Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

406results about "Mounting of arm assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

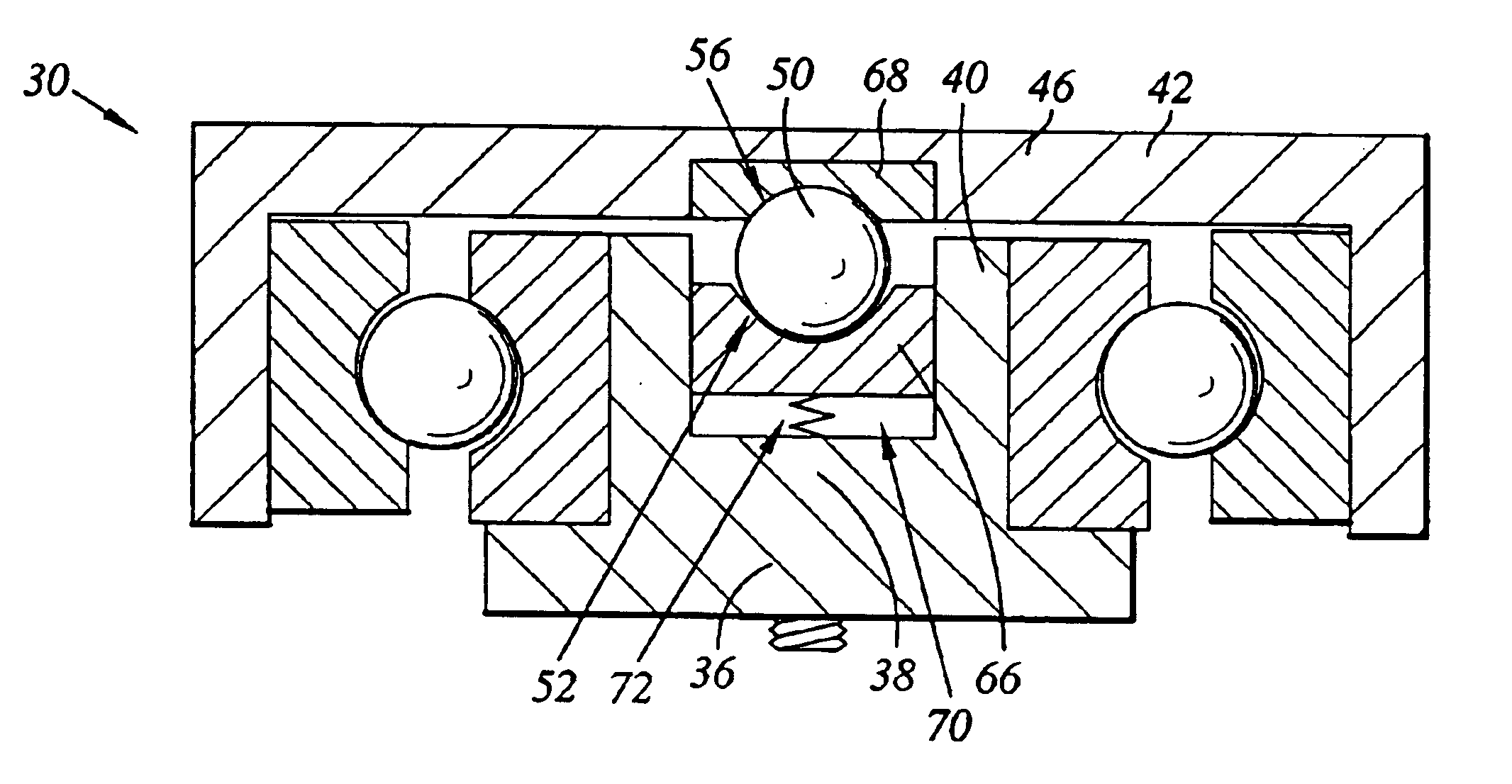

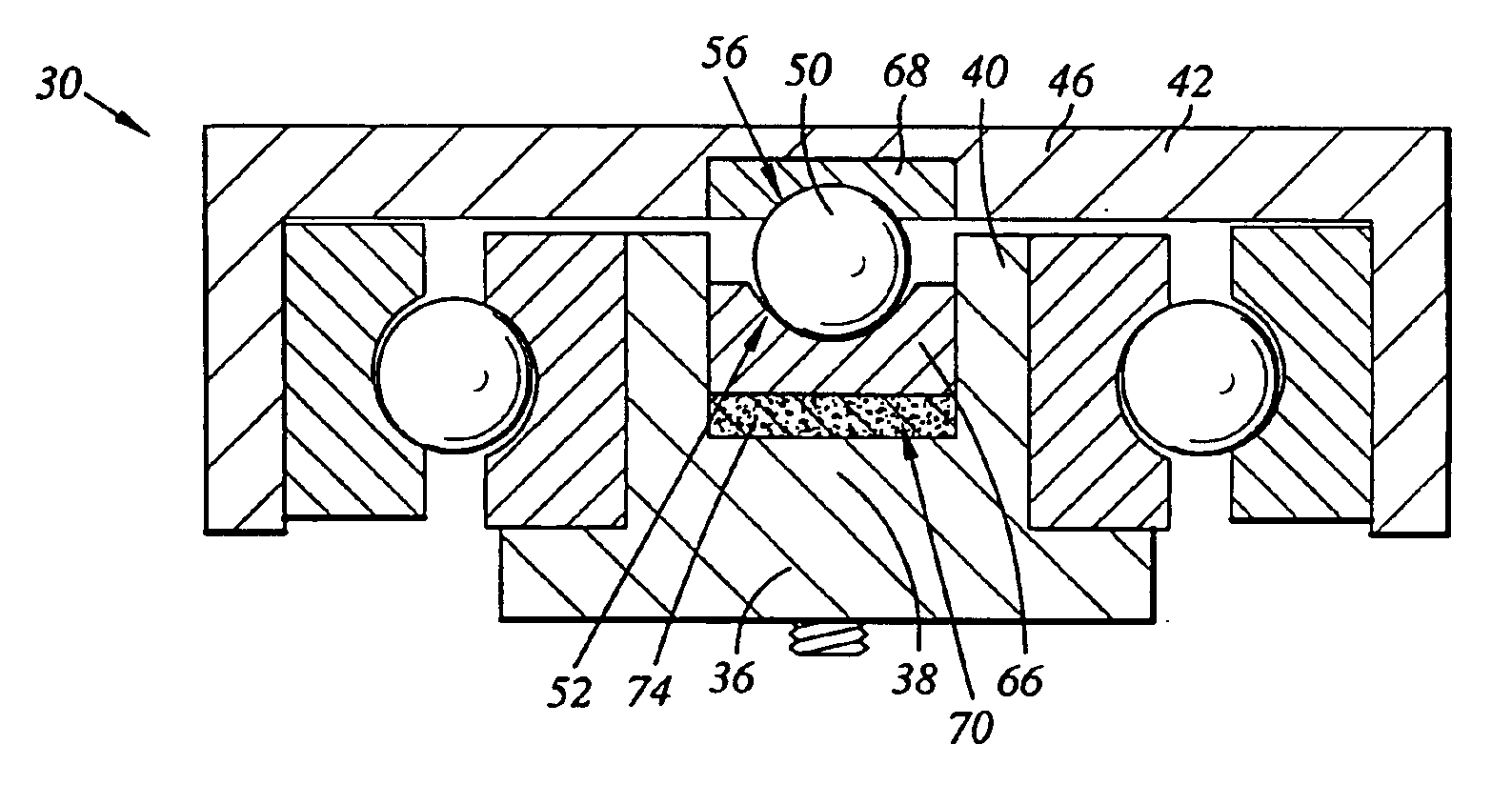

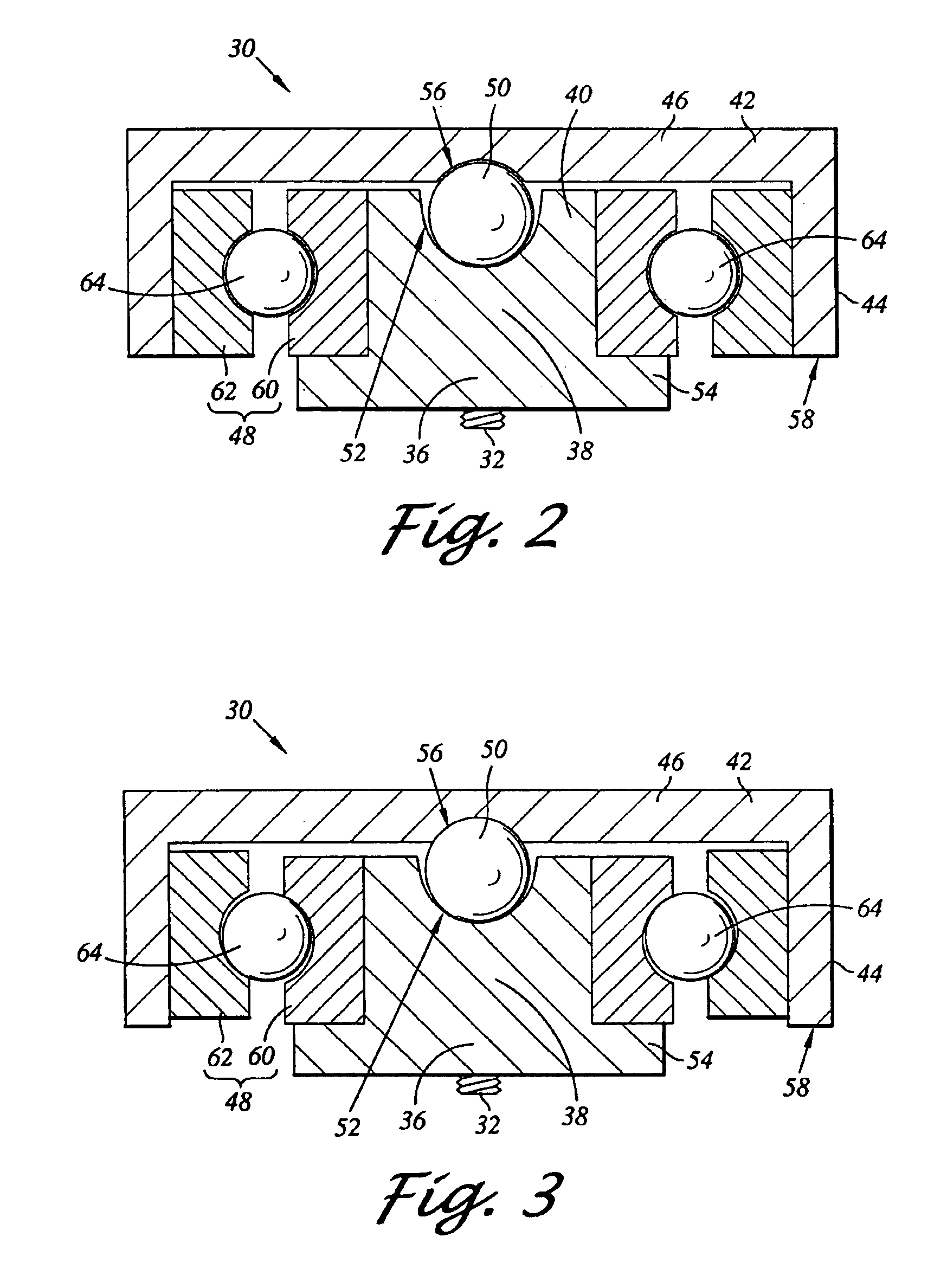

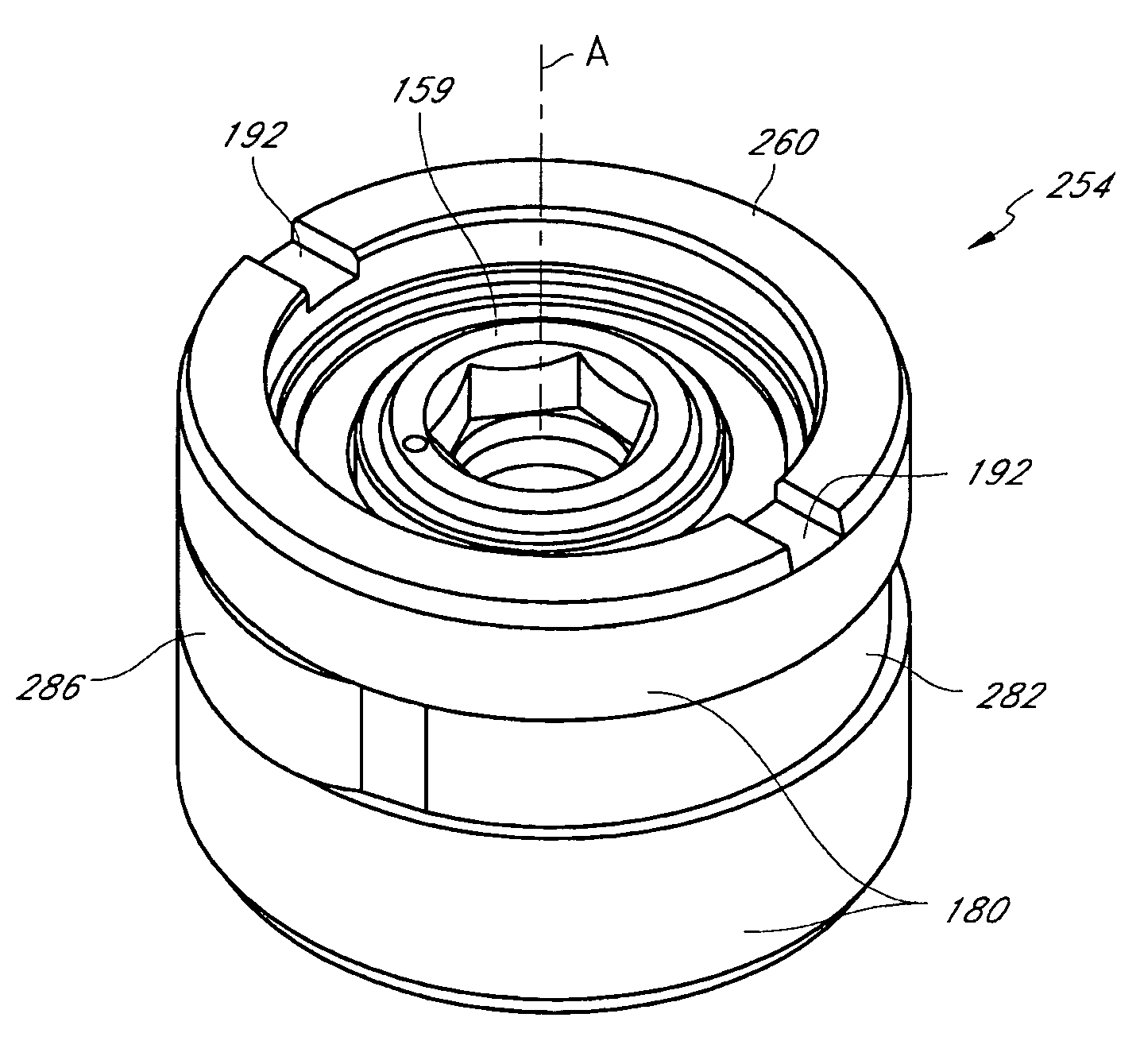

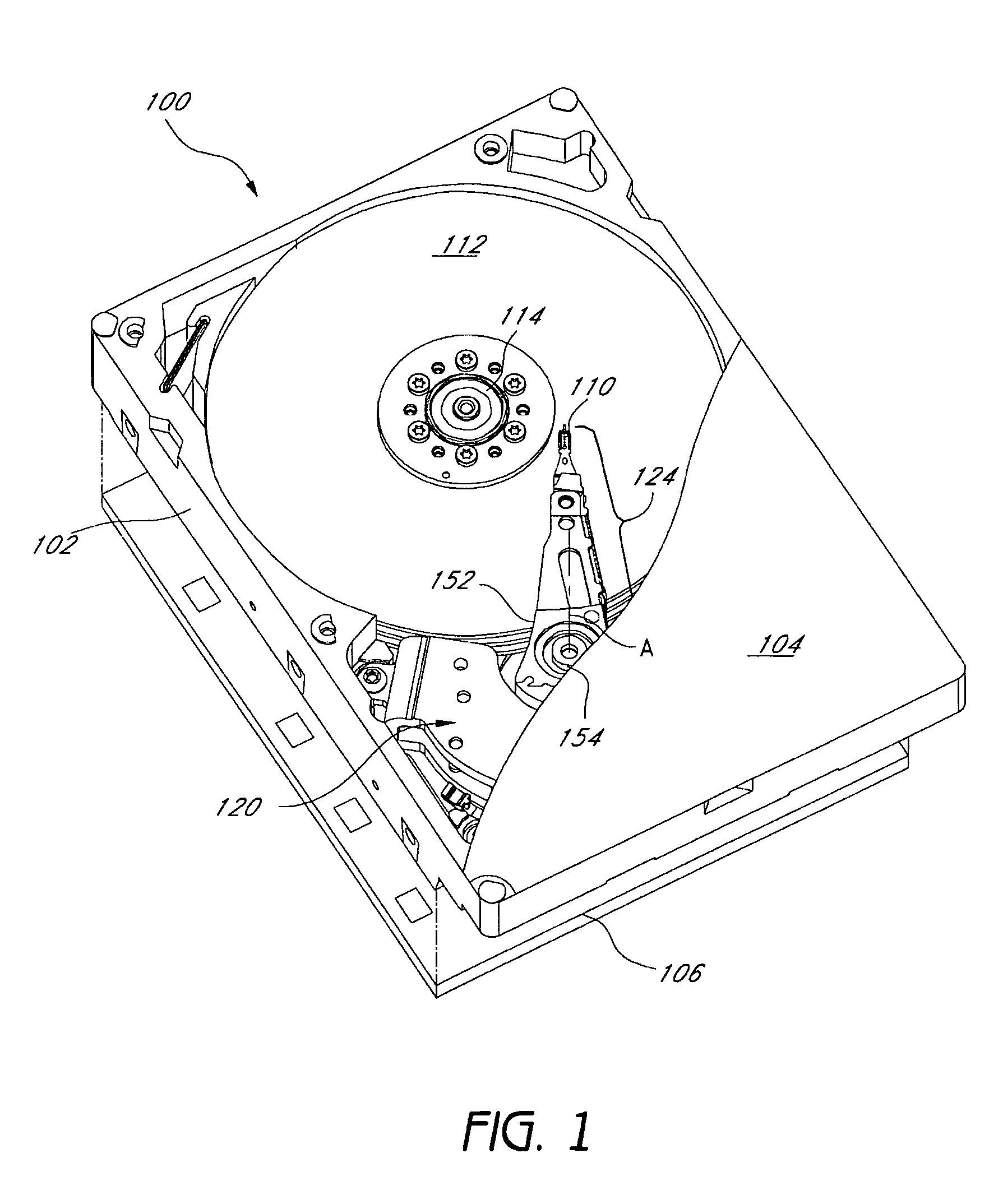

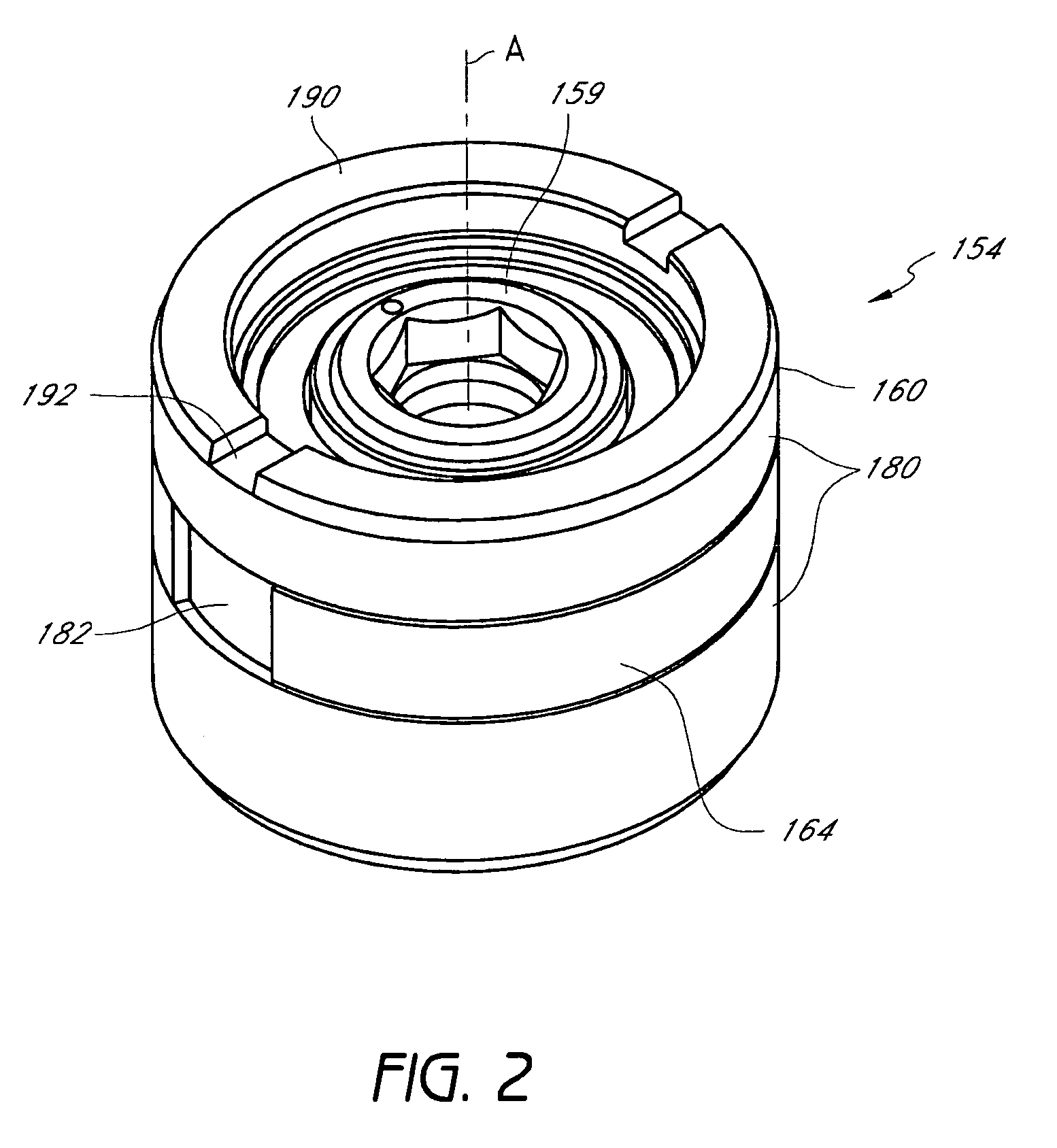

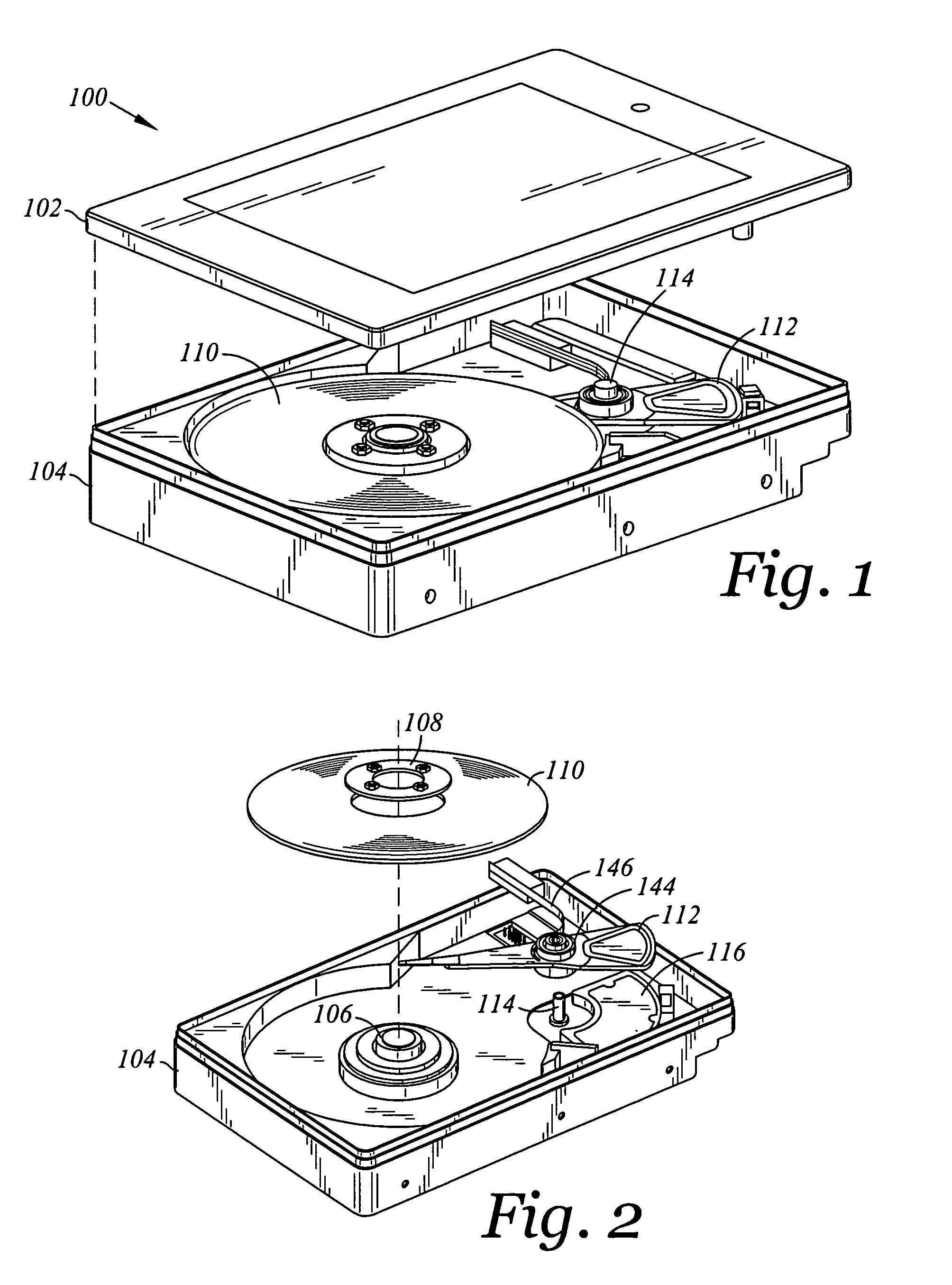

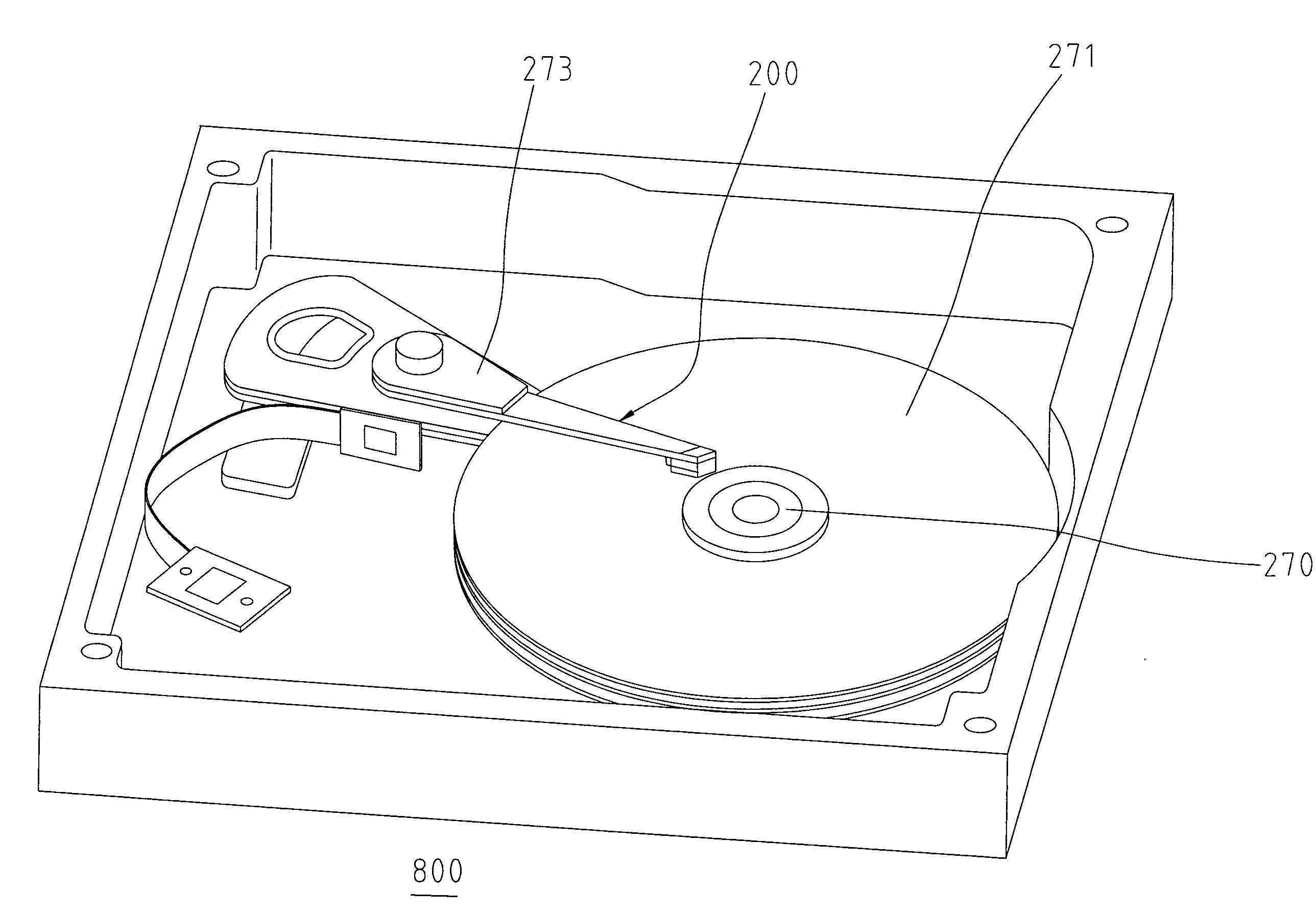

Disk drive including pivot-bearing cartridge tolerance ring having a damping layer for actuator resonance reduction

InactiveUS7085108B1Apparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionResonanceEngineering

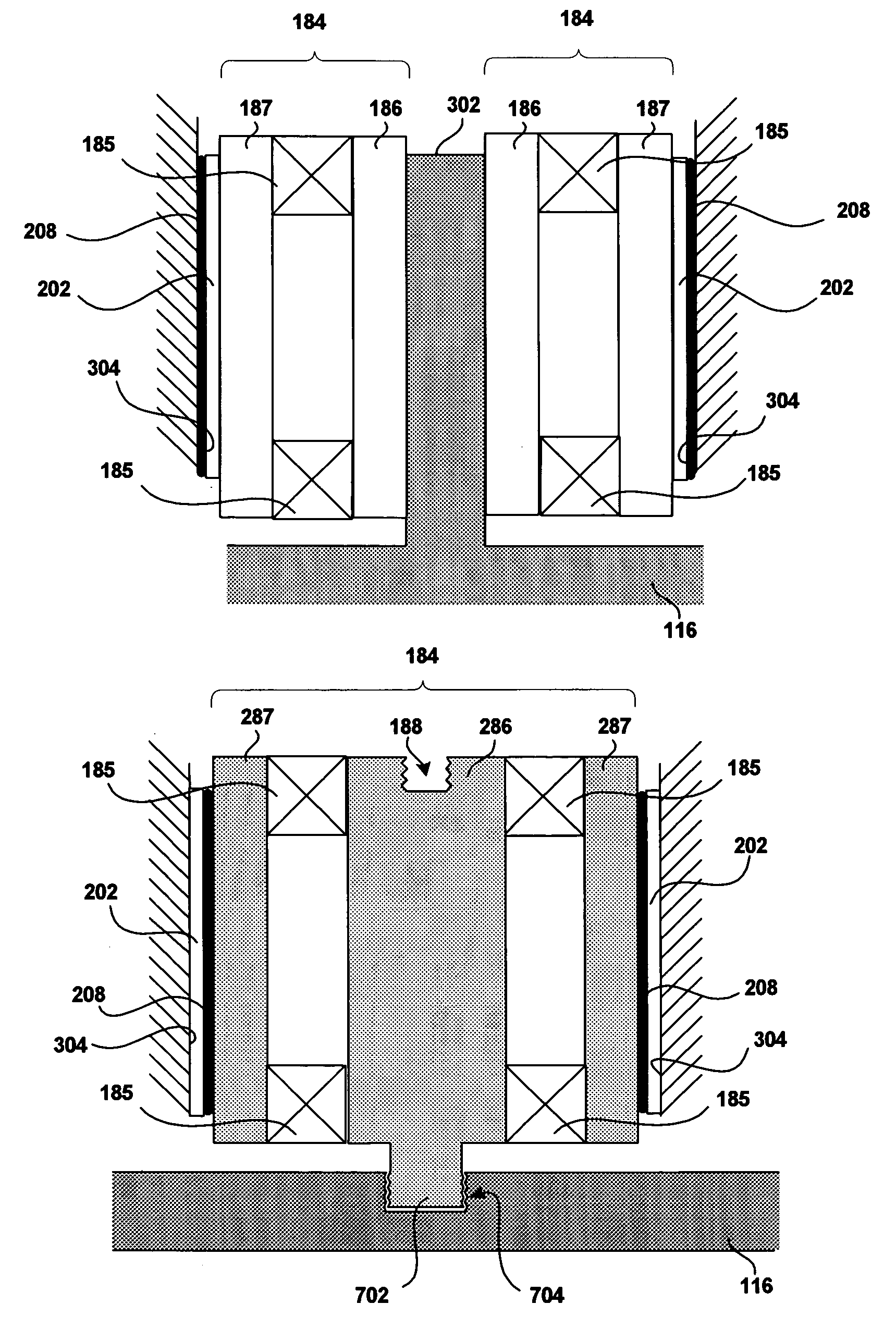

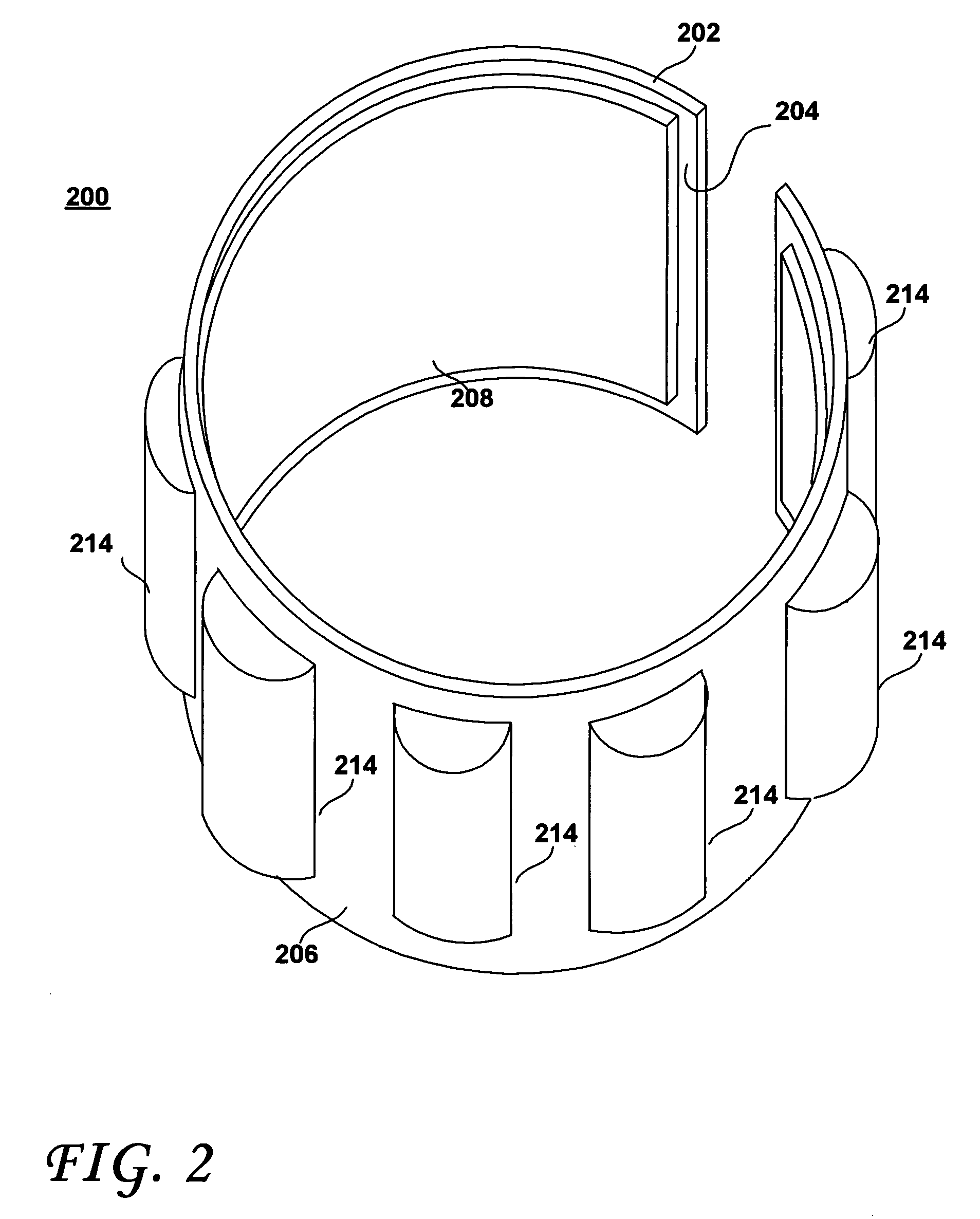

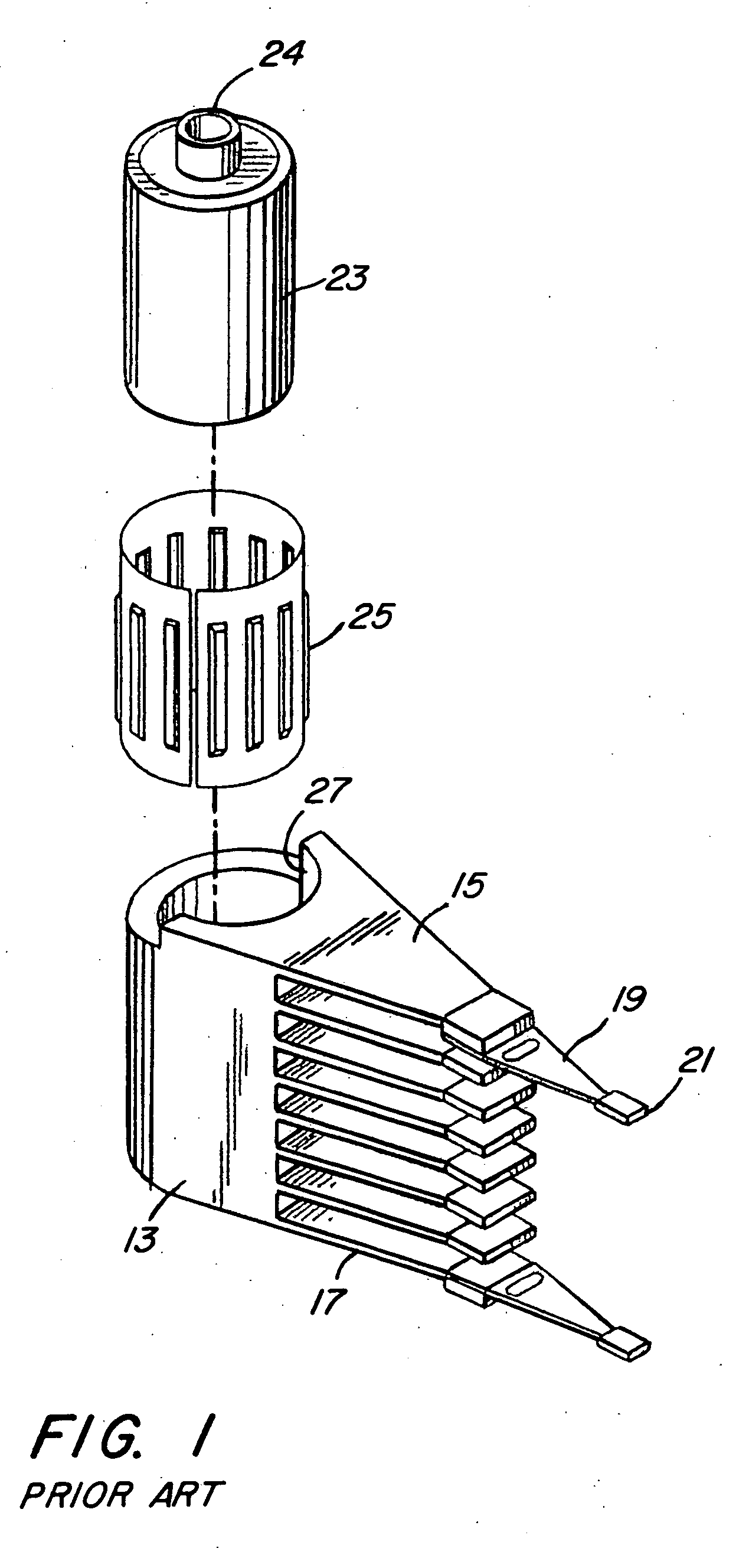

A disk drive includes a pivot-bearing cartridge configured to pivotally support the head stack assembly on the base of the drive. A tolerance ring is coupled to the pivot-bearing cartridge and includes a single sleeve defining an inner sleeve surface facing the pivot-bearing cartridge and an outer sleeve surface facing away therefrom, and a layer of dampening material disposed on the inner or outer sleeve surfaces so as to be in contact with the pivot-bearing cartridge or the bore surface of the through bore that is defined in the body portion of the head stack assembly, respectively.

