Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about "Eccentric-shafts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

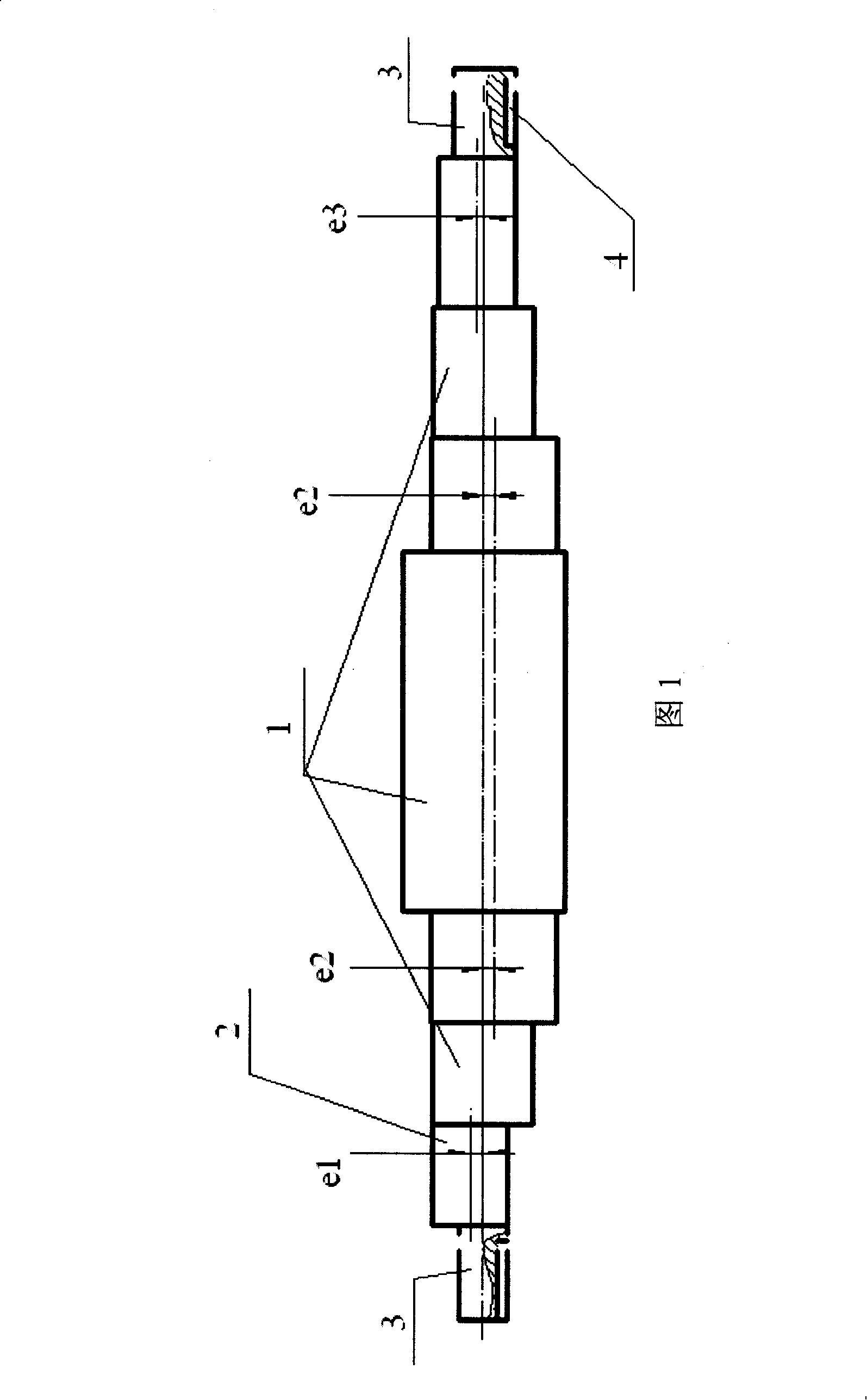

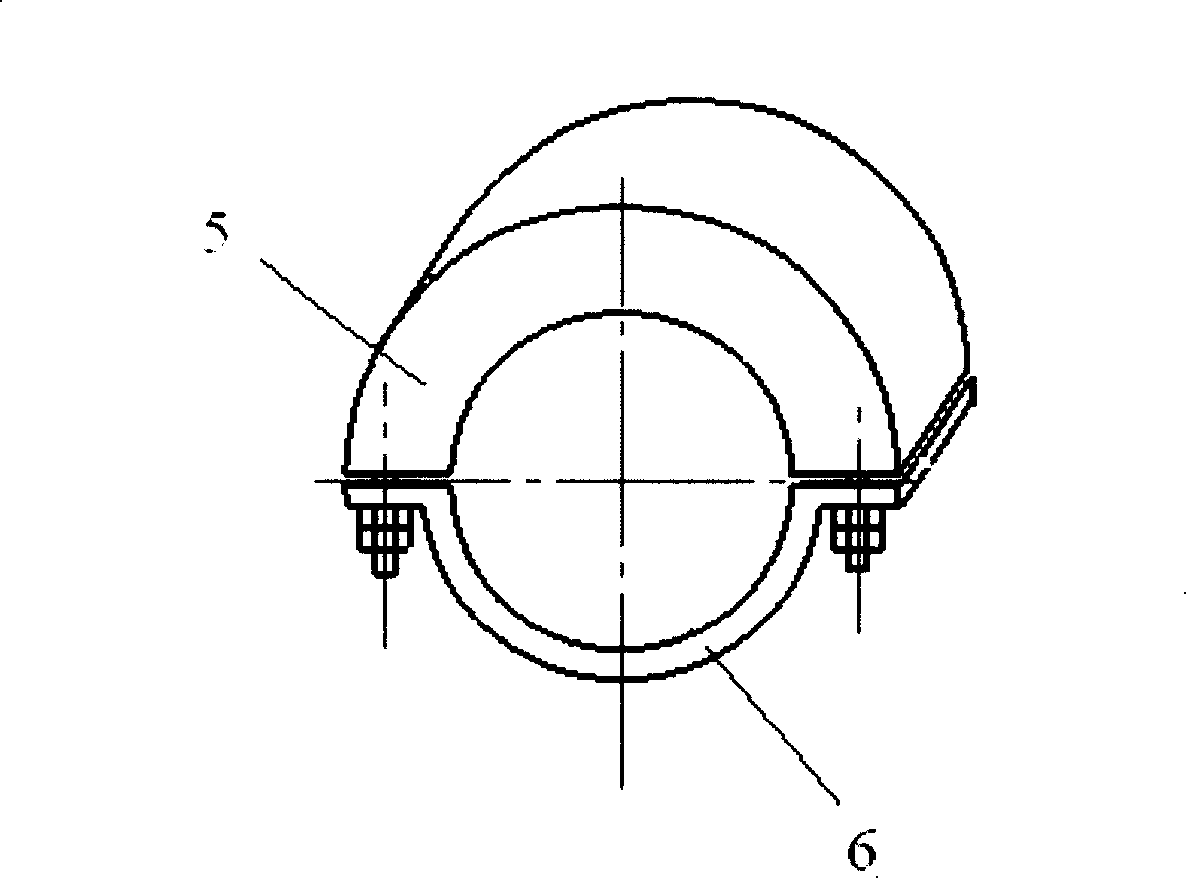

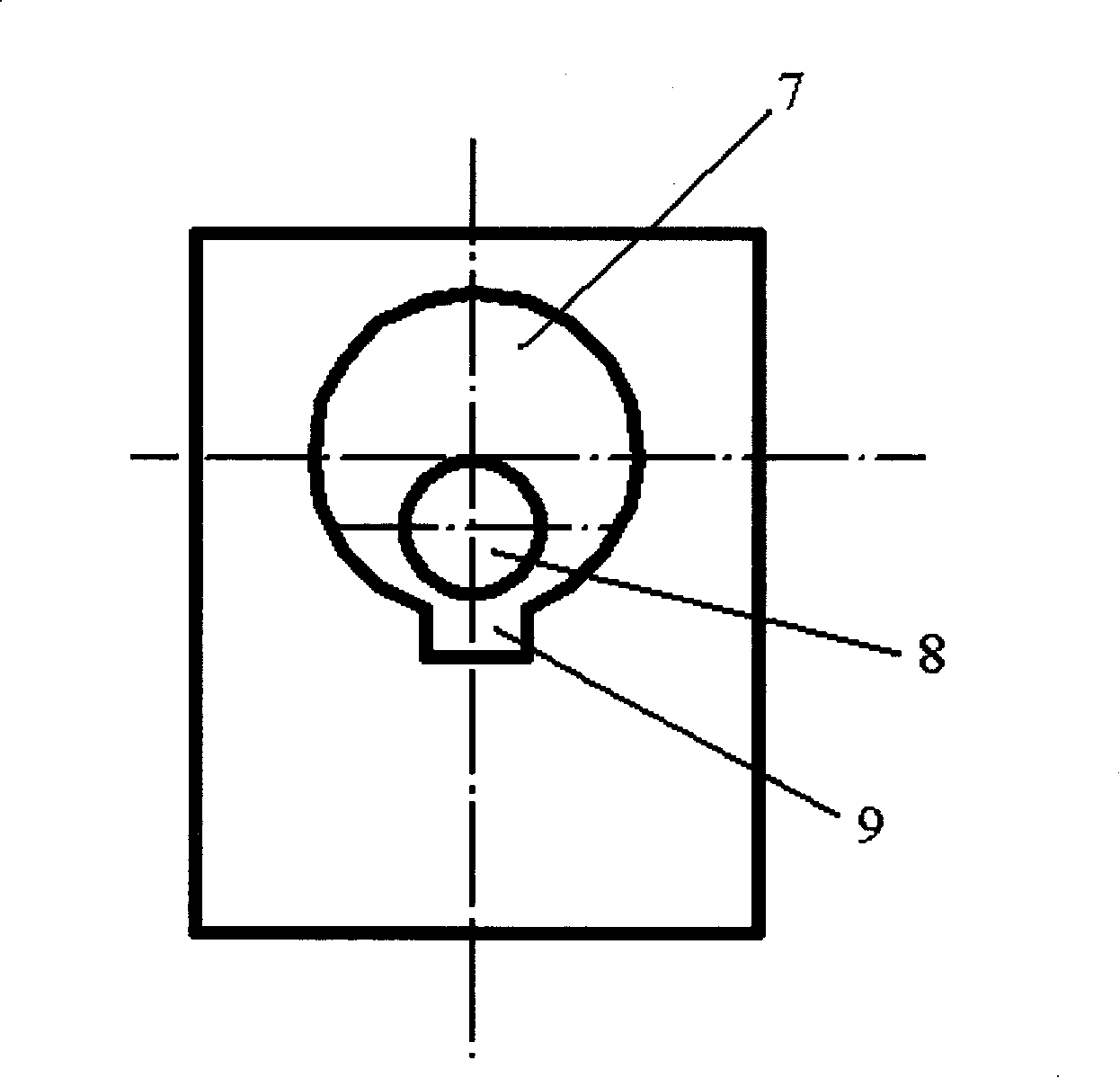

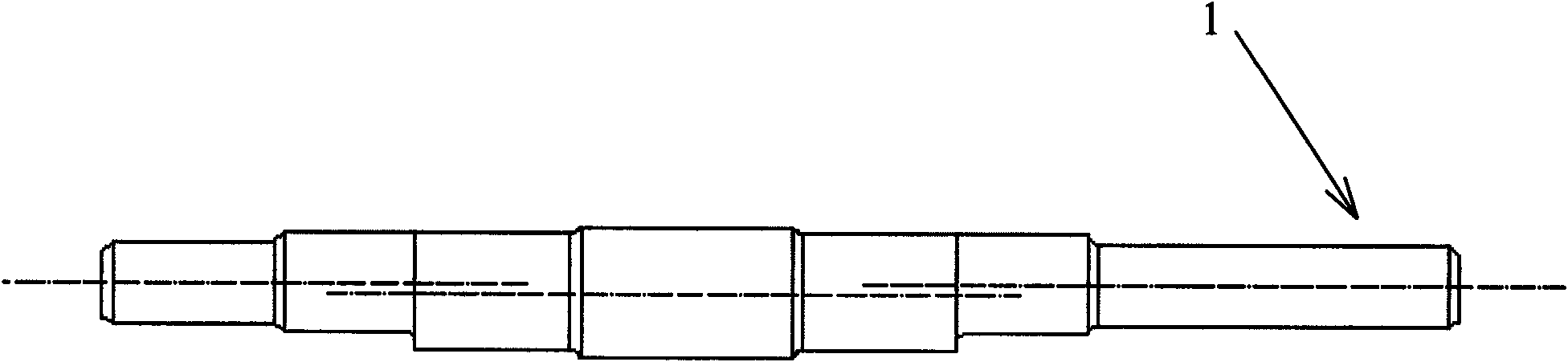

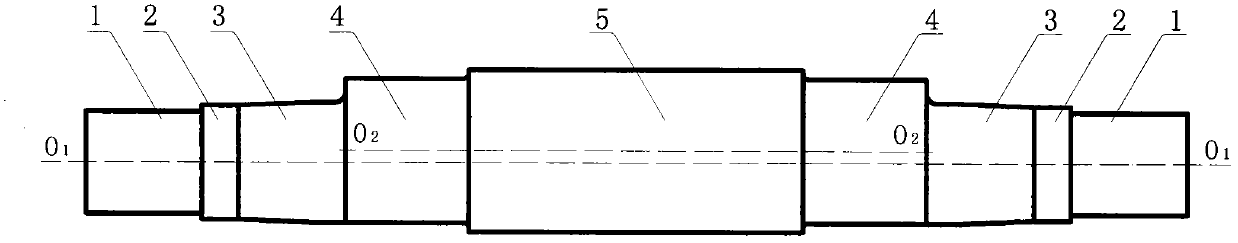

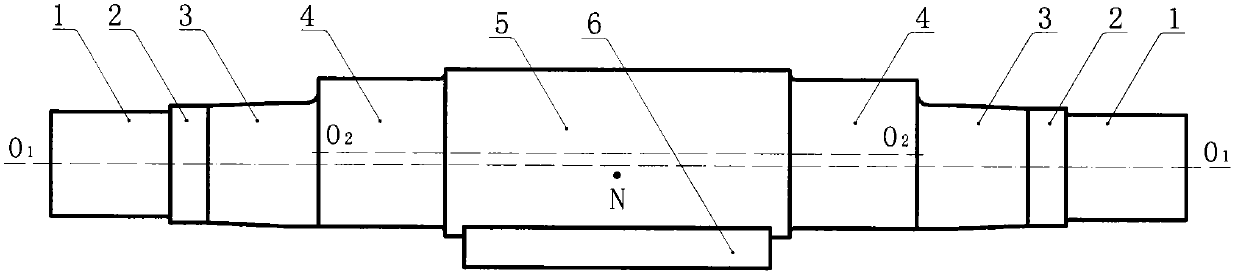

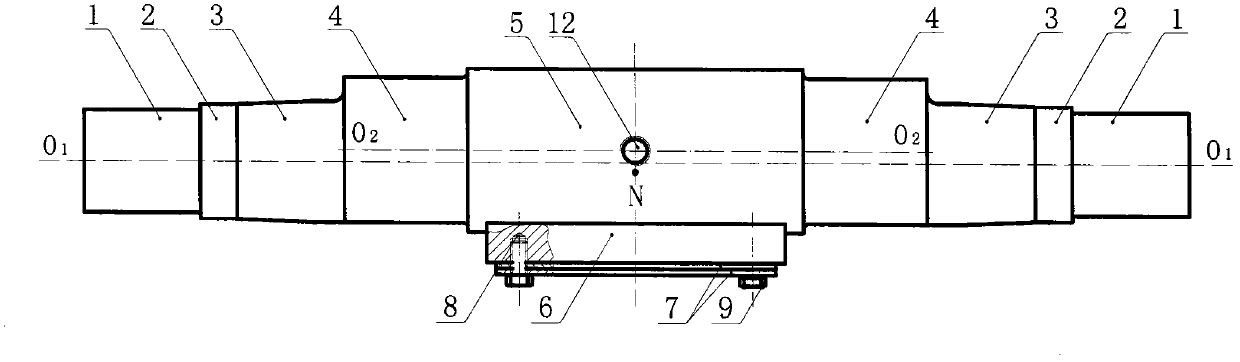

Multiple eccentric shaft processing method and using counterbalance and eccentric sleeve

The invention discloses a processing method of multiple eccentric shaft; lengthened ends are arranged on both ends of the multiple eccentric shaft; after that a counterbalance is arranged at the position of eccentric crosspiece, and a reference crosspiece is processed, then counterbalance is dismounted; a eccentric sleeve is arranged at the lengthened end, and an eccentric crosspiece is processed; finally the lengthened end of the multiple eccentric shaft is removed, and a multiple eccentric shaft is obtained. The invention also discloses the counterbalance use in the method, comprising a balance section and a fixation section; the balance section and the fixation section can clasp the eccentric crosspiece after being installed. The invention also disclosed the eccentric sleeve use in the method, comprising a lengthened end hole and a processing hole; the axial line of the lengthened end hole is in parallel with the axial line of the processing hole, the eccentric crosspiece is processed by taking the axial line of the eccentric crosspiece as the processing axial line. The counterbalance and the eccentric sleeve provided by the invention has simple structure, and is easy to make; and relative high precision can be easily achieved; the processing method of the multiple eccentric shaft of the invention has simple steps, and the multiple eccentric shaft with relative high precision can be made with convenience and rapidness.

Owner:SHANGHAI JIANSHE LUQIAO MASCH CO LTD

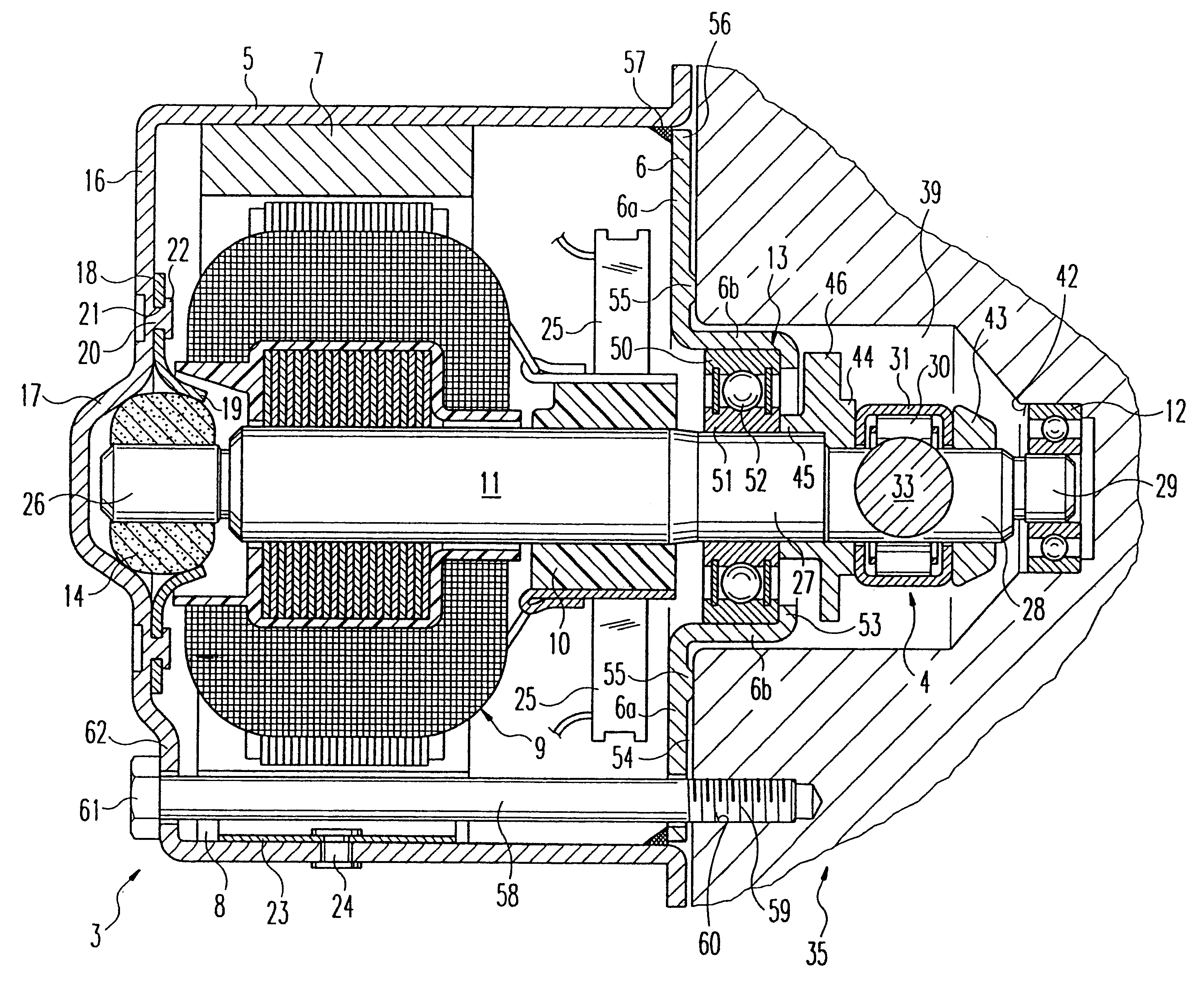

Electric motor

An electric motor having a cup-shaped motor housing for containing a shaft and a motor cover that closes the motor housing. The motor cover has a peripheral section extending essentially radial to the shaft and an inner section extending essentially axial to the shaft. The inner section at least partially, radially encloses a bearing for supporting the shaft. The electric motor is fastened to a connecting block in order to be connected to a subassembly to be rotated by the shaft. The peripheral section of the motor cover and the connecting block touch each other on at least one support. The motor housing and the connecting block are axially clamped in relation to each other by means of a clamping element. The peripheral section of the motor cover is axially connected to the motor housing in detent fashion.

