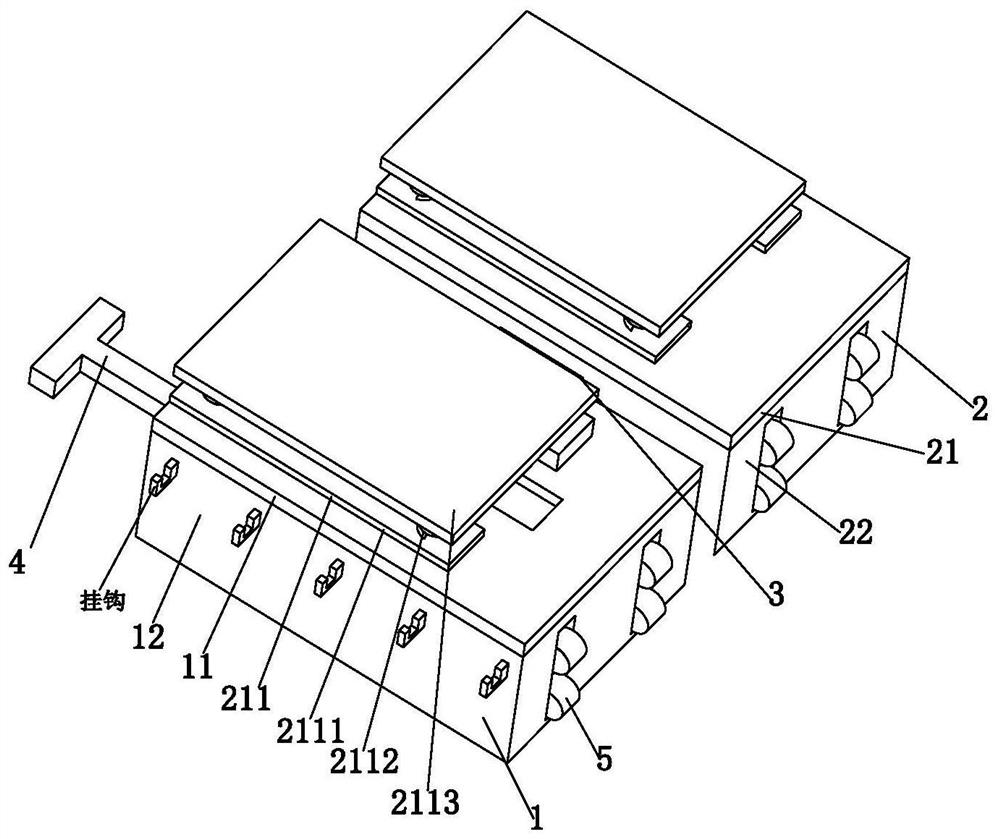

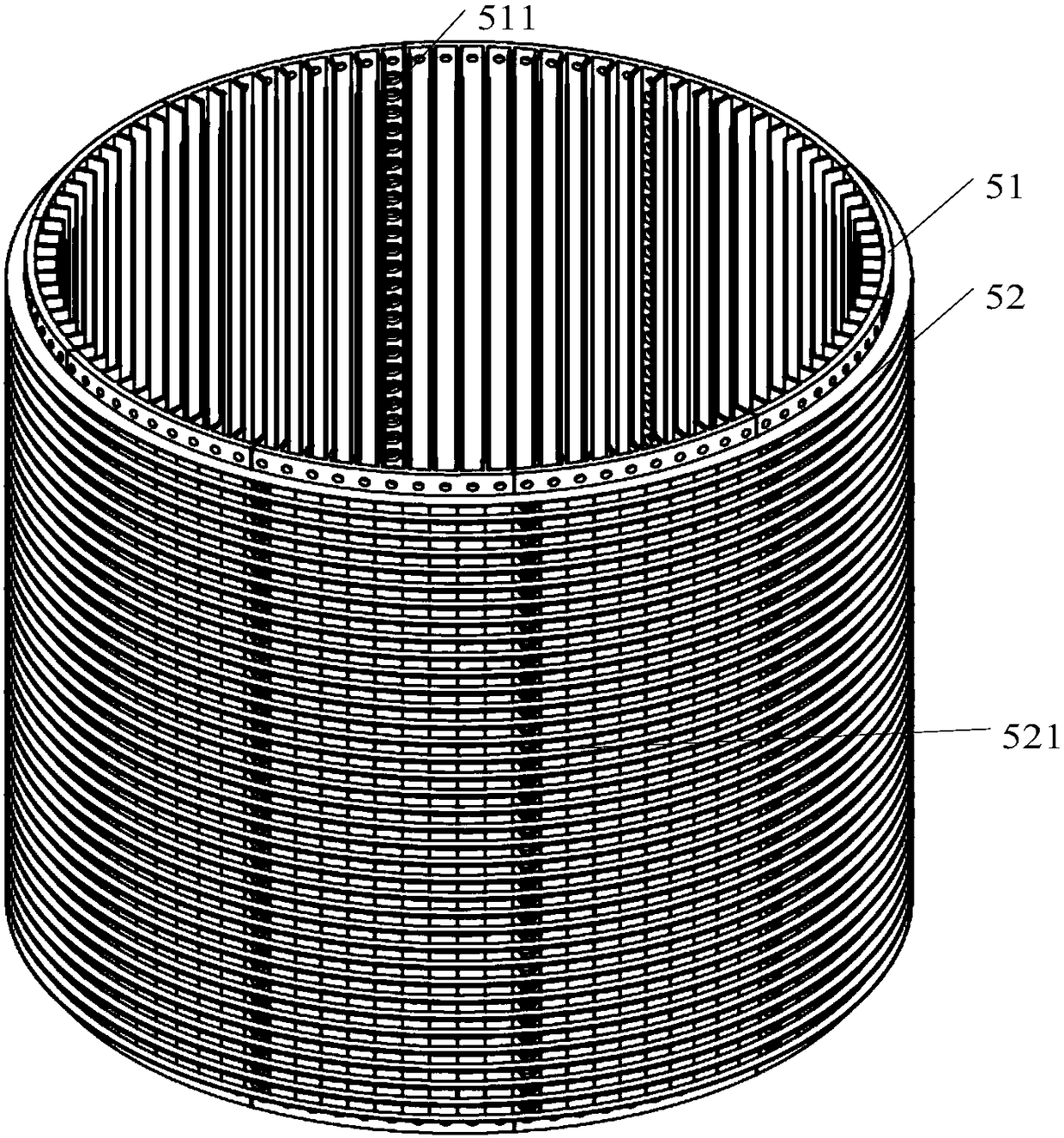

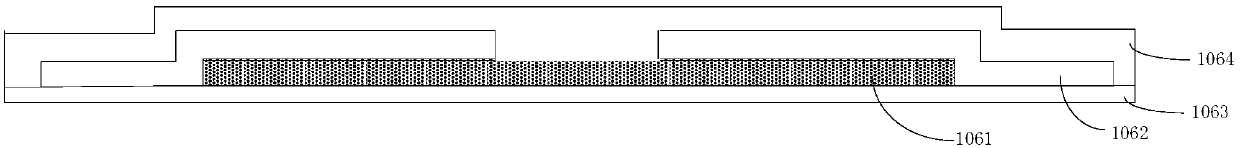

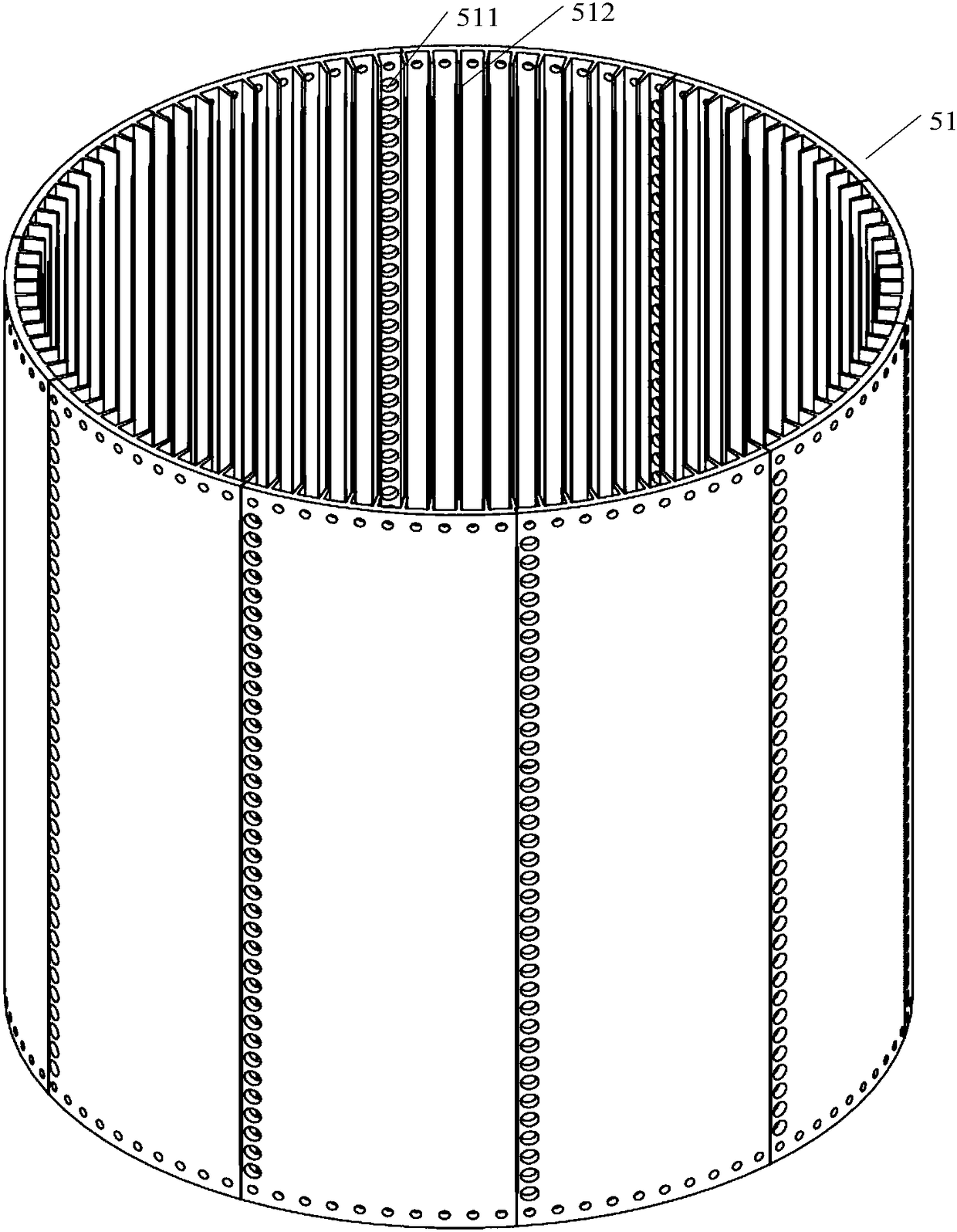

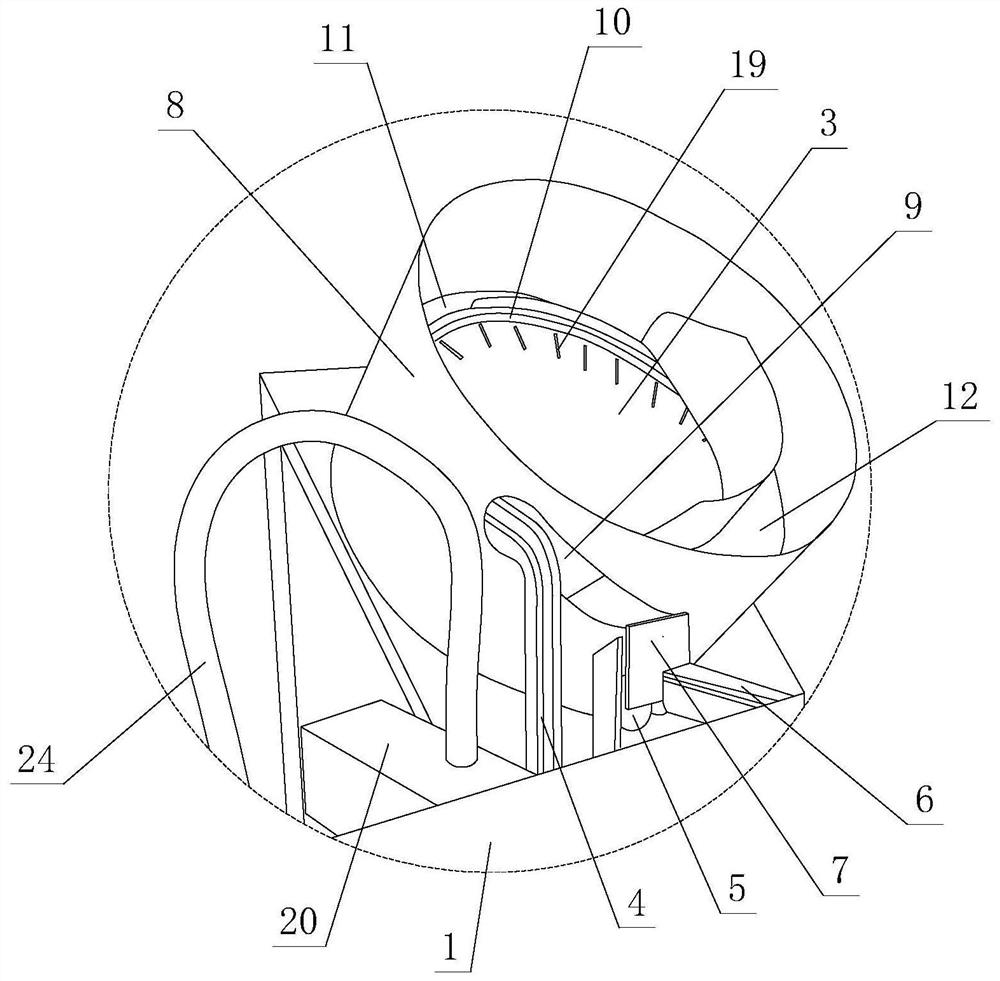

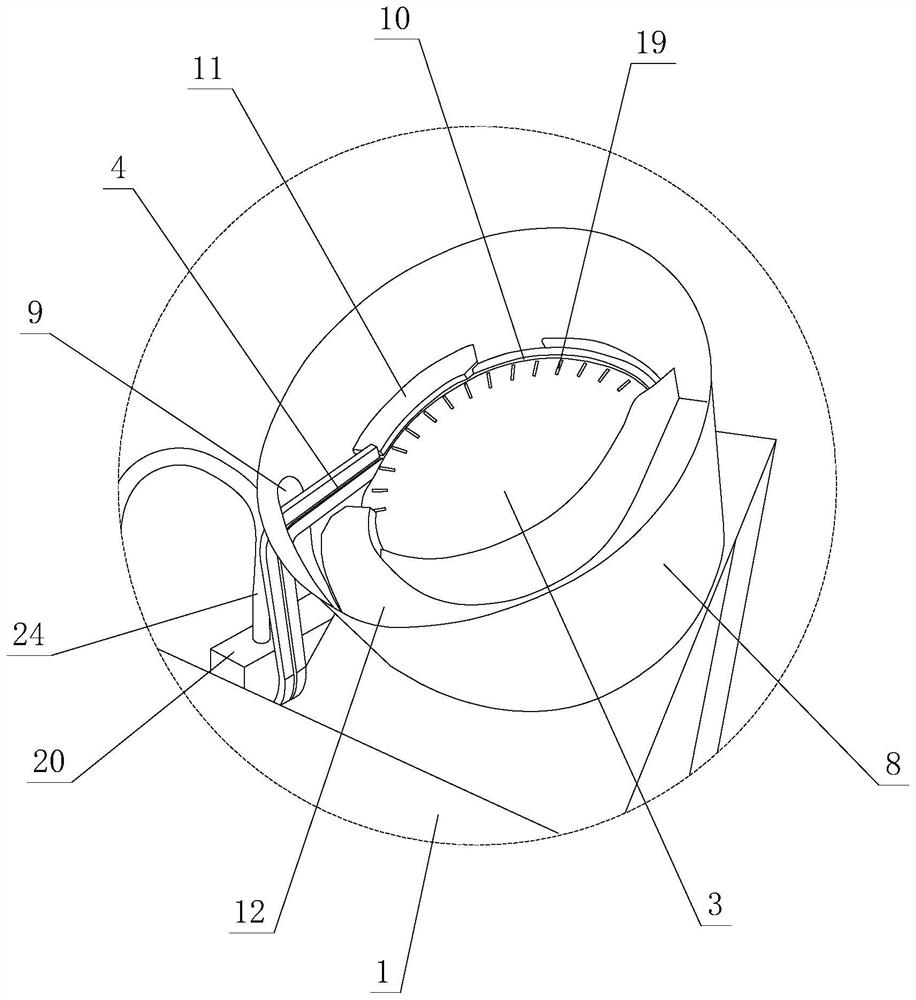

