Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146 results about "Engine balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Engine balance refers to those factors in the design, production, engine tuning, maintenance and the operation of an engine that benefit from being balanced. This article is currently limited to structural and operational balance within an engine in general, and balancing of piston engine components in particular.

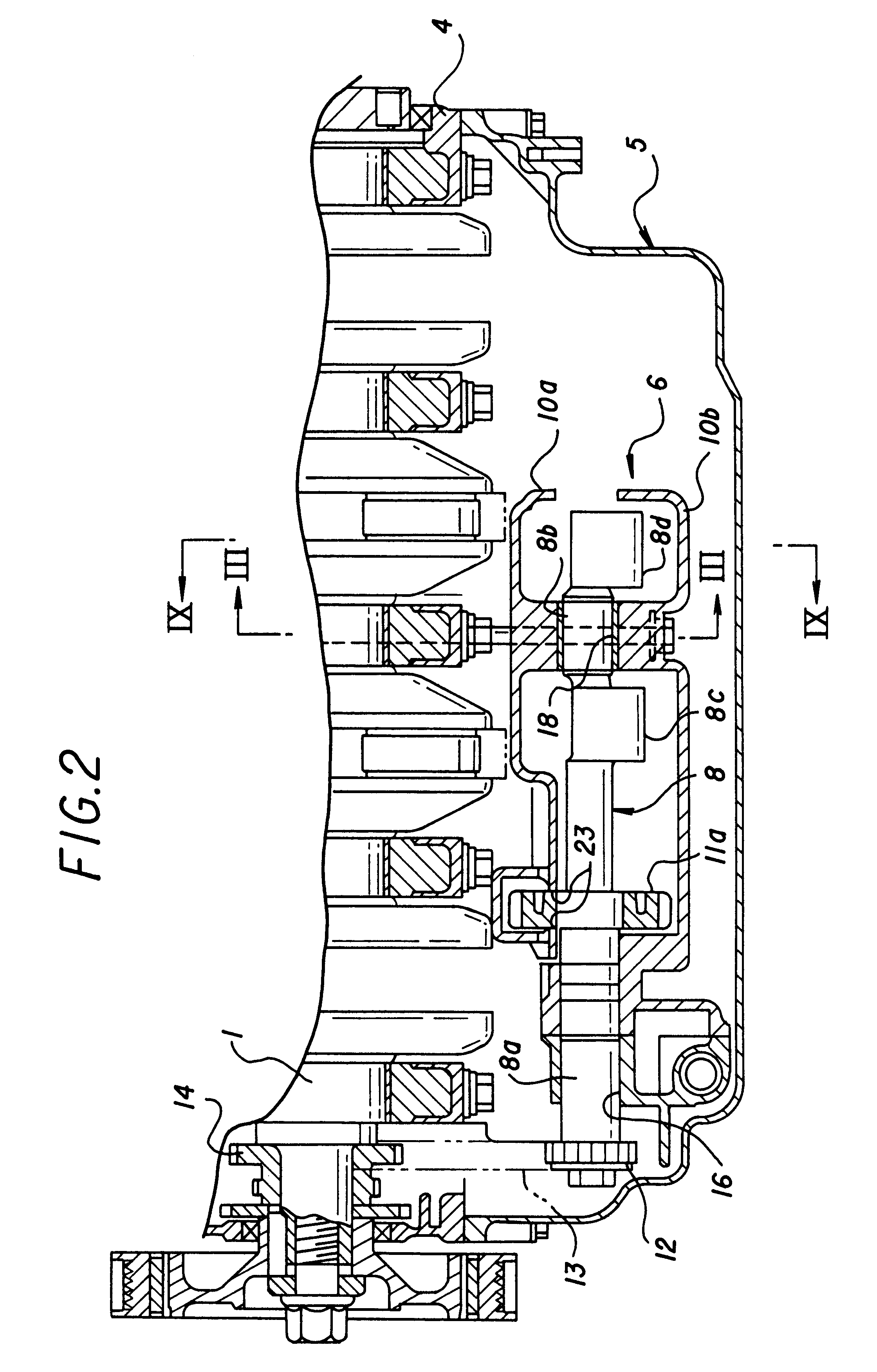

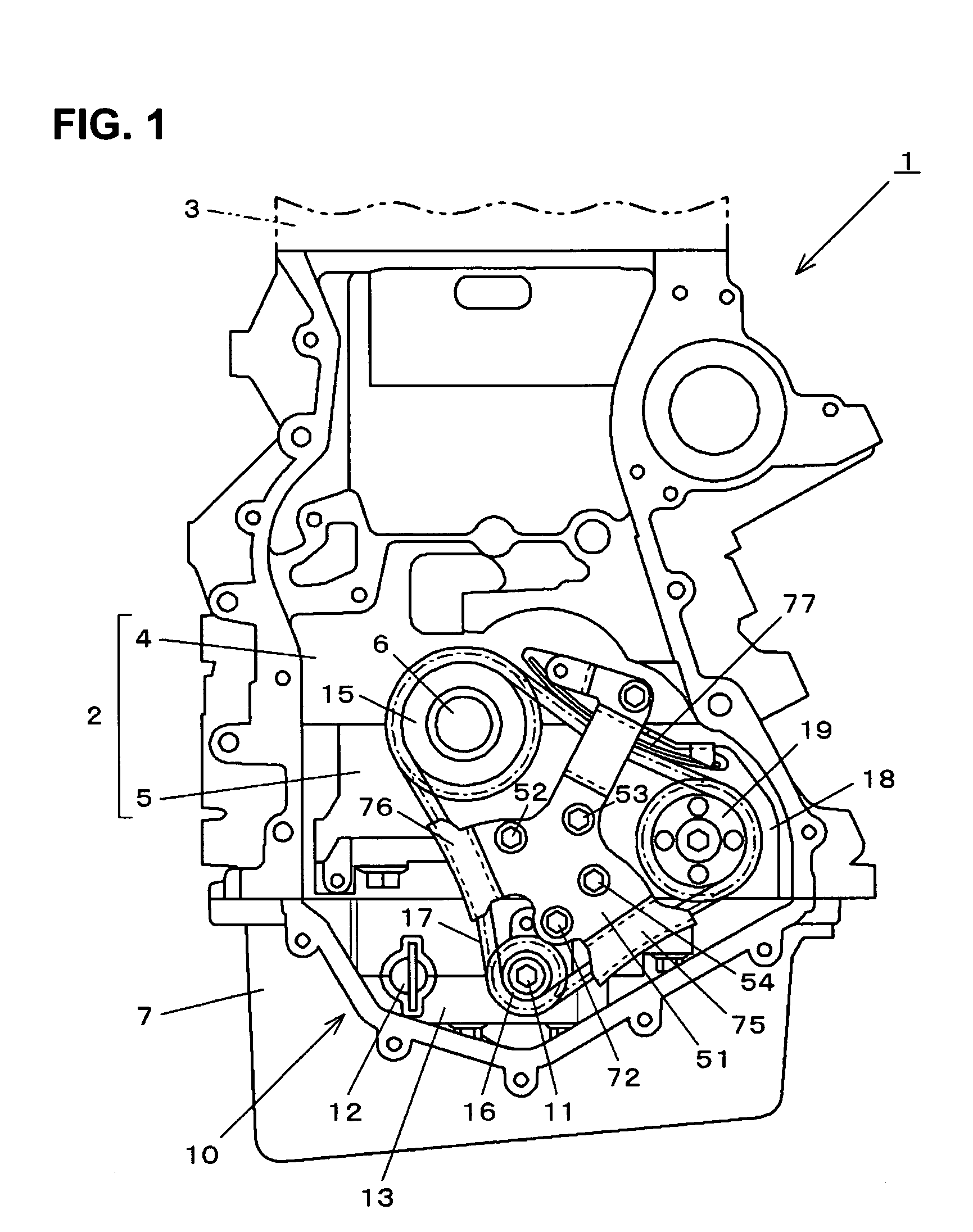

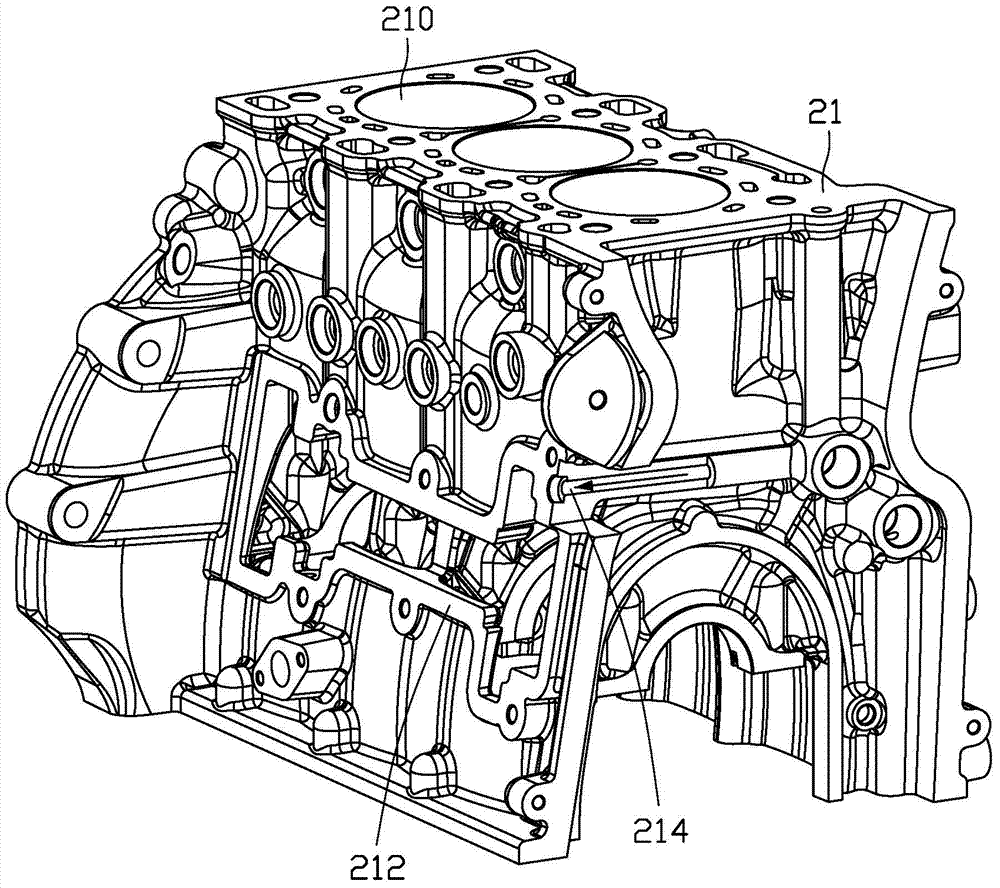

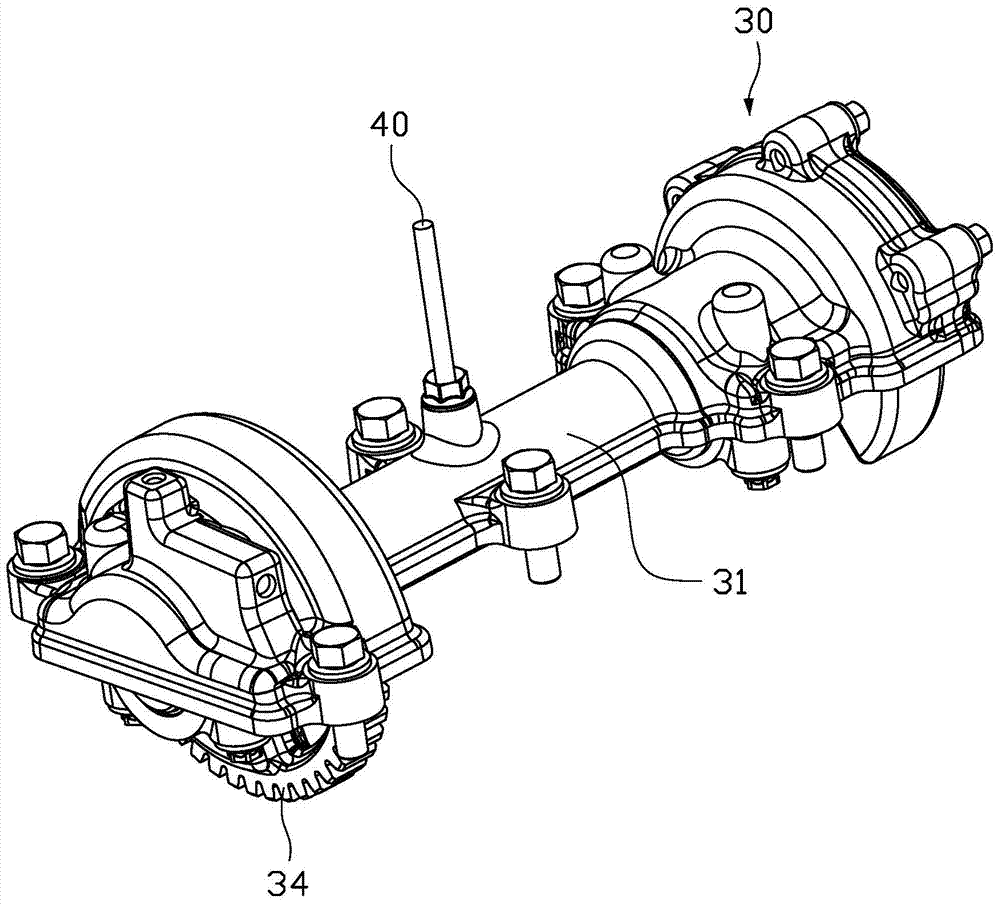

Engine balance shafts supporting structure

A casing accommodating therein a pair of balance shafts below the cylinder block comprises an upper casing and a lower casing that can vertically be split, and an oil pump body is molded integrally with one of the upper and lower casings. In addition, one end of each of the two casings is inserted into the oil pump body for support therein, and the two balance shafts are each supported on a bearing provided between the two casings in such a manner as to be split into two halves at an intermediate portion or the other end thereof. With this construction, the oil pump body can be molded together with the casing, thereby making it possible to reduce the number of components used and man hours for assembling. In addition, since the bearings can be split into two halves, when compared with other portions of the balance shafts, the journal portion can be thinned, thereby making it possible not only to reduce the sliding friction