Nonlinear inverse decoupling controller for bearingless synchronous reluctance motor and construction method thereof

A synchronous reluctance motor, bearingless technology, used in motor generator control, AC motor control, electronic commutation motor control, etc., can solve the problem that the parameters of the decoupling compensator are easily affected by magnetic saturation, and dynamic decoupling is not realized. To achieve the effect of simple structure, simplified control system design and simple control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

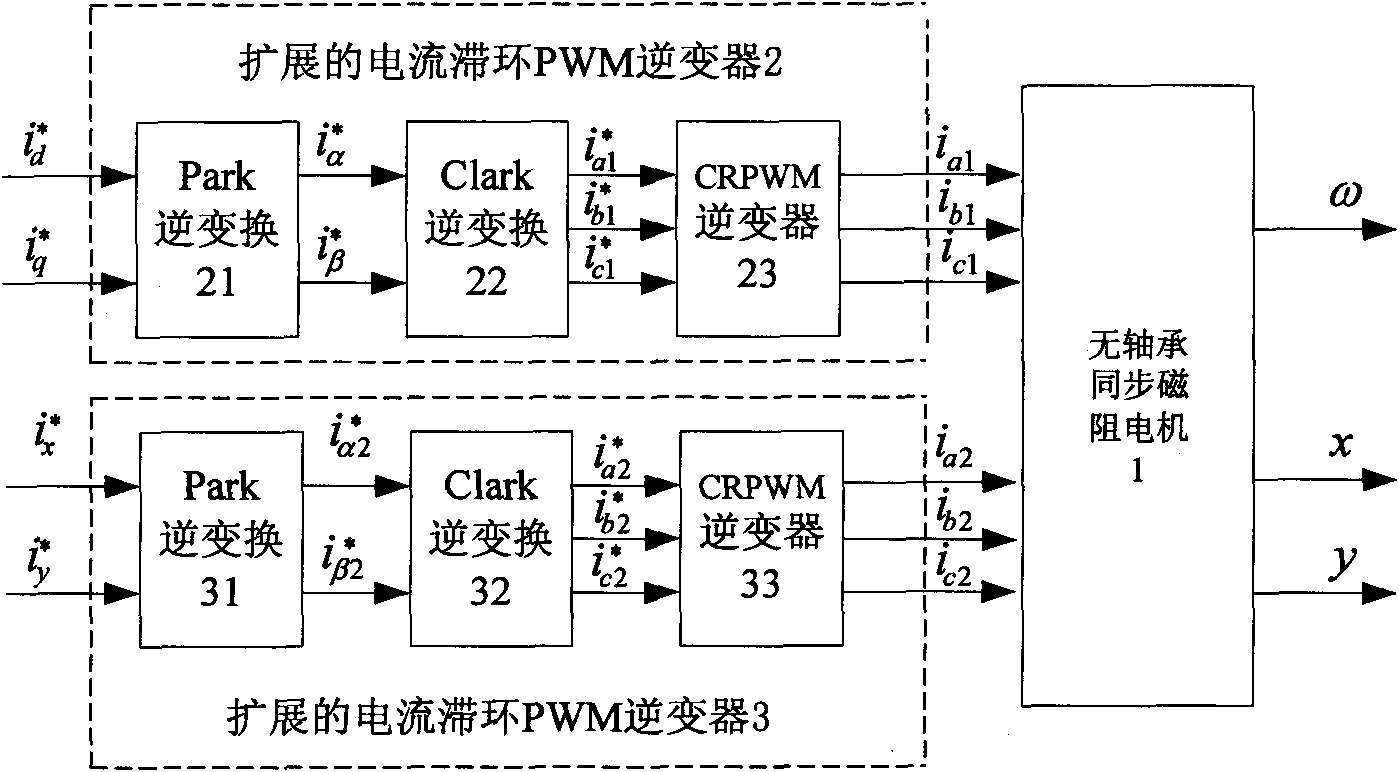

[0031] Further description will be made below in conjunction with the accompanying drawings. It is composed of Park inverse transformation, Clark inverse transformation and current hysteresis PWM inverter connected sequentially, such as figure 1 As shown, the first and second expanded current hysteresis PWM inverters 2 and 3 are formed by sequentially connecting Park inverse transforms 21, 31, Clark inverse transforms 22, 32 and current hysteresis PWM inverters 23, 33. The first and second extended current hysteresis PWM inverters 2 and 3 are used as an integral part of the compound controlled object 5 .