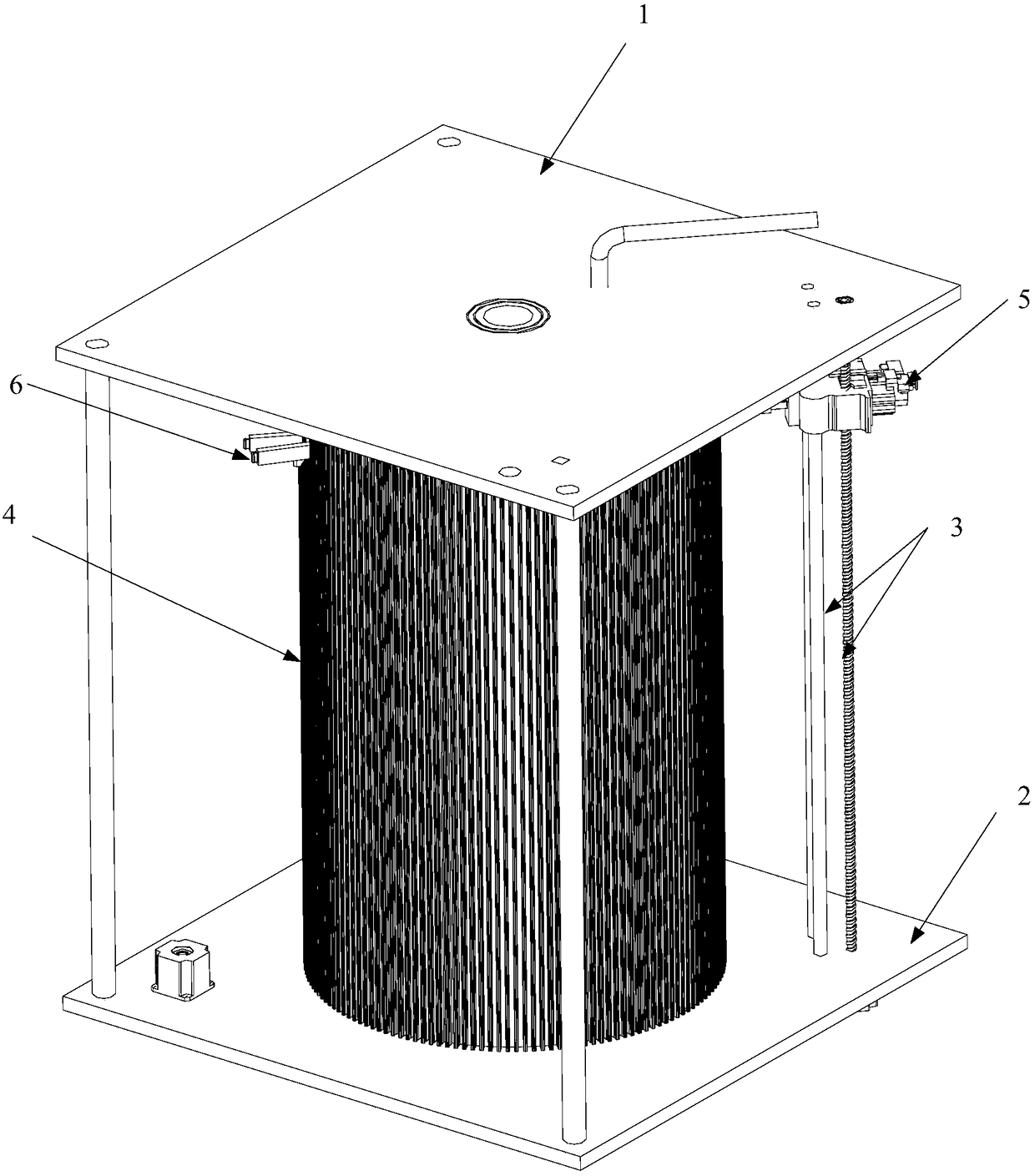

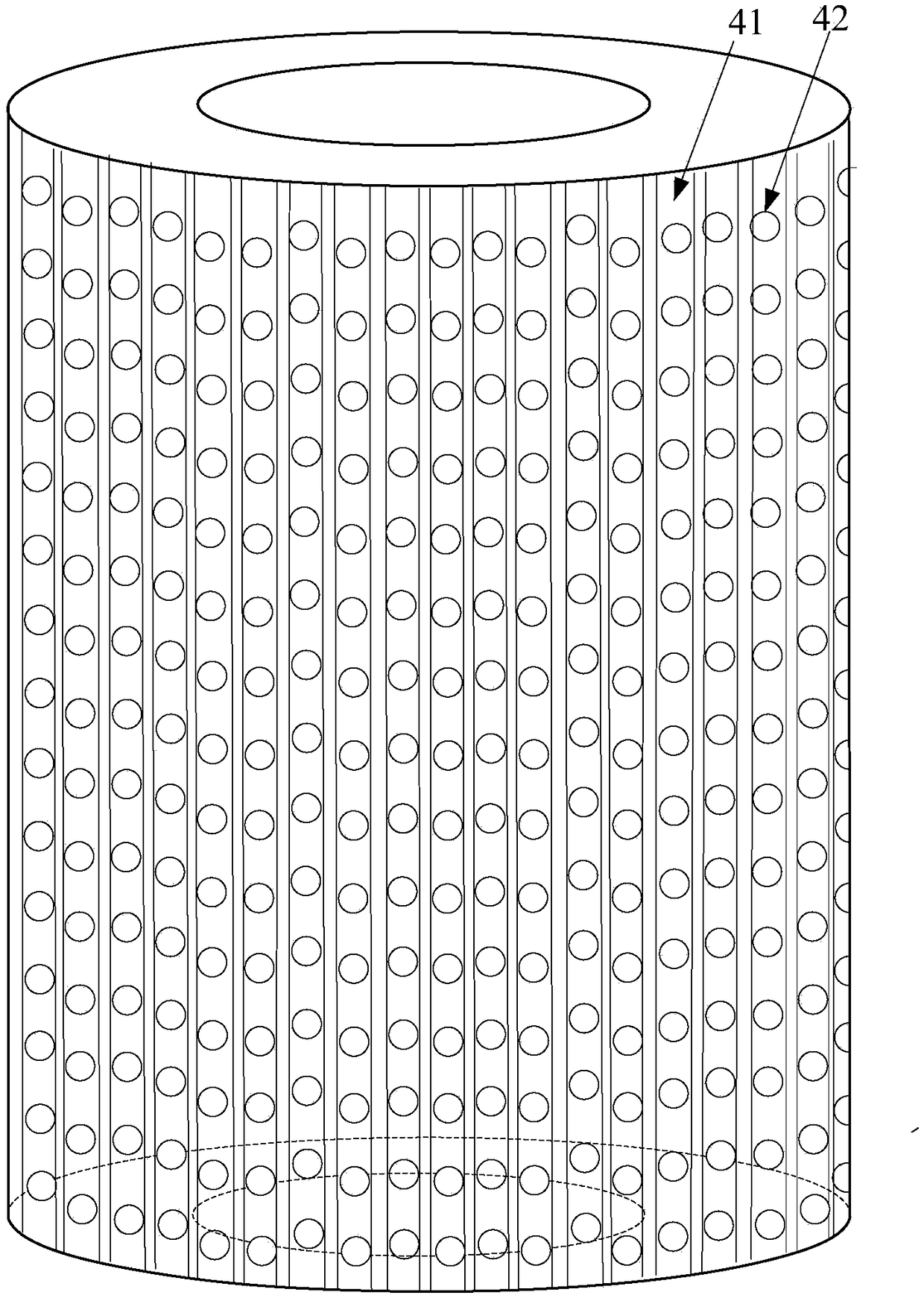

Optical fiber core butting matrix structure

ActiveCN106772823AHigh strengthAvoid leaningCoupling light guidesEngineeringUltimate tensile strength

