Automatic cutting equipment for aerosol can valve pipes

A technology for automatic cutting and valve pipes, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of unguaranteed finished product quality, high production cost, low efficiency, etc., to reduce labor costs and error rates, High power transmission efficiency and uniform length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

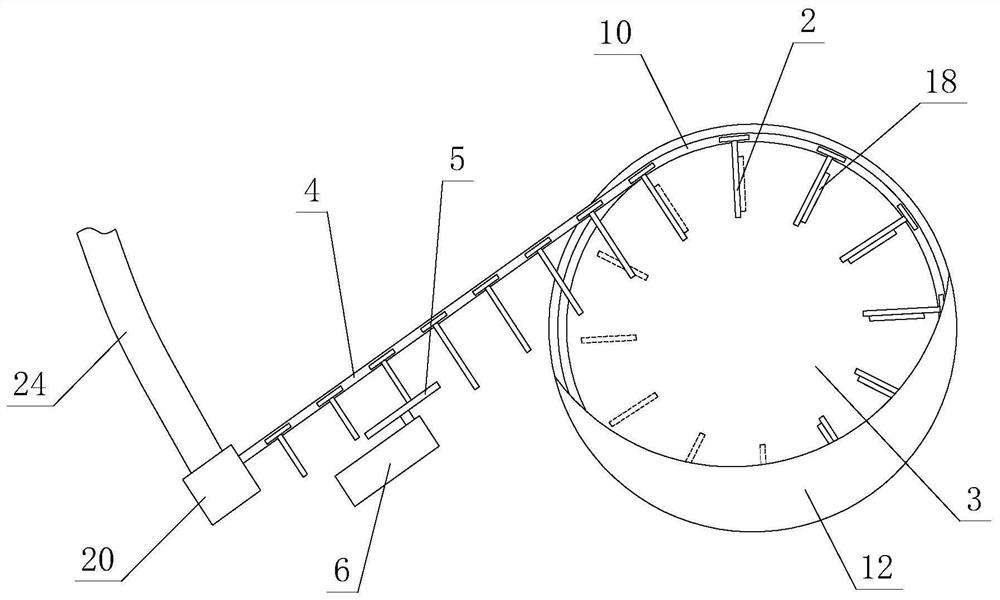

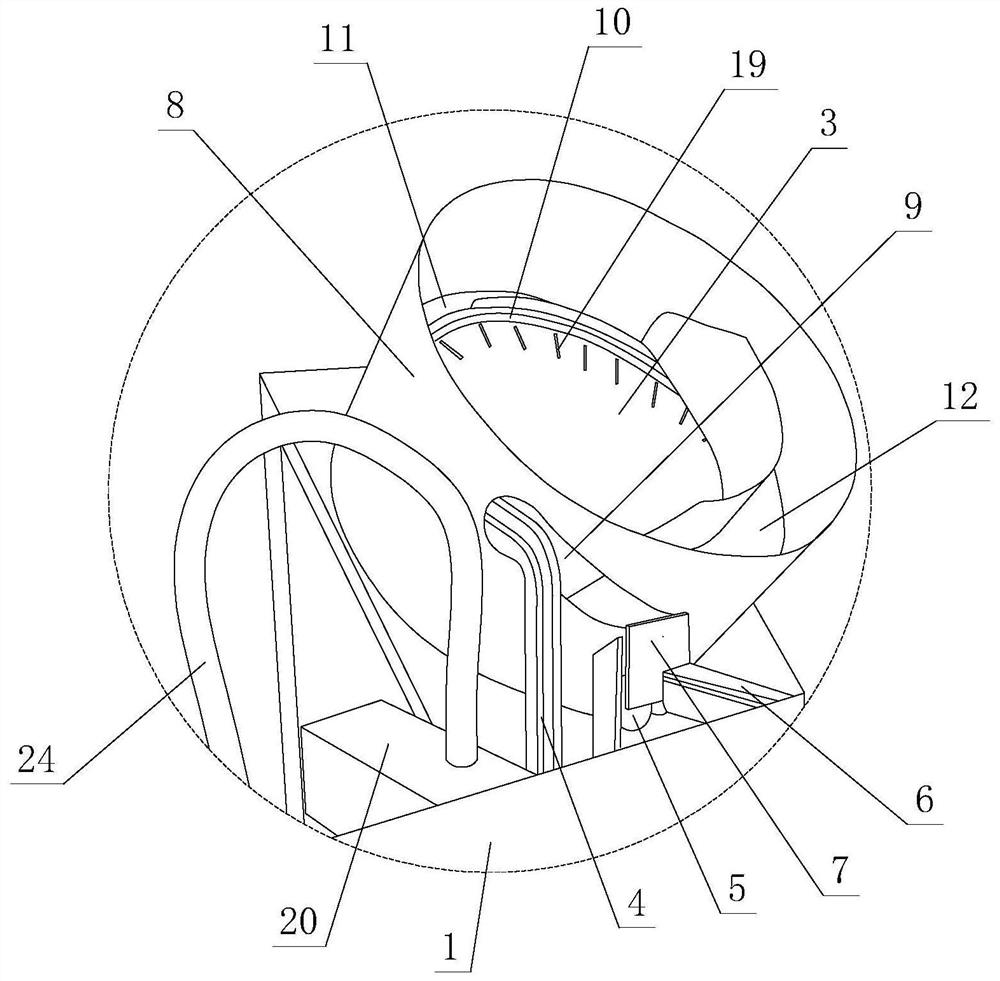

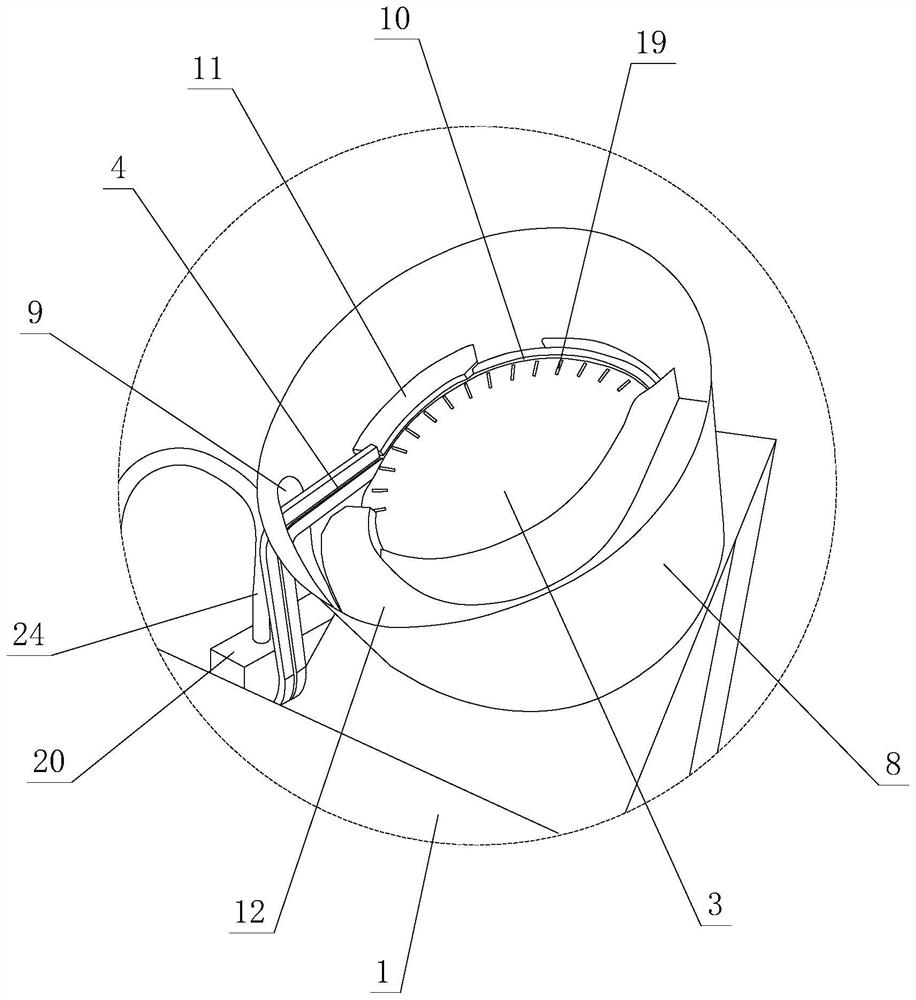

[0030] see Figure 1-Figure 6 , the automatic cutting equipment used for the valve pipe of the spray can, including a bracket 1, a conveying rotating disk 3 for conveying the valve pipe 2 is arranged on the supporting frame 1, and a conveying guide rail 4 is arranged on the side of the conveying rotating disk 3, and the conveying rotating disk 3 can A plurality of valve pipes 2 are arranged, and the arranged valve pipes 2 are transported to the conveying guide rail 4, so as to reduce labor intensity of workers.

[0031] Also be provided with saw blade 5 on the support 1, saw blade 5 is positioned at conveying rail 4 side parts, and rotation is arranged on the support 1; 2 are conveyed to the conveying guide rail 4 one by one; the saw blade 5 automatically cuts the length of the valve pipe 2 conveyed on the conveying guide rail 4.

[0032] When the val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com