Owner:ROBERT BOSCH GMBH

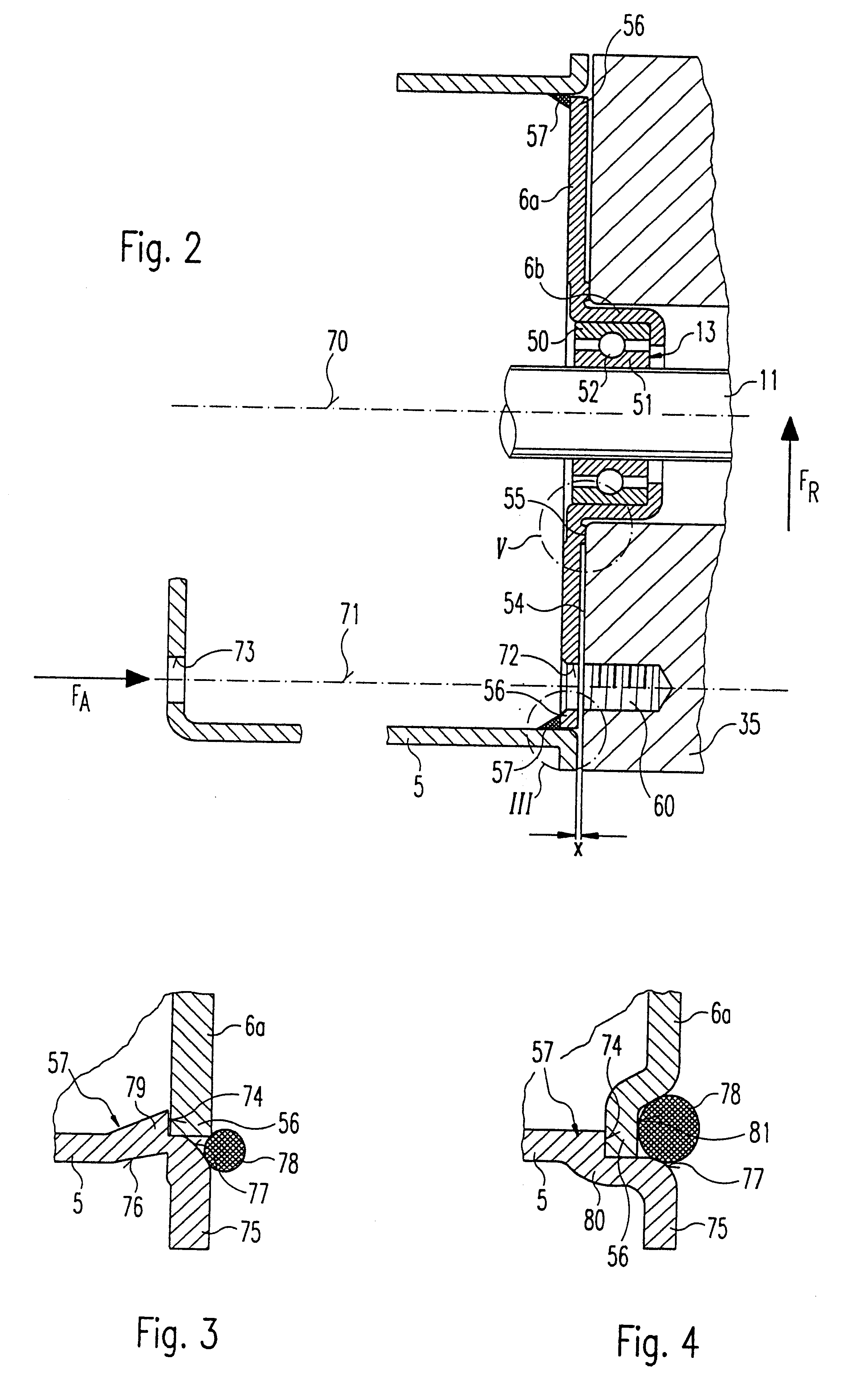

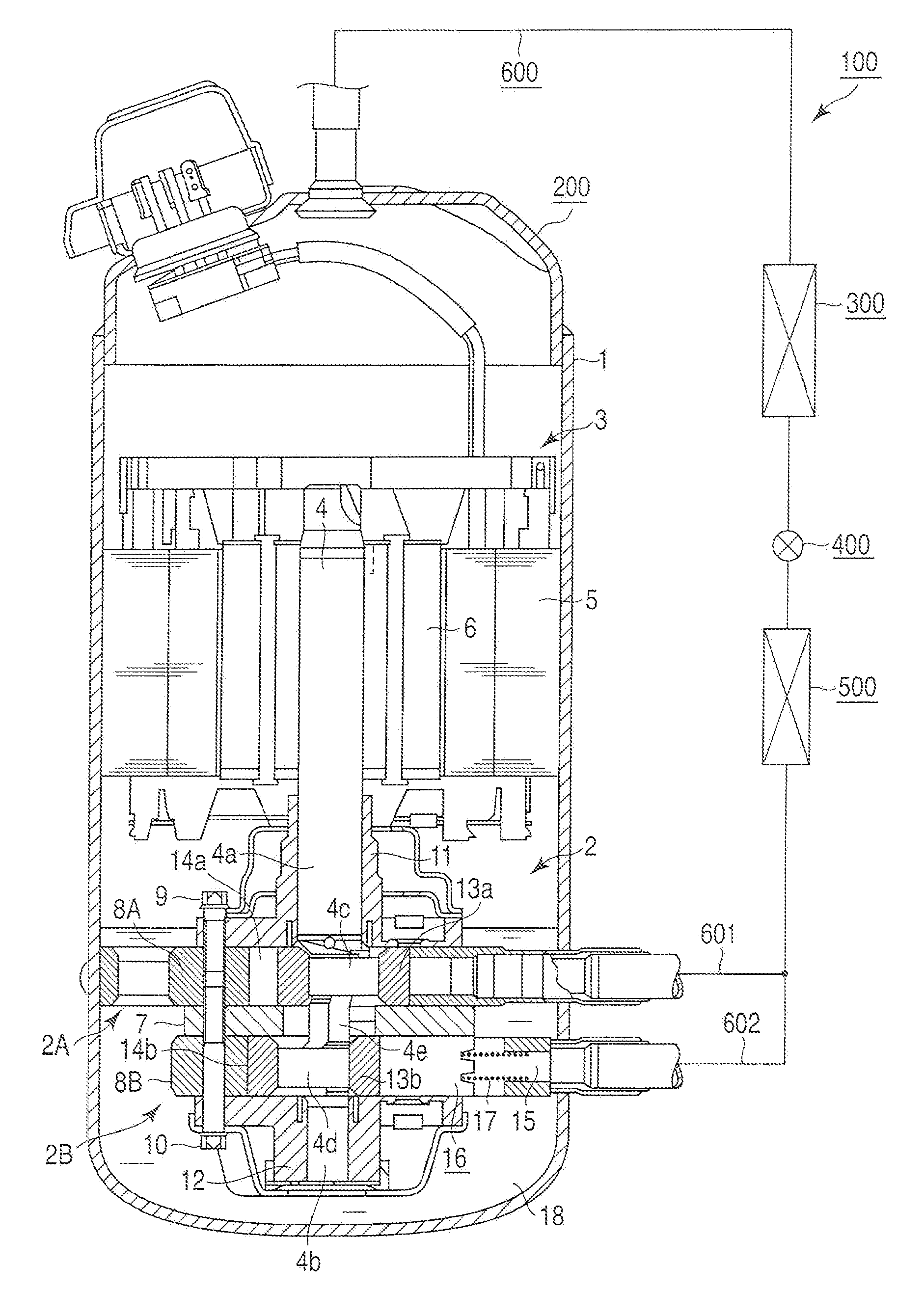

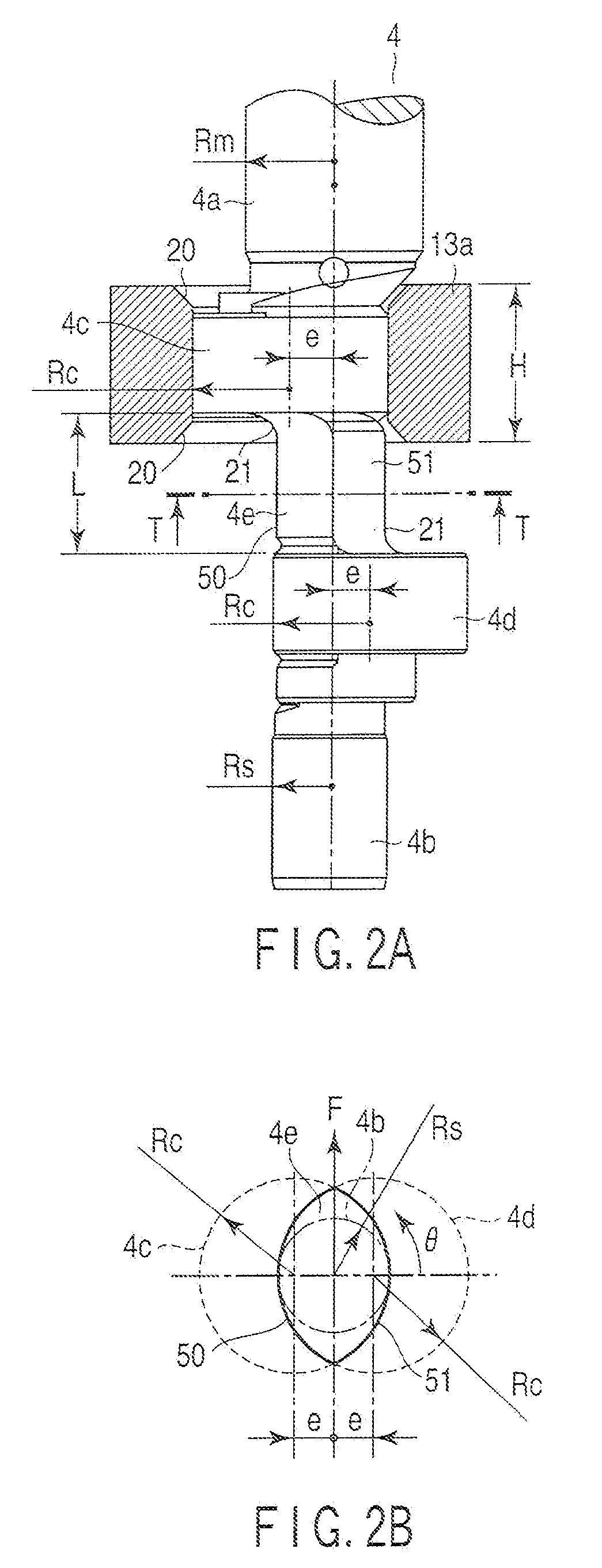

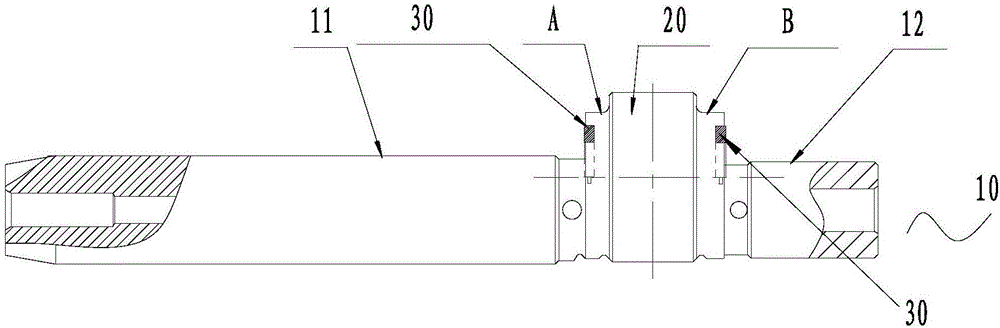

Multi-cylinder rotary compressor and refrigeration cycle equipment

ActiveUS20100147013A1Convenience to workReduce stiffnessRotary/oscillating piston combinations for elastic fluidsEccentric-shaftsRefrigerationCrankshaft

A rotary compressor, in which formulas Rc<Rm+e and RC≧Rs+e are established, when the radius of a main shaft is Rm, the radius of a countershaft is Rs, the radius of a crankshaft is Rc, and the eccentricity is e, a connecting part has a A-periphery which is formed on the counter-eccentric side periphery of the second crankshaft, and a B-periphery formed on the counter-eccentric side periphery of a first crankshaft, and a formula H>L≧H−Cr−Cs is established, when the axial direction of the connecting part is L, the axial length of the first roller is H, the axial length of a bevel formed at the inside edge of the first roller is Cr, and the axial direction of a bevel of the second crankshaft is Cs.

Owner:TOSHIBA CARRIER CORP

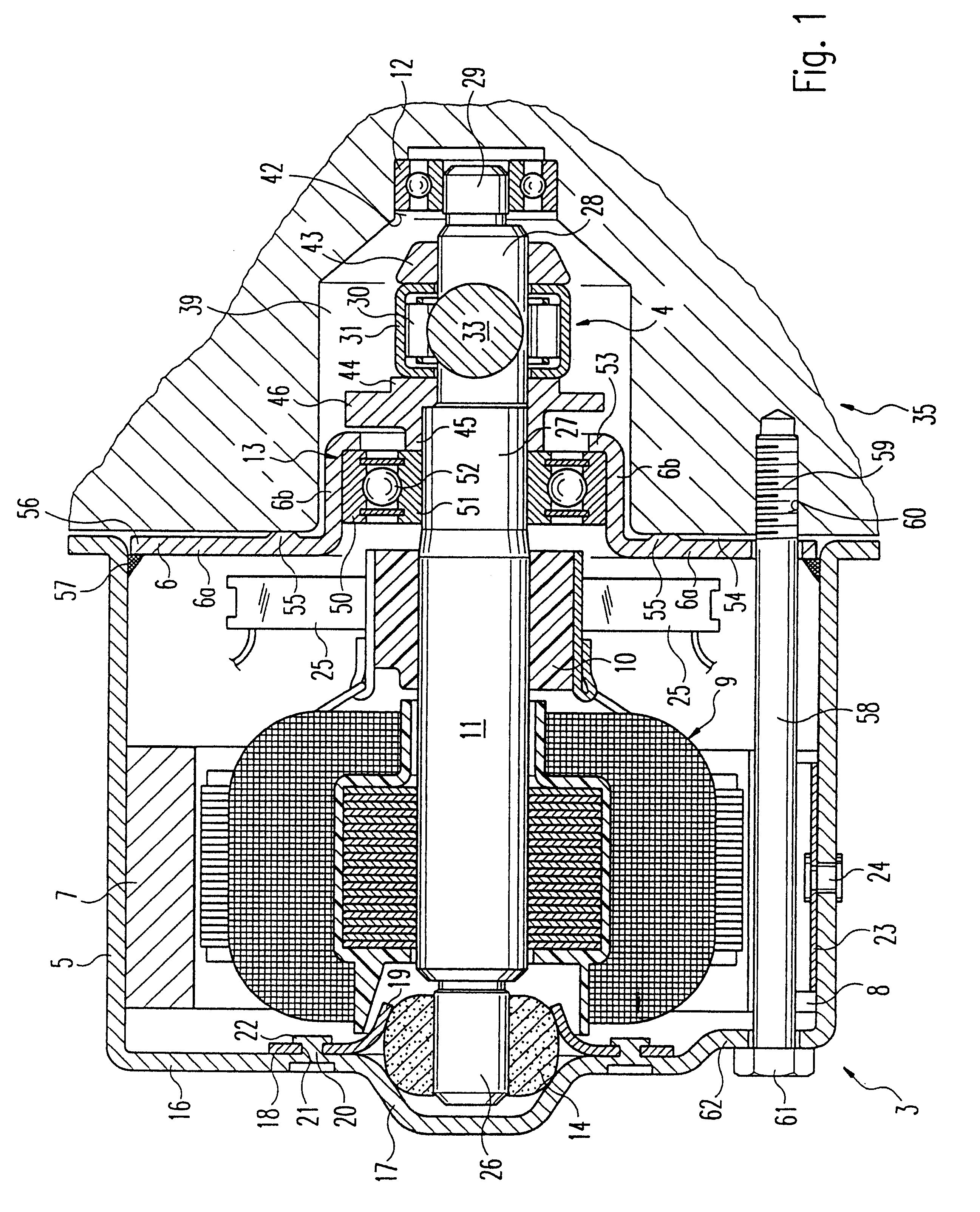

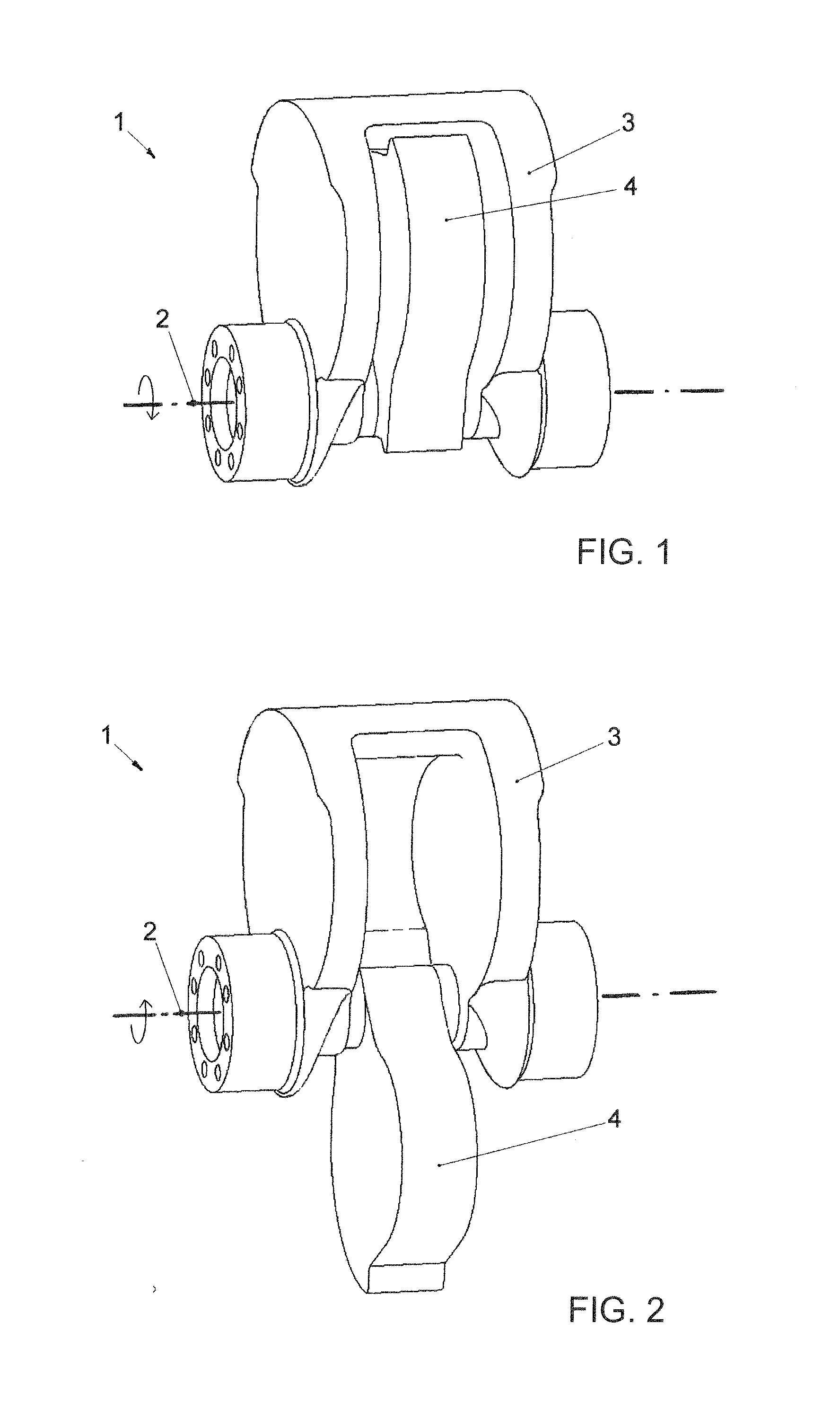

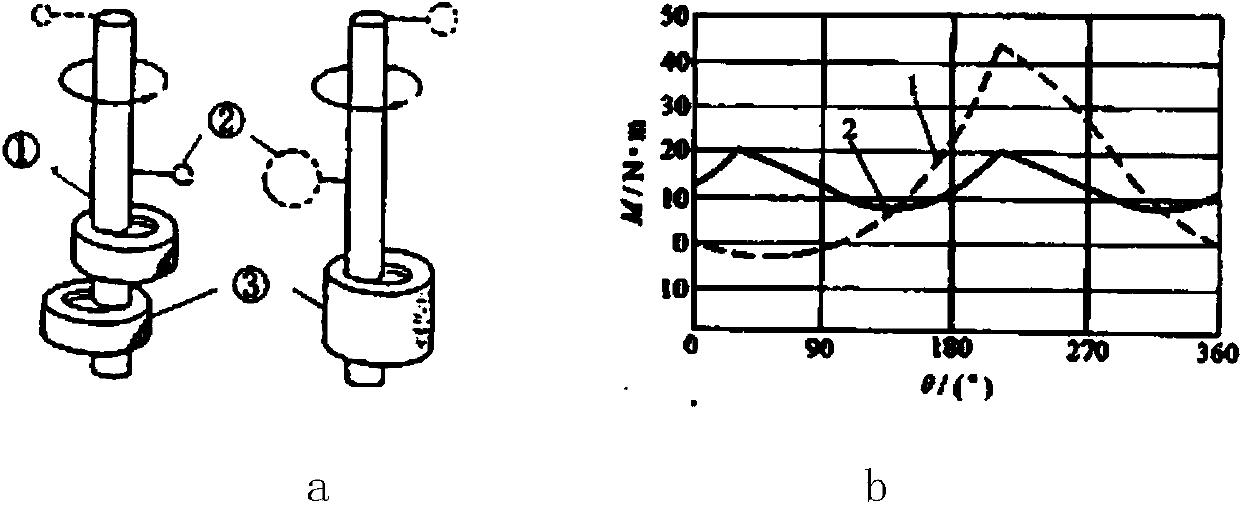

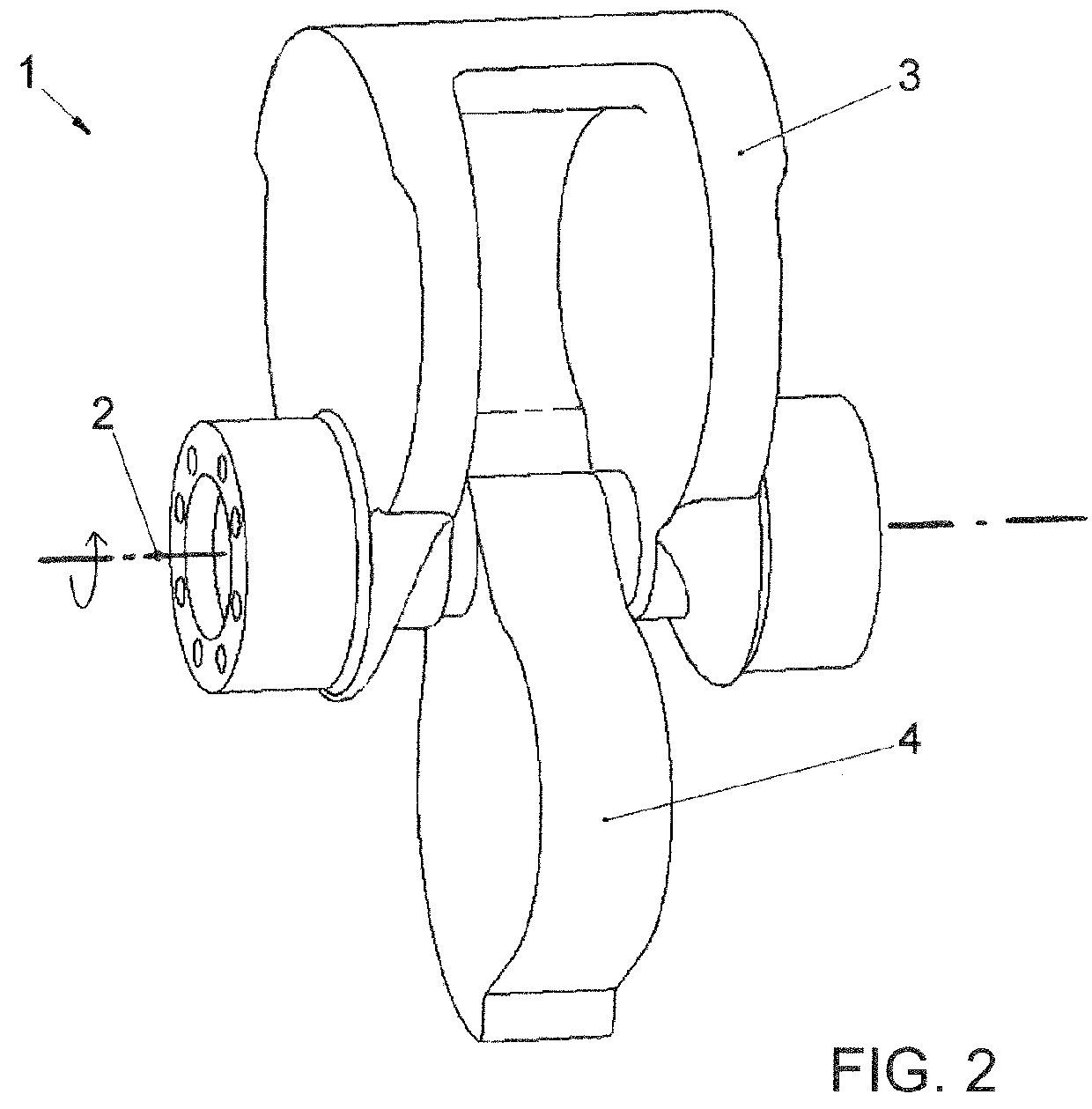

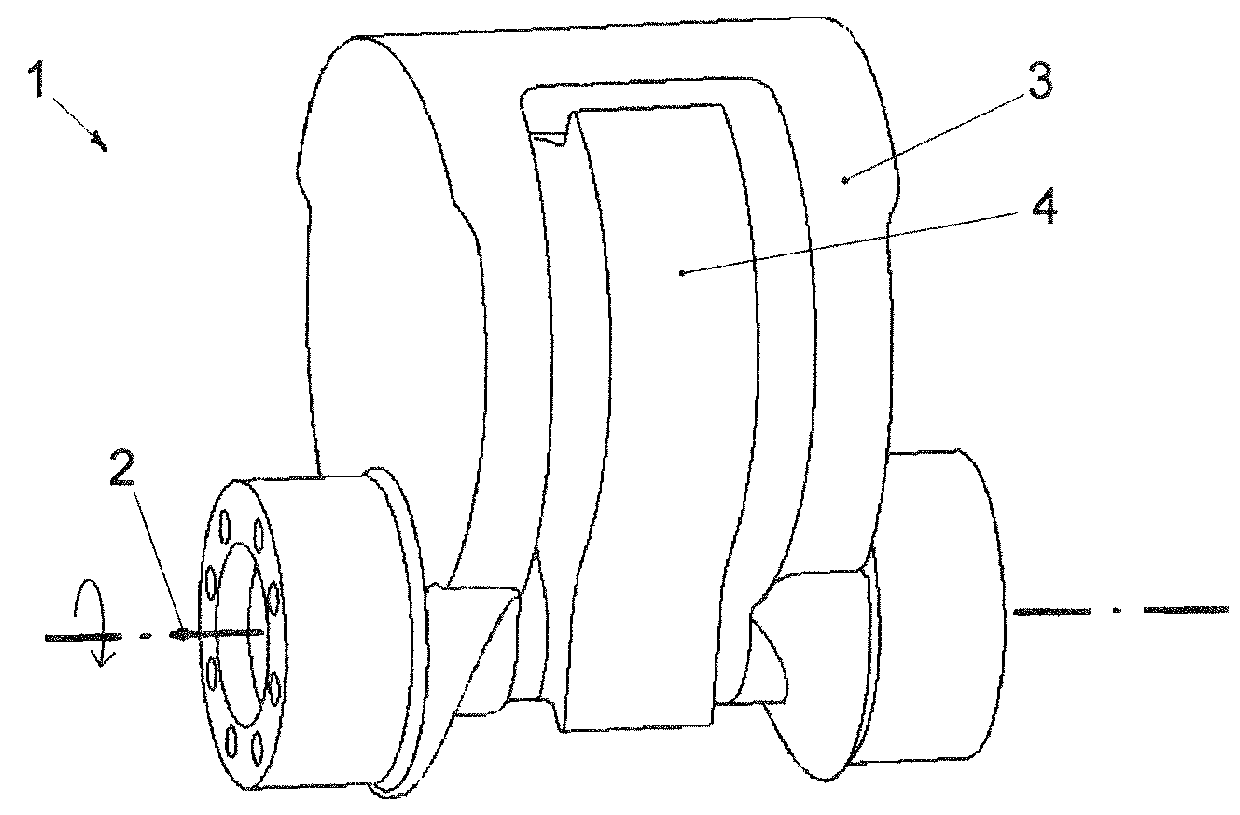

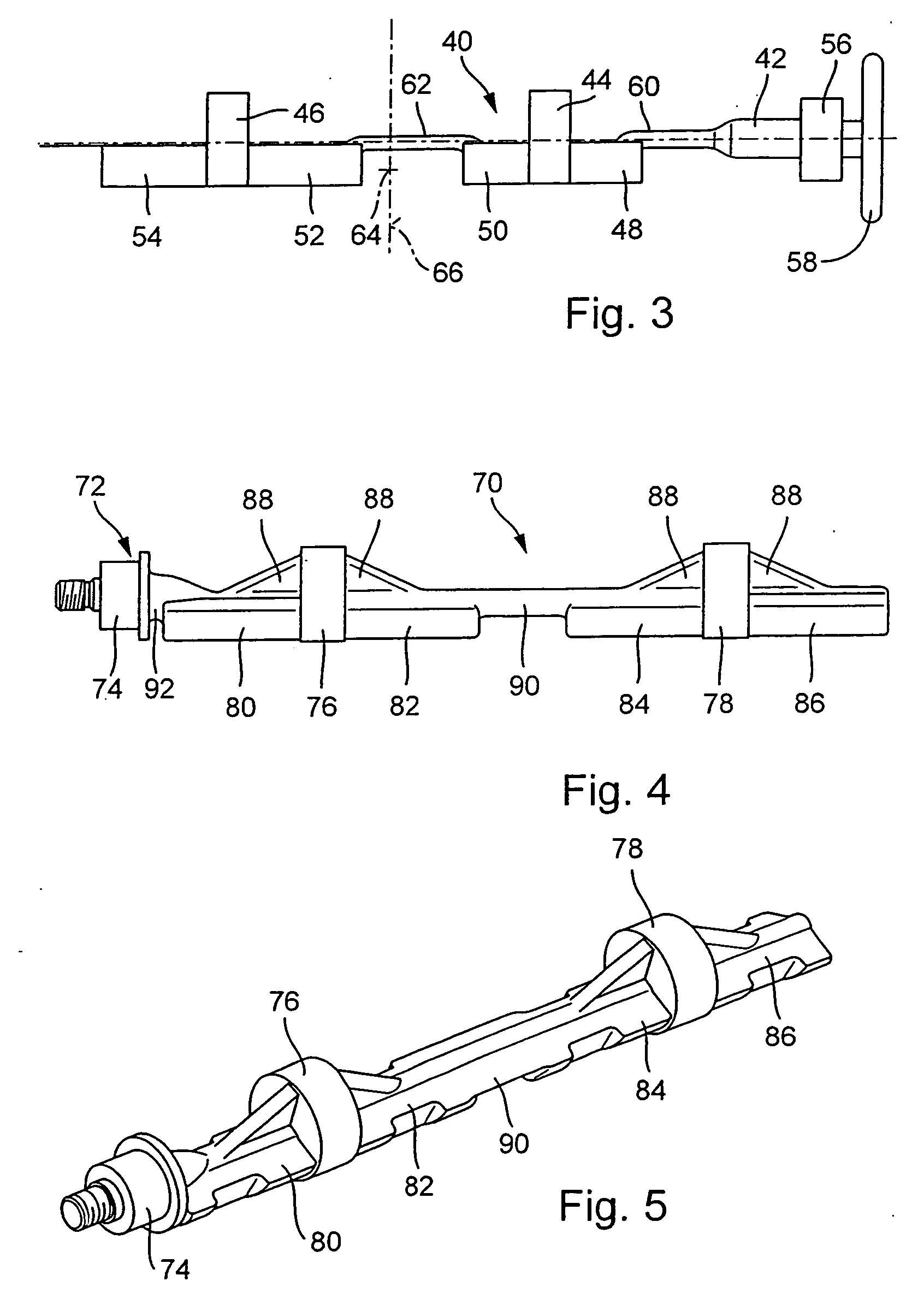

Balance shaft for a multicylinder in-line engine

ActiveUS7444976B2Less disturbed deflectionAvoid leaningEccentric-shaftsInertia force compensationCouplingEngineering

In a balance shaft for a multi-cylinder in-line engine with at least two imbalance weight sections and at least one bearing structure wherein the balance shaft has imbalance weight sections being arranged symmetrically relative to the bearing position and at least one of the imbalance weight sections is connected to a further shaft section at an end facing away from the bearing position, a flexible coupling element that enables a deflection of the end of the connected imbalance weight section in the direction of the resulting centrifugal forces when the balance shaft rotates is provided between the end of the at least one imbalance weight section facing away from the bearing position and the further shaft section.