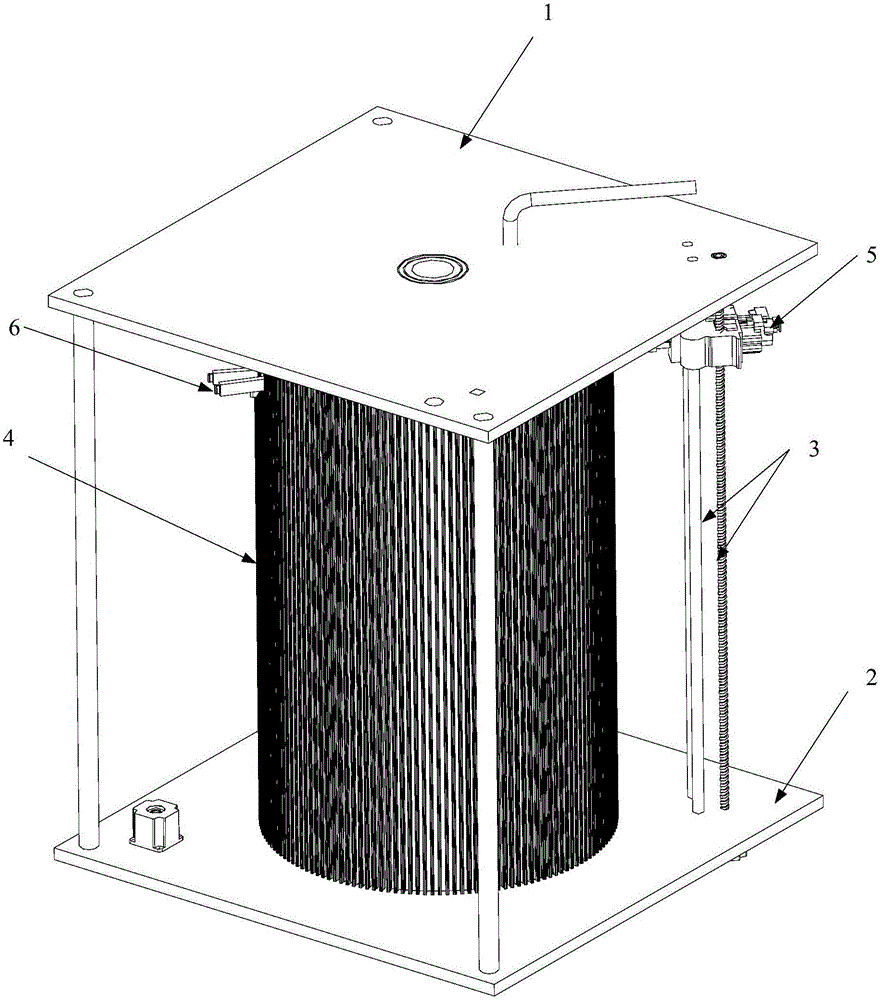

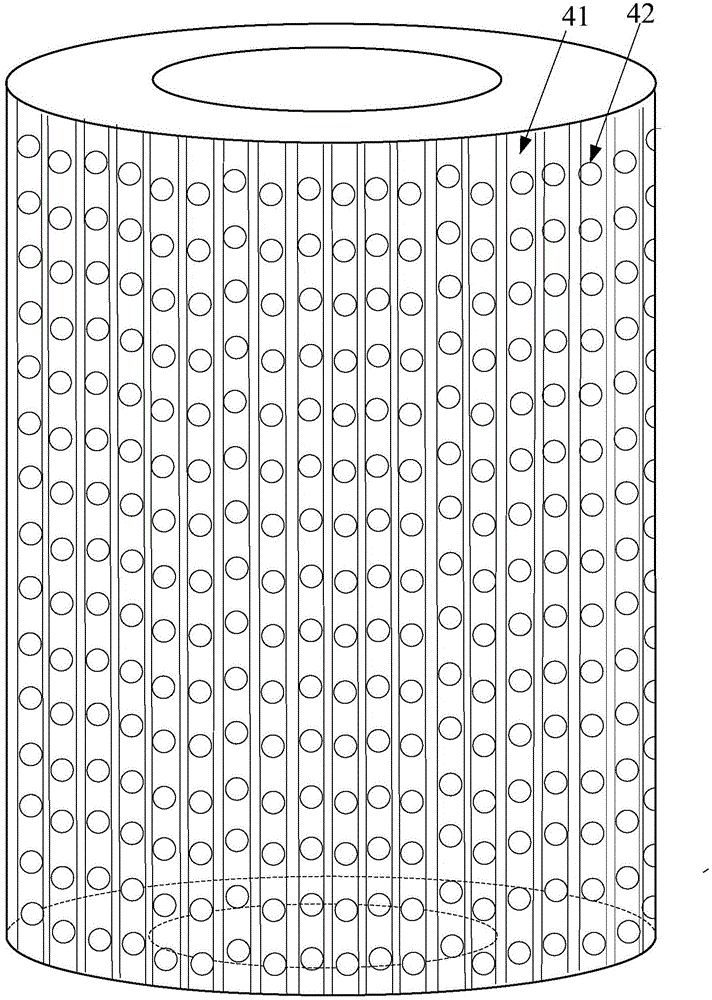

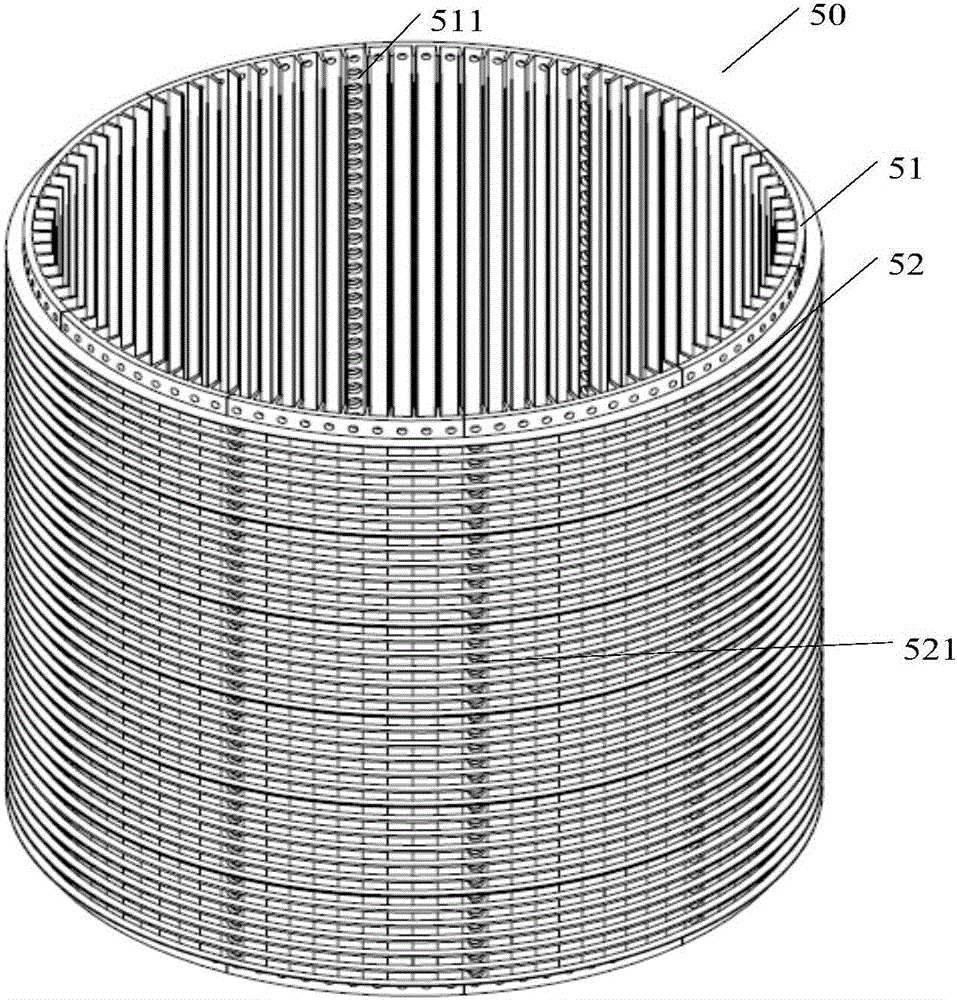

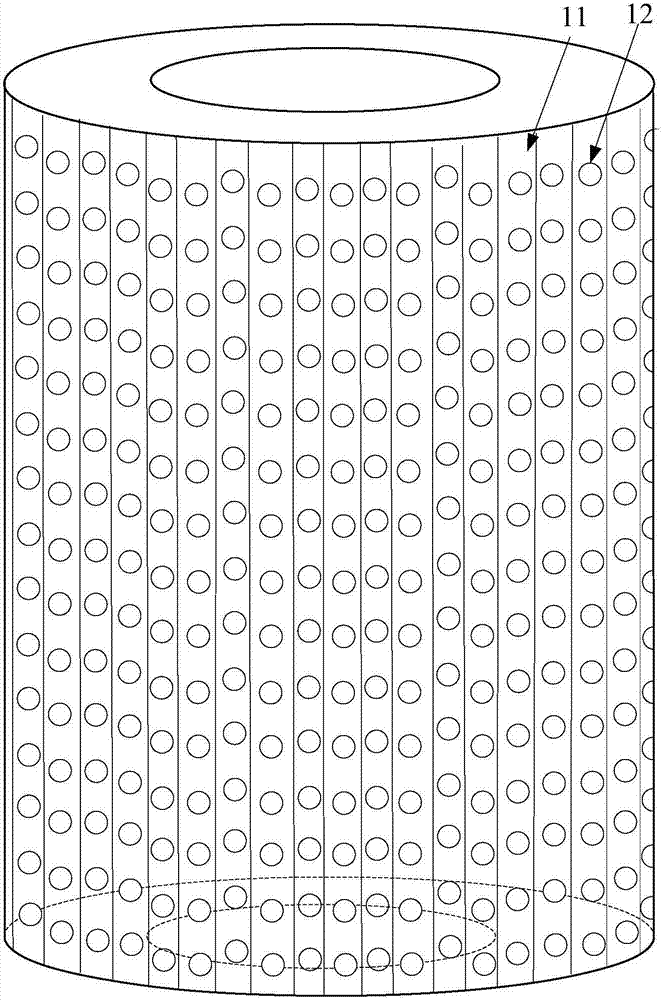

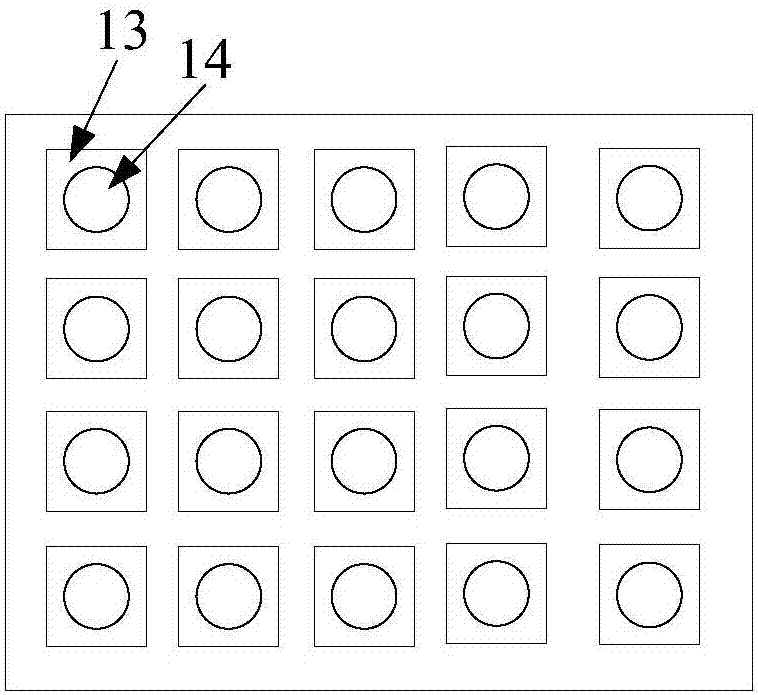

The embodiment of the invention discloses an optical fiber core butting matrix structure, which comprises a base, a first motor, a synchronization disk and a butting matrix barrel, wherein the first motor and the synchronization disk are fixedly arranged on the base, and the synchronization disk is driven by the first motor to rotate along a preset direction through a synchronous belt, and is fixedly connected with the butting matrix barrel. During specific work, the synchronization disk is driven by the first motor to rotate along the preset direction through the synchronous belt, and the butting matrix barrel is driven by the synchronization disk to synchronously rotate along the preset direction, so that the butting matrix barrel can perform rotation motion along the preset direction. Moreover, the butting matrix barrel comprises a metal support structure and a plastic wrapping structure positioned on the outer surface of the support structure, wherein the metal support structure is used for strengthening the strength of the butting matrix barrel and avoiding the top end of the butting matrix barrel inclining relative to the bottom end, and the plastic wrapping structure is used for correcting the shape of the metal support structure into a cylinder to facilitate subsequent optical fiber butting.

Owner:NINGBO POWER SUPPLY COMPANY STATE GRID ZHEJIANG ELECTRIC POWER

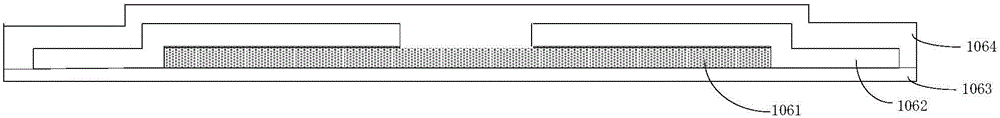

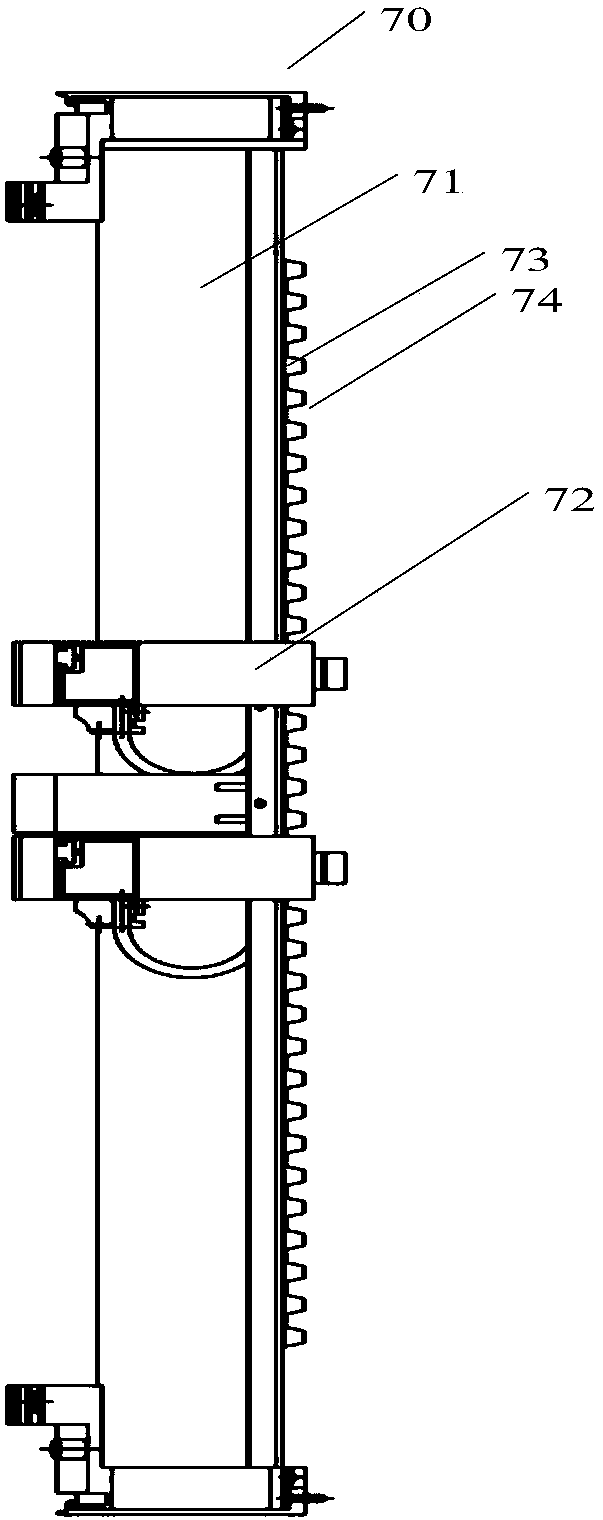

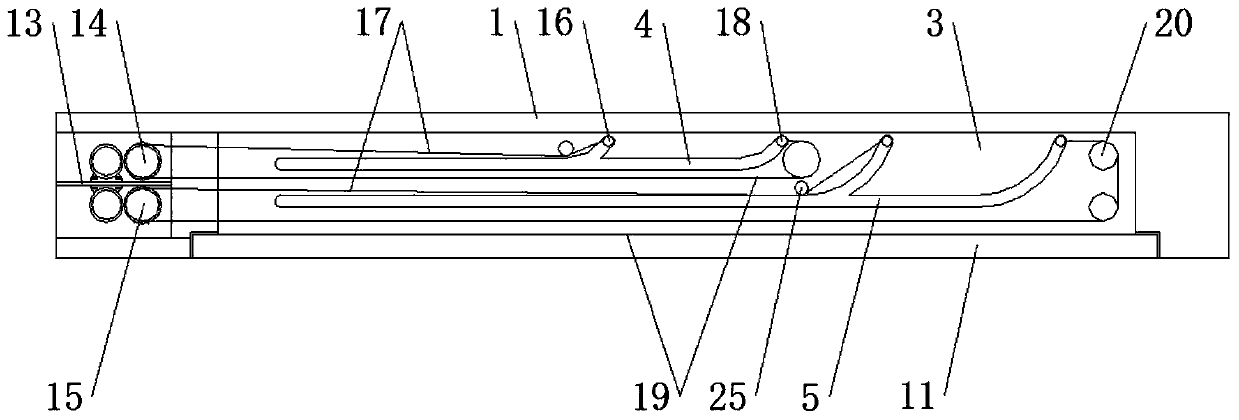

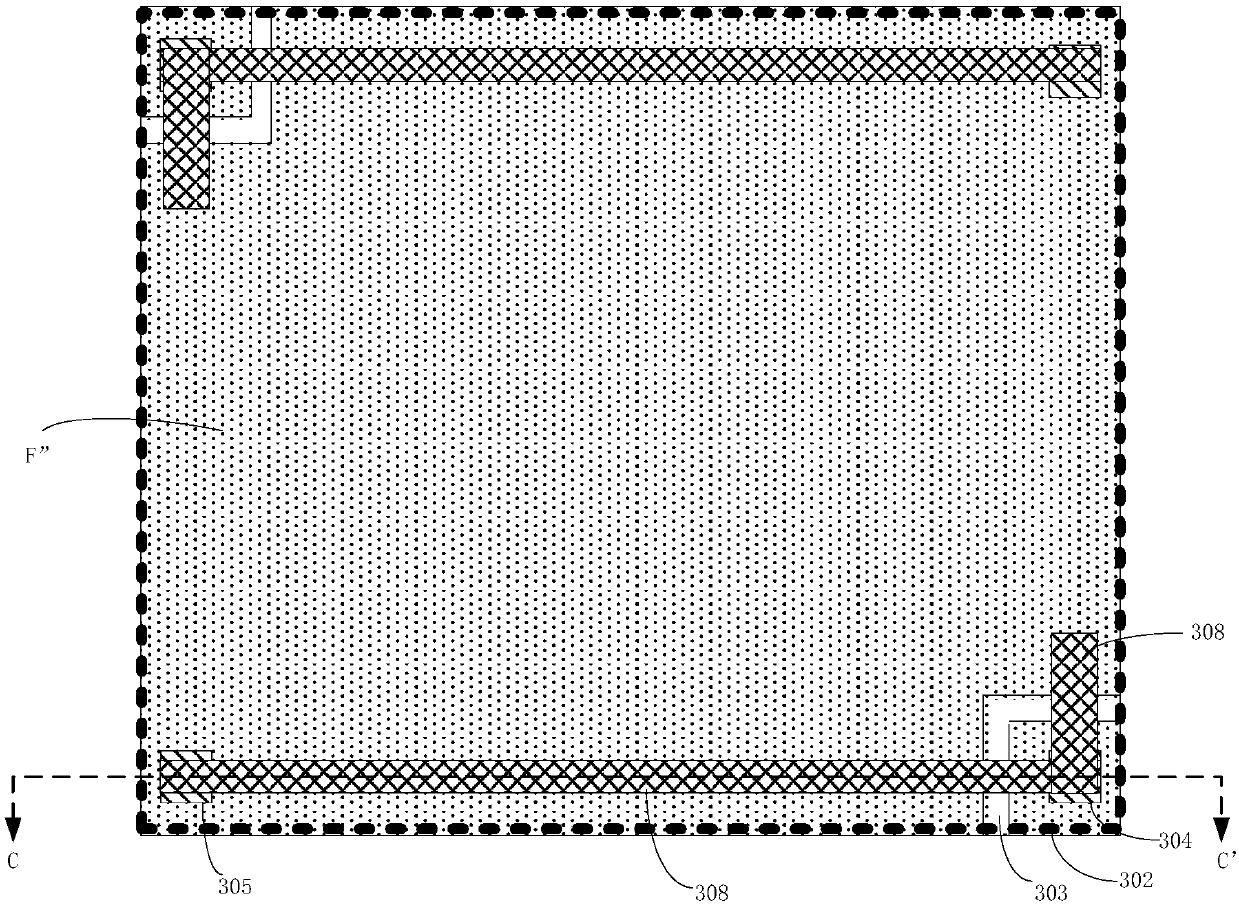

Dielectric phase shifter and 5G base station antenna

ActiveCN111585024ALarge amount of phase shiftReduce volumeAntenna supports/mountingsHigh level techniquesDielectric plateCopper foil