but also to make the casing smaller in size and lighter in weight. More over, the degree of freedom of designing balance shafts can also be improved. With the balance shaft supporting structure for an engine the durability of a balancer, as well as the degree of freedom of designing the same are improvided without making the engine larger in size and increasing the number of components used.

Owner:HONDA MOTOR CO LTD

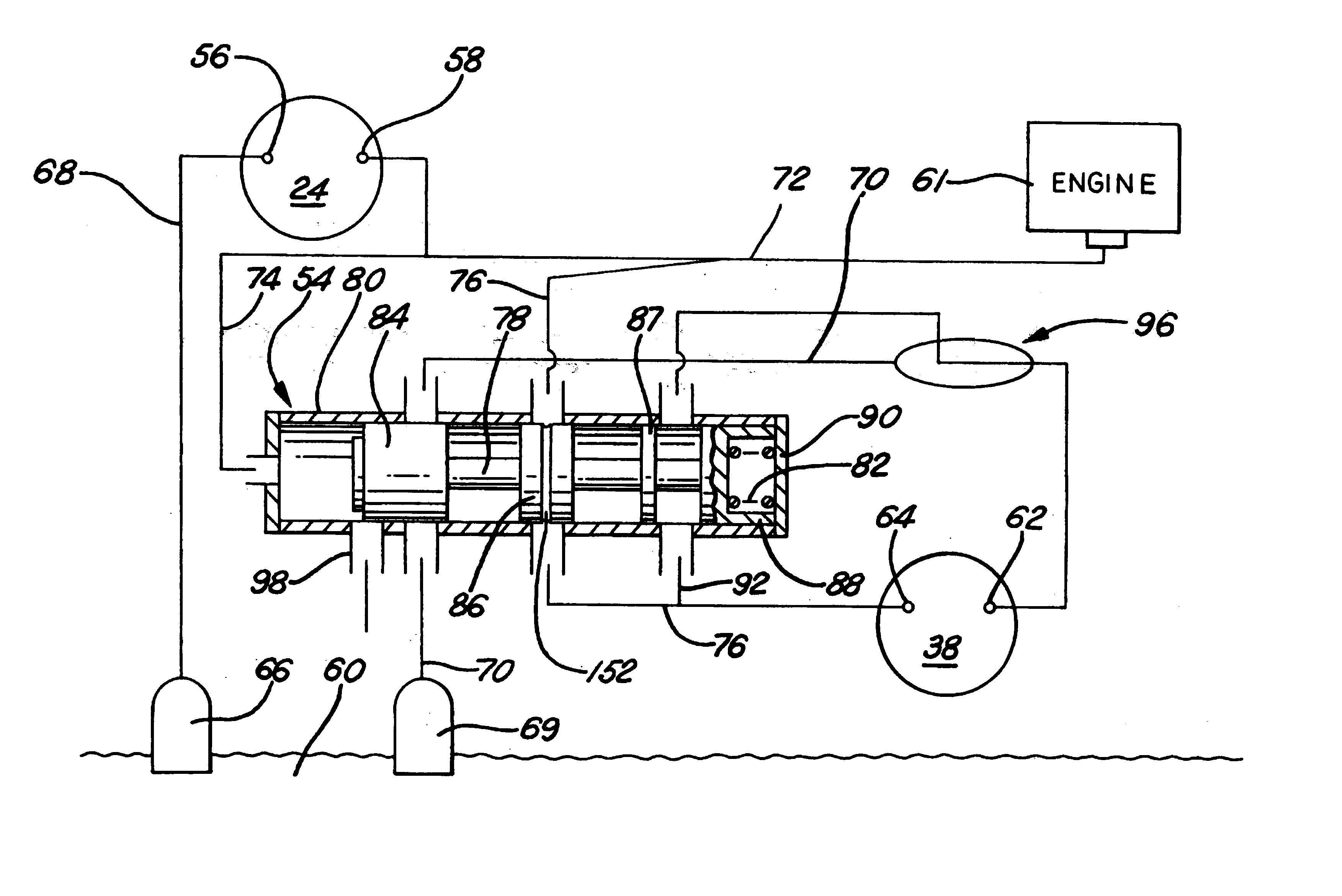

Energy efficient fluid pump

InactiveUS7086366B1Reduce noiseImprove efficiencyMachines/enginesPressure lubrication with lubrication pumpLow speedCavitation

A dual pumping element fluid system for an engine or other system which reduces the driving power consumption by unloading one pumping element through the use of recirculation when a fluid pressure target value is achieved. A cross-over port fluid system prevents cavitation of the unloaded pump. A pressure-activated flow control valve mechanism is utilized to open and close the passageways from the secondary pump. The fluid system works in conjunction with an engine balance shaft system to control gear rattle at low speeds without adding undue gear loads at high speeds.

Owner:METALDYNE BSM

Gas turbine engine balancing

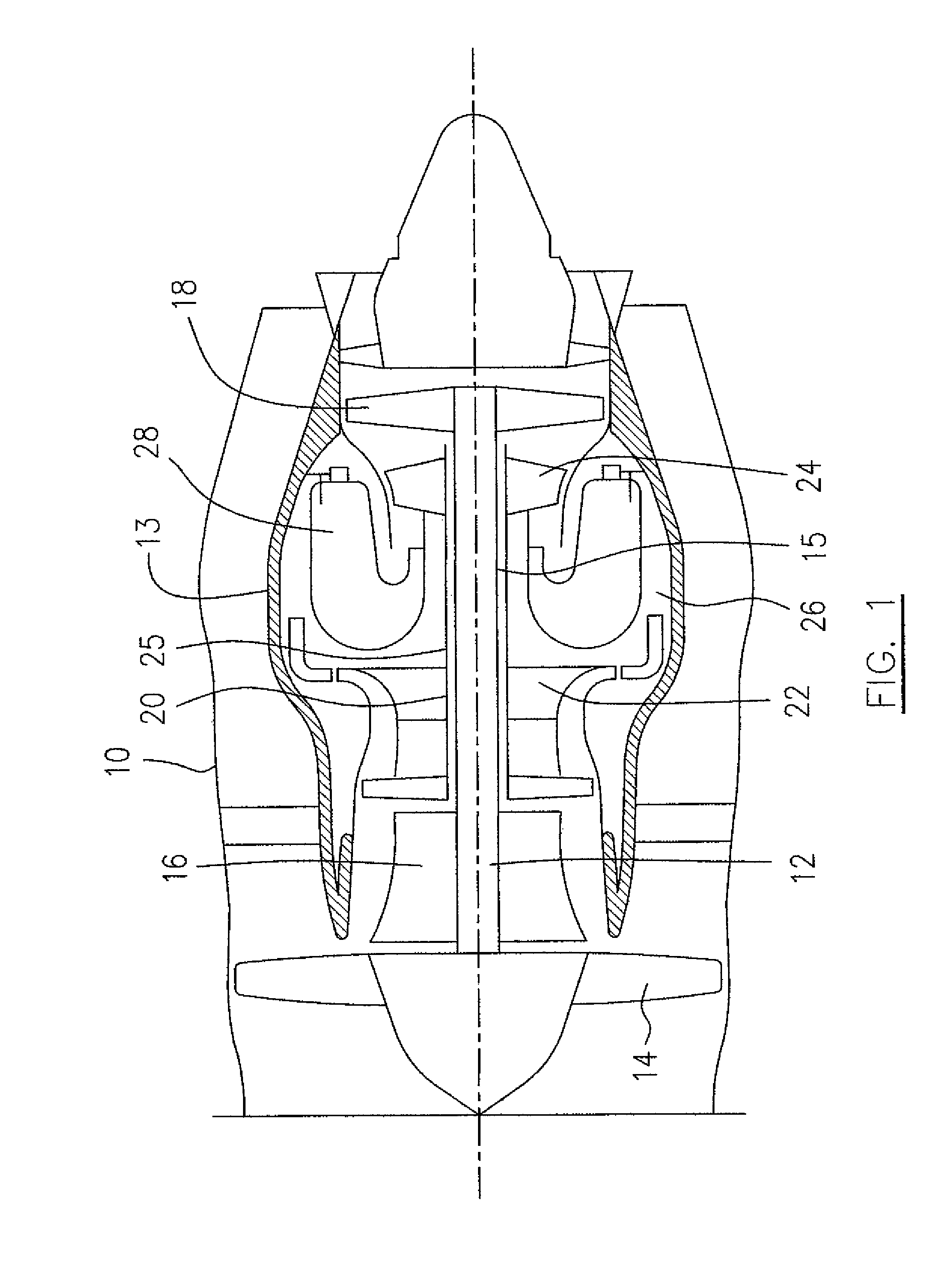

An apparatus and method for balancing a gas turbine engine rotor includes a plurality of balancing weights adapted to be selectively attached to at least one of inlets or outlets of a cooling passage of the rotor. The weights include cooling access which permits coolant to communicate with the cooling passage.

