Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Reduce meshing noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

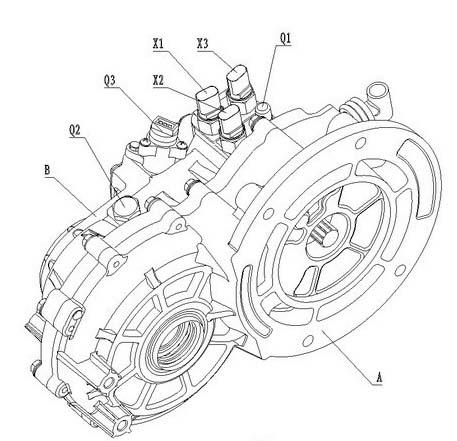

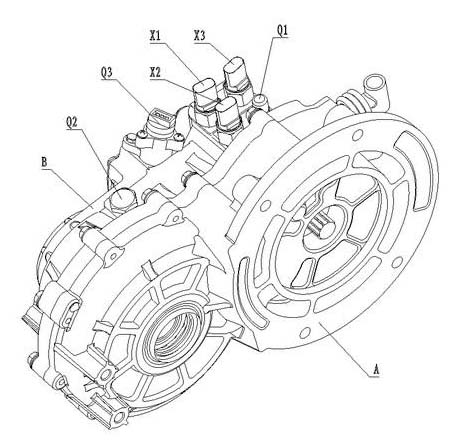

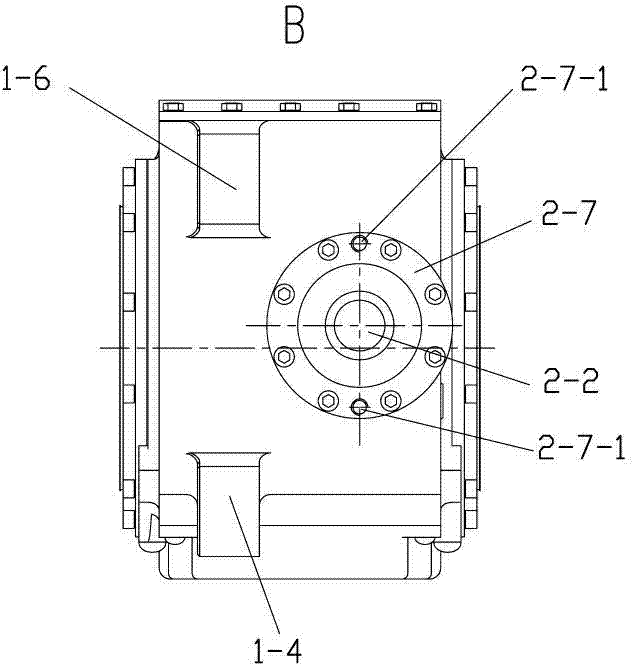

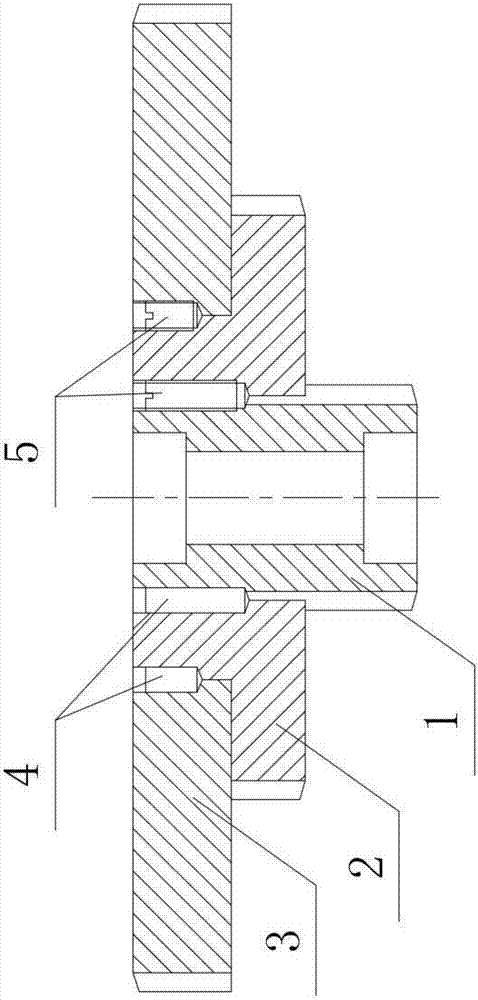

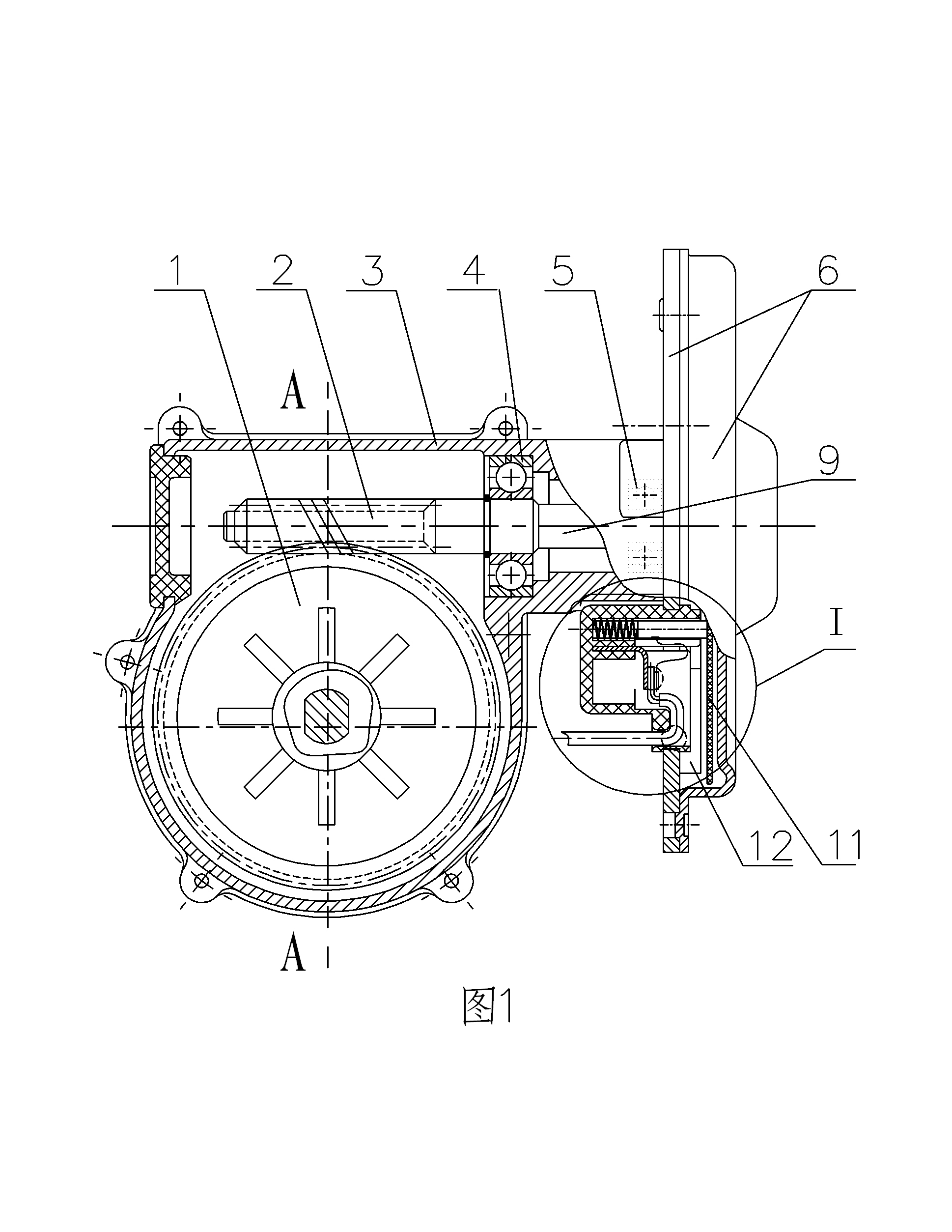

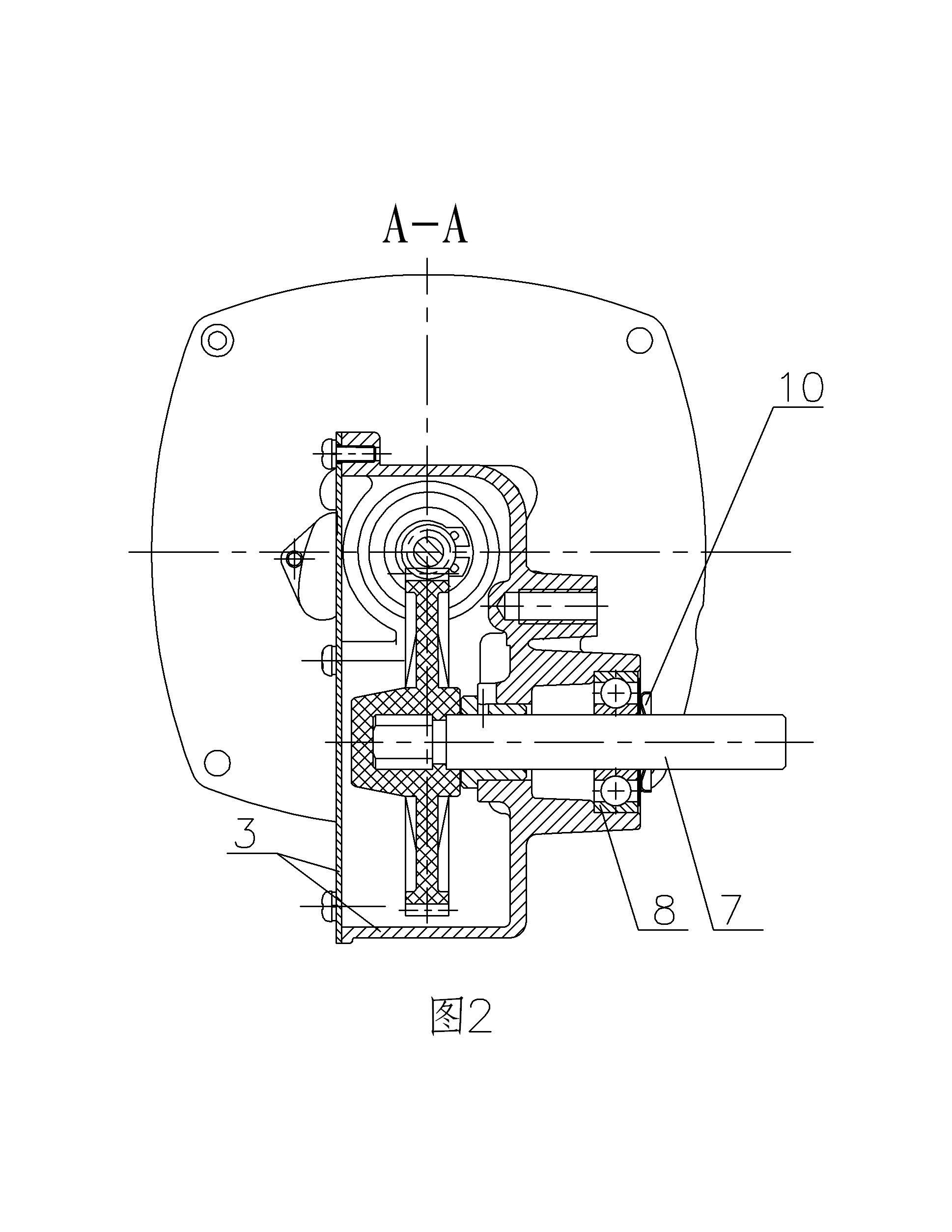

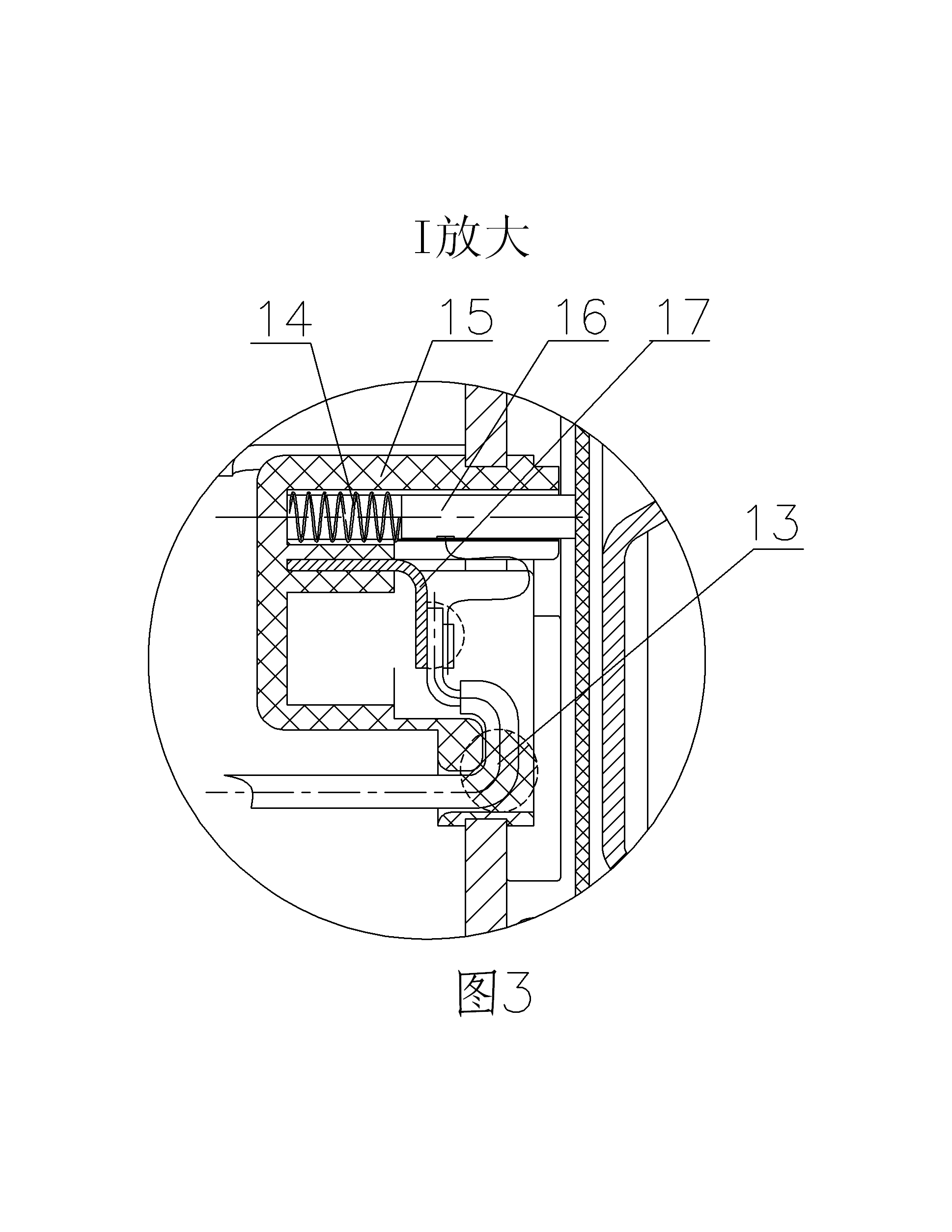

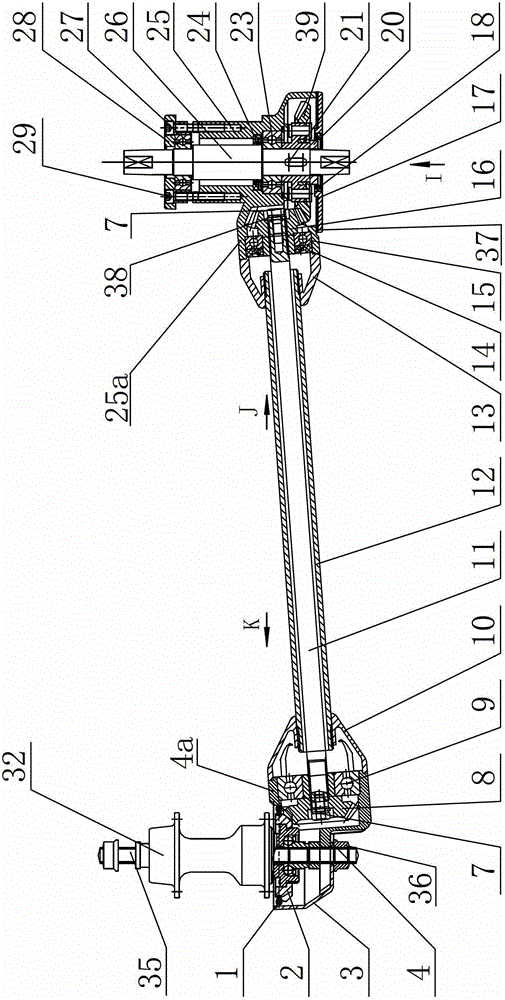

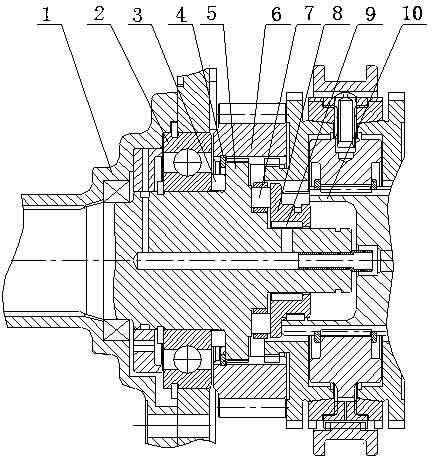

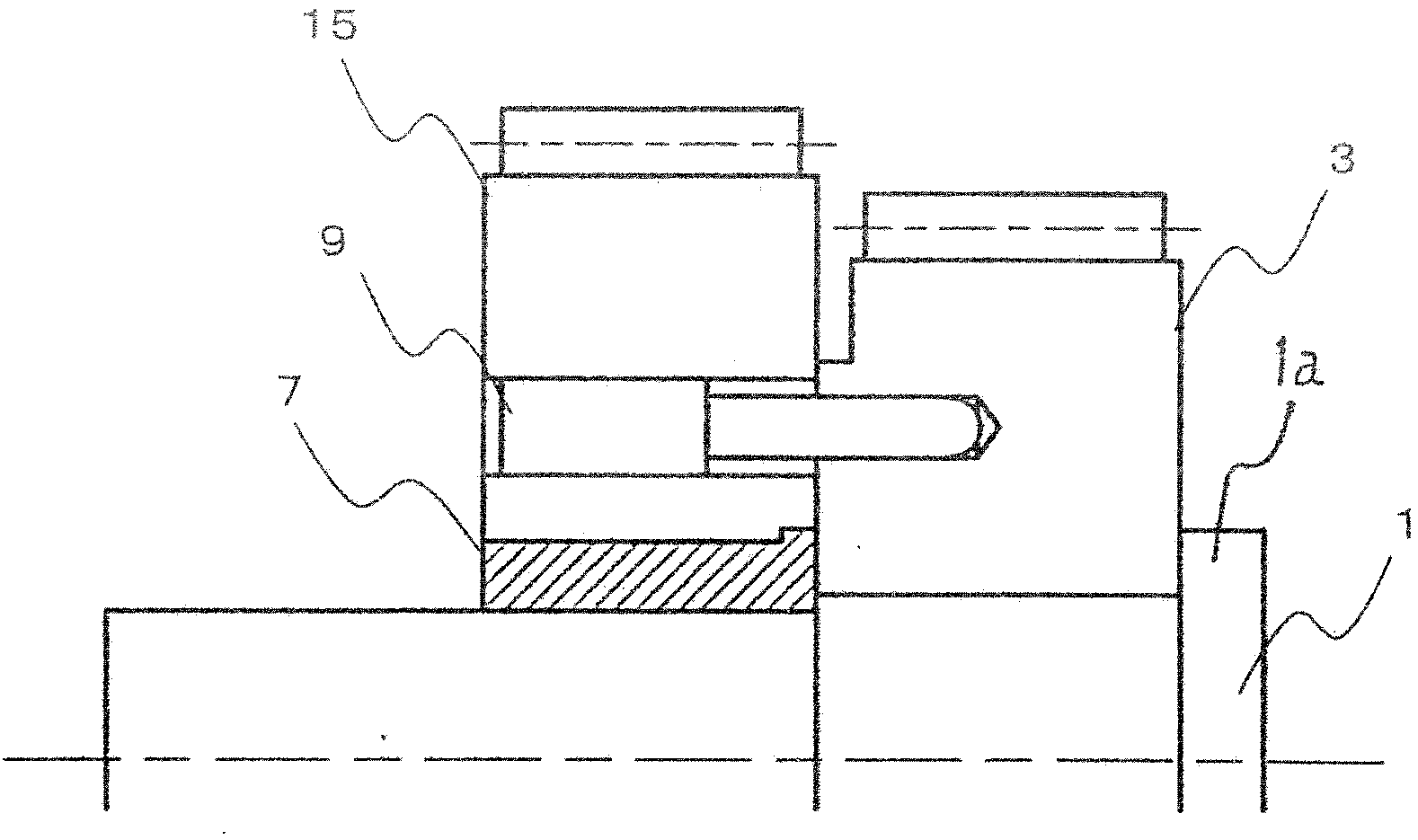

Gearbox with 2+1 gears for electric automobile

ActiveCN102072290AReduced power ratingReduce meshing noiseToothed gearingsTransmission elementsExhaust valveGear wheel

The invention relates to a gearbox with 2+1 gears for an electric automobile. An exhaust valve, a bolt of an oil injection opening, an automobile speed mileage output sensor, a high-speed gear signal switch, a low-speed gear signal switch and a reverse gear switch are installed on a back box body of a speed changer; a box body of the speed changer is provided with a driving mechanism, a reverse gear idler mechanism, an intermediate shaft mechanism, a differential assembly and a gear shifting mechanism; the gearbox with the 2+1 gears for the electric automobile has the advantages that two forward gear speed changers are adopted, and the rated power of an adopted motor can be lowered; meanwhile, a transmission gear of a high-speed input shaft can work by a tooth face at a single side through adding a reverse gear, the fatigue life of teeth is enhanced, and the engagement noise of the tooth face is lowered; the difference value of the transmission speed ratio of two gears is large, the adopted power of a drive motor is effectively lowered, and the integral dynamic performance of a power assembly is enhanced; and the gearbox with the 2+1 gears for the electric automobile can be widelyapplied to an electric car, a wagon and a passenger car to serve as a variable-speed transmission mechanism.