The invention relates to the technical field of mobile communication base station antennas, and discloses a dielectric phase shifter and a 5G base station antenna. The dielectric phase shifter comprises a strip line PCB, a first dielectric plate, a second dielectric plate, and a cavity with one end open. Copper foil wires are arranged on two opposite side surfaces of the strip line PCB, and starting points and ending points of the copper foil wires are positioned at the same end of the strip line PCB; the strip line PCB is fixedly arranged in the cavity; and the first dielectric plate and thesecond dielectric plate which are clamped on the two sides of the strip line PCB are installed in the cavity in a sliding mode. The dielectric phase shifter provided by the invention is large in phaseshifting amount, small in size and easy to install, and vertical installation can be realized, so that the transverse occupied size is reduced, and flexible layout is facilitated.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

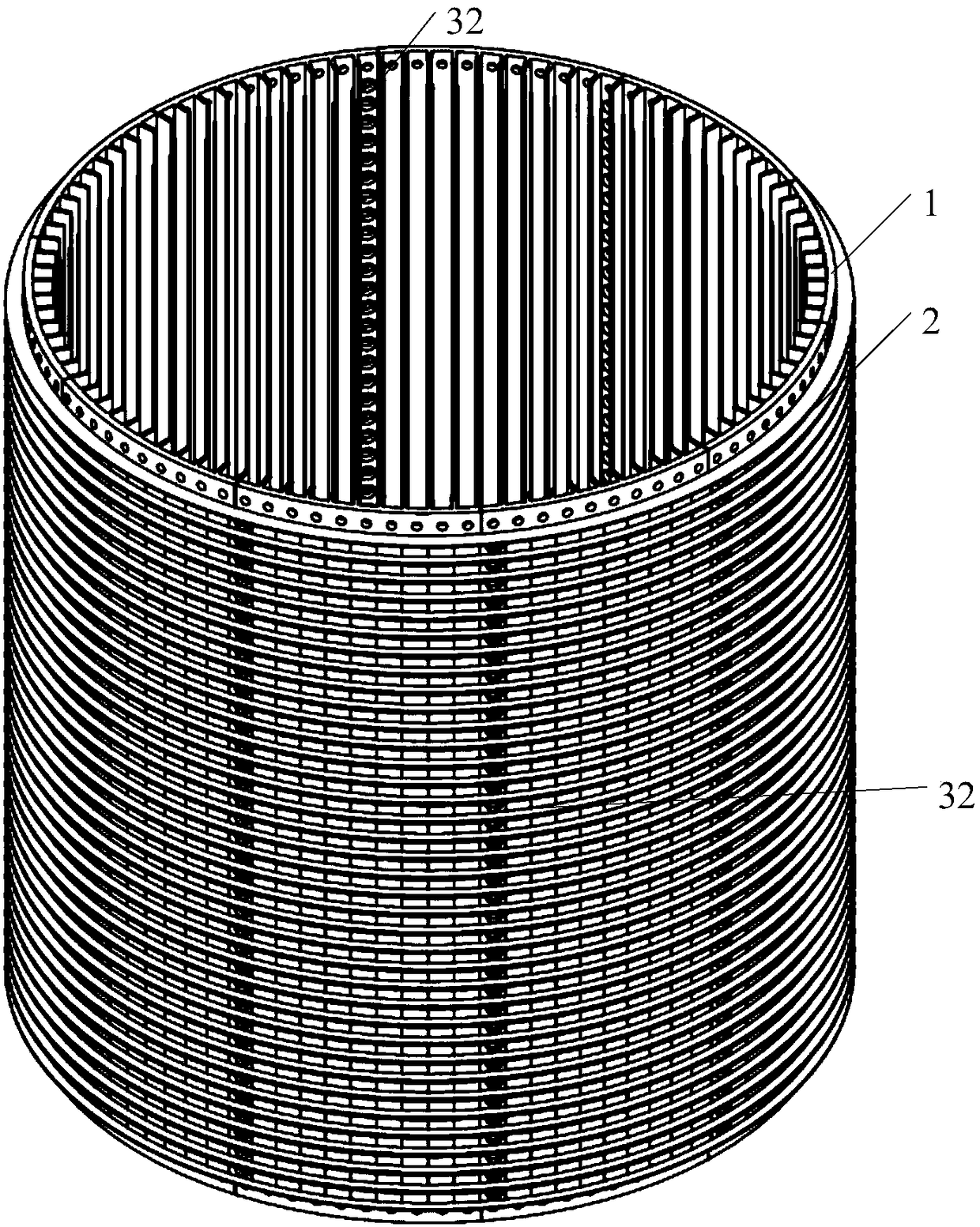

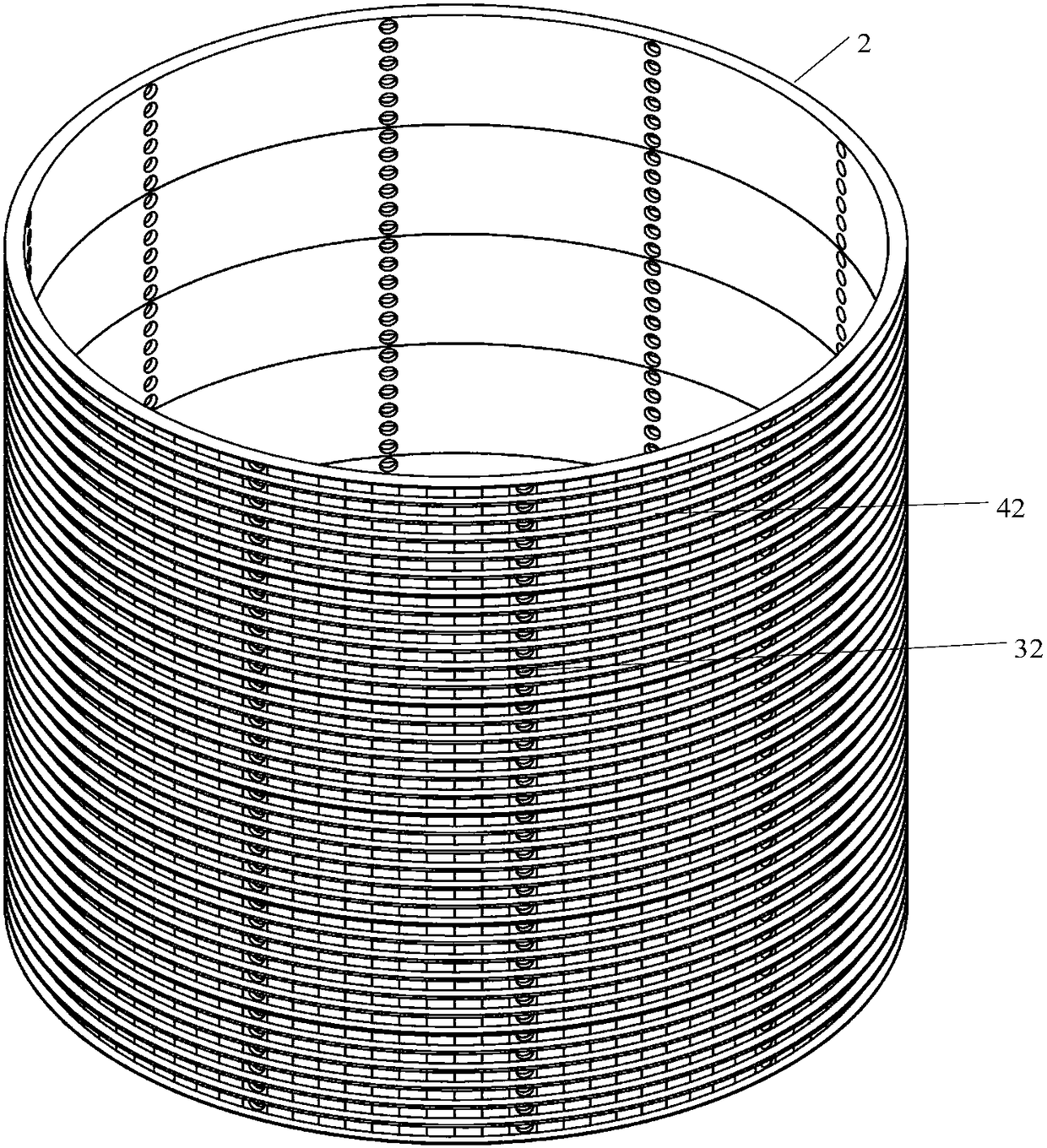

An optical fiber core butt matrix structure

An embodiment of the invention discloses an optical fiber core butt joint matrix structure. The optical fiber core butt joint matrix structure is a hollow columnar structure, a plurality of parallelly arranged butt joint grooves are arranged on an outer side wall, and each butt joint groove is internally provided with a plurality of butt joint holes arranged along an extending direction of the butt joint grooves. During specific operation, a user only needs to connect tail fibers used for being connected with fiber cores of optical fibers to be butt jointed to two different first butt joint holes in advance, and then controls a linker that carries fiber cores of external line optical fibers to be butt jointed to transport the fiber cores of the external line optical fibers to be butt jointed to the positions of the first butt joint holes and insert the fiber cores of the external line optical fibers to be butt jointed into the first butt joint holes, and thus the butt joint of the fiber cores of the external line optical fibers can be completed. The design is reasonable, the operation is simple, artificial participation can be greatly reduced, and plenty of manpower and material resources are saved. Moreover, the horizontal occupied area of the optical fiber core butt joint matrix structure is greatly reduced on the premise of the same number of first butt joint holes.

Owner:NINGBO YINGMING ELECTRIC TECH

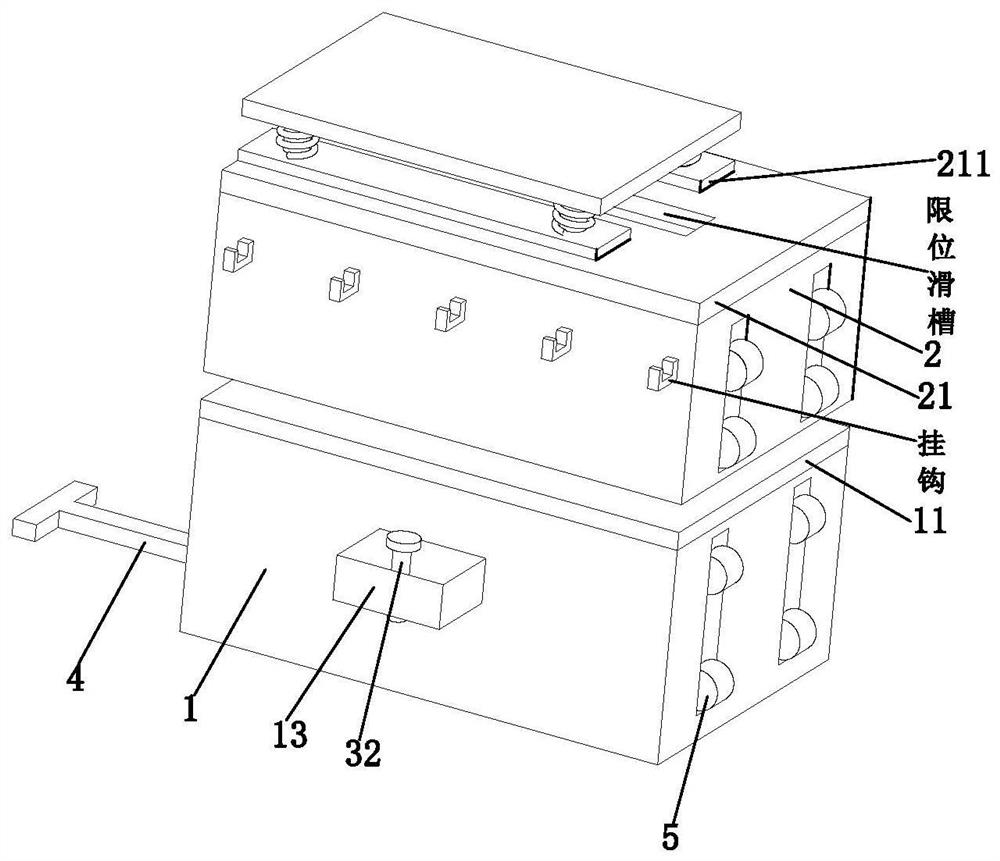

Draw-bar box

InactiveCN113040485AImprove space utilizationIncrease expansionPursesLuggageTrunk compartmentIndustrial engineering

The invention relates to a draw-bar box which comprises a first box, a second box, a clamping mechanism, a draw bar and rollers, and can solve the following problems in the use process of the draw-bar box: a, the space in the draw-bar box is not fully used due to non-uniform space distribution in the traditional draw-bar box and different sizes of luggage when the luggage is stored, and so the space utilization rate of the interior of the draw-bar box is low; b, in the general short-time business trip process, people do not carry too many clothes, so that the clothes need to be cleaned in time, and when people need to be urgently on a business trip after the clothes are cleaned, the clothes are wet and placed in the draw-bar box, the clothes are smelly, and follow-up wearing of the clothes is affected; and c, in the business trip process, when two cases are needed due to too much luggage, two hands need to pull the draw-bar box at the same time, other hand activities such as navigation and ticket checking cannot be carried out, inconvenience is caused to travel, and the travel experience of people is affected.

