Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "To achieve gathering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

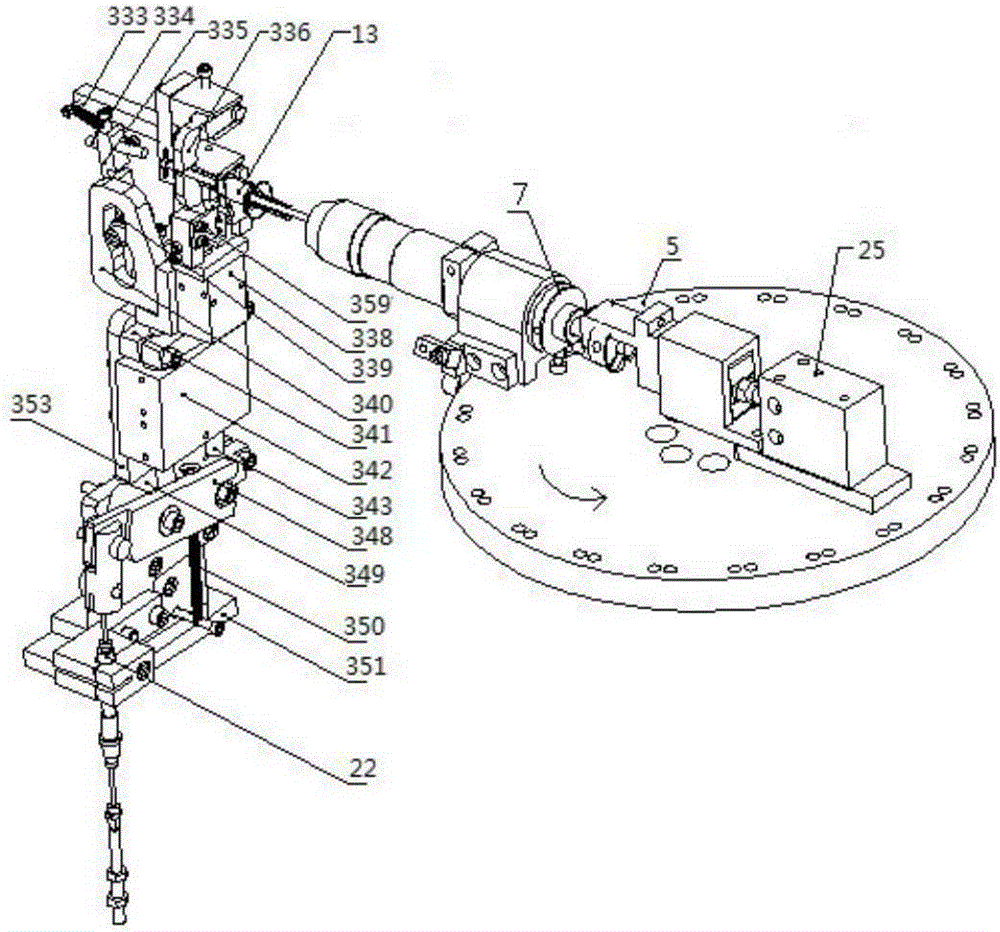

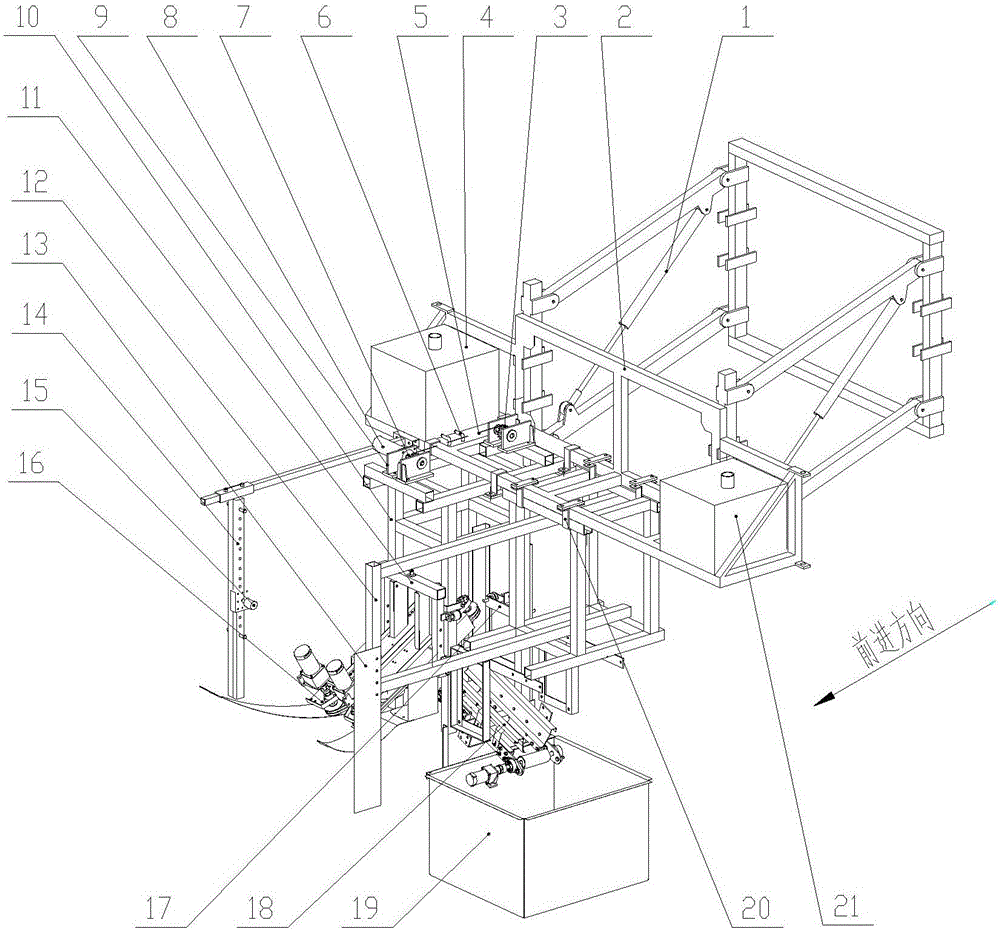

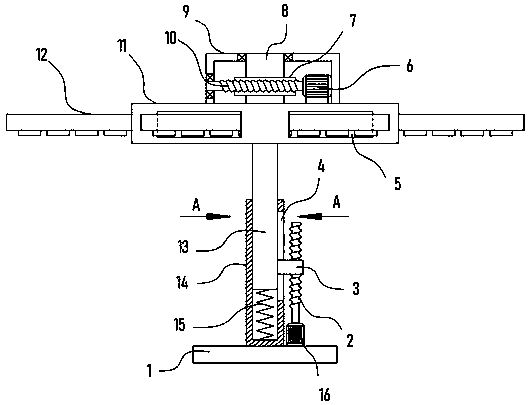

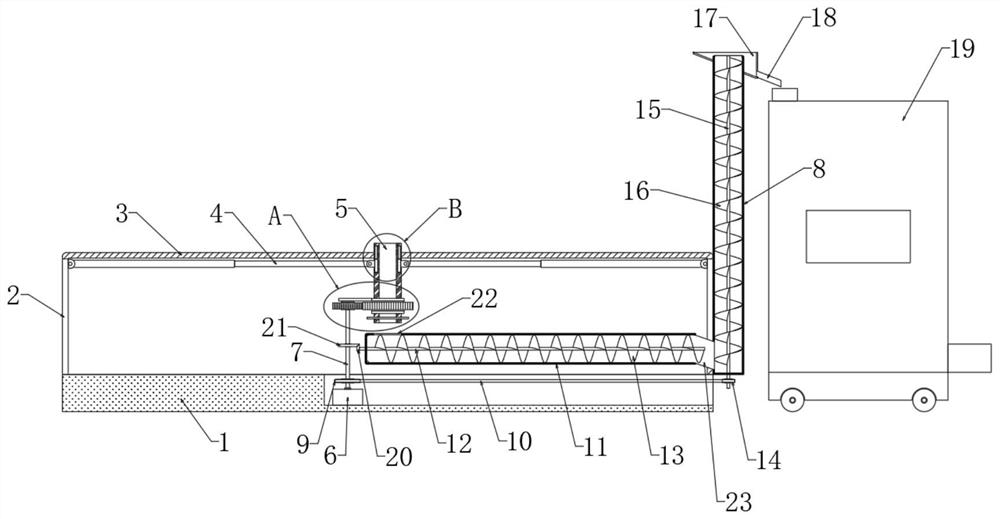

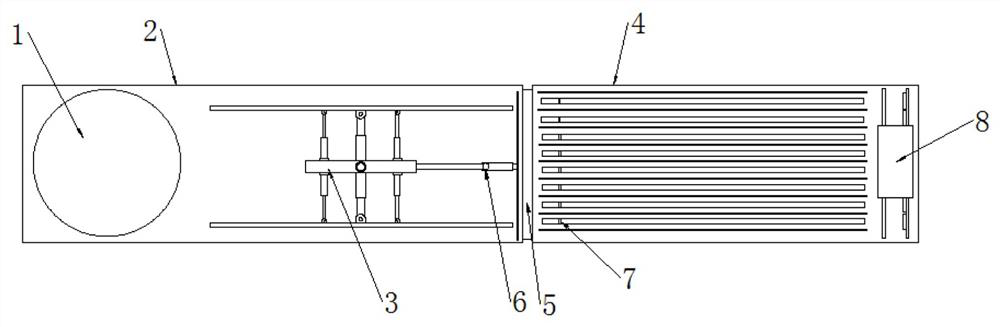

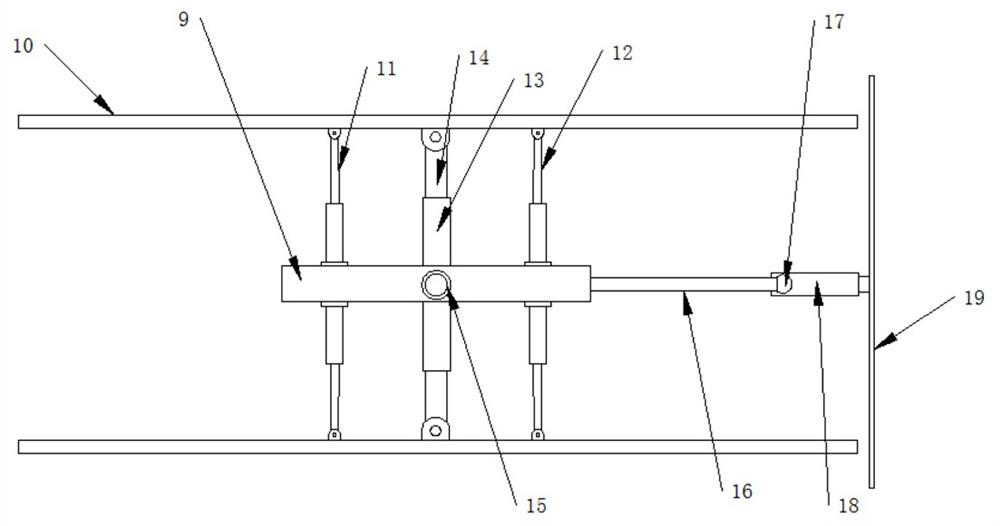

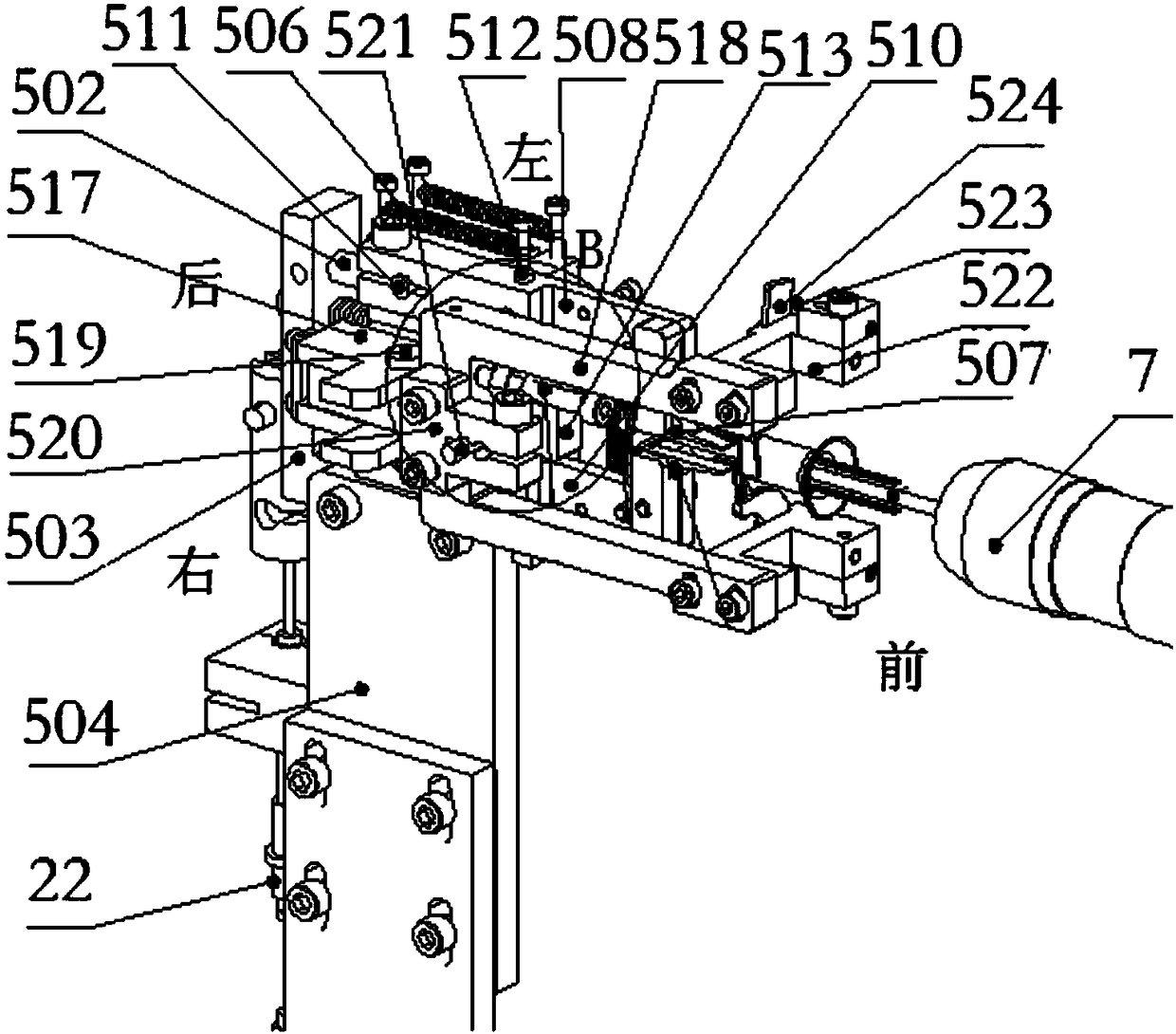

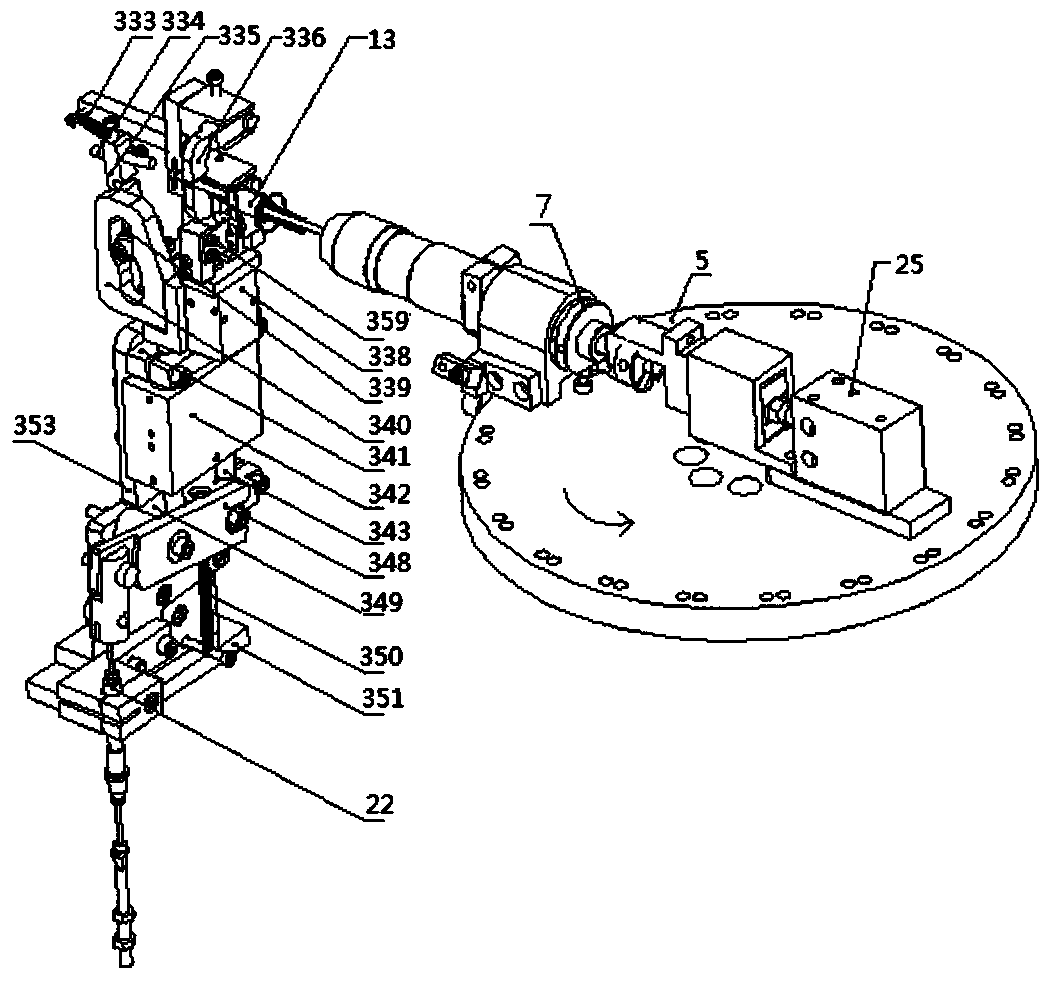

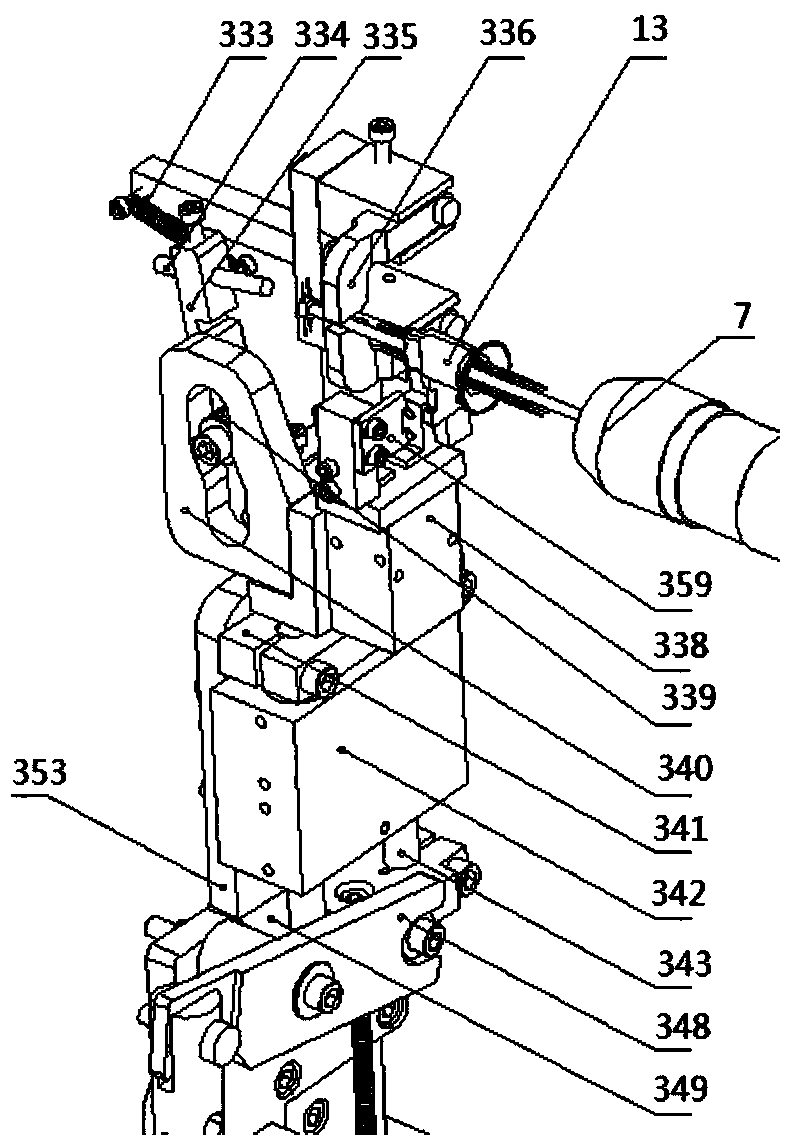

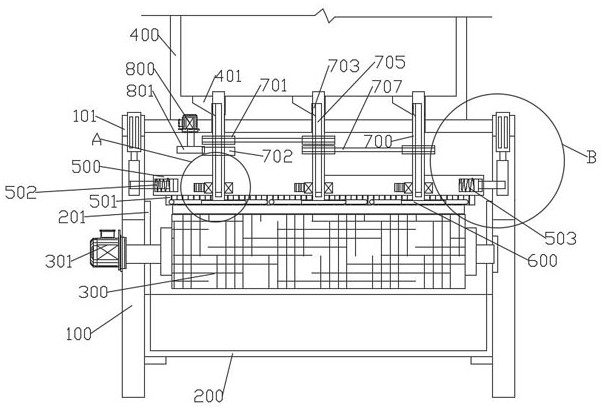

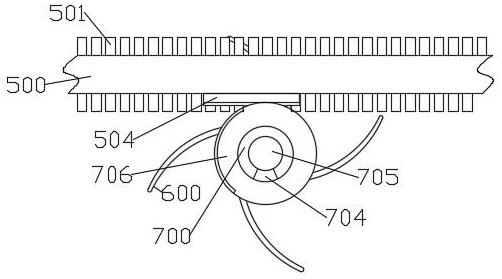

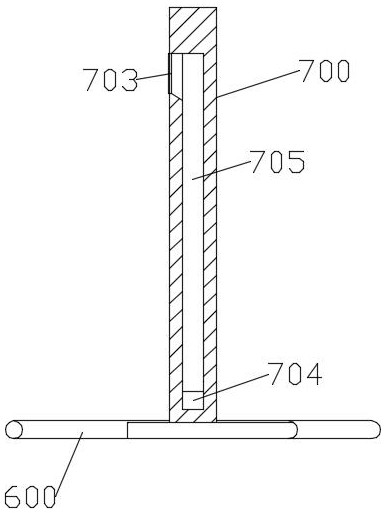

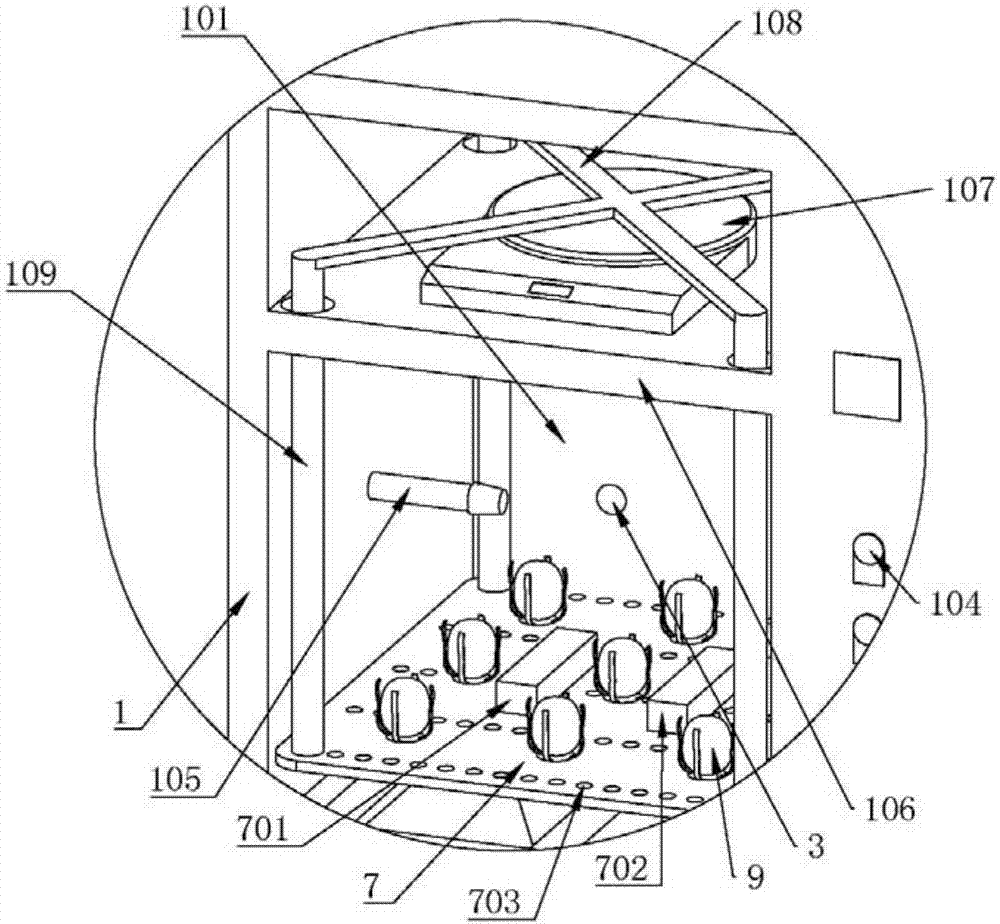

Full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration

ActiveCN105345470AFacilitate automated processing operationsEasy to operateOther manufacturing equipments/toolsCircular discReduction drive

The invention discloses full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration. The full-automatic production equipment comprises a main bottom plate, a platen and an upper bracket, wherein the upper end of the main bottom plate supports the platen through four thick bracket legs. A discharging mechanism and a buffering conveying mechanism are arranged on the left and the right of the side surface of the platen respectively, and a feed mechanism is arranged at the end of the buffering conveying mechanism. The platen is provided with a gap divider. An index plate rotates anticlockwise and is provided with a stem clamp. The main bottom plate is provided with a speed reducer, a station main shaft and a cam mechanism. A stem locating mechanism, a long foot arranging mechanism, a short foot poking mechanism, a 45-degree long foot poking assembly mechanism, a 45-degree short foot poking assembly mechanism, a foot straightening mechanism, an LED light strip shearing and conveying mechanism, an automatic LED light strip rotating and conveying mechanism and a welding mechanism are sequentially arranged on the platen from the front end of the feed mechanism and surround the index plate. The full-automatic production equipment is high in automation degree, high in welding and shaping efficiency and high in shaping accuracy.