Owner:PRATT & WHITNEY CANADA CORP

Engine balancer apparatus

InactiveUS20070079786A1Reduce vibrationMore assembledShaftsMachines/enginesEngineeringGravity center

Owner:GASOLINEIAM NASIONAL BERHAD

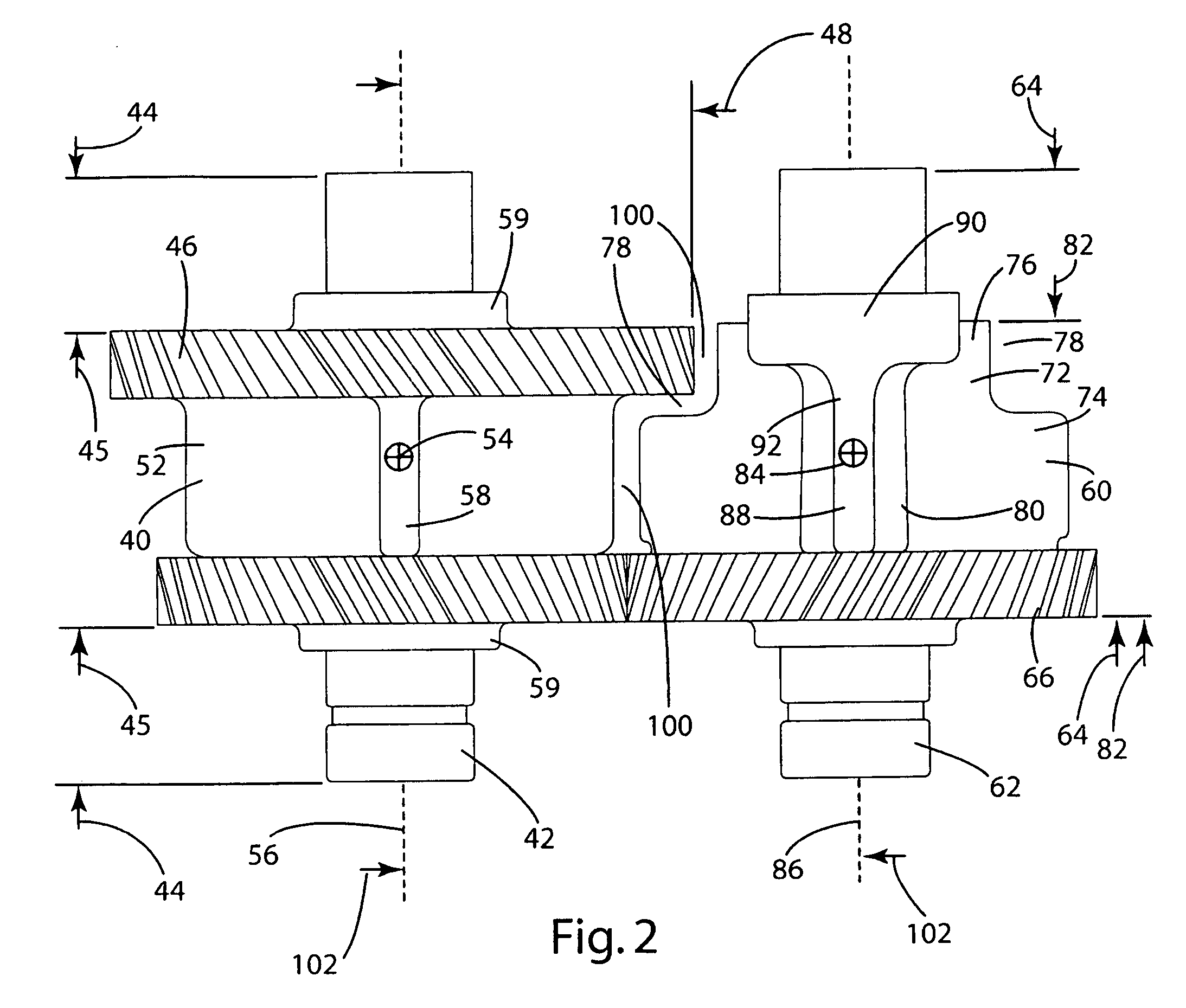

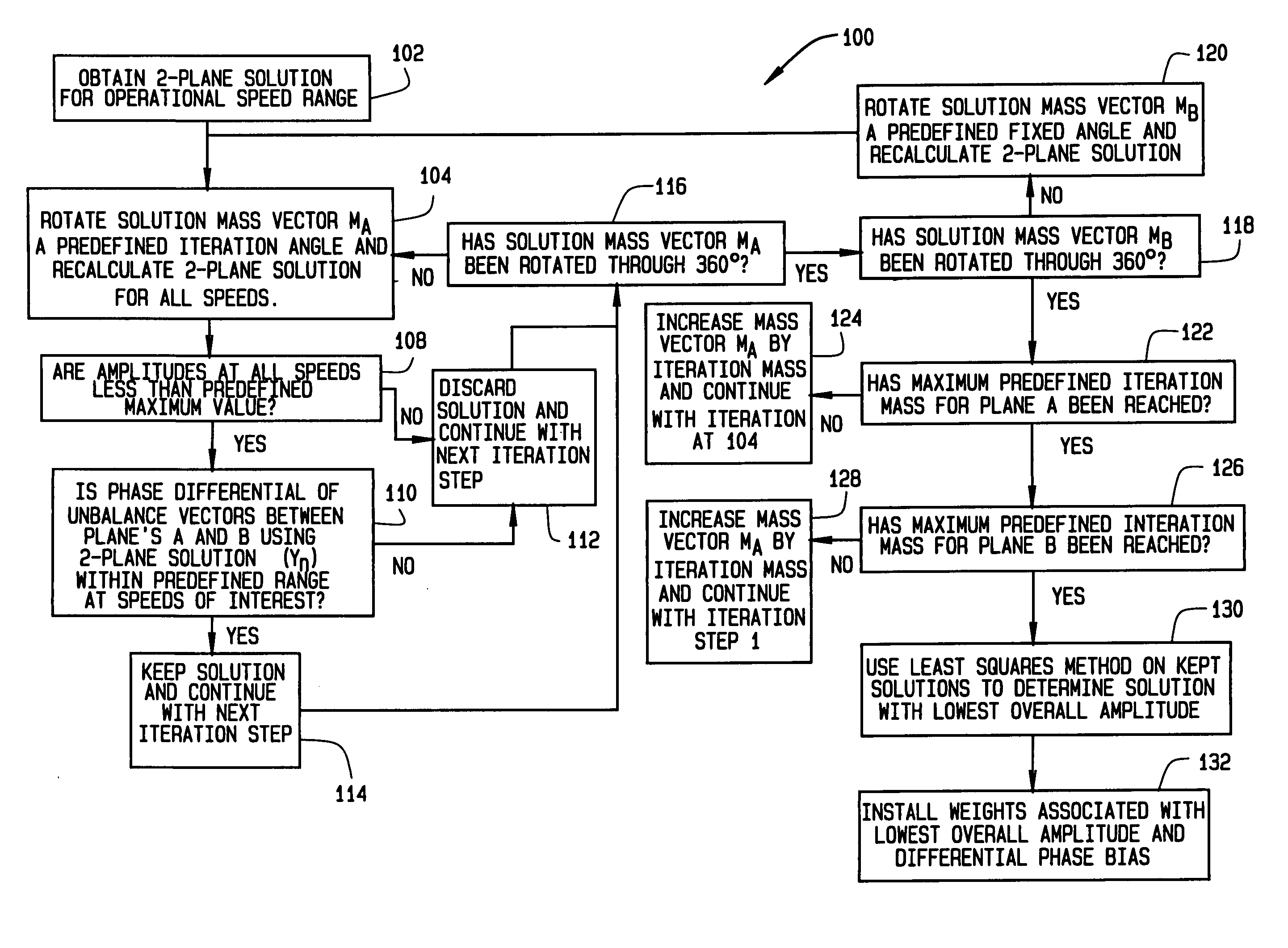

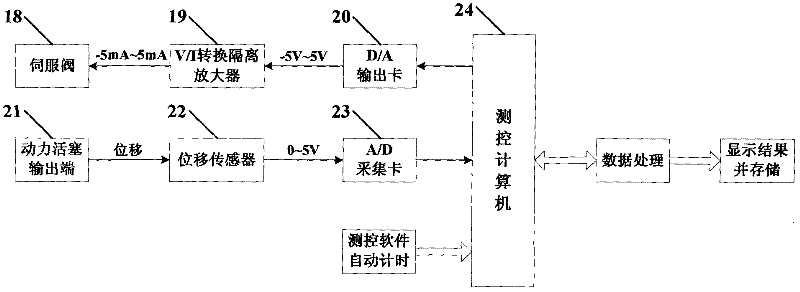

Engine balancing system and method

ActiveUS20050065712A1Reduce vibrationAchieve relative motionDigital data processing detailsTemperatue controlPhase differenceComputational physics

