A treatment device for oil slick polluted waters

A treatment device and water area technology, applied in general water supply conservation, cleaning of open water surfaces, water conservancy projects, etc., can solve the problems of wide spread of oil pollution, high difficulty, low treatment efficiency, etc., and achieve simple operation, simple structure, and fast Efficient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

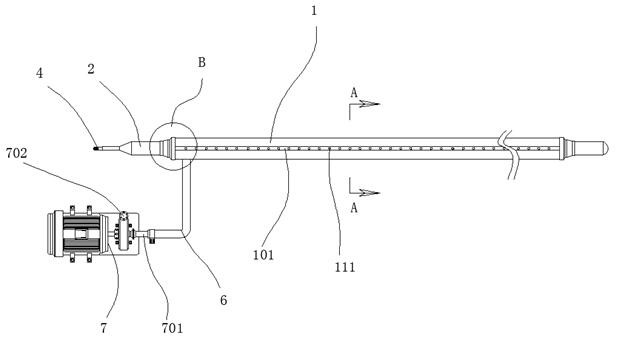

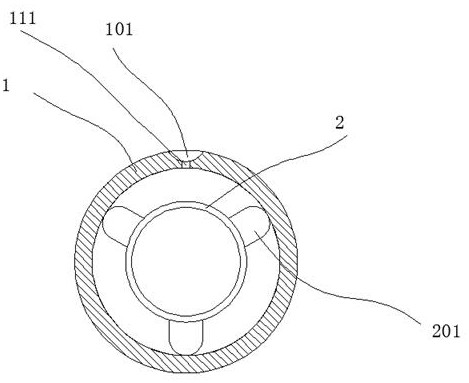

[0035] refer to figure 1 , figure 2 , image 3 and Figure 4The shown oil slick polluted waters treatment device includes an outer pipe 1 made of rubber, the thickness of the outer pipe is 3mm, the outer pipe is mainly responsible for contacting oil pollution, and the inner pipe 2 sleeved on the inner side of the outer pipe 1 , the thickness of the inner pipe is 0.85mm. The main function of the inner pipe is to be responsible for inflation and provide buoyancy. There are a plurality of raised parts 201 formed by injection molding at the center. The raised part is mainly to separate the inner pipe and the outer pipe. When the inner pipe is inflated, if no raised part is provided, the inner pipe may be inflated with the outer pipe. Form a contact seal between the outer pipes and inner pipes, which will affect the circulation of oil pollution between the outer pipe and the inner pipe. Therefore, we designed the raised part to ensure that there is a gap between the outer pipe ...

Embodiment 2

[0037] refer to Figure 5 and Figure 6 As shown, the outer wall of the outer pipe 1 is sheathed with a plurality of retaining sleeves 8, and the transition fit between the retaining sleeves 8 and the outer pipe 1, when the inner pipe 2 is inflated, the outer The outer diameter of the pipe 1 is expanded, and the expanded outer pipe 1 is in interference fit with the retaining sleeve 8 .

[0038] A stud 801 is welded at the outer wall of the retaining sleeve 8, and a counterweight ball 802 is fitted through the stud 801; the counterweight ball is mainly used for counterweighting, and the purpose of its design is that the density of salt water and fresh water is different. The same, the buoyancy produced is also different, so the reasonable floating height of the outer pipe can be maintained by the ball balance.

[0039] The weight ball 802 is a solid shot or steel ball.

Embodiment 3

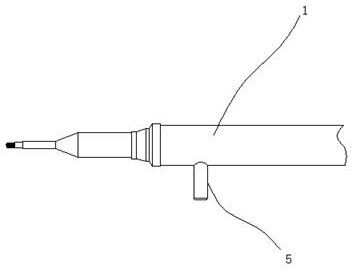

[0041] refer to Figure 7 As shown, a locking piece 9 is arranged in the suction tube 5, the locking piece is U-shaped, the two ends of the locking piece 9 are expanded outwards, and both ends of the locking piece 9 are bent outwards. The claw part 901 is formed, and the locking member is made of spring steel. When assembling the liquid suction tube, firstly, a socket through the liquid suction tube is opened on the outer wall of the outer pipe, and the liquid suction tube is inserted into the socket , and then insert the locking piece, the locking piece slides in along the inner wall of the suction tube, and opens when the claw moves to the outside of the suction tube, at this time the claw is locked on the inner side of the outer tube The setting of the locking piece is mainly to limit the insertion depth of the suction pipe. When the insertion depth of the suction pipe is too large, it will contact with the inner pipe. After contact, the suction pipe will be located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com