Owner:南通睿博电器有限公司

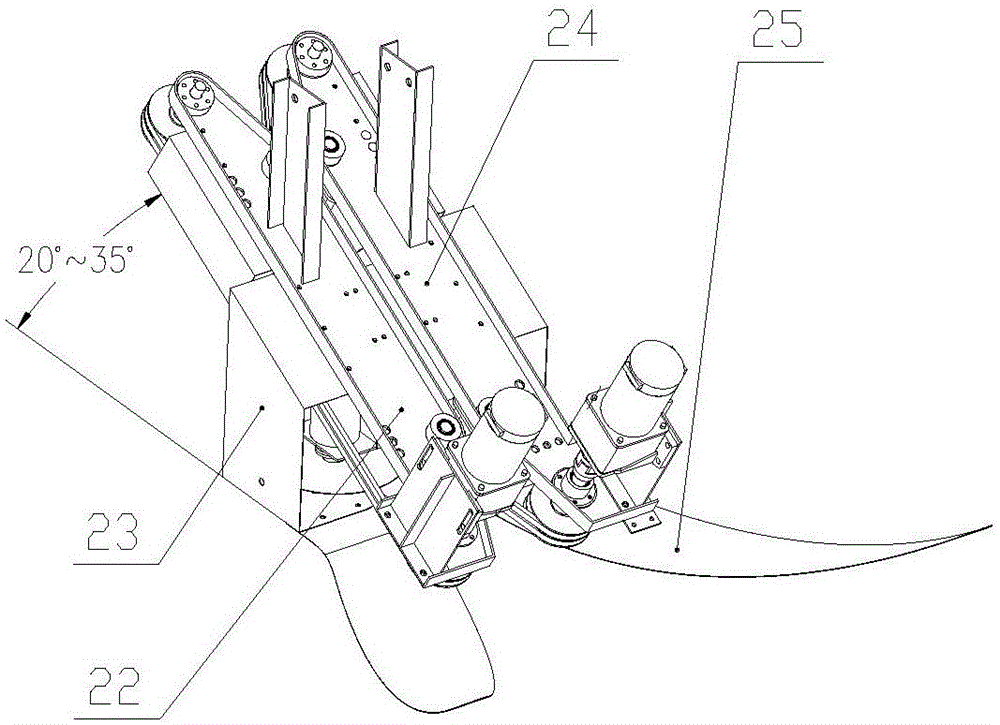

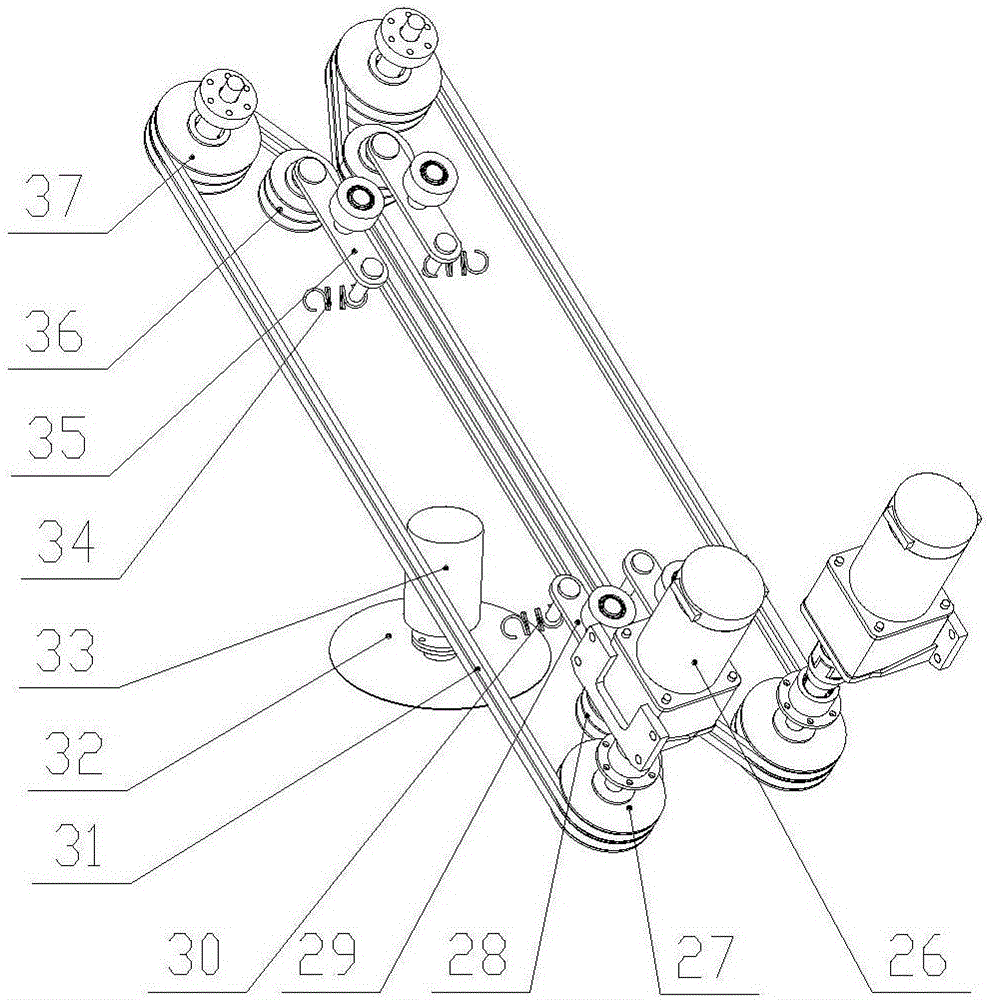

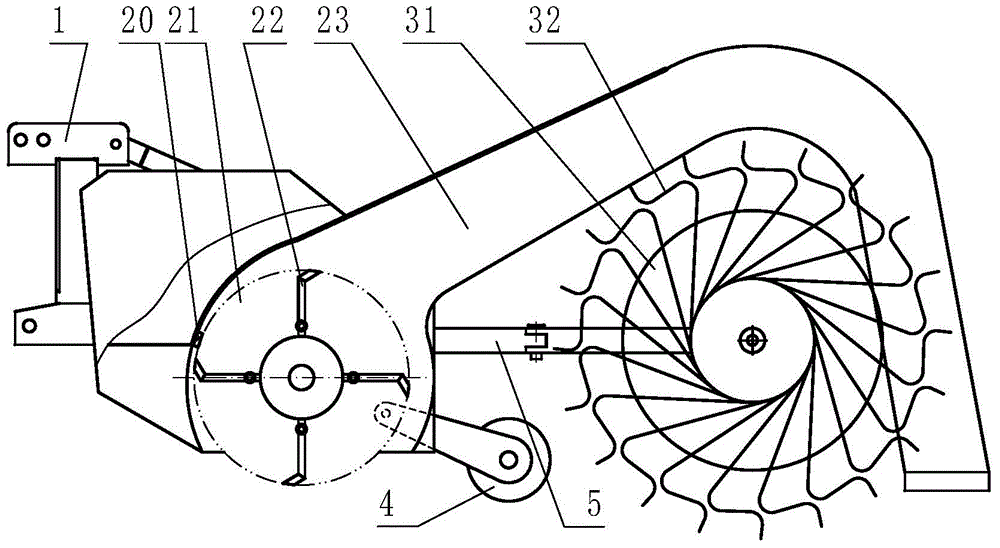

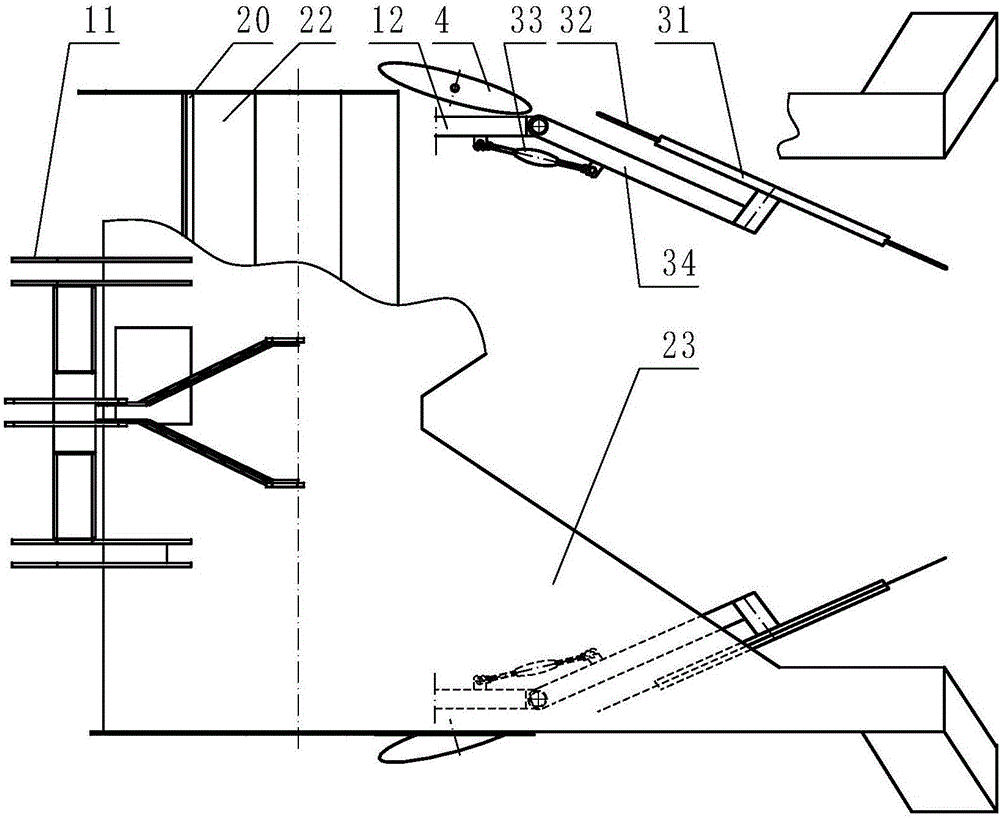

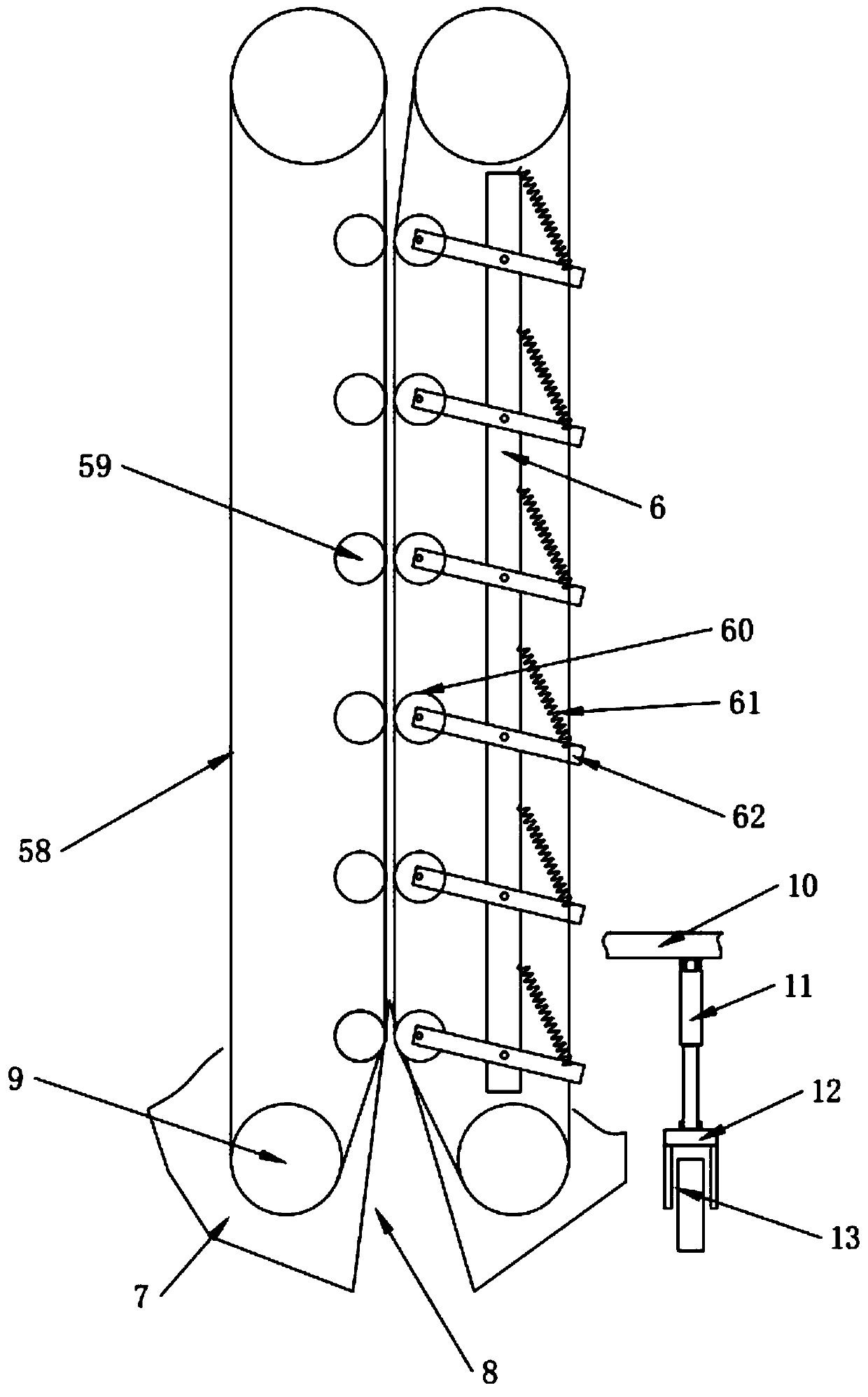

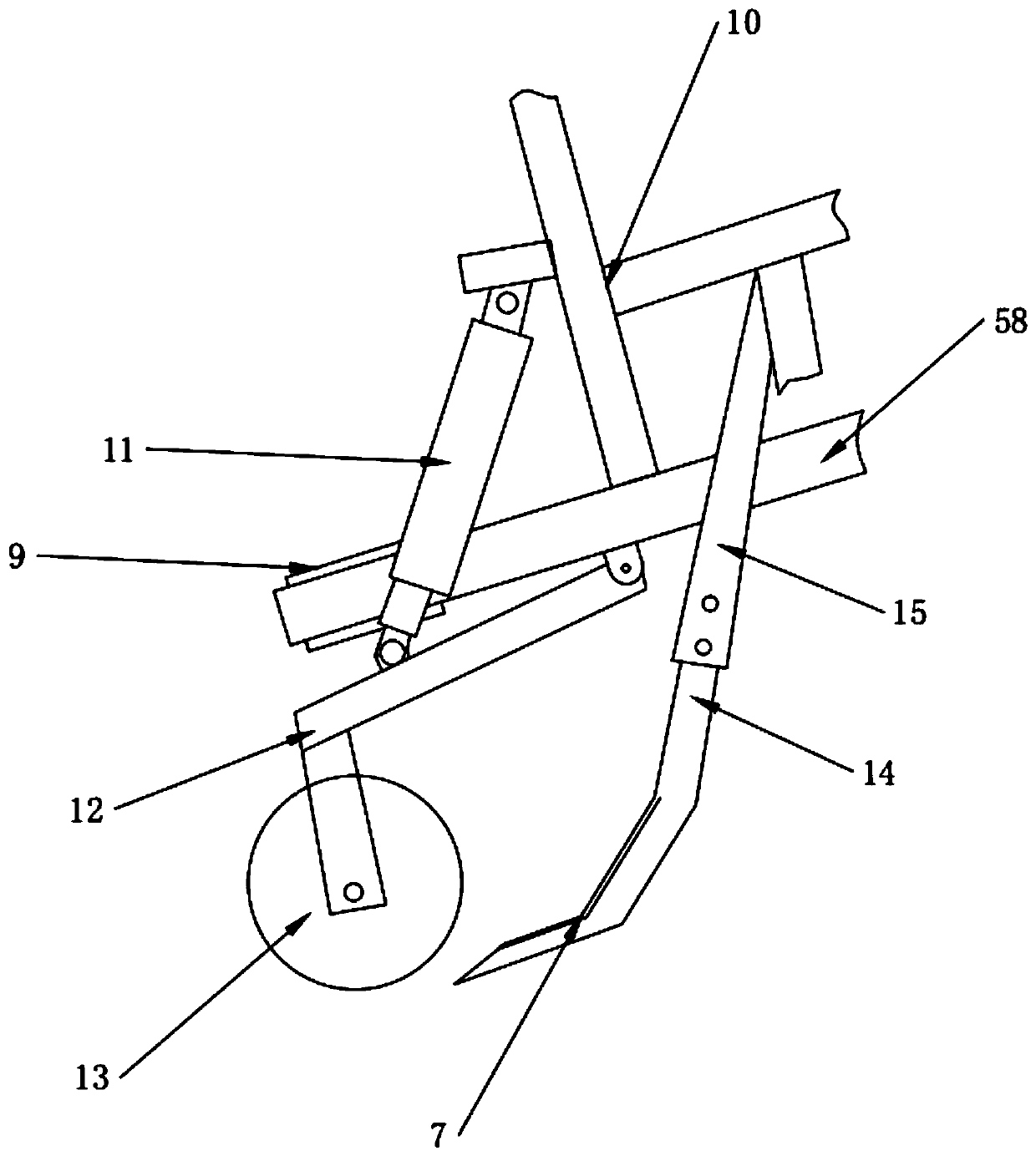

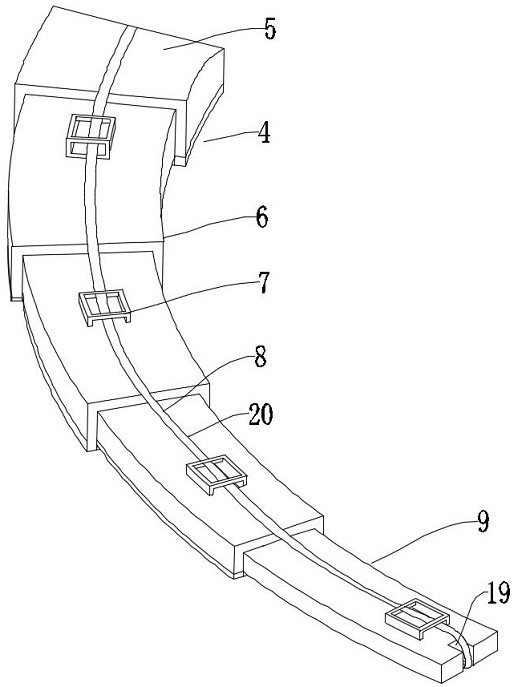

Crop clamping type intelligent topping device

InactiveCN106069241ATo achieve gatheringRealize clamping and conveyingCuttersCutting implementsControl systemEngineering

The invention relates to a crop clamping type intelligent topping device. The crop clamping type intelligent topping device comprises a fixing joint, a tobacco height recognition system, a clamping type topping mechanism, a cutter sterilization system, an automatic bud inhibitor spraying system, a lifting driving mechanism and a delivering and collecting device. The height recognition system calculates the height of crops, and a single-chip microcomputer control system controls the lifting driving mechanism to adjust the height of the topping mechanism. When the clamping type topping mechanism moves forward along a tractor, motors in left and right clamping transmission mechanisms drive two clamping belts to clamp crop tops, bottom cutters cut off the crop tops, and cut crop tops are clamped by the clamping belts on two sides and transported backwards and are automatically collected by the delivering and collecting device. The cutter sterilization system is used for spray sterilization of the cutters. The crop clamping type intelligent topping device has advantages that accurate topping and automatic collection of each crop can be realized, and cutter sterilization and bud inhibitor spraying can be completed.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

