Gear torsional vibration absorber structure and gear torsional vibration method

A torsional vibration damper and gear technology, which is applied in the field of gear torsional vibration damping and torsional vibration damper for gears, can solve the problems of gear noise, gear precision reduction, and difficult manufacturing, etc., to reduce gear meshing noise , Reduce the effect of speed fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

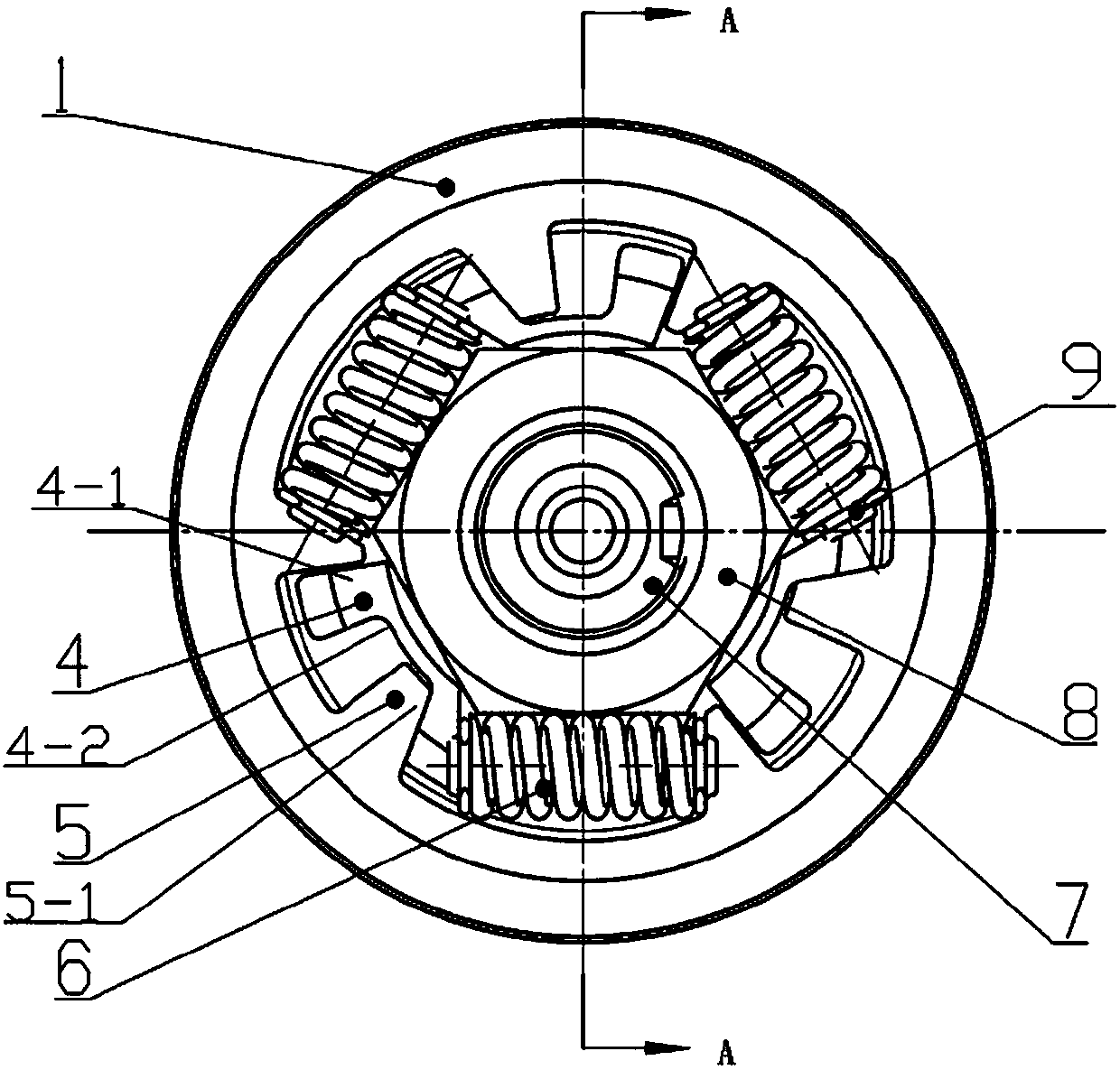

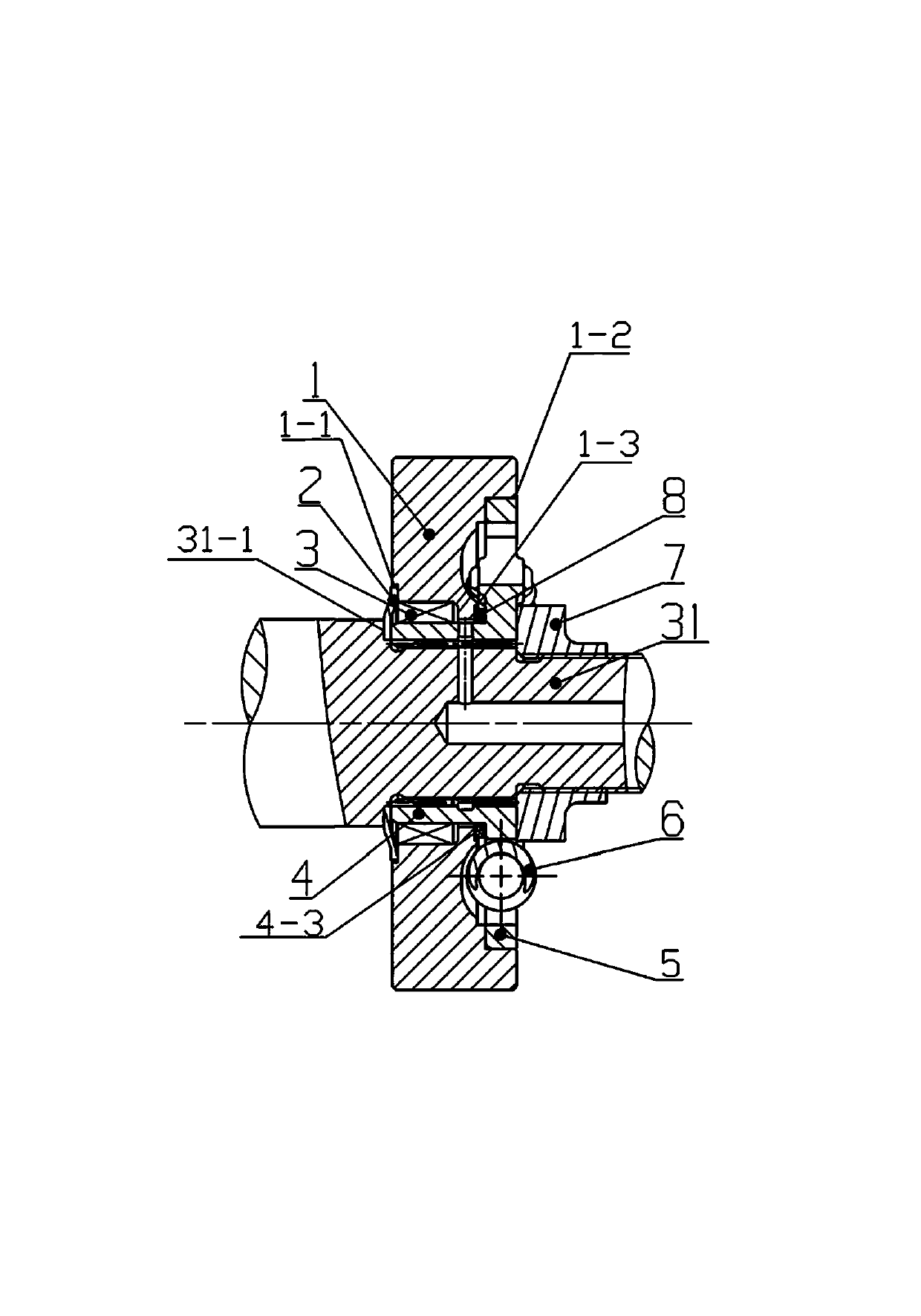

[0035] see figure 1 , figure 2 As shown, a gear torsional damper structure of the present invention includes an output gear 1, a disc spring 2, a bearing 3, a damping element 6, an input shaft 31, a lock nut 7, a damping element 8, and a spring fixing block 9. It is characterized in that: it also includes a spring drive frame 4 and a spring driven frame 5; the output gear 1 is set on the bearing 3, the bearing 3 is press-fitted on the spring drive frame 4, and the spring drive frame 4 and the input shaft 31 pass through Involute spline connection; the spring drive frame 4 is set on the input shaft 31; one end of the output gear 1 has a mounting groove 1-1, and the other end has an annular connection groove 1-2; one side of the input shaft 31 has The limit cylinder 31-1 is higher than other parts; the outer circle of one end of the spring driving frame 4 has an outer spline 4-1, and an installation groove 4-2 is formed between adjacent outer splines 4-1; There is an inner sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com