Owner:武汉立驰科技有限公司

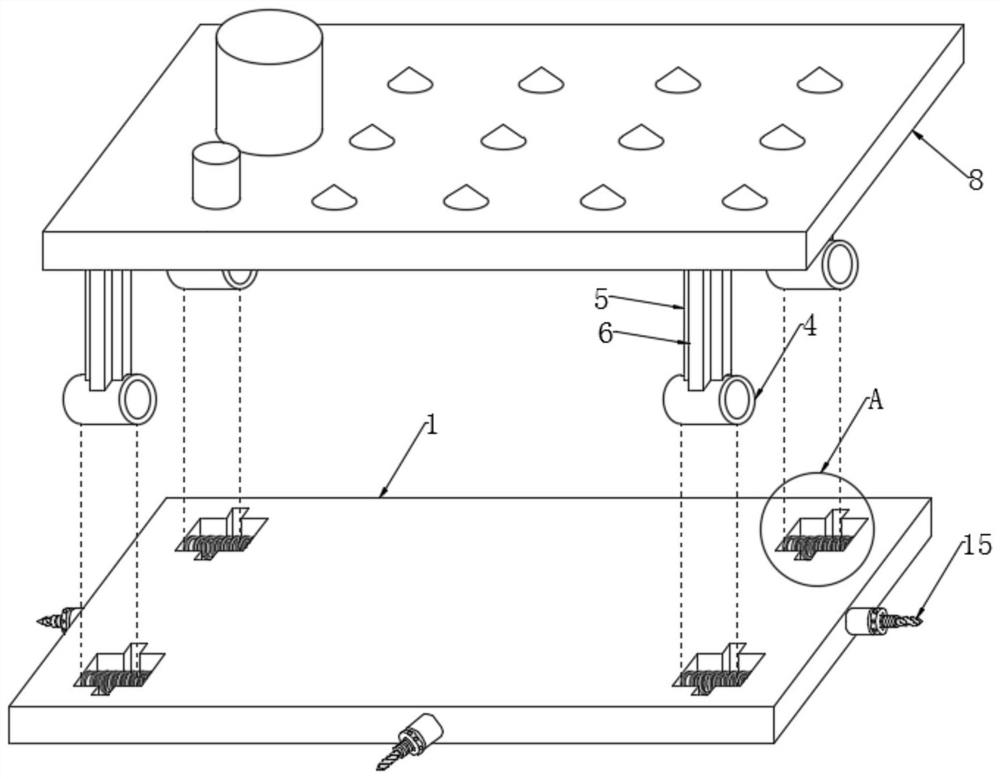

Punch forming die for producing automobile brake pedal

PendingCN114226567AReduced horizontal footprintSmall footprintShaping toolsMetal-working feeding devicesStampingBrake

The invention discloses a punch forming die for automobile brake pedal production, and relates to the technical field of punching dies. Comprising a stamping supporting frame and a hydraulic push rod, a handle is installed at the top end of the stamping supporting frame, a control panel is attached to the inner side wall of the L-shaped stamping supporting frame, a transverse adjusting mechanism is arranged on the inner wall of the top end of the stamping supporting frame, and the hydraulic push rod is arranged on one side of the control panel. A stamping plate is installed below the hydraulic push rod, and a clamping mechanism is arranged at the upper end of the side wall of the stamping base. The whole device adopts a splicing type structure, due to the fact that the size is small, the device can be used for production tests of different types of brake pedals, the unfolded stamping base can be folded and stored through a rotating structure of the connecting shaft body, and therefore the transverse occupied area of the whole device is reduced, the device is more portable, the stamping plate also adopts the sleeving detachable design, and the practicability is high. And different stamping shapes can be achieved by freely replacing structures, and the application range is wider.

Owner:苏州杰泰龙精密压铸工业有限公司

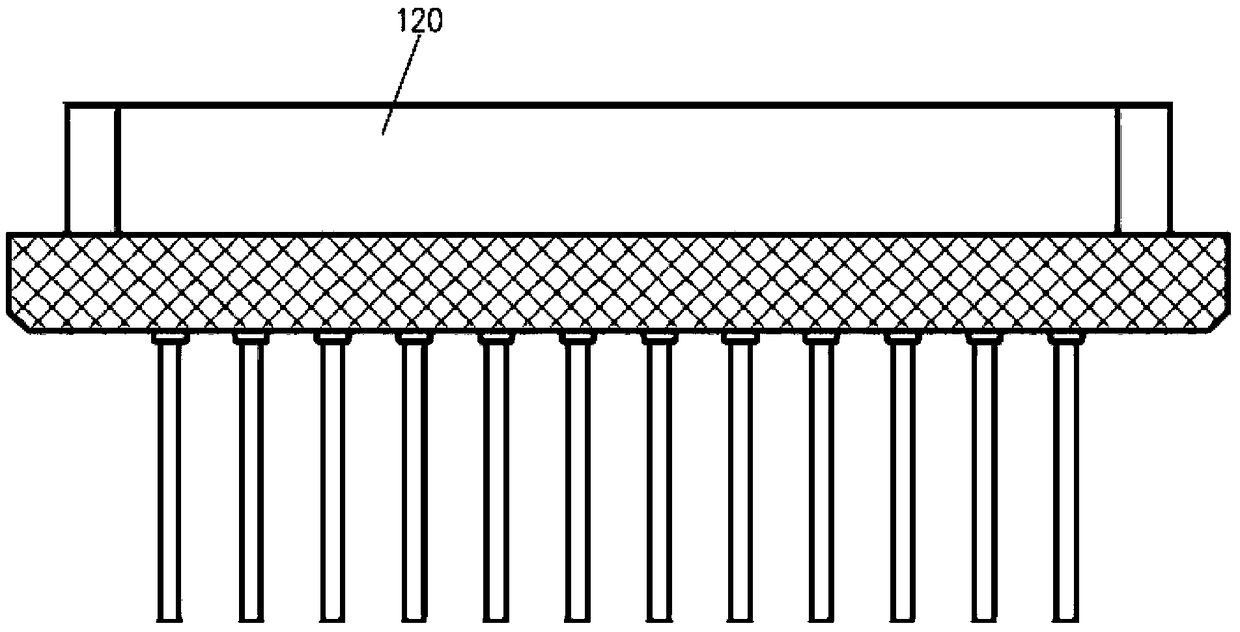

Three-dimensional infrared detector pixel structure and preparation method therefor

ActiveCN106448972AImprove performanceImprove integration densityNegative temperature coefficient thermistorsResistors adapted for applying terminalsElectric signalSilicon

The invention provides a three-dimensional infrared detector pixel structure and a preparation method therefor. The three-dimensional infrared detector pixel structure comprises a conductive metal region, an infrared detection structure and a conductive beam structure, wherein the conductive metal region is located on the surface of a silicon substrate; the infrared detection structure is positioned above the silicon substrate and used for detecting infrared light and generating an electric signal; the conductive beam structure is electrically connected with the infrared detection structure and used for transmitting the electric signal generated by the infrared detection structure to the conductive metal region; the conductive beam structure comprises at least one layer of conductive beams and multiple layers of conductive trenches arranged in a vertical direction; the two ends of the conductive beams in each layer are in contact with two layers of conductive trenches, the bottoms of which are not positioned on the same plane; the infrared detection structure is in contact with one corresponding layer of the conductive trenches or the conductive beams; the conductive metal region is in contact with the bottoms of the other layer of the conductive trenches; and the electric signal generated by the infrared detection structure is transmitted in the height direction of the conductive trenches and in the horizontal direction of the conductive beams so as to be transmitted downwardly to the conductive metal region along a roundabout path in the vertical direction.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

A kind of tile gluing device, gluing method and paving equipment

ActiveCN111760747BFully automatedImprove transfer efficiencyLiquid surface applicatorsFinal product manufactureStructural engineeringMechanical engineering

The invention belongs to the technical field of construction robots, and discloses a tile gluing device. The device comprises a rack, and the rack is provided with a tile storage area. The carrying and conveying mechanism is located above the tile storage area, and the carrying and clamping platform of the carrying and conveying mechanism includes two clamping plates for carrying and limiting the tiles to be glued, an opening is formed between the two clamping plates, at least one of them The clamping plate is movable relative to the other clamping plate. The lifting and grabbing mechanism is installed on the rack and is used to grab the tiles from the tile storage area and place them on the load-bearing clamping platform. The gluing mechanism is installed on the frame and located above the bearing and conveying mechanism, and the gluing mechanism is used for gluing the tiles placed on the bearing and clamping platform. The invention also discloses a gluing method and a paving device equipped with the gluing device. The gluing device can utilize the space in the height direction, reduce the horizontal occupation area, and facilitate the operation of the device in a narrow space.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Small-sized vacuum ring main unit

ActiveCN102780171BGuaranteed to workHigh working reliabilityBus-bar/wiring layoutsSwitchgear arrangementsEngineeringElectrical and Electronics engineering

The invention discloses a small-sized vacuum ring main unit. A three-position disconnecting switch (4), a mechanical interlocking assembly (5) and a spring operating mechanism (2) are arranged at the upper part of a casing (1) and are sequentially connected; an operation button (4.1) of the three-position disconnecting switch (4) is arranged outside the casing (1); an insulated bus (6) is arranged below the spring operating mechanism (2); the upper end of the insulated bus (6) is connected with the spring operating mechanism (2); an arcing chamber pole column (3) is arranged below the three-position disconnecting switch (4) in the casing (1), the arcing chamber pole column (3) is connected to the insulated bus (6), and a wiring terminal (6.1) of the insulated bus (6) is arranged outside the casing (1); the casing (1) is a closed casing; and the spring operating mechanism (2), the three-position disconnecting switch (4) and the mechanical interlocking assembly (5) are arranged in the closed casing. The small-sized vacuum ring main unit is small in size and high in work reliability.

Owner:SUNRISE GRP CO LTD

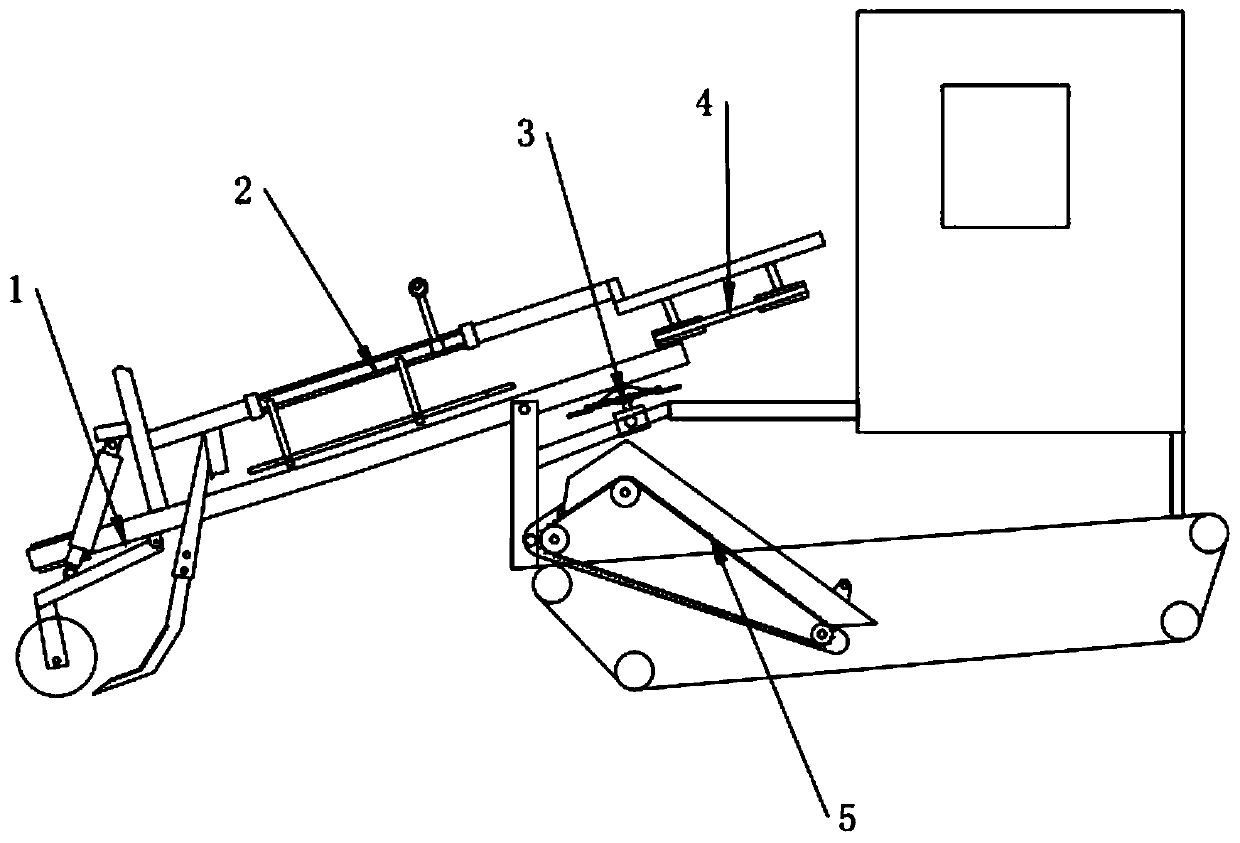

Ginger harvester

InactiveCN110959360ATo achieve gatheringImprove protectionSpadesLiftersEngineeringMechanical engineering

The invention discloses a ginger harvester, and relates to the technical field of ginger harvesting devices. The ginger harvester comprises a ginger pulling mechanism, a soil shaking mechanism, a ginger arranging mechanism, a separating mechanism and a guiding-out mechanism; the ginger arranging mechanism comprises a conveying belt which is rotatably arranged, the conveying belt is provided with ginger supporting sections which are arranged in a height increasing mode in the feeding direction and further provided with ginger arranging sections which are connected to the supporting sections andarranged in a height decreasing mode in the conveying direction, and ginger guiding plates which are arranged in a shape following mode are further arranged on the portions, located on the ginger supporting sections and the ginger arranging sections, of the conveying belt. The problems that in the prior art, ginger receiving rods are used for basically pulling out gingers from a field, but are limited by the characteristics of the gingers, and the gingers are prone to being broken are solved; and the problems that through an unordered feeding mode, the separated gingers need to be manually operated, and the workload is not reduced even if the manpower is saved are solved.

