An optical fiber core butt matrix structure

A technology of optical fiber core and docking matrix, which is applied in the field of optical fiber core docking matrix structure, can solve the problems of huge workload and time-consuming, and achieve the effects of simple operation, reduced horizontal occupation area and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] As mentioned in the background technology section, in the prior art, people usually go to the site to perform fiber jumping operations to realize the docking and switching between different optical fibers. This manual method is time-consuming and labor-intensive.

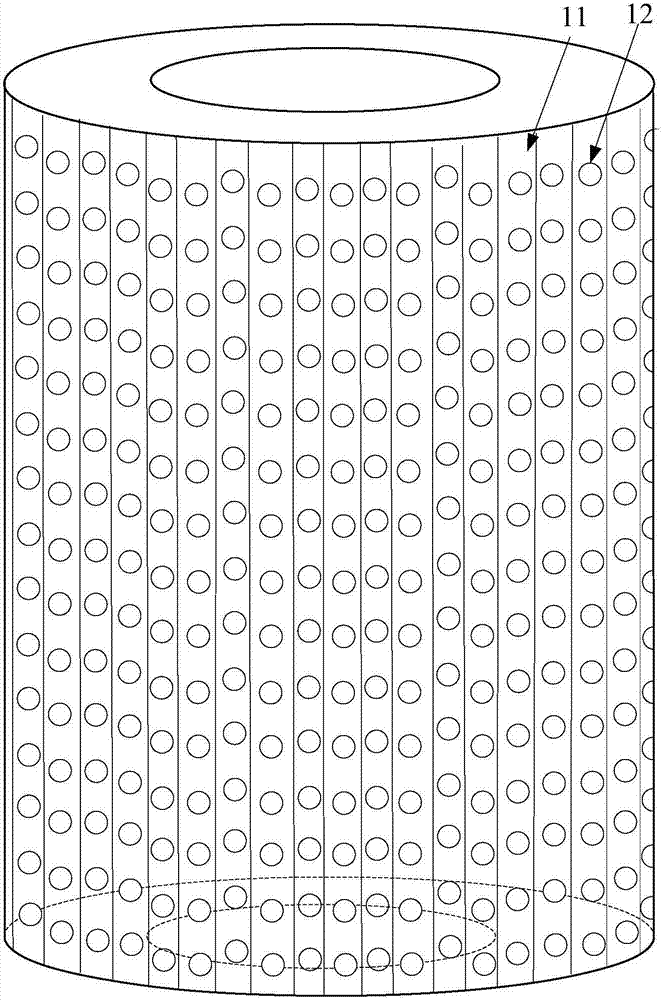

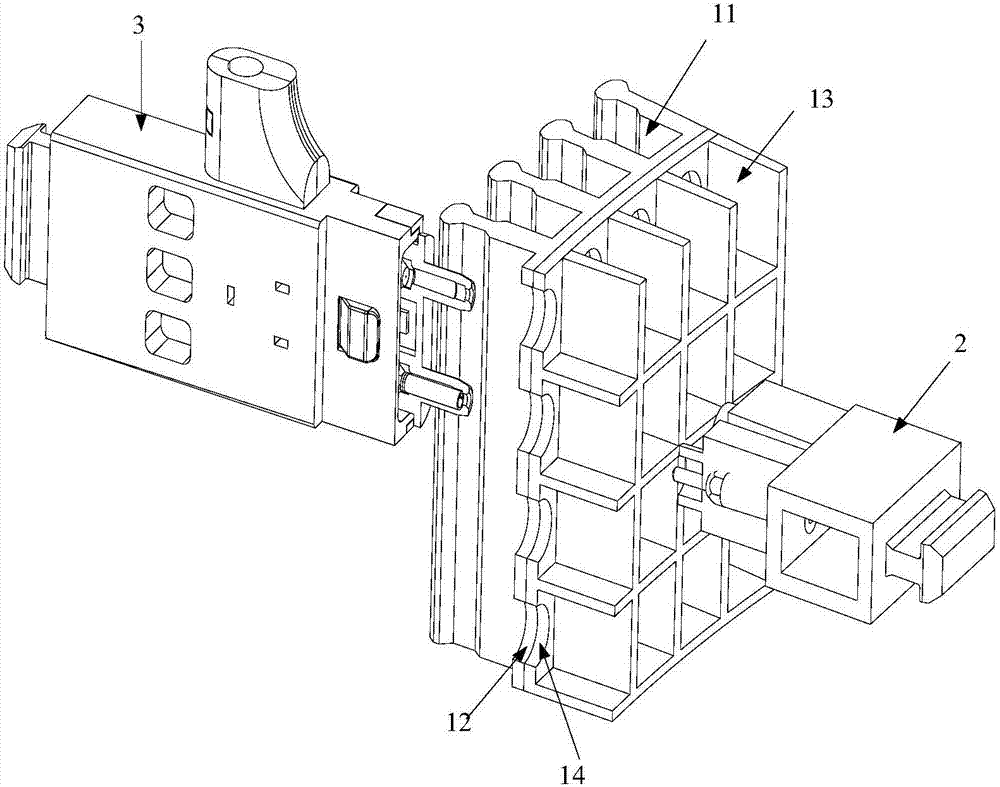

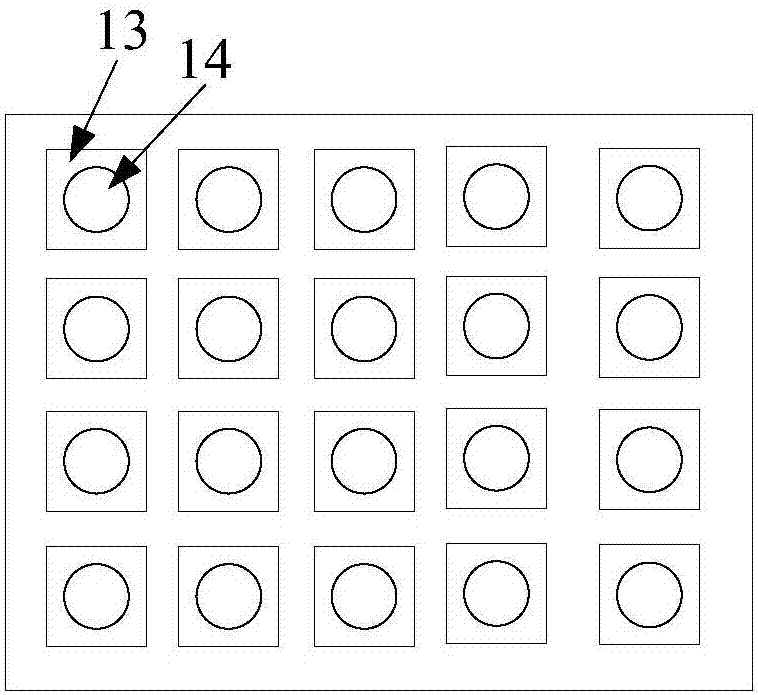

[0021] In view of this, an embodiment of the present invention provides an optical fiber core butt matrix structure, the optical fiber core butt matrix structure is a hollow columnar structure, and the outer wall of the optical fiber core butt matrix structure is provided with a plurality of edge The docking grooves are arranged side by side in the first direction, and each docking groove is provided with a plurality of first docking holes arranged along the extending direction of the docking grooves.

[0022] The side wall of the optical fiber core docking matrix structure provided by the embodiment of the present invention is provided with a plurality of first docking holes. In different first docking hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com