Owner:WESTERN DIGITAL TECH INC

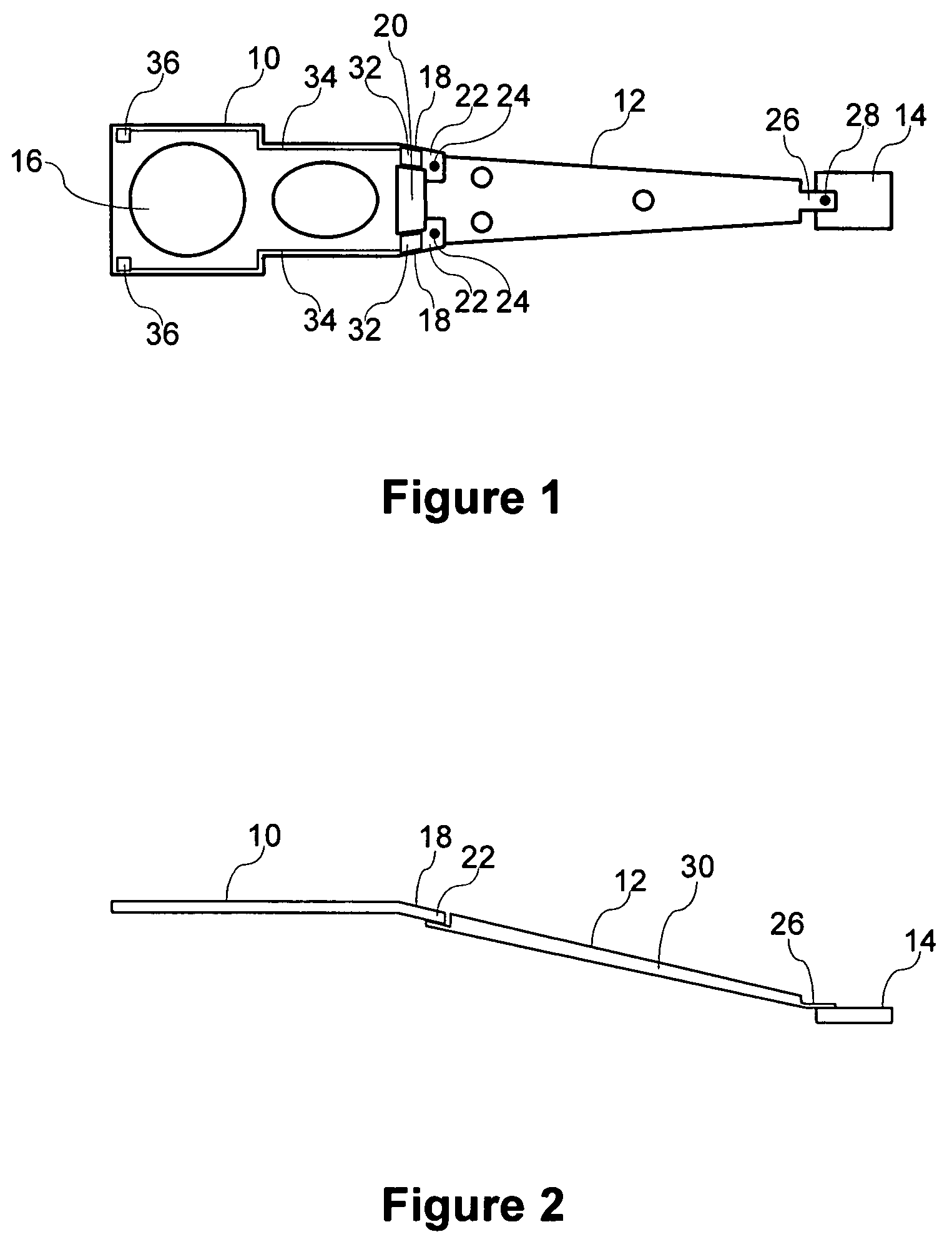

Mounting assembly

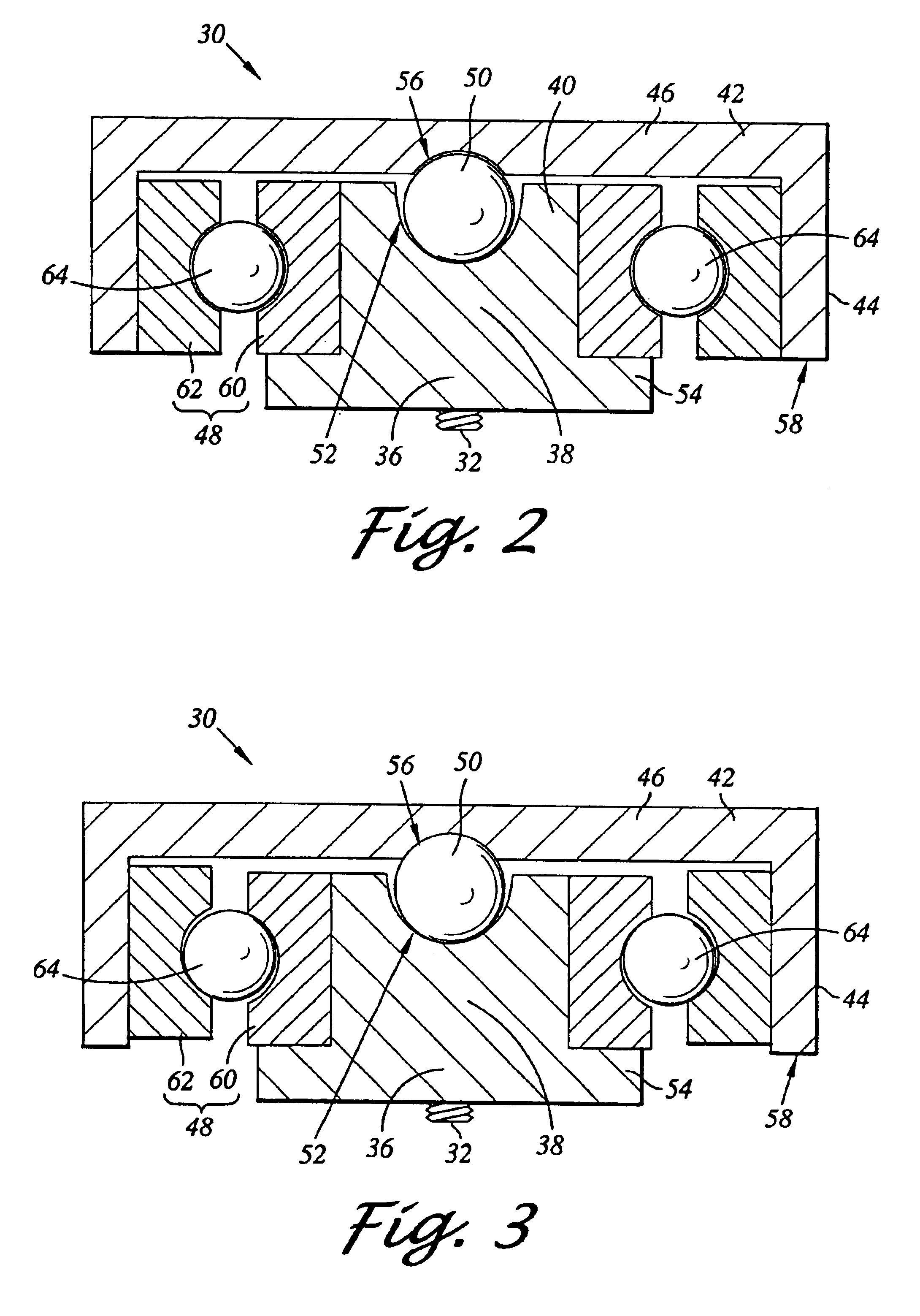

ActiveUS20080199254A1Less sensitiveEasy to controlRecord information storagePivotal connectionsEngineeringMechanical engineering

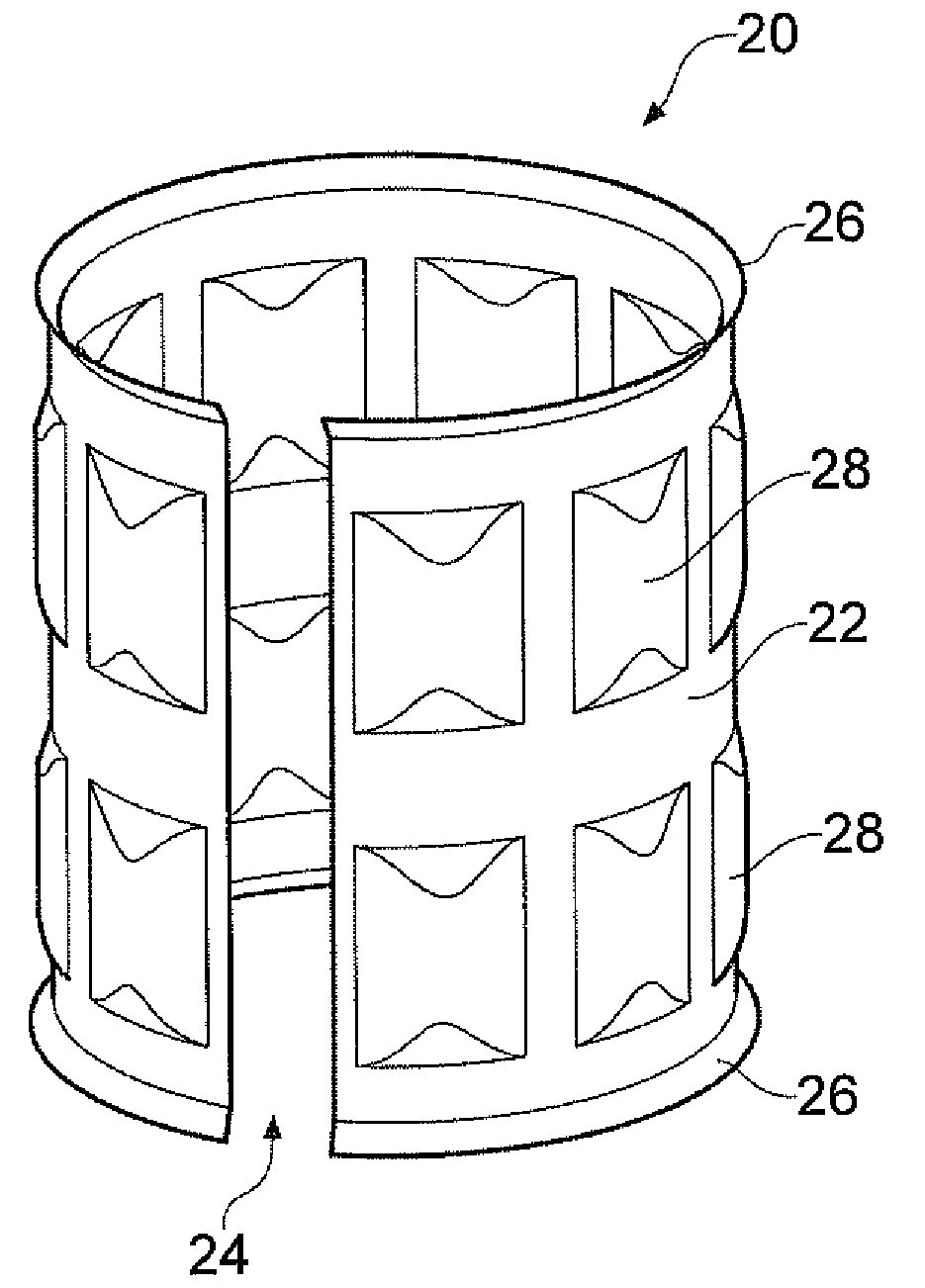

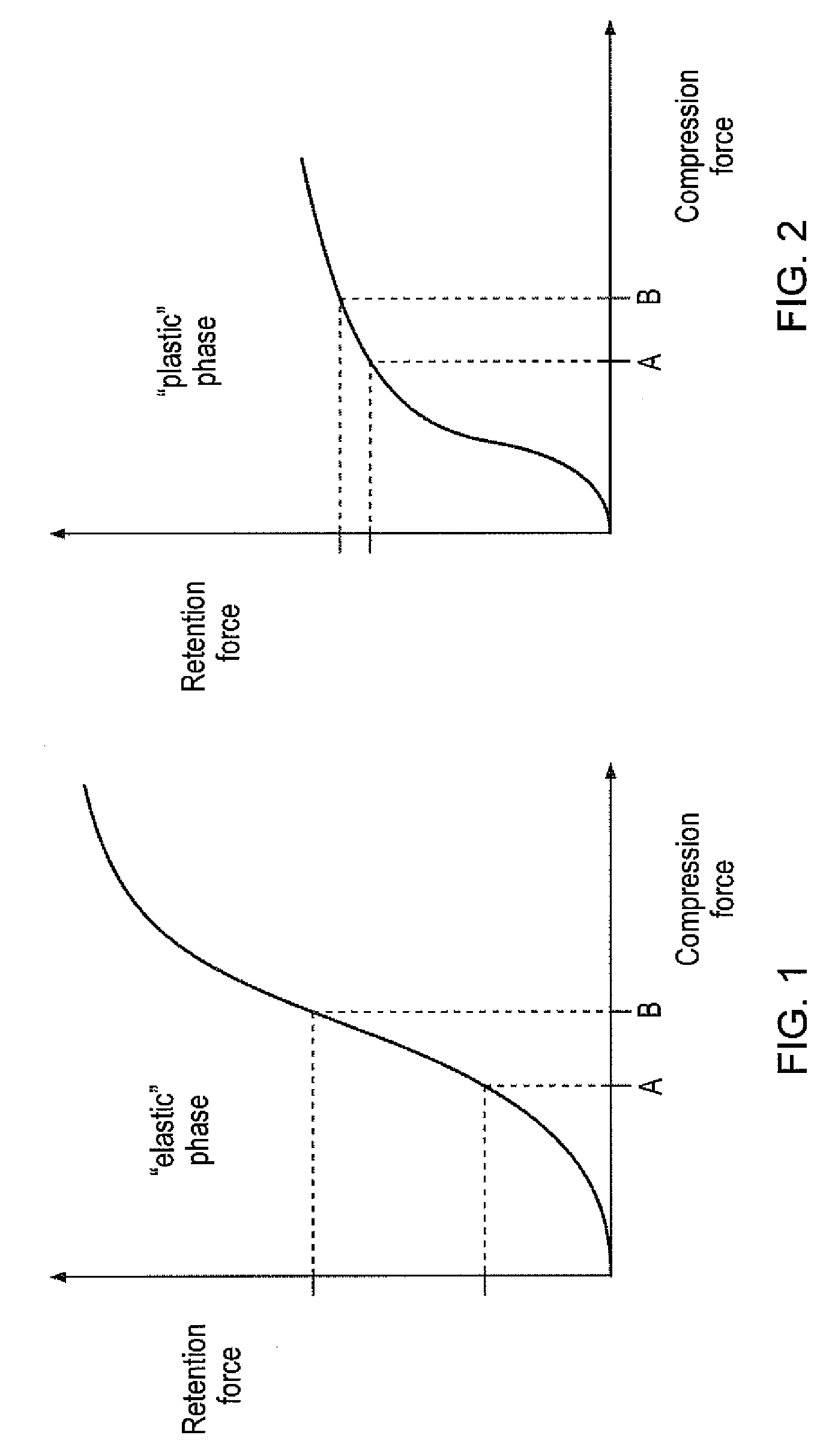

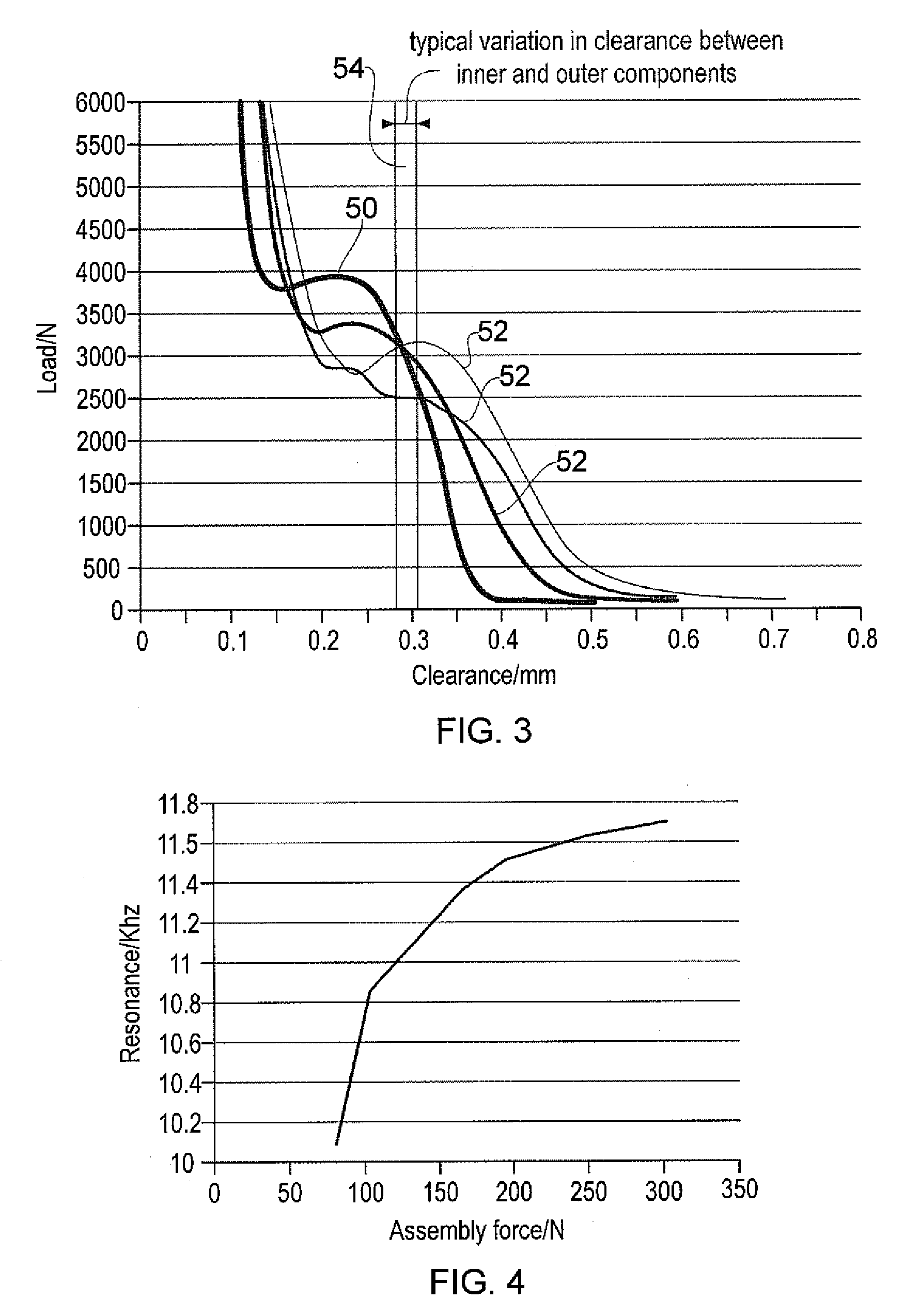

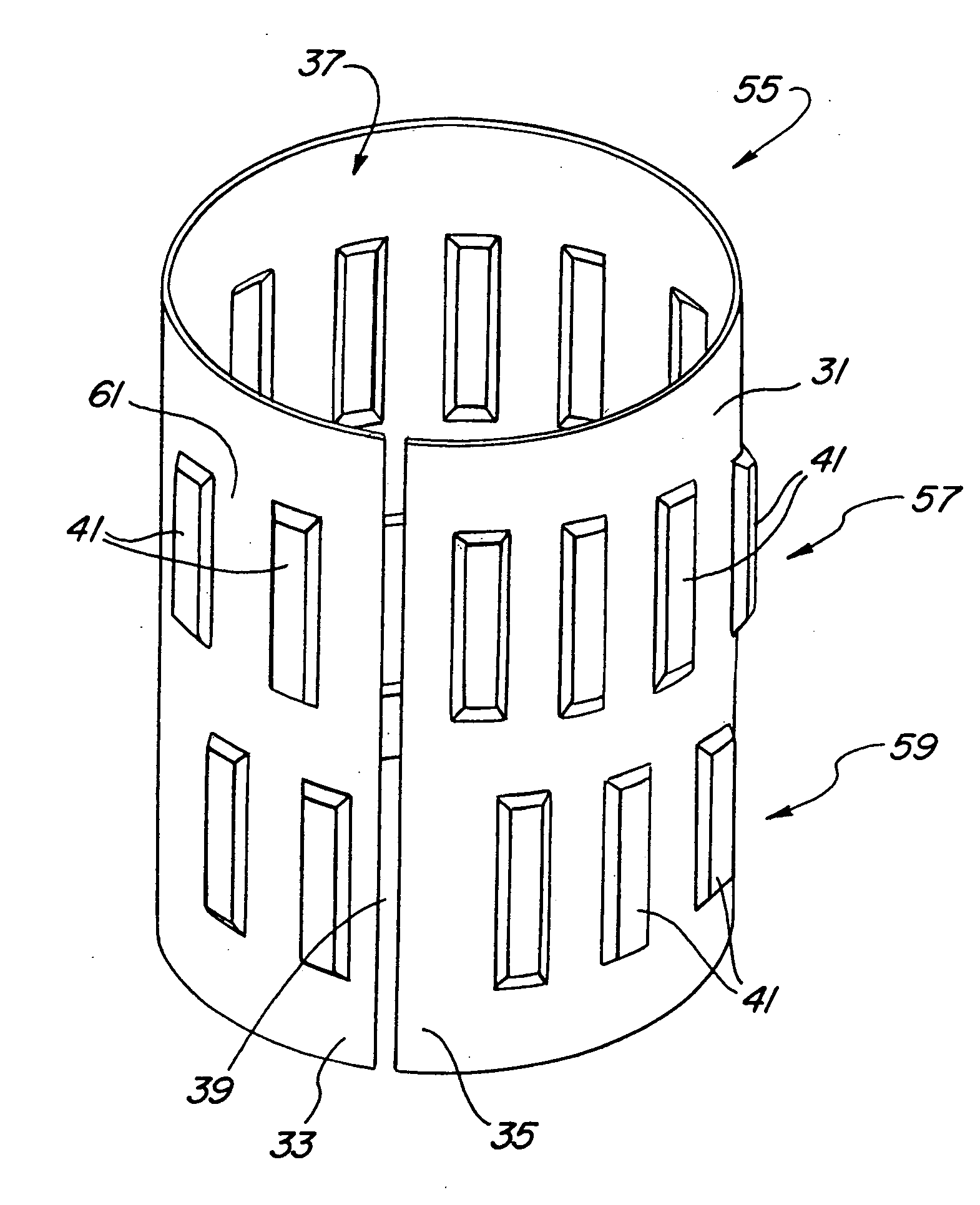

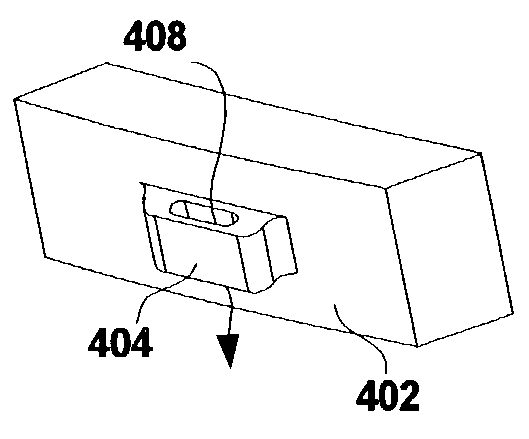

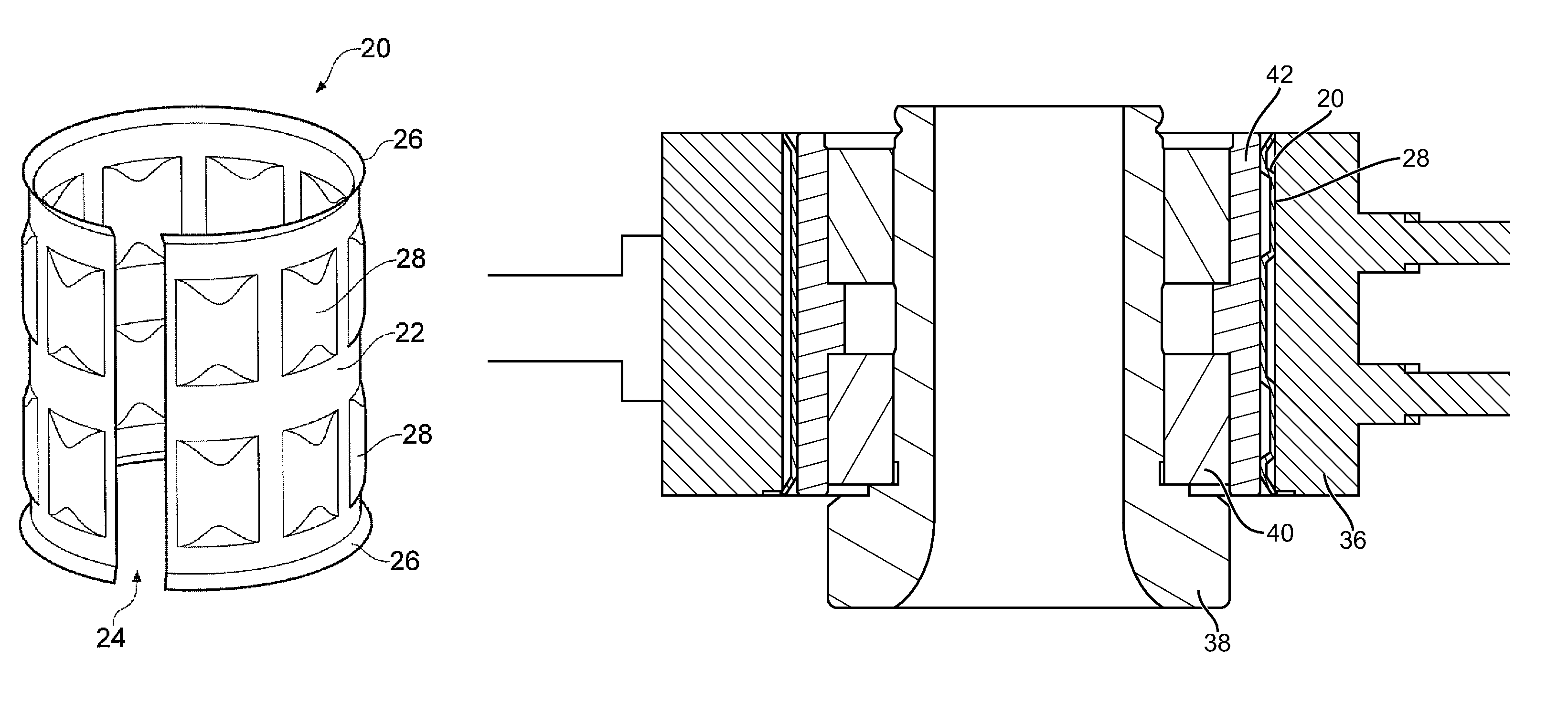

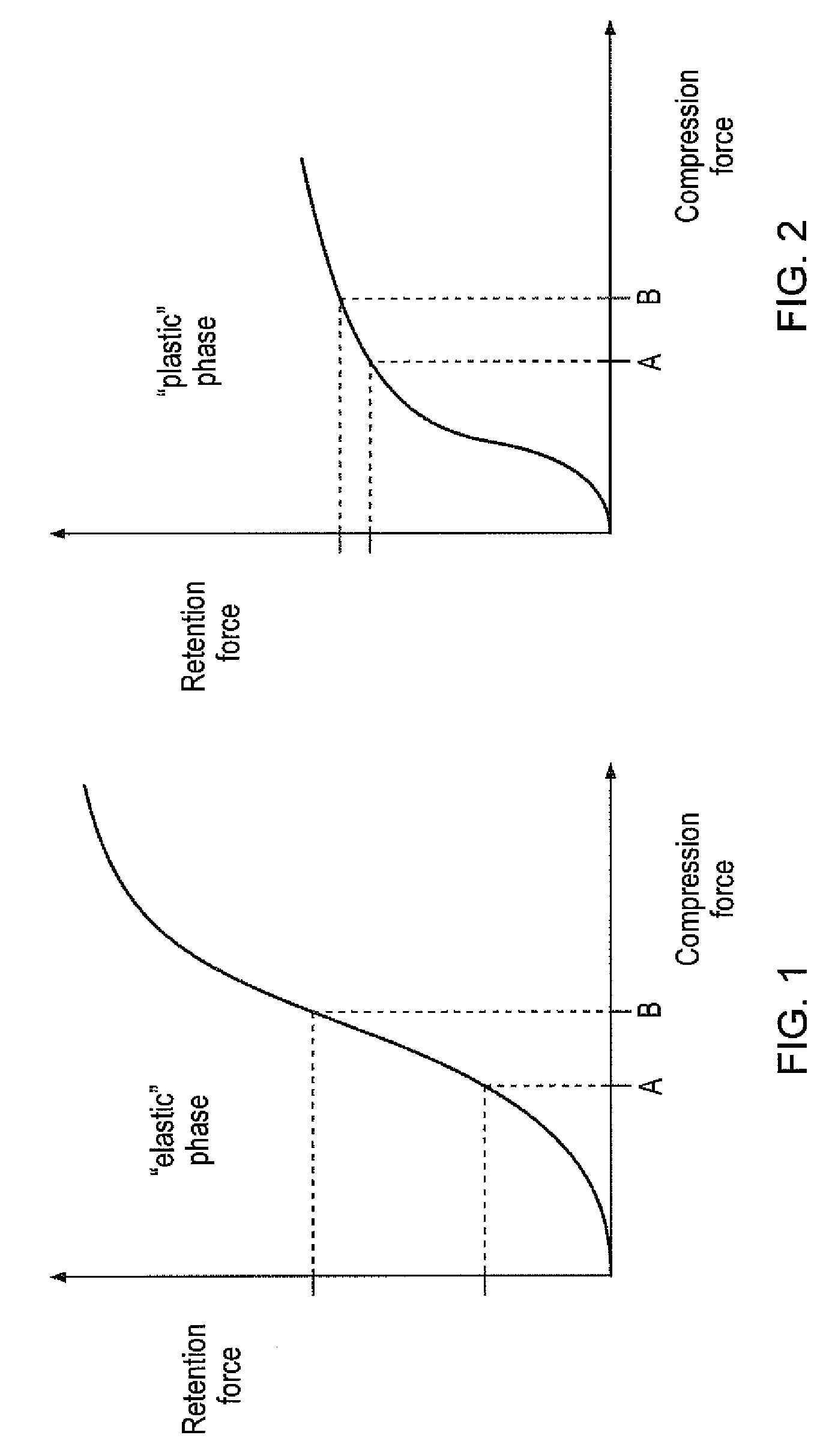

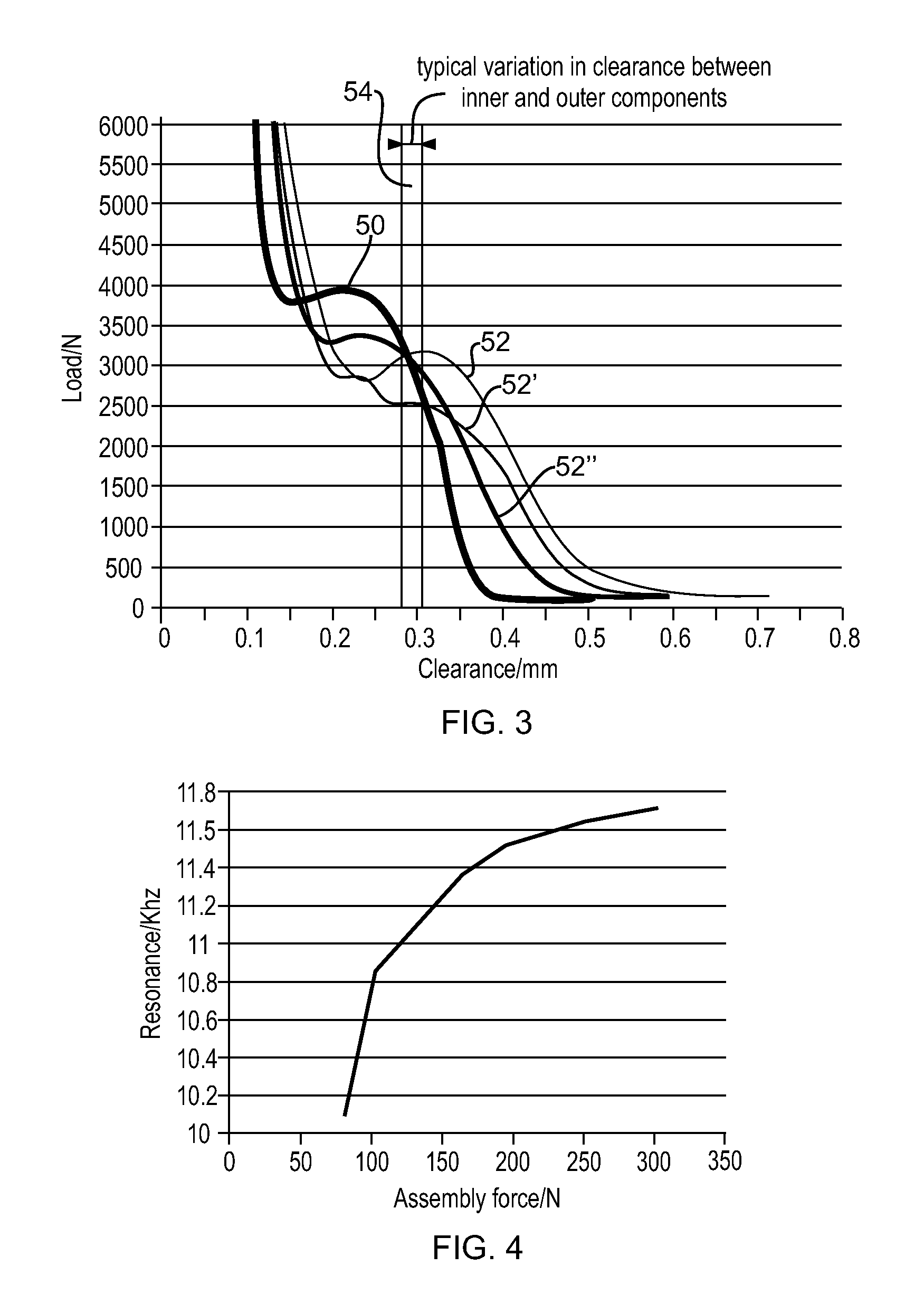

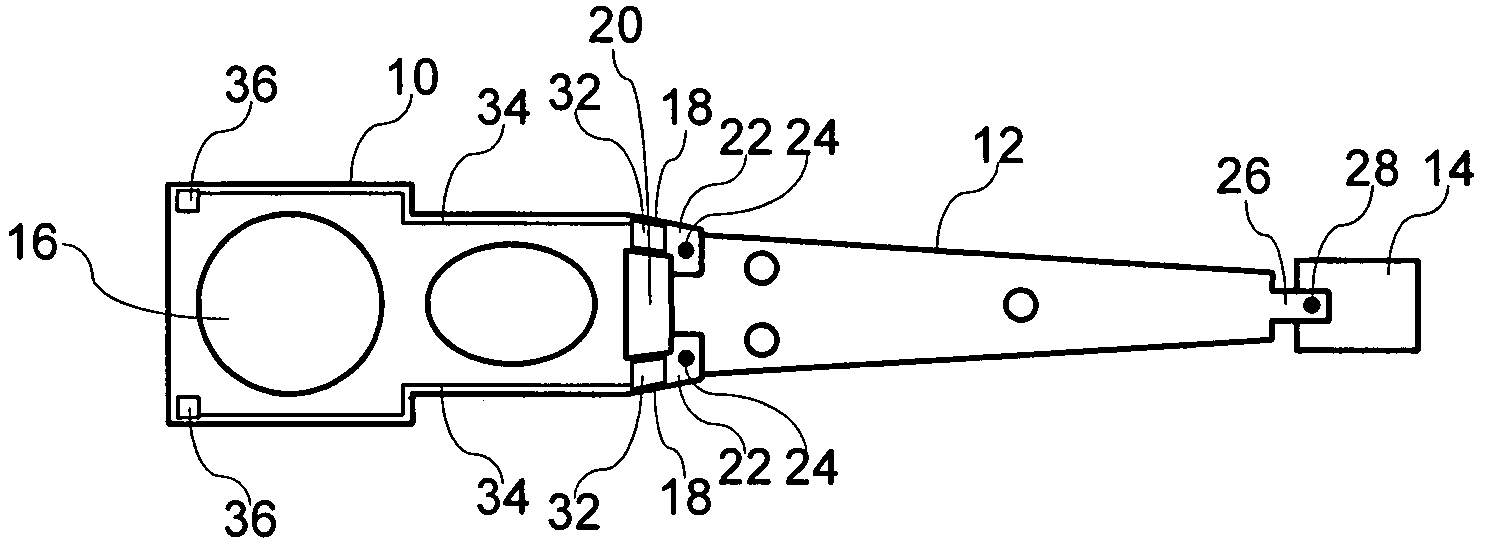

A mounting assembly comprising mating inner and outer components (36, 38) mounted together using a tolerance (20) is disclosed. The tolerance ring (20) has radially extending projections (28) that are configured to cause the tolerance ring (20) to operate into the plastic phase of its compression force / retention force characteristic. This can be achieved by using softer projections than those found in conventional tolerance rings. The force required to mount the tolerance ring and a range of retention forces exhibited by it for a given variance in sizes of mating components is thereby stabilised.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