Owner:付国良

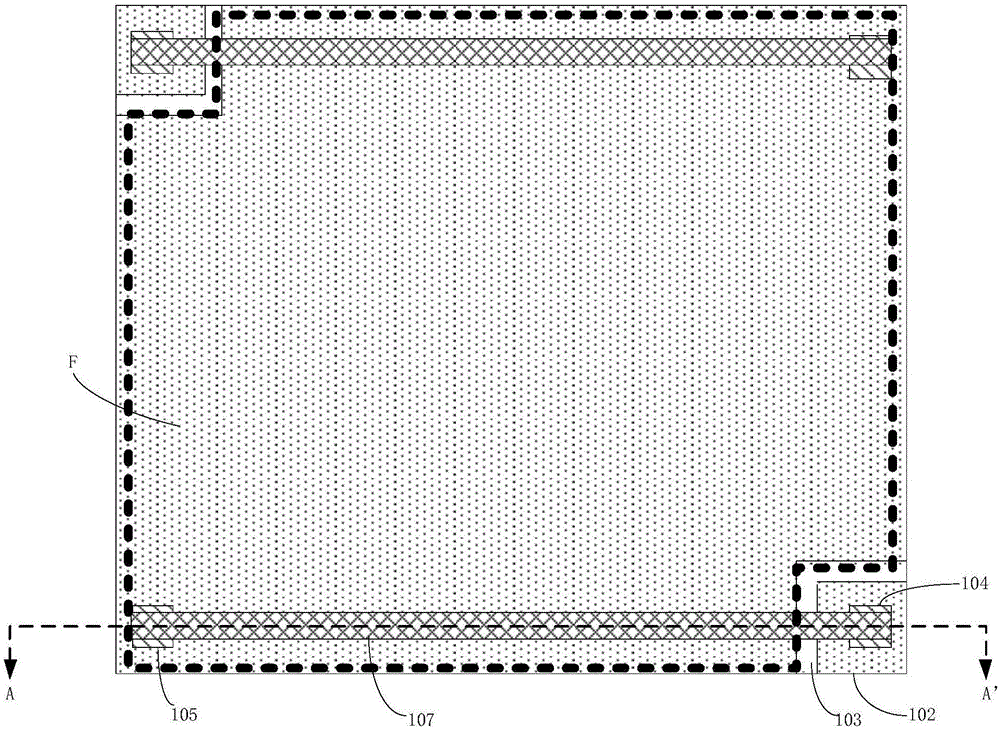

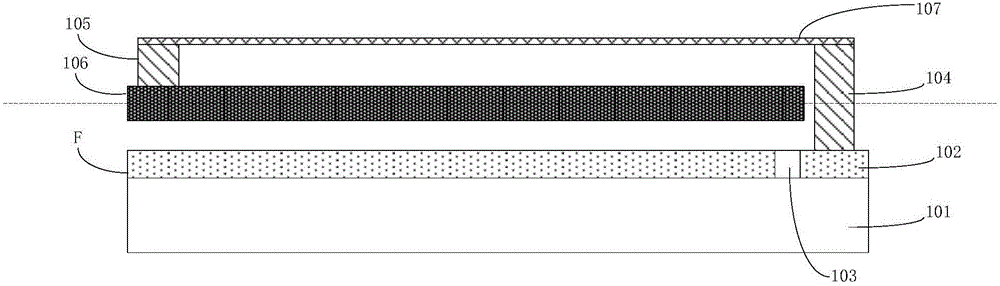

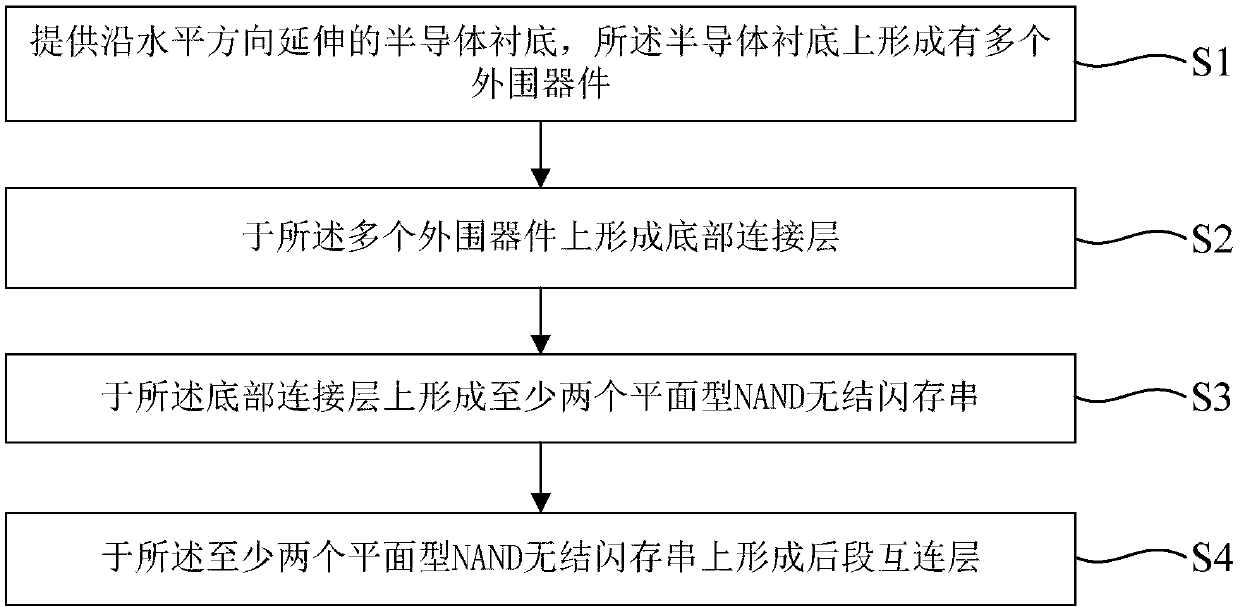

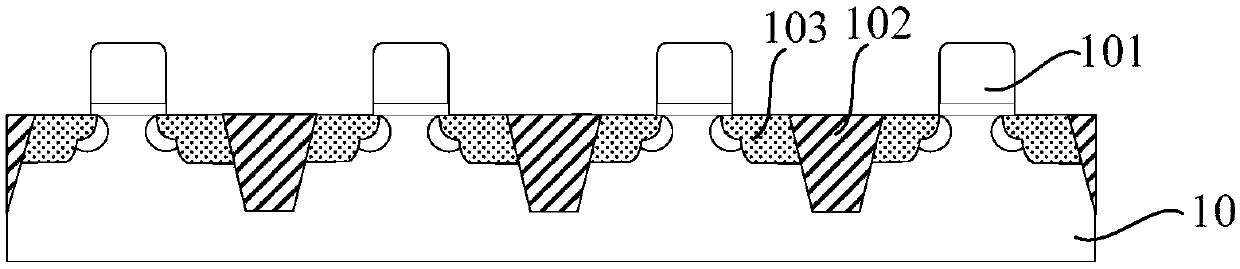

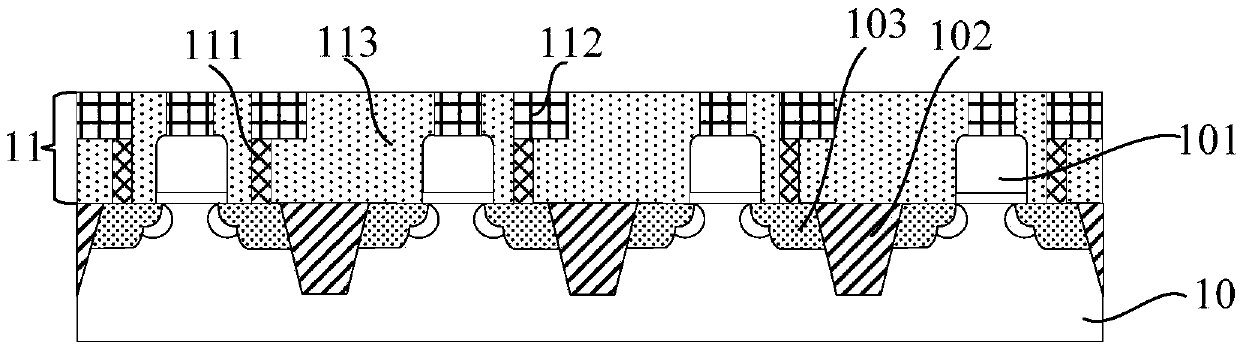

Three-dimensional NAND flash memory device and preparation method thereof

InactiveCN111430350AReduced horizontal footprintImprove space efficiencySolid-state devicesSemiconductor devicesEngineeringSemiconductor

The invention provides a three-dimensional NAND flash memory device and a preparation method thereof. The preparation method comprises the steps of providing a semiconductor substrate extending alongthe horizontal direction, and forming a plurality of peripheral devices on the semiconductor substrate; forming a bottom connection layer on the plurality of peripheral devices; forming at least two planar NAND junctionless flash memory strings on the bottom connecting layer; and forming a back-end interconnection layer on the at least two planar NAND junctionless flash memory strings; combining aplanar NAND junctionless flash memory string structure with a peripheral device to construct the three-dimensional NAND flash memory device. According to the present invention, the quick reading characteristic of the planar NAND junctionless flash memory strings is well utilized, the planar NAND junctionless flash memory strings can be well compatible with a logic unit, a standard independent NAND flash memory product can be manufactured, but also an embedded NAND flash memory product can be manufactured according to the use condition under the condition that the product performance is guaranteed; and on the other hand, by adopting the mode, the horizontal occupied area of the two-dimensional NAND flash memory device can be effectively reduced, and the space use efficiency of the device is improved.

Owner:SIEN QINGDAO INTEGRATED CIRCUITS CO LTD

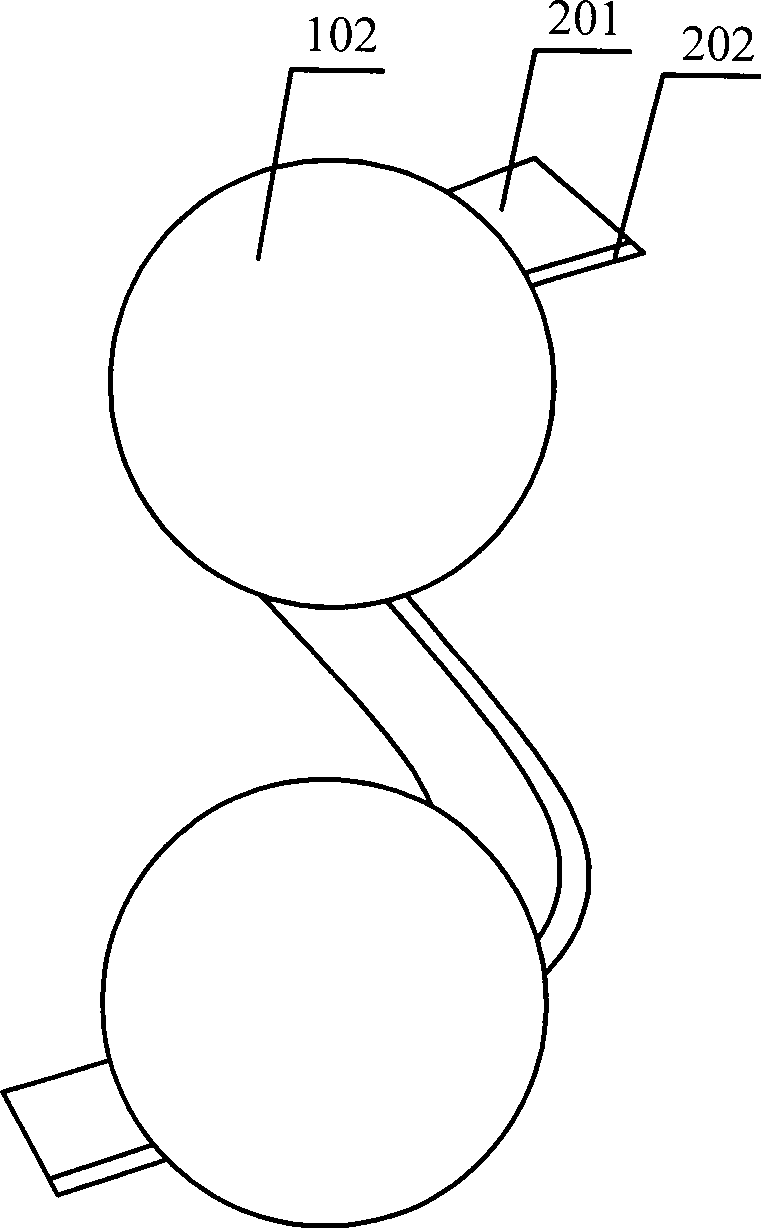

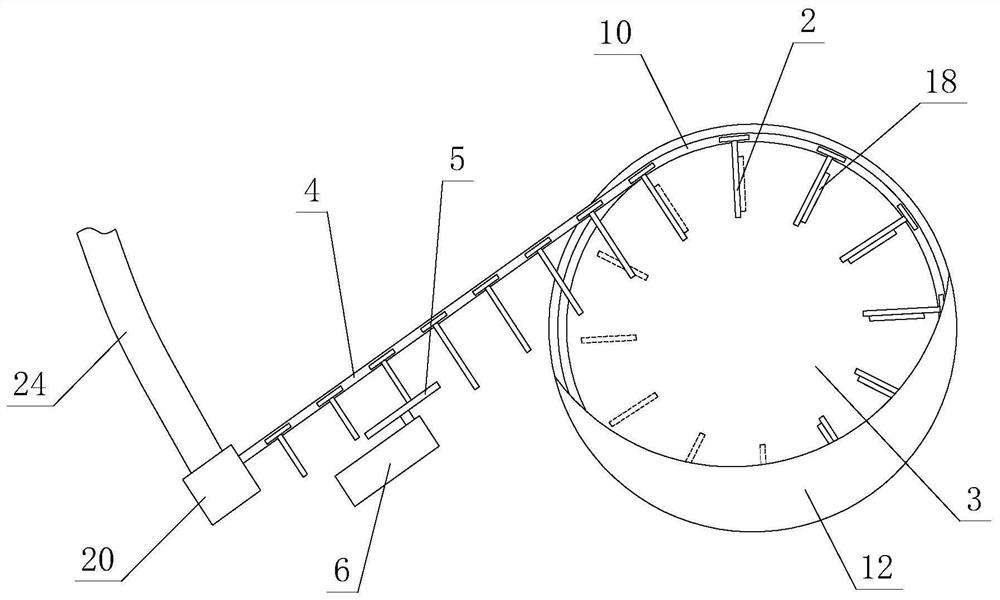

An optical fiber docking device

ActiveCN106526758BRealize automatic dockingEasy to operateCoupling light guidesFiberMaterial resources

The embodiment of the invention discloses an optical fiber butting device, including a butting matrix barrel and a plurality of line butting devices located in a butting matrix barrel cavity and fixedly connected with the butting matrix barrel, one line butting device is fixes an external optical fiber, during specific working, only the line butting devices need to be utilized to fix external optical fibers, the external optical fibers are inserted in butting holes of the butting matrix barrel, then the tail fibers or two cord circuit butting pieces connected by the tail fibers are utilized to be inserted in the butting holes into which two external optical fibers to be butted are inserted, thus automatic butting of the two external optical fibers can be realized, the operation is simple, manual participation can be greatly reduced, and plenty of manpower and material resources are saved. In addition, in the optical fiber butting device provided by the embodiment of the invention, the butting matrix barrel is of a hollow columnar structure, and the butting holes are arranged on the side wall of the butting matrix barrel, and thus on the premise of the same number of butting holes, the horizontal occupation area of an optical fiber core butting matrix structure is greatly reduced.