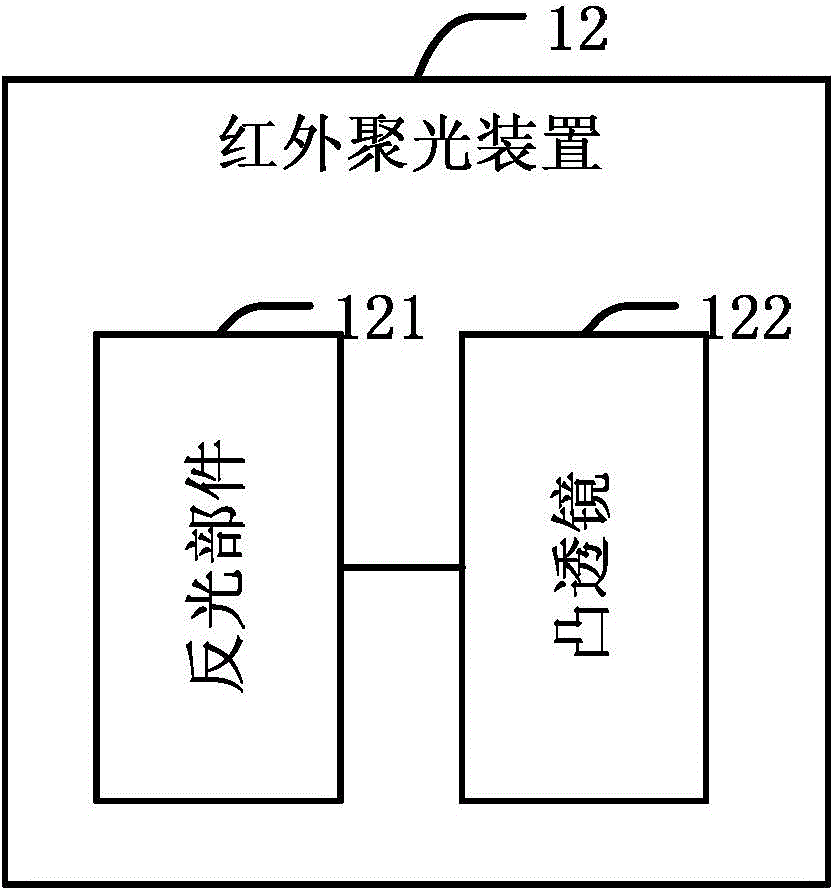

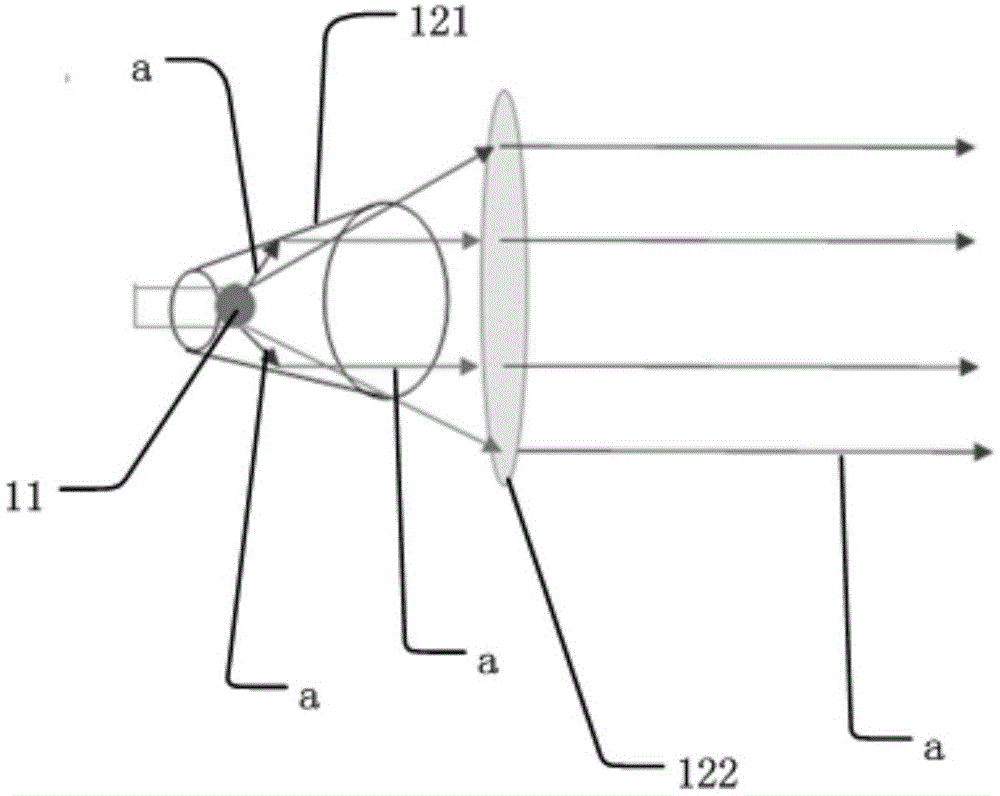

Infrared emission device, infrared remote control device, and infrared light emitting and receiving method

ActiveCN104868950ATo achieve gatheringImprove reliabilityNon-electrical signal transmission systemsClose-range type systemsRemote controlOptoelectronics

The embodiment of the invention discloses an infrared emission device, an infrared remote control device, and an infrared light emitting and receiving method. The infrared emission device comprises at least one emission head for emitting infrared light corresponding to one or more remote control codewords when a user presses a remote control key, an infrared light converging device for converging the infrared light emitted by the emission head, a deflecting device for deflecting the infrared light converged by the infrared light converging device for different angles according to different sending times of the codewords. When the infrared light converging device of the embodiment of the invention is employed, the transmission distance of the infrared light can be increased.

Owner:HUAWEI TECH CO LTD

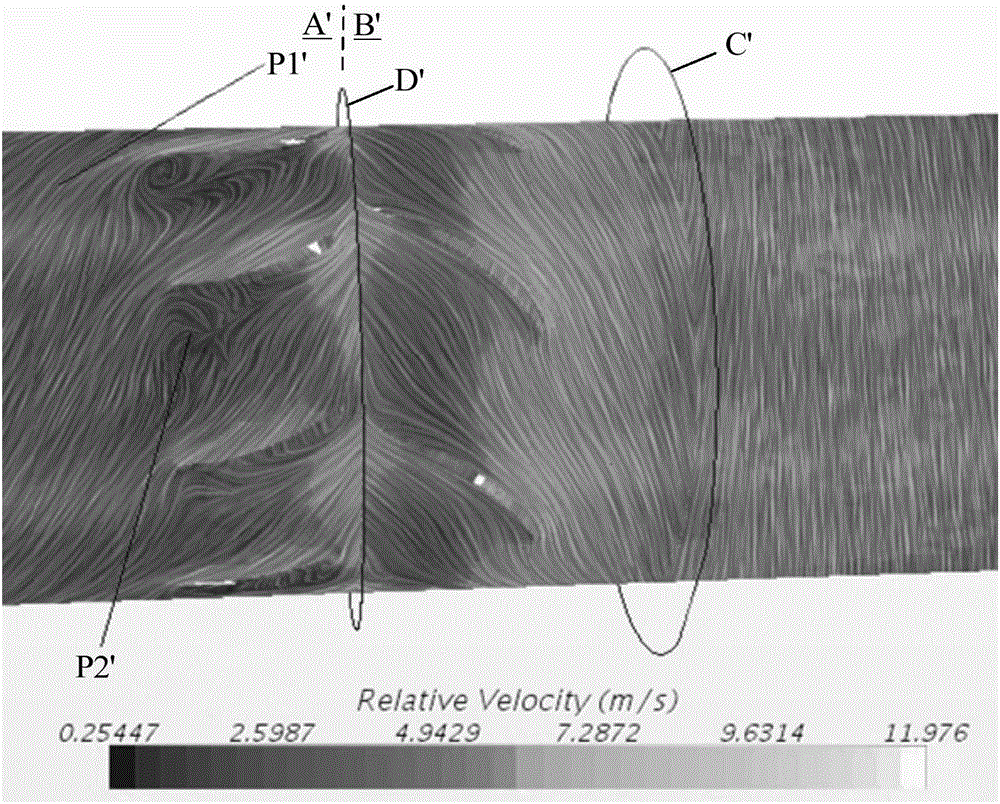

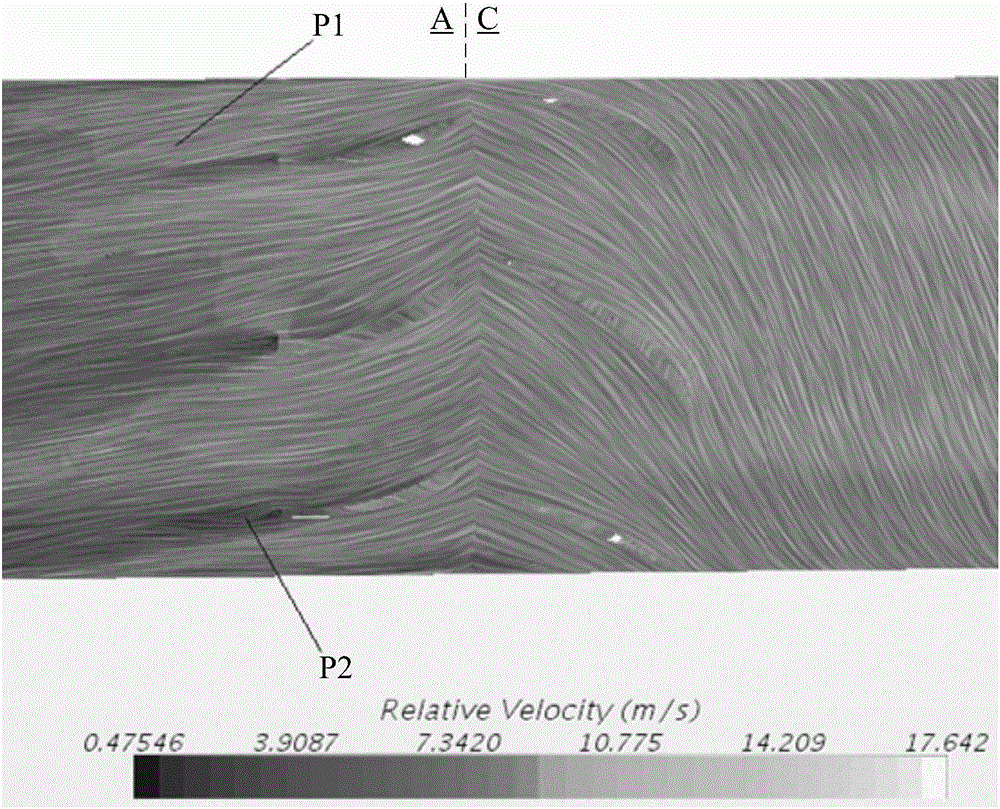

Air conditioner, axial flow fan and stator blade of axial flow fan

ActiveCN106015104AAvoid the problem of left biasTo achieve gatheringPump componentsLighting and heating apparatusEngineeringTrailing edge

The invention provides an air conditioner, an axial flow fan and a stator blade of the axial flow fan. The stator blade of the axial flow fan comprises a blade body and a lug boss. Particularly, the blade body has a pressure surface and a suction surface. The pressure surface is concave. The suction surface is convex. The blade body is provided with a front edge and a rear edge. The lug boss is arranged at the rear edge of the blade body. The lug boss protrudes from the pressure surface of the blade body. The stator blade of the axial flow fan, provided by the invention, has the advantages that air flow at an air outlet of the axial flow fan can be straightened, the separation phenomenon generated at the air inlet of the axial flow fan can be prevented, trailing edge loss is reduced, and the purpose of reducing the kinetic energy loss of the air flow and the noise of the air flow are achieved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

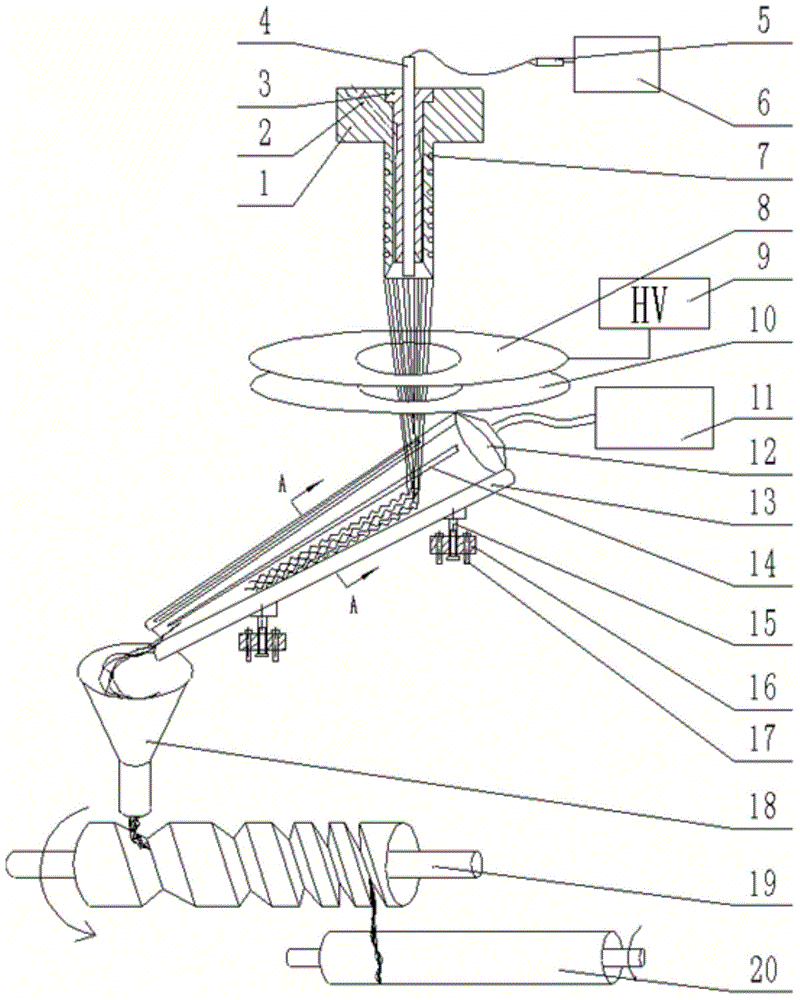

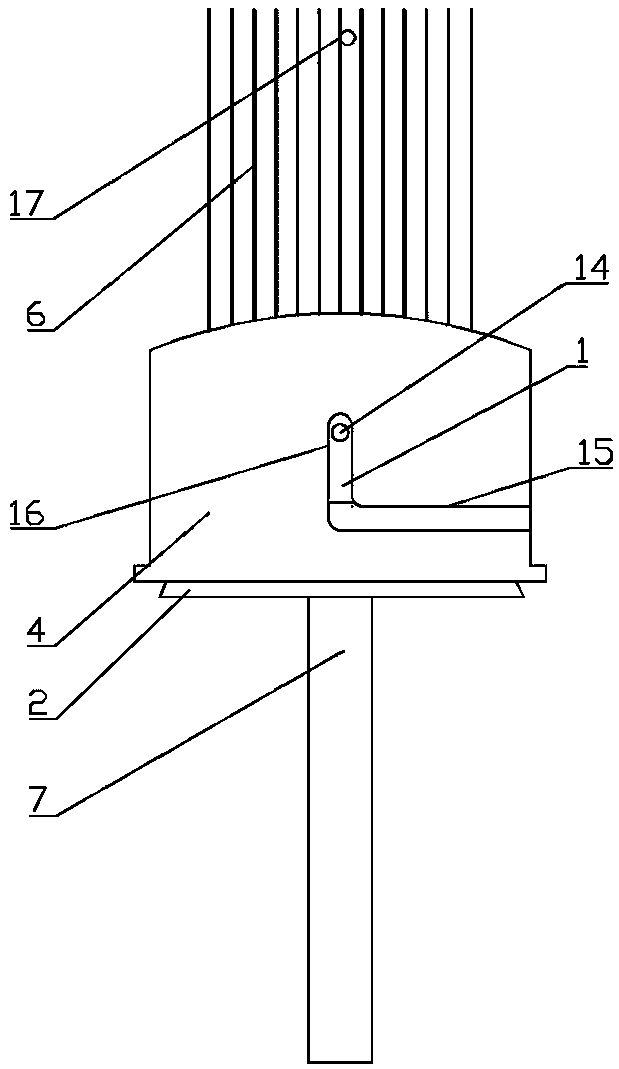

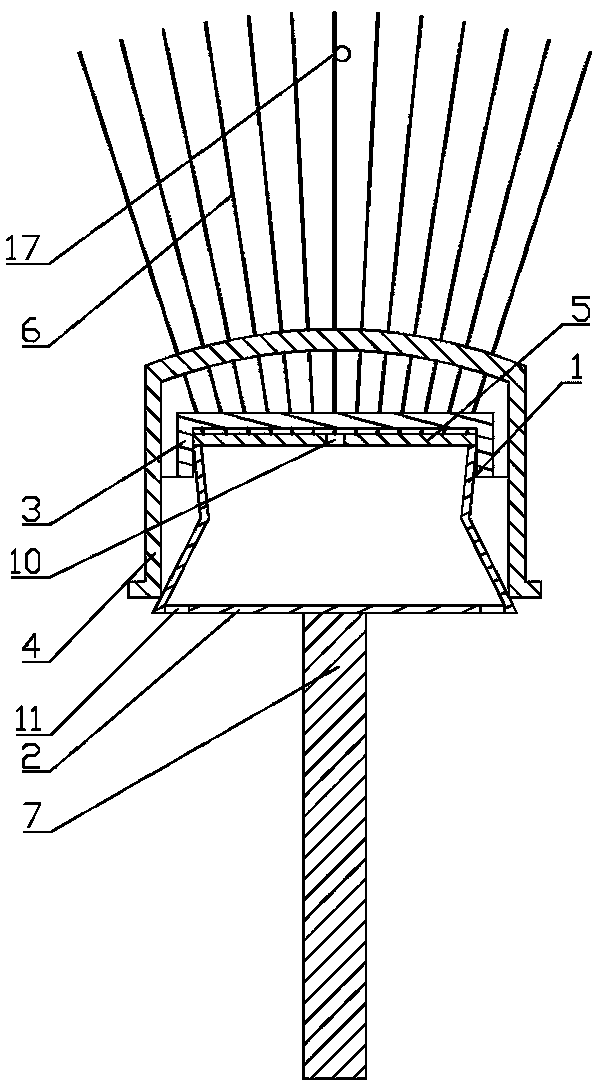

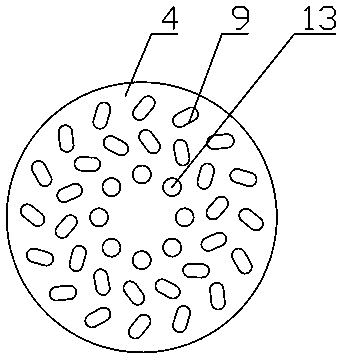

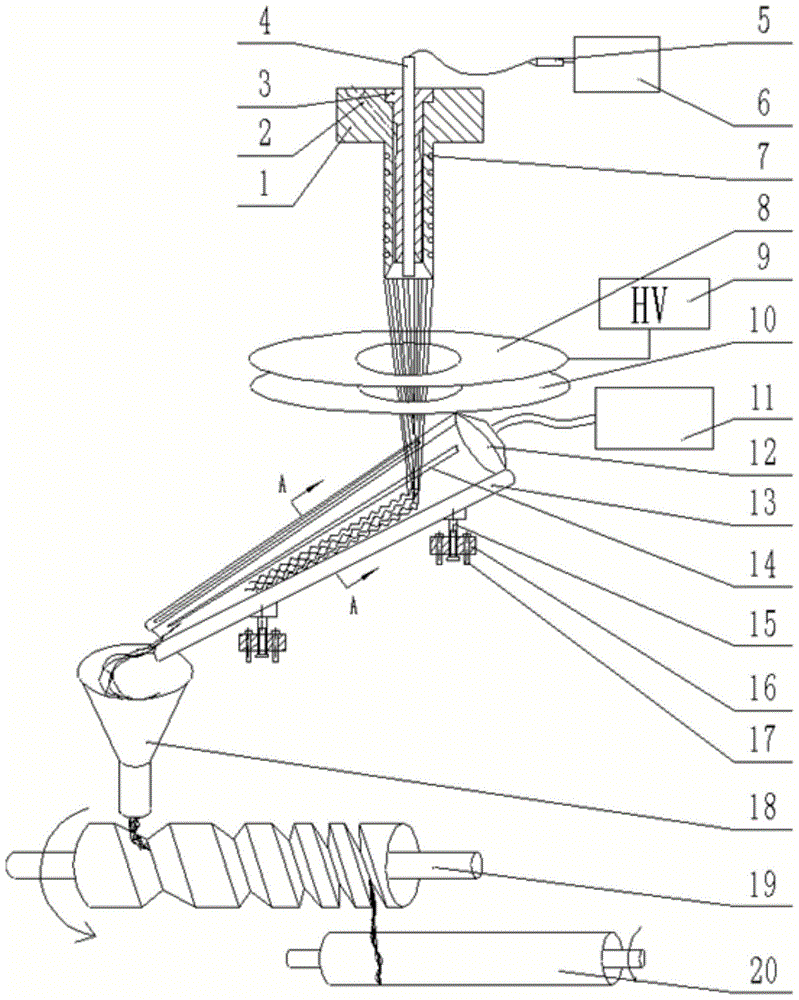

Differential melt electro-spinning device adopting high-velocity water flow assisted twisting

ActiveCN104963008AGuaranteed validityEvenly distributed around the circumferenceFilament/thread formingAir compressorWater channel

The invention relates to a differential melt electro-spinning device adopting high-velocity water flow assisted twisting and belongs to the field of electrostatic spinning. The differential melt electro-spinning device mainly comprises a spray head outer cylinder, a material flow pass, a spray head core rod, an air flow guide tube, a hot air gun, an air compressor, a heating coil, a perforated electrode plate, an electrostatic generator, a perforated insulation plate, a water pump, a water flow inlet channel, an annular water channel, an annular water flow channel, adjusting screws, adjusting-fixing plates, fixing screws, a twisting funnel, a grooved roller and a collection roller. The differential melt electro-spinning device utilizes high-velocity water flow to orderly arrange and deliver multiple fibers in the water channel, the fibers are fed into the twisting funnel along with the water flow to be rotatably twisted, the twisting degree can be adjusted by controlling an inclination angle of the water channel, twisted fibers fall into the grooved roller to be drawn close through compaction, and finally compact twisted single-fiber bundles are collected through the collection roller. The differential melt electro-spinning device can efficiently card fibers on the premise that normal spinning of an original spinning device is not influenced, and polymer melts can be made into twisted threads through electrostatic spinning in a one-time forming mode.

Owner:BEIJING UNIV OF CHEM TECH

Anti-electrostatic anti-blocking and breaking-free bird thorn

The present invention relates to the technical field of bird thorn devices, in particular to an anti-electrostatic anti-blocking and breaking-free bird thorn. The bird thorn comprises a base, a fixingbolt, an inner barrel, an outer barrel, a baffle sheet, needle thorns and an operating rod, wherein the base is in a barrel shape with an upward opening; the center of the lower end of the base is fixedly provided with the fixing bolt; the outer side of the upper end of the base is fixedly provided with the inner barrel with the lower end located on the outer side of the middle of the base; the inner barrel is in a barrel shape with a downward opening; the outer side of the inner barrel is sleeved with the outer barrel with the lower end located on the outer side of the lower end of the bottom; and the outer barrel is in a barrel shape with a downward opening. The bird thorn is reasonable and compact in structure and convenient to use; by arrangement of an upper discharge hole and a lowerdischarge hole, rainwater and gravel dust can be conveniently discharged from the inner barrel and the base; the outer barrel is rotated relative to the inner barrel, and the upper ends of the needlethorns are tilted outwards under the cooperation of an inner positioning hole and an outer positioning hole, so that the needle thorns are unfolded; and the bird thorn has the characteristics of being stable, efficient and long in service life.