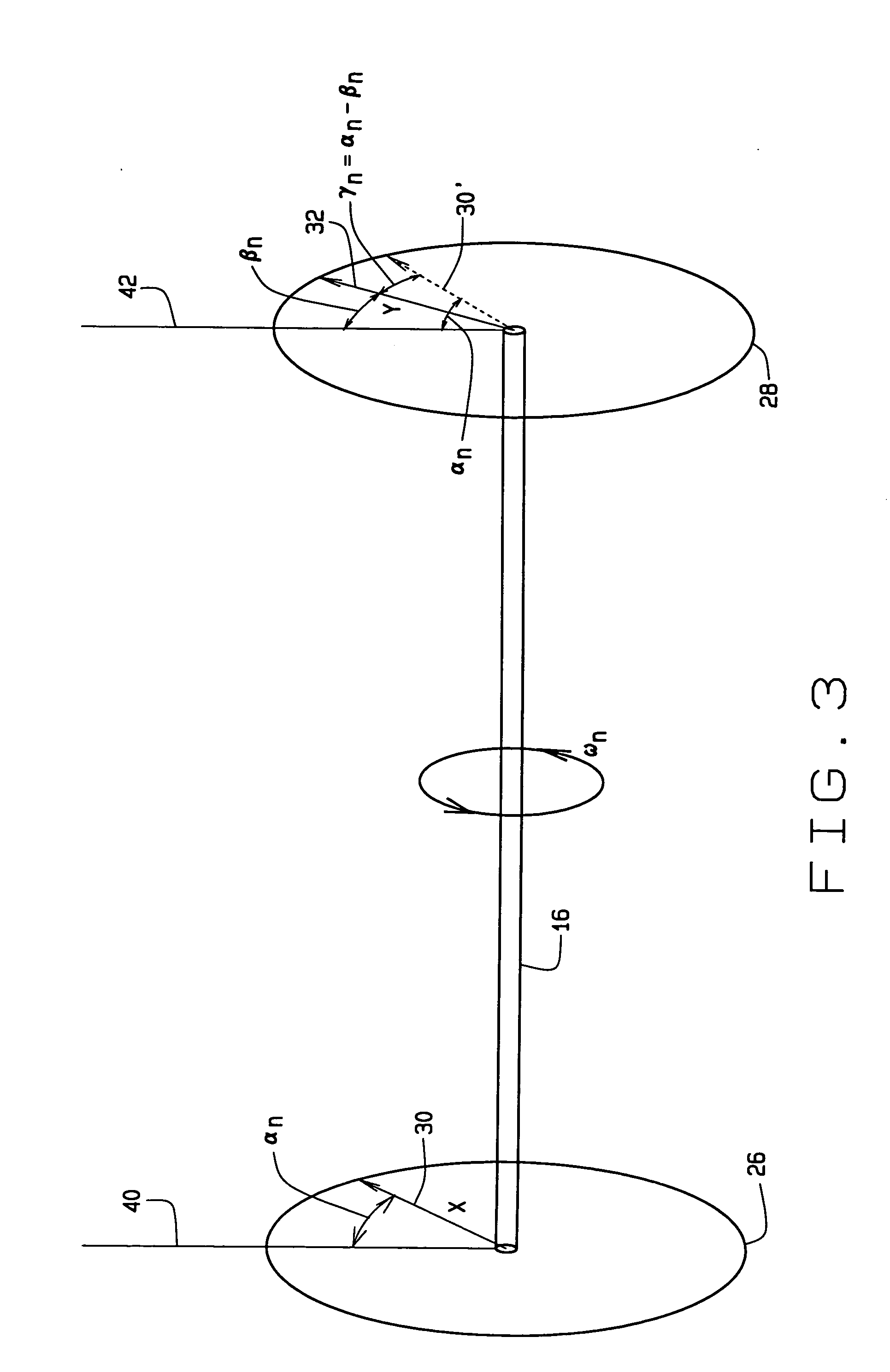

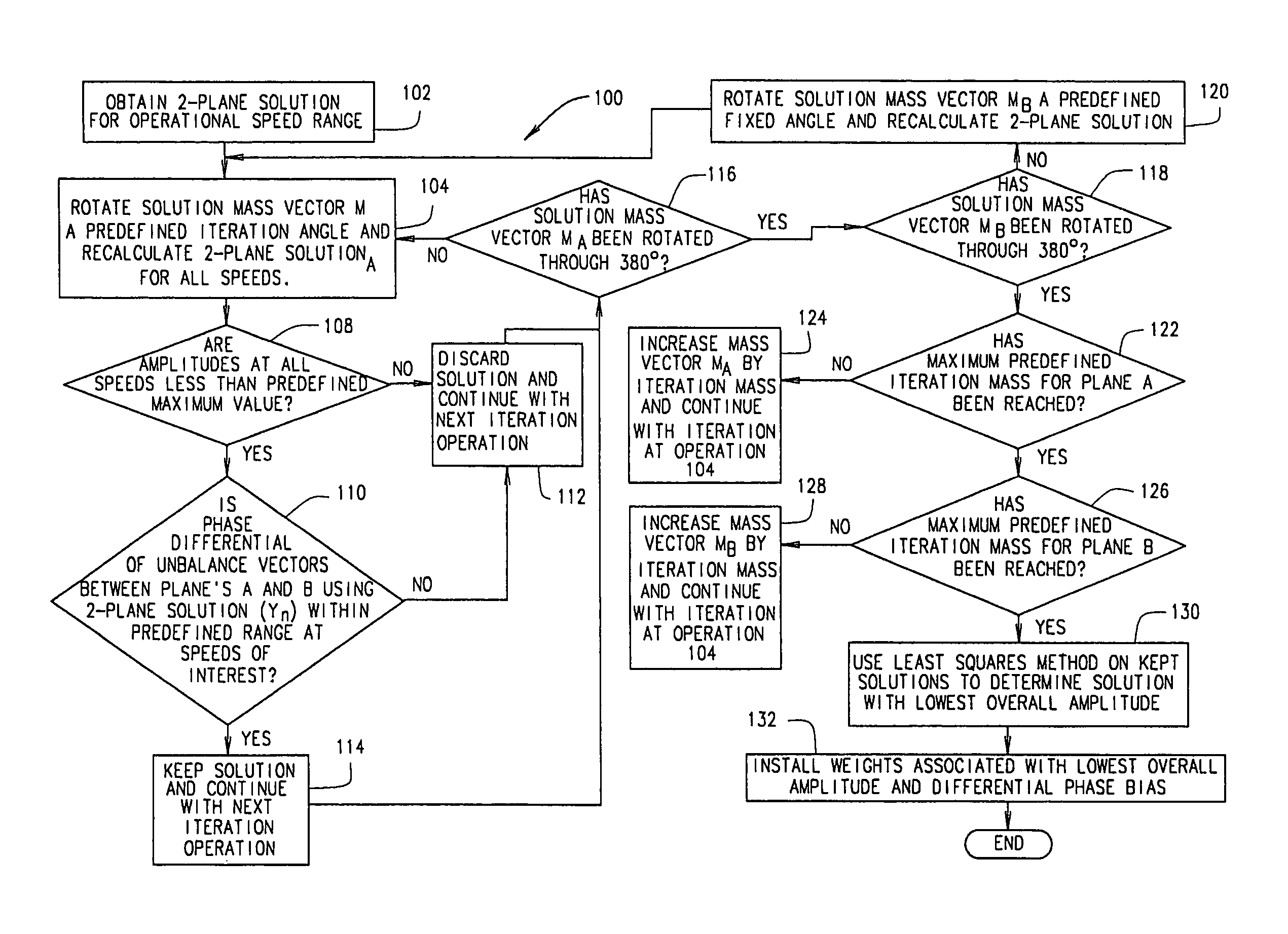

A method for balancing vibrations in a rotating machine is provided. The rotating machine has a first and a second plane of imbalance. The method includes determining a first set of solution mass vectors that includes a first solution mass vector for the first plane and a first solution mass vector for the second plane. Each first solution mass vector includes a mass and a phase angle. A first phase difference between a phase angle of the first solution mass vector for the first plane and a phase angle for the first solution mass vector for the second plane is calculated. The first phase difference is compared to a pre-selected value. If the first phase difference is less than the pre-selected value, the first set of solution mass vectors is retained. The first set of solution mass vectors is then incremented to create a second set of solution mass vectors that includes a second solution mass vector for the first plane and a second solution mass vector for the second plane. A second phase difference between a phase angle of the second solution mass vector for the first plane and a phase angle for the second solution mass vector for the second plane is then compared to the pre-selected value. If the second phase difference is less than the pre-selected value, the second set of solution mass vectors is retained. Finally, selected retained solution mass vectors are determined that balance the rotating machine such that vibration of the rotating machine is reduced.

Owner:THE BOEING CO

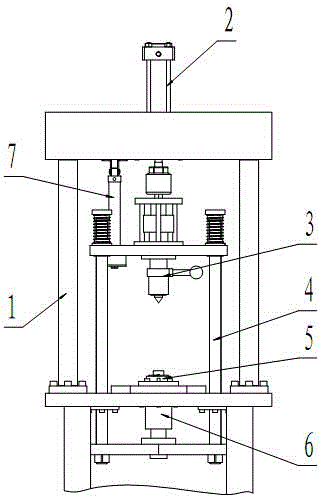

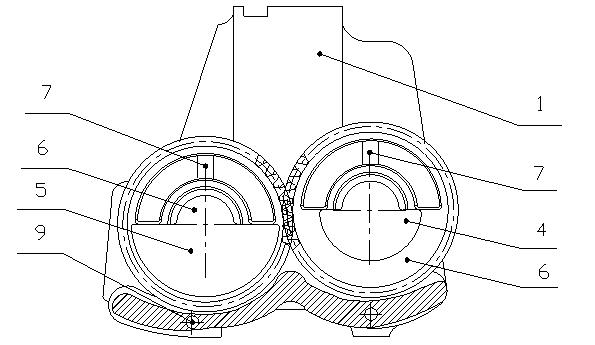

Press fitting device for timing gear of engine balance shaft

ActiveCN104308507AImprove versatilityVersatileMetal working apparatusProgrammable logic controllerControl system

The invention discloses a press fitting device for a timing gear of an engine balance shaft. The press fitting device comprises a main body framework, a press fitting oil cylinder, a press fitting execution mechanism, a following mechanism, a gear positioning mechanism, a balance shaft positioning mechanism and a PLC (Programmable Logic Controller) control system, wherein the main body framework consists of an upper cover plate, an upright post, a base plate and a bracket; the press fitting oil cylinder is fixed on the upper cover plate of the main body framework; a telescopic rod of the press fitting oil cylinder and the press fitting execution mechanism are assembled; the press fitting execution mechanism and the upper end of the following mechanism are fixedly assembled; the lower end of the following mechanism and the balance shaft positioning mechanism are assembled; the balance shaft positioning mechanism and the gear positioning mechanism are respectively matched with the base plate of the main body framework. The press fitting device disclosed by the invention has the characteristics of simple structure, high automatic degree and high generality; the requirement on timing angle when the balance shaft and the timing gear are assembled is met; besides, the working efficiency is improved, and the production cost is reduced.

Owner:GREAT WALL MOTOR CO LTD

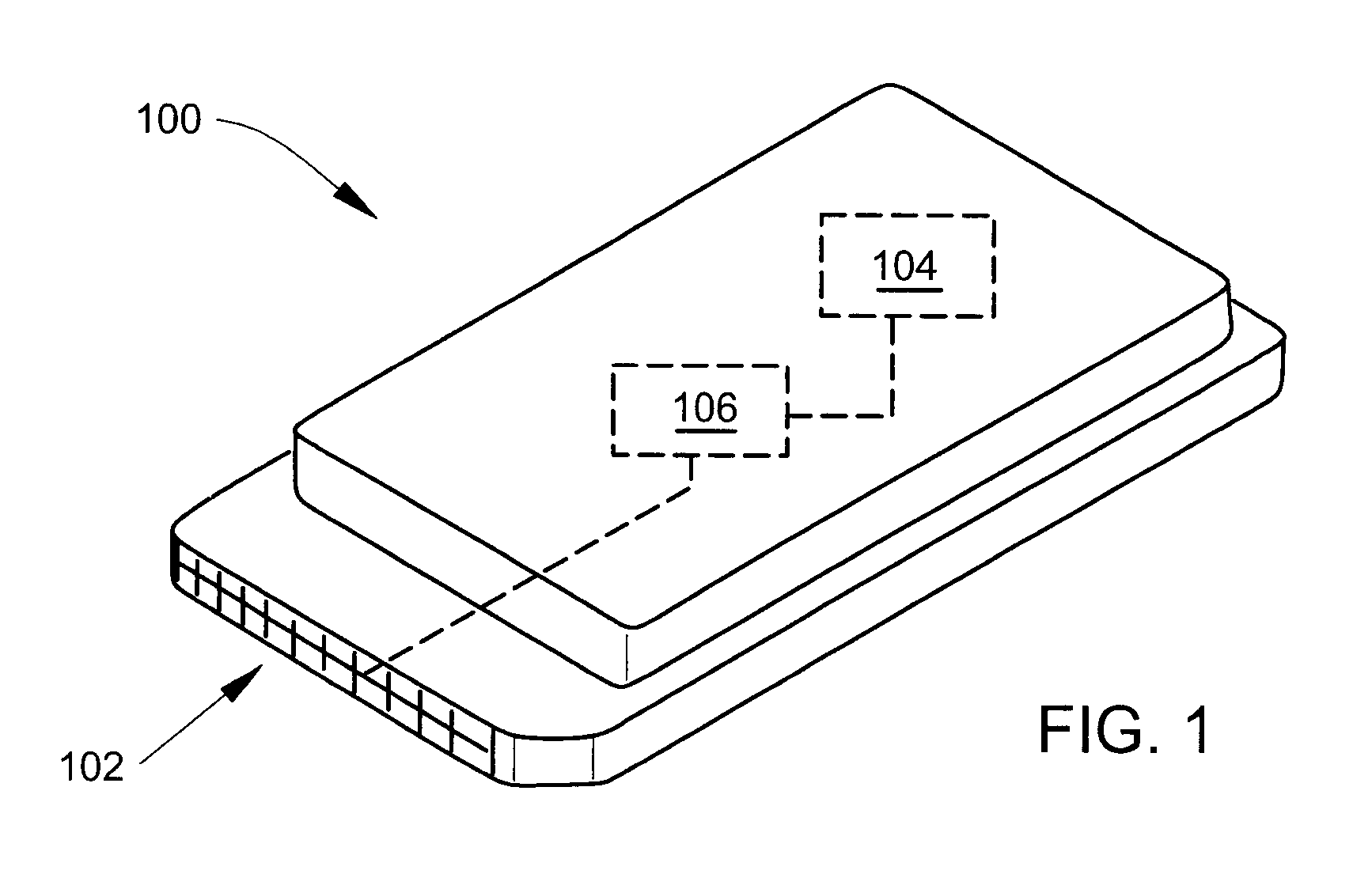

Adjustable error correction code length in an electrical storage device

Owner:SEAGATE TECH LLC

Engine balancing system and method

ActiveUS7243023B2Temperatue controlDigital data processing detailsPhase differenceComputational physics

A method for balancing vibrations in a rotating machine is provided. The rotating machine has a first and a second plane of imbalance. The method includes determining a first set of solution mass vectors that includes a first solution mass vector for the first plane and a first solution mass vector for the second plane. Each first solution mass vector includes a mass and a phase angle. A first phase difference between a phase angle of the first solution mass vector for the first plane and a phase angle for the first solution mass vector for the second plane is calculated. The first phase difference is compared to a pre-selected value. If the first phase difference is less than the pre-selected value, the first set of solution mass vectors is retained. The first set of solution mass vectors is then incremented to create a second set of solution mass vectors that includes a second solution mass vector for the first plane and a second solution mass vector for the second plane. A second phase difference between a phase angle of the second solution mass vector for the first plane and a phase angle for the second solution mass vector for the second plane is then compared to the pre-selected value. If the second phase difference is less than the pre-selected value, the second set of solution mass vectors is retained. Finally, selected retained solution mass vectors are determined that balance the rotating machine such that vibration of the rotating machine is reduced.

Owner:THE BOEING CO

Gas turbine engine balancing

An apparatus and method for balancing a gas turbine engine rotor includes a plurality of balancing weights adapted to be selectively attached to at least one of inlets or outlets of a cooling passage of the rotor. The weights include cooling access which permits coolant to communicate with the cooling passage.

Owner:PRATT & WHITNEY CANADA CORP

Balancer device for engine

InactiveUS6880512B2Improve rigidityReliable supportInertia force compensationLubrication of auxillariesEngine balanceWaste management

A balancer housing of a balancer device disposed to face an oil pan below a crankshaft of an engine, includes oil discharge bores for discharging an oil accumulated in the balancer housing with the rotation of balancer weights. The oil discharge bores are covered by baffle plates for inhibiting the turbulence of a surface of the oil stored in the oil pan. Thus, it is possible to inhibit the entrance of the oil into the balancer housing through the oil discharge bores without provision of a special cover member for covering the oil discharge bores.