Owner:NINGBO YINGMING ELECTRIC TECH

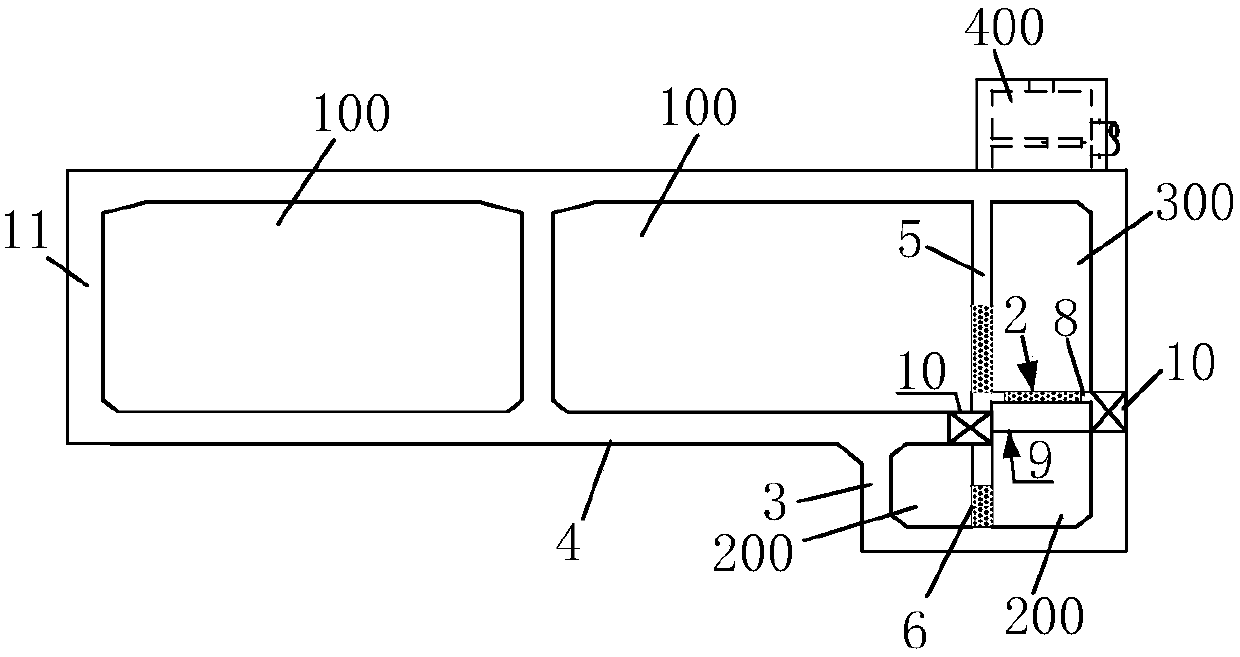

Attached rainwater pump house structure

ActiveCN105863040BReduced horizontal footprintLateral footprint savingsSewerage structuresPipeflowEngineering

The invention discloses an attached rainwater pump house structure which comprises a water collecting basin, a plurality of reserved pipeline holes and lifting holes. The water collecting basin is arranged at the bottom of a pump house, the reserved pipeline holes and the lifting holes are longitudinally formed in positions along the pump house side by side, and an external wall of the water collecting basin is arranged below a bottom plate of a vehicle lane hole; the pump house is separated from the vehicle lane hole by a middle partition wall; the middle partition wall extends to bottom plates of the water collecting basin from top plates of the pump house, and water holes and man holes are formed in the lower portion of a wall body of the middle partition wall; the pump house is separated from the water collecting basin by a pump house middle plate, a transverse beam is arranged below the pump house middle plate, and longitudinal beams are respectively arranged at two ends of the transverse beam; at least three transverse ditches with gradient are arranged on the bottom plate of the vehicle lane hole at intervals. The attached rainwater pump house structure has the advantages that the transverse occupied land width of the rainwater pump house can be reduced, accordingly, spaces required when underground pipelines are about to be relocated can be greatly increased, and the total engineering investment can be saved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Automobile skylight

InactiveCN111516472AIncrease the opening areaReduced horizontal footprintEngine sealsVehicle sealing arrangementsStructural engineeringMechanical engineering

The invention discloses an automobile skylight. The automobile skylight comprises a top shell and bolts, a first window is formed in the top of the top shell, a protective frame is fixed at the bottomof the top shell, a first sliding groove and a second sliding groove are formed in the front side and the rear side of the protective frame, the second sliding groove is formed in the lower side of the first sliding groove, a first telescopic plate and a second telescopic plate are arranged in the protective frame, rotating shafts are rotatably connected to the bottoms of the first telescopic plate and the second telescopic plate, the front end and the rear end of the rotating shaft at the bottom of the first telescopic plate are slidably connected with the first sliding groove, and the frontend and the rear end of the rotating shaft at the bottom of the second telescopic plate are slidably connected with the second sliding groove. The automobile skylight is provided with the protectiveframe, the bolts and a bottom cover, the bolts are taken down by rotating, the bottom cover is taken down, the protective frame is exposed, and the first sliding groove and the second sliding groove are formed in the protective frame, so that the first sliding groove, the second sliding groove and other parts on the protective frame are cleaned conveniently, dust and other impurities are preventedfrom accumulating in the automobile skylight, and the service life of the automobile skylight is prolonged.

Owner:马程

Highly filled infrared detector pixel structure and its preparation method

ActiveCN106430076BImprove performanceImprove integration densityDecorative surface effectsSolid-state devicesElectric signalSilicon

The present invention provides a highly filling infrared detector pixel structure and a manufacture method thereof. A conductive beam structure is formed on a silicon substrate and an infrared detection structure is formed on the conduction beam structure; the bottom of each layer of conductive groove is contacted with the top of a below adjacent layer of conductive groove and is connected to two ends of one conductive beam; the bottom of one layer of conductive groove is contacted with a conductive metal area; the topmost layer of the conductive beam structure has a top layer of conductive groove and a top layer of conductive beam; the top layer of conductive beam is contacted and connected with the infrared detection structure, so that a micro-bridge structure is above the conductive beam structure; each layer of conductive groove and conductive beam form a roundabout step structure, so that a transmission path of an electronic signal generated by the micro-bridge structure takes on a roundabout step shape; and the electric signal generated by the micro-bridge structure is transmitted to the top of the top layer of conductive groove from the top layer of conductive beam, and then is transmitted to the bottom of the top layer of conductive groove, and finally is transmitted to the conducive metal area after being transmitted among multiple layers of conductive groove and conductive beam.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

An optical fiber core butt matrix structure

The embodiment of the present invention discloses a fiber core butt joint matrix structure which is a hollow cylindrical structure. The structure comprises a metal support structure and a coating structure located at the outer surface of the support structure; the metal support structure is configured to improve the intensity of the butt joint matrix structure to prevent the top of the butt joint matrix structure from the inclination compared to the bottom of the butt joint matrix structure; and the coating structure is configured to correct the shape of the metal support structure to allow the shape of the metal support structure to be cylindrical shape so as to facilitate the butt joint of the subsequent fibers. The side walls of the support structure and the coating structure have butt joint holes in the matrix arrangement along a plurality of first directions and second directions, the butt joint holes of the support structure are in the one-to-one correspondence with the butt joint holes of the coating structure, and the fiber core butt joint matrix structure is applied to the fiber butt joint, the fiber core butt joint matrix structure is simple to operate so as to greatly reduce the participation of workers and save lots of manpower and material resources. Besides, the fiber core butt joint matrix structure has a hollow cylindrical structure, each butt joint hole is arranged at the side wall of the hollow cylindrical structure, and on the premise of the butt joint holes with the same quantity, the horizontal occupying areas of fiber core for the butt joint matrix structure are greatly shortened.

Owner:NINGBO YINGMING ELECTRIC TECH

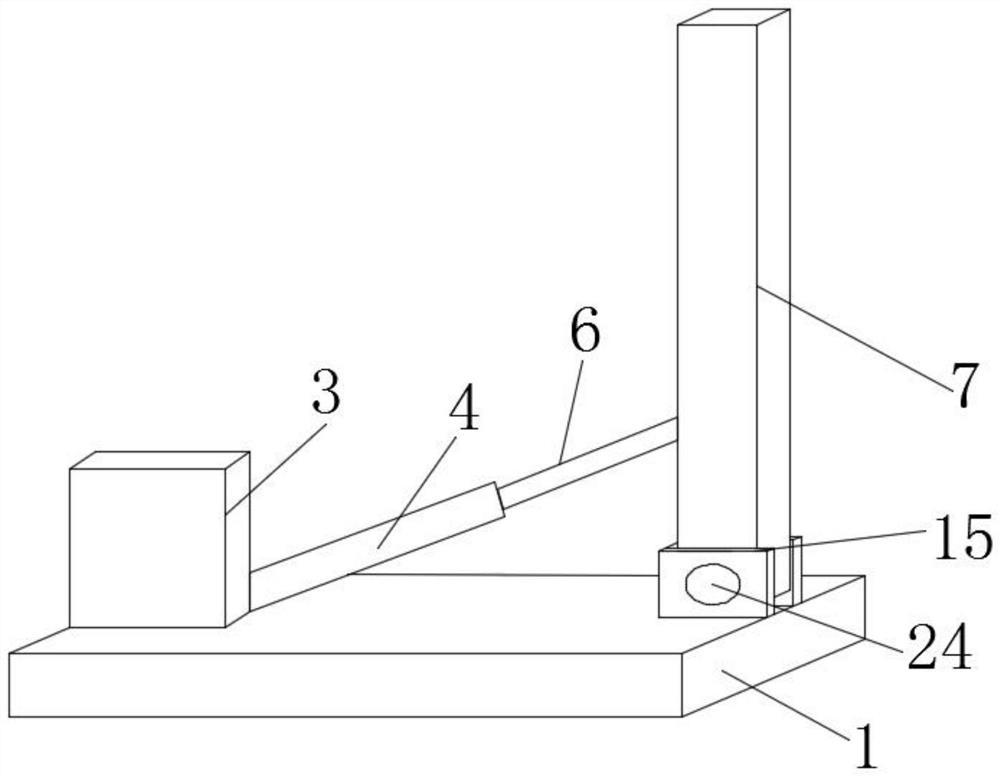

Automatic cutting equipment for aerosol can valve pipes

The invention relates to automatic cutting equipment for aerosol can valve pipes. The automatic cutting equipment for the aerosol can valve pipes comprises a support, a conveying rotating disc used for conveying the valve pipes is arranged on the support, and a conveying guide rail is arranged on the side portion of the conveying rotating disc. The support is further provided with a saw blade, and the saw blade is located on the side portion of the conveying guide rail and rotationally arranged on the support. The conveying rotating disc is obliquely and rotationally arranged on the support, and the valve pipes are conveyed to the conveying guide rail one by one during rotation. The saw blade is used for automatically cutting the length of the valve pipes conveyed on the conveying guide rail. According to the automatic cutting equipment for the aerosol can valve pipes, automatic operation of feeding, conveying, length cutting and discharging of the valve pipes can be achieved, the automation degree of the equipment is high, and therefore the production and machining efficiency is improved.