Owner:DAIMLER AG

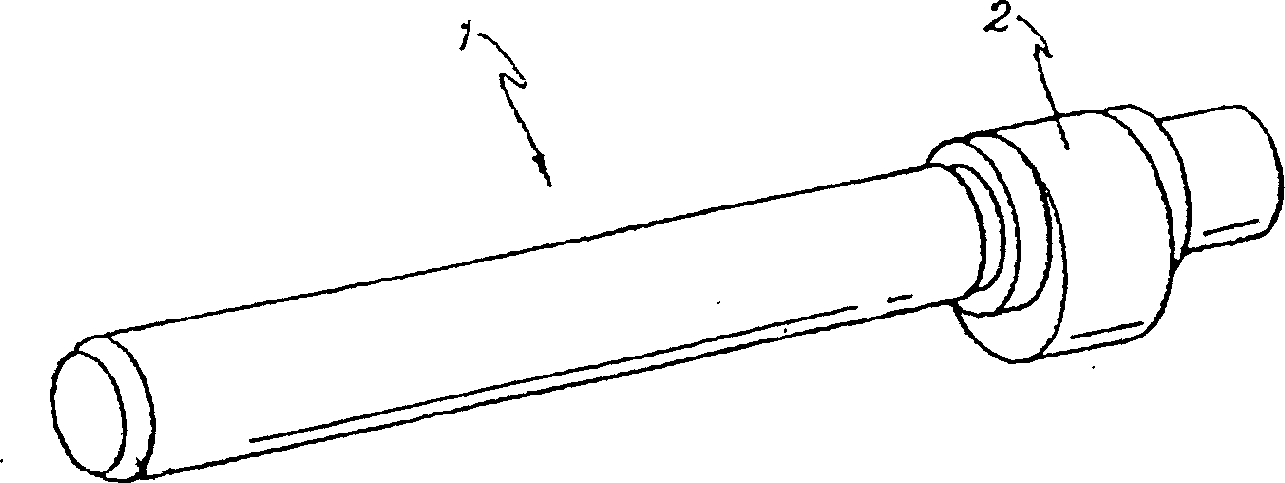

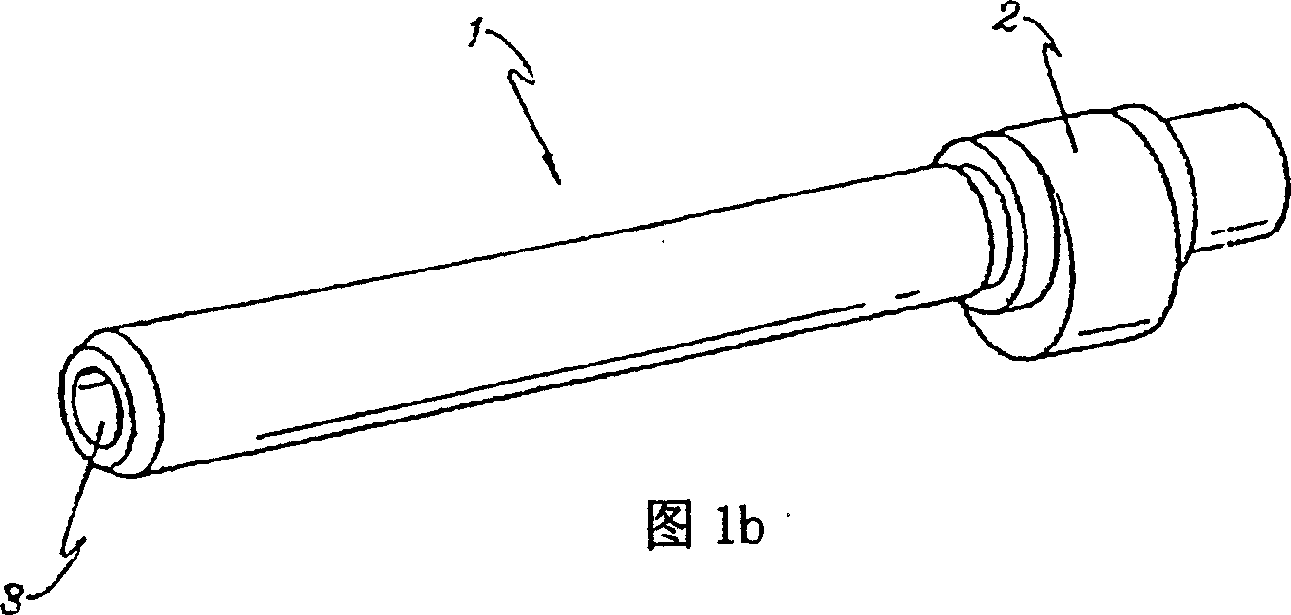

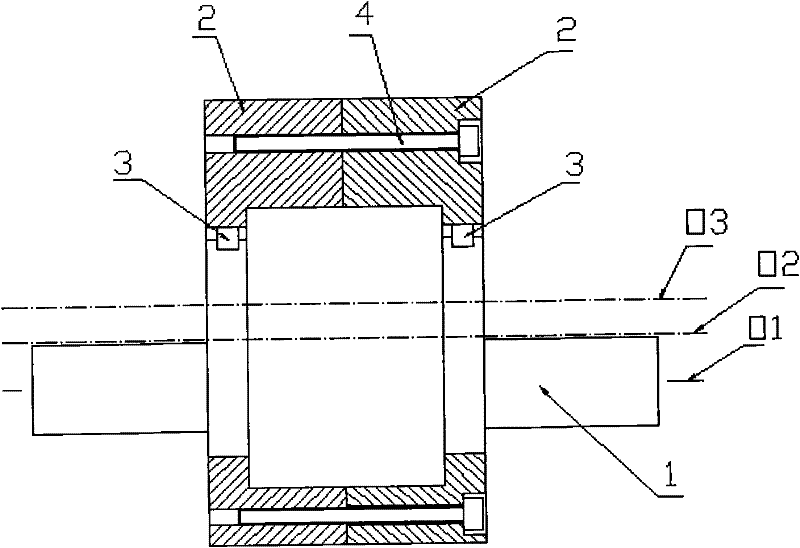

Eccentric shaft with adjustable eccentricity

InactiveCN101049675ASolving precise measurementsResolve correct confirmationEccentric-shaftsPositioning apparatusEngineeringMachine tool

An eccentric axle with adjustable eccentricity for machining the thin-wall sleeve barrel is composed of a core axle body and an eccentricity adjusting block with two central holes at it's both ends and matched with the head and tail centers of machine-tool. Said eccentricity can be adjusted by adjusting the distance between the central axis of said core axle body and the central hole of said eccentricity adjusting block.

Owner:CHANGZHOU BAOLING HEAVY IND MACHINERY

Engine balance shaft system

ActiveCN102996707ASimple structureLower the altitudeInertia force compensationEccentric-shaftsEngineeringSprocket

The invention aims to provide an engine balance shaft system for solving the problems that a traditional balance shaft system is inconvenient to arrange and prone to deforming and being stuck. The engine balance shaft system disclosed by the invention comprises a balance shaft with a balance shaft chain wheel, wherein the balance shaft is provided with a front balance block and a rear balance block. The engine balance shaft system is characterized in that the balance shaft chain wheel is arranged inside a triangle formed by a fuel pump drive chain wheel, a crankshaft timing chain wheel and a camshaft drive chain wheel; and the balance shaft chain wheel, the fuel pump drive chain wheel, the crankshaft timing chain wheel and the camshaft drive chain wheel are on a same plane and are chained by timing chains. Therefore, the whole structure of the engine balance shaft system is simpler. Simultaneously, the balance shaft is arranged on one side of a crankshaft rather than below the crankshaft, so that the whole height of the engine balance shaft system can be reduced, and the engine balance shaft system is easier to arrange.

Owner:CHERY AUTOMOBILE CO LTD

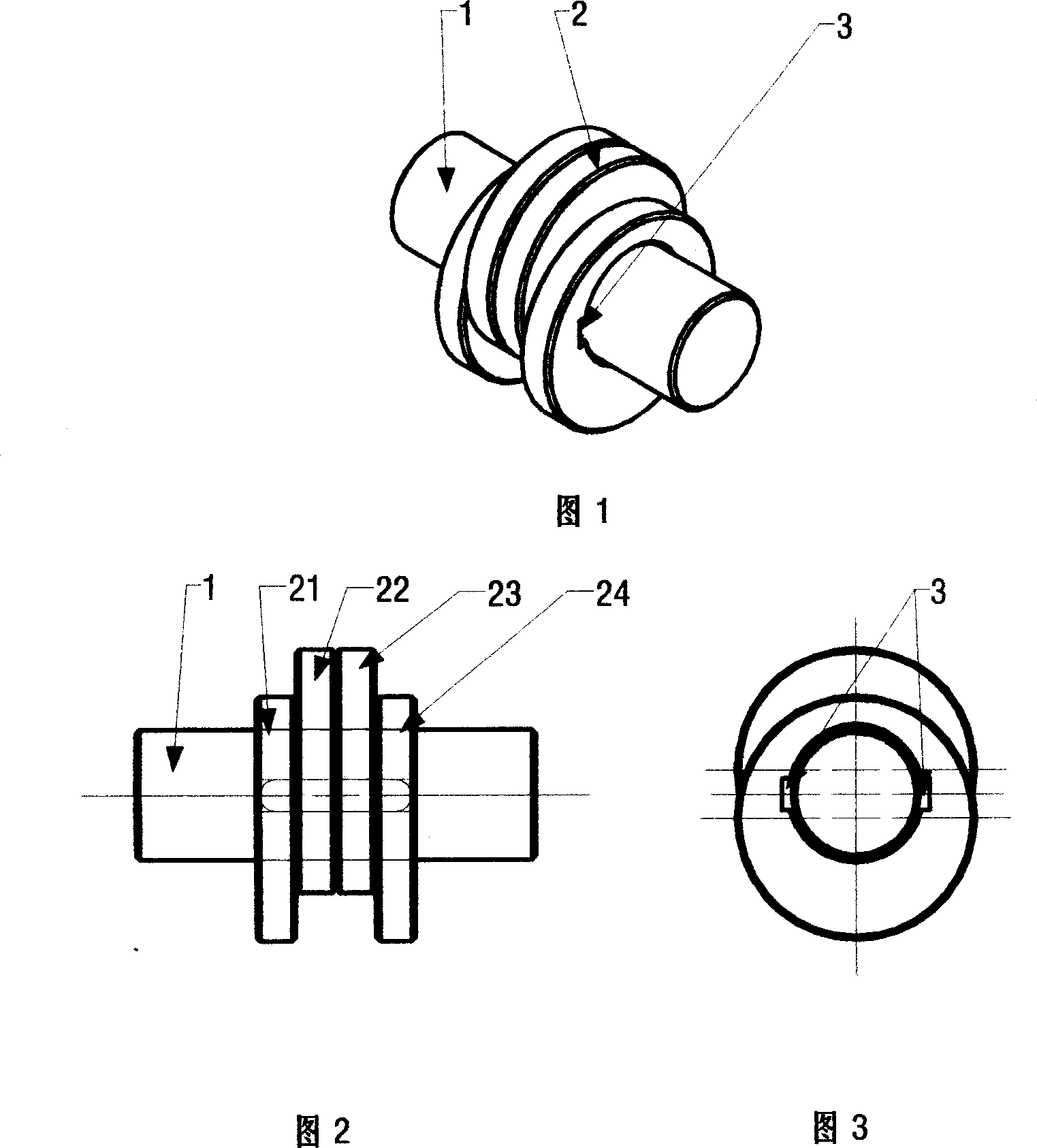

Eccentric rotation shaft and electric motor shaft mfg. method

InactiveCN1515804AHigh hardnessShorten production timeEccentric-shaftsMetal-working apparatusForeign matterMotor shaft

The manufacturing method of crank shaft comprises a pipe making process; a drawing process; a cutting process; a forging process; and a processing process. The manufacturing method of crank shaft also could only comprise a pipe making process; a cutting process; a forging process; and a processing process. The manufacturing method of motor shaft comprises a pipe making process; a drawing process; a cutting process; and a processing process of forming a key groove on the motor shaft finally completed through the cutting process.

Owner:金英基

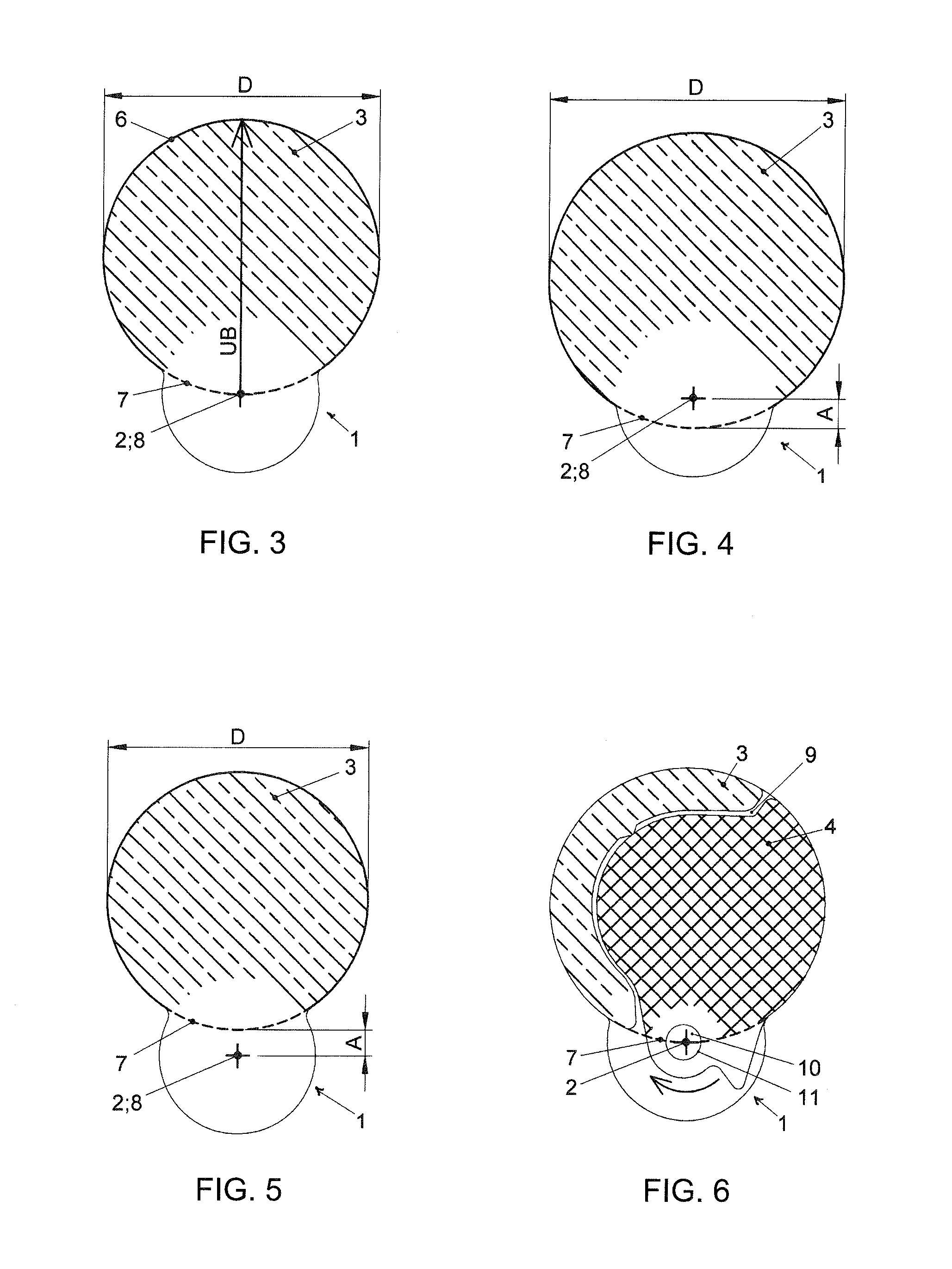

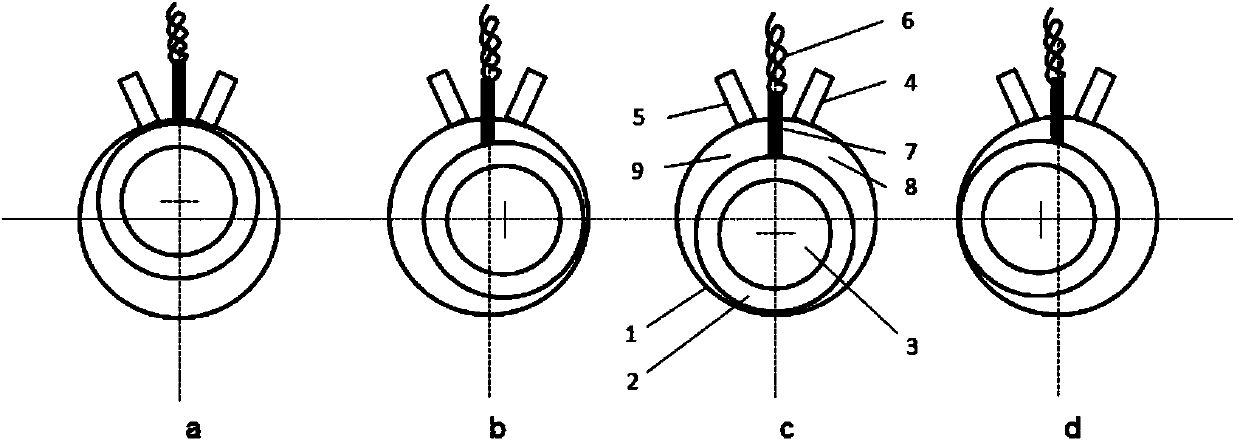

Eccentric shaft assembly having fixed and movable eccentric masses

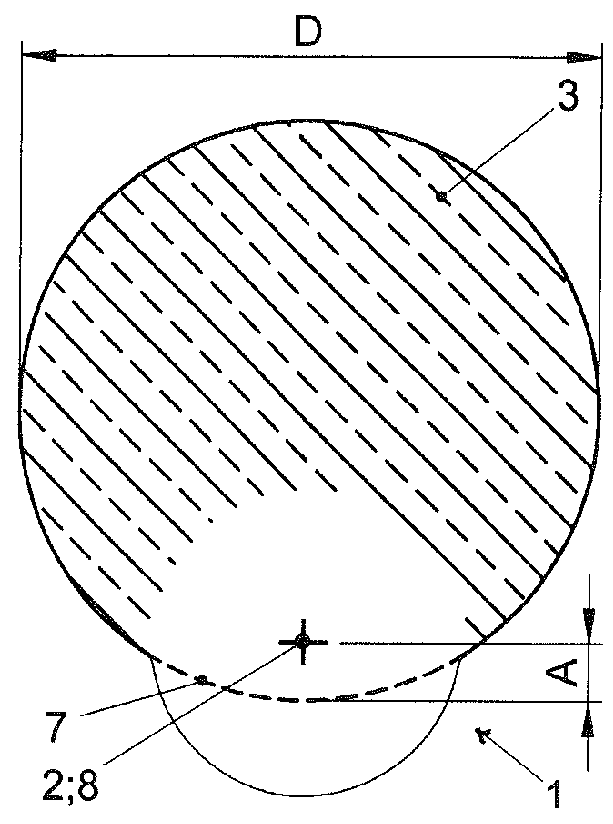

ActiveUS20150139731A1Energy consumptionHigh mass-moment of inertiaControlling membersEccentric-shaftsRotational axisSection plane

An eccentric shaft for a compacting machine is rotatable about a rotational axis and includes a fixed and movable eccentric mass where the movable eccentric mass cooperates with the fixed eccentric mass in one of the directions of rotation of the eccentric shaft to partly balance the fixed eccentric mass in the other rotation direction of the eccentric shaft. At least one section of the fixed eccentric mass shows a maximal radial extension (UB) in relation to the rotational axis, limited by an arc-shaped curve, which extends to a circle shape, with the diameter (D) showing a distance (A), between the point (P) on the circle-shaped curve that is located closest to the point of intersection of the rotational axis and the section plane, and the point of intersection, from 0 up to 0.1(D).

Owner:DYNAPAC COMPACTION EQUIP

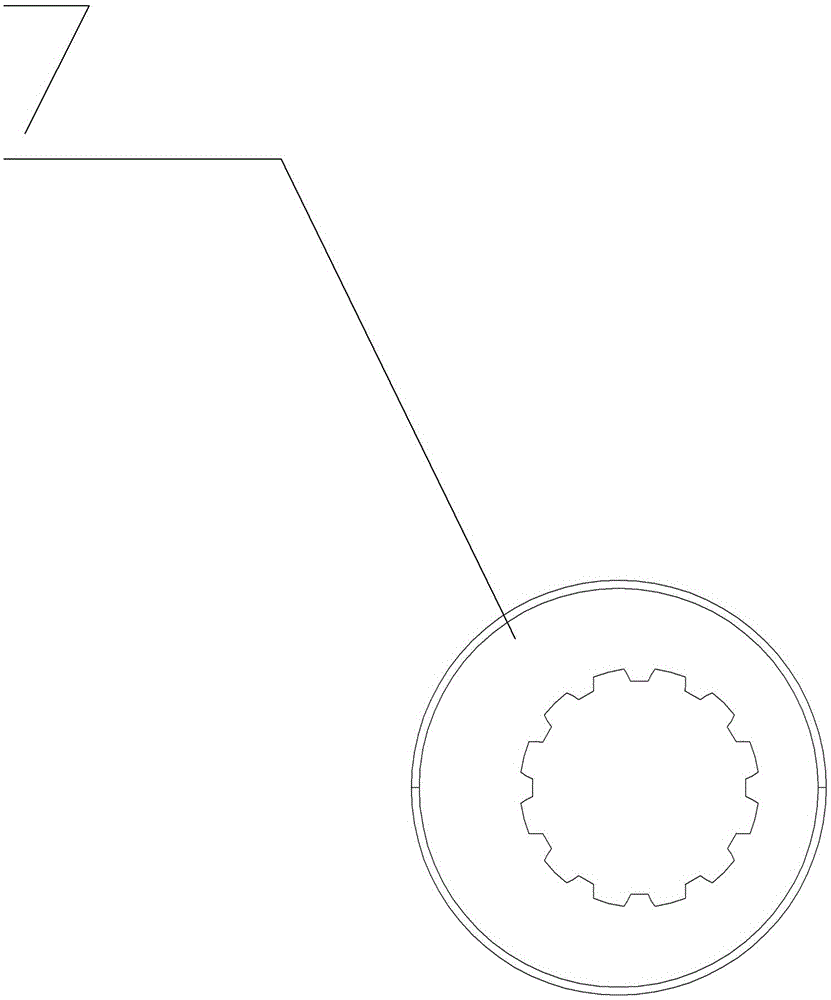

Machining method for high-precision eccentric spline shaft

InactiveCN104400363AGuaranteed deflection angle requirementsGuaranteed concentricity requirementsEccentric-shaftsNumerical controlSingle process

The invention relates to the machining field and in particular relates to a machining method of the high-precision eccentric spline shaft. The machining method comprises the following steps: making position lines for central holes and eccentric holes in two ends of the shaft; forming the central holes in the two ends through machining according to the positioning lines; machining the shaft roughly and leaving a proper amount of machining allowance; detecting flaws and conducting tempering; conducting semi-finish machining for the maximal shaft diameter; boring two ends until length sizes required in a drawing are met; selecting the central lines and making new position lines of new central holes and eccentric holes and punching sample holes ; forming central holes and eccentric holes in the two ends by using a numerical control or digital display boring machine through machining; machining shaft shoulders; and mounting the shaft on a large gear hobbing machine and machining the shaft in a single-tool cutting mode. According to the invention, requirements for deflection angles in a method utilizing a tooth-shaped central line and an eccentric distance of a spline shaft are guaranteed. At the same time, a problem that a spline groove is difficult to align to a cutter is solved and the work piece concentricity and verticality are guaranteed in single-process clamping and machining. Influence on the manufacturing of the spline shaft caused by eccentric weight is also avoided completely and tempering reliability and operability are guaranteed.

Owner:SHAANXI QIYUAN TECH DEV

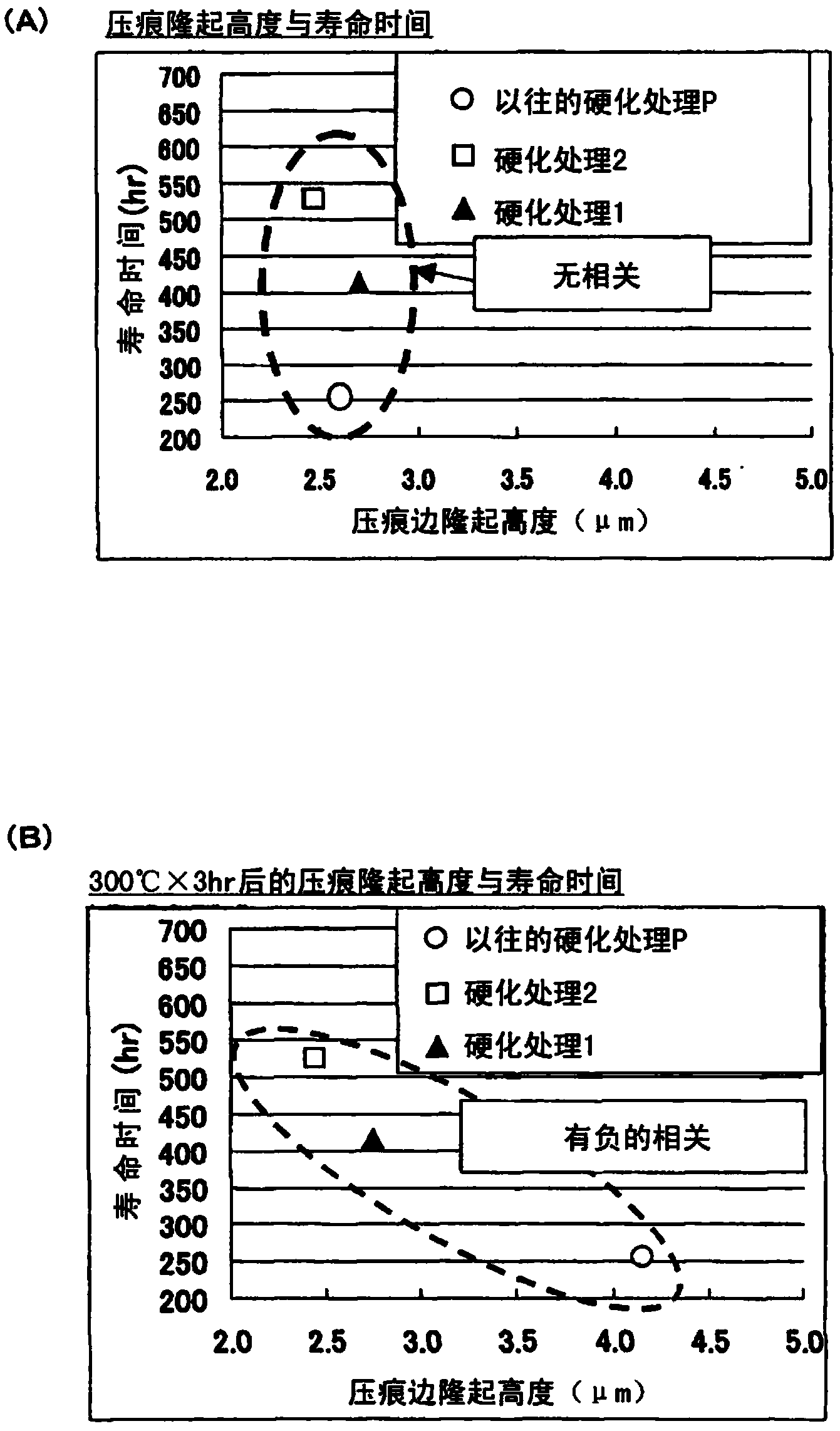

Eccentrically oscillating reduction gear, and method for manufacturing eccentric body shaft

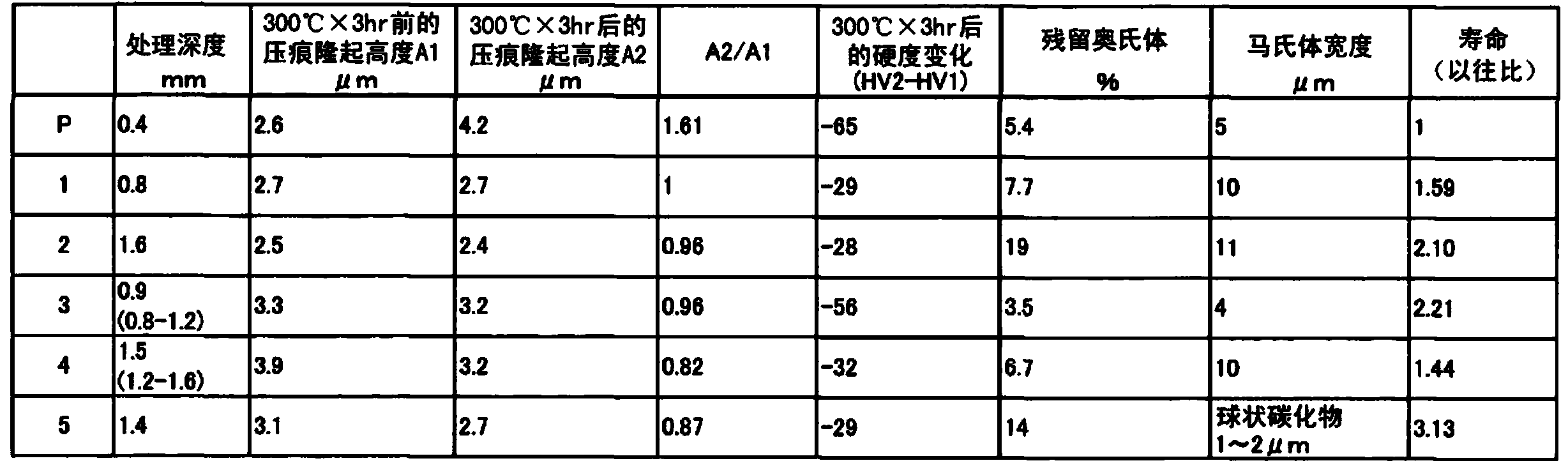

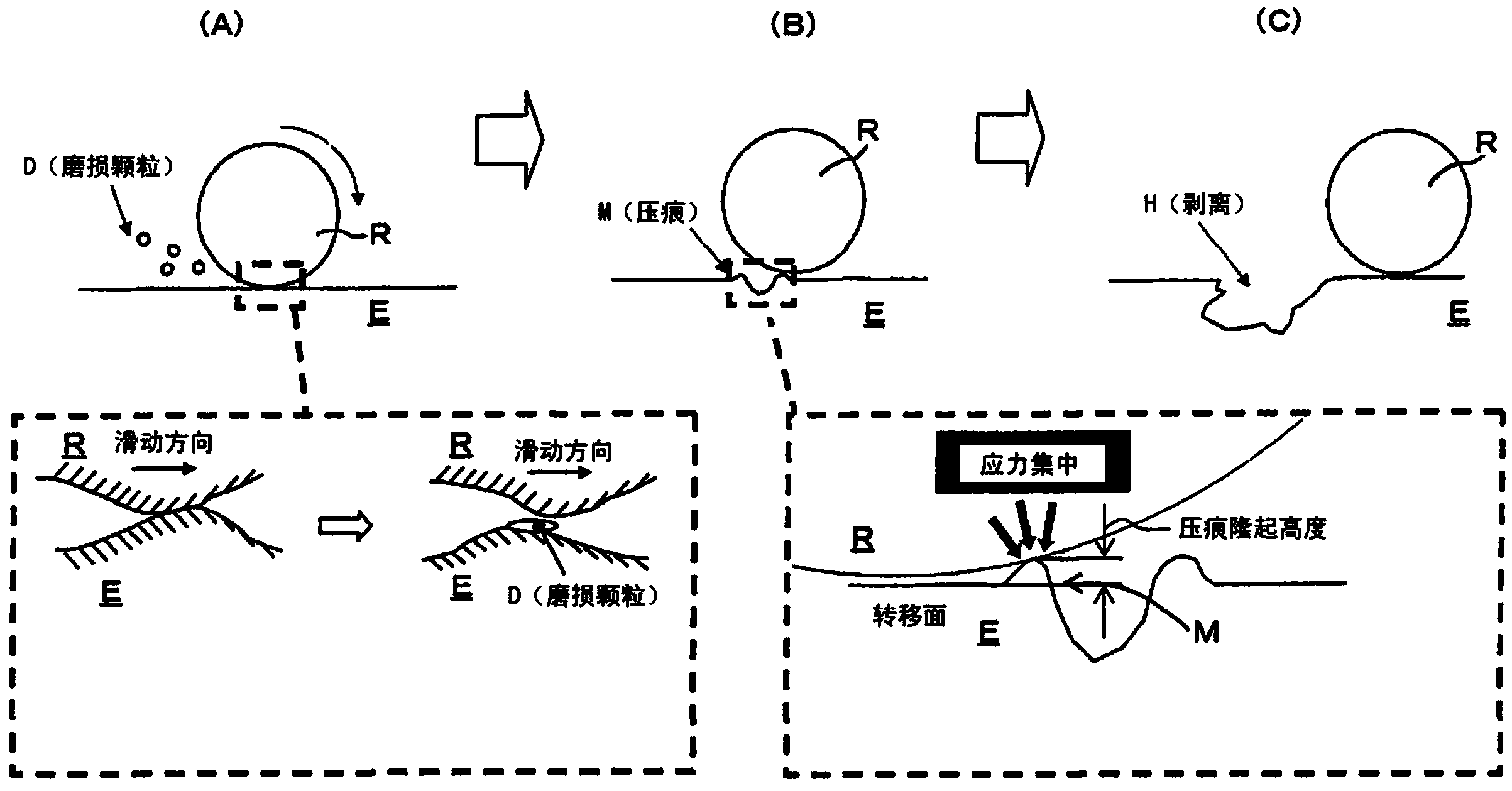

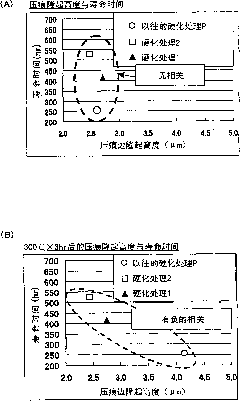

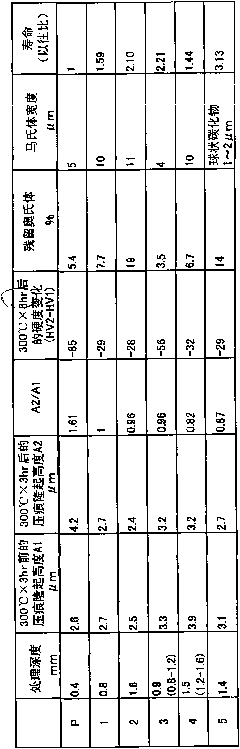

ActiveCN103591120AExtend your lifeIncreased durabilityEccentric-shaftsToothed gearingsEngineeringReducer

The invention provides an eccentric oscillating type speed reducer and a method for manufacturing an eccentric shaft thereof which may greatly prolong the service life of the eccentric shaft of the eccentric oscillating type speed reducer so as to further improve the durability of the speed reducer. In the eccentric oscillating type speed reducer (12) in which outer gears (24A, 24B) are internally engaged with an inner gear (28) while biasing or crookedly oscillating through the eccentric shaft (20), before applying a thermal load causing a change in the material characteristics of the eccentric shaft (20) to the eccentric shaft (20), a projection resulting from an indentation protrusion test has a height (A1); and after applying the thermal load to the eccentric shaft (20), a projection resulting from the indentation protrusion test has a height (A2); and hardening treatment having such a characteristic that the ratio of A2 to A1 is less than 1.0 is performed on the eccentric shaft.