Owner:新疆雷烨防雷科技有限公司

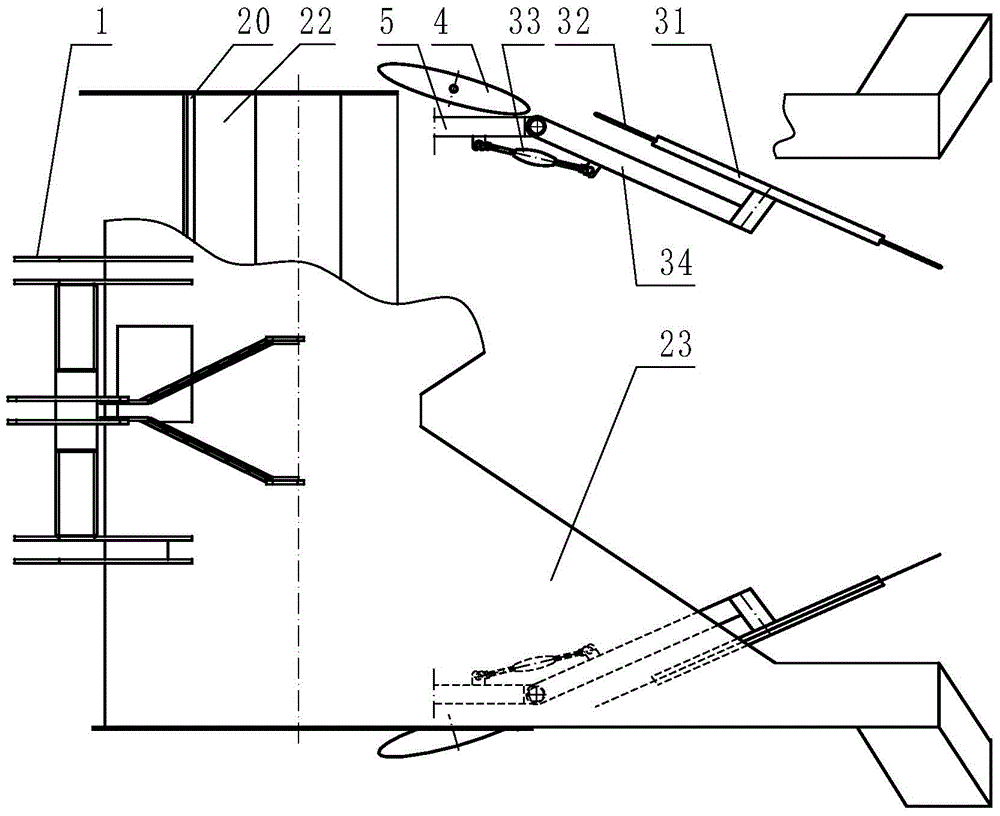

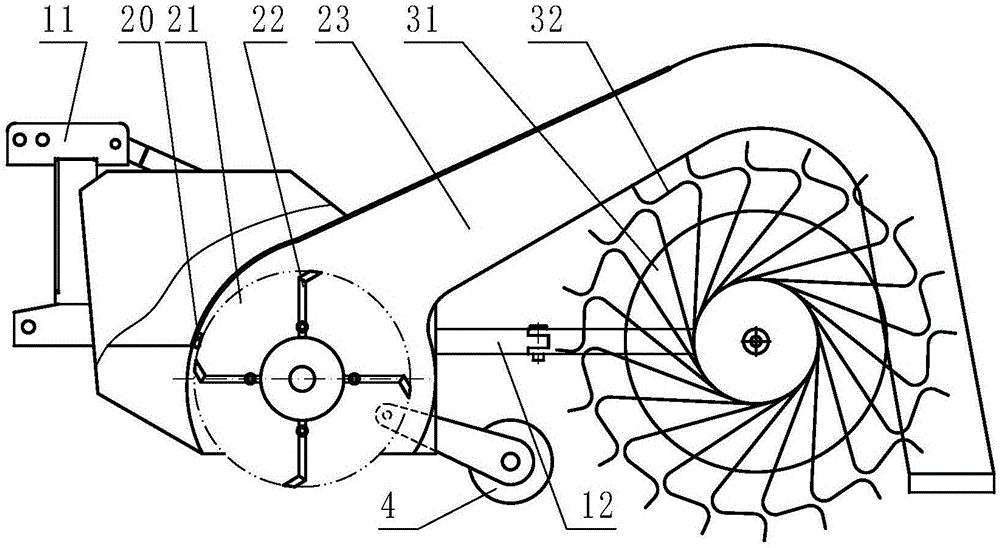

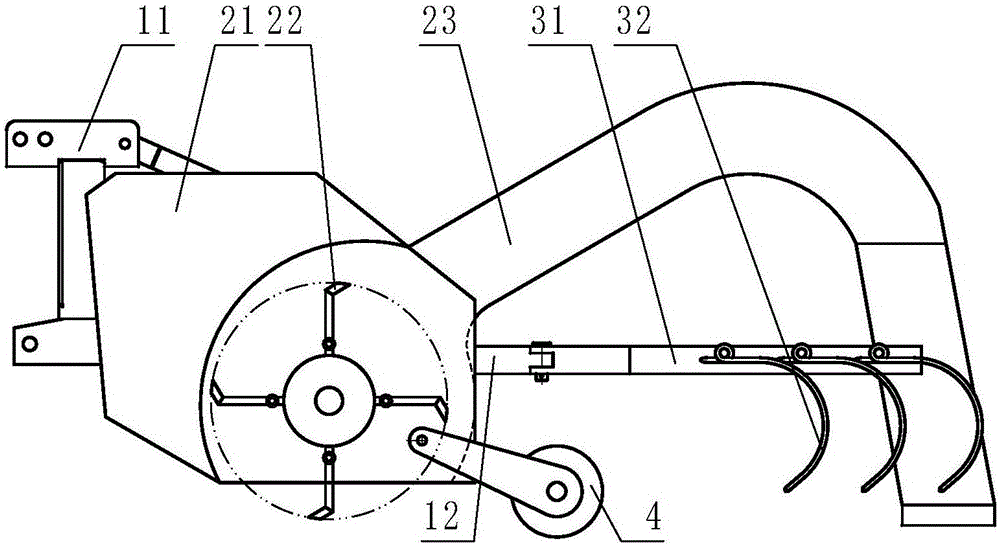

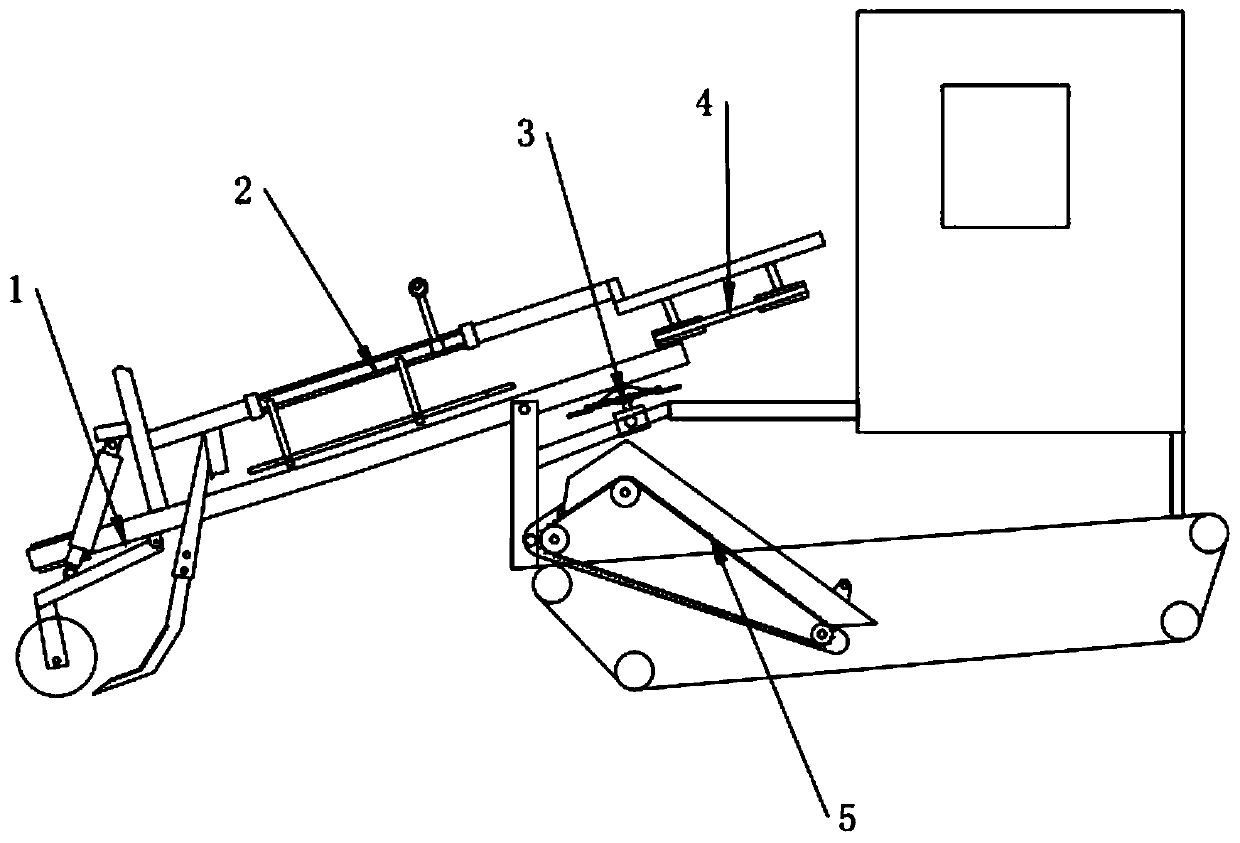

Method for straw crushing and field-returning and mulching film recycling operation

InactiveCN104969725ATo achieve gatheringRealize smashing and returning to the fieldCrop conditionersMowersEngineering

The invention discloses a method for straw crushing and field-returning and mulching film recycling operation. Firstly, crop straws are crushed and collected to a conveying channel, that is, the crop straws on the mulching film portions are removed in a crushing mode, crushed, and not returned to field immediately; secondly, edge raising and gathering are performed on the mulching film on which the crop straws are removed, the mulching film is gathered into narrower mulching film strips, wider open space is vacated among the mulching film strips, and then the crop straws which are crushed and collected in the conveying channel are released to the open space among the mulching film strips. Compared with the prior art, the method for the straw crushing and field-returning and mulching film recycling operation has the advantages that not only can edge raising and gathering be performed on the mulching film, but also the crop straws can be crushed and returned to the field, and the operation efficiency is high.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Building construction gravel crushing device

ActiveCN113680510AEfficient crushingPromote fragmentationSievingScreeningArchitectural engineeringMechanical engineering

The invention is applicable to the related technical field of crushing, and provides a building construction gravel crushing device. The building construction gravel crushing device comprises a machine body, and a feeding part and a discharging port are arranged on the machine body. The building construction gravel crushing device further comprises a crushing assembly, the crushing assembly comprises a telescopic part, the telescopic part is installed on the machine body, a pressing seat is fixed to the extending end of the telescopic part, a center tip crushing part and a crushing impact part are fixed to the bottom of the pressing seat, multiple rotating tip crushing parts are further rotationally installed on the pressing seat and are annularly distributed, and the rotating directions of every two adjacent rotating tip crushing parts are opposite. According to the building construction gravel crushing device, the combined action of multiple crushing modes is achieved, the crushing effect is guaranteed, and materials on a circular screen plate can be stirred in an all-dimensional reciprocating manner, so that gravel gathering is achieved, gravel screening is accelerated, and the crushing process is accelerated.

Owner:徐州聚能道路安全设施有限公司

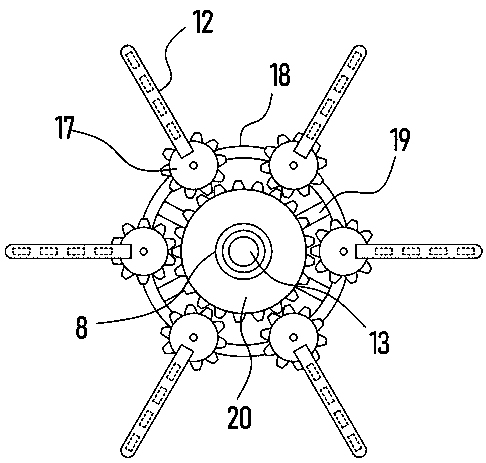

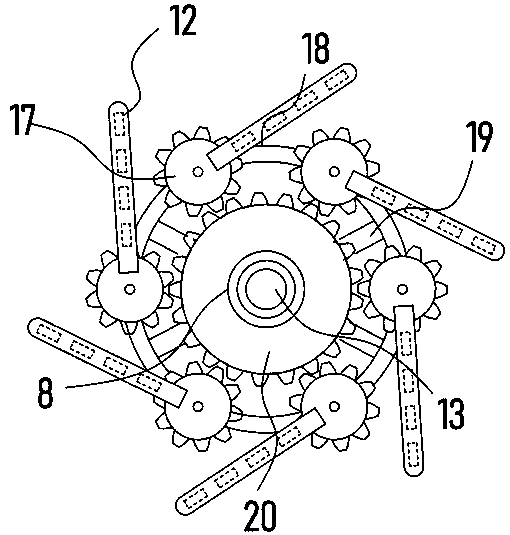

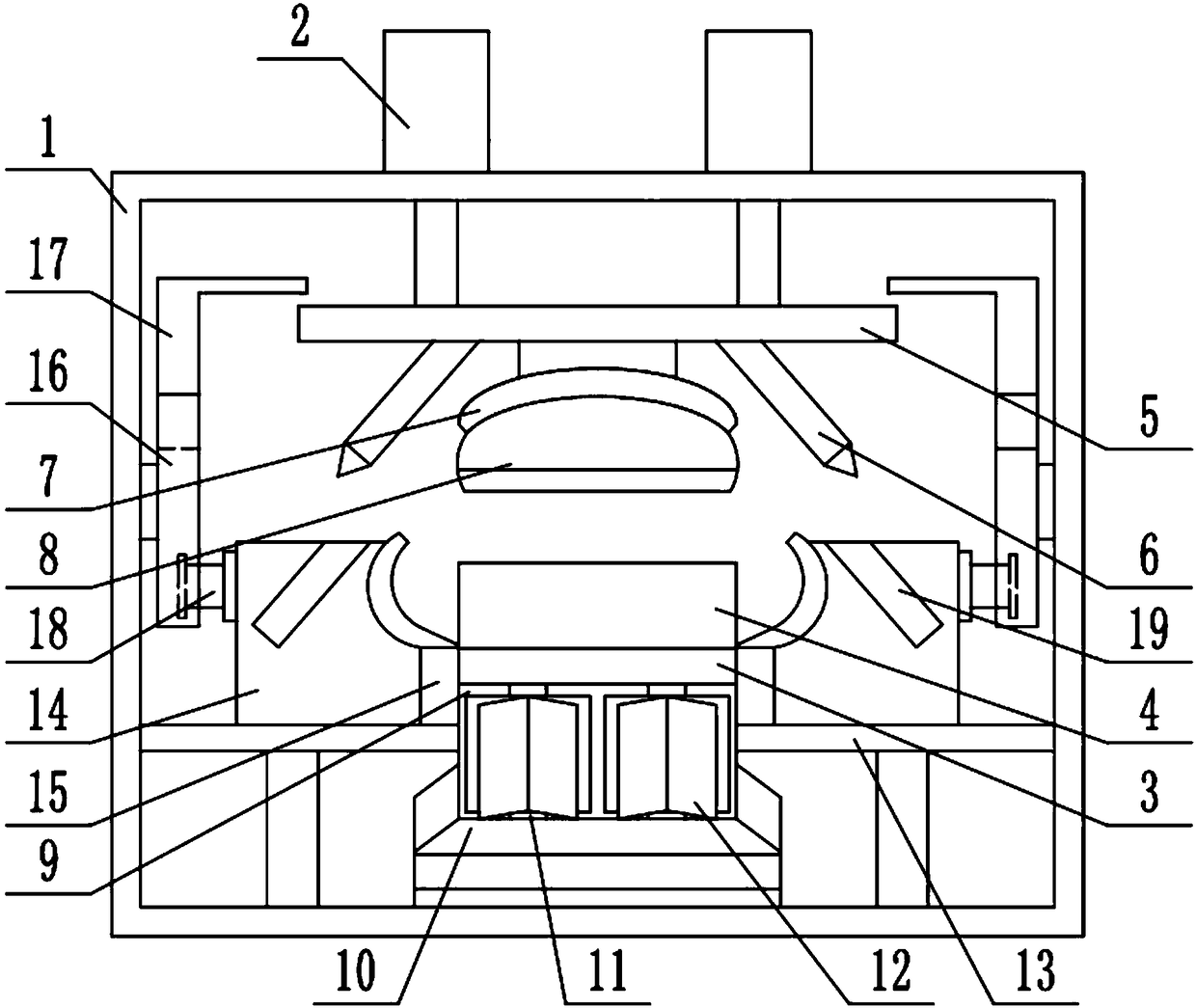

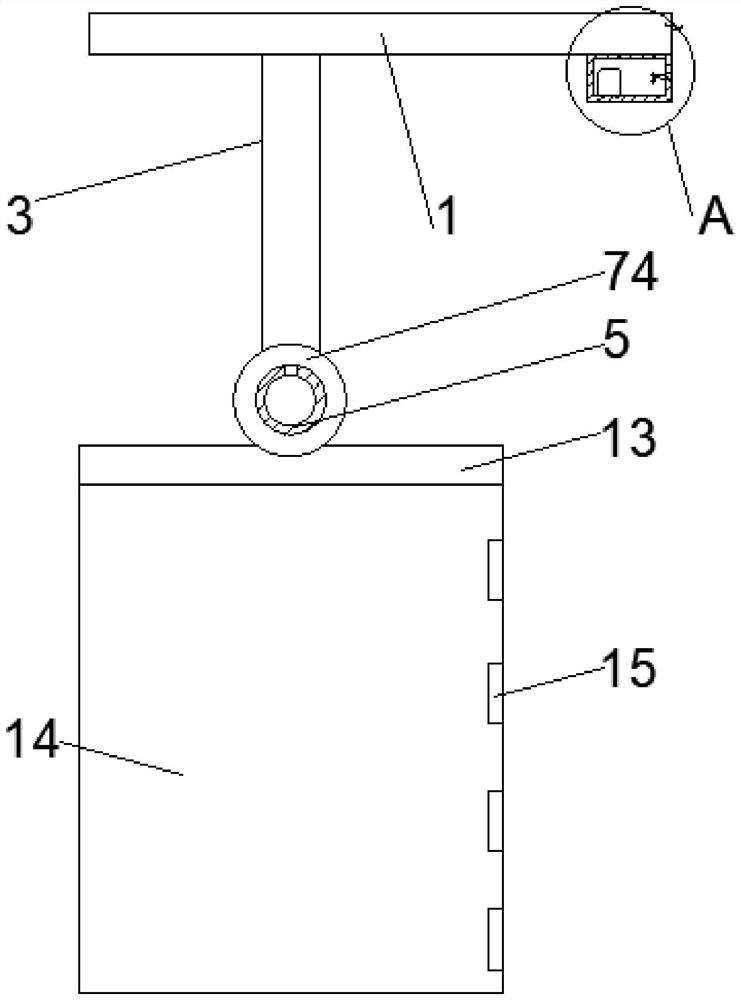

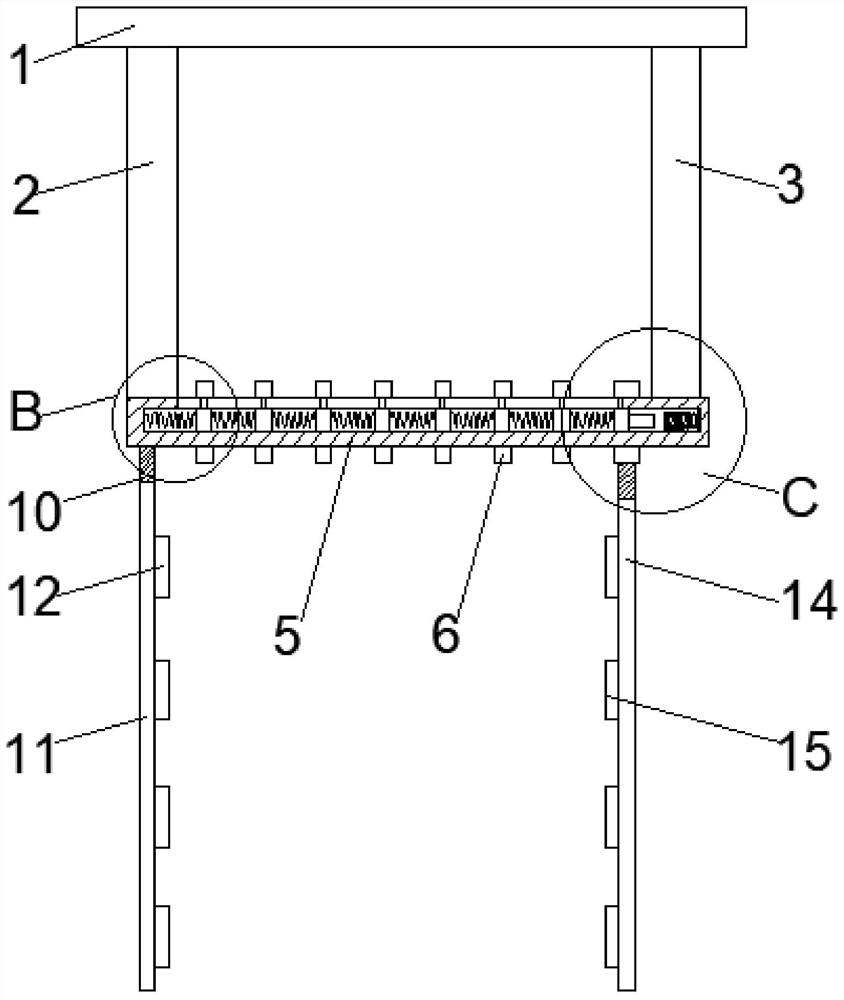

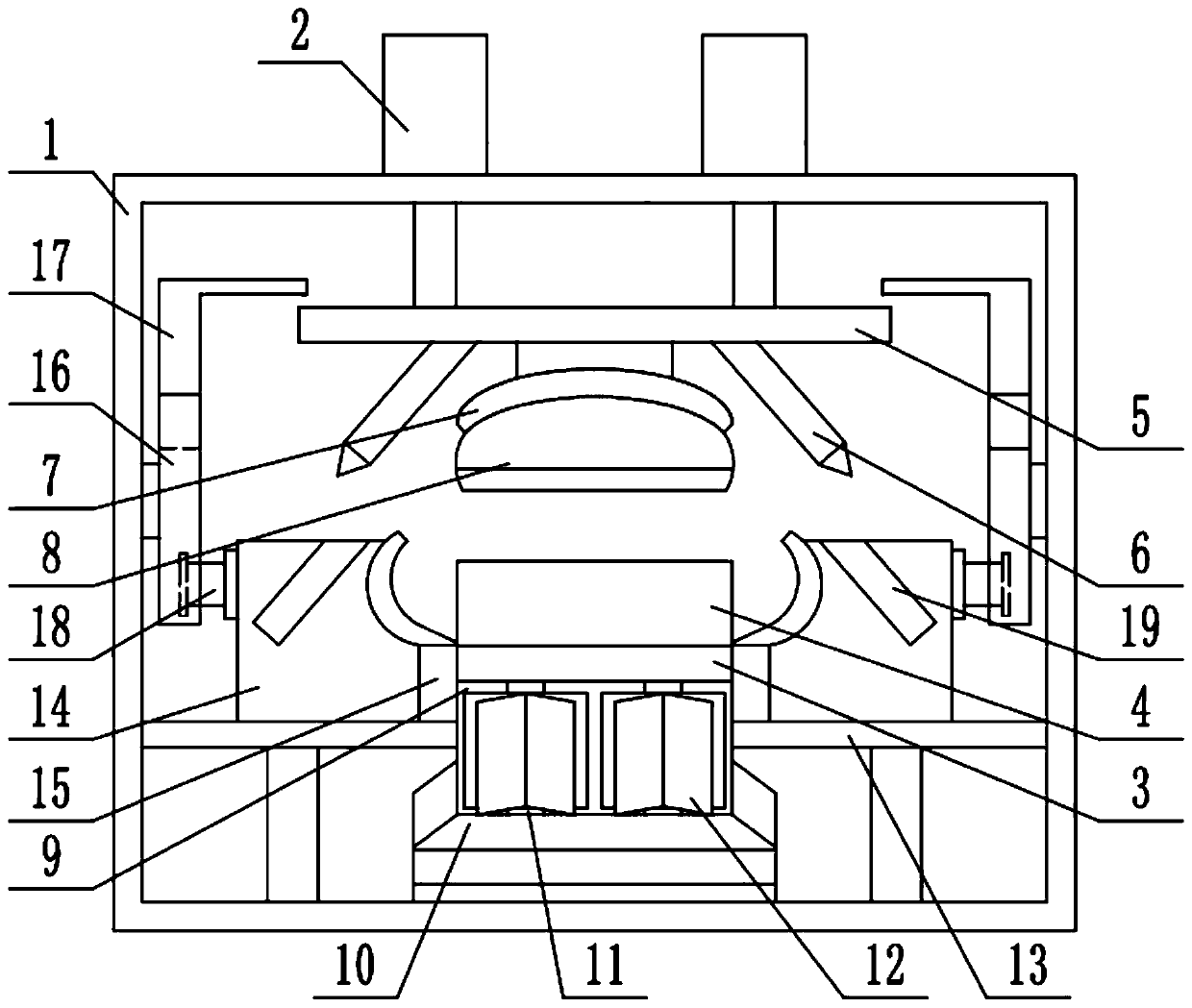

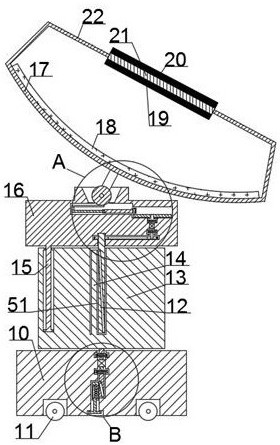

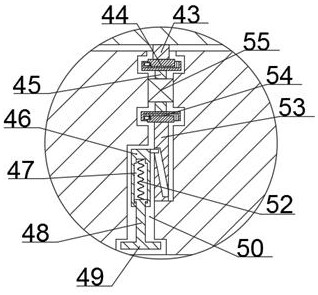

Lighting lifting device used for Internet type recording and broadcasting studio

InactiveCN109882778ATo achieve gatheringAchieve decentralizationLighting support devicesLight fasteningsGear driveThe Internet

The invention discloses a lighting lifting device for used for an Internet type recording and broadcasting studio, and relates to the technical field of lighting devices. The device includes a base, the base is connected with a lifting rod through a lifting mechanism, an annular frame is fixed on the lifting rod, a plurality of circularly uniformly distributed driven gears are connected with the annular frame, the bottoms of the driven gears are eccentrically and fixedly provided with radially arranged LED lamp panels, the upper end of the lifting rod is movably sleeved with a sleeve pipe, a protection cover covers the annular frame, and the protection cover is provided with an adjustment mechanism in drive connection with the sleeve pipe. An arranged servo motor I drives a worm and a wormgear to cooperate in driving, rotation adjustment of a driving gear at a certain angle is achieved, then the driven gears drive the LED lamp panels to achieve deflection, the several LED lamp panelscan be clustered or scattered, and the rapid adjustment of the local lighting intensity is achieved. An arranged lifting mechanism can achieve the adjustment of the lighting range of the LED lamp panels, the adjustment requirements of light rays can be met in the recording and broadcasting processes, and the device is easy and convenient to operate and use.