Owner:锦州万得汉拿电机有限公司

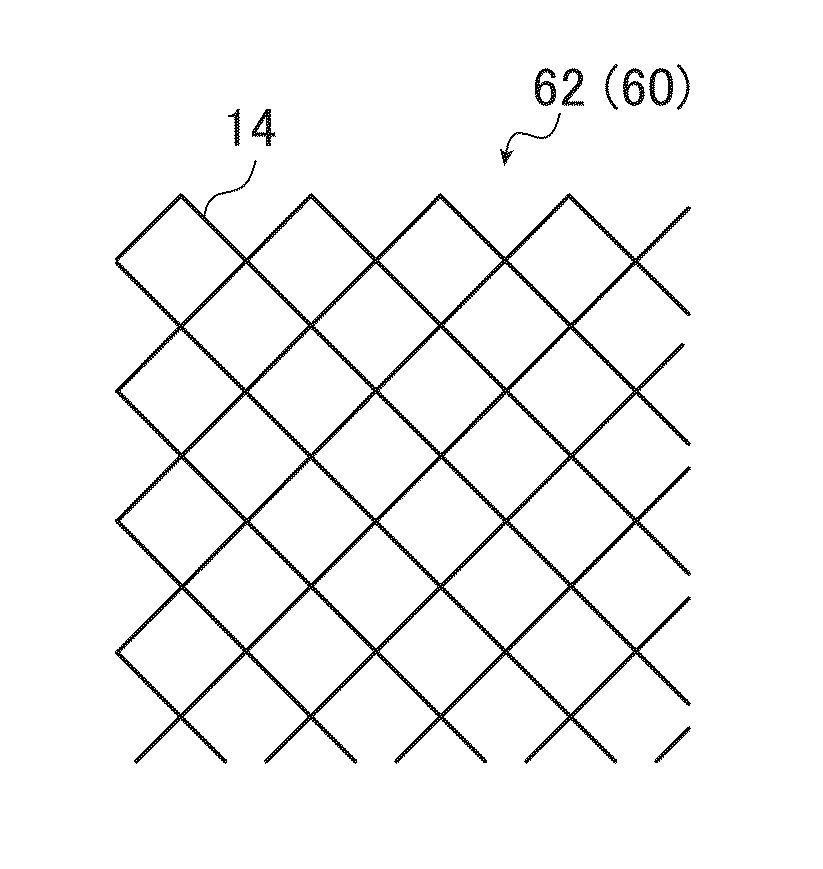

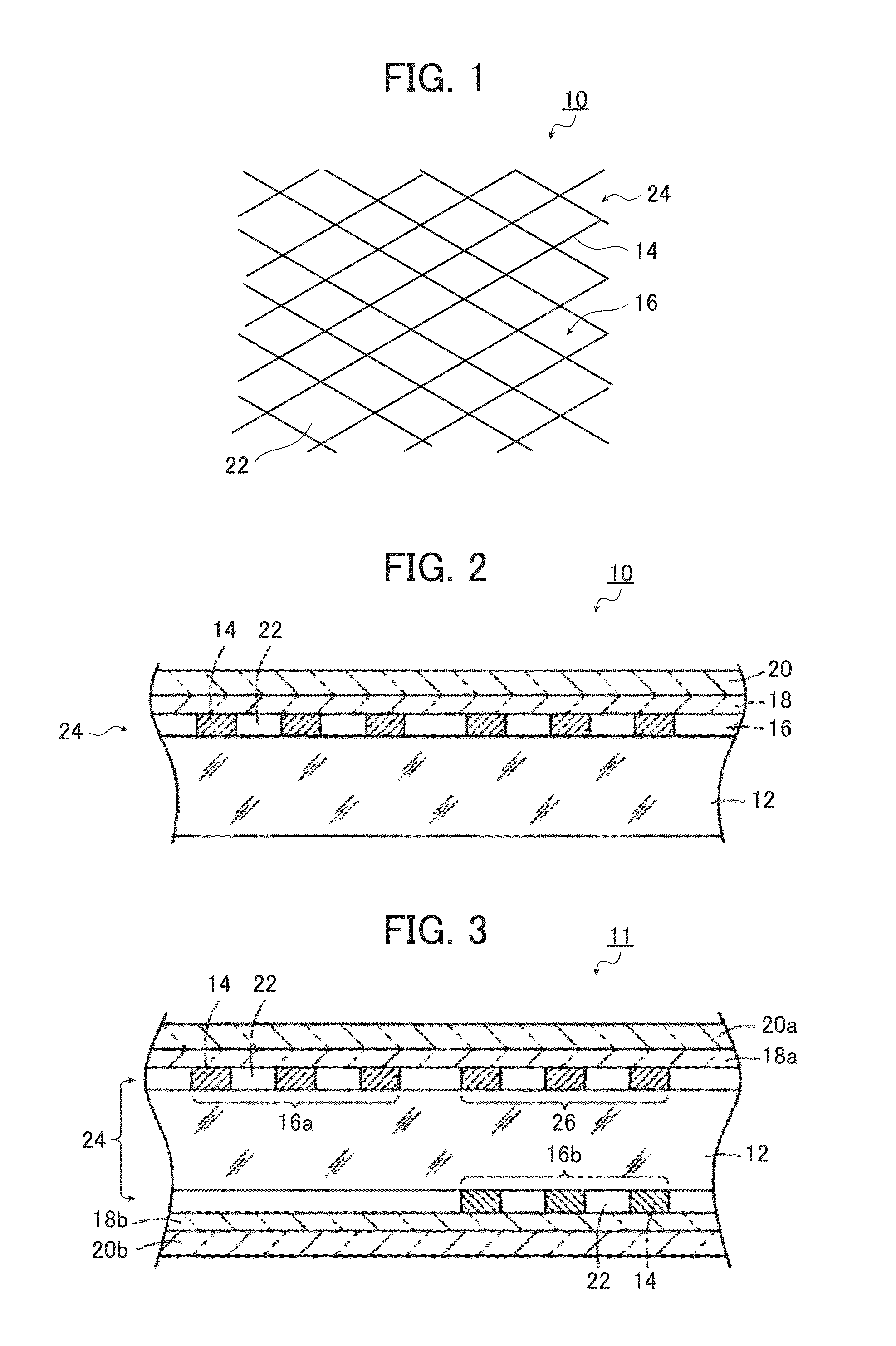

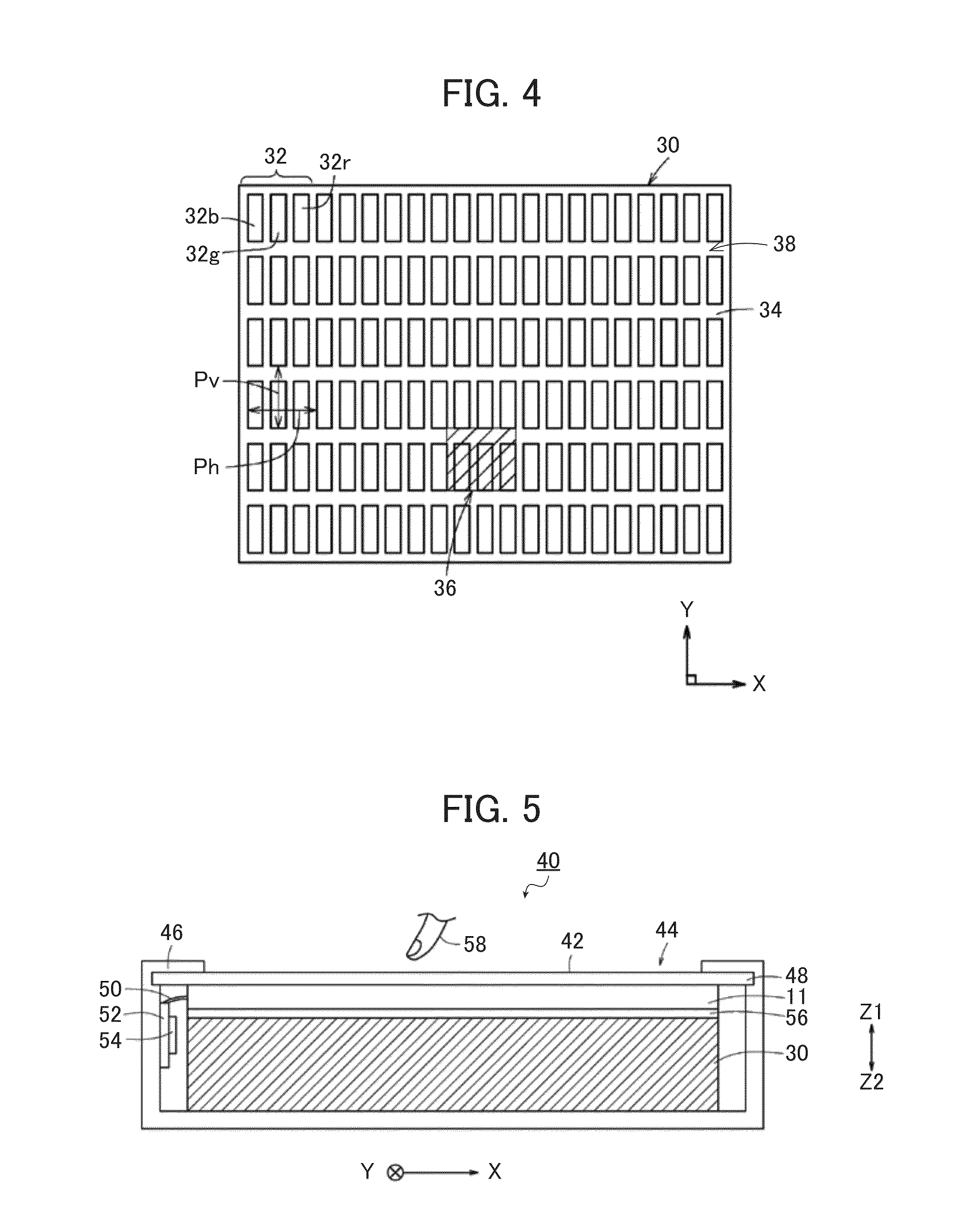

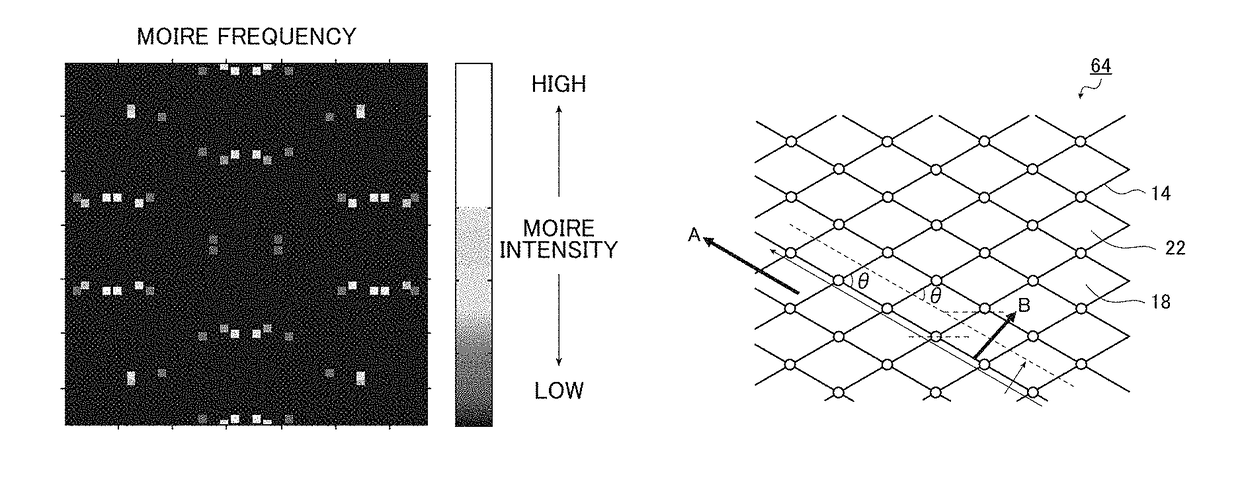

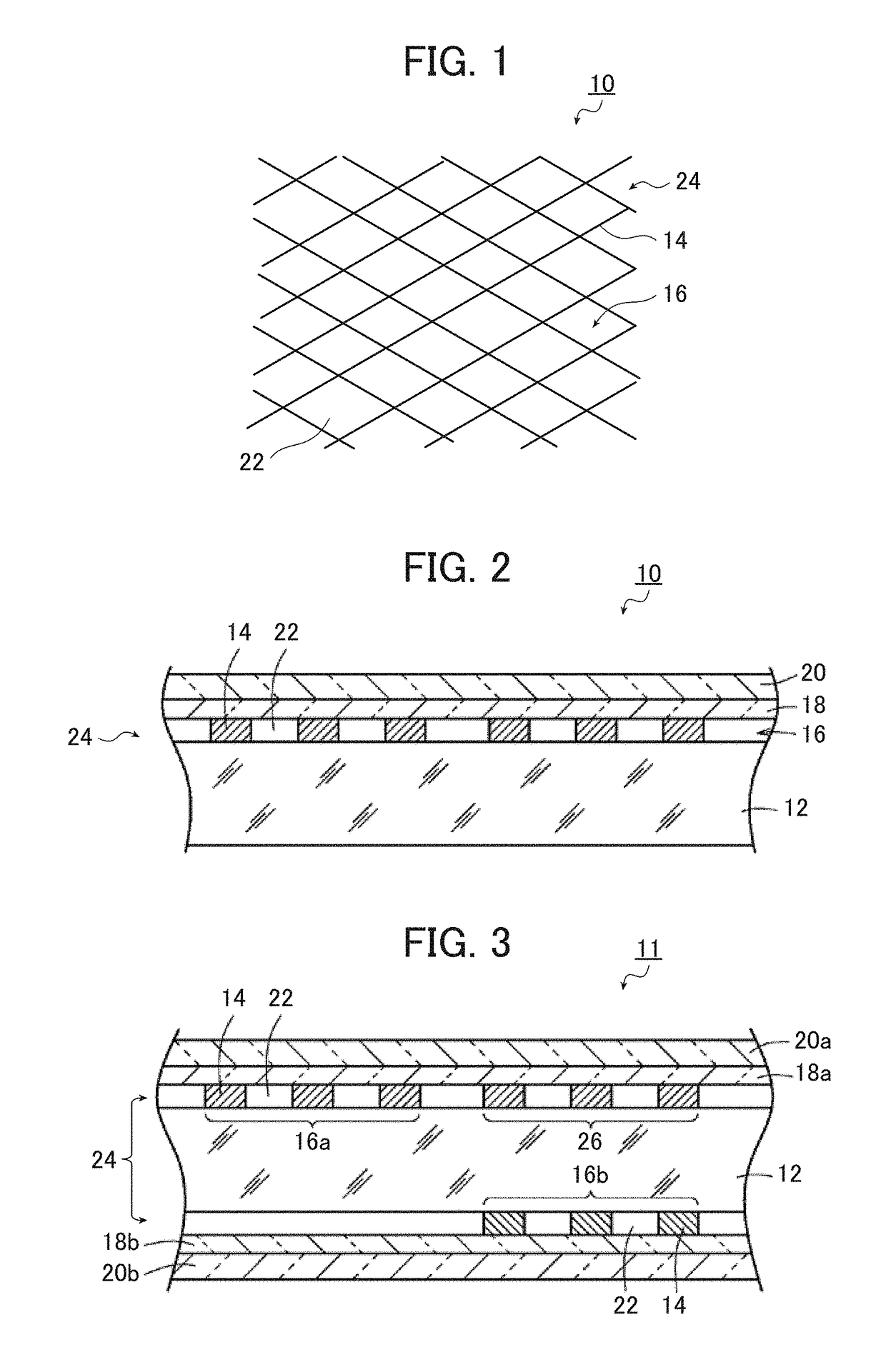

Conductive film, display device equipped with same, and method for determining pattern of conductive film

InactiveUS20150015979A1InhibitionIncrease awarenessConductive layers on insulating-supportsMagnetic/electric field screeningVisibilityDisplay device

The conductive film has a wiring pattern which, with respect to the frequencies and intensities of moire obtained by applying a human visual response characteristic to the frequency information and intensity information of moire calculated from peak frequencies and peak intensities of the two-dimensional Fourier spectrums of the transmittance image data of the wiring pattern and the transmittance image data of a pixel array pattern, causes the sum of intensities of moire each corresponding to frequencies of moire falling within a frequency range predetermined depending on the visual response characteristic to be less than or equal to a predetermined value. The conductive film allows suppression of moire and significant improvement in visibility.

Owner:FUJIFILM CORP

Conductive film, display device equipped with same, and method for determining pattern of conductive film

ActiveUS20150015980A1Improve visibilitySuppress occurrenceConductive layers on insulating-supportsCircuit optical detailsTransmittanceRhomboid

This conductive film has a randomized wiring pattern having randomized rhomboid shapes obtained by giving irregularity in a predetermined range to rhomboid shapes of a rhomboidal wiring pattern which, with respect to frequencies of moire and intensities of moire obtained by applying a visual response characteristic of human beings to frequency information of moire and intensity information of moire calculated from peak frequencies and peak intensities in both two-dimensional Fourier spectra of transmittance image data of the wiring pattern and transmittance image data of the pixel array pattern, causes a sum of intensities of moire each corresponding to each of frequencies of moire falling within a predetermined frequency range determined depending on the visual response characteristic to be less than or equal to a predetermined value. The conductive film allows suppression of moire and significant improvement in visibility.

Owner:FUJIFILM CORP

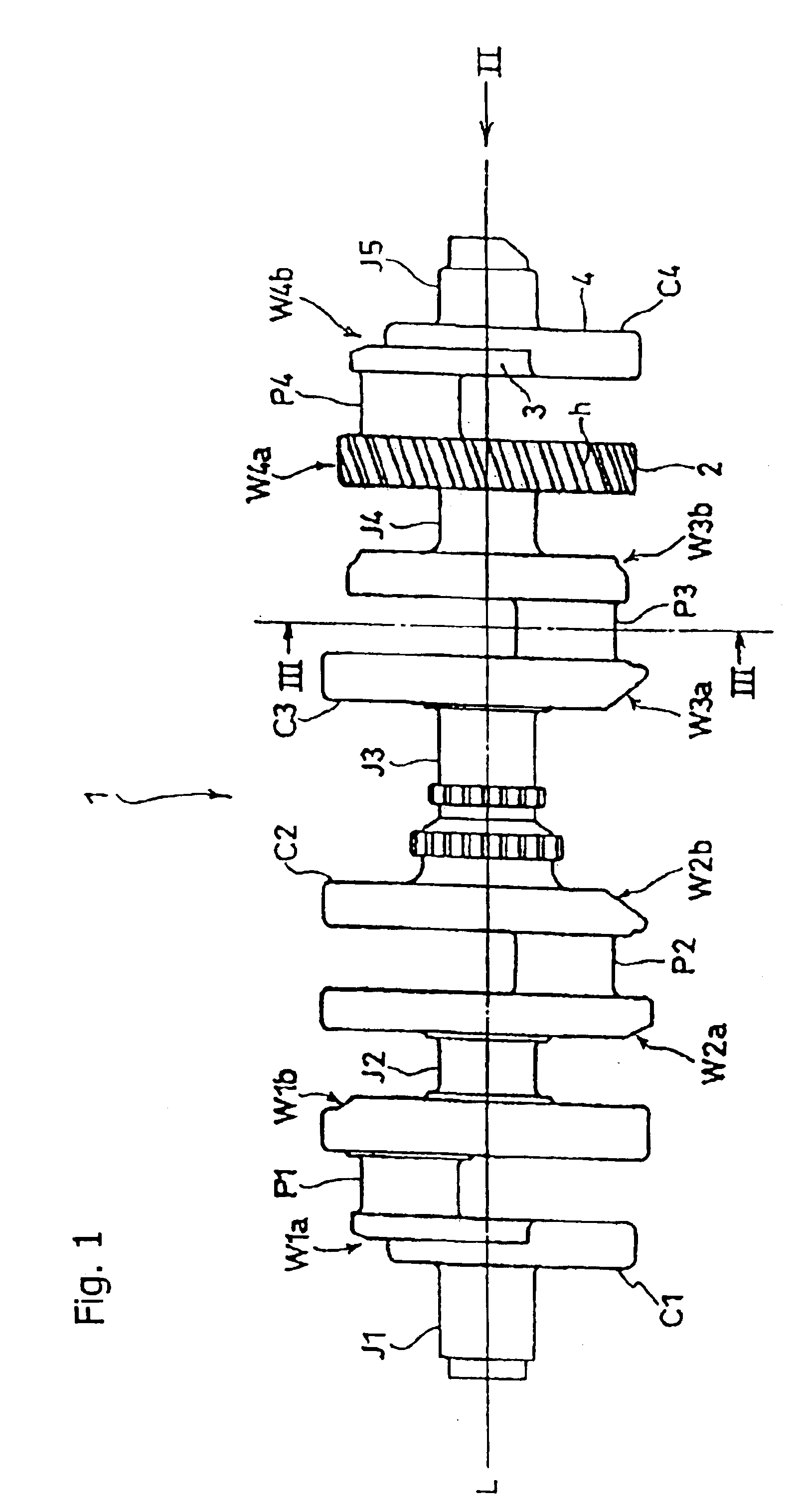

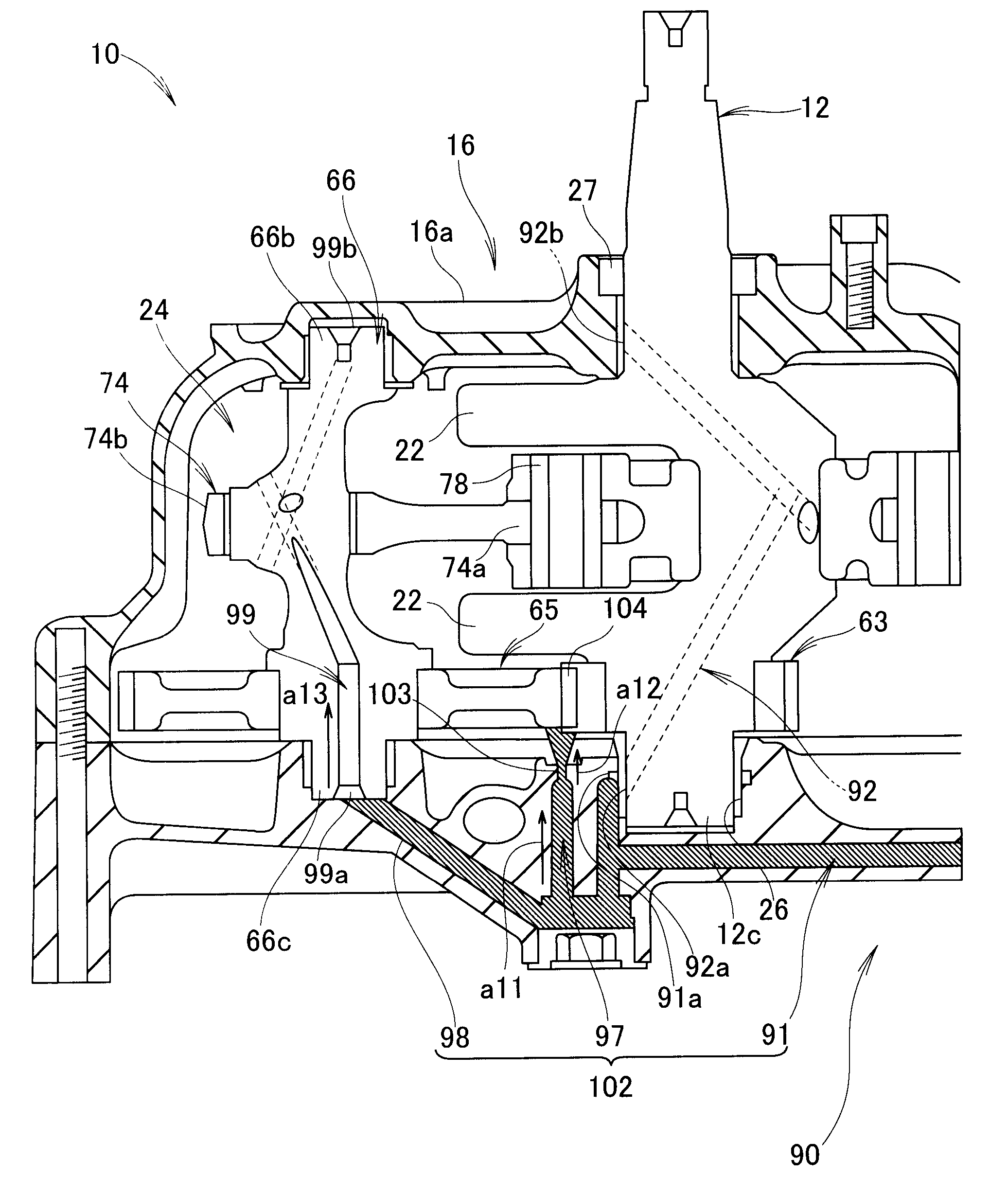

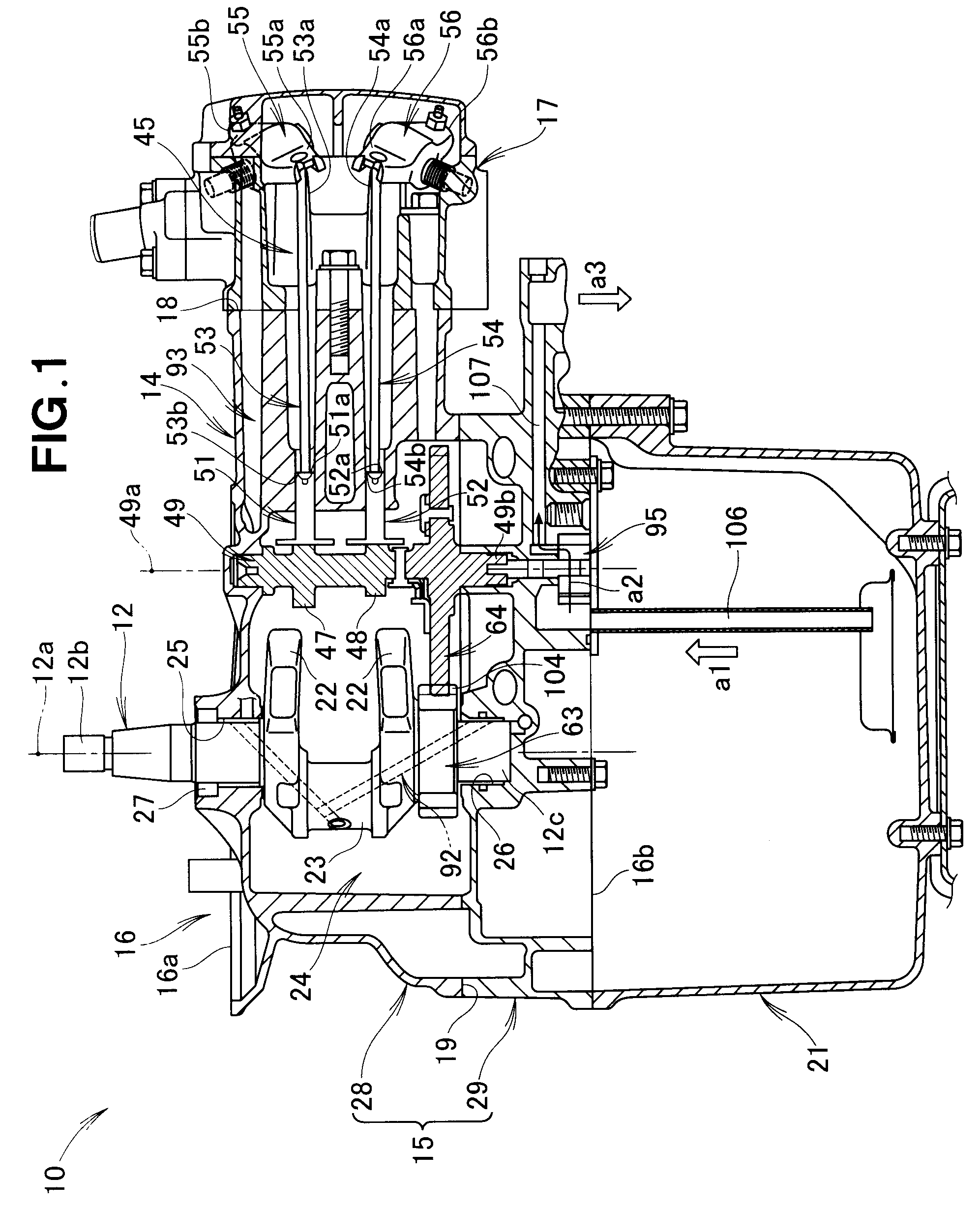

Crankshaft for an internal combustion engine

InactiveUS6959683B2Easy to useIncrease chanceCrankshaftsInertia force compensationInternal combustion engineCrankpin

A crankshaft has a helical drive gear formed as one of the crank webs at an end portion thereof. Another crank web outside of the drive gear is made in two parts, an integral balance weight mounting portion and a removable balance weight. In one embodiment, a crankshaft 12 features a crankshaft body 33 including a gear 24 for outputting rotation formed on one side of a crankpin 17d. The crankshaft also includes a first balance weight mounting portion 30g formed on the other side of the crankpin 17d and a first balance weight 31g to be mounted to the first balance weight mounting portion 30g. The crankshaft body 33 may be formed with a second balance weight mounting portion 30a separately from the first balance weight mounting portion 30g, and a second balance weight 31a mounted to the second balance weight mounting portion.