Owner:佛山市顺德区香江精细化工实业有限公司

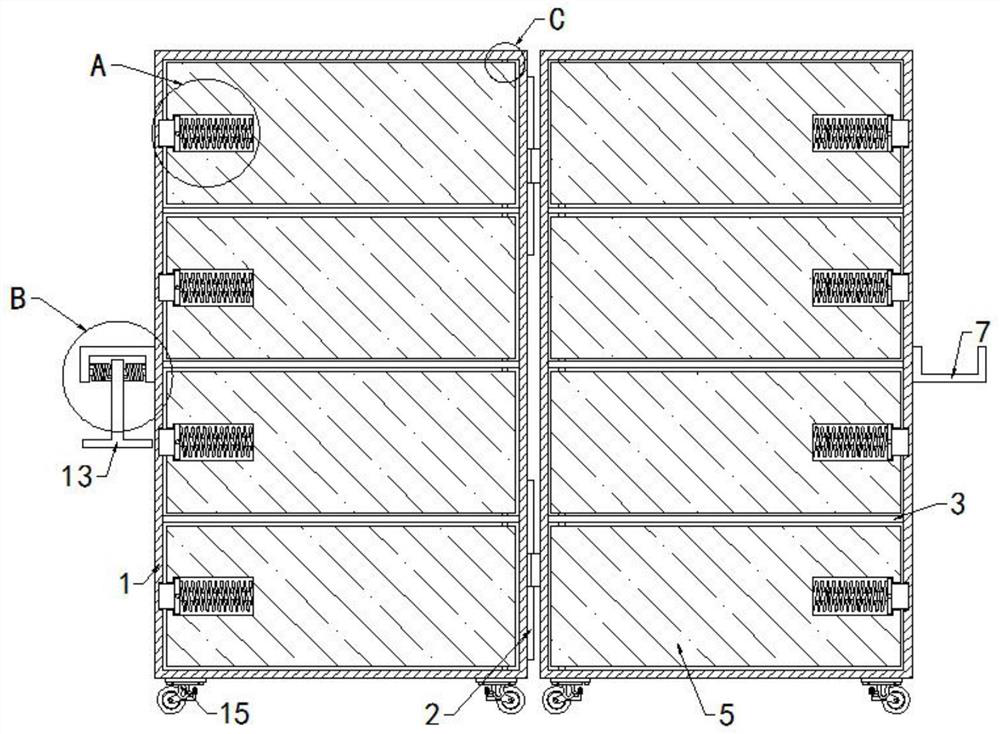

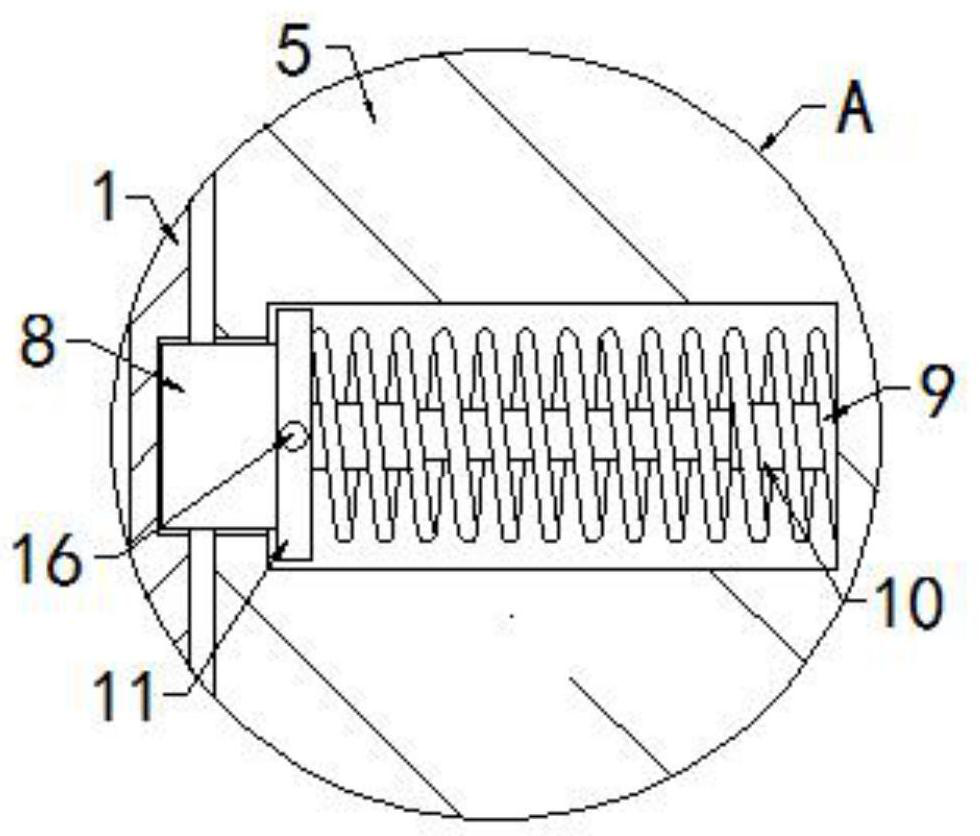

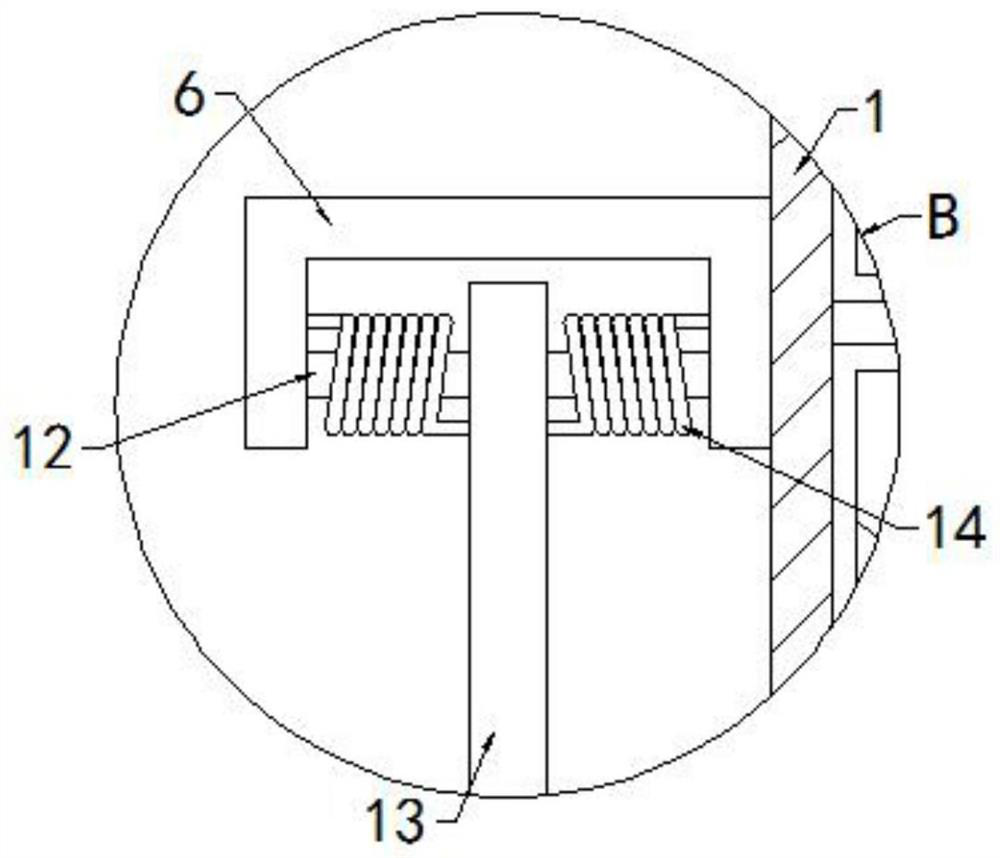

Safety tool storage device for transformer substation

PendingCN114571421ASave spaceReduced horizontal footprintWork tools storageStructural engineeringMechanical engineering

The invention relates to the technical field of safety tool storage, and discloses a safety tool storage device for a transformer substation, which comprises two symmetrically arranged placing cabinets, the two placing cabinets are rotatably connected through two symmetrically arranged hinges, and a plurality of symmetrically arranged partition plates are transversely and fixedly arranged in the two placing cabinets; vertical rods are longitudinally and fixedly arranged between the partition plates and between the inner surfaces of the placement cabinets and the partition plates, the rod walls of the multiple vertical rods are rotationally sleeved with baffles, pressing grooves are formed in the front sides of the ends, away from the hinges, of the baffles, inserting limiting mechanisms are arranged in the groove walls of the pressing grooves, and a first U-shaped block is fixedly arranged on the left side of the outer surface of the left placement cabinet; a second U-shaped block is fixedly arranged on the right side of the outer surface of the right placing cabinet, and a connecting limiting mechanism is arranged in the first U-shaped block. According to the tool box, the placement of other tools is not affected when tools are taken.

Owner:陕西赛普瑞电气有限公司

An optical fiber docking device

ActiveCN105717582BRealize data exchangeRealize automatic dockingCoupling light guidesEngineeringHuman power

The embodiment of the invention discloses an optical fiber butting device which comprises a first fixing plate and a second fixing plate which are oppositely arranged, multiple sliding rods, a butt matrix structure, at least one manipulator and an optical fiber core butting apparatus, wherein the multiple sliding rods are arranged between the first fixing plate and the second fixing plate and are fixedly connected with the first fixing plate and the second fixing plate; the butt matrix structure is positioned in a space formed by the first fixing plate, the second fixing plate and the multiple sliding rods and is of a hollow columnar structure; the side wall of the butt matrix structure is provided with multiple parallel butt slots; each butt slot is internally provided with multiple butt holes formed along the butt slots, and the extension direction of the butt slots is parallel to that of the sliding rods; the manipulator is movably connected with the sliding rods and can slide along the slide rods; the optical fiber core butting apparatus is used for fixing external optical fiber cores and is driven to move in a preset direction by virtue of the manipulator. The optical fiber butting device is capable of realizing automatic butt of multiple optical fiber cores, greatly reducing participation of manpower and saving lots of financial resources.

Owner:NINGBO YINGMING ELECTRIC TECH

A bridge inspection vehicle with self-removable frame

The invention discloses a bridge inspection vehicle with a self-detachable and replaceable frame, which includes a bottom plate, a weight block and a support column. First hydraulic cylinders are respectively arranged at the four corners of the top of the bottom plate, and the four first hydraulic cylinders are all fixedly arranged. On the top surface of the bottom plate, four through holes are opened on the bottom plate below the four first hydraulic cylinders, and four first piston rods are arranged inside the four first hydraulic cylinders. The bottom ends of the four through holes protrude from the bottom of the bottom plate respectively. When the frame needs to be replaced, the first piston rod inside the first hydraulic cylinder moves to make the sliding block of the detection frame and the bottom of the bottom platform move. There is no force in the vertical direction between the slide rails, and the inspection vehicle is controlled to move forward, so that the slider of the inspection frame is separated from the slide rail, and the slider on the new inspection frame enters the slide rail to complete the disassembly of the inspection frame. It is easy to replace the new inspection frame when changing jobs, and it does not need to be fixed by bolts. The replacement is simple and the replacement efficiency is improved.

Owner:江苏祥瑞港机设备有限公司

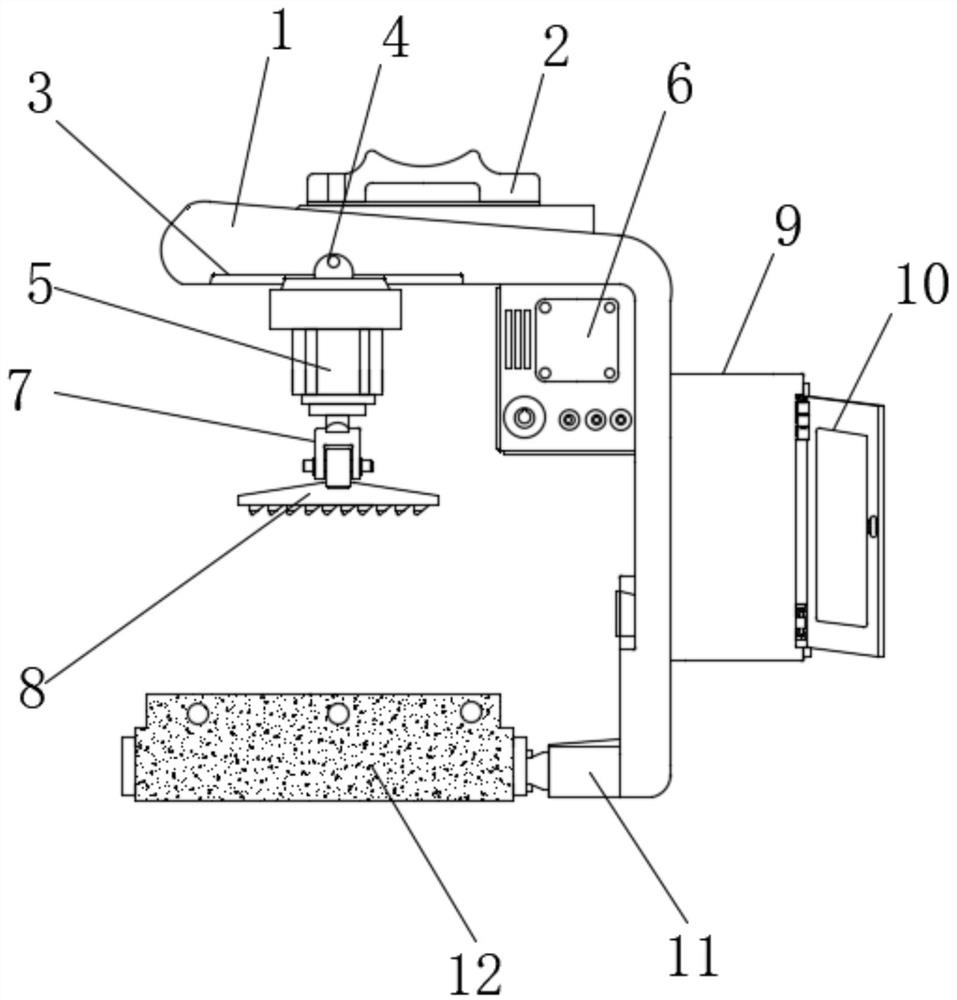

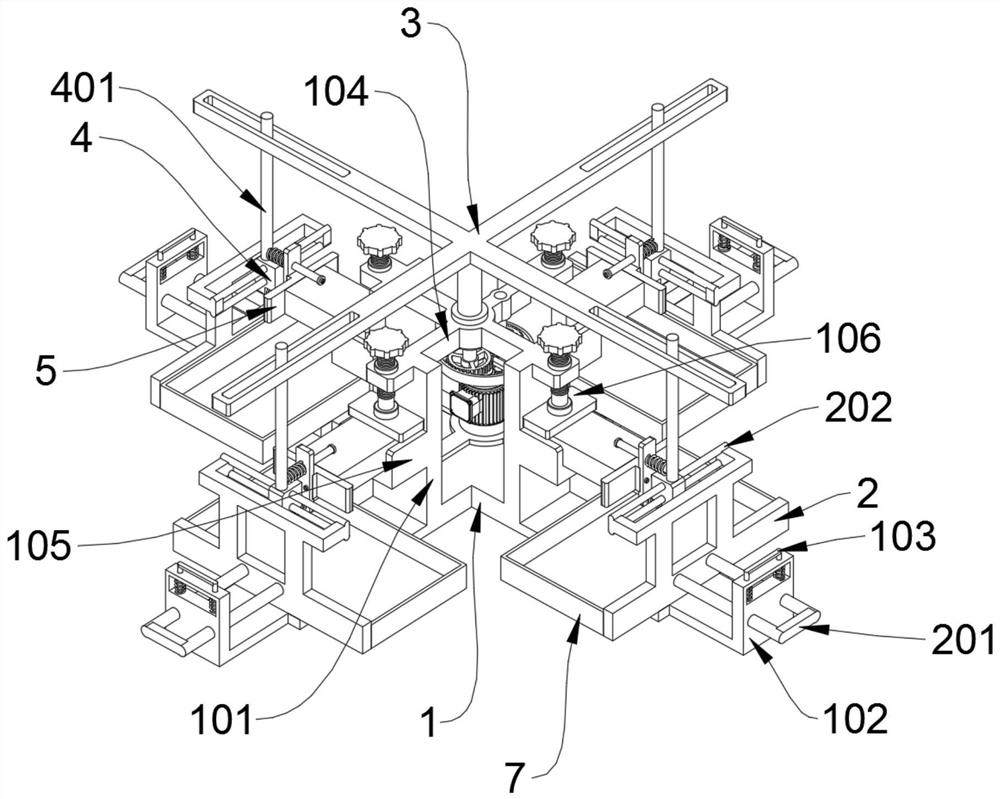

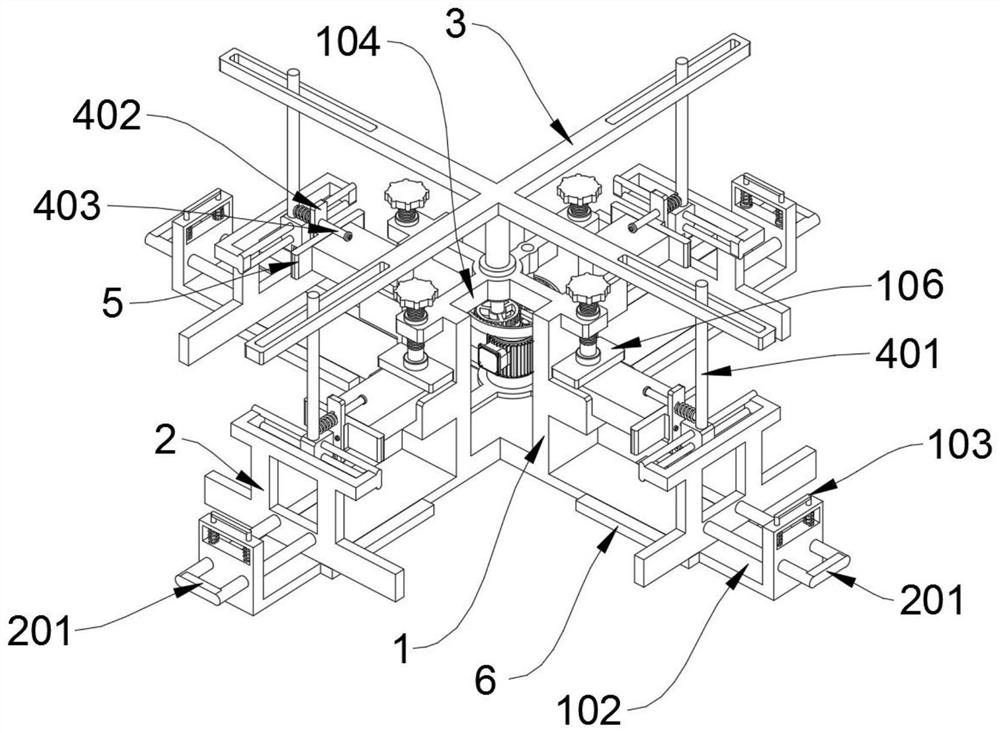

Multi-module grinding device based on high polymer material test

ActiveCN112844538AReduce weight and costReduced horizontal footprintPreparing sample for investigationGrain treatmentsGrindingHigh polymer

The invention discloses a multi-module grinding device based on a high polymer material test, relates to the technical field of multi-module grinding devices, and solves the problem that a plurality of materials need to be ground step by step and in batches when an existing grinding device is used for grinding and comparing the performance of the materials at different positions or in different batches. The multi-module grinding device based on the high polymer material test comprises a base; the whole base is of a cross-shaped structure; four vertical supporting plates are symmetrically welded to the middle of the base; a clamping groove is welded to the middle section of each vertical supporting plate in a supporting mode; a cross-shaped connecting frame is welded and supported among the top end sections of the four vertical supporting plates; a cross-shaped driving frame is rotatably inserted in the center of the cross-shaped connecting frame in a penetrating mode; and four L-shaped supporting plates are symmetrically welded to the bottom sections of the four vertical supporting plates. The multi-module grinding device can grind a plurality of material plates at one time, can conveniently compare and detect the density and other properties of the material plates at a plurality of positions, and is relatively good in practicability.

Owner:上海高分子功能材料研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com