Owner:OCEAN UNIV OF CHINA

Environment-friendly urban road gutter inlet

ActiveCN114150753AReduce the likelihood of cloggingImprove environmental performanceSewerage structuresGeneral water supply conservationMechanical engineeringUrban road

The invention relates to the field of municipal engineering, in particular to an environment-friendly urban road gutter inlet which comprises a drainage well, an overflow cylinder with a hollow interior and an opening in the top is arranged in the drainage well, and a drainage cavity is formed between the outer wall of the overflow cylinder and the inner wall of the drainage well. A flow guide part used for guiding rainwater on the road into the overflow cylinder is arranged at the top of the drainage well, and a stirring assembly used for driving the rainwater in the overflow cylinder to rotate to form rotational flow is further arranged in the drainage well. The gutter inlet has the advantage that the environmental protection performance of the gutter inlet is improved.

Owner:无锡市鸣腾建设工程股份有限公司

Straw smashing device

The invention belongs to the technical field of crop processors for agriculture harvesting and specifically discloses a straw smashing device which comprises a box body, and a first power device is arranged at the top of the box body; a working table is arranged in the middle of the box body, one end of the working table is a feeding end, and a discharge baffle is arranged arranged on table surface at the other end of the working table; a lifting plate is arranged above the working table, a driving rod is arranged at the bottom of the lifting plate, a top clamping arc-shaped plate is arrangedin the center of the bottom of the lifting plate, and a plurality of first smashing cutters are equally distributed at the bottom of the top clamping arc-shaped plate; a secondary smashing cavity withan inclined bottom surface is arranged below the working table, two second smashing mechanisms which are symmetric along the center line of the box body is arranged at the discharge end, fixing and supporting plates are arranged on the two sides of each second smashing cavity, and a slide surface clamping block is connected to each fixing and supporting plate in a horizontal sliding manner. According to the straw smashing device, the smashed straw doesn't bend, and bundling is convenient.

Owner:重庆洛瀚商贸有限公司

Cleaning device for sludge treatment

The invention relates to a cleaning device for sludge treatment. The cleaning device comprises a base, a sedimentation tank, a support rod, a cleaning mechanism and a moving mechanism, wherein the cleaning mechanism comprises a motor, a screw rod, a moving block and a cleaning assembly, and the moving mechanism comprises a moving assembly and a limiting assembly. According to the cleaning device for sludge treatment, the motor drives the moving block to move, so that an extendable plate is in an inclined state, at the moment, a moving force of a cleaning block on the extendable plate in the direction away from the screw rod is increased, and the movement of the cleaning block, the cleaning of the two sides of the inner wall of the sedimentation tank and the cleaning of the extendable plate are realized at the same time; and when a baffle plate abuts against a sliding rod, a second ball screw is separated from a limiting plate, and moving of a moving plate is achieved through restoring force of a second spring, so that cleaning of the inner walls of the two ends of the sedimentation tank is achieved, linkage of a plurality of mechanisms is achieved through the same driving source, and the use practicability is improved.