Owner:HONDA MOTOR CO LTD

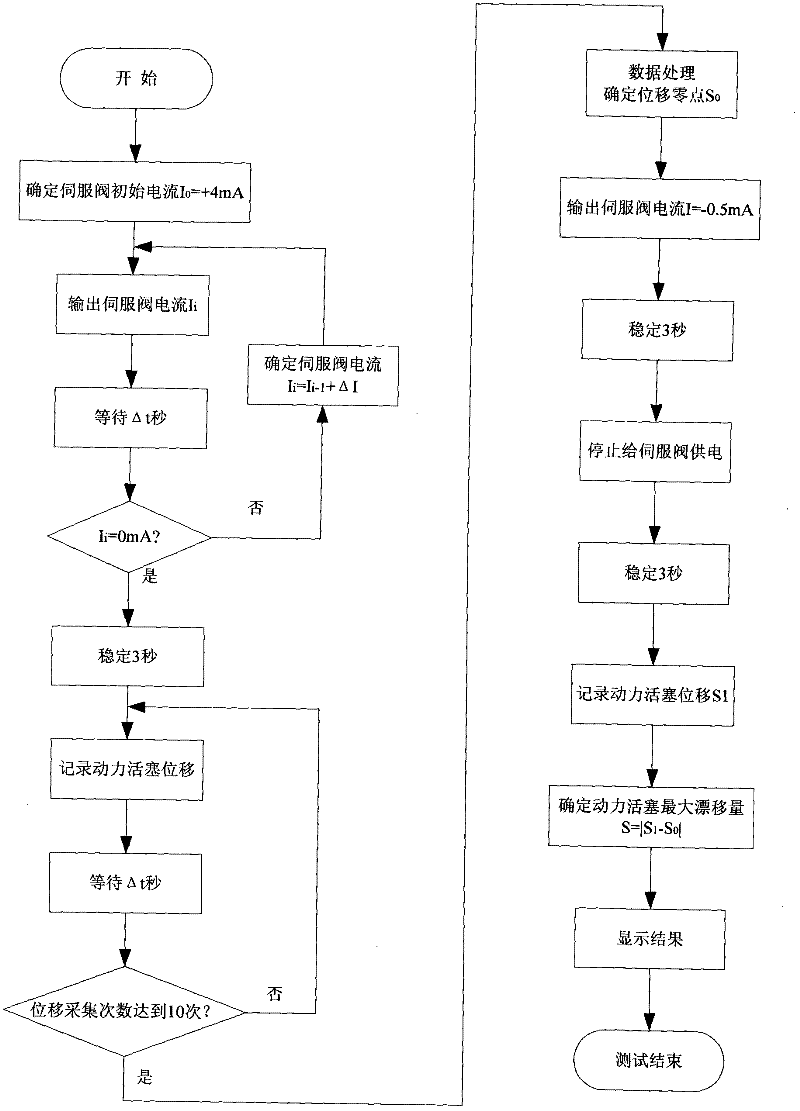

Device and method for automatically testing performance of steering engine servo valve

ActiveCN102287419AHigh degree of automationReduce dependencyFluid-pressure actuator testingTest performanceEngine power

The invention discloses a device and a method for automatically testing the performance of a steering engine servo valve. The device comprises a tested steering engine, a hydraulic system and a circuit system, and is characterized in that: the hydraulic system consists of a hydraulic source, a steering engine oil supply oil way, a steering engine balancing valve oil supply oil way and an oil return oil way; in the circuit system, a digital / analog (D / A) analog output board card and a voltage / current (V / I) conversion isolating amplifier are arranged on a servo valve current control circuit of the tested steering engine; a displacement sensor is arranged at an output end of an electro-hydraulic steering engine power piston; and during test, control software of a measurement and control computer outputs current to the servo valve through the D / A analog output board card and the V / I conversion isolating amplifier according to a control rule determined by the selected testing items, controls movement of the power piston, acquires displacement of the power piston, records control voltage of the servo valve current, movement time of the power piston and other data, and processes and computes the data so as to automatically determine whether the performance of the servo valve meets requirements of related indexes. The device has high testing degree of automation, high precision and good application and popularization prospects.

Owner:NAVAL AERONAUTICAL & ASTRONAUTICAL UNIV PLA

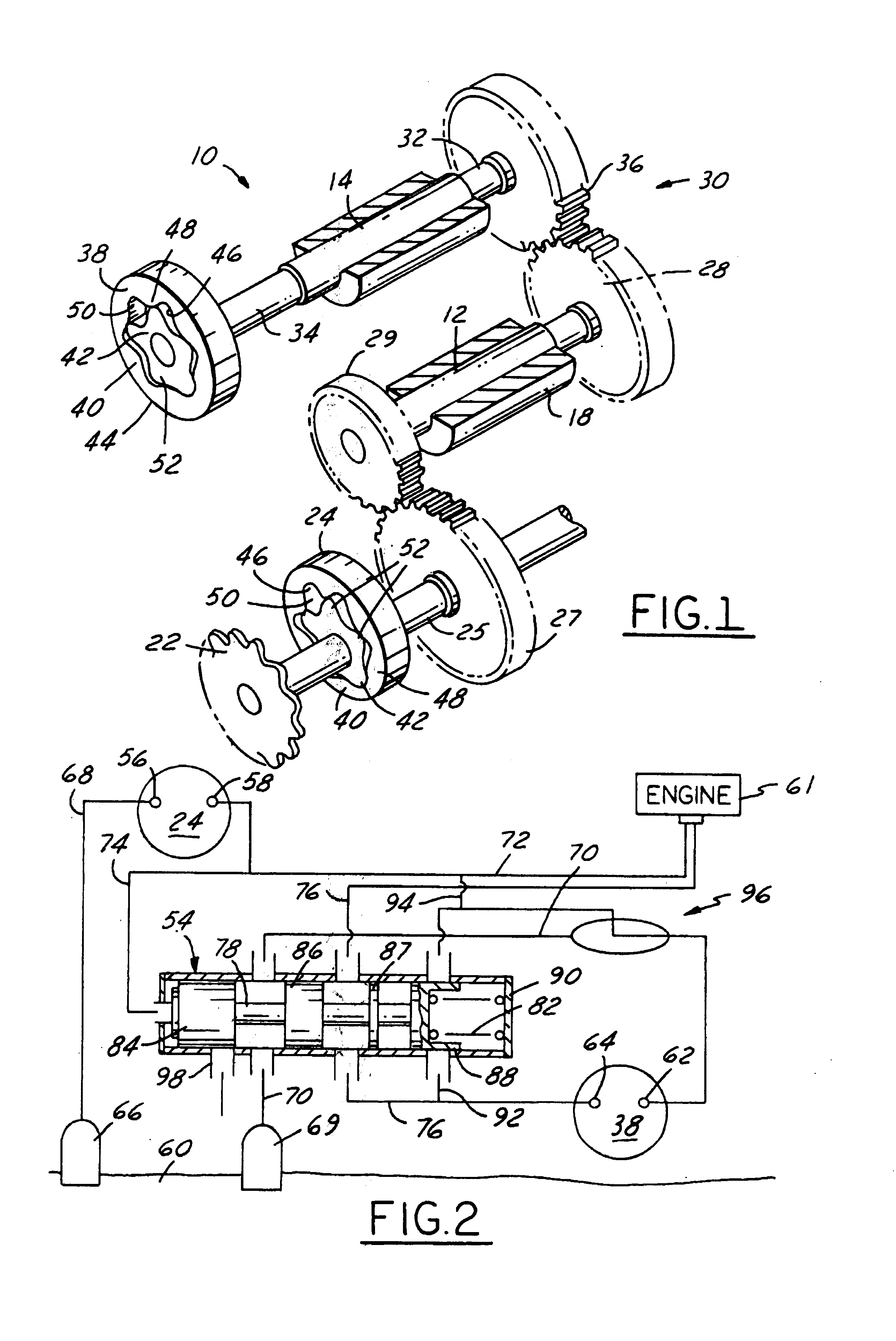

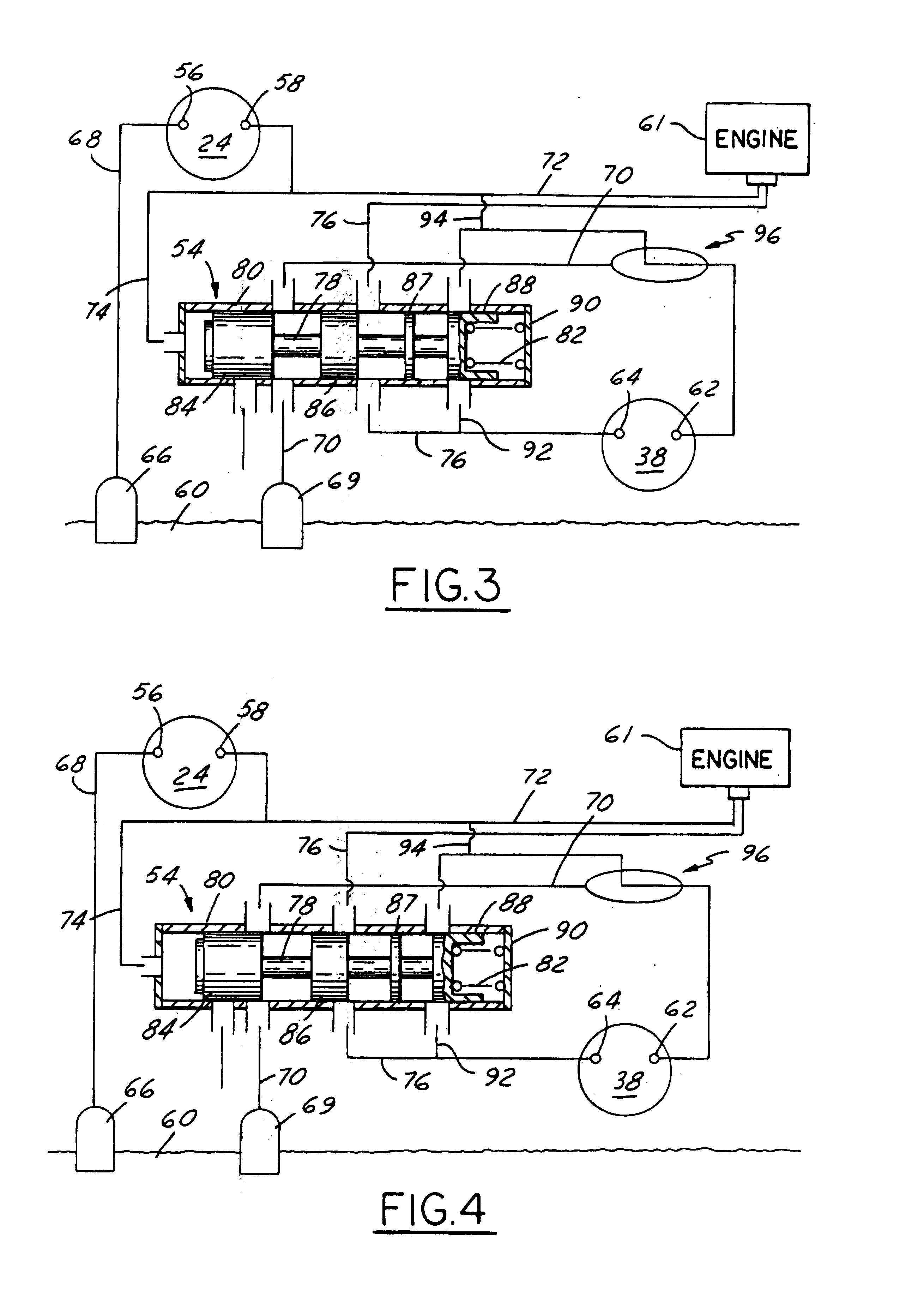

Engine balance masses and drives

ActiveUS8210148B2Reduce spacingMinimizes weight packaging spaceShaftsMachines/enginesEngineeringPinion

The present application relates to a drive and balance mass. In one example, an engine includes, a camshaft, a balance shaft disposed within an interior of the camshaft, and a first gear, intermediate the balance shaft and the camshaft and driving the balance shaft to rotate about a first axis substantially parallel to a crankshaft of the engine in a direction opposite of the crankshaft. In another example, a balance mass and drive for an engine includes, a planetary gear set including a sun gear, a ring gear and a plurality of pinions mounted on a carrier, an input coupled to an input gear of the planetary gear set, a balance mass coupled to an output gear of the planetary gear set, the output gear configured to drive the balance mass to rotate about a first axis substantially parallel to the crankshaft in a direction opposite of the crankshaft.