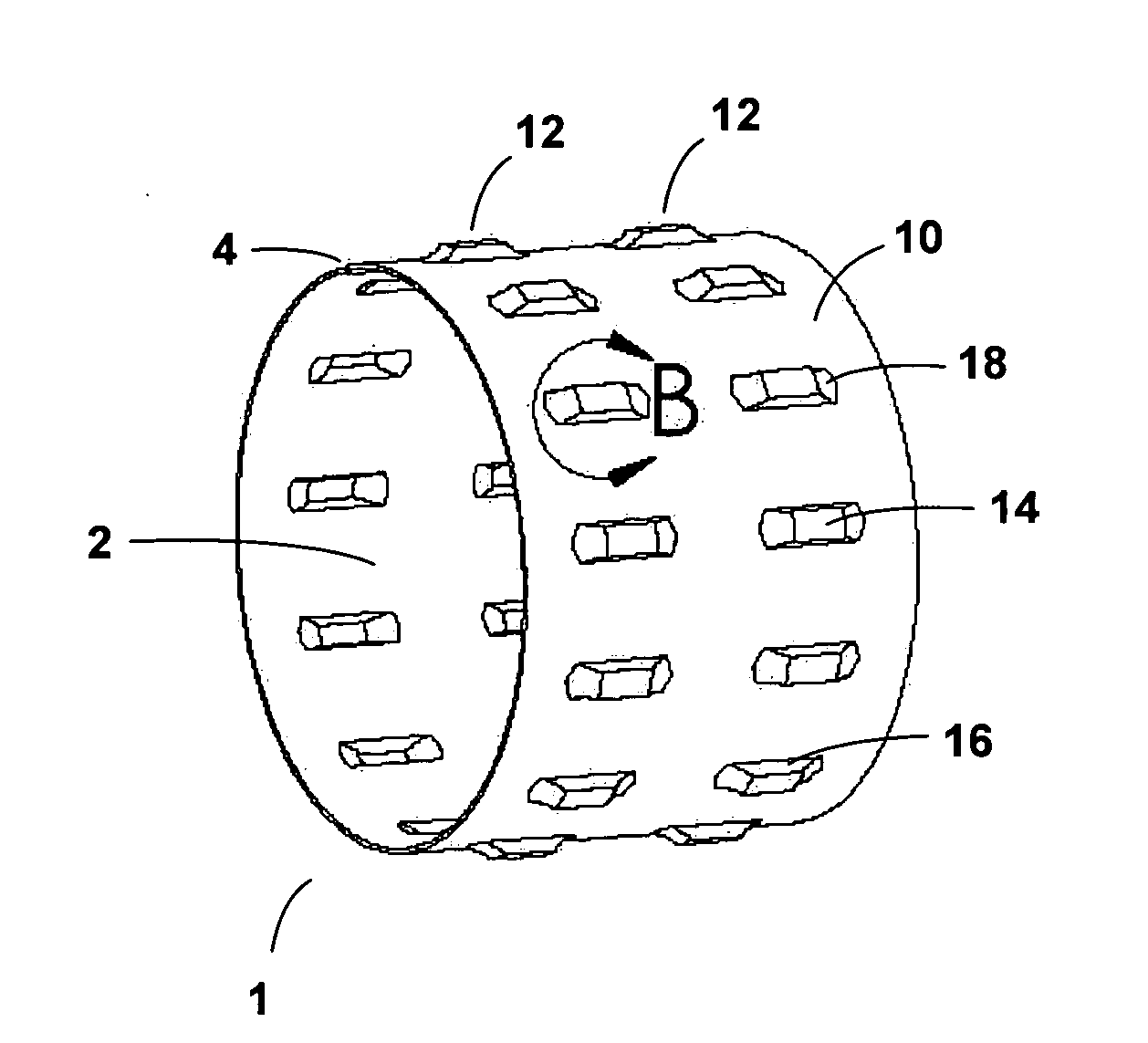

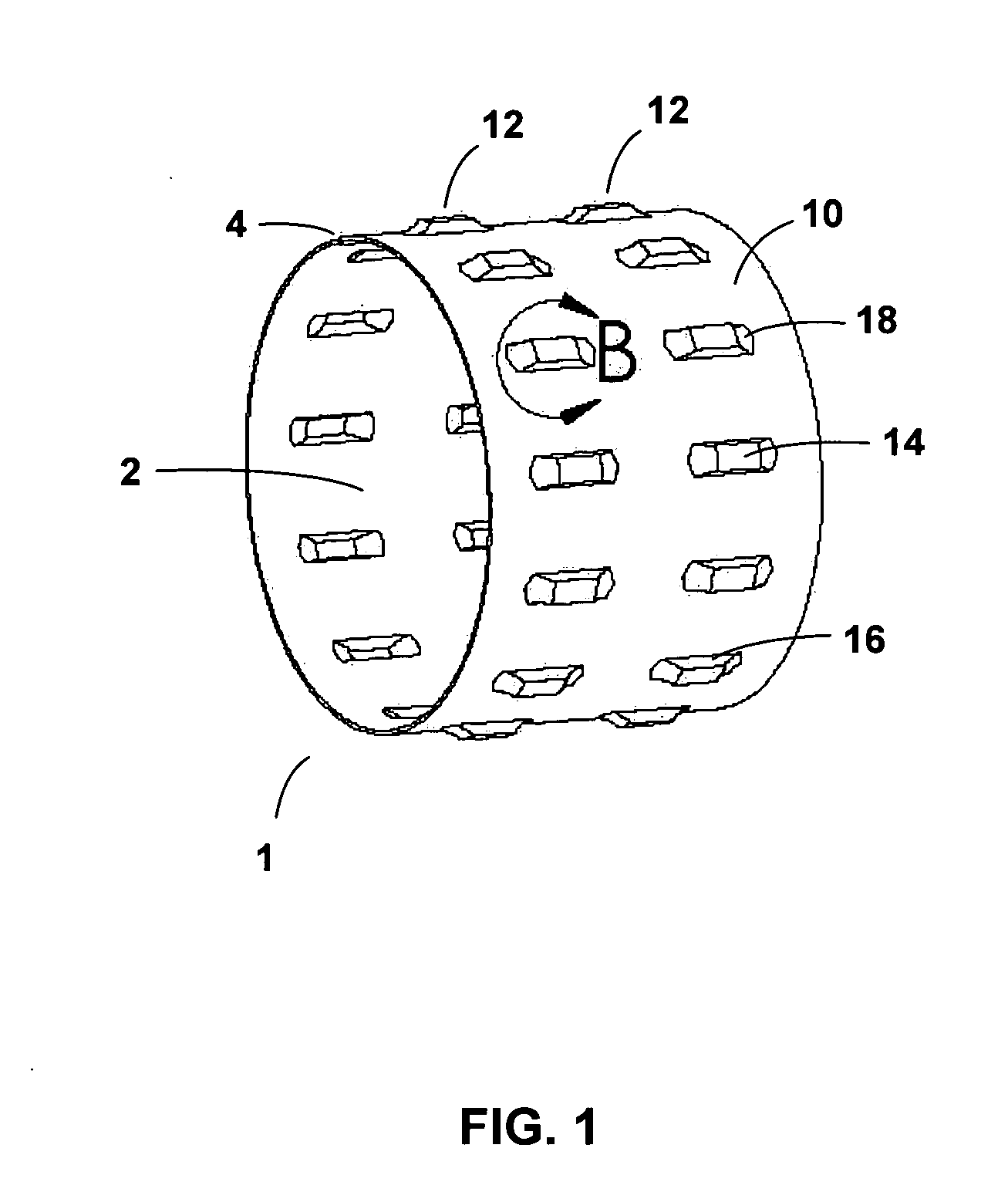

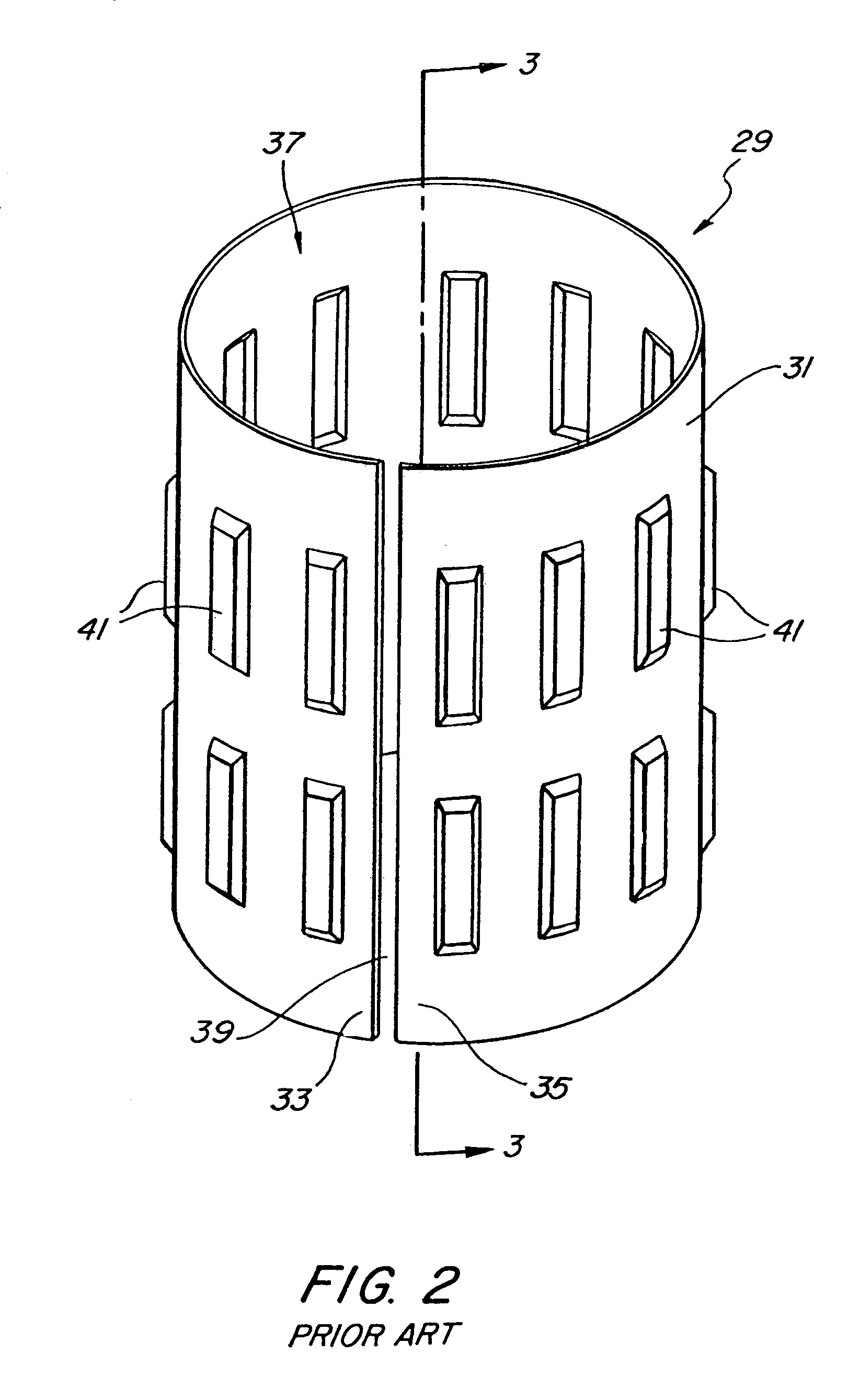

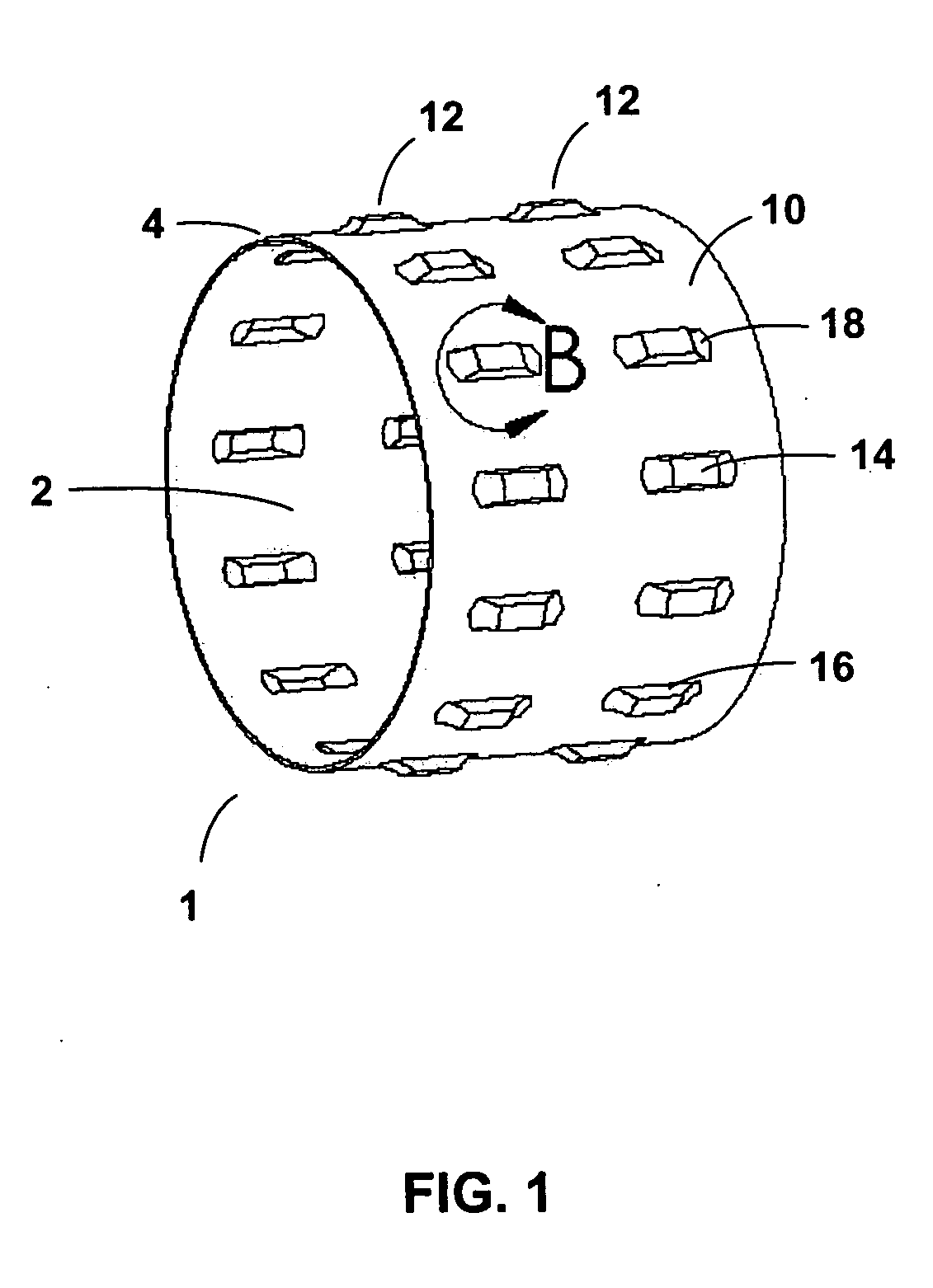

Tolerance ring having variable height and/or assymmetrically located bumps

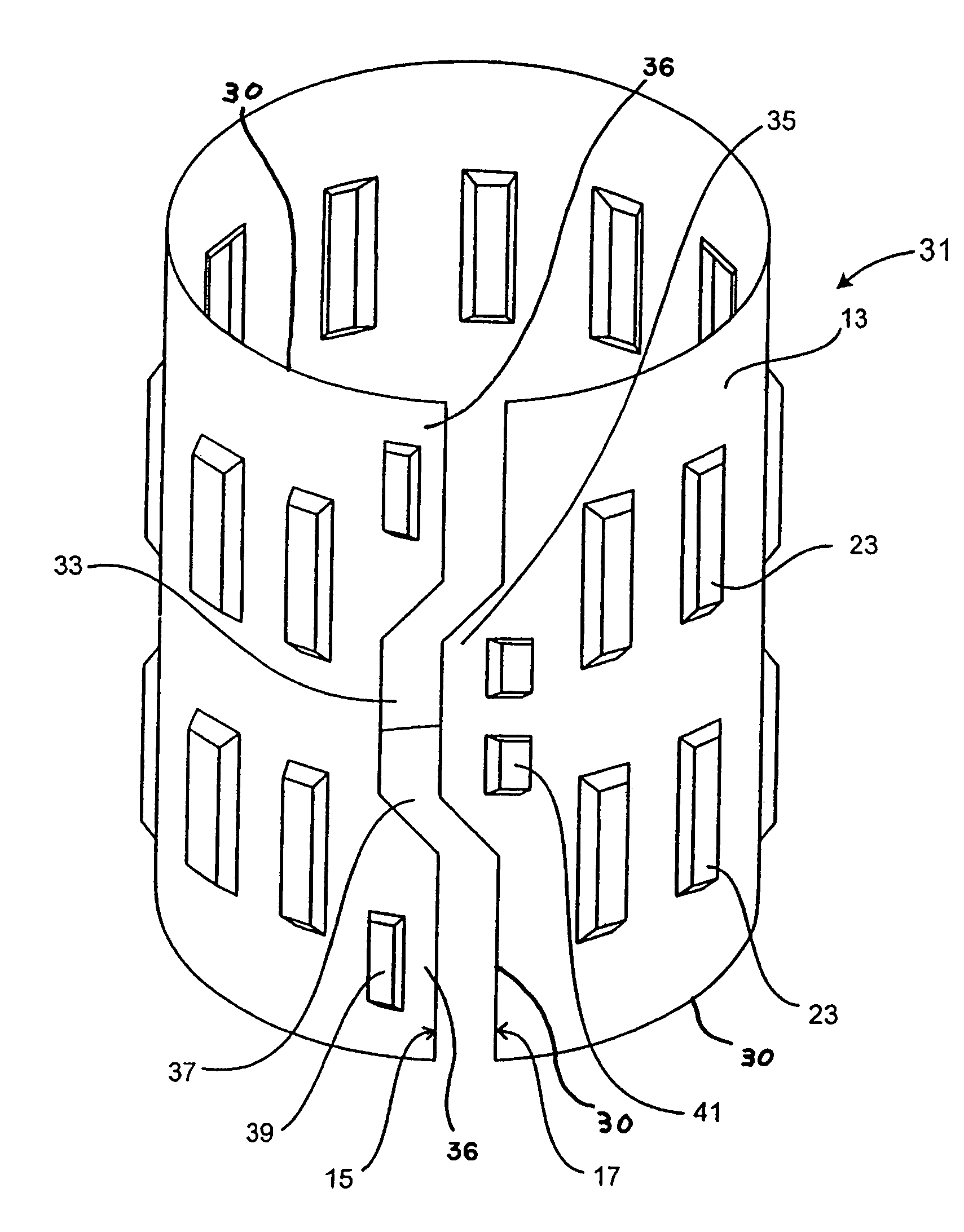

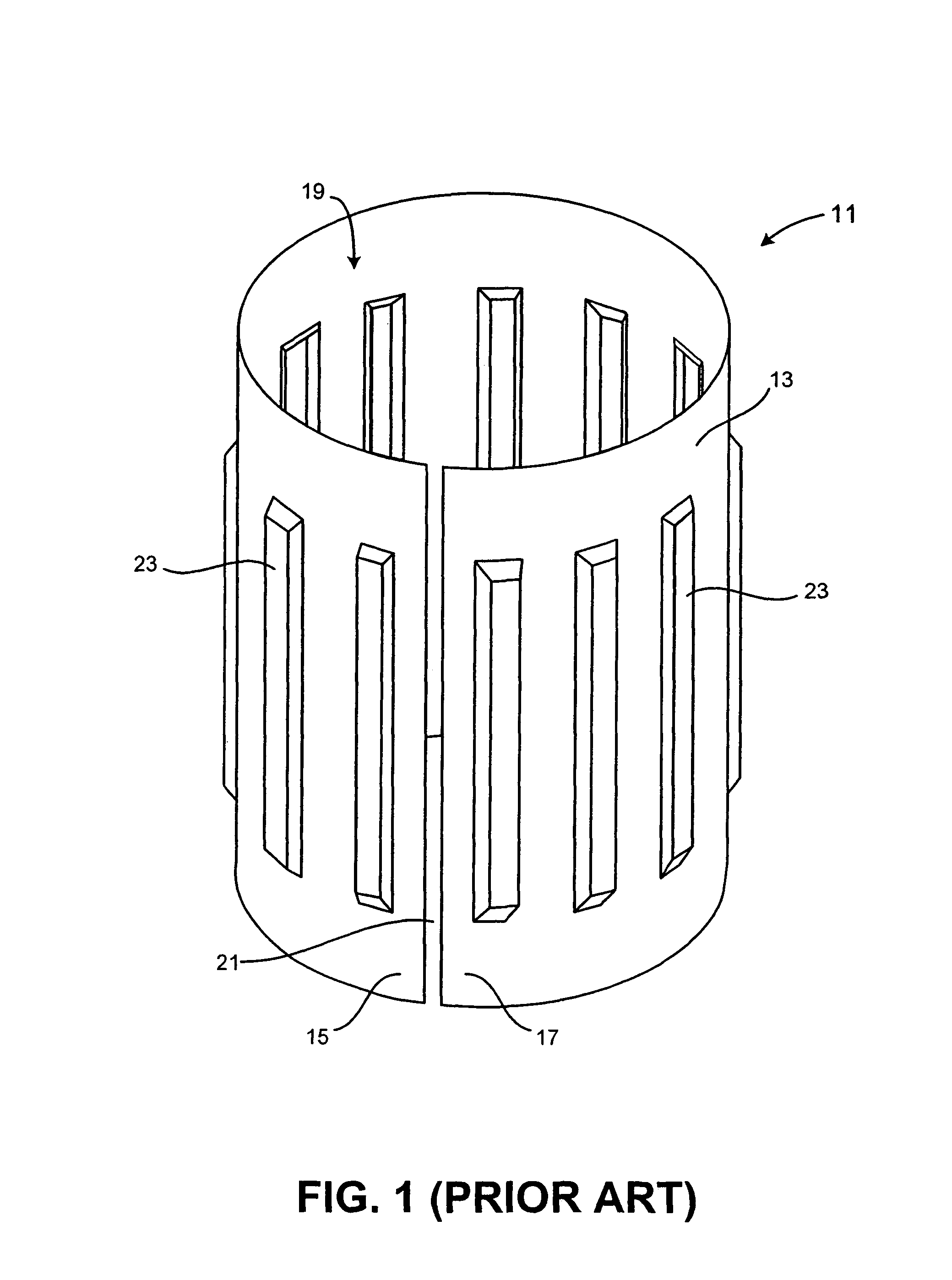

A tolerance ring configured to reduce torque ripple for a pivot bearing in an actuator arm assembly. The tolerance ring comprises a cylinder having a predetermined length, and a first and a second row of contacting portions arranged around the surface of the cylinder, the contacting portions of the second row are circumferentially displaced with respect to the first row by a distance greater than zero but less than the distance of the contacting portion and the spacing between adjacent contacting portions in the first row.

Owner:INTRL PLEX TECH INC

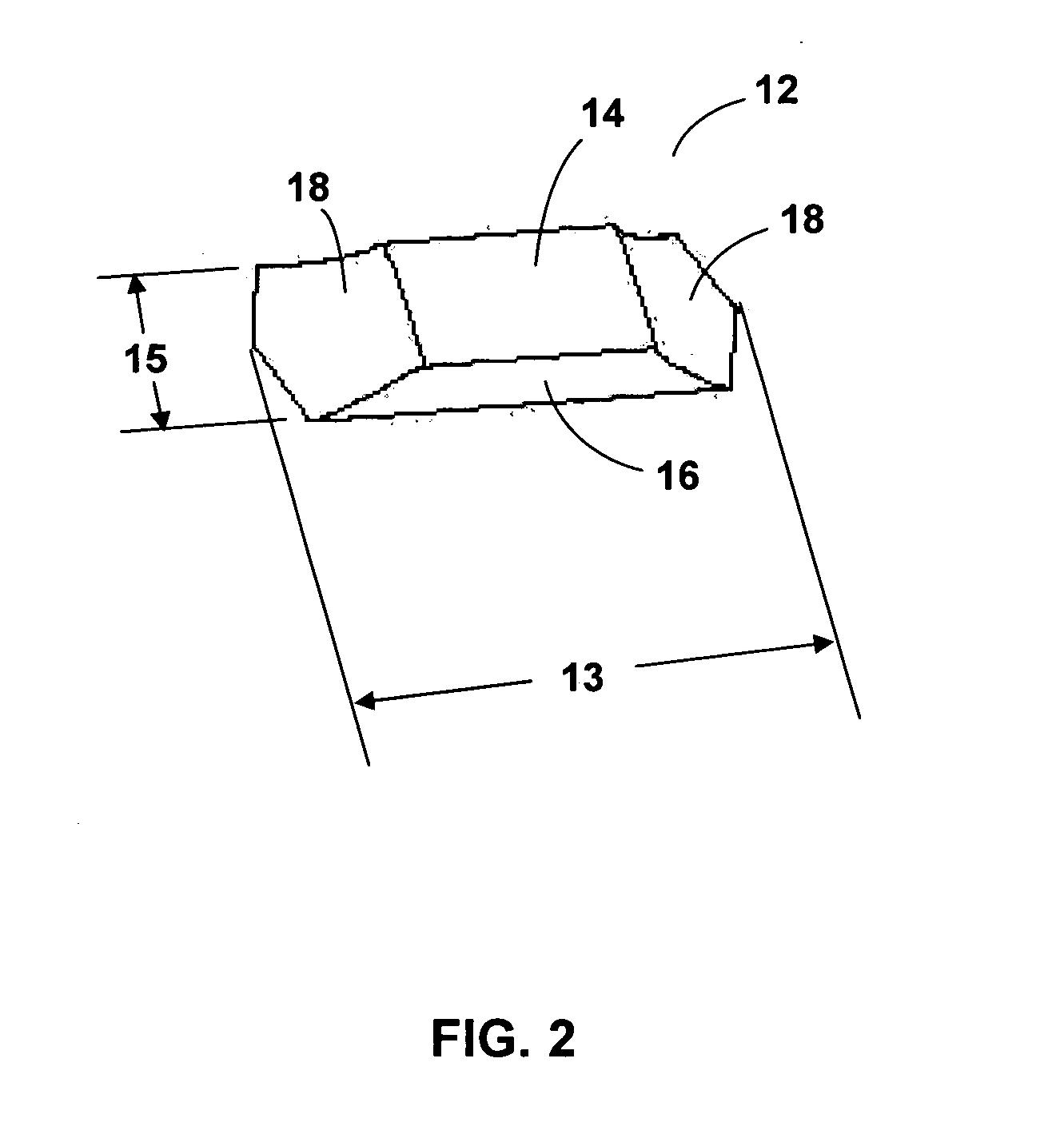

Tolerance ring with debris-reducing profile

A tolerance ring for applications requiring cleanliness has contacting portions having a novel profile that reduces debris generation during installation of the tolerance ring while still providing adequate stiffness after installation. The tolerance ring is suitable for cylindrical interface applications where both a reduction in debris generation and high interface stiffness are desirable, such as the interface between an actuator pivot bearing and an actuator arm in a magnetic hard disk drive.

