Sliding mode variable structure-based load disturbance resistance control system of bearingless induction motor

A sliding mode variable structure, asynchronous motor technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems of affecting the performance of the controller, the decline of control performance, the instability of the system, etc., and meet the model accuracy requirements. High, effective control, simple physical realization of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

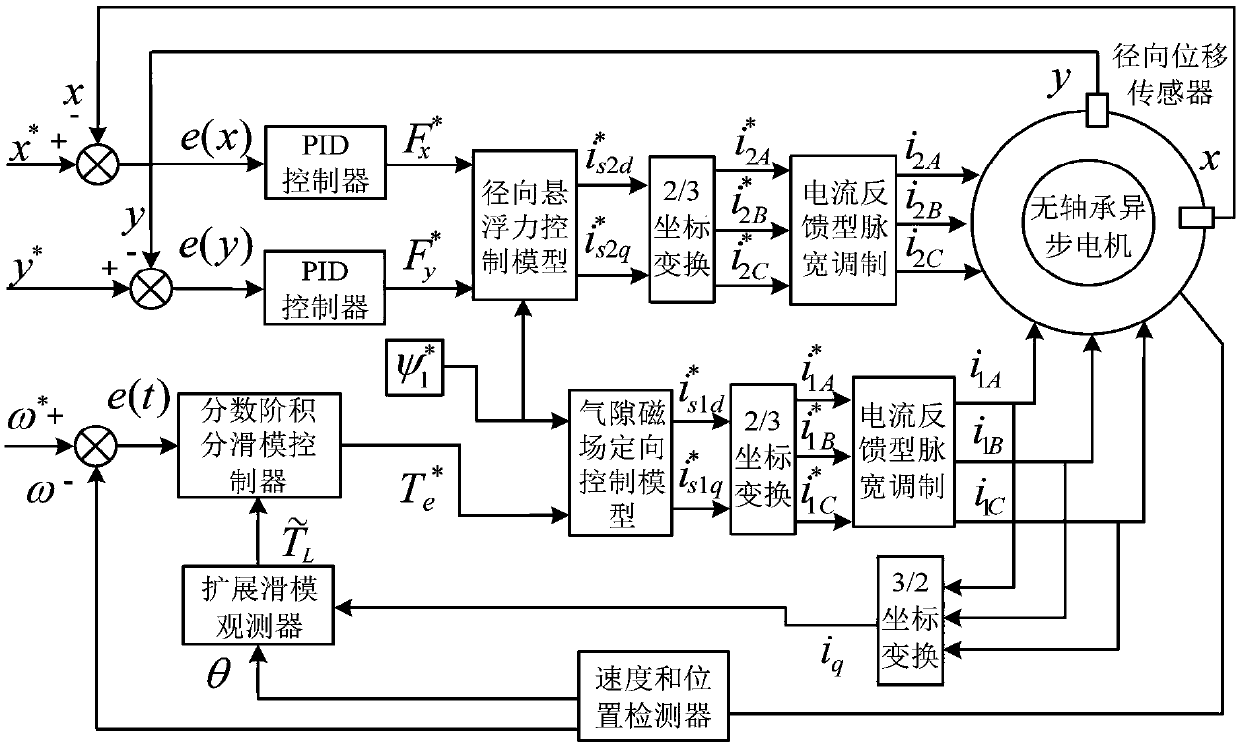

[0015] Such as figure 1 As shown, the present invention is composed of a torque control part and a suspension control part. Among them, the suspension control part is composed of a PID regulator, a radial suspension force control model, a first 2 / 3 coordinate transformation module and a current feedback pulse width modulation module connected in sequence. The displacement signals x, y of the bearingless asynchronous motor are obtained through the detection of the radial displacement sensor, and the displacement signals x, y are compared with the displacement given value x * 、y * By comparison, the displacement differences e(x), e(y) are obtained, and the displacement differences e(x), e(y) are respectively input into a corresponding PID regulator, and corresponding PID regulators are processed to generate corresponding The given radial suspension force The output ends of the two PID regulators are respectively connected to the input ends of the radial suspension force co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com