Owner:HONDA MOTOR CO LTD

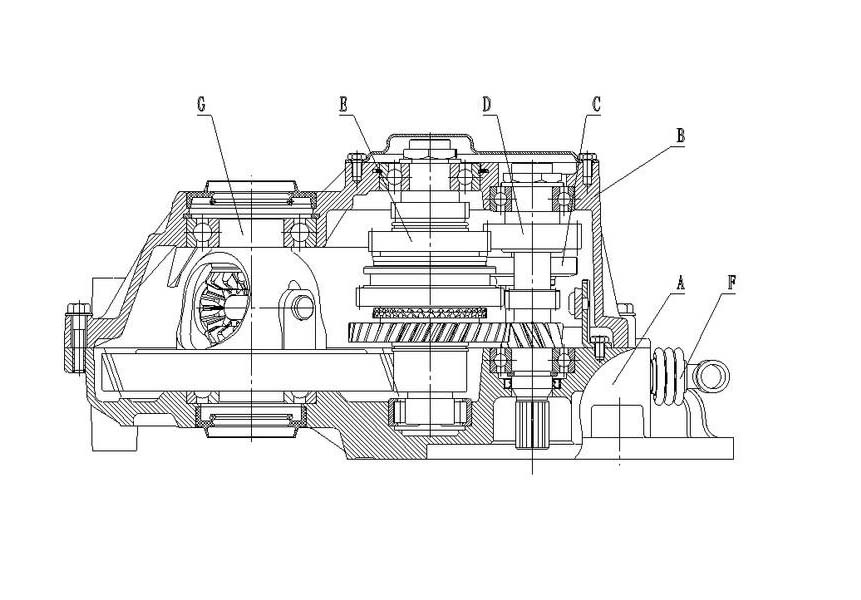

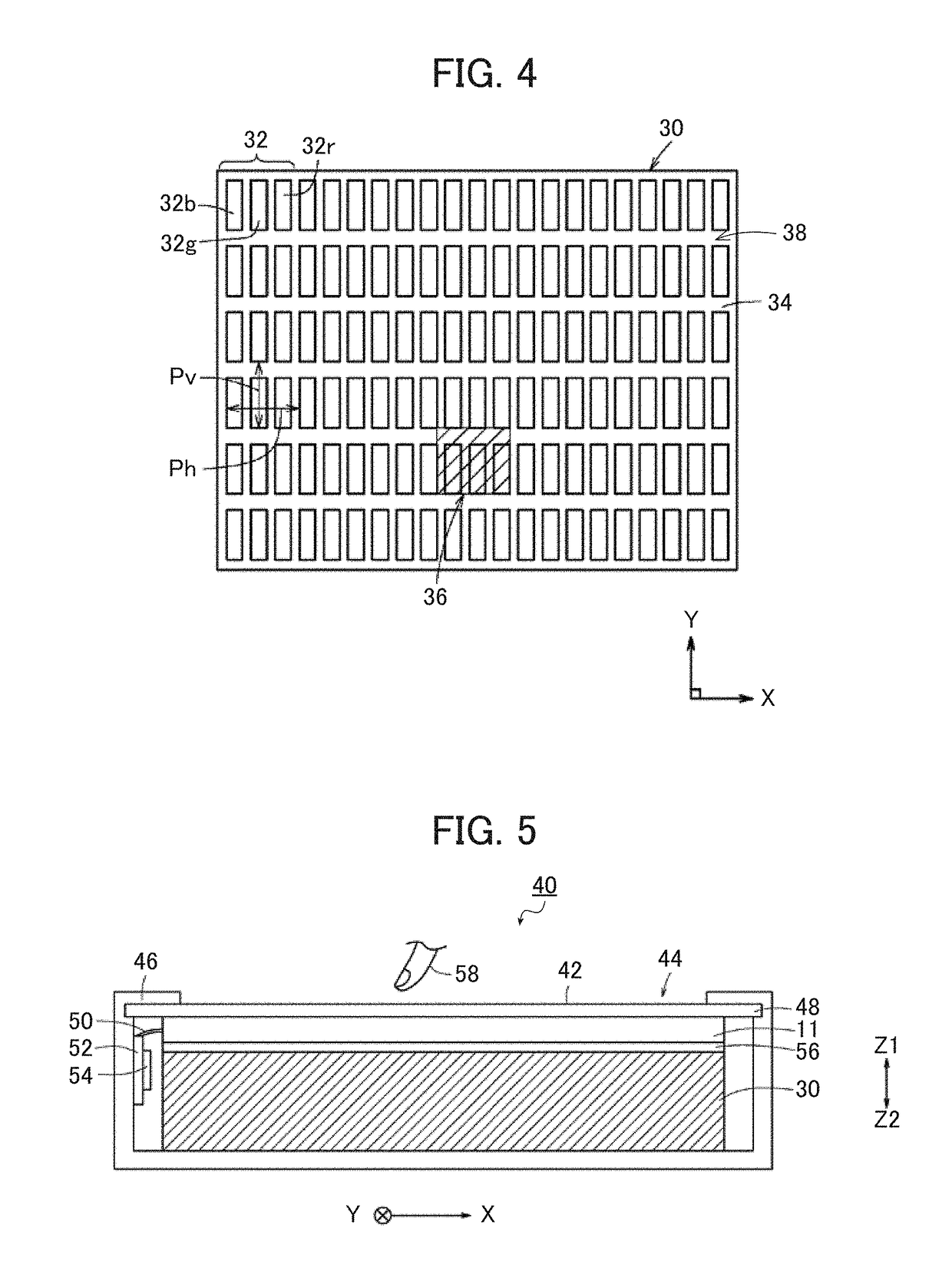

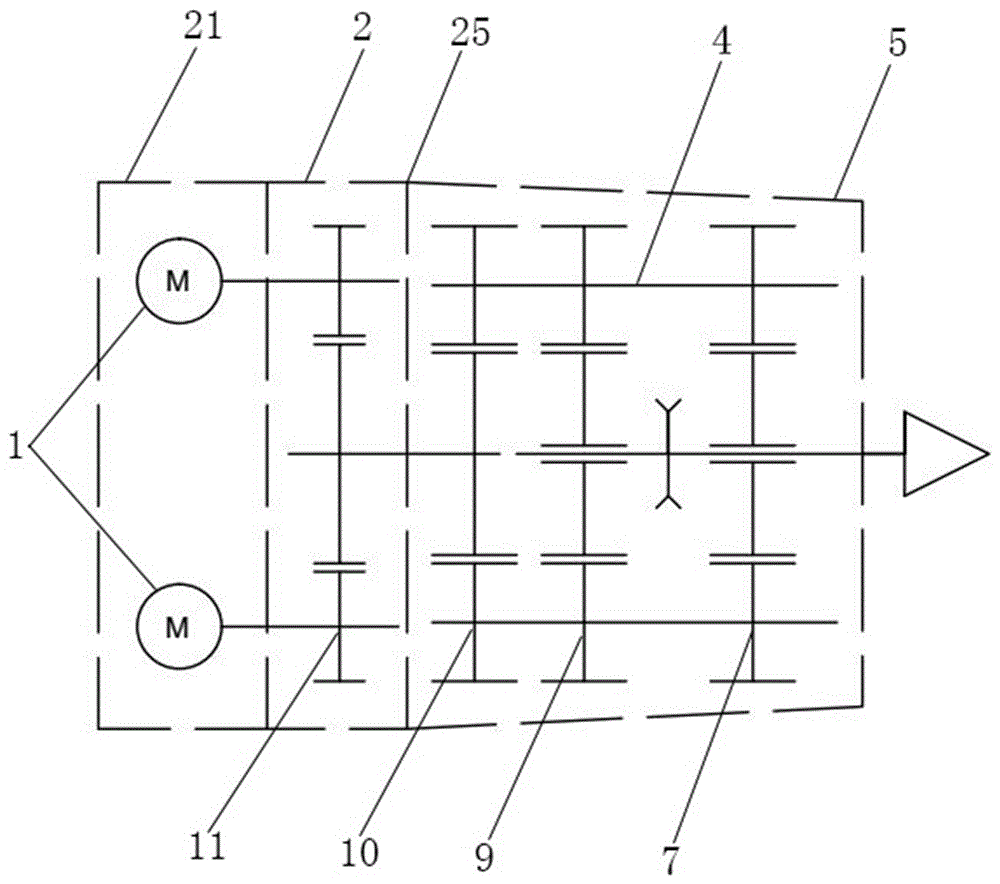

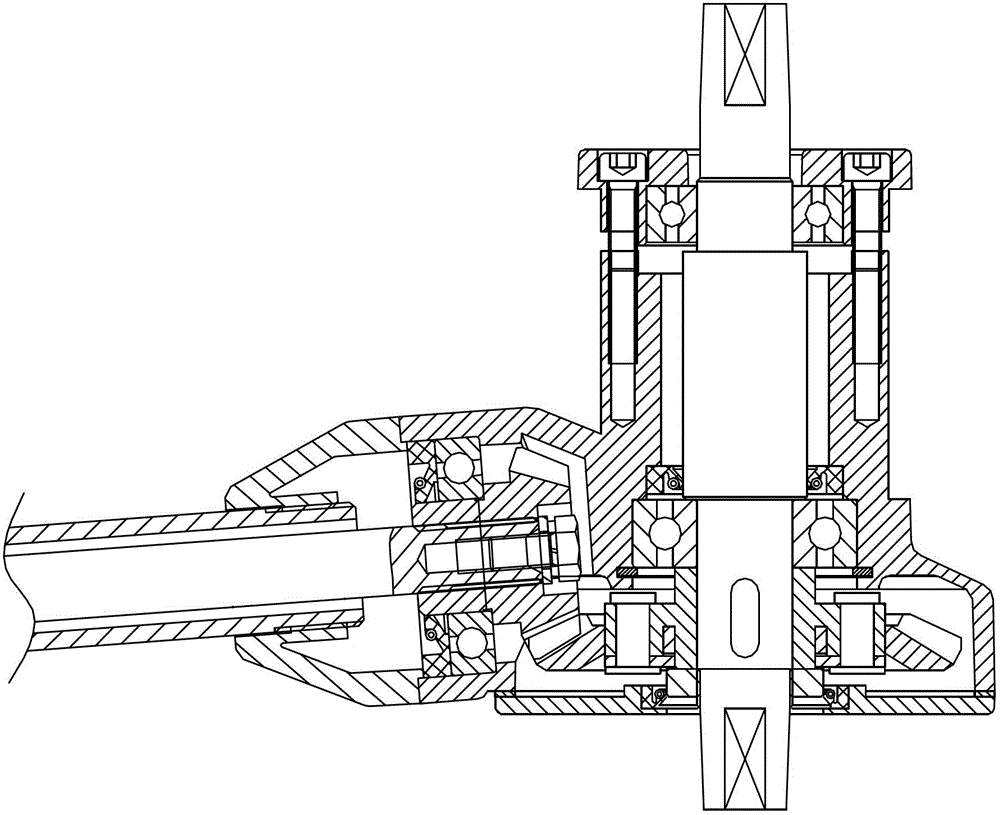

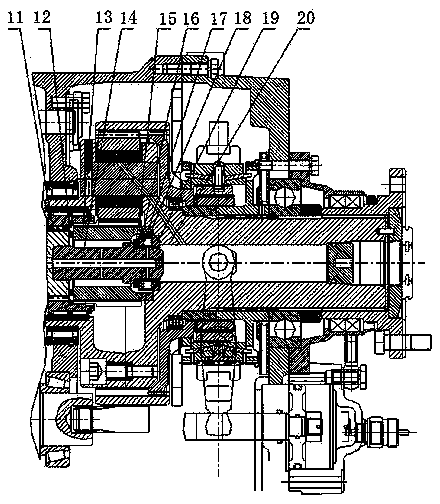

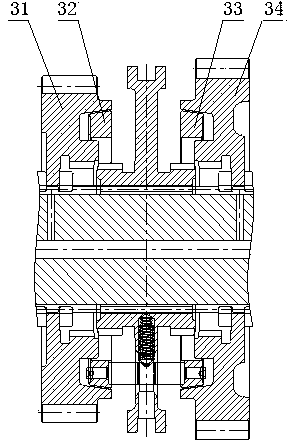

Washing machine and driving system thereof

ActiveCN107287829AImprove efficiencyHigh positioning accuracyOther washing machinesTextiles and paperLaundry washing machineClutch control

The invention relates to the field of washing machines and discloses a washing machine driving system and a washing machine with the same. A clutch mechanism of the driving system is axially positioned between a stator portion (40) and a rotor portion (50) of a motor component and can be driven by a clutch control mechanism to slide towards the stator portion (40) or the rotor portion (50) to make a first joint tooth portion (3) mesh with an upper tooth portion (51) or a second joint tooth portion (4) mesh with a lower tooth portion (52). Precision in positioning between the rotor portion (50) and the stator portion (40) is improved, an rotor-stator air gap can be reduced reasonably, efficiency of the motor component is improved, and simplification of a mounting structure and matching design is facilitated due to joint manufacturing of the clutch mechanism and the motor component.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