Owner:INTRL PLEX TECH INC

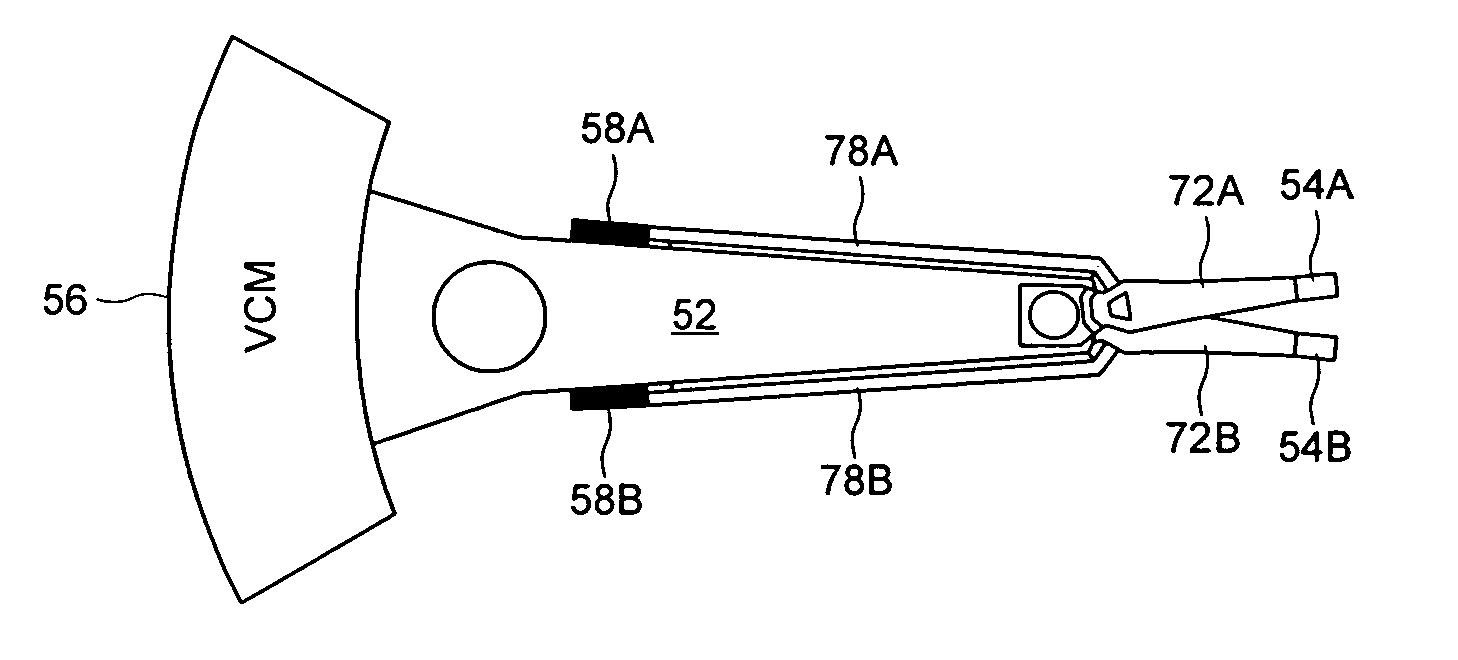

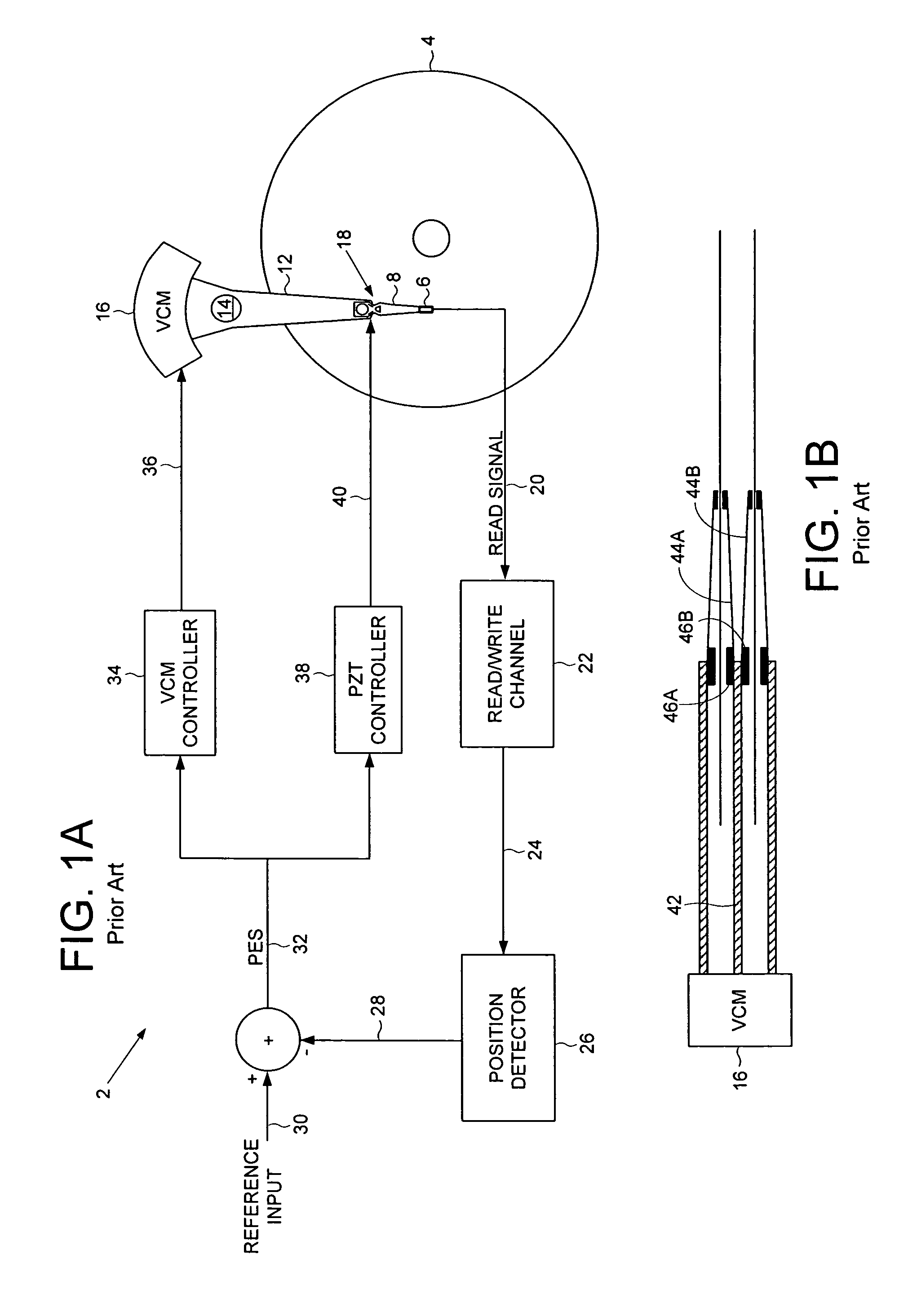

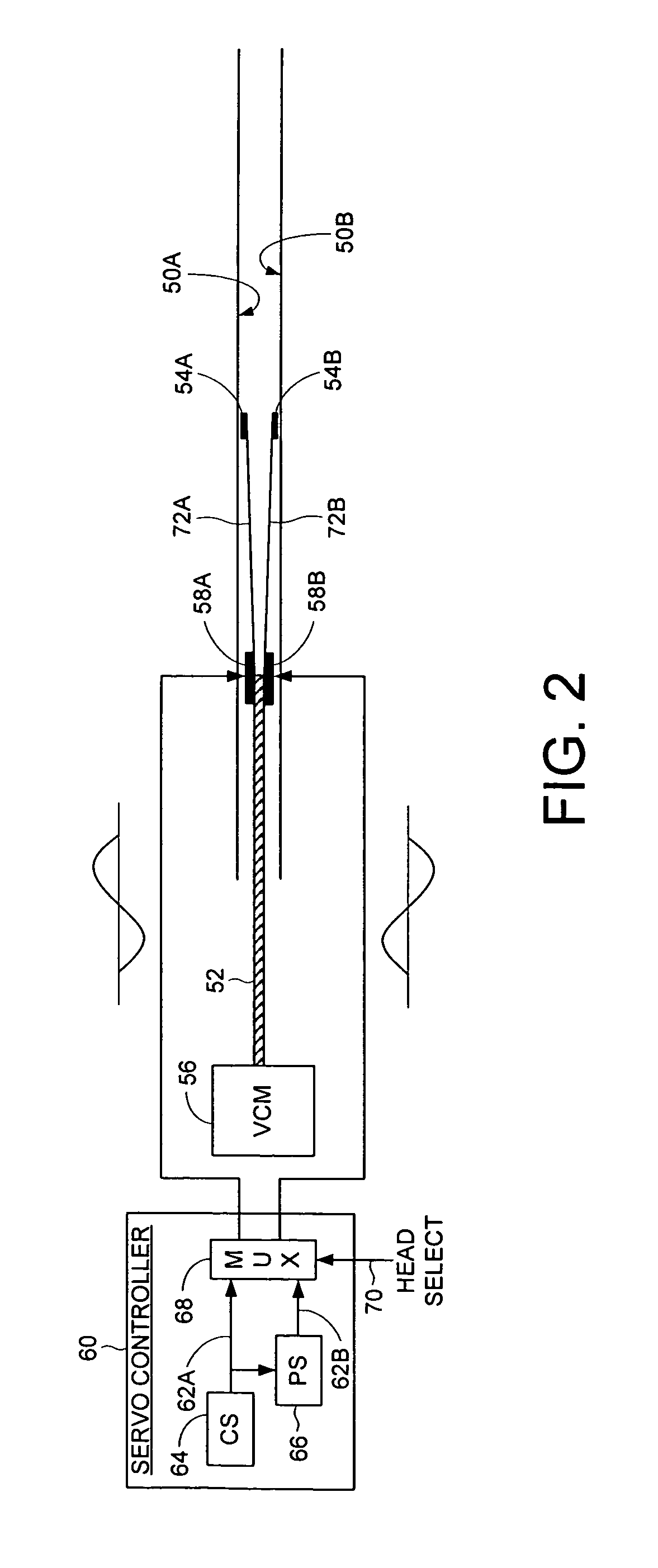

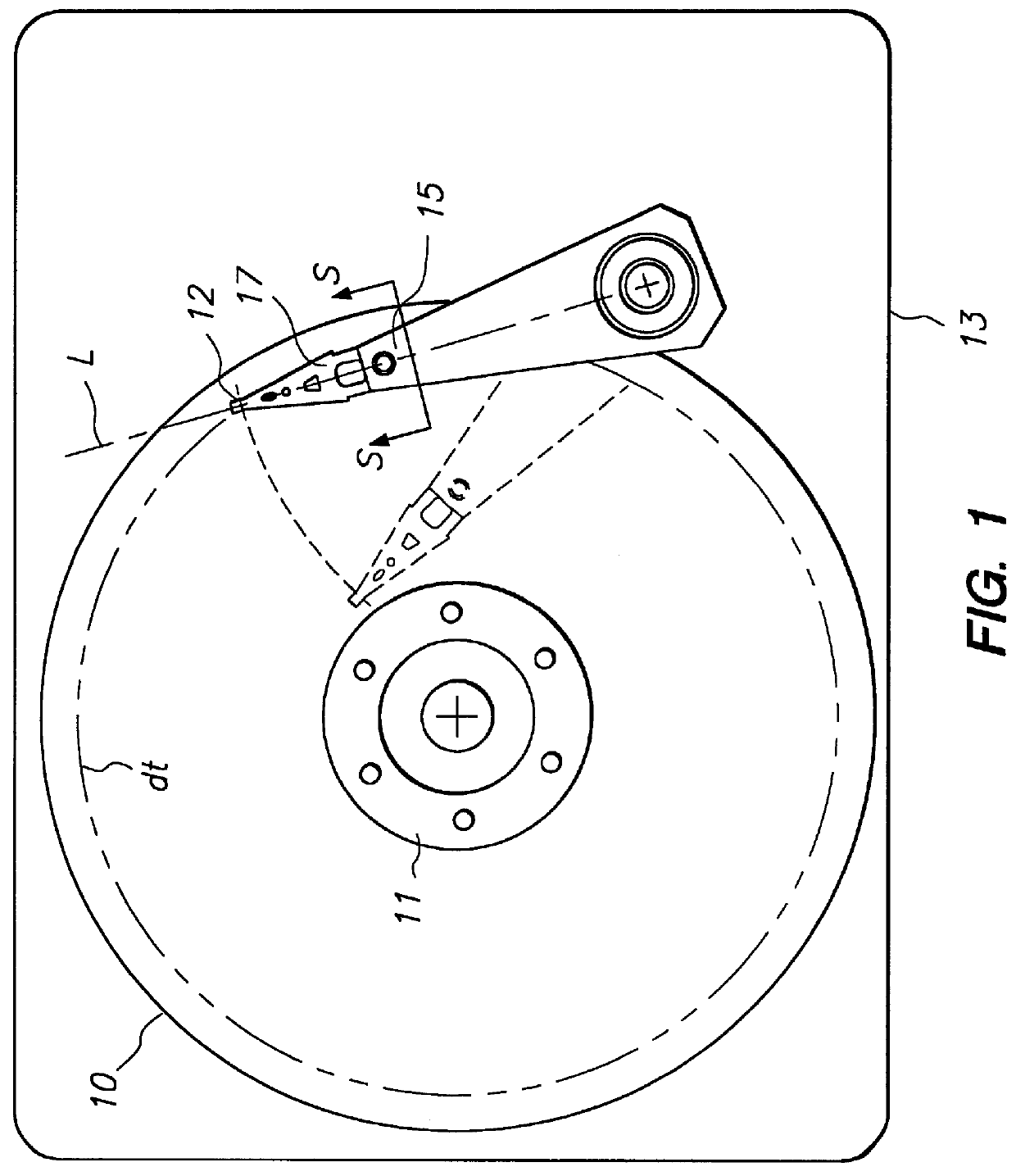

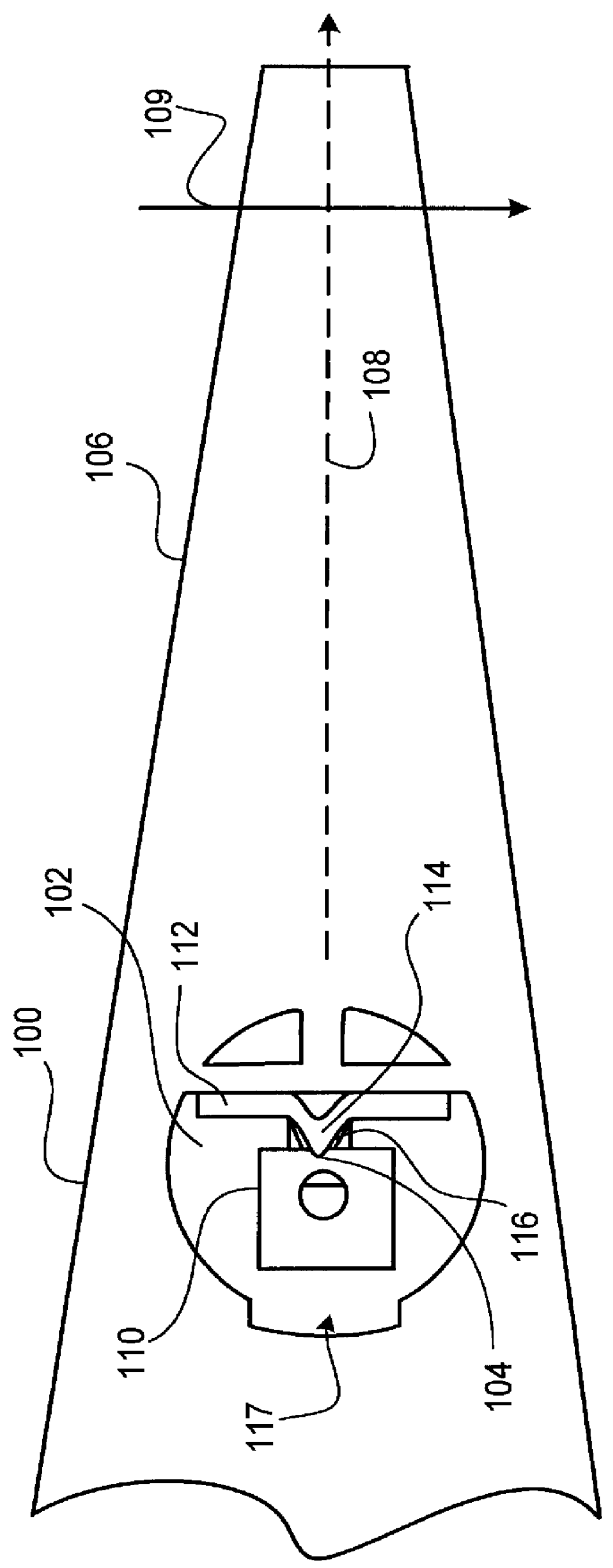

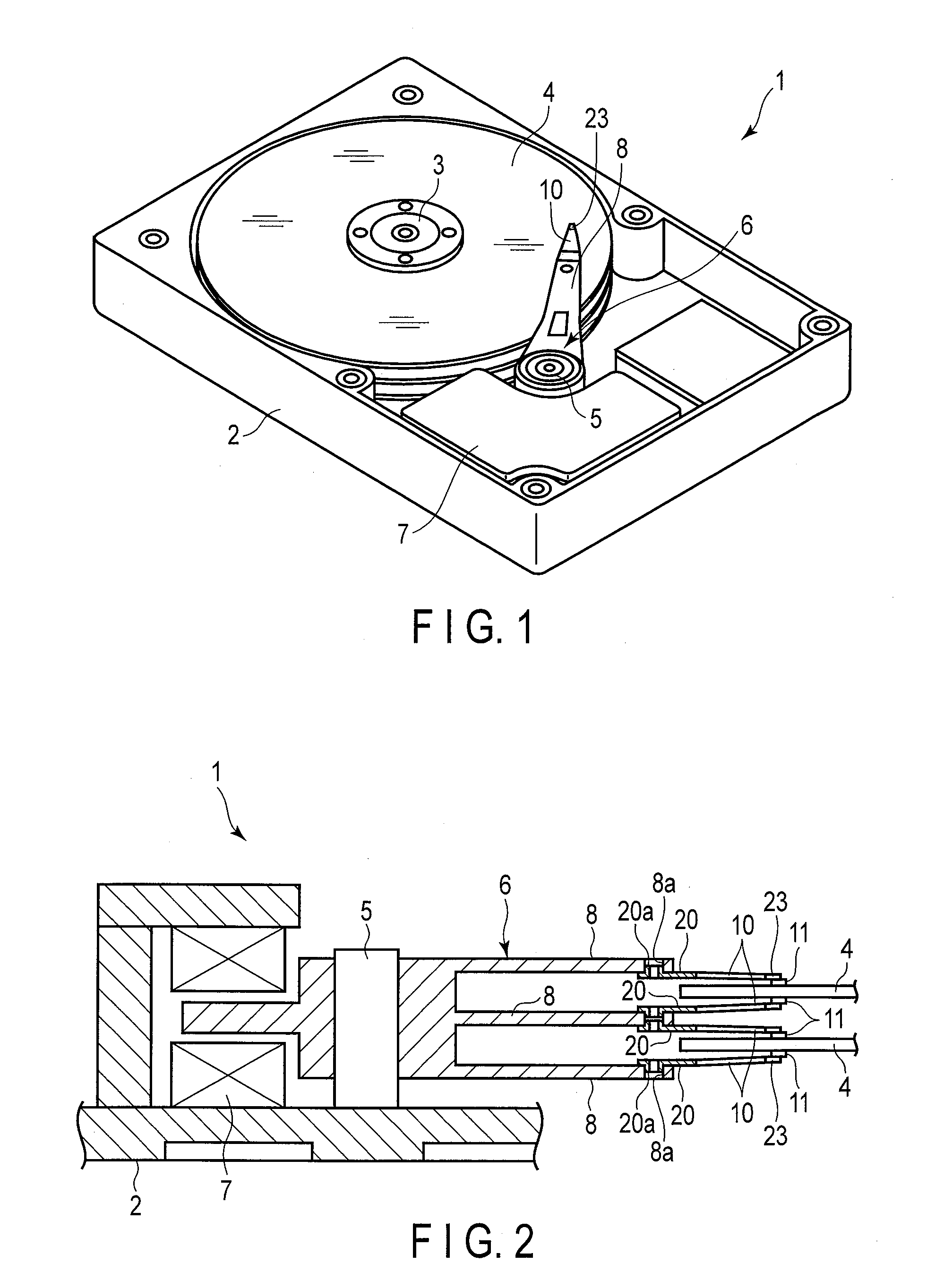

Disk drive attenuating excitation of arm vibration mode by simultaneously driving secondary actuator for non-active head

InactiveUS6972924B1Reduce excitementRecord information storageAlignment for track following on disksPhase shiftedControl system

A disk drive is disclosed employing a primary actuator for rotating an actuator arm about a pivot in coarse movements, and first and second secondary actuators coupled to the actuator arm for actuating first and second heads in fine movements. A servo control system generates a first control signal applied to the first secondary actuator to position the first head over the first disk surface in fine movements while accessing the first disk surface. The servo control system phase shifts the first control signal by a predetermined phase to generate a second control signal applied to the second secondary actuator to attenuate excitation of at least one arm vibration mode.

