Driven gear of engine balance shaft

A technology of driven gear and balance shaft, used in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problem of high meshing noise, ineffective spring buffering and shock absorption, and inability to quickly attenuate impact force, etc. problem, to achieve the effect of reducing vibration and meshing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

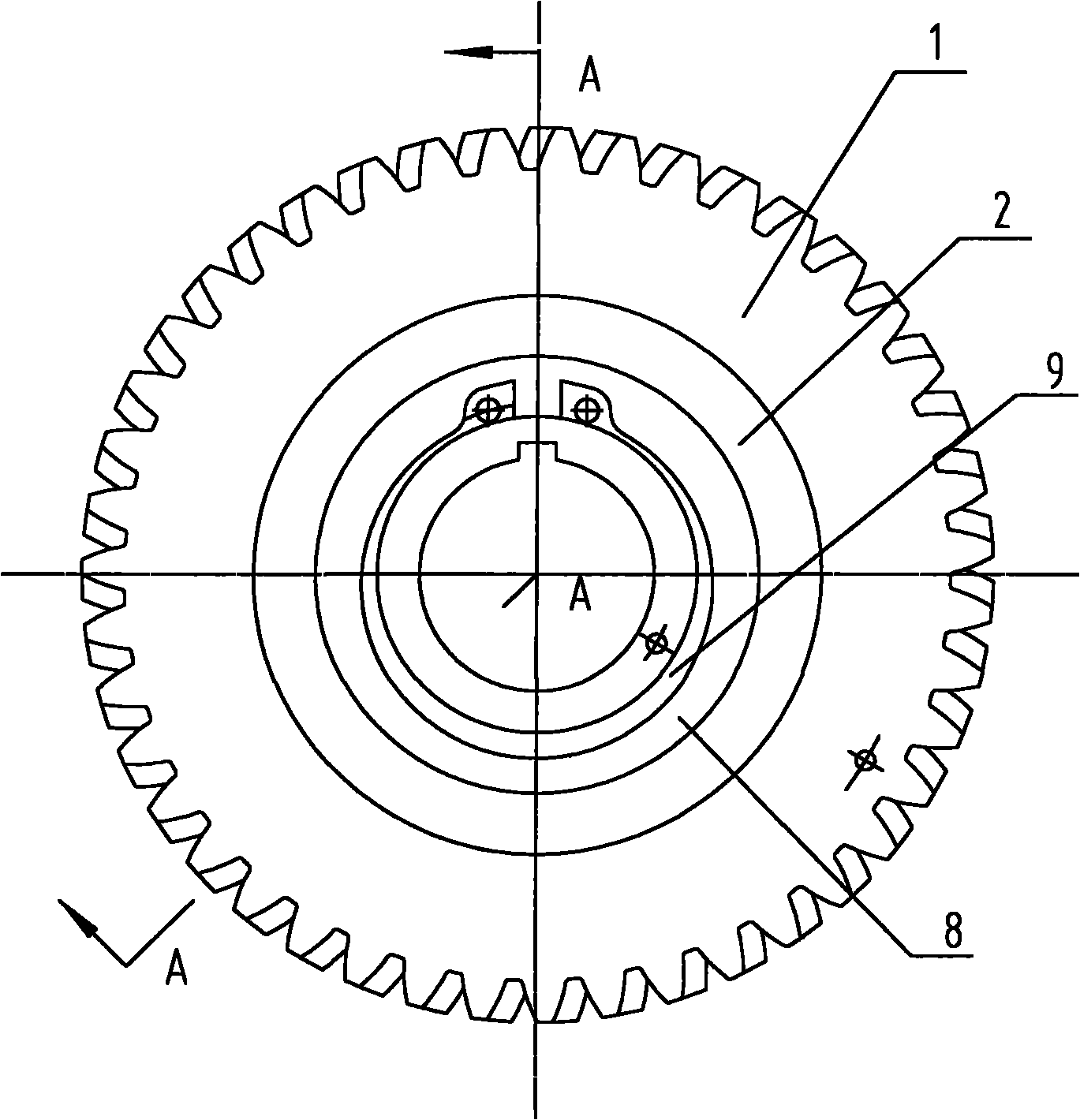

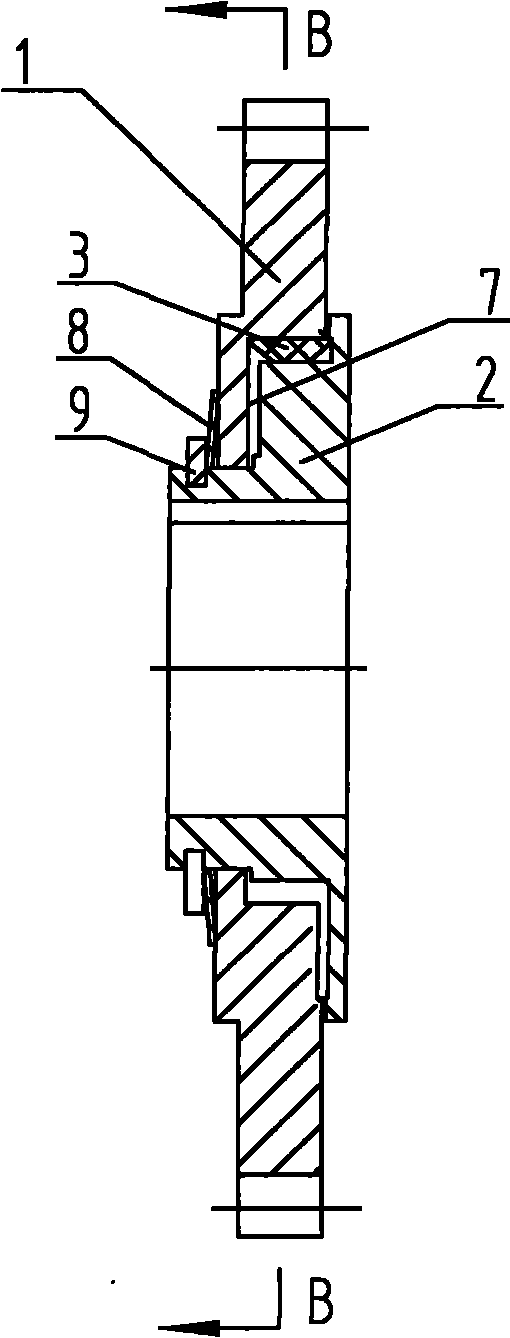

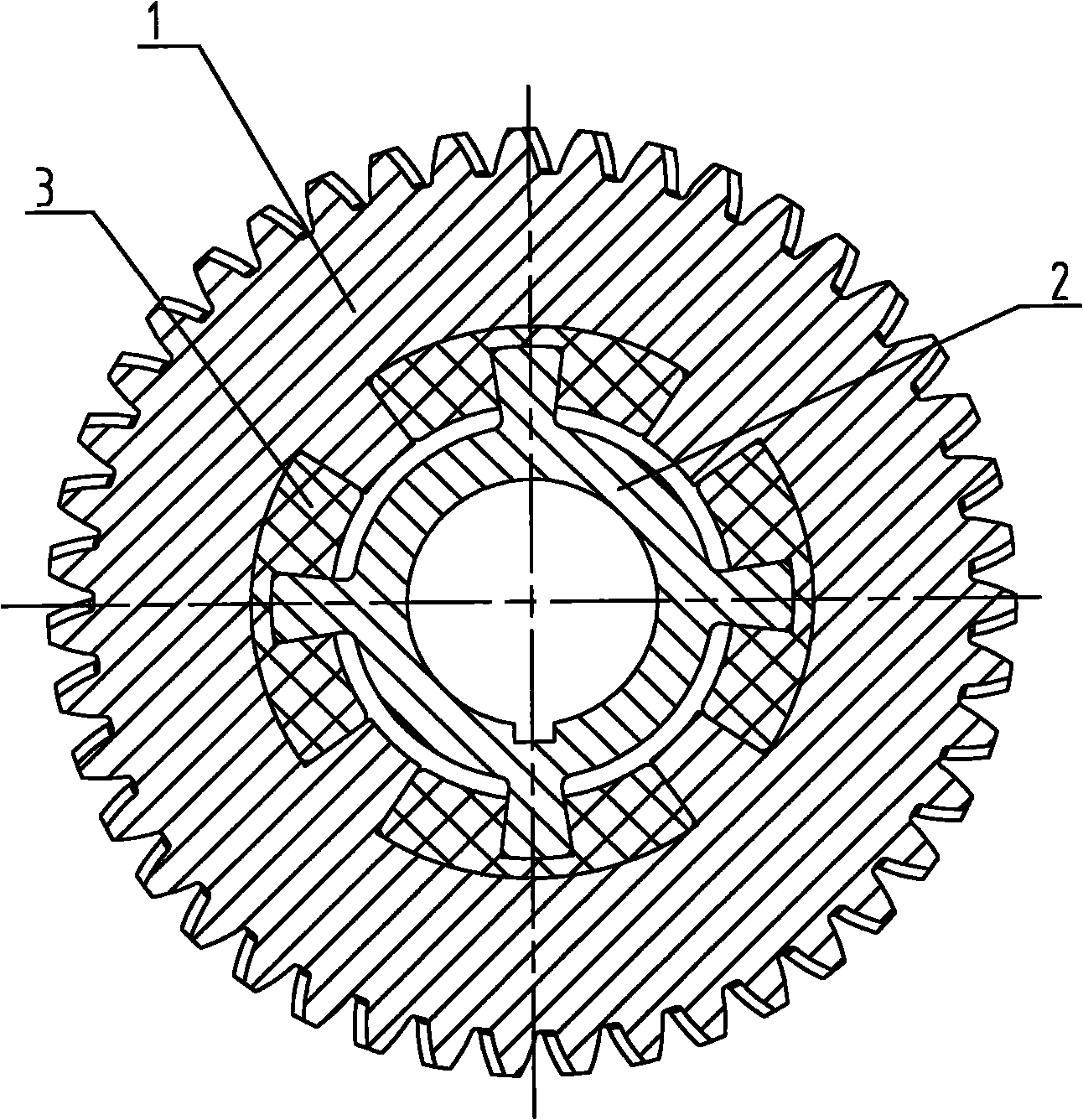

[0024] Such as figure 1 , 2 , 3, and 4, the engine balance shaft driven gear of the present invention has an outer ring gear 1 and an inner ring wheel 2, the outer ring gear 1 is assembled on the inner ring wheel 2, the outer ring gear 1 and the inner ring Between the ring wheels 2 is a gap fitting structure similar to splines, and a rubber block 3 is arranged between the adjacent key teeth of the outer ring gear 1 and the inner ring wheel 2 .

[0025] In the present invention, the shock absorbing structure of the outer ring gear 1 and the inner ring wheel 2 in the direction of rotation is designed as a full rubber shock absorber. The rubber has relatively large damping and can quickly attenuate impact, thereby achieving a good shock absorbing effect. At the same time, the rubber block 3 prevents mechanical contact between the outer ring gear 1 and the inner ring whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com