Owner:南京鸿音工程技术有限公司

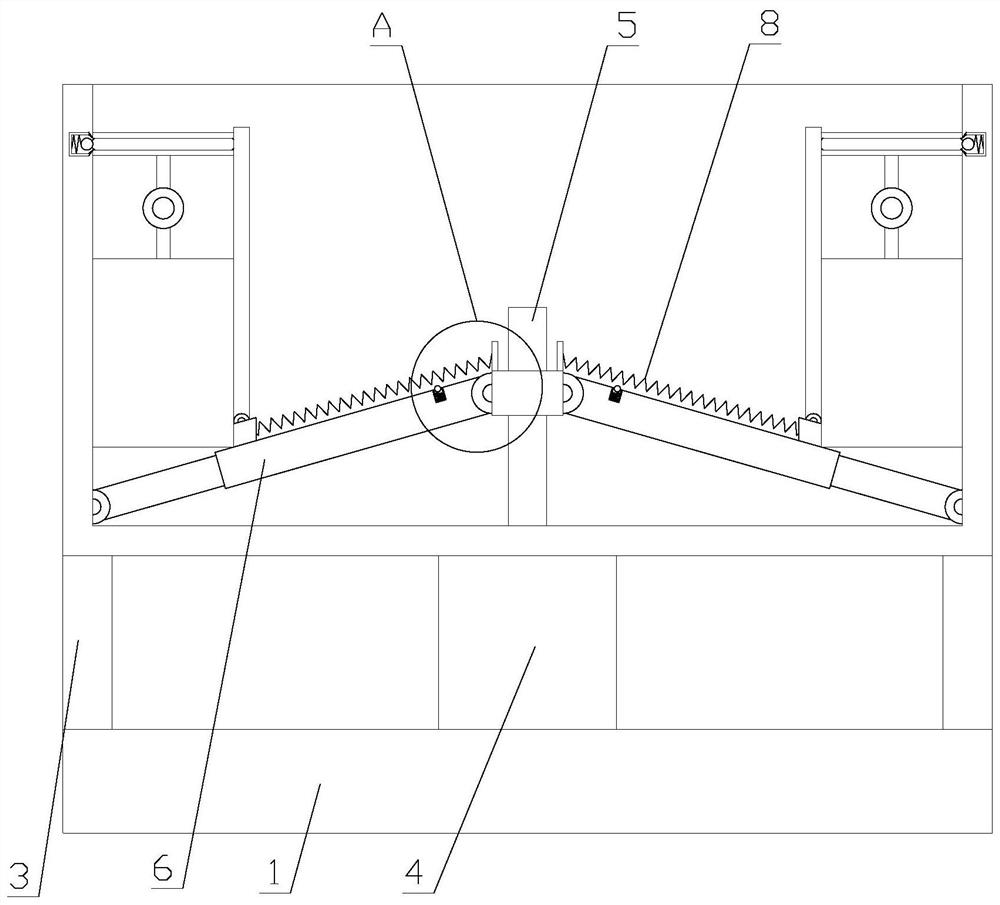

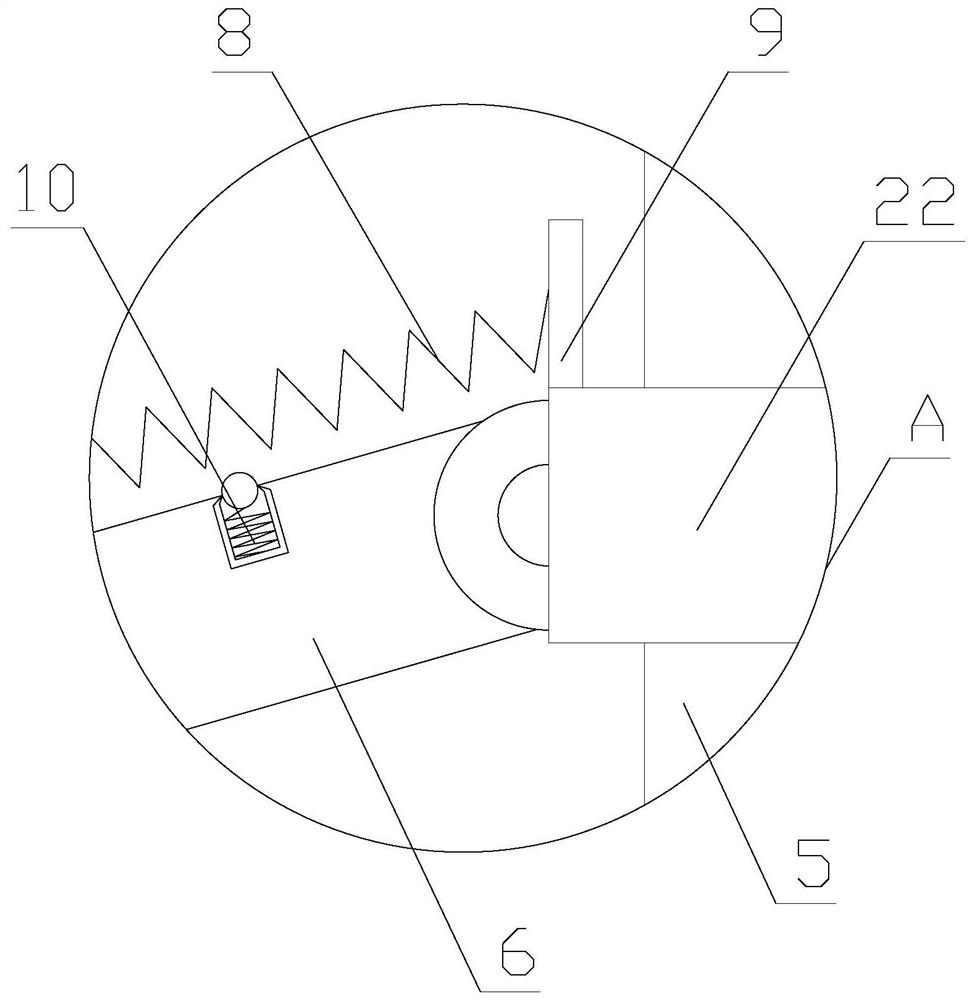

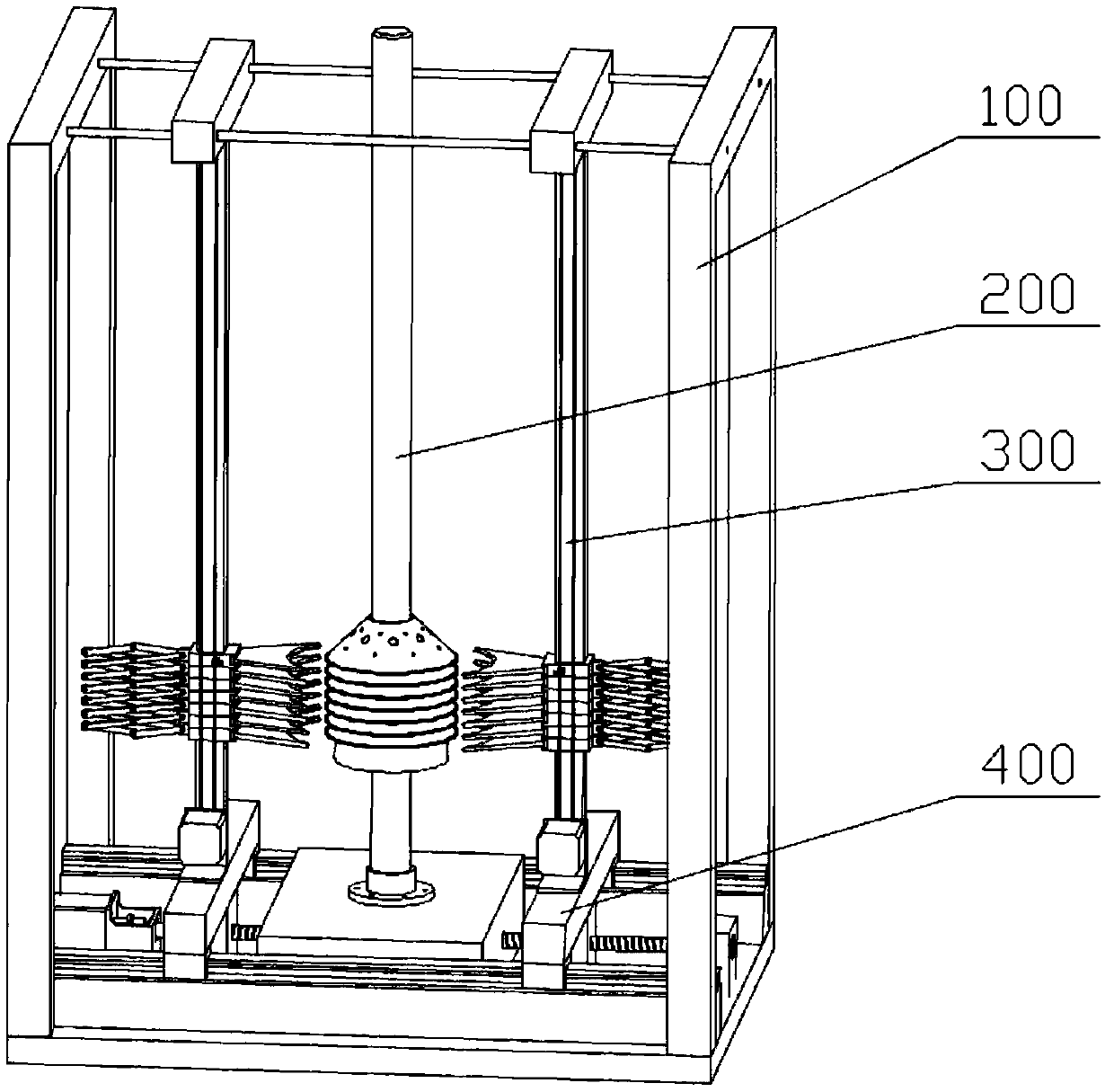

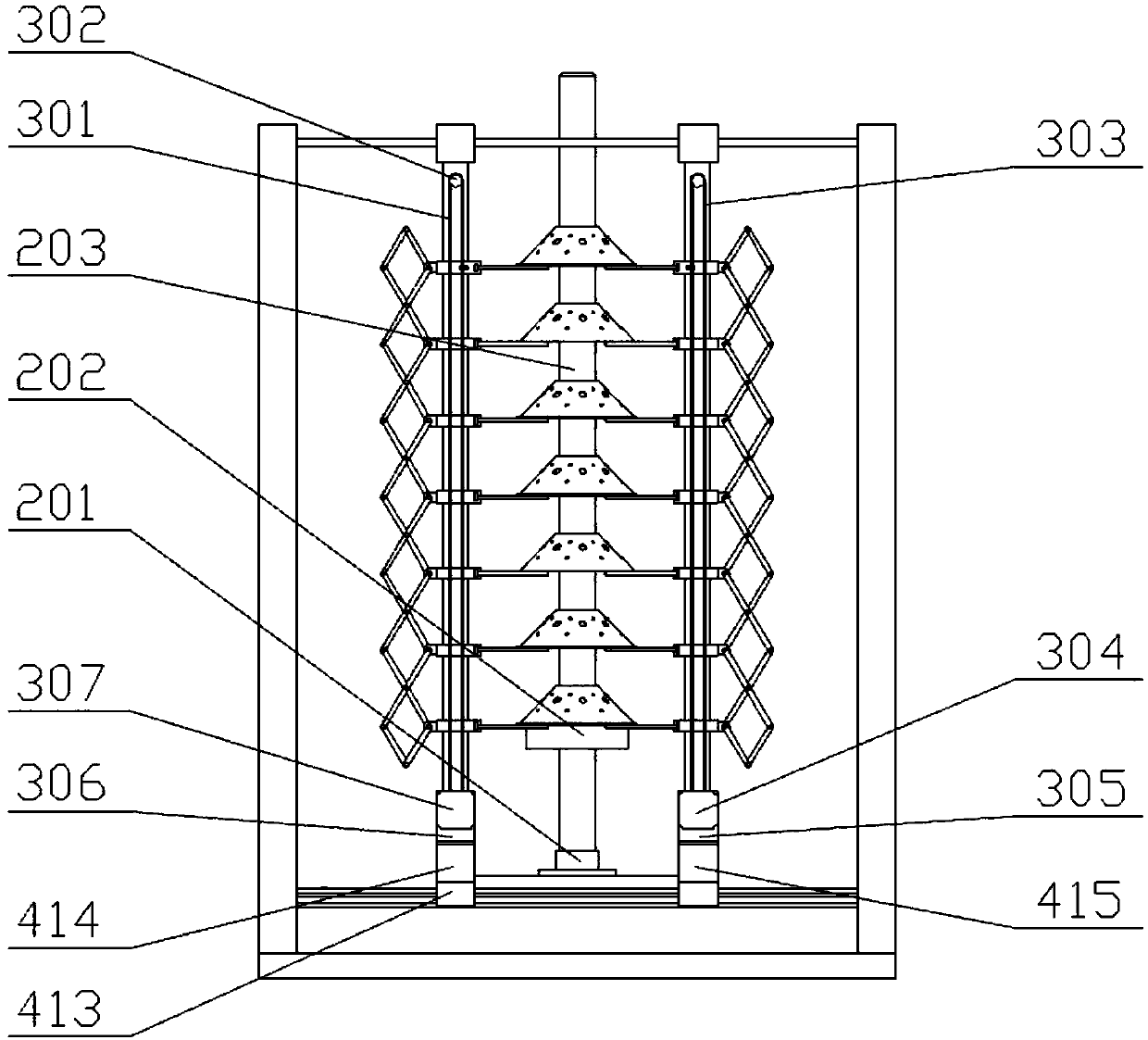

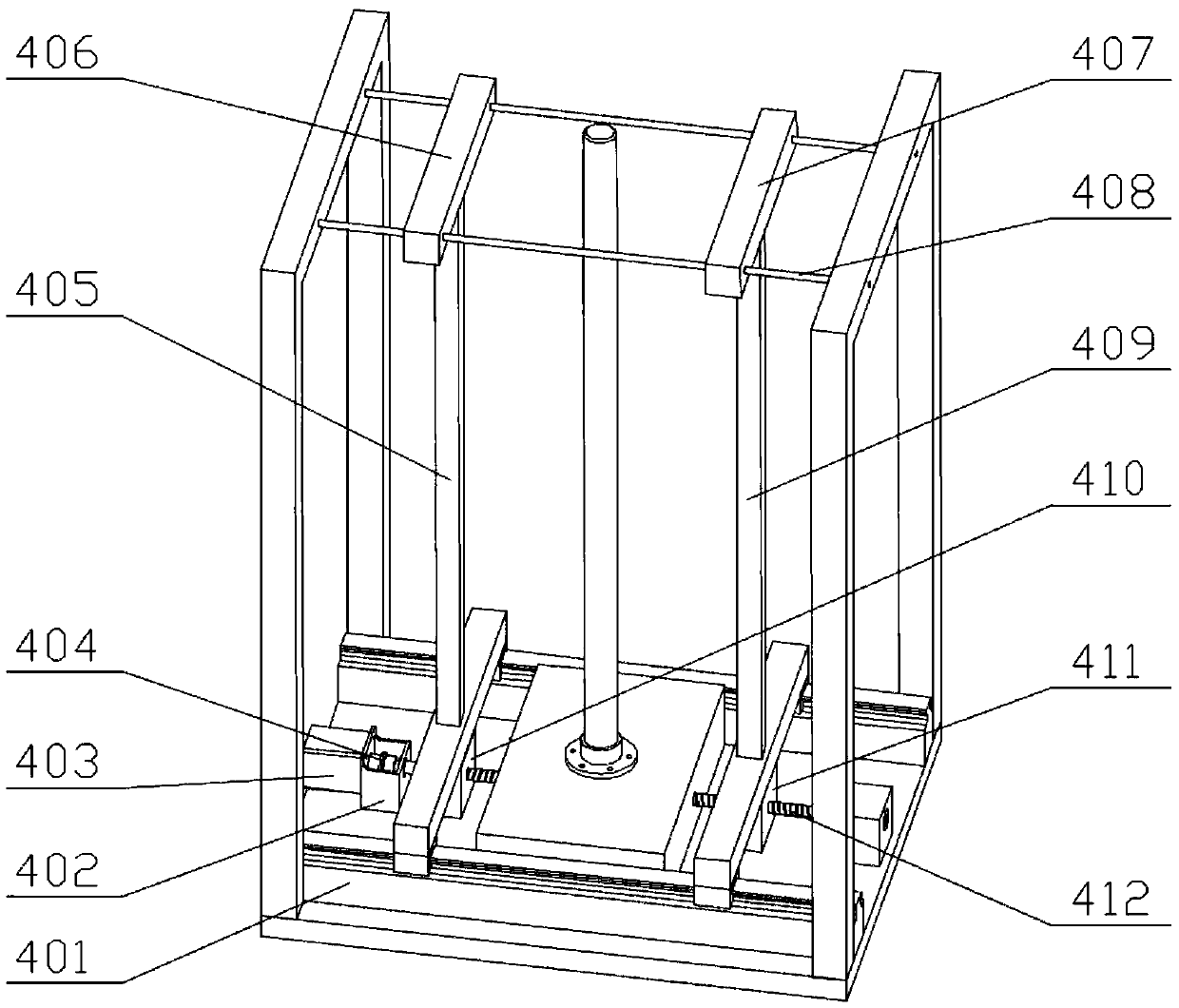

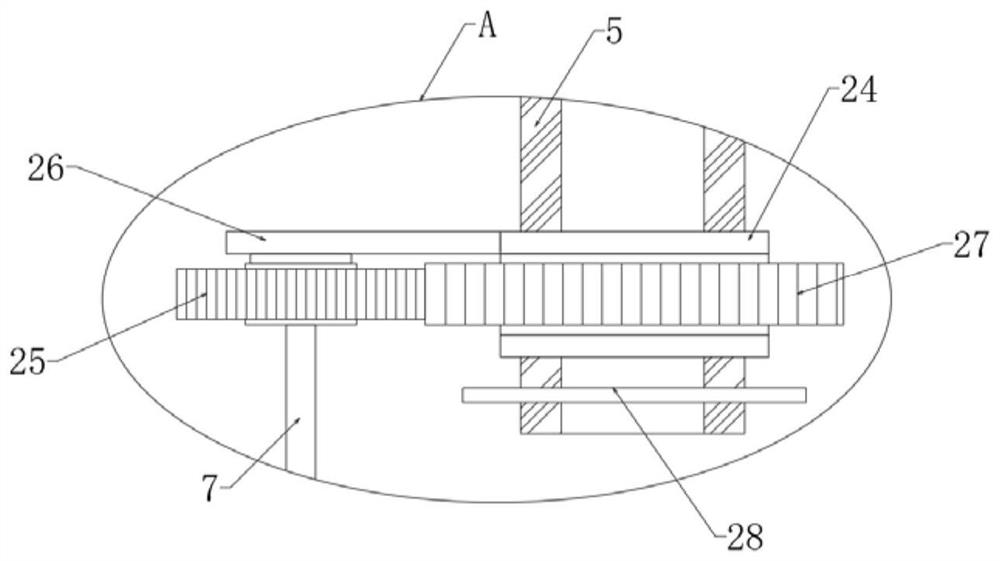

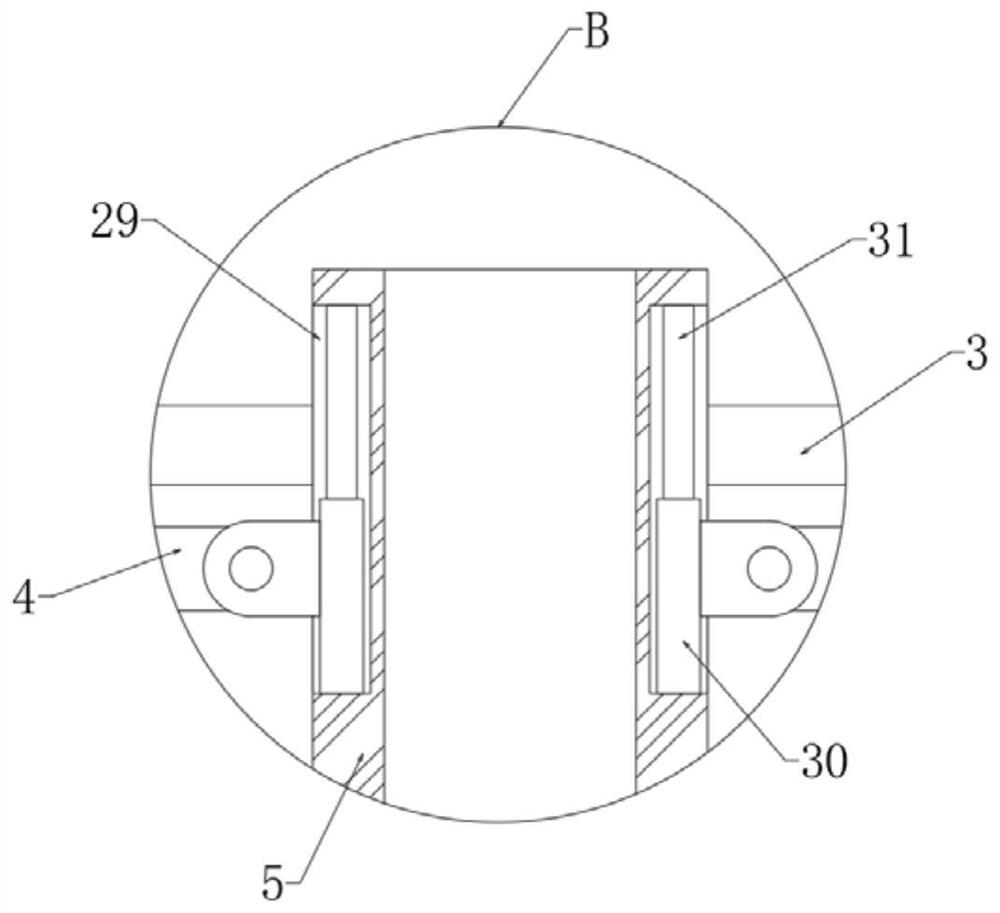

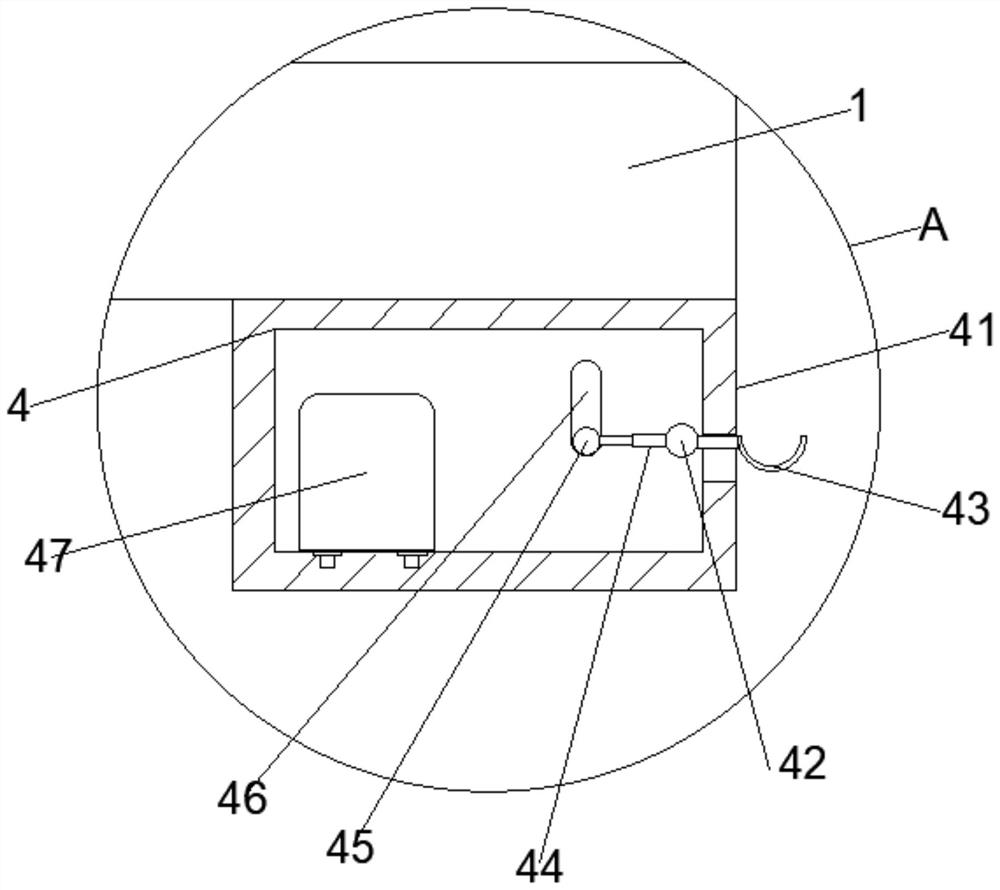

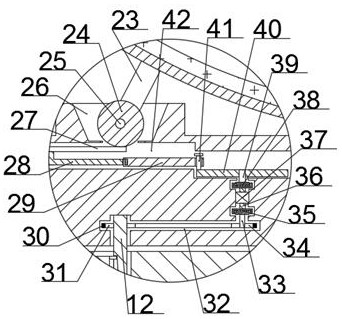

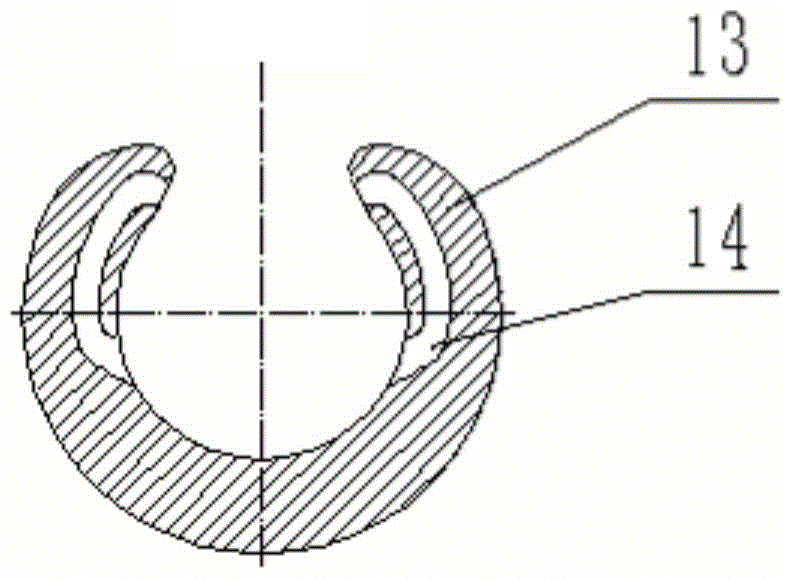

Shifting piece type separating and gathering device for centrifugal disc

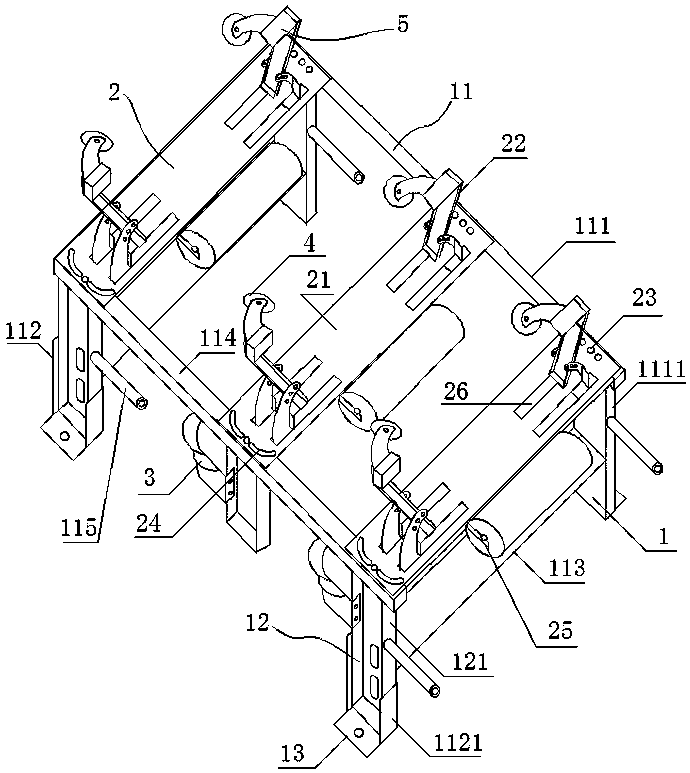

PendingCN109530104AAchieve separationTo achieve gatheringCentrifugesPlastic recyclingEngineeringSmall footprint

The invention provides a shifting piece type separating and gathering device for centrifugal disc. The shifting piece type separating and gathering device for centrifugal disc comprises a machine frame, a centrifugal disc guiding device, shifting piece opposite moving devices and centrifugal disc separating and gathering devices, wherein the machine frame is arranged on the ground, a centrifugal disc guiding device is arranged on the surface of the machine frame, the centrifugal disc guiding device comprises a centrifugal disc guiding rod, and the centrifugal disc guiding device is used for guiding the sliding of the centrifugal disc in the vertical direction; and the shifting piece opposite moving devices are arranged on the upper surface of the machine frame and on two sides of the centrifugal disc guiding device, and are used for realizing a gap between the insertion and withdrawal of the U-shaped shifting pieces on the two sides from the centrifugal disc; and the centrifugal disc separating and gathering devices are arranged on the shifting piece opposite moving devices, and are used for realizing separating and gathering of the supporting the centrifugal disc along the direction of the centrifugal disc guiding rod. The separating and gathering device is simple in overall structure, small in occupied area, simple to operate, and high in economical efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

Screening equipment with automatic rice gathering and conveying functions

ActiveCN112093395ATo achieve gatheringReduce workloadPackagingAgricultural scienceAgricultural engineering

The invention discloses screening equipment with automatic rice gathering and conveying functions. The screening equipment comprises a screening machine body and a base, an annular support is fixedlyconnected to the base, elastic airing cloth is fixedly connected to the annular support, a U-shaped support is fixedly connected to the inner wall of the annular support, and a first gear is installedin the U-shaped support. A feeding pipe movably connected with the U-shaped support is arranged on the U-shaped support in an up-down penetrating mode, the feeding pipe penetrates through the first gear and is in threaded connection with the first gear, and the feeding pipe penetrates through the center of the elastic airing cloth and is fixedly connected with the elastic airing cloth. The screening equipment is reasonable in structure, rice can be gathered without arranging a plurality of power sources, the gathering effect is good, the rice can be conveyed into the screening machine body while gathering is conducted, a farmer does not need to gather the rice and pour the rice into the screening machine body through a farm tool, the workload of the farmer is greatly reduced, therefore, the farmer can do other farming activities for more time, and convenience is brought to the farmer.

Owner:林敏

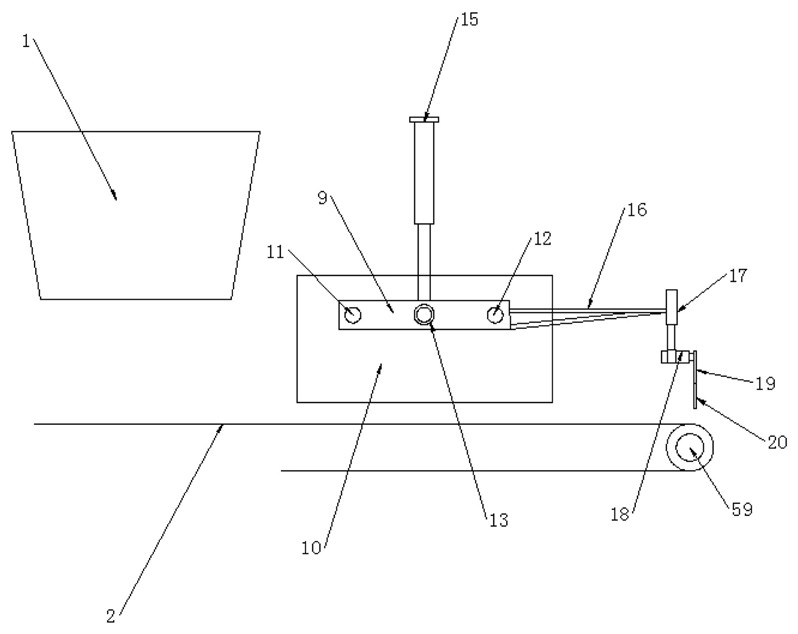

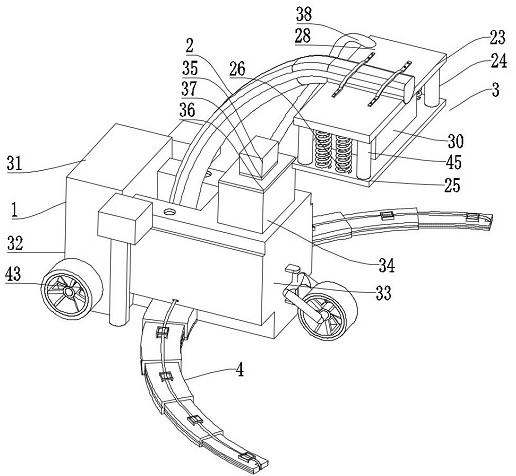

A bar cold shear conveying production line and its control system

ActiveCN112676652BRealize Orientation CorrectionTo achieve gatheringAutomatic control devicesFeeding apparatusControl systemEngineering

A bar cold shearing conveying production line relates to the technical field of conveying devices, comprising a material receiving conveyor located under a hopper, a bar guiding device is arranged above the material receiving conveyor, and a cutting end is provided at the discharge end of the material receiving conveyor Support platform, a transition connection device is arranged between the cutting support platform and the material receiving conveyor, a power relay device is arranged above the material receiving conveyor, a bar feeding device is arranged under the cutting support platform, and a bar feeding device is arranged above the cutting support platform. The bar limit feeding device, and the end of the cutting support platform is also provided with a bar cutting device. The invention solves the problem that the bar material in the traditional technology cannot be introduced into the conveying equipment in an orderly manner after falling from the silo; limited by the safety interval, the phenomenon of material jamming is easy to occur, and the feeding component on the cutting platform cannot be realized. The power relay between the conveyor and the conveyor; when cutting long bars, the phenomenon of power loss is easy to occur; and the consistency of the cutting surfaces of several bars cannot be guaranteed.

Owner:WEIFANG SPECIAL STEEL GRP CO LTD

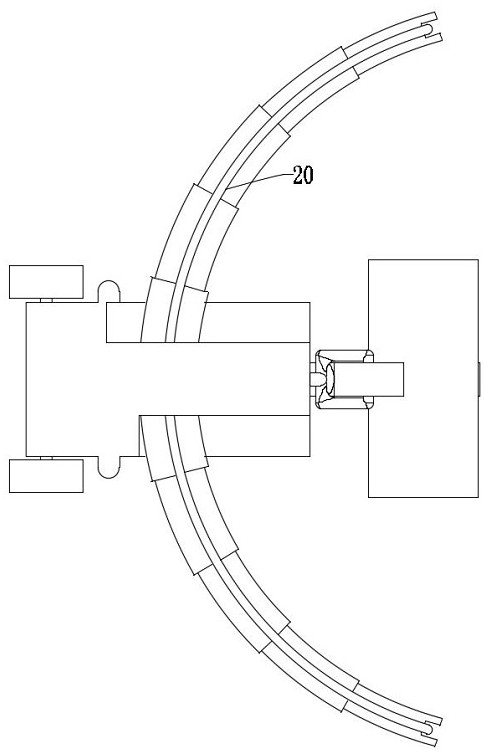

Large-angle turning device of belt conveyor

InactiveCN109319417AAchieve deviationTo achieve gatheringConveyorsSupporting framesSurface mountingBelt conveyor

The invention discloses a large-angle turning device of a belt conveyor. The device is formed by combining a plurality of turning units; each turning unit comprises a bottom frame mechanism and a carrier roller mechanism, the bottom frame mechanism comprises a base frame and an adjusting frame, the adjusting frame is arranged on one side of the base frame, the carrier roller mechanism comprises anend surface mounting frame, side carrier roller frames and a main carrier roller frame, one end of the end surface mounting frame is arranged on the uppermost end surface of the base frame, the otherend of the end surface mounting frame is arranged on the uppermost end surface of the adjusting frame, the corresponding mounting surfaces of the carrier roller mechanism, the base frame and the adjusting frame are each provided with an adjusting unit; every two side carrier roller frames are arranged on the two sides, close to the corresponding base frame and the corresponding adjusting frame respectively, of each end surface mounting frame, and adjusting grooves are formed in the corresponding mounting positions, two side carrier rollers are arranged on the corresponding side carrier rollerframes, and the main carrier roller frame is arranged on a middle frame of the corresponding end surface mounting frame. According to the device, through the adjustments of the bottom frame mechanismand the carrier roller mechanism of each turning unit and the side carrier roller frames, the maximum 45-degree angle and resistance-free turning can be realized, material fling is avoided, deviationis avoided, and the device is suitable for turning in any direction.

Owner:安徽省皖矿机电装备有限公司

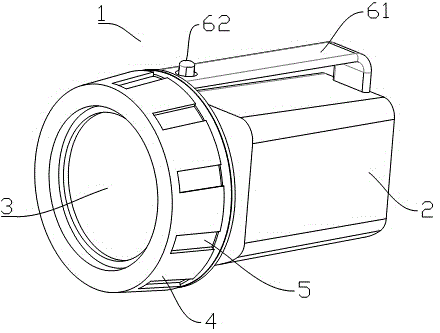

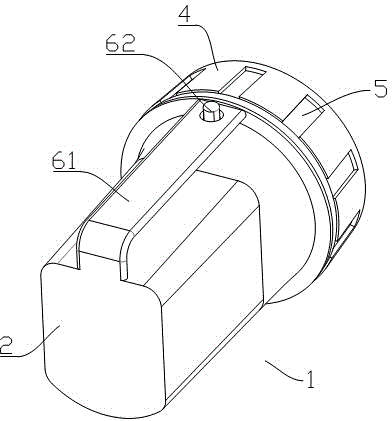

Night fishing light

InactiveCN104565868ATo achieve gatheringIncrease light intensityWith electric batteriesElectric lighting with batteriesEngineeringLight head

The invention discloses a night fishing light comprising a light body. The front end of the light body is provided with an illuminating head, an adjusting ring is arranged on the periphery of the illuminating head and is provided with a plurality of anti-skip grooves, the top of the light body is provided with a handle provided with a power supply switch, the illuminating head emits blue light, and a waterproof film is arranged in front of the illuminating head. Since the adjusting ring which is capable of adjusting the light gathering and dispersion effects is arranged on the illuminating head, the adjust ring can be rolled to gather the light, the illumination intensity is increased, and a far float also can be illuminated clearly.

Owner:邹中宝

Integrated automatic production equipment based on stem guide wire shaping and LED light bar welding

ActiveCN105345470BFacilitate automated processing operationsEasy to operateOther manufacturing equipments/toolsCircular discReducer

The invention discloses full-automatic production equipment based on stem guide wire shaping and LED light strip welding integration. The full-automatic production equipment comprises a main bottom plate, a platen and an upper bracket, wherein the upper end of the main bottom plate supports the platen through four thick bracket legs. A discharging mechanism and a buffering conveying mechanism are arranged on the left and the right of the side surface of the platen respectively, and a feed mechanism is arranged at the end of the buffering conveying mechanism. The platen is provided with a gap divider. An index plate rotates anticlockwise and is provided with a stem clamp. The main bottom plate is provided with a speed reducer, a station main shaft and a cam mechanism. A stem locating mechanism, a long foot arranging mechanism, a short foot poking mechanism, a 45-degree long foot poking assembly mechanism, a 45-degree short foot poking assembly mechanism, a foot straightening mechanism, an LED light strip shearing and conveying mechanism, an automatic LED light strip rotating and conveying mechanism and a welding mechanism are sequentially arranged on the platen from the front end of the feed mechanism and surround the index plate. The full-automatic production equipment is high in automation degree, high in welding and shaping efficiency and high in shaping accuracy.

Owner:南通睿博电器有限公司

The method of stalk crushing and mulching film recovery operation

InactiveCN104969725BTo achieve gatheringRealize smashing and returning to the fieldCrop conditionersMowersRecovery methodPlastic mulch

The invention discloses a method for straw crushing and field-returning and mulching film recycling operation. Firstly, crop straws are crushed and collected to a conveying channel, that is, the crop straws on the mulching film portions are removed in a crushing mode, crushed, and not returned to field immediately; secondly, edge raising and gathering are performed on the mulching film on which the crop straws are removed, the mulching film is gathered into narrower mulching film strips, wider open space is vacated among the mulching film strips, and then the crop straws which are crushed and collected in the conveying channel are released to the open space among the mulching film strips. Compared with the prior art, the method for the straw crushing and field-returning and mulching film recycling operation has the advantages that not only can edge raising and gathering be performed on the mulching film, but also the crop straws can be crushed and returned to the field, and the operation efficiency is high.