Owner:WESTERN DIGITAL TECH INC

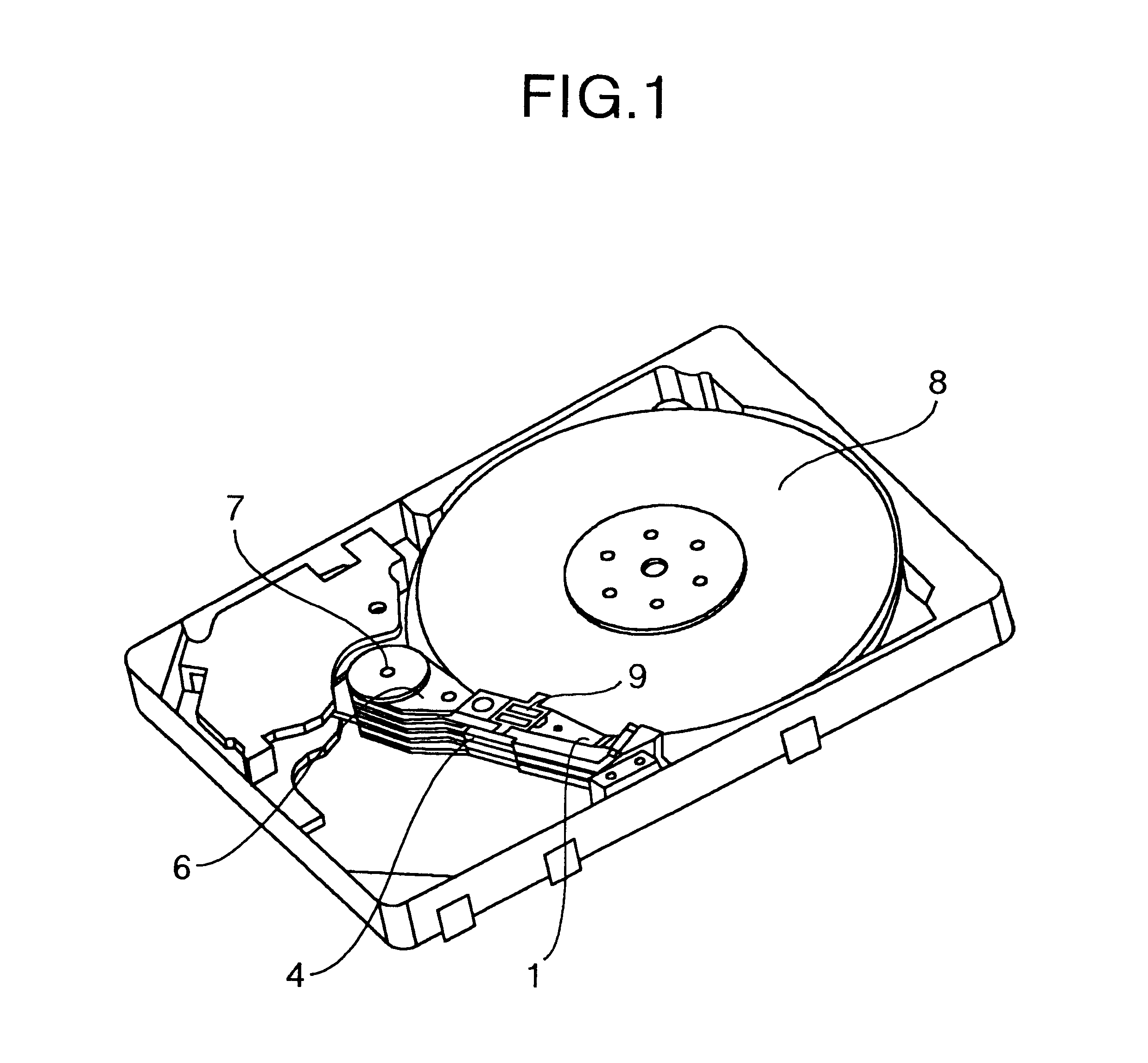

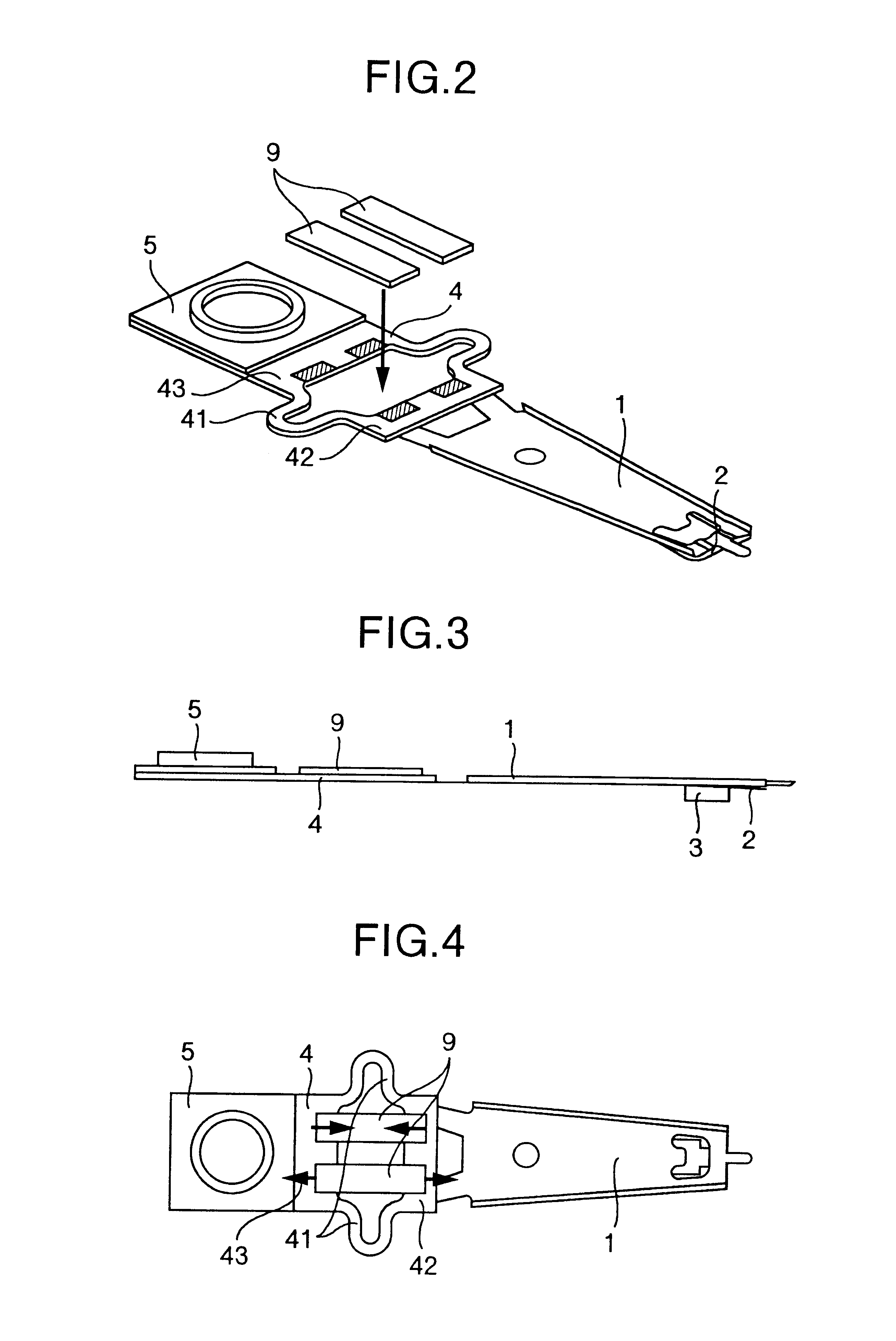

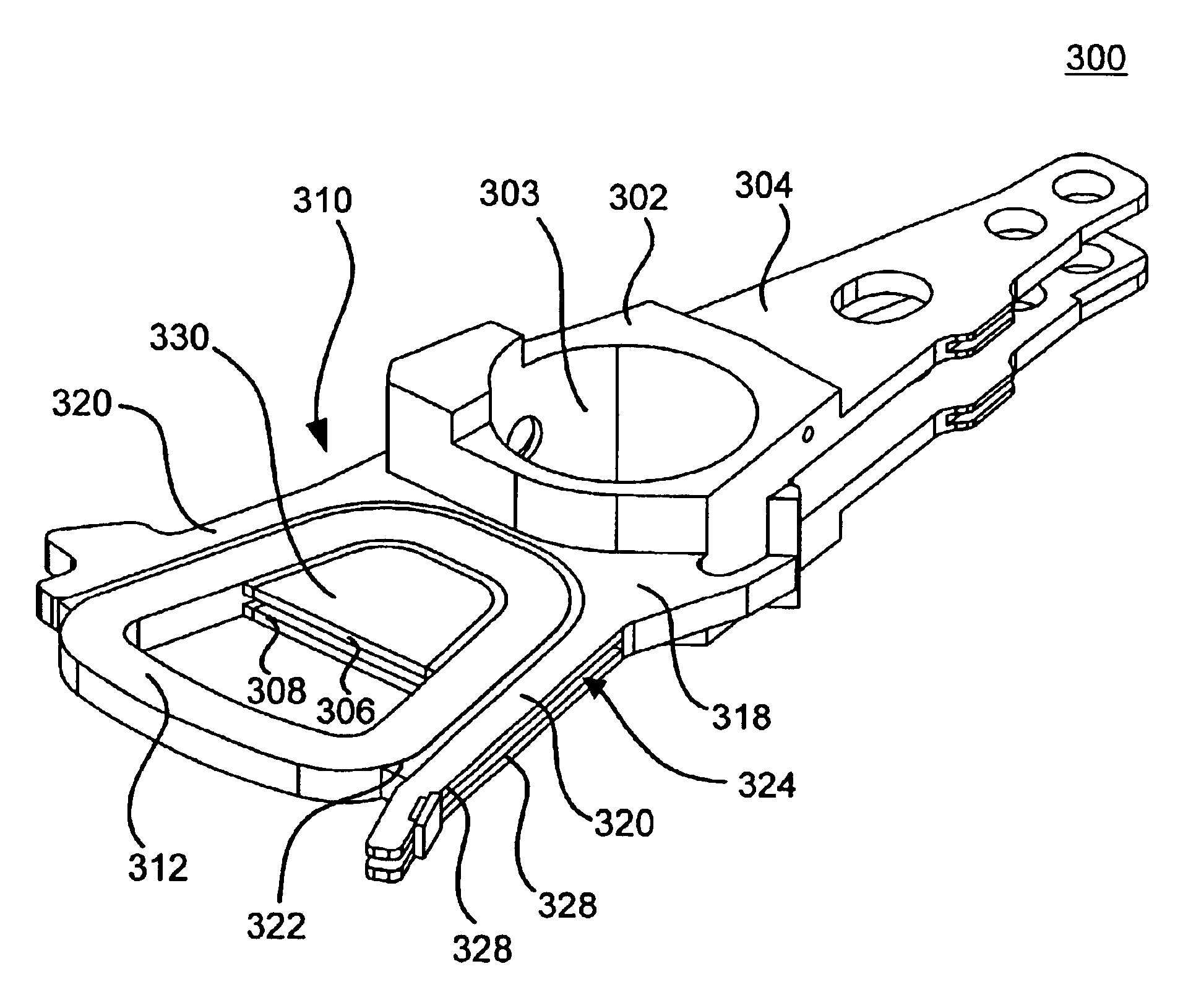

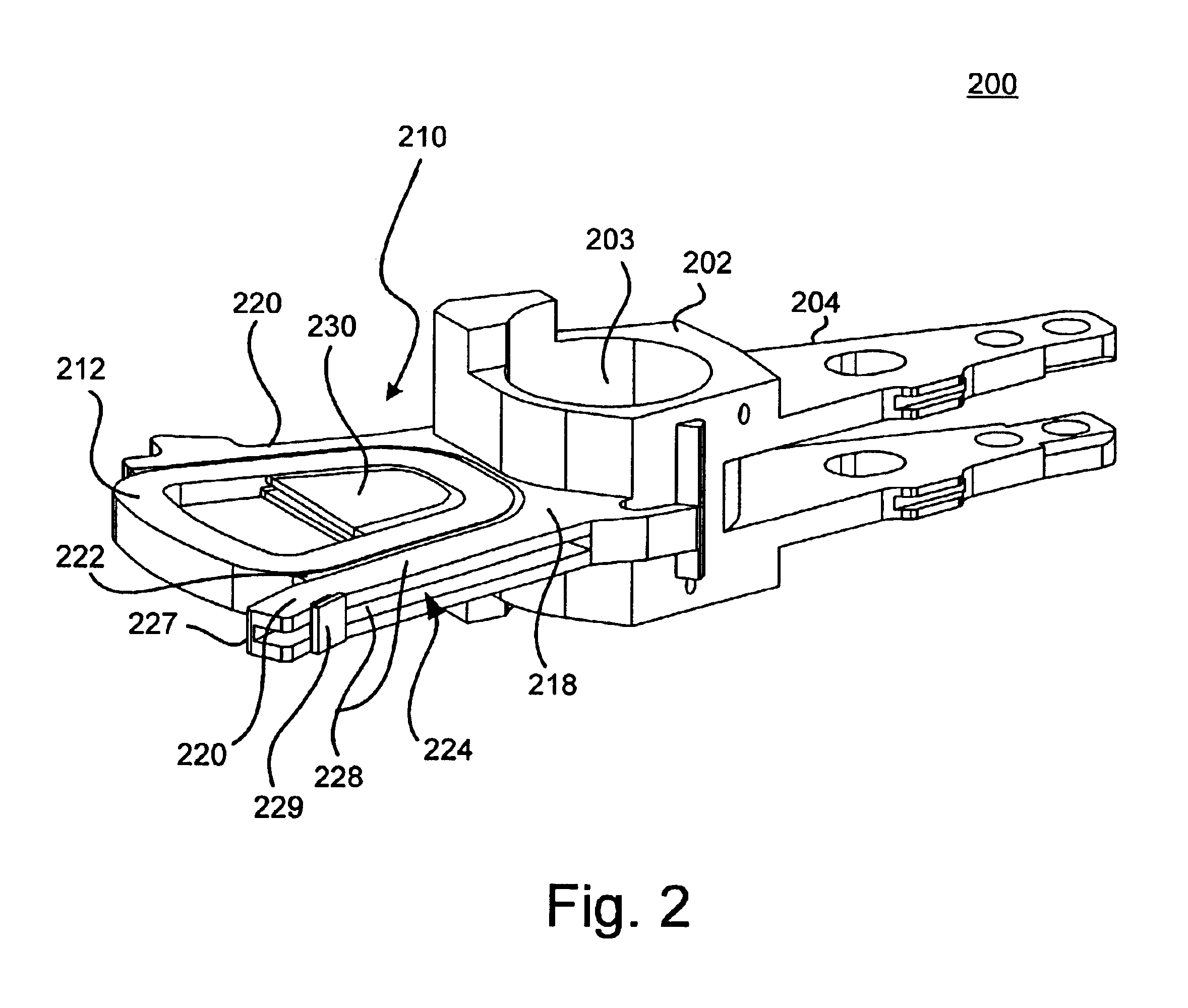

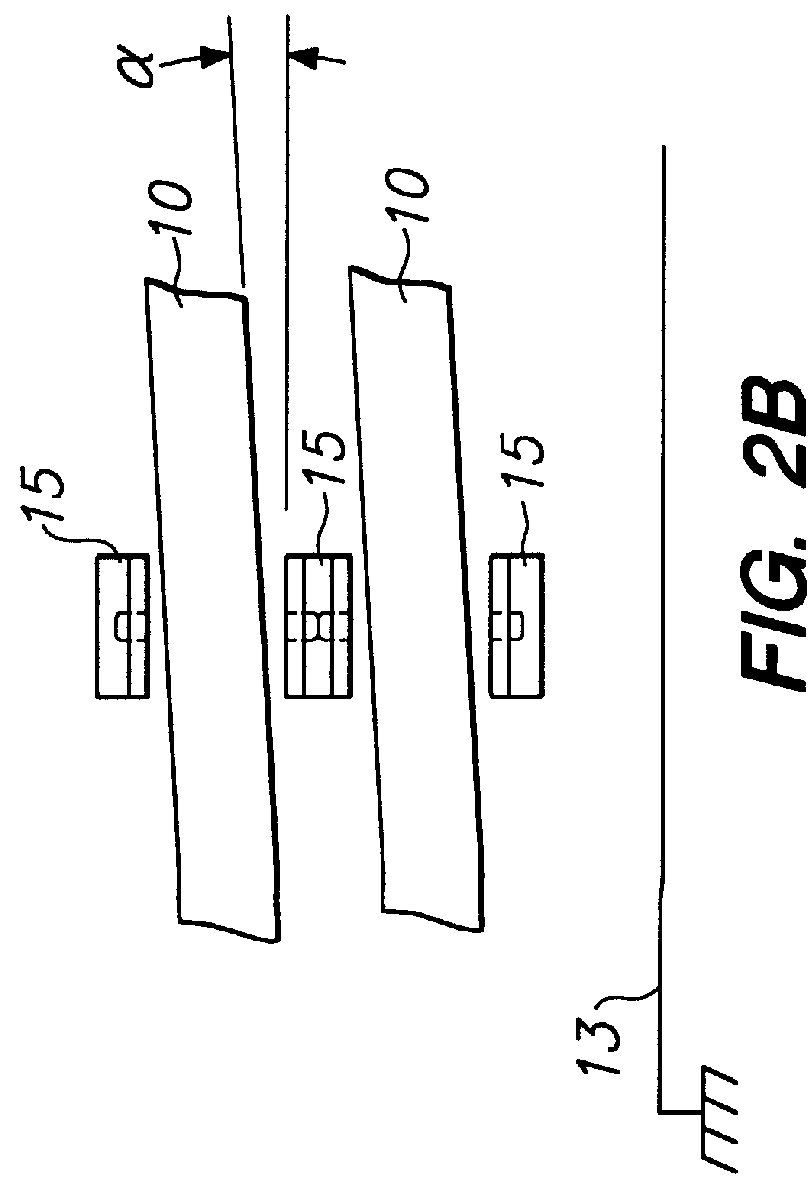

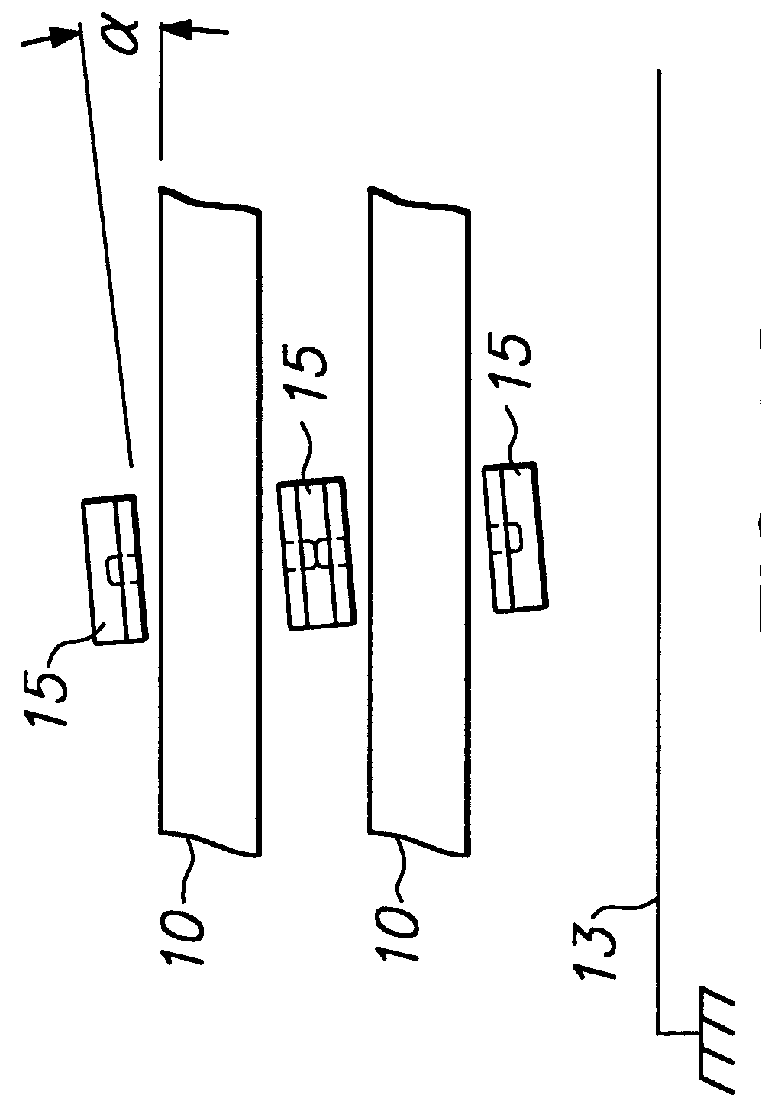

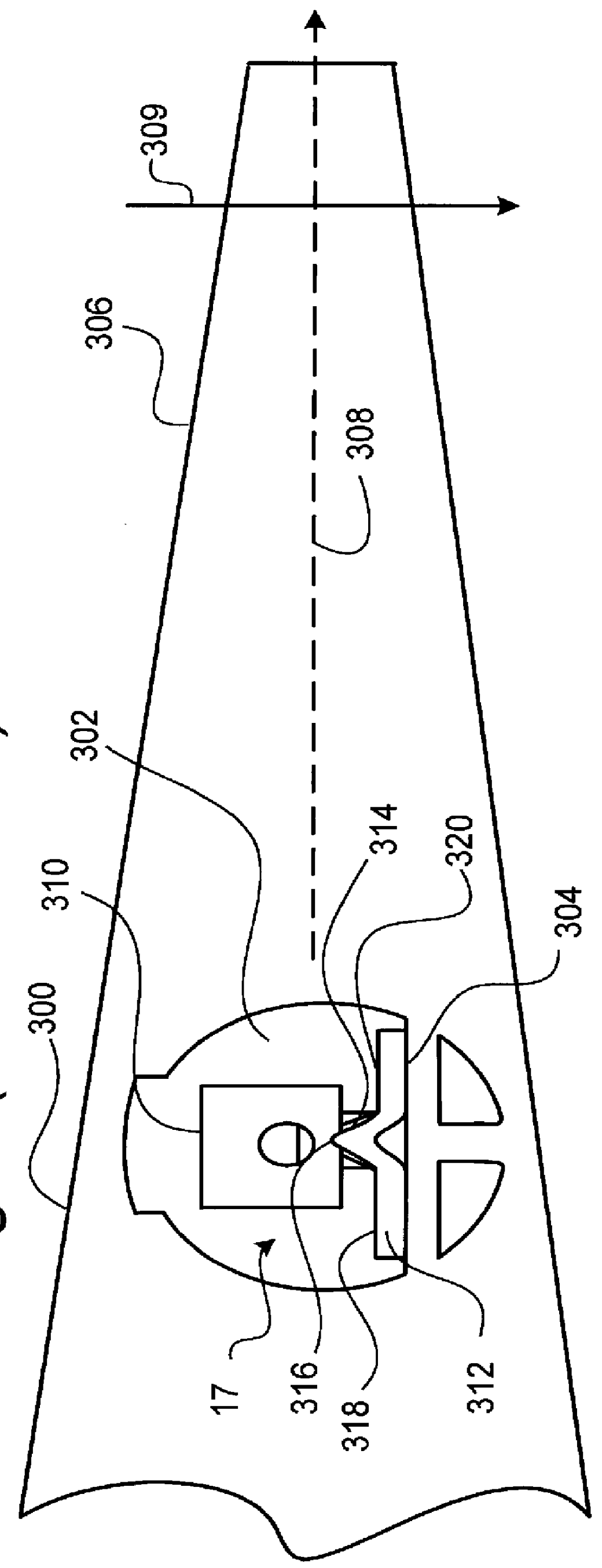

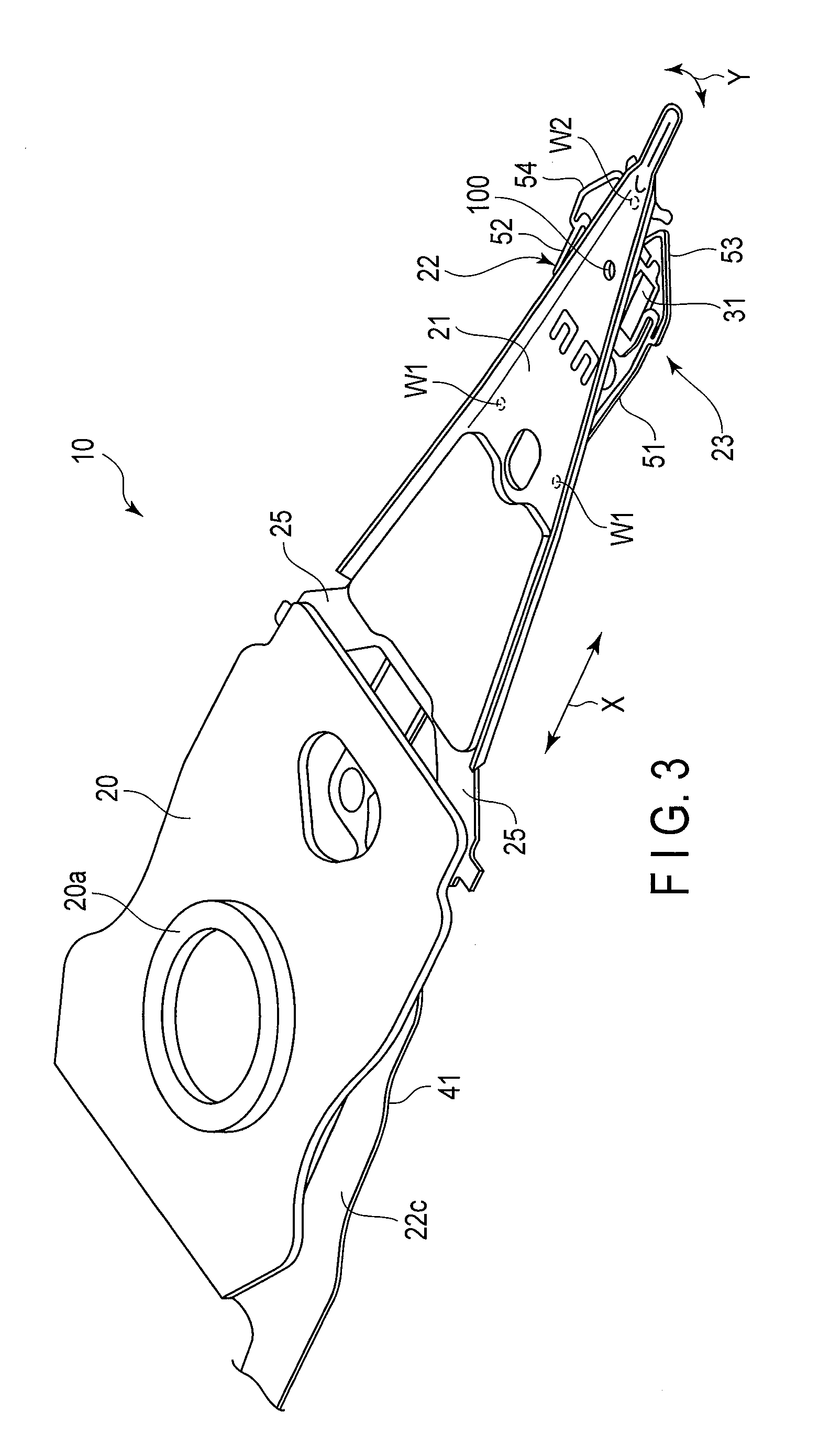

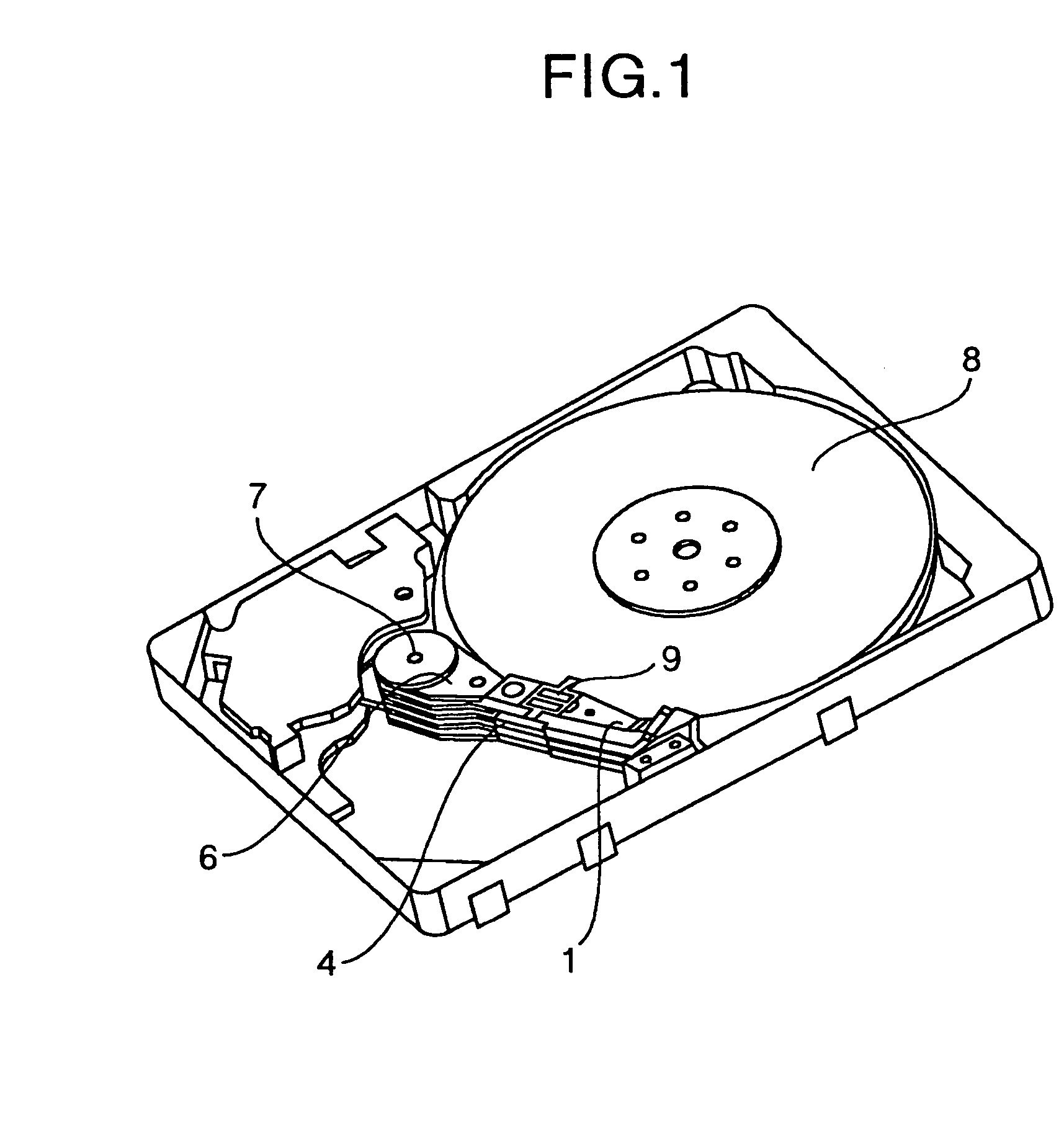

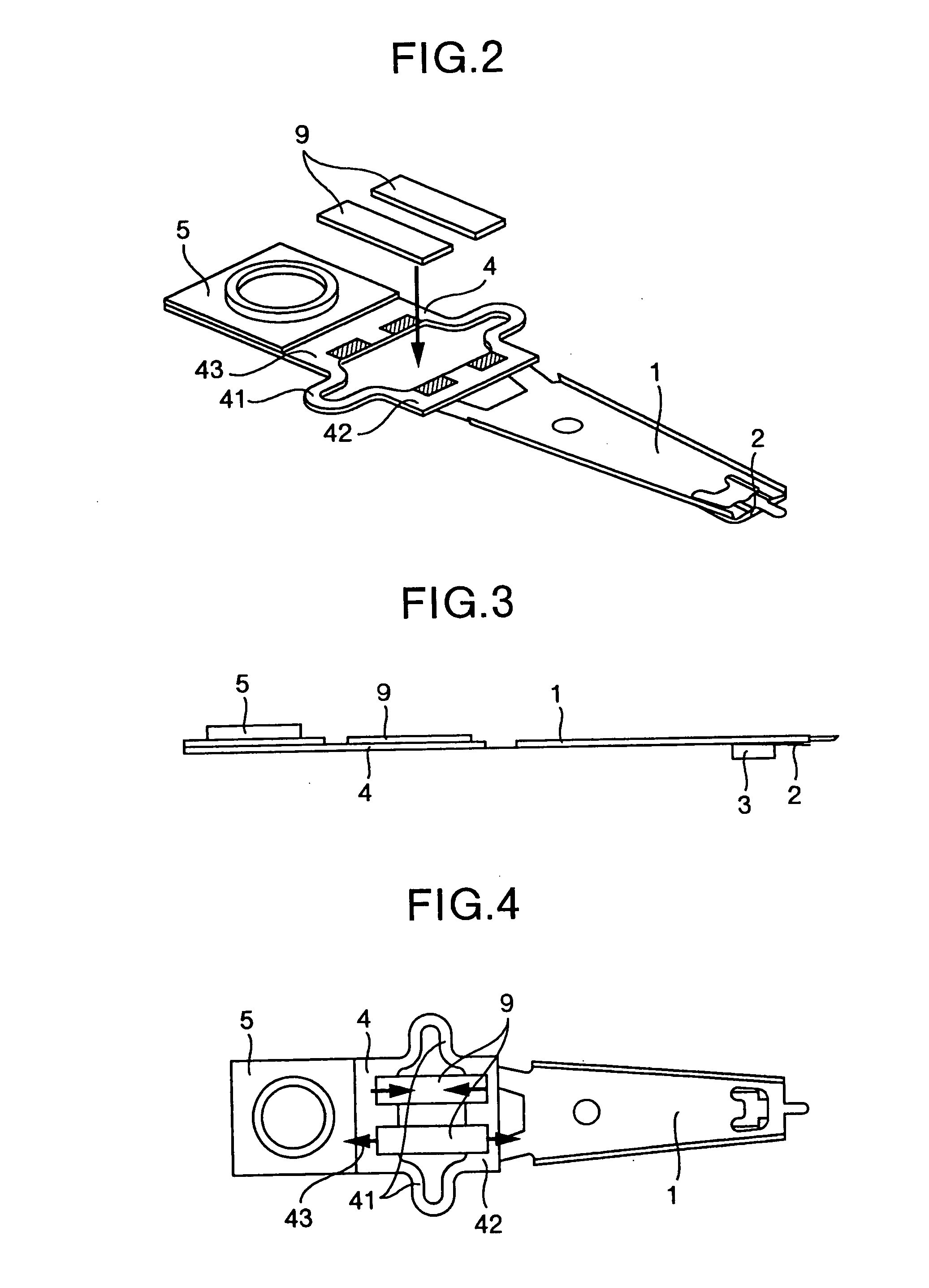

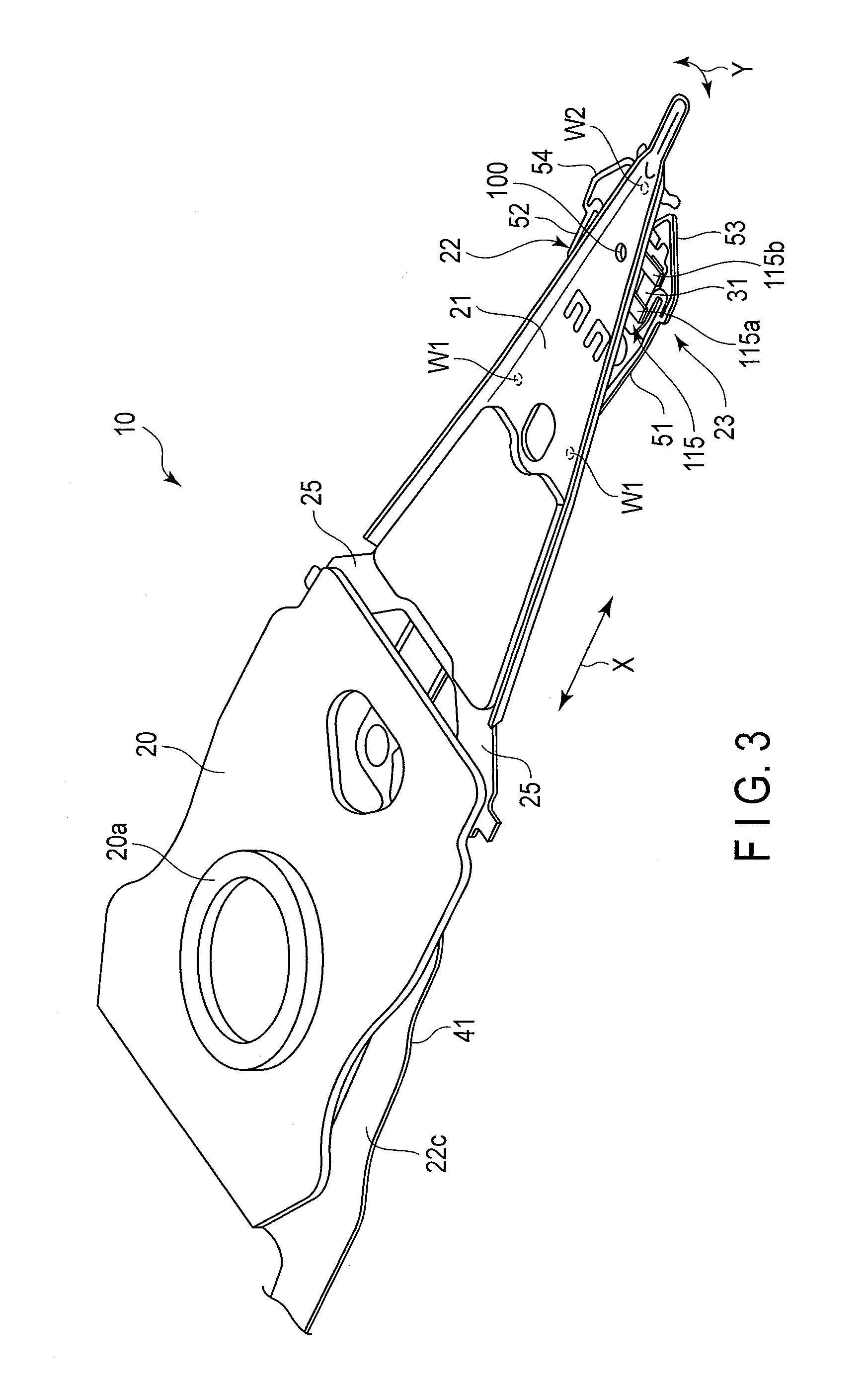

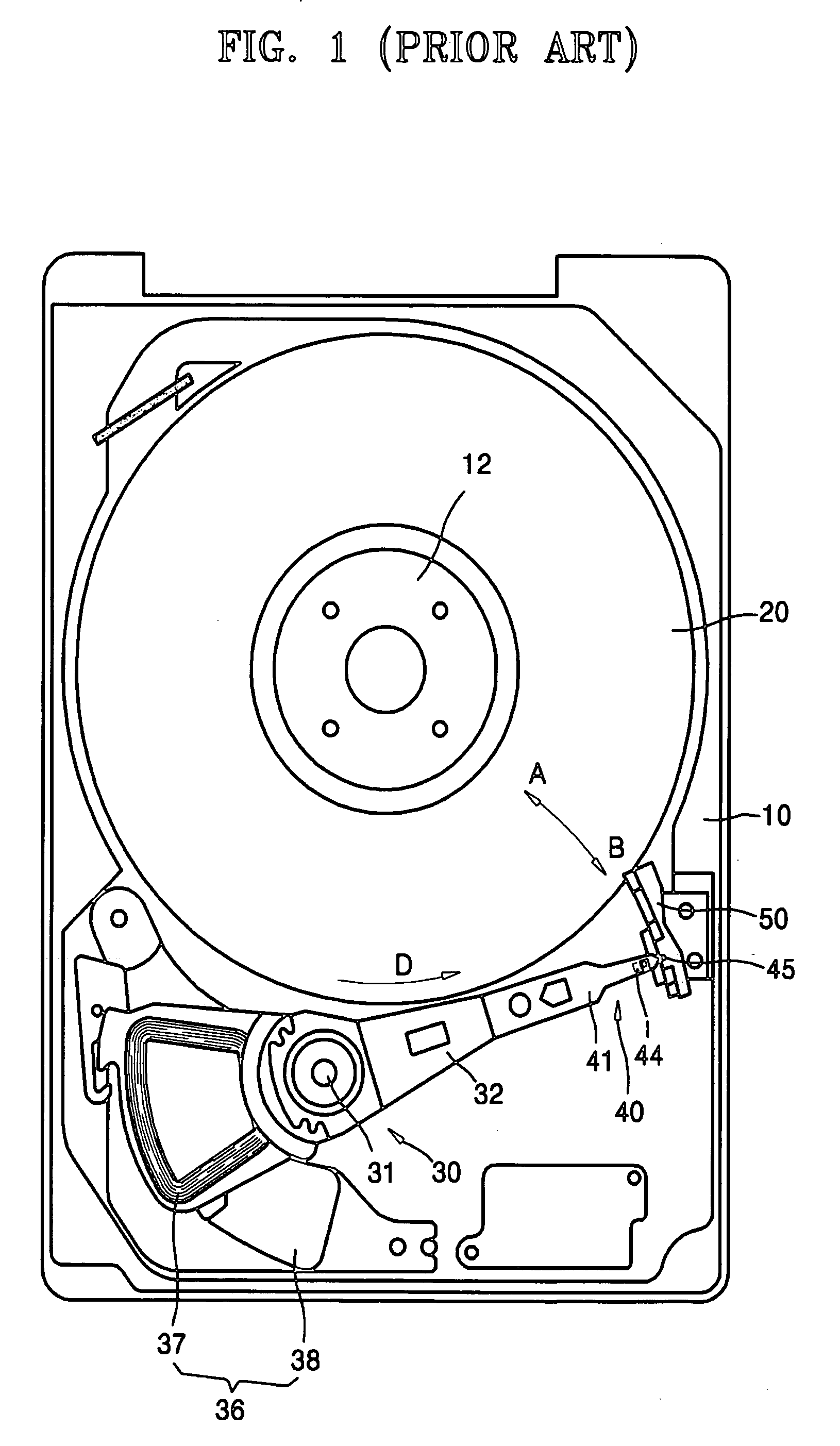

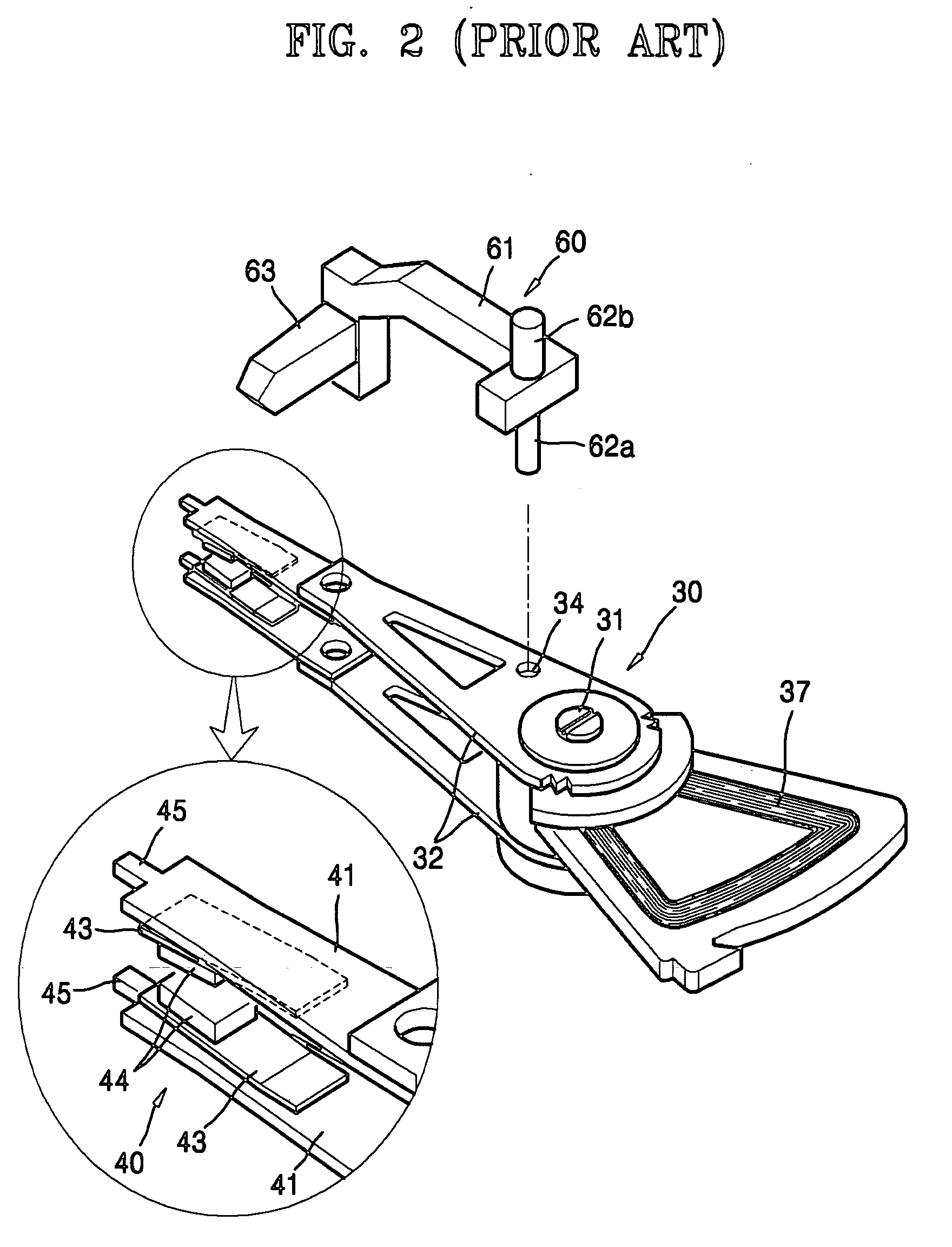

Magnetic disk apparatus

InactiveUS6614627B1Precise positioningSimple structureArm with actuatorsRecord information storageCouplingEngineering

A magnetic disk apparatus of the present invention is equipped with a microactuator for micro motion using piezoelectric elements in addition to a coarse adjustment actuator such as a voice coil motor or the like, eliminates parts that slide between the microactuator and surrounding members, and alleviates stress on the piezoelectric elements even if an impact is given to the magnetic disk apparatus. Thus, a first actuator fixing portion on a carriage side and a second actuator fixing portion on a magnetic head side of a microactuator mounting portion are coupled with a plurality of flexible coupling portions and coupling portions are placed outside the microactuator in substantially symmetric with respect to a centerline in a longitudinal direction of a suspension.

Owner:WESTERN DIGITAL TECH INC +1

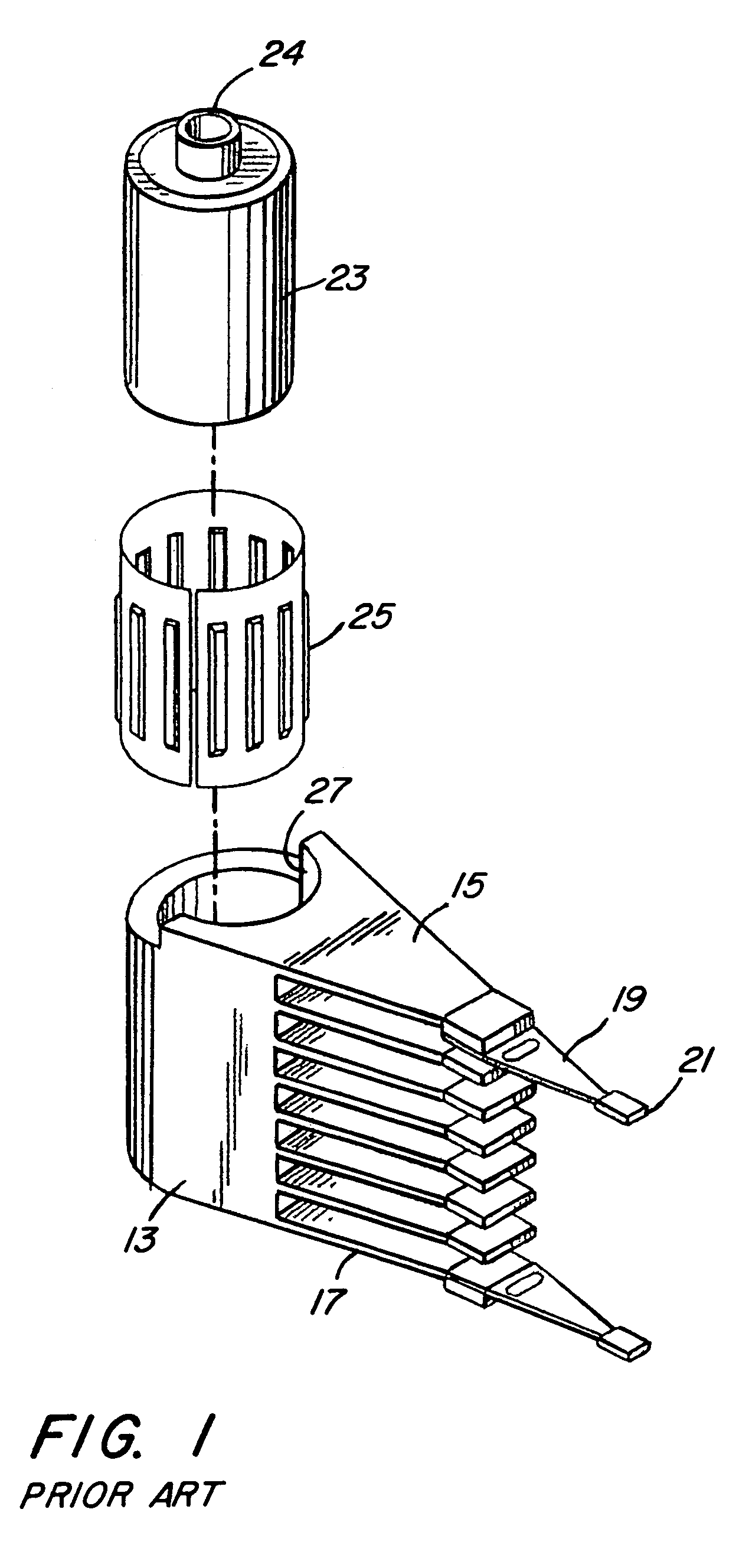

Pivot bearing cartridge including central pivot element and ball bearing set

A pivot bearing cartridge for use in a head stack assembly. The pivot bearing cartridge includes a pivot shaft including a shaft body and a shaft distal end. The pivot bearing cartridge further includes a cap disposed about the pivot shaft. The cap includes a cap annular body and a cap closed end. The pivot bearing cartridge further includes a ball bearing set in mechanical communication with the pivot shaft and the cap annular body. The pivot bearing cartridge further includes a central pivot element disposed between and in mechanical communication with the shaft distal end and the cap closed end for facilitating rotation of the cap relative to the pivot shaft.

Owner:WESTERN DIGITAL TECH INC

Actuator for use with a disk drive having a coil assembly designed to aid in heat convection from the coil of the coil assembly

Disclosed is an actuator for use with a disk drive having a coil assembly designed to aid in heat convection from the coil of the coil assembly. The actuator includes a body portion for pivotally coupling to the disk drive and an actuator arm cantilevered from the body portion for supporting a head gimbal assembly (HGA). The actuator further includes a coil assembly having a coil and a fork. The fork is cantilevered from the body portion in an opposite direction from the actuator arm and includes a pair of opposed prongs to mount the coil. At least one of the prongs of the fork includes at least two opposed fins to aid in the convection of heat from the coil.