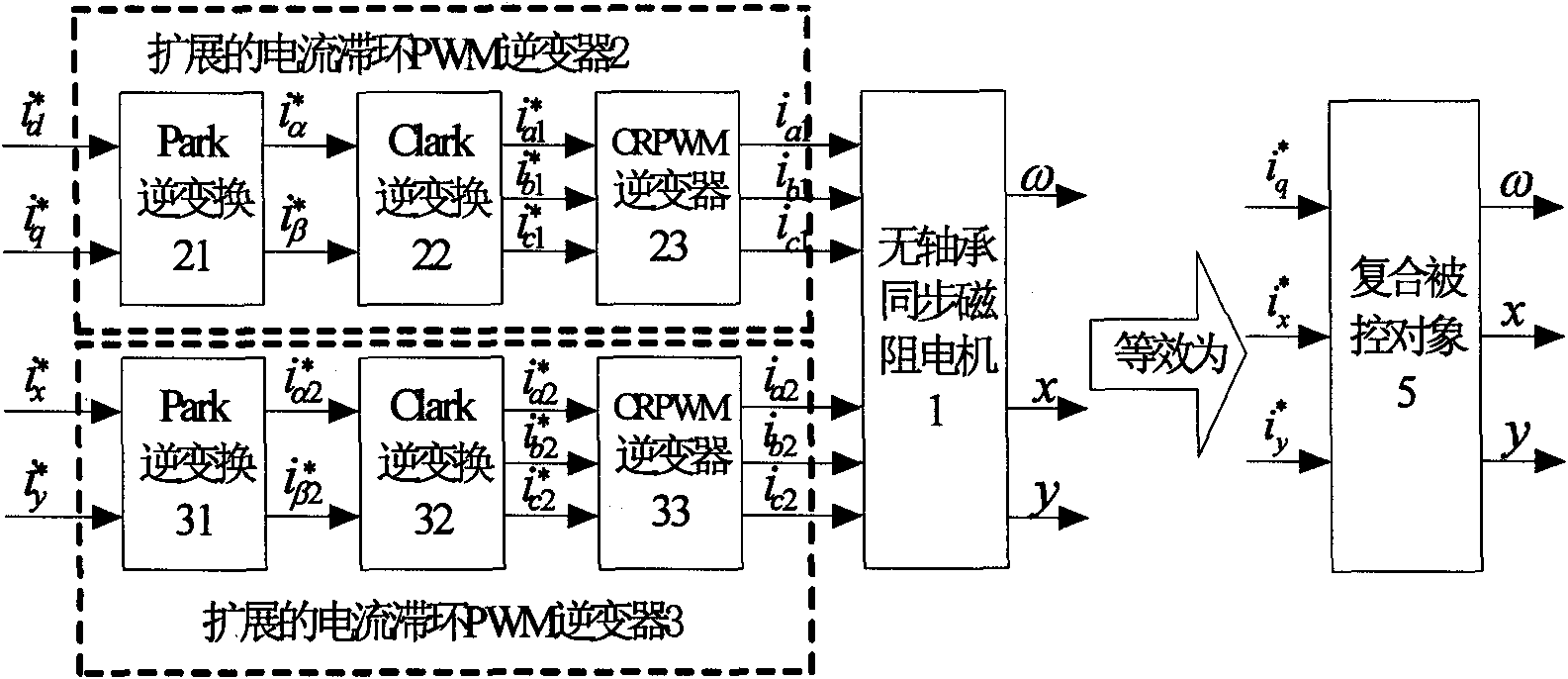

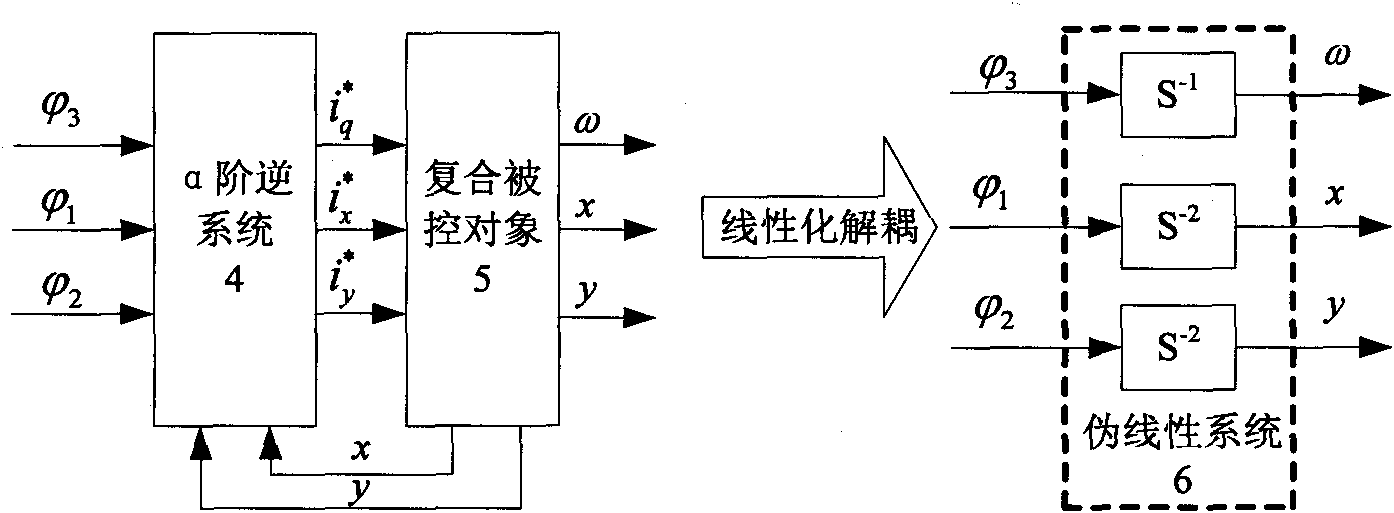

[0032] Such as figure 2 As shown, two extended current hysteresis PWM inverters 2, 3 and bearingless synchronous reluctance motor 1 constitute a compound controlled object 5, in which the bearingless synchronous reluctance motor winding is composed of torque winding and radial levitation force winding composition. Such as image 3 As shown, the α-order inverse system 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com