Owner:SUMITOMO HEAVY IND LTD

Eccentric oscillating type speed reducer and method for manufacturing eccentric shaft thereof

ActiveCN102192275AIncreased durabilityImprove qualitative propertiesEccentric-shaftsToothed gearingsReducerEngineering

The invention provides an eccentric oscillating type speed reducer and a method for manufacturing an eccentric shaft thereof which may greatly prolong the service life of the eccentric shaft of the eccentric oscillating type speed reducer so as to further improve the durability of the speed reducer. In the eccentric oscillating type speed reducer (12) in which outer gears (24A, 24B) are internally engaged with an inner gear (28) while biasing or crookedly oscillating through the eccentric shaft (20), before applying a thermal load causing a change in the material characteristics of the eccentric shaft (20) to the eccentric shaft (20), a projection resulting from an indentation protrusion test has a height (A1); and after applying the thermal load to the eccentric shaft (20), a projection resulting from the indentation protrusion test has a height (A2); and hardening treatment having such a characteristic that the ratio of A2 to A1 is less than 1.0 is performed on the eccentric shaft.

Owner:SUMITOMO HEAVY IND LTD

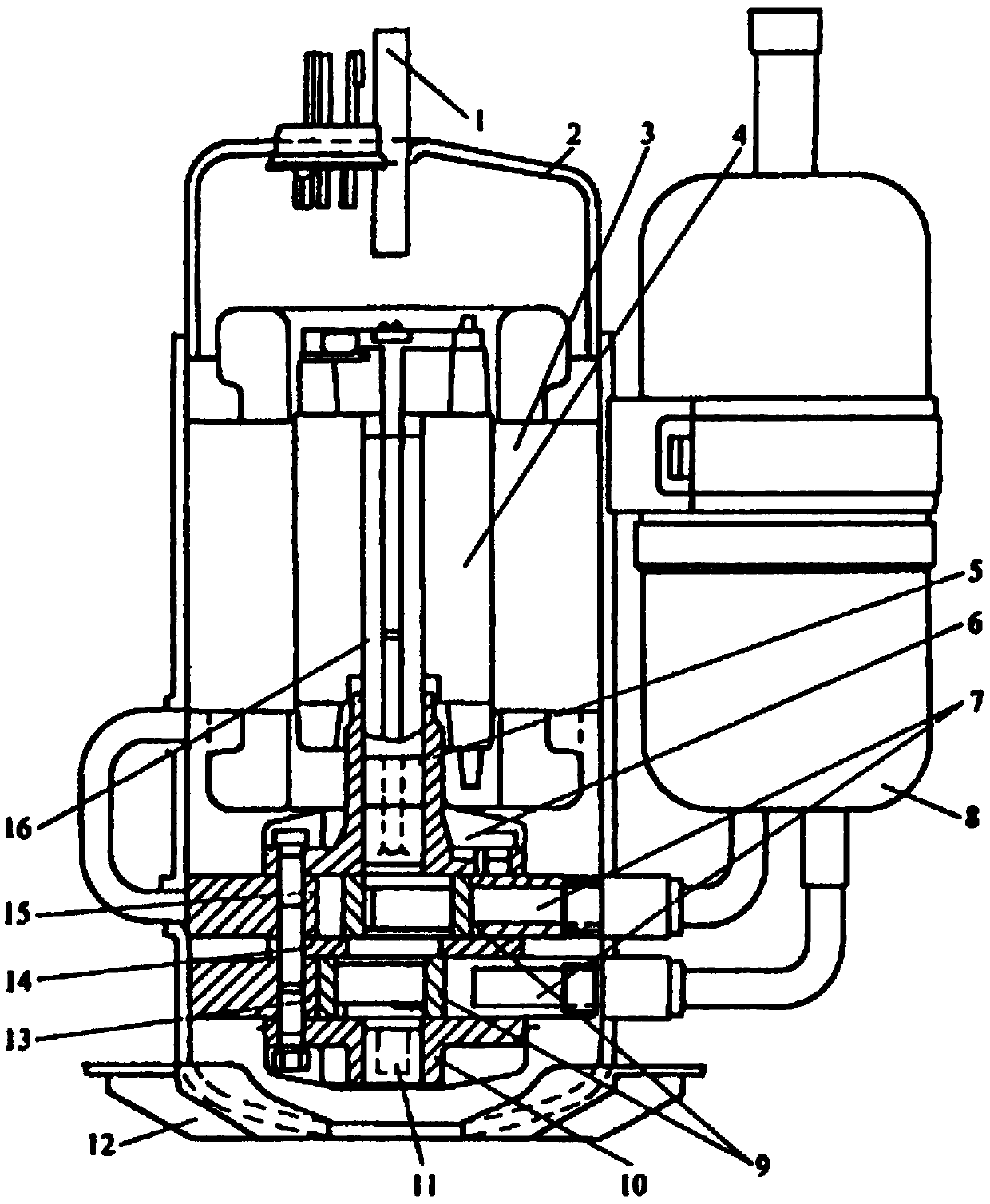

Three-cylindrical rolling rotor type compressor

InactiveCN103807174ALarge displacementLoad torque balanceCrankshaftsEccentric-shaftsLoad torqueEngineering

The invention discloses a three-cylindrical rolling rotor type compressor. The three-cylindrical rolling rotor type compressor comprises a liquid storage device, a sealed container, an electromotor, and an air cylinder component; a stator of the electromotor is fixed in the sealed container; a rotor of the electromotor is connected to an eccentric shaft for driving the air cylinder component comprising three air cylinder units; angles of slide sheets of two adjacent air cylinders are staggered with 120 degrees, and a slide sheet of a third air cylinder and each of the slide sheets of the other two air cylinders are staggered with 60 degrees; two adjacent eccentric shafts on an integrated processed crankshaft has the complete same eccentric directions, and a third eccentric shaft and each of the other two eccentric shafts are staggered with 180 degrees; the centric shaft which is staggered with 180 degrees individually is provided with a torque balance mechanism; two air cylinders the slide sheets of which are staggered with 120 degrees and the two eccentric shafts with the completely same eccentric directions are installed at the same side; the eccentric shaft which is staggered with 180 degrees and the third air cylinder are assembled at the other side. By adopting the three-cylindrical roller rotor compressor provided by the invention, the displacement and the power of the rolling rotor type compressor are increased, the vibration of load torque is reduced, and the vibration and the noise are reduced.

Owner:吴月广

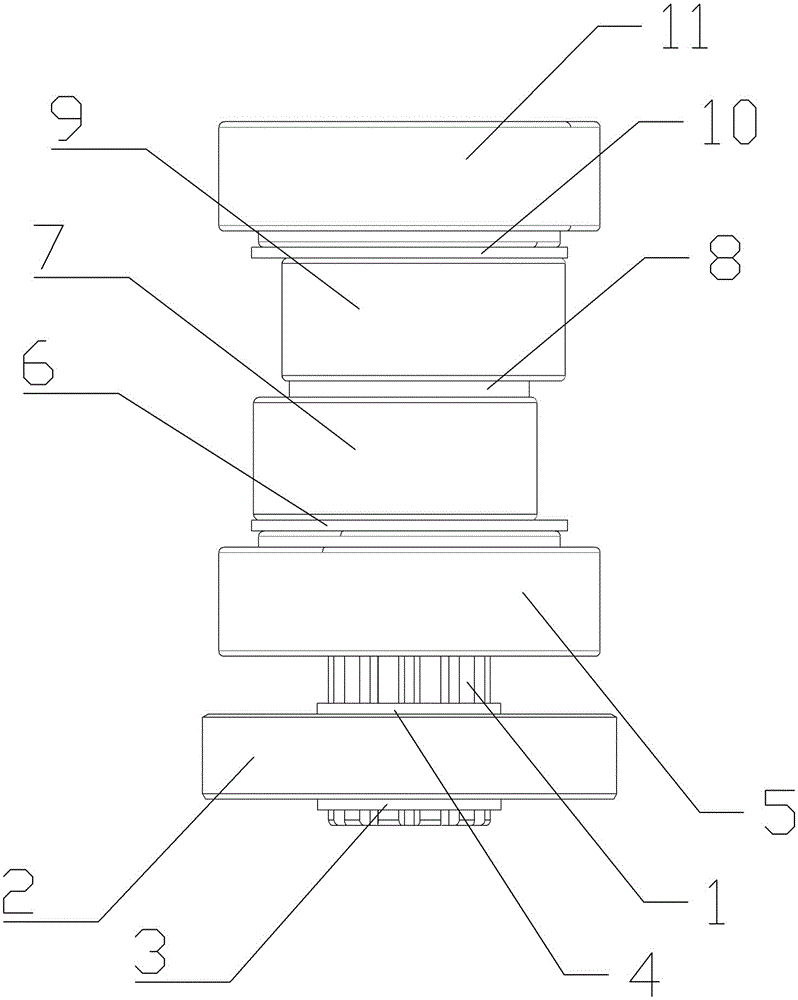

RV precise speed reducer eccentric shaft and precise speed reducer

ActiveCN108799316AIncrease load capacityImprove impact resistanceEccentric-shaftsToothed gearingsBall bearingAgricultural engineering

The invention provides a RV precise speed reducer eccentric shaft and a precise speed reducer. An annular reinforcement block is arranged in a sunken groove between two adjacent cams of the eccentricshaft; the precise speed reducer comprises a pin wheel housing, the eccentric shaft, a planet wheel, an input shaft, an output plate rack, an angular contact ball bearing and a cycloidal wheel; the planet wheel is arranged at one end of the eccentric shaft; the input shaft is located in the center of the pin wheel housing; one end of the input shaft is connected with a motor; a center gear is arranged at the other end of the input shaft; the center gear and the planet wheel are in mesh connection on the same rotation plane so as to form a first-stage planet speed reduction mechanism; and the angular contact ball bearing is arranged between the pin wheel housing and the output plate rack. According to the RV precise speed reducer provided by the invention, through increasing the diameter ofa cam connecting part, the impact resistance of the RV precise speed reducer eccentric shaft is greatly improved, the fatigue life of the RV precise speed reducer eccentric shaft is greatly prolonged, and the carrying capacity, the impact resistance, the service life and the running precision of the RV speed reducer are further improved.

Owner:NANTONG ZHENKANG WELDING ELECTROMACHINERY +1

Bearing system and balancer

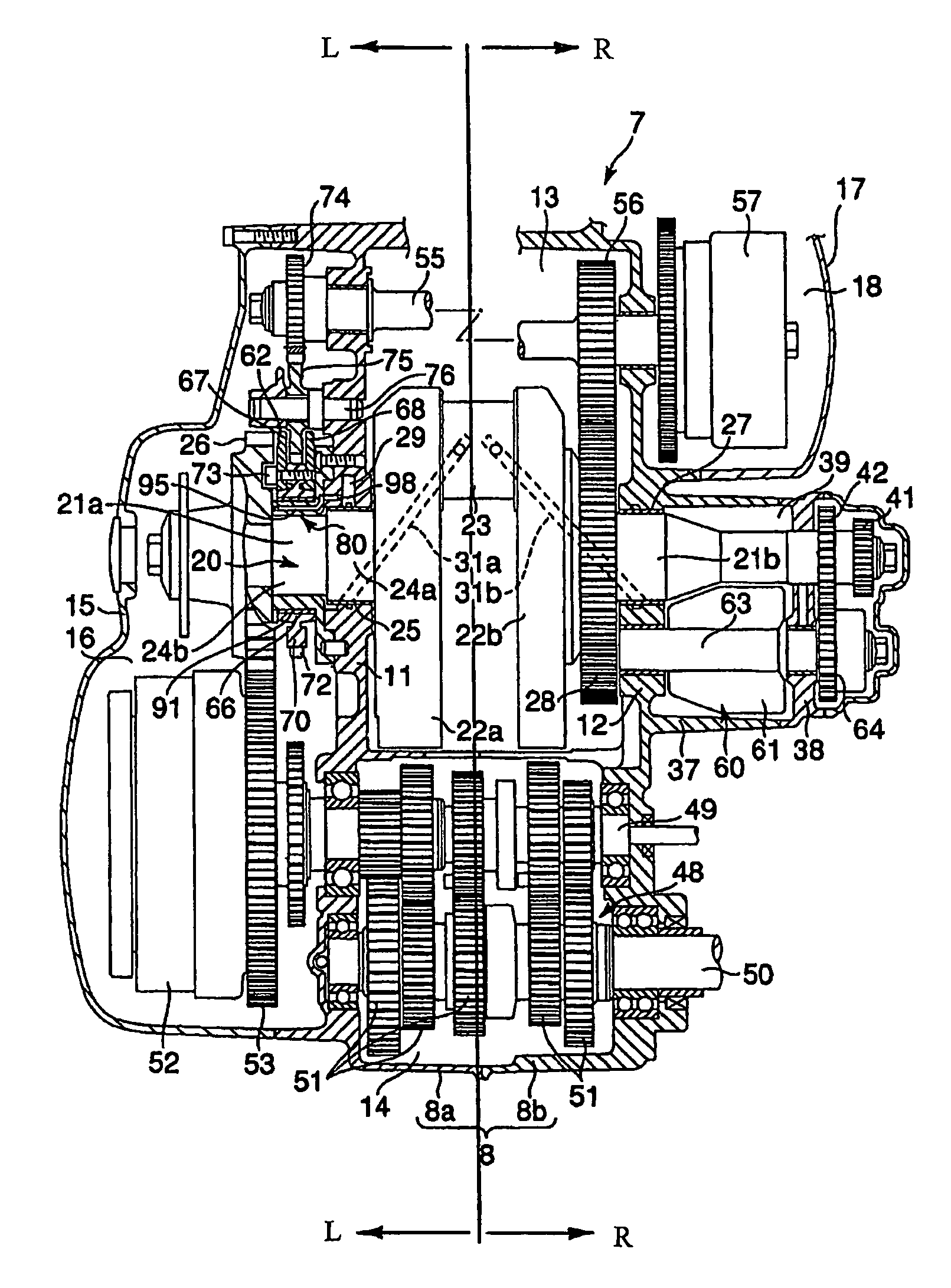

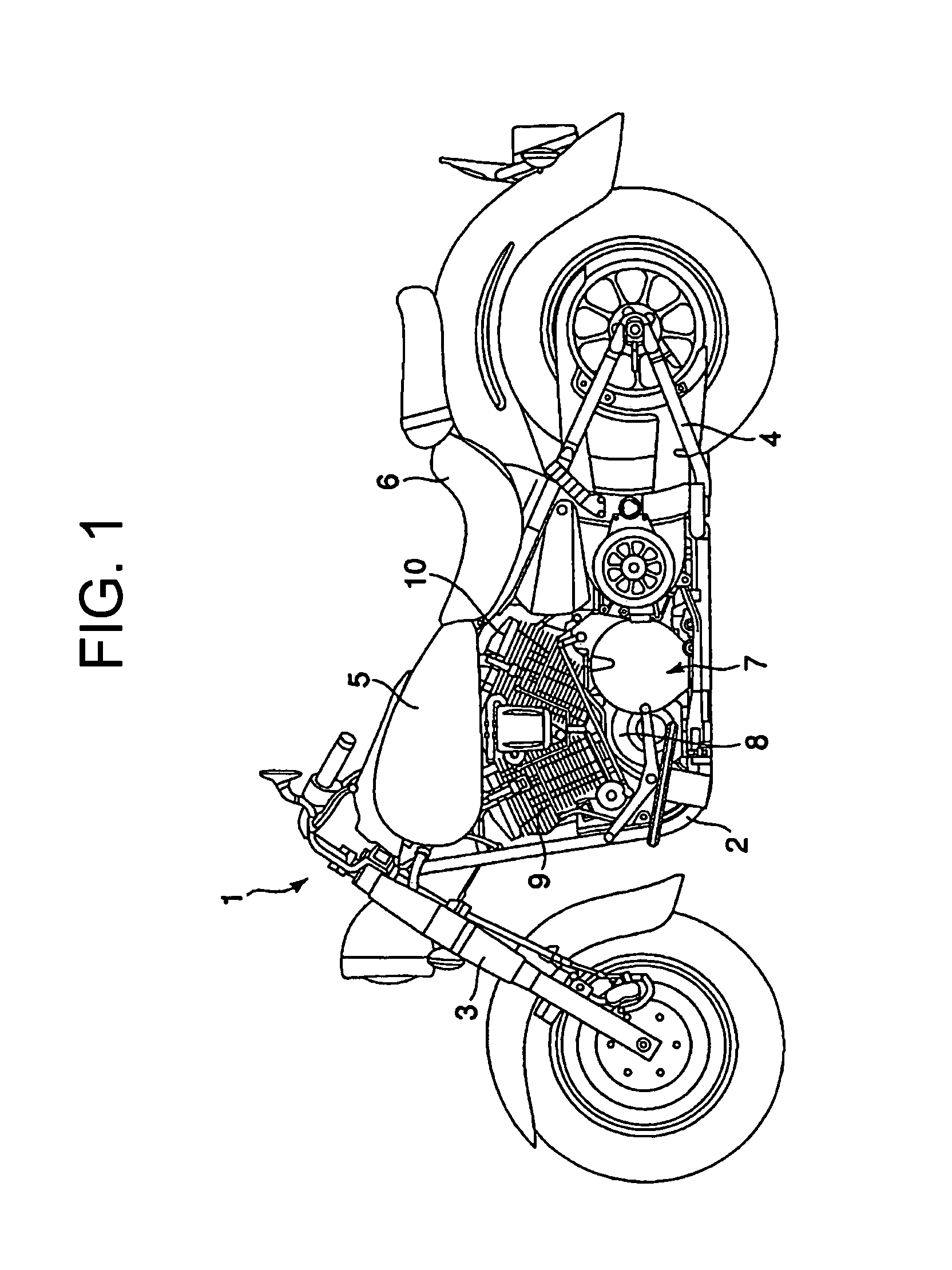

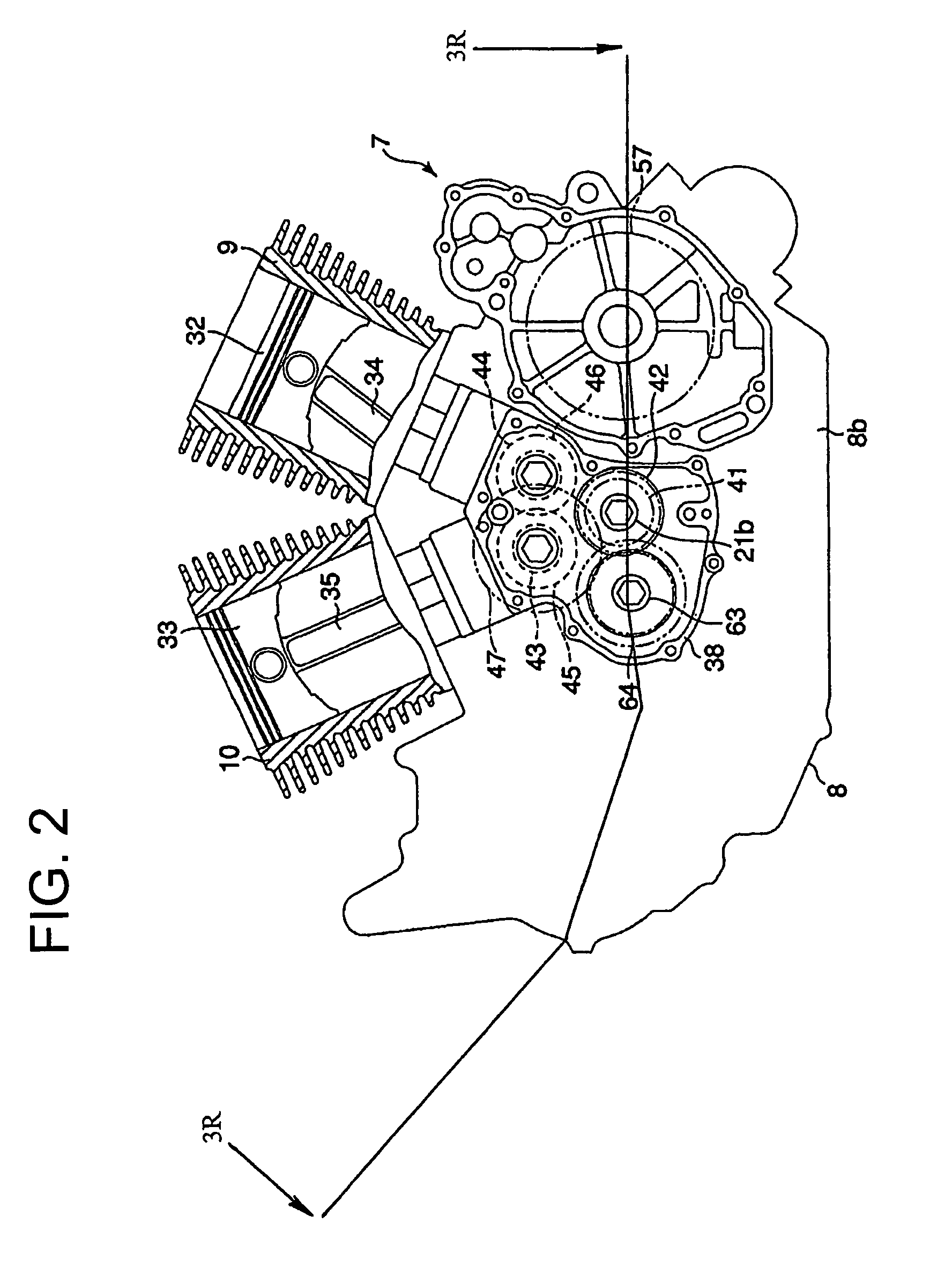

ActiveUS7748292B2Reduce loadShorten speedCrankshaftsValve arrangementsEngineeringMechanical engineering

A bearing system can reduce the relative velocity between a bearing member and a rotation shaft and a rotating member to decrease a load on the bearing member although the rotation shaft and the rotating member rotate in opposite directions with the bearing member therebetween. The bearing system includes a case and a rotation shaft supported by the case. A rotating member is disposed coaxially outside the rotation shaft and rotates in the direction opposite to that of the rotation shaft. A housing is interposed between the rotation shaft and the rotating member and is fixed to the case. A bearing member that rotatably supports the rotating member is interposed between the housing and the rotating member.