Owner:WESTERN DIGITAL TECH INC

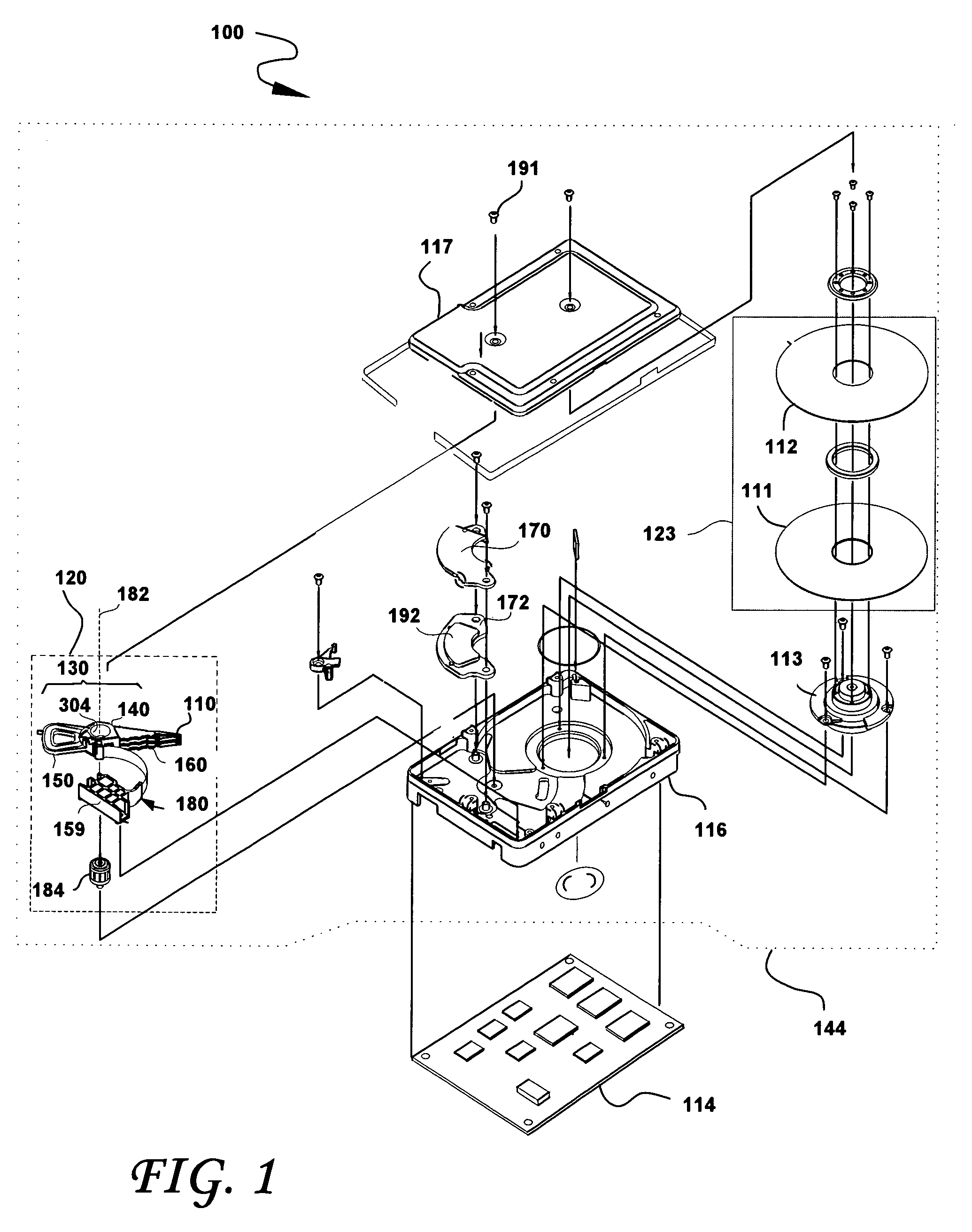

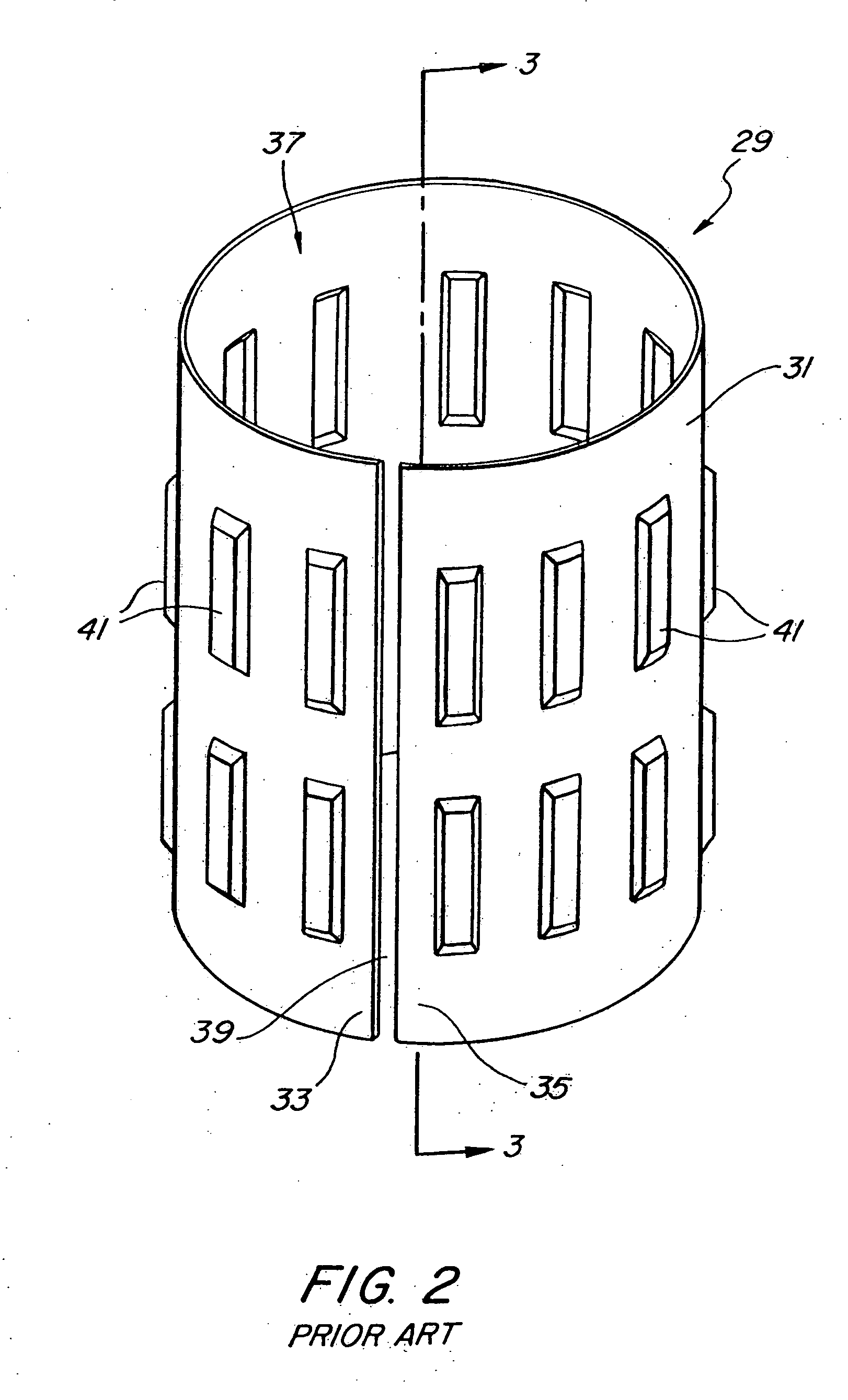

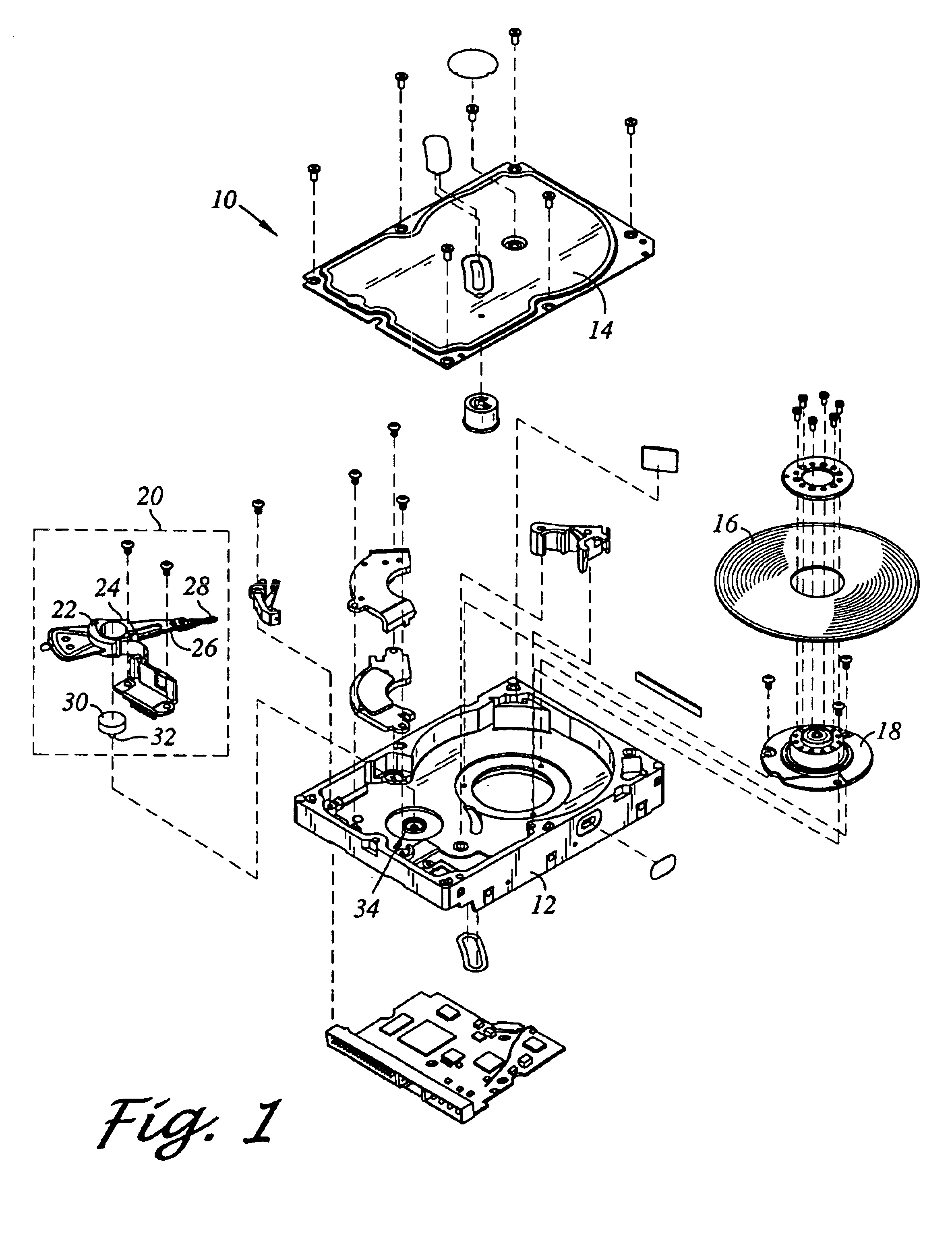

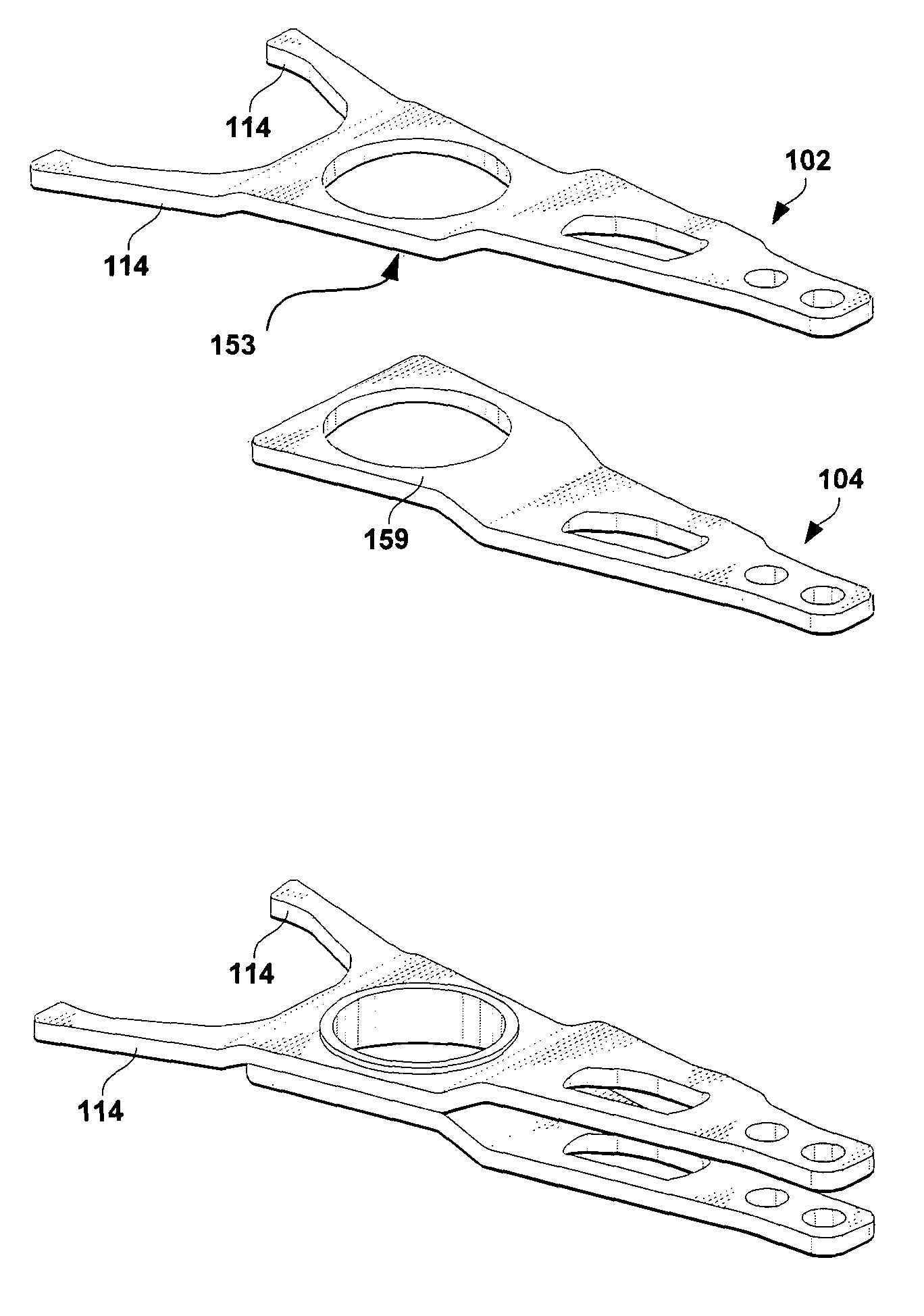

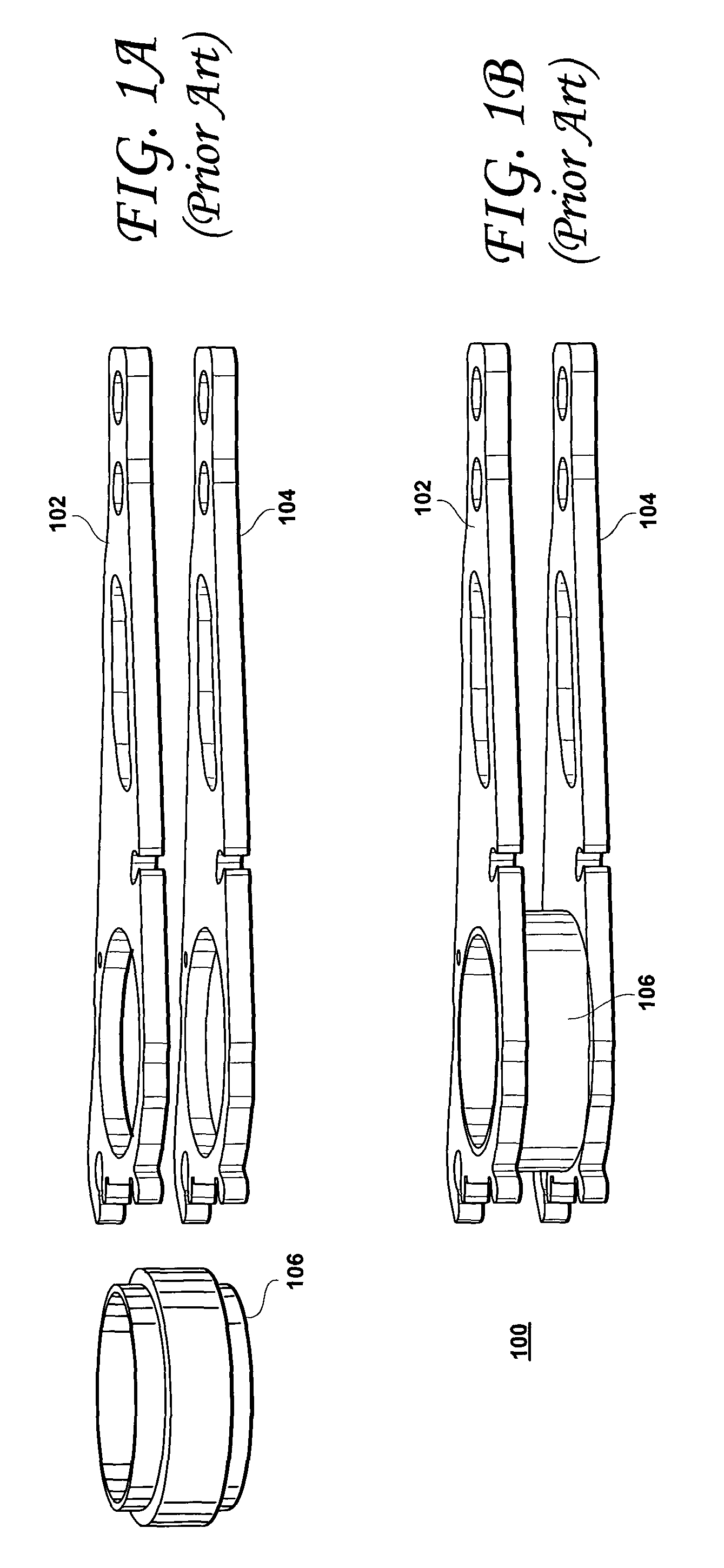

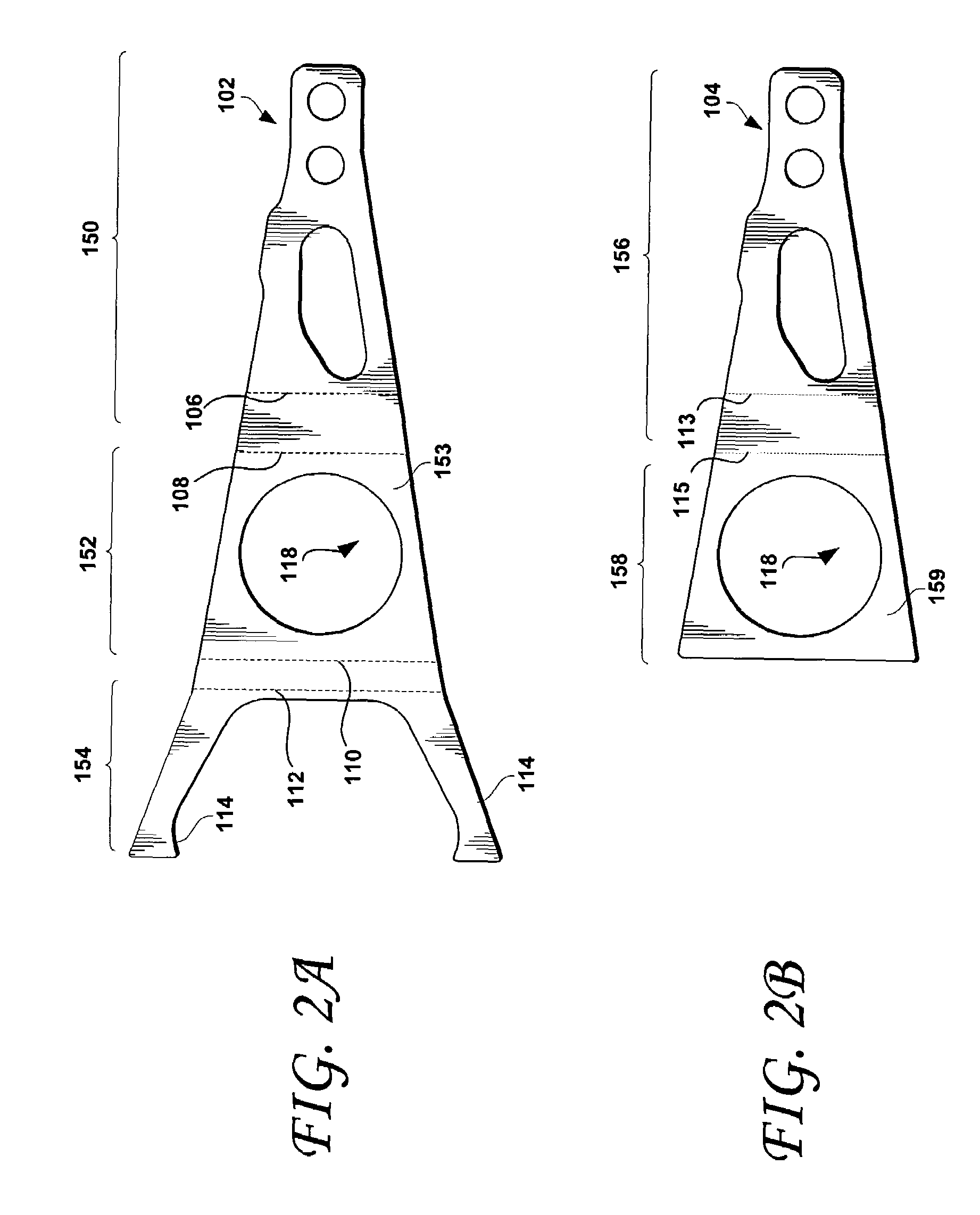

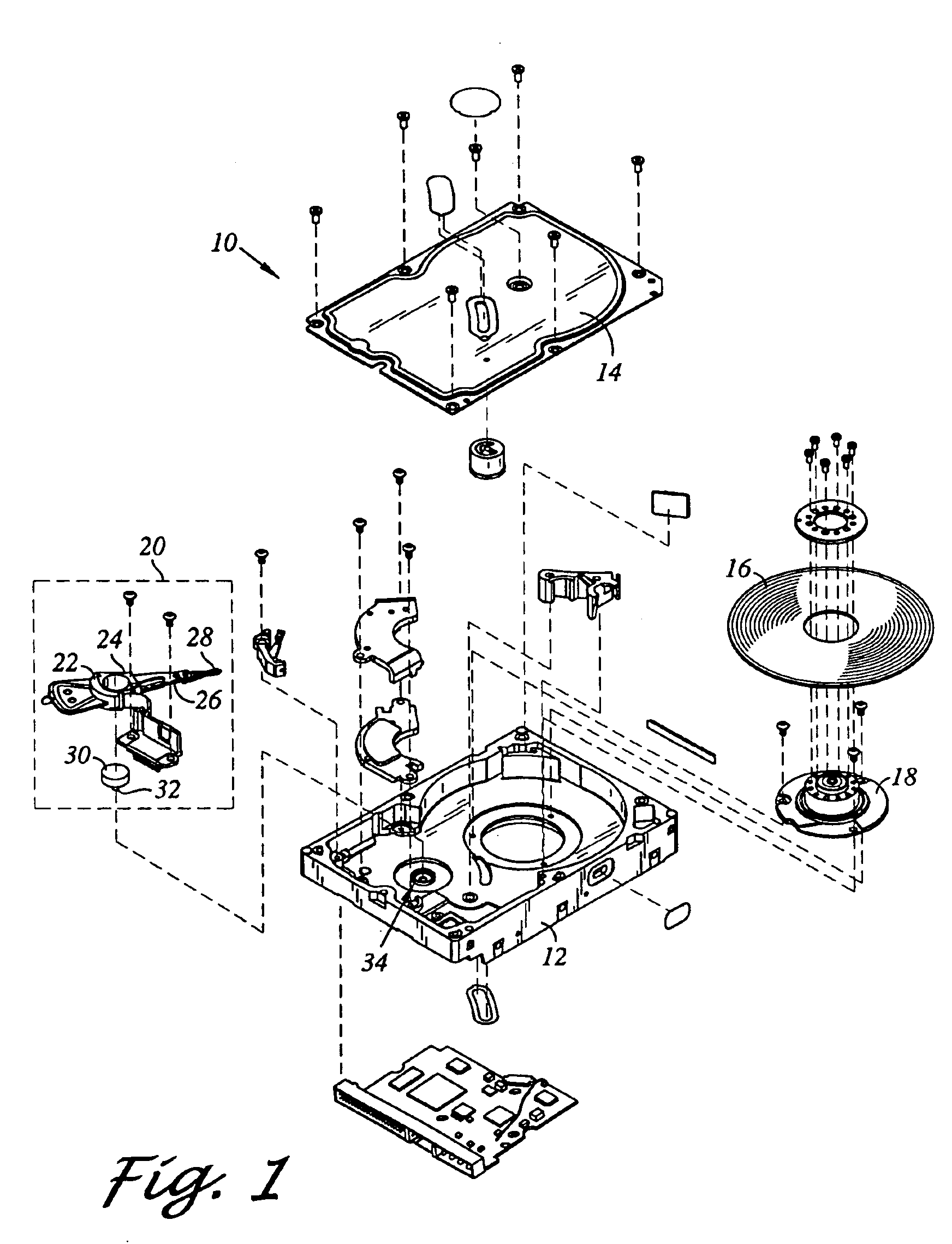

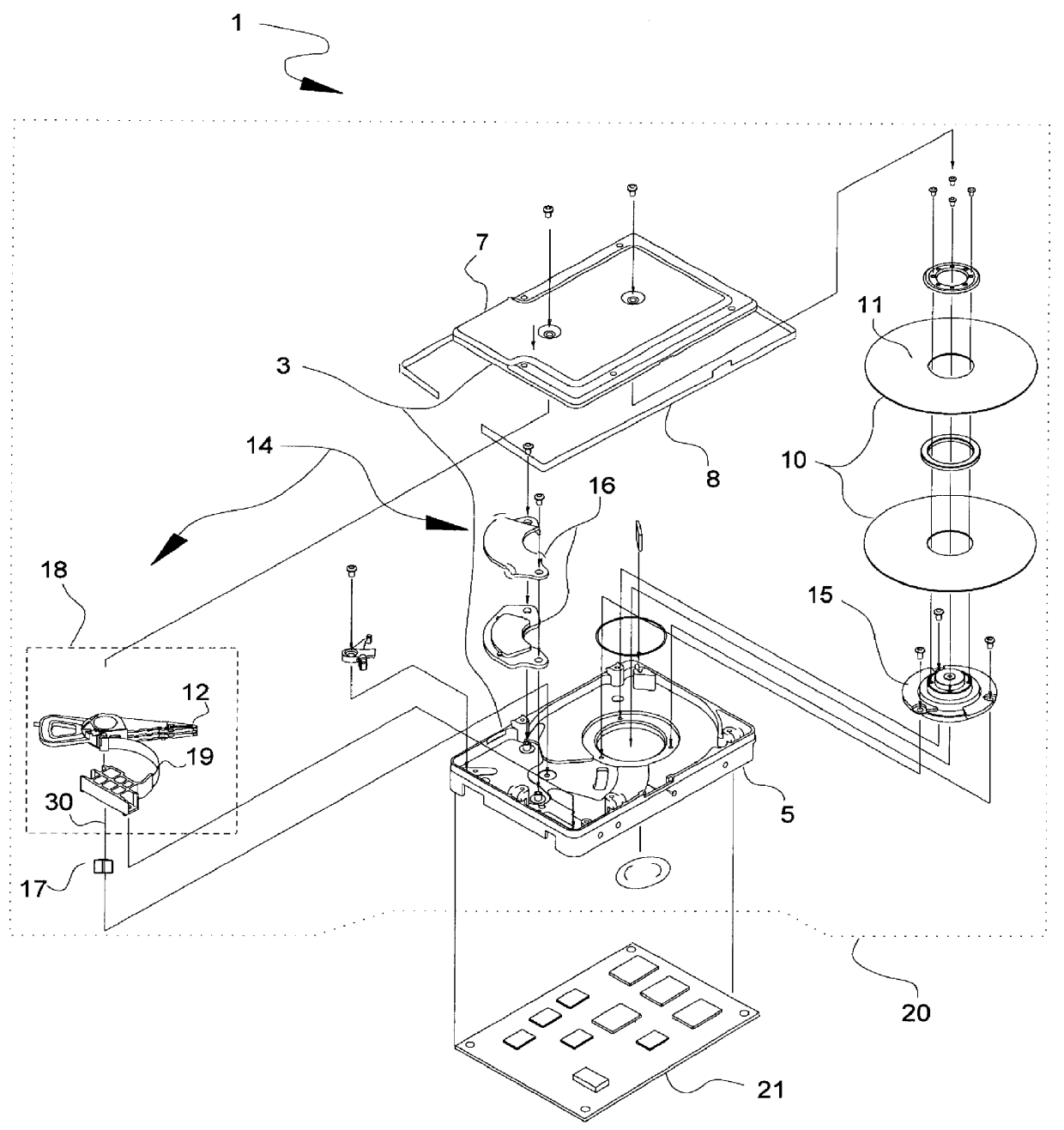

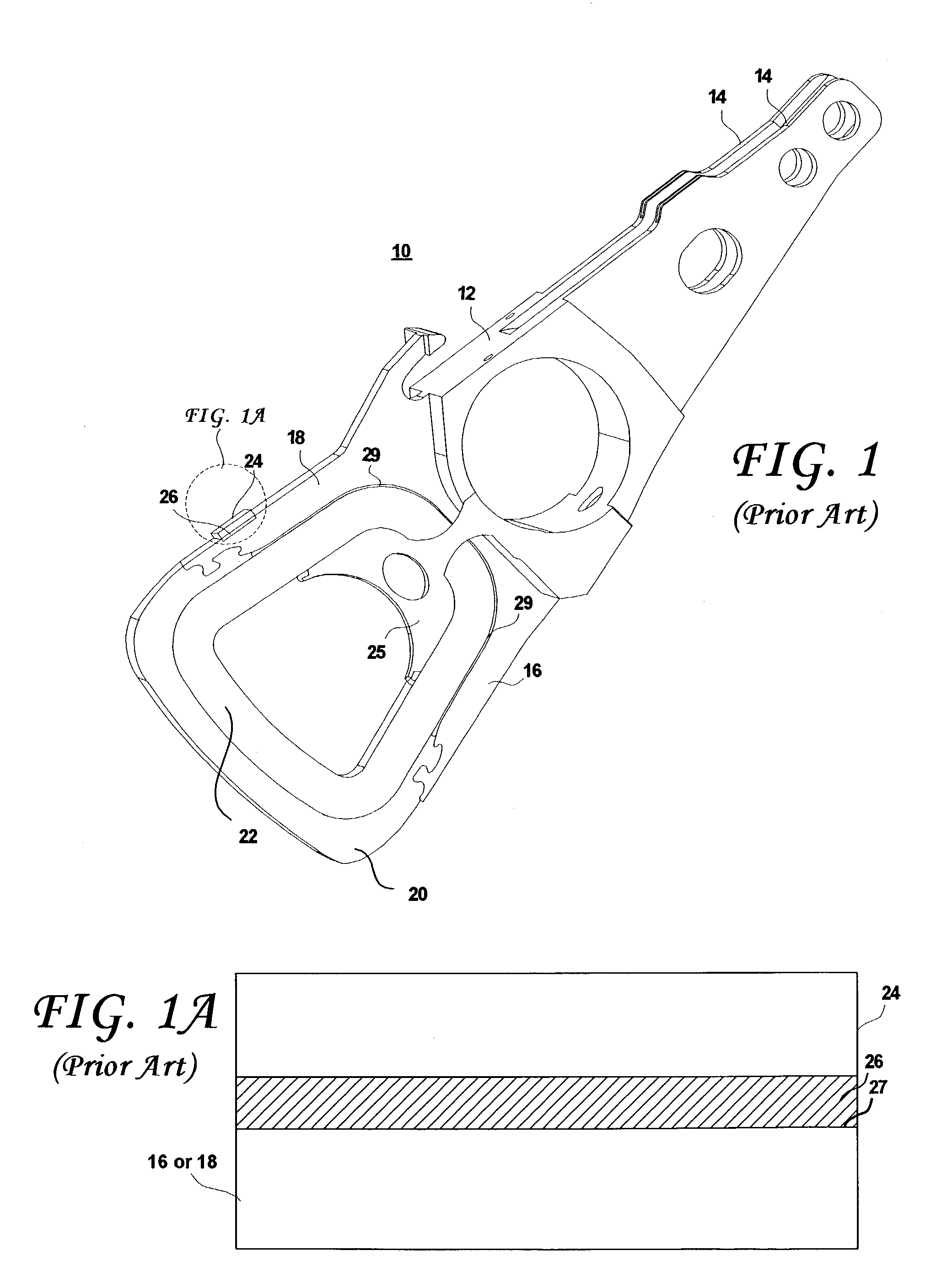

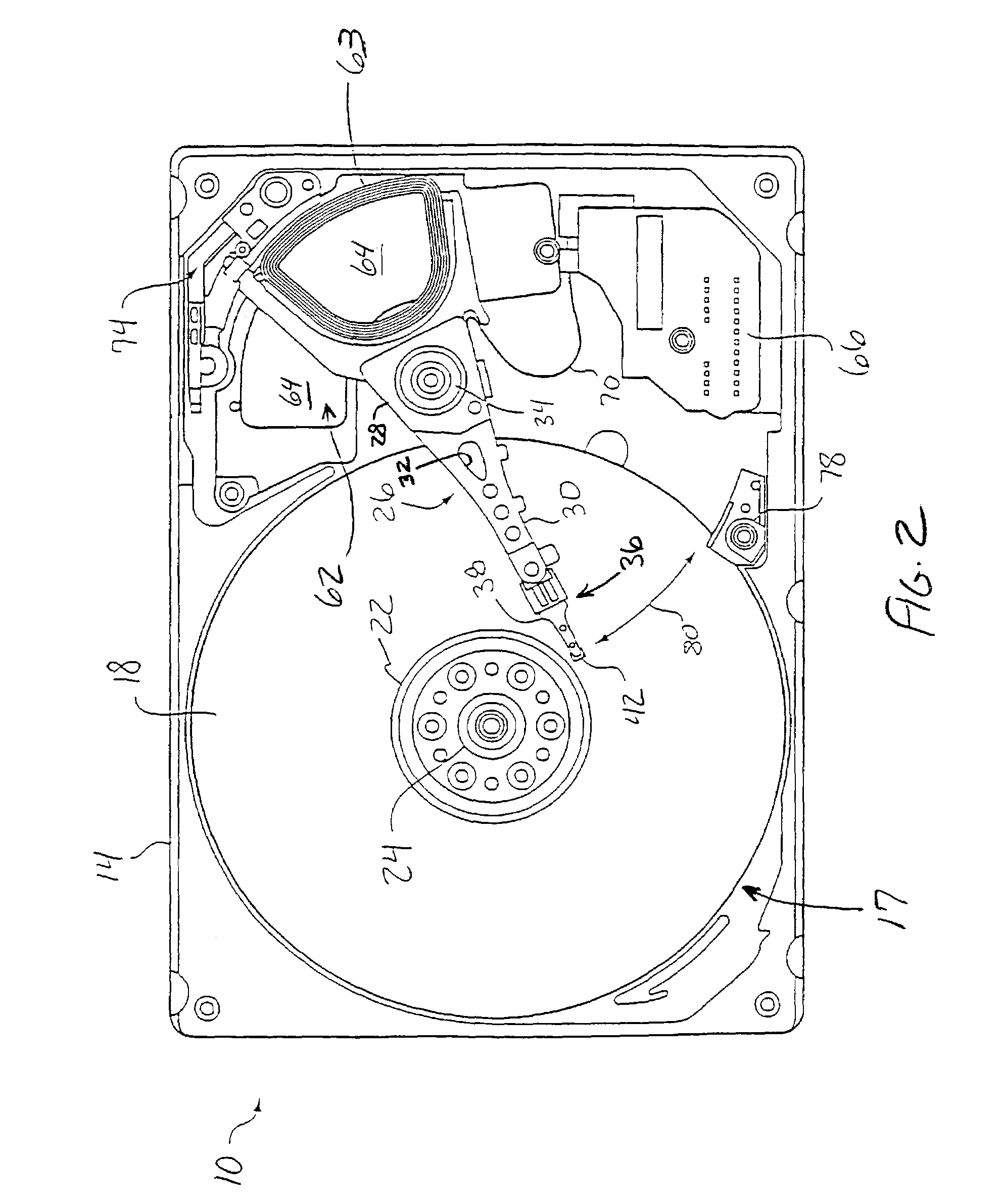

Disk drive having an actuator arm assembly that includes stamped actuator arms

A disk drive includes a disk and a head stack assembly. The head stack assembly includes an actuator arm assembly that includes first and second stamped actuator arms. The first stamped actuator arm may include a first arm portion, a first body portion and a coil-supporting portion for supporting a coil of a VCM. The first body portion defines a first contact surface. The second stamped actuator arm may include a second arm portion and a second body portion, the second body portion defining a second contact surface. According to one embodiment, the first and second stamped actuator arms may be attached to one another such that the first contact surface faces and contacts the second contact surface.