Owner:FORD GLOBAL TECH LLC

Cavitation-deterring energy-efficient fluid pump system and method of operation

InactiveUS20080273992A1Increase fluid pressureLubrication of auxillariesJet pumpsCavitationLow speed

A variable nozzle area jet pump is provided having a nozzle-sealing member resiliently urged to form a sealing closure. The sealing member is part of a normally non-passing pressure control valve that recirculates excess fluid back to the inlet of a positive displacement fluid pump. The fluid is recirculated with elevated pressure after a threshold fluid pressure is exceeded. The disclosed system provides for energy conservation and pump cavitation speed increase. The system may be integrated with an engine balance shaft module so as to provide low cost robustness to low speed gear noise emissions by application of the oil pump's drive torque to at lease one gearset.

Owner:METALDYNE BSM

Balancer device of engine

Owner:MAZDA MOTOR CORP

Engine balance masses and drives

ActiveUS20110073060A1Minimizes weightMinimizes packaging spaceShaftsMachines/enginesEngine balanceBalance shaft

The present application relates to a drive and balance mass. In one example, an engine includes, a camshaft, a balance shaft disposed within an interior of the camshaft, and a first gear, intermediate the balance shaft and the camshaft and driving the balance shaft to rotate about a first axis substantially parallel to a crankshaft of the engine in a direction opposite of the crankshaft. In another example, a balance mass and drive for an engine includes, a planetary gear set including a sun gear, a ring gear and a plurality of pinions mounted on a carrier, an input coupled to an input gear of the planetary gear set, a balance mass coupled to an output gear of the planetary gear set, the output gear configured to drive the balance mass to rotate about a first axis substantially parallel to the crankshaft in a direction opposite of the crankshaft.

Owner:FORD GLOBAL TECH LLC

Engine balance shaft system

ActiveCN102996707ASimple structureLower the altitudeInertia force compensationEccentric-shaftsEngineeringSprocket

The invention aims to provide an engine balance shaft system for solving the problems that a traditional balance shaft system is inconvenient to arrange and prone to deforming and being stuck. The engine balance shaft system disclosed by the invention comprises a balance shaft with a balance shaft chain wheel, wherein the balance shaft is provided with a front balance block and a rear balance block. The engine balance shaft system is characterized in that the balance shaft chain wheel is arranged inside a triangle formed by a fuel pump drive chain wheel, a crankshaft timing chain wheel and a camshaft drive chain wheel; and the balance shaft chain wheel, the fuel pump drive chain wheel, the crankshaft timing chain wheel and the camshaft drive chain wheel are on a same plane and are chained by timing chains. Therefore, the whole structure of the engine balance shaft system is simpler. Simultaneously, the balance shaft is arranged on one side of a crankshaft rather than below the crankshaft, so that the whole height of the engine balance shaft system can be reduced, and the engine balance shaft system is easier to arrange.

Owner:CHERY AUTOMOBILE CO LTD

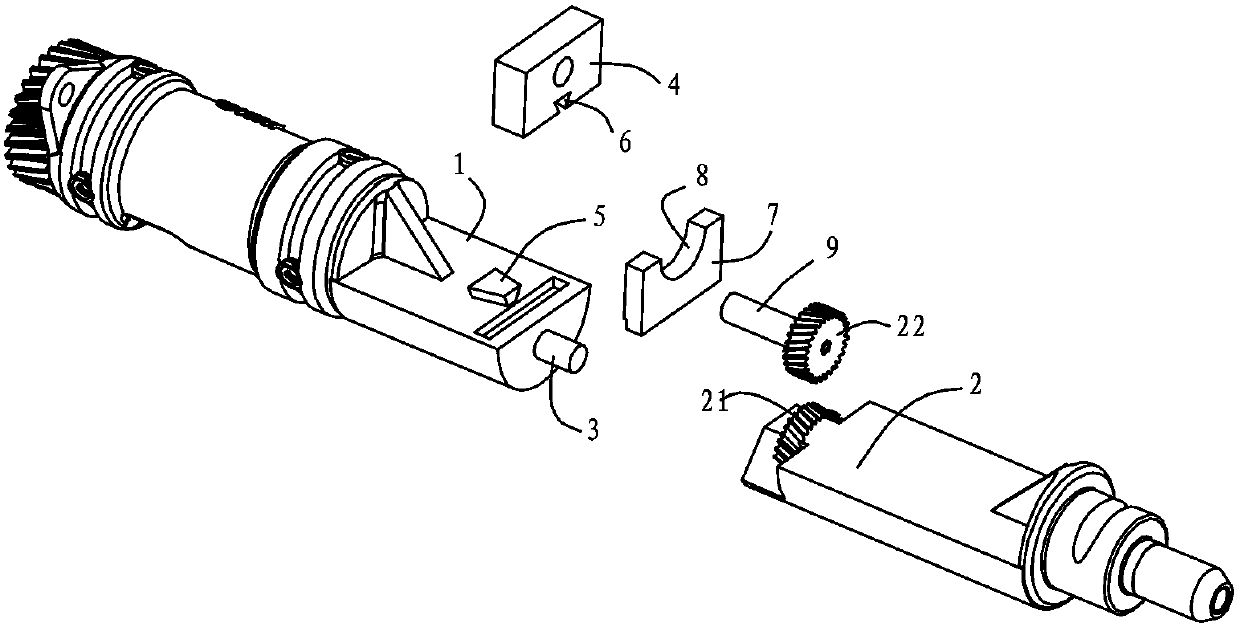

Engine balance shaft

ActiveCN103438147AAdapt to the needs of different speedsImprove general performanceInertia force compensationEngineeringEngine balance

The invention relates to a balance shaft structure, in particular to an engine balance shaft. The engine balance shaft is provided with a first balance block and a second balance block, wherein the first balance block is connected with the second balance block through a rotary shaft; the engine balance shaft further comprises a drive device which drives the second balance block to rotate relative to the first balance block, and the second balance block is rotated by taking the rotary shaft as a shaft. The drive device drives the second balance block to enable the relative angle between the first balance block and the second balance block to be adjusted, the adjustment to the whole unbalance amount of the balance shaft is achieved, therefore, the engine balance shaft changes the equilibrium rate of an engine during running, meets the requirement of different revolving speeds of the engine, can adapt to unbalance amount needed by different engines, and improves universality.

Owner:GREAT WALL MOTOR CO LTD

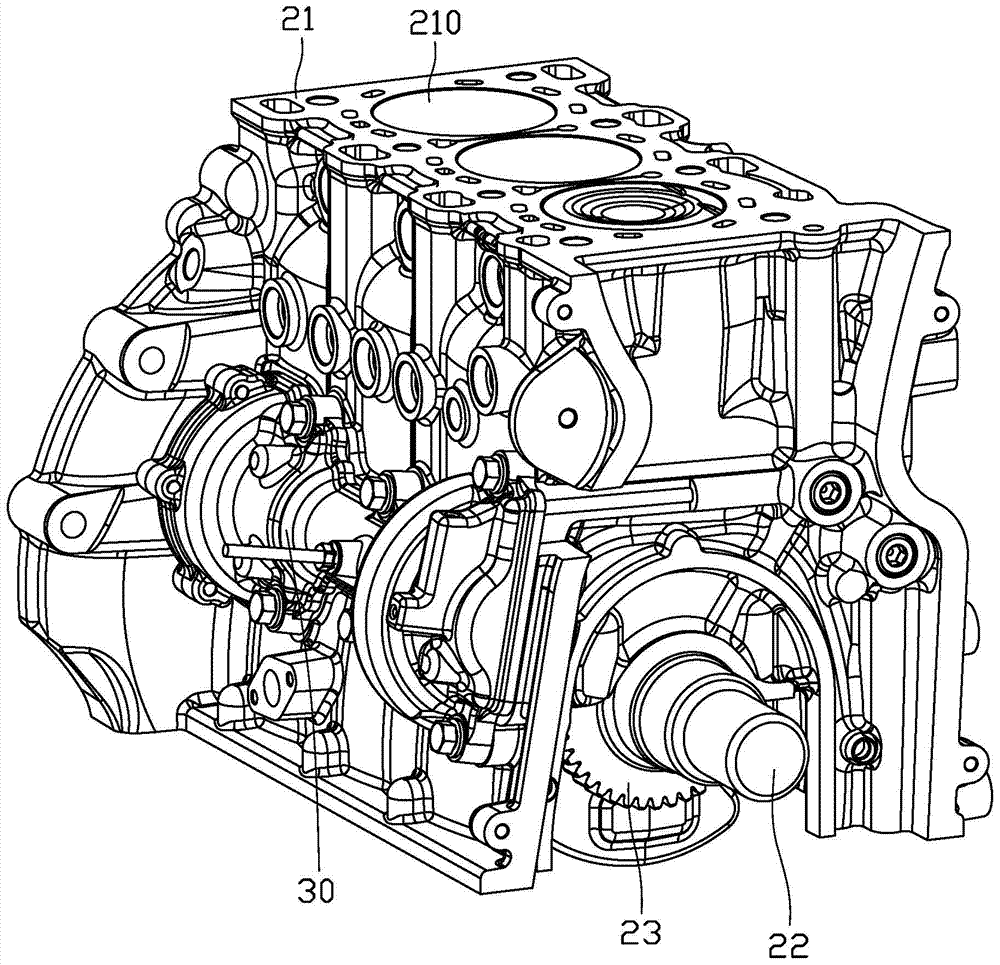

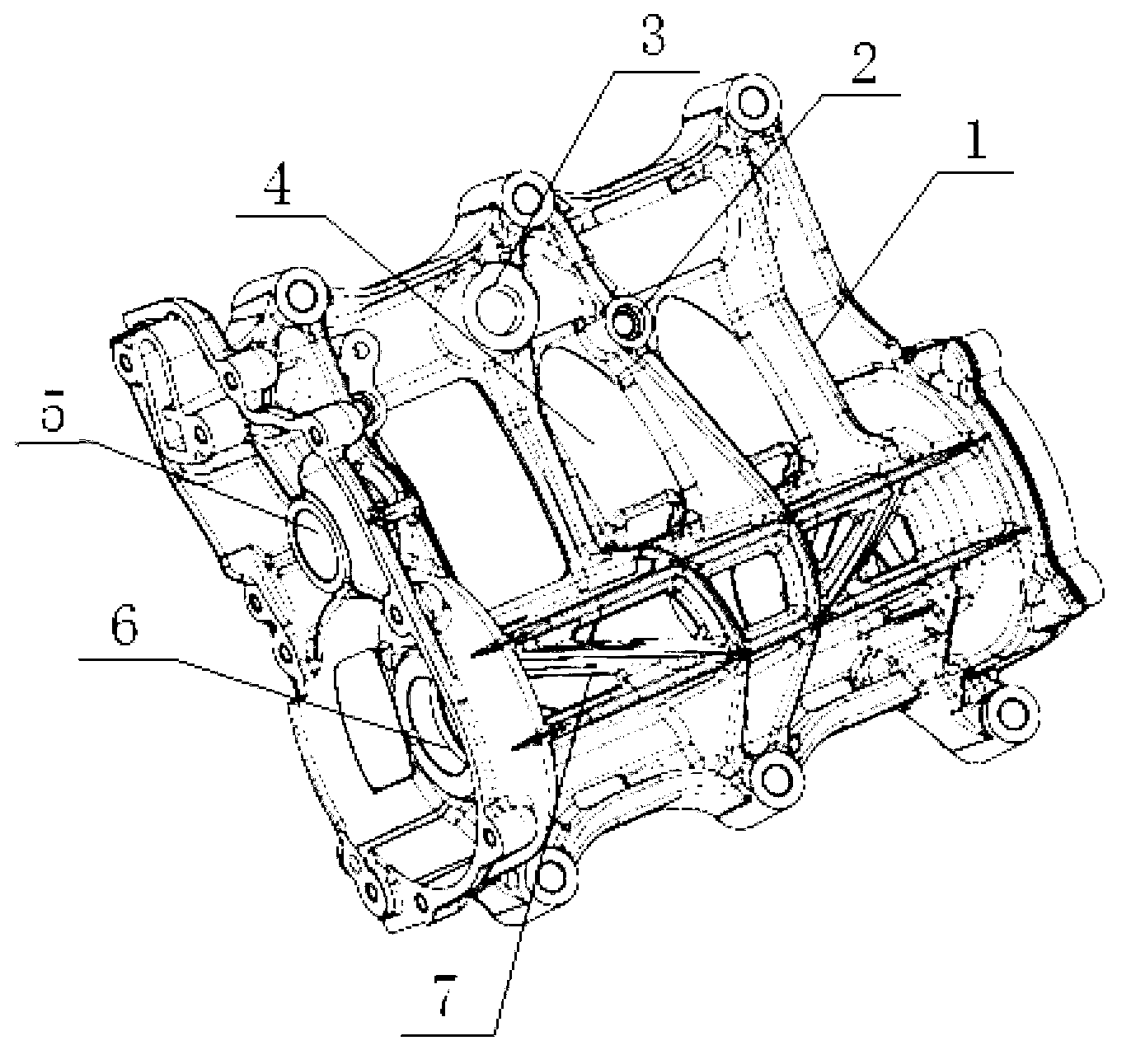

Engine balance shaft mechanism and engine assembly

ActiveCN103485888ADoes not increase heightCompact structureInertia force compensationCylinder headsEngineeringCylinder block

An engine balance shaft mechanism comprises a balance shaft shell, a balance shaft, a rear balance weight, a balance shaft gar and a front balance weight. The balance shaft comprises a front end, a rear end, and a middle connecting segment connected between the front end and the rear end. The rear balance weight is fixed at the rear end of the balance shaft. The balance shaft gear and the front balance weight are fixed at the front end of the balance shaft. The front balance weight and the rear balance weight are disposed in an angular opposition form. The balance shaft shell covers the balance shaft, the rear balance weight, the balance shaft gear and the front balance weight. The side of the balance shaft shell is provided with a first mounting face used for being mounted on the side of a cylinder block of an engine; the side of the cylinder block is provided with a second mounting face; the first mounting face is in mounting fit with the second mounting face. The engine balance shaft mechanism is simple in structure, small in size, and convenient to arrange. The invention further relates to an engine assembly.