Owner:YAMAHA MOTOR CO LTD

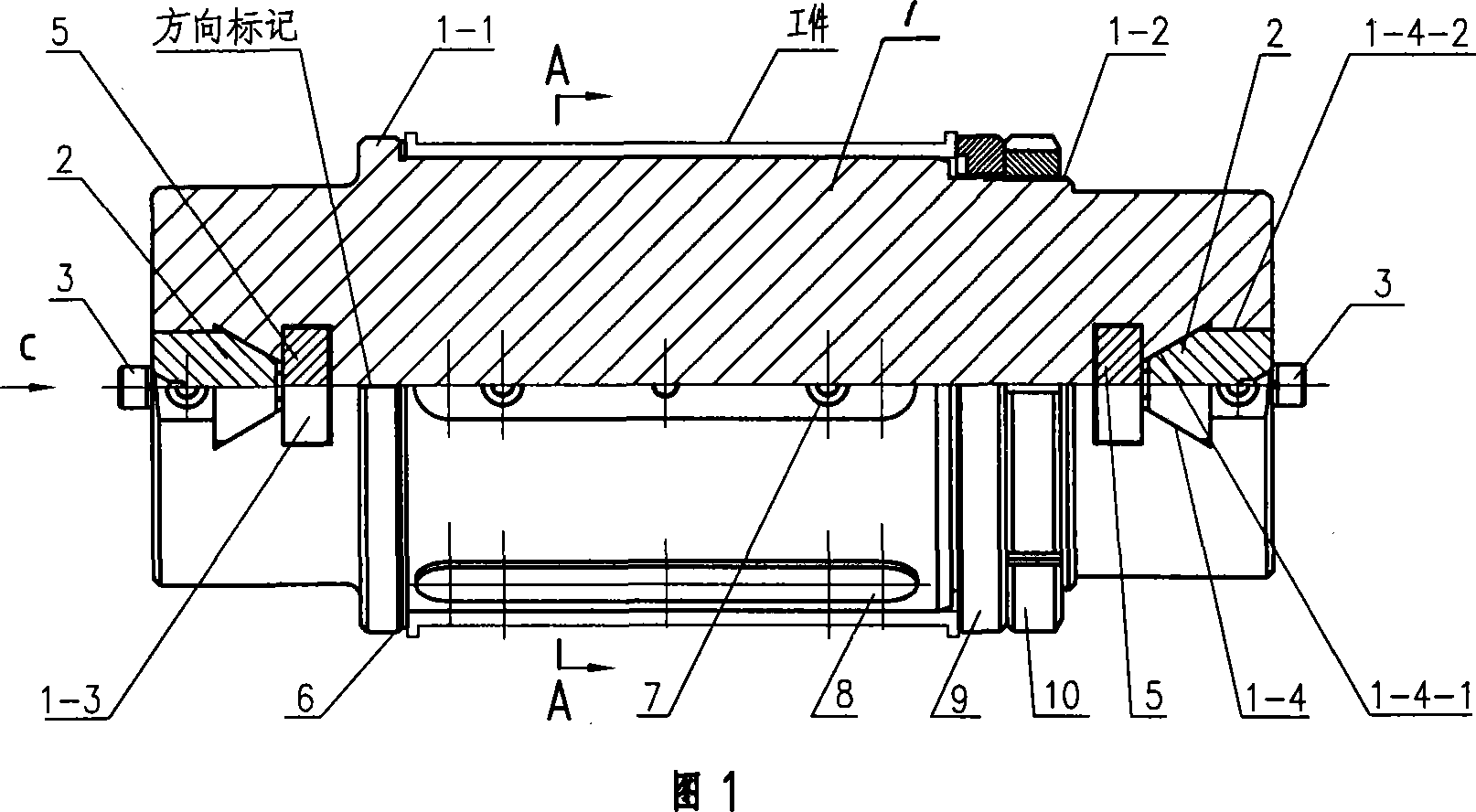

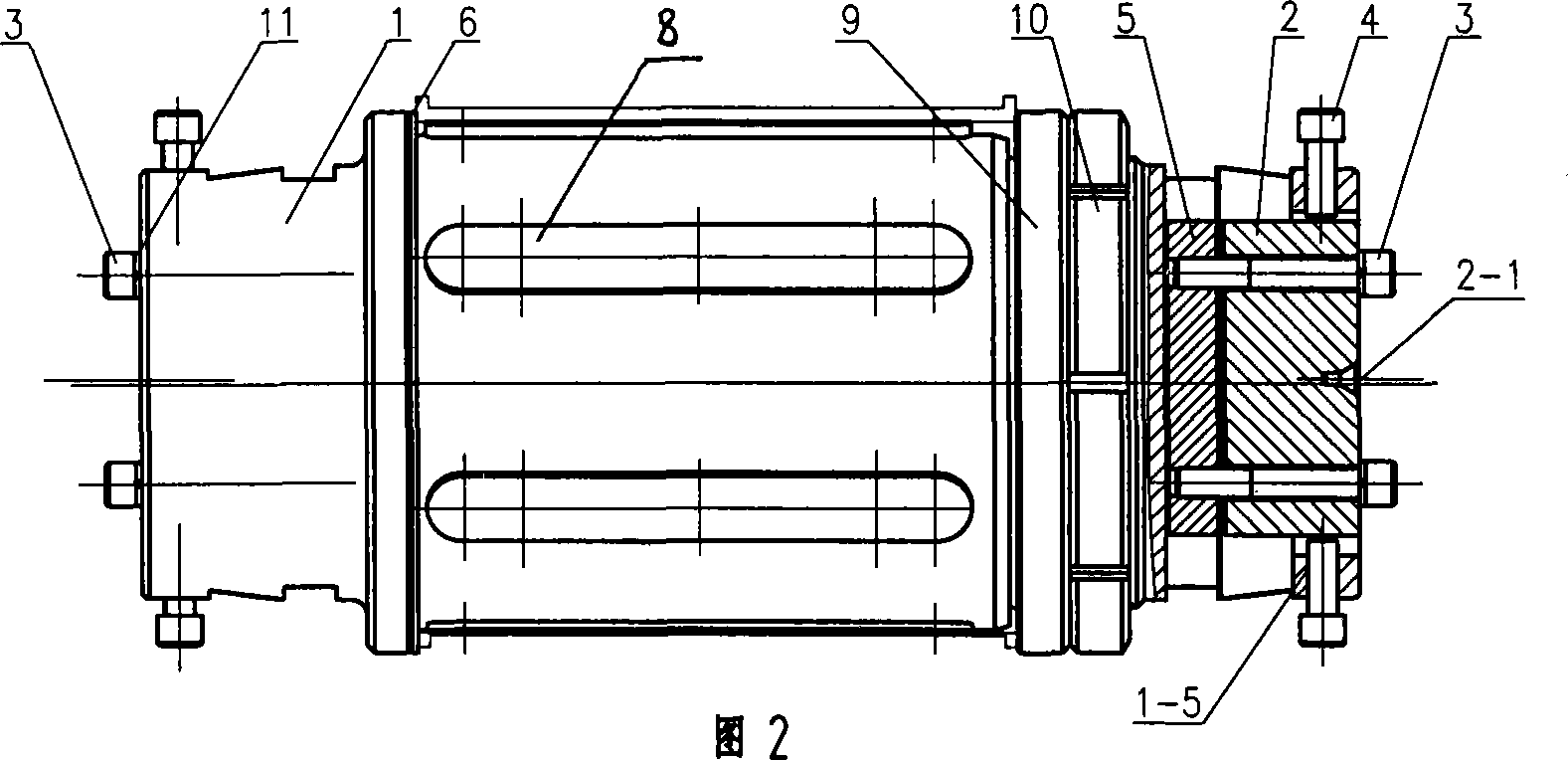

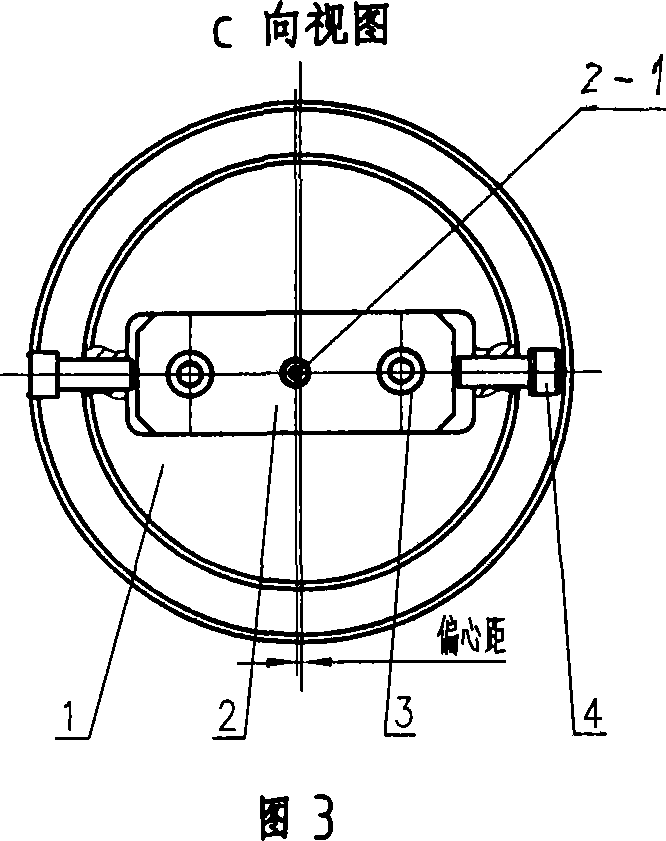

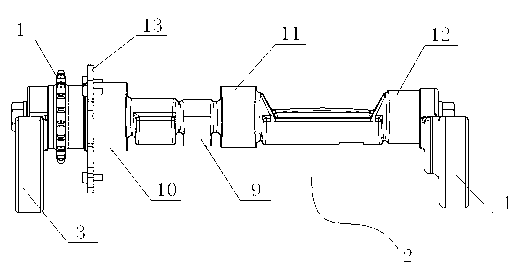

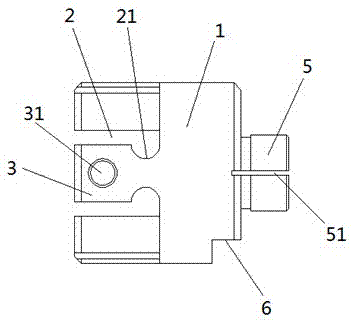

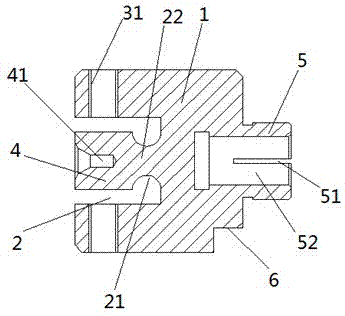

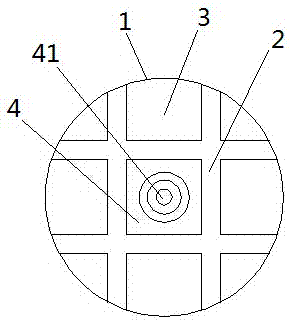

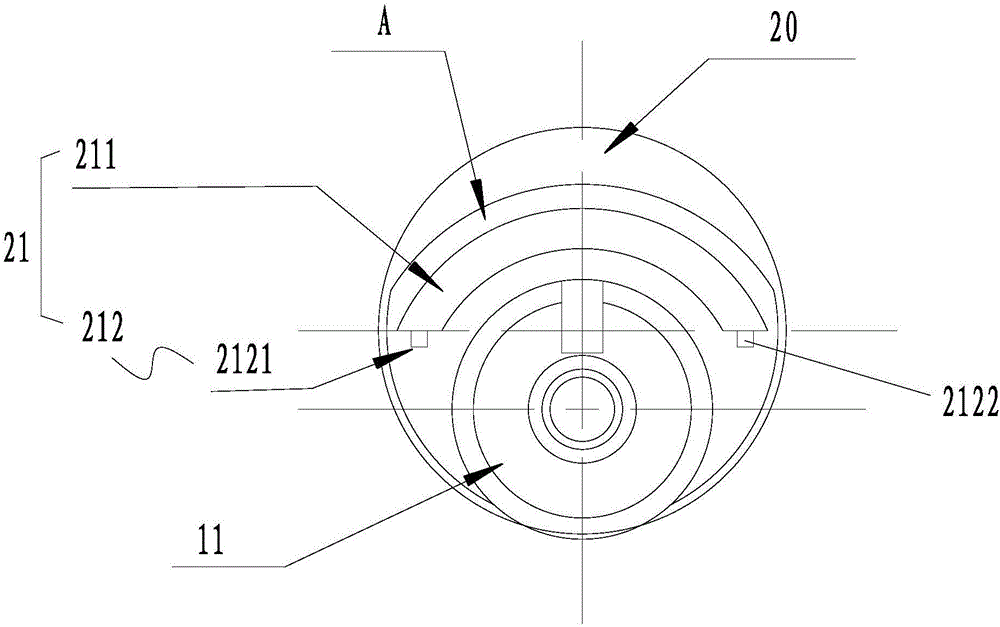

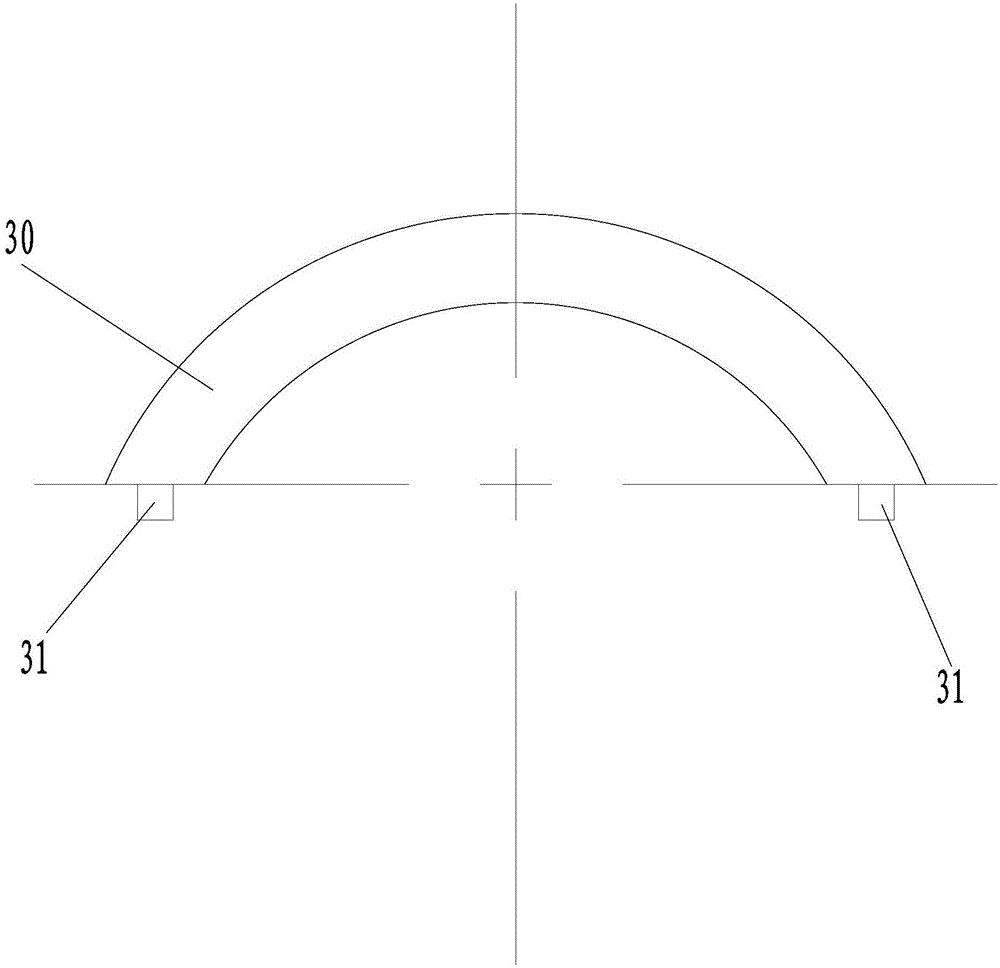

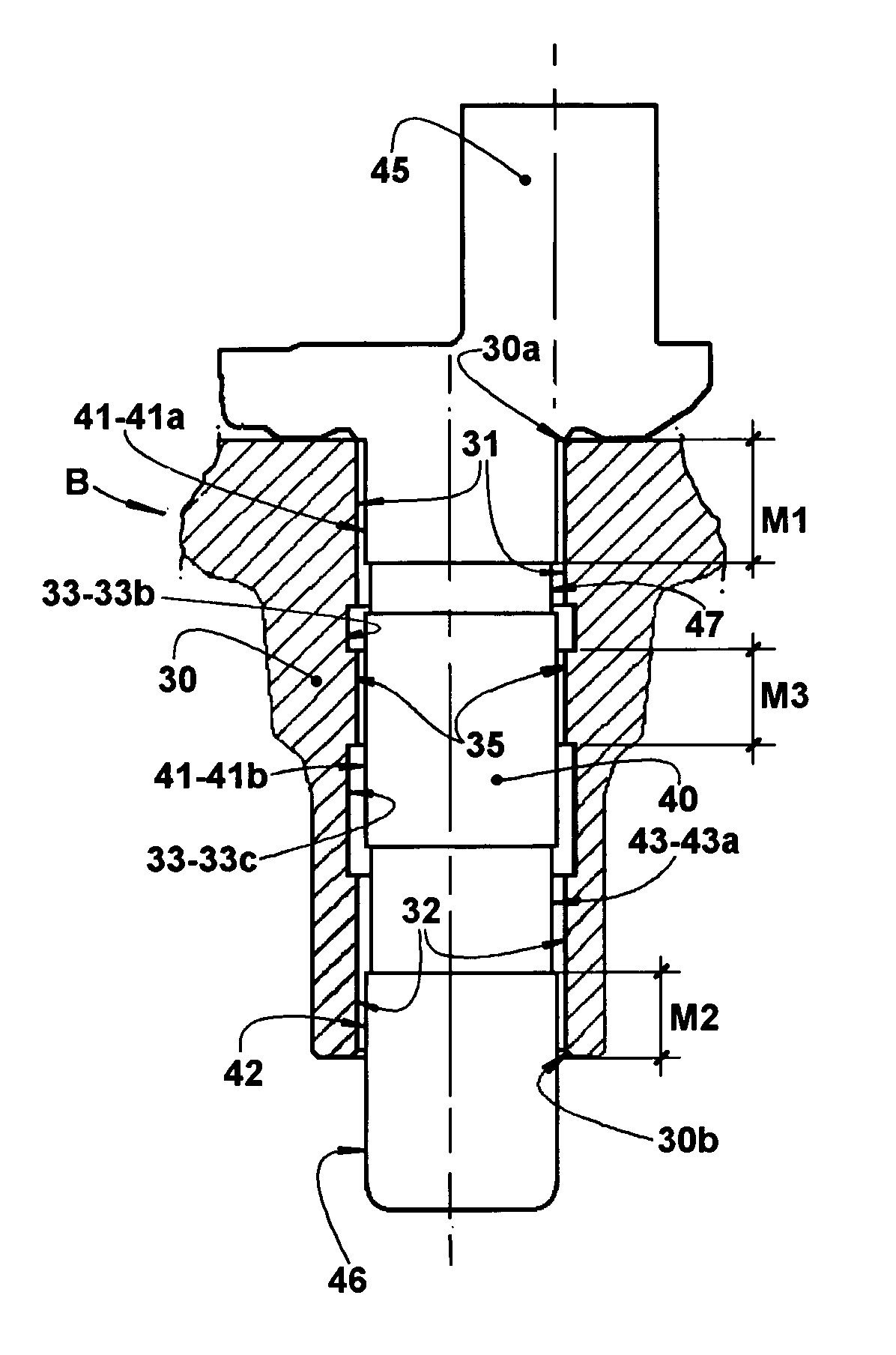

An eccentric fixture and a method for producing eccentric shafts by using the eccentric fixture

ActiveCN106891173ASimple structureEasy to manufactureEccentric-shaftsWork clamping meansChinese charactersSteel ball

The invention provides an eccentric fixture comprising a fixture body and a clamping ring. The fixture body is cylindrical in shape, and the left end thereof is provided with a center hole and a steel ball; the left end face of the fixture body is provided with a groove in the shape of Chinese character jing; the groove in the shape of Chinese character jing divides the left end face of the fixture body into a central block and four eccentricity adjusting top blocks, wherein the central block is located at the center of the left end face of the fixture body and the four eccentricity adjusting top blocks are provided with screw holes in the radial direction of the fixture body; eccentricity adjusting screws are screwed into the screw holes; a circular arc groove facing the eccentric blocks is arranged at the bottom of the groove in the shape of Chinese character jing; the right end face of the fixture body is provided with a journal bush in the shape of a round tube; the inner circle hole of the journal bush is coaxial with the fixture body; the journal bush is provided with a clamping groove; the clamping ring is arranged on the outer circle wall of the journal bush in a sleeving manner. The eccentric fixture has the advantages of simple structure, convenient manufacture and use, small error in eccentric distance of parts, great uniformity, high precision and high production efficiency, and is suitable for machining parts with small eccentric distances.

Owner:上海上机精密量仪有限公司

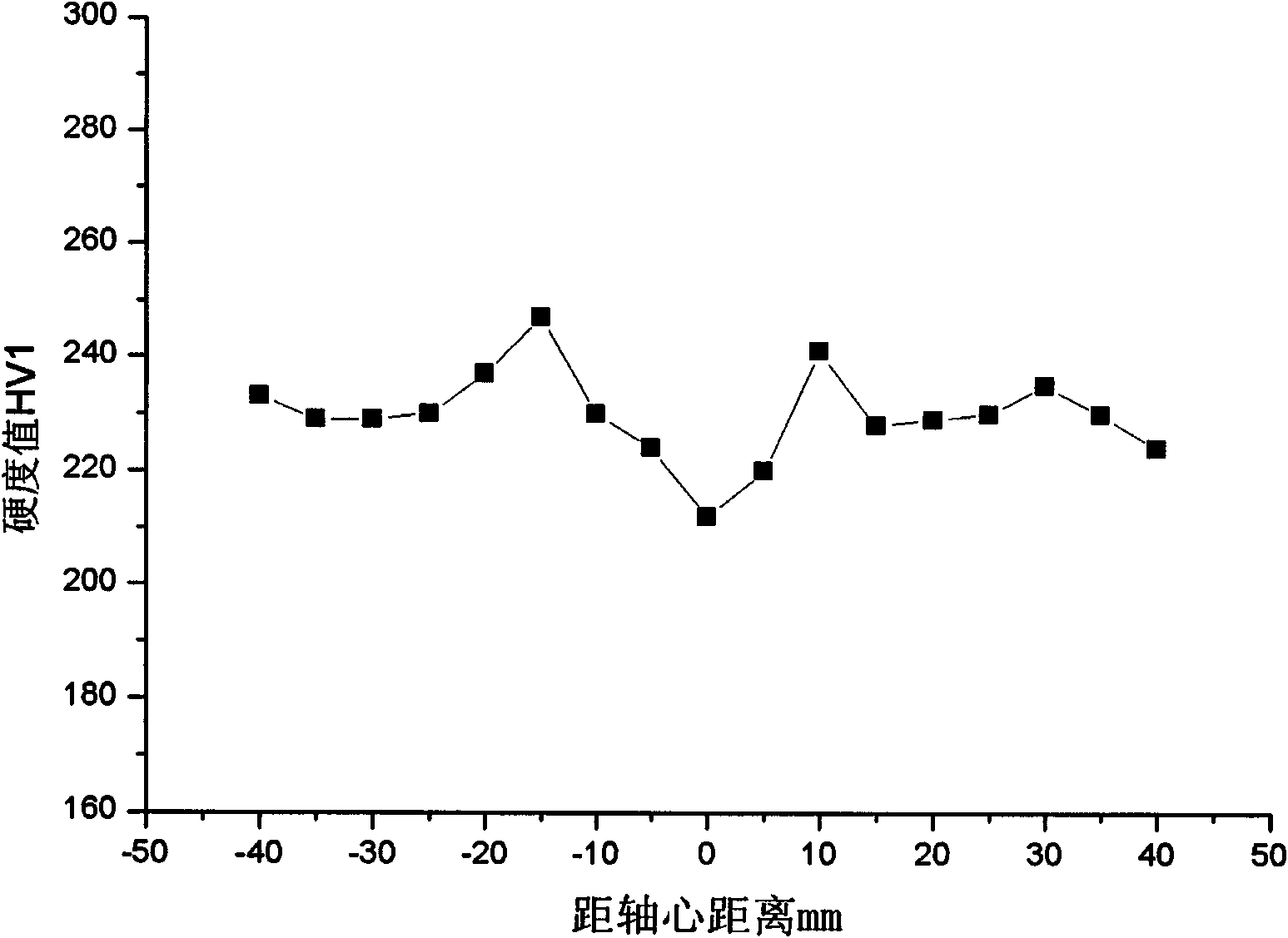

Eccentric shaft and manufacturing method thereof

InactiveCN101598172AImprove performanceSmall section size effectEccentric-shaftsFurnace typesTemperature controlThermal treatment

The invention discloses an eccentric shaft and a manufacturing method thereof. The eccentric shaft is made from non-quenched and tempered steel with ferrite-pearlite structure, in particular 38MnVS6 non-quenched and tempered steel. The manufacturing method thereof includes: heating, the heating temperature ranges from 1150 to 1200 DEG C; forging, one-time forging is used in a forging process, both ends of the eccentric shaft are forged at the multi-step low final forging temperature, and the final forging temperature is controlled to range from 800 to 850 DEG C; and cooling, a forged workpiece is suspended to be air-cooled. The non-quenched steel eccentric shaft manufactured by the invention dispenses with the quenching and heating processing working procedure, thereby generating obvious positive effects, namely that the production period is shortened, the phenomena of product deformation and cracking are reduced, the rate of finished products is increased, and energy consumption and environmental pollution are reduced. Compared with the process, the eccentric shaft manufactured by the non-quenched and tempered steel can save 39 percent of electrical energyaccording to the calculation.

