Worm-gear speed-reducing wire-feeding motor equipment as well as wire feeding device provided with same and welding system provided with same

A technology of worm gear and motor equipment, which is applied in the direction of electromechanical devices, arc welding equipment, welding equipment, etc., can solve the problems that affect the working accuracy and product life, the motor cannot work normally, and the dynamic response speed is slow, so as to ensure stable and high precision Normal operation, prevent the motor from malfunctioning, and improve welding quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

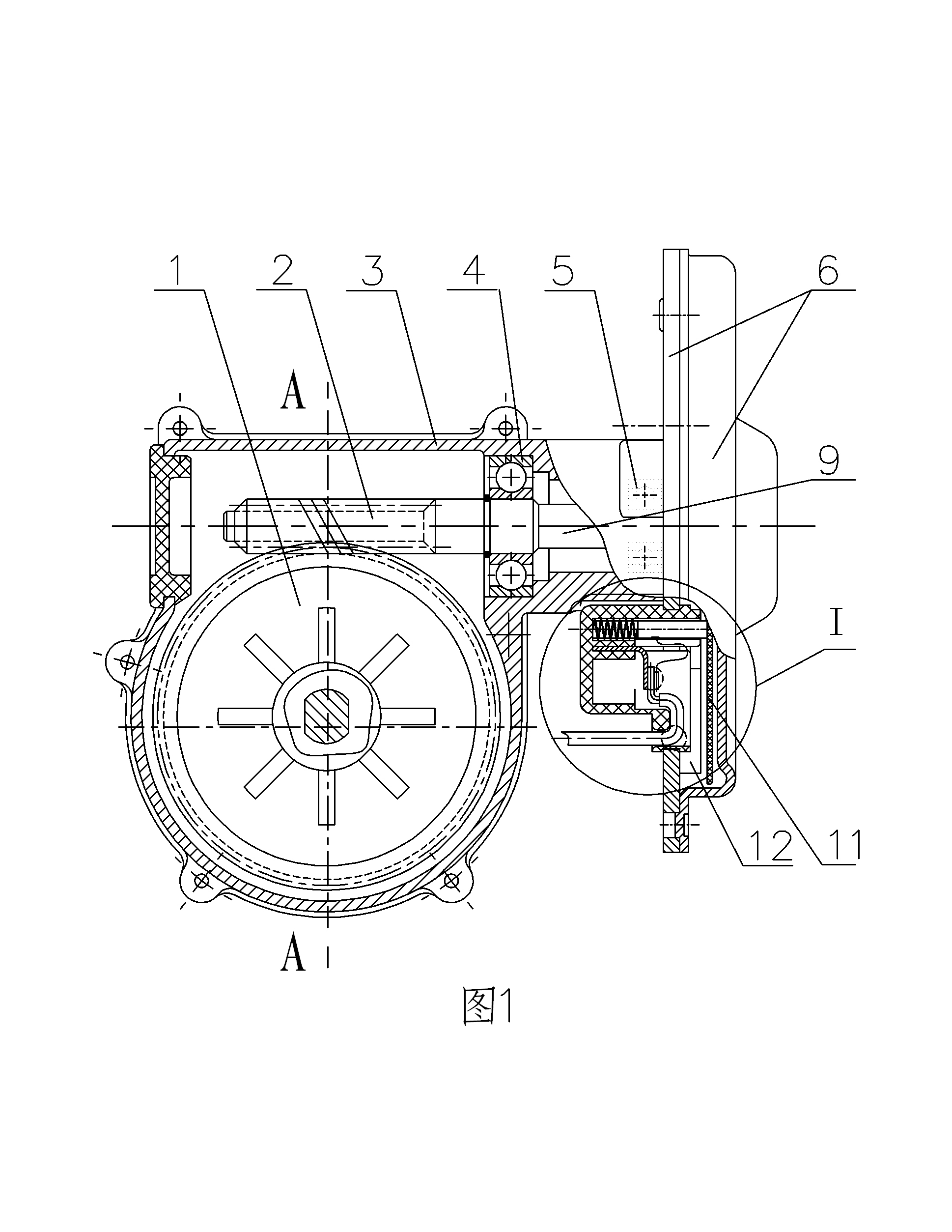

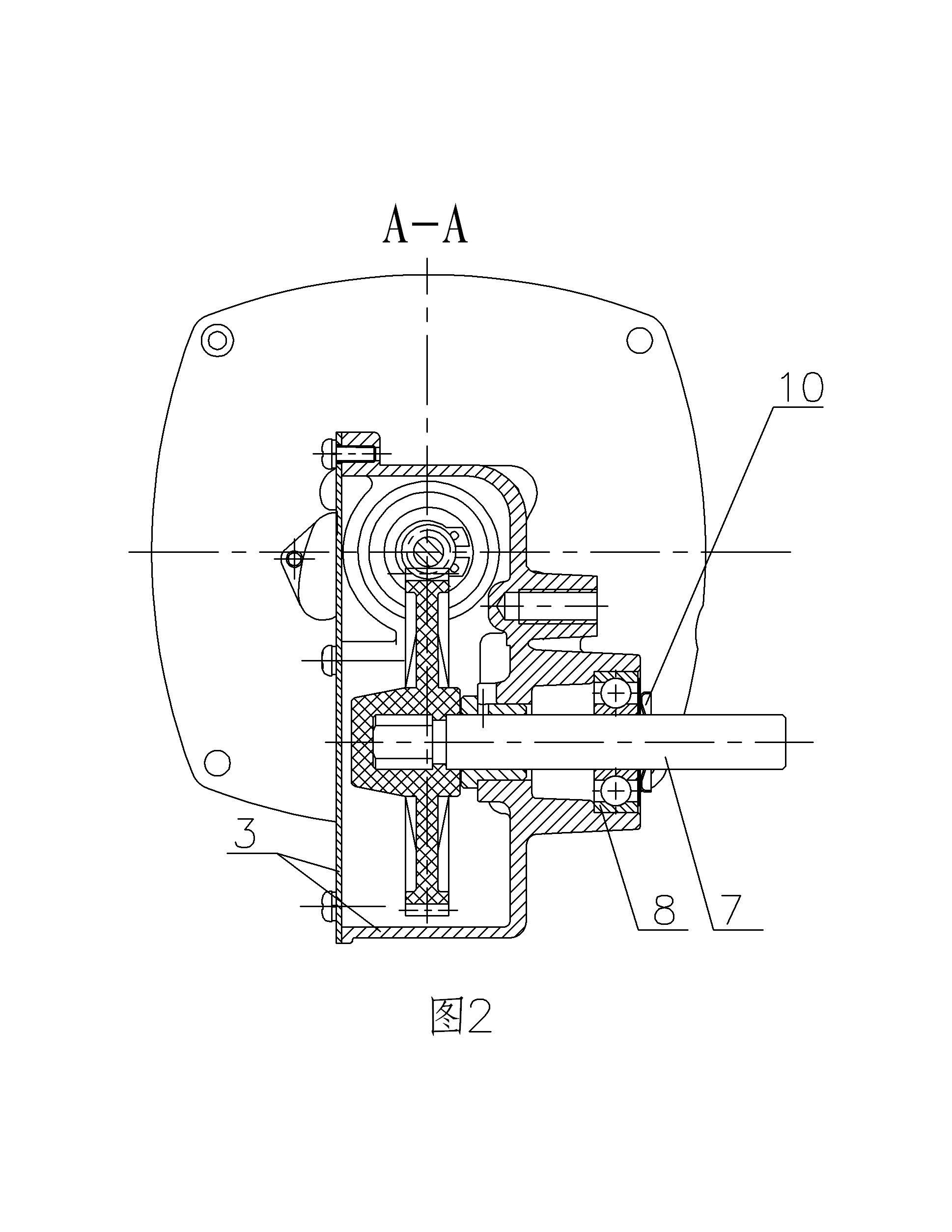

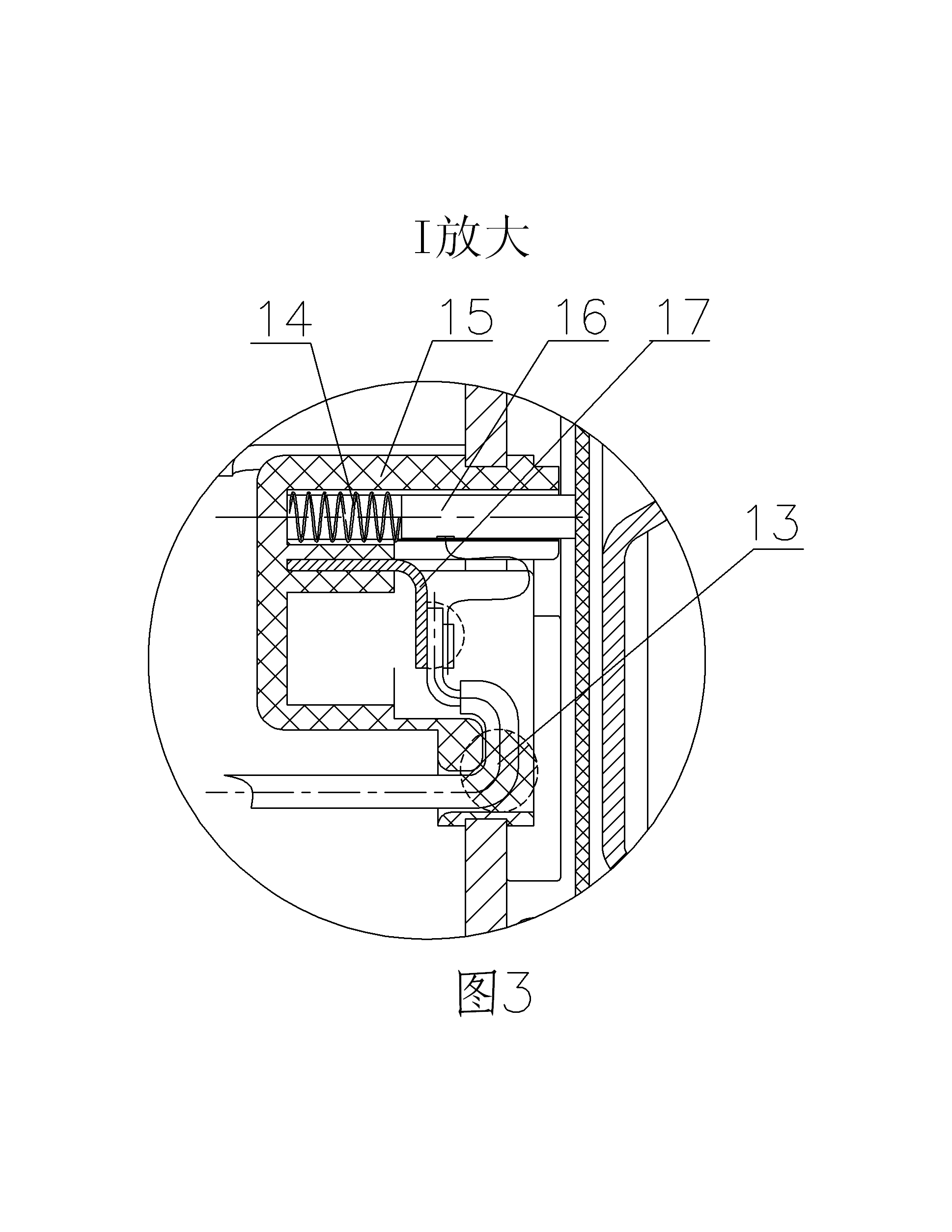

[0033] like Figure 1-Figure 3 Shown is a worm gear reduction type wire feeding motor equipment provided by the present invention, which includes a motor, a power output shaft 7 and a reduction transmission device connected between the power output shaft 7 and the motor output shaft 9 of the motor, and is characterized in that : the motor adopts a flat motor, and the reduction transmission device adopts a worm gear reduction transmission device.