Owner:ZHEJIANG GEELY HOLDING (GROUP) CO LTD +1

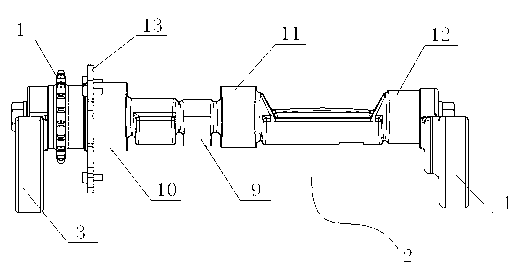

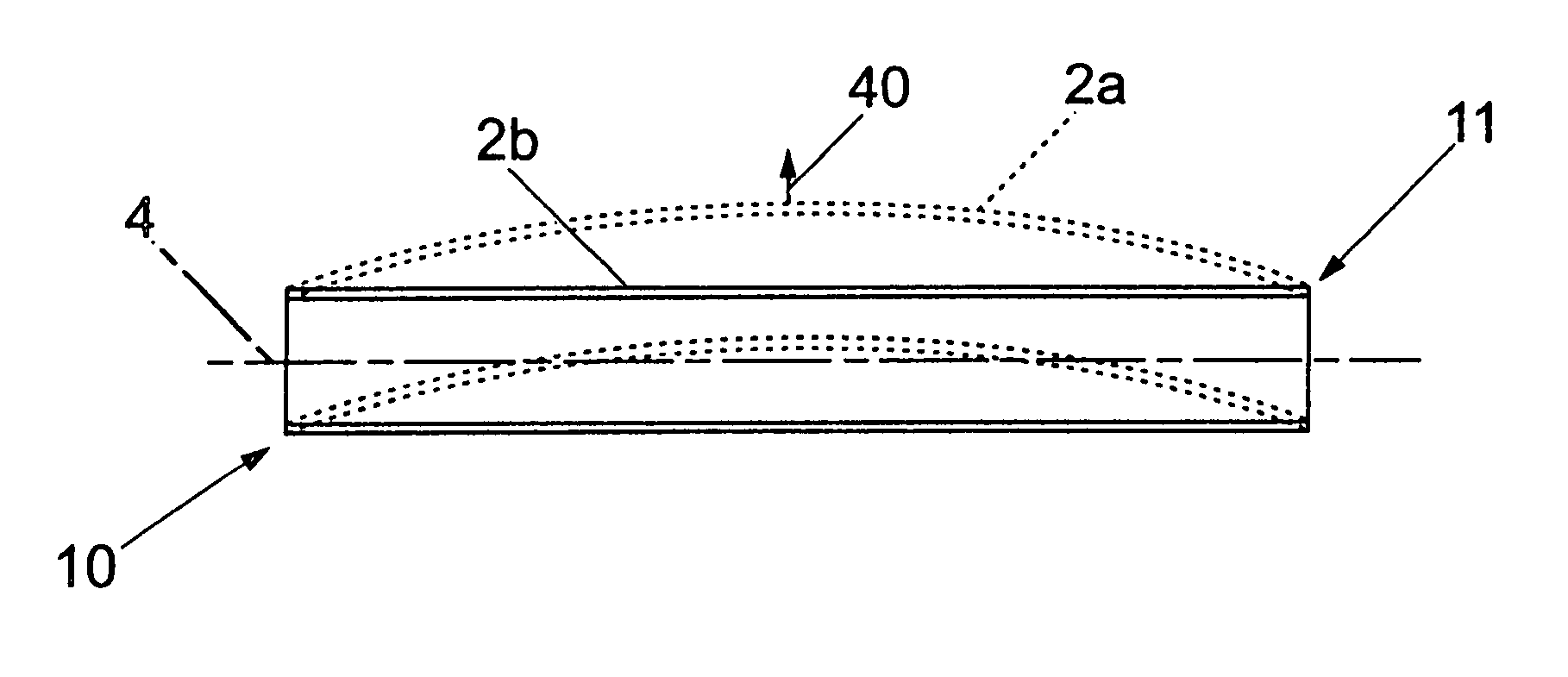

Balance shaft assembly

InactiveUS6971361B2Increase the rotation frequencyInertia force compensationShaftsCombustionEngineering

Balance shaft assemblies are used in internal combustion engines to dampen primary and second order inertia forces. Known balance shaft assemblies typically require precision manufacturing and a rigid frame or housing. A balance shaft assembly (1) in accordance with this invention provides a low cost and less complex solution to engine balancing. The balance shaft assembly (1) includes an elongate housing (2) having a front end and a rear end, a balance shaft (5) which is rotatably supported between a front end bearing (6), a rear end bearing (7) and an intermediate bearing (12) in the housing (2). The housing (2) is transversely flexible relative to the balance shaft (5) to accommodate misalignment of the intermediate bearing (12) relative to the front and rear end bearings (6, 7). Consequently, the balance shaft assembly (1) can be less complicated and manufactured at a lower cost than known balance shaft assemblies.

Owner:PERKINS ENGINES

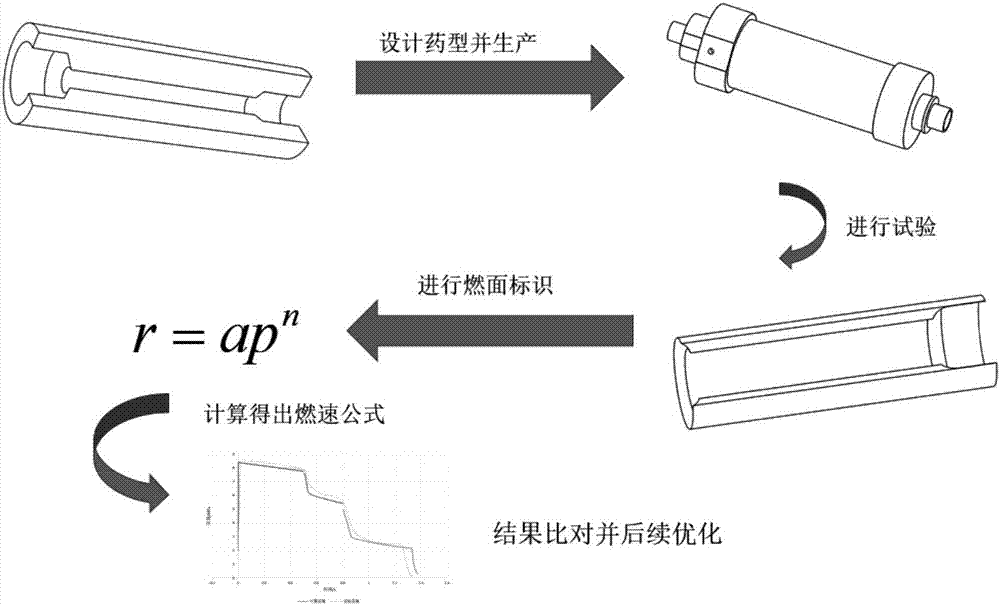

Burning surface identification-based solid propellant burning rate identifying method

The invention relates to a burning surface identification-based solid propellant burning rate identifying method. The method comprises the following steps: designing a propellant with three different diameters, and carrying out combustion test; knowing the current burning surface area according to the time and the pressure of three different burning propellant web propellant s in recorded pressure-time curves and the remaining shape; and solving the instantaneous burning rates of four characteristic points by combining the pressure-time curves obtained through the test with an engine balance pressure expression to obtain the burning rate expression of three segments AB, BC and CD in different pressure ranges, and carrying out burning rate identification. The method has the following advantages: the tree curves are obtained by one-shot test in to carry out identification in order to obtain three burning rates, so the efficiency is increased, and the cost is reduced; the burning rates are solved through combining the identification of the burning surface with the test pressure-time curves, so the method is simple, can be easily known; and the method has wide applicability, and can realize the measurement of the burning rates under different test pressures by changing the sizes of a propellant grain and a jet tube.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

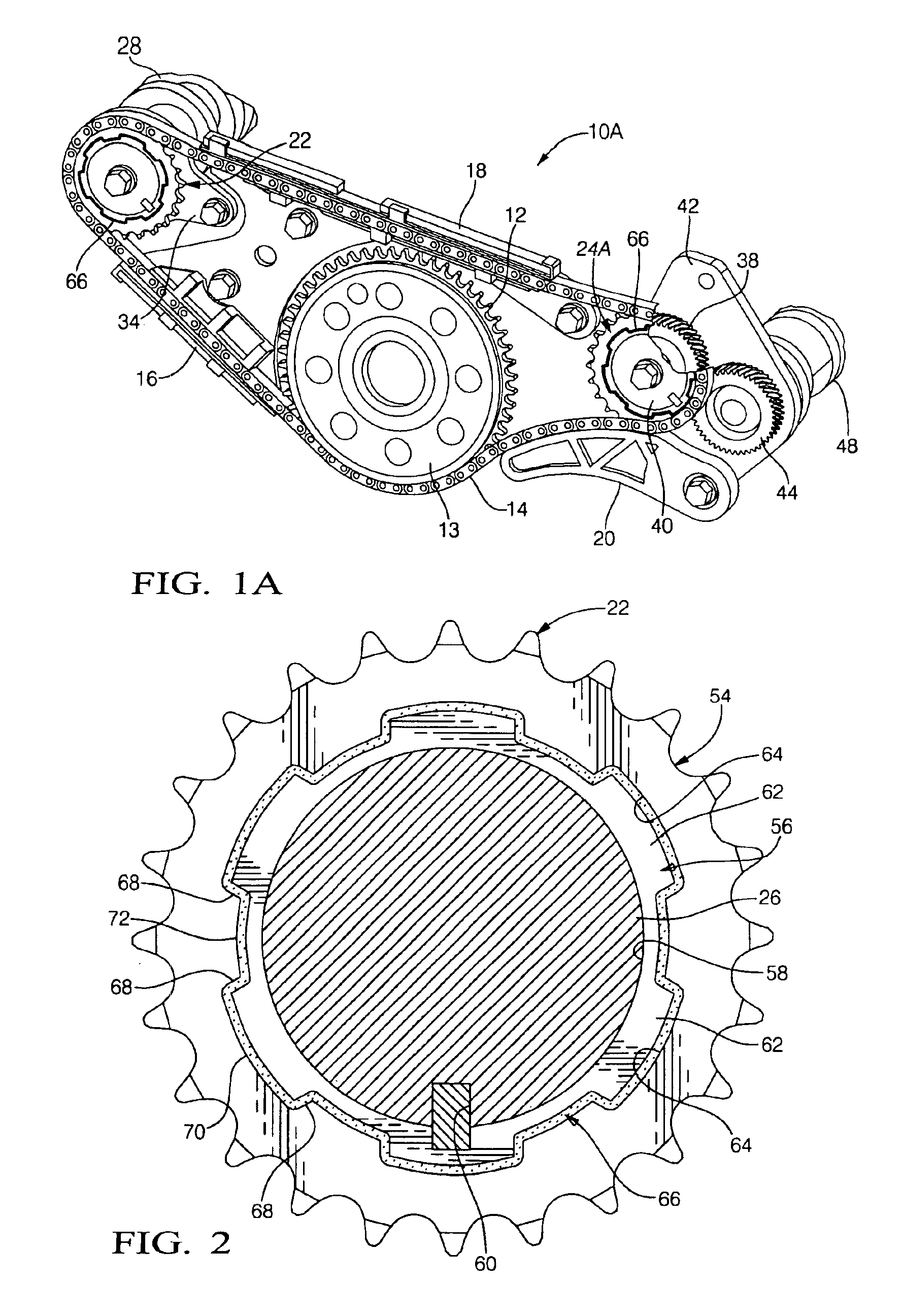

Engine balancer with chain drive vibration isolation

InactiveUS6959682B2Reduces audible transmitted chain whine noiseEliminate structureRotating vibration suppressionInertia force compensationSprocketEngineering

A chain-driven engine balancer has an elastomeric or compliant isolator ring in a balancer drive sprocket to decouple chain whine vibration from an associated balance shaft. The isolator substantially reduces the transmission of chain whine noise to the engine structure. A splined isolator ring is placed between internal and external splines formed on a toothed outer ring and hub respectively of the associated sprocket. The splines are configured to be in loose engagement so that, upon failure of the elastomeric isolator ring, direct engagement of the hub and ring splines with one another will maintain the timing of the balance shafts with respect to the engine crankshaft. In a specific embodiment, application of an isolator ring in only the most heavily loaded sprocket of dual balance shaft sprockets driven in series by the chain eliminates most of the vibration transmission. However, isolation of multiple chain sprockets could be desirable.