Owner:上海市机械制造工艺研究所有限公司

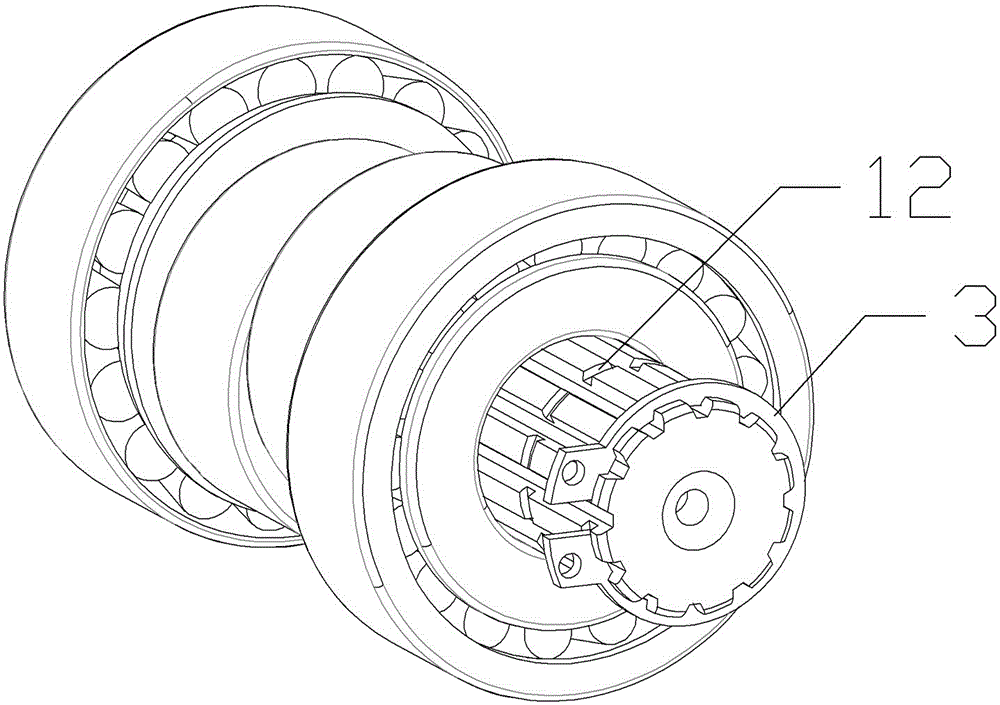

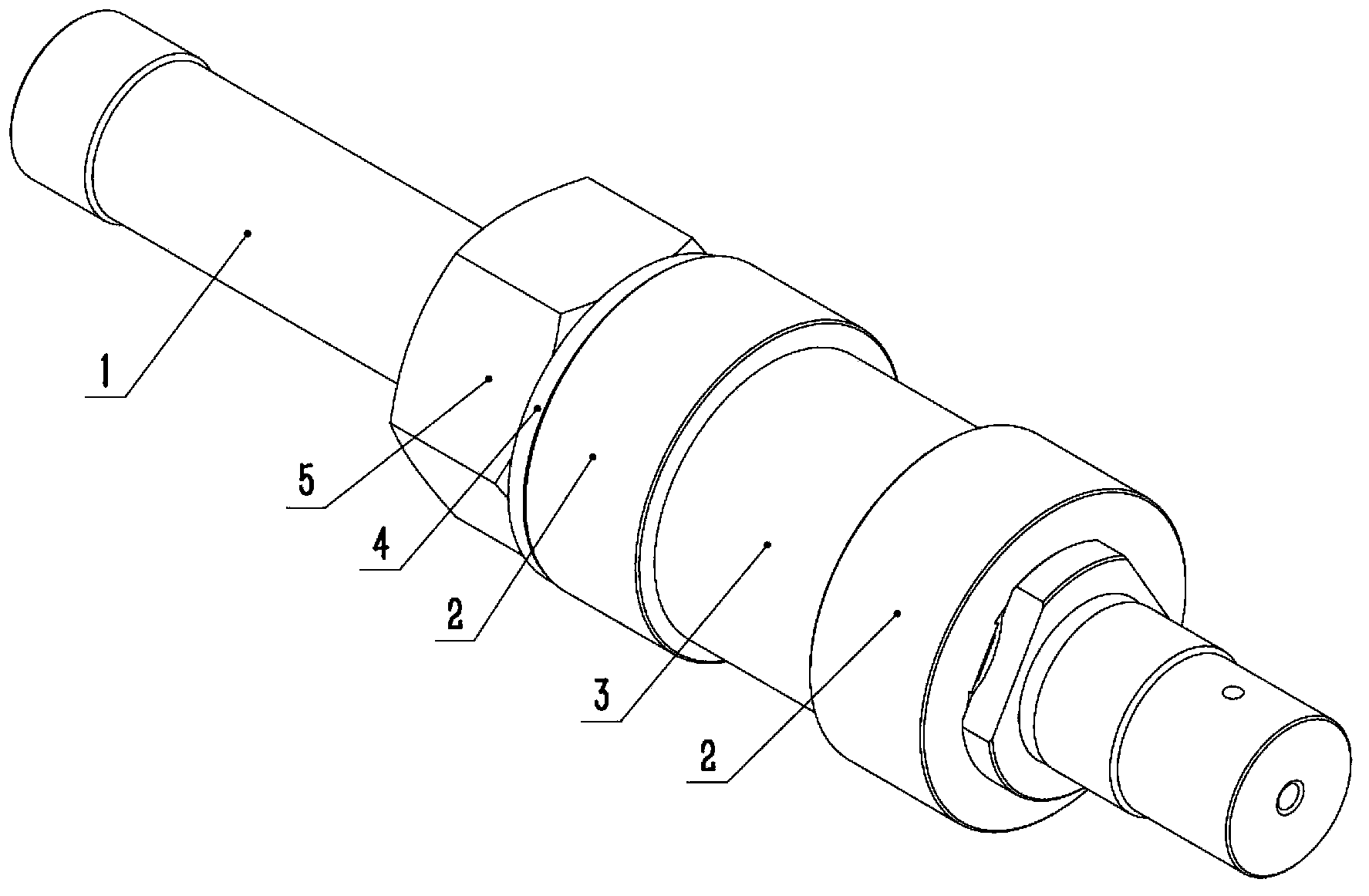

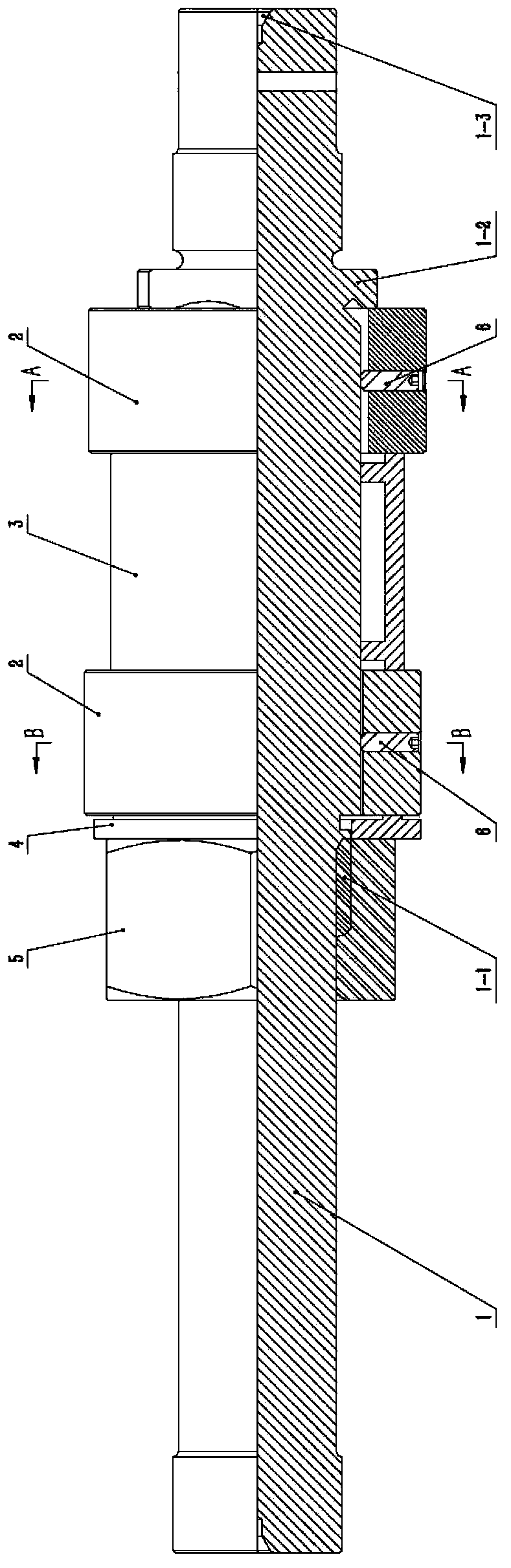

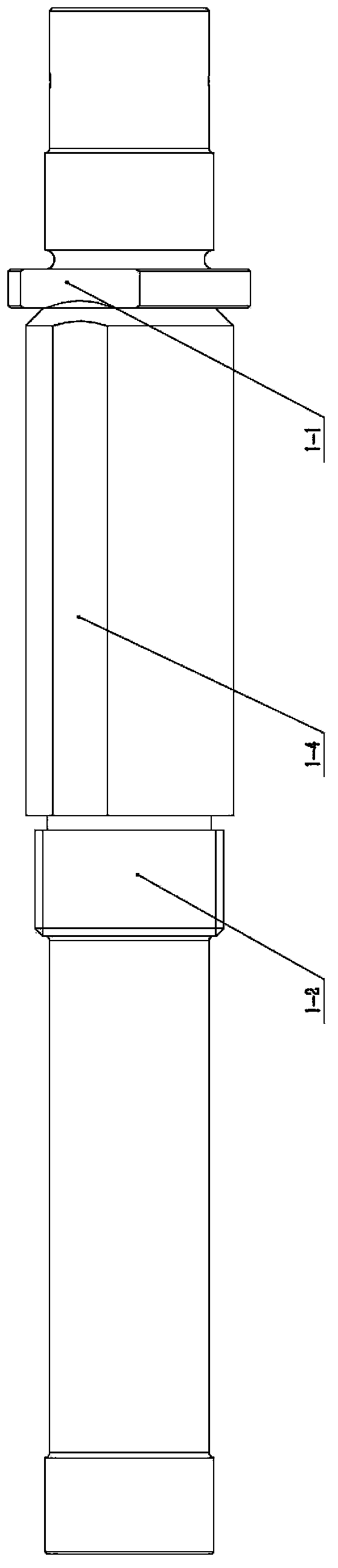

Eccentric shaft assembly for recreational vehicle (RV) reducer

InactiveCN105020256AEasy to disassemble and repairEnsure consistencyEccentric-shaftsPortable liftingReducerEngineering

The invention discloses an eccentric shaft assembly for a recreational vehicle (RV) reducer. The eccentric shaft assembly is easy to machine and convenient to replace and comprises a main shaft. An outer spline is arranged on the periphery of the main shaft which is connected with a first eccentric wheel and a second eccentric wheel through splines. An eccentric wheel gasket is arranged between the first eccentric wheel and the second eccentric wheel. One end face of the eccentric wheel gasket abuts against the first eccentric wheel. The other end face of the eccentric wheel gasket abuts against the second eccentric wheel. The main shaft is further provided with a first annular groove and a second annular groove. A first clamp spring is arranged in the first annular groove and abuts against the end face of the first eccentric wheel. A second clamp spring is arranged in the second annular groove and abuts against the end face of the second eccentric wheel. The main shaft is sleeved with a first bearing and a second bearing. One end face of the first bearing abuts against the first clamp spring, and one end face of the second bearing abuts against the second clamp spring.

Owner:CHONGQING YANGDI ELECTROMECHANICAL

Eccentric shaft machining method

InactiveCN104625600AGuaranteed Distance DimensionsGuaranteed machining accuracyEccentric-shaftsEngineeringAxial distance

The invention relates to the field of machining, in particular to an eccentric shaft machining method. The eccentric shaft machining method comprises the following steps of conducting feeding, wherein a proper blank material is selected, and certain working allowance is reserved; conducing coarse machining, wherein the left end of a workpiece is clamped, the right end face and the outer circle of the workpiece are turned, 0.5 mm machining allowance is reserved, a center hole is drilled through a standard center drill, the right end of the workpiece is clamped through reversing, the left end face of the workpiece is turned, the overall length of the left end face of the workpiece is measured, and a center hole of the left end face is drilled; conducting semi-finish machining, wherein an eccentric sleeve is clamped to the outer circle of the workpiece. The eccentric sleeve is used as a locating element, the outer circles of all sections of an eccentric shaft are machined, the axial distances of the outer circles of the sections of the eccentric shaft are easy to guarantee, and accurate and reliable locating reference is provided for machining of the center holes. During grinding, the part is installed in the mode that one center hole is used for clamping and the other center hole is used for ejecting, the machining precision of the part can be conveniently guaranteed, a turning clamp which is complexly designed is omitted, the production cycle is shortened, and the productivity is increased.

Owner:施剑秋

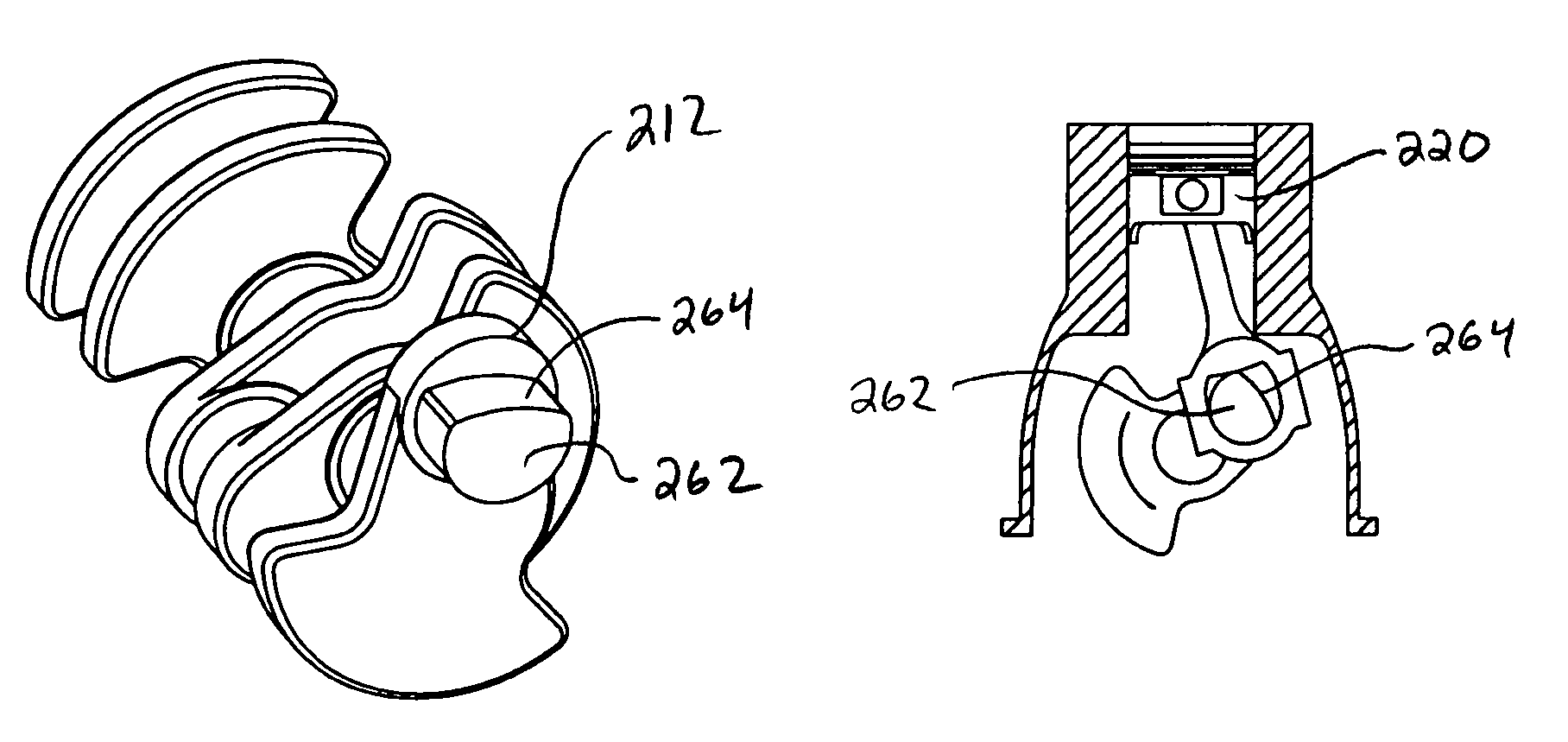

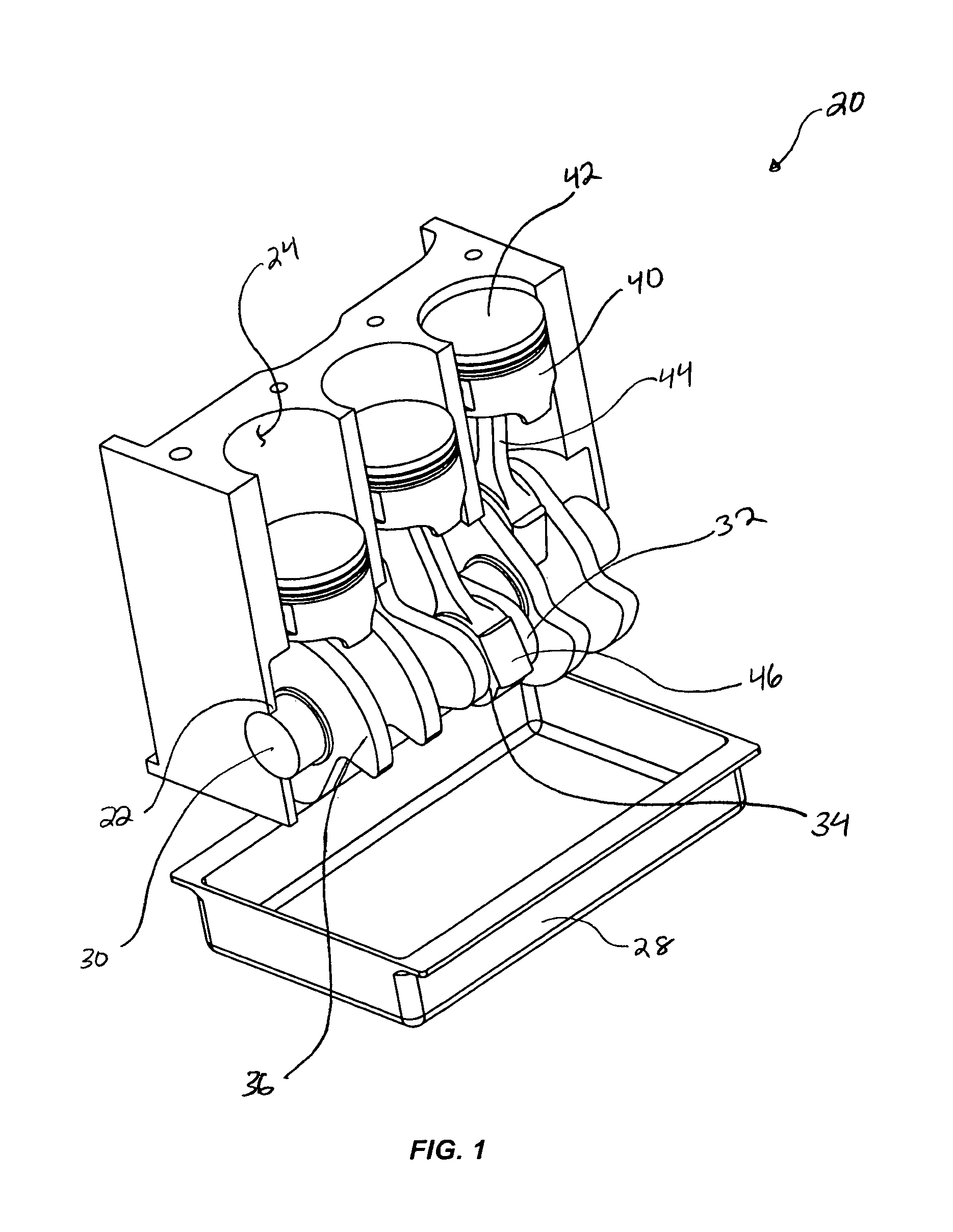

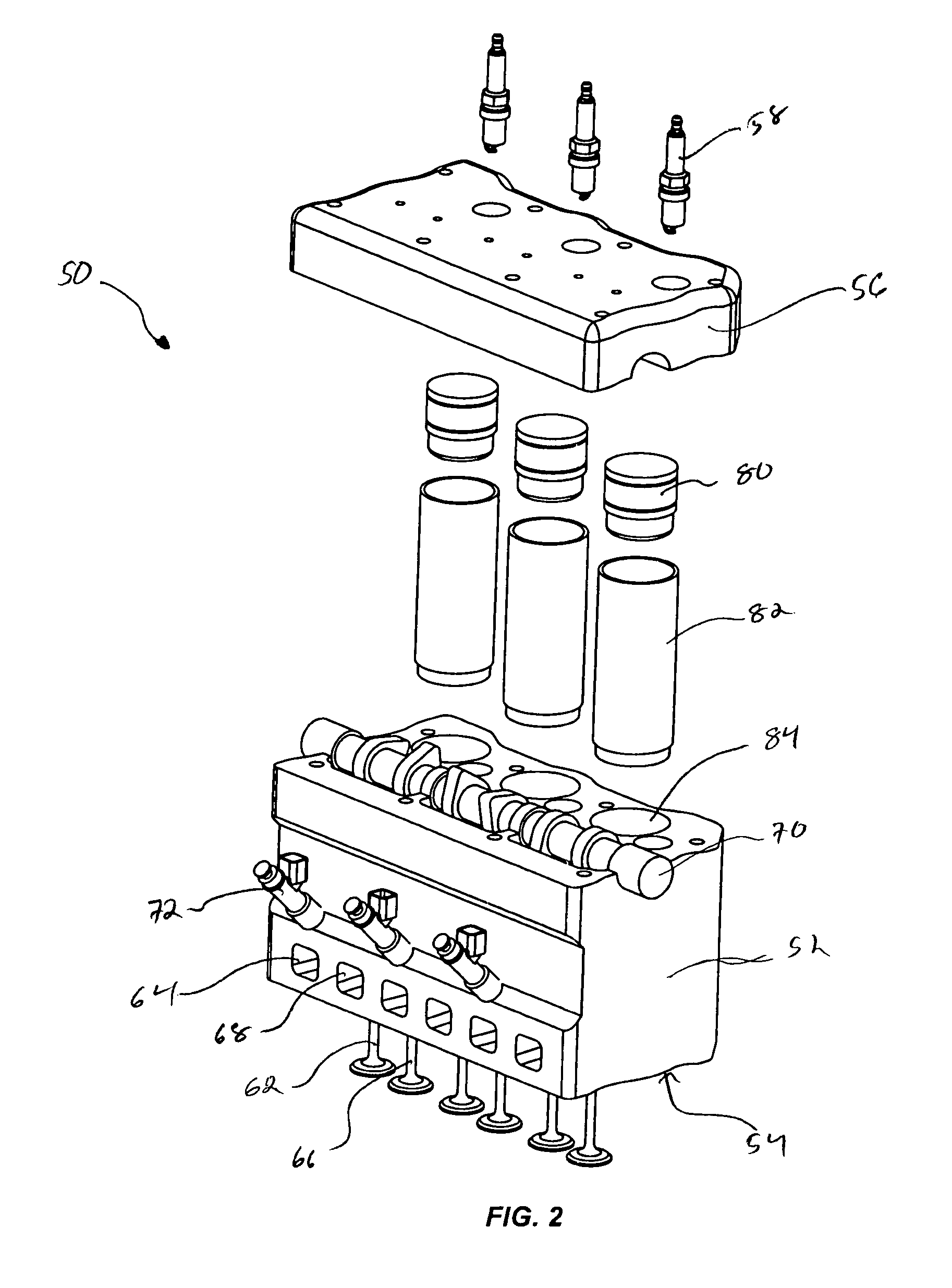

Power linkage assembly for a high efficiency internal explosion engine

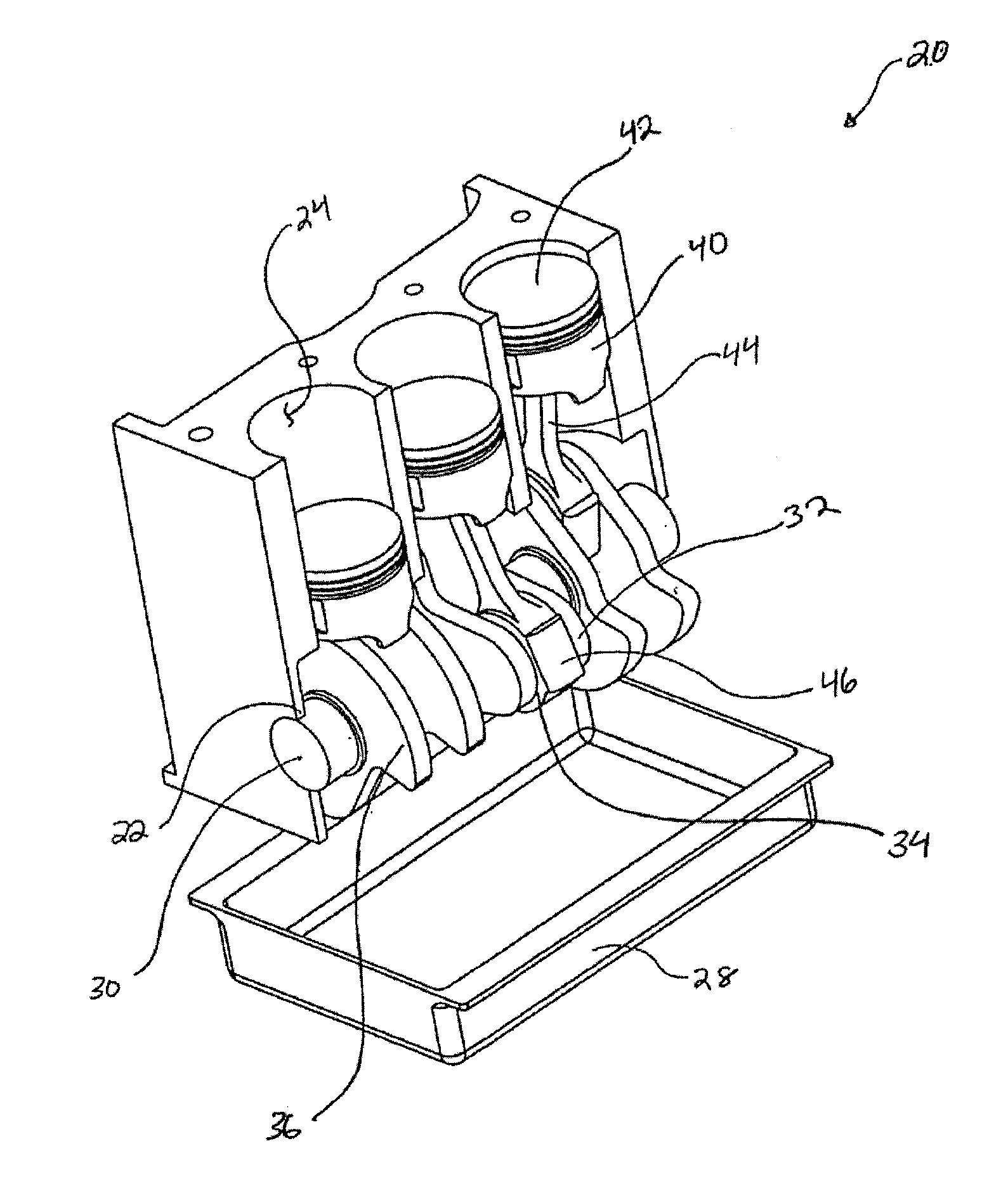

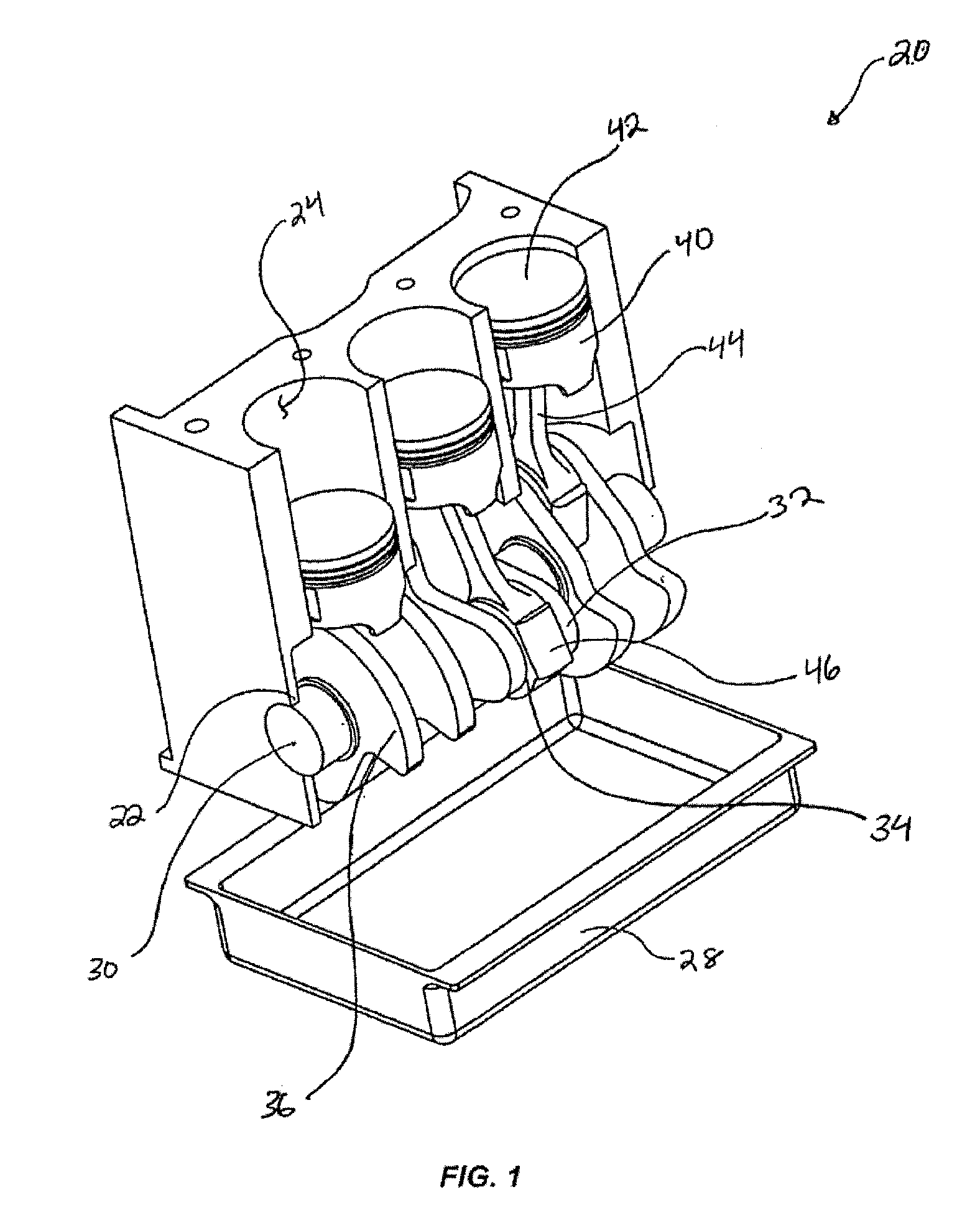

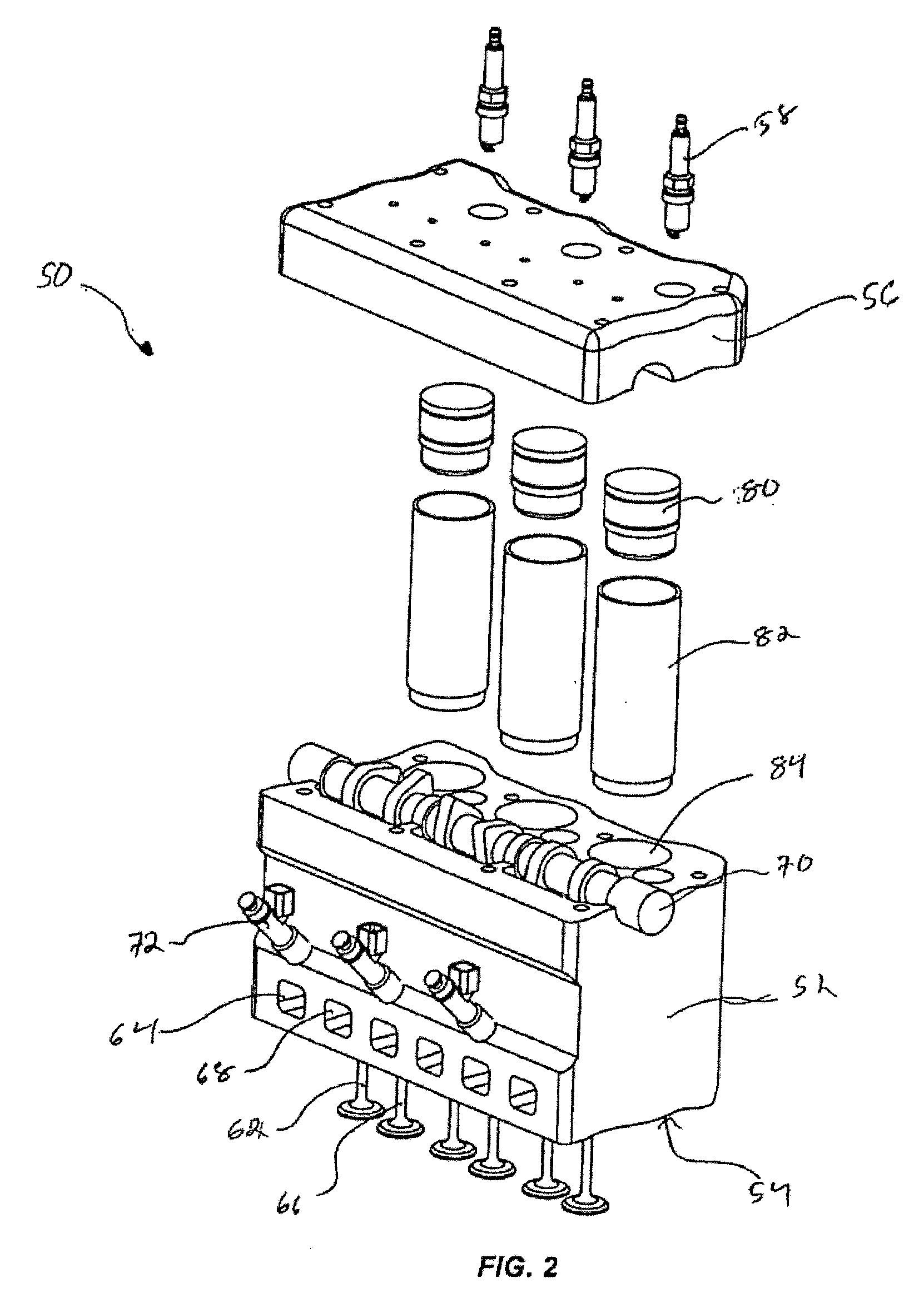

A four-stroke, piston-powered internal explosion (“IE”) engine for providing power output through a rotating crankshaft. The IE engine includes an engine block having power cylinders formed therein for receiving working pistons, bearing means for supporting the crankshaft, and a crankshaft supported within the bearing means having an output end extending outside of the engine block and a plurality of offset power cranks. The IE engine further includes connecting rods operably coupled to the power cranks and configured to transfer power from the working pistons to rotate the crankshaft, and working pistons that are received into the power cylinders and operably coupled to the power cranks. Each working piston has a head end positioned adjacent to a cylinder head to form a compression chamber and is configured to receive power from an explosion of a compressed volume of air / fuel mixture located within the compression chamber, and to transfer the received power to the connecting rods. The IE engine is further configured so that the compressed volume of air / fuel mixture is substantially constant, and a peak compression ratio is maintained, from an angular position of the rotating crankshaft of at least 20 degrees prior to a TDC position of a compression stroke, to an angular position of at least 20 degrees after the TDC position of a power stroke, and prior to detonation.

