General loading test system based on parallel connection multi-DOF mechanism

A technology of loading test and degree of freedom, which is applied in the field of generalized loading test system, can solve the problems of loading test system with no multi-degree of freedom, test system with single degree of freedom, etc., and achieve a wide range of test objects, good control performance indicators, and mechanism stiffness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

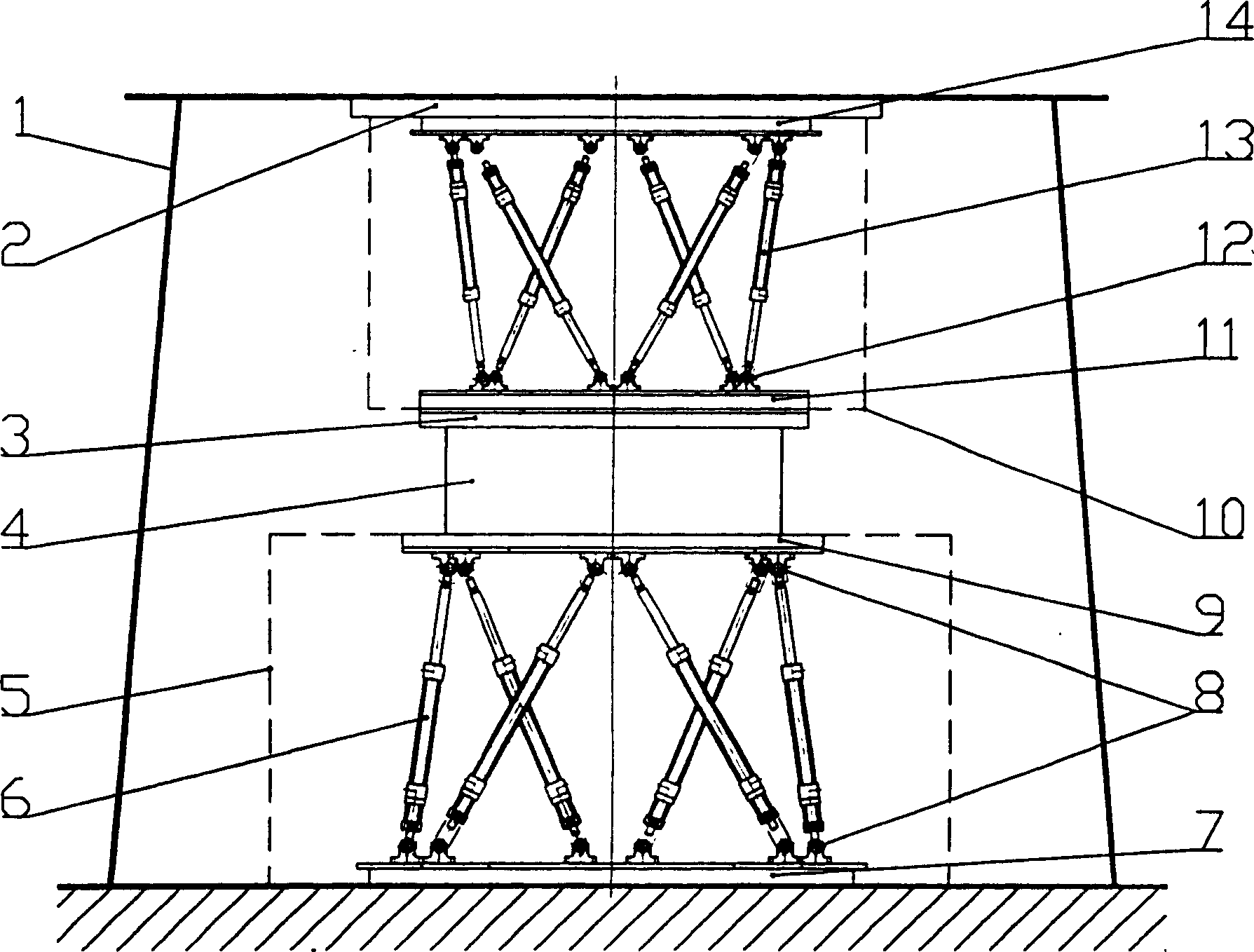

[0009] As shown in the drawings, the present invention includes a generalized loading mechanism based on a parallel six-degree-of-freedom mechanism composed of a loading mechanism fixed platform 7, a loading mechanism joint hinge 8, six sets of parallel loading mechanism linear actuators 6 and a loading mechanism movable platform 9 5. The loaded mechanism 10 based on the parallel multi-degree-of-freedom mechanism composed of the fixed platform 14 of the loaded mechanism, the joint hinge 12 of the loaded mechanism, multiple sets of parallel linear actuators 13 of the loaded mechanism and the movable platform 11 of the loaded mechanism; The mechanism fixed platform 7 is installed on the ground or on other fixed planes, and a set of six-dimensional force sensor 4 is installed on the loading mechanism movable platform 9. The other side of the six-dimensional force sensor 4 is connected with the loading connection mechanism 3. The loading connection mechanism 3 is coaxially installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com