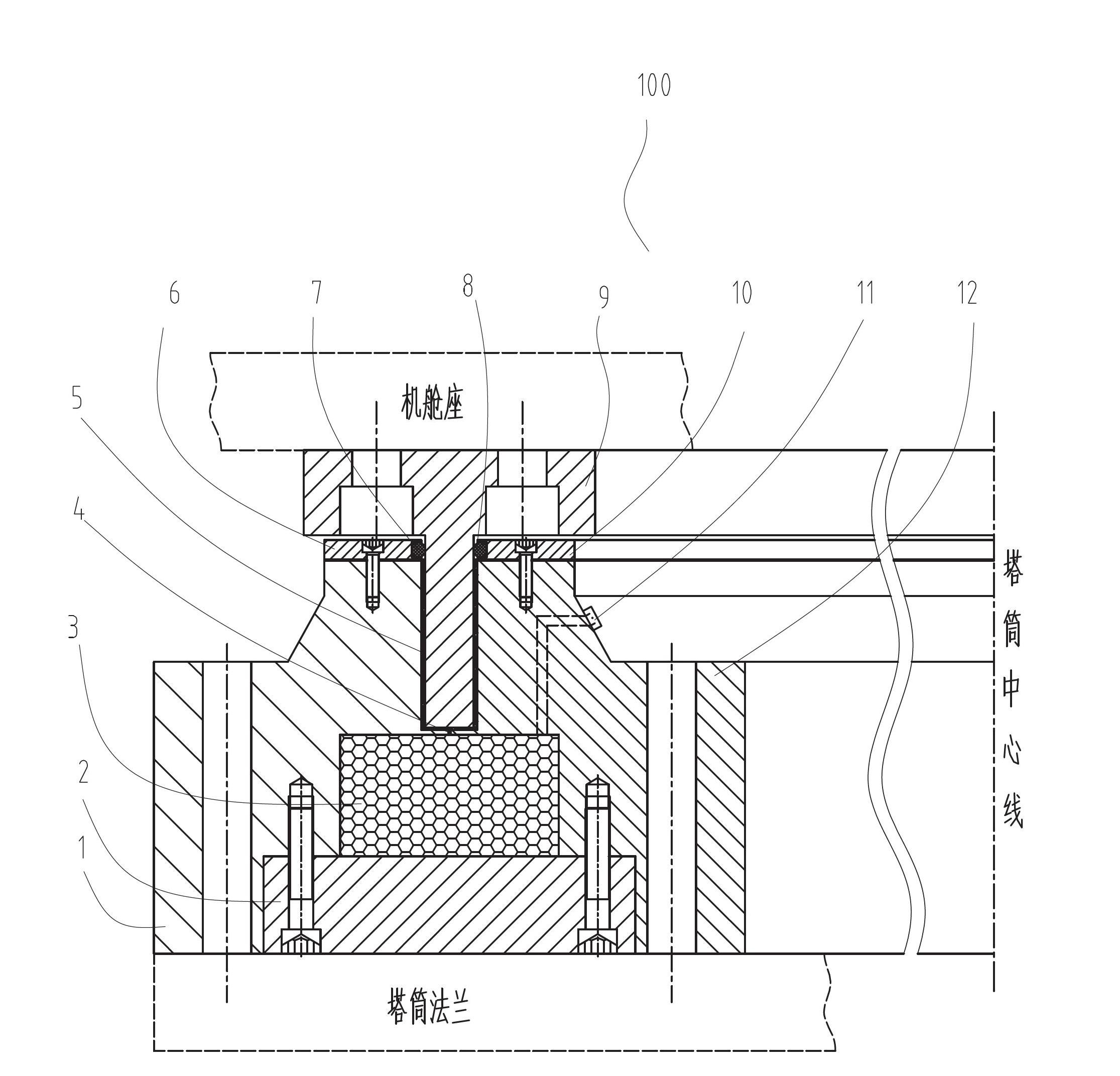

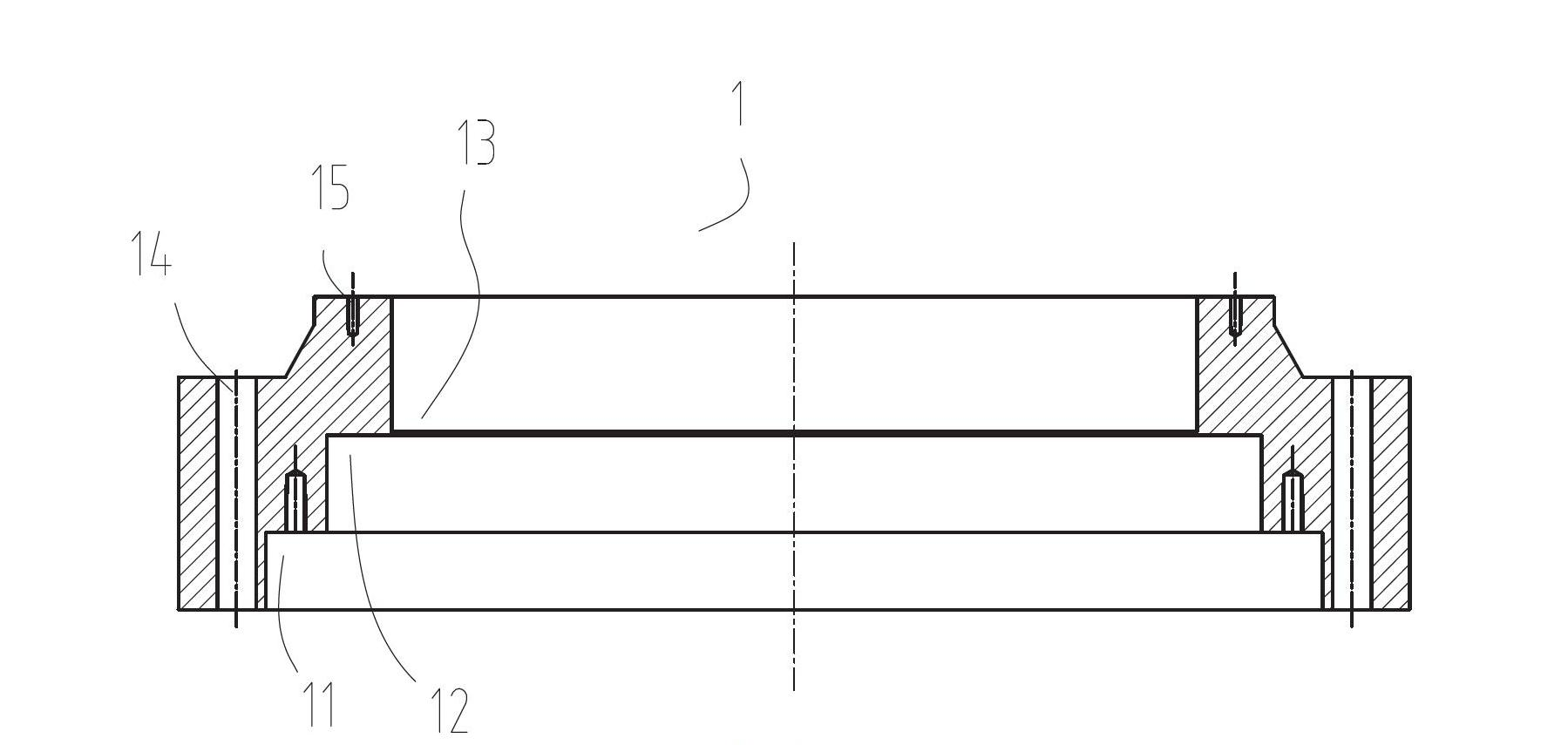

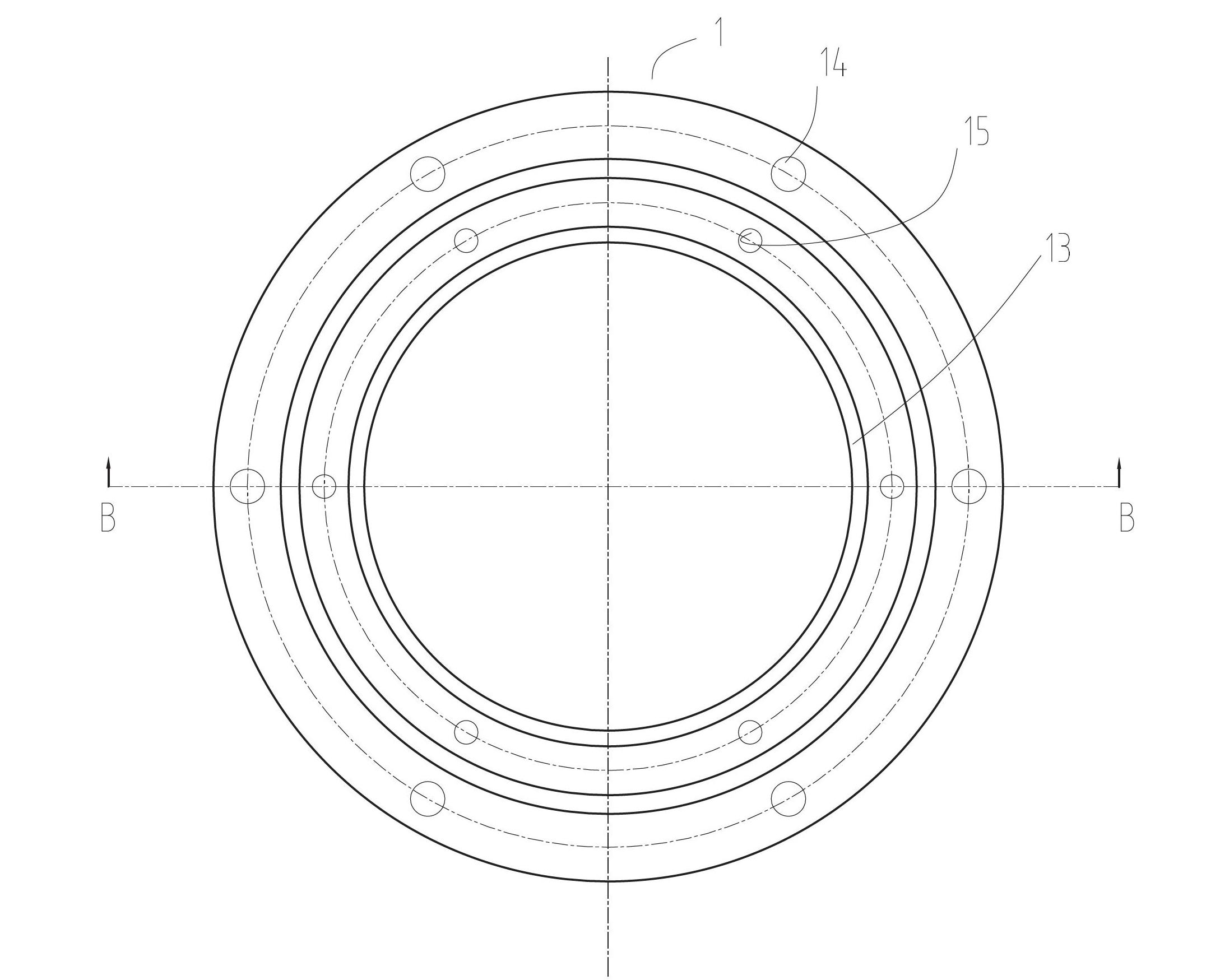

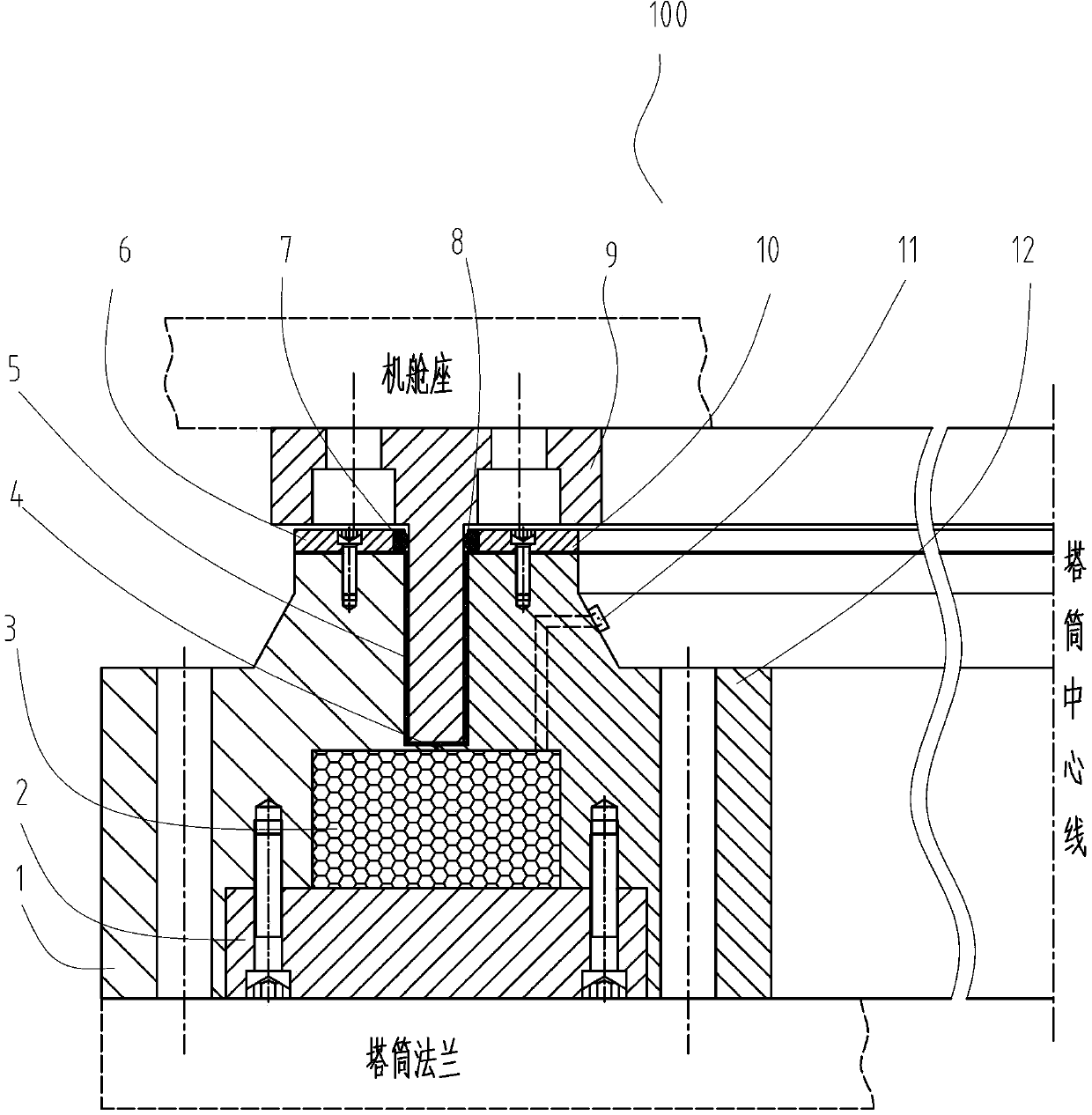

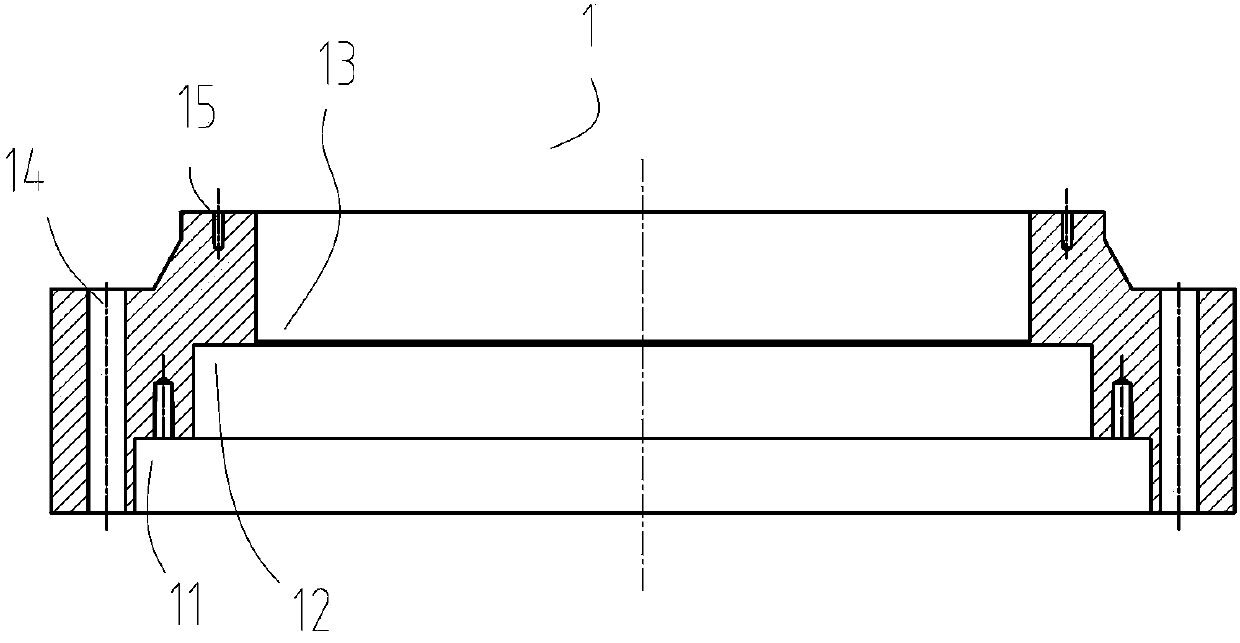

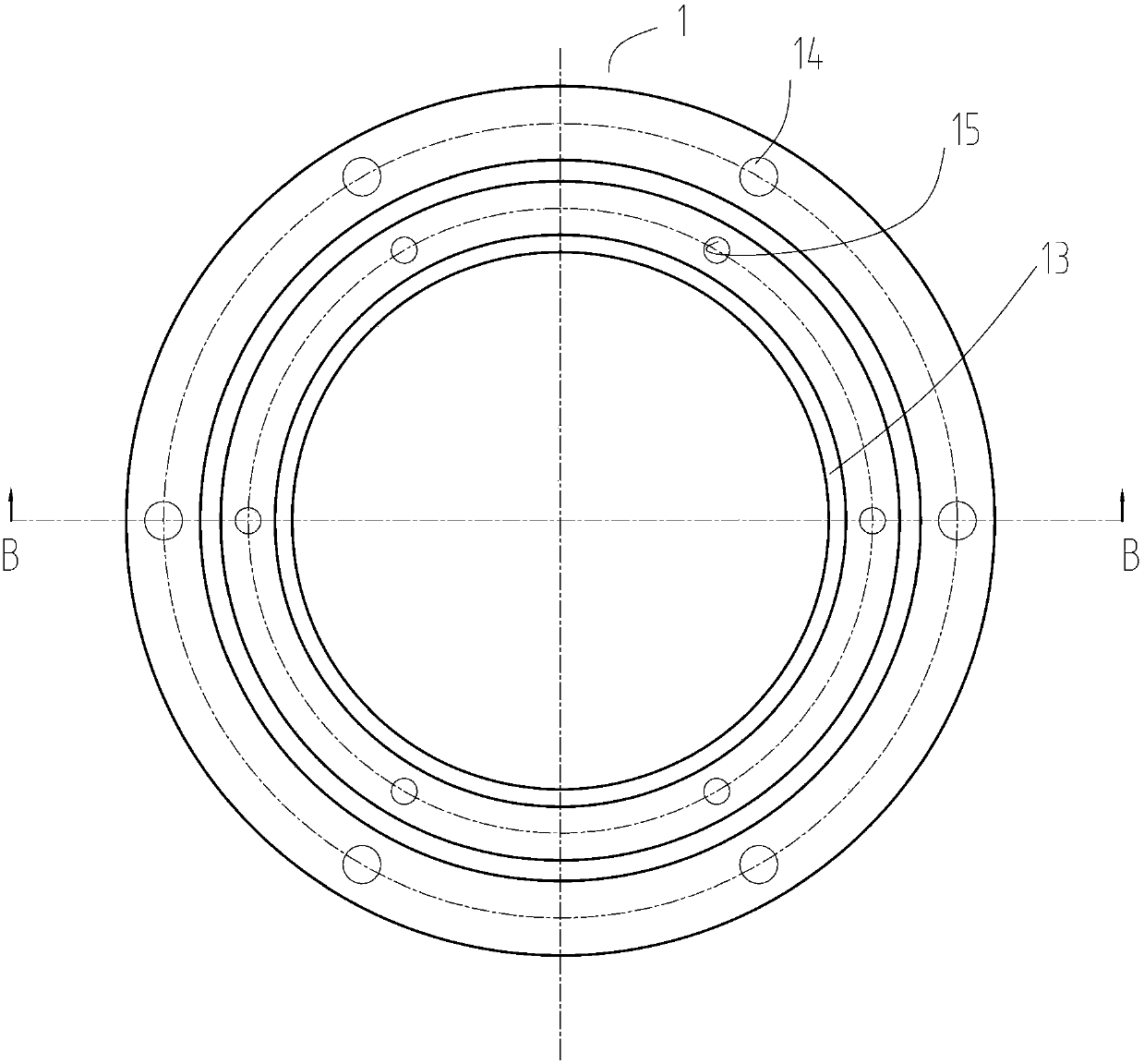

Wind power generator set and yawing-braking magnetic thixotropic flexible braking device of wind power generator set

ActiveCN102661245ARealize uninterrupted continuous flexible braking functionContinuous momentLiquid resistance brakesWind motor controlElectricityNacelle

The invention discloses a wind power generator set and a yawing-braking magnetic thixotropic flexible braking device of the wind power generator set. The braking device comprises an outer ring, an inner ring, a magnetic yoke, a coil winding, a braking wheel and a magnetic thixotropic adhesive, wherein the outer ring and the inner ring are connected with each other through the magnetic yoke and can be fixed on a tower flange of the wind power generator set; the braking wheel comprises a fixed part and a braking part and can be fixed on a cabin seat; the outer ring and the inner ring are connected to form a braking slot for accommodating the braking part of the braking wheel and a coil winding slot for accommodating the coil winding; the braking part of the braking wheel is arranged in the braking slot in a rotatable manner, and a clearance is formed between the braking part and each of the inner ring and the outer ring; and the magnetic thixotropic adhesive is accommodated in the clearances. According to the braking device, abrasion and spot corrosion of wheel teeth of a yawing driving system are effectively reduced, the braking noise and the vibration during yawing braking are reduced, the service life of a gear box is effectively prolonged, and the running cost of a fan is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

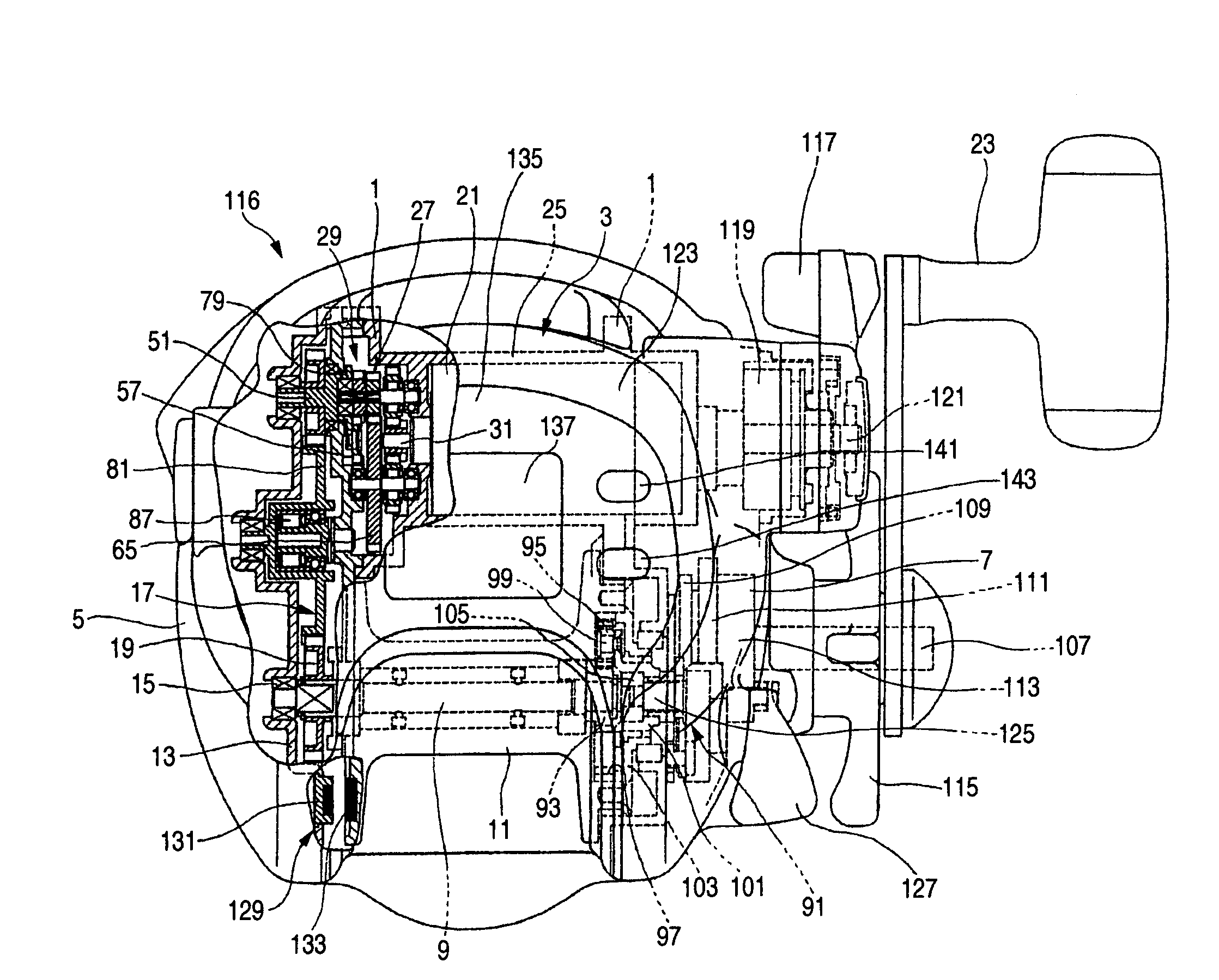

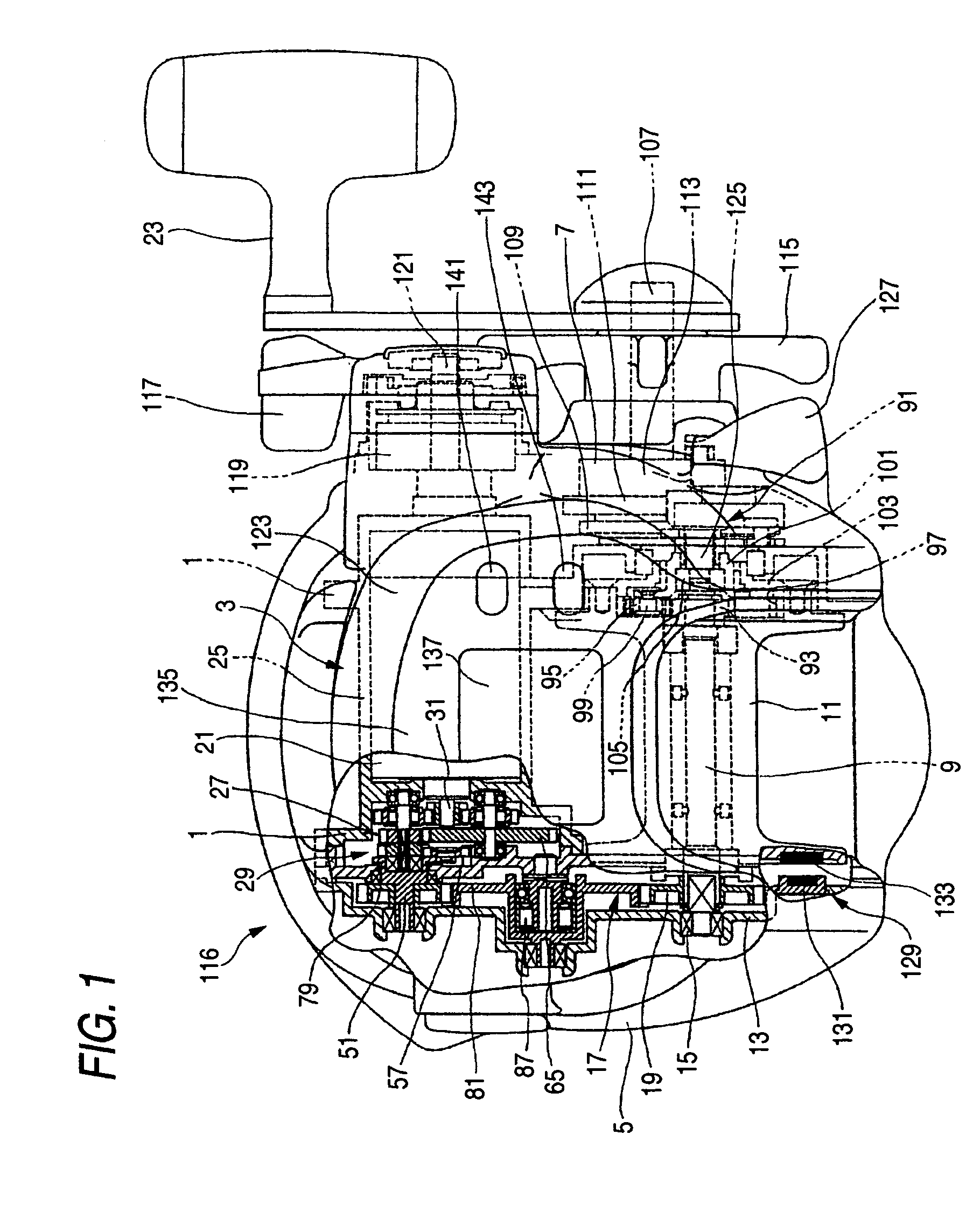

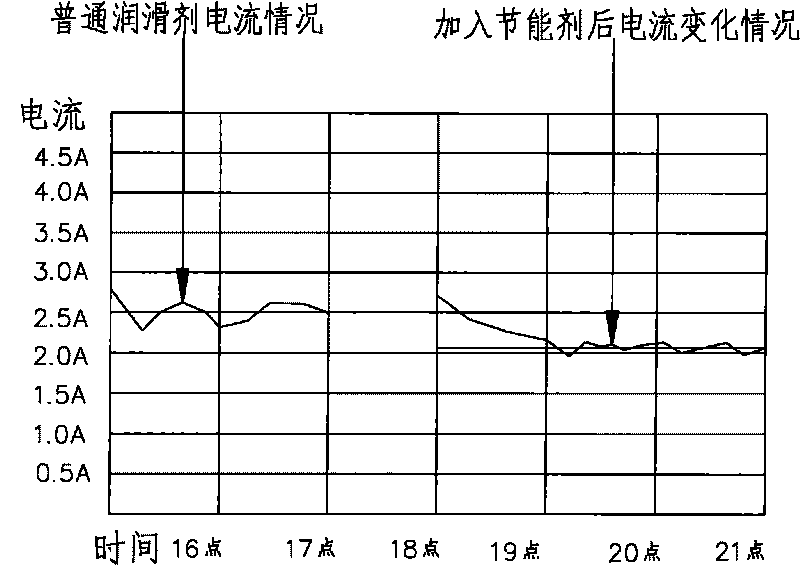

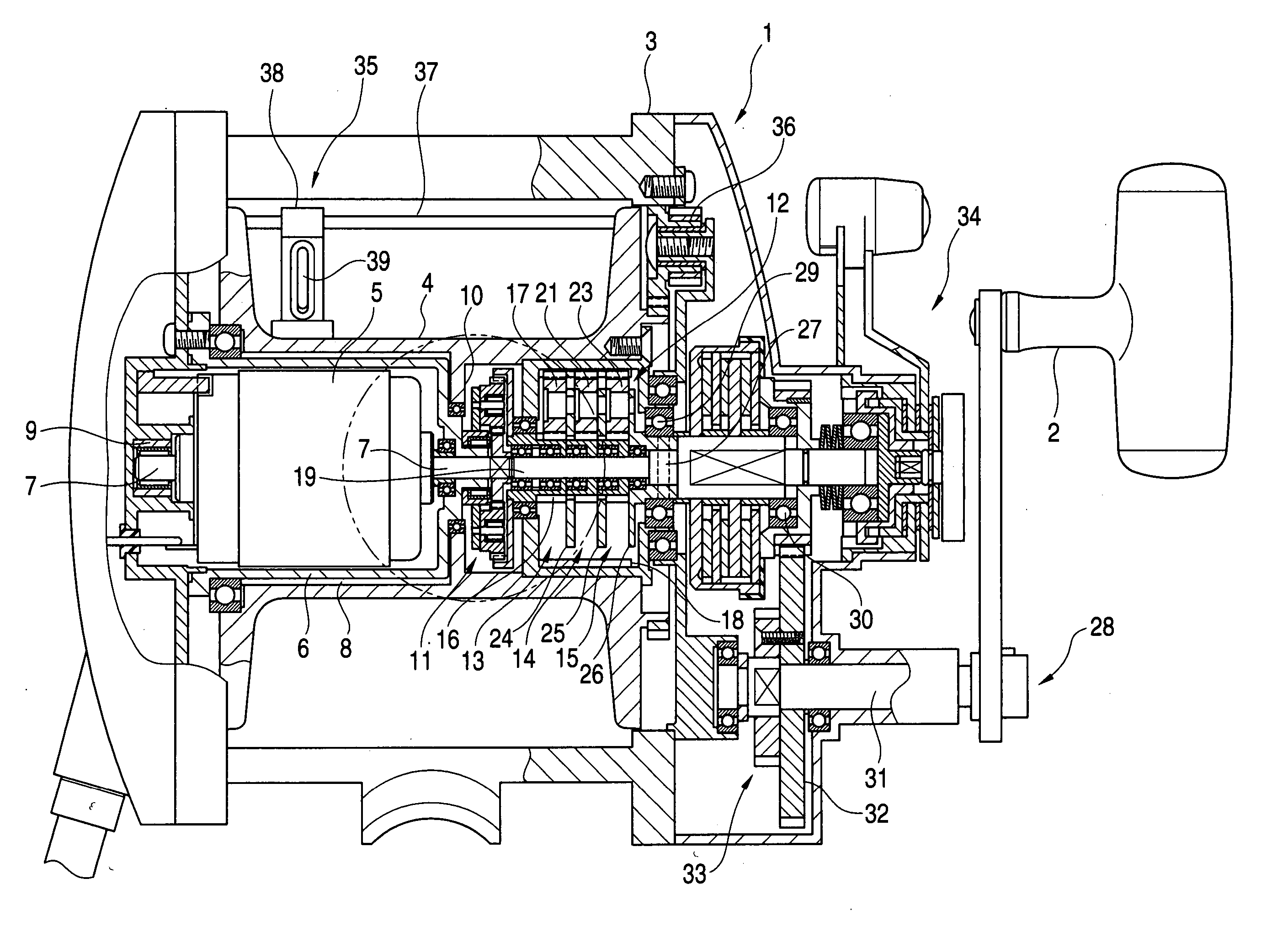

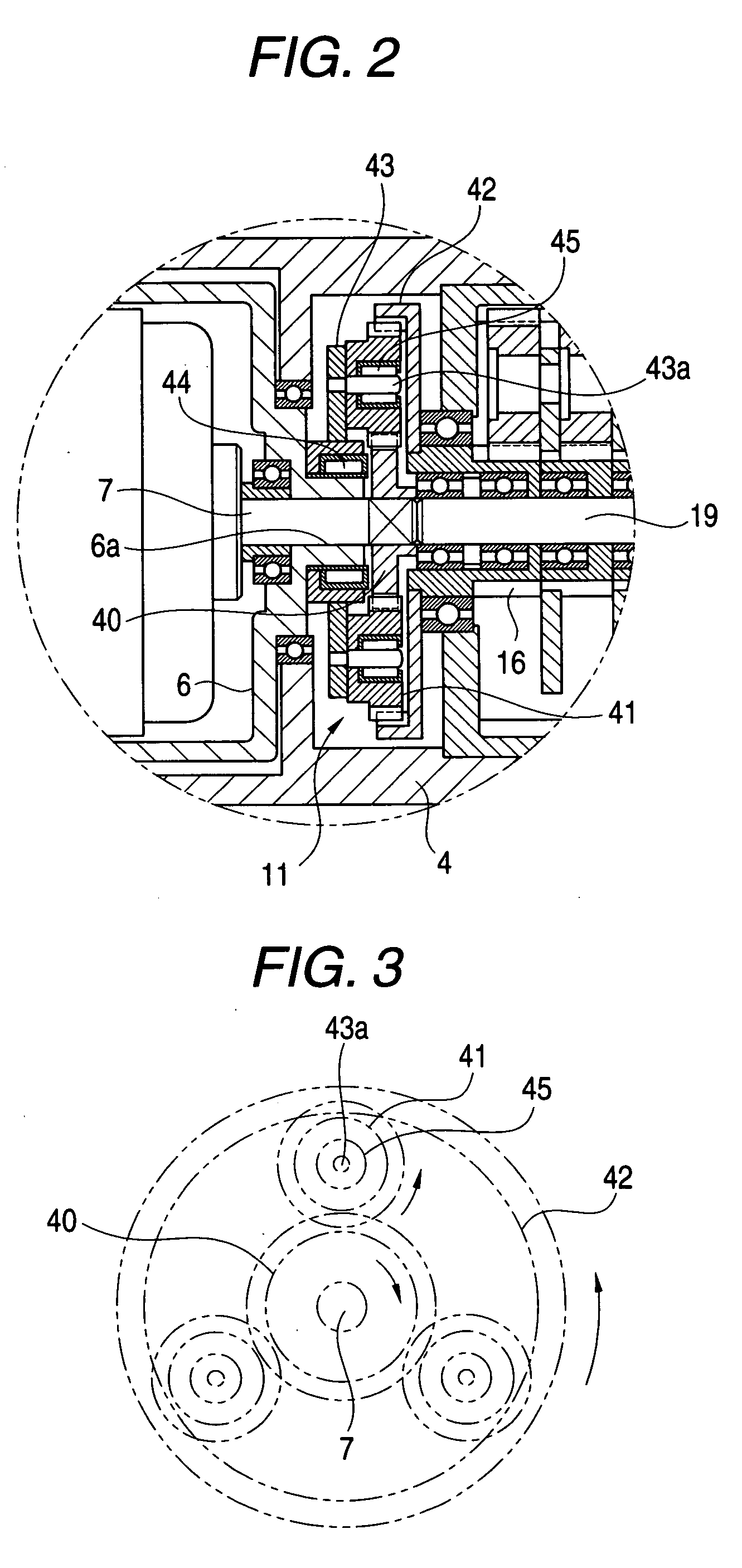

Electric-powered fishing reel

An electrically-powered fishing reel includes a drive motor which rotationally drives a spool, and a speed change unit connected between an output section of the drive motor and a power transmission mechanism which transmits a rotation of the output section to the spool, and provided with a high-speed-driving gear transmission mechanism and a low-speed-driving gear transmission mechanism, and the electrically-powered fishing reel is operative to select, according to the rotating direction of the drive motor, either one of the high-speed-driving gear transmission mechanism or the low-speed-driving gear transmission mechanism and vary the rotational speed of the spool. A high-speed-driving output gear of the high-speed-driving gear transmission mechanism is connected to a power transmission mechanism for the spool without a low-speed-driving output gear of the low-speed-driving gear transmission mechanism being inserted between the high-speed-driving output gear and the power transmission mechanism.