Owner:DF RESERVE LC

Eccentric shaft assembly having fixed and movable eccentric masses

ActiveUS9334621B2Energy consumptionHigh mass-moment of inertiaEccentric-shaftsRoads maintainenceRotational axisSection plane

Owner:DYNAPAC COMPACTION EQUIP

High efficiency internal explosion engine

A piston-powered internal explosion engine for providing power output through a rotating crankshaft. The engine includes an engine block having power cylinders for receiving working pistons, bearing means for supporting the crankshaft, and a crankshaft supported within the bearing means having an output end extending outside of the engine block and a plurality of offset power cranks. The engine includes connecting rods operably coupled to the power cranks and configured to transfer power from the working pistons to rotate the crankshaft, and working pistons that are received into the power cylinders and operably coupled to the power cranks. Each working piston has a head end positioned adjacent to a cylinder head to form a compression chamber and is configured to receive power from an explosion of a compressed volume located within the compression chamber, and to transfer the received power to the connecting rods.

Owner:DF RESERVE LC

High-precision standard eccentric shaft with adjustable eccentric distance

InactiveCN103398087AEasy to adjustQuick Measurement CalibrationEccentric-shaftsEngineeringScrew thread

The invention discloses a high-precision standard eccentric shaft with an adjustable eccentric distance. The eccentric shaft comprises a main shaft; one side of the main shaft is provided with an external thread section, and the other side of the main shaft is provided with a shaft shoulder; the external thread section is sleeved with a gasket and a locknut which can be screwed on the external thread section; two inclined planes are located between the external thread section and the shaft shoulder, form an angle of 60 DEG and are a same distance away from a central axis and symmetrical with a shaft body; a shaft sleeve, an isolation sleeve and another shaft sleeve are successively sleeved between the shaft shoulder and the gasket; the spindle sleeves are in the shape of rings, two planes forming a 60-DEG angle are arranged in the rings, the two planes respectively match with the two inclined planes of the main shaft, and a pair of replaceable standard-thickness blocks with same height are respectively arranged in a corresponding plane and a corresponding inclined plane. According to the invention, accurate adjusting of the eccentric distance can be realized; through changing of the standard-thickness blocks, a desired standard eccentric distance can be obtained, and influence of manual adjusting can be eliminated; and on a same standard eccentric shaft, rapid measurement and calibration can be realized, and the standard eccentric shaft has a simple and reliable structure.

Owner:SHANGHAI INST OF MEASUREMENT & TESTING TECH

Weight type self-balancing eccentric shaft

InactiveCN103307089ASimple structureReduce manufacturing costEccentric-shaftsGrain treatmentsFillet weldSpin moment

The invention discloses a weight type self-balancing eccentric shaft. A balance weight is fillet-welded on the opposite side, close to an eccentric center line, of a connecting guard in an eccentric shaft in the prior art, so that the center of mass of the connecting guard shifts toward the opposite side, relative to a rotary center line, of eccentric bearing guards and the eccentric inertia moment generated by the connecting guard is equal to the eccentric inertia moments generated by the eccentric bearing guards but the directions are opposite, thus achieving self-balancing of the eccentric inertia spin moment of the eccentric shaft. The eccentric inertia spin moment of the eccentric shaft in the prior art is self-balanced by the interior of the eccentric shaft instead of original external flywheels, thus eccentric balance weights on the external flywheels can be omitted. The weight type self-balancing eccentric shaft has high balance precision and a simplified structure, is easy to detect and control, reduces the manufacturing cost of equipment and saves the operating cost.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

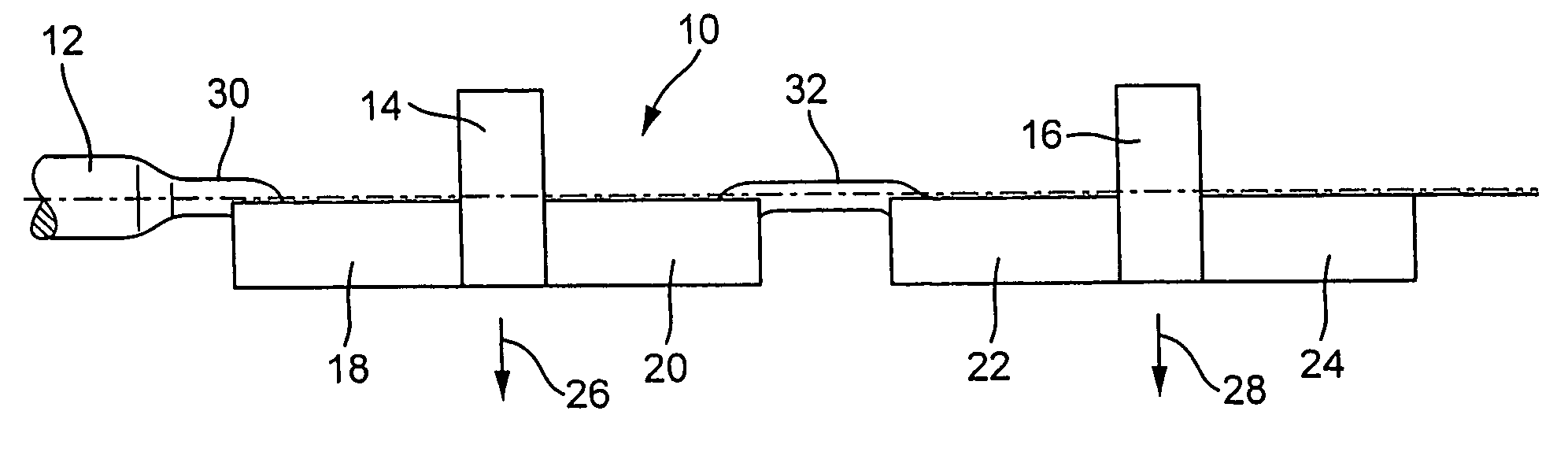

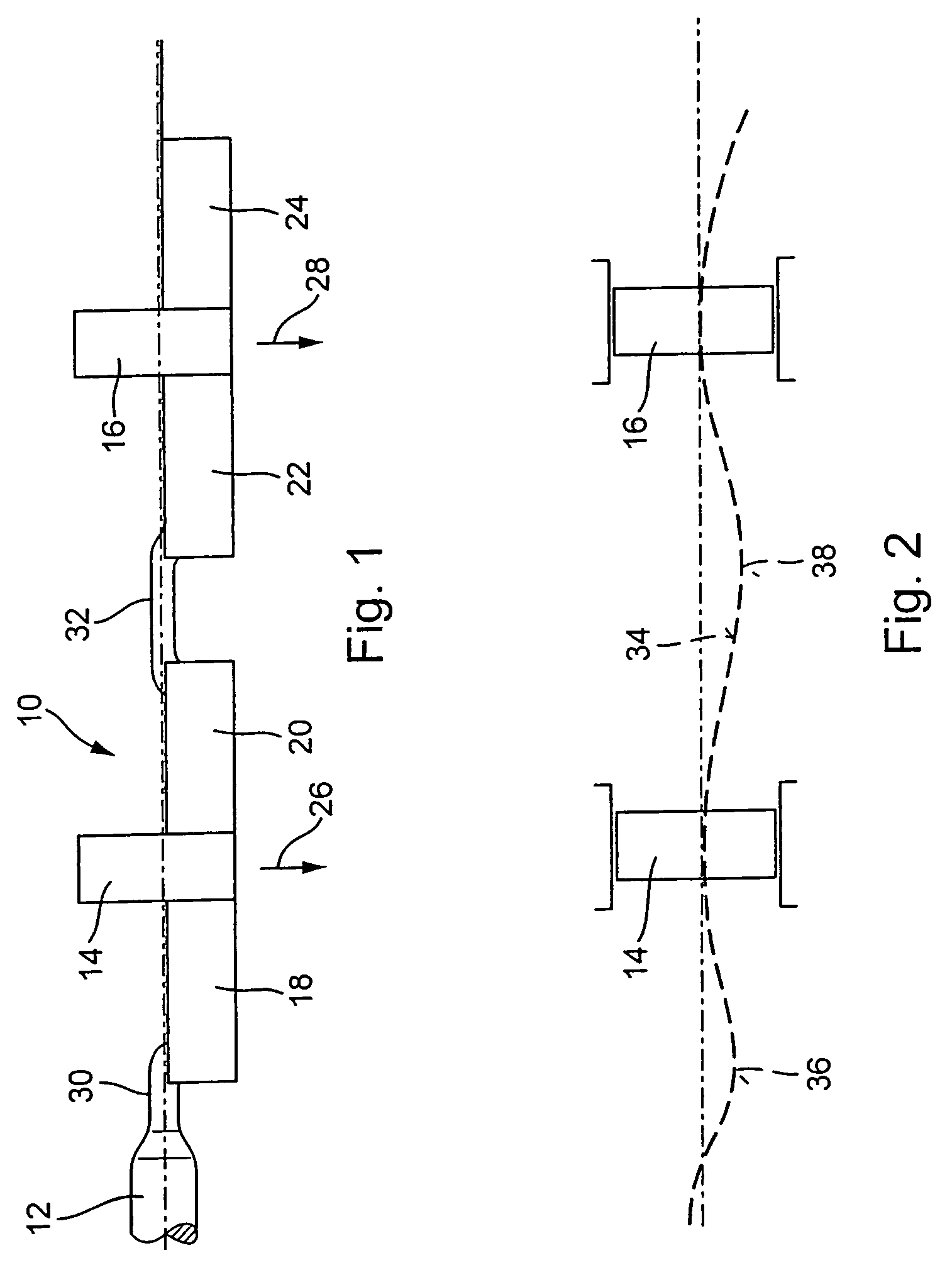

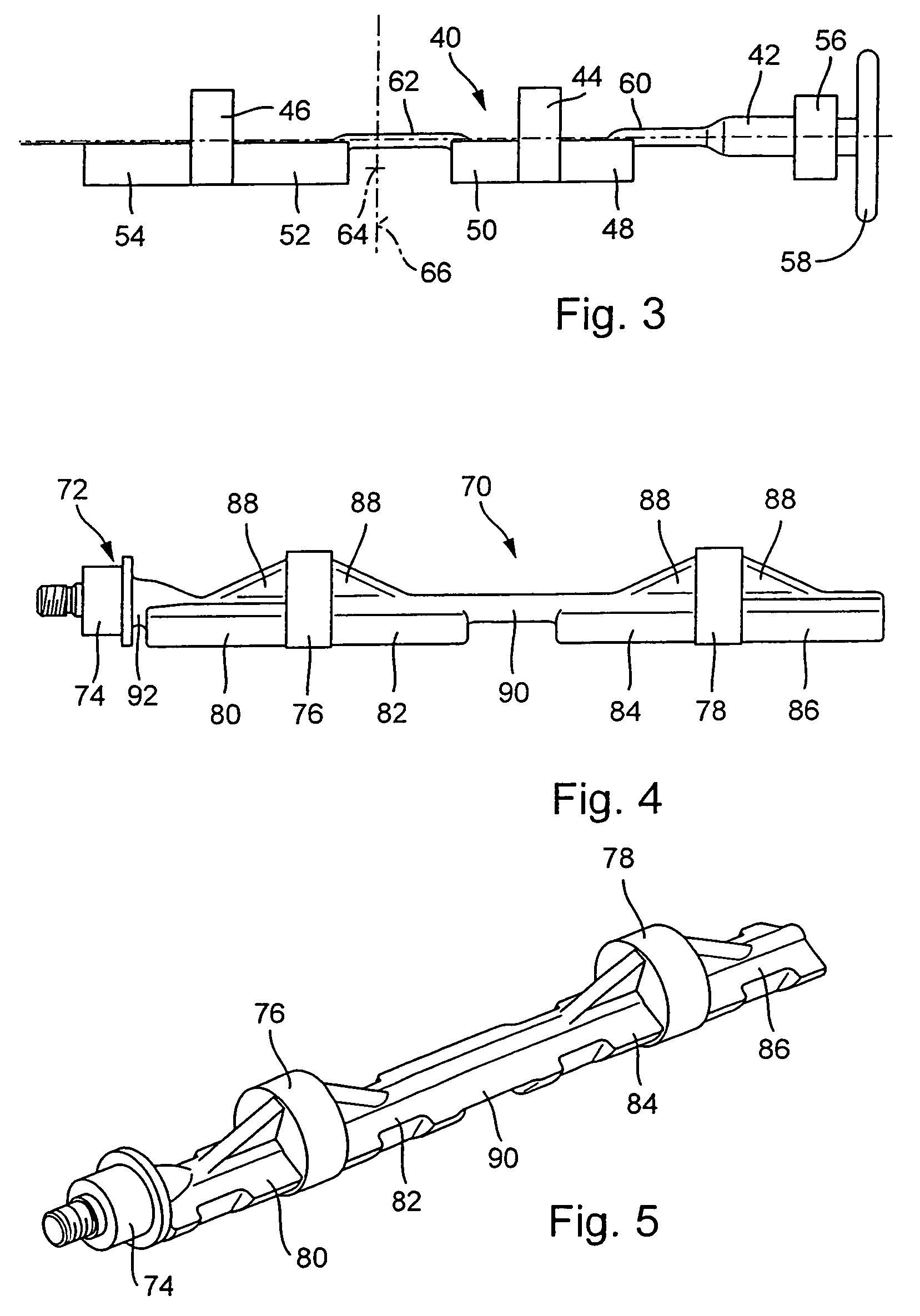

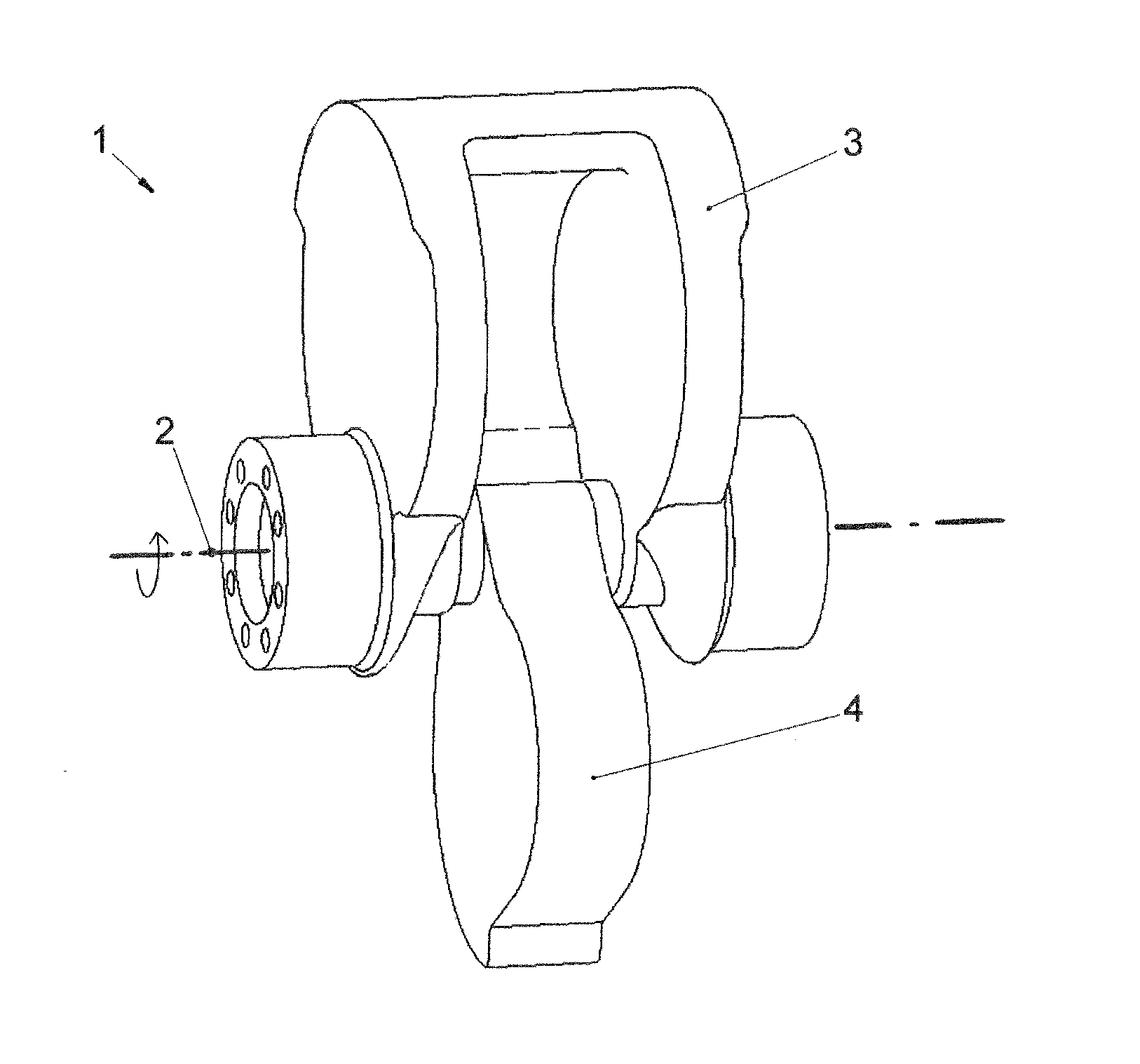

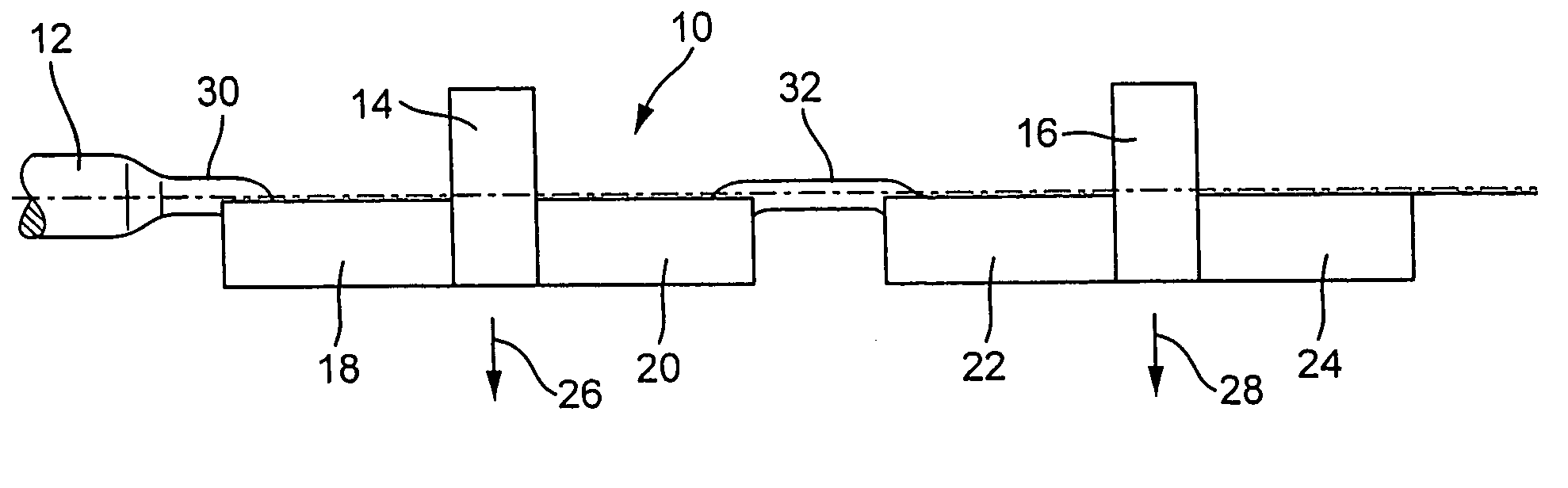

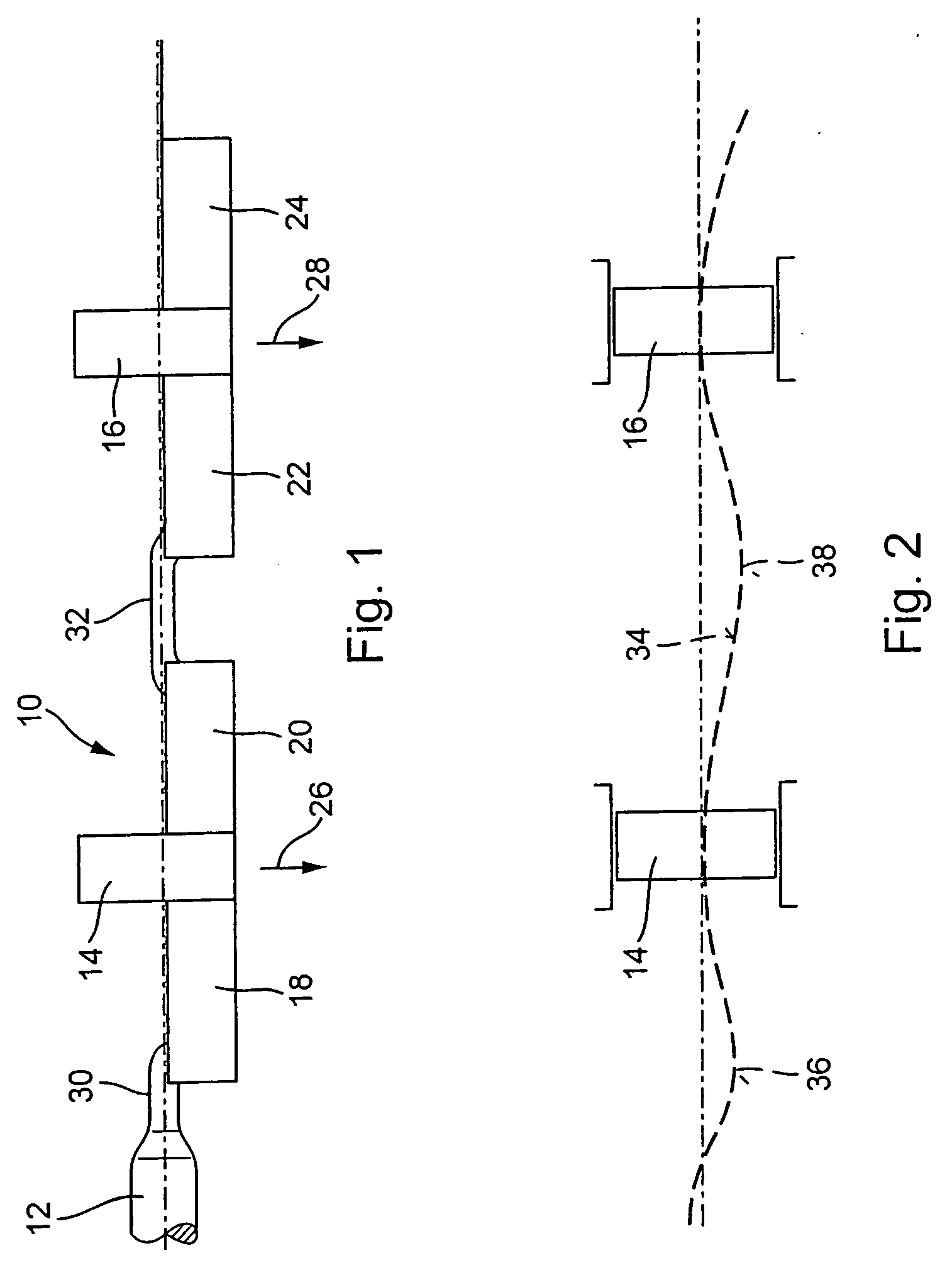

Balance shaft for a multicylinder in-line engine

ActiveUS20070062329A1Lighter designMinimal deflectionEccentric-shaftsInertia force compensationCouplingEngineering

In a balance shaft for a multi-cylinder in-line engine with at least two imbalance weight sections and at least one bearing structure wherein the balance shaft has imbalance weight sections being arranged symmetrically relative to the bearing position and at least one of the imbalance weight sections is connected to a further shaft section at an end facing away from the bearing position, a flexible coupling element that enables a deflection of the end of the connected imbalance weight section in the direction of the resulting centrifugal forces when the balance shaft rotates is provided between the end of the at least one imbalance weight section facing away from the bearing position and the further shaft section.

Owner:DAIMLER AG

High-precision eccentricity-adjustable eccentric shaft

The invention discloses a high-precision eccentricity-adjustable eccentric shaft, wherein a circular table concentric with an eccentric circle is manufactured in the middle of the eccentric circle of the eccentric shaft; each eccentric bushing is cut into two bilaterally symmetrical parts along a plane vertical to a self axis of the eccentric bushing; large holes and small holes which are concentric are respectively manufactured in the middle of each eccentric bushing; free sizes of the large holes and the small holes are respectively the same as the diameters of the circular table and the eccentric circle on the eccentric shaft; in a cooperative relationship, the large holes and the circular table are in tight fit; the small holes and the eccentric circle are in clearance fit; a plurality of key slots are uniformly manufactured on the middle small holes of each eccentric bushing along a circumferential direction; each eccentric bushing and the eccentric shaft are located through a key in a circumferential direction; and left and right eccentric bushings are fixed together through a bolt so as to form an integral body.