Owner:XINJIANG ACADEMY OF AGRI & RECLAMATION SCI

Clothesline pole for gathering and protecting clothes in rainy days

InactiveCN112726149AAffect drying speedSpeed up dryingOther drying apparatusTextiles and paperMechanical engineeringEnvironmental geology

Owner:罗广元

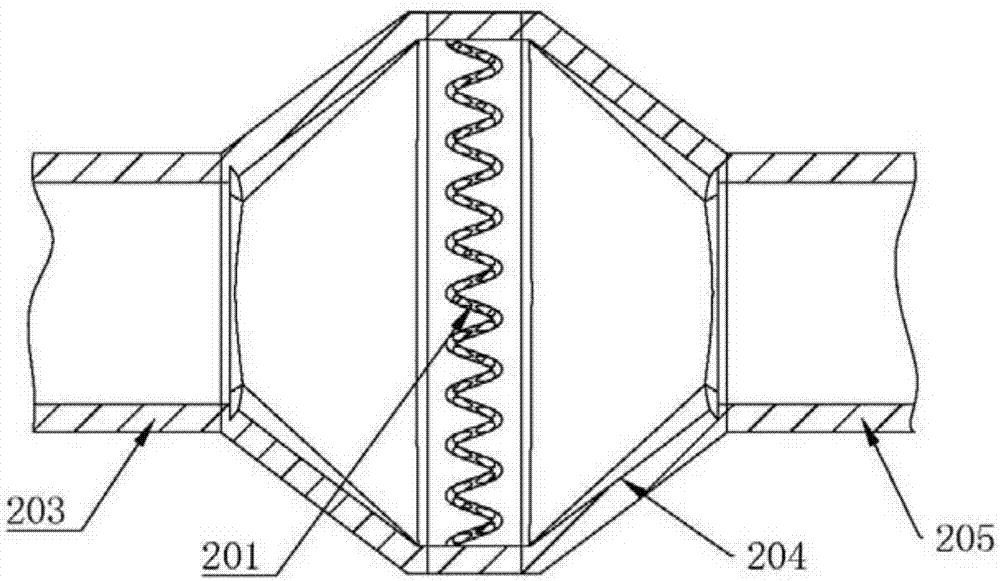

A treatment device for oil slick polluted waters

ActiveCN110528488BTo achieve gatheringEasy to cleanWater cleaningGeneral water supply conservationContaminated waterPetroleum engineering

The invention discloses a floating oil contaminated water area processing device. The floating oil contaminated water area processing device comprises an outer pipeline and an inner pipeline, whereinthe outer pipeline is made of rubber, is 2-3 mm thick and is mainly used for making contact with oil contamination; the inner pipeline line is arranged on the inner side of the outer pipeline in a sleeving mode, is 0.85-1.25 mm thick, and is mainly used for inflation expanding so that buoyancy force can be provided; thus, the wall thickness does not need to be too large, and inflation expanding ofthe inner pipeline can be influenced by the too-large wall thickness; and the outer wall of the inner pipeline is provided with a plurality of convex strip parts through injection molding, and the convex strip parts are mainly used for insulating the inner pipeline from the outer pipeline. Through the floating oil contaminated water area processing device, gathering and collecting of the oil contamination can be achieved.

Owner:永康市能泽科技有限公司

Surface powder spraying equipment for production of polyester wadding

The embodiment of the invention is applicable to the field of polyester wadding production equipment, and provides surface powder spraying equipment for production of polyester wadding,which comprises a powder spraying device, wherein the powder spraying device comprises an adhesive groove; and the powder spraying device further comprises a powder uniformizing mechanism, the powder uniformizing mechanism comprises sweeping uniformizing assemblies and stirring uniformizing assemblies, the multiple stirring uniformizing assemblies are sequentially installed at the bottom of the adhesive groove, and every two adjacent stirring uniformizing assemblies are in linkage. According to the embodiment of the invention, through a rotating feeding pipe, dispersion and gathering of adhesive powder particles on the polyester wadding can be realized, and sweeping uniformizing rods can horizontally reciprocate, so that the adhesive powder particles are uniformly flattened on the polyester wadding, and when the sweeping uniformizing rods reciprocate in the horizontal direction, sweeping uniformizing brushes can be driven to clean the surfaces of stirring uniformizing arc-shaped rods, and the adhesive powder particles are prevented from being adhered to the stirring uniformizing arc-shaped rods; and moreover, the adhesive powder particles can be intermittently conveyed to the stirring uniformizing assembly through the rotating feeding pipe, so that the accumulation of the adhesive powder particles is avoided, and the uniform powder spraying process is ensured.

Owner:南通富士抽纱品有限公司

Ginger harvester

InactiveCN110959360ATo achieve gatheringImprove protectionSpadesLiftersEngineeringMechanical engineering

The invention discloses a ginger harvester, and relates to the technical field of ginger harvesting devices. The ginger harvester comprises a ginger pulling mechanism, a soil shaking mechanism, a ginger arranging mechanism, a separating mechanism and a guiding-out mechanism; the ginger arranging mechanism comprises a conveying belt which is rotatably arranged, the conveying belt is provided with ginger supporting sections which are arranged in a height increasing mode in the feeding direction and further provided with ginger arranging sections which are connected to the supporting sections andarranged in a height decreasing mode in the conveying direction, and ginger guiding plates which are arranged in a shape following mode are further arranged on the portions, located on the ginger supporting sections and the ginger arranging sections, of the conveying belt. The problems that in the prior art, ginger receiving rods are used for basically pulling out gingers from a field, but are limited by the characteristics of the gingers, and the gingers are prone to being broken are solved; and the problems that through an unordered feeding mode, the separated gingers need to be manually operated, and the workload is not reduced even if the manpower is saved are solved.

Owner:付国良

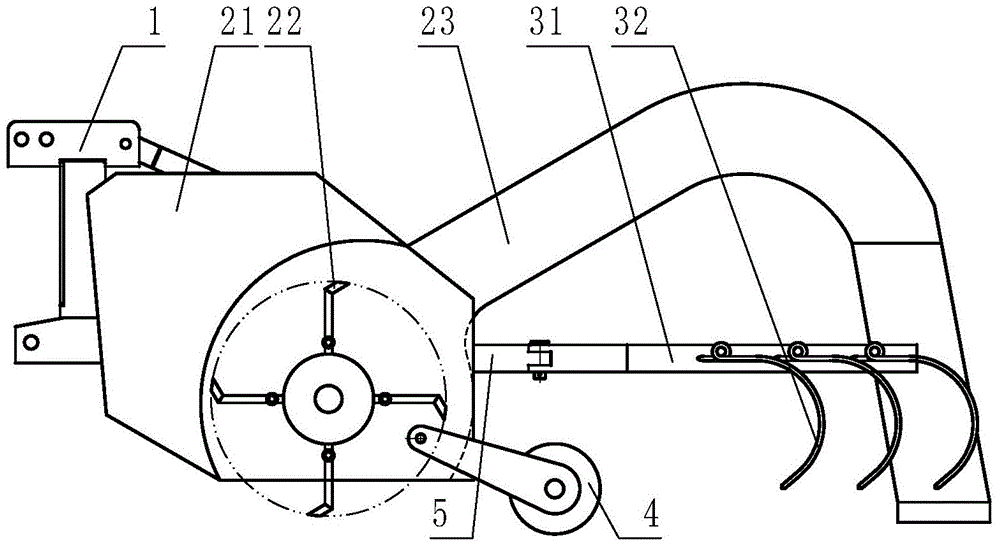

Straw crushing device

ActiveCN108353657BTo achieve gatheringGuaranteed crushing effectCuttersAgricultural engineeringStructural engineering

The invention belongs to the technical field of crop processors for agriculture harvesting and specifically discloses a straw smashing device which comprises a box body, and a first power device is arranged at the top of the box body; a working table is arranged in the middle of the box body, one end of the working table is a feeding end, and a discharge baffle is arranged arranged on table surface at the other end of the working table; a lifting plate is arranged above the working table, a driving rod is arranged at the bottom of the lifting plate, a top clamping arc-shaped plate is arrangedin the center of the bottom of the lifting plate, and a plurality of first smashing cutters are equally distributed at the bottom of the top clamping arc-shaped plate; a secondary smashing cavity withan inclined bottom surface is arranged below the working table, two second smashing mechanisms which are symmetric along the center line of the box body is arranged at the discharge end, fixing and supporting plates are arranged on the two sides of each second smashing cavity, and a slide surface clamping block is connected to each fixing and supporting plate in a horizontal sliding manner. According to the straw smashing device, the smashed straw doesn't bend, and bundling is convenient.

Owner:重庆洛瀚商贸有限公司

Anisotropic qualitative change type fixed-point regulation and control portable surveying and mapping vehicle

ActiveCN114517879ARealize the purpose of fixed-point regulationReduce vibrationNon-rotating vibration suppressionSurveying instrumentsControl engineeringBiology

The invention discloses an incongruous qualitative change type fixed-point regulation and control portable surveying and mapping vehicle which comprises a surveying and mapping vehicle body, a supporting bent back, a biomass fixed-point regulation and control device and a qualitative change type impact two-way gathering and dispersing device, one end of the supporting bent back is arranged on the surveying and mapping vehicle body, and the biomass fixed-point regulation and control device is arranged at the other end of the supporting bent back; the qualitative change type impact two-way gathering and scattering device is arranged on the side wall of the surveying and mapping vehicle. The invention belongs to the technical field of measurement engineering equipment, particularly relates to an incongruous qualitative change type fixed-point regulation and control portable surveying and mapping vehicle, and provides a qualitative change type impact two-way gathering and scattering device in order to meet different states of the surveying and mapping vehicle, namely flexibility during transportation and stability during surveying and mapping. According to the surveying and mapping vehicle, the impact force of fluid is matched with the concave-convex gathering parts which are in central symmetry and opposite directions, the qualitative change type impact two-way gathering device is unfolded, the technical effect that the surveying and mapping vehicle is stable during surveying and mapping is achieved, and the technical effect that the surveying and mapping vehicle is flexible to move is achieved by means of pressure difference and mechanical force and folding of the qualitative change type impact two-way gathering device.

Owner:徐州环测数遥科技有限公司

A solar power generation device that can enhance sunlight exposure

ActiveCN111293966BIncrease light intensityTo achieve gatheringPhotovoltaic supportsSolar heating energyElectric machineEngineering

The invention relates to the field of solar power generation, in particular to a solar power generation device capable of enhancing sunlight irradiation. The solar power generation device capable of enhancing sunlight irradiation comprises a movable base. Roller wheels which are arranged in a bilateral symmetry mode are rotationally arranged on the lower wall face of the movable base. A first motor is arranged in the movable base; and the first motor is in power connection with a first rotating shaft in the vertical direction. According to the solar power generation device capable of enhancing sunlight irradiation, the structure is simple; and sunlight within a certain range can be gathered, then light rays are reflected to a solar panel, so that the illumination intensity of the solar panel is enhanced, and the power generation efficiency of the solar panel is improved.

Owner:浙江晴天太阳能科技股份有限公司

A high-speed water-assisted twisting melt differential electrospinning device

ActiveCN104963008BGood for pre-gatheringAvoid accumulationFilament/thread formingEngineeringAir compressor