Owner:DAIWA SEIKO CORPORATION

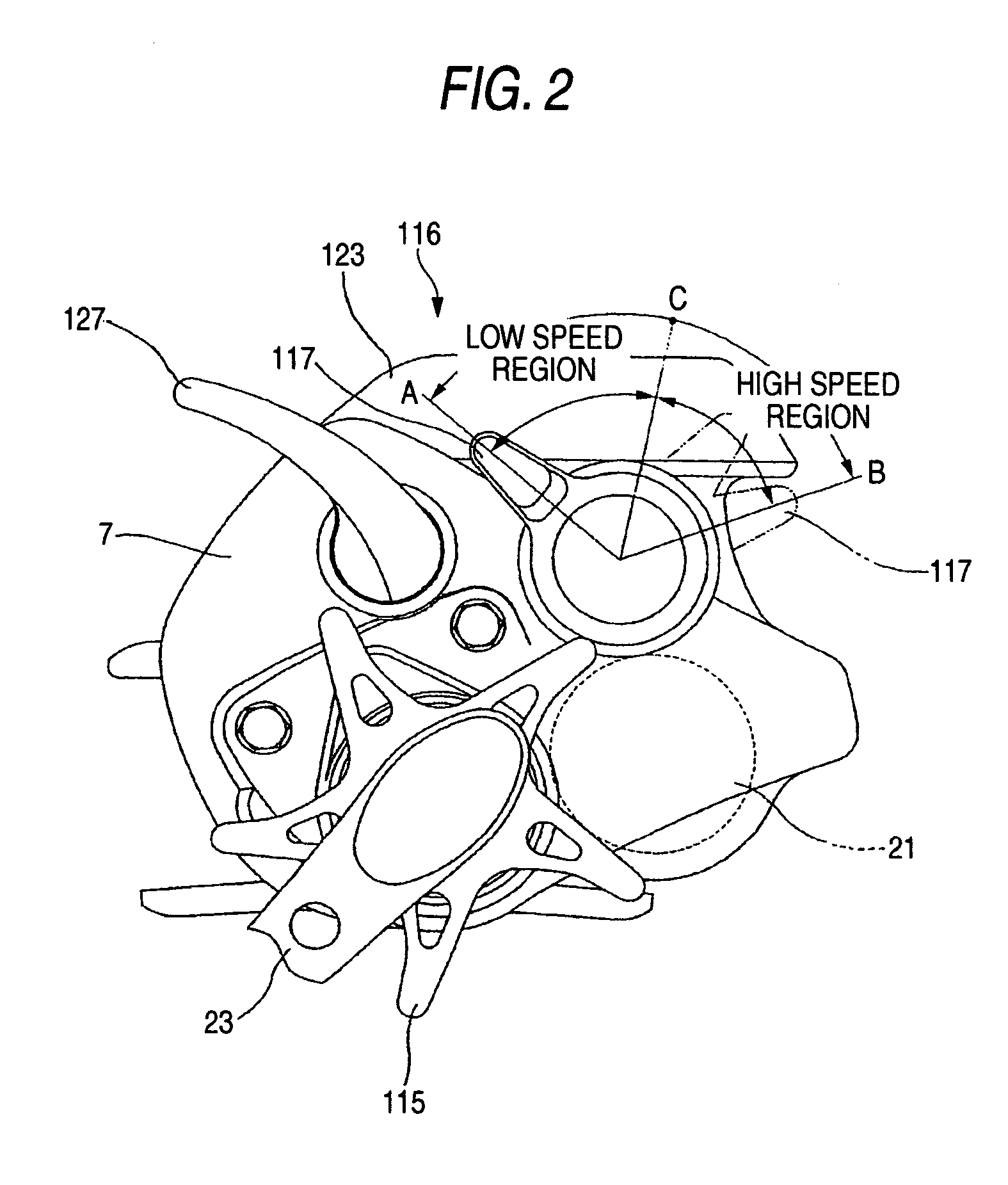

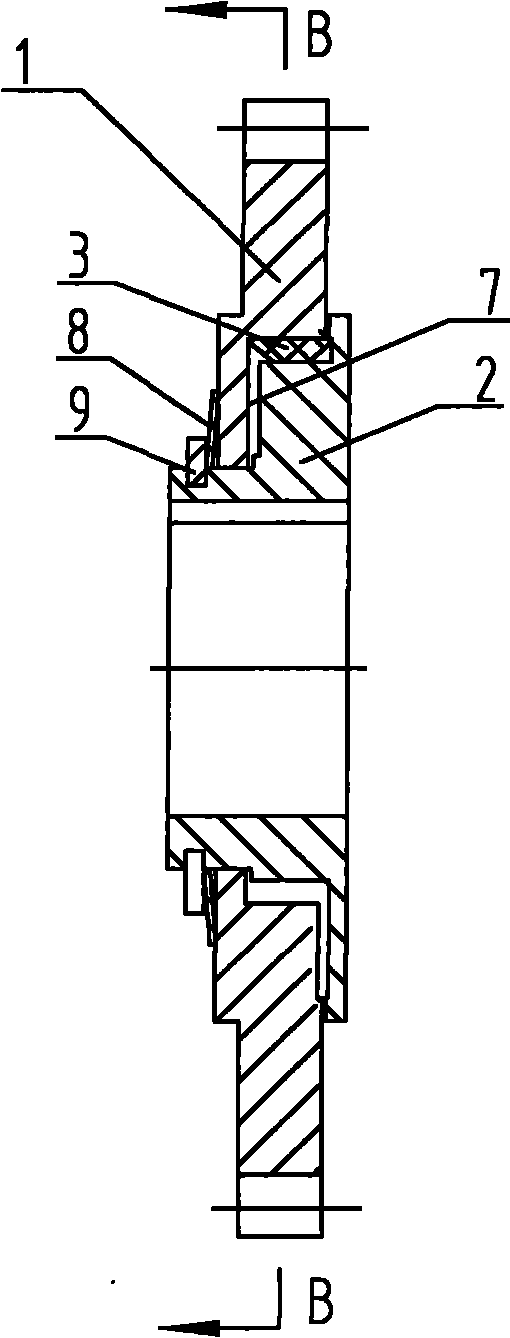

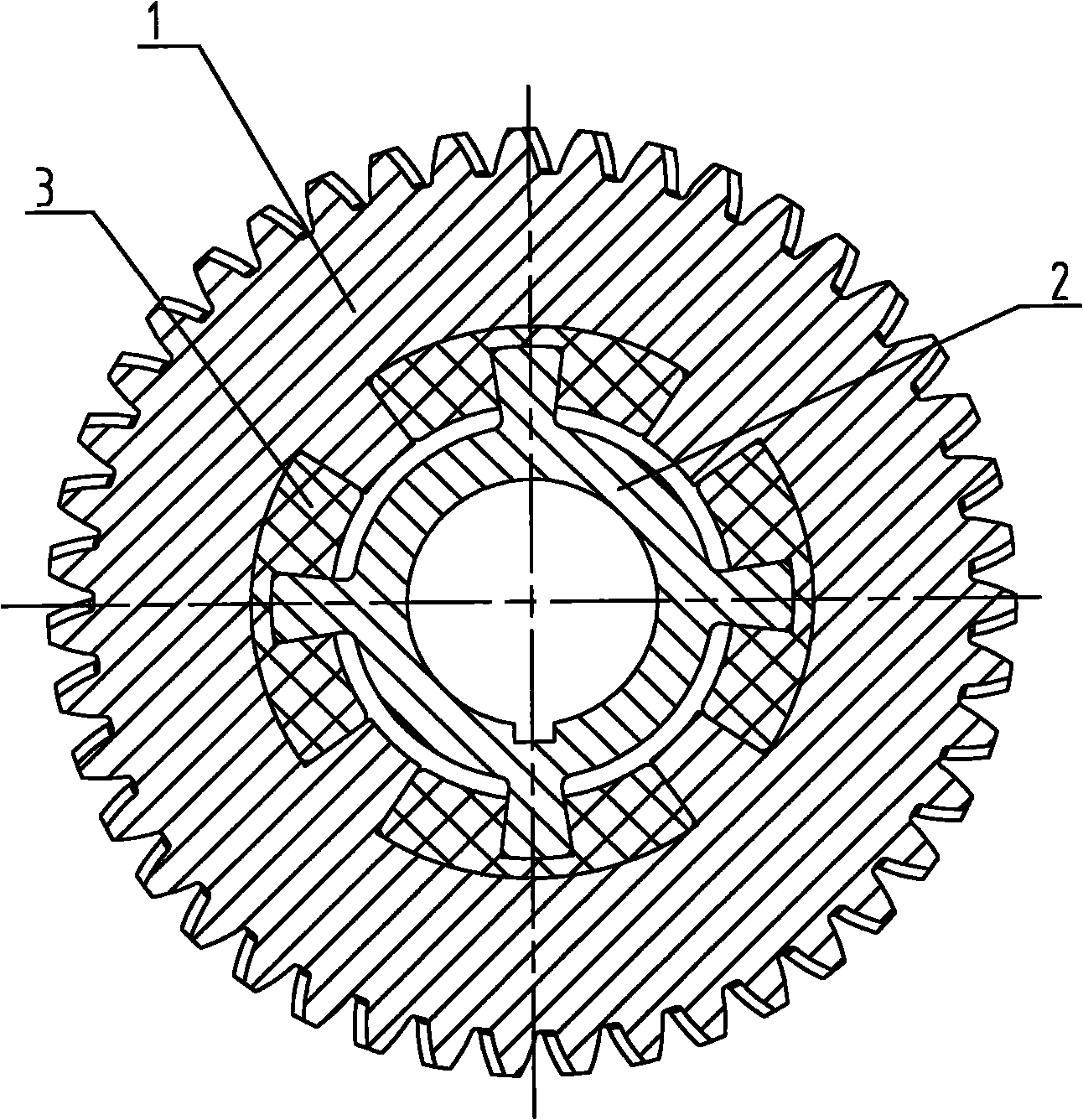

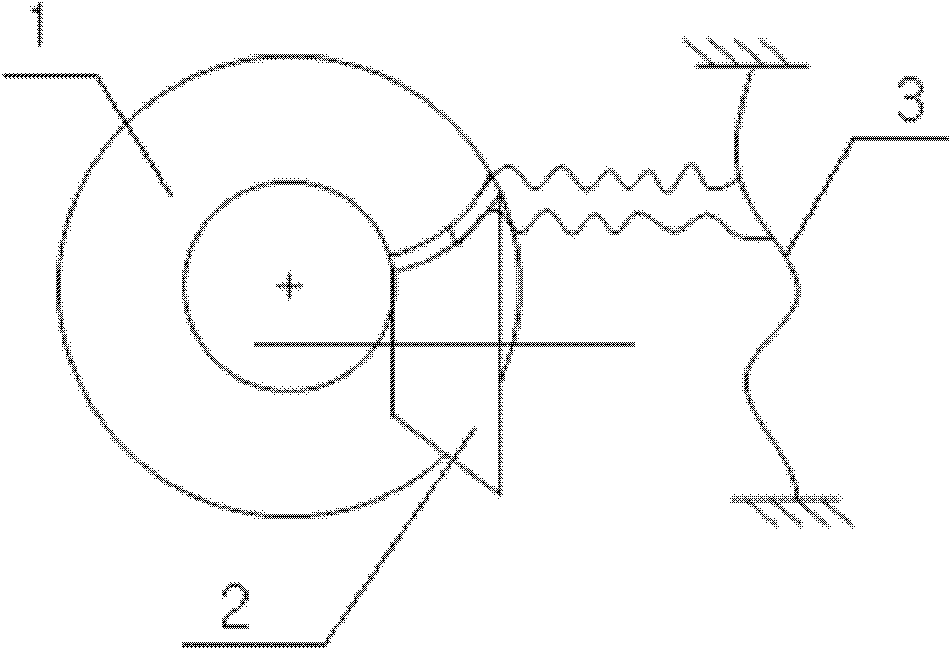

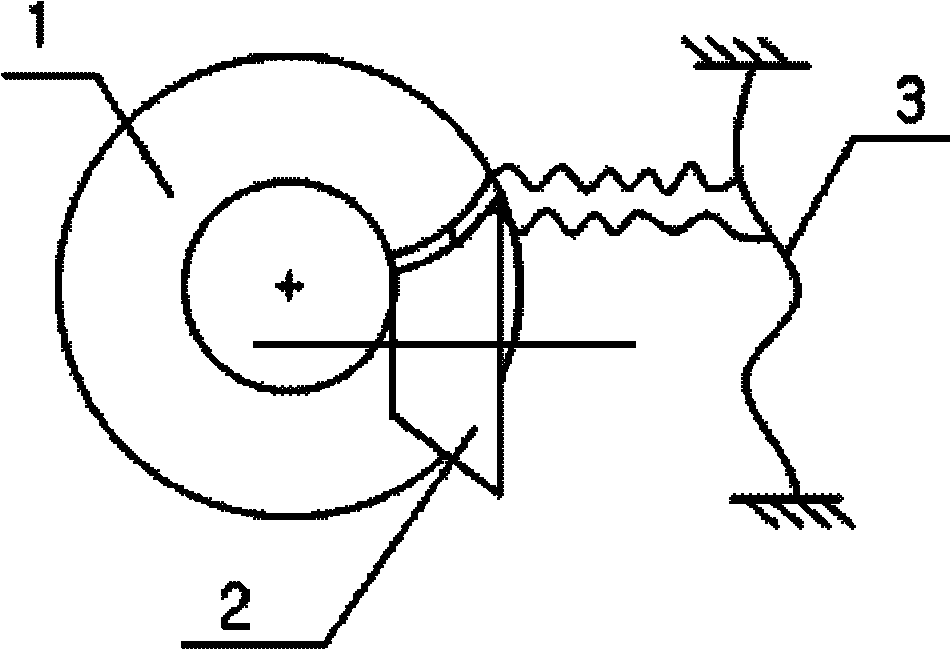

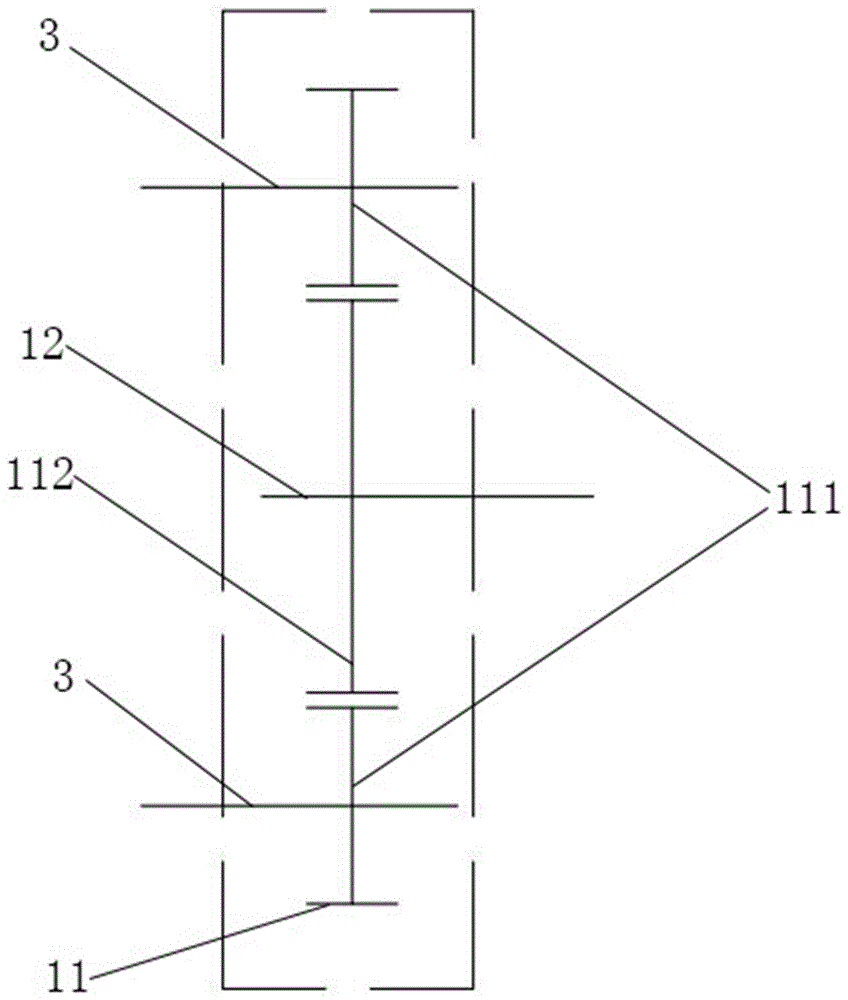

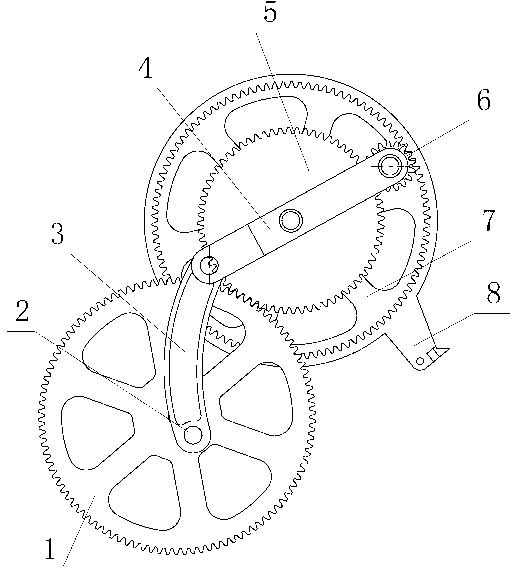

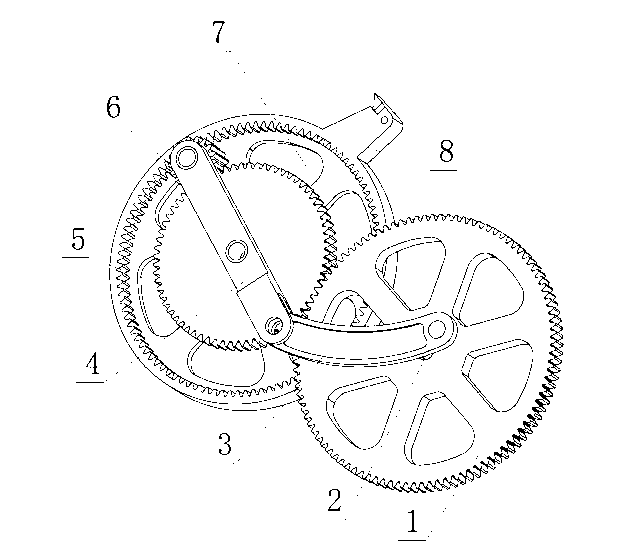

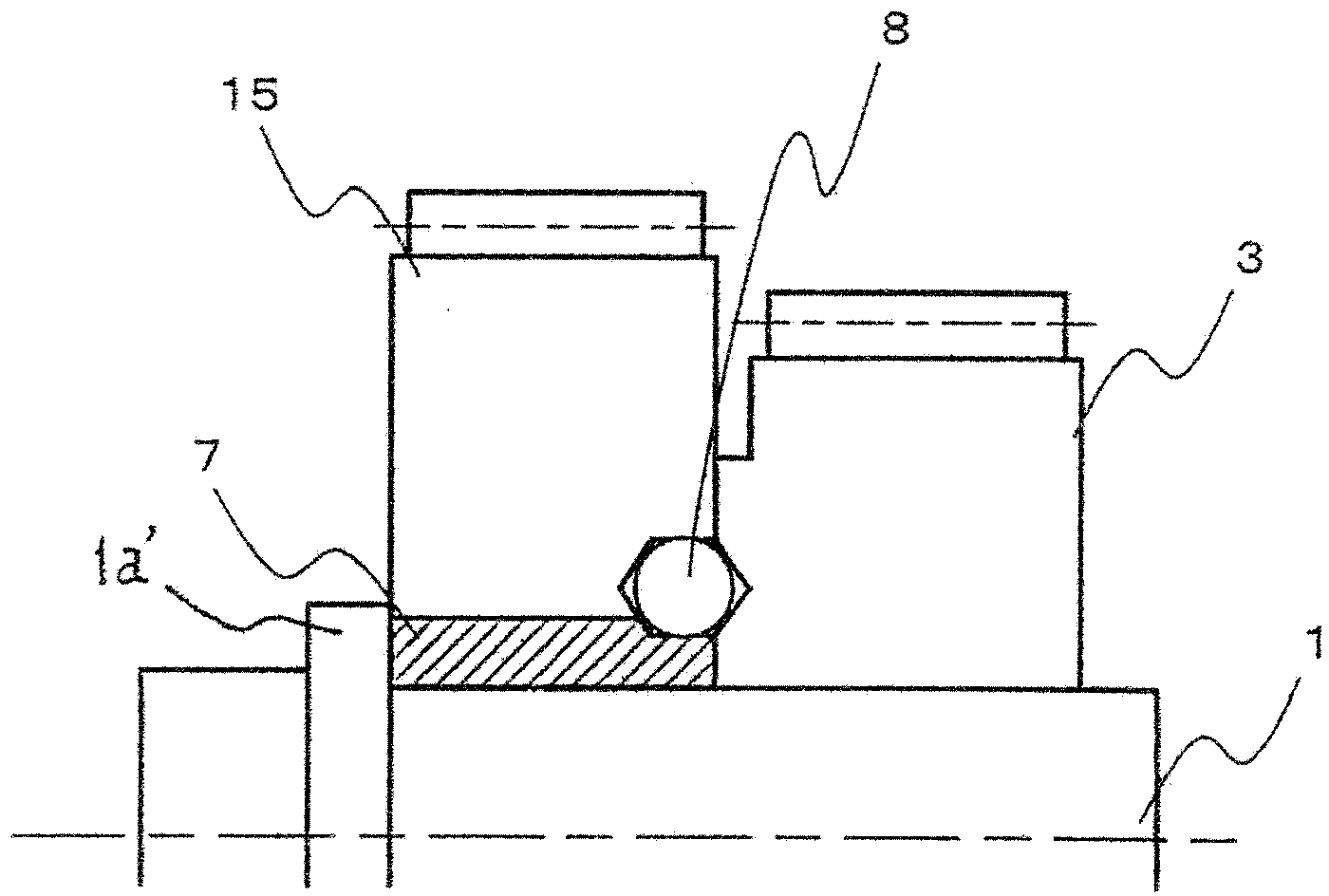

Driven gear of engine balance shaft

InactiveCN101893081AReduce vibrationReduce meshing noisePortable liftingGearing elementsEngineeringEngine balance

The invention provides a driven gear of an engine balance shaft, comprising an outer ring gear (1) and an inner ring wheel disc (2). The outer ring gear (1) is assembled on the inner ring wheel disc (2), a spline-like gap assembly structure is arranged between the outer ring gear (1) and the inner ring wheel disc (2), a rubber block (3) is arranged between adjacent spline teeth of the outer ring gear (1) and the inner ring wheel disc (2), and teeth engaged with a drive gear of a balance shaft arranged on the outer ring gear (1) are skewed teeth. By using the technical scheme, the invention can effectively reduce the vibration of an engine and decrease engagement noise between the drive gear and the driven gear of the balance shaft.

Owner:CHONGQING LONCIN MOTOR

Streetcar gear transmission device

ActiveCN104500700AOmit designSimplify the transmission processGearboxesGear lubrication/coolingGear wheelLubrication

The invention discloses a streetcar gear transmission device for a low-floor streetcar. The streetcar gear transmission device comprises an upper box body, a lower box body, a driving bearing seat assembly and a driven bearing seat assembly, wherein the upper box body is also provided with an oil inlet window, an oil collecting cavity, an oil discharging oil passage and a small oil window, the top of the upper box body is provided with a cover plate, the cover plate covers above a top opening of the oil collecting cavity, the driving gear seat assembly also comprises an oil baffle ring, a sealing ring, a small sealing cover, a first separation sleeve and a second separation sleeve, the driven bearing assembly also comprises a large sealing cover, a first oil seal, a second oil seal and a positioning sleeve, a driven gear is in interference connection onto a driven bearing seat, one end of the driven bearing seat is provided with a driving end surface fluted disc, a matched hole and a first positioning pin hole, the outer periphery of the driven bearing seat is provided with a first step and a second step, the other end of the driven bearing seat is provided with an operation hole and a first screw bolt hole, the matching hole and the operation hole are communicated through a center hole, and an upper end hanging element and a lower end hanging element are arranged on the upper box body. The streetcar gear transmission device has the advantages that the structure is simple and compact, the lubrication sealing effect is good, and the oil level can be conveniently observed.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Gear honing method and device

The invention relates to a gear honing method and device, belonging to the technical field of a gear processing method and gear processing mechanical equipment. The gear honing method comprises the following steps: (1) clamping two gear workpieces to be mutually meshed on a first centre group and a second centre group with parallel axes so that the two gear workpieces are mutually meshed and certain pressing force is formed between the meshing surfaces of the two gears; (2) marking the initial meshing positions of mutual meshing on the two gear workpieces respectively; (3) driving one gear workpiece to rotate and move with the other gear workpiece in a meshed manner by the first centre group or the second centre group; and (4) after the two gear workpieces are subject to meshed movement for a period of time, removing the two gear workpieces for pair package or installation.