Owner:WESTERN DIGITAL TECH INC

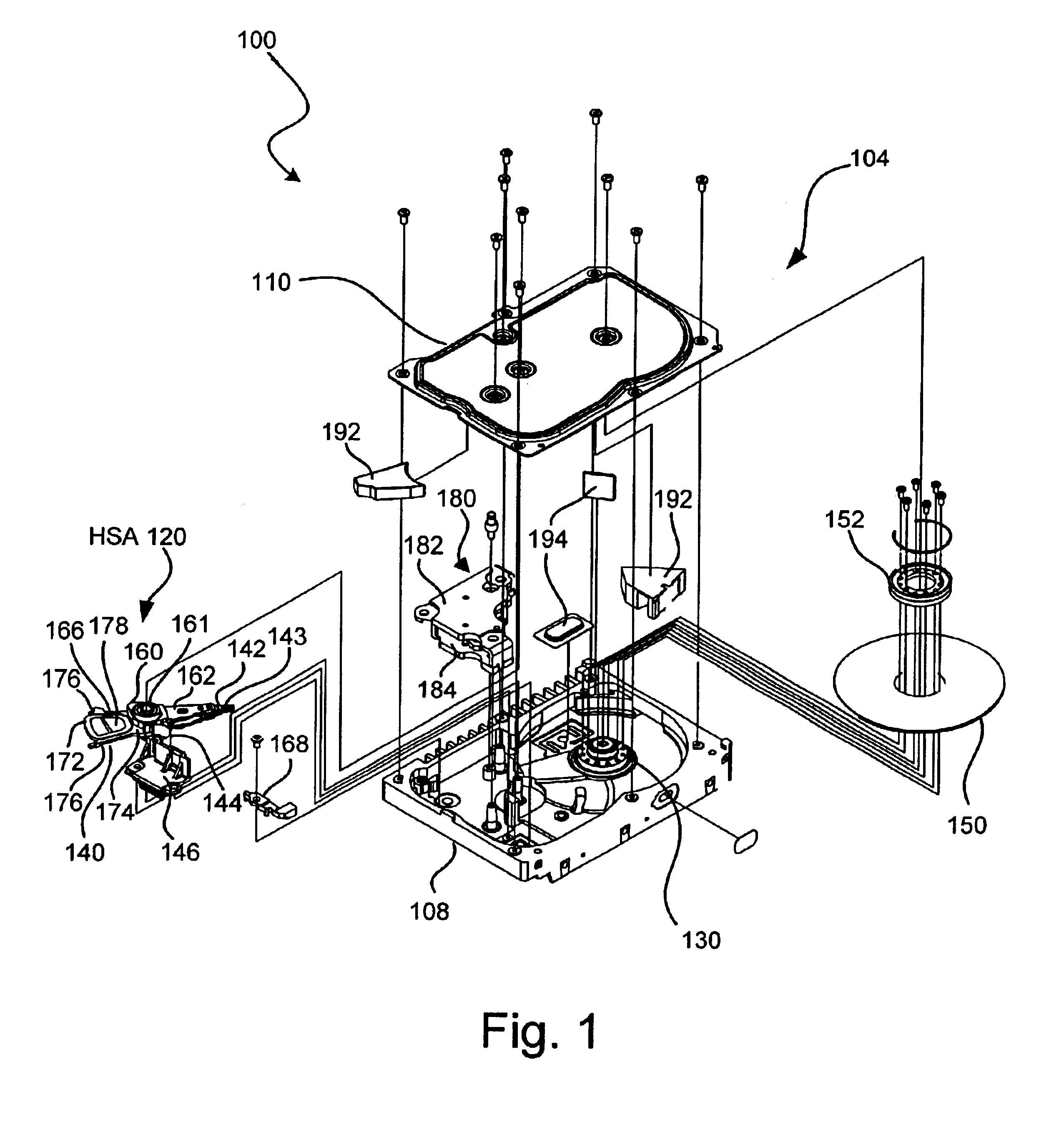

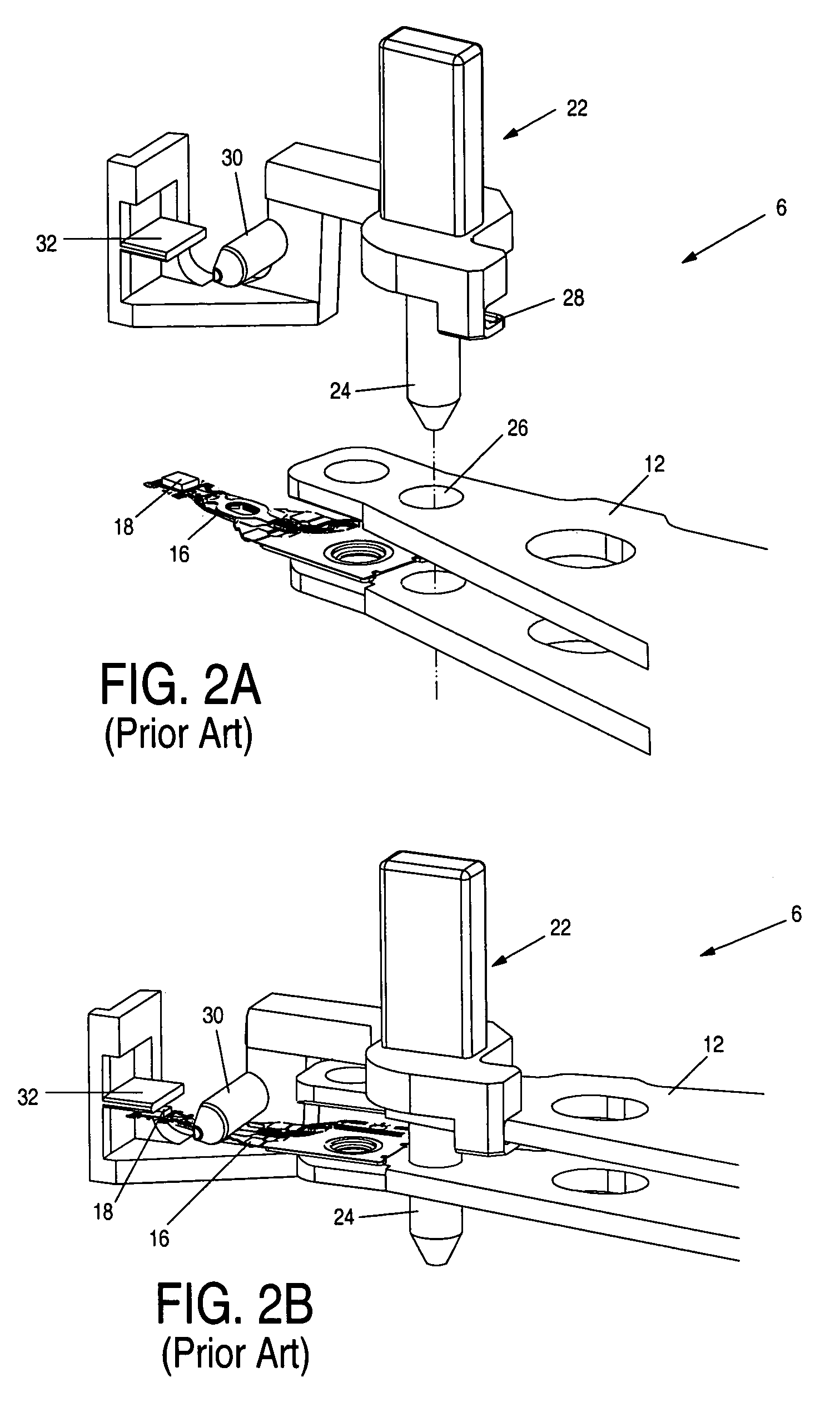

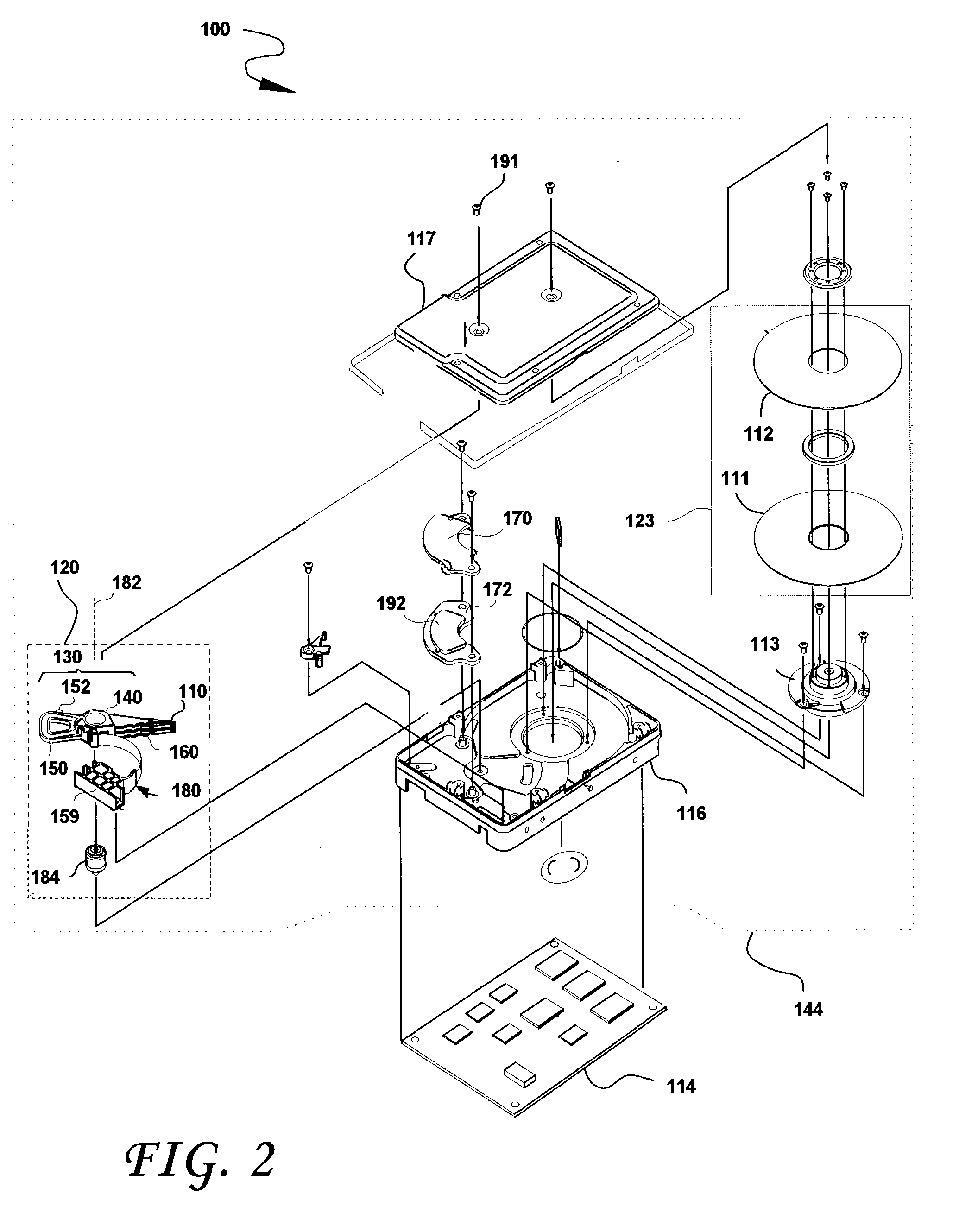

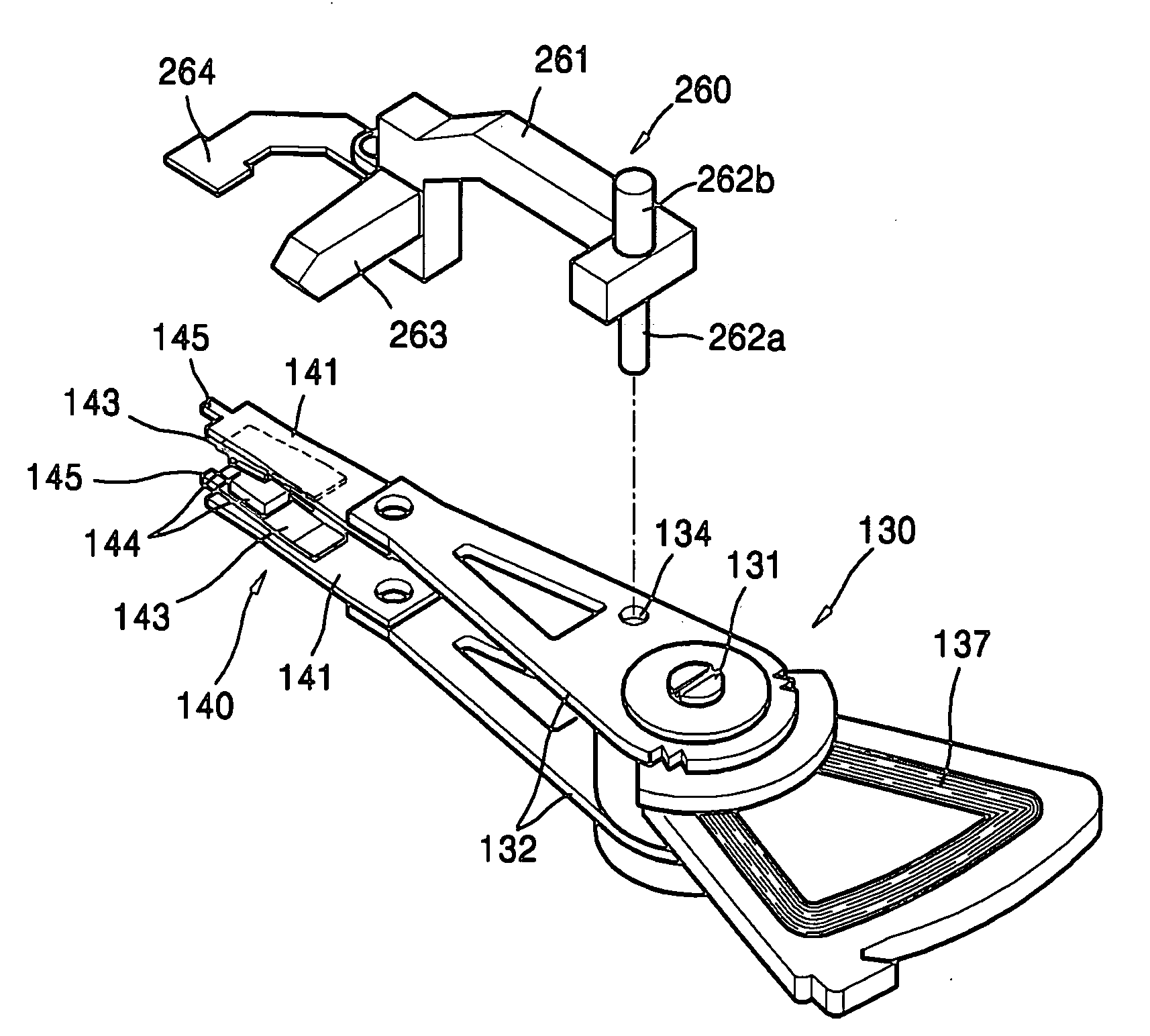

Method of assembling a disk drive including actuating a shipping comb to bend a suspension vertically to facilitate a merge tool

InactiveUS7193819B1Reduce frictionRecord information storageMounting head within housingEngineeringActuator

A head stack assembly (HSA) is disclosed for use in a disk drive comprising a disk, wherein a merge tool is used to merge the HSA with the disk. The HSA comprises at least one actuator arm with a suspension connected to the distal end of the actuator arm. A multi-level shipping comb attached to the actuator arm comprises a finger having a first surface and a second, raised surface. During shipping of the HSA, the first surface of the finger contacts the suspension to protect against overstressing. During manufacture of the disk drive, the shipping comb is actuated so that the second surface contacts the suspension thereby bending the suspension in a vertical direction to facilitate the insertion of the merge tool.

Owner:WESTERN DIGITAL TECH INC

Pivot bearing cartridge including central pivot element and ball bearing set

A pivot bearing cartridge for use in a head stack assembly. The pivot bearing cartridge includes a pivot shaft including a shaft body and a shaft distal end. The pivot bearing cartridge further includes a cap disposed about the pivot shaft. The cap includes a cap annular body and a cap closed end. The pivot bearing cartridge further includes a ball bearing set in mechanical communication with the pivot shaft and the cap annular body. The pivot bearing cartridge further includes a central pivot element disposed between and in mechanical communication with the shaft distal end and the cap closed end for facilitating rotation of the cap relative to the pivot shaft.

Owner:WESTERN DIGITAL TECH INC

Roll-biased head suspension for reduced track misregistration

InactiveUS6088192ADecreased TMRReduce TMR otherwiseCarrier indicating/warning arrangementsRecord information storageHard disc driveOut of plane motion

Owner:MAXTOR

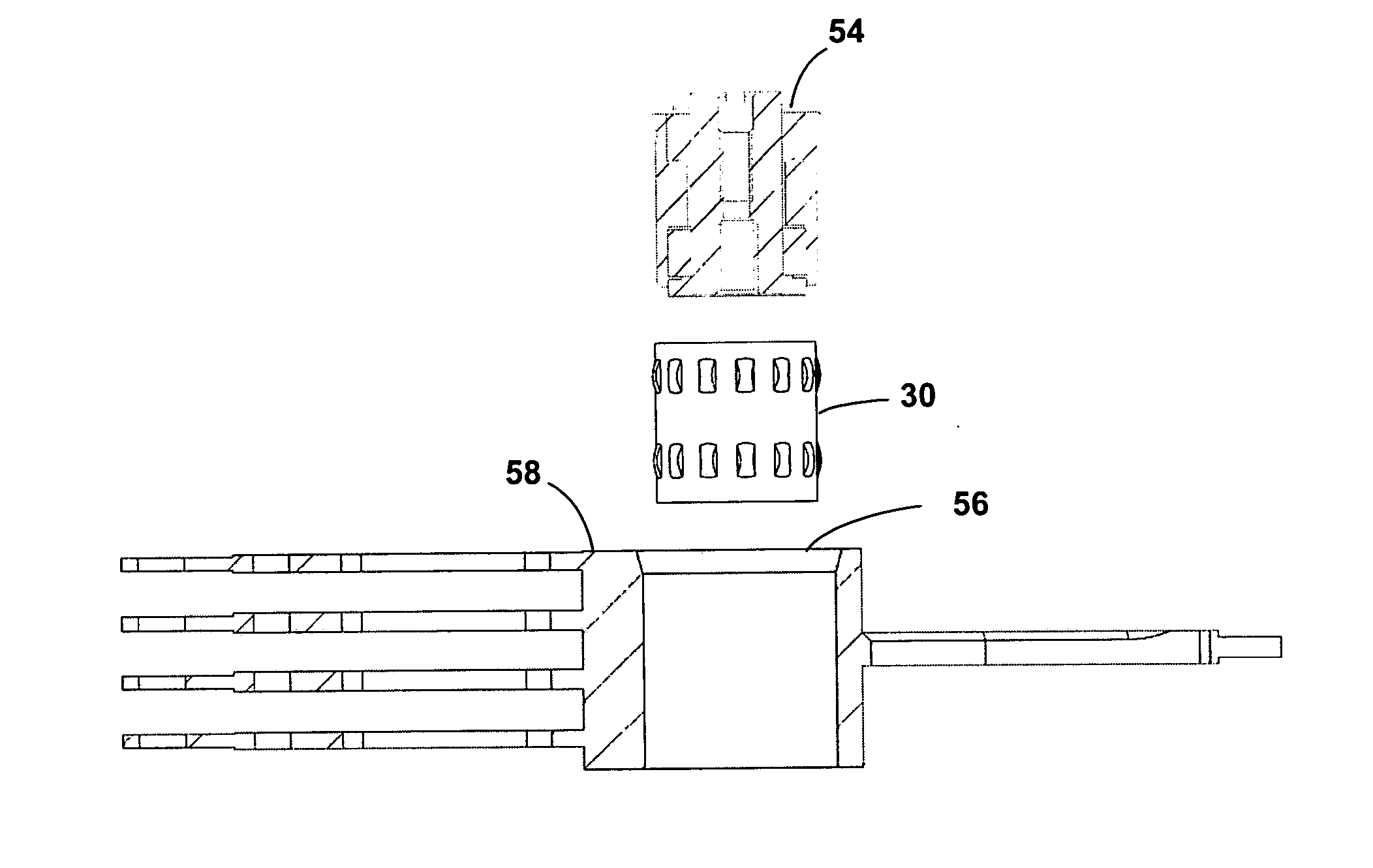

Disk drive actuator rotary bearing attachment with cam member

InactiveUS7633722B1Easy swivel movementRecord information storageMounting of arm assembliesCamActuator

A head stack assembly for use in a disk drive is provided that includes an actuator body, a rotary bearing, a sleeve, and a cam member. The actuator body is pivotable about an axis of rotation. The actuator body has an actuator bore that extends along the axis of rotation. The actuator bore includes an actuator bore surface. The sleeve is disposed between the rotary bearing and the actuator body and comprises a first surface that engages the actuator bore surface. The cam member has a second surface eccentric to said first surface. The second surface engages the actuator bore surface.

Owner:WESTERN DIGITAL TECH INC

Disk drive having a pivot assembly which defines a knife edge facing in a direction perpendicular to the longitudinal axis of an actuator arm

A disk drive includes a base, a spindle motor coupled to the base, a disk mounted on the spindle motor, a pivot assembly coupled to the base, and a head stack assembly. The head stack assembly includes an actuator body defining a bore for surrounding the pivot assembly, a supporting surface, and an actuator arm cantilevered from the actuator body and defining a longitudinal axis. The bore defines a pivot axis of the head stack assembly. The pivot assembly includes a stationary member coupled to the base, the stationary member having a length, and a rotatable member positioned on the supporting surface such that the rotatable member is between the stationary member and the supporting surface. The stationary member and the rotatable member define a projecting member and a recessed portion, the projecting member and the recessed portion interacting to allow the head stack assembly to pivot about the pivot axis. The projecting member defines a knife edge extending parallel to the length and facing in a direction substantially perpendicular to the longitudinal axis.

Owner:WESTERN DIGITAL TECH INC

Head stack assembly having an actuator body with multiple slots adjacent to a bore

A head stack assembly for a disk drive includes an actuator body. The actuator body includes a pair of sides, a bore defining a longitudinal axis, a first slot extending between the pair of sides, a second slot extending along a direction perpendicular to the longitudinal axis, the second slot extending from the first slot to the bore. The head stack assembly further includes a coil portion cantilevered from the actuator body in one direction and an actuator arm cantilevered from the actuator body in a direction opposite from the coil portion.

Owner:WESTERN DIGITAL TECH INC

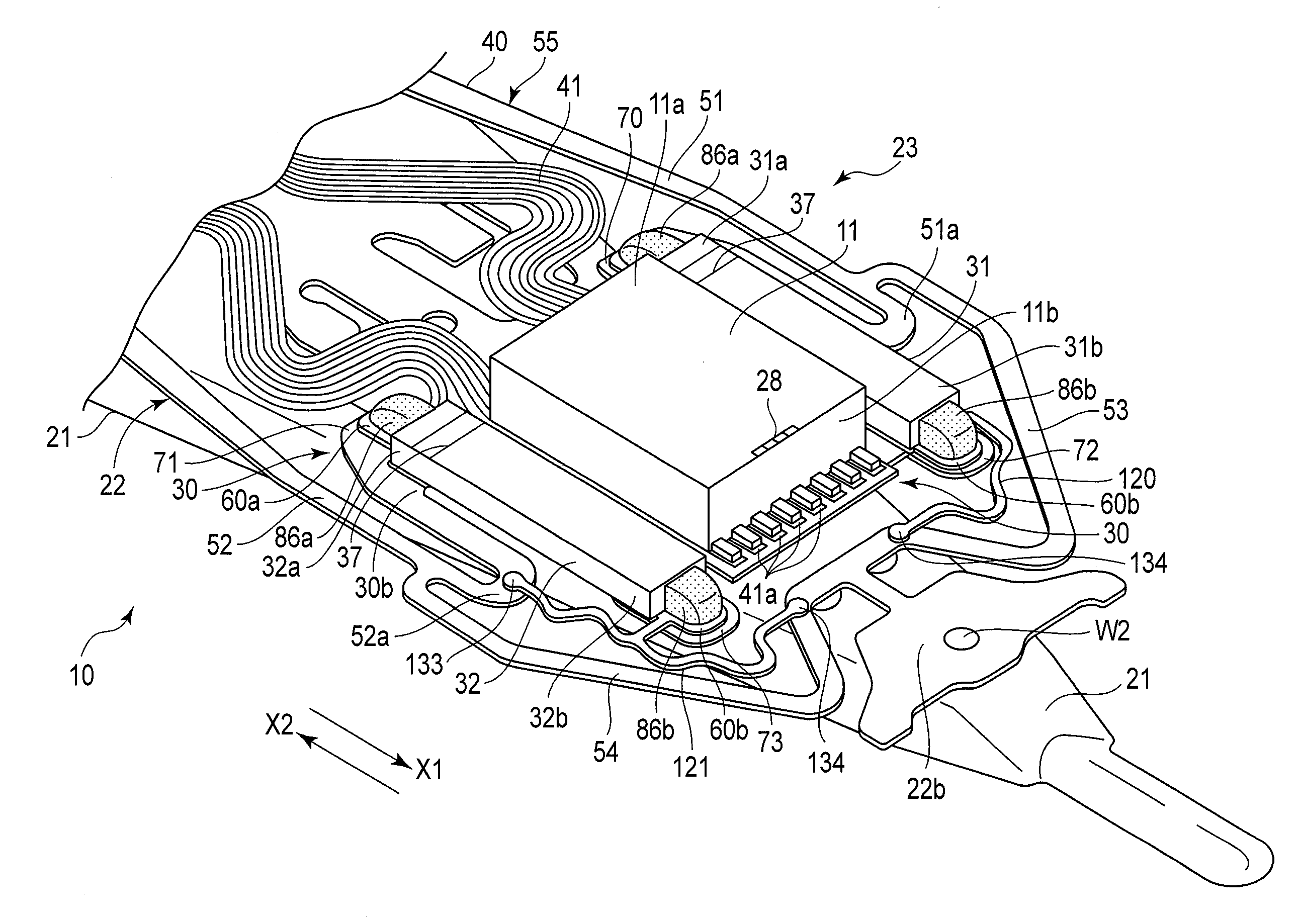

Disk drive suspension

ActiveUS20140022675A1Ensure electrical connectionEasy to separateRecord information storageMounting of arm assembliesElectrically conductiveAdhesive

A microactuator element is disposed on a gimbal portion of a flexure. A first end of the element is secured to a first supporting portion by a first insulating adhesive. A second end is secured to a second supporting portion by a second insulating adhesive. A first conductor is disposed on the first supporting portion. A second conductor on the ground side is disposed on the second supporting portion. A first electrode is disposed on a first end of the element. A first electrically conductive paste is provided between the first electrode and the first conductor. A second electrode is disposed on a second end of the element. A second electrically conductive paste is provided between the second electrode and the second conductor.

Owner:NHK SPRING CO LTD

Tolerance ring having variable height and/or assymmetrically located bumps

A tolerance ring configured to reduce torque ripple for a pivot bearing in an actuator arm assembly. The tolerance ring comprises a cylinder having a predetermined length, and a first and a second row of contacting portions arranged around the surface of the cylinder, the contacting portions of the second row are circumferentially displaced with respect to the first row by a distance greater than zero but less than the distance of the contacting portion and the spacing between adjacent contacting portions in the first row.

Owner:INTRL PLEX TECH INC

Cleating features to improve adhesive interface between an actuator tang and a tang-supporting surface of an actuator assembly of a hard disk drive

InactiveUS6950284B1Increase surface areaRecord information storageMounting of arm assembliesHard disc driveEngineering

A disk drive includes a disk, a latch assembly including a magnet and a head stack assembly for reading and writing to the disk. The head stack assembly includes a body portion defining a through bore that defines a pivot axis; an actuator arm cantilevered from the body portion; a head gimbal assembly coupled to the actuator arm; a coil portion cantilevered from the body portion in an opposite direction from the actuator arm, the coil portion defining first and second actuator fork members, one of the first and second actuator fork members defining a tang-supporting surface, the tang-supporting surface defining at least one cleating feature configured to increase a surface area of the tang-supporting surface, and a tang configured to interact with the magnet, the tang being attached to the tang-supporting surface by a layer of adhesive disposed on the tang-supporting surface.

Owner:WESTERN DIGITAL TECH INC

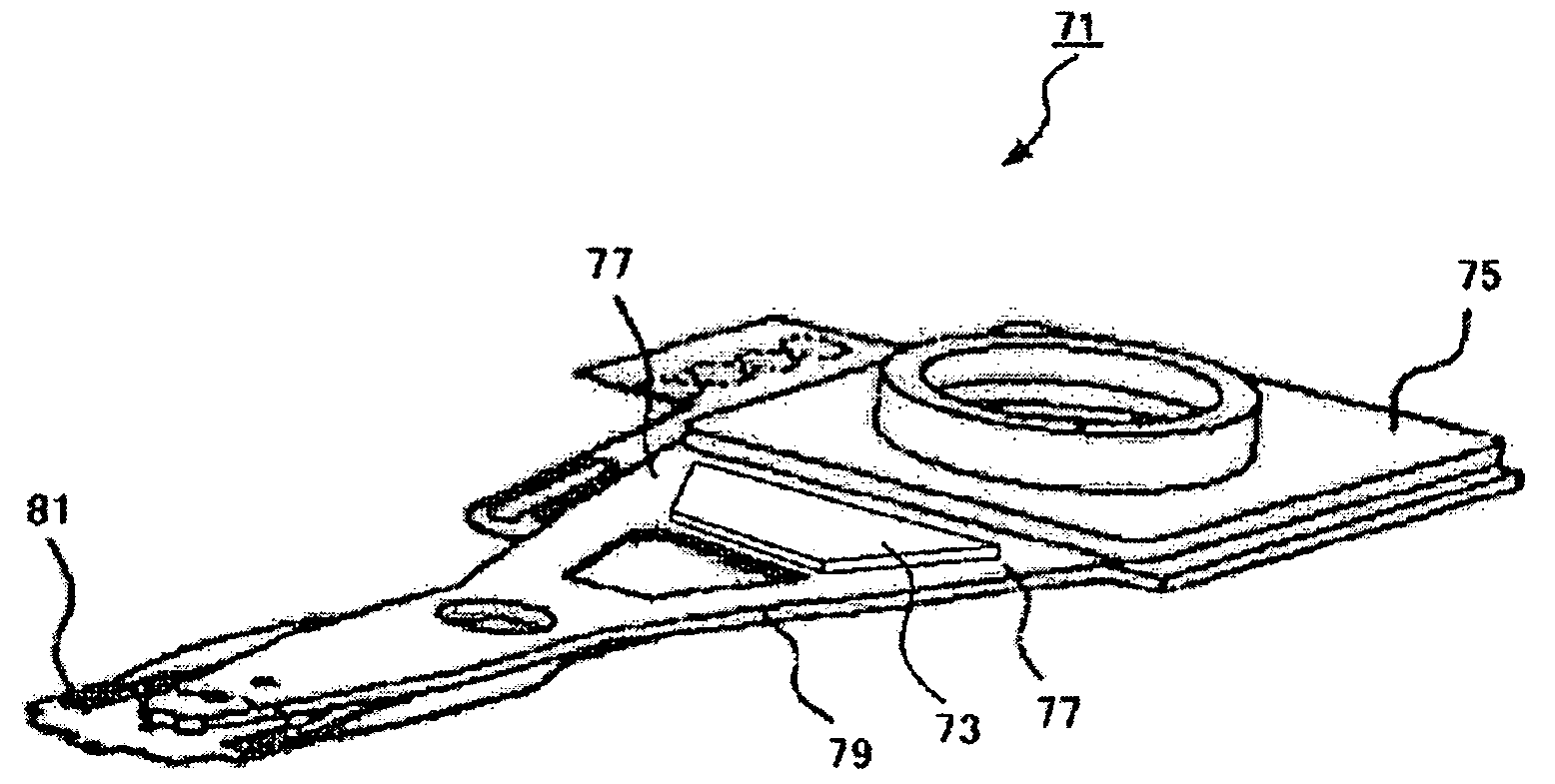

Head gimbal assembly having balanced weight, disk drive unit with the same and manufacturing method thereof

InactiveUS20090027807A1High bandwidthImprove performanceRecord information storageMounting of arm assembliesLeading edgeTrailing edge

A HGA includes a load beam having a dimple formed thereon; a flexure including a suspension tongue and a support plate connected with the suspension tongue; and a slider having a leading edge and trailing edge opposite to the leading edge. The slider is mounted on the flexure such that the slider is supported by the dimple at the center of the slider. The leading edge is attached on the suspension tongue and trailing edge is attached on the support plate. A weight-balance structure is formed on the suspension tongue of the flexure to balance the weight of the HGA between a portion from the trailing edge to the slider center and another portion from the leading edge to the slider center. The invention also discloses various methods of manufacturing HGA with the balanced weight.

Owner:SAE MAGNETICS (HK) LTD

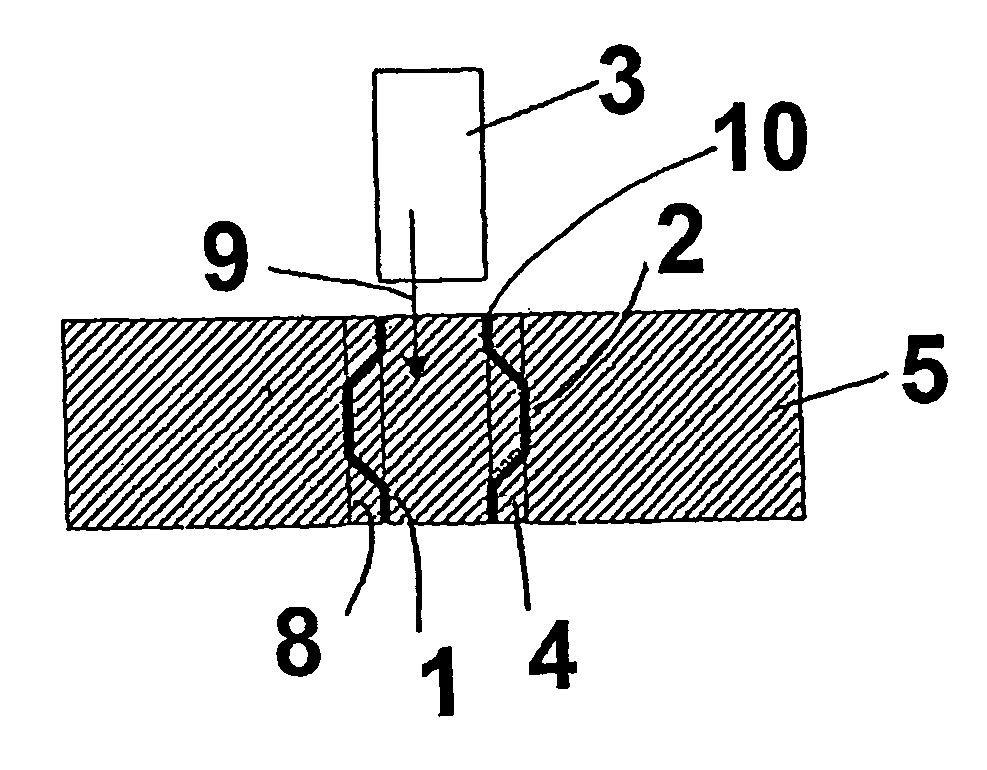

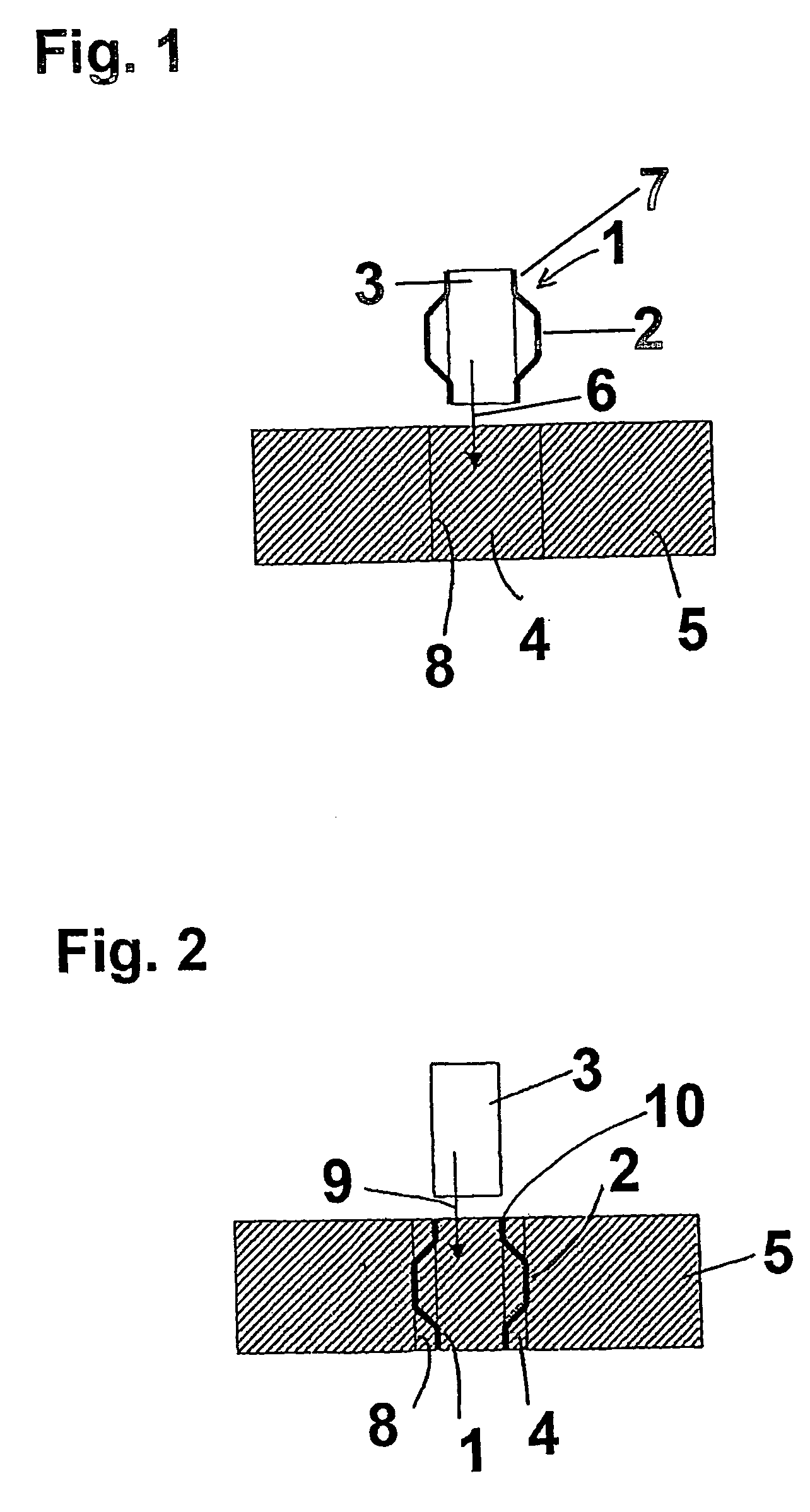

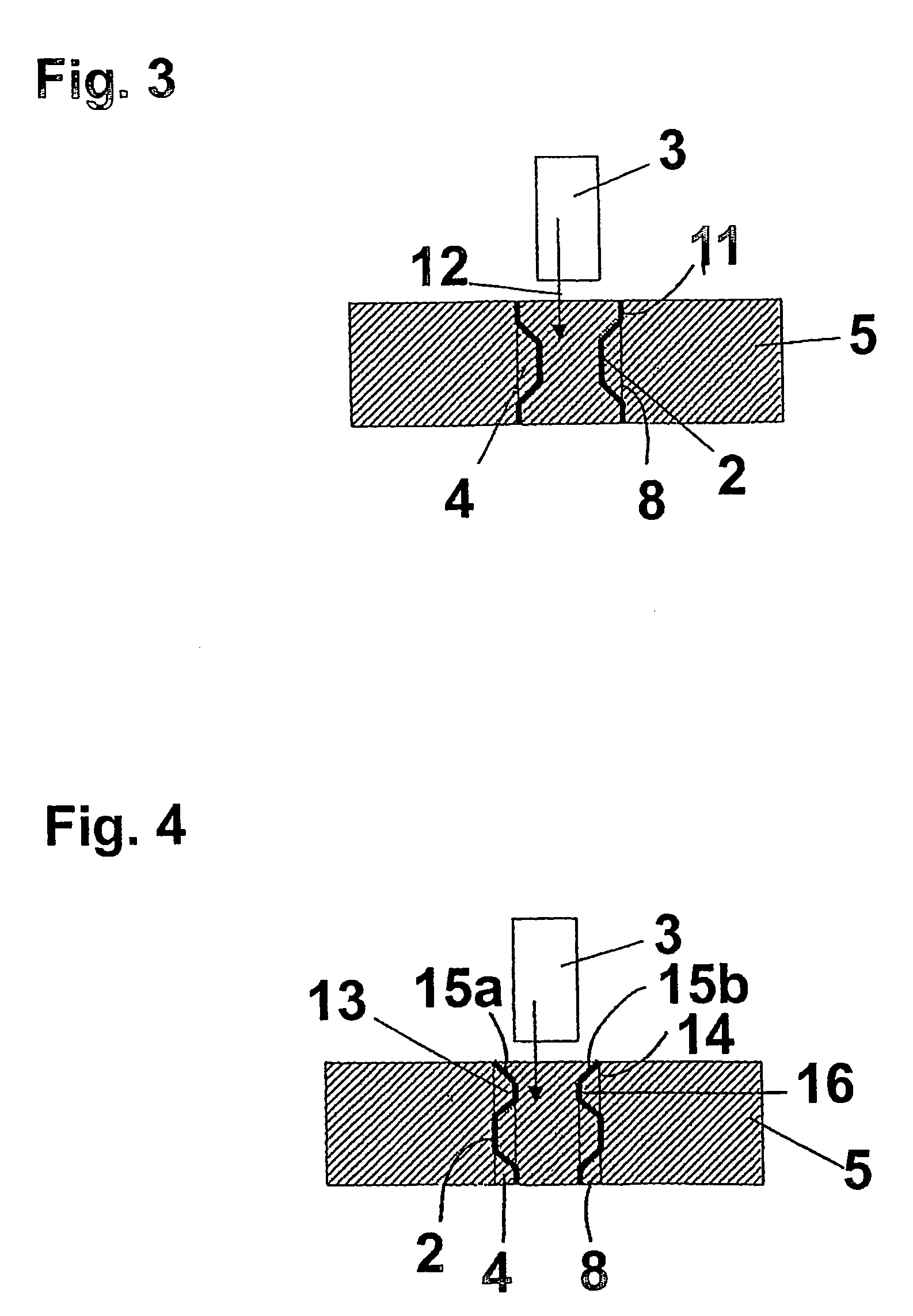

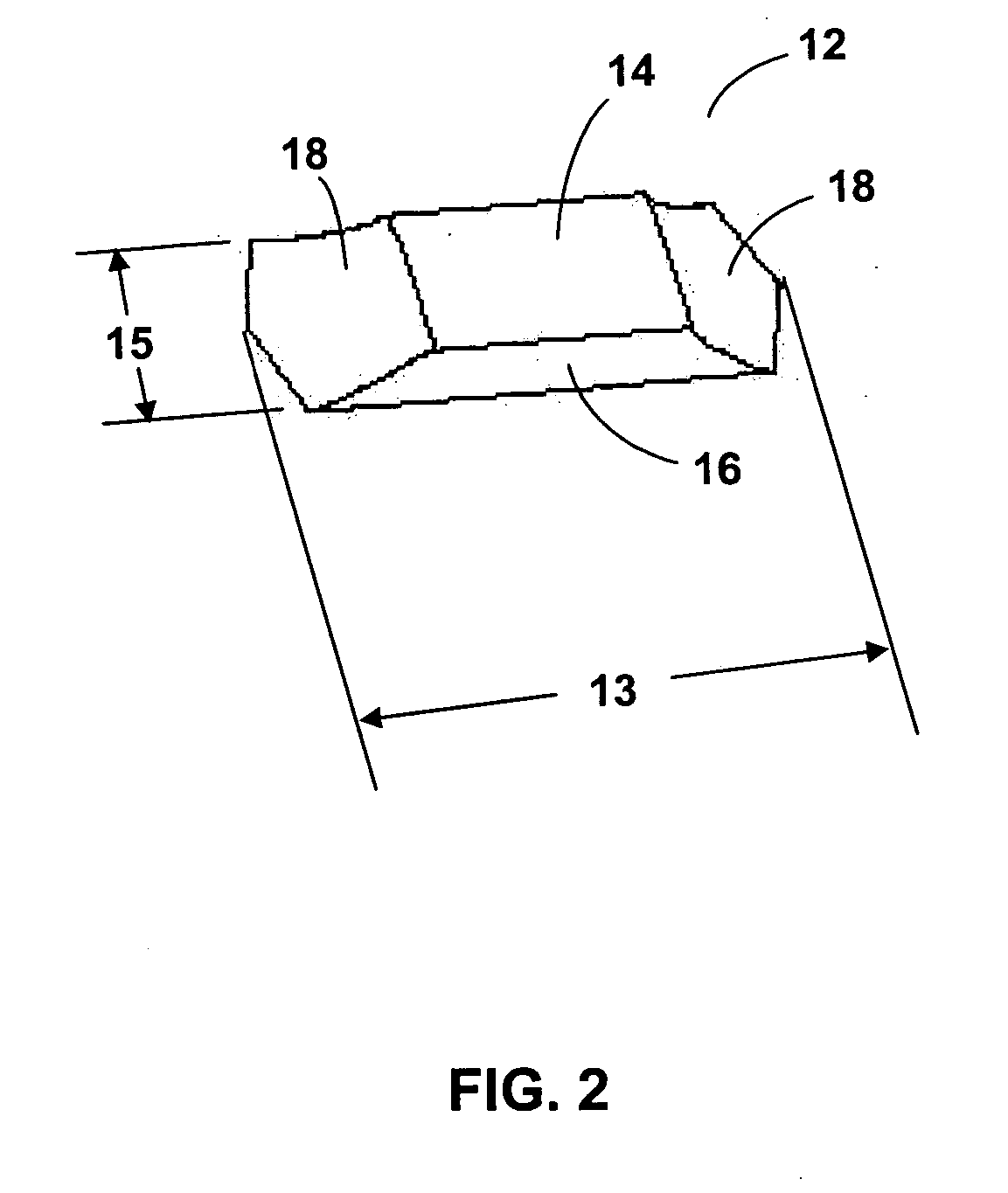

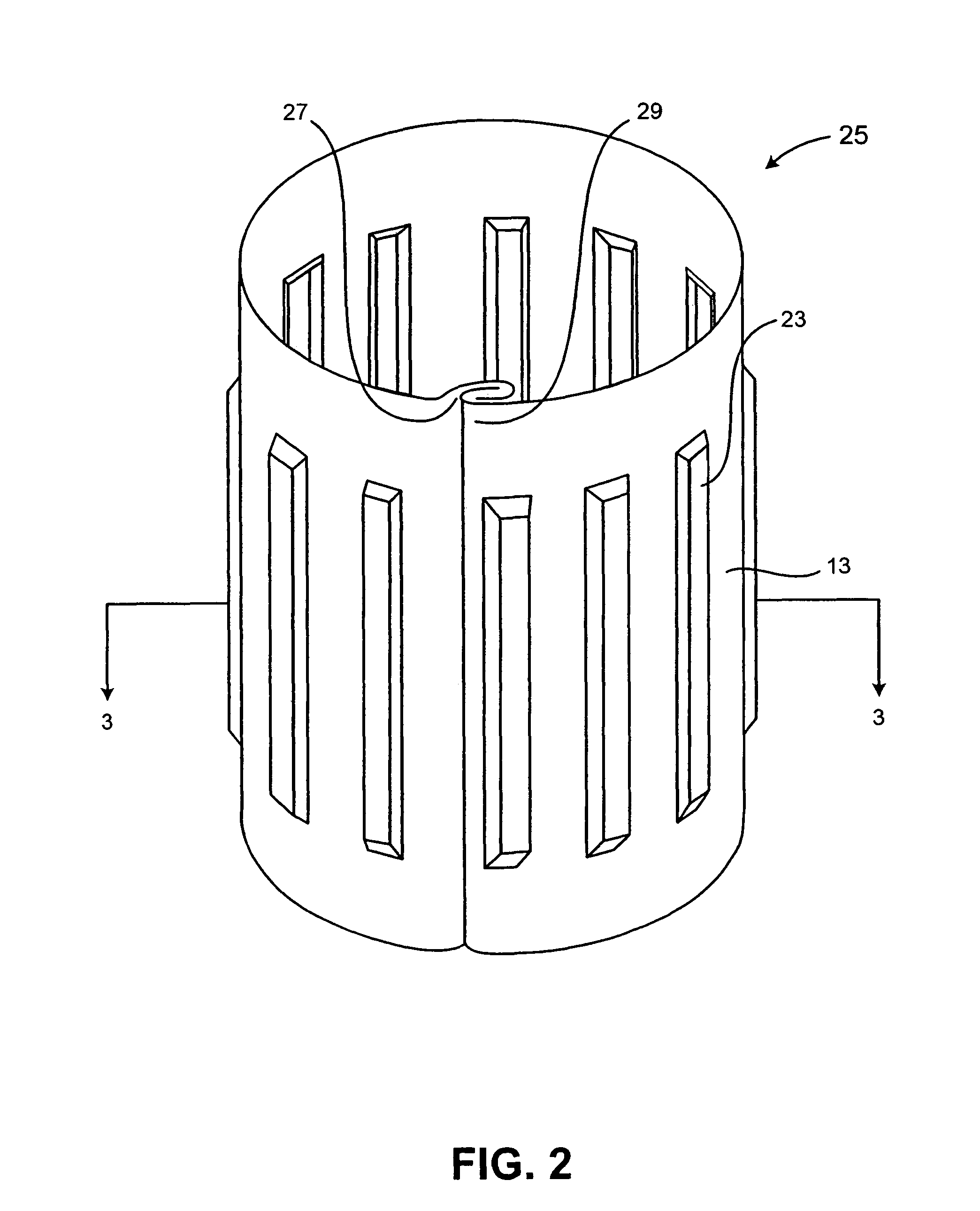

Tolerance ring assembly

ActiveUS20060228174A1Assembly precisionRecord information storageFriction grip releasable fasteningsBiomedical engineering

A tolerance ring has a band (16) with outwardly extending corrugated protrusions forming waves (2) which engage a surface (8) of the bore (4) in a housing (5). At one end of the tolerance ring is an outwardly flared guide surface (15a, 15b) extending axially from the band (16). The guide surface (15a, 15b) acts as an enlarged entrance to the band (16) for a shaft (3) to be mounted in the bore (4) by insertion into the tolerance ring. The use of the guide surface (15a, 15b) assists assembly and reduces or eliminates particle production. It is also possible for the corrugated portions to extend inwardly, for the guide surface to be inwardly flared, and for the tolerance ring to be mounted on the shaft prior to insertion in the bore.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

Tolerance ring with debris-reducing profile

A tolerance ring for applications requiring cleanliness has contacting portions having a novel profile that reduces debris generation during installation of the tolerance ring while still providing adequate stiffness after installation. The tolerance ring is suitable for cylindrical interface applications where both a reduction in debris generation and high interface stiffness are desirable, such as the interface between an actuator pivot bearing and an actuator arm in a magnetic hard disk drive.

