Ginger harvester

The technology of harvesting machine and smoothing ginger is applied in the field of ginger harvesting devices, which can solve the problems of increasing labor force, belt clamping, affecting the yield of good products, etc., and achieve the effects of reducing labor force, ensuring firmness and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

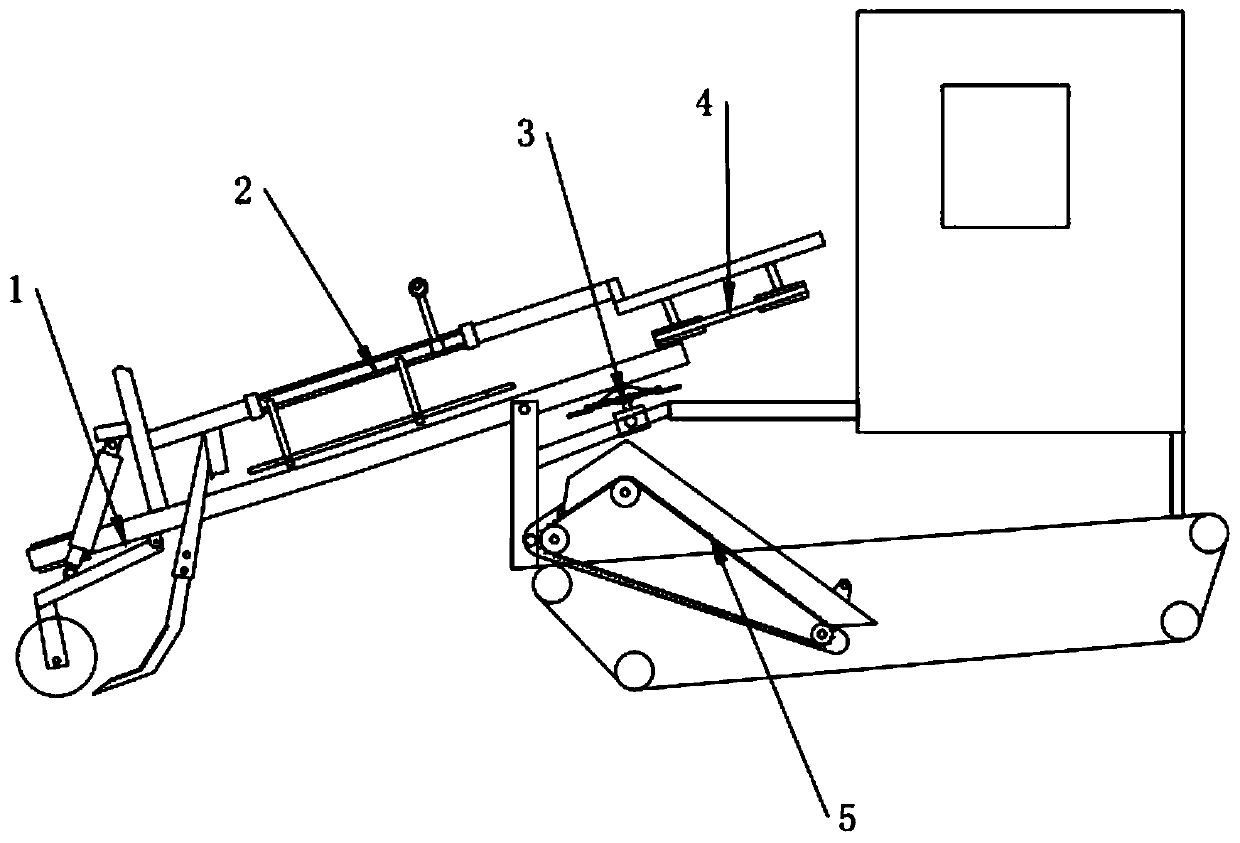

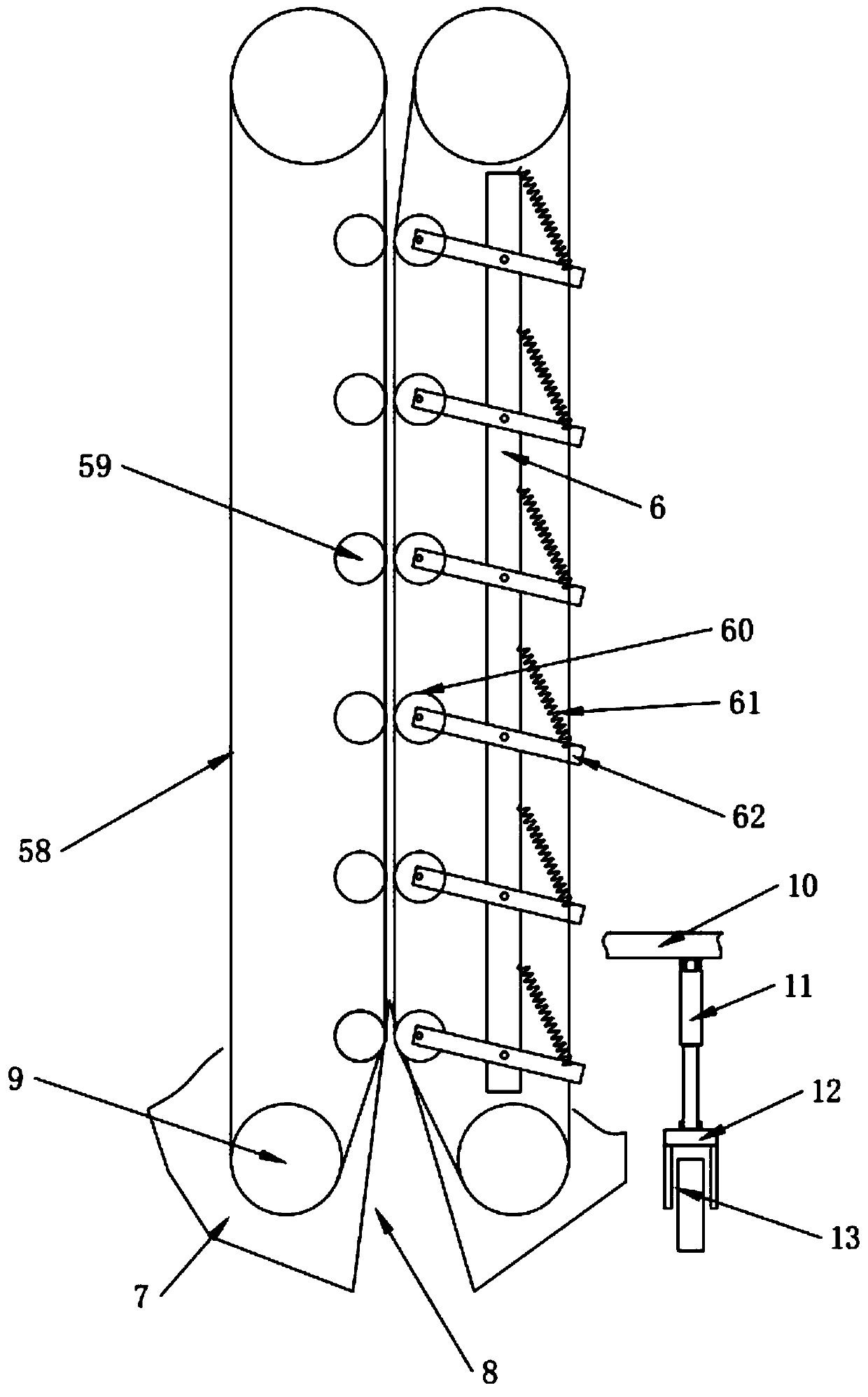

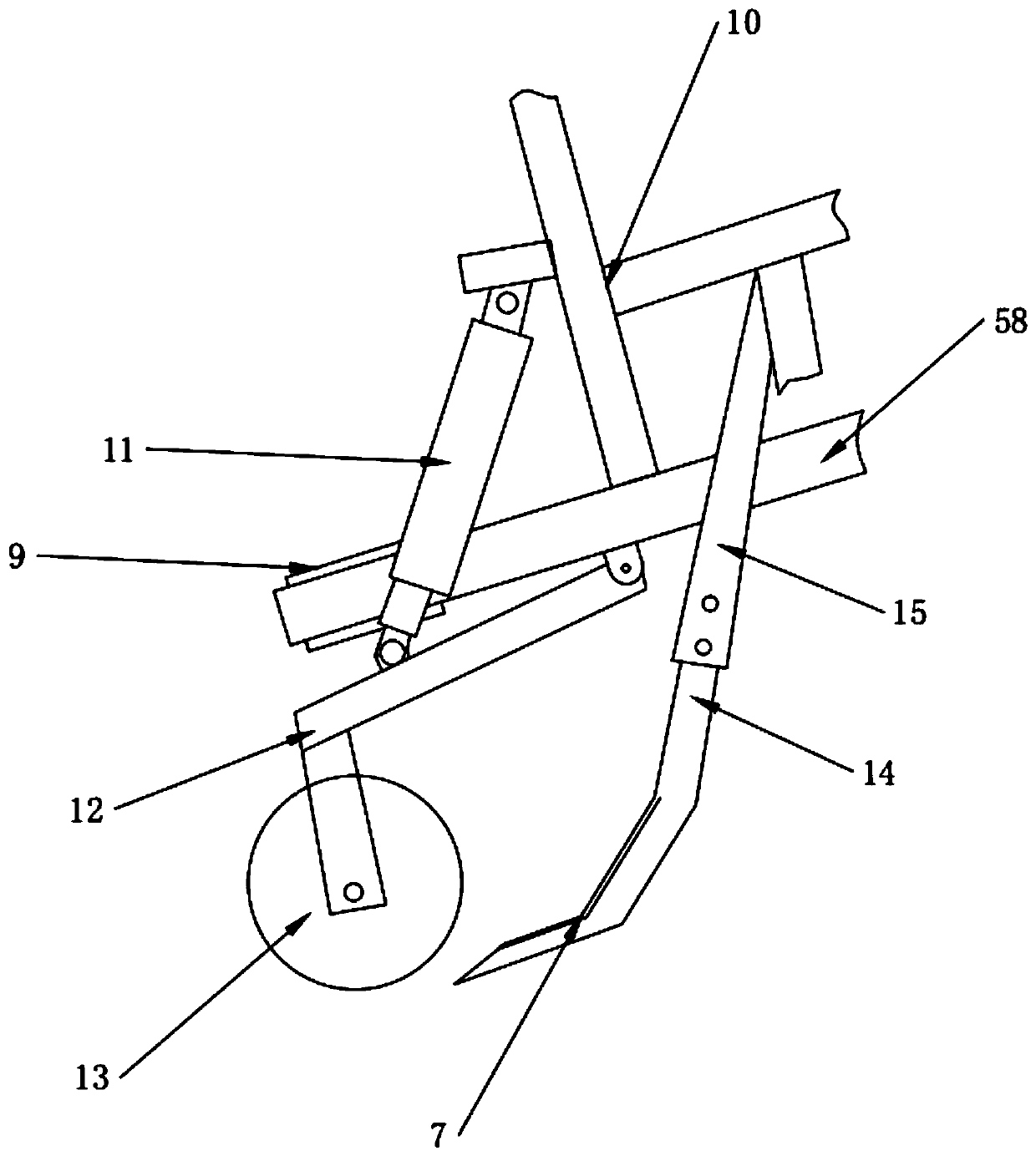

[0100] Such as figure 1 with figure 2 As shown, the ginger harvester includes a ginger pulling mechanism 1, a soil shaking mechanism 2, a ginger smoothing mechanism 5, a separating mechanism 3, and a deriving mechanism 4; 31 With the conveying channels of the ginger pulling mechanism 1 arranged side by side, the ginger stalks of the ginger can be slapped to shake the soil during the process of the ginger pulling mechanism 1 conveying the ginger; the separation mechanism 3 is arranged at the rear end of the ginger pulling mechanism 1 The top of the part, after the ginger bar is cut, it is exported along the top o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com