Owner:许晓华

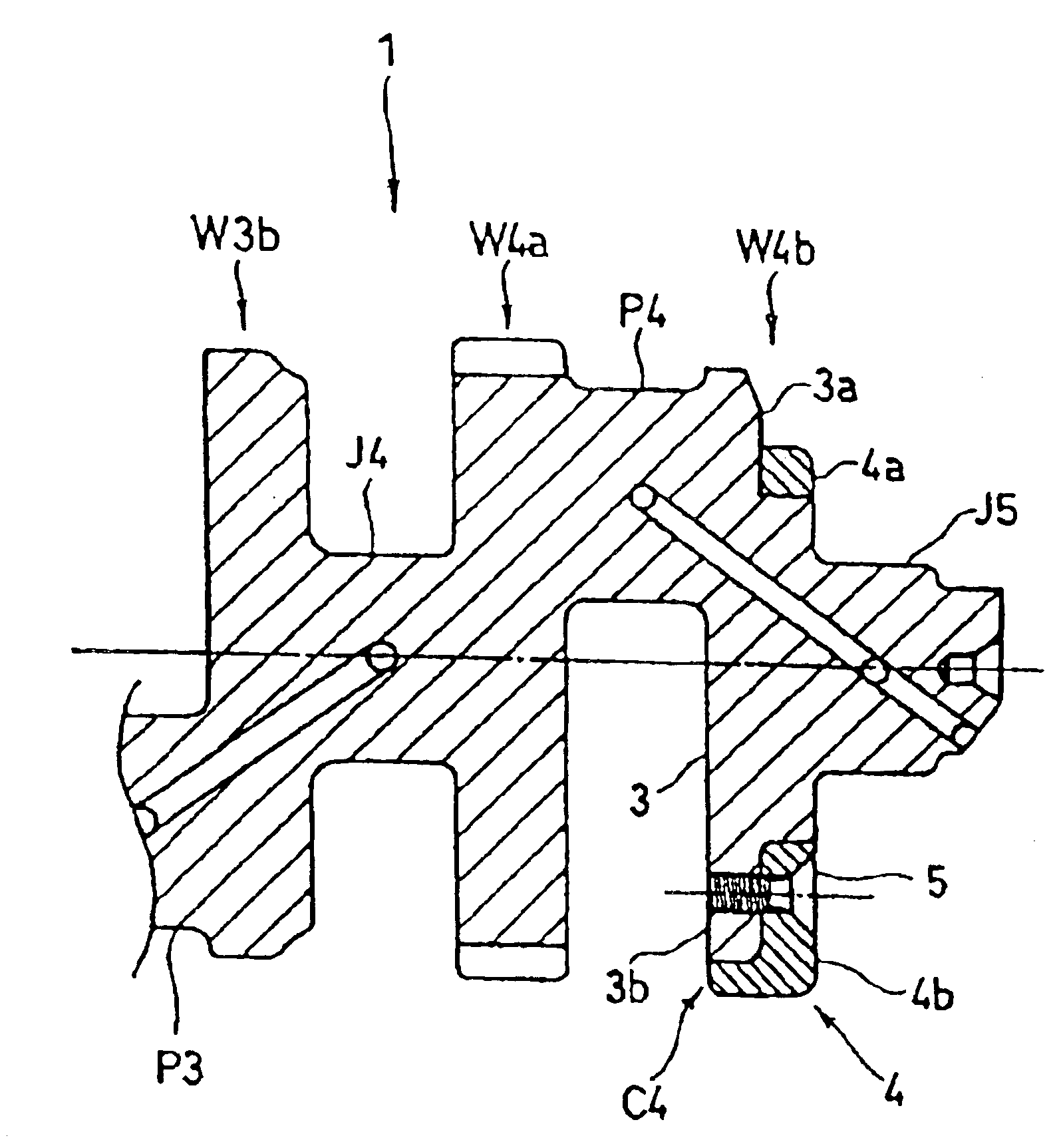

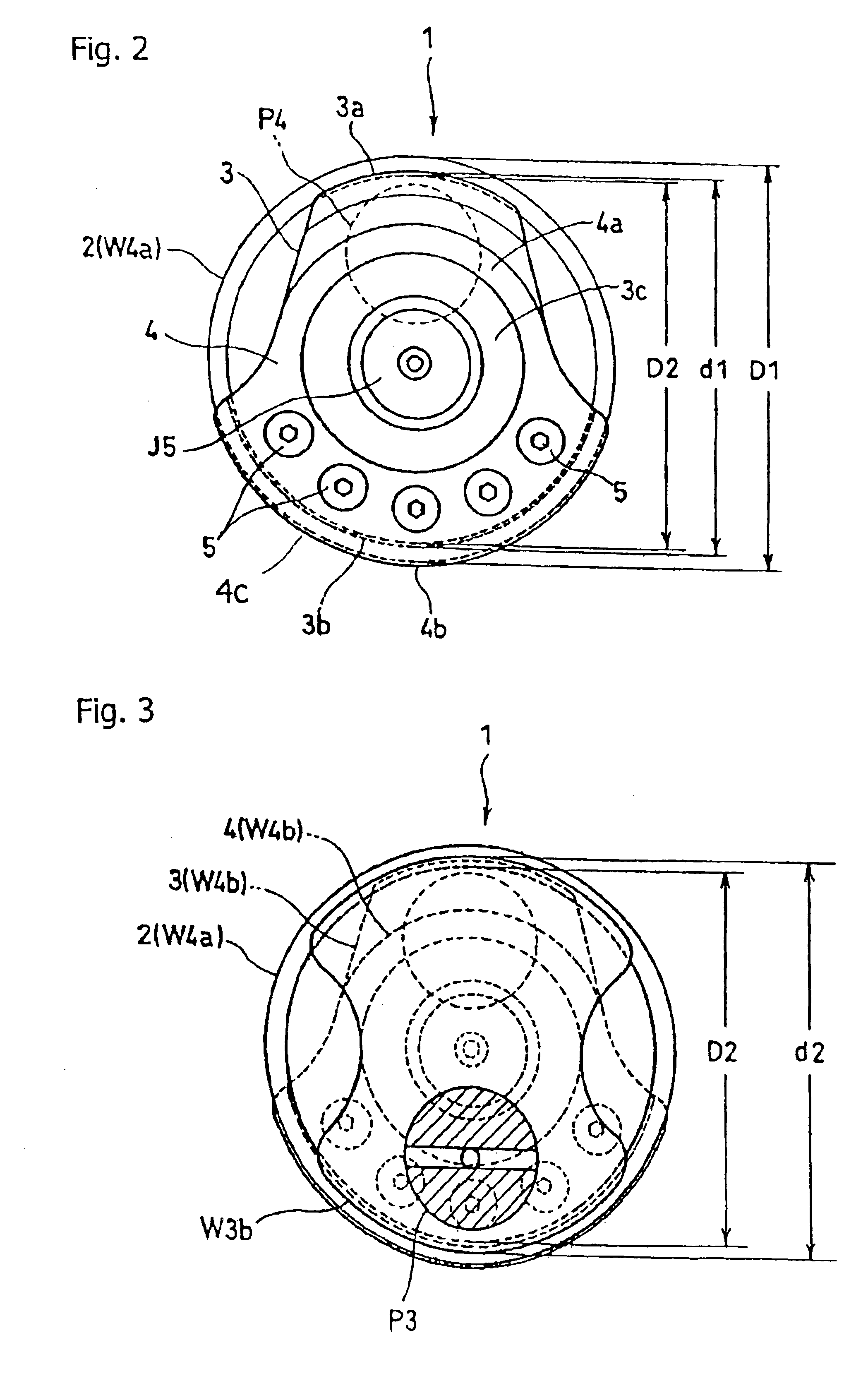

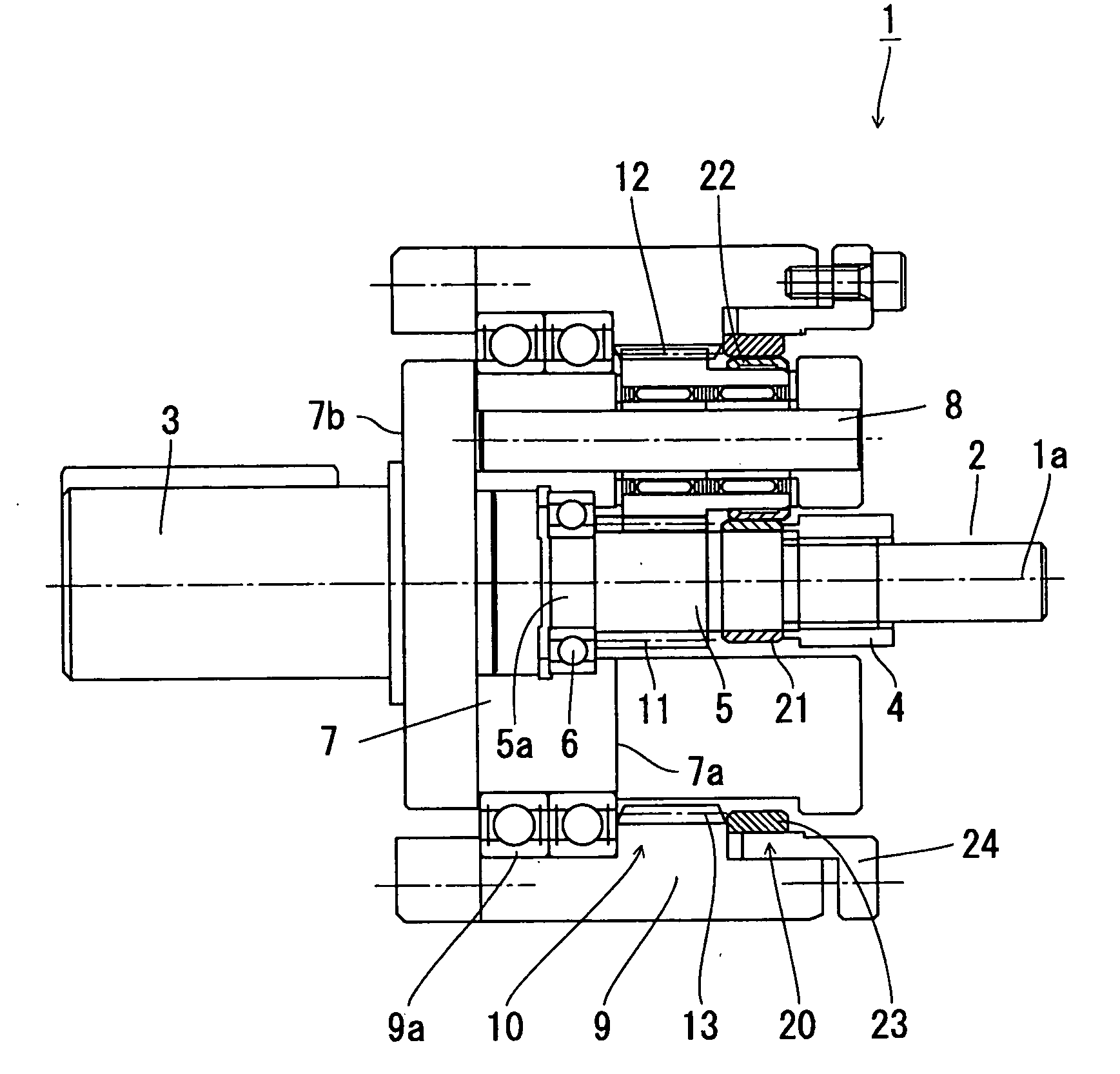

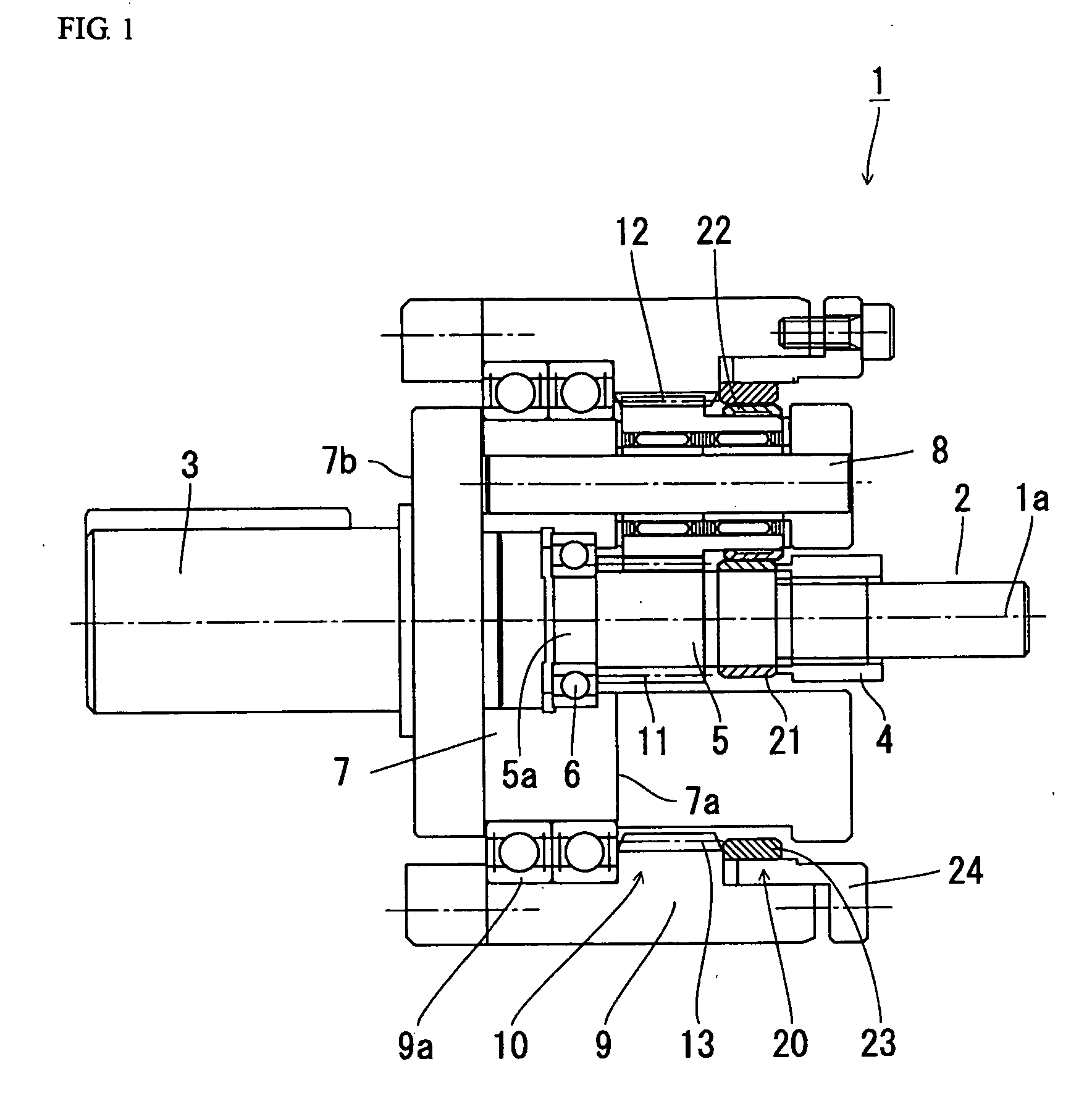

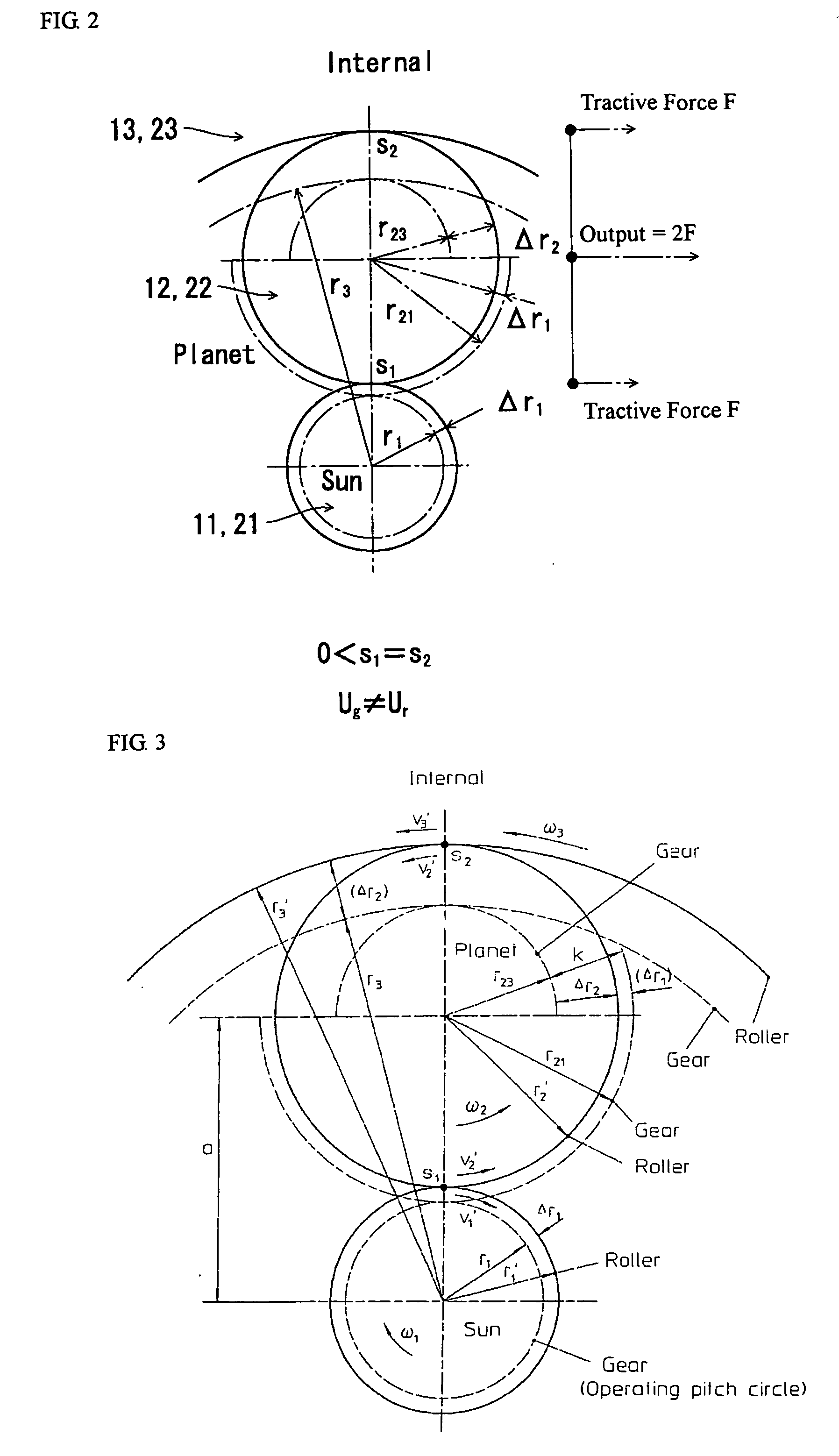

Composite planetary device

ActiveUS20060166781A1Increase output torqueReduce impactGear vibration/noise dampingToothed gearingsEngineeringSpur gear

A composite planetary speed reduction device (1), wherein gears (11), (12), and (13) and rollers (21), (22), and (23) forming a planetary gear speed reduction mechanism (10) and a planetary roller speed reduction mechanism (20) are integrally rotated around a common rotating center axis, respectively. The radius of the sun roller (21) is larger by Δr1 than the radius r1 of the working pitch circle of the sun gear (11), the radius r21 of the working pitch circle of the planetary gear (12) meshing with the sun gear (11) and the radius r23 of the working pitch circle of the planetary gear (12) meshing with an internal gear (13) are different from each other, and the radius of the planetary roller (22) is smaller by Δr1 than the radius r21 of the working pitch circle of the planetary gear (12). Thus, a slippage ratio s1 between the sun roller (21) and the planetary roller (22) and a slippage ratio s2 between the planetary roller (22) and the ring roller (23) are made equal to each other, and a large output torque can be provided from the planetary roller speed reduction mechanism (20).

Owner:HARMONIC DRIVE SYST IND CO LTD

Machining method for multi-gear

The invention discloses a processing method of a multi-link gear, which comprises the steps of blanking, forging heat treatment, turning processing, inner hole grinding, tooth processing, shot peening treatment, fine grinding of the tooth and the like. The processing method of this multi-link gear adopts the method of hole positioning, and realizes the matching installation and connection between the small gear and each large gear through positioning pins and set screws, so the coaxiality is effectively guaranteed, and better processing accuracy is achieved. , so as to achieve better meshing conditions for multiple gears and reduce meshing noise; because welding is not used for connection, welding deformation and welding internal stress can be avoided; because shot peening is carried out before fine grinding, it can eliminate The mechanical internal stress of the rough machining of the teeth, thereby prolonging the service life of the multiple gears.

Owner:燕凌飞

Conductive film, display device equipped with same, and method for determining pattern of conductive film

ActiveUS9791712B2Reduced sensationImprovement in moire visibilityConductive layers on insulating-supportsCircuit optical detailsDisplay deviceEngineering

Owner:FUJIFILM CORP

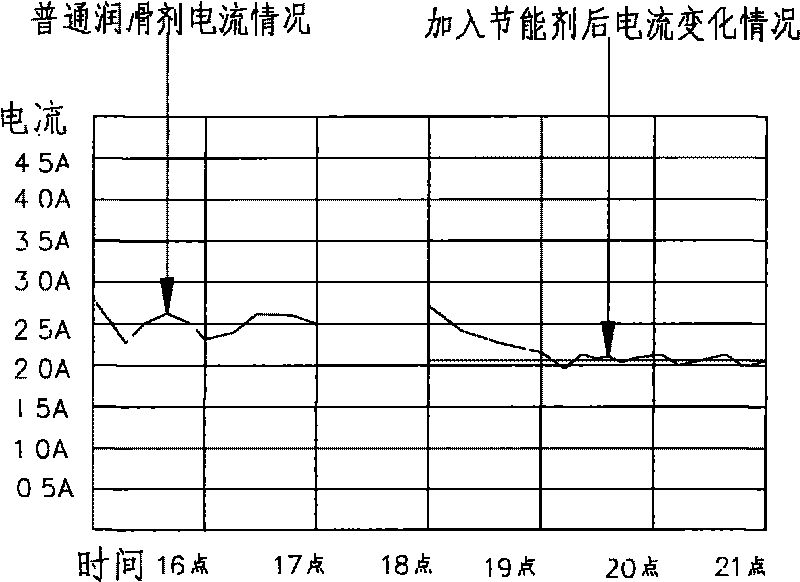

Energy-saving agent special for gear of textile machine and preparation method thereof

InactiveCN101760290AHas a repairing effectReduced meshing noiseAdditivesPolyvinyl alcoholAntioxidant

The invention relates to an energy-saving agent special for gear of textile machine and a preparation method thereof. The energy-saving agent comprises nanometer copper powder, base oil or lubricating oil, nanometer copper powder dispersing agent, lubricating oils antioxidant, polyving akohol solution or chitosan ramification solution. The preparation method comprises the steps of: mixing the nanometer copper powder, the nanometer copper powder dispersing agent with the polyving akohol solution or the chitosan ramification solution; dispersing in a stirring way for at least 2h with the rotation speed of 4500-6000r / min at 38-50 DEG C; adding the lubricating oil antioxidant to perform ultrasound compulsory dispersing; and adding the base oil or the lubricating oil, and stirring while raising the temperature for 1-2h. The product has good stability; has the performance characteristics of good abrasion resistance, demulsibility, oxidation resistance, rust resistance, reducing the running noise when meshing the gear, and prolonging the service life of the gear, and the like; can repair the coarse metal surface of gear; has the long period of the lubrication function on the gear of the textile machine; and has obvious oil-saving and energy-saving effect.

Owner:郑州宏大纺纱新技术咨询有限公司

Electric fishing reel

An electric fishing reel which is provided with a speed change mechanism excellent in silence and durability while realizing the size reduction. The electric fishing reel comprises: a drive motor for rotationally driving a spool rotatably supported on a reel body; a speed change mechanism rotatably mounted on a motor spindle and including an output gear having a rotational speed switched into a high speed or a low speed in accordance with the rotational direction of the motor spindle; and a power transmission mechanism for transmitting the rotation of the output gear to the spool. The speed change mechanism switches the rotational speed of the output gear by regulating the transmission of the rotation of the motor spindle with respect to the output gear.

Owner:DAIWA SEIKO CORPORATION

Worm-gear speed-reducing wire-feeding motor equipment as well as wire feeding device provided with same and welding system provided with same

ActiveCN102075030AReduce weightExtend your lifeArc welding apparatusMechanical energy handlingWelding power supplyElectric machinery

The invention relates to worm-gear speed-reducing wire-feeding motor equipment as well as a wire feeding device provided with the same and a welding system provided with the same. The wire-feeding motor equipment comprises a motor, a power output shaft and a speed-reducing transmission device connected between the power output shaft and the motor output shaft of the motor, wherein the motor is a flat motor and the speed-reducing transmission device is a worm-gear speed-reducing transmission device. The wire feeding device provided with the wire-feeding motor equipment further comprises a frame assembly and a support assembly. The welding system provided with the wire feeding device comprises welding power source equipment, a control device and a welding gun, wherein the control device comprises a voltage and / or current value detection module, a speed control module, voltage and / or current fluctuation detection equipment and a wire drawing and feeding control module. According to the invention, not only can the service life of the wire-feeding motor equipment and the service life of the wire feeding device be prolonged, but also the dynamic response speed of the wire-feeding motor equipment and the dynamic response speed of the wire feeding device are greatly improved, so that the dynamic response speed of the welding system, which meets the requirements of low spattering and even no spattering, is achieved during welding.

Owner:贝姆勒精密机电(厦门)有限公司

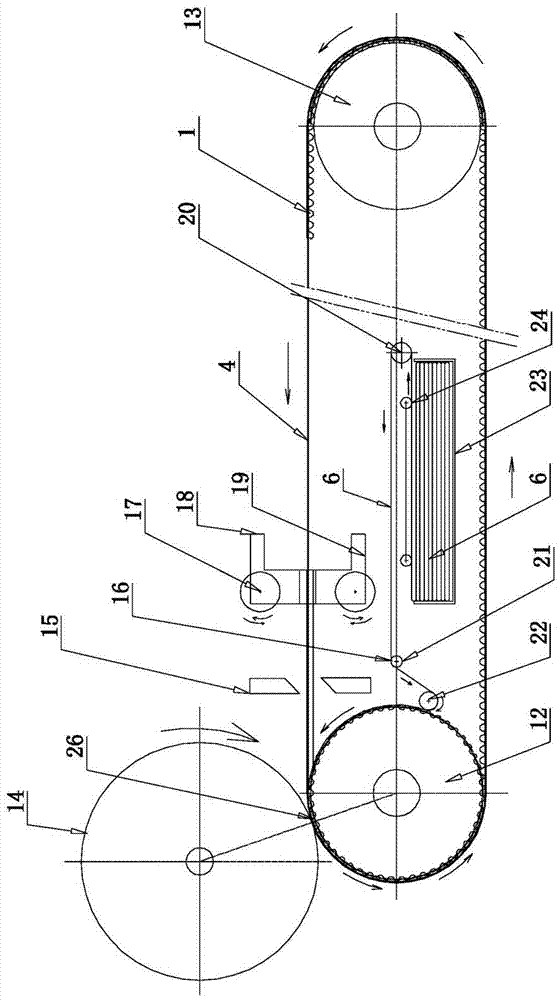

Super-long seamless polyurethane synchronous belt, and production equipment and preparation method thereof

PendingCN107191539AImprove transmission reliability and service lifeImprove wear resistanceDriving beltsBeltsAgricultural engineeringPolyurethane

The invention belongs to the technical field of synchronous belt production and processing, and particularly relates to a super-long seamless polyurethane synchronous belt, and production equipment and a preparation method thereof. The invention provides the super-long seamless polyurethane synchronous belt, and the production equipment and the preparation method thereof. The super-long seamless polyurethane synchronous belt provided by the invention comprises a belt body, and is characterized in that the belt body is annular; the belt body and a skeleton rope in the belt body do not have a seam.