[0034] The worm gear reduction transmission device includes a reduction box body 3 and a worm wheel 1 and a worm 2 assembly that are arranged in the reduction box body 3 for transmission, and the worm wheel 2 is connected to the motor output shaft 9 for transmission, and the motor output shaft 9 It is integrally connected with the worm 2 coaxially, and is connected with the reduction box body 3 through the front support bearing 4 and the rear support bearing 5 in rotational support.

[0035] The power output shaft 7 is connected to th...

Embodiment 2

[0039] like Figure 4 Shown is a wire feeding device provided by the present invention with the above-mentioned worm gear reduction type wire feeding motor device, which includes a frame assembly 18, a bracket assembly 19 and a wire feeding motor device 21 installed on the frame assembly 18 , the wire feeding motor equipment 21 includes a motor, a power output shaft 7 and a deceleration transmission device connected between the power output shaft 7 and the motor output shaft 9 of the motor, wherein the motor adopts a flat motor, and the deceleration The transmission device adopts the worm gear reduction transmission device.

[0040] The above-mentioned wire feeding device may be provided with a disk shaft assembly 20 or not provided with a disk shaft assembly 20 as required. In addition, the shapes and combinations of the parts such as the frame assembly 18, the bracket assembly 19, the disk shaft assembly 20 and the wire feeding motor equipment 21 of the wire feeding device ...

Embodiment 3

[0045] like Figure 5 Shown is a welding system provided by the present invention with the above-mentioned wire feeding device, which includes a wire feeding device 22, a welding power supply device 23, a control device 24, and a welding torch 25; the wire feeding device includes a frame assembly 18 and an installation The bracket assembly 19 and the wire feeding motor equipment 21 on the frame assembly 18; the wire feeding motor equipment 21 includes a motor, a power output shaft 7 and a speed reducer connected between the power output shaft 7 and the motor output shaft 9 of the motor Transmission device; one output electrode of the welding power supply device 23 is connected to the bracket assembly 19 through a welding power supply output cable 26 to provide a welding power supply, and the other output electrode is used to connect with the workpiece to be welded through another welding power supply output cable 27 The welding torch 25 is connected to the welding wire 29 deli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com