Owner:BEIJING UNIV OF CHEM TECH

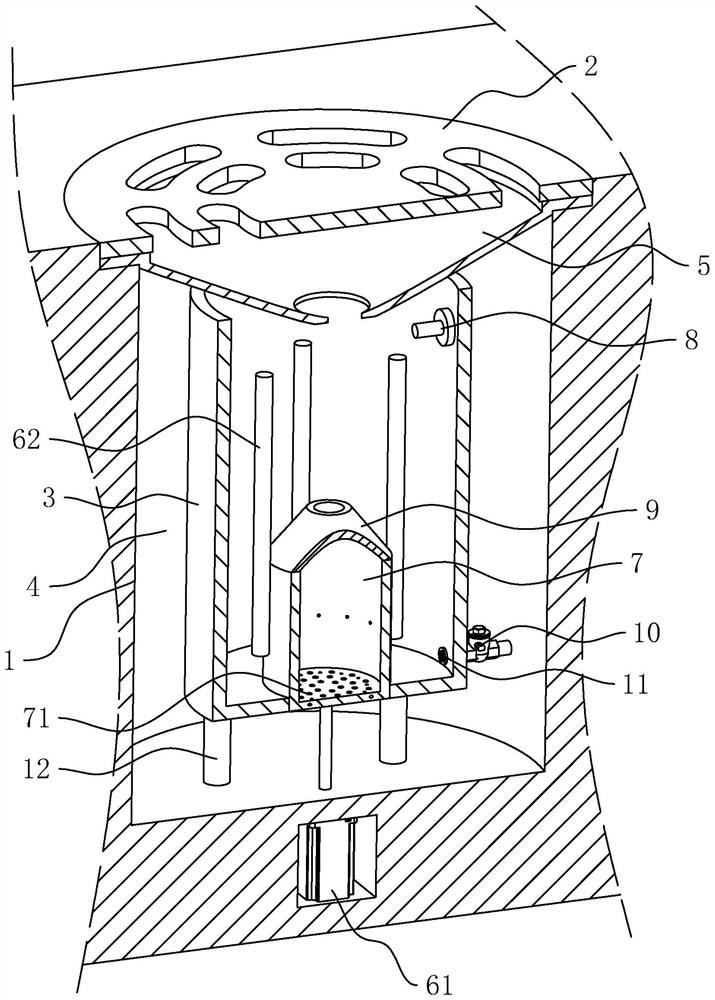

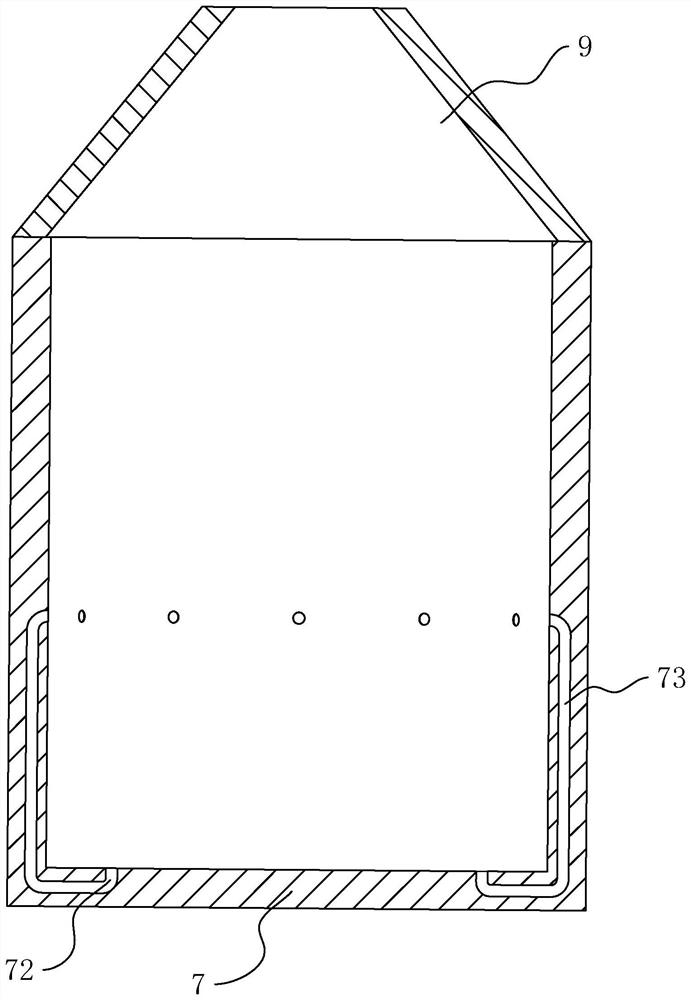

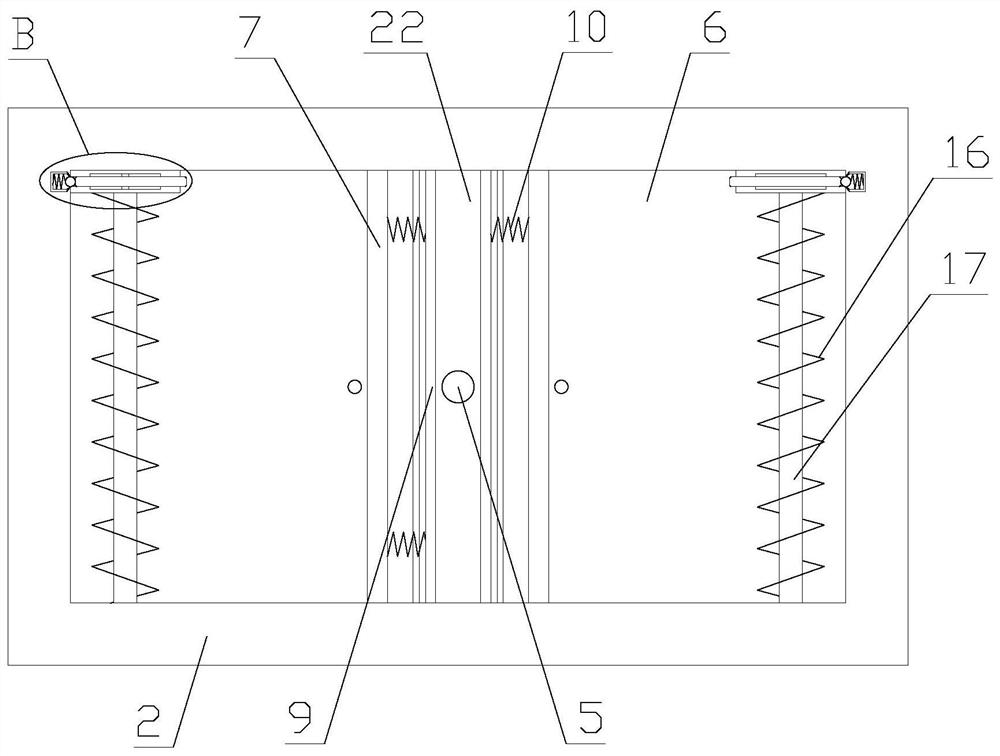

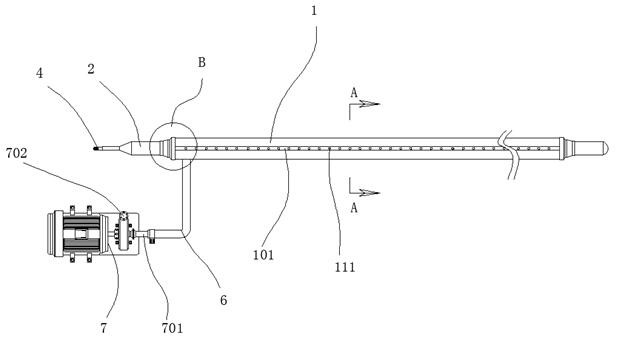

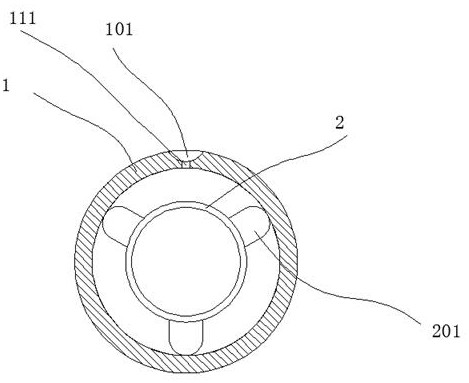

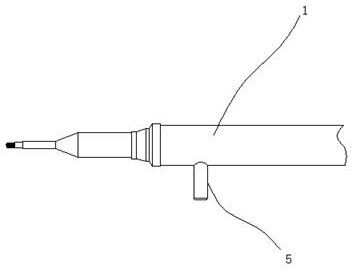

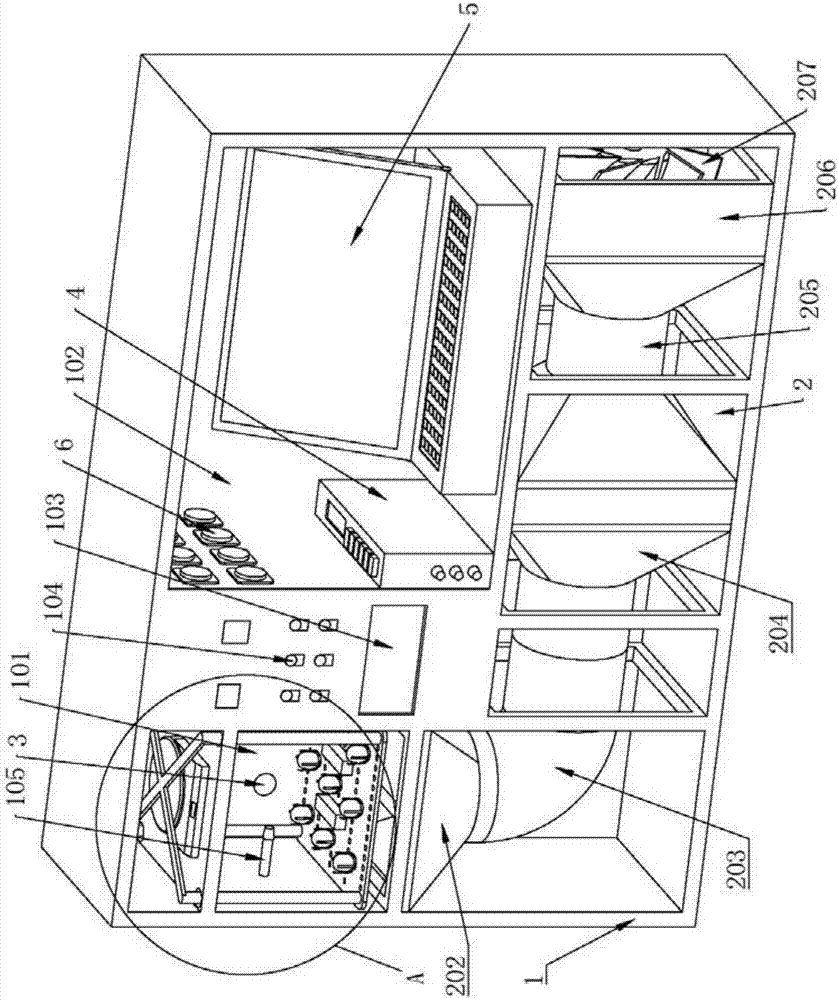

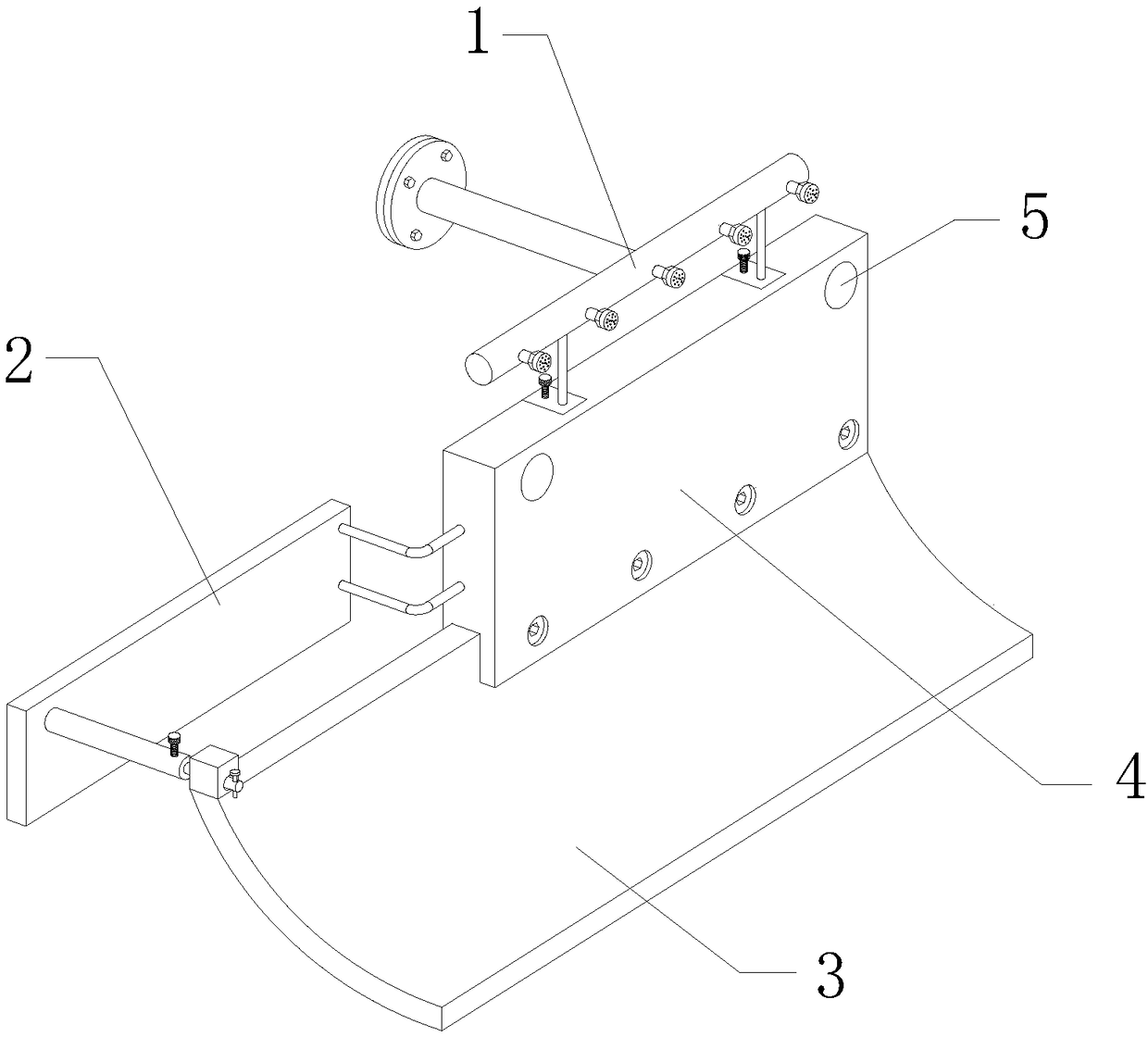

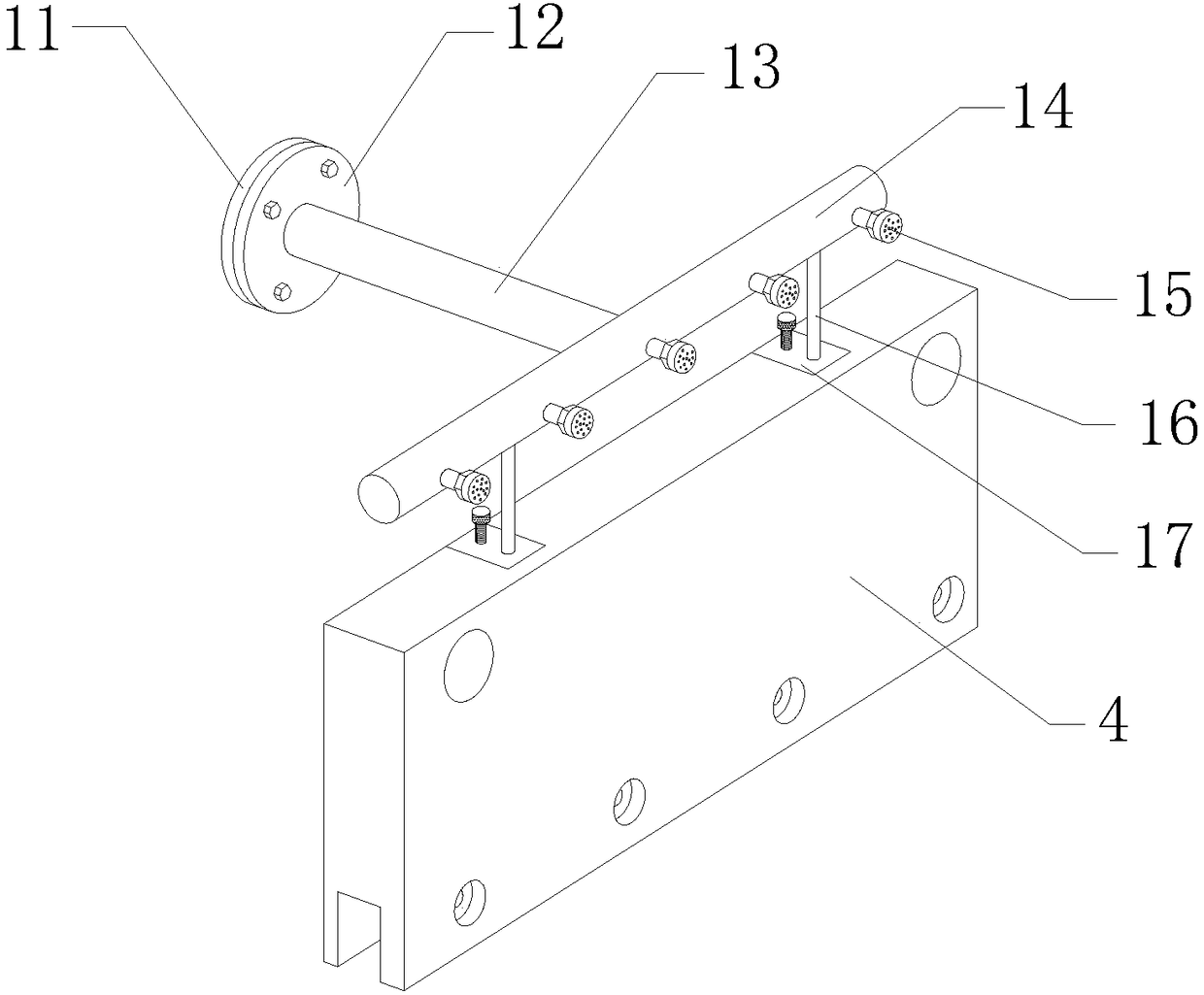

Red date drying dielectric property online detection device

PendingCN106997010AImprove hygieneEasy to operateDielectric property measurementsEngineeringHeating element

The invention discloses a red date drying dielectric property online detection device comprising a rack which is provided with a drying room and a control room. The rack is also provided with an air supply mechanism and an air exhaust pipe which are communicated with the drying room. The air supply mechanism is internally provided with a heating element. A control room is internally provided with an LCR digital bridge tester and an electric control unit. The support plate of the drying room is provided with a balance which is provided with a bracket with a tray. The tray is provided with a data acquisition device, a wireless transmitter, ventilation holes and a clamping mechanism. The clamping mechanism is provided with a dielectric test electrode connected with the data acquisition device. The data acquisition device is connected with the wireless transmitter. The LCR digital bridge tester, the heating element, the clamping mechanism and the wireless transmitter are connected with the electric control unit. The physical properties and the dielectric properties of the red date can be detected and monitored in real time online, and the detection result can be synchronously displayed so that operation is easy, use is convenient and the working efficiency is high; meanwhile, the red date does not need to be moved in the detection process so that the wholesomeness and the detection accuracy of the red date can be guaranteed.

Owner:TARIM UNIV

Blocking edge device for logistical-transport-tape type conveying machine

InactiveCN108190385AImprove air qualityTo achieve the purpose of auxiliary dust suppressionConveyorsUsing liquid separation agentEngineeringRubber sheet

The invention provides a blocking edge device for a logistical-transport-tape type conveying machine. The locking edge device for the logistical-transport-tape type conveying machine includes a flangeplate, a water injection pipe, a water distributing pipe, an atomizing sprinkler, fixed plates, sleeves, movable rods and rubber blocks, wherein the water distributing pipe is arranged on the upper side of a baffle, and the atomizing sprinkler is assembled on the front side of the annular side face of the water distributing pipe. The front end of the water injection pipe is arranged in the middleof the rear side of the annular side face of the water distributing pipe, and the flange plate is assembled at the rear end of the water injection pipe. The purpose of assisting to reduce dust is realized, the fixed plates are arranged on the rear sides of rubber sheets, and the fixed plates are mounted on the left end face of the baffle through connecting rods. The rear ends of the sleeves are fixed on the left sides of the front end faces of the fixed plates, the rear ends of the movable rods are embedded in the sleeves, and the front ends of the movable rods penetrate through the rubber blocks and extend to the front sides of the rubber blocks. The purpose of adjusting the bending angle of the rubber sheets is realized. The locking edge device for the logistical-transport-tape type conveying machine has the function of assisting to reduce the dust, and is capable of achieving material gathering, good in stability and high in reliability.

Owner:杭州蔓漫文化创意有限公司

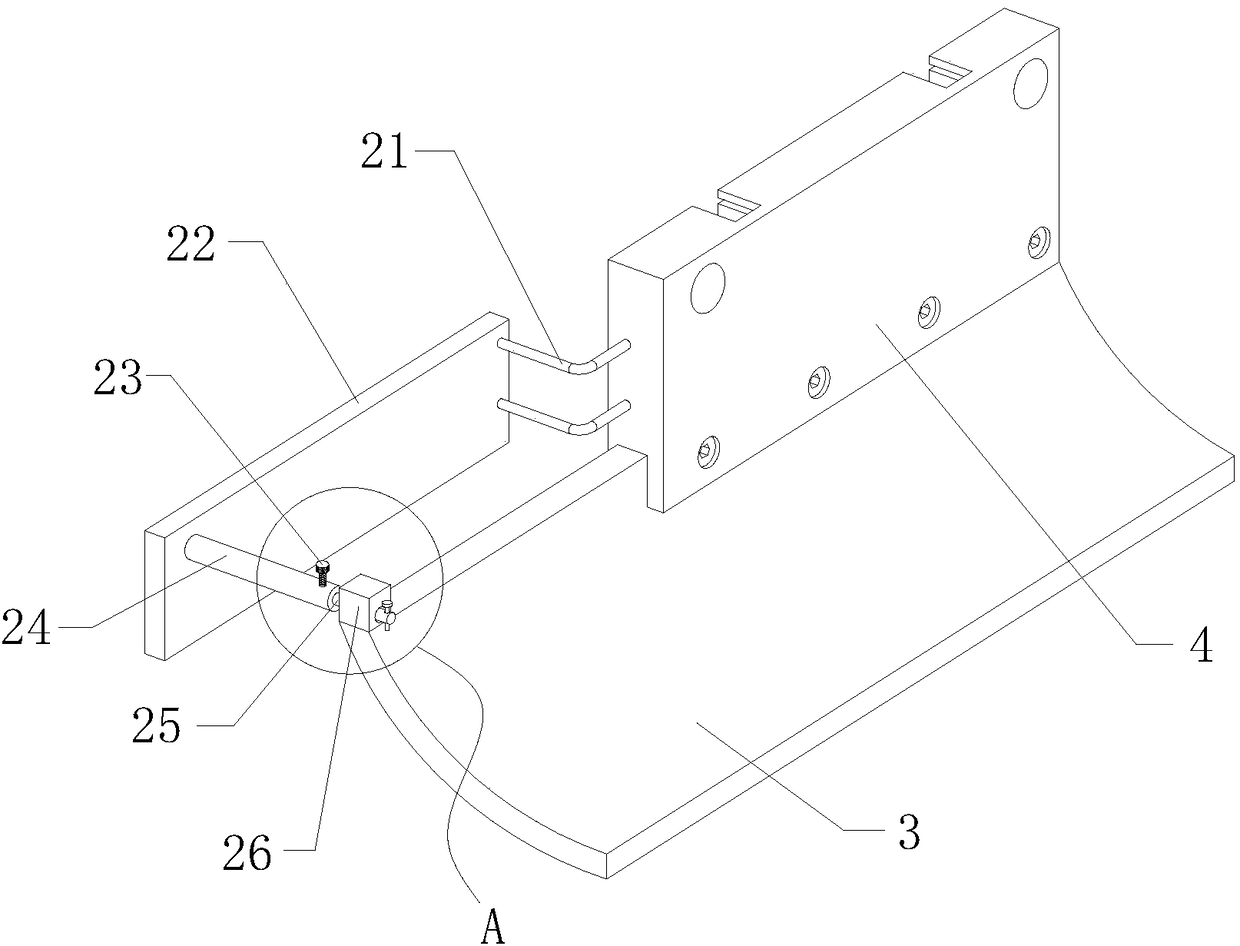

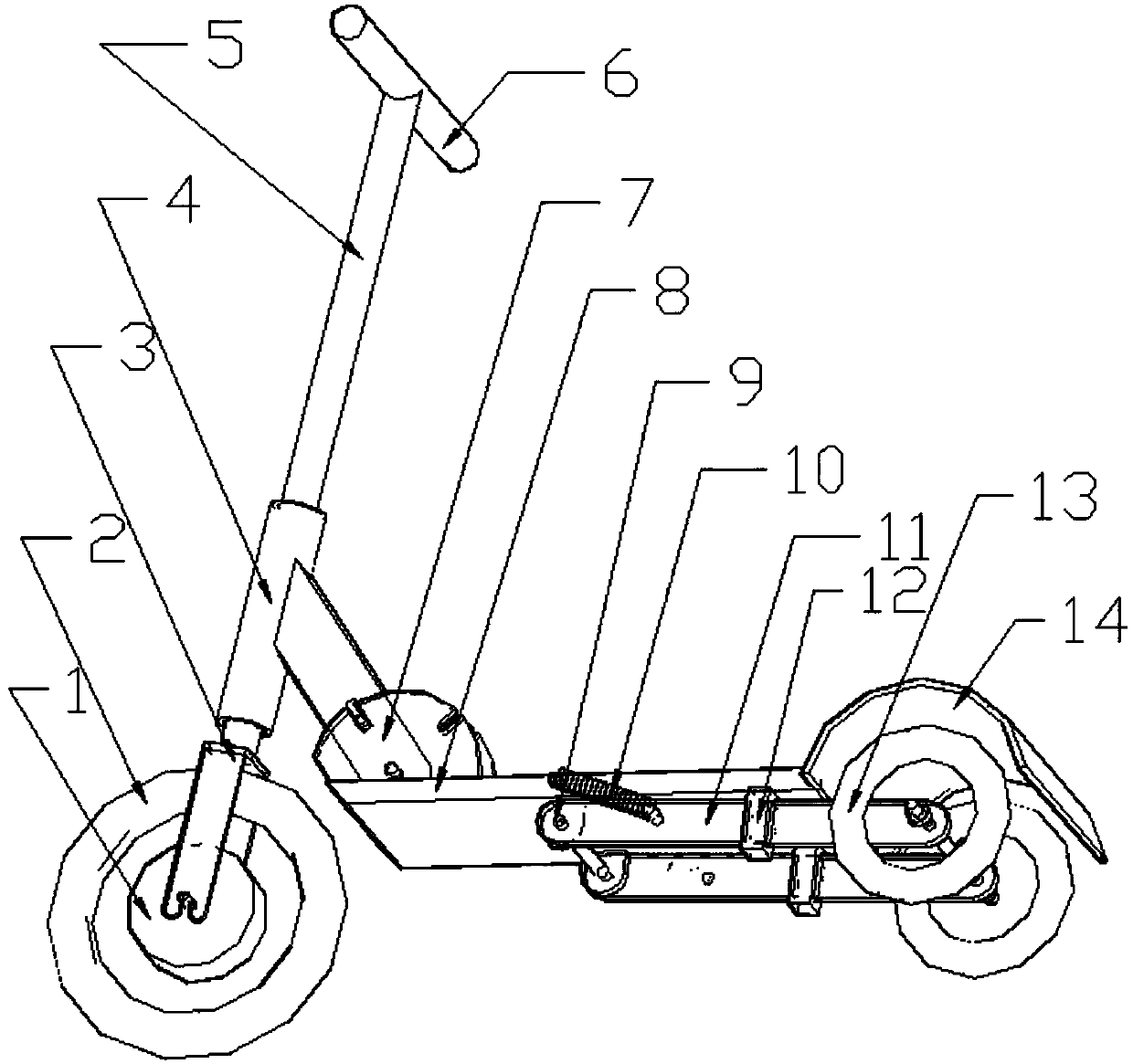

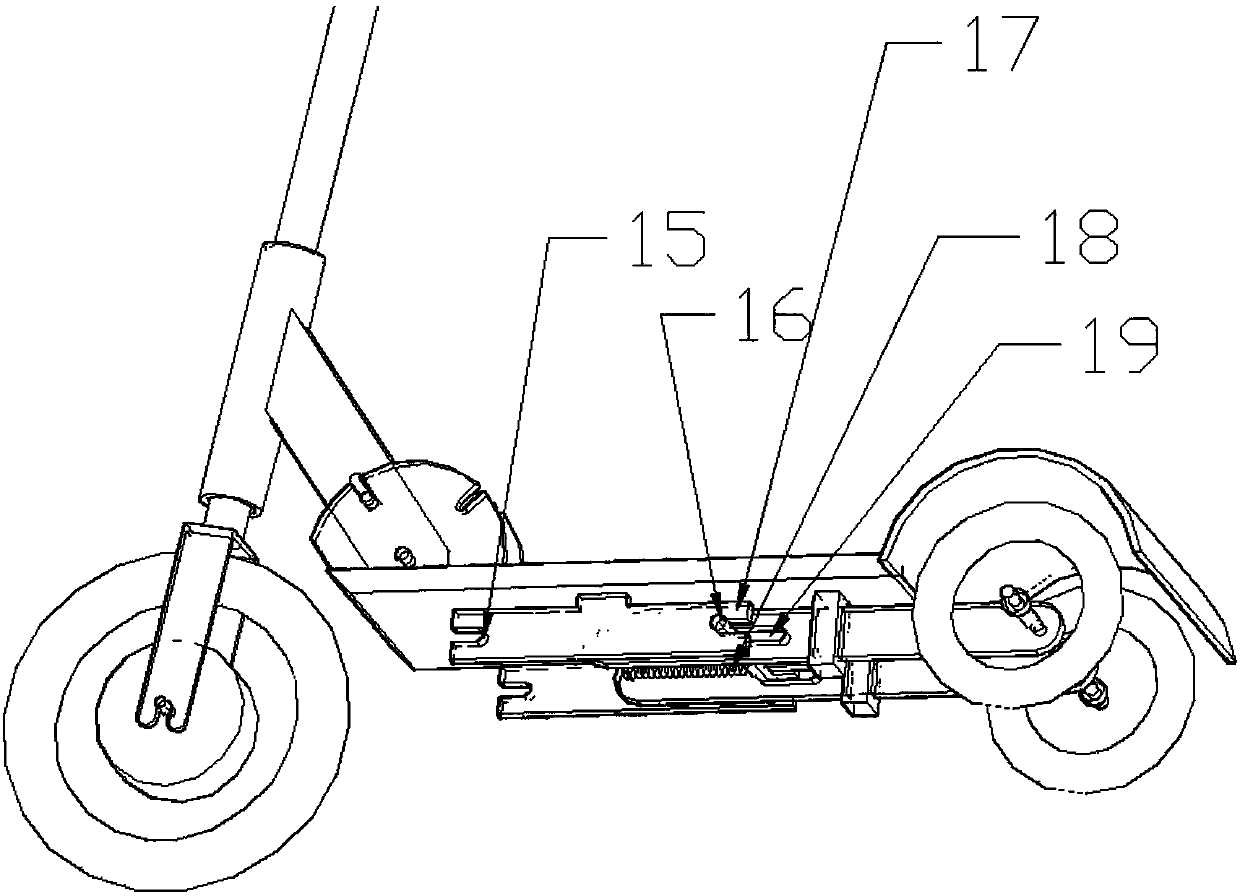

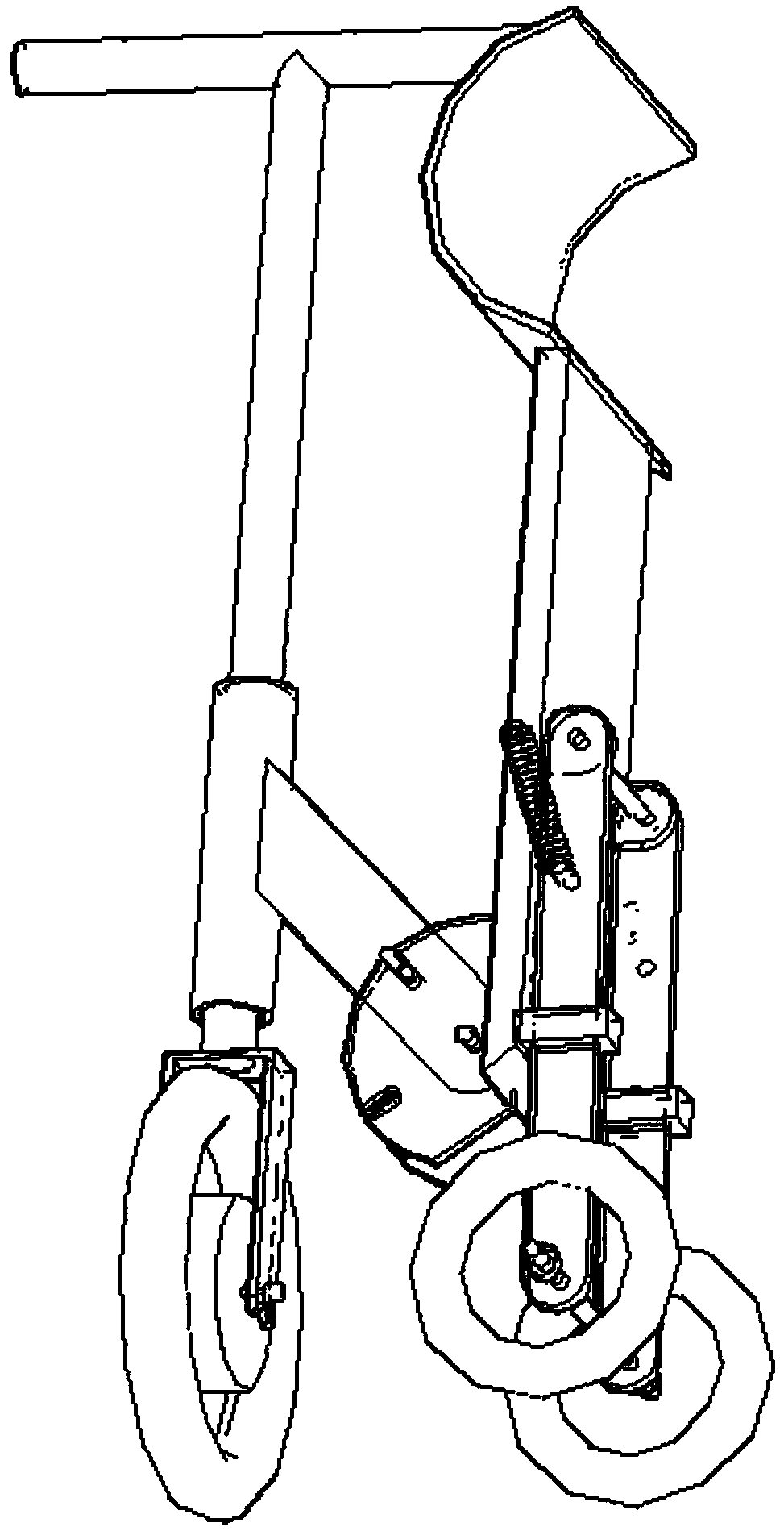

Portable and foldable scooter

PendingCN107914812ATo achieve gatheringSolve climbing stairsFoldable cyclesEngineeringMechanical engineering

The invention belongs to the field of traffic tools, and particularly provides a portable and foldable scooter. After the portable and foldable scooter is folded, a front wheel and rear wheels are gathered at one end, a handlebar is arranged at the other end, when the portable and foldable scooter is carried, the handlebar is held in hands, vehicle wheels touch the ground to walk, clothes are prevented from being contaminated, the weight of the scooter can also be overcome, and the portable and foldable scooter is easy to carry. The portable and foldable scooter is mainly constituted by the front wheel, a bibcock assembly, a bibcock folder, a plate body, rear wheel supports and the rear wheels, the bibcock folder is connected with a bibcock head pipe and the front end of the plate body, the bibcock assembly and the plate body are folded, one end of each rear wheel support is installed in the middle of the plate body, the rear wheel is installed at the other end of each rear wheel support, installation ends of the rear wheel supports are in shaft linkage with the middle of the plate body, and the rear wheel supports can be folded forwards and backwards. Under the folding state, through the folder, after the bibcock assembly and the plate body are folded, the rear wheel supports are folded forwards, the rear wheels are folded to the front end of the plate body, and the front wheel and the rear wheels are gathered to one end. Clamping devices are arranged on the rear supports, and the portion of the rear wheel supports after the rear wheel supports are folded forwards and backwards is clamped.

Owner:吴结华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com