Owner:奥力孚传动科技股份有限公司

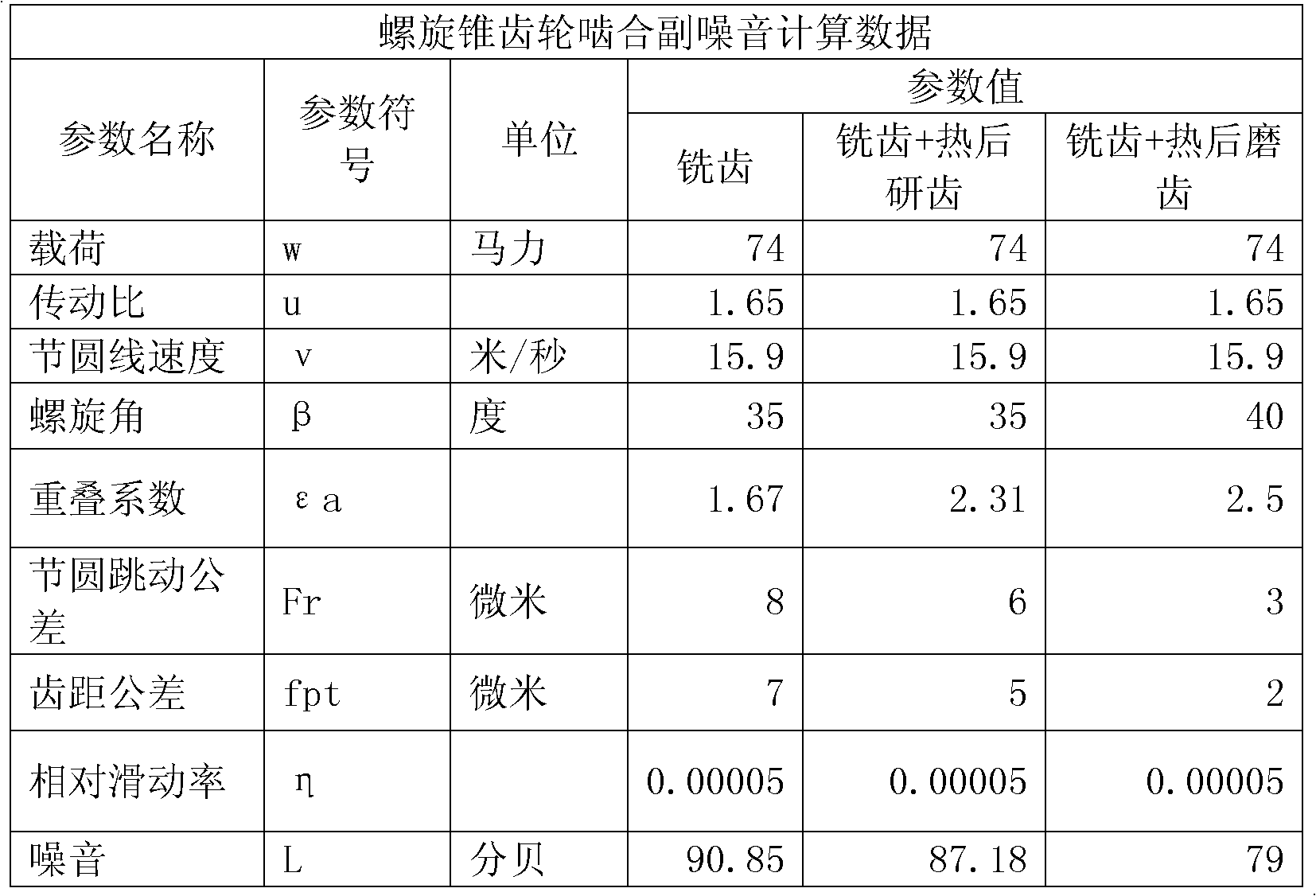

Method for calculating engagement noises of spiral bevel gear pair

ActiveCN102192303AReduce mistakesImprove accuracyPortable liftingGearing elementsDrive wheelEngineering

The invention relates to a method for calculating engagement noises of a spiral bevel gear pair. The calculating method comprises the followings steps: taking a tooth of the spiral bevel gear pair as a spring, and taking a gear body as a mass vibration system; setting a mounting system in a rigid non-vibration state except the environment noises; selecting a reference point according to a given load and noise value, confirming the noise value, the load, the transmission ratio of the spiral bevel gear pair and the pitch circle speed of a driving wheel according to the design requirement of a finished vehicle, and calculating the relative sliding ratio and the superposition degree; calculating the vibration speed coefficient of a spiral bevel gear and the amplitude of vibration of the spiral bevel gear pair, converting a helical angle, calculating the engagement noises of the spiral bevel gear pair, and analyzing the result. The calculating method provided by the invention is simple, the calculation time is short, the error is small, and the accuracy is high; through the calculation and analysis, the structural parameters of the spiral bevel gear pair is optimized, and references are provided for selecting manufacturing process and accuracy reasonably and reducing the engagement noises; and the design efficiency is improved, the design and manufacturing cycle is shortened, and the manufacturing cost is lowered effectively.

Owner:ZHUZHOU GEAR CO LTD

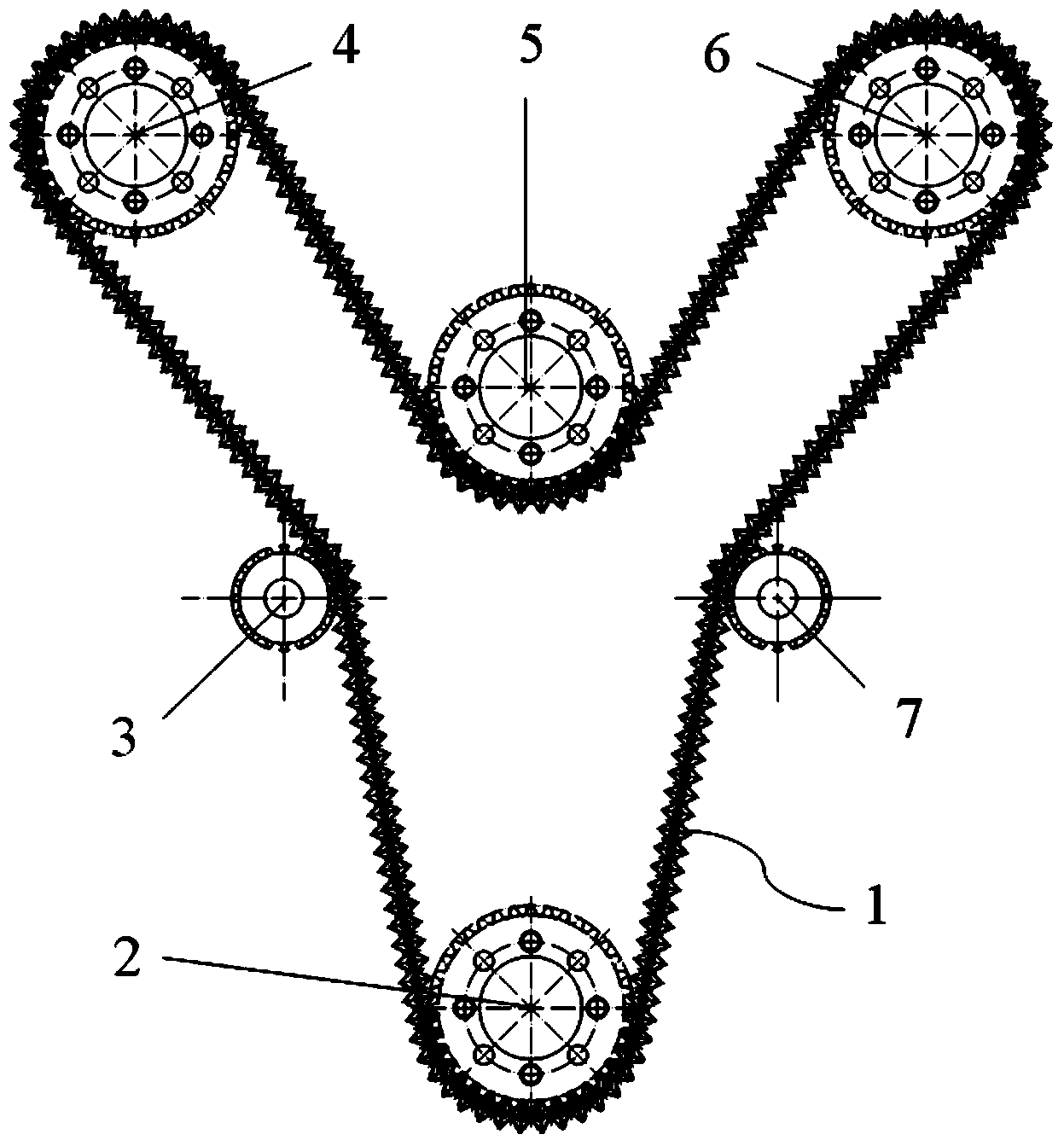

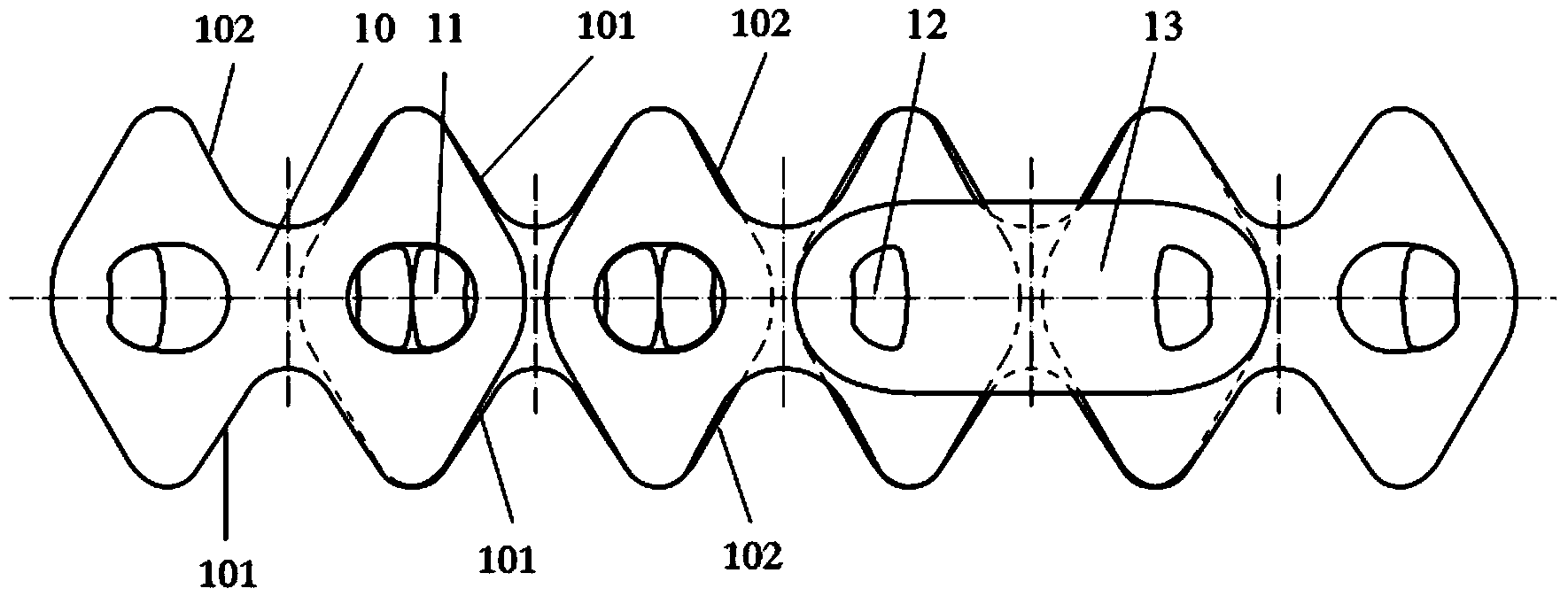

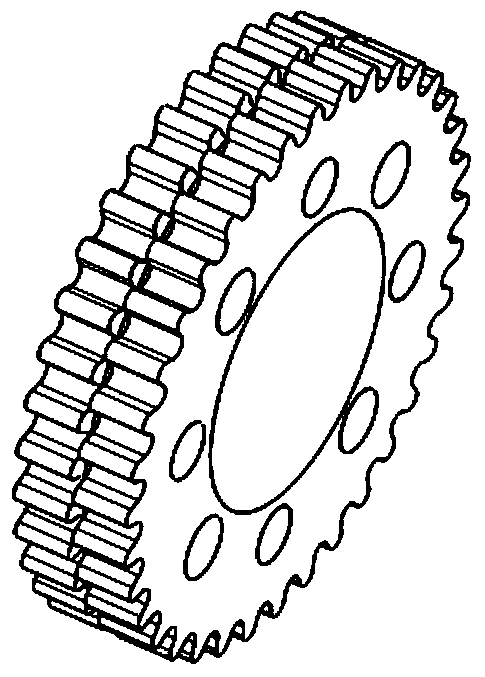

Biphase multi-shaft drive system

InactiveCN103629315ARealize multi-axis transmissionImprove fatigue lifeGearingDriving chainsRolling resistanceSprocket

The invention discloses a biphase multi-shaft drive system. The biphase multi-shaft drive system consists of an H(y)-V(o) tooth-shaped chain, a driving chain wheel, a tightening chain wheel A, a driven chain wheel B, an intermediate shaft chain wheel, a driven chain wheel C and a tightening chain wheel D, wherein the H(y)-V(o) tooth-shaped chain is meshed with the driving chain wheel, the tightening chain wheel A, the driven chain wheel B, the intermediate shaft chain wheel, the driven chain wheel C and the tightening chain wheel D in a drive mode; all the chain wheels are biphase chain wheels, that is, all the chain wheels consist of two rows of chain wheels, and the two rows of chain wheels are different by half tooth-shaped angles. According to the invention, the biphase chain wheels which are different by half tooth-shaped angles replace the traditional single-row chain wheels; chain plates of three kinds of different meshed mechanisms are ranked sequentially, the meshing noise can be reduced by adjusting the meshing rhythm and frequency, and the biphase multi-shaft drive system also can be applied to the working conditions of heavy load and variable load; and heart-shaped contact wires of pin shafts replace the traditional circular arc wires, so that the slide friction among the pin shafts is converted into rolling friction, and the fatigue service lives of chains are prolonged.

Owner:JILIN UNIV

Multi-link, adjustable-stroke type engine

Owner:HONDA MOTOR CO LTD

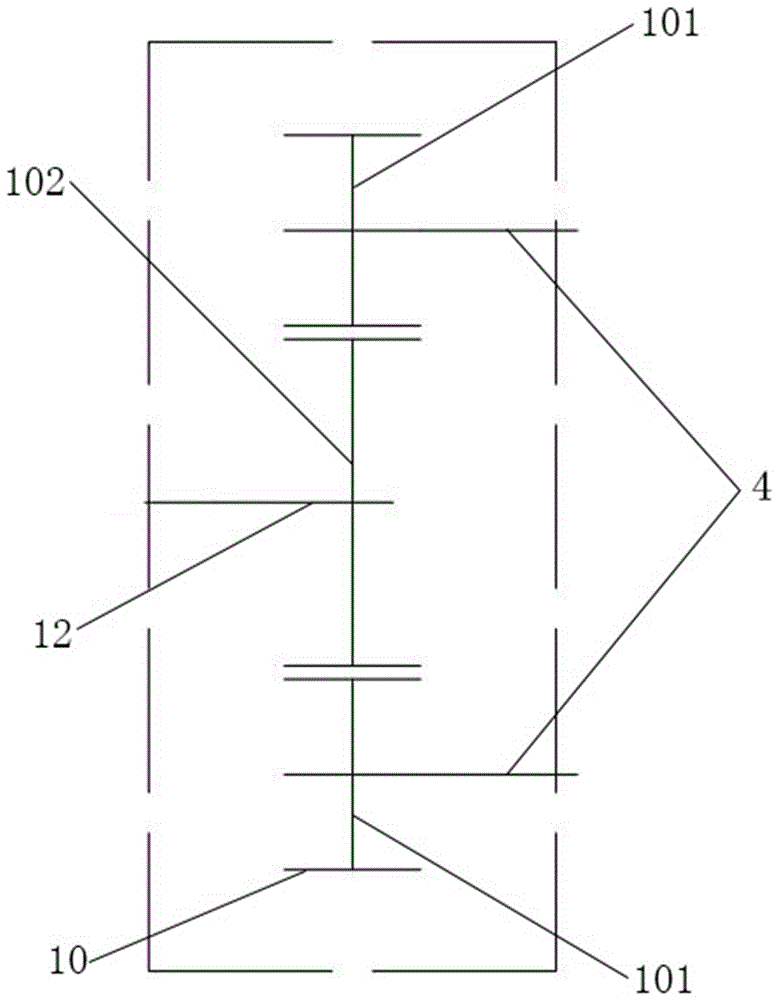

Electric power transfer device with high-speed dual-power source input

InactiveCN106183799AReduce the maximum input torqueExtended service lifeElectric propulsion mountingControl devicesGear driveElectric machinery

The invention provides an electric power transfer device with high-speed dual-power source input. The electric power transfer device comprises a gearbox and a power input device, wherein the gearbox comprises a gearbox auxiliary box and a gearbox main box; speed reducing gears are symmetrically arranged in the gearbox auxiliary box; the gearbox main box adopts a two-gear shifting structure with two middle shafts; and the two middle shafts, gear transmission mechanisms which are symmetrically arranged, and a connection sleeve mounted on an output shaft are arranged in the gearbox main box. According to the technical scheme of the electric power transfer device disclosed by the invention, the power transfer is guaranteed, and the noise and the phenomenon of reducing vibration led by the high-speed transmission can be effectively reduced; through the technical structural design, torque borne by the gearbox is reduced, the service life of motors and the service life of a transmission system are prolonged, and the efficiency of the transmission system is improved.

Owner:湖州伊立机械有限公司

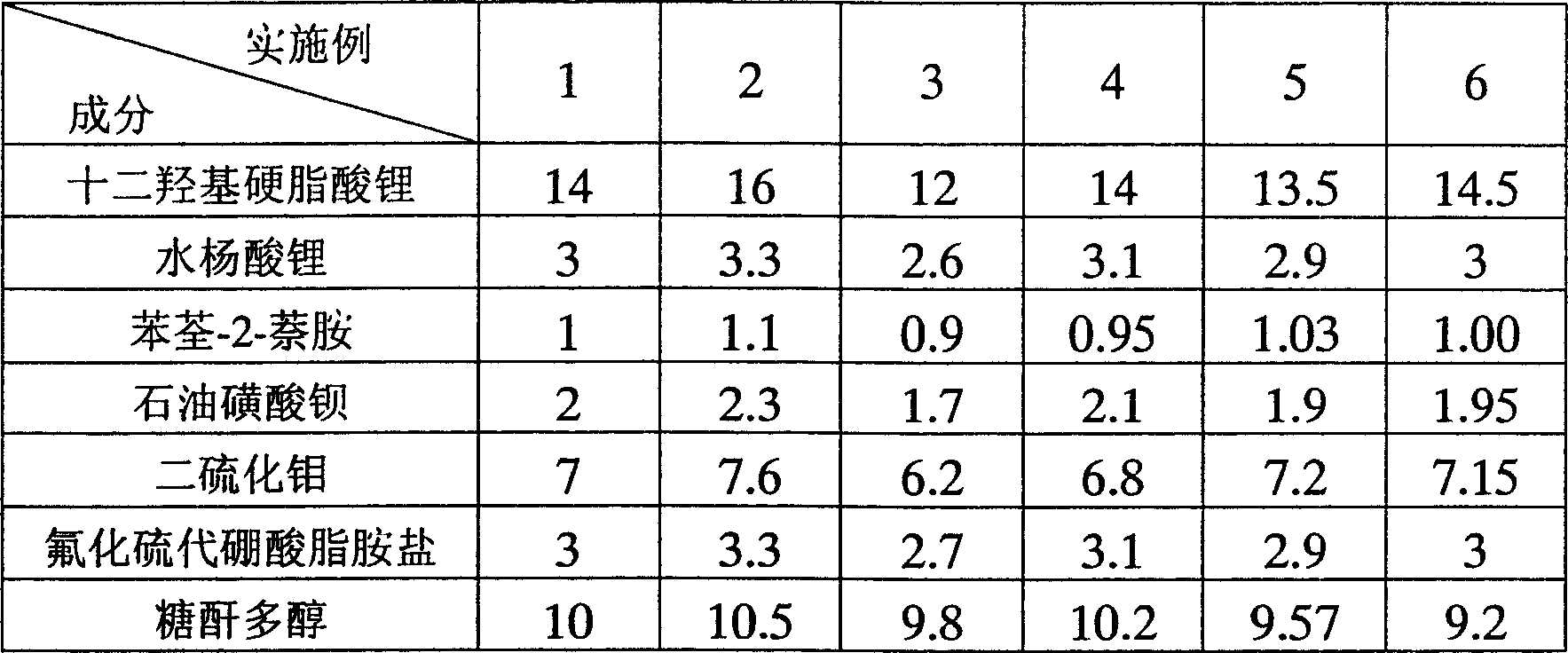

Lubricating grease composition for motor gearbox

The present invention is the recipe of lubricant oil for motor gear box. The present invention features that the lubricant oil consists of: lithium dodecahydroxyl stearate 12-16 wt%, lithium salicylate 2.6-3.3 wt%, benzaldehyde-2-naphthylamine 0.9-1.1 wt%, barium petroleum sulfonate 1.7-2.3 wt%, molybdenum disulfide 6.2-7.6 wt%, ammonium fluorothiobarate 2.7-3.3 wt% and glycoside polyol 9.2-10.5 wt% except synthetic base oil. The lubricant oil has the functions of reducing gear meshing operation noise and prolonging the service life of gears, and can also repair rough metal surface of gears.

Owner:许晓华

Wind power generator set and yawing-braking magnetic thixotropic flexible braking device of wind power generator set

ActiveCN102661245BRealize uninterrupted continuous flexible braking functionContinuous momentLiquid resistance brakesWind motor controlElectricityNacelle

The invention discloses a wind power generator set and a yawing-braking magnetic thixotropic flexible braking device of the wind power generator set. The braking device comprises an outer ring, an inner ring, a magnetic yoke, a coil winding, a braking wheel and a magnetic thixotropic adhesive, wherein the outer ring and the inner ring are connected with each other through the magnetic yoke and can be fixed on a tower flange of the wind power generator set; the braking wheel comprises a fixed part and a braking part and can be fixed on a cabin seat; the outer ring and the inner ring are connected to form a braking slot for accommodating the braking part of the braking wheel and a coil winding slot for accommodating the coil winding; the braking part of the braking wheel is arranged in the braking slot in a rotatable manner, and a clearance is formed between the braking part and each of the inner ring and the outer ring; and the magnetic thixotropic adhesive is accommodated in the clearances. According to the braking device, abrasion and spot corrosion of wheel teeth of a yawing driving system are effectively reduced, the braking noise and the vibration during yawing braking are reduced, the service life of a gear box is effectively prolonged, and the running cost of a fan is reduced.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Transmission device

InactiveCN103144735AReduce impactReduce suitabilityWheel based transmissionGearboxesDrive shaftBevel gear

The invention discloses an oil bath type transmission device with a buffer function, which comprises an output gear box and an input gear box, wherein the input gear box is provided with a first driving bevel gear and a first driven bevel gear that are engaged with each other; the first driven bevel gear is in power transferring connection with a wheel train in the output gear box by a transmission shaft; the first driving bevel gear is fixedly connected with a middle shaft of a bicycle by a shaft sleeve; the shaft sleeve is limited and fixed on the middle shaft by a spline; the first driving bevel gear is arranged on a plummer block of the shaft sleeve in a sleeving manner, positioned and fixed; a groove and convex teeth that are matched mutually are formed between the adjacent end faces of a shaft shoulder of the shaft sleeve and the first driving bevel gear; a buffer sleeve is arranged among the groove and the convex teeth; a counter bore is formed in the end face of the first driving bevel gear adjacent to the shaft shoulder of the shaft sleeve; and a shock-absorbing pad which is higher than the counter bore and pushes against the shaft sleeve and the first driving bevel gear respectively is arranged in the counter bore. According to the transmission device, a gap between a gear pair is eliminated, and noise, trembling and numbness of the gear pair is reduced.