Owner:GM GLOBAL TECH OPERATIONS LLC

Balancing shaft and its forging method for engine

InactiveCN101029371AImprove metal structureHigh mechanical strengthInertia force compensationMetal-working apparatusNiobiumManganese

A balancing shaft of engine and its forging method are disclosed. The balancing shaft consists of carbon 0.47-0.55%, silicon 0.17-0.37%, manganese 0.50-0.80%, vanadium 0.01-0.03%, niobium 0.001-0.002%, phosphor<=0.035, sulfur<=0.035%, copper<=0.17% and iron residues. The process is carried out by cutting carbon steel, heating, blanking and forming to obtain blank, heating, blanking, cutting fringe and drawing slope, transferring by conveyor belt, cooling, heat treating, heat correcting and surface treating to obtain the final product. It has better quality and longer usage life, improves metal tissue structure, mechanical strength and impact toughness and saves energy resources.

Owner:温州三联锻造有限公司

Engine balancer shell cleaning system

PendingCN111906074AImprove efficiencyEfficient removalEdge grinding machinesGrinding machine componentsThermodynamicsProcess engineering

The invention relates to an engine balancer shell cleaning system. The engine balancer shell cleaning system comprises a first conveying unit, a middle processing station and a second conveying unit which are connected in sequence. A first deburring device, a pre-cleaning device and a first cleaning device are sequentially arranged in the conveying direction of the first conveying unit. The firstdeburring device can be used for deburring an oil hole of a workpiece. A second deburring device, a second cleaning device, a third cleaning device and a first drying device are arranged in the middleprocessing station in the direction from the first conveying unit to the second conveying unit. The second deburring device can be used for deburring an oil hole in the bottom of the workpiece. A second drying device, a third drying device and a fourth drying device which can be used for finally drying the workpiece are sequentially arranged in the conveying direction of the second conveying unit. By means of the engine balancer shell cleaning system, it can be achieved that the whole process is automated, and a better cleaning effect and a higher cleaning efficiency can be achieved.

Owner:上海柯灵实业发展有限公司

Engine balance shaft housing and method of assembling same

InactiveUS20100147248A1Efficiently pulledMinimizing added weightShaftsMachines/enginesAir cycleEngineering

A balance shaft housing is provided that includes a first housing portion, a second housing portion operatively connected to the first housing portion, with the first housing and the second housing configured to cooperatively define first and second balance shaft chambers. A cover member is secured to the second housing portion and cooperates with the first and second housing portions to define an air flow path outside of the chambers for circulating air to the balance shaft chambers. A method of assembling a balance shaft housing is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

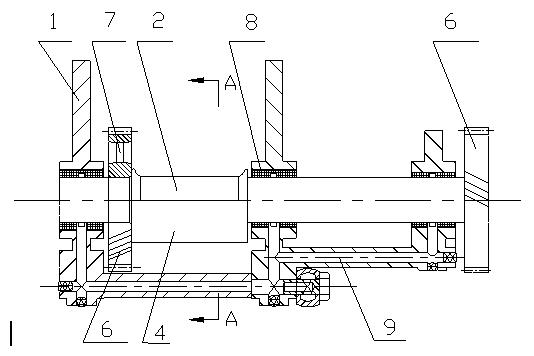

In-line arrangement four-cylinder diesel engine balance mechanism

InactiveCN101782128AReduce stressLess prone to fatigue damageInertia force compensationLubrication of auxillariesLow noiseEngineering

The invention relates to an in-line arrangement four-cylinder diesel engine balance mechanism, which comprises a balance mechanism case and two balance shafts, wherein the two balance shafts are arranged inside the balance mechanism case through balance mechanism sliding bearings, the two balance shafts are both provided with balance blocks, balance shaft gears which are mutually engaged are respectively arranged on the balance shafts, the two balance blocks are uniformly arranged on the two balance shafts, the two balance blocks have different mass-radius products, the diameter of the balance block with large mass-radius product equals to the diameter of a dedendum circle of the balance shaft gear, both end surfaces of the balance shaft gear in the axial direction are provided with grooves, and balance block gravity center regulators are arranged in the grooves. Engine oil pumps are arranged on the flange surface of the balance mechanism case and can move. The invention has the advantages of reasonable structure, small vibration of the mechanism per se, low noise, convenient repairing and maintenance and long service life, and can realize the 100 percent balance of the secondary reciprocating inertia of the engine and the 19.51 percent inertia overturning moment counteraction. Through the test, the vibration intensity grade reaches grade B level, and the work noise is reduced by 5.0 dB(A).

Owner:SHANDONG UNIV +1

Balance shaft of three-cylinder engine

The invention discloses a balance shaft of a three-cylinder engine. The balance shaft comprises a balance shaft body, a front balance block installed at the front end of the balance shaft body, a rearbalance block installed at the rear end of the balance shaft body, and a balance shaft drive gear; and the rear balance block thermally sleeves the rear end of a rear shaft neck of the balance shaftbody, the front balance block and the balance shaft drive gear are sequentially connected to the front end of a front shaft neck of the balance shaft body through keys, the mass of the rear balance block is larger than that of the front balance block, and the eccentric arrangement direction of the front balance block and the eccentric arrangement direction of the rear balance block are opposite. The balance shaft body, the front balance block, the rear balance block and the drive gear form a balance system, when the balance system rotates along with the engine, the rotating direction of the balance system is opposite to the rotating direction of a crankshaft of the engine, and the rotating speed of the balance system is the same as the rotating speed of the crankshaft, so that first-orderreciprocating inertia moment generated by a piston connecting rod assembly is counteracted, then the vibration of the engine is reduced, and the comfort of an automobile is improved.

Owner:CHERY AUTOMOBILE CO LTD

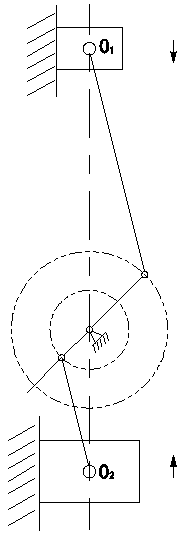

Engine balance system

PendingCN108533402ASmall form factorExtended service lifeInertia force compensationMachines/enginesEngineeringEngine balance

The invention discloses an engine balance system which comprises an engine body component. The engine balance system is characterized in that at least two crank-slider mechanisms are arranged in the engine body component; one crank-slider mechanism and the other crank-slider mechanism are arranged face to face; and the velocity and the acceleration of slider movement in one crank-slider mechanismare similar to the velocity and the acceleration of slider movement in the other crank-slider mechanism. The engine balance system provided by the invention has the advantages of ingenious structure design, reliability in use, and low cost; by adopting the engine balance system, first-order, second-order and high-order vibration produced during an engine operating process can be effectively eliminated, the equipment damage rate is reduced, and the experience feeling of a user is improved; and meanwhile, by adopting an arrangement form of a guide pillar mechanism and a slave connecting rod, notonly is a structure basis provided for eliminating second-order and high-order vibration, but also the problem that an engine tank occupies space is further solved, the boundary dimension of an engine is reduced, and in addition, the service life of the engine is further improved.

Owner:CHONGQING ZONGSHEN GENERAL POWER MACHINE

Balance shaft case structure of engine

ActiveCN102797789AIncrease stiffnessHigh strengthInertia force compensationEngineeringEngine balance

The invention relates to a balance shaft case structure of an engine. The balance shaft case structure comprises a case body, a shaft hole, a reinforcing rib, a hollow structure, and an oil damper structure, wherein the reinforcing rib is arranged on the water wall of the case body for enhancing the balance shaft case structure; the hollow structure is arranged on the outer wall of the case body around the shaft hole for reducing the weight of the balance shaft case structure; the shaft hole is formed on the lower side of the case body and used for allowing the balance shaft to pass through and for mounting the balance shaft on the balance shaft case; and the oil damper structure is arranged on the upper side of the case body and used for preventing oil splashing. The balance shaft case structure provided by the invention is simple and compact in structure, and convenient in arrangement. After mounted on the engine, the balance shaft can rotate synchronously together with a crankshaft; a balancing weight on the balance shaft can counteract the rotation imbalance of the crankshaft caused by less number of cylinders of the engine, thereby reducing engine vibration and improving comfort of automobiles.

Owner:CHERY AUTOMOBILE CO LTD

Device for detecting bending degree of balance shaft of automobile engine

ActiveCN111998754APrecise positioningEasy to disassembleAngles/taper measurementsMechanical counters/curvatures measurementsGear wheelElectric machinery

The invention discloses a device for detecting the bending degree of a balance shaft of an automobile engine. The device comprises a bottom plate, and fixing cylinders are fixedly connected to the twosides of the top of the bottom plate through fixing plates. Ring bodies are fixedly connected to the sides, close to each other, of the two fixing cylinders, the upper portions of the surfaces of thering bodies communicate with semi-ring bodies, fixing blocks are fixedly connected to the upper portions of the surfaces of the fixing cylinders, and driving motors are fixedly connected to the topsof the fixing blocks. According to the device for detecting the bending degree of a balance shaft of an automobile engine, the driving motors, a rotating disc, a gear, an arc-shaped groove, driving teeth, movable rods, a sliding disc and a reset spring are arranged; the four movable rods can be driven to get close to each other and quickly clamp the balance shaft in four directions at the same time only by starting the driving motors, the clamping stability is high, manual clamping is not needed, the fixing effect is good, errors can be reduced when the balance shaft is detected, and the measurement precision can be further improved.

Owner:湖北隐冠轴业有限公司

Tool for detecting bending degree of balance shaft of automobile engine

InactiveCN111307010APrecise positioningEasy to disassembleMechanical counters/curvatures measurementsEngine balanceThreaded rod

The invention discloses a tool for detecting the bending degree of a balance shaft of an automobile engine. The tool comprises a base, a fixed seat, a mounting seat and a balance shaft body. The top of the mounting seat is movably connected with a fixed rod; a mounting groove matching the fixed rod is formed in the top of the mounting seat; and a sleeve is fixedly connected to the top of the mounting seat and located at the top of the mounting groove, threaded rods are in threaded connection with the two sides of the sleeve correspondingly, and the ends, close to the sleeve, of the threaded rods penetrate the sleeve and extend into the sleeve. The invention relates to the technical field of balance shaft bending degree detection. According to the tool, the top of the mounting seat is provided with the mounting groove matching the fixing rod, and the dial indicator is used for detecting the curvature of the balance shaft, so that the detection accuracy is improved, the detection efficiency is higher, and the economic cost is reduced; the dial indicator is convenient to locate and disassemble, and the stability of the dial indicator is improved during detection.

Owner:湖北隐冠轴业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com