Owner:INTRL PLEX TECH INC

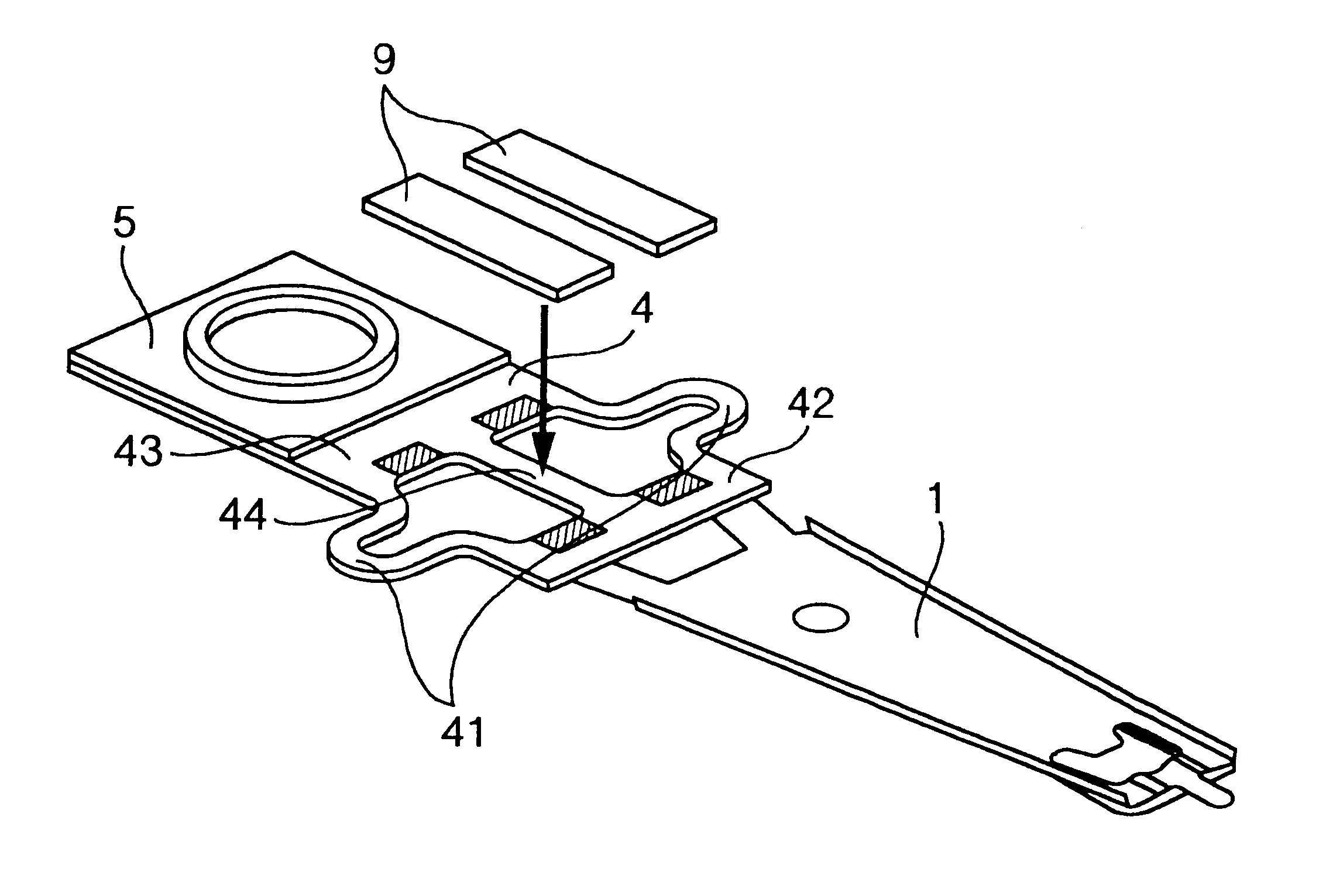

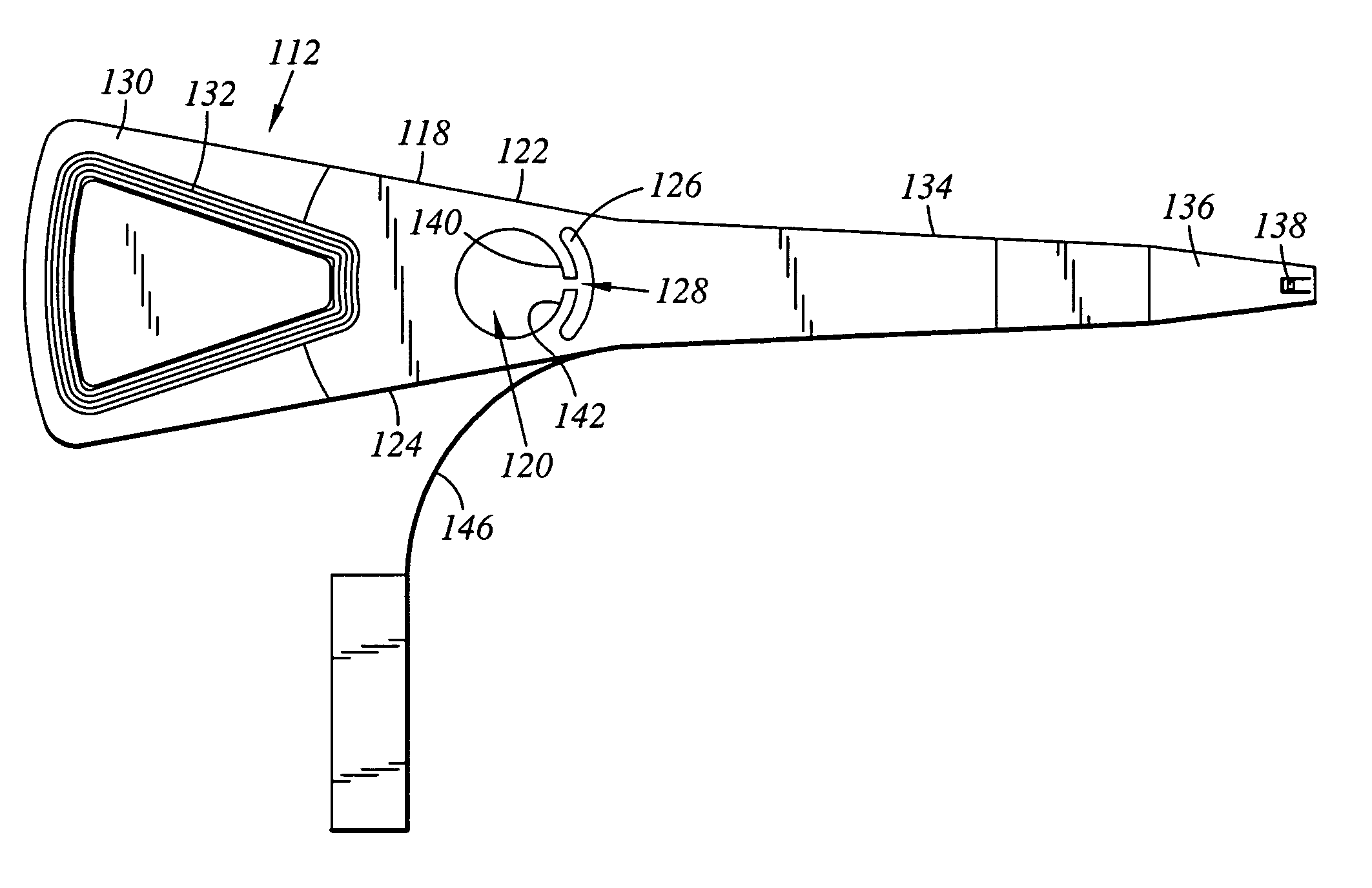

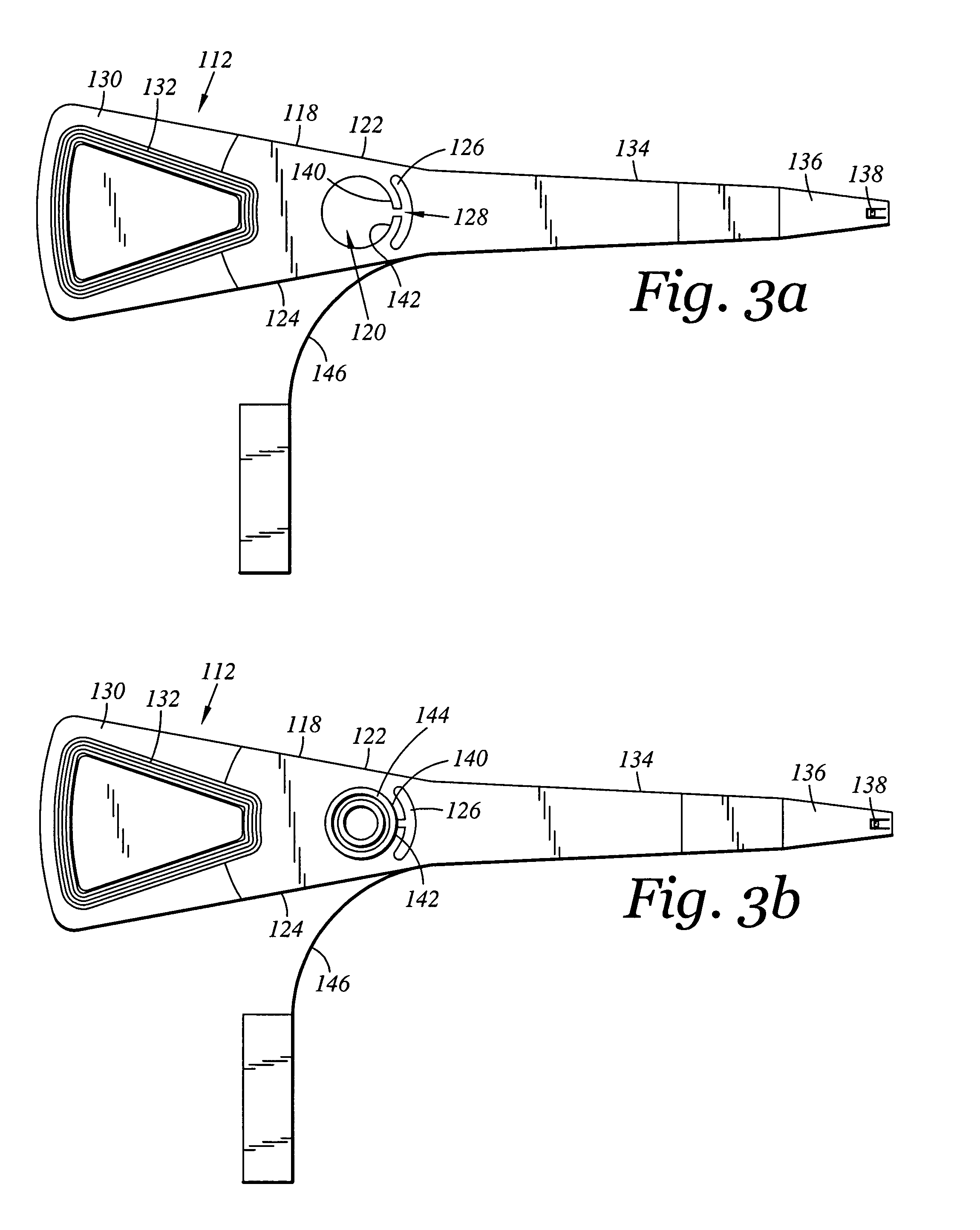

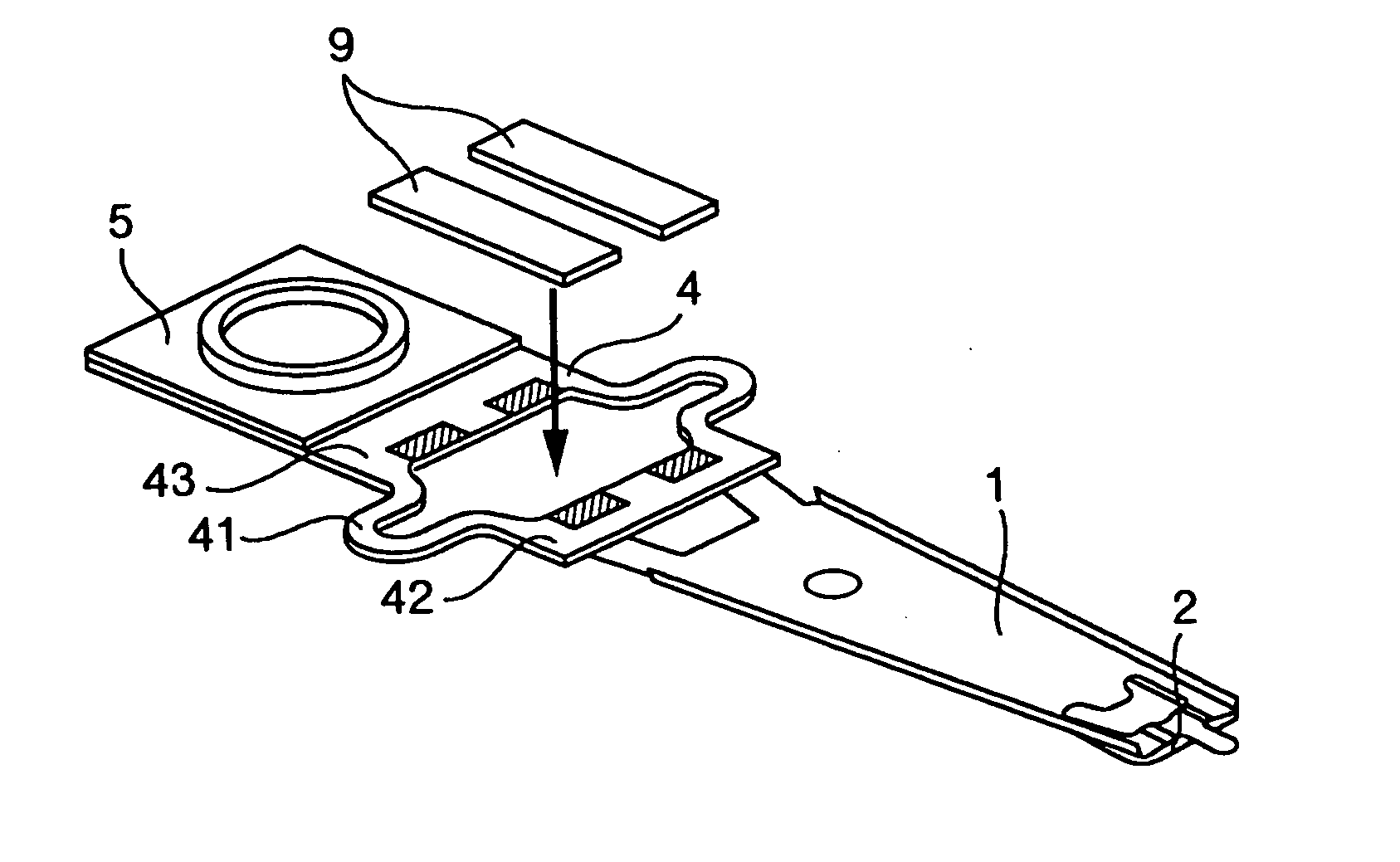

Magnetic disk apparatus

InactiveUS20040027727A1Precise positioningReduce stress concentrationArm with actuatorsRecord information storageControl theoryMicroactuator

A head support mechanism includes a slider equipped with a magnetic head to read / write information from / to a magnetic disk, a load beam to provide the slider with an appropriate load, the load beam being flexible in a direction substantially perpendicular to the disk, and a microactuator mounting portion equipped with a microactuator. A first actuator fixing portion, which connects the microactuator mounting portion to a carriage, and a second actuator fixing portion on the magnetic head side of the microactuator mounting portion, which connects the microactuator mounting portion to the load beam, are coupled by two arm portions of the microactuator mounting portion. The microactuator is mounted on the microactuator mounting portion so that the microactuator does not come into contact with the microactuator mounting portion between the first actuator fixing portion and the second actuator fixing portion.

Owner:WESTERN DIGITAL TECH INC +1

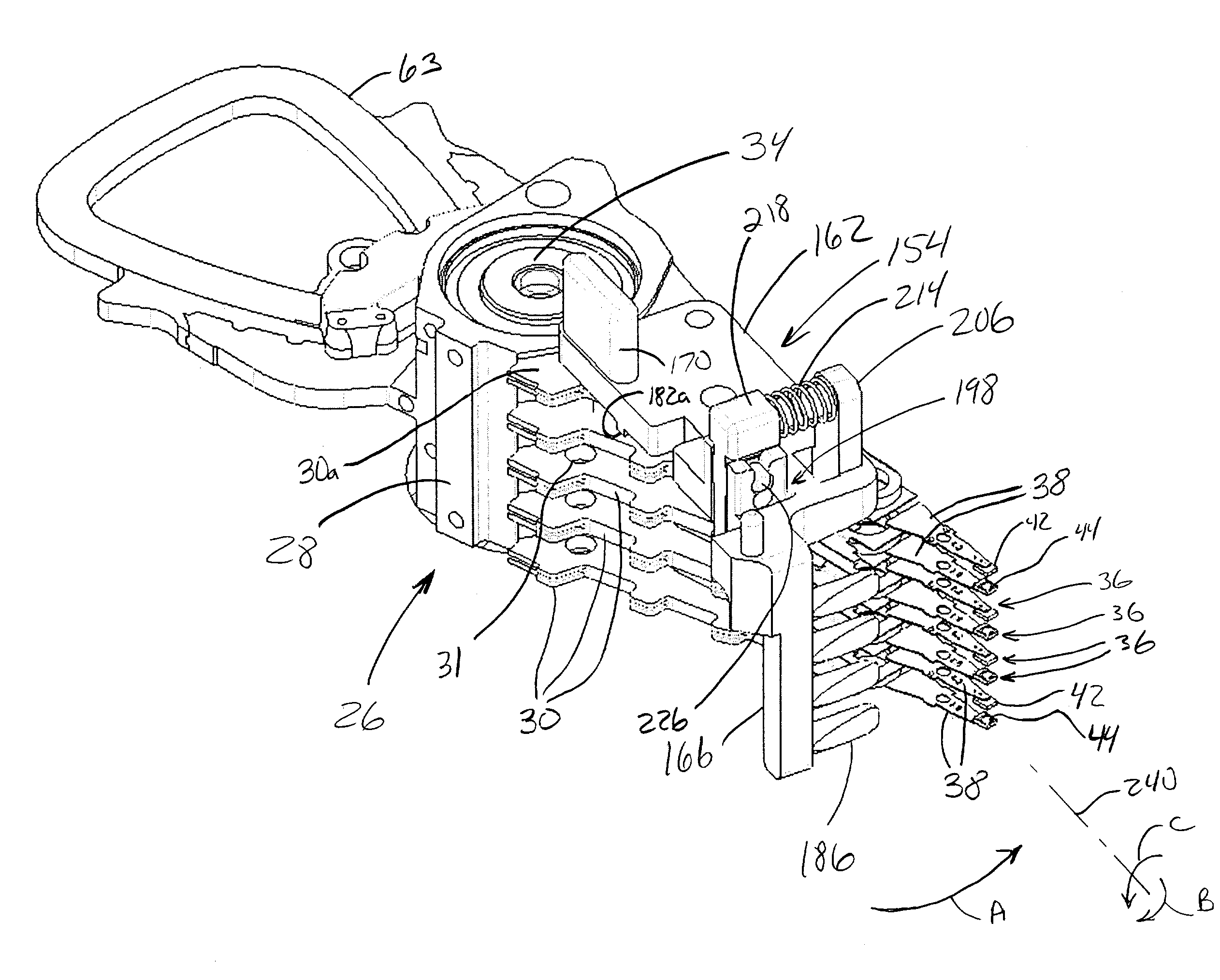

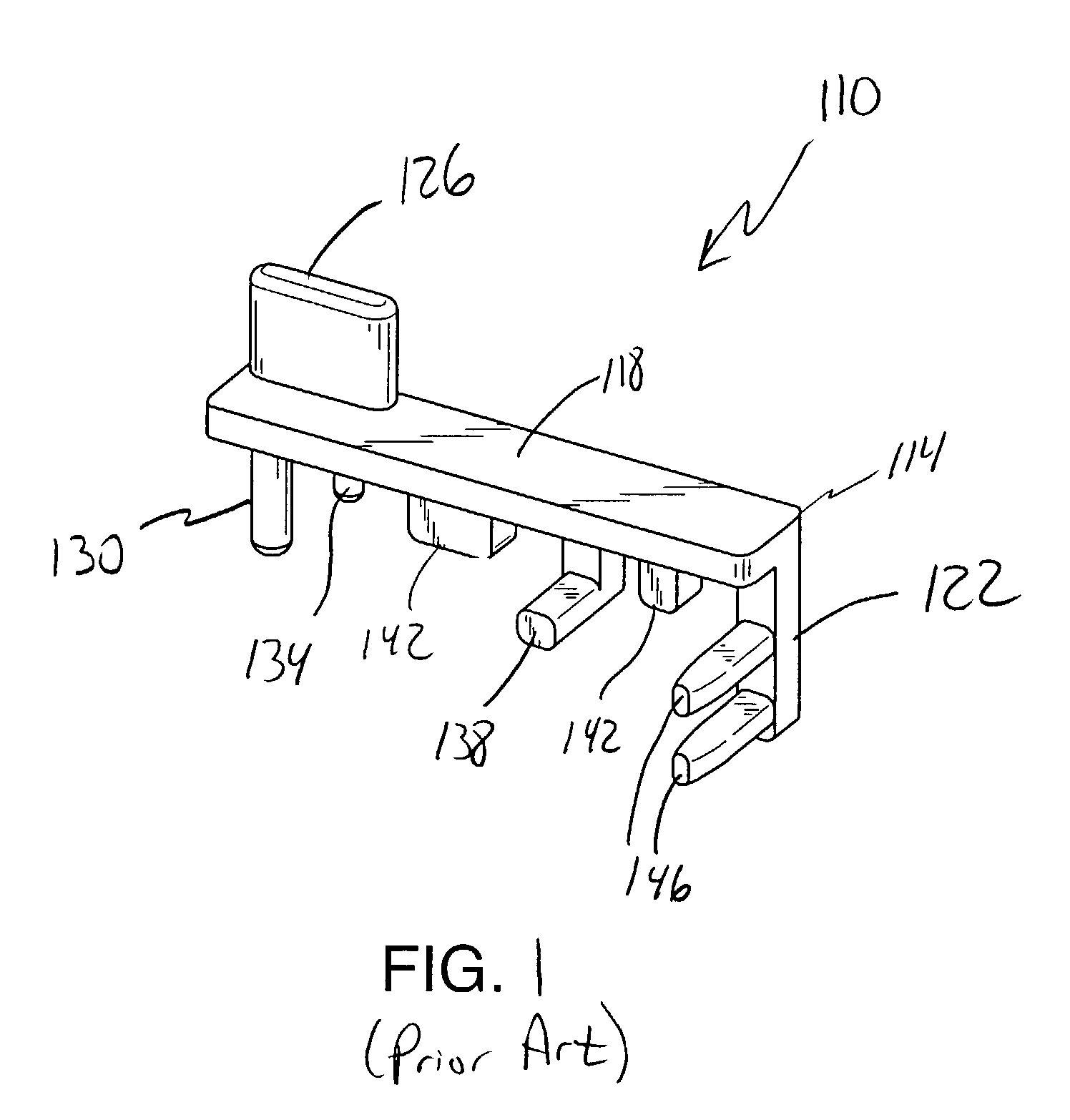

Spring assisted head stack assembly comb

A head stack assembly comb (154) for maintaining the heads (44) of a head stack assembly (26) in spaced relation is disclosed. The head stack assembly comb (154) includes a comb body (158) and a latch (218). The comb body (158) engages an upper surface of an uppermost actuator arm (30a) in the head stack assembly (26). The latch (218) engages a lower surface of this same actuator arm (30a). When installing the comb (154), the comb (154) is pivoted relative to the head stack assembly (26). This brings the latch (218) into engagement with the noted actuator arm (30a) and causes the latch (218) to pivot in a first direction against a spring (214), and then in the opposite direction by the action of the spring (214) on the latch (218) to engage the latch (218) with the lower surface of the noted actuator arm (30a).

Owner:MAXTOR

Tolerance ring having various end tab designs to prevent interlocking

A tolerance ring configured to prevent interlocking during shipping and handling. The tolerance ring has a cylinder with a first radius about an axis of rotation and a gap in the cylinder surface having a first edge and second edge extending along the axis. The gap in the cylindrical base has a first tab on the first edge and a second tab on the second edge. The first tab is adapted for coupling to the second tab and thereby prevents the interlocking of one tolerance ring with another. The gap can be configured to be non-linear.

Owner:INTRL PLEX TECH INC

Mounting assembly

ActiveUS7922418B2Less sensitiveEasy to controlRecord information storagePivotal connectionsMechanical engineering

A mounting assembly comprising mating inner and outer components (36, 38) mounted together using a tolerance (20) is disclosed. The tolerance ring (20) has radially extending projections (28) that are configured to cause the tolerance ring (20) to operate into the plastic phase of its compression force / retention force characteristic. This can be achieved by using softer projections than those found in conventional tolerance rings. The force required to mount the tolerance ring and a range of retention forces exhibited by it for a given variance in sizes of mating components is thereby stabilized.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

Disk drive load arm structure having a strain sensor and method of its fabrication

A load arm for a disk drive may include a base section that has an opening for receiving a spindle of a voice coil motor. The base section may have hinge arms that extend from the base section and terminate in tab portions. An arm section may be affixed to the tabs of the hinge arms of the base section such as by spot welding. A head suspension assembly may be affixed to a distal end of the arm section such as by spot welding. A sensor may be provided on a hinge arm of the base section. The sensor may comprise a piezoelectric polymer sensing element and an electrode formed over the piezoelectric polymer sensing element.

Owner:SEAGATE TECH LLC

Disk drive suspension

ActiveUS20140085754A1Reduce vibrationVibrationArm with actuatorsRecord information storageControl theoryShock absorber

A slider and microactuator elements are disposed on a gimbal portion of a flexure. A tongue of the gimbal portion has a first tongue portion, a second tongue portion, and a hinge portion. A leading-side portion of the slider is movably disposed on the first tongue portion. A trailing-side portion of the slider is secured to the second tongue portion. The hinge portion is formed between the first tongue portion and the second tongue portion. The gimbal portion is provided with a damper member includes a viscoelastic material layer and a constrained plate. The damper member comprises a first damper and a second damper. The hinge portion is exposed between the first damper and the second damper. A dimple on a load beam contacts the hinge portion at a point of contact.

Owner:NHK SPRING CO LTD

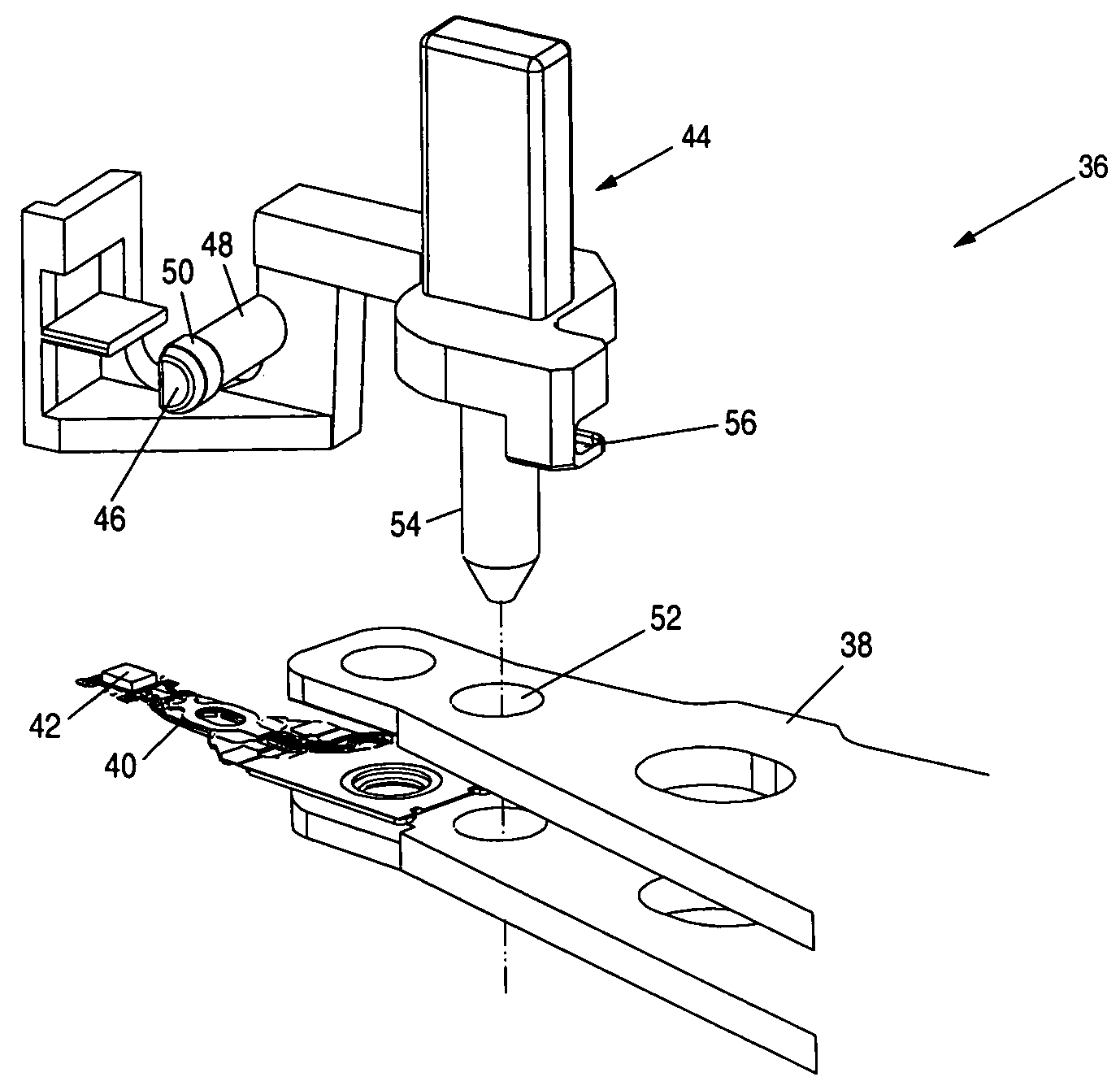

Method for manufacturing a head suspension

ActiveUS8151440B2Dispersion suppressionImprove productivityElectrical transducersRecord information storageProduction rateVibration control

A method for manufacturing a head suspension is capable of suppressing the dispersion in the vibration control effect of a head suspension and improve productivity, the manufacturing method includes a step of punching, by use of a hollow punch having a tooth portion at a distal end thereof, a vibration damper piece out from a base material having a vibration damper provided detachably on a liner through an attaching surface, to hold the vibration damper piece on a hollow internal surface of the punch, a step of positioning the punch holding the vibration damper piece on an objective portion of a semi-finished head suspension, and a step of attaching, by use of an extruding implement, the vibration damper piece on the objective portion with the attaching surface through extruding the vibration damper piece from the punch.

Owner:NHK SPRING CO LTD

Method, apparatus and jig for manufacturing head suspension, and head suspension

ActiveUS20090183359A1Dispersion suppressionImprove productivityElectrical transducersRecord information storageProduction rateVibration control

A method for manufacturing a head suspension is capable of suppressing the dispersion in the vibration control effect of a head suspension and improve productivity, the manufacturing method includes a step of punching, by use of a hollow punch having a tooth portion at a distal end thereof, a vibration damper piece out from a base material having a vibration damper provided detachably on a liner through an attaching surface, to hold the vibration damper piece on a hollow internal surface of the punch, a step of positioning the punch holding the vibration damper piece on an objective portion of a semi-finished head suspension, and a step of attaching, by use of an extruding implement, the vibration damper piece on the objective portion with the attaching surface through extruding the vibration damper piece from the punch.

Owner:NHK SPRING CO LTD

Shipping comb for moving actuator of hard disk drive

InactiveUS20060117558A1Avoid collisionElectrical transducersUndesired vibrations/sounds insulation/absorptionHard disc driveActuator

A shipping comb for use when moving an actuator of a hard disk drive, the actuator including a swing arm installed on a base member of the hard disk drive capable of pivoting, at least a pair of load beams coupled to an end portion of the swing arm, and at least a pair of sliders respectively coupled to the load beams to face each other. The shipping comb includes a frame operative to be coupled to the actuator and capable of pivoting, a first finger provided at the frame and for maintaining an interval between the load beams by being inserted between the load beams, and a second finger provided at the frame and for preventing collision between the sliders by being inserted between the sliders.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com