Owner:重庆弘劼机械有限公司

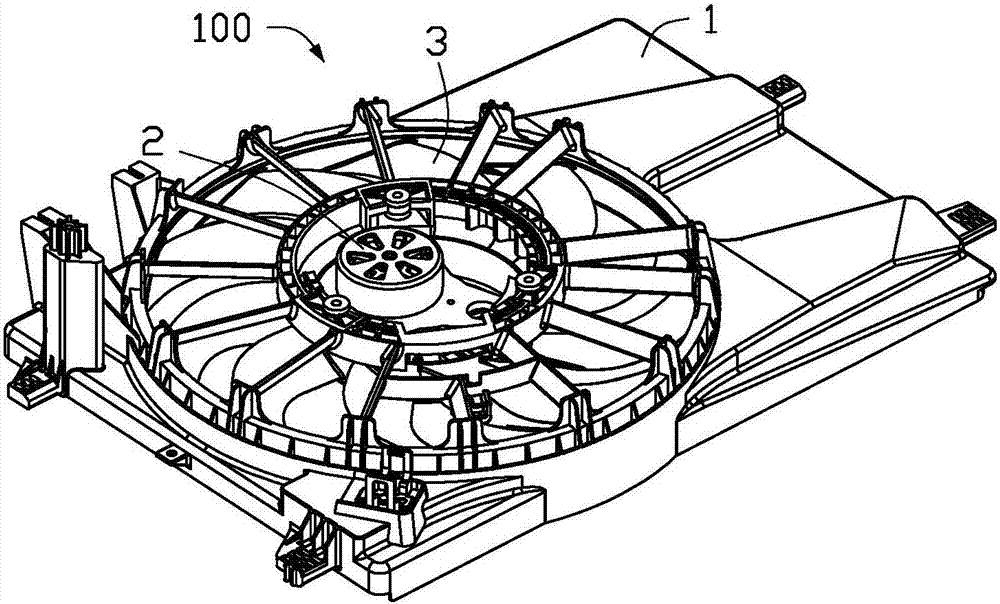

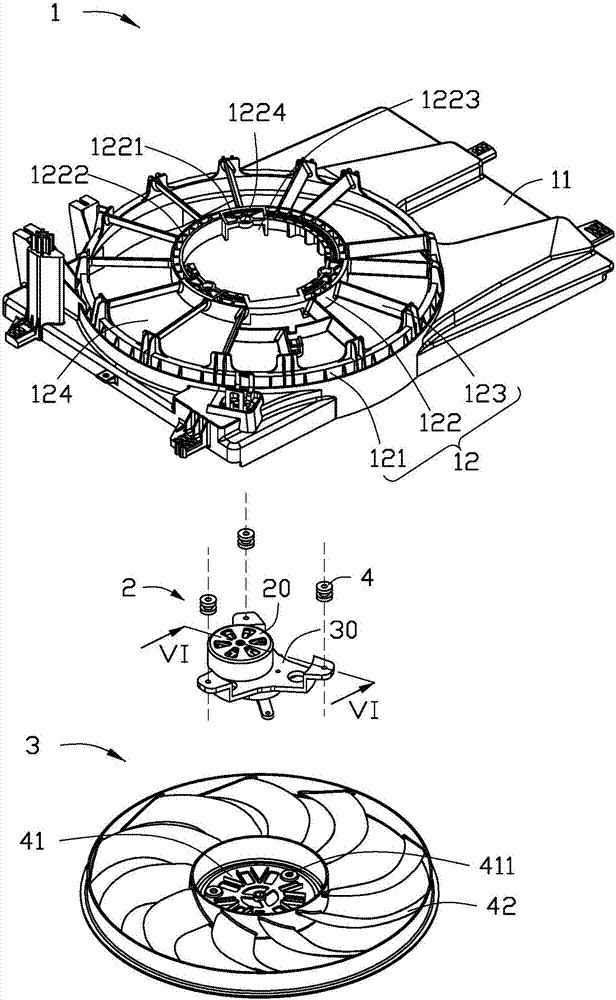

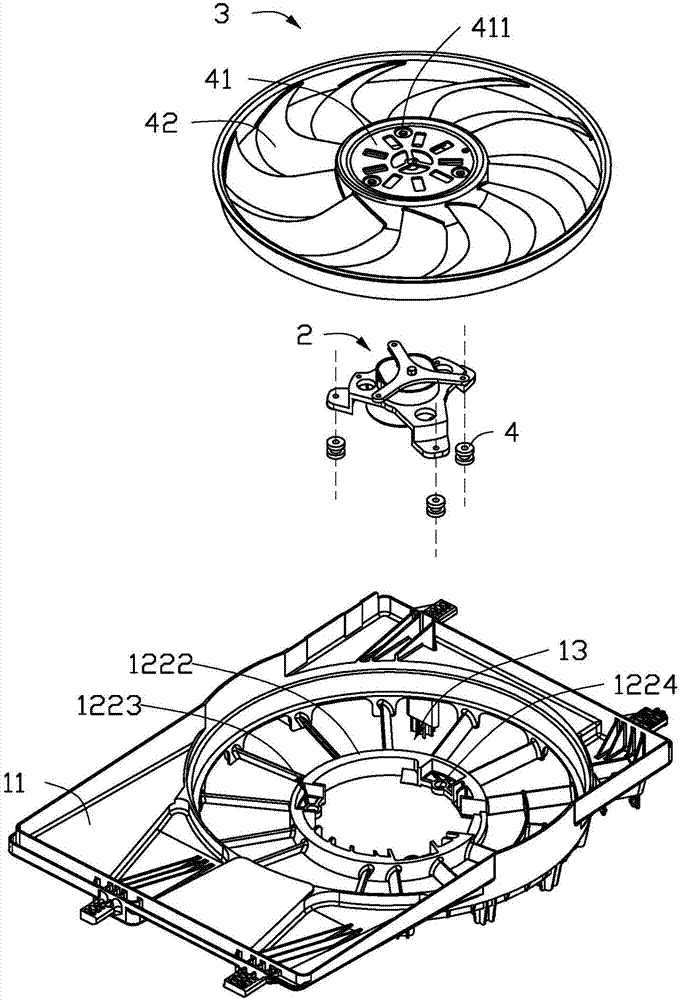

Driving device and electrical equipment with same

InactiveCN107237882AReduce meshing noiseReduce noiseGear vibration/noise dampingMechanical energy handlingImpellerEngineering

The invention provides a driving device, which includes a motor and a gearbox assembly. The motor includes a rotor and a stator. The rotor has a rotating shaft, and a first bearing is accommodated on the stator. frame and driving gear, a second bearing is accommodated on the mounting frame, and the other end of the rotating shaft passes through the driving gear and the second bearing, so that the driving gear is located between the first bearing and the second bearing. The present invention also provides an electrical device using the above-mentioned driving device. The electrical device includes a housing and an impeller. The driving device is installed on the housing. The driving device is connected to the impeller to drive the impeller to rotate. In the electrical equipment of the present invention, the driving gear in the driving device is placed on the rotating shaft, and the driving gear is located between two bearings, so as to reduce the noise of the driving device during operation, and further reduce the noise of the electrical equipment during operation.

Owner:JOHNSON ELECTRIC SHENZHEN

Planet gear connecting rod combined paper feeding device

InactiveCN103057260ASimple installationGear processing is convenientRotary pressesPrinting press partsEngineeringEpicyclic gearing

The invention discloses a planet gear connecting rod combined paper feeding device which comprises a driving gear, a set of planet gear mechanism and a group of four-connecting-rod device. The paper feeding device is characterized in that the number of teeth and modulus of the driving gear is equal to that of teeth and modulus of a gear ring in the planet gear mechanism, the driving gear is fixedly connected with a crank in the four-connecting-rod device, a rocker in the four-connecting-rod device and a tie bar in the planet gear mechanism are the same component, and paper feeding teeth are mounted on and move along the gear ring of the planet gear mechanism. When the paper feeding device works, the driving gear drives a sun gear and a crank in the planet gear mechanism to rotate simultaneously to lead a planet gear in the planet gear mechanism to move so as to realize the moving law of the paper feeding teeth on the gear ring. The driving gear rotates for a circle, the gear ring rotates for a circle, the paper feeding teeth feed paper for one time, and the moving law of the paper feeding teeth meets requirements of paper taking and paper delivering by optimizing structural parameters.

Owner:SHANGHAI UNIV

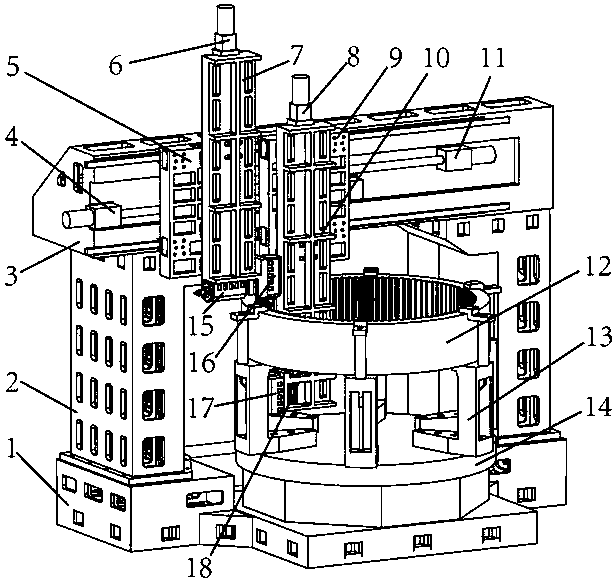

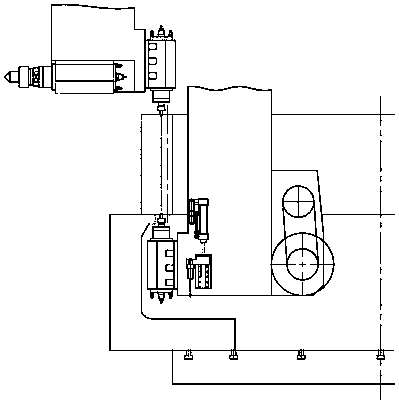

Large gantry polar coordinate CNC gear compound chamfering machine tool

ActiveCN106825786BImprove chamfering efficiencyShape adjustableLarge fixed membersGear teethNumerical controlMilling cutter

The invention discloses a large-size gantry polar coordinate numerical control gear compound chamfering machine tool. Based on a polar coordinate machining theory and a numerical control enveloping principle, compound chamfering of the end surfaces of the two sides of a tooth profile of an inner / outer straight / helical gear and simultaneous chamfering of the two sides in a tooth direction are realized by utilizing a hard alloy mill tool which rotates at a high speed; burs of tooth roots and edges and corners can be polished. The compound chamfering machine tool mainly comprises a machine tool body (1), an upright post (2), a cross beam (3), a rotary working table (14), an X1 axial and radial feeding system (4), an X2 axial and radial feeding system (11), a Z1 axial feeding system (6), a Z2 axial feeding system (8), a C shaft transmission worm gear pair (G5), a polishing wheel (SP4), a Z3 axial online probe system (18) and a chamfering main shaft system. The compound machine tool disclosed by the invention has the distinctive advantages that all chamfers in the tooth profile and the tooth direction can be completed by clamping a workpiece once; the sizes and the shapes of the chamfers are adjustable; the chamfer sizes are consistent; tooth grooves are centred automatically; the automation degree is high; the chamfering efficiency of a gear is improved.

Owner:NANJING GONGDA CNC TECH

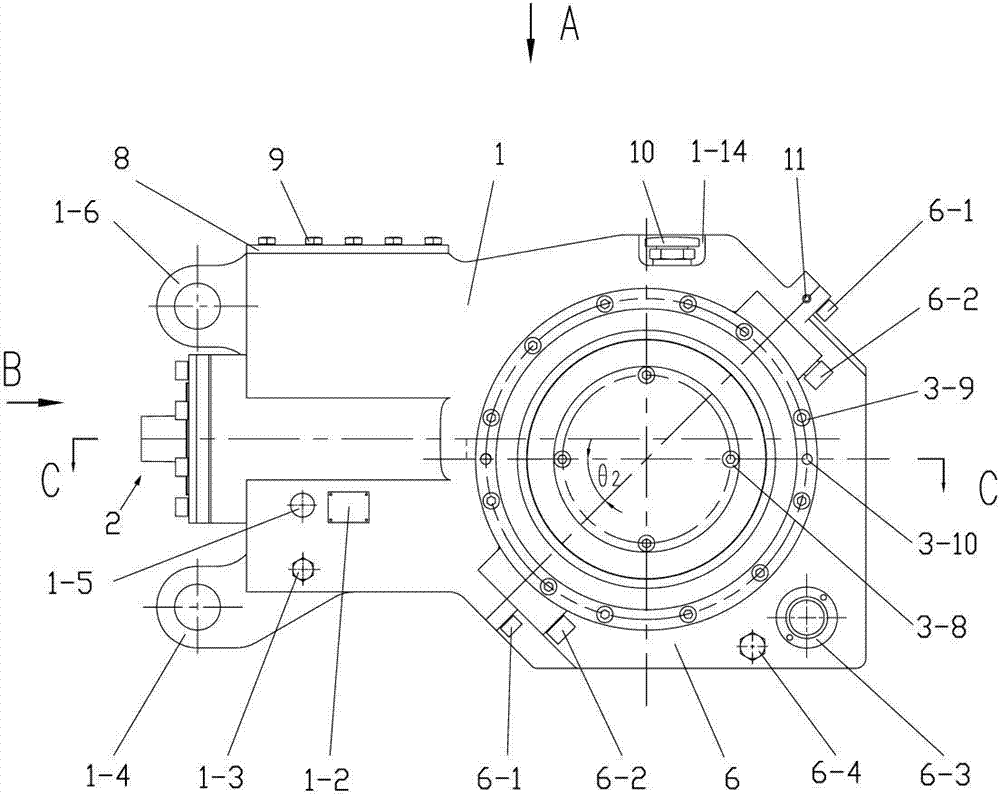

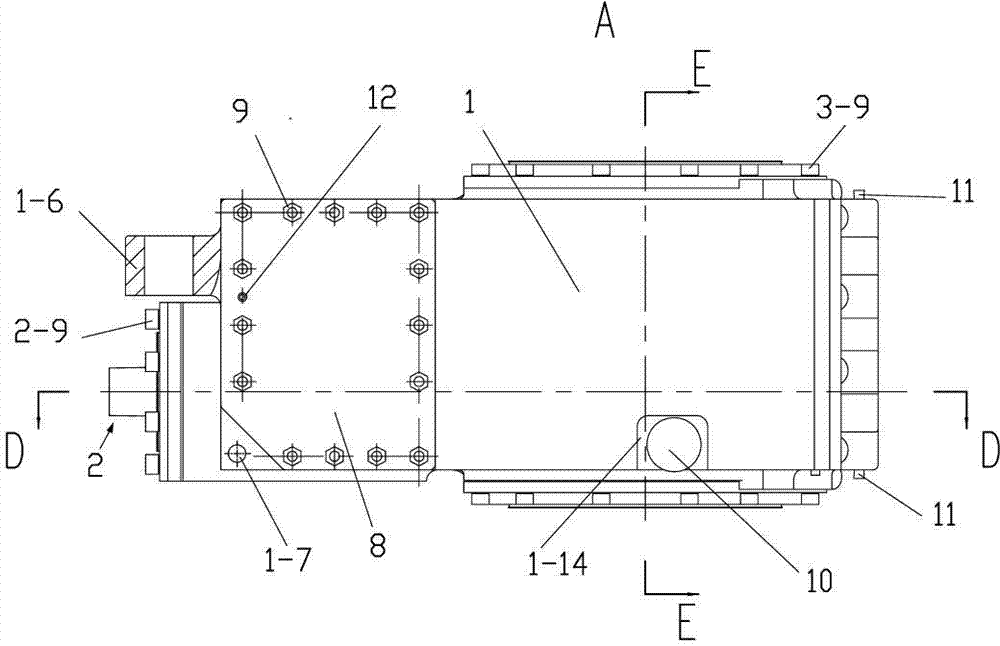

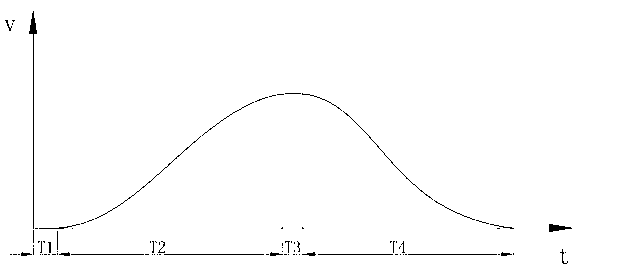

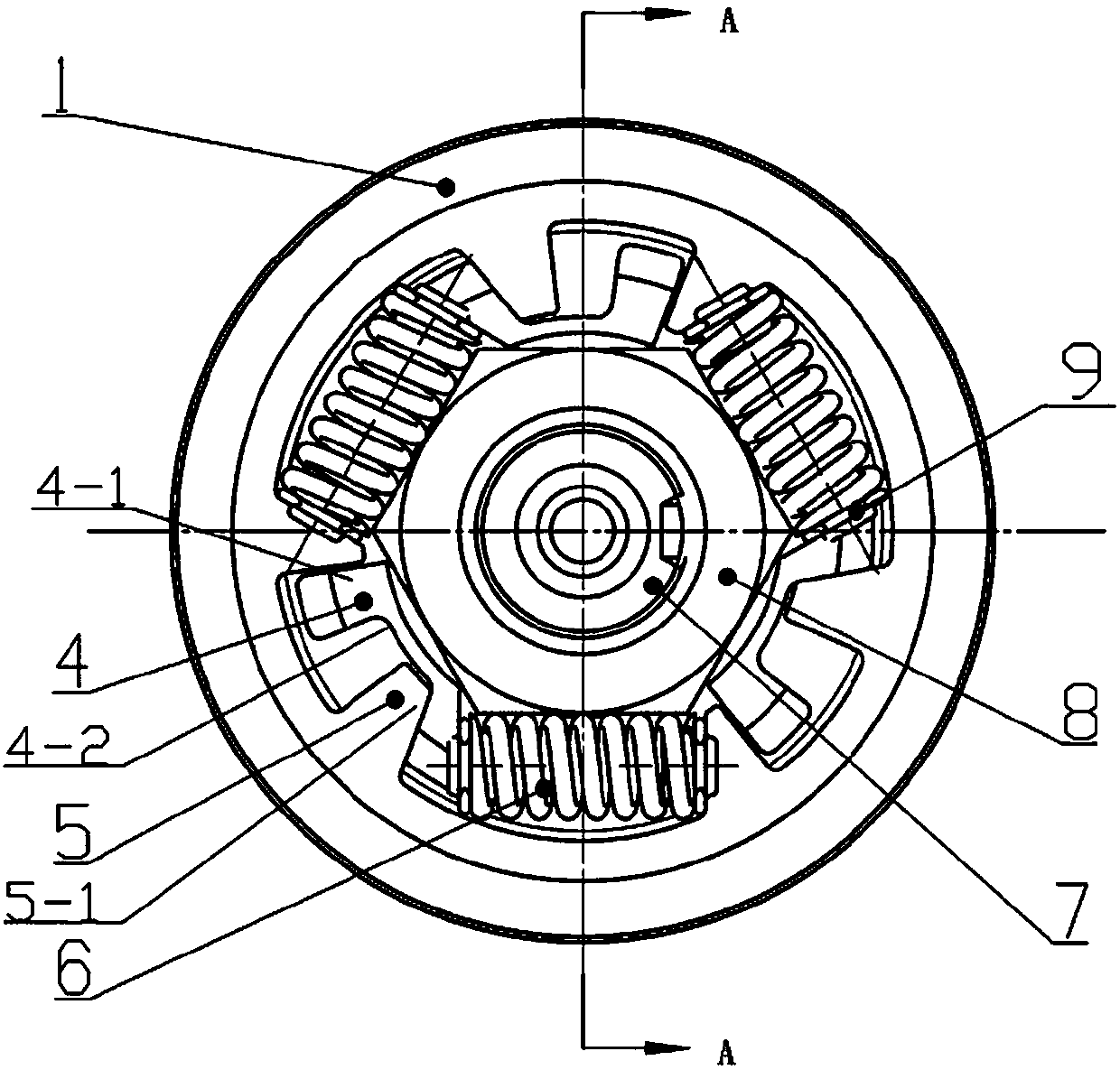

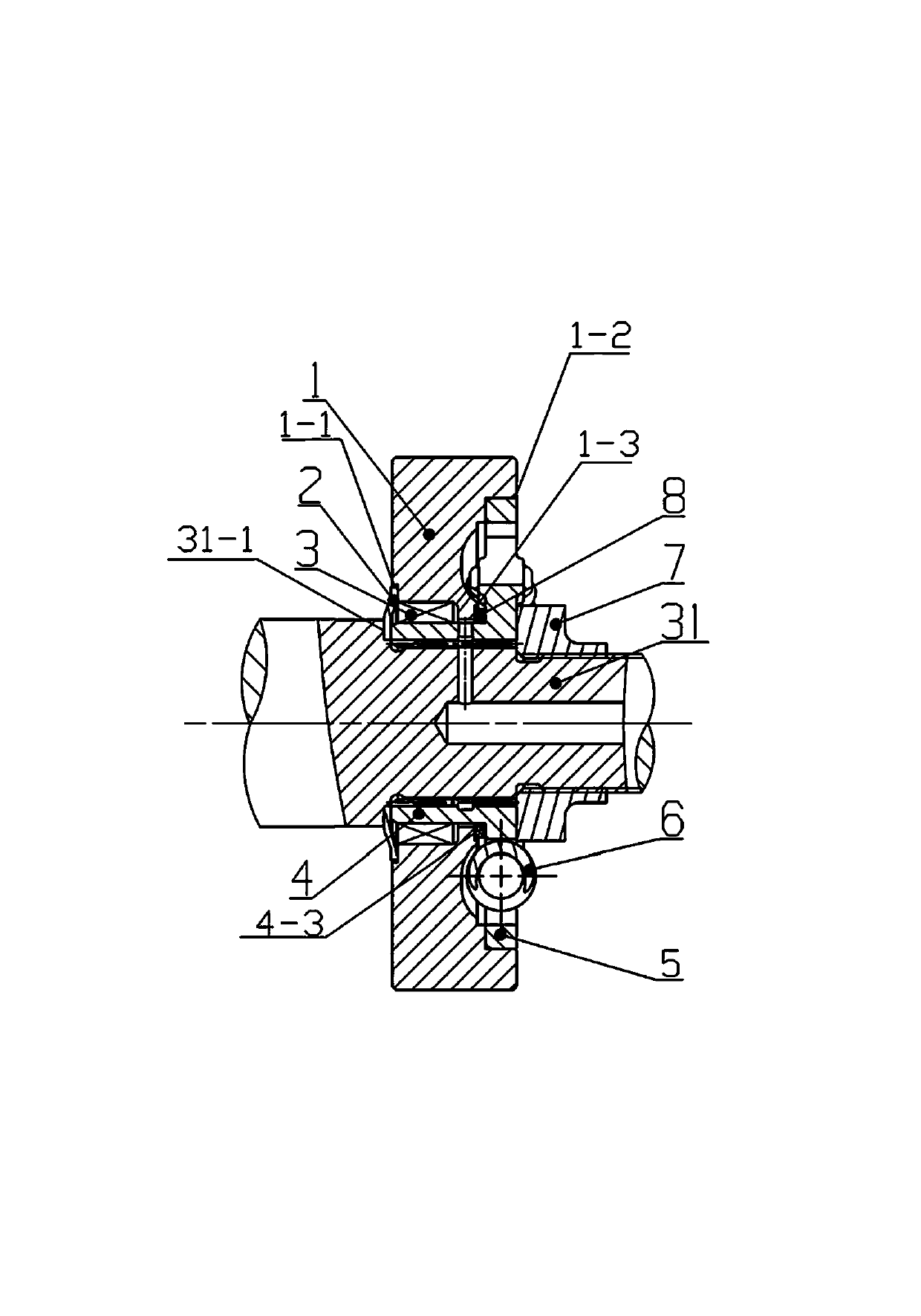

Gear torsional vibration absorber structure and gear torsional vibration method

InactiveCN103363061AReduce speed fluctuationReduce meshing noiseRotating vibration suppressionPortable liftingTorsional vibrationClassical mechanics

The invention discloses a gear torsional vibration absorber structure comprising an input gear (1), a bearing (3) a spring driving rack (4) and an input shaft (31) which are sequentially sleeved from the outside to the inside, a spring driven rack (5), a disc spring (2) and a damping element (8), wherein the excircle of the spring driven rack (5) is sleeved in an annular connecting trough (1-2) of a gear; the disc spring (2) is arranged in a mounting slot (1-1) of the gear, and the other end of the disc spring (2) is tightly adhered to a limiting column body (31-1) of an input shaft (31); the damping element (8) is arranged between the annular connecting trough of an output gear and one side of outer splines (4-1) of the spring driving rack; a mounting slot (4-2) is formed among the adjacent outer splines (4-1) on the excirlce of one end of the spring driving rack; inner splines (5-1) on the inner circle of the spring driven rack extend into the mounting slot (4-2); two sides of the mounting slot (4-2) are provided with spring fixing blocks (9) for fixing vibration damping elements (6). The gear torsional vibration absorber structure and gear torsional vibration method disclosed by the invention has the beneficial effect of reducing meshing noises.

Owner:CHONGQING TSINGSHAN IND

Novel 10-gear double-intermediate-shaft synchronizer gearbox

ActiveCN103388656AImprove gear load capacity and meshing stabilityReduce meshing noiseToothed gearingsGearing detailsEngineeringMechanical engineering

The invention discloses a novel 10-gear double-intermediate-shaft synchronizer gearbox, which comprises a novel three-section shell, an input shaft and a main shaft connected with the input shaft, wherein the main shaft is connected with a sun wheel in a sub-box through a spline taper reduction sleeve, the front end and the rear end of the main shaft are provided with a main shaft front positioning mechanism and a main shaft rear positioning mechanism respectively, the main shaft is also provided with a gear-shifting bevel gear group which comprises five forwarding bevel gears and a reversing bevel gear, a single-cone lock ring synchronizer is arranged between the fourth gear and the fifth gear on the main shaft, a single-cone lock pin synchronizer is arranged between the second gear and the third gear on the main shaft, a twin cone lock pin synchronizer is arranged at the first gear on the main shaft, the sub-box part comprises two gear positions and forms a 5*2 structure of ten forward gears and two reverse gears with a main box part, and a planetary gear train mechanism and a widened twin cone lock ring synchronizer are arranged in the sub-box part. The gearbox has the advantages that the operation is labor-saving, the gear shifting operation and the transmission are smooth, the noise is small, and the physical life is prolonged.

Owner:SINO TRUK JINAN POWER

Engine balancer

InactiveCN103671705ALow percussionNo damageInertia force compensationYielding couplingDrive shaftEngineering

Owner:HITACHI AUTOMOTIVE SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com