Owner:武勇

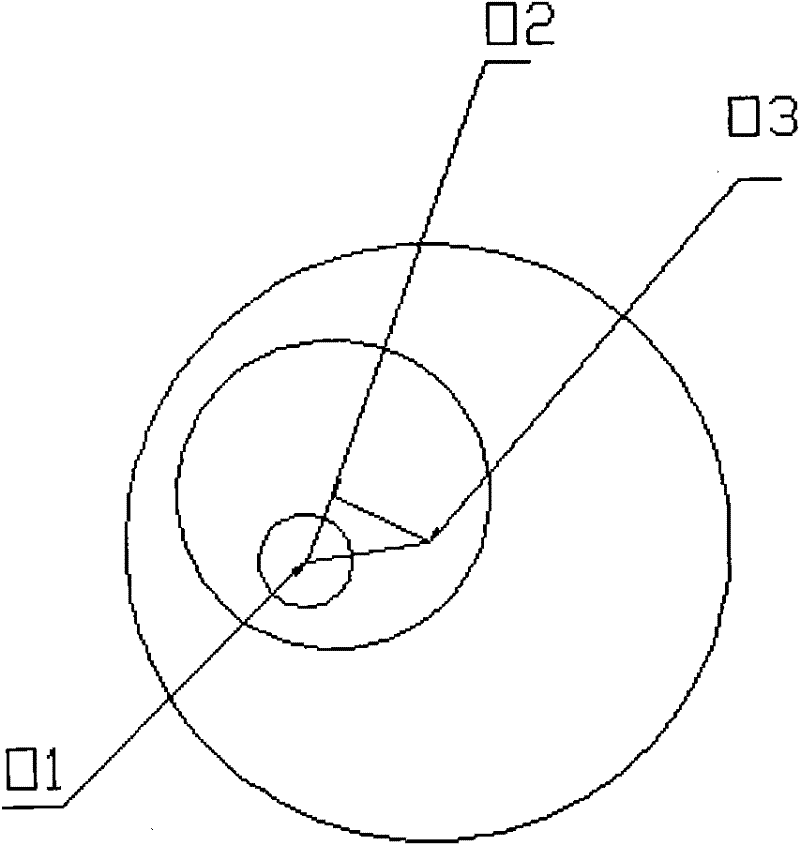

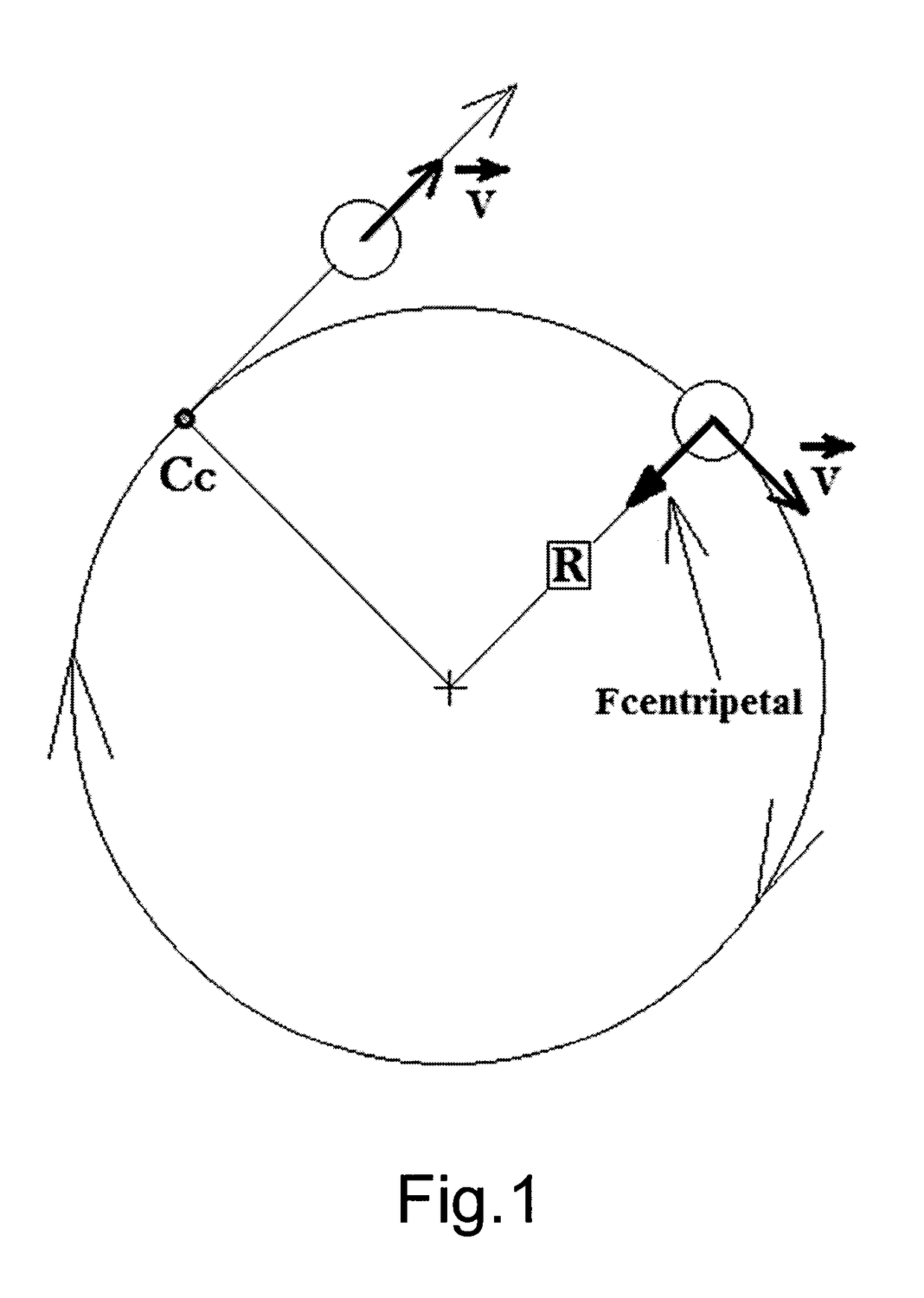

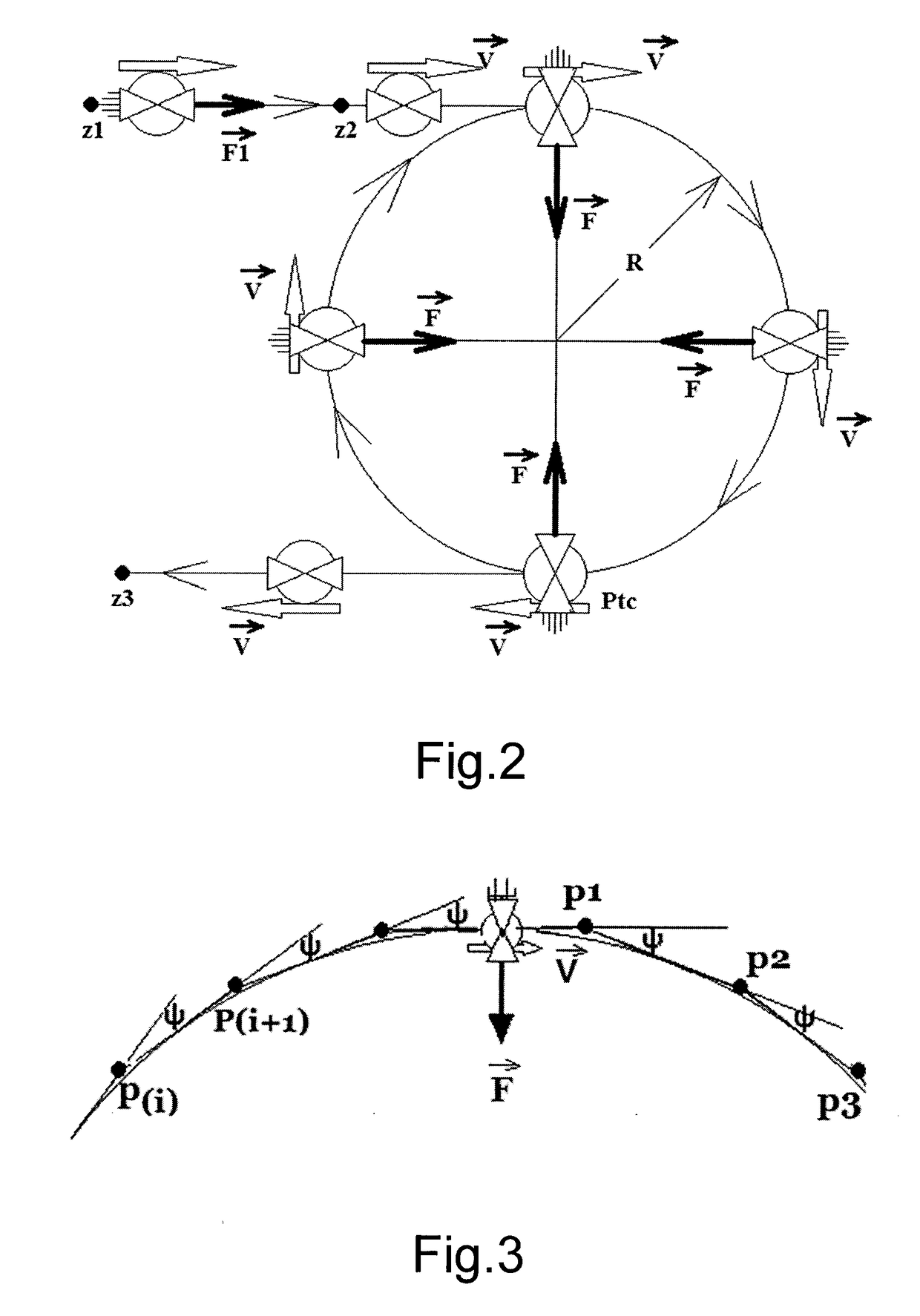

Machine generating centrifugal forces from eccentrics with variable radius

ActiveUS20180003276A1Cancel gravitational weight of bodyEasy accessEccentric-shaftsGearingMechanical energyEngineering

A generator (100) and / or machine (110) generating mechanical energy and functioning on the principle of exploitation of an energy allowing the existence of centrifugal forces (Fc) on masses (M) being displaced in rotation along an eccentric trajectory (150) within a system (130, 132, 166, 170, 190, 210) driving a progressive or sudden variation of their radius of rotation, principle of a generator of centrifugal forces from an eccentric with variable radius (100).

Owner:JEBARI JAMEL

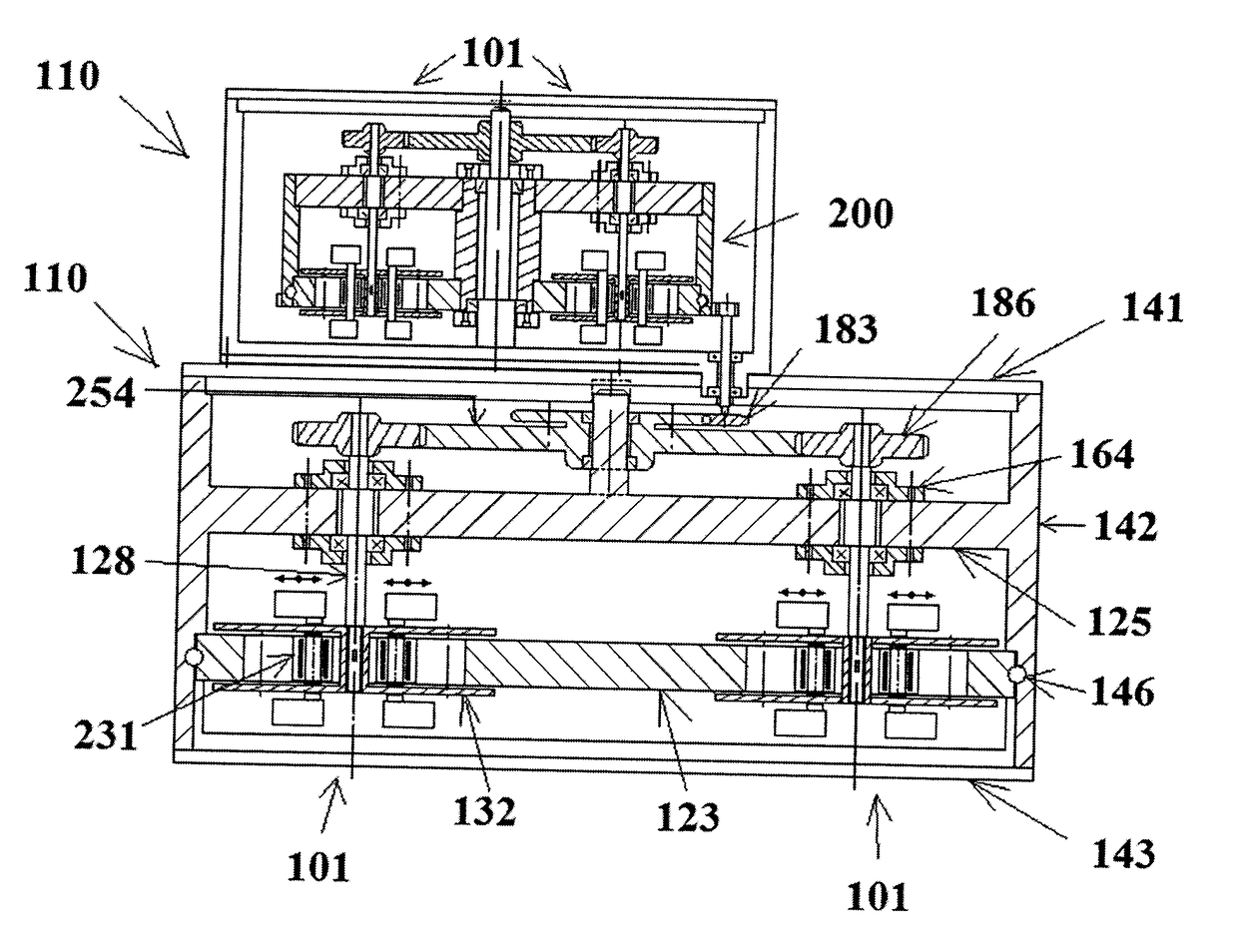

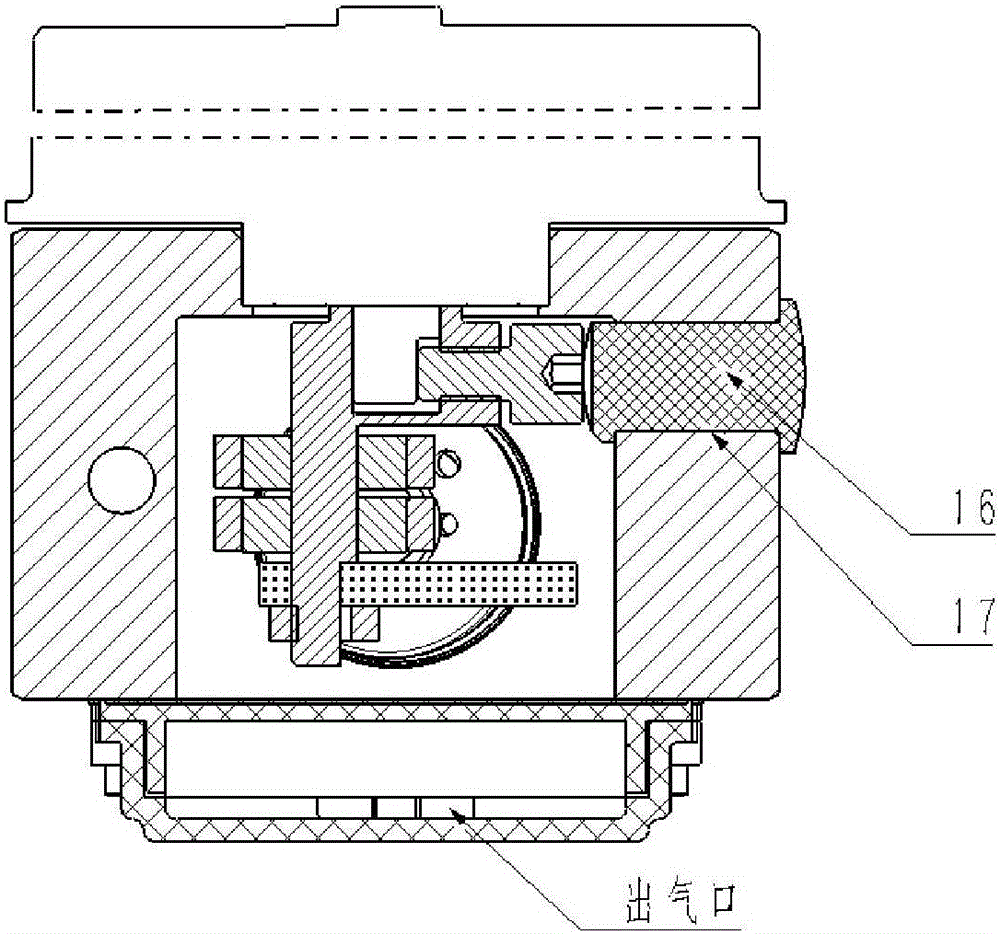

Combined piston type electronic vacuum pump for automobile

InactiveCN105804967AEvenly sealedEven by forceEccentric-shaftsPositive displacement pump componentsDynamic balanceEngineering

The invention discloses a combined piston type electronic vacuum pump for an automobile. The combined piston type electronic vacuum pump comprises a valve body, an electric motor assembly, a noise reduction and exhaust assembly, an eccentric shaft assembly, two piston assemblies and two air inlet one-way valves. The valve body is provided with a center inner cavity, a motor mounting hole is formed in the upper end face of the valve body, the valve body is provided with a left ladder hole and a right ladder hole, and the left ladder hole, the right ladder hole and the motor mounting hole are all communicated with the center inner cavity; a combined type dynamic balance transmission eccentric shaft assembly is mounted in the center inner cavity, the center inner cavity is connected with the noise reduction and exhaust assembly for carrying out covering and sealing, and the electric motor assembly is mounted in the motor mounting hole; and the end face of the left ladder hole and the end face of the right ladder hole are connected with end covers for sealing, the piston assemblies and the air inlet one-way valves are arranged in the left ladder hole and the right ladder hole, and the electric motor assembly is mounted on the left ladder hole and the right ladder hole, and is connected with the eccentric shaft assembly to drive the assembly to rotate. A new transmission balance mechanism, a piston structure and the like are adopted in the vacuum pump, the assembly cost and the machining cost are reduced, the assembly safety is improved, sealing of the pump is obviously improved, the noise of the pump is obviously lowered, the service life of the pump is obviously prolonged, and various requirements of automobile use can be met.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Rotary shaft, compressor and air conditioner

ActiveCN106438368APrevent axial movementImprove stabilityCrankshaftsEccentric-shaftsAerospace engineering

Owner:GREE ELECTRIC APPLIANCES INC

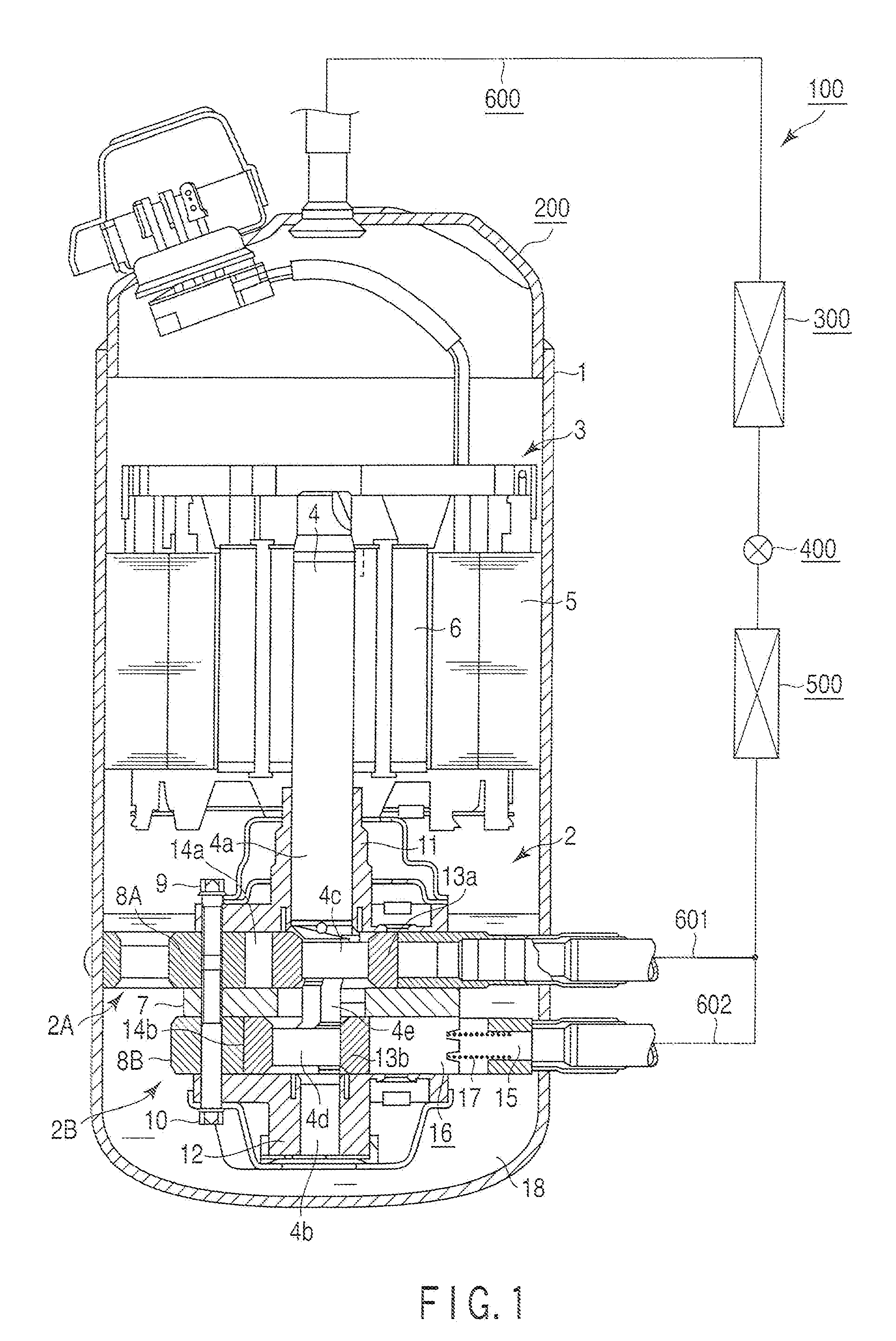

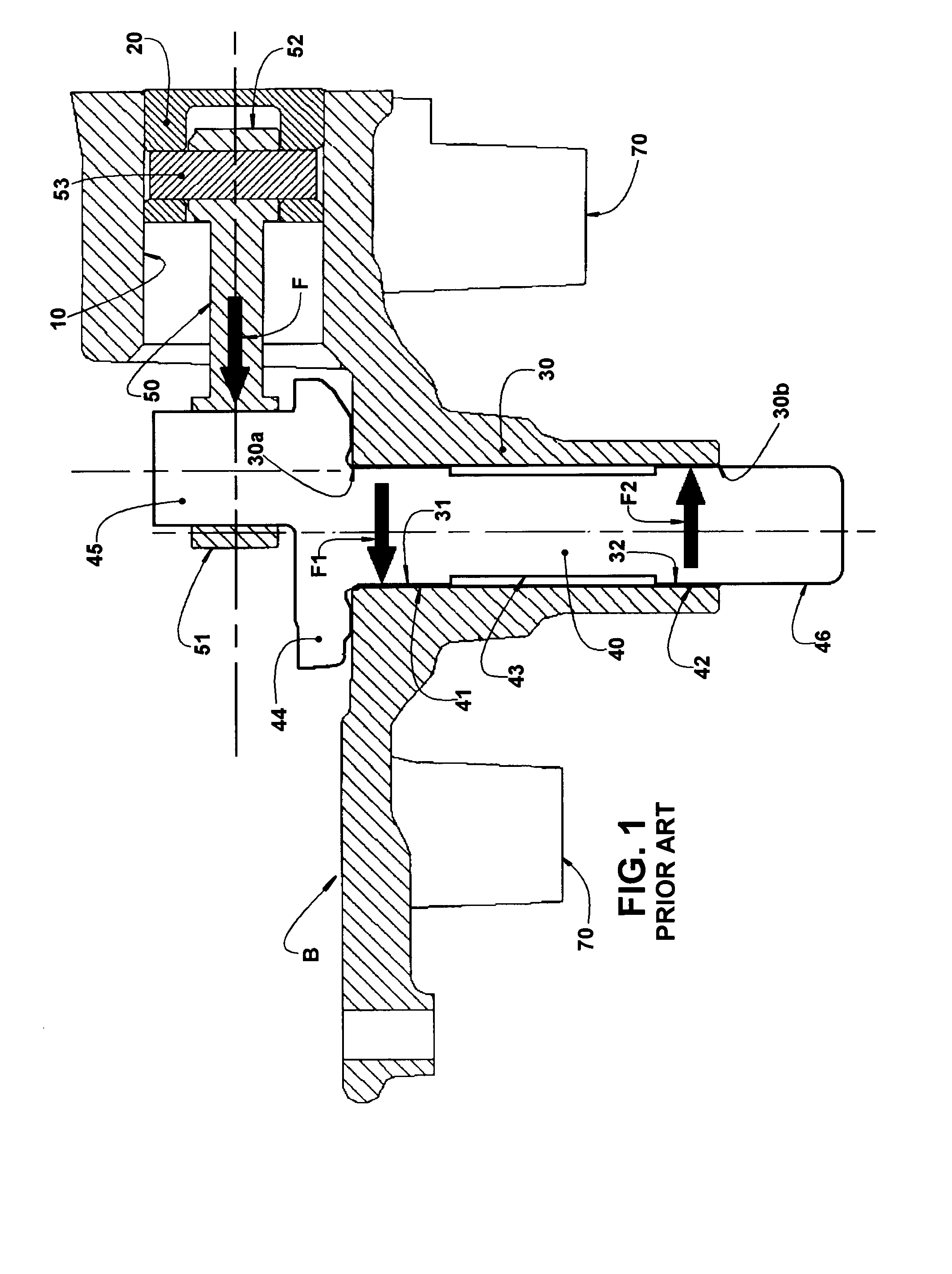

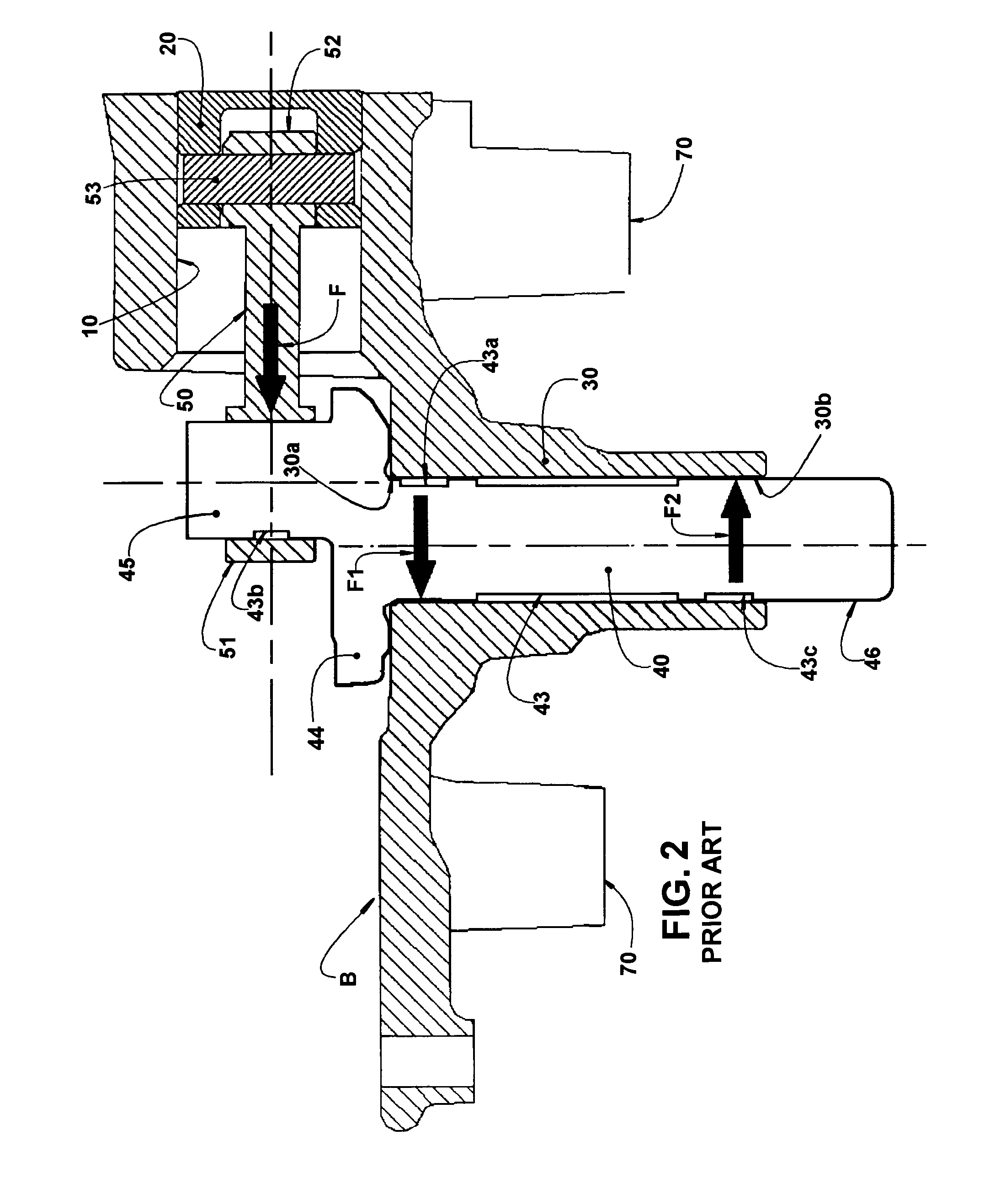

Bearing arrangement for a reciprocating compressor

ActiveUS20130323030A1Minimize power consumptionMaintaining the surfaces of the crankshaft and bearing hub reliable and adequateCrankshaftsEccentric-shaftsViscous frictionEngineering

The arrangement of the present invention is applied to a compressor which comprises a bearing hub housing a crankshaft and presenting at least a first and a second bearing portion, spaced apart by a circumferential recess. The crankshaft presents at least a first and a second support portion, spaced apart by a circumferential recess, which is offset from the circumferential recess of the bearing hub. At least one of the bearing portions and support portions has an axial extension superior to that required for radially bearing the crankshaft, the first and second bearing portions defining, with the first and second support portions, respectively, a first and a second radial bearing regions having the axial extensions required for a radial bearing for the crankshaft, presenting lower loss by viscous friction.

Owner:EMBRACO IND DE COMPRESSORES E SOLUCOES EM